Page 1

Service

PM6005 /

N1B/N1SG/U1B/K1B

Manual

Integrated Amplier

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

PM6005

Copyright 2014 D&M Holdings Inc. All rights reserved.

S0835-1V05DM/DG1404

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 5

Please refer to the

MODIFICATION NOTICE.

Page 2

CONTENTS

ABOUT THIS MANUAL .............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................6

NOTE FOR SCHEMATIC DIAGRAM .........................................7

NOTE FOR PARTS LIST ...........................................................7

TECHNICAL SPECIFICATIONS ................................................9

DIMENSION ...............................................................................9

CAUTION IN SERVICING ........................................................10

Initializing INTEGRATED AMPLIFIER .....................................10

DISASSEMBLY ........................................................................11

1. FRONT PANEL ASSY ........................................................12

2. DIGTAL ASSY ....................................................................13

3. STANDBY PWB .................................................................14

4. POWER TRANS ................................................................14

5. MAIN ASSY ........................................................................14

SERVICE MODE ......................................................................15

PROCEDURE AFTER REPLACING THE

MICROPROCESSOR, ETC. ...................................................15

FIRMWARE UPDATE PROCEDURE .....................................15

ADJUSTMENT .........................................................................22

IDLING CURRENT ALIGNMENT ............................................22

DC OFFSET VOLTAGE ADJUSTMENT..................................23

TROUBLE SHOOTING ............................................................24

1. The power can not be turned on. .......................................24

2. The power can not be turned on. .......................................24

3. STANDBY LED ashes while using unit. ...........................25

4. The power turned on, but a sound does not output

normally. .................................................................................25

LEVEL DIAGRAM ....................................................................27

POWER DIAGRAM ..................................................................28

WIRING DIAGRAM ..................................................................29

PRINTED WIRING BOARDS ...................................................30

SCHEMATIC DIAGRAMS (1/4) ...............................................32

SCH01_MAIN ..........................................................................32

SCH02_FRONT ......................................................................33

SCH03_POWER .....................................................................34

SCH04_DIGITAL .....................................................................35

EXPLODED VIEW ...................................................................36

PACKING VIEW .......................................................................37

SEMICONDUCTORS ...............................................................38

1. IC's .....................................................................................38

2

Page 3

ABOUT THIS MANUAL

Read the following information before using the service manual.

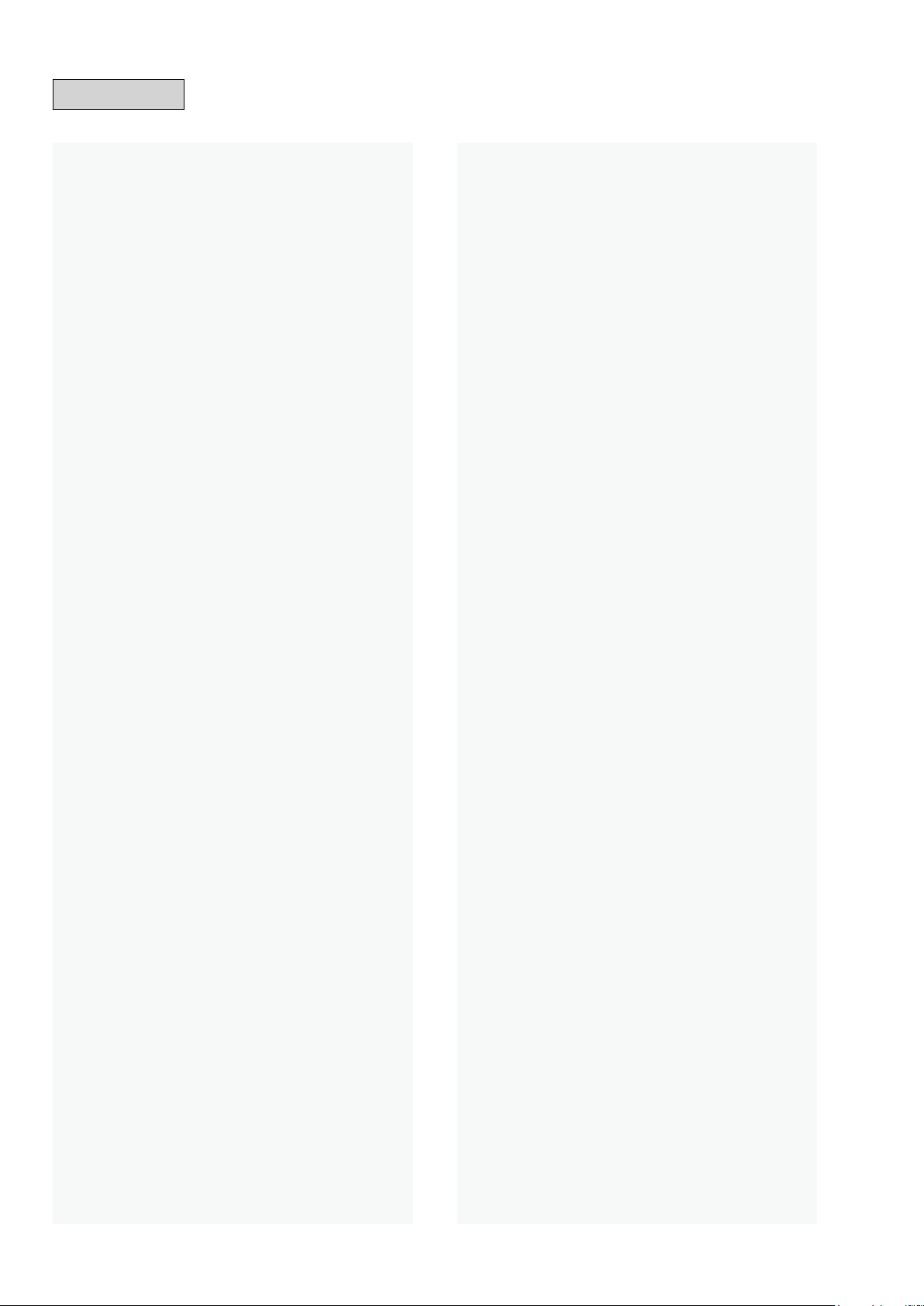

What you can do with this manual

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring board diagrams, block diagrams, and parts

lists.

1.Press Ctrl+Shift+Fonthekeyboard.

• The Search window appears.

F

Shift

Ctrl

2.EntertheRef.No.youwanttosearchforinthe

Search window, and then click the Search button.

•A list of search results appears.

Jump to the target of a schematic

diagram connector

Click the Ref. No. of the target connector in the red

box around a schematic diagram connector.

•The screen jumps to the target connector.

3.Click an item on the list.

• The screen jumps to the page for that item, and the

searchphraseisdisplayed.

•Pagemagnicationstaysthesameasbeforethe

jump.

3

Page 4

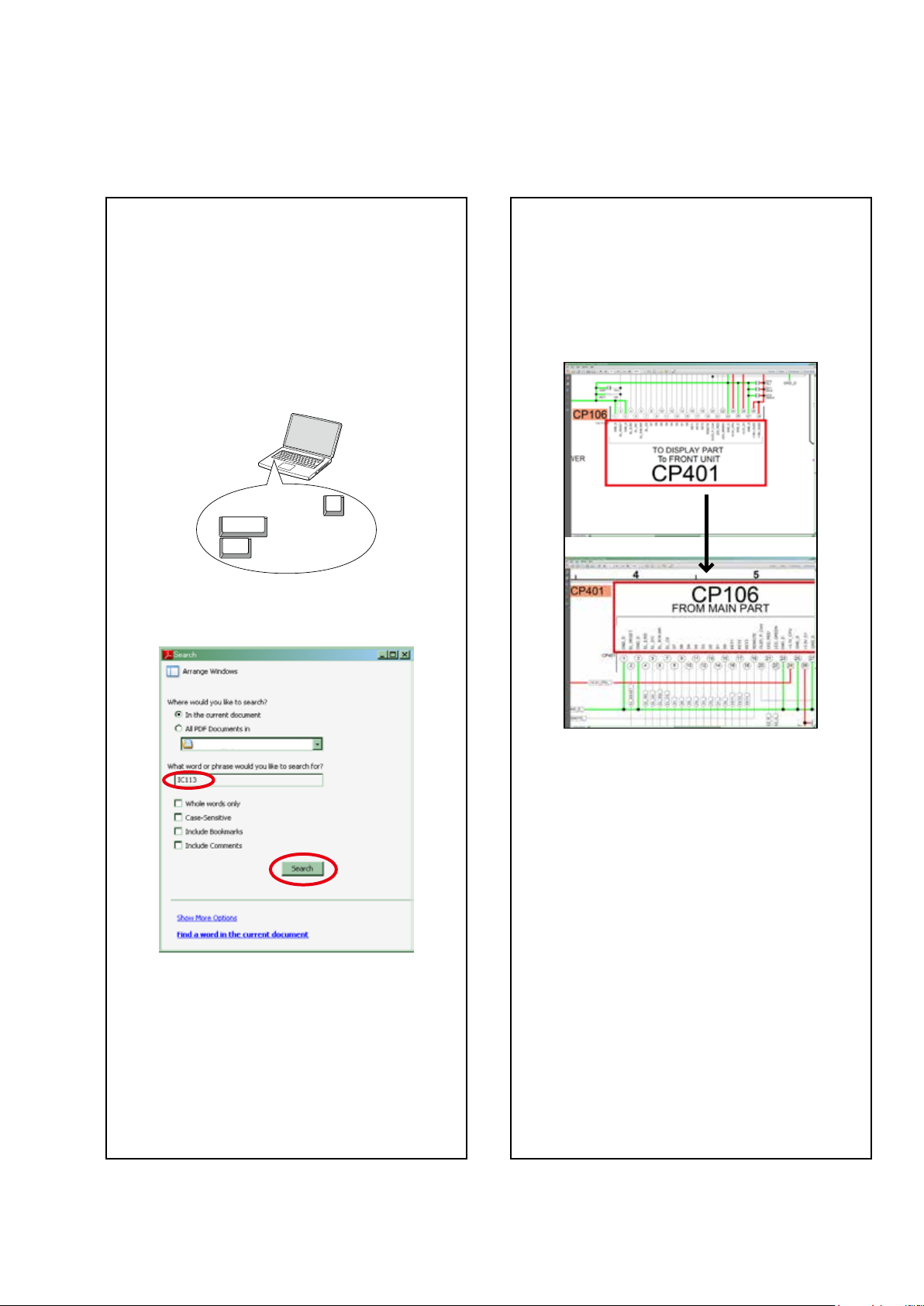

Using Adobe Reader (Windows version)

Add notes to this data (Sign)

TheSignfunctionletsyouaddnotestothedatain

this manual.

Savetheleonceyouhavenishedaddingnotes.

[Example using Adobe Reader X]

On the "View" menu, click "Sign".

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "Document" menu, click "Sign".

Magnify schematic / printed wiring

board diagrams - 1

(Ctrl+Space, mouse operation)

Press Ctrl+Spaceonthekeyboardanddragthe

mousetoselecttheareayouwanttoview.

• Theselectedareaismagnied.

0

Ctrl Space

• Whenyouwanttomovetheareashown,hold

down Space and drag the mouse.

• Whenyouwanttoshowafullpageview,press

Ctrl+0onthekeyboard.

Print a magnied part of the manual

ThePropertiesdialogboxandfunctionswillvarydependingonyourprinter.

1. Dragthemousetomagnifythepartyouwanttoprint.

2. On the "File" menu, click "Print".

3. CongurethefollowingsettingsinthePrintdialogbox.

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

"More Options" : "Current View"

• Page Sizing & Handling

Select the following checkbox.

"Size" / "Size Options" : "Fit"

4. Click the Print button to start printing.

4

Page 5

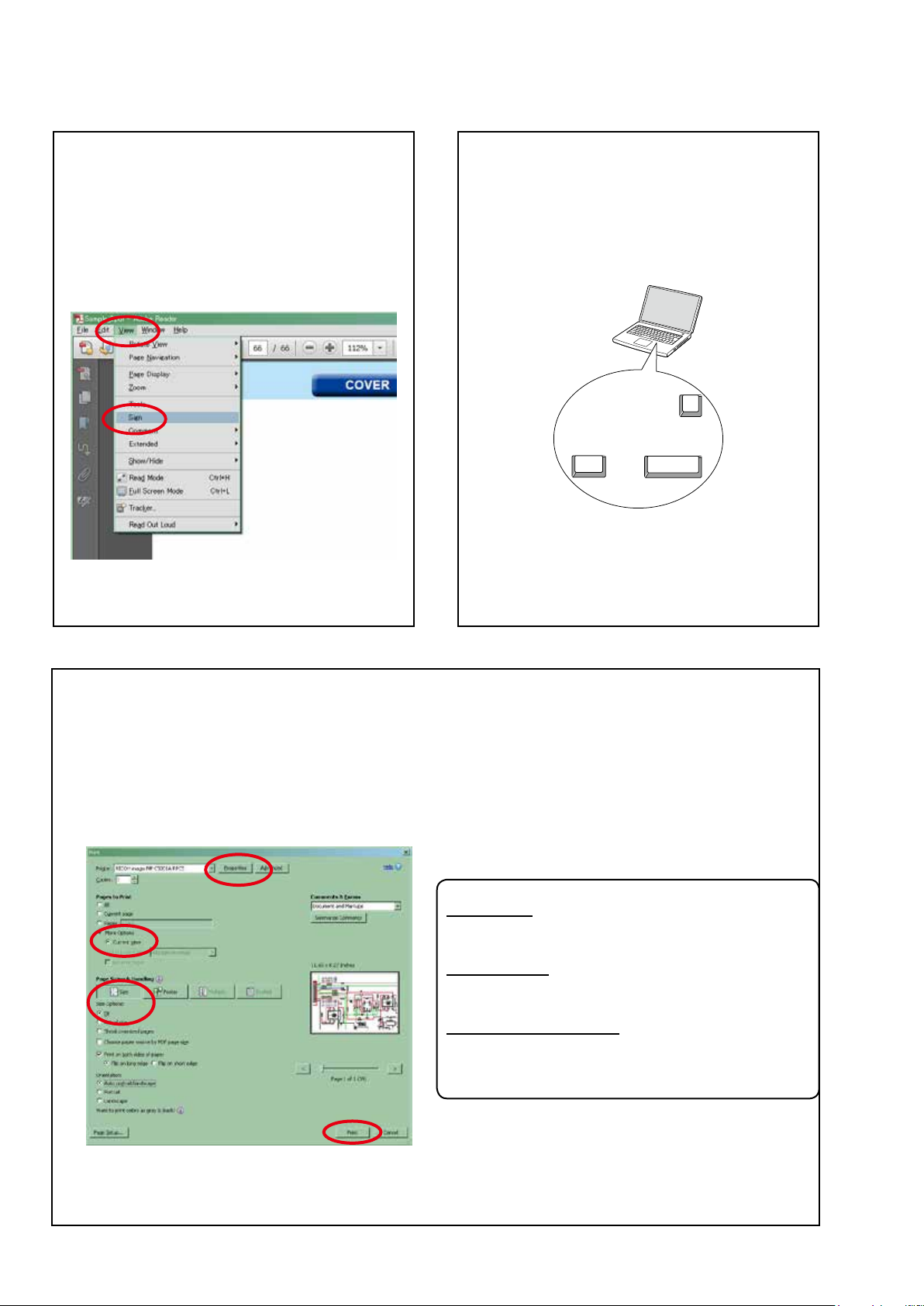

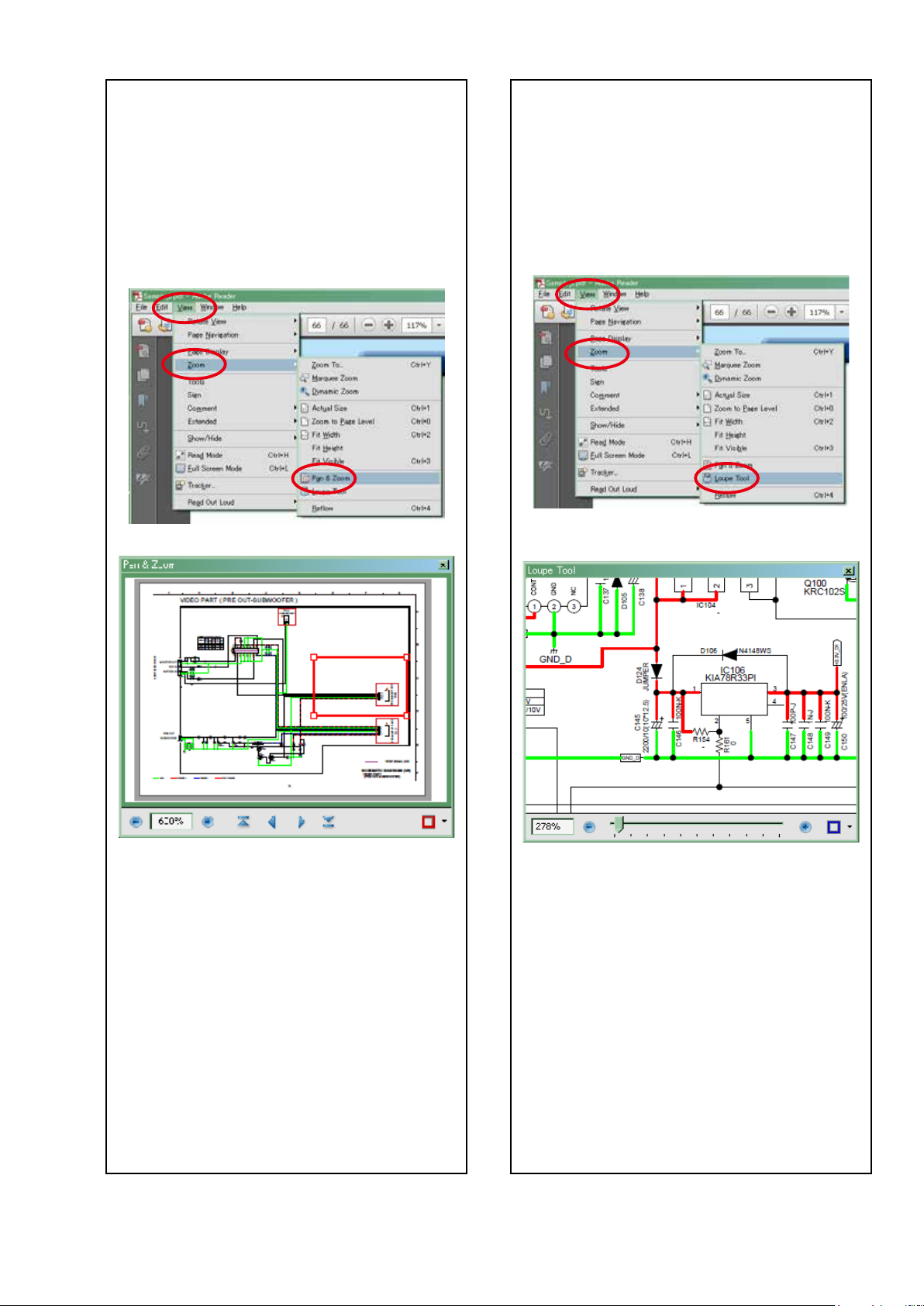

Magnify schematic / printed wiring

board diagrams - 2

(Pan & Zoom function)

ThePan&Zoomfunctionletsyouseewhichpartof

amagnieddiagramisbeingshowninaseparate

window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Pan & Zoom".

Magnify schematic / printed wiring

board diagrams - 3

(Loupe Tool function)

TheLoupeToolfunctionletsyoumagnifyaspecic

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Loupe Tool".

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Pan & Zoom Window".

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Loupe Tool Window".

5

Page 6

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

leakage current check

Beforereturningthesettothecustomer,besuretocarryouteither(1)aleakagecurrentcheckor(2)alinetochassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state

(on,offandstandbymode),ifapplicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) AnACvoltageisimpressedonthisset,soifyou

touch internal metal parts when the set is energized,

youmaygetanelectricshock.Avoidgettingan

electricshock,byusinganisolatingtransformer

and wearing gloves when servicing while the set is

energized,orbyunpluggingthepowercordwhen

replacing parts, for example.

(2) Therearehighvoltagepartsinside.Handlewith

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufacturedfromsheetmetal,theremaybeburrson

theedgesofparts.Theburrscouldcauseinjuryifngers

are moved across them in some rare cases. Wear gloves

toprotectyourhands.

◎Use only designated parts!

Theset'spartshavespecicsafetyproperties(re

resistance,voltageresistance,etc.).Besuretouseparts

which have the same properties for replacement. The

burrs have the same properties. In particular, for the

importantsafetypartsthatareindicatedbythez mark

on schematic diagrams and parts lists, be sure to use

the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

Forsafetyseasons,somepartsusetapes,tubesorother

insulatingmaterials,andsomepartsaremountedaway

from the surface of printed circuit boards. Care is also

takenwiththepositionsofthewiresbyarrangingthem

andusingclampstokeepthemawayfromheatingand

highvoltageparts,sobesuretoseteverythingbackas

itwasoriginallyplaced.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in their

original positions, check that no serviced parts have

deteriorate the area around. Then make an insulation

check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safetyisensured.

(Insulationcheckprocedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and on the power. Using a 500V

insulation resistance tester, check that the insulation

resistancevaluebetweentheinplugandtheexternally

exposedmetalparts(antennaterminal,headphones

terminal,inputterminal,etc.)is1MΩorgreater.Ifitis

less, the set must be inspected and repaired.

CAUTION

Concerning important

safety parts

Manyoftheelectricandthestructuralpartsusedinthe

sethavespecialsafetyproperties.Inmostcasesthese

propertiesaredifculttodistinguishbysight,andtheuse

ofreplacementpartswithhigherratings(ratedpower

andwithstandvoltage)doesnotnecessarilyguarantee

thatsafetyperformancewillbepreserved.Partswith

safetypropertiesareindicatedasshownbelowonthe

wiring diagrams and the parts list in this service manual.

Be sure to replace them with the parts which have the

designated part number.

(1) Schematicdiagrams .......Indicatedbythez mark.

(2) Partslists .......Indicatedbythez mark.

The use of parts other than the

designated parts could cause electric

shocks,resorotherdangerous

situations.

6

Page 7

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Partsindicatedbythezmarkhavecriticalcharacteristics.UseONLYreplacementpartsrecommendedbythemanufacturer.

CAUTION:

Beforereturningthesettothecustomer,besuretocarryouteither(1)aleakagecurrentcheckor(2)alinetochassisresistancecheck.If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DONOTreturnthesettothecustomerunlesstheproblemisidentiedandremedied.

NOTICE:

ALLRESISTANCEVALUESINOHM.k=1,000OHM/M=1,000,000OHM

ALLCAPACITANCEVALUESAREEXPRESSEDINMICROFARAD,UNLESSOTHERWISEINDICATED.PINDICATESMICRO-MICRO

FARAD.EACHVOLTAGEANDCURRENTAREMEASUREDATNOSIGNALINPUTCONDITION.CIRCUITANDPARTSARESUBJECT

TOCHANGEWITHOUTPRIORNOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

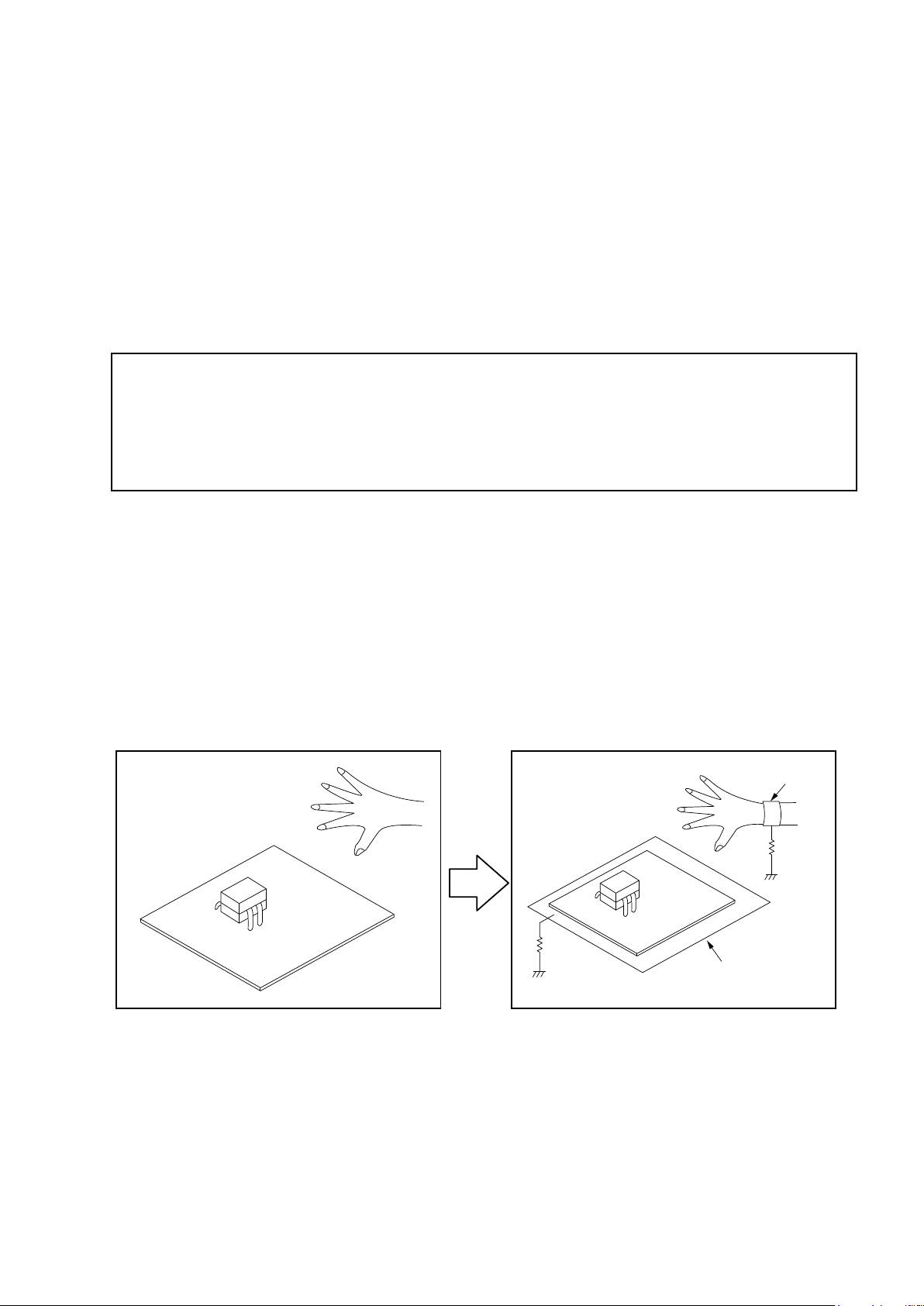

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostaticbreakdownofthesemi-conductorsoropticalpickupmayoccurduetoapotentialdifferencecausedby

electrostatic charge during unpacking or repair work.

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

1. GroundforHumanBody

Besuretowearagroundingband(1MΩ)thatisproperlygroundedtoremoveanystaticelectricitythatmaybe

chargedonthebody.

2. GroundforWorkbench

Besuretoplaceaconductivesheetorcopperplatewithpropergrounding(1MΩ)ontheworkbenchorothersurface,

wherethesemi-conductorsaretobeplaced.Becausethestaticelectricitychargeonclothingwillnotescapethrough

thebodygroundingband,becarefultoavoidcontactingsemi-conductorswithyourclothing

<Incorrect>

<Correct>

CBA

CBA

1MΩ

Grounding Band

1MΩ

Conductive Sheet or

Copper Plate

7

Page 8

Personal notes:

8

Page 9

TECHNICAL SPECIFICATIONS

• RMS Power output

(20 Hz – 20 kHz simultaneous drive of both channels) :

45 W x 2 (8 Ω/ohms load)

60 W x 2 (4 Ω/ohms load)

• Total harmonic distortion

(20 Hz – 20 kHz simultaneous drive of both channels, 8 Ω/ohms load) :

0.08 %

• Output band width (8 Ω/ohms load, 0.06 %) :

10 Hz – 50 kHz

• Frequency response (CD, 1 W, 8 Ω/ohms load) :

10 Hz – 70 kHz +0 dB, –1 dB

• Dumping factor (8 Ω/ohms load, 40 Hz – 20 kHz) :

100

• Input sensitivity/Input impedance

PHONO (MM) :

CD, TUNER, NETWORK, RECORDER :

• Maximum allowable PHONO input level (1 kHz) MM :

100 mV

• RIAA deviation (20 Hz – 20 kHz) :

±1.0 dB

2.2 mV/47 kΩ/kohms

200 mV/20 kΩ/kohms

• S/N (IHF-A, 8 Ω/ohms load)

PHONO (MM) :

CD, TUNER, NETWORK, RECORDER :

• Tone control

Bass (50 Hz) :

Treble (15 kHz) :

• Digital input

Coaxial :

Optical :

Power requirement (for U model) :

Power requirement (for N model) :

Power requirement (for K model) :

Power requirement (for F model) :

Power consumption :

Power consumption during standby :

83 dB (5 mV input, 1 W output)

±10 dB

±10 dB

0.5 Vp-p

–27 dBm or later

155 W

102 dB (2 V input, Rated output)

AC 120 V, 60 Hz

AC 230 V, 50/60 Hz

AC 220 V, 50 Hz

AC 100 V, 50/60 Hz

0.3 W

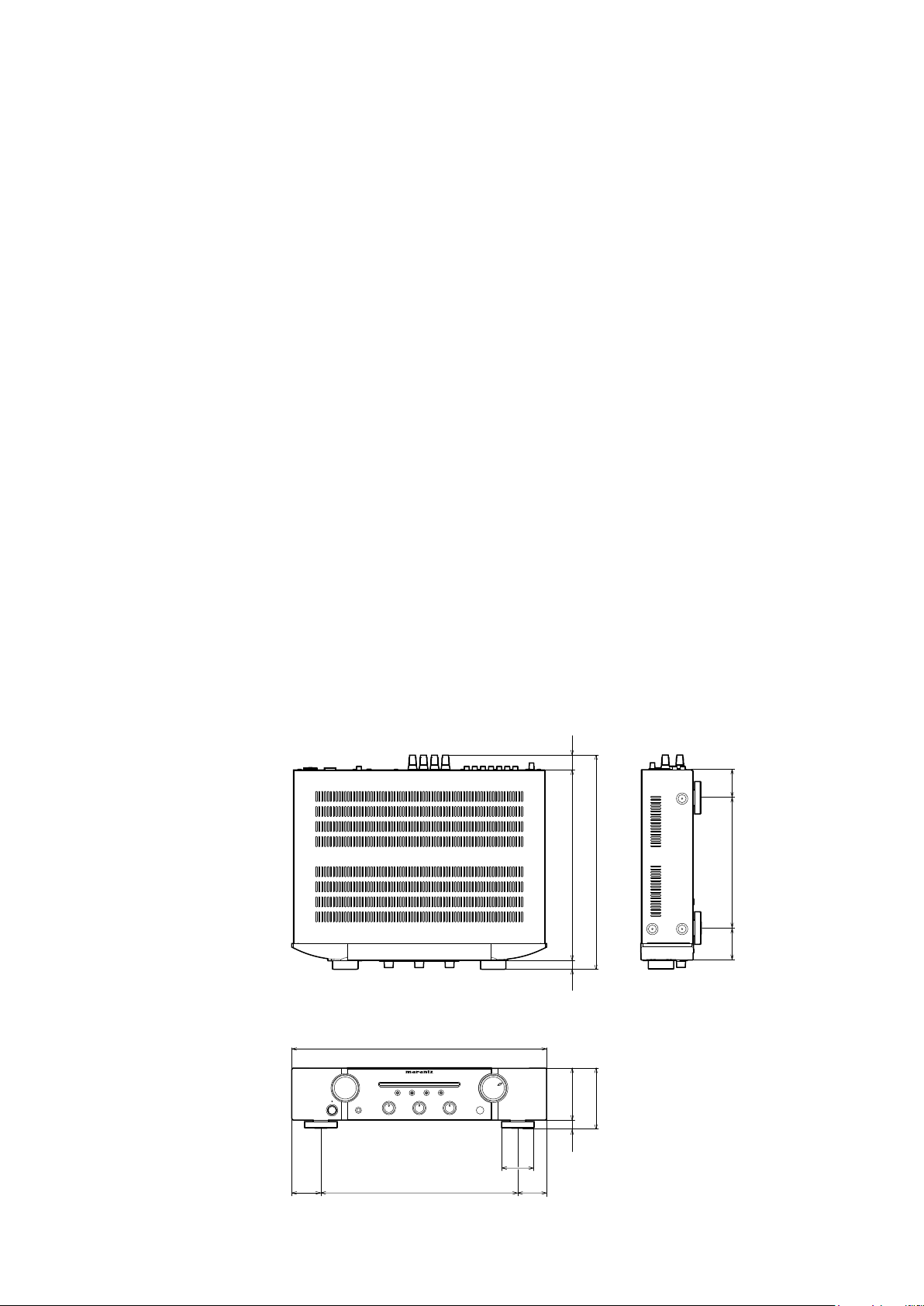

DIMENSION

Unit : in. (mm)

Weight : 7.6 kg

440

329

16 25

91

370

105

45

225

59

56

50

340

14

50

9

Page 10

CAUTION IN SERVICING

Initializing INTEGRATED AMPLIFIER

INTEGRATED AMPLIFIER initialization should be performed when the μcom and peripheral parts of μcom were replaced.

1. Turn off the power pressing "POWER" button.

2. Press "POWER" button while simultaneously while pressing "SOURCE DIRECT" buttons.

3. Check the set entered the service mode.(See "SERVICE MODE" 15page.)

SOURCE DIRECTPOWER

Service Jigs

The following jigs are used when updating the rmware.

(RS232C → connector conversion board in this product + 7P cable kit)

Request service from your dealer if necessary.

8U-210100S : WRITING KIT : 1 Set

606050028012P : 7P FFC (Straight) : 1 Set

(See "FIRMWARE UPDATE PROCEDURE" 15 page.)

f

10

Page 11

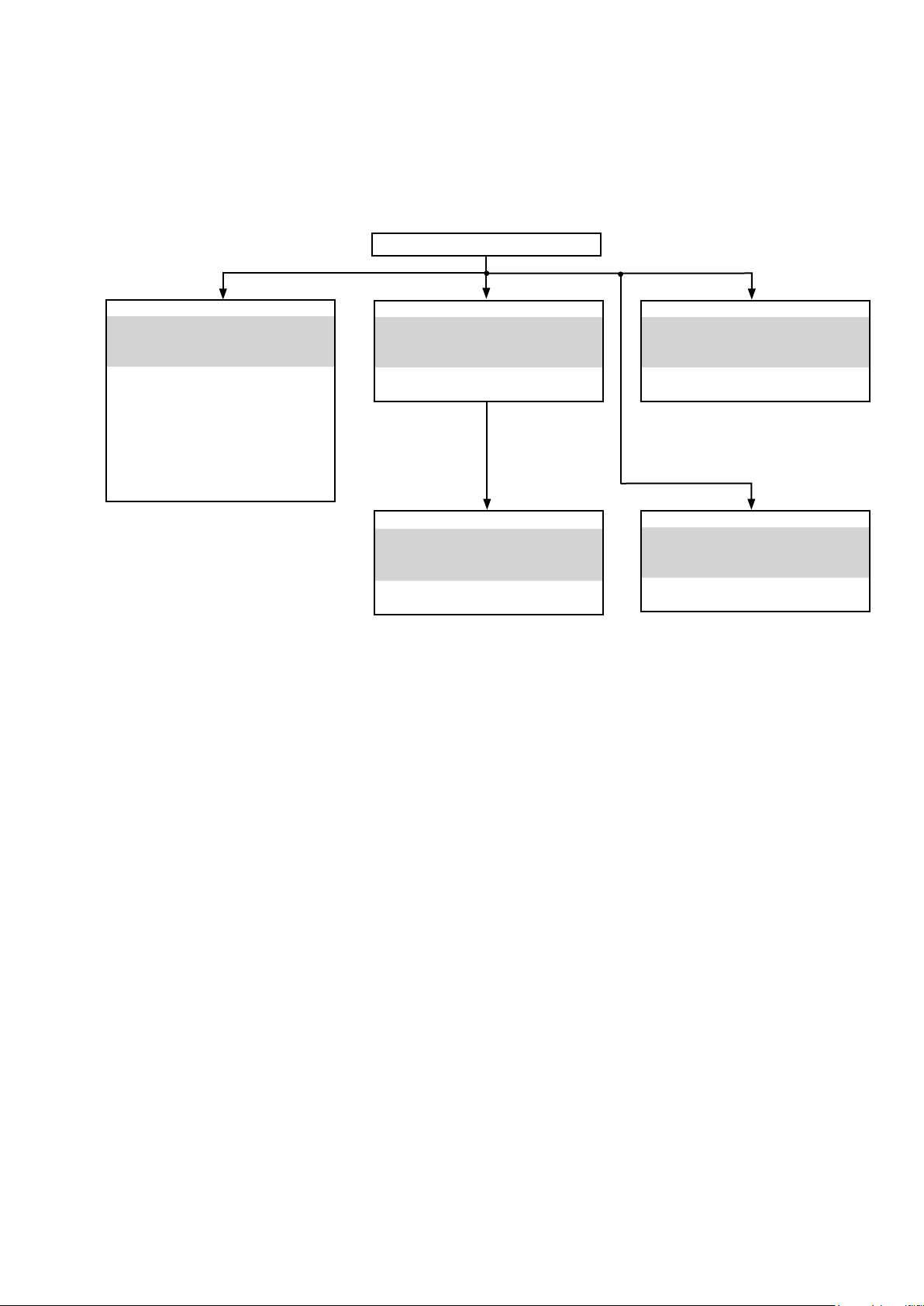

DISASSEMBLY

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

POWER SW PWB

(Ref. No. of EXPLODED VIEW : C1)

HEADPHONE PWB

(Ref. No. of EXPLODED VIEW : C2)

FRONT PWB

(Ref. No. of EXPLODED VIEW : C3)

VOLUME PWB

(Ref. No. of EXPLODED VIEW : C4)

DIGTAL PWB

Refer to "DISASSEMBLY

2. DIGTAL ASSY"

and "EXPLODED VIEW"

DIGTAL PWB

(Ref. No. of EXPLODED VIEW : C10)

MAIN

ASSY

Refer to "DISASSEMBLY

5. MAIN

and "EXPLODED VIEW"

MAIN PWB ASSY

(Ref. No. of EXPLODED VIEW : C7)

ASSY

"

STANDBY PWB

Refer to "DISASSEMBLY

3. STANDBY PWB"

and "EXPLODED VIEW"

STANDBY PWB

(Ref. No. of EXPLODED VIEW : C6)

POWER TRANS

Refer to "DISASSEMBLY

4. POWER TRANS"

and "EXPLODED VIEW"

POWER TRANS

(Ref. No. of EXPLODED VIEW : C5)

11

Page 12

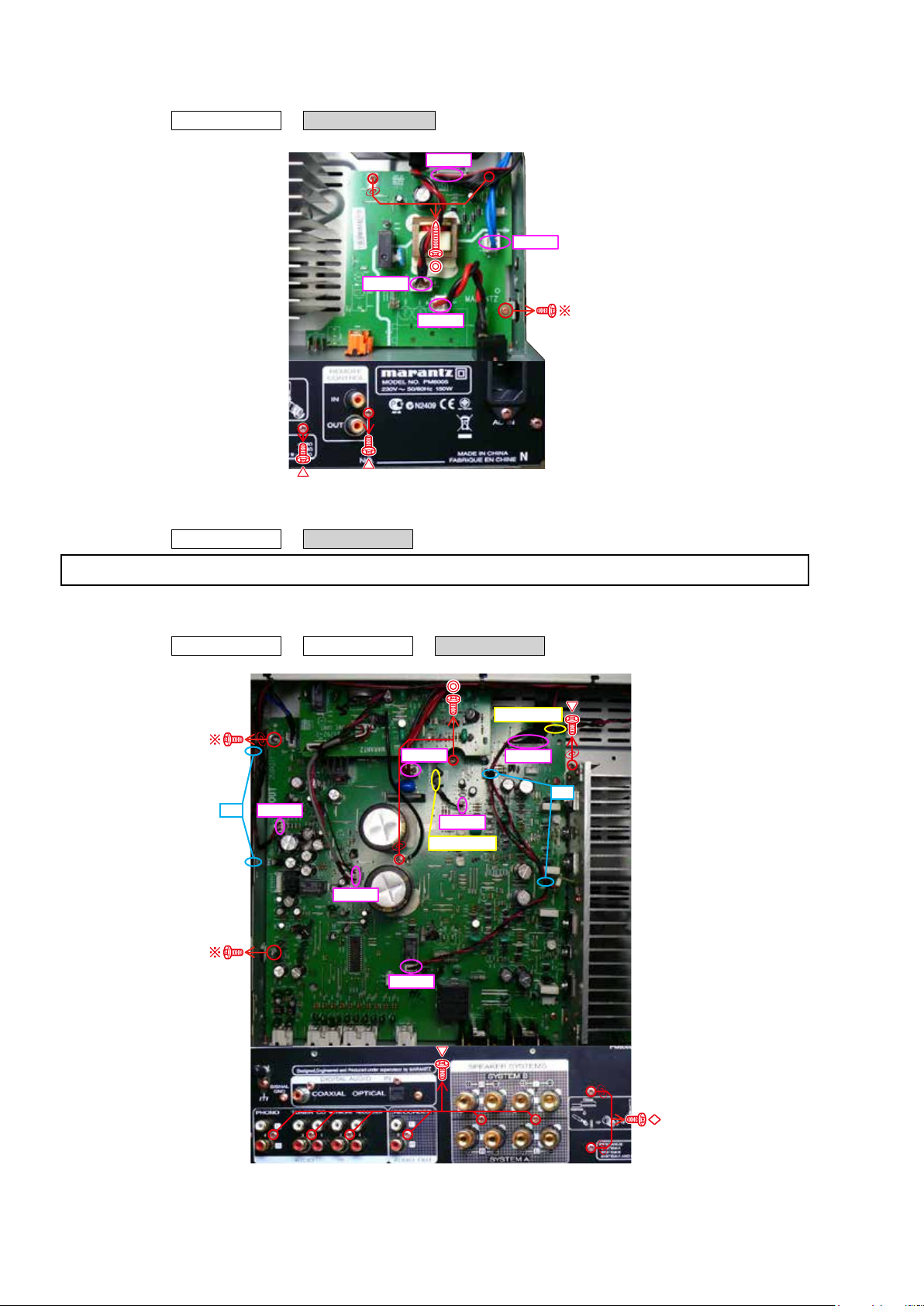

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction X)

[View from the top]

Shooting direction: C

1. FRONT PANEL ASSY

Proceeding : TOP COVER

(1) Remove the screws.

Shooting direction: B

Shooting direction: A

FRONT PANEL ASSY

→

View from the bottom Shooting direction: CShooting direction: D

Front side

Shooting direction: D

(2) Cut the wire clamp band, then remove the style pin and screws. Disconnect the connector wires.

cut

cut

N3001

BN302

N7501

STYLE PIN

N6001

N3002

STYLE PIN

cut

cut

N8504

N8502

12

Page 13

2. DIGTAL ASSY

Proceeding : TOP COVER

DIGTAL ASSY

→

(1) Remove the screws.

(2) Cut the wire clamp band, then remove the PCB HOLDER. Disconnect the connector wires.

cut

N8301

BN302

PCB HOLDER

N8302

(3) Disconnect the shield cover. Remove the soldering.

Lock the shield cover

Soldering

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in DIGITAL ASSY.

13

Page 14

3. STANDBY PWB

Proceeding : TOP COVER

(1) Remove the screws. Disconnect the connector wires.

STANDBY PWB

→

N8503

N8501

4. POWER TRANS

Proceeding : TOP COVER

POWER TRANS

→

N8504

N8502

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in POWER TRANS.

5. MAIN ASSY

Proceeding : TOP COVER

(1) Cut the wire clamp band, then remove the style pin and screws. Disconnect the connector wires.

cut

N8303

DIGTAL ASSY

→

N3001

→

N8001

N7501

MAIN ASSY

STYLE PIN

N3002

cut

N6001

STYLE PIN

14

Page 15

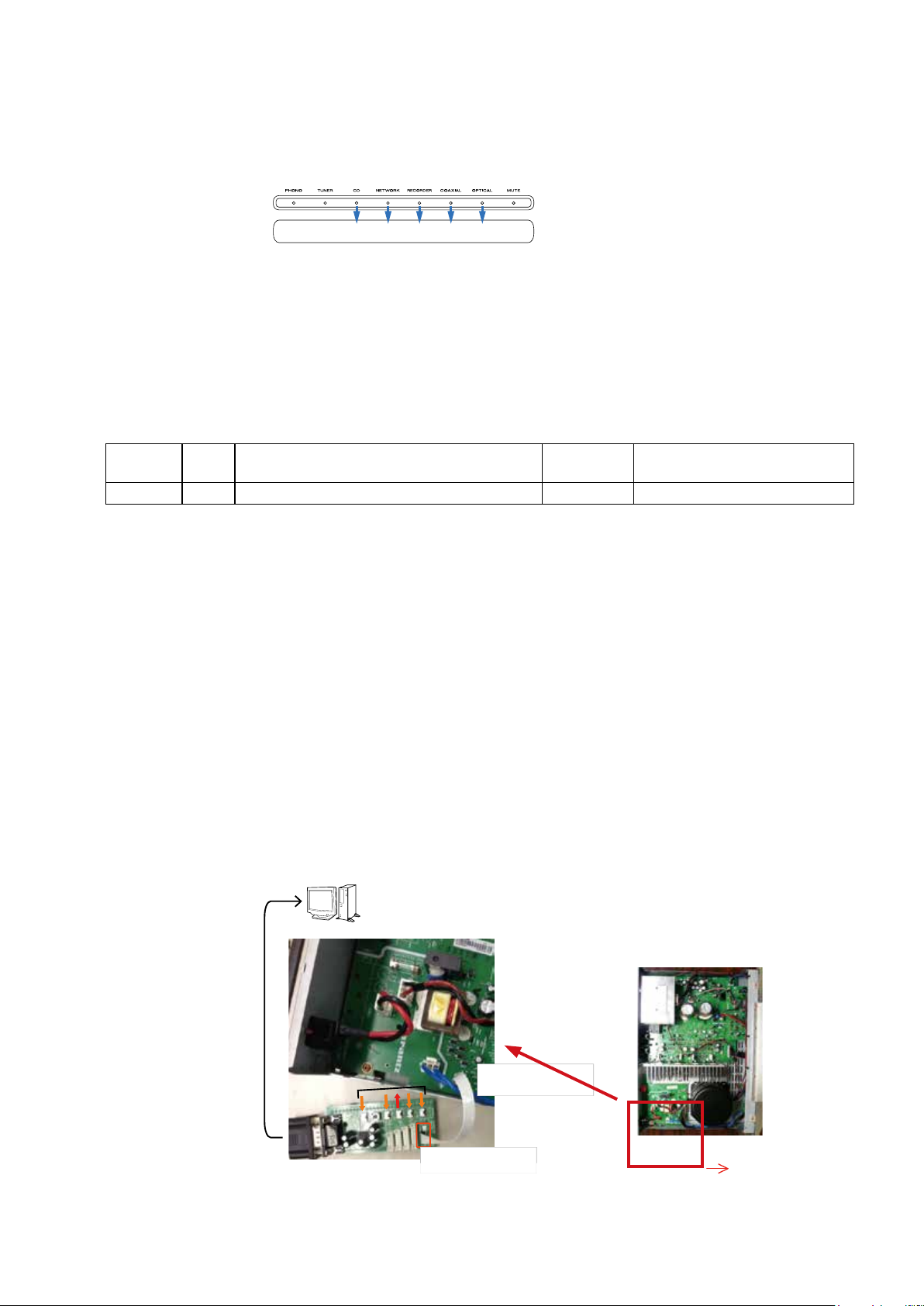

SERVICE MODE

Microprocessor (U1001) version check

(1) Press the POWER button with pressing the SOURCE DIRECT button on the unit.

(2) The rmware version is displayed on the front LED. (Display time is only for 3 seconds.)

The rmware version is displayed in the lighting position of LED.

12416Version: 8

Example

Light up OPTICAL [1 ], Version : 1

Light up OPTICAL [1 ] and RECORDER [4 ], Version : 5

Light up OPTICAL [1 ] and NETWORK [8 ], Version : 9

(3) Each LED light up then all LED light up.

(4) Turn off the power to quit Service Mode. (The unit to the default status)

PROCEDURE AFTER REPLACING THE MICROPROCESSOR, ETC.

The procedure after replacing the u-COM (microprocessor), ash ROM, etc. is as follows.

PWB Name Ref. No. Description

FRONT U1001 STM32F100R8T6 B

Procedure after Replacement

A : The software has been written. The software is not written at the time of replacement.

B : The software has been written. The software may need to be rewritten by version updates. Check the version.

C : The software has not been written. The software needs to be written after replacement. See “Firmware Update

Procedure” for information on writing the software.

D : The software has been written. Be sure to rewrite with the latest software for your service region. See “Firmware

Update Procedure” for information on writing the software.

After

replaced

f

備考

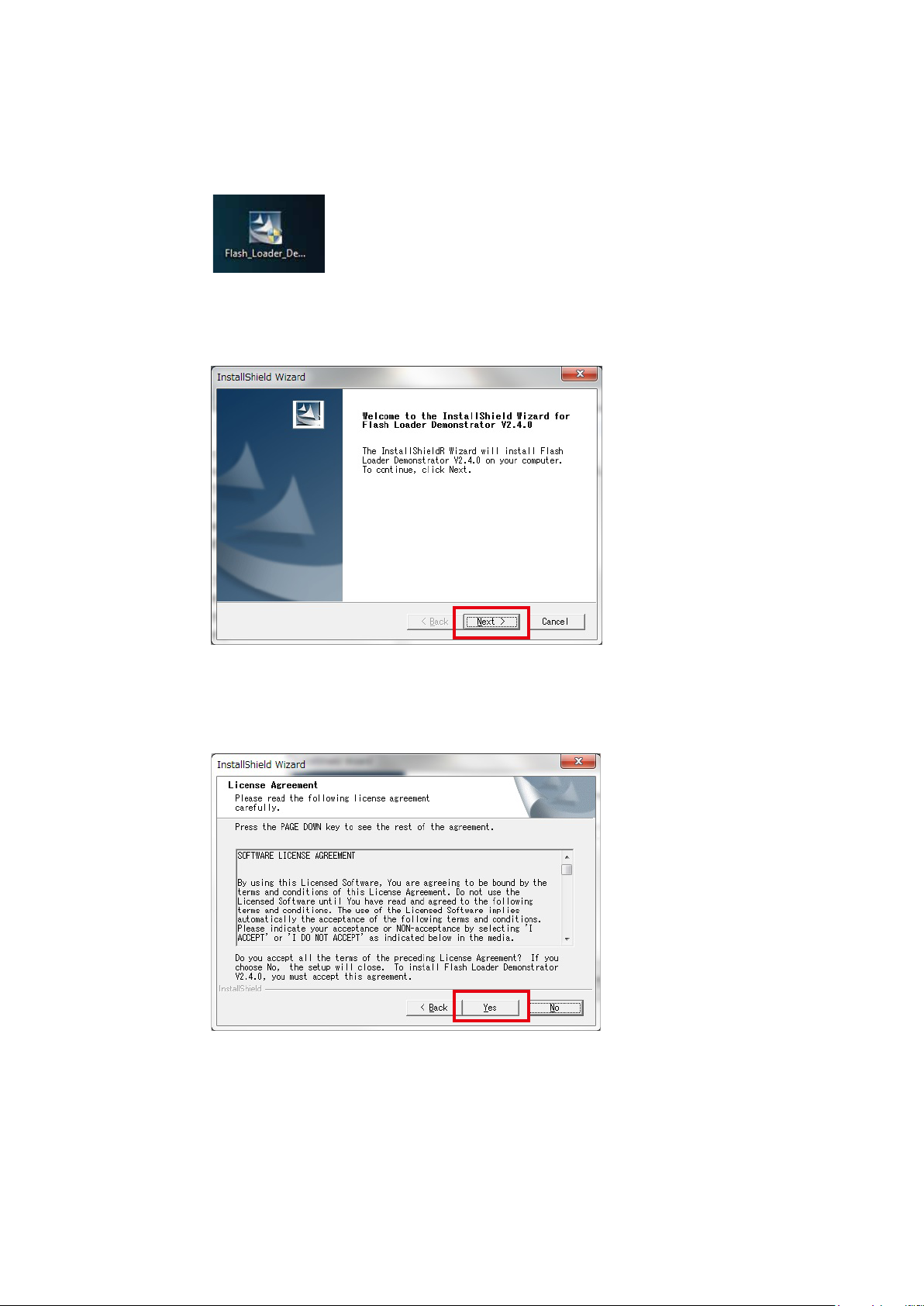

FIRMWARE UPDATE PROCEDURE

f

1. Items to Be Prepared

(1) PC

(2) RS-232C cable (9P (Male), Straight)

(3) 8U- 210100S:WRITING KIT.

606050028012P:7P FFC (Straight)

2. Connecting the WRITING KIT to This Unit

(1) Check that the power of this unit is turned off.

(2) Connect the WRITING KIT to the update terminal of this unit.

(3) Connect the RS-232C cable from PC with the WRITING KIT.

PC

①Connect windows PC with RS-232C cable.(Straight cable.)

→ This side is contacts of FFC.

Switch to the direction of the arrow.

②

7P FFC (Straight)

→ This side is contacts of FFC.

7P FFC (Straight)

15

Front

Page 16

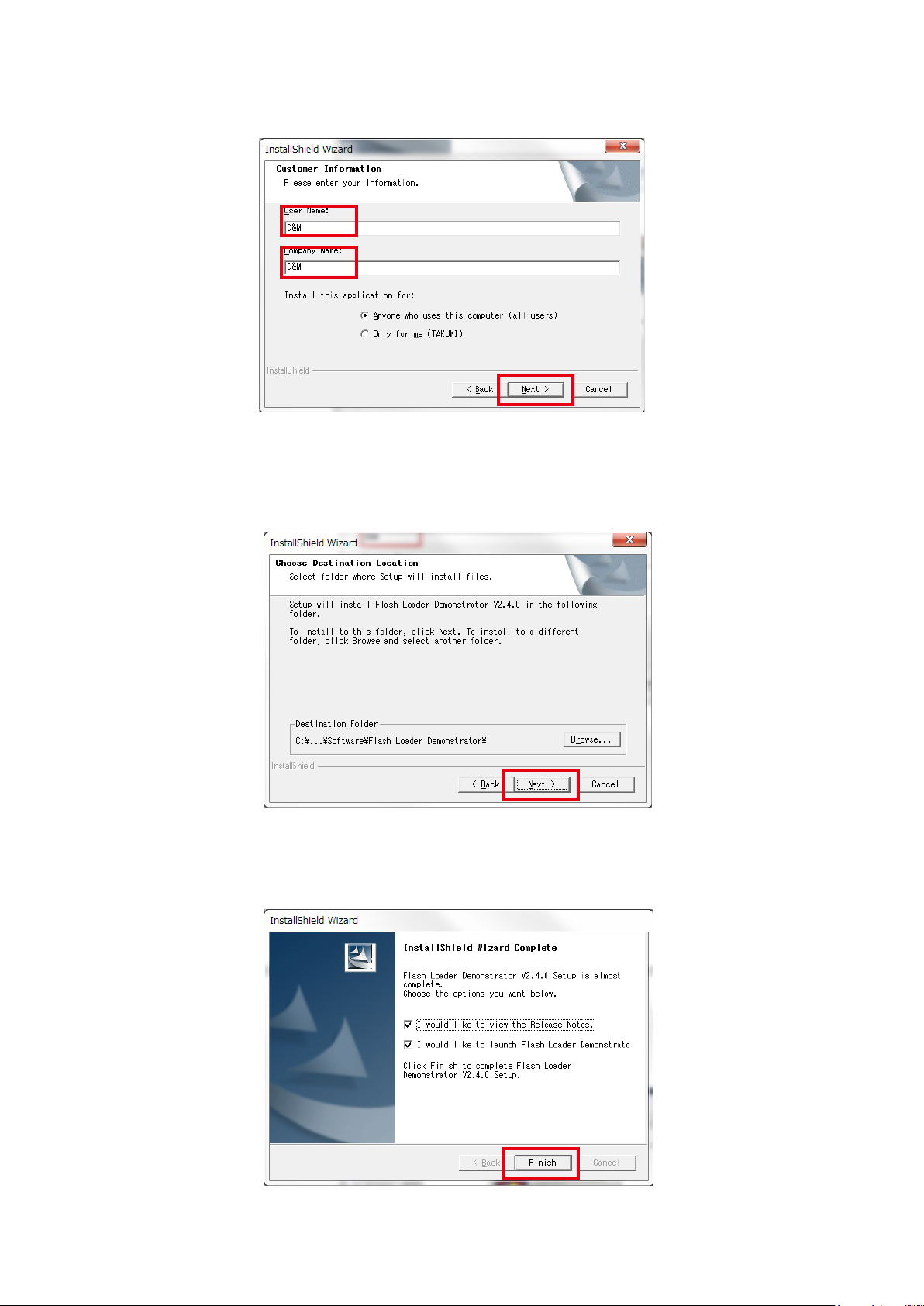

3. Installation of software

Installed on the PC Flash Loader Demonstrator.

(1) Download Flash Loader Demonstrator from SDI.

(2) Double click the "Flash_Loader_Demonstrator_v2.4.0_Setup.exe".

(3) Click "Next".

(4) Click "Yes".

16

Page 17

(5) Enter the company name and the name. Click "Next".

(6) Click "Next".

(7) Click "Finish".

17

Page 18

4. Starting This Unit

(1) Press the power button to turn on the power.

5. Run the Flash Loader Demonstrator

Execute the program "Flash Loader Demonstrator" that was installed on your computer.

(1) Click "Start" button, "All Programs" "STMicroelectronics", "Flash Loader Demonstrator" and select "Flash Loader

Demo".

(2) Select the RS-232C serial port number on your computer. Click "Next".

18

Page 19

(3) Click "Next"

(4) Click "Next"

(5) Check the "Download to device".

Click the Open le button.

19

Page 20

(6) Select the specied update le and click the “Open(O) ” button.

(7) Click "Next"

(8) "Update completed" is displayed when the rmware update nishes normally. Click "Close" button.

(9) Checking the rmware version after an update.

"SERVICE MODE " (Page 15)

20

Page 21

Personal notes:

21

Page 22

ADJUSTMENT

IDLING CURRENT ALIGNMENT

Adjusting Procedure

Set the power voltage to rated voltage for this adjustment.

(1) Adjust the Idling Current with the variable resistor V6001 and V6002 on the PWB CUP12578Z.

(2) Turn off the power.

(3) "+" of Connect Digital Voltage is connected to the No. 1 pin and connected "-" to No. 3 pin of N6003.

(4) "+" of Connect Digital Voltage is connected to the No. 1 pin and connected "-" to No. 3 pin of N6004.

(5) Before turning on the power, V6001 and V6002 have been counter clockwise turned with the adjustment driver.

(6) Turn on the power, VOLUME is set as (cmin.).

(7) After 2 minutes.

With seeing the digital voltage meter turn the variable resister clockwise slowly to adjust the idling current.

Idling adjustment with V6001 (V6002).

•Turn V6001 (V6002) clockwise to increase the idling current.

•The adjustment value of idling current is 10 mV(22.5 mA) ± 0.5 mV(1.1 mA) each.

(8) After 6 minutes.

Repeat the same procedure as 7.

•The adjustment value of idling current is 20 mV(45 mA) ± 0.5 mV(1.1 mA) each.

Adjustment is completed.

(9) Remove connection cable, attach the top cover.

NOTE : Idling current decreases with the temperature rise inside the unit, and it is set to 20 mV (45 mA) of setting value in

about 30 minutes after turn on the power.

22

Page 23

DC OFFSET VOLTAGE ADJUSTMENT

Digital Voltmeter Digital Voltmeter

V

R ch

V6003 V6004

L ch

V

N6004

31

1 3

N6003

V6001

V6002

Adjusting Procedure

DC Offset Voltage Adjustment

(1) Before turning on the power, Insert Digital Voltage Meter between the SPEAKERS SYSTEM A (L CH) "+" and "-".

Insert Digital Voltage Meter between the SPEAKERS SYSTEM A (R CH) "+" and "-".

(2) Adjust the VOLUME to MIN.

(3) Turn on the power. Then turn the SPAKERS SW to A.

Adjustment is started immediately after a speaker relay turns on.

(4) First L CH is adjusted.

The variable resistor V6003 on CUP12578Z is turned with adjustment driver, and the Digital Voltage Meter is adjusted

to "0 mV ± 3 mV".

(5) Then, R CH is adjusted.

The variable resistor V6004 on CUP12578Z is turned with adjustment driver, and the Digital Voltage Meter is adjusted

to "0 mV ± 3 mV".

NOTE : DC offset voltage drops when turn the semi-xed resistor (V6003 and V6004) clockwise. DC offset voltage rises

when turn the semi-xed resistor un-clockwise. Please turn it slowly, because value of Digital Voltage Meter

changes slowly.

(6) Although after-adjustment DC offset voltage has some change, Please check that the range of DC offset voltage

between L ch (R ch) "+" and L ch (R ch) "-" terminal of SPEAKERS SYSTEM A is "0 mV ± 20 mV". CHART OF

FACTORY MODE.

23

Page 24

TROUBLE SHOOTING

1. The power can not be turned on.

(STANDBY LED does not light (STANDBY MODE))

Check insertion of the

CUP12579Z-1 STANDBY

PWB UNIT.

Check insertion of the

CUP12580Z FRONT PWB

UNIT.

Check whether power is

being supplied to the coil of

the SUB TRANS T8501.

2. The power can not be turned on.

(STANDBY LED lights→ash)

Power not supplied.

Power supplied.

Broken wire in SUB TRANS

T8501.

Check whether power

is being supplied to the

D8501-8506.

Power not supplied.

Power supplied.

Malfunction of D8501-8506

Malfunction of

U8501,U1001.

Check each connector.

Check whether power is

being supplied to the F8510.

Check whether power is

being supplied to the coil of

the POWER TRANS T0001

Check whether power

is being supplied to

the D8001,D81018104,D8201-8202.

Power not supplied.

Power not supplied.

Power not supplied.

Power supplied.

(z1)

Broken wire in STANDBY

F8510.

Broken wire in POWER

TRANS T0001.

Broken D8001,D81018104,D8201-8202.

STANDBY LED repeats ON/

OFF for 0.5 seconds each.

Check input level,

SPEAKER connection and

SPEAKER resistance value.

Damaged DC OFFSET DETECT.

Damaged OVER HEAT DETECT.

Damaged OVER CURRENT

DETECT.

24

Damaged P_DWN detection

circuit and U1001.

Damaged power amplier circuit

Damaged power circuit.

Page 25

3. STANDBY LED ashes while using unit.

(protection circuit is set)

Check each connector

Refer to (z1) in "The power can not be turned on.

(STANDBY LED lights→ash)"

4. The power turned on, but a sound does not output normally.

(Both channels)

4.1 STANDBY LED does not ash (protection mode is not set)

Check each connector Broken wire in POWER TRANS T0001.

Check whether power is

being supplied to the coil of

the POWER TRANS T0001

4.2 When the volume is turned up, Mute LED ashes. (protection mode is set)

Repeats ON/OFF for 0.5 second each, and automatically returns to normal operation.

Power not supplied.

Power supplied.

Power supplied.

Damaged Selector (U3501)

Mute Circuit (Q6001-6002,L7501-7502).

Damaged Mute circuit, U1001.

Check input level and each

connector

Check SPEAKER connection

and SPEAKER short, SPEAKER

resistance value.

When you turn up the volume again after the unit

automatically returns to normal operation and if the

protection circuit is activated, STANDBY LED will

repeat ON/OFF for 0.25 seconds each.

Damaged power amplier circuit

Malfunction of C7501-7504

25

Page 26

Personal notes:

26

Page 27

LEVEL DIAGRAM

[dB] [dB]

+30

SP out:45W/8Ω +25.56dB(18.97V)

+30

+20

+10

0

-10

-20

-30

-40

-50

-60

DIG ITAL

BL OCK

OP T.

IN

CD:-13.97dB(200mV)

MM:-53.15dB(2.2mV)

INP UT

24.576MHz

Phono Amp Gv=39.2dB

MCK

HDAM

LP F

HDAM

S A2

Power Amp Gv=24.1dB

+1.43dB

Pre Amp Gv=15.4dB

-13.97dB

INPUT BLOCK PRE AMP BLOCK TONE AMP BLOCK POWER AMP BLOCK

+20

+10

0

-10

-20

-30

-40

-50

-60

CO AX.

IN

PHONO B LOC K

PHONO

TUN ER

CD

NETWORK

R EC ORDER

IN

R EC ORDER

OUT

PHONO AMP

R IAA

PC M

R EC BUF FE R

LINE DE TE CT

AMP

LOUDNESS

BL OCK

ON

OF F

LOUDNESS

LINE DE TE CT

VOLUME

PR E AMP B LOC K

PR E AMP

NFB

TO NE AMP BLOCK

TO NE AMP

TR E BLE

BAS S

S OUR CE DIR EC T

BAL ANCE

ON

OF F

MUTE

MAIN AMP BLO CK

PO WER AMP

NFB

PR OT EC TION

S PE AKE R

R ELAY

S PE AKE R

R ELAY

HE ADPHONE

R ELAY

S PE AKE R-A

(+)

S PE AKE R-A

(-)

S PE AKE R-B

(+)

S PE AKE R-B

(-)

HE ADPHONE

MAIN B LOCK

27

Page 28

POWER DIAGRAM

DIGI TAL I NPUT

OP T.

BL OC

IN

K

24.576MHz

PM6005 BLOCK DIAGRAM

MCK

HDAM

LP F

HDAM

S A2

CO AX.

IN

PHO NO BL OCK

PHO NO

TUN ER

CD

NETWORK

R EC ORDE R

IN

R EC ORDE R

OUT

PHO NO AMP

R IAA

PC M

R EC BUF FE R

LINE DE TE CT

AMP

LOUD NES S

BL OCK

ON

OF F

LOUD NES S

LINE DE TE CT

VOL UME

PR E AMP B LOC K

PR E AMP

NFB

TO NE AMP BLO CK

TO NE AMP

TR E BLE

BA

S S

S OURC E DIR EC T

BAL ANCE

ON

OF F

MUTE

MAIN AMP BLO CK

PO WER AMP

NFB

PR OT EC TION

S PE AKE R

R ELAY

S PE AKE R

R ELAY

HE ADPHON E

R ELAY

S PE AKE R-A

(+)

S PE AKE R-A

(-)

S PE AKE R-B

(+)

S PE AKE R-B

(-)

HE ADPHON E

R EG ULATOR B LOC K

US A VE RS ION ONLY

AC OUTL ET

FUS E

FUS E

AC IN

S TANDBY

R ELAY

PO WER S W

FUS E

MAIN T RANS .

S UB T RANS .

MAIN B LOCK

±38V

PR OT EC TION

±15V

+12V

+5V FUN CTIO N LE D

±12V

+5V DAC

+3.3V DIR / DAC

+3.3V

P_OF F DE TE CT

PO WER AMP

PR E AMP

FUN CTIO N R ELAY

DAC AMP

MCU

U-CO M BLOC K

PO WER DE TE CT

LINE DE TE CT

PR OT EC TION

FR ONT SW

E EP ROM

FL ASHE R IN

MCU

R C5I/R S E NSO R

FL ASHE R

US A VE RS ION ONLY

DIR

DAC

R ELAY DR IVE R

MUTE

MOTO R DR IVE R

FUN CTIO N LE D

INP UT S EL EC TOR

R C5 IN/OUT

28

Page 29

WIRING DIAGRAM

N8502

AC INLET

L

N

AC outlet

U1B/FN--ONLY

N8501

<POWER PCB>

<CUP12579Z-1>

N8503

B9901

<CUP12579Z-3>

<Headphone Jack PCB>

<Protection PCB>

B6501

<DIGIT PCB>

123

N8302

123

123

123

BN301

<CUP12581Z-A>

N7501

1234

1234567

N8301

5

67

BN300

1 2 3 54 6 7 8 9 14131210 11

BN302

< MAIN PCB>

<CUP12578Z-A>

1

1

23

2

N9001

3

2

2

1

B8901

1

1 2 3 54 6 7 8 9 131210 11

1 2 3 54 6 7 8 9 131210 11

N8504

<Power Transformer>

1 2 3

B1001

N

N

L

N3001

345 12

345 12

B5001

L

N8101

2

345 12

1

2

345 1

N8303

1 2 3

N8001

1 2 3

1 2 3 54 6 7 8 9 1514131210 11

N3002

N6001

1 2 3

<Volume PCB>

<CUP12579Z-2>

1 2 3 54 6 7 8 9 1514131210 11

B1002

1 2 3 1 2 3 54 6 7 8 9 14131210 11

B1003

B1004

N1002

123456

123456

N5002

<FRONT PCB>

<CUP12580Z-A>

<CUP12579Z-4>

B1006

<POWER SWitch PCB>

29

345 12

345 12

N5001

Page 30

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

PRINTED WIRING BOARDS

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

A

A

DIGITAL (A SIDE)

B

B300

C351

C350

IC303

R381

R375

C357

R390

C338

R391

C332

R378

R392

C333

C359

C358

X300

R399

R400

L301

IC301

R376C337

R403

R383

C

R384

C344

R372

C336

R385

R401

R377

C340

R371

R368

C343

C331

C342

R374

C335

R373

R370

R369

R397

R328

R389

R318

R388

R322

R393

R398

R319

R394

R402

C315

IC300

C302

C317

R304

C352

R306

C312

C318

C313

R325

R337

R326

C319

D

pb

JK300

C309

R300

R311

R310

R312

R307

C308

Q305

R329

R338

R340

R339

R343

C320

C328

C316

R361

R367

R363

R364

R365

C303

Q321

C324

R347

R348

R351

R352

R353

C305

C325

C304

R396

BN302

R395

PM6005 DIGIT INPUT UNIT

PM6005_DIGIT_LPP_CUP12581Z_A

C300

Q301

R302

R301

R333

R334

R332

C321

Q311

Q323

C329

R345

R344

R360

R359

R362

Q318

C322

INTI

GND

MUTE

GND

CS4398_RST

CS4398_M3

CS4398_M2

C347

Q300

R303

Q308

Q302

R314

Q309

R341

Q313

Q327

R366

Q325

R354

Q322

R356

Q319

R346

Q316

CUP12581Z

INTO

CDT0

PDN

CLK

CDT1

C345

C346D317

R382D316

Q304

R309

D300

D301

D303

D302

R313

D305

R308

C311

D307

D304

R327

D306

Q310

Q324

D314

R358

D315

D312

D313

R350

D311

D309

C327

D310

R349

D308

Q320

GND

CSN

Q303

R315

C306

JK301

R316

C310

Q306

R320

R323

R324

Q312

C330

Q326

R342

R357

C326

R330

Q314

R335

C323

R355

C314

Q317

BAR CODE LABEL

B301

C348

C349

C307

C353

C354

Q307

L OUT

GND

R317

R321

R OUT

BN301

C301

+3.3V

GND

+5V

GND

+12V

GND

-12V

BN300

Q315

R331

R336

C356

C355

MAIN (A SIDE)

R4008

R4002

R4006

K4001

E

F

G

H

J

C4002

3

25 4

1

L4001

C4001

R4001

K3001

C3010

C3009

2 57

C3012

C3011

41 63

C3014

K3002

C3013

2 7

1 63

C3016

C3015

5

4

C3022

C3021

K3004

3

1

5 42

R7505

R7506

Q7504

8

CH_R

4 6

2

CH_L

R4010

C4004

L4002

R4004

R4003

C4003

R4007

R4005

R3002

R3004

J3001

R3001

J3002

R3003

R3006

J3005

R3008

R3005

J3008

R3007

R3010

R3012

R3009

R3011

R3014

J3014

R3016

R3013

J3015

R3015

R3026

J3016

R3028

R3025

J3017

R3027

6

1

D7502

45

32

S7502

J7003

10 7

C7502

C7504

C7501

J6006

J7006

9 3 5

K7501

1

Q9001

N6003

C4008

J4001

C4006

C4005

C4007

R4009

J3003

J3004

J3006

J3007

30

J3009

J3049

J3050

J3010

J3011

J3012

6

45

J7007

C7503

R9005

R9003

1

U3501

J3013

1.DIG_L

3.DIG_R

N8302

N7501

1.HP_L

2.NC

3.HP_R

1 3

R7503

J7001

Q7503

D7501

1

C6024

S7501

J7002

C6023

32

R6105

C6007

R6023

J6007

C6019

R6057

C6011

D9001

R9007

J6093

J6094

R6093

J6058

R6083

Q6033

E B

R9001

R6067

R6089

Q6111

E3B

Q6131

SOLDERING

IN

C4014

C4012

R4014

C4010

R4012

R4013

C4013

C4009

C4011

R4011

J3022

J3023

R3510

J3024

C3506

R3505

D3501

15

R3511

J3045

J3046

S7503

R7504

R7507

R6106

J6118

J6119

R6019

Q6011

Q6007

D6001

Q6015

Q6019

D6005

R6035

R6031

R6043

Q6023

R6053

J6091

Q6027

J6049

R6073

J6095

J6096

J6050

R6077

V6001

R6081

R6087

R6069

B

E

J6057

R6071

Q6031

CH_L

OUT

N8301

1.-12V

2.GND

6.GND

3.+12V

5.+5V

4.GND

C4016

C4019

R4020

R4018

R4016

R4021

C4018

C4017

R4019

R4017

C4020

C4015

R4022

R4015

J4002

J4003

J3025

R3901

R3902

R3504

C3502

R3802

16

C3802

R3502

J3033

R3804

J3032

R3501

C3501

R3503

R3803

C3801

R3801

J3039

J3047

J6010

J6011

J7004

J6012

Q7501

D7503

R7501

R7502

R7508

J6115

R9010

J7008

L6002

J6020

J6002

R9009

J6116

J6001

L6001

J6117

Q6001

R6003

R6005

C6003

R6009

R6011

C6001

Q6005

R6029

R6017

J6052

R6027

Q6009

R6101

Q6003

R6099

R6097

R6015

C6017

Q6017

C6015

R6045

Q6021

J6051

R6041

R6039

D6007

R6061

J6048

Q6029

J6046

R6051

R6049

R6047

R6055

Q6025

J6047

R6095

J6097

R6085

E B

J6055

R6079

J6056

Q6112

EB

Q6035

Q6132

7.+3.3V

J8025

1 7

U8303

U8302

C8305

D8310

C8302

S8301

D8309

J8020

J3026

C3804

C3901

C3803

J3029

J3027

J3028

J3048

51

J3034

J3037

J3036

5.CH_R

3.CH_L

4.A_GND

J6013

J6014

J6015

J6016

J6017

J6021

J6114

J6018

J6022

J6019

R6007

J6112

J6113

J6111

J6110

R6001

J6029

J6030

J6031

D6003

C6009

J6032

R6021

J6102

J6103

R6025

Q6013

R6103

J6105

J6104

R6033

R6109

R6037

J6033

C6013

C6014

J6100

J6101

J6045

R6059

J6043

J6044

R6075

J6099

J6098

R6076

J6054

J6053

R6091

R6022

R6026

R6104

R6034

R6038

D6008

C8307

C8304

J3030

J3031

R3806

1.+15V

2.-15V

J6036

R6096

C8306

D8311

C8303

R3805

N3001

J3040

C8002

B8001

J6023

R6066

V6003

D6014

R6110

J6034

J6035

J6106

Q6122

EB

Q6142

U8301

N8303

C8308

OGI

J8022

J8019

U8304

R8301

R8302

J3042

J3043

D3901

J3041

R3906

R3905

D3903

C3904

C8001

J6026

J6024

J6025

D6011

R6063

D6009

D6013

J6028

J6027

Q6014

D6004

C6010

R6102

J6037

R6046

Q6018

R6062

J6039

R6060

Q6026

R6056

Q6030

J6107

R6080

R6086

Q6036

E B

R6092

R6068

J6059

C8309

1 3

D8301

D8302

D8303

D8304

C8301

D8305

D8306

D8308

C8311

D6010

D8307

C8310

R8303

R3904

C3903

C3902

J6003

R3903

D3902

J8004

J3044

J6078

J6077

R6064

R6065

R6108

2.A_GND

1.CH_L

N6001

D6012

J6073

V6004

1 3

J6072

R6008

Q6002

R6012

R6010

C6004

C6002

Q6010

R6018

R6016

Q6006

R6030

J6074

Q6004

R6028

Q6008

R6098

R6100

J6075

J6038

Q6020

C6018

C6016

Q6022

R6042

R6040

J6060

J6092

R6052

R6054

Q6028

R6050

R6048

J6108

J6061

J6040

J6041

J6109

J6042

R6094

R6082

R6088

R6084

Q6034

J6065

R6078

V6002

R6070

R6072

EB

EB

Q6032

BAR CODE

OGI

U8101

R9104

J8018

D8105

D8106

J6089

R9106

C8101

D8104

C8103

C8104

U8102

C8201

J6088

D8102

C8102

J8016

J8014

D8103

J8015

D8101

D8201

D8202

R9105

J8017

G OI

U8201

J6120

J6090

-

~

~

N8001

R8001

D8001

+

R9103

R9101

Z4002

R9102

Q9003

C9001

R9011

3.CH_R

J6087

J6070

J6071

J6079

J6069

C9003

R6002

R6004

R6006

C6008

N9001

D6002

Q6012

R6020

D9002

R9008

R6024

J6076

C6020

R6032

R6036

D6006

Q6016

R6044

R6058

1

C6012

R6074

Q6024

J6062

3

J6063

J6064

R3514

R3513

E B

R3512

J6067

J6066

Q6121

R6090

Q6141

CH_R

B8101

N8101

J8021

1 5

J8011

R8102

J8012

C8110

C8109

J8013

R8101

J8009

PM6005 MAIN PCB_MP_CUP12578Z_A 130618

C9101

J8008

C8202

J8007

J8006

J8024

J8003

U8202

G OI

C8203

J8023

J6004

J6005

J8001

ICTIC

ADJ-2

RPADJ-1

J6080

J6081

C9004

J6068

J6082

J6083

R9006

J6084

Q9002

J6085

15

R9004

R9002

J6086

15.DIG ON/OFF

14.AUDIO DET

D6203

13.SPK_B

12.SPK_A

N6004

11.PROTECT_2

10.+12V

9.P_RELAY

8.PROTECT_1

7.A_MUTE

6.F_MUTE

5.D_GND

N3002

1 7

4.+5VD

3.CLK

2.DATA

1.CE

Z4001

DIGITAL (B SIDE)

MAIN (B SIDE)

R8307

R8306

C8105

Q9102

R9107

R9108

Q9103

Q9101

C8206

C8207

R9012

R9013

Q9008

C9005

Q9007

R9014

R3516

R3517

Q3503

R6201

C8108

C8204

C8205

C9002

R9016

R9015

Q9005

Q9006

Q9004

R9017

Q3502

Q3501

R3515

B

C

D

E

C8107

C8106

Q8301

U3901

C3905

R3907

U3801

C3503

C3504

C3505

R3506

R3507

R3508

R6013

C6005

Q7505

Q7502

U4001

C4021

C3001

C3002

C3003

C3004

F

G

C3007

H

C7506

C7505

J

K

FRONT (A SIDE)

TO STANDBY N8504

+10V

D_GND

POW_ON

RC5

L

D1802

C1606

C1605

C1607

U1004

C1005

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

CUP12580Z_A

B1001

137

REM+5V

POW_RELAY

BOOT0

POW_DOWN

RXD

D1501

MP

B1004

7

14

M2

M3

INTI

RST

GND

GND

INTO

CDT0

CDT1

CSN

CLK

PDN

MUTE

TO DIGITAL INPUT BOARD

TXD

DGND

RESET

BOOT1

Q1001

C1501

R1052

R1501

R1043

R1046

R1065

Q1014

4

S1411

U1003

5 8

R1411

C1411

C1009

R1030

R1020

R1047

R1031

R1412

C1412

R1011

R1012

GND

R1066

R1072

R1040

C1018

R1067

R1050

R1051

R1041

C1017

R1042

33

48

C1015

49

C1014

32

R1044

R1045

U1001

R1039

R1005

R1038

R1029

R1037

64

R1014

17

C1016

16

R1026

C1011

C1012

R1028

R1048

R1049

C1001

C1008

8

5

R1025

U1002

X1001

C1007

U2002

R2015

4

R2019

R2017

C2015

R2013

C2011

++

+

R1004

C1006

R1015

Q1015

R1016

D1503

D1502

R1502

Q1017

R1053

C1502

R1503

C1503

R1054

TUNER

PHONO

Q1003

R1073

R1022

R1001

Q1016

Q1002

Q1004

D1513

R1036

R1069

C1013

R1068

R1070

R1071

R1027

R1017

R1008

C1004

C1515

S1401

SOURCE

R1032

R1033

R1034

R1035

R1024

R1018

C2017

C1002

Q1605

R1002

R1006

C1003

V2003

C2013

C2012

U2003

C2018

R2016

1 4 25 36

TO MAIN N3002

B1002

8 15

CE

CLK

+12V

DATA

SPKB

SPKA

+5VD

D1505

D1504

D-GND

R1055

C1608

R1504

C1504

NETWORK

CD

Q1005

Q1018

C1505

Q1607

Q1608

Q1006

D1510

Q1011

Q1010

SPKA

S1402

R1511

R1062

R1061

R1510

C1511

C1510

R1405

R1403

R1402

R1404

R1401

C1401

8

5

C2016

R2014

R2018

R2020

4

C2014

FMUTE

R1056

V2002

AMUTE

R1505

PROTECT1

241 5 6 3

D1508

DIG_POW

PROT2

AUDET

D1603

POW_RELAY

REC

COAX

R1506

R1057

D1506

C1506

Q1020

Q1012

D1511

R1512

R1063

C1512

S1403

SPKB

R2005

R2007

R2006

C2007

85

C2009

U2001

4

C2010

C2005

R2008

TO VOLUME N5001

Q1804

R1808

5

D1509

MUTE

6

TO VOLUME N5002

N1002

C2001

C2003

C2004

C2002

7

R1806

Q1803

+12V

D-GND

MOT+

MOT-

LOUND

D1801

R1809

R1807

Q1801

Q1802

R1212

R1804

R1805

R1013

C1801

C2020

C2019

R2022

R2021

R2001

S2001

Q1604

BAR CODE LABEL

R1604

R1603

D1601

R2002

B1003

TO MAIN N6001

R1605

D2001

C1604

Q2001

Q1609

Q1603

Q1610

Q1601

LOUT

ROUT

AGND

ADJ-1

IC ICT RPADJ-2

C1603

R1602

Q1602

C1010

Pb

R1601

C1601

C1602

U1601

B1006

R1801

D1507

R1059

R1507

R1508

C1507

C1508

R1058

OPTICAL

R1060

C1509

R1509

Q1009

Q1008

Q1007

Q1019

Q1013

D1512

R1513

R1064

C1513

S1404

LOUND

R2003

R2004

V2001

C2008

C2006

R2011

R2009

R2010

R2012

6

2

415

3

FRONT (B SIDE)

JTAG_DI

+3.3V

RESET

JT_CLK

N1001

GND

JTAG_DO

JTAG_MS

JTAG_RST

GND

K

L

M

30

Page 31

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

STANDBY (A SIDE) HEADPHONE (A SIDE)

N8504

RC5

RXD

TXD

+10V

POW_ON

B8501

J8510

B

C

D

B8502

D8702

K8701

J8511

BAR CODE LABEL

S8501

J8513

J8514

C8701

U8701

Z8701

D8701

K8501

Japan/USA:T3.15AL 250V

Europe/China:T1.6AL 250V

(Sec.)

C8506

J8512

Q8501

D8508

C8502

F8510

H8512

J8516

F8620

H8511

T5.0AL 250V

(Pri.)

C8504

F8610

T5.0AL 250V

N8503

D8507

J8506

R8501

J8515

N8501

BOTT1

D-GND

BOTT0

MCU_RST

POW_DOWN

POW_RELAY

REMOTE 5V

J8507

J8508

J8509

D8505

D8502

D8504

D8503

T8501

K8601

E

C8503

J8505

J8504

D8506

D8501

N8502

LPP

Pb

CUP12579Z-1

STANDBY UNIT

J8502

J8501

J8503

N8505

(Sec.)

(Pri.)

STANDBY (B SIDE) HEADPHONE (B SIDE)

Q8503

C8509

R8503

C8505

R8505

D8509

Q8502

R8502

C8510

U8501

R8702

Q8701

C8702

Pb

R8504

R8701

C8507

C8508

K9901

H/P UNIT

C9902

C9901

R9902

R9901

Pb

B9901

CUP12579Z-3

POWER SW (A SIDE)

B8901

C8901

Pb

CUP12579Z-4

S8901

POWER SW

Pb

POWER SW (B SIDE)

Pb

A

B

C

D

E

F

VOLUME (A SIDE)

C2503

R2503

R2501

R5013

Q5011

C5005

Q5015

R5003

R5009

J5017

R5015

D5003

R5021

Q5003

R5047

R5035

R5033

C5001

C5009

R5027

R2504

R5017

J5019

R2502

J5011

R5039

C2501

C2502

R5002

R5001

V5001

J5014

J5012

J5013

J5015

Z5001

Q5007

N5002

R5041

R5043

R5045

N5001

G

H

J

K

J5001

Pb

CUP12579Z-2

B5001

R5048

C5004

J5005

R5006

Q5002

R5008

R5012

Q5006

D5002

R5020

Q5010

R5026

D5006

R5024

R5030

R5032

C5008

Q5014

J5020

D2501

C2505

S2501

VOLUME UNIT

J5002

J5003

J5004

B5002

C5011

C5012

C5002

R5004

J5006

J5010

J5008

J5009

J5007

R5005

Q5004

Q5016

R5036

R5034

C5010

Q5001

R5007

Q5008

R5011

R5042

Q5005

D5001

R5018

J5018

R5019

Q5009

R5044

D5005

R5023

R5028

R5029

R5031

R5046

C5007

Q5013

R5040

R5010

R5014

J5016

R5038

R5016

D5004

R5022

Q5012

C5006

C2504

C5003

R5025

J5021

R5037

VOLUME (B SIDE)

C5013

Q2501

POSISTER (A SIDE)

B6501

Pb

T6501

POSISTER (B SIDE)

Pb

Pb

F

G

H

J

K

L

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L

M

31

Page 32

K-A-L C H

PK-B-L CH

K-A-R CH

PK-B-R C H

FROM HP PWB B9901

FROM MAIN TRA NS

FROM MAIN TRA NSFORMER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

A

TO B1003

DIG-R

REC-IN-R

REC1-ROUT

47

R3502

10uF/50V

C3502

C3803

V+

U3801

A OUTPUT

1 2 3 4

R3806

10

R3805

10

R

R_CH

R3510

220K

A_GND

R6003

R6001

10

R6002

B OUTPUT

+-

A

A-INPUT

123

N6001

L

3P-BASE

FROM FRONT P CB B1003

R6005

L_CH

330

R6007

220K

1K

10

R6006

330

R6008

220K

R6004

1K

B-INPUT

B

+ -

A+INPUT

C6011

470/63V

SHORT

R6023

C6007

OPEN

33K

R6019

T

Q6011

D6001

133M

22

Q6007

22UF/25V

C6001

R6009

KTC2874BT

Q6001

22UF/25V

C6002

R6010

KTC2874BT

Q6002

R3902

R3901

R3803

C3801

10uF/50V

R3801

100K

5678

B+INPUT

V-

100K

R3802

R3804

1K

C3802

10uF/50V

R6015

R6011

100

FAS

47K

100PF

C6003

C6009

OPEN

470/63V

C6012

470/63V

C6008

R6012

100

FAS

47K

100PF

C6004

D3901

133MT

39K

OPEN

C3903

R3904

10K

10K

220PF

C3901

1K

R6027

KSA992

Q6003

R6029

KSC1845

Q6005

22

R6017

Q6009

D6003

133MT

Q6013

33K

R6021

SHORT

R6025

C6013

R6097

100

SHORT

R6024

OPEN

33K

R6020

Q6012

D6002

133MT

22

Q6008

R6016

R6028

KSA992

Q6004

R6030

KSC1845

Q6006

22

R6018

Q6010

D6004

133MT

Q6014

33K

R6022

C6010

OPEN

SHORT

R6026

C6014

470/63V

R6098

100

U3901

A OUTPUT

V+

1234

B OUTPUT

A

+-

A-INPUT

B

+ -

A+INPUT

B-INPUT

V-

5 6 7 8

B+INPUT

C3902

10uF/50V

100

R3903

D_

GND2

150

470

R6035

R6031

R6043

4.7K

D6005

133MT

KSA992

Q6015

Q6019

KSC1845

KSC1845

FNS

330PF

C6015

1M

R6039

22

22

1M

R6041

KSA992

Q6021

KSA992

KSC1845

Q6017

470

R6033

R6099

R6101

330

330

470

R6032

KSA992

Q6016

Q6020

KSC1845

KSC1845

FNS

330PF

1M

C6016

R6040

22

22

1M

R6042

KSA992

Q6022

KSA992

KSC1845

Q6018

470

R6034

R6100

R6102

330

R6057

KTA1024

KTC3198

Q6023

R6053

22

R6049

KTA1266

22

47/25V

C6017

R6047

22

R6051

KTC3198

R6055

KTC3206

KTA1266

Q6025

R6059

D6007

133MT

R6045

4.7K

150

R6037

R6109

R6103

390

390

150

R6036

R6044

4.7K

D6006

133MT

KTA1024

KTC3198

Q6024

KTA1266

47/25V

C6018

22

22

KTC3198

R6052

R6048

KTC3206

KTA1266

D6008

133MT

R6046

4.7K

150

R6038

R6104

R6110

390

390

330

F_MUTE

A_MUTE

R3905

100K

C3904

10/63V

47K

R3906

D3902

133MT

D3903

133MT

OPEN

100K

C3905

R3907

C6005

TEM PROT ECT

0.022uF

R6013

1M

R6108

SHORT

PEN

O

R6201

OPEN

D6203

R6073

22

KIA7815API

Q7501

R7501

KTA1266YT

47K

4.7K

R7502

HVTKRC107S

Q7502

31

2

GND2

D_

A_MUTE

L_CH

R7503

4.7K

KTC3198YT

Q7503

47K

R7504

GND2

D_

R7505

4.7K

KTC3198YT

Q7504

47K

R7506

GND2

D_

L_CH

D7501

D7502

R_CH R_CH

D7503

HVTKRC107S

Q7505

31

A_MUTE

2

D_

R_CH

32451

133MT

133MT

133MT

GND2

S7501

6

CSL3A018ZE

L_CH

32451

S7502

6

CSL3A018ZE

R7507

330

5643817

S7503

2

CSL4A016ZU

R7508

330

C7501-C7504:N/K ONLY

C7503

0.01uF/100V

C7501

0.01uF/100V

J6006

1

+

SHORT

J6007

SHORT

C7502

0.01uF/100V

C7504

0.01uF/100V

C7505

0.01uF

C7506

0.01uF

N7501

S

-

3

2

+

SP

-

4

7

+

S

-

5

8

+

SP

-

6

9

10

K7501

CJJ5Q006Z

TO B9901

HP_L

123

N7501

3P-BASE

HP_R

2

D8001

CVDD30XBN20

NICHICON

10000uF/63v

A_GND1

C8001

GND2

A_

A_

GND

R8303

22K

R9106

22K

22K

22K

R9104

R9105

INOUT

123

U8101

0.1uF

GND

C8105

C8101

470/35V

0.1uF

C8106

GND

C8102

OUT IN

U8201

470/35V

U8102

CVIKIA7812APIVA

INOUT

123

GND

0.1uF

C8201

C8204

470/25V

3

1

2

B8001

GND-TERMINAL

C8308

0.01UF

D8302

D8301

11EQS10GT

11EQS10GT

C8301

6800uF/16V

D8101

R8101

11EQS10GT

1(1W)

D8102

11EQS10GT

D8103

11EQS10GT

D8104

11EQS10GT

B

8101

1

2

3

D8202

1N4003ST

D8201

1N4003ST

C8109

0.01UF

C8110

0.01UF

R8102

1(1W)

R8306

R8307

1234

VINVOU T

GND

330

100

Q8301

KRC107S

C8002

10000uF/63v

NICHICON

C8309

0.01UF

22K

D8303

U8301

CTRL

220/16V

C8306

N8301

+3.3V

R8301

D8304

11EQS10GT

11EQS10GT

KIA278R33PI

133MT

D8309

S8301

CSL4A016ZU

U8304

1

INOUT

2

GND

3

KIA7805API

C8307

10/50V

GND

1234567

GND

GND

+5V

+12V

1

3

D8306

D8305

11EQS10GT

11EQS10GT

22K

R8302

C8310

220UF/35V

2

U8302

KIA7812API

N8301

CJP07GI236ZW

-12V

FROM DIGITA L UNIT BN300

4

C8311

220UF/35V

5643817

RA2.ELNA

C8302

220UF/35V

1

2

OUT IN

COMMON

3

D8311

133MT

C8304

220UF/35V

RA2.ELNA RA2.ELNA

R8001

0.68uF/125VAC

D8307

RA2.ELNA

C8303

220UF/35V

1

133MT

D8310

C8305

220UF/35V

123

AC

GND

N8001

AC

12345

AC

GND

GND

3P-BASE-B OX

GND

AC

5P-BASE

N8101

123

CJP03GI237ZW

N8303

FROM MAIN TRA NS

D8308

11EQS10GT

11EQS10GT

2

GND

OUT IN

U8303

KIA7912PI

3

47K

22

Q6027

Q6029

22

47K

C6019

220/35V

47K

R6058

22

R6054

Q6028

Q6030

22

R6056

47K

R6060

C6020

220/35V

DC_DETECT

R6077

100

KTC3026

Q6033

R6083

47

6.2K

R6067

Q6031

820

R6069

47

R6071

31

2

V6001

220

R6061

100K

R6075

22

R6074

22

6.2K

R6068

Q6032

820

R6070

47

R6072

31

2

V6002

220

R6062

100K

R6076

1K

R6081

2SC4495

R6085

47

R6079

100

Q6035

KTA1024YT

1

R6063

2

4.7K

470

K

3

V6003

R6064

2

470K

V6004

R6078

100

KTC3026

Q6034

R6084

47

2SC4495

1K

R6082

R6086

47

R6080

100

Q6036

KTA1024YT

22

KSA992FTA

R9012

31

2

0.1uF

C9005

Q9008

HVTKRC102S

22K

R9014

KTC3875SY

Q9006

10/50V

C9004

KTA1504SY

Q9103

D_

GND2

Q6131

KTC3423Y

R6089

Q6111

10

2SC4467

3P_BASE

N6003

221

R6087

Q6112

KTA1360Y

D6013

133MT

D6011

133MT

D6009

133MT

1

D6010

133MT

4.7K

D6012

133MT

3

D6014

133MT

KTC3423Y

Q6121

3P_BASE

N6004

221

R6088

Q6122

KTA1360Y

6.8K

R9011

Q9003

22K

KTA1504SY

R9013

22K

68K

R9108

KTC3875SY

Q9102

R9001

123

R6093

0.22/5W

R6095

0.22/5W

Q6132

R6091

10

2SA1694

R9009

22K

R6065

22K

R6066

Q6141

R6090

10

2SC4467

R9002

1K

123

R6094

0.22/5W

R_CH

R6096

0.22/5W

Q6142

R6092

10

2SA1694

R9010

C9001

0.47/50V

100K

R9015

Q9007

R9016

68K

KTC3875SY

KTC3875SY

Q9005

Q9004

D_

KTC3875SY

Q9101

R9107

R9005

1K

22K

KSC1845FTA

Q9001

1.5K

R9003

L_CH

J6001

OPEN

L6001

22K

R9007

C6023

D9001

GND

A_

0.039UF

10

133MT

R6105

SPK_A

82K

SPK_B

R9006

22K

KSC1845FTA

Q9002

1.5K

R9004

J6002

OPEN

L6002

22K

R9008

C6024

0.039UF

10

R6106

D9002

133MT

A_GND

82K

R9101

R9102

33K

33K

33K

R9103

0.1uF

C9002

+15V

47K

47/50V

R9017

GND2

C9003

10K

47/50V

C9101

D8105

-15V

D8106

+12V

HVIKIA7805API

47/50V

C8203

0.1uF

C8207

J6004

SHORT

D_GND2

0.1uF

47/25V

C8103

C8107

1N4003ST

0.1uF

47/25V

C8104

1N4003ST

C8108

312

INOUT

123

U8202

GND

CVIKIA7915PI

0.1uF

0.1uF

47/50V

C8206

C8205

C8202

SHORT

J6003

J6005

SHORT

D_GND2

B

C

D

E

F

G

H

J

K

B

N6001

6.8K

R4013

C4013

L4001/L4002£ºN/K ONLY

R4001/R4002£ºN/K--6.8K

5

1

L

TUNER

CD IN

R

K4001

L

R

K3001

L

R

L

R

K3002

L

R

N8302

N8302

L

R

K3004

2

C4021

3

4

1

2

3

0.1uF

C3001

4

5

6

C3002

7

1

2

3

0.1uF

C3003

4

5

6

C3004

7

123

CJP03GI236ZW

5

1

2

3

4

PHONO IN

C

D

E

NETWOR K IN

RECORDER IN

F

TO BN301

DIGITA L.R_IN

FROM DIGITAL PCB BN301

DIGITA L.L_IN

RECORDER OUT

G

H

U/L--SHORT

10uF/50V

C4003

R4001

C4001

L4001

0.1uF

3 462

220P/100V

L4002

C4002

220P/100V

R4002

C3009

C3010

C3011

0.1uF

C3012

C3013

C3014

C3015

0.1uF

C3016

C3007

0.1uF

C3021

C3022

Z4001

1

LAND

Z4002

1

LAND

R4007

6.8K

1

6.8K

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

220P/100V

100

56K

C4005

R4005

R4003

1

3462

R4004

10

220K

R3001

220K

R3002

220K

R3005

220K

R3006

220K

R3009

220K

R3010

220K

R3013

220K

R3014

220K

R3025

220K

R3026

220P/100V

330K

56K

330K

C4006

R4006

220P/100V

C4004

R4008

100

uF/50V

R3003

220

R3004

220

R3007

220

R3008

220

R3011

220

R3012

220

R3015

220

R3016

220

R3027

560

R3028

560

J

K

C4007

220/35V

100

R4009

V-

B+INPUT

5 6 7 8

C4008

R4010

100

220/35V

TUNER-L

TUNER-R

CD-L

CD-R

NET-L

NET-R

REC-IN-L

REC-IN-R

DIG-R

DIG-L

REC1-LOUT

REC1-ROUT

120

120

R3506

R3507

680

R3515

GND2

D_

C4009

0.039UF

A-INPUT

A+INPUT

A

+ -

+-

B

B OUTPUT

B-INPUT

R4016

100

82K

C4010

0.039UF

R4012

DIG-L

NET-L

REC-IN-L

REC1-LOUT

R3511

220K

C3505

330P

C3504

330P

C3503

120

330P

R3508

Q3502

KRC107S

R3516

680

D_

GND2

KRC107S

Q3501

0.01UF

82K

R4011

10/50V

C4011

C4015

R4015

100

1234

A OUTPUT

V+

R4014

-L

CD-L

TUNER

PHONO-L

R3501

10uF/50V

R3517

GND2

D_

R4019

1000PF

100

R4022

10

100K

OPEN

R4017

C4017

-15V

C4020

100/25V

U4001

+15V

C4019

100/25V

R4021

100K

OPEN

C4018

R4018

10

C4016

R4020

100

10uF/50V

C4014

0.01UF

C4012

6.8K

1000PF

PHONO-R

PHONO-L

INPUT1

U3501

CD-R

NET-R

TUNER-R

PHONO-R

123456789101112131415

L1

R1

L2

R2

HVILC78212

R3

L3

LCOM1

RCOM1

L4

R4

R5

L5

R6

L6

LCOM2

RCOM2

L7

R7

L8

R8

LCOM3

RCOM3

VDD

VEE

R3505

RES

CE

10K

D3501

DI

S

133MT

CL

VSS

16 1 7 18 19 20 21 22 23 24 25 26 27 28 29 3 0

C3506

47

R3503

100K

C3501

R3512

R3513

R3514

KRC107S

680

4.7/50V

R3504

100K

100/25V

4.7K

4.7K

4.7K

100/25V

Q3503

C3804

TO BN300

SPK_B

AUDIO DET

1 2 3

GND

HEAT

DIG POWER O N/OFF

TO B6501

NC

N9001

N9001

L

L

MAIN

1 2 3 4 5

+15V

N3001

SP-BASE

FROM FRONT B 5001

L

R

GND

-15V

A_

TO N1002

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

+12V

LC78212-CE

LC78212-CLK

LC78212-DATA

D_GND

F_MUTE

A_MUTE

MCU +5VD

TO B1002

N3002

Y

CJP15GA19Z

FROM FRONT P WB B1002

SPK_A

P_RELAY

PROTECT_ 1

PROTECT_ 2

N3002

M

SCHEMATIC DIAGRAMS (1/4)

STBY POWERGND POWER + POWER -

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L ch SIGINAL LINE

R ch SIGINAL LINE

SCHEMATIC DIAGRAMS (1/2)

SCH01_MAIN

8U-310014 SACD UNIT (1/2)

M

32

Page 33

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

5VD

+3.3V

330

150

R1504

R1501

B

C

RED

OPEN

BLUE

OPEN

C1501

D1504

R1052

D1501

Q1001

HVTKRC102S

STANDBY_LED

HVTKRC102S

D

CD_LE

R1411

D

C1411

GND

9

JTAG_DI

7

JTAG_CLK

5

RESET

3

+3.3V

1

D-GND

D-GND

+3.3V

8

JTAG Debug

JTAG_RST

JTAG_MS

JTAG_DO

6

4

2

GND

E

330

R1505

10K

BLUE

0.01uF

R1055

D1505

C1504

Q1004

HVTKRC102S

UPDATE_TX/NETWORK_LED

+3.3V+3.3V

47K

47K

R1412

S1411

INPUT SELECT

0.01uF

0.01uF

C1412

D-GND

330

R1506

10K

BLUE

0.01uF

C1505

D1506

R1056

Q1005

HVTKRC102S

REC_LED

330

R1509

10K

RED

0.01uF

R1057

C1506

D1509

Q1006

HVTKRC102S

MUTE_LED

N1001

F

G

H

J

K

L

M

1

MUTE

GND

16-WIRE

M1

M2

RST

BN302

GND

INTI

INTO

CDT0

CDT1

CCLK

PDN

TO Digital Input Board

TO BN302

CSN

GND

B1004

B1004

D-GND

D-GND

14 13 12 11 10 9 8 7 6 5 4 3 2 1

D-GND

+3.3V

+3.3V

100/16V

C1607

REM+5V

U1601

R94EV1A

100

R1601

Vcc GND VOUT

3 2 1

C1602

0.1uF

C1601

100/16V

D-GND

Q1610

HVTKRC102S

D-GND

R1065

HVTKRA102S

HVTKRA102S

OPEN

10K

10K

10K

10K

10K

OPEN

10K

R1066

R1067

R1068

R1069

R1070

R1072

R1071

5VD

D1802

1SS133MT

NJM2845DL133

U1004

3 1

0.1uF

5

C100

Q1601

Q1602

IN

0.1uF

100/25V

OUT

GND

2

C1605

C1606

D-GND

Q1609

HVTKRC102S

Q1603

HVTK

RA102S

D-GND

1SS133MT

D1601

R1603

47K

R1604

18K

Q1604

B1001

B1001

+3.3V

100

R1602

33K

R1605

100/16V

0.1uF

C1604

C1603

HVTKTC3875SYRTK

D-GND

REM+5V

D-GND

RC5

+10V

D_GND

POW_ON

REMOTE+5V

TO N8504

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

SOURCE DIRECT SPK_A SPK_B LOUDNESSSTANDBY PHONO TUNERCD NETWORK RECORDER OPTICALMUTE

PHONO/TUNER_LED_POW

LOUND

AK4117_INTO

100

R1040

VOL_DOWN_MOTOR

AK4117_INTO

POWER_ON_DC_DETECT

POWER_DET

VSSA

0.1uF

C1012

+3.3V

R1004

47K

0.1uF

D-GND

HVTKRC102S

SOURCE

LOUND

VOL_UP_MOTOR

BOOT1/F_MUTE

AUDIO_DET

STANDBY_LED

AK4117_CDTI

AK4117_CTTO

AK4117_CLK

AK4117_CSN

VDDA

C1006

Q1017

R1502

HVTKRA102S

Q1018

HVTKRC102S

PHONO/OPTICAL_LED

SPKB

SPKA

AUDIO_DET

0.01uF

C1017

0.01uF

C1018

130429: ADD

C1014

VDD_1

32

VSS_1

0.1uF

31

SPKB

SPKA

SOURCE

30

29

28

27

RC5_IN

26

25

24

23

22

21

20

C1013

VDD_4

19

VSS_4

0.1uF

18

POWER_ON

17

ENC+