MARANTZ NR1402 Service manual

Service

NR1402 /

N1SG/N1B

/U1B/K1B

Manual

AV Surround Receiver

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

NR1402

S0738-1V04DM/DG1309

Copyright 2013 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 4

Please refer to the

MODIFICATION NOTICE.

CONTENTS

SAFETY PRECAUTIONS

NOTE FOR SCHEMATIC DIAGRAM

TECHNICAL SPECIFICATIONS

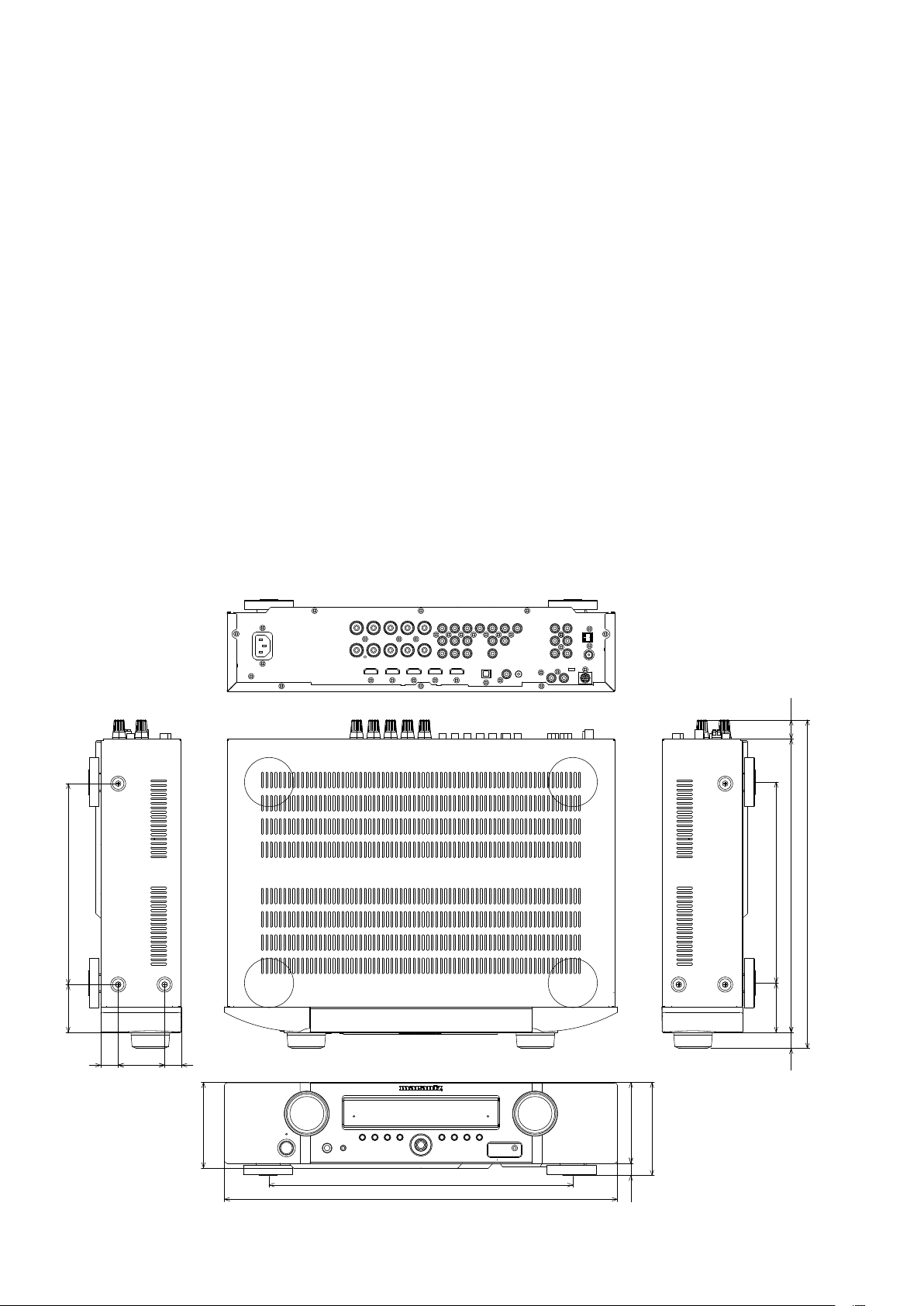

DIMENSION

CAUTIONS IN SERVICING

Initializing AV Surround Receiver ..............................................7

Service Jig ................................................................................7

DISASSEMBLY

1. FRONT PANEL ASSY ...........................................................9

2. RADIATOR ASSY ................................................................ 11

3. REG ASSY ..........................................................................13

4. PCB RC5_MX .....................................................................14

5. PCB HDMI ASSY.................................................................15

6. POWER TRANS MAIN ........................................................16

7. AV ASSY ..............................................................................18

8. PCB SMPS ..........................................................................18

9. PCB SPK .............................................................................19

Special mode setting button ....................................................20

1. µcom/DSP Version display mode ........................................21

2. Errors checking mode (Displaying the protection history) ...23

3. DUAL BACKUP MEMORY ..................................................25

4. DIAGNOSTIC MODE

(Video/Audio(signal)pathconrmationmode) ...................26

BLOCK DIAGRAM

JIG FOR SERVICING

WHEN THE MICROPROCESSOR IS REPLACED WITH

A NEW ONE

PROCEDURE FOR UPGRADING THE VERSION

OF THE FIRMWARE

1. How to update by DFW .......................................................41

ADJUSTMENT

SURROUND MODES AND PARAMETERS

TROUBLE SHOOTING

1. POWER ...............................................................................50

2. Analog video ........................................................................51

3. HDMI ...................................................................................55

4. AUDIO .................................................................................60

6. SMPS ..................................................................................63

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK

LEVEL DIAGRAM

PRINTED WIRING BOARDS

5CH AMP ................................................................................72

SPK ........................................................................................73

SPMS .....................................................................................75

RC5_MX .................................................................................75

REG .......................................................................................76

FRONT_CNT ..........................................................................76

SIDE_CNT ..............................................................................77

REG_CNT ..............................................................................77

USB .........................................................................................77

H/P ..........................................................................................77

FRONT ...................................................................................78

AV ...........................................................................................79

HDMI ......................................................................................80

...............................................................................6

..........................................................................8

.............................................................................41

.........................................................................45

..........................................................4

.........................................5

................................................6

.......................................................7

...................................................................28

..............................................................39

................................................................41

............................46

............................................................50

.............66

....................................................................67

...................................................72

SCHEMATIC DIAGRAMS

5CH-AMP UNIT (1/2) ..............................................................82

5CH-AMP UNIT (2/2) ..............................................................83

SPK UNIT ................................................................................84

SMPS UNIT .............................................................................85

REG UNIT ...............................................................................86

SIDE_CNT UNIT .....................................................................87

FRONT_CNT UNIT .................................................................88

RC5_MX UNIT ........................................................................89

AUDIO_VIDEO UNIT (1/3) ......................................................90

AUDIO_VIDEO UNIT (2/3) ......................................................91

AUDIO_VIDEO UNIT (3/3) ......................................................92

HDMI UNIT (1/8) .....................................................................93

HDMI UNIT (2/8) .....................................................................94

HDMI UNIT (3/8) .....................................................................95

HDMI UNIT (4/8) .....................................................................96

HDMI UNIT (5/8) .....................................................................97

HDMI UNIT (6/8) .....................................................................98

HDMI UNIT (7/8) .....................................................................99

HDMI UNIT (8/8) ...................................................................100

FRONT UNIT .........................................................................101

USB UNIT..............................................................................101

H/P UNIT ...............................................................................101

WIRING DIAGRAM

EXPLODED VIEW

PARTS LIST OF EXPLODED VIEW

PACKING VIEW

PARTS LIST OF PACKING & ACCESSORIES

SEMICONDUCTORS

1. IC's ....................................................................................11 0

2. FL DISPLAY.......................................................................134

PARTS LIST OF P.C.B. UNIT

PCB 5CH_AMP ASS'Y ..........................................................136

PCB SPK ASS'Y ....................................................................139

PCB REG_CNT ASS'Y ..........................................................142

PCB FRONT ASS'Y...............................................................144

PCB AUDIO_VIDEO ASS'Y ..................................................147

PCB HDMI ASS'Y ..................................................................149

.....................................................................108

........................................................82

................................................................102

..................................................................103

......................................105

.....................108

.............................................................11 0

................................................136

2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

marantz

parts can insure that your

marantz

productwillcontinuetoperformtothespecicationsforwhichitis

marantz

company has created the ultimate in stereo sound.

famous.

Parts for your

marantz

equipment are generally available to our National

marantz

Subsidiary or Agent.

ORDERING PARTS :

PartscanbeorderedeitherbymailorbyFax..Inbothcases,thecorrectpartnumberhastobespecied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

2F,YEON BLDG.,

88-5, BANPO-DONG, SEOCHO-GU,

SEOUL KOREA

PHONE : +82 - 2 - 715 - 9041

FAX : +82 - 2 - 715 - 9040

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol z .

Anyothercomponentsubstitution(otherthanoriginaltype),mayincreaseriskofreorelectricalshockhazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号の部品を使用して下さい。

z

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION :

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

andveriedbeforeitisreturntotheuser/customer.

Ref. UL Standard No. 60065.

After servicing this appliance and prior to returning to customer, measure the resistance between either primary

Incaseofdifculties,donothesitatetocontacttheTechnical

Department at above mentioned address.

3

091105DM/DG

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

ngersaremovedacrosstheminsomerarecases.

Wear gloves to protect your hands.

◎Use only designated parts!

The set's parts have specicsafetyproperties(re

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphonesterminal,inputterminal,etc.)is1MΩor

greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

thesepropertiesaredifculttodistinguishbysight,and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks,resorotherdangerous

situations.

4

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DONOTreturnthesettothecustomerunlesstheproblemisidentiedandremedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

5

TECHNICAL SPECIFICATIONS

nAudio Section

• Power amplier

Rated output :

Front :

50W+50W(8Ω,20Hz–20kHzwith0.08%T.H.D.)

Center :

50W(8Ω,20Hz–20kHzwith0.08%T.H.D.)

Surround :

50W+50W(8Ω,20Hz–20kHzwith0.08%T.H.D.)

Maximum effective output power:

Front :

75W+75W(6Ω,1kHzwith10%T.H.D.)

Center :

75W(6Ω,1kHzwith10%T.H.D.)

Surround :

75W+75W(6Ω,1kHzwith10%T.H.D.)

Output connectors :6–8Ω

• Analog

Input sensitivity/Input impedance : 130mV/47kΩ

Frequency response:10Hz–100kHz—+1,–3dB(DIRECTmode)

S/N :98dB(IHF–Aweighted,DIRECTmode)

nVideo section

• Standard video connectors

Input/output level and impedance : 1Vp-p,75Ω

Frequency response :5Hz–10MHz—0,–3dB

• Color component video connector

Input/output level and impedance:

Y(brightness)signal—1Vp-p,75Ω

PB/CBsignal—0.7Vp-p,75Ω

PR/CRsignal—0.7Vp-p,75Ω

Frequency response :5Hz–60MHz—0,–3dB

DIMENSION

nTuner section

[FM](Note:μVat75Ω,0dBf=1x10–15W)

Receiving Range (for U model) :

[FM]87.5MHz–107.9MHz [AM]520kHz–1710kHz

Receiving Range (for N, K model) :

[FM]87.5MHz–108.0MHz [AM]522kHz–1611kHz

Usable Sensitivity :

[FM]1.2μV(12.8dBf) [AM]18μV

50 dB Quieting Sensitivity (for U model) :

[FM]MONO2.8μV(20.2dBf)

50 dB Quieting Sensitivity (for N, K model) :

[FM]MONO2.0μV(17.3dBf)

STEREO42μV(34.5dBf)

S/N (IHF-A) (for U model) :

[FM]MONO70dB(IHF–Aweighted,DIRECTmode)

STEREO67dB(IHF–Aweighted,DIRECTmode)

S/N (IHF-A) (for N, K model) :

[FM]MONO72dB(IHF–Aweighted,DIRECTmode)

STEREO67dB(IHF–Aweighted,DIRECTmode)

Total harmonic Distortion (at 1 kHz) (for U model) :

[FM]MONO0.7%

STEREO1.0%

Total harmonic Distortion (at 1 kHz) (for N K model) :

[FM]MONO0.3%

STEREO0.7%

nGeneral

Power supply (for U model) : AC 120 V, 60 Hz

Power supply (for N model) : AC 230 V, 50/60 Hz

Power supply (for K model) : AC 220 V, 50 Hz

Power consumption :

180 W

0.2 W (Standby)

3 W (CEC standby)

225

53.5

19.5

52

19.0

95.8

90.5

105

22.5

225.0

328.518

27.6

369

340

440

14.5

6

CAUTIONS IN SERVICING

Initializing AV Surround Receiver

AVSurroundReceiverinitializationshouldbeperformedwhentheμcom,peripheralpartsofμcom,andDigitalP.W.B.

were replaced.

1. Turn off the power pressing ON/STANDBY button.

2. Press ON/STANDBY button while simultaneously while pressing ENTER and RETURN buttons.

3. Checkthattheentiredisplayisashingatintervalsofabout1second,andthenreleasethe2buttons.

The microprocessor will be initialized.

Note: • If step 3 fails, start over from step 1.

• All user settings will be lost and the factory setting will be recovered after the set is initialized.

So make sure to note down your setting beforehand for restoring after the initialization.

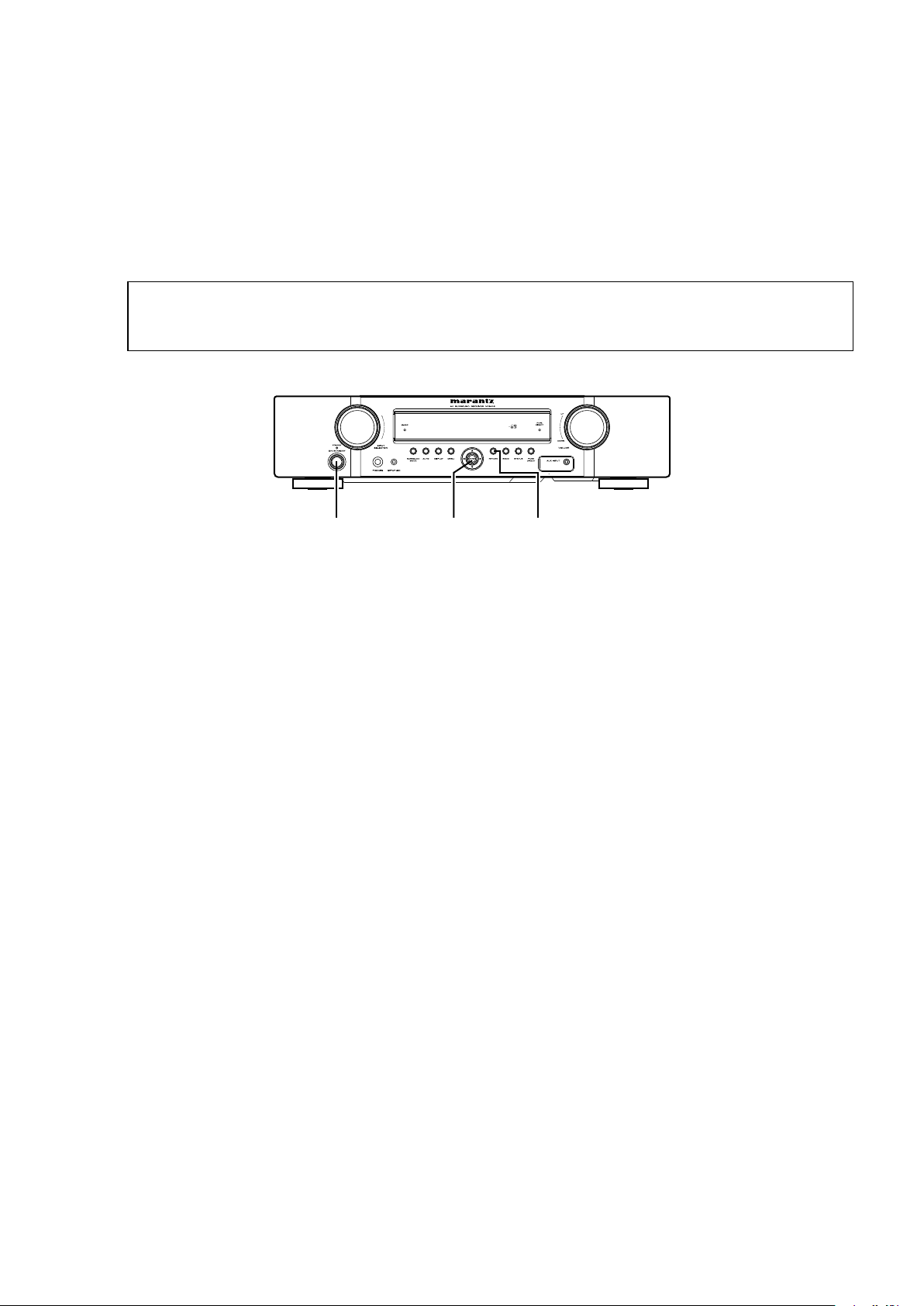

ON/STANDBY ENTER RETURN

Service Jig

When you repair the printing board, you can use the following JIG (Extension cable kit).

PleaseorderitfrommarantzOfcialServiceDistributorinyourregionifnecessary.

8U-110084S : EXTENSION UNIT KIT : 1 Set

(Refer to 39 page.)

WhenyouupdatethermwarebyDFW,youcanusethefollowingJIG(RS232Ctointernalconnectorconversionadapter

with 4P FFC cable kit ).

PleaseorderitfrommarantzOfcialServiceDistributorinyourregionifnecessary.

8U-210100S : WRITING KIT : 1 Set

(Refer to 41 page.)

7

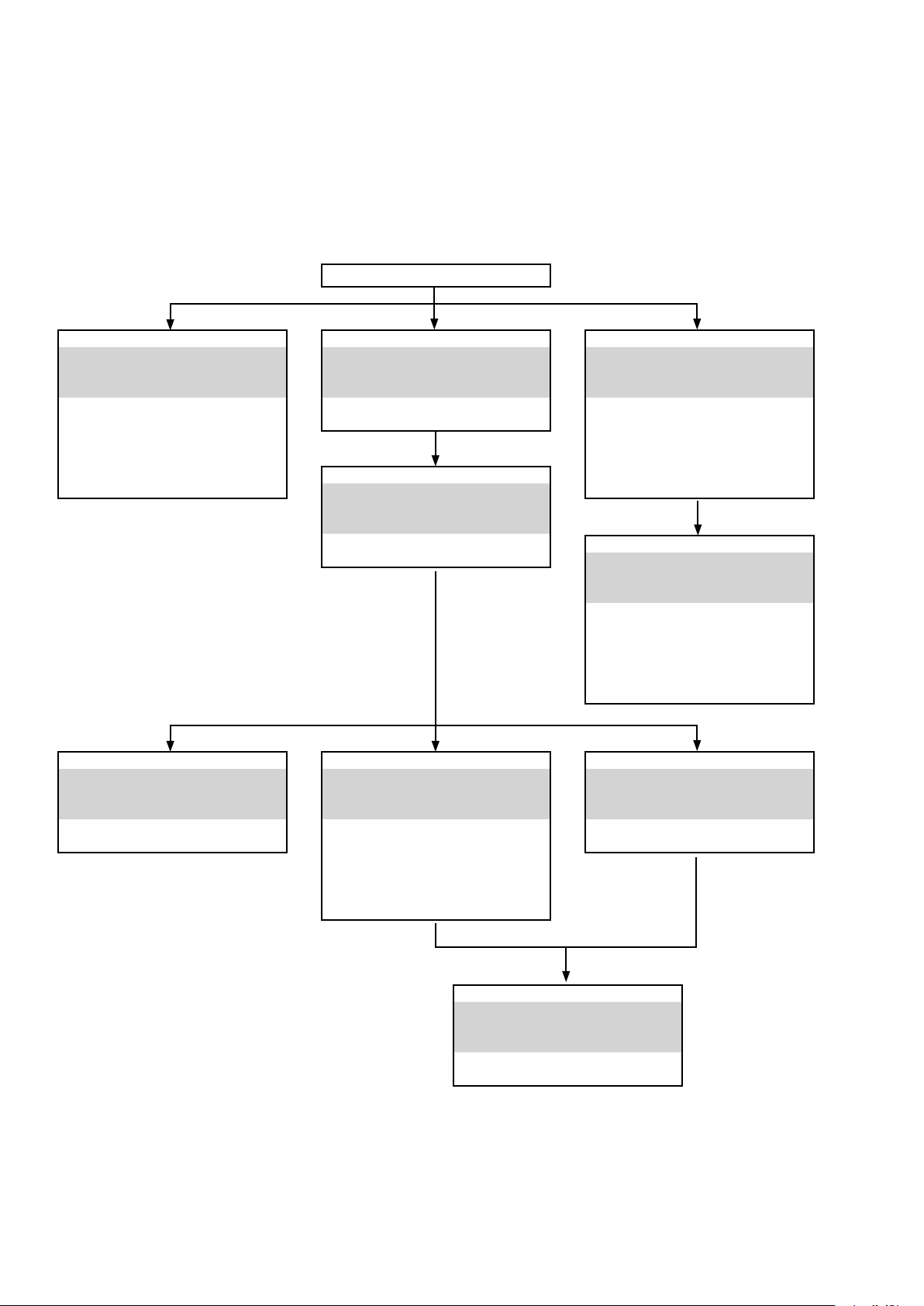

DISASSEMBLY

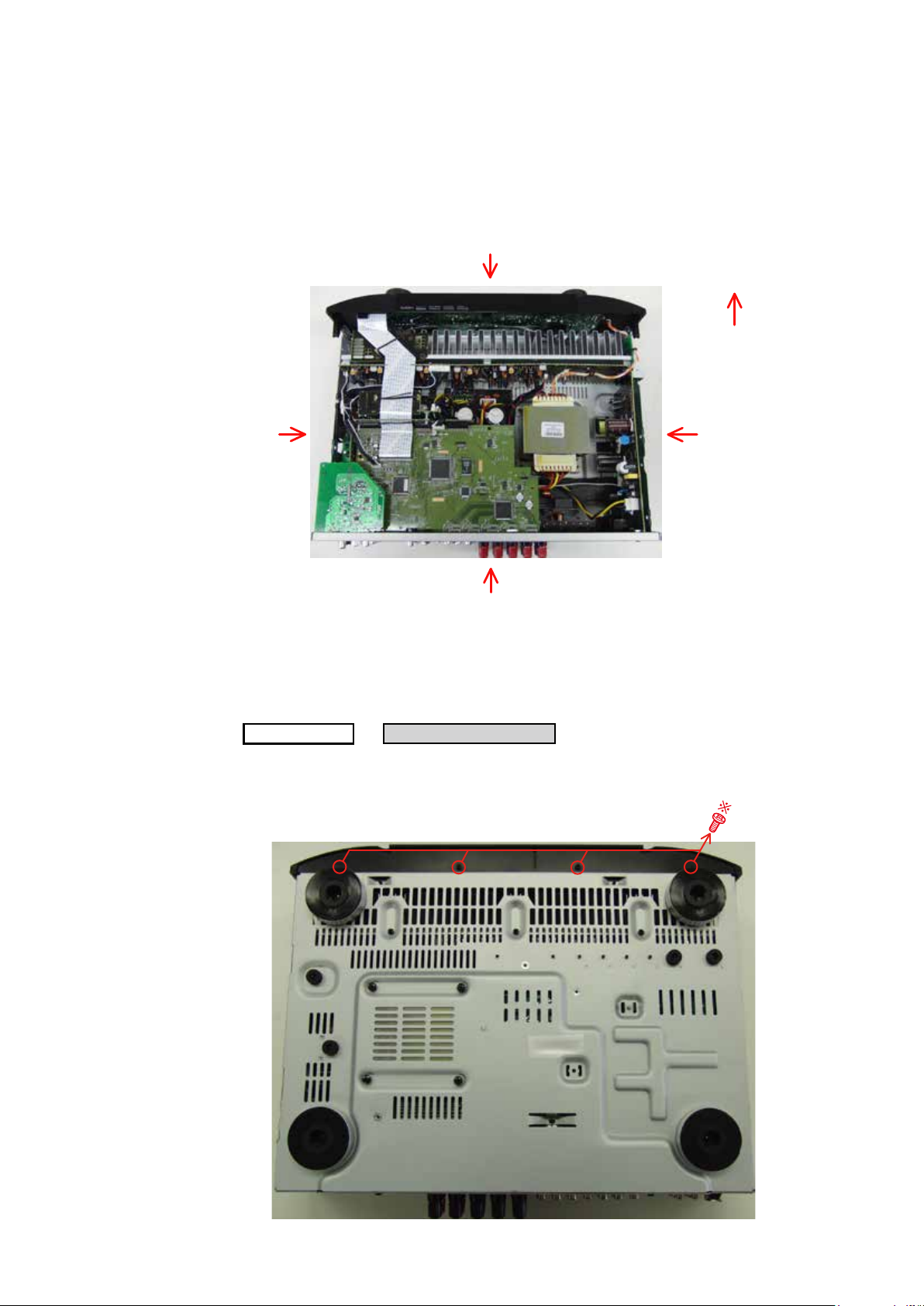

• Disassembleinorderofthearrowinthefollowinggure.

• Inthecaseofthere-assembling,assembleitinorderofthereverseofthefollowingow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

"DISASSEMBLY

Refer to

1. FRONT PANEL ASSY"

"EXPLODED VIEW"

and

PCB H/P

(Ref. No. of EXPLODED VIEW : 9)

PCB USB

(Ref. No. of EXPLODED VIEW : 14)

PCB FRONT

(Ref. No. of EXPLODED VIEW : 15)

POWER TRANS MAIN

"DISASSEMBLY

Refer to

6. POWER TRANS MAIN"

"EXPLODED VIEW"

and

POWER TRANS MAIN

(Ref. No. of EXPLODED VIEW : 31)

PCB RC5_MX

"DISASSEMBLY

Refer to

4. PCB RC5_MX"

"EXPLODED VIEW"

and

PCB RC5_MX

(Ref. No. of EXPLODED VIEW : 48)

PCB HDMI ASSY

"DISASSEMBLY

Refer to

5. PCB HDMI ASSY"

"EXPLODED VIEW"

and

PCB HDMI ASSY

(Ref. No. of EXPLODED VIEW : 47)

AV ASSY

"DISASSEMBLY

Refer to

7. AV ASSY"

"EXPLODED VIEW"

and

PCB FRONT_CNT

(Ref. No. of EXPLODED VIEW : 43)

PCB SIDE_CNT

(Ref. No. of EXPLODED VIEW : 45)

PCB AUDIO_VIDEO ASSY

(Ref. No. of EXPLODED VIEW : 46)

RADIATOR ASSY

"DISASSEMBLY

Refer to

2. RADIATOR ASSY"

"EXPLODED VIEW"

and

PCB 5CH_AMP ASSY

(Ref. No. of EXPLODED VIEW : 23)

PCB GUIDE_L

(Ref. No. of EXPLODED VIEW : 18)

PCB TOP_GUIDE

(Ref. No. of EXPLODED VIEW : 24)

REG ASSY

"DISASSEMBLY

Refer to

3. REG ASSY"

"EXPLODED VIEW"

and

PCB REG

(Ref. No. of EXPLODED VIEW : 40)

PCB REG_CNT

(Ref. No. of EXPLODED VIEW : 39)

PCB FFC_GUIDE

(Ref. No. of EXPLODED VIEW : 42)

PCB SMPS

"DISASSEMBLY

Refer to

8. PCB SMPS"

"EXPLODED VIEW"

and

PCB SMPS

(Ref. No. of EXPLODED VIEW : 37)

PCB SPK

"DISASSEMBLY

Refer to

9. PCB SPK"

"EXPLODED VIEW"

and

PCB SPK

(Ref. No. of EXPLODED VIEW : 38)

8

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction)

Shooting direction: B

[View from the top]

1. FRONT PANEL ASSY

Front side

Shooting direction: DShooting direction: C

Shooting direction: A

Proceeding :

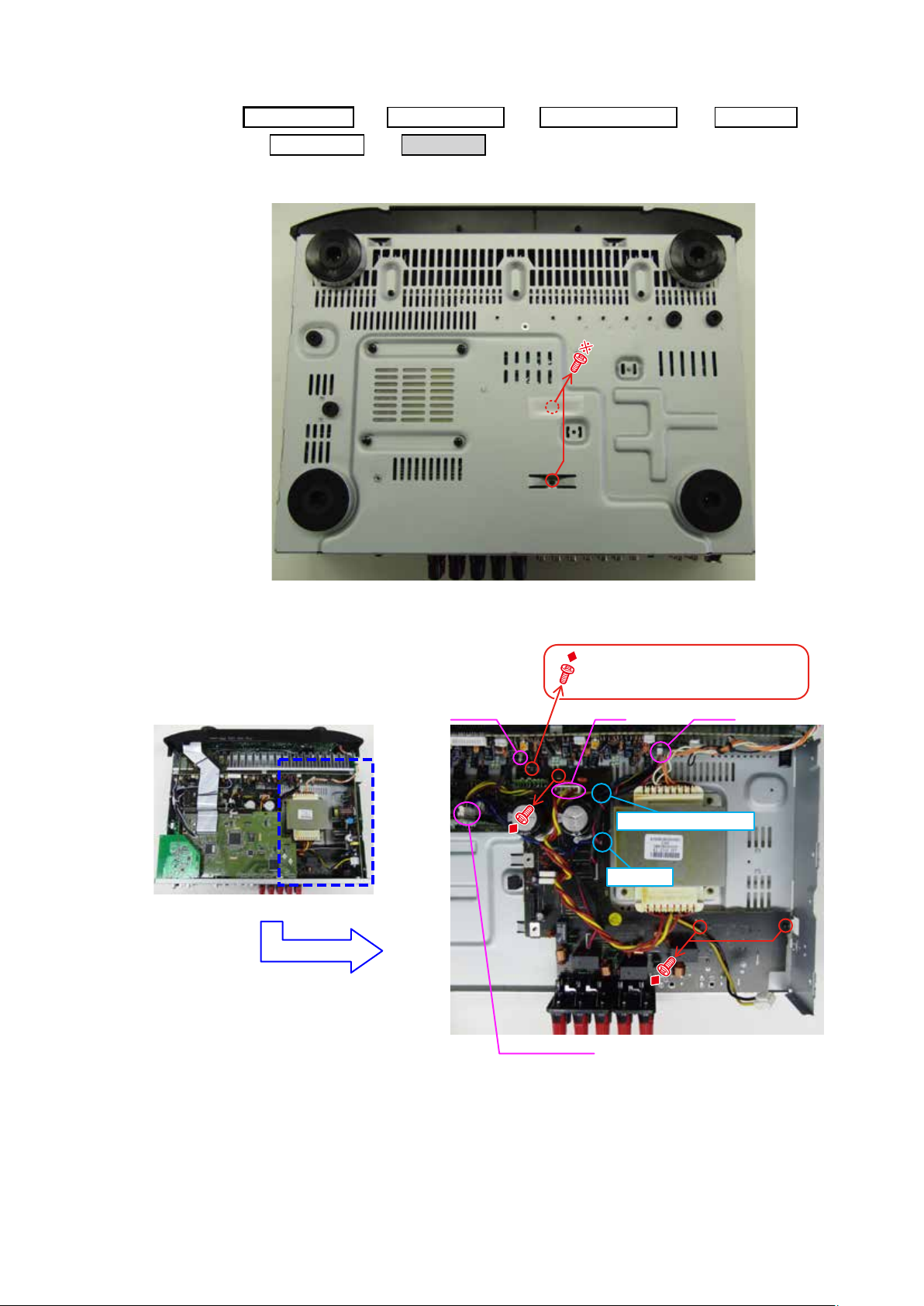

(1) Remove the screws.

View from the bottom

TOP COVER

FRONT PANEL ASSY

→

9

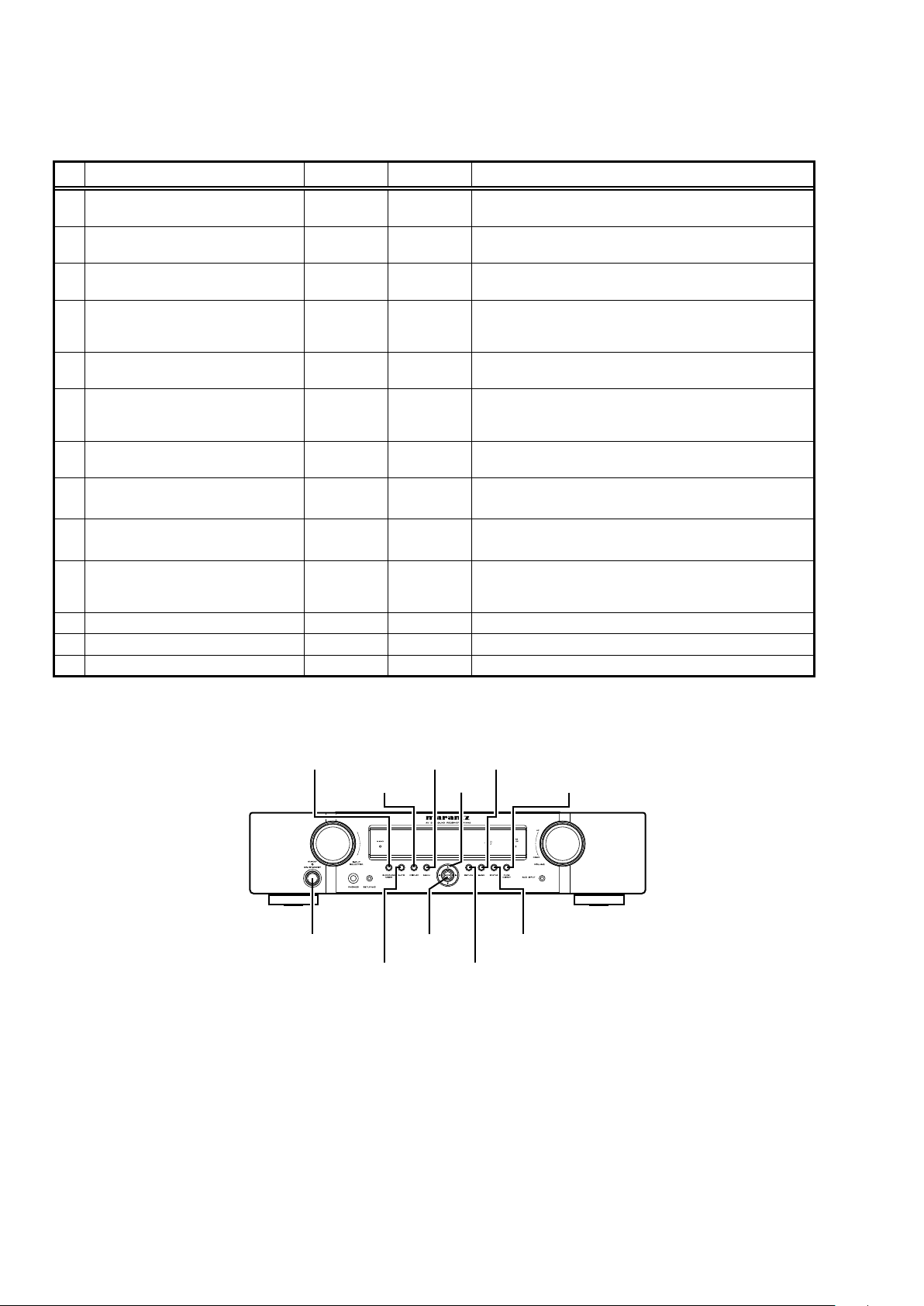

(2) Disconnect the connector wire and FFC cable, then remove the screws.

STYLE PIN : Loosen

FFC cable

CP303

STYLE PIN : Loosen

(3) Cut the wire clamp band, then remove the screws.

Shooting direction: C

Shooting direction: D

STYLE PIN : Loosen

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each P.C.B included in FRONT PANEL ASSY.

10

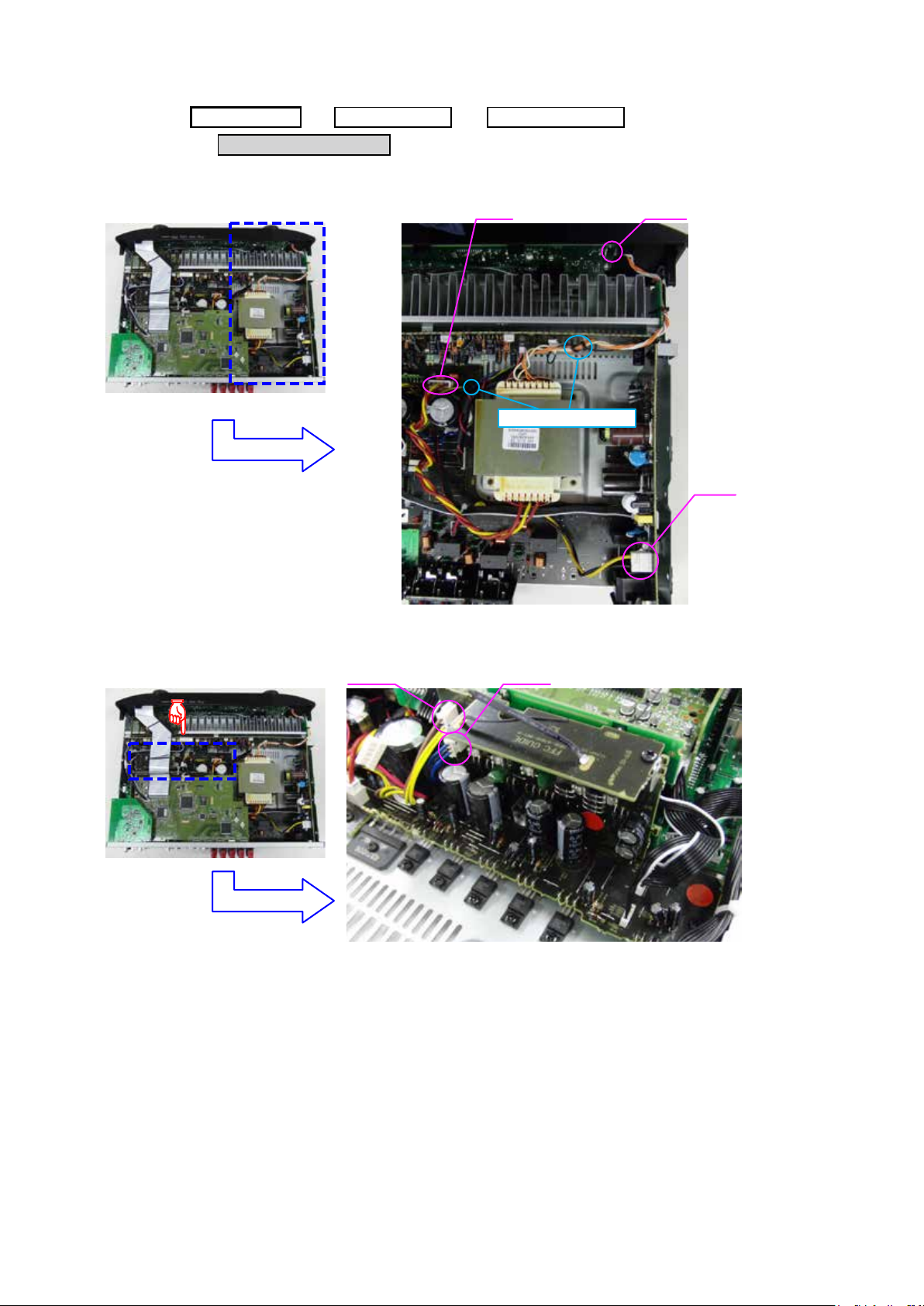

2. RADIATOR ASSY

Proceeding :

(1) Remove the screws.

View from the bottom

TOP COVER

RADIATOR ASSY

→

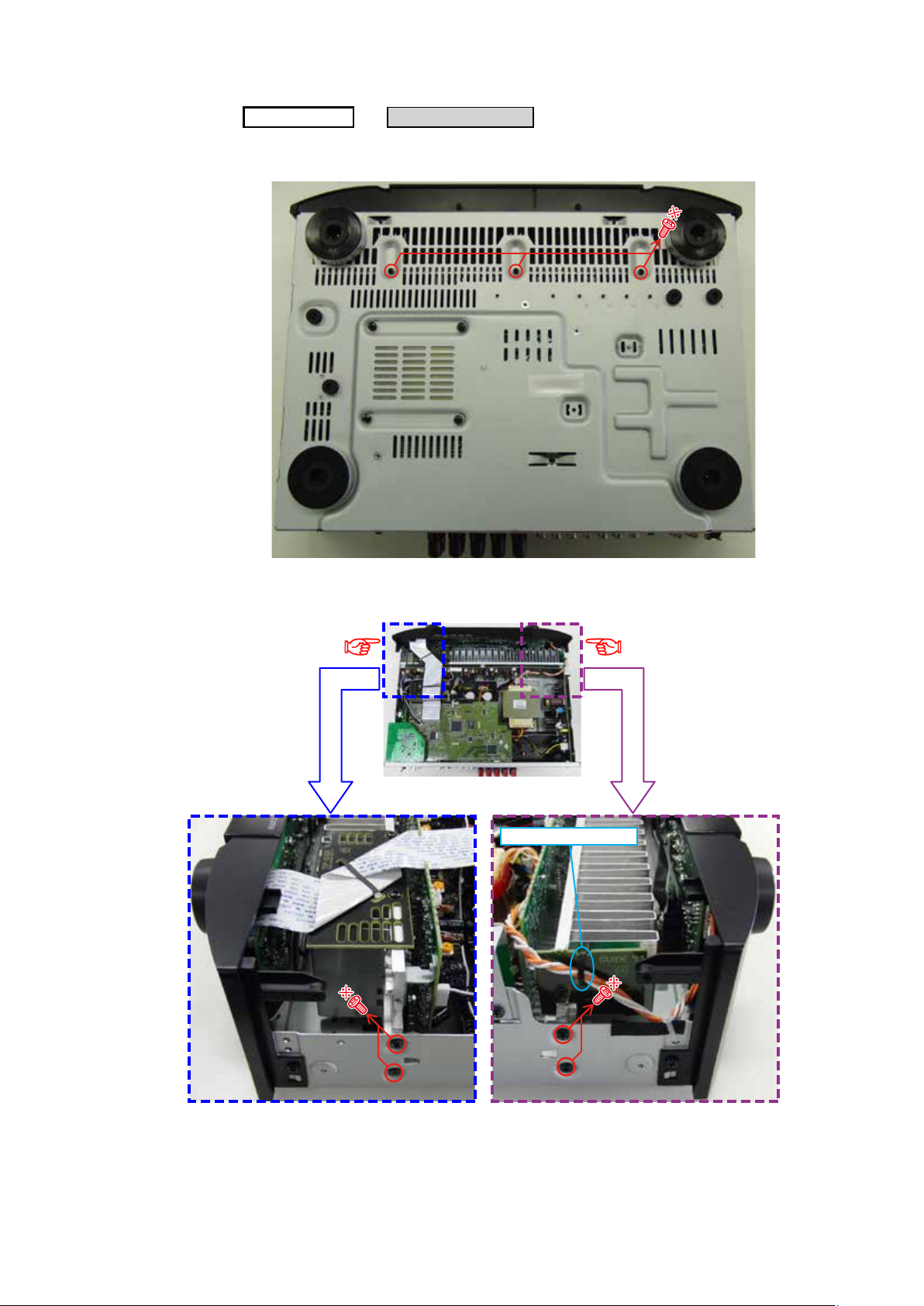

(2) Remove the screws.

Shooting direction: C

Shooting direction: D

STYLE PIN : Loosen

11

(3) Cut the wire clamp band, then disconnect the connector wire and FFC cable.

cut

STYLE PIN : Loosen

FFC cableCN8

(4) Disconnect the connector wires.

STYLE PIN : Loosen

CP401 CP402 CP403

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in RADIATOR ASSY.

12

3. REG ASSY

Proceeding :

(1) Disconnect the connector wires, then remove the screws.

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in REG ASSY.

TOP COVER

Shooting direction: B

RADIATOR ASSY

→

REG ASSY

→

CP104CP102 CP13ACP13B

13

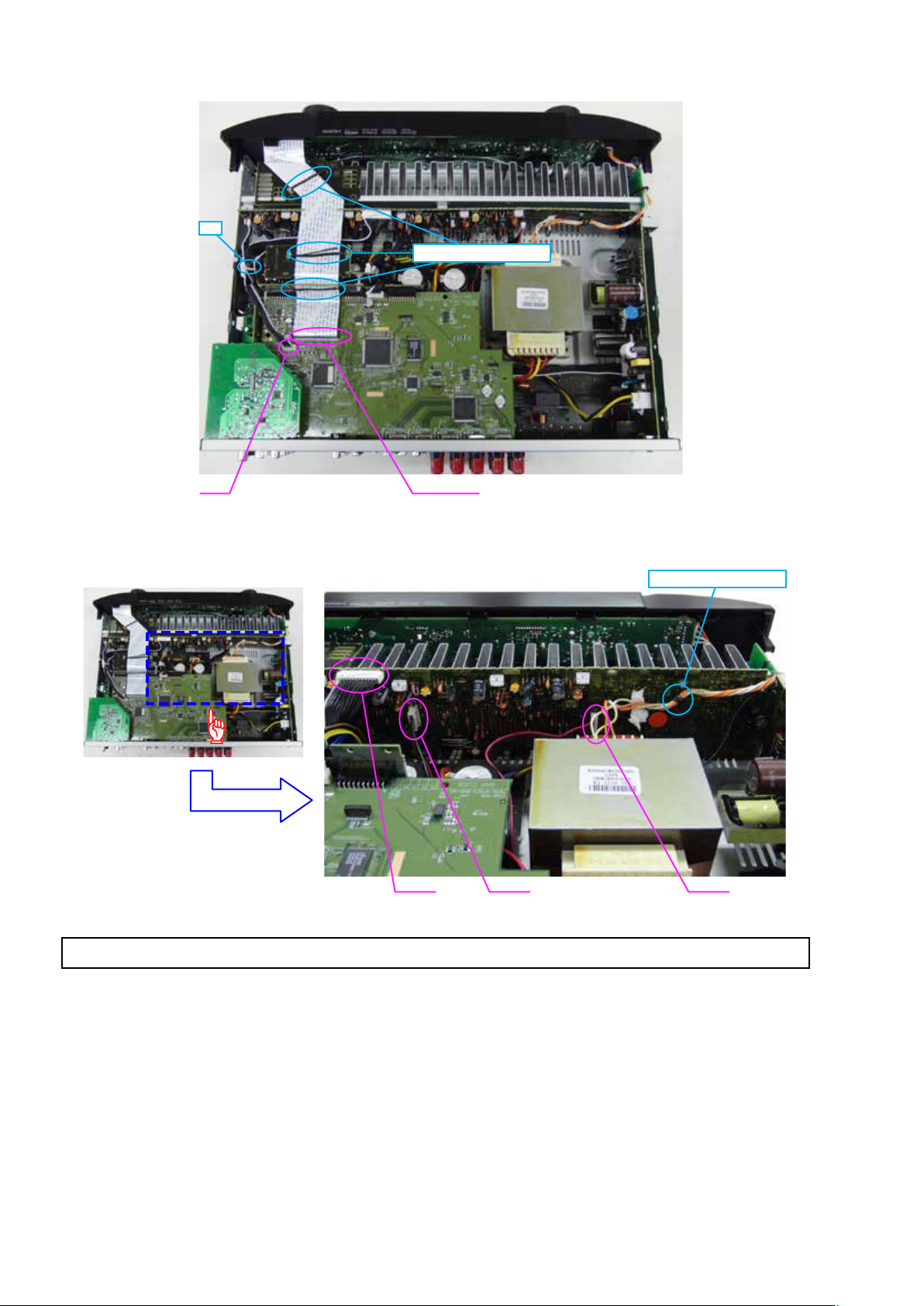

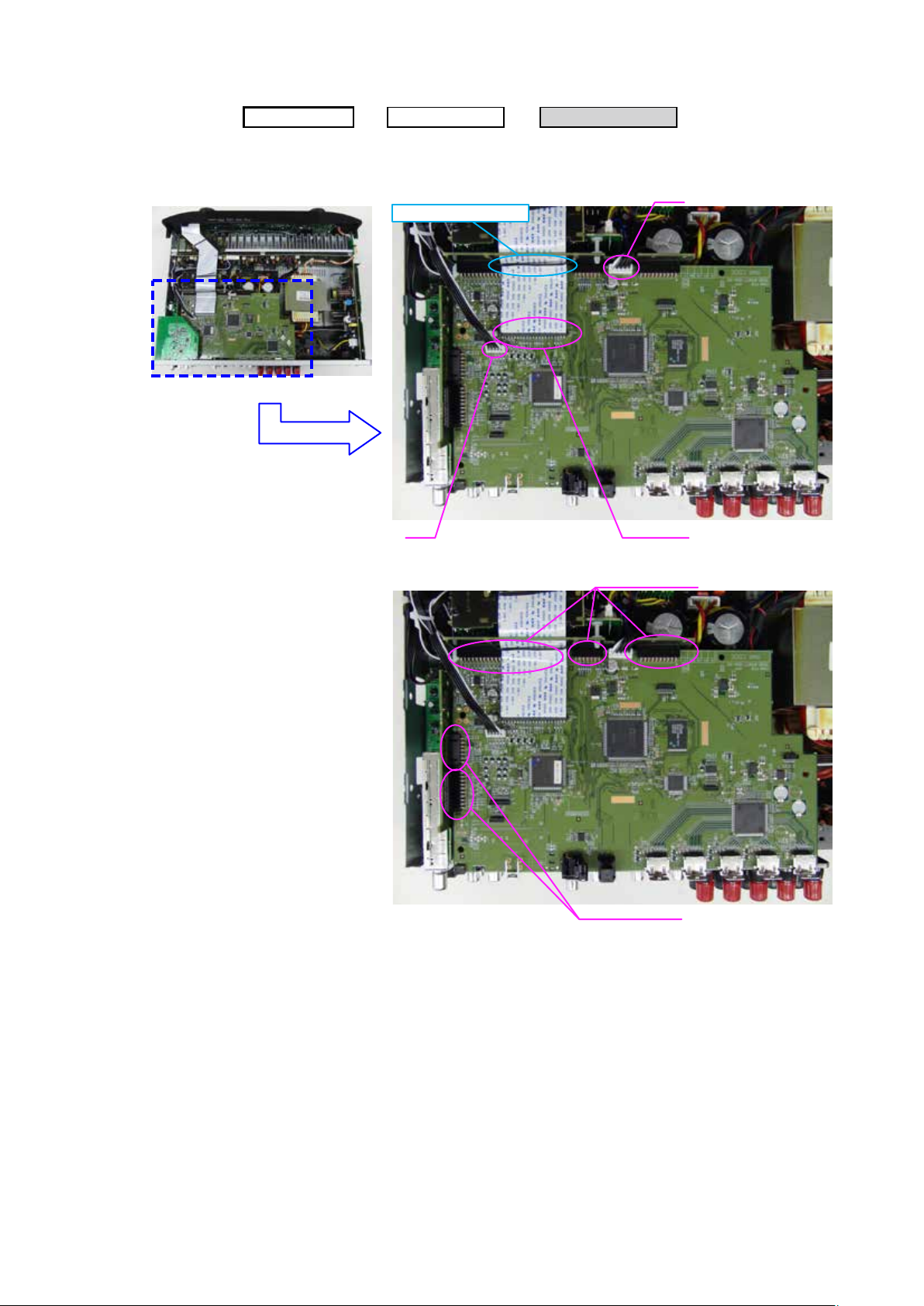

4. PCB RC5_MX

Proceeding :

(1) Remove the screws.

Shooting of photograph: A

(2) Disconnect the connector board.

TOP COVER

PCB RC5_MX

→

Board to board

14

5. PCB HDMI ASSY

Proceeding :

(1) Disconnect the connector wires and FFC cable, then disconnect the connector board.

TOP COVER

PCB RC5_MX

→

STYLE PIN : Loosen

CN8

PCB HDMI ASSY

→

CX1

FFC cable

Board to board

Board to board

15

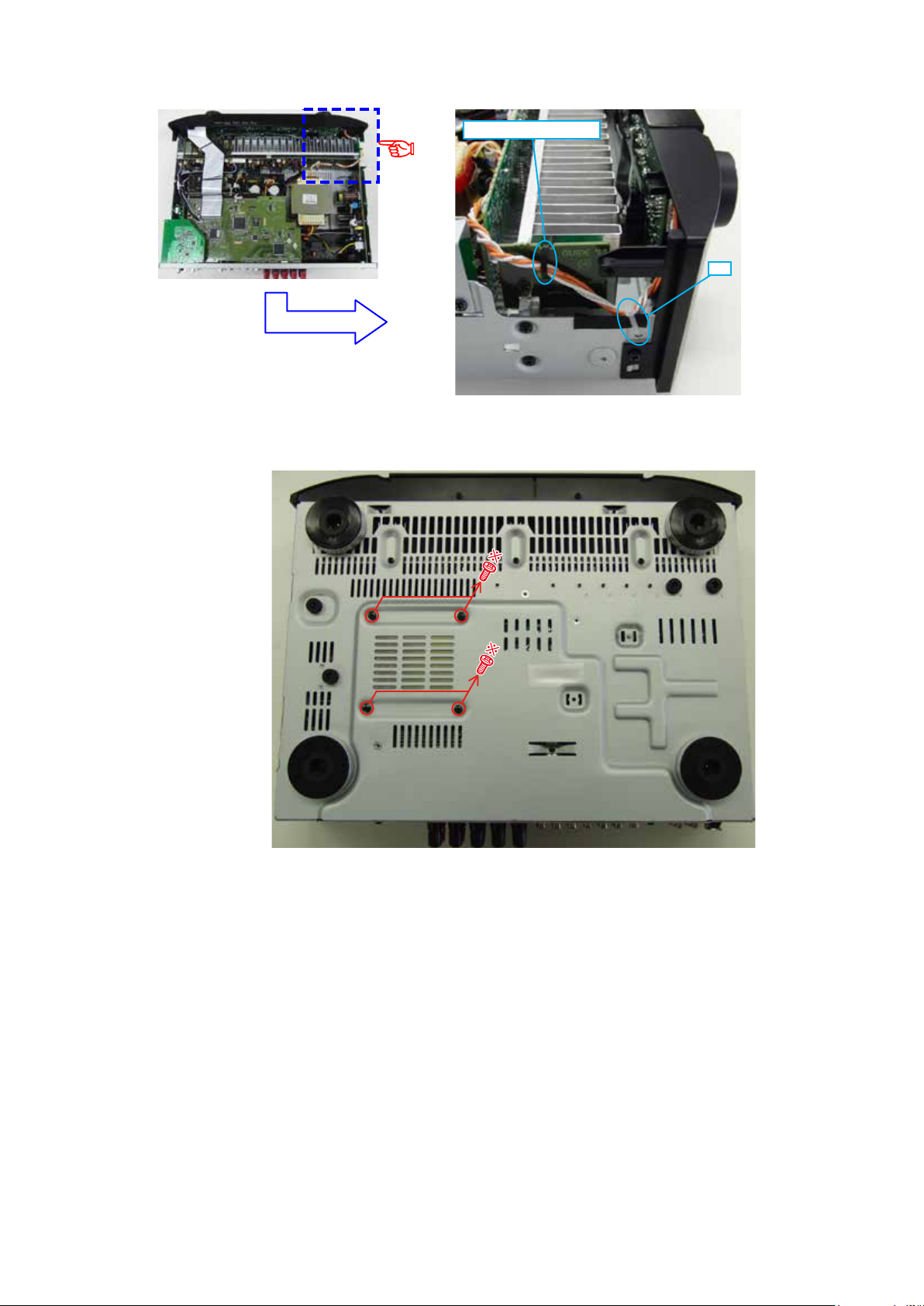

6. POWER TRANS MAIN

→

Proceeding :

TOP COVER

POWER TRANS MAIN

(1) Disconnect the connector wires.

PCB RC5_MX

→

PCB HDMI ASSY

→

CP1

STYLE PIN : Loosen

CP303

CX102

(2) Disconnect the connector wires.

Shooting direction: B

CP104CP102

16

(3) Cut the wire clamp band.

Shooting direction: D

(2) Remove the screws.

STYLE PIN : Loosen

cut

View from the bottom

17

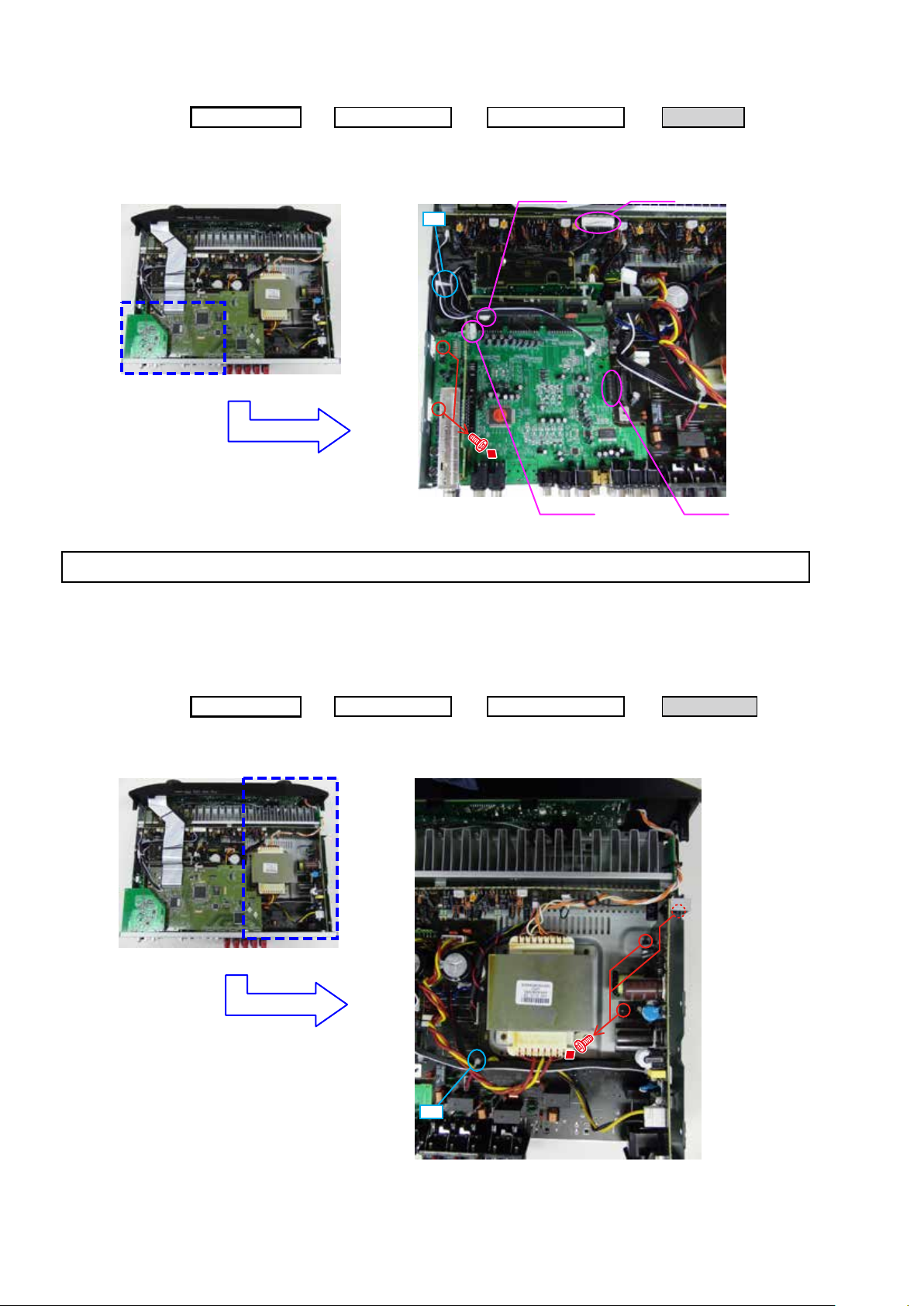

7. AV ASSY

Proceeding :

(1) Cut the wire clamp band, then disconnect the connector wires. Remove the screws.

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in AV ASSY.

TOP COVER

PCB RC5_MX

→

cut

PCB HDMI ASSY

→

→

CP401 CP13B

AV ASSY

CN12 CP13A

8. PCB SMPS

Proceeding :

(1) Cut the wire clamp band, then remove the screws.

TOP COVER

PCB RC5_MX

→

cut

PCB HDMI ASSY

→

PCB SMPS

→

18

9. PCB SPK

→

→

Proceeding :

(1) Remove the screws.

View from the bottom

TOP COVER

PCB SMPS

PCB RC5_MX

→

PCB SPK

PCB HDMI ASSY

→

→

AV ASSY

(2) Disconnect the connector wires, then remove the screws and HLDER.

CP102, CP104

Remove the screws, after remove

the RADIATOR ASSY.

CP1CP402

STYLE PIN : Loosen

HOLDER

CP403

19

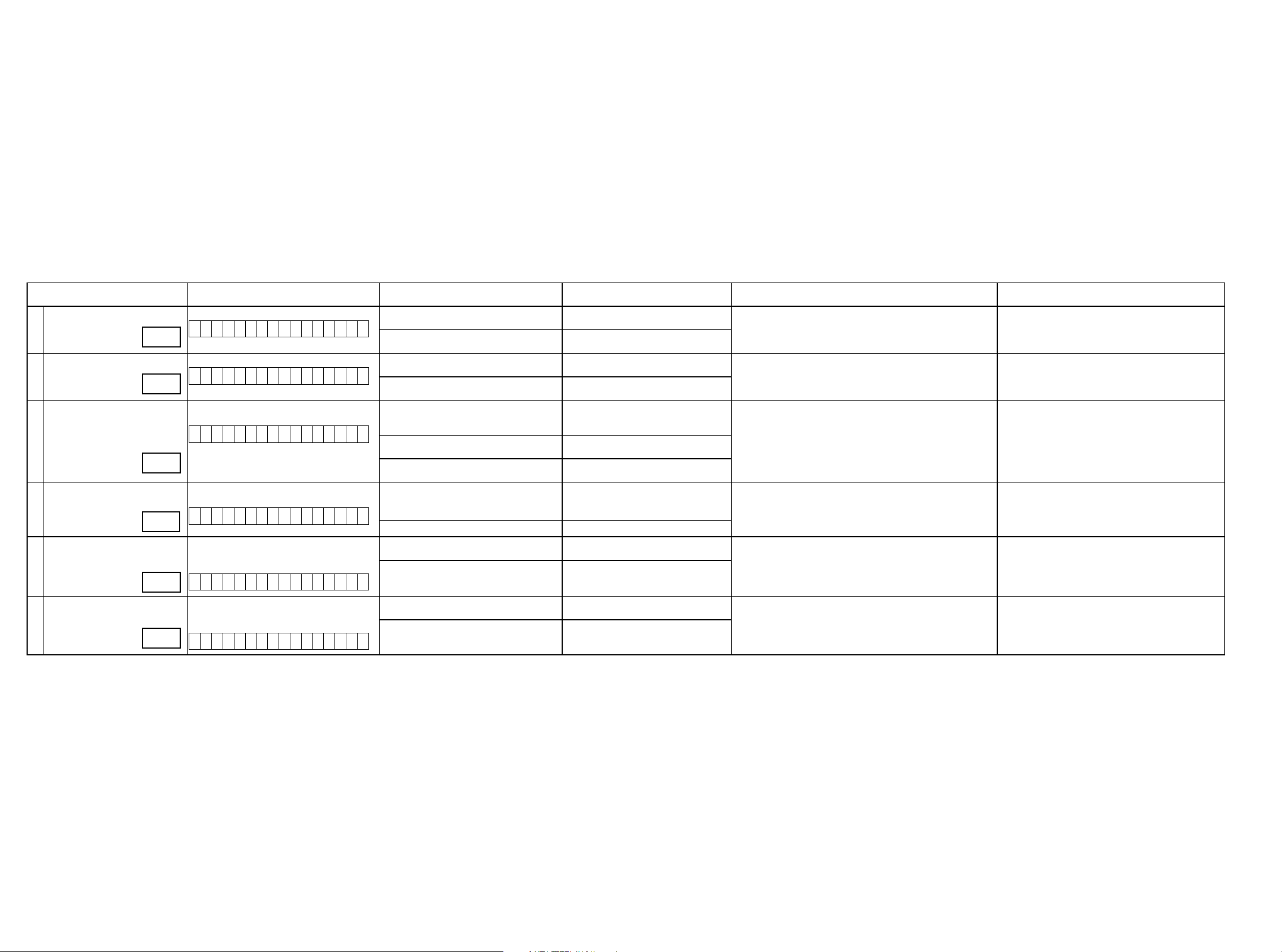

Special mode setting button

No.1 - 10 : Press the ON/STANDBY button to turn on the power while pressing both the button A and the button B at the same

b

No.11 - 13 : Press and hold both buttonsA and B for over 3 second with the power turned on.

b

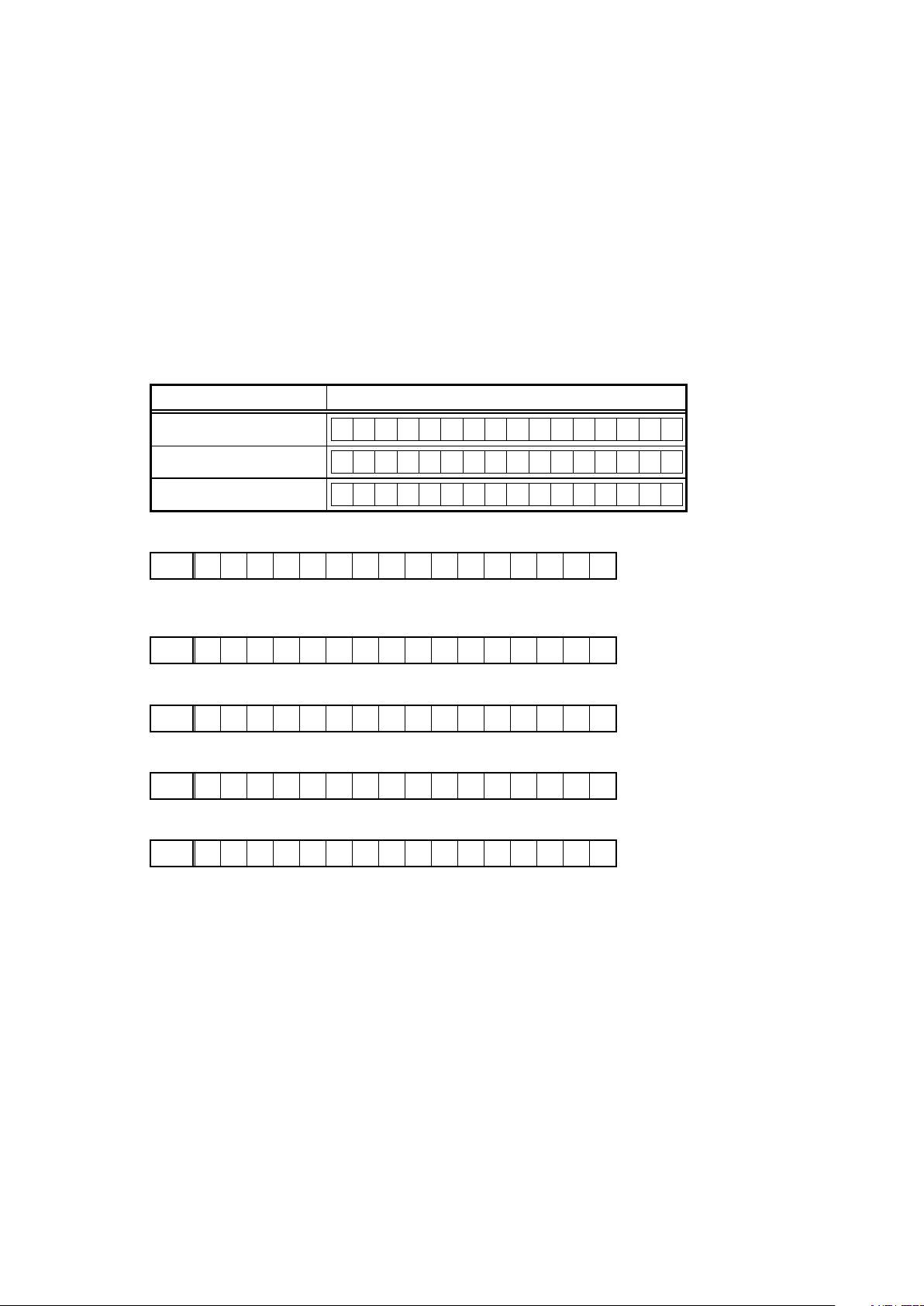

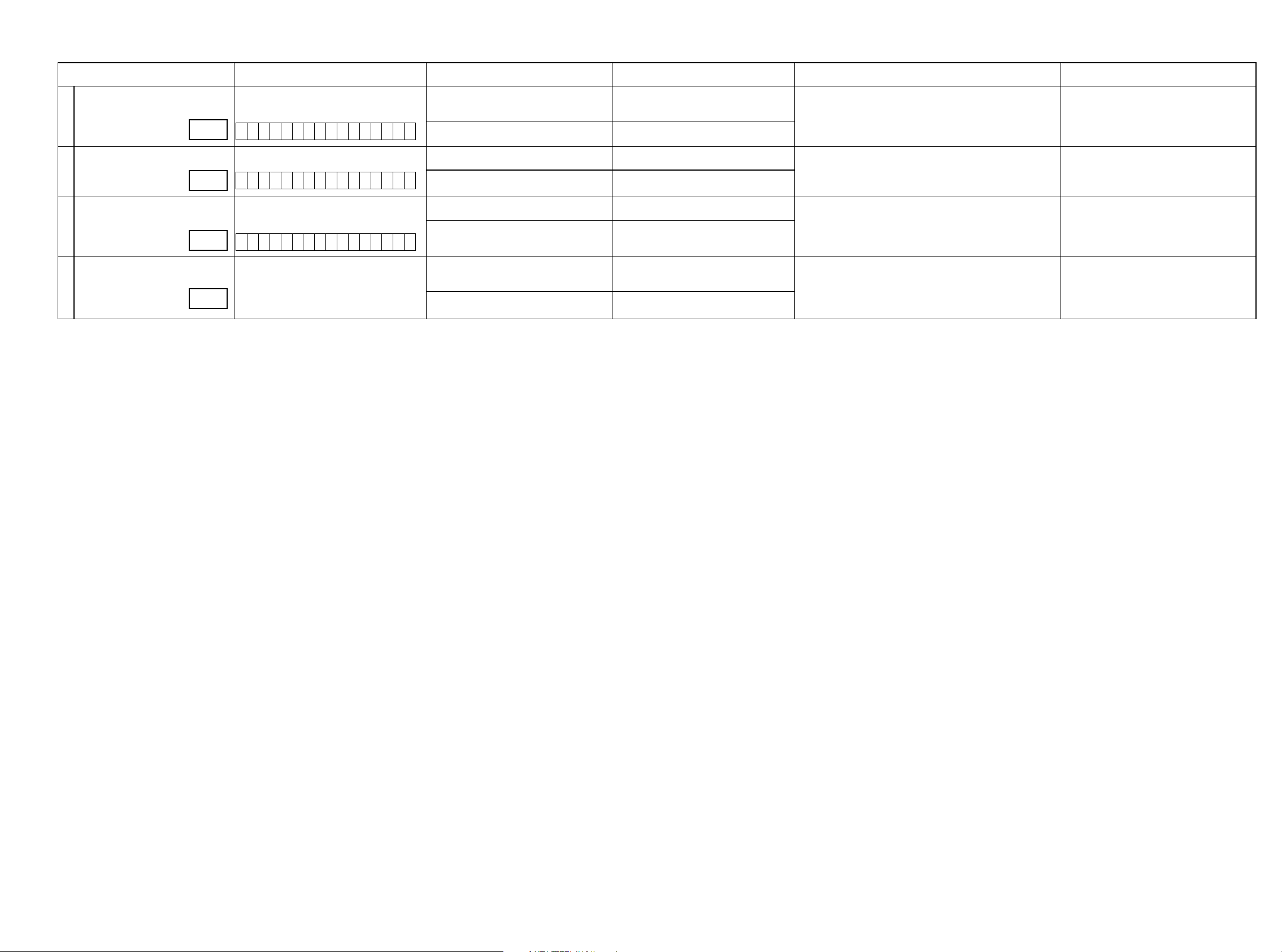

No. Mode Button A Button B Contents

Version display

1

(μcom/DSPErrorDisplay)

2 Displaying the protection history mode

User Initialization mode

3

(Installer Setup settings are not initialized.)

Factory Initialization mode

4

(Installer Setup settings are also

initialized.)

Mode for switching tuner frequency step

5

(U/N model only)

Mode for preventing remote control

6

acceptance

7 Panel lock mode

Panel lock mode

8

(Master volume is not locked.)

9 Cancellation of panel lock mode

10 Diagnostic mode

11 Memory Backup

12 Memory Recovery

13 Memory Backup Clear

time.

d

SURROUND

MODE

ENTER RETURN

MENU DISPLAY

MENU BAND Change tuner frequency step to FM:200kHz/AM:10kHzSTEP

SURROUND

MODE

PURE

DIRECT

PURE

DIRECT

PURE

DIRECT

ENTER

d

d

d

MENU

BAND

STATUS

BAND

DISPLAY

RETURN Panel lock mode is cancelled.

SURROUND

MODE

MENU DUAL BACKUP MEMORY is performed. (Refer to 25 page)

DISPLAY DUAL BACKUP MEMORY is performed. (Refer to 25 page)

AUTO DUAL BACKUP MEMORY is performed. (Refer to 25 page)

Firmware versions such as Main or DSP are displayed in the FL

Display. Errors are displayed when they occur. (Refer to 21 page)

The protection history is displayed.

(Refer to 23 page)

Backup data initialization is carried out.

(Installer Setup settings are not initialized.)

Backup data initialization is carried out.

(Installer Setup settings are also initialized.)

Operations using the remote control are rejected.

(Mode cancellation: Turn off the power and execute the same

button operations as when performing setup.)

Operations using the main unit panel buttons or the master volume

knob are rejected.

Operations using the main unit panel buttons are rejected.

ThismodeisusedforconrmingtheVideoandAudio(signal)

paths. (Troubleshooting)

Thesignalpathsofthesetcanbeeasilyconrmedafterrepair.

SURROUND MODE MENU BAND

DISPLAY

ON/STANDBY

ENTER

AUTO

d

STATUS

RETURN

PURE DIRECT

20

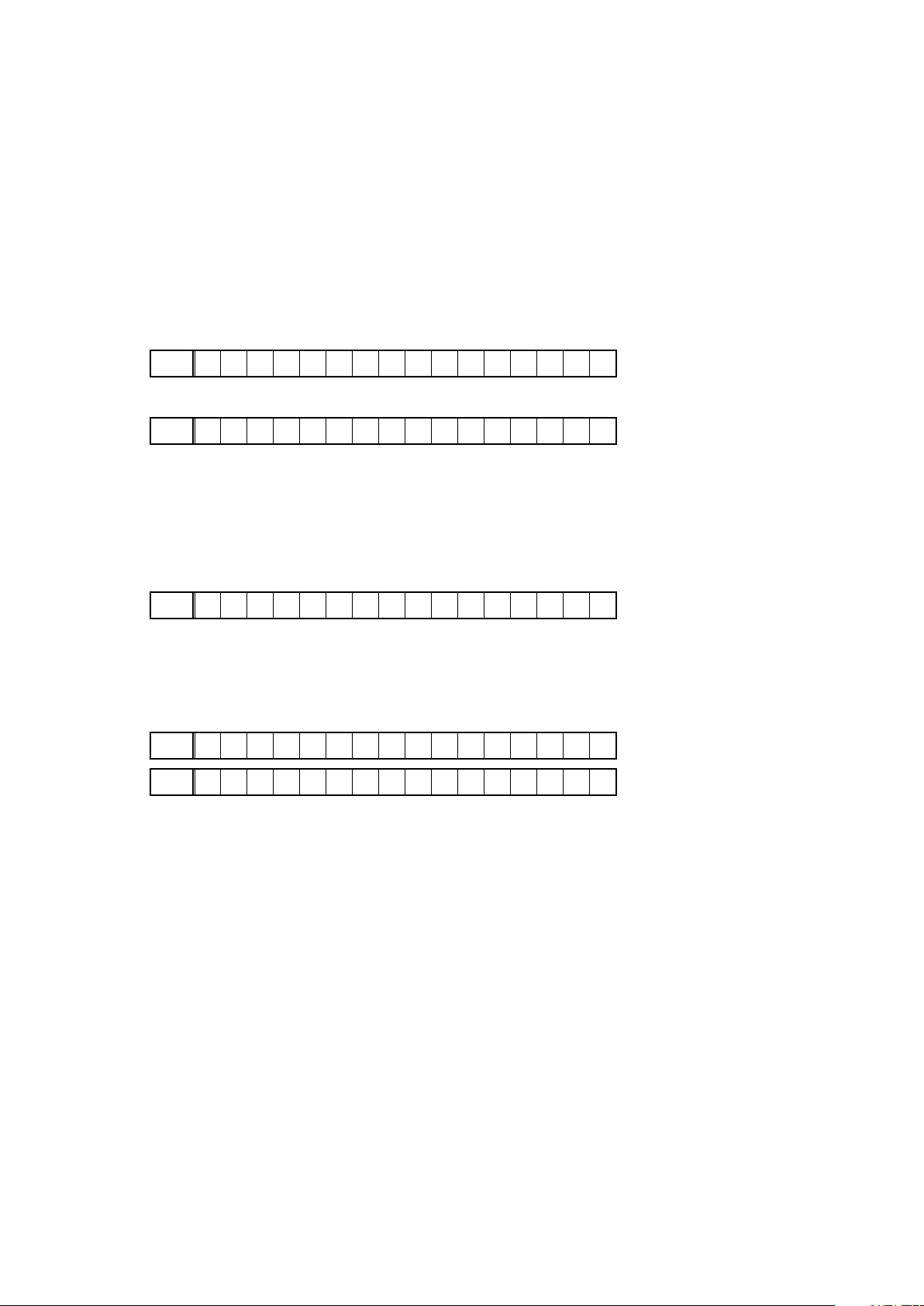

1. µcom/DSP Version display mode

1.1. Operation specications

µcom/DSP version display mode:

When the set is started up in this mode, the version information is displayed.

Starting up:

Press the "ON/STANDBY" button to turn on the power while pressing the "d" and "MENU" buttons.

Now, press the "STATUS" button to the display the 2nd item information on the FL Display.

When the version is displayed on the FL Display, the version list is also displayed on the OSD.

b

1.2. Display Order

Error information(Refer to

→eMain1stBootLoader→rDSPROMVersion→tAudioPLDVersion→y OSD FLASH ROM Version

Model destination information :

q

Model FLD

1.3. Error display

)→qModeldestinationinformation→w Main µ-com Version

NR1402 U model

NR1402 N model

NR1402 K model

Main µ-com Version :

w

FLD

(* : Main version, #: Sub version)

Main 1st Boot Loader :

e

FLD

DSP ROM Version:

r

FLD

Audio PLD Version :

t

FLD

OSD FLASH ROM Version:

y

FLD

(@: Model code, $: Brand code, x: Region code, *: version)

M a i n : * * * * # # # #

M a i n F B L : * * . * *

D S P : * * . * *

A u d i o P L D : * * . * *

O S D : @ @ $ x * * * *

N R 1 4 0 2 U

N R 1 4 0 2 N

N R 1 4 0 2 K

21

1.3. Error display

See the following table for each "Error information" display and its explanation (status).

Display order is q,w,e,r,t.

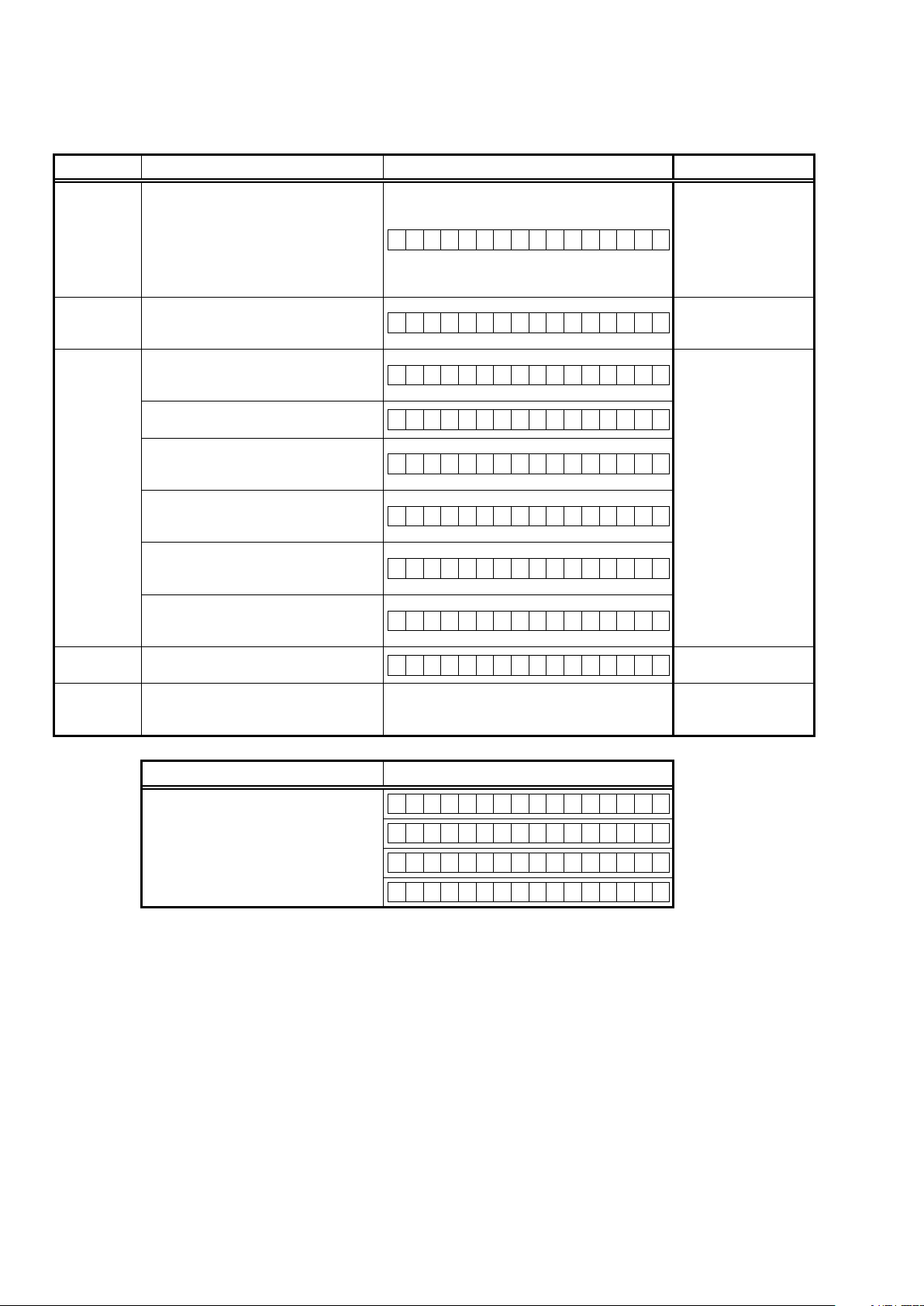

Condition Status FL Display Trouble shooting

• Please check the

q

Firm Check

NG

w

DIR NG

e

DSP NG

r

EEPROM NG

t

Both DSP /

EEPROM OK

Compared with the destination setting

on the board. This is displayed when the

model name or destination information

writtenintothermwaredoesnotmatch.

(b)

No response from DIR

When DSP code boot is performed, the

DSP FLAG0 port does not change to "H"

even if DSP reset is executed.

Before DSP command is issued, the DSP

FLAG0 port does not change to "H".

When DSP data read is performed,

executing WRITE="L" does not result in

ACK="H".

When DSP data read is performed,

executing REQ="L" does not result in

ACK="L".

When DSP data writing is performed,

executing WRITE="H" does not result in

ACK="H".

When DSP data writing is performed,

executing REQ="L" does not result in

ACK="L".

Error occurs in EEPROM checksum.(*** is

a block address number.)

F I R M E R R O R

D I R E R R O R 0 1

D S P E R R O R 0 1

D S P E R R O R 0 2

D S P E R R O R 0 3

D S P E R R O R 0 4

D S P E R R O R 0 5

D S P E R R O R 0 6

E 2 P R O M E R R * * *

(No error display, version display only)

destination-resistors

R773/R776, HDMI

(

B'D).

• Please write the

rmwareofcorrect

destination.

• Please check DIR

IC21, HDMI B'D) and

(

around circuits.

• Please check DSP

U8, HDMI B'D) and

(

around circuits.

Status FL Display

b

Whenthermwareversionisdisplayed,

▲isdisplayedatthestartofthermware.

–

M a i n : * * * * * * * *

–

D S P : * * . * *

–

A u d i o P L D : * * . * *

–

O S D : * * * * * * * *

22

2. Errors checking mode (Displaying the protection history)

2.1. Operation specications

Error mode (Displaying the protection history):

When the set is started up in this mode, the error information is displayed.

Starting up:

Press the "ON/STANDBY" button to turn on the power while pressing the "SURROUND MODE" and "BAND" buttons.

The error (protection history display) mode is set.

Now, press the "STATUS" button to turn on the FL display.

2.2. About the display on the FL display

When the "STATUS" button is pressed after the error (protection history display) mode is set, a history like the one shown

below is displayed, depending on the conditions.

(1) Normal (when there has been no protection incident)

FLD

N O P R O T E C T

(2) For ASO (when the last protection incident was ASO protection)

FLD

P R T : A S O

Cause:

Supplementary information:

If the power is turned on without correcting the abnormality, the protection function will work about 5 seconds later

and the power supply will be shut off.

(3) For DC (when the last protection incident was DC protection)

Cause:

If the power is turned on without correcting the abnormality, the protection function will work about 5 seconds later

and the power supply will be shut off.

(4) For THERMAL (when the last protection incident was THERMAL(A) or THERMAL(B) protection)

Cause:

If the power is turned on without correcting the abnormality, the protection function will work about 5 seconds later

and the power supply will be shut off.

b

The line between speaker terminals is shorted, or speakers with impedance of less than the rated value.

As the excess current is detected after operation of the speaker relay, a short on the

speakerterminalandtheconnectedspeakercanbeidentied.

FLD

P R T : D C

DCoutputofthepoweramplierisabnormal.

FLD

P R T : T H E R M A L A

FLD

P R T : T H E R M A L B

The temperature of the heat sink is excessive.

Additional causes of protection can be due to loose connections, associated components, Microprocessor, etc.

When the "STATUS" button is pressed again after the protection history as shown above is displayed, the normal display

reappears.

23

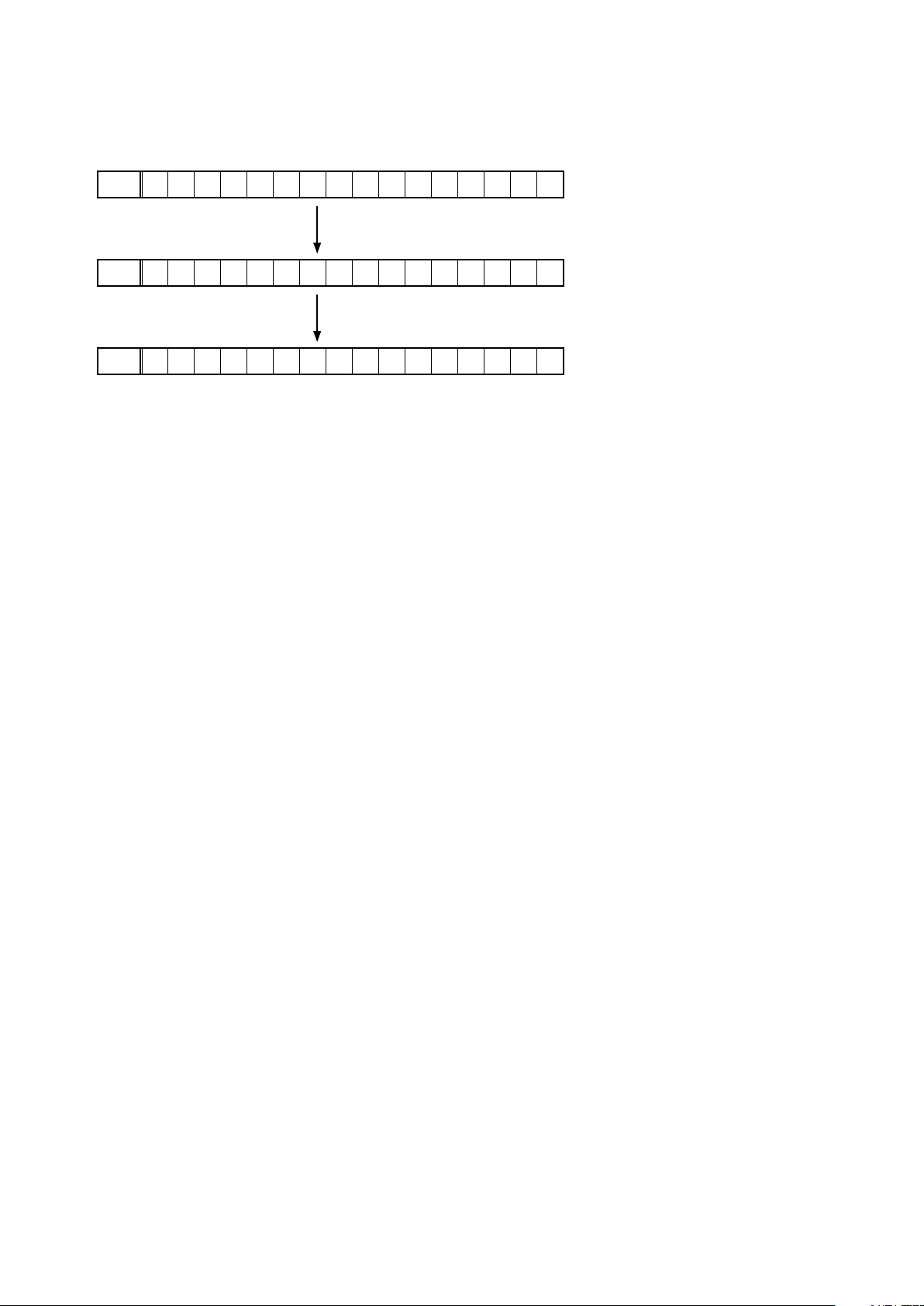

2.3. Clearing the protection history

There are two ways to clear the protection history, as described below.

(1) Start up the set in error (protection display) mode and display the error, then press and hold down the "PURE

DIRECT" button for 3 seconds.

FLD

P R T : D C

Press and hold down "PURE DIRECT" button for 3 seconds.

FLD

P R T : C L E A R

The above is displayed and the protection history is cleared.

FLD

N O P R O T E C T

(2) Initialize. (Refer to "Initializing AV Surround Receiver" 7 page.)

If you want to save a backup, perform the method in 2.3.(1).

b

Warning indication by the POWER LED

Ifthepoweristurnedoffwhenaprotectionincidenthasbeendetected,thePOWERLED(red)ashesasawarning

according to the conditions in which the protection incident occurred.

(1) ASO/DC PROTECTION : Flashes at intervals of 0.5 seconds (0.25 seconds lit, 0.25 seconds off)

(2) THERMAL (A/B) PROTECTION : Flashes at intervals of 2 seconds (1 second lit, 1 second off)

24

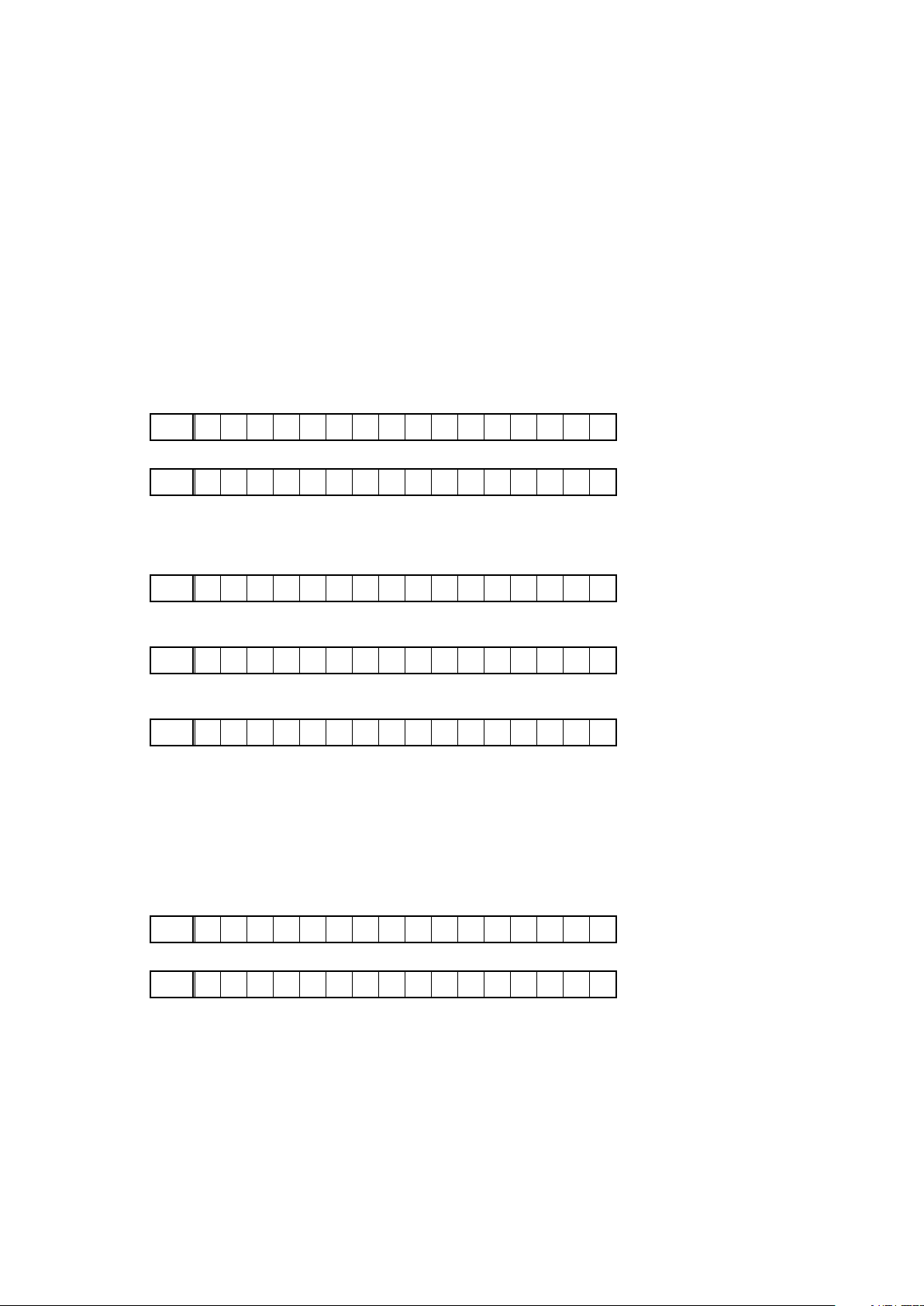

3. DUAL BACKUP MEMORY

This product has a Dual Backup Memory function. The conventional Backup functions to memorize, in the EEPROM

(U5302) in the circuit, a current setting of the moment the main power is turned off so that it can be restored when it

is turned ON again. Meanwhile, the DUAL BACKUP MEMORY is capable of memorizing any arbitrary setting that is

conguredwhiletheproductisinoperationsoastorestoreitatanytime.Whenservicingunitsreturnedfromend-users

for repairs, use this function to back up the current setting (e.g. Tuner Preset). This will enable the units to be returned to

the users after repairs, with the setting unchanged.

NOTE:

If end-users use this function, the data will be overwritten.

The contents of the memory do not disappear even if you initialize this unit.

If you want to erase, please refer to

3.2. SERVICE PRECAUTIONS

.

3.1. HOW TO OPERATE

-Backup-

(1) CongureasettingyouwouldliketosaveintheMEMORYandholddownthe"d" and "MENU" buttons on the Front

Panel at the same time for 3 seconds or more.

(2) The FL Display indicates "MEMORY LOAD" while the Recovery is being performed.

FLD

(3) The FL Display indicates "COMPLETE" when the Backup is completed.

FLD

M E M O R Y S A V I N G

C O M P L E T E

-Recovery-

(1) Hold down the "d" and "DISPLAY" buttons at the same time for 3 seconds or more.

(2) The FL Display indicates "MEMORY SAVING" while the Backup is being performed.

FLD

(3) After the FL Display indicates "COMPLETE", the product goes into Standby mode. When the power is restored, the

Recovery is completed.

FLD

M E M O R Y L O A D

C O M P L E T E

The FL Display indicates "NO BACKUP" if the DUAL BACKUP MEMORY has not been activated with no data to be

recovered saved in the Memory.

FLD

N O B A C K U P

3.2. SERVICE PRECAUTIONS

When the Flash Rom (U5302) on the HDMI PWB is replaced make sure, in order to maintain consistency with the

Backup Memory, to clear the DUAL BACKUP MEMORY in thefollowing way :

-How to clear the Backup Memory-

(1) Hold down the "d" and "AUTO" buttons at the same time for 3 seconds or more.

(2) The FL Display indicates "BACKUP CLEAR" while the memory is being cleared.

FLD

(3) After the FL Display indicates "COMPLETE", the operation is completed.

FLD

B A C K U P C L E A R

C O M P L E T E

25

4. DIAGNOSTIC MODE (Video/Audio (signal) path conrmation mode)

ThismodeisusedforconrmingtheVideoandAudio(signal)paths.(Troubleshooting)

Conrmingtheoperationofunitcanbeeasilydoneafterrepair.

Backup data will not be lost.

4.1. Starting diagnostic mode

Press the "ENTER" and "SURROUND MODE" button while simulltaneously pressing those two buttons of this unit.

Q1, Q2 and Q3 are lit in FL display.

4.2. Canceling diagnostic mode

Turn off the power by pressing the ON/Standby button.

4.3. Operation

When you perform remote operation in accordance with the instructions in "Details of how to operate remote controller" *a) in the table below using the remote control unit (RC013SR).

Youwillndusinganotherremotecontrolunitwiththemacrofunctionsveryuseful.Tousethemacrofunctions,programamacrofunctiontooutputaremotecontrolcodeinaccordancewiththestepsin*b)inthetablebelow.

4.4. Video system conrmation items

g.XX:Refertotheblockdiagramoftheg.XXth.

Conrmation item Setting and display

Analog Video (signal) Path Display:

1

HDMI (signal) Path

2

OSD FUNCTION Menu : ON

3

g.1

g.2

V 0 1 D V D

Display:

V 0 1 D V D

Display:

V 0 2 D V D

g.3

CEC FUNCTION

(Control Monitor : HDMI Monitor)

4

g.4

HDMI Audio (signal) Path

(Audio : AMP)

5

g.5

HDMI Control : ON

Display:

V 0 3 D V D

Audio : AMP(When checking the audio output

from AMP)

Display:

V 0 5 D V D

Details of how to operate remote controller *a)

1.Press [AMP]

2.Press [1/AUTO]

3.Press [AMP]

4.Press [DVD] twice

1.Press [AMP]

2.Press [1/AUTO]

3.Press [AMP]

4.Press [DVD] twice

1.Press [AMP]

2.Press [2/STEREO]

3.Press [AMP]

4.Press [DVD] twice

5.Press [AMP]

6.Press [MENU]

1.Press [AMP]

2.Press [3/M-DAX]

3.Press [DVD] twice

1.Press [AMP]

2.Press [5/HT-EQ]

3.Press [DVD] twice

Output sequence of remote control codes

It is useful to form a macro program. *b)

※

KEY1/AUTO (Main Zone)

q

(Initialization & Video Convert All OFF)

DVD (Main Zone)

w

KEY1/AUTO (Main Zone)

q

(Initialization & Video Convert All OFF)

DVD (Main Zone)

w

KEY2/STEREO (Main Zone)

q

(Initialization &VideoConvert All ON &

IP Scaler"Analog&HDMI")

DVD (Main Zone)

w

GUI MENU (Main Zone)

e

KEY3/M-DAX (Main Zone)

q

(Initialization & CEC Control ON &

Select Control Monitor 1)

DVD (Main Zone)

w

KEY5/HT-EQ (Main Zone)

q

(Initialization & Select Audio AMP)

DVD (Main Zone)

w

Contents of conrmation Remarks

·Input : CVBS / Output : CVBS

·Input : Component / Output : Component

·Input HDMI / Output : HDMI

(b As the input source, you can switch from DVD to other ones.)

·OSD Display / Output : HDMI

(b As the input source, you can switch from DVD to other ones.)

· When the power supply of a TV is put in the standby mode, make sure

that the power supply of this unit is also put in the standby mode.

(b

As the input source, you can switch from DVD to other ones.)

·Input : HDMI (Signal of PCM, DolbyDigital or DTS) / Output : Speakers

·Input : HDMI (Signal of HD Audio) / Output : Speakers

(b

As the input source, you can switch from DVD to other ones.)

HDMI Audio (signal) Path

(Audio : TV)

6

g.6

Audio : TV(When checking the audio output

from TV)

Display:

V 0 6 D V D

1.Press [AMP]

2.Press [6/V.SEL]

3.Press [DVD] twice

KEY6/V.SEL (Main Zone)

q

(Initialization & Select Audio TV)

DVD (Main Zone)

w

26

· Input : HDMI (Signal of PCM or DolbyDigital or DTS) / Output : HDMI

(Audio output from connected TV)

(b

As the input source, you can switch from DVD to other ones.)

4.5. Audio system conrmation items

g.XX:Refertotheblockdiagramoftheg.XXth.

Conrmation item Setting and display Details of how to operate remote controller

Analog (signal) Path Input Mode : Fixed ANALOG

SURROUND mode : DIRECT

1

g.7

Display:

A 0 1 D V D

1.Press [AMP]

2.Press [7/T.TONE]

3.Press [DVD] twice

Output sequence of remote control codes

It is useful to form a macro program.

b

KEY7/T.TONE (Main Zone)

q

Initialization & Input Mode Fixed ANALOG

& SURROUND mode DIRECT

DVD (Main Zone)

w

Contents of conrmation Remarks

·Input : Analog / Output : Speakers (Front L/R)

·Input : Analog / Output : Pre OUT (Front L/R)

(b As the input source, you can switch from DVD to other ones.)

DIGITAL (signal) Path

(MAIN)

2

g.8

HDMI (signal) Path Input Mode : Fixed HDMI

3

g.9

A/D (signal) Path

(Main Zone)

5

g.10

Input Mode : Fixed DIGITAL

Display:

A 0 2 D V D

Amp assign : NORMAL

Display:

A 0 5 D V D

SURROUND mode : Multi ch STEREO

Vol -20dB

SpeakerCong:SSSSY

(Front/Center/Surround/SourroundBack :

Small, SW : Yes)

1.Press [AMP]

2.Press [8/CH LVL]

3.Press [DVD] twice

1.Press [AMP]

2.Press [SURROUND]

3.Press [DVD] twice

1.Press [AMP]

2.Press [PURE DIRECT]

3.Press [DVD] twice

KEY8/CH LVL (Main Zone)

q

Initialization & Input Mode Fixed DIGITAL

DVD (Main Zone)

w

SURROUND

q

Initialization & Input Mode Fixed HDMI

DVD (Main Zone)

w

PURE DIRECT

q

Initialization & SURROUND mode : Multi ch

STEREO & Volume -20dB

DVD (Main Zone)

w

·Input : DIGITAL / Output : Speakers (Front L/R)

·Input : DIGITAL / Output : Pre OUT (Front L/R)

(b As the input source, you can switch from DVD to other ones.)

·Input : HDMI / Output : Speakers (Front L/R)

·Input : HDMI / Output : Pre OUT (Front L/R)

(b As the input source, you can switch from DVD to other ones.)

·Input : Analog / Output : Speakers (Front L/R)

·Input : Analog / Output : Pre OUT (Front L/R), SW(20Hz)

(b As the input source, you can switch from DVD to other ones.)

27

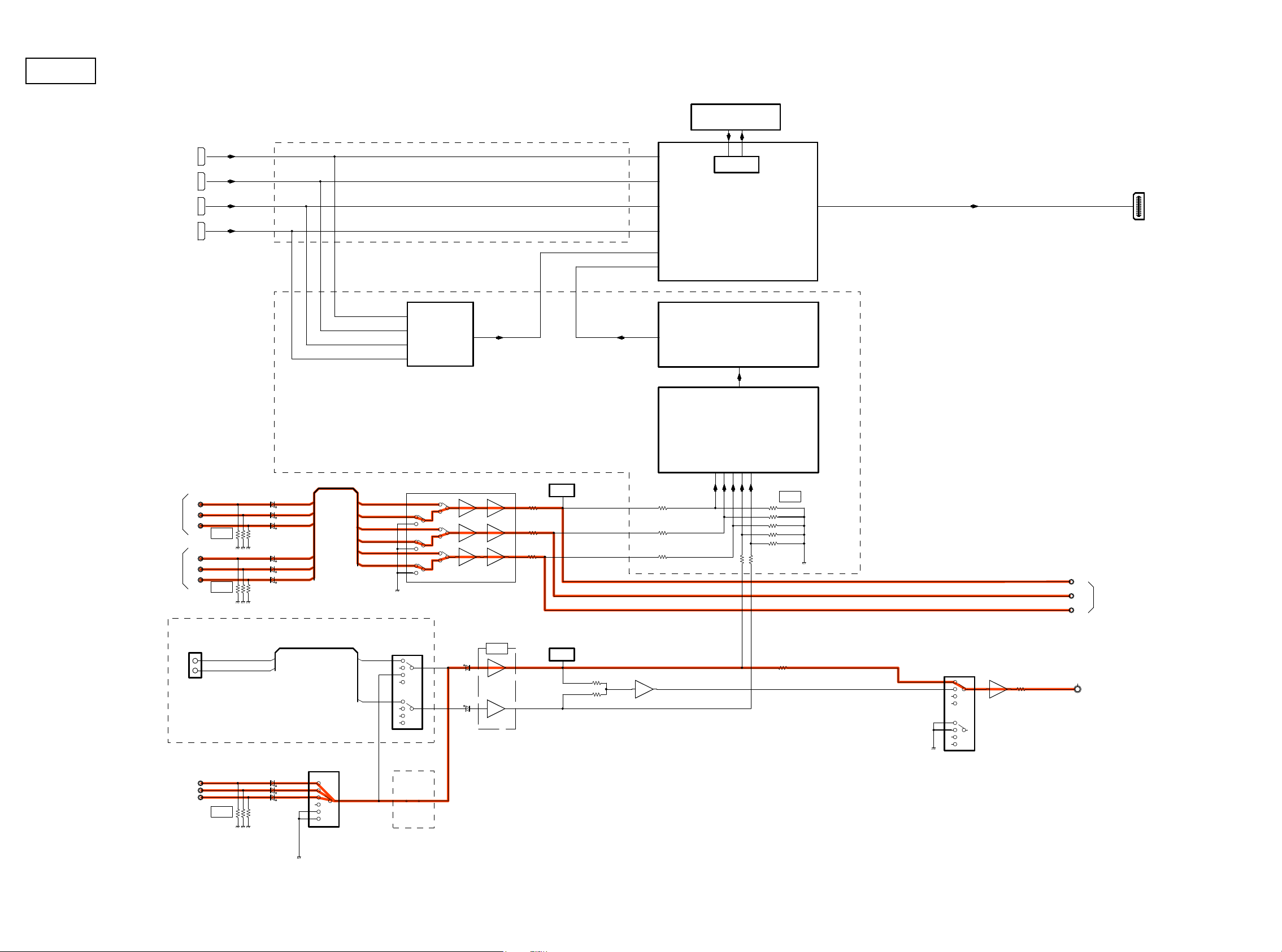

BLOCK DIAGRAM

g.1

HDMI1

HDMI2

HDMI IN

HDMI3

HDMI4

VIDEO BLOCK DIAGRAM

SPI FLASH

NR1402 ONLY

OSD

HDMI OUT

ADV7623

HDMI TRANSCEIVER

NR1602 ONLY

COMPONENT

IN

NR1602 ONLY

IN1

IN2

TMDS SW

ADV3002

TMDS OUTPUT

TRANSMITTER

ADV7511

36-BIT YCbCr/RGB

HDMI Rx

VIDEO DECODER

ADV7844

HDMI

NJM2586M

75

Y

Cb

Cr

-6dB

Y

Cb

Cr

-6dB

Y

C

COMP1-Y

COMP1-Cb

COMP1-Cr

COMP2-Y

COMP2-Cb

COMP2-Cr

NET_Y

NET_C

COMP1-Y

COMP2-Y

COMP1-Cb

COMP2-Cb

COMP1-Cr

COMP2-Cr

INPUT SELECT

NET_Y

NET_C

TC4052

Y

C

6dB

6dB

6dB

75

75

6dB

2V

DET.

75

75

75

24

24

24

75 75

DET.

2.2K

2.2K

Y/C MIX

10

-6dB

51

51

51

51

51

Y

COMPONENT

Cb

OUTPUT SELECT

TC4052

Cr

75

OUT

CVBS OUT

BUFFER

CVBS IN

IN1

IN2

IN3

-6dB

INPUT SELECT

TC4051

NR1402 ONLY

28

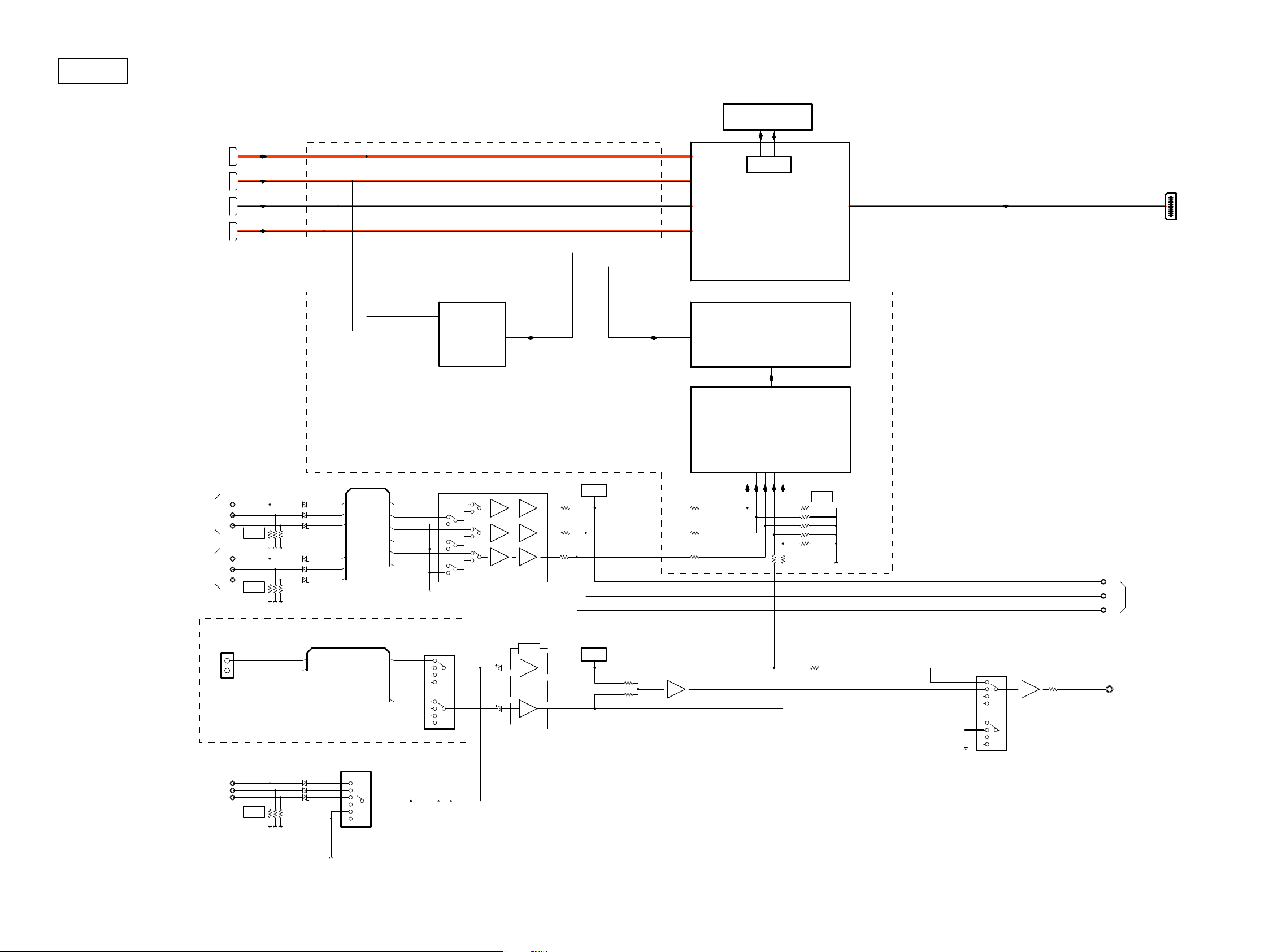

g.2

HDMI IN

HDMI1

HDMI2

HDMI3

HDMI4

VIDEO BLOCK DIAGRAM

SPI FLASH

NR1402 ONLY

OSD

HDMI OUT

ADV7623

HDMI TRANSCEIVER

NR1602 ONLY

COMPONENT

IN

NR1602 ONLY

IN1

IN2

TMDS SW

ADV3002

TMDS OUTPUT

TRANSMITTER

ADV7511

36-BIT YCbCr/RGB

HDMI Rx

VIDEO DECODER

ADV7844

HDMI

NJM2586M

75

Y

Cb

Cr

-6dB

Y

Cb

Cr

-6dB

Y

C

COMP1-Y

COMP1-Cb

COMP1-Cr

COMP2-Y

COMP2-Cb

COMP2-Cr

NET_Y

NET_C

COMP1-Y

COMP2-Y

COMP1-Cb

COMP2-Cb

COMP1-Cr

COMP2-Cr

INPUT SELECT

NET_Y

NET_C

TC4052

Y

C

6dB

6dB

6dB

75

75

6dB

2V

DET.

75

75

75

24

24

24

75 75

DET.

2.2K

2.2K

Y/C MIX

10

-6dB

51

51

51

51

51

Y

COMPONENT

Cb

OUTPUT SELECT

TC4052

Cr

75

OUT

CVBS OUT

BUFFER

CVBS IN

IN1

IN2

IN3

-6dB

INPUT SELECT

TC4051

NR1402 ONLY

29

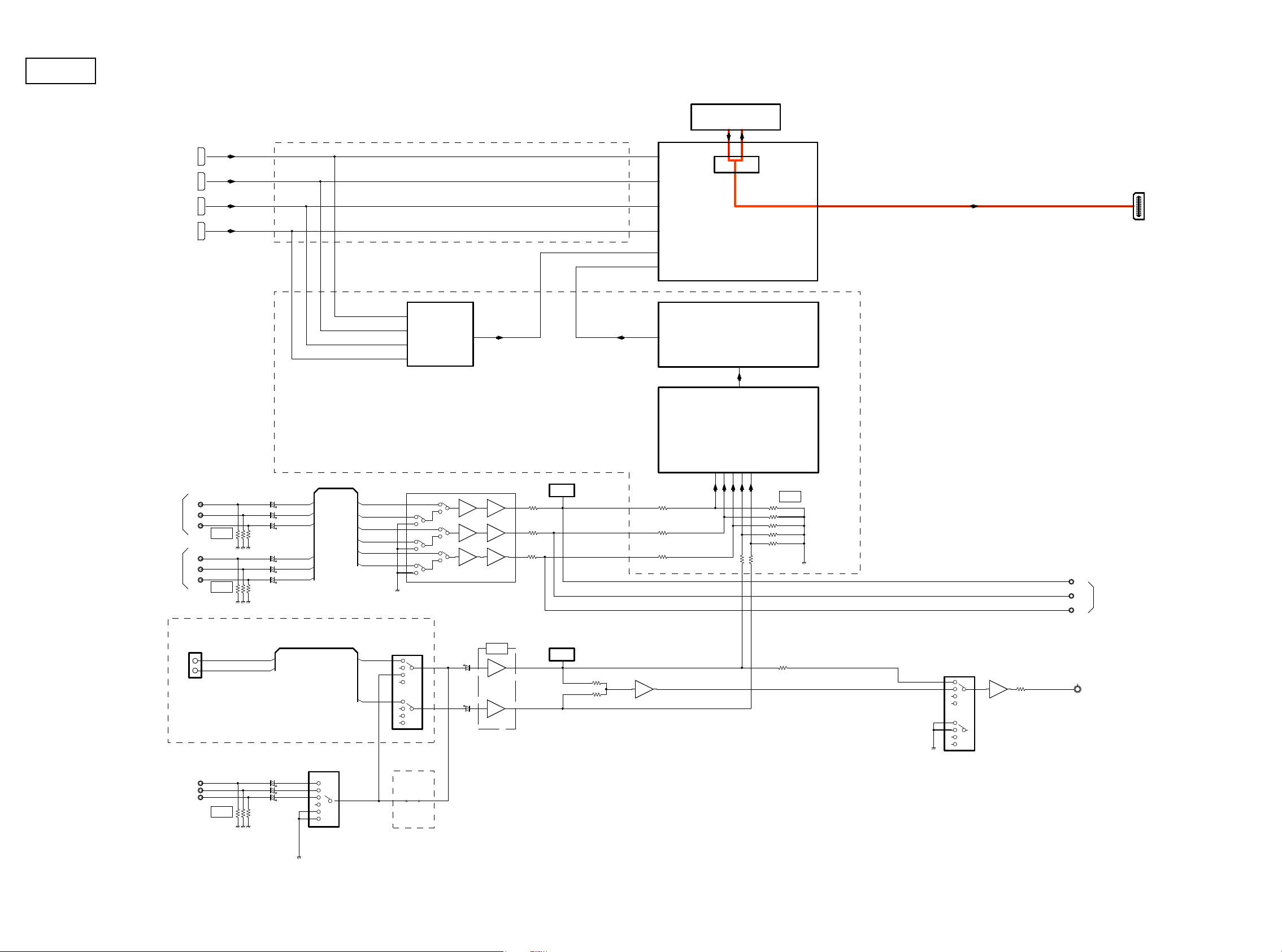

g.3

HDMI IN

HDMI1

HDMI2

HDMI3

HDMI4

VIDEO BLOCK DIAGRAM

SPI FLASH

NR1402 ONLY

OSD

HDMI OUT

ADV7623

HDMI TRANSCEIVER

NR1602 ONLY

COMPONENT

IN

NR1602 ONLY

IN1

IN2

TMDS SW

ADV3002

TMDS OUTPUT

TRANSMITTER

ADV7511

36-BIT YCbCr/RGB

HDMI Rx

VIDEO DECODER

ADV7844

HDMI

NJM2586M

75

Y

Cb

Cr

-6dB

Y

Cb

Cr

-6dB

Y

C

COMP1-Y

COMP1-Cb

COMP1-Cr

COMP2-Y

COMP2-Cb

COMP2-Cr

NET_Y

NET_C

COMP1-Y

COMP2-Y

COMP1-Cb

COMP2-Cb

COMP1-Cr

COMP2-Cr

INPUT SELECT

NET_Y

NET_C

TC4052

Y

C

6dB

6dB

6dB

75

75

6dB

2V

DET.

75

75

75

24

24

24

75 75

DET.

2.2K

2.2K

Y/C MIX

10

-6dB

51

51

51

51

51

Y

COMPONENT

Cb

OUTPUT SELECT

TC4052

Cr

75

OUT

CVBS OUT

BUFFER

CVBS IN

IN1

IN2

IN3

-6dB

INPUT SELECT

TC4051

NR1402 ONLY

30

Loading...

Loading...