Marantz NA-7004 Service Manual

Service

NA7004 /

N1B/N1SG

U1B/K1B

NA70 4

Manual

Network Audio Player

For purposes of improvement, specifi cations and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

NA7004

S0162-1V02DM/DG1010

Ver. 2

Please refer to the

MODIFICATION NOTICE.

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for

company has created the ultimate in stereo sound.

which it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

2F,YEON BLDG.,

88-5, BANPO-DONG, SEOCHO-GU,

SEOUL KOREA

PHONE : +82 - 2 - 715 - 9041

FAX : +82 - 2 - 715 - 9040

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol z .

Any other component substitution (other than original type), may increase risk of fi re or electrical shock hazard.

安全上の注意:

zがついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and verifi ed before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

2

091105DM/DG

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if fi ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be sure to use parts which have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslation check on the external metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fi res

or other dangerous situations.

3

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

PARTS INFORMATION

RESISTORS

1) 00MGD05

2) 00MGD05

Examples ;

0.5Ω .....005 18Ω .....180 2.7kΩ .....272 680kΩ .....684

1Ω .....010 100Ω .....101 10kΩ .....103 1MΩ .....105

6.8Ω .....068 390Ω .....391 22kΩ .....223 4.7MΩ .....475

Note : Please distinguish 1/4W from 1/6W by the shape of parts

CAPACITORS

CERAMIC CAP.

3) 00MDD1 × × × × 370, Ceramic capacitor

Examples ;

±0.25pF......

±0.5pF...... 1

±5%...... 5

Tolerance of COMMON PARTS handled here are as follows :

0.5pF〜 5pF .....±0.25pF

6pF〜 10pF .....±0.5pF

12pF〜 560pF .....±5%

0.5pF

1pF .....010 10pF .....100 220pF .....221

1.5pF .....015 47pF .....470 560pF .....561

ERAMIC CAP.

C

4) 00MDK16

Examples ;

100pF

470pF .....471 2200pF ..... 222

ELECTROLY CAP. ( )

5) 00MEA

Examples ;

0.1μF .....

0.33μF .....334 10μF .....106 330μF ... 337

1μF .....105 22μF .....226 1100μF ...118

2200μF ... 228

6.3V .....

10V .....010 35V .....035

16V .....016 50V .....050

FILM CAP. ( )

6) 00MDF15

00MDF15

00MDF16

Examples ;

0.001μF (1000pF)

0.0018μF ...........................182 0.56μF .... 564

0.01μF ...........................103 1μF .... 105

0.015μF ...........................153

× × ×

140, Carbon fi lm fi xed resistor, ±5% 1/4W

× × ×

160, Carbon fi lm fi xed resistor, ±5% 1/6W

}

Resistance value

Resistance value

0.1Ω .....001 10Ω .....100 1kΩ .....102 100kΩ .....104

used actually.

}

Disc type

Temp.coeff.P350〜N1000, 50V

Tolerance (Capacity deviation)

Capacity value

}

× × ×

capacitor

Disc type

Temp.chara. 2B4, 50V

Capacity value

× × × × × ×

}

One-way lead type, Tolerance ±20%

Capacity value

Working voltage

× × ×

× × ×

× × ×

}

One-way type, Mylar ±10% 50V

Capacity value

Capacity value

Tolerance

0

.....005 3pF .....030 100pF .....101

300, High dielectric constant ceramic

Capacity value

.....101 1000pF ..... 102 10000pF .....103

10, Electrolytic capacitor

}

Working voltage

Capacity value

104 4.7μF .....475 100μF ... 107

006 25V .....025

350 Plastic fi lm capacitor

310 One-way type, Mylar ±5% 50V

310 Plastic fi lm capacitor

▲

▲

Capacity value

...........102 0.1μF ....104

NOTE ON SAFETY FOR FUSIBLE RESISTOR :

The suppliers and their type numbers of fusible resistors

are as follows;

1. KOA Corporation

Part No. (MJI) Type No. (KOA) Description

00MNH05 × × × 140 RF25S × × × × ΩJ (±5% 1/4W)

00MNH05 × × × 120 RF50S × × × × ΩJ (±5% 1/2W)

00MNH85 × × × 110 RF73B2A × × × × ΩJ (±5% 1/10W)

00MNH95 × × × 140 RF73B2E × × × × ΩJ (±5% 1/4W

2. Matsushita Electronic Components Co., Ltd

Part No. (MJI) Type No. (MEC) Description

00MNF05 × × × 140 ERD-2FCJ × × × (±5% 1/4W)

00MRF05 × × × 140

00MNF02 × × × 140

00MRF02 × × × 140

Examples ;

0.1Ω .....001 10Ω .....100 1kΩ .....102 100kΩ ....104

0.5Ω .....005 18Ω .....180 2.7kΩ .....272 680kΩ ....684

1Ω .....010 100Ω .....101 10kΩ .....103 1MΩ ....105

6.8Ω .....068 390Ω .....391 22kΩ .....223 4.7MΩ ....475

}

}

Resistance value

*

▲▲

▲ ▲

Resistance value

▲

▲

ERD-2FCG

Resistance value

}

Resistance value

(0.1 − 10kΩ)

}

× × × (±2% 1/4W)

Resistance value

ABBREVIA TION AND MARKS

ANT. : ANTENNA BATT. : BATTERY

CAP. : CAPACITOR CER. : CERAMIC

CONN. : CONNECTING DIG. : DIGITAL

HP : HEADPHONE MIC. : MICROPHONE

μ-PRO : MICROPROCESSOR REC. : RECORDING

RES. : RESISTOR SPK : SPEAKER

SW : SWITCH

TRIM. : TRIMMING TRS. : TRAMSISTOR

VAR. : VARIABLE X’TAL : CRYSTAL

TRANSF.

: TRANSFORMER

NOTE ON FUSE :

Regarding to all parts of parts code 00MFS20xxx2xx, replace

only with Wickmann-Werke GmbH, Type 372 non glass type fuse.

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts

should be used to replaced any part marked with symbol z.

Any other component substitution (other than original type), may

increase risk of fi re or electrical shock hazard.

安全上の注意:

z がついている部品は、安全上重要な部品です。必ず指定

されている部品番号の部品を使用して下さい。

060522 MZ

4

)

SPECIFICATIONS

n Audio section

• Analog output

Channels 2 channels

Playable frequency range 2 Hz – 96 kHz

Playable frequency response 2 Hz – 50 kHz (–3dB)

S/N 110 dB (Audible Range)

Dynamic Range 110 dB (Audible Range)

Harmonic Distortion 0.001 % (1 kHz, Audible Range)

• Output Level

Unbalanced 2.35V RMS Stereo

Headphone output 18mW/33Ω (variable maximum)

• Digital output

Output level (cinch JACK) 0.5 Vp-p

Output level (optical) –19 dBm

• Digital input

Signal format

Input level (cinch JACK) 0.5 Vp-p

Input level (optical) –27 dBm or later

Emission wavelength (optical) 660 nm

n Tuner section (for N model)

• FM tuner

Range of receivable frequencies 87.5 to 108.0 MHz

S/N ratio (mono) 65 dB

Sensitivity (S/N 30 dB) 9 dBμV (IHF)

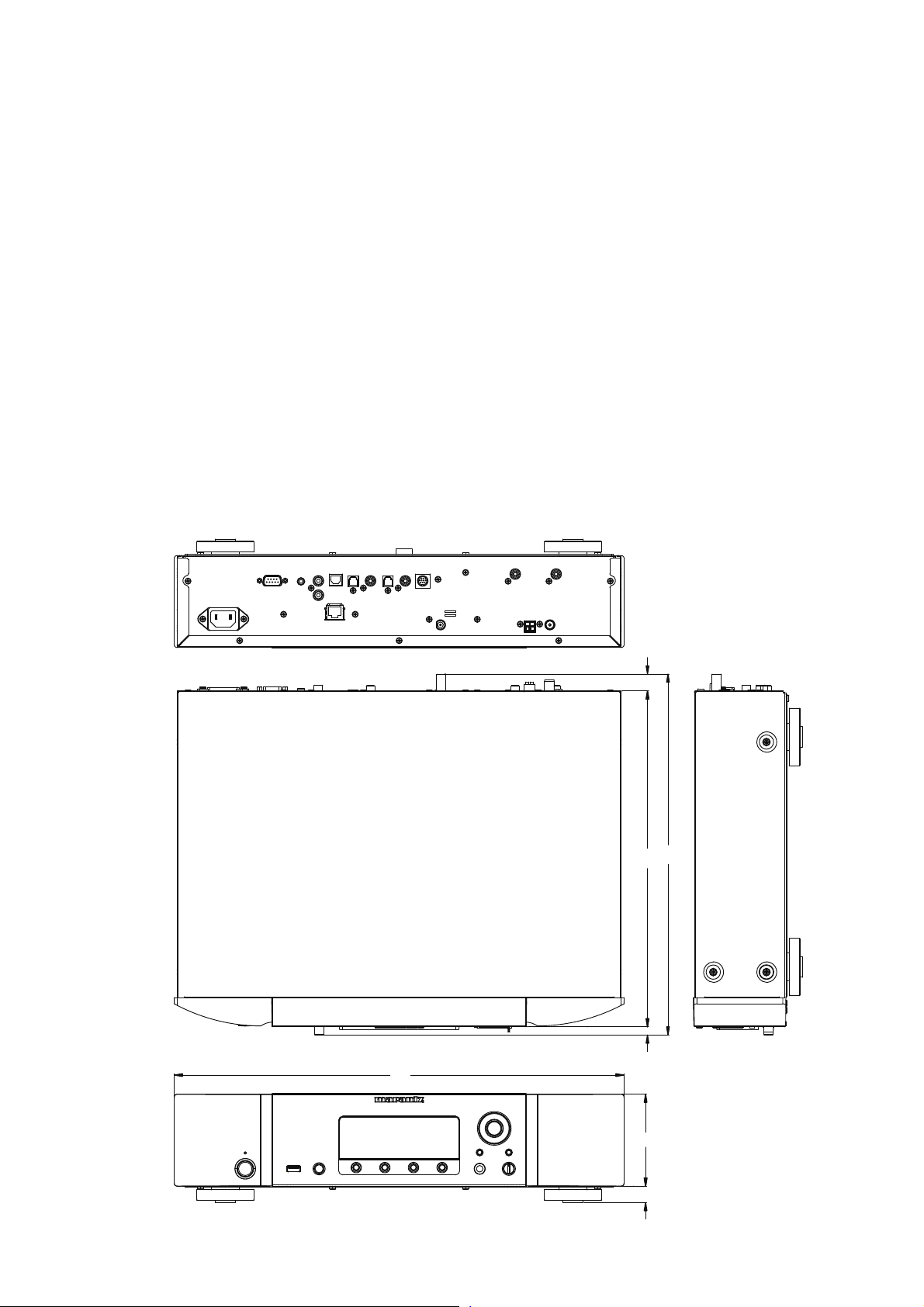

DIMENSION

(Sampling frequency: 192 kHz)

2 Hz – 20 kHz

(Sampling frequency: 44.1 kHz)

DIGITAL AUDIO INTERFACE ]

(linear PCM)

• AM tuner

Range of receivable frequencies 522 to 1611 kHz

S/N ratio 40 dB

Sensitivity (S/N 20 dB) 55 dBμV/m

n DAB tuner section (for N model)

Frequency range 174.928 (5A) ~ 239.200 (13F) MHz

Sensitivity –90 dBm

Signal-to-noise ratio 95 dB

THD+N 0.025 % (1 kHz)

Channel separation 70 dB (1 kHz)

(BAND III)

n Power supply

Power supply voltage/frequency AC 230 V, 50/60 Hz (for N model)

Power consumption 30W

Power consumption in standby

mode

AC 120 V, 60 Hz (for U model)

AC 220 V, 50 Hz (for K model)

0.4 W

n General

External dimensions

(width x height x depth)

Weight 6.5 kg

440 x 106 x 354 mm (for N model)

440 x 106 x 343 mm (for U,K model)

440

178 329

354

9115

The illustration is N model.

5

CAUTION IN SERVICING

Firmware update

• When you replace the IC912, you need software updates.

Refer to "After replacing IC912".

• When you replace the ETHERNET PWB, you need software updates. And MAC Address seal replacement is required.

Refer to "After replacing ETHERNET PWB Assy".

Initializing Network Audio Player (Factory Rerset)

Network Audio Player initialization should be performed when the μcom, peripheral parts of μcom, and ETHERNET PWB.

are replaced.

1. Turn off the power using ON/STANDBY button, unplug the power cord.

2. Plug the power cord into a power outlet while pressing CURSOR f and M-DAX button simultaneously.

Initialize.

*

Note: • All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to memorize your setting for restoring after the initialization.

CURSOR f

ON/STANDBY

M-DAX

6

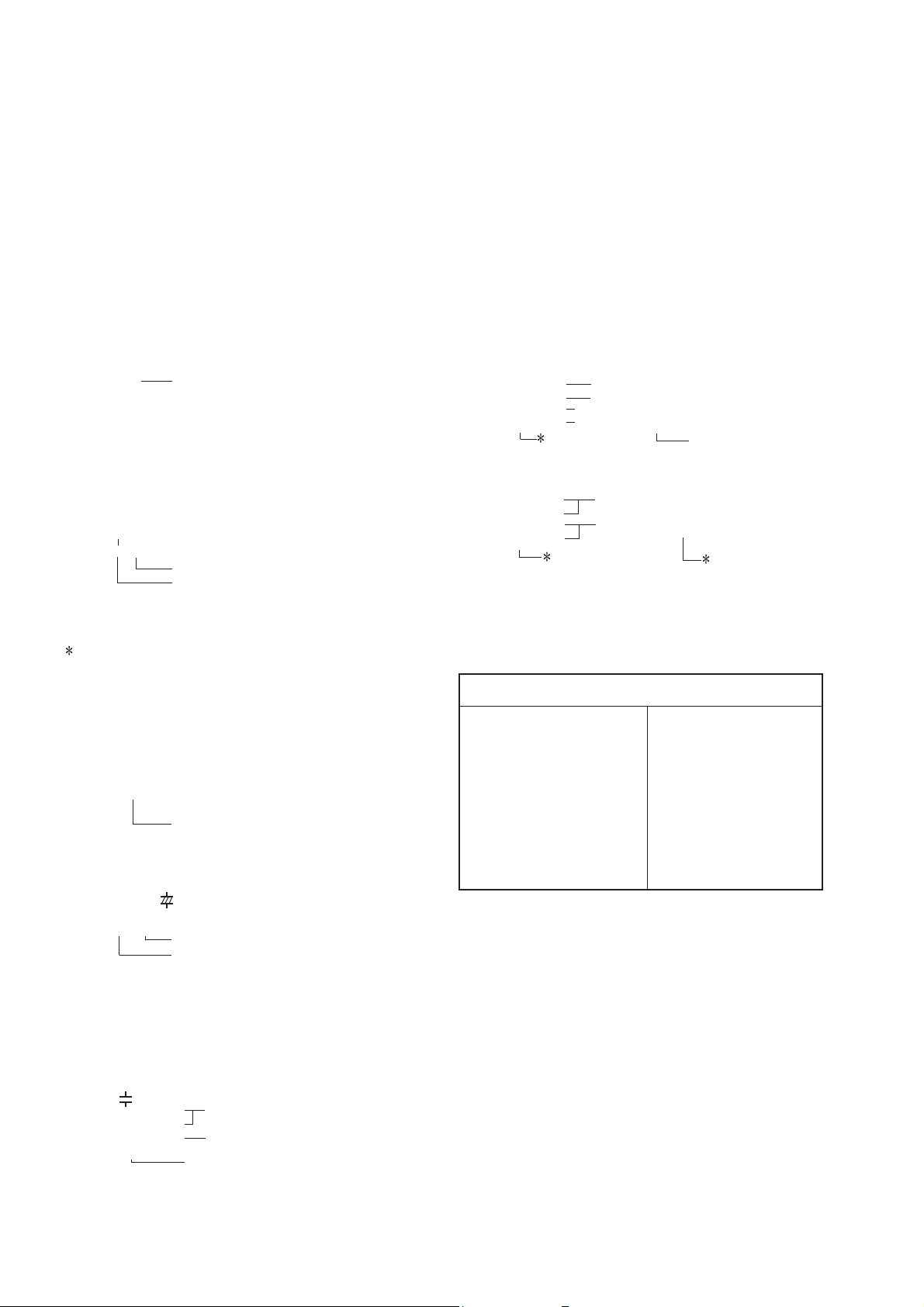

DISASSEMBLY

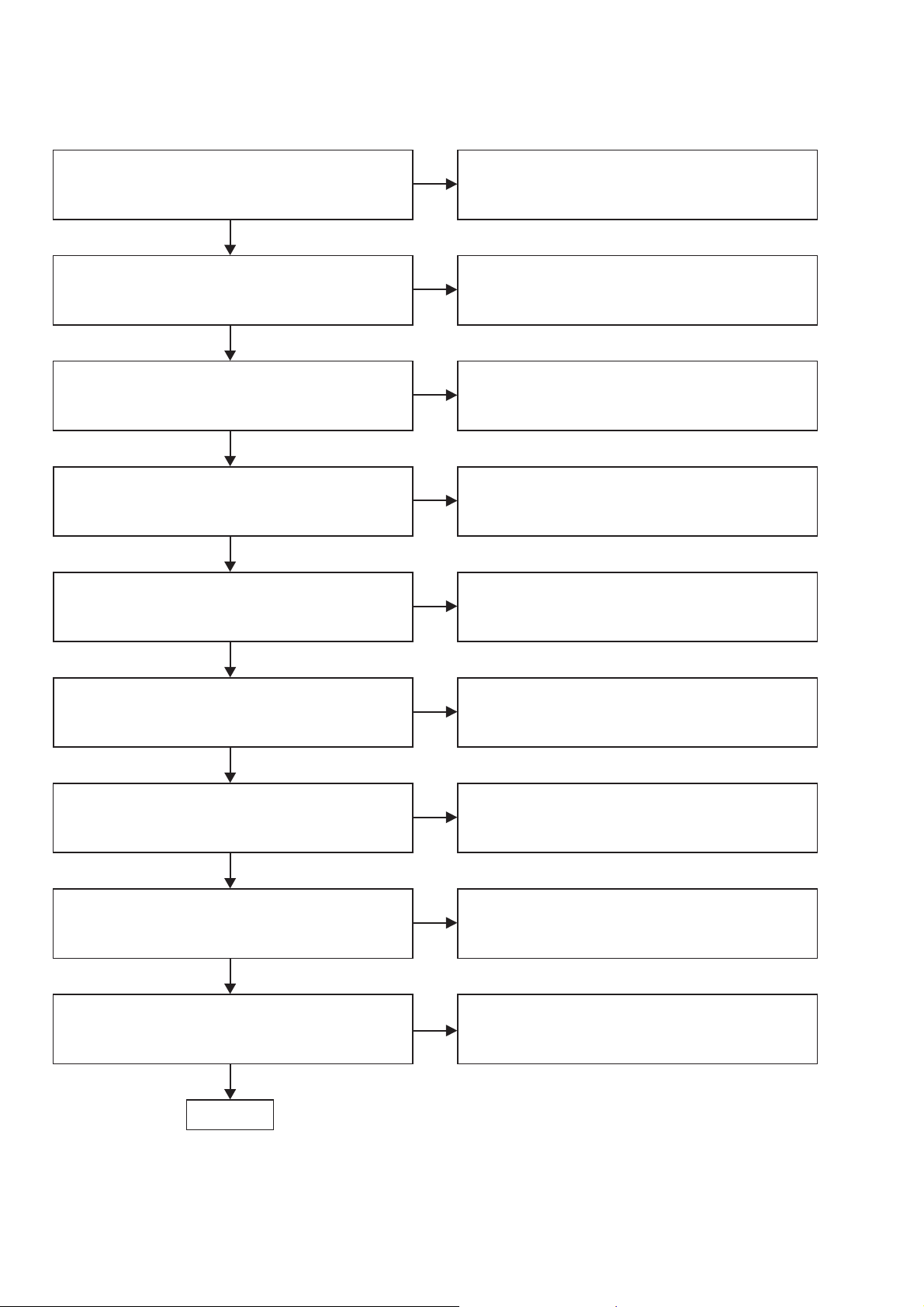

• Disassemble in order of the arrow of the fi gure of following fl ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following fl ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

PHONE PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P1)

USB PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P2)

STANDBY PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P3)

DISPLAY PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P4)

ETHERNET PCB ASS'Y

Refer to "DISASSEMBLY

2. ETHERNET PCB ASS'Y "

and "EXPLODED VIEW"

ETHERNET PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P9)

MAIN PCB ASS'Y

Refer to "DISASSEMBLY

4. MAIN PCB ASS'Y"

and "EXPLODED VIEW"

MAIN PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P6)

TUNER MODULE & DAB PCB ASS'Y

(N model only)

Refer to "DISASSEMBLY

3. TUNER MODULE"

and "EXPLODED VIEW"

DAB PCB ASS'Y

(Ref. No. of EXPLODED VIEW : P7)

TUNER MODULE

(Ref. No. of EXPLODED VIEW : P8)

AUDIO PCB ASSY

Refer to "DISASSEMBLY

5. AUDIO PCB ASSY"

and "EXPLODED VIEW"

AUDIO PCB ASSY

(Ref. No. of EXPLODED VIEW : P5)

About the photos used for descriptions in the DISASSEMBLY" section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***"

at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

• The photograph is NA7004 N1SG model.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

Direction of photograph: A

7

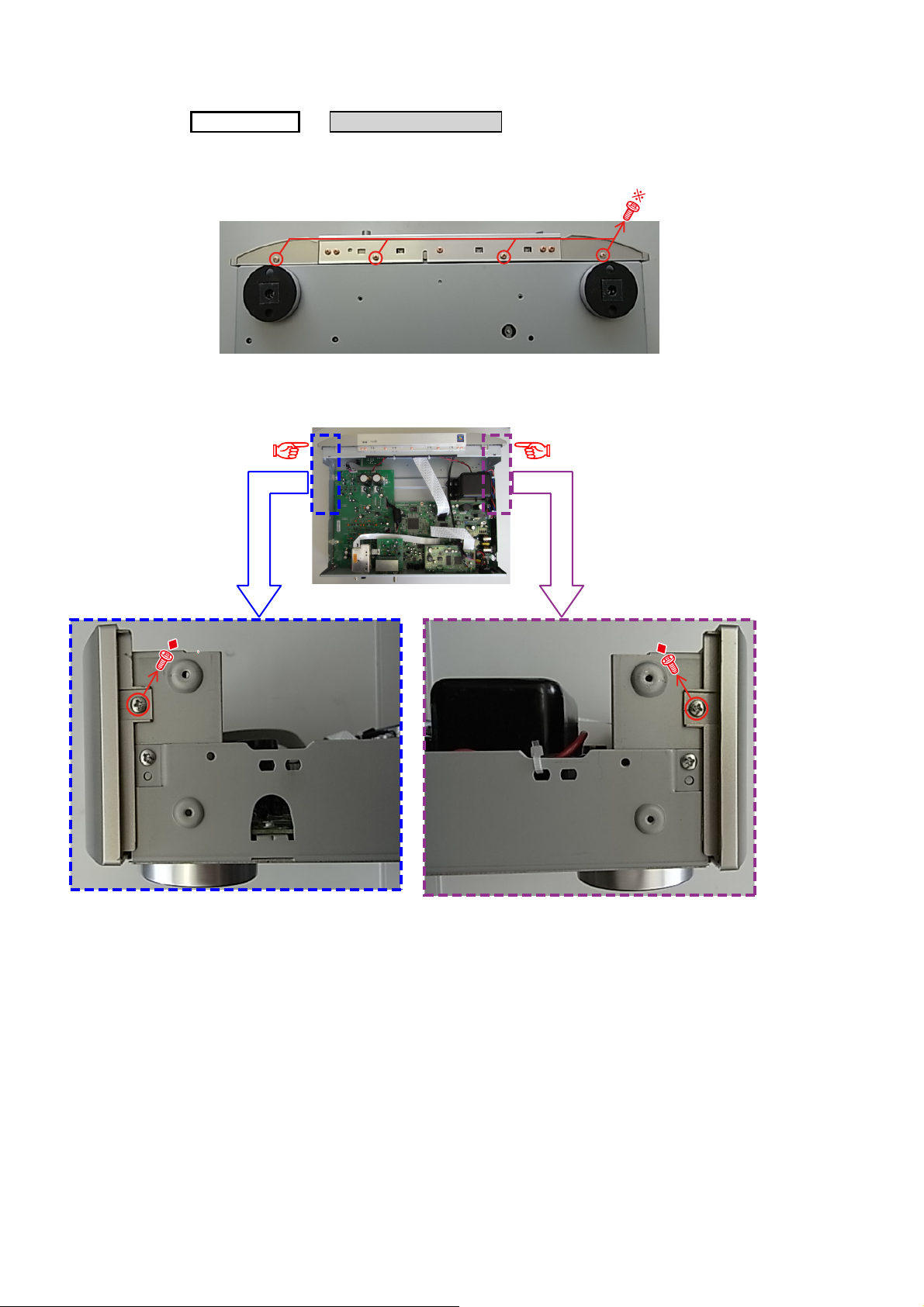

1. FRONT PANEL ASSY

Proceeding :

(1) Remove the screws.

View from bottom

(2) Remove the screws.

TOP COVER

FRONT PANEL ASSY

→

Direction of

photograph: C

Direction of

photograph: D

8

(3) Cut the wire clamp band, then disconnect the connector wires and FFC cable. Remove the screws.

CN81

cut

FFC cable

Direction of

photograph: B

N101

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

9

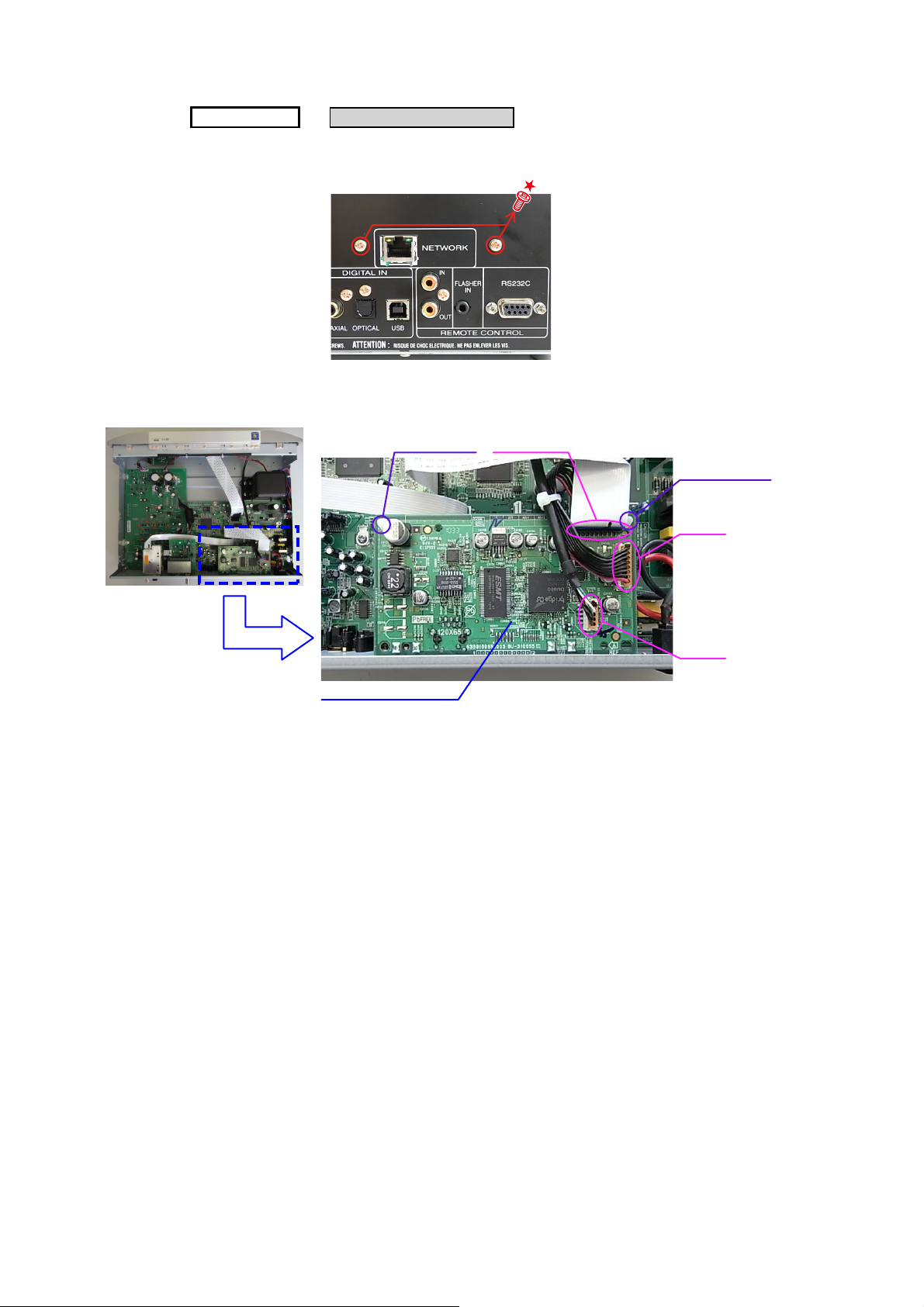

2. ETHERNET PCB ASS'Y

Proceeding :

(1) Remove the screws.

(2) Disconnect the connector wires and FFC cable, then remove the PWB Clamper.

TOP COVER

Direction of photograph: A

ETHERNET PCB ASS'Y

→

PWB Clamper

FFC Cable

PWB Clamper

N0103

ETHERNET PCB ASS'Y

N0101

10

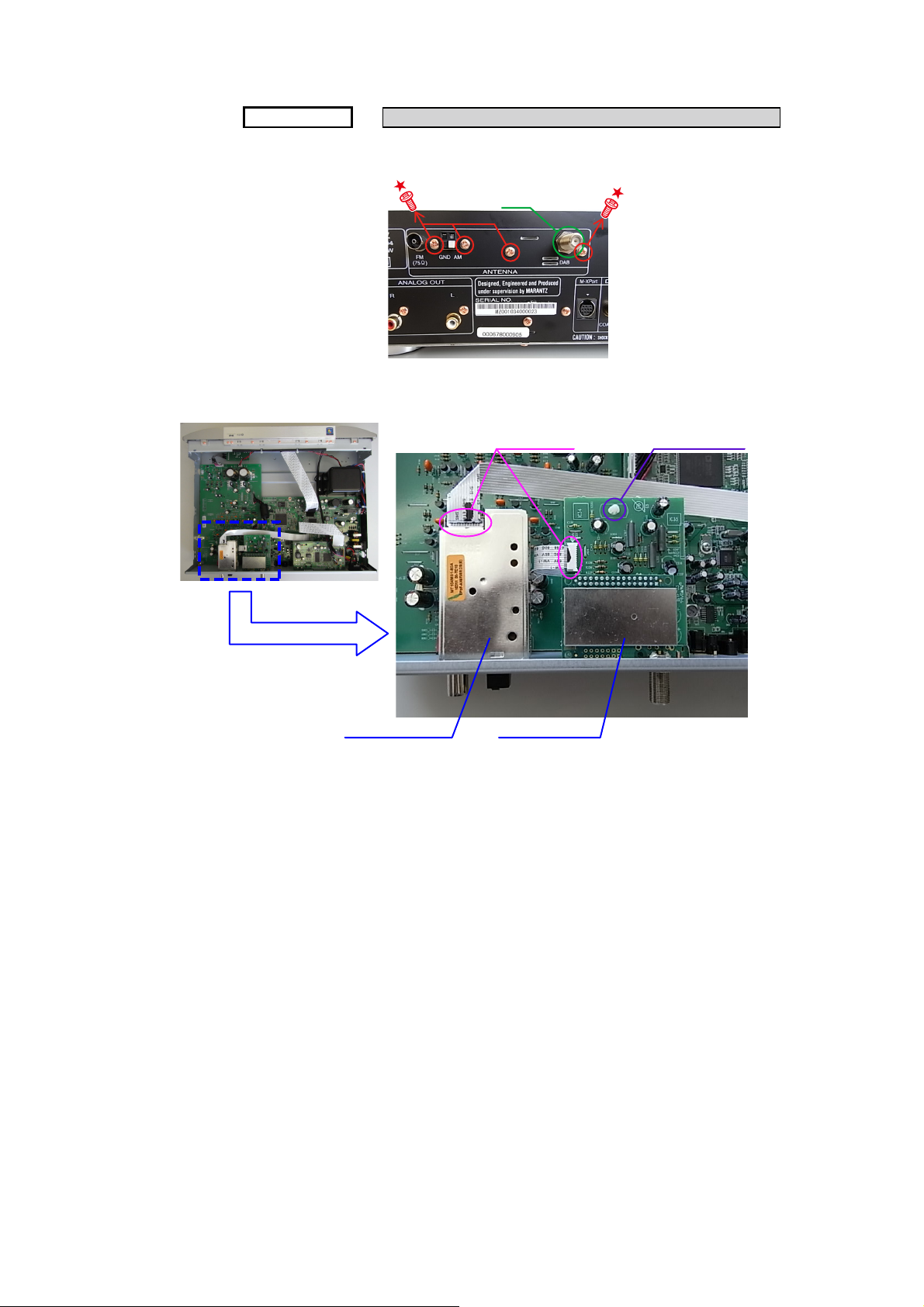

3. TUNER MODULE & DAB PCB ASS'Y (N model only)

Proceeding :

(1) Remove the screws and NUT.

(2) Disconnect the FFC cable, then remove the PWB Clamper.

TOP COVER

Direction of photograph: A

TUNER MODULE & DAB PCB ASS'Y (N model omly)

→

NUT

FFC Cable

PWB Clamper

TUNER MODULE DAB PCB ASS'Y

11

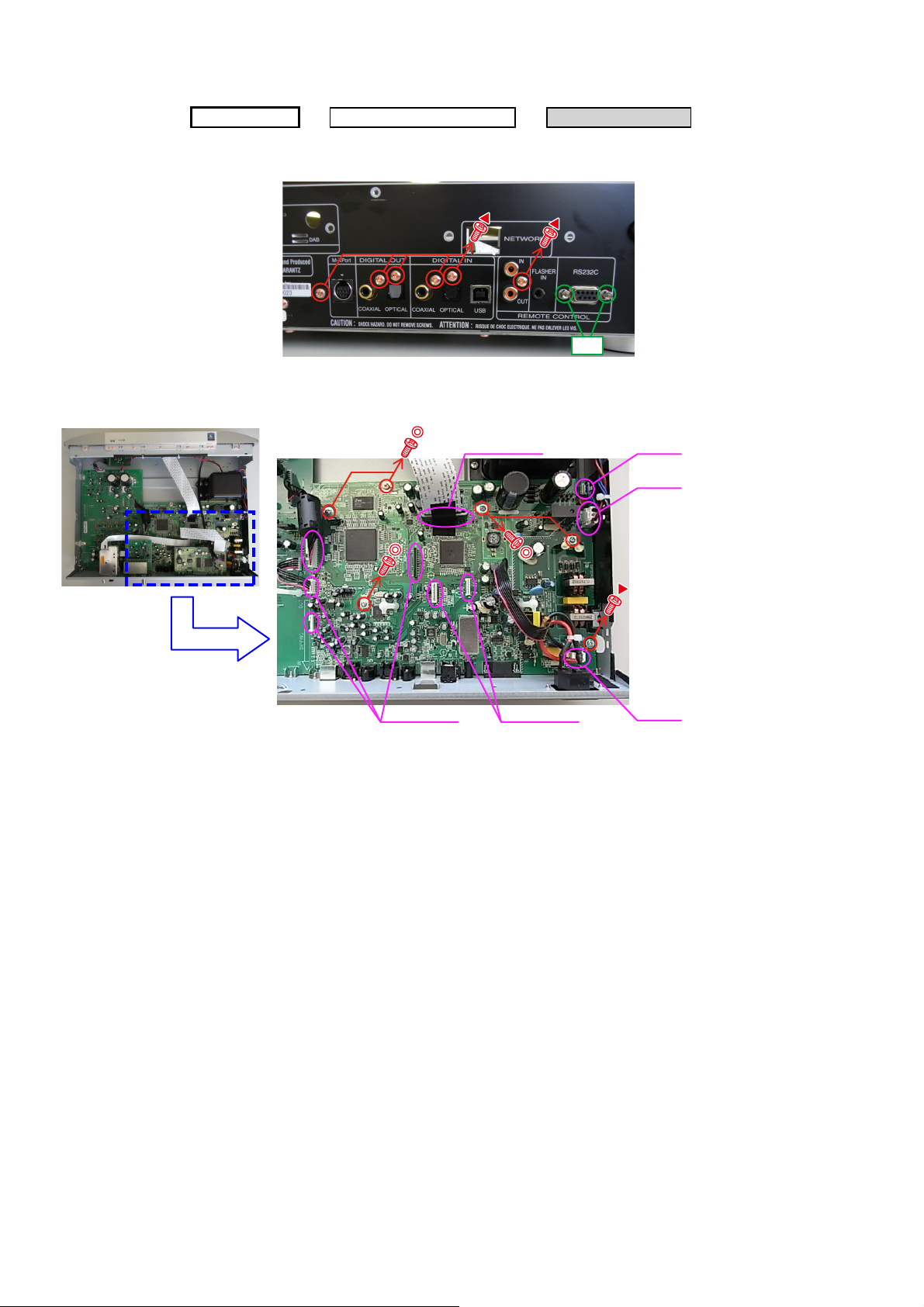

4. MAIN PCB ASS'Y

Proceeding :

(1) Remove the screws and NUT.

Direction of photograph: A

(2) Disconnect the connector wires and FFC cable, then remove the screws.

TOP COVER

ETHERNET PCB ASS'Y

→

→

FFC Cable CN93

MAIN PCB ASS'Y

NUT

CN92

FFC Cable

FFC Cable

CN91

12

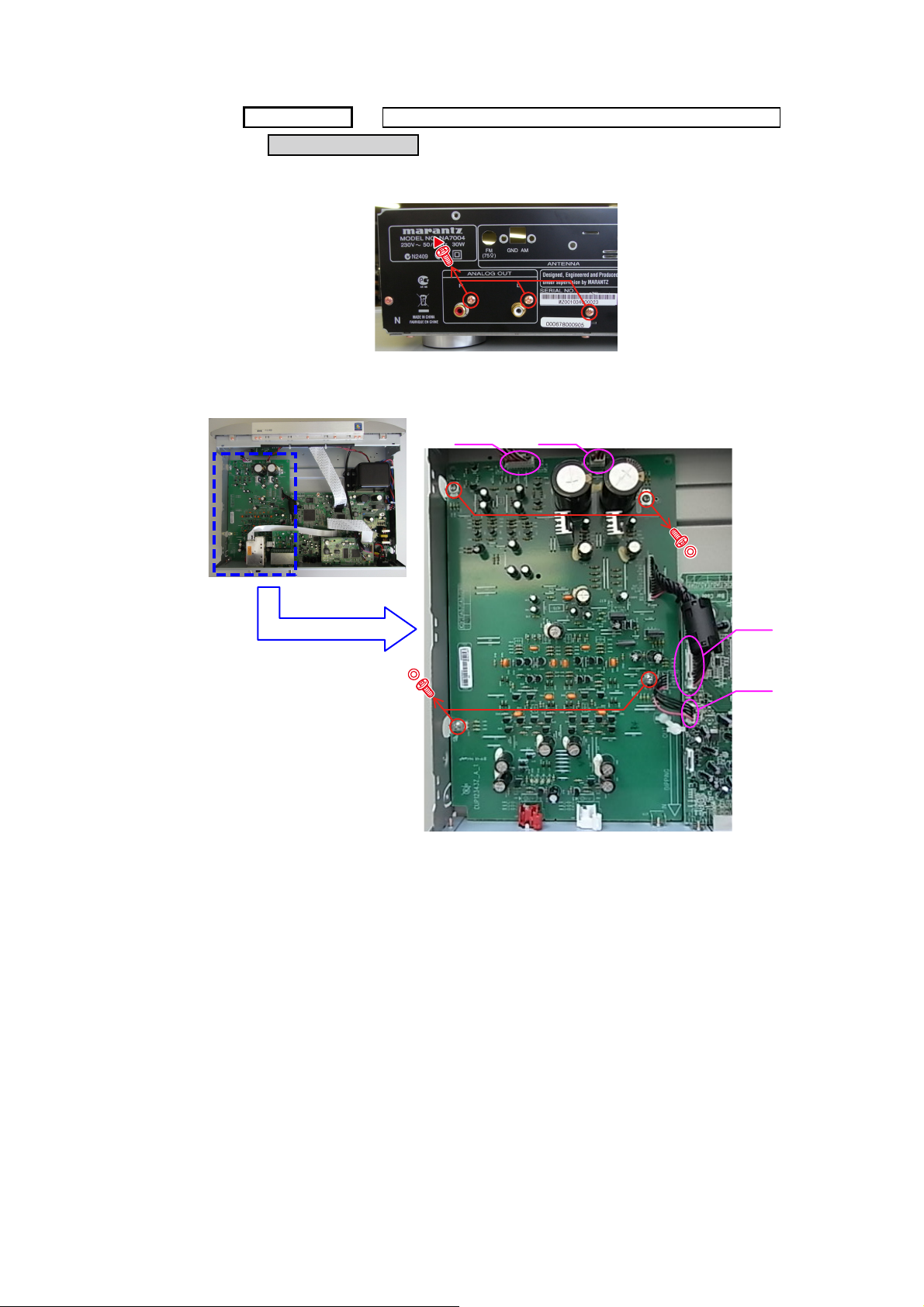

5. AUDIO PCB ASSY

Proceeding :

(1) Remove the screws.

Direction of photograph: A

(2) Disconnect the FFC cable, then remove the screws

TOP COVER

AUDIO PCB ASS'Y

→

TUNER MODULE & DAB PCB ASS'Y (N model omly)

→

CN81 CN94

CN40

BN93

13

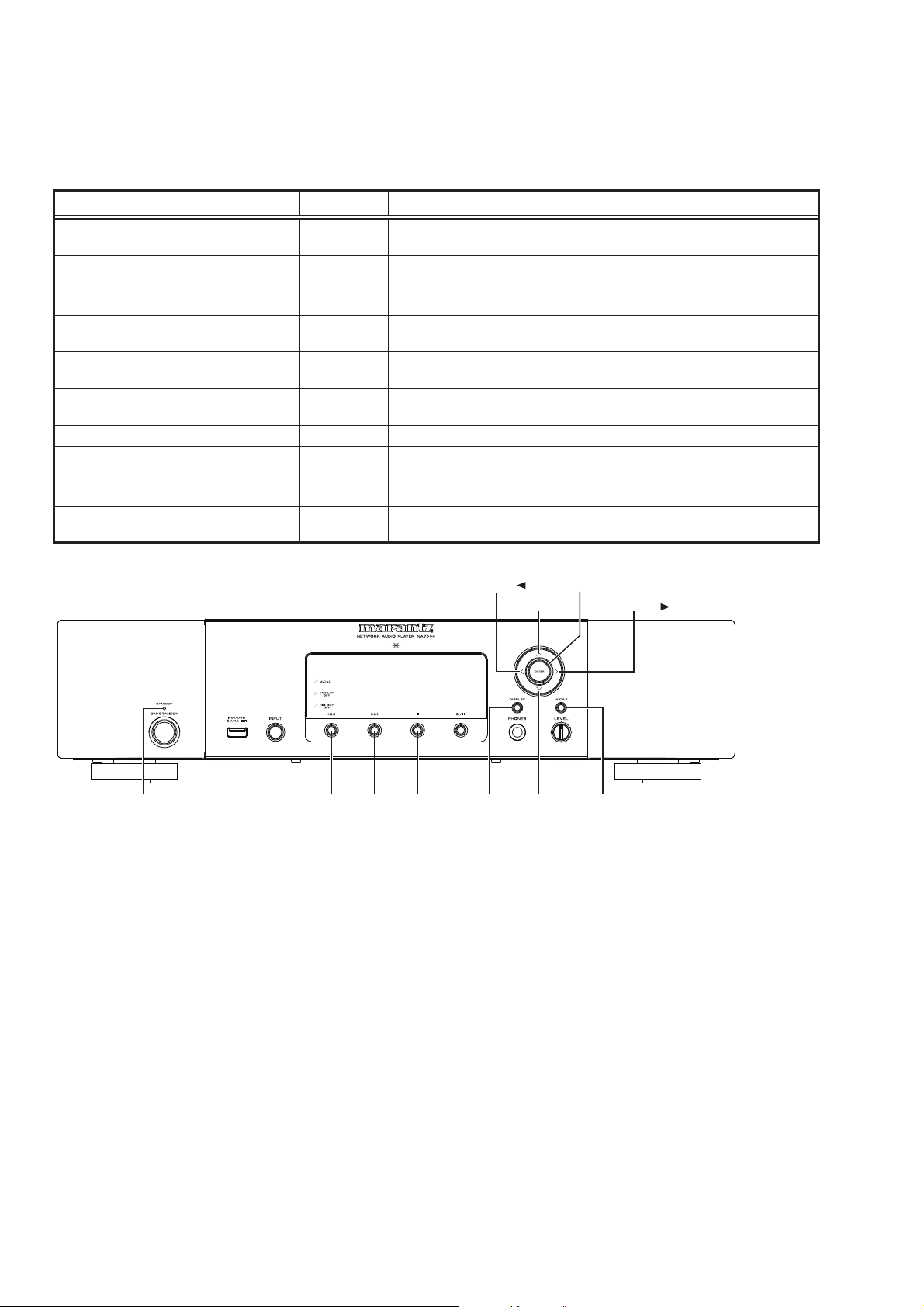

SPECIAL MODE

Special mode setting

Plug AC cord into power outlet while pressing buttons A and B.

Each button continue to press until the turning on STANDBY LED.

No. Mode Button A Button B Contents

Initialization mode

1

(Factory Reset)

Initialization mode

2

( User Reset)

3 Version display CURSOR UP

4 Product mode 1 STOP

5 Prodcut mode 2

6 Protection history mode

7 DPMS update mode DISPLAY CURSOR UP DPMS Up date Mode

8 Update mode (by RS232C) DISPLAY ENTER Development/Fuctory use. The details cannot be disclosed.

9 MAC Address rewrite mode DISPLAY

10 Access to development server mode DISPLAY

CURSOR

DOWN

DISPLAY M-DAX Initializing. (Contents User's Guide is published)

CURSOR

LEFT

REVERSE-

SKIP

M-DAX Initializing. Factory Reset

-

REVERSE-

SKIP

M-DAX Factory use.

FORWARD-

SKIP

CURSOR

RIGHT

CURSOR

RIGHT

Version Display

Factory use.

Protection history view and reset

Development/Fuctory use. The details cannot be disclosed.

Development/Fuctory use. The details cannot be disclosed.

CURSOR

CURSOR

8

9

2

DISPLAY

CURSOR

ENTER

d

f

CURSOR

M-DAX STANDBY LED

14

1. Initialization mode (Factory Reset)

Backup data initialization is carried out. Refer to Initialization Items.

After initialization, move on to nomal mode.

CAUTION

Version information (such as rewriting failed log) Clear.

Clear the history of protection.

Startup display

All lights display(2 seconds) - All off display(2 seconds)

"Factory Reset" displayed for 5 seconds.

Initialization Items (Default setting)

Default

source Internet Radio

TUNER(band) FM

DIMMER 100%

TUNER Preset Clear all

Favorite list Clear all

iPod mode Direct mode

AUTO STANDBY OFF

DAB Module Module Initialization

Protection history NO PROTECT

Network setting DHCP (On)

PC Language English

Screen Saver Off

IR Setting Enable

2. Initialization mode (User Reset)

Backup data initialization is carried out. Refer to Initialization Items.

After initialization, move on to nomal mode.

CAUTION

The difference is the following two points.

Version information (such as rewriting failed log) not cleared.

History of protection not cleard.

Startup display

"Initialized" displayed for 5 seconds.

15

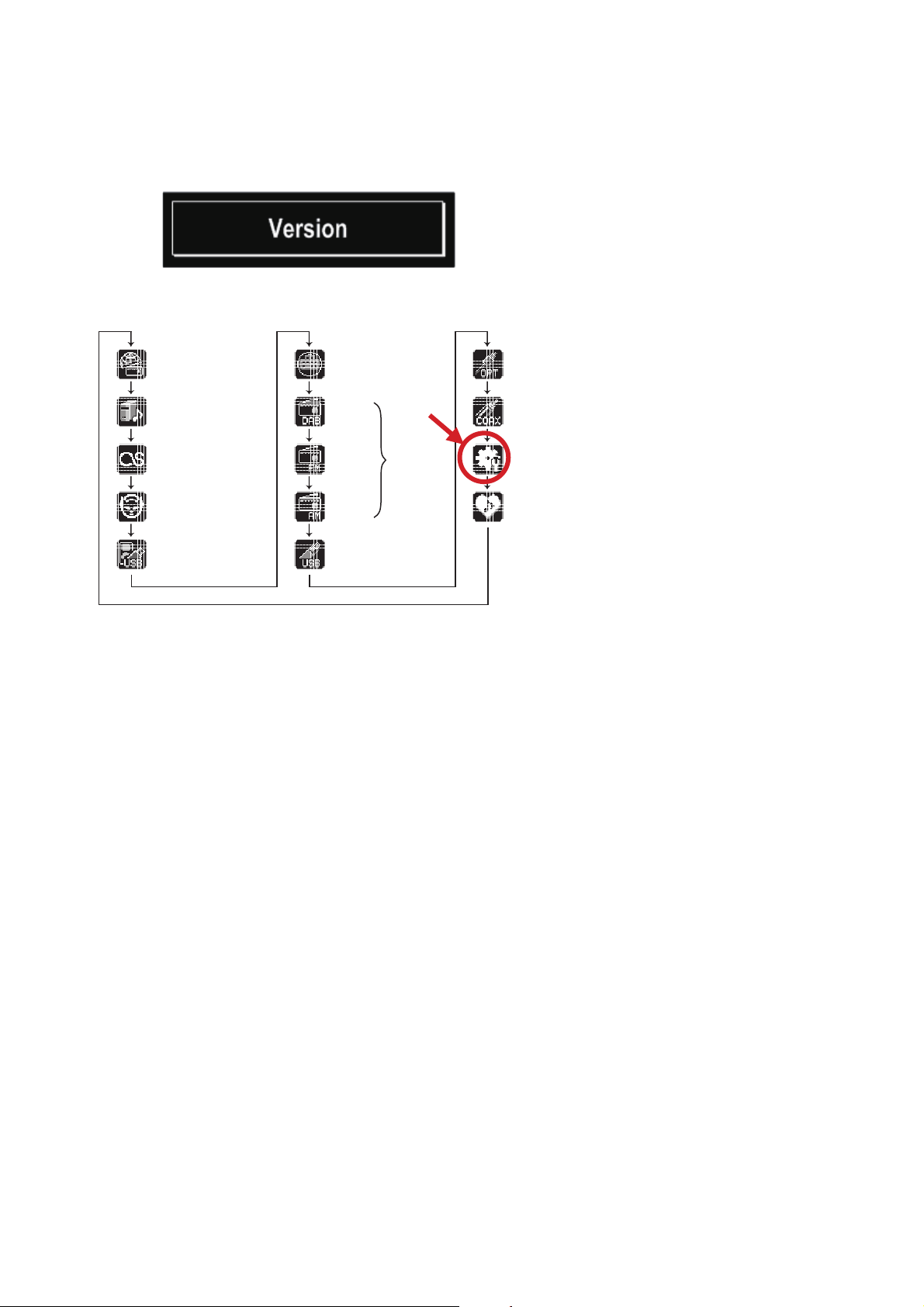

3. Version display

Menu items appear in the Add Version.Otherwise, normal operation.

To exit this mode, unplug the power cord.

Startup display

"Version" displayed for 5 seconds.

How to Display Version

Select the Menu, and press ENTER button.

z2

z1

㪛㫀㪾㫀㫋㪸㫃 㪠㫅 㪦㪧㪫

㪛㫀㪾㫀㫋㪸㫃 㪠㫅 㪚㪦㪘㪯

㪤㪼㫅㫌

㪝㪸㫍㫆㫉㫀㫋㪼

㪠㫅㫋㪼㫉㫅㪼㫋 㪩㪸㪻㫀㫆

㪤㫌㫊㫀㪺 㪪㪼㫉㫍㪼㫉

㪣㪸㫊㫋㪅㪽㫄

㪥㪸㫇㫊㫋㪼㫉

㫀㪧㫆㪻㪆㪬㪪㪙

1 The icon is not displayed when you do not connect RX101 sold separately.

z

2 Only N

z

㪤㪄㪯㪧㫆㫉㫋

㪛㪘㪙

㪝㪤

㪘㪤

㪛㫀㪾㫀㫋㪸㫃 㪠㫅 㪬㪪㪙

16

Pressing the ENTER button will be displayed below.

Network

1/4

Press Cursor

The version of the system-μ Processor.

Press Cursor

The version of the boot loader(system-μ Processor).

Press Cursor

The version of the display-μ Processor.

Press Cursor

1

f

f

f

The version of the boot loader(network-μ Processor).

Press Cursor

The version of the image(network-μ Processor).

Press Cursor

Serial number displayed.

(Serial:MZ_bccdddddd, MZ:Fixed, b:One digits of the year, cc:Week number, dddddd:Serial number)

f

f

17

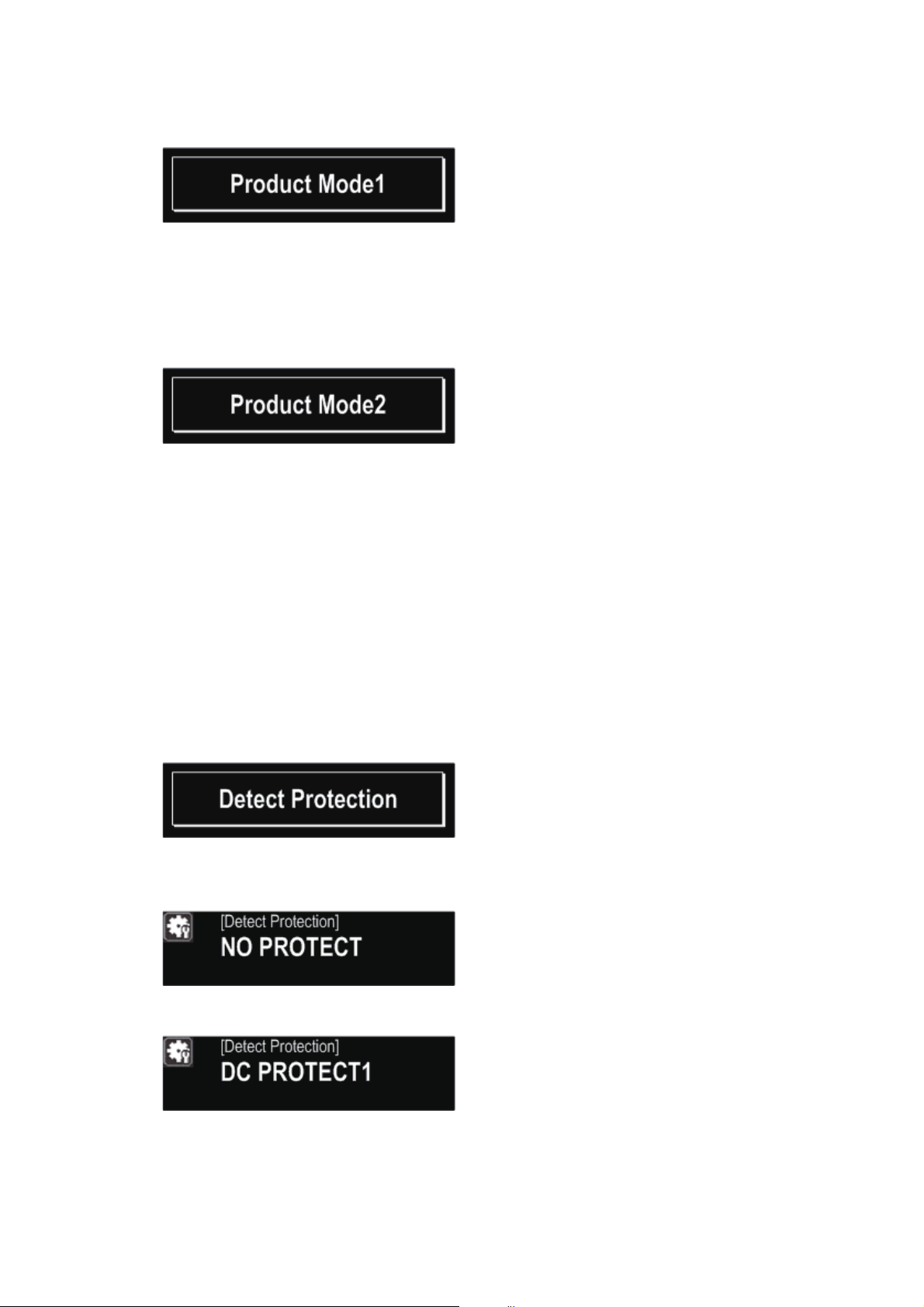

4. Product Mode 1

Startup display

"Product Mode1" displayed for 5 seconds.

Tested during production to perform the following settings automatically.

Tuner Preset

To exit this mode, unplug the power cord.

5. Product Mode 2

Startup display

"Product Mode2" displayed for 5 seconds.

Tested during production to perform the following settings automatically.

Sleep setting : 1 minutes

Auto Standby :1 minutes

Sleep setting and timer started.

Auto Standby to set up and will stand under the following conditions.

Auto Standby Conditions

USB/iPod : No Connection or continue no operation and Stop state.

Network : No Connection or continue no operation and Stop state.

Digital In USB, Digital In OPT, Digital In COAX : No Input(unlock)

M-XPort : No Input

To exit this mode, unplug the power cord.

6. Protection history display mode

Startup display

"Detect Protection" displayed for 5 seconds.

To exit this mode, unplug the power cord.

No history found

DC protect 1

Overvoltage of +B/-B

18

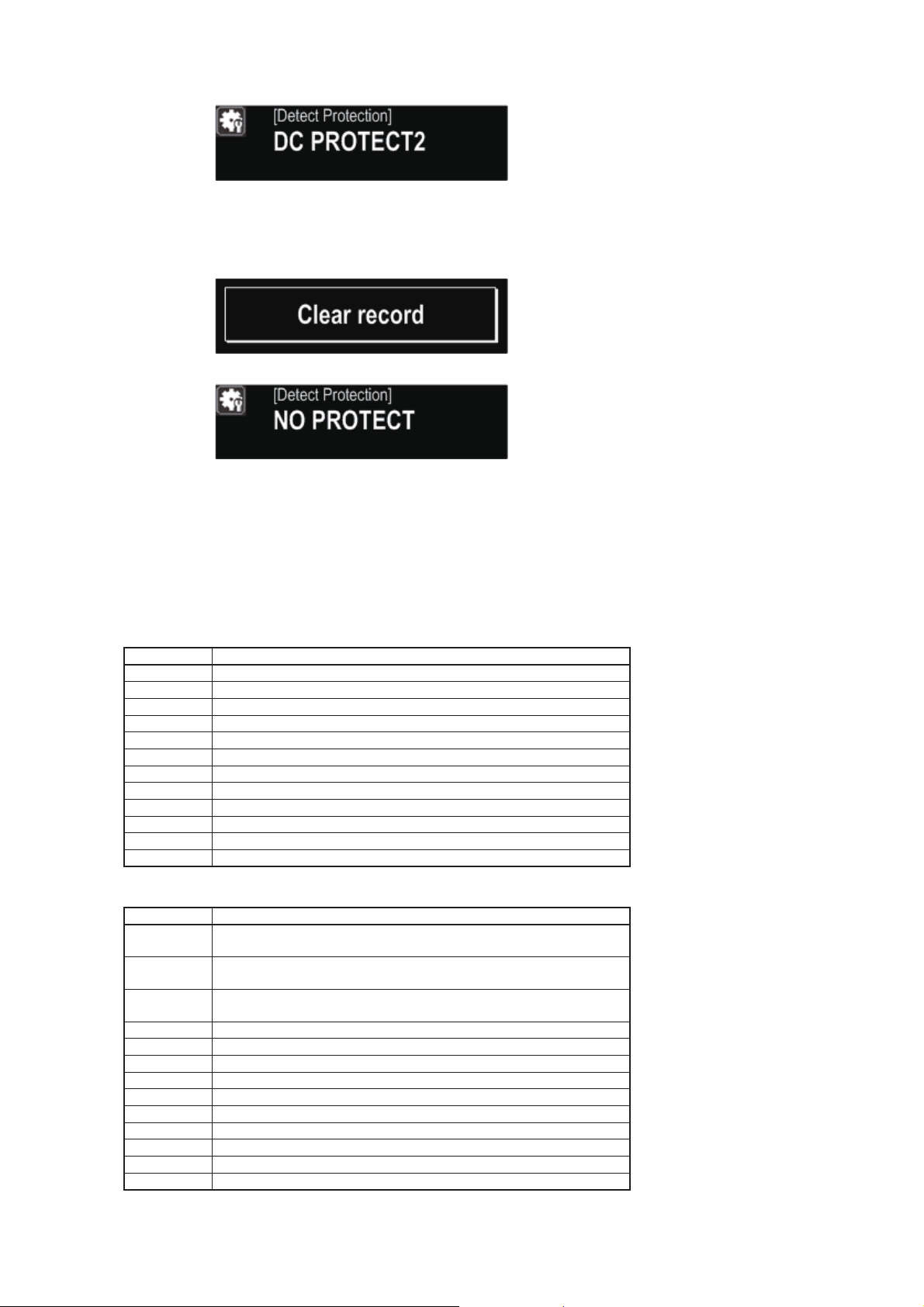

DC protect 2

Short of '+B/-B

Protection history is reset.

When the Cursor d button is pressed for over 5 seconds while the protection history is displayed, the count value is

reset.

After the reset is complete, the display “No Protection“.

Protection history is not cleared, even when the set is reset (Factory/User).

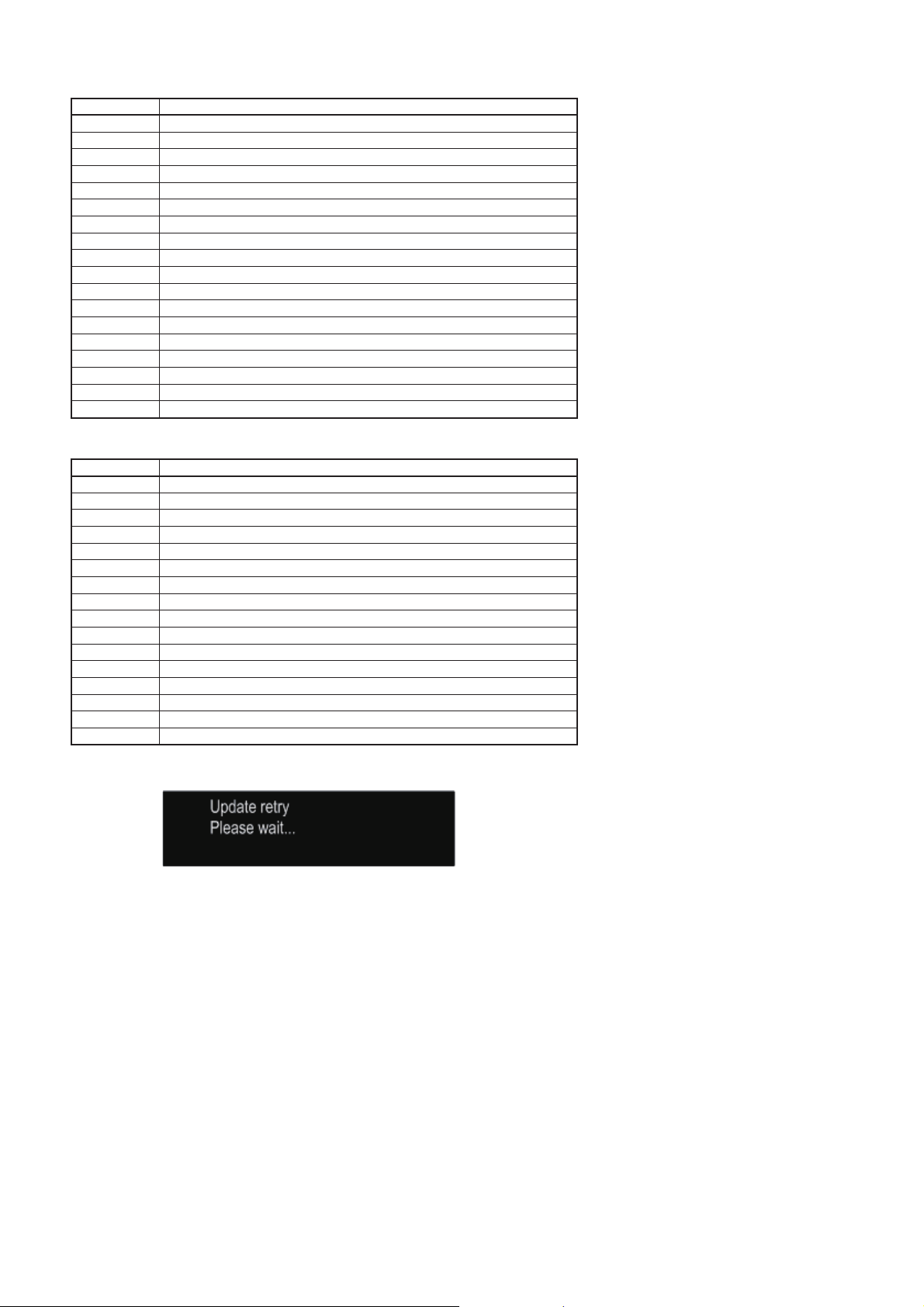

7. DPMS UP date mode

Update the fi rmware of DPMS.

Refer to VERSION UPGRADE PROCEDURE OF FIRMWARE

Error code table

• Preparation operation rewritten, Update error code checking.

Error Code Details of Error code

01 Login failed(DPMS Access Login Incorrect notifi cation)

02 Login failed(DPMS Access Server Busy information)

03 Login failed(DPMS Access link failure information)

04 Firm Info response acquisition error recived

05 Firm Info response acquisition TimeOut

06 All Firm Info response acquisition error recived

07 All Firm Info response acquisitionTimeOut

08 Main Firm Info response acquisition error recived

09 Main Firm Info response acquisition TimeOut

0A DownLoad failed ((NG)information recieved)

0B DownLoad failed((ServerBusy) information recieved)

0C DownLoad failed((connection failed)information recived)

• Firm error codes at the main microprocessor rewritten.

Error Code Details of Error code

10 Firm Info response acquisition TimeOut(Main rewrite Firmware recived

failure(TimeOut))

11 Firm Info response acquisition recived error(Main rewrite Firmware recived

failure(Error)

12 Firm Info response acquisition recived error (Main rewirte Firmware recived

data incorrect(CheckSumError))

13 Rewrite failure (BlockErase failued before Main rewriting )

14 Rewrite failure (BlockWrite failued before Main rewriting)

15 Rewrite failure (Verify incorrect after Main rewriting)

36 Login failure(DPMSAccess Login incorrect infomation)

37 Login failure(DPMSAccess Server busy infomation)

38 Login failure(DPMSAccess connection failed infomation)

39 Login failure(DPMSAccess access TimeOut)

3A DownLoad failure(Download error (NG)information recieved)

3B DownLoad failure(Download error (ServerBusy) information recieved)

3C DownLoad failure(Download error (connection failed)information recived)

19

• Firm error codes at the display microprocessor rewritten.

Error Code Details of Error code

50 After download request, Login Failed

51 After download request, Login Failed

52 After download request, Login Failed

54 Error receiving response FirmInfo acquisition

55 FirmInfo Get Response TimeOut

56 Failure of DownLoad

57 Failure of DownLoad

58 Failure of DownLoad

5A C command error

5B L command error

5C Receive error update data

5D Receive error update data

5E Receive error update data

5F Receive error update data

60 P command error

61 I command error

62 Launch failure

70 T command error

• DM8x0 system Firm error codes when rewriting

Error Code Details of Error code

A0 Net not connected

A1 Net Connection TimeOut can not get status

A2 Login failed

A3 Login failed

A4 Login failed

A6 Error receiving response FirmInfo acquisition

A7 FirmInfo Get Response TimeOut

A8 Net not connected

A9 Net Connection TimeOut can not get status

AA After download request, Login Failed

AB After download request, Login Failed

AC After download request, Login Failed

AE Failure of DownLoad

AF Failure of DownLoad

B0 Failure of DownLoad

B2 Update error

Failure to update, After the move again 8x0 selfe display retry processing

8. Update mode (by RS232C)

Development / Factory use.

9. MAC Address rewrite mode

Development / Factory use.

10. Access to development server mode

Development / Factory use.

20

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, confi rm contents of the following.

PWB Name Ref. No. Description

DISPLAY IC81 R5F64169DFD B

MAIN IC31 R5F64169DFD B

After

replaced

Remark

After replaced

A : Mask ROM (With software). No need write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you should be

write-in of the new software to the microprocessor or fl ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or fl ash ROM.

Refer to "Update procedure" or "writing procedure", when you should be write-in the software.

VERSION UPGRADE PROCEDURE OF FIRMWARE

You can update by downloading the latest fi rmware from the Internet.

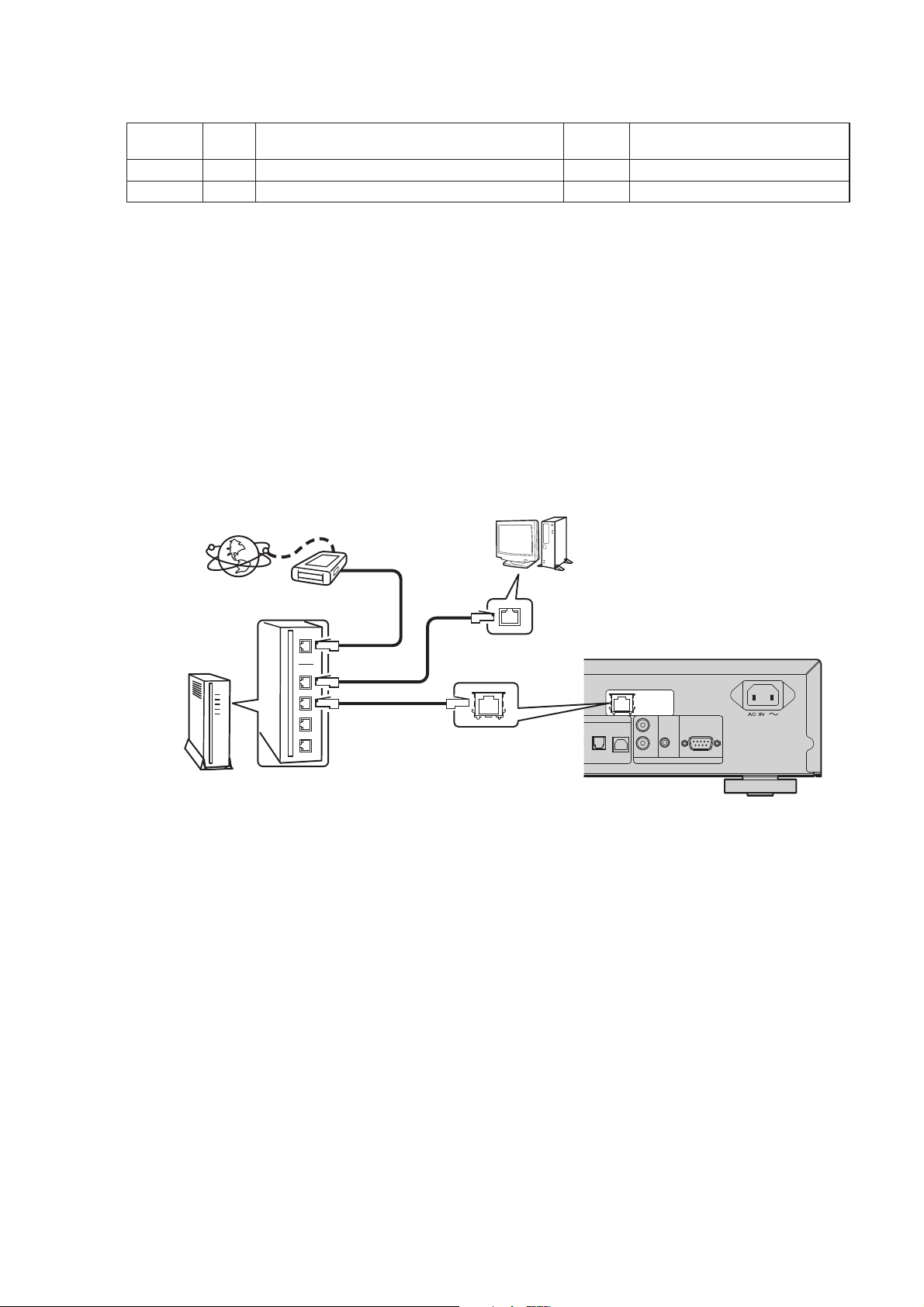

1. Connecting to the Network

(1) System Requirement

Internet Connection by Broadband Circuit

・

Modem

・

Router

・

Ethernet cable (CAT-5 or greater recommended)

・

(2) Setting

Internet

Computer

Router

Modem

To WAN port

To LAN port

To LAN port

ETHERNET

connector

LAN port/

Ethernet

connector

DIGITAL IN

OPT CALLUSB

NETWORK

IN

OUT

FLASHER

N

REMOTE CONTROL

RS232C

2. Check for Update and Update

Check if the latest fi rmware exists. You can also check approximately how long it will take to complete an update.

(1) Press ON/STANDBY button to turn on power.

(2) Press MENU button to display menu.

Press Cursor d / f buttons select to Others. Press <ENTER>.

・

Press Cursor d / f buttons select to Firmware Update. Press <ENTER>.

・

Press Cursor d / f buttons select to CHECK For UPDATE.

・

(3) Press the ENTER buttom.

The latest version of the fi rmware uploaded to the web is displayed.

・

If the latest fi rmware version is on the web, proceed to (4).

・

If the latest fi rmware is already installed, press the MENU button to close the Update menu.

・

(4) Press ENTER button. Select YES, then press ENTER button.

(5) To start the update.

--- Cautions on Firmware Update ---

In order to use these functions, you must have the correct system requirements and settings for a broadband Internet

・

connection.

Do not turn off the power until updating is completed.

・

Even with a broadband connection to the Internet, approximately about 1 hour is required for the updating procedure

to be completed.

Once updating starts, normal operations on the NA7004 cannot be performed until updating is completed.

Also, setting items may be initialized.

Make a note of the settings before updating, and set them again after updating.

21

CAUTION IN REPLACEMENT PARTS

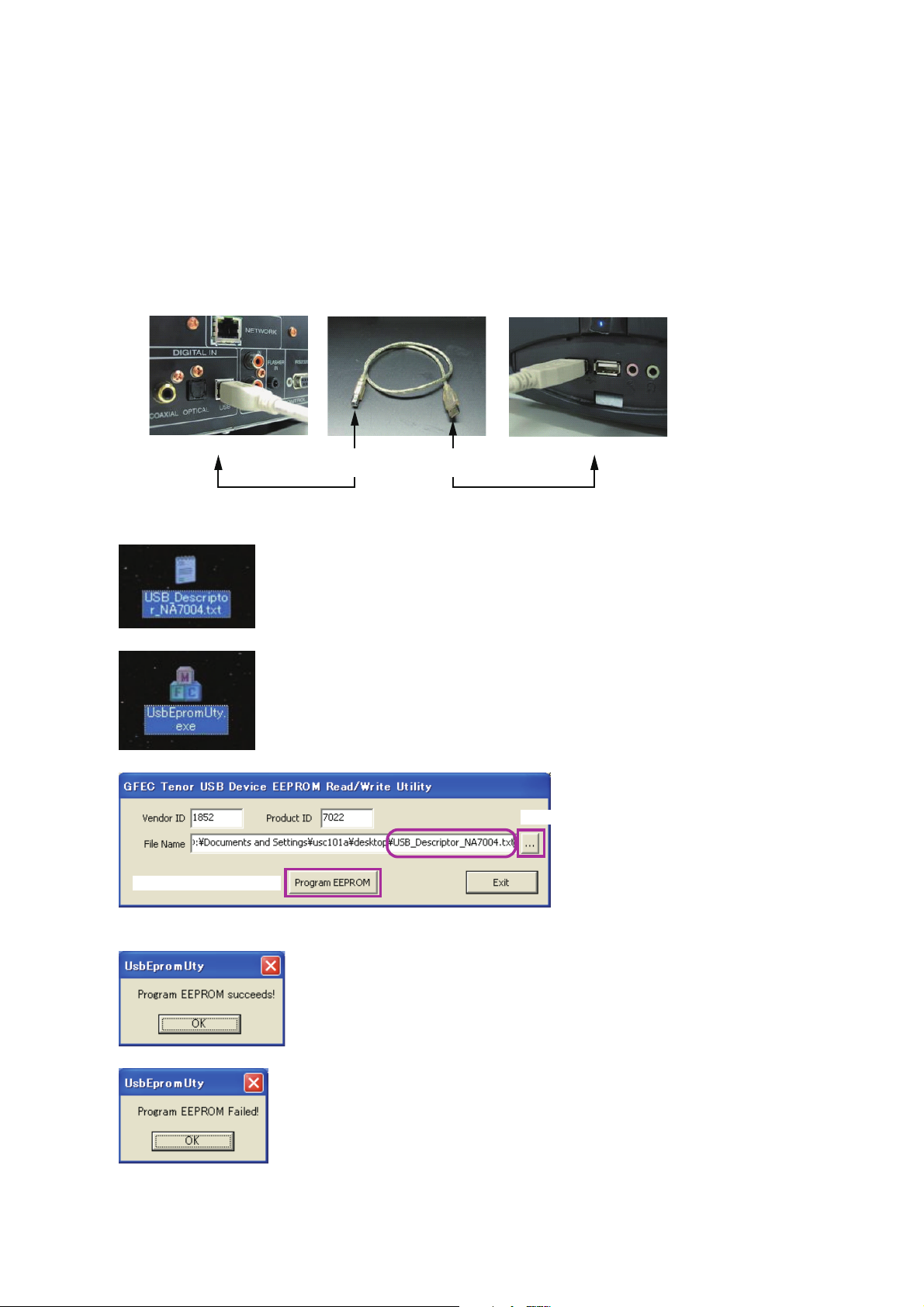

1. After replacing IC912.

(IC912 is EEPROM (M24C16WMN6TP) for USB DAC(IC910 TE7022LDS))

When replacing the EEPROM, the following procedure as required to write the confi guration.

If you do not do the following, please note that no sound output.

- Preparation -

• USB cable (Type B-TypeA)

• Writing data:USB_Descriptor_NA7004.txt

• Burning software:UsbEpromUty.exe

(1) The rear of the unit and the USB connector (B-type), PC's USB connection terminal (A-type).

Please use the USB cable on the market.

REAR PANEL (B-Type)

USB(B-Type)

NA7004 side

USB(A-Type)

PC side

(2) Turn on this unit. Press Input source select "DIGITAL In USB".

(3) Paste the "USB_Descriptor_NA7004.txt" to your desktop of PC.

(4) Run ”UsbEpromUty.exe”.

(5) Select the fi le.

(6) Implementation writing

PC (A-Type)

(5) Select the file

(6) Click the "Program EEPROM" button.

(7) When writing of the fi rmware is completed, you can see the ”Program EEPROM succeeds!” messsage.

(8) If you can't complete the update, you can see ”Program EEPROM Failed!” message and please retry from (6).

Fails to write again, please do the following check.

Check USB cable connection.

Check IC910 and IC912 soldering.

22

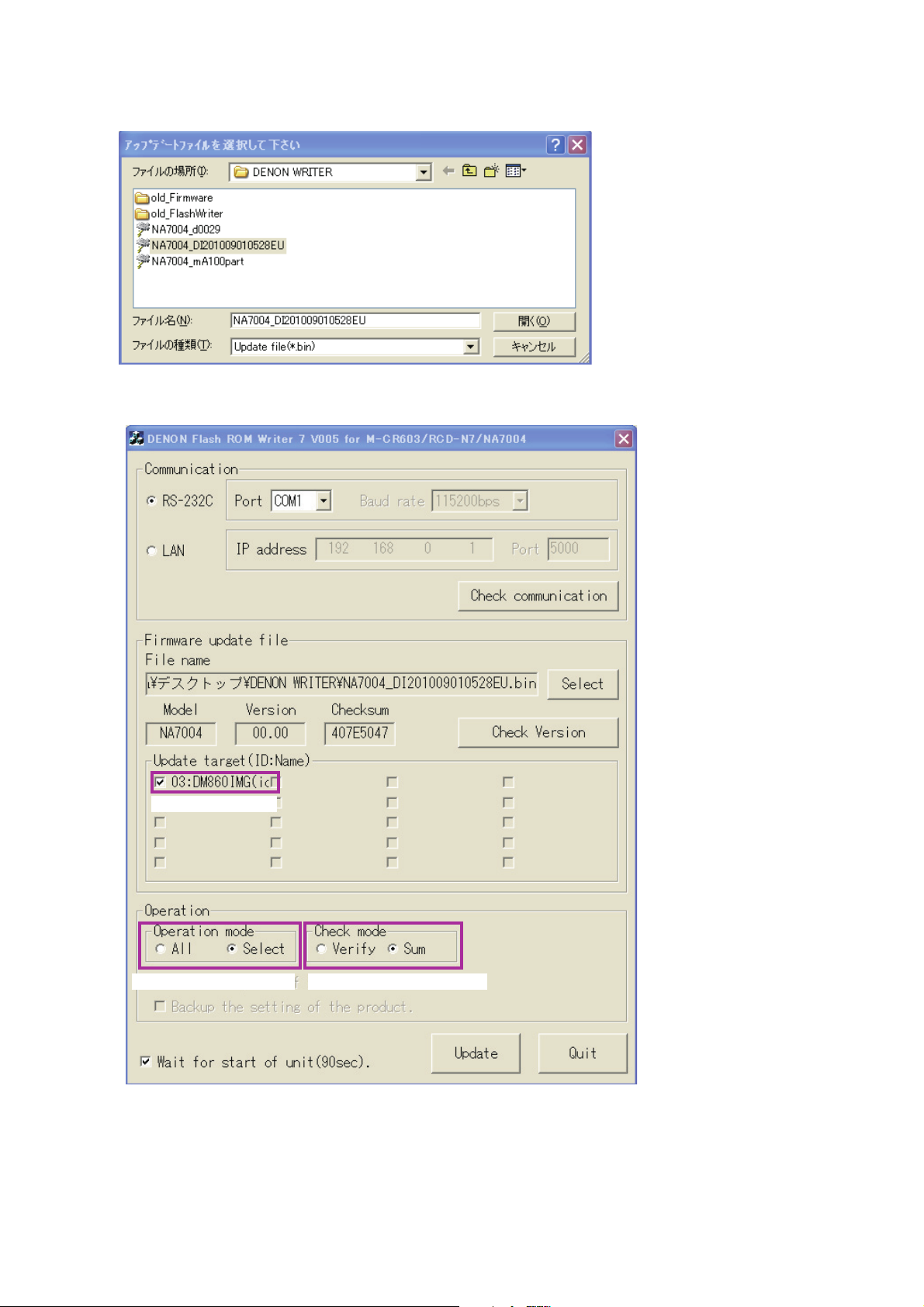

2. After replacing Ethernet Unit Assy

When you replace this unit, you need software updates.

And MAC Address seal replacement is required.

- Preparation -

• RS-232 cable (Male to female, Straight).

• Burning software:FlashWriter7_005_forM-CR603_RCD-N7_NA7004.exe

(1) Connect the RS-232C cable from PC.

(2) Turn on the unit. Display is lit, wait for the normal state. (More than 1 minute)

(3) Run "FlashWriter7_005_forM-CR603_RCD-N7_NA7004.exe".

(4) Click "RS-232C" and "COM1"of Communication.

(4) Select the RS232C

(5) Check the communication status

(6) Select File

(5) Click "Check communication"button. Clik "OK".

NG was the case, please try again to change the port.

23

(6) Click "Select" button. Select the fi le.

For writing fi les, please use the latest version and then check the region.

(Example NA7004_DI201009010528EU.bin)

(7) Click "Select" of "Operation mode".

(8) Click "03:DM860IMG(i)".

(8) Select File Write

(7) Write MODE selection

(9) Click "Sum" of "Check mode".

(9) CHECK MODE selection

24

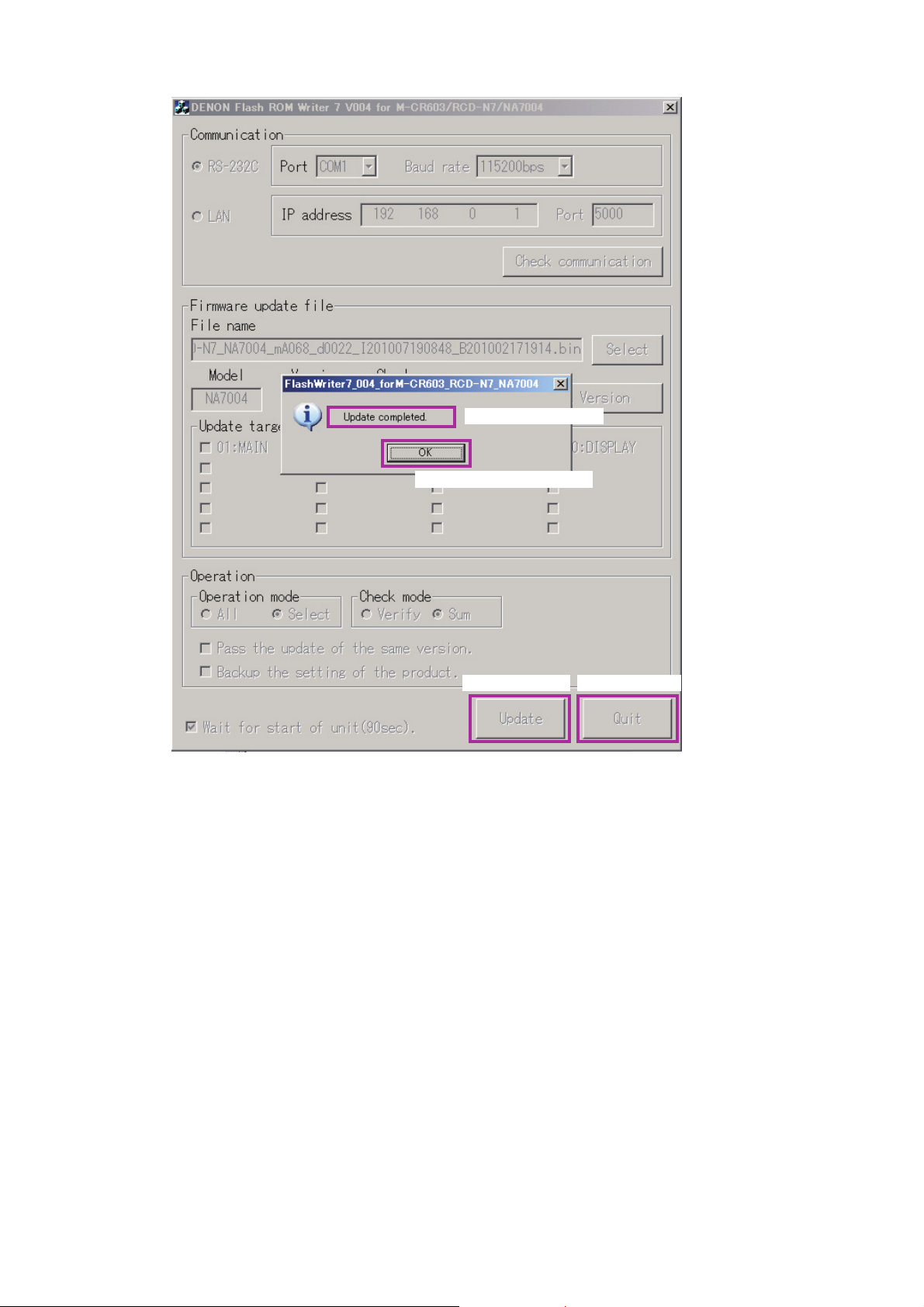

(10) Click "Update" button. (DM860IMG : about 29 minutes).

(11) Complete writing

(12) Complete check writing

(10) Start writing (11) End of write

(11) When rewriting is completed, the dialog of "Update completed" is displayed.

(12) Click "OK".

(13) Click "Quit".

(14) Unplug the AC power.

(15) Plug the AC power.

Turn on this unit.This unit sets the version display mode.

Please confi rm the fi rmware version.

(16) Check MAC Address.

MENU → Network → Network Info → MAC Address

(17) The back panel of the unit, MAC Address seals, please change new one.

Please confi rm the MAC Address display is corresponding to the seal.

(18) Plug the power cord into a power outlet while pressing "Cursor

Reset)

"

button and "M-DAX" button simultaneously.(Fuctory

f

25

TROUBLE SHOOTING

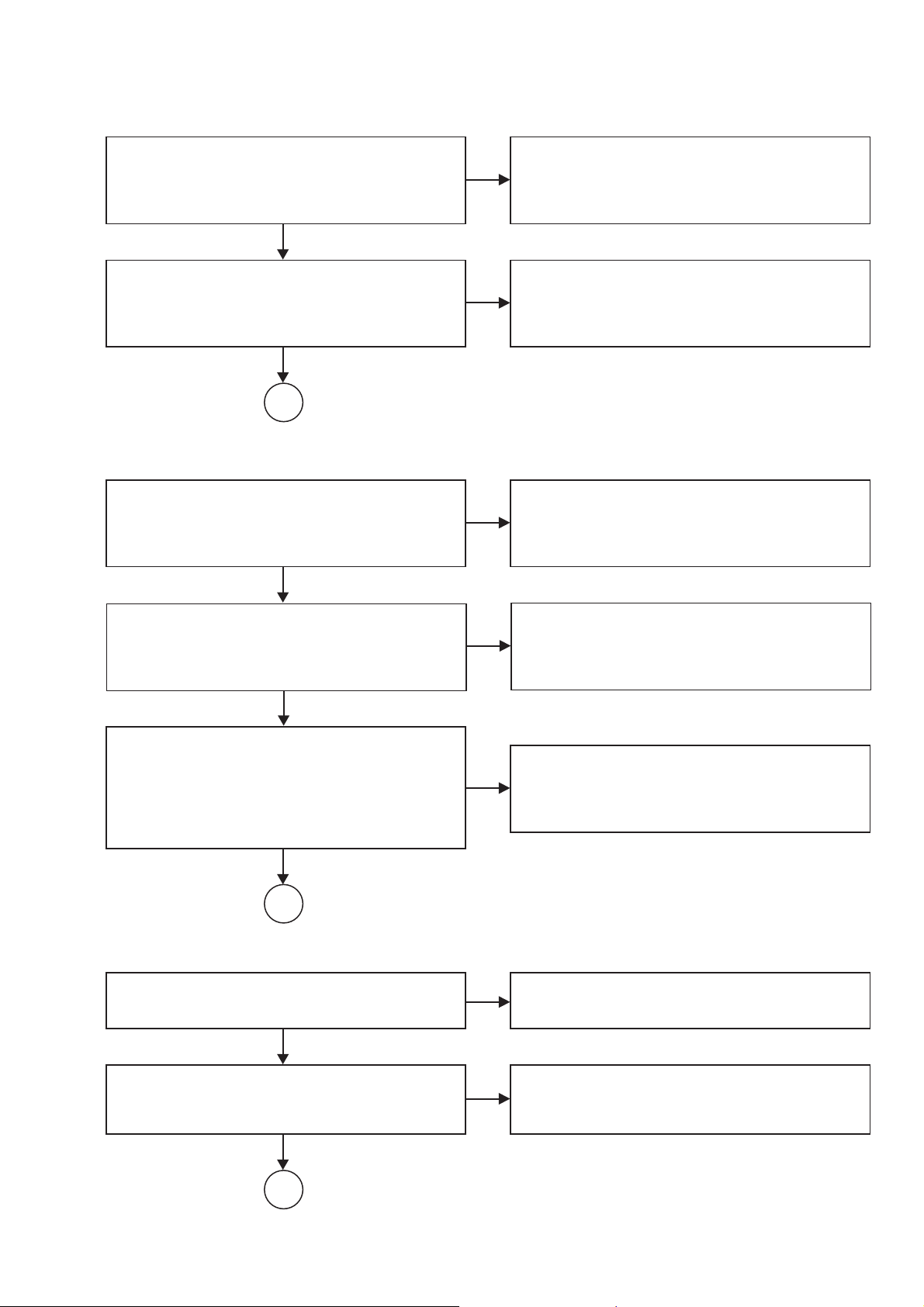

1. OLED dosen't light

Check Power Supply Voltages for System μ-com.

MAIN B'D

• +6V_CPU, [IC91] : 3pin

• +3.3V_CPU, [IC91] : 2pin

OK

Check Reset signal for System μ-com.

MAIN B'D

• [IC31] : 19pin RESET

"H" level O.K.?

OK

Check Oscillation waveform.

MAIN B'D

• [IC31] : 20pin

16MHz OK?

OK

Check Power Supply Voltage for OLED μ-com.

DISPLAY B'D

• +3.3V_OLED, [Q813] : 1pin

OK

Check Reset signal for OLED μ-com.

DISPLAY B'D

• [IC81] : 19pin RESET

"H" level O.K.?

OK

NG

NG

NG

NG

NG

Check Soldering.

• [IC91] on MAIN B'D

Check Soldering.

• [IC31] on MAIN B'D

Check Soldering.

• [X202] on MAIN B'D

Check Soldering.

• [Q813] on DISPLAY B'D

Check Soldering.

• [IC81] on DISPLAY B'D

Check Oscillation waveform.

DISPLAY B'D

• [IC81] : 20pin

16MHz OK?

OK

Check Power Supply Voltages for OLED.

DISPLAY B'D

• [CN84] : 24pin +3.3V

• [CN84] : 3pin +16V

OK

Check Reset Signal for OLED.

DISPLAY B'D

• [CN84] : 20pin

"H" level O.K.?

OK

Check OLED dirive Signal.

DISPLAY B'D

• [CN84] : 13-6pin DA0-DA7

END

NG

NG

NG

NG

Check Soldering.

• [X802] on DISPLAY B'D

Check Soldering.

• [CN88] on DISPLAY B'D

• [CN80] on MAIN B'D

Check Soldering.

• [IC81] on DISPLAY B'D

Check Soldering.

• [IC81] on DISPLAY B'D

26

2. No Sound,Noise generated

2.1. AM/FM TUNER-in (N Version)

Check Power Supply Voltages for AM/FM TUNER.

MAIN B'D

• [CN31] : 4pin +9V

• [BN93] : 5pin +12V

OK

Check Analog Audio Data output from TUNER PACK.

MAIN B'D

• [TUNER PACK] output and [CN31]

: 7,5pin TUNER_L_IN, TUNER_R_IN

• [IC23] : 60,61pin

OK

A

2.2 . DAB TUNER-in (N Version)

Check Power Supply Voltages for DAB TUNER.

MAIN B'D

• [CN10] : 9pin +3.3V

DAB B'D

• [CN10] : 3pin +3.3V

OK

NG

NG

NG

Check Soldering.

• [BN93] : 5pin +12V on MAIN B'D

• AUDIO B'D

Check Parts

• [IC26]

Check Soldering.

• [CN31]

: 7,5 pin TUNER_L_IN, TUNER_R_IN on MAIN B'D

• [C241],[C242] on MAIN B'D

Check Soldering.

• [CN10] : 9pin +3.3V on MAIN B'D

• [IC105] : SW. Regulator on MAIN B'D

• [CN10] : 3pin +3.3V on DAB B'D

Check Power Supply Voltages for DAB TUNER.

DAB B'D

• +3.3V [IC92] : 3pin +1.2V OK?

• [CN32] : 2pin +3.3V

• [CN32] : 1pin +1.2V

OK

Check Digital Audio Data output from DAB TUNER.

MAIN B'D

• [CN10] : 5pin DAB_SPDIF

• [IC23] : 6pin DAB_SPDIF

DAB B'D

• [CN32] : 20pin DAB_SPDIF

• [CN10] : 7pin DAB_SPDIF

OK

A

2.3. OPTICAL IN

Check Power Supply Voltages for OPTICAL Input IC.

MAIN B'D

• [JK92] : 3pin +3.3V

OK

NG

NG

NG

Check Soldering.

• [IC92] on DAB B'D

• [CN92] on DAB B'D

Check Soldering.

• [CN10] : 5pin DAB_SPDIF on MAIN B'D

• [CN23] : 6pin DAB_SPDIF on MAIN B'D

• [CN32] : 20pin DAB_SPDIF on DAB B'D

• [CN10] : 7pin DAB_SPDIF on DAB B'D

Check Soldering.

• [JK92] : 3pin +3.3V

• [IC505] : SW. Regulator on MAIN B'D

Check Digital Audio Data from OPTICAL Input IC

MAIN B'D

• [CN902] : 5,6pin OPT_IN

• [CN23] : 2pin OPT/COAX_IN

OK

A

NG

27

Check Soldering.

• [IC903] [IC902] on MAIN B'D

• [IC41] OPT/COAX_IN on MAIN B'D

Loading...

Loading...