Marantz DV-4000 Service Manual

Service

DV4000/F1N, /K1G

/N1B, /S1G, /U1B

Manual

POWER

1. TECHNICAL SPECIFICATION ...............................................................................1

2. CONNECTION FACILITIES....................................................................................2

3. INFORMATIONS.....................................................................................................3

4. SERVICING HINT...................................................................................................4

5. DISASSEMBLY.......................................................................................................5

6. PRINCIPAL PARTS LOCATION..............................................................................6

7. REPLACEMENT OF PRINCIPAL COMPONENTS.................................................7

8. SERVICE MODE ....................................................................................................9

9. ELECTRICAL ADJUSTMENT...............................................................................15

10. BLOCK DIAGRAM ................................................................................................16

11. WIRING DIAGRAM...............................................................................................22

12. SCHEMATIC DIAGRAM AND PARTS LOCATION ...............................................24

13. EXPLODED VIEW AND PARTS LIST...................................................................38

14. ELECTRICAL PARTS LIST...................................................................................40

15. SCHEMATIC DIAGRAM AND PARTS LOCATION (TKM1000MZ) ................... 15-1

16. MICROPROCESSOR AND IC DATA .............................................................. 15-15

17. EXPLODED VIEW AND PARTS LIST (TKM1000MZ) .................................... 15-28

18. ELECTRICAL PARTS LIST (TKM1000MZ)..................................................... 15-30

DVD PLAYER DV4000

STANDBY / ON

TABLE OF CONTENTS

DVD Player

/

CLOSE

OPEN

DTS

SURROUND

DOLBY DIGITAL

DIMMER

SPATIALIZER

MPEG

PLAY

PAUSE

WIDE

PREV NEXT

STOP

Please use this service manual with referring to the user guide (D.F.U) without fail.

DV4000

DV4000DV4000

294W855010 AO

3120 785 22290

First Issue:2000.05

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AMERICAS

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

AUSTRALIA

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 - 9181

FAX : +66 - 2 - 224 - 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIP DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

MARANTZ JAPAN, INC.

Technical

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

991207A.O

1. TECHNICAL SPECIFICATIONS

Discs played

DVD video disc................................................... 12 cm single sided, single layer

12 cm single sided, double layer

12 cm double sided, single layer

12 cm double sided, double layer (one layer per side)

8 cm single sided, single layer

8 cm single sided, double layer

8 cm double sided, single layer

8 cm double sided, double layer (one layer per side)

Compact disc

(CD-DA, Video CD).............................................12 cm, 8 cm

Video system..........................................................PAL (625/50)/NTSC (525/60)

Audio system..........................................................Linear PCM audio

MPEG 1/2 audio

Dolby Digital (AC-3)

DTS audio (Digital output only)

Video output

Line output level.................................................1.0 Vp-p / 75 ohms, unbalanced

RCA pin Jack x 1

S1-output level.................................................... Y output: 1.0 Vp-p/75 ohms unbalanced

C output: 0.3 Vp-p/75 ohms (PAL)

0.286 Vp-p/75 ohms (NTSC)

4 pin mini DIN x 1

R/G/B output....................................................... R/G/B output: 0.7 Vp-p 21-pin SCART connector x 1 (/N1B)

Audio output

Line output ......................................................... 2.0 Vrms / 10 kohms

RCA pin Jack x 1 system

Digital audio output

Optical output ..................................................... Optical connector x 1

Coaxial output .....................................................RCA pin Jack x 1

DVD Iinear audio characteristics

Frequency response ...........................................4 Hz-22 kHz (Fs = 48 kHz)

4 Hz-44 kHz (Fs = 96 kHz)

S/N ratio ..............................................................100 dB (Fs = 48 kHz/24 bit PCM)

Dynamic range....................................................100 dB (Fs = 48 kHz/24 bit PCM)

Total harmonic distortion.....................................0.0025% (Fs = 48 kHz/24 bit PCM)

CD audio characteristics:

Frequency response ...........................................4 Hz-20 kHz (EIAJ)

S/N ratio ..............................................................100 dB (EIAJ)

Dynamic range....................................................100 dB (EIAJ)

Total harmonic distortion.....................................0.0025% (EIAJ)

Pickup.................................................................... Wavelength: 655 nm (DVD)

Wavelength: 790 nm (CD)

Power requirements............................................. 120V AC, 60 Hz (/U1B)

100-240V AC, 50/60 Hz (/N1B)

100V AC, 50/60 Hz (/F1N)

100-240V AC, 50/60 Hz (/K1G,/S1G)

Power consumption............................................. 20 W (standby mode = approx 1.2 W, power off = 0 W)

Operation temperature.........................................5 C-35 C

Operation humidity range

....................................5%-90% (no condensation)

Dimensions............................................................440 (W) x 88 (H) x 332 (D) mm (excluding protrusions)

Weight.................................................................... 3.3 kg

Supplied accessories

AC power cable...................................................x 1

Auido / Video cable.............................................x 1 (/F1N, /K1G, /S1G, /U1B)

D-BUS remote cable...........................................x 1

Remote control unit ............................................x 1

Batteries..............................................................x 2

21-pin SCART cable............................................x 1 (/N1B)

• For improvement purposes, specifications and design are subject to change without notice

1

2. CONNECTION FACILITIES

2.1

Video performance (/N1B only)

135791113151719

2 4 6 8 10 12 14 16 18 20

2.1.1

SCART

- Pin 1 Audio R out :1.8V RMS

- Pin 2 not connected

- Pin 3 Audio L out :1.8V RMS

- Pin 4 GND

- Pin 5 GND

- Pin 6 not connected

- Pin 7 Blue out :0.7Vpp ( 0.1V into 75 Ohm (*)

- Pin 8 funcion switching :

2V TV

>4.5V / <7V asp. ratio 16:9 DVD

>9.5V / <12Vasp. ratio 4:3 DVD

- Pin 9 GND

- Pin 10 not connected

- Pin 11 Green out :0.7Vpp ( 0.1V into 75 Ohm (*)

- Pin 12 not connected

- Pin 13 GND

- Pin 14 GND

- Pin 15 Red out :0.7Vpp ( 0.1V into 75 Ohm (*)

- Pin 16 fast switching RGB/ CVBS : <0.4V

21

- Pin 17 GND

- Pin 18 GND

- Pin 19 CVBS/RGB sync out : 1Vpp ( 0.1V into 75 Ohm )

- Pin 20

- Pin 21 GND

(*) for 100% white

into 75 Ohm = CVBS

<1V/ <3V into 75 Ohm = RGB

not connected

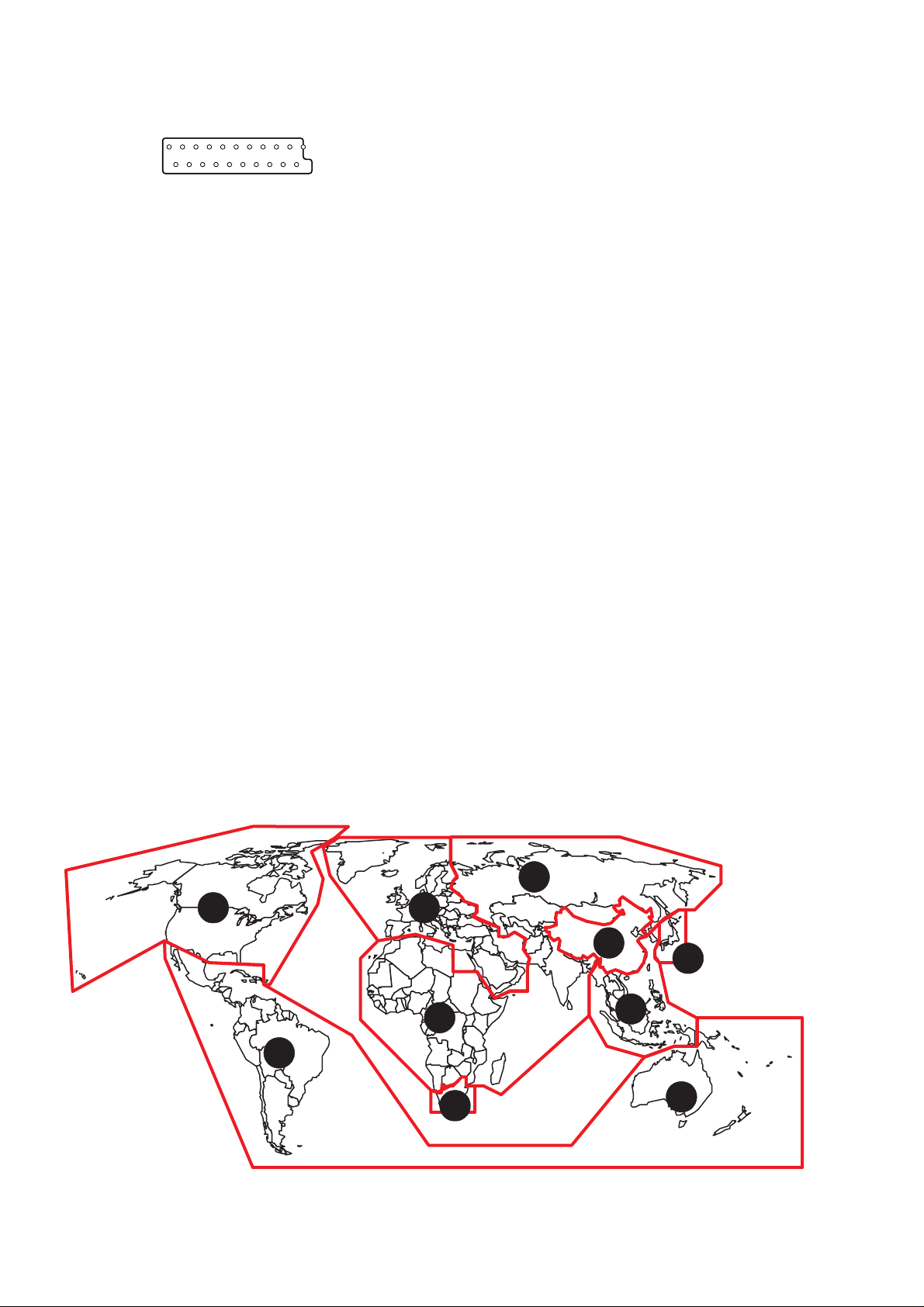

What are "regional codes"?

Motion picture studios want to control the home release of movies in different countries because theater releases arenít

simultaneous (a movie may come out on DVD in the US when itís just hitting screens in Europe). Therefore they have

required that the DVD standard include codes which can be used to lock out the playback of certain discs in certain geographical regions. Players sold in each region will have that regionís code built into the player. The player will refuse to play

these "region coded" discs which are not allowed in the region. However, regional codes are entirely optional. Discs without

codes will play on any player in any country. Some studios have already announced that only their new releases will have

regional codes. There are six regions:

1. United States and Canada

2. Europe and Japan

3. Far East (except Japan & China)

4. South America and Oceania

5. Africa and the Middle East

6. China (except Hong Kong)

5

1 2

6

2

5

3

4

2

Map of DVD Regions

2

4

3. INFORMATIONS

REGION CODE

VERSION REGION CODE COUNTRY

/FXX 2 JAPAN

/KXX 6 CHINA

/NXX 2 EUROPE

/SXX 3 SINGAPORE/HONGKONG

/UXX 1 USA/CANADA

THE DISCS THAT THE DV4000 CAN HANDLE

The following discs can be played back with a DV4000.

Multi-angles:

On some DVDs, scenes have been filmed from different angles

(up to a maximum of 9). On these discs, you can select the

angle that you want to watch. Please refer to the DVD’s manual

to see which scenes have multi-angles.

Parental guide:

Some discs have restriction levels that allow you to cut scenes

or prevent playback of discs that have contents that you do

not want children to watch.

disc mark playback capability size side

DVD Audio/Video

CD Audio

VCD Audio/Video single

Note: The regional code of the discs must meet to the regional

code of the DV4000.

12 cm

8 cm

12 cm

8 cm

12 cm

8 cm

single/double

single

DVD INFORMATION

Below is a glossary of the new terms related to DVD.

Title:

A disc may have more than one story/movie on it, so each

story/movie is called a “title”.

For example, if there are 2 movies on the disc, they are

separated into Title 1 and Title 2.

Chapter:

A title may also be separated into chapters.

For example, a movie (title) may be separated into 3 scenes

(chapters).

Safety Lock

The safety look prevents children from playing discs. When

the Safety Lock is set, discs can not be played back.

Cancelling Safety Lock

Press the CLEAR button and hold for 10 seconds while the

player is stopped.

Title 1 Title 2

Chapter1Chapter

Subtitles:

DVDs are recorded with up to 32 different subtitle languages.

If a disc has more than one subtitle language, you can select

the subtitle language that you want to read.

Soundtrack language:

DVDs are recorded with up to 8 different soundtrack languages.

If a disc has more than one language, you can select the

soundtrack language that you want to listen to.

Chapter3Chapter1Chapter2Chapter

2

3

3

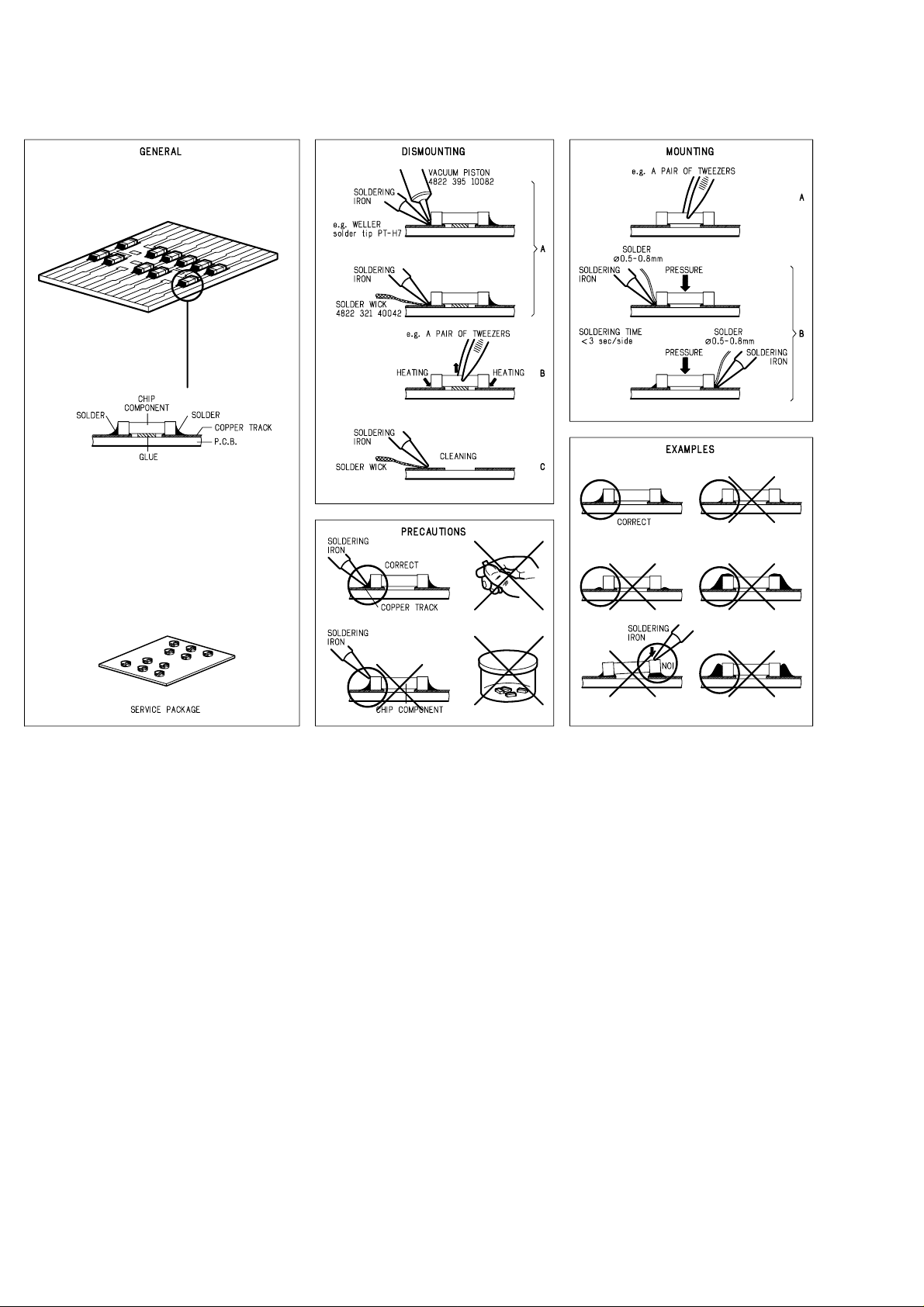

4. SERVICING HINT

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc 4822 397 10131

4

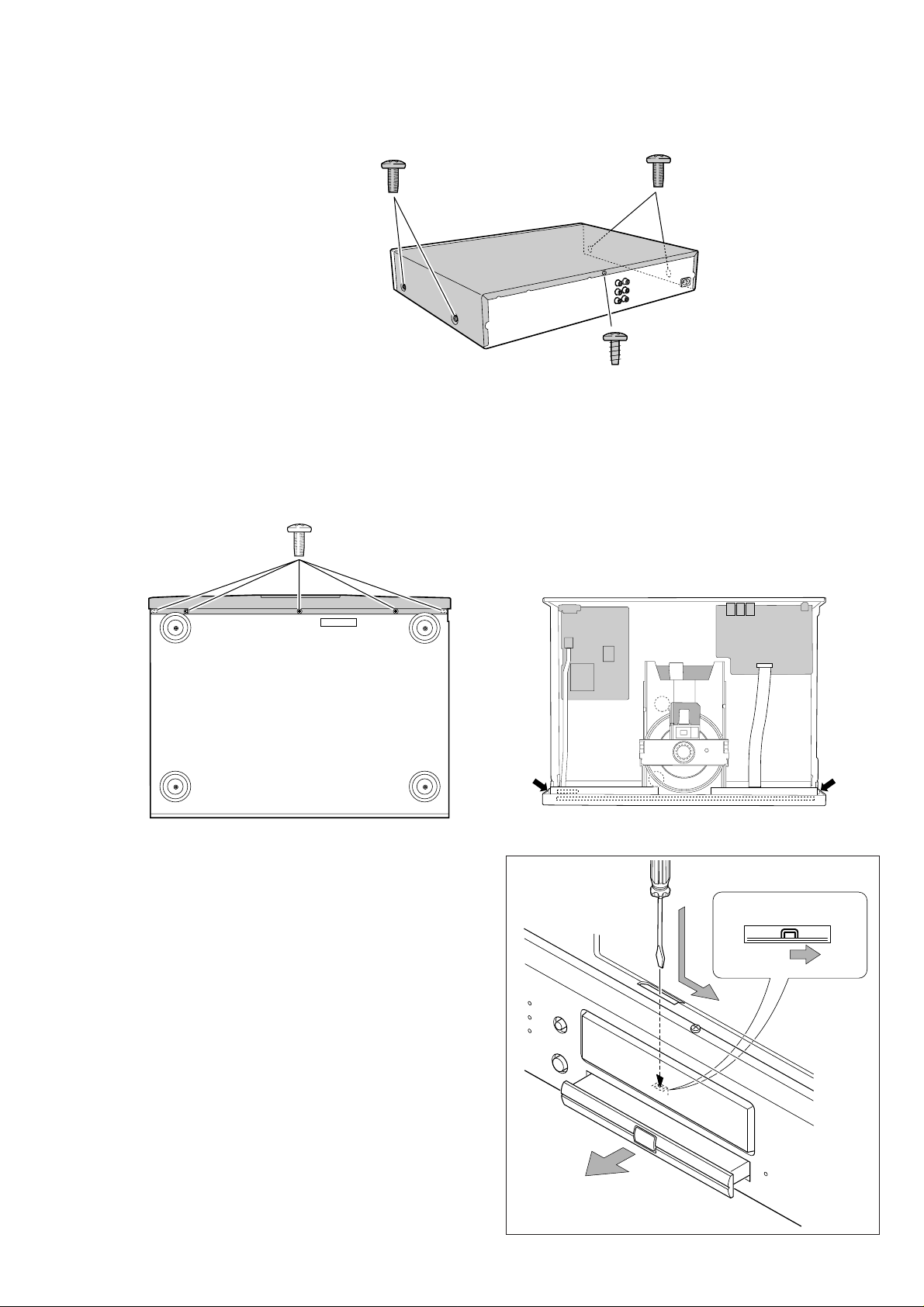

5. DISASSEMBLY

In case of trouble, etc., necessitating dismantling, please

dismantle in the order shown in the illustrations. Reassemble

in the reverse order.

1. Removal of the UPPER COVER

2. Removal of the FRONT PANEL

1) Press the “EJECT” button while the unit’s power is turned on and open the DISC TRAY.

2) Remove the decoration plate on the DISC TRAY by pulling it upward.

3) Remove the three retaining screws on the bottom and two screws on each left and right side of the FRONT PANEL as

shown.

4) Disconnect the flat cable from the P702 connector on the OUTPUT PCB .

5) Remove the FRONT PANEL by pulling it forward while releasing the TABs on both left and right ends of the FRONT

PANEL.

REMARK : Before disassemble the front panel.

Press open/close button to open the tray.

If the tray doesn’t work, put a small screwdriver into the

hole as shown in picture and slide the knob.

Then the tray comes out. After the first centimeter it is

possible to pull the tray out by hand. Release the door

cover of the tray.

P702

TABTAB

5

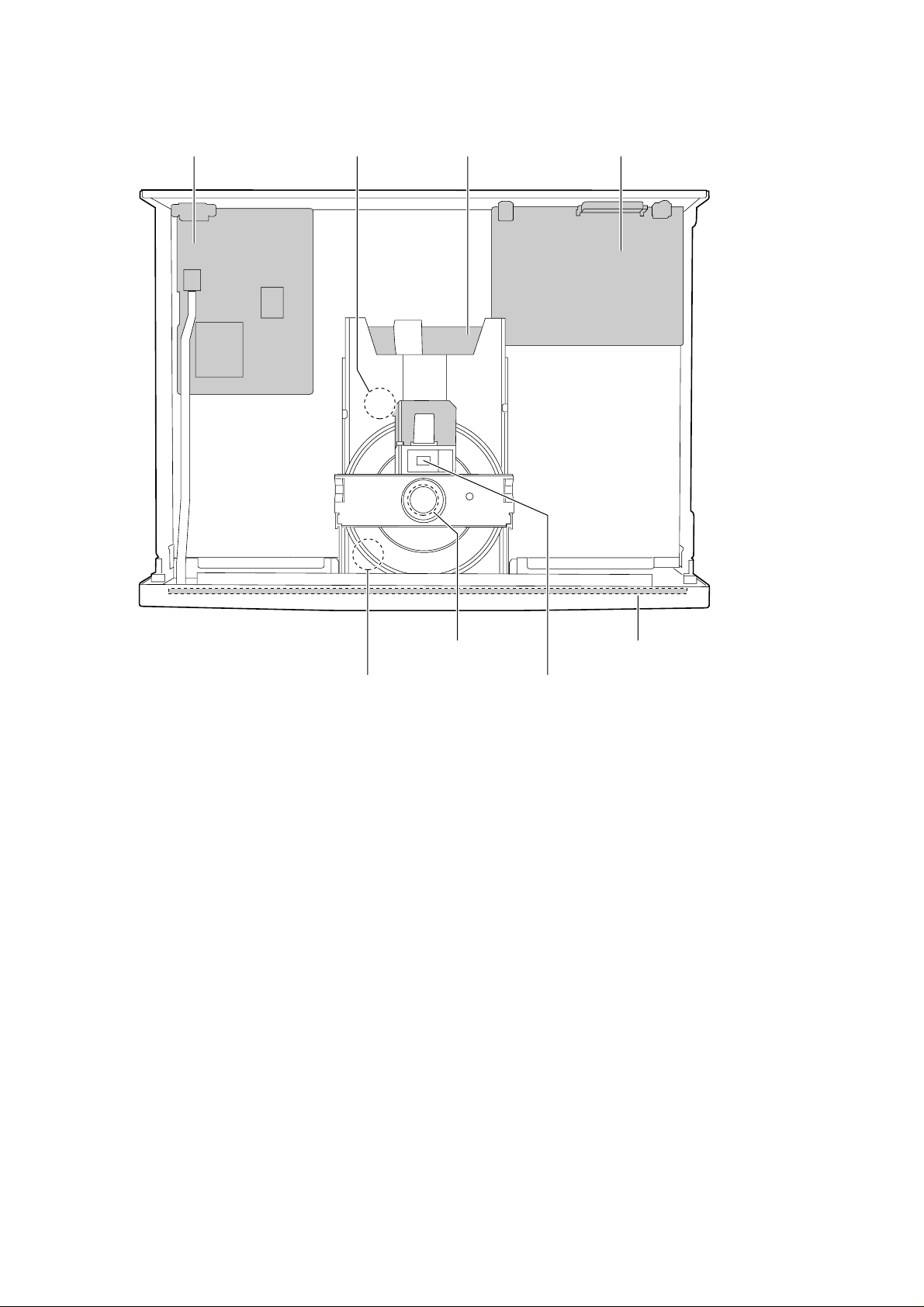

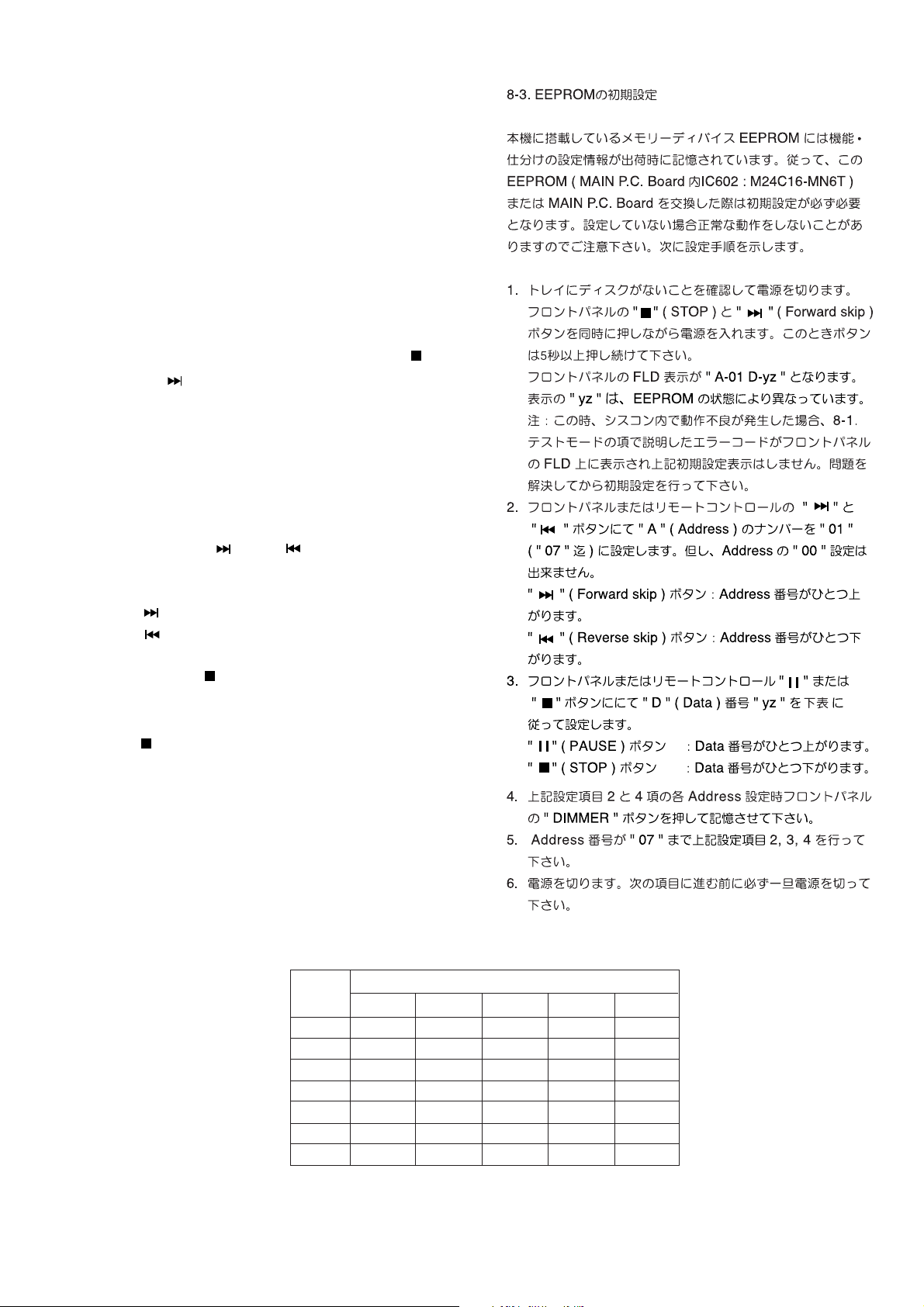

6. PRINCIPAL PARTS LOCATION

POWER SUPPLY PCB

SLED MOTOR

MAIN PCB OUTPUT PCB

SPINDLE MOTOR OPERATION PCB

LOADING MOTOR

Fig. 6-1 Top view (DV4000)

PICKUP

6

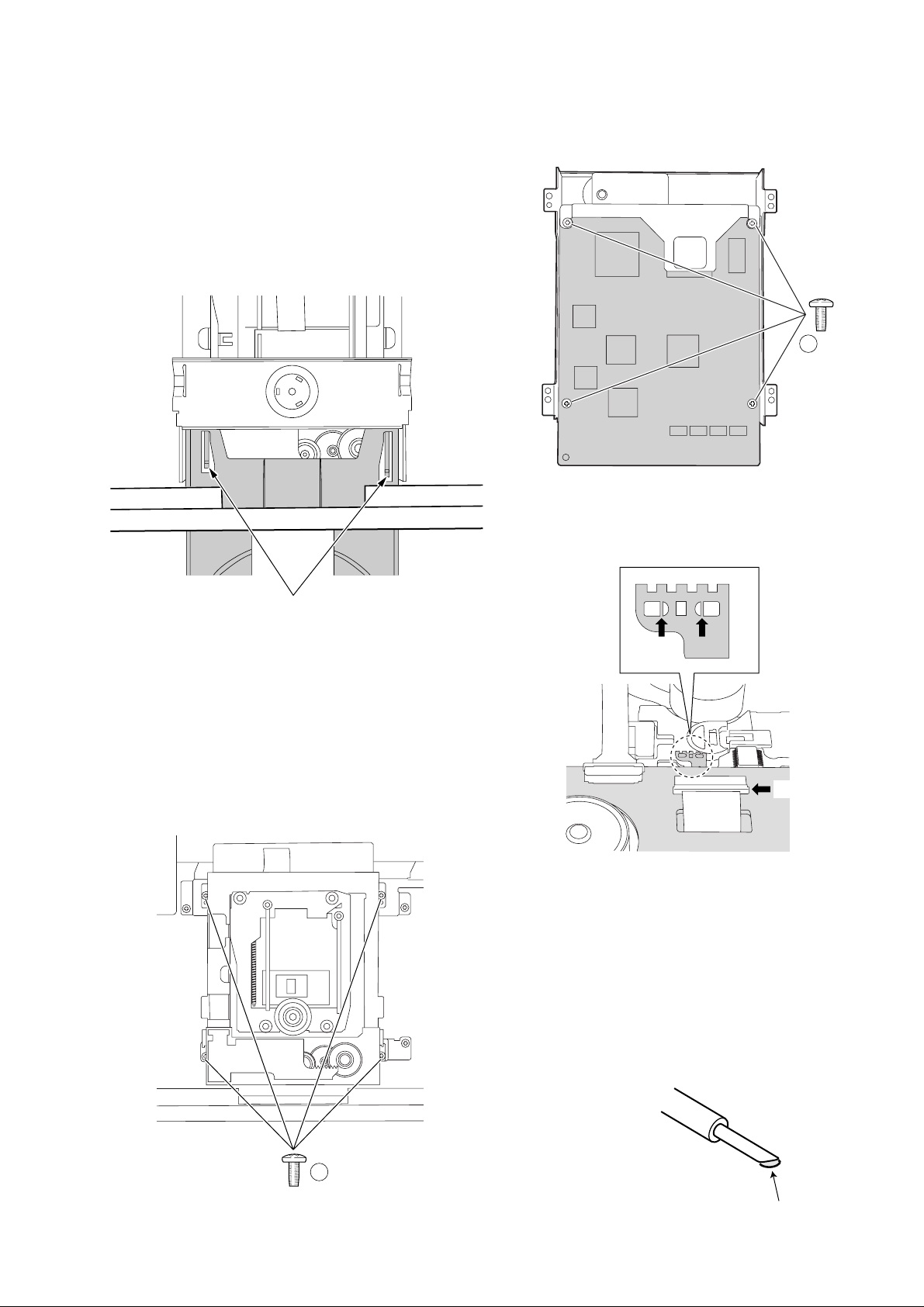

7. REPLACEMENT OF PRINCIPAL COMPONENTS

7-1. Removal of the TRAVERSE MECHA.

7-1-1. Removal of the MECHANISM BLOCK

1) Turn the unit’s power on and press the “EJECT” button to

eject the DISC TRAY.

2) Disconnect the power cord and remove the DISC CLAMPER

BLOCK.

3) Completely remove the DISC TRAY by pulling it outwards

while pulling up both of the stopper tabs alternately.

7-1-2. Removal of the TRAVERSE MECHA.

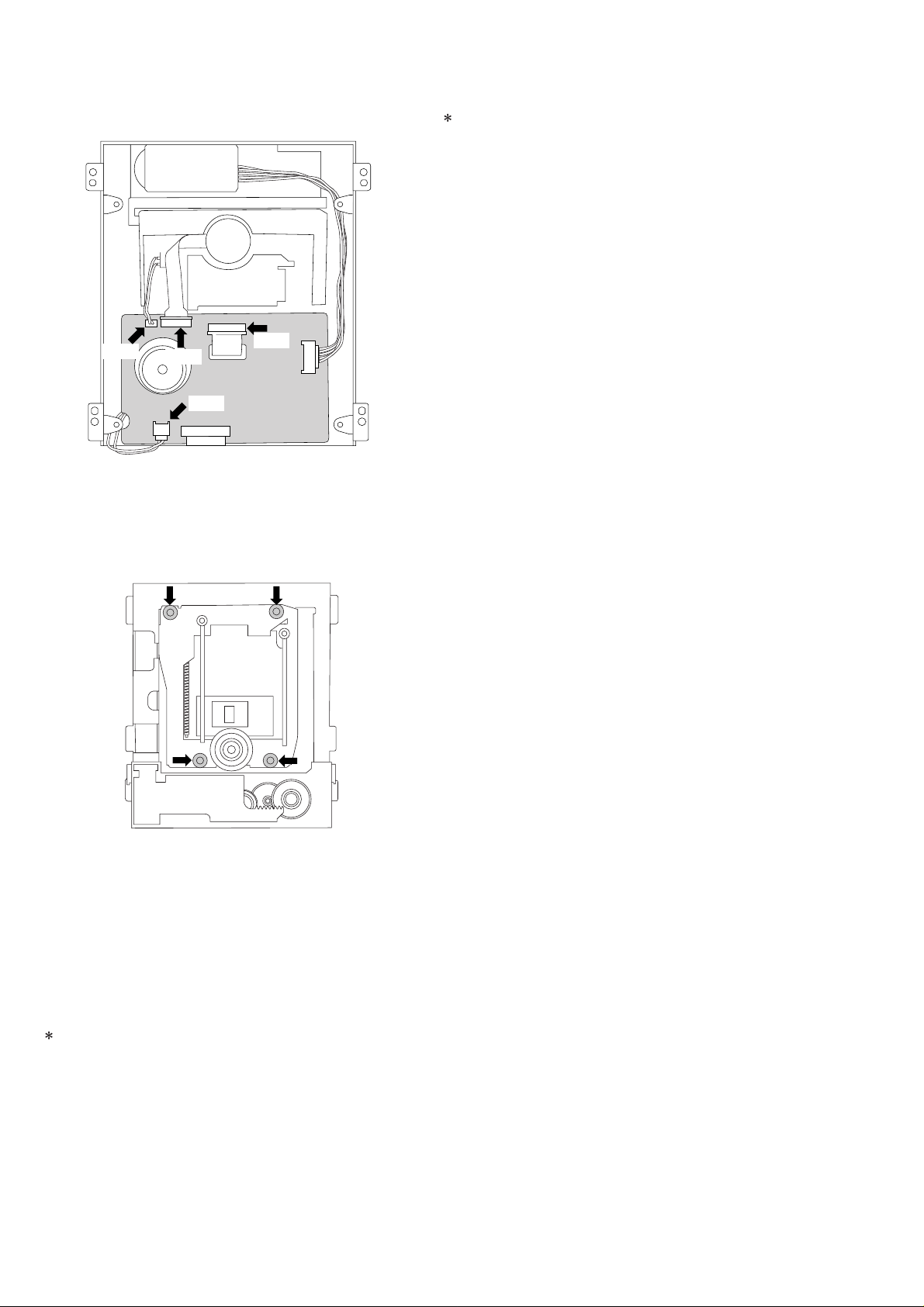

1) Remove the four b screws on the MAIN PCB and then

disconnect the P800 connector on the MAIN PCB.

B SCREW

Fig. 7-3

2) Short the laser diode protection circuit on the PICK UP

BLOCK’s flexible cable with solder as shown.

STOPPER TUB

Fig. 7-1

4) Disconnect the two flat cables from the P803 connectors

and one flat cable from the P808 connector on the MAIN

PCB.

5) Disconnect the P807 connector on the MAIN PCB.

6) Remove the four a retaining screws and remove the

MECHANISM BLOCK from the chassis.

P200

Fig. 7-4

Caution

T o protect the laser diode from damage caused by high voltage

static electricity, a laser diode protection circuit has to be

shorted before disconnecting the flexible cable (P200

connector on the MECHANISM PCB). It is recommended that

you put solder on the top of the soldering iron as shown in Fig.

3-5 then short the circuit at once. When you replace the

TRA VERSE MECHA., be sure to connect the P200 connector

before removing the solder at the shorted parts.

Fig. 7-2

A SCREW

SOLDER

Fig. 7-5

7

3) Carefully disconnect the two connectors (P500, P600) and

the two flat cables (P200, P300) on the MECHANISM PCB.

7-3. Replacement of the PICK UP BLOCK

Replacement of the PICK UP BLOCK itself is not

recommended because its azimuth adjustment is very

critical and requires a special jig. If PICK UP BLOCK

replacement is necessary, replace with an entire

TRAVERSE MECHANISM only.

P600

P300

P500

P200

Fig. 7-6

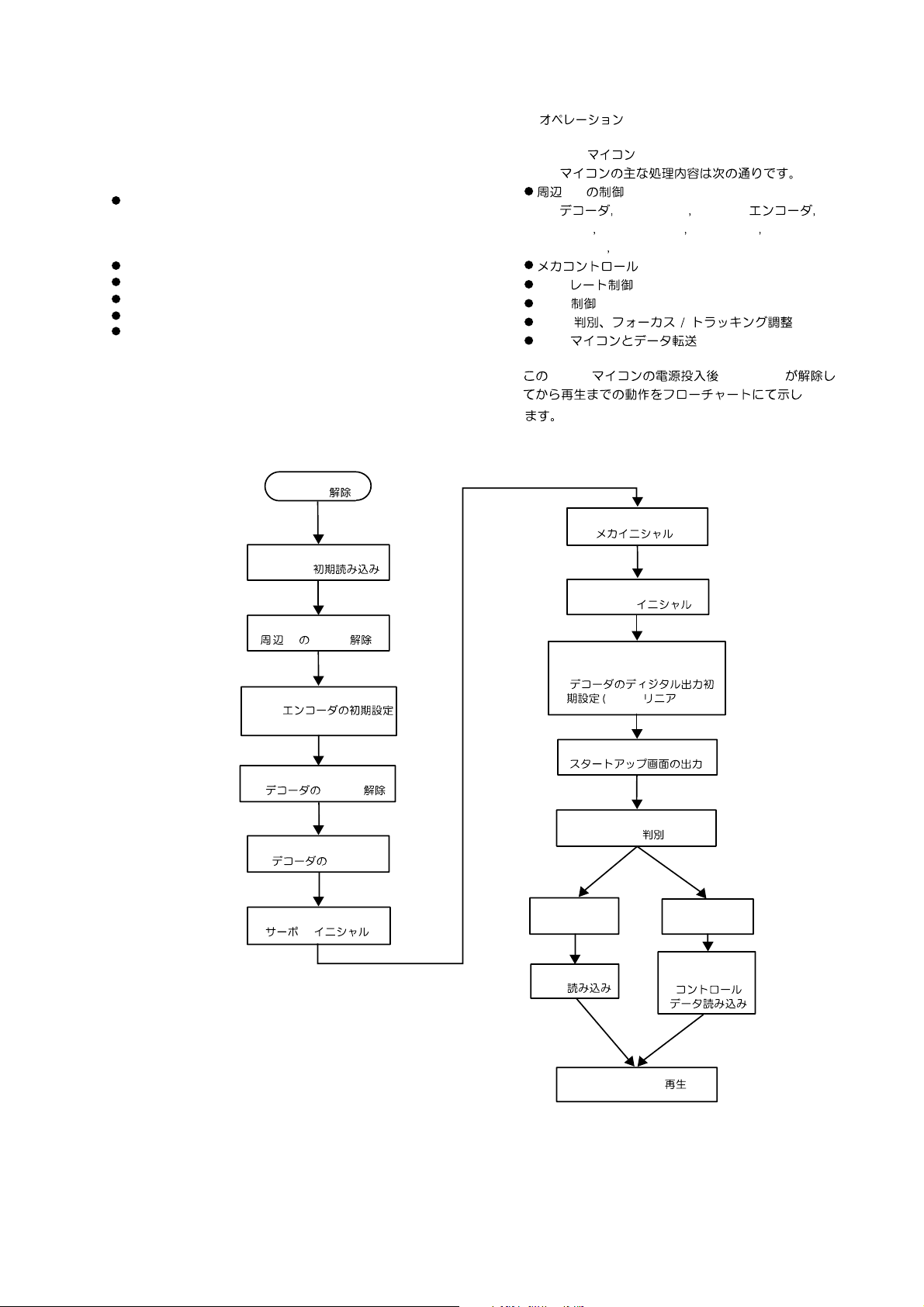

4) Using tweezers, release the four retaining HOOKs of the

TRAVERSE MECHA. from the rubber insulators being

careful not to damage the rubber insulators.

Fig. 7-7

5) Remove the TRAVERSE MECHA. from the MECHANISM

BLOCK.

6) Reassemble in the reverse order for installation. Never

remove the solder on the flexible cable before connecting

the P200 connector on the MECHANISM PCB.

7-2. Replacement of the SPINDLE MOTOR

Because the SPINDLE MOTOR position is very critical, jitter

adjustment should be performed after replacement.

1) Disconnect the P300 connector on the MECHANISM PCB.

2) Insert a Philips type screw driver into the hole on the TURN

TABLE of the SPINDLE MOTOR and remove the two

screws.

8

8. SERVICE MODE

8-1 OPERATION

8-1-1. Main Microprocessor (IC600 : MB90574)

Functions which operated by main microprocessor

are follows.

Control of following IC's.

AV decoder, DEM/ECC, VIDEO encoder, CDDSP, AUDIO-DAC, PRE-AMP, READ-CHANNEL,

SERVO

Mechanism control

DVD rate control

OSD control

DISC detect, Focus/Tracking alignment

Data transmission between OPE microprocessor

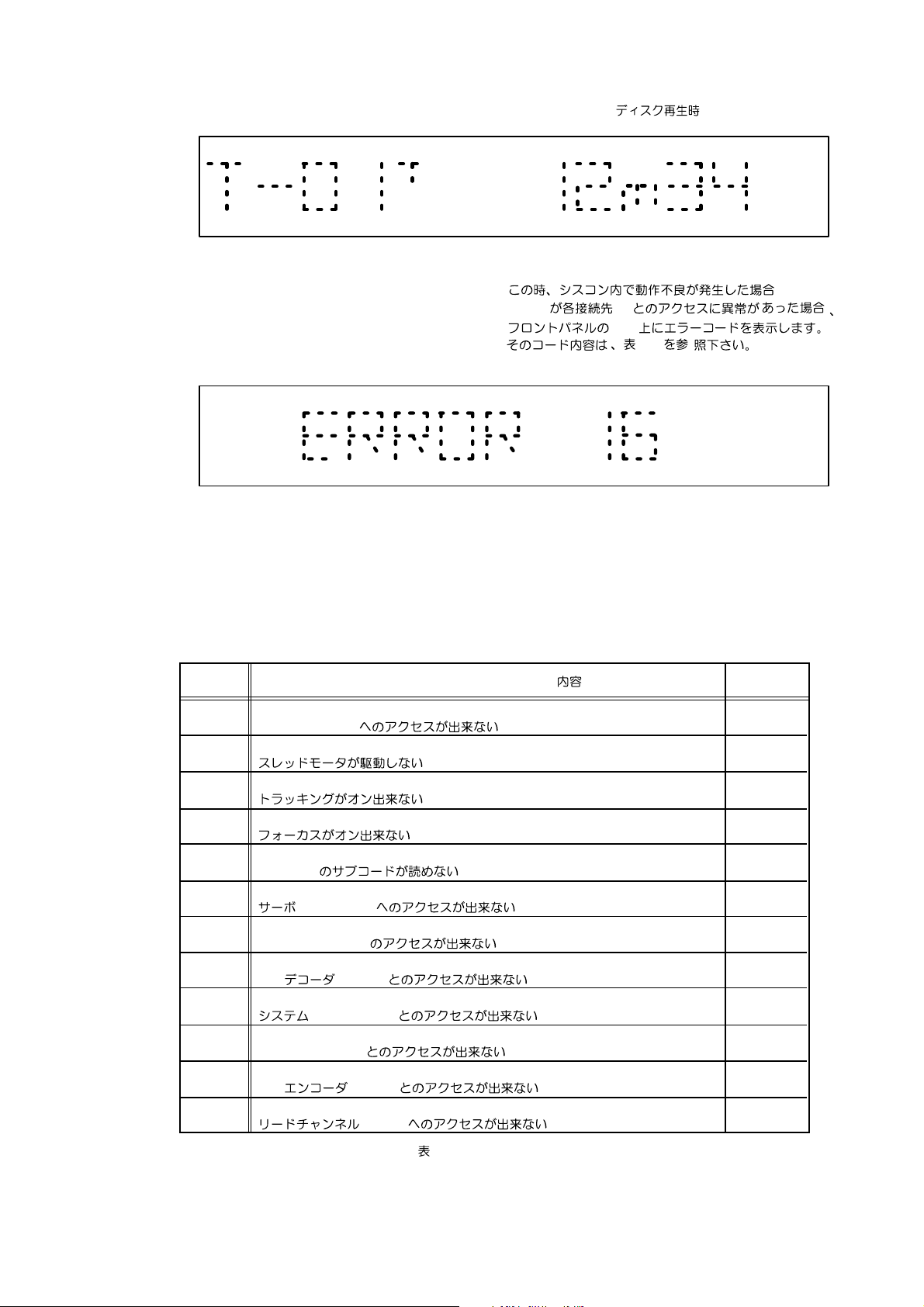

Process from POWER ON (RESET RELEASE) till

PLAY BACK are described in the chart below.

Release REST

RESET

Initial read EEPROM

EEPROM

Release RESET (IC's)

IC RESET

VIDEO Encoder initial setup

VIDEO

(PAL or NTSC)

8-1.

8-1-1. MAIN (IC600:MB90574)

NAIN

IC

AV DEM/ECC VIDEO

CD-DSP AUDIO-DAC PRE-AMP READCHANNEL

SERVO

DVD

OSD

DISC

OPE

MAIN RESET

Mechanism initialize

DEM/ECC initialize

DEM/ECC

Digital out of the AV decoder

initial set up. (48Khz liner PCM)

AV

48KHz PCM

Show the start up frame

)

Release RESET (AV Decoder)

AV RESET

Boot up AV Decoder

AV BOOT UP

Servo IC initialize

IC

DISC detect

DISC

CD/VCD DVD

Control data

TOC reading

TOC

PLAY BACK /

reading

9

8-1-2. Output Control Microprocessor

(IC700:M38022)

Main operation features of this microprocessor is

as follows.

Power supply control : Power efficiency switching.

3.3V line ON/OFF

5.0V line ON/OFF

9.0V line ON/OFF

Out put selection of the OUTPUT PCB.

VIDEO output stage control

21PIN SCART output signal selection

21PIN SCART control signal selection

(TV/DVD, SQUEEZE, RGB)

S-Video out S1 control

AUDIO output control

Output MUTE control

Feedback to the MAIN microprocessor

OPERATION PCB

Operation Button key scan

Remote control code reading

FLD indication

LED indication

Communication between MAIN microprocessor

Command transmission (by user controlable)

Data receiving for FLD/LED indication

8-1-2. OUTPUT CONTROL (IC700: M38022)

OUTPUT CONTROL

3.3V ON/OFF

5.0V

9.0V

OUTPUT

VIDEO

21PIN SCART

21PIN SCART

(TV/DVD, SQUEEZE, RGB)

S

AUDIO

MAIN

OPERATION

FLD

LED

MAIN

FLD/LED

ON/OFF

ON/OFF

S1

MUTE

8-2. TEST MODE

How to set up the TEST MODE

1. Remove any Disc from the tray, and turn OFF

the mains power.

2. Turn ON the mains power while depress the " "

(STOP) and " " (PAUSE) buttons together. Do

not release buttons till FLD shows follows.

8-2.

1.

2.

(STOP) (PAUSE)

FLD

/ In case of no DISC

While DVD Video playback

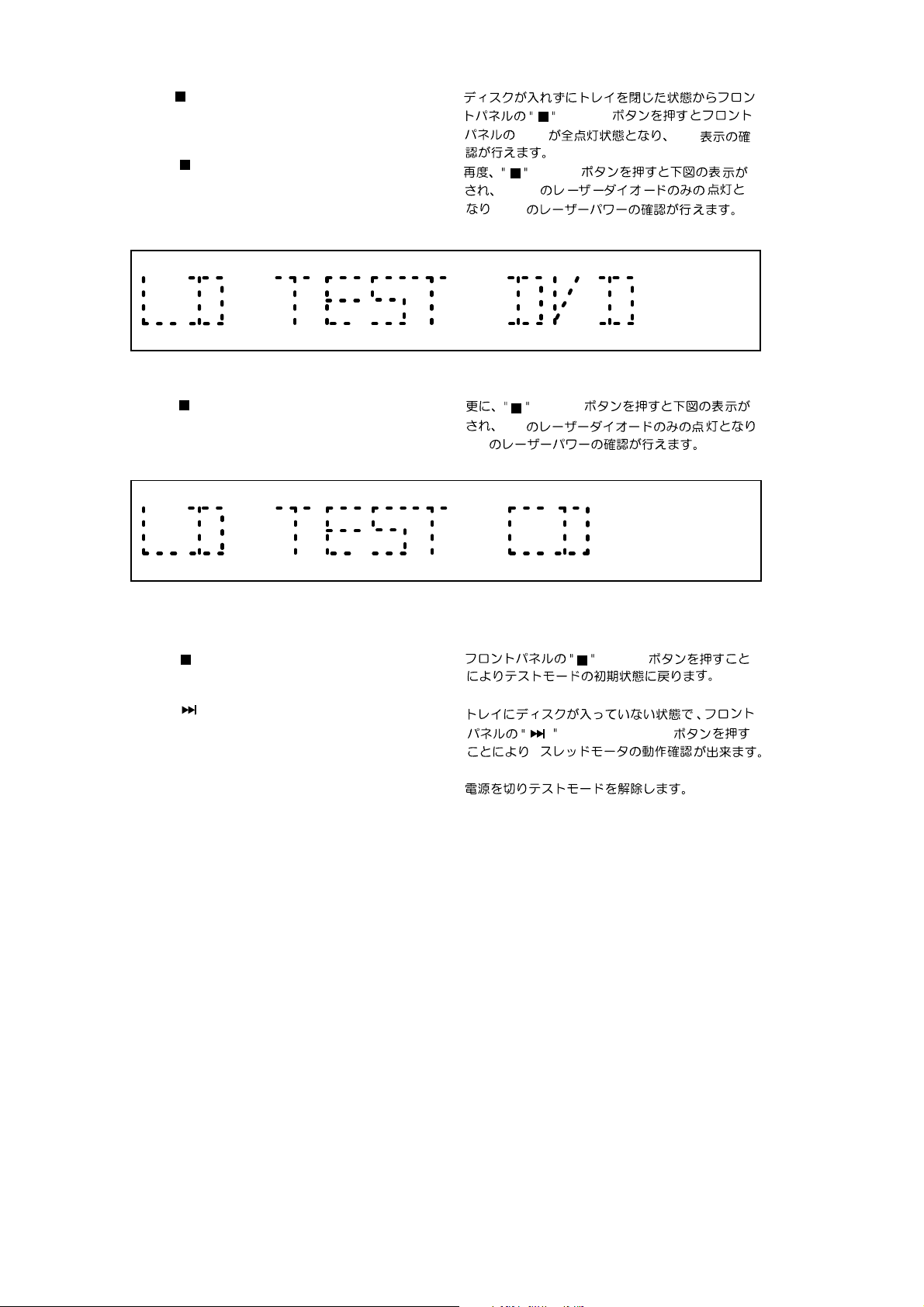

10

/

DVD

/ While VCD and CD Video playback

VCD/CD

In case of some fault has happened. (caused with

communications between CPU: IC600 and related

IC's) Some Error code is shown on the FLD.

Each Error codes are described on the table 8-1.

ERORR

CODE

16

17

No access with CD-DSP (IC490).

CD-DSP(IC490)

Sledge motor is not working.

ERORR DESCRIPTION /

IC600

IC

FLD

(CPU :

)

8-1

DISC

D/V/C

D/V/C

18

19

20

32

33

34

35

36

37

38

Tracking ON error.

Focus ON error.

Sub code read error. (CD/VCD)

CD, VCD

No access

with Servo-DSC (IC300).

DSC(IC300)

No access (IC500).

with DEM/ECC

DEM/ECC(IC500)

No access

with A/V decoder (IC700).

A/V (IC700)

No access with system ROM (IC602).

ROM(IC602)

No access with EEPROM(IC603).

EEPROM(IC603)

No access with A/V encoder (IC850).

A/V (IC850)

No access with Read channel (IC200).

(IC200)

8-1. / Table 8-1.

D/V/C

D/V/C

V/C

D/V/C

D/V/C

D/V/C

D/V/C

D/V/C

D/V/C

D/V/C

D : DVD, V : Video CD, C : CD

11

3. Press the " " (STOP) button while close the

disctray without any disc. Then all segments of

the FLD right ON.

3.

FLD

(STOP)

FLD

4. Press the " " (STOP) button again. The FLD

indication shows below. Then the laser diode for

DVD will right ON.

5. Press the " " (STOP) button again. The FLD

indication shows below. Then the laser diode for

CD will right ON.

4.

5.

(STOP)

DVD

DVD

(STOP)

CD

CD

6. Press the " " (STOP) button again. Then the

TEST MODE back to the first step.

7. Press the " " (Forward Search) button while

close the disc tray without any disc. Then the

sledge motor will move.

8. Turn OFF the mains power. Then service mode

will be released.

6.

7.

8.

(STOP)

(Forward Search)

12

8-3. EEPROM initialize

The memory device (EEPROM) which used in this DVD player

is programmed each functions by products regions at factory.

When that EEPROM (MAIN P.C. Board IC602 : M24C16MN6T) or MAIN P.C. Board has exchanged, EEPROM initialization is necessary. If that the initialization will not be done

correctly, the product might not be work correctly.

The initialize procedure are as follows.

1. Remove any Disc from the tray, and turn OFF the mains

power.

Turn ON the mains power while depress the “ “ (STOP)

and “ “ (Forward skip) buttons together. Do not release

buttons till FLD shows “ A-01 D-XX “. (XX = is depended

on EEPROM status)

REMARK : In case of some failure with the product. The

ERROR code will be shown on the FLD and above

indication will not be shown. Then other confirmation or

repair is necessary before this EEPROM initialization.

2. The address shown as “ A-01 D-XX “ is can be changed

by pressing “ “ and “ “ buttons on the front panel or

remote controller. Which can be changed to “ 0 “ till “ 07 “.

(Address “ 00 “ is not available.)

“ “ (Forward skip) button : Address UP

“ “ (Reverse skip) button : Address DOWN

3. The DATA shown as “ XX “ is can be changed by pressing

“ II “ and “ “ buttons on the front panel or remote

controller. Set up data are shown in following table.

“ II “ (PAUSE) button : Data UP

“ “ (STOP) button : Data DOWN

4. Press the “ DIMMER “ button, then address data will be

memorize.

5. Memorize data by each address ( from “ 01 “ to “ 07 “), as

order 2., 3. And 4. processes.

6. Turn OFF the mains switch. (This procedure is necessary

for next procedure.)

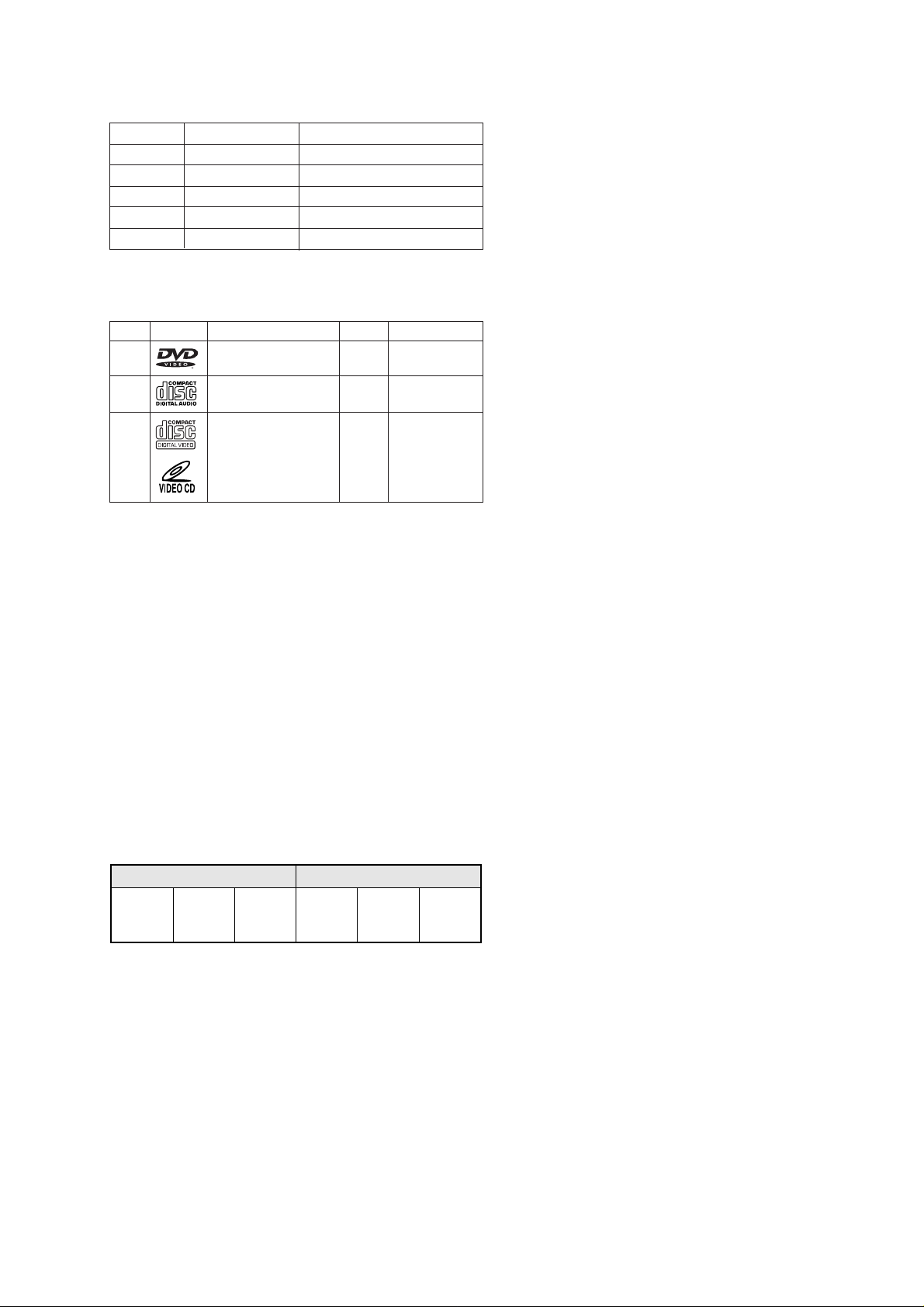

Address

U1B F1N N1B S1G K1G

01 E1 E9 F7 E7 E7

02 30 30 70 30 30

03 00 08 00 00 06

04 53 50 00 00 00

05 55 4A 00 00 00

06 C5 C5 C5 C5 C5

07 A9 A9 A9 A9 A9

Data

13

7. Turn ON the mains power while depress the “ DIMMER “

and “ “ (Reverse skip) buttons together. Then the FLD

shows “ -- -- -- -- “.

8. Send the commands “ 1999 “ by the remote controller.

(Press buttons “ 1 “, “ 9 “, “ 9 “ and “ 9 “.) Then the FLD

shows “ A-00 D-XX “. (XX = is depended on EEPROM

status)

9. Send the commands “ D-XX “ (Data) as your product version shows in following table by the remote controller.

U1B F1N N1B S1G K1G

Data

10. Press the “ ENTER “ button, then address data will be

memorize and the FLD shows a data number which you

stored. ( EX: “ D-02 “ )

11. Turn OFF the mains switch, then EEPROM initialization

mode will be release.

01 02 02 04 20

14

9. ELECTRICAL ADJUSTMENT

TP107

TP105

P800

TP300

VR120

VR121

TP120

VR110

VR202

P807

TP201

P804 P803

JITTER ADJ

SCREW B

JITTER ADJ

SCREW A

Fig. 9-1

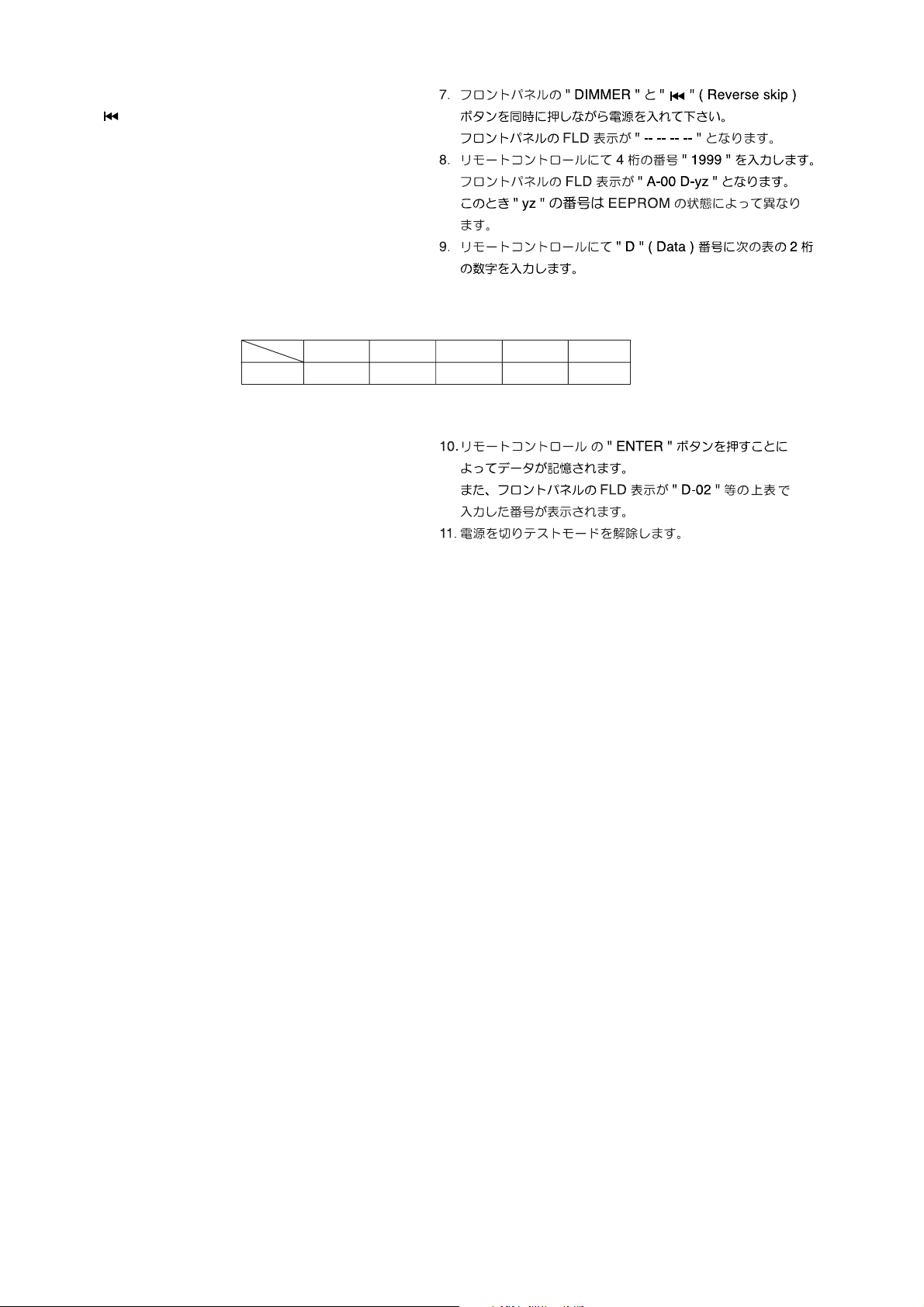

9-1. DVD JITTER ADJUSTMENT

1. Stick the provided small round sticker (0.1 mm thickness)

at the innermost position of a DVD disc as shown and make

a swayed DVD disc.

Signal recorded side

STICKER

Fig. 9-2

2. Play back the swayed DVD disc and press the F.F button

repeatedly until the pickup block reaches the outermost

position of its movable range. Next, press the P AUSE button.

3. Set the oscilloscope to the DC input mode and connect it to

the TP201 (HOT) and the TP102 (D.GND) on the MAIN

PCB.

4. Adjust the a screw and b screw alternately so that the AC

and DC level of the waveform is minimum. (DC level should

be less than 1.8 V, AC component should be minimum.)

2. Set the oscilloscope to the DC input mode and connect it to

the TP201 (HOT) and the TP102 (D.GND) on the MAIN

PCB.

3. Adjust the VR202 so that the DC level is minimum. (The DC

level should be less than 1.8 V)

9-3. CD TRACKING BALANCE

1. Set the VR1 10 at its center position prior to the adjustment.

2. Connect an oscilloscope to the TP150 (TE) on the MAIN

PCB.

3. Play back an ordinary CD-disc and then set it to the P AUSE

mode. If the play mode does not be engage, turn the VR110

at ±15 degrees. If the play mode does still not be engage

even when the VR110 is turned at ±15 degrees, turn the

VR110 at ± 30 degrees and try it again.

4. Observe the waveform and adjust it so that the level A of

the waveform is the same as level B.

A

B

500mV

Fig. 9-4

Less than 1.8V

Fig. 9-3

NOTE: If the SPINDLE MOTOR is replaced, this jitter

adjustment should be performed for proper performance.

9-2. SLICE LEVEL ADJUSTMENT

1. Play back an ordinary DVD disc (single side, one layer) and

press the F.F button repeatedly until the pickup block

reaches almost the center position of its movable range.

minimum

9-4. AS ADJUSTMENT

Adjustment point : VR120

Test point : TP120

1. Turn ON the mains power while depress the “ ” (STOP)

and “ II ” (PAUSE) buttons together. (TEST MODE)

2. Connect the multi meter to test point TP120. Set the multi

meter in DC voltage mode.

3. Press the “ ” (STOP) button several times till the FLD

shows “ LD TEST CD ”. Measure the voltage at that

status.

4. Press the “ ” (STOP) button several times till the FLD

shows “ LD TEST DVD ”.

5. Adjust the voltage at that status 50mV lower than “ LD TEST

CD ” status by the trim resister VR120.

15

Loading...

Loading...