Page 1

Service

DV3100 /N1B

Manual

STANDBY

POWER

SECTION PAGE

1. TECHNICAL SPECIFICATIONS ................................................................................................................ 1

2. PRODUCT SAFETY SERVICING GUIDELINE FOR VIDEO PRODUCTS................................................ 2

/SERVICING PRECAUTIONS .................................................................................................................... 3

3. INFORMATIONS ........................................................................................................................................ 4

4. SERVICING HINT....................................................................................................................................... 5

5. REGIONAL CODES ................................................................................................................................... 6

6. LOCATION OF CUSTOMER CONTROLS.................................................................................................7

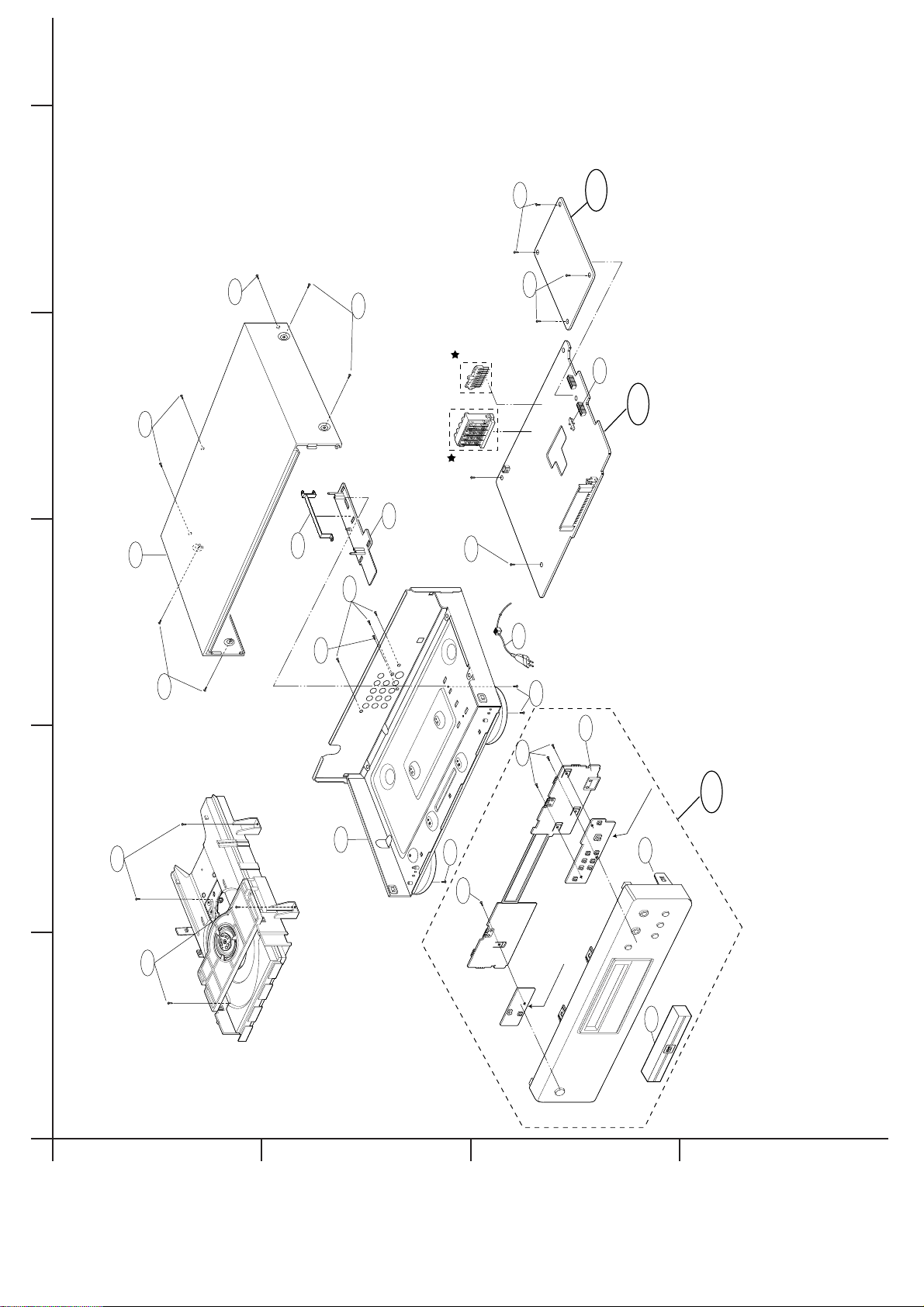

7. DISASSEMBLY .......................................................................................................................................2-2

8. EXPLODED VIEWS/PARTS LIST ...........................................................................................................2-4

9. ELECTRICAL TROUBLESHOOTING GUIDE .........................................................................................3-2

10. BLOCK DIAGRAMS .............................................................................................................................. 3-12

11. CIRCUIT DIAGRAMS ............................................................................................................................ 3-18

12. PRINTED CIRCUIT DIAGRAMS/ELECTRICAL PARTS LIST .............................................................. 3-38

13. DECK MECHANISM................................................................................................................................ 4-1

DVD Player

DVD PLAYER DV3100

STANDBY/ON

TABLE OF CONTENTS

OPEN/CLOSE STOP

PLAY

PAUSE

Please use this service manual with referring to the user guide (D.F.U) without fail.

DV3100

DV3100

R

304W855020 ACT

3120 785 22450

First Issue:2000.10

Page 2

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INC

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before A C po w er is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

001010 ACT

Page 3

1

TECHNICAL SPECIFICATIONS

DVD VIDEO PLAYER

Power supply AC 120V, 60Hz(U1B)

/AC100V, 50/60Hz(F1N)

/AC220~240V, 50Hz(N1B)

/110~240V, 50Hz(K1G, A1B)

Power consumption 16W

Mass 3.2kg(7.1lbs)

External dimensions 430 x 88 x 215 (W x H x D)

Signal system NTSC 525/60, PAL 625/50

Laser Semiconductor laser, wavelength 650nm

Frequency range (audio) 4Hz to 20 kHz

Signal-to-noise ratio (audio) More than 100 dB (EIAJ)

Dynamic range (audio) More than 95 dB (EIAJ)

Harmonic distortion(audio) 0.008%

Wow and flutter Below measurable level (less than +0.001%(W.PEAK)) (EIAJ)

Operating conditions Temperature : 5˚C(41˚F) to 35˚C(95˚F),

Operation status : Horizontal

OUTPUTS

Video output 1.0V(p-p), 75Ω, negative sync., RCA jack x 1 / SCART

S-video outputs (Y)1.0V(p-p), 75Ω, negative sync.,Mini DIN 4-pin x 1

(C)0.286V(p-p), 75Ω

Audio output(digital audio) 0.5V(p-p), 75Ω, RCA jack x 1

Audio output(analog audio) 2.0Vrms (1kHz, 0dB), 330Ω, RCA jack (L, R) x 1 / SCART

*Designs and specifications are subject to change without notice.

Page 4

2

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR

ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS, FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD), AND REPLACE IF NECESSARY.

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUDING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS AN X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY. WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE AND THAT THE HIGH VOLTAGE READING BE RECORDED ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IT IS NECESSARY TO LOCATE THE CAUSE OF EXCESSIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT, MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS. A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM. BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS.

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 5

3

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and ADDENDUMS, read and follow

the SAFETY PRECAUTIONS. NOTE : if unforeseen circum-

stances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1)Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a GROUNDED-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 6

4

3. INFORMATIONS

REGION CODE

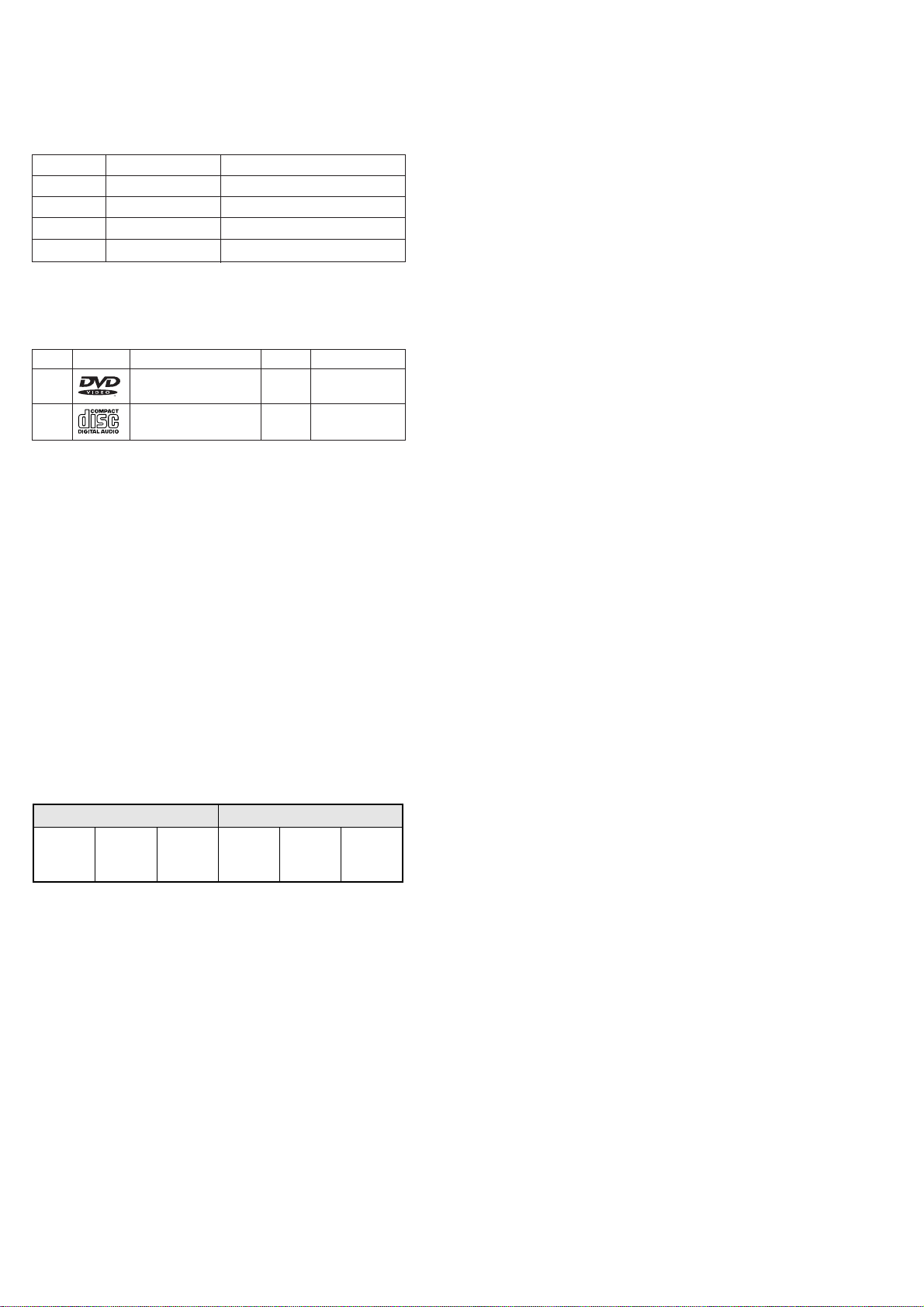

THE DISCS THAT THE DV3100 CAN HANDLE

The following discs can be played back with a DV3100.

Note: The regional code of the discs must meet to the regional

code of the product.

DVD INFORMATION

Below is a glossary of the new terms related to DVD.

Title:

A disc may have more than one story/movie on it, so each

story/movie is called a “title”.

For example, if there are 2 movies on the disc, they are

separated into Title 1 and Title 2.

Chapter:

A title may also be separated into chapters.

For example, a movie (title) may be separated into 3 scenes

(chapters).

Subtitles:

DVDs are recorded with up to 32 different subtitle languages.

If a disc has more than one subtitle language, you can select

the subtitle language that you want to read.

Soundtrack language:

DVDs are recorded with up to 8 different soundtrack languages.

If a disc has more than one language, you can select the

soundtrack language that you want to listen to.

Multi-angles:

On some DVDs, scenes have been filmed from different angles

(up to a maximum of 9). On these discs, you can select the

angle that you want to watch. Please refer to the DVD’s manual

to see which scenes have multi-angles.

Parental guide:

Some discs have restriction levels that allow you to cut scenes

or prevent playback of discs that have contents that you do

not want children to watch.

disc mark playback capability size side

DVD Audio/Video

12 cm

single/double

8 cm

CD Audio

12 cm

single

8 cm

VERSION REGION CODE COUNTRY

/N1B 2 EUROPE

/F1N 2 JAPAN

/A1B 4 AUSTRALIA

/U1B 1 USA/CANADA

Title 1 Title 2

Chapter3Chapter1Chapter2Chapter

3

Chapter1Chapter

2

Page 7

5

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc 4822 397 10131

SERVICE HINTS

4. SERVICING HINT

Page 8

6

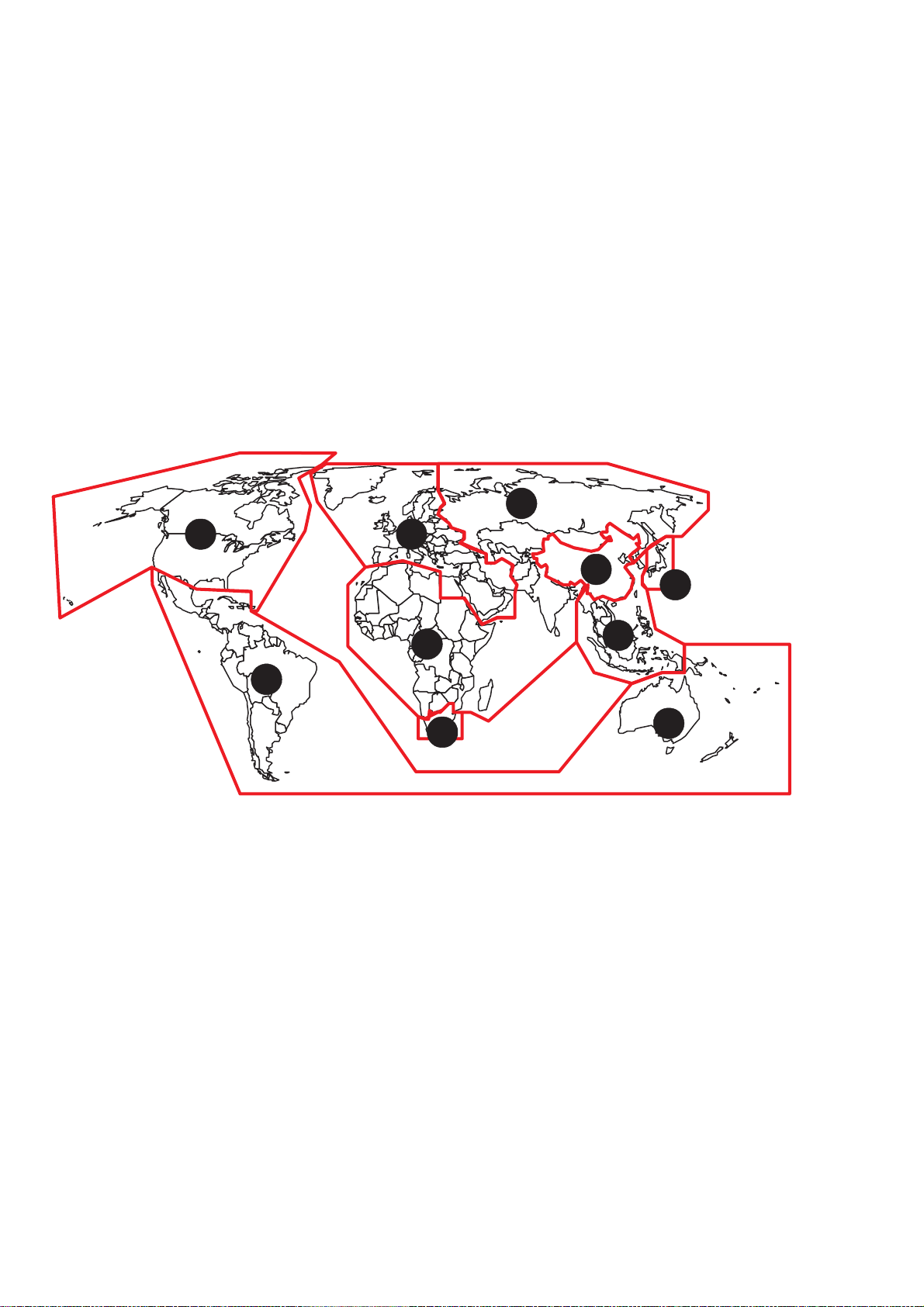

REGIONAL CODES

1 2

2

2

5

5

4

4

3

6

Map of DVD Regions

What are "regional codes"?

Motion picture studios want to control the home release of movies in different countries because theater releases arenít

simultaneous (a movie may come out on DVD in the US when itís just hitting screens in Europe). Therefore they have

required that the DVD standard include codes which can be used to lock out the playback of certain discs in certain geographical regions. Players sold in each region will have that regionís code built into the player. The player will refuse to play

these "region coded" discs which are not allowed in the region. However, regional codes are entirely optional. Discs without

codes will play on any player in any country. Some studios have already announced that only their new releases will have

regional codes. There are six regions:

1. United States and Canada

2. Europe and Japan

3. Far East (except Japan & China)

4. South America and Oceania

5. Africa and the Middle East

6. China (except Hong Kong)

Page 9

7

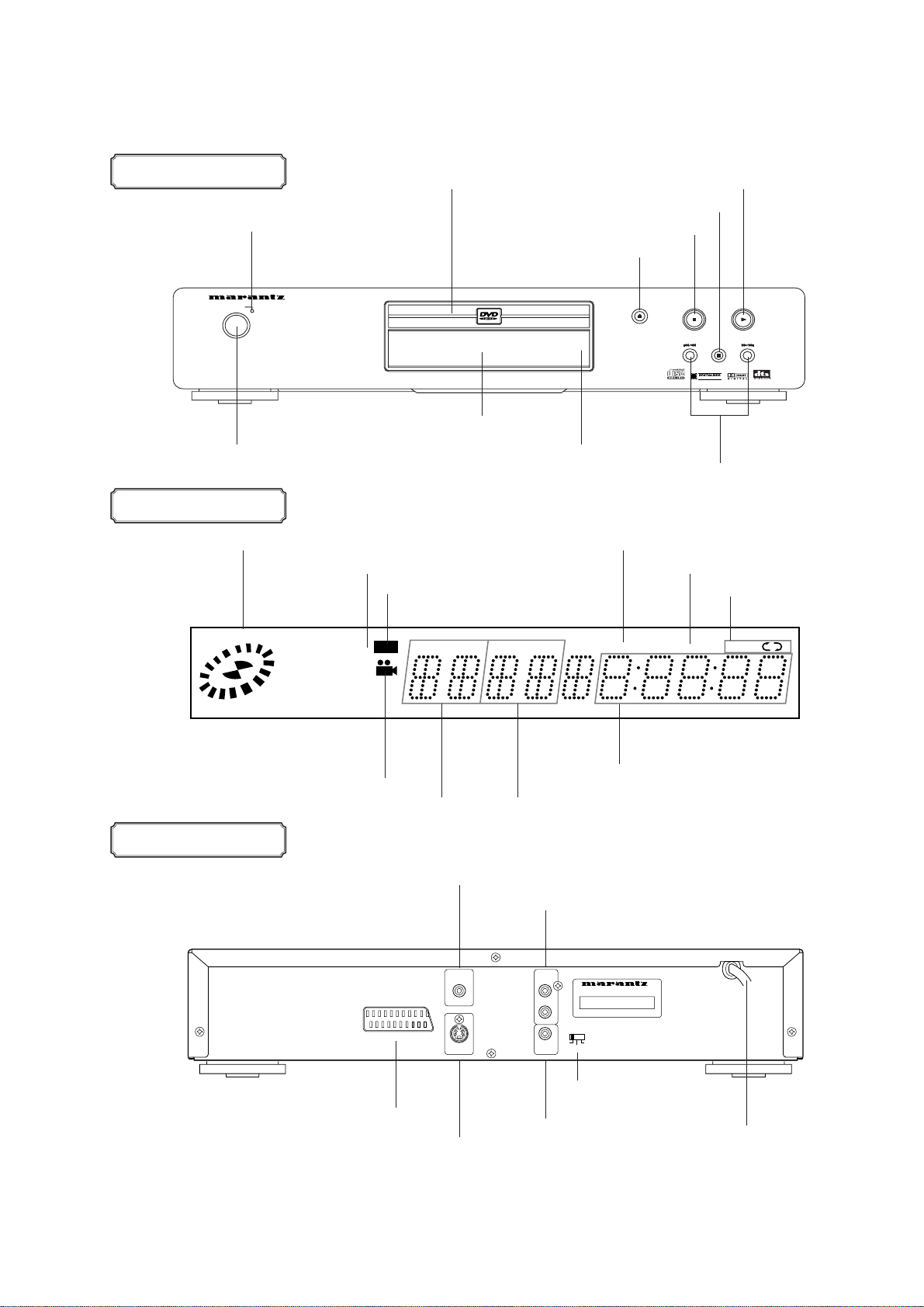

LOCATION OF CUSTOMER CONTROLS

DVD PLAYER DV3100

STANDBY

STANDBY/ON

POWER

OPEN/CLOSE STOP

PAUSE

PLAY

TITLECD

PROG. NKS

RANDOM ALL

AB

CHP/TRK

DVD

MODEL NO.DV3100

COAXIAL

OUT

DIGITAL

OUT

S-VIDEO

OUT

AUDIO

OUT

VIDEO

L

R

PAL

NTSC

AUTO

A/V EUROCONNECTOR

TV

FRONT PANEL

DISPLAY WINDOW

REAR PANEL

POWER INDICATOR

POWER BUTTON

DISPLAY WINDOW

REMOTE SENSOR

OPEN/CLOSE BUTTON

SKIP/SCAN BUTTONS

DISC TRAY

PLAY BUTTON

PAUSE BUTTON

STOP BUTTON

ANGLE ICON INDICATOR

TITLE NUMBER INDICATOR

S-VIDEO OUT JACK

AV-EURO CONNECTOR

VIDEO OUT JACK

PAL/NTSC

CHAPTER/TRACK NUMBER INDICATOR

TOTAL PLAYING TIME/ELAPSED

TIME INDICATORS

AUDIO OUT1(L/R) JACKS

POWER CORD

Connect to an AC 220~240V, 50Hz

outlet only.

COAXIAL DIGITAL AUDIO OUT JACK

OPERATING STATUS INDICATOR PROGRAM INDICATOR

DVD INDICATOR

REPEAT PLAYBACK

MODE INDICATORS

CD INDICATOR RANDOM INDICATOR

Page 10

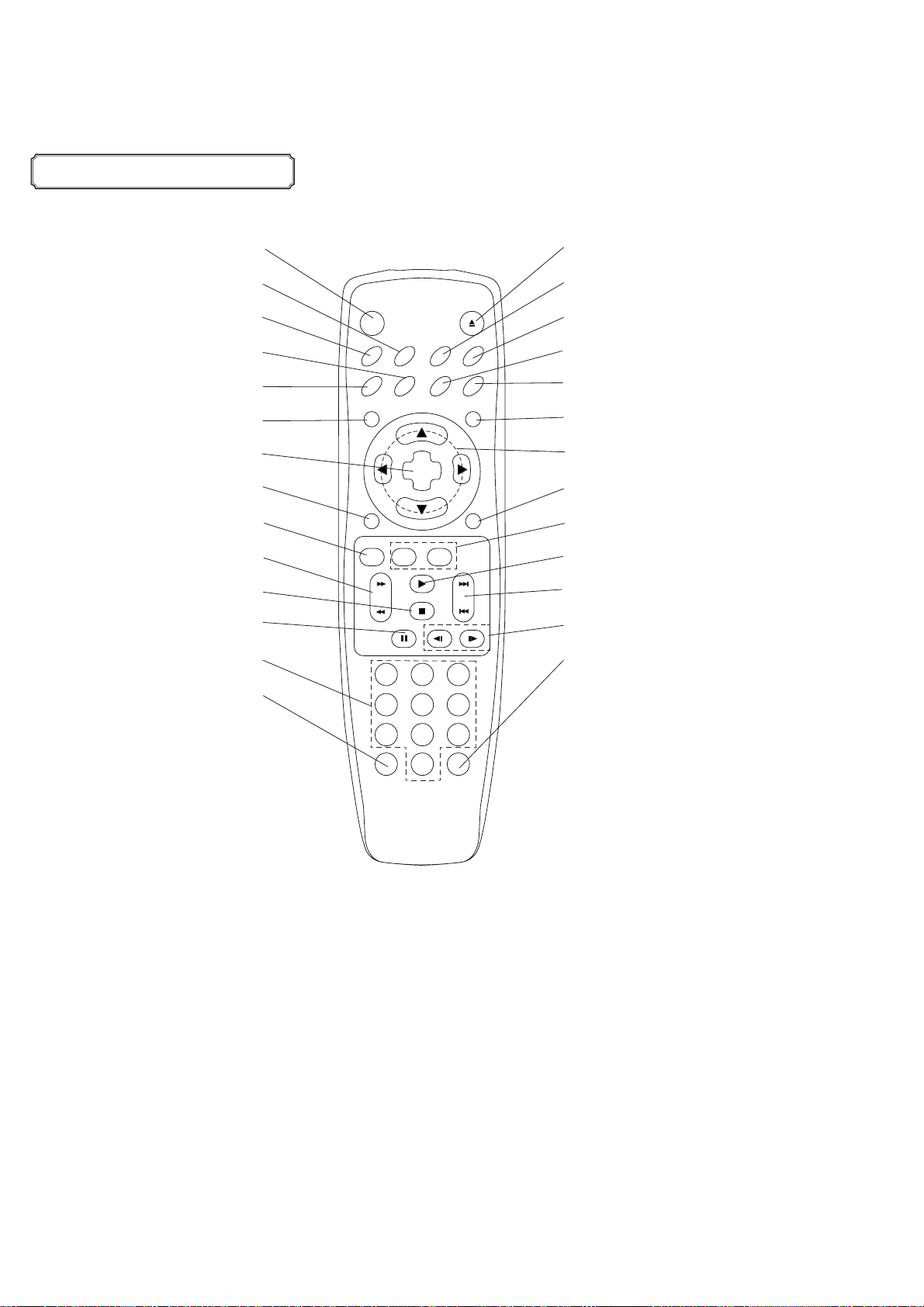

8

REMOTE CONTROL

POWER button

STOP button

AUDIO button

FWD/REV SCAN button

REPEAT button

TOP MENU button

MENU button

ARROW buttons

RETURN button

PLAY button

FWD/REV SKIP button

SLOW buttons

MARKER-SEARCH button

OPEN/CLOSE button

RANDOM button

A-B button

ANGLE button

SURR. button

OSD button

ZOOM button

SELECT/ENTER button

SUBTITLE button

SETUP button

231

564

8097

PROGRAM

SKIPSCAN

PLAY

ZOOM

OSD

TOP MENU MENU

ANGLE

SELECT

/ENTER

SURR.SUBTITLEAUDIO

A-B RANDOMREPEAT

POWER OPEN/CLOSE

SETUP

RETURN

STOP

PAUSE

MARKER – SEARCH

SLOW

CLEAR

PAUSE button

Number buttons

CLEAR button

PROGRAM button

Page 11

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

1. DISASSEMBLY.........................................................................................................................2-2

CABINET DISASSEMBLY ............................................................................................................2-2

CIRCUIT BOARD DISASSEMBLY................................................................................................2-3

2. EXPLODED VIEWS.................................................................................................................2-4

1. Cabinet and Main Frame Section ...........................................................................................2-4

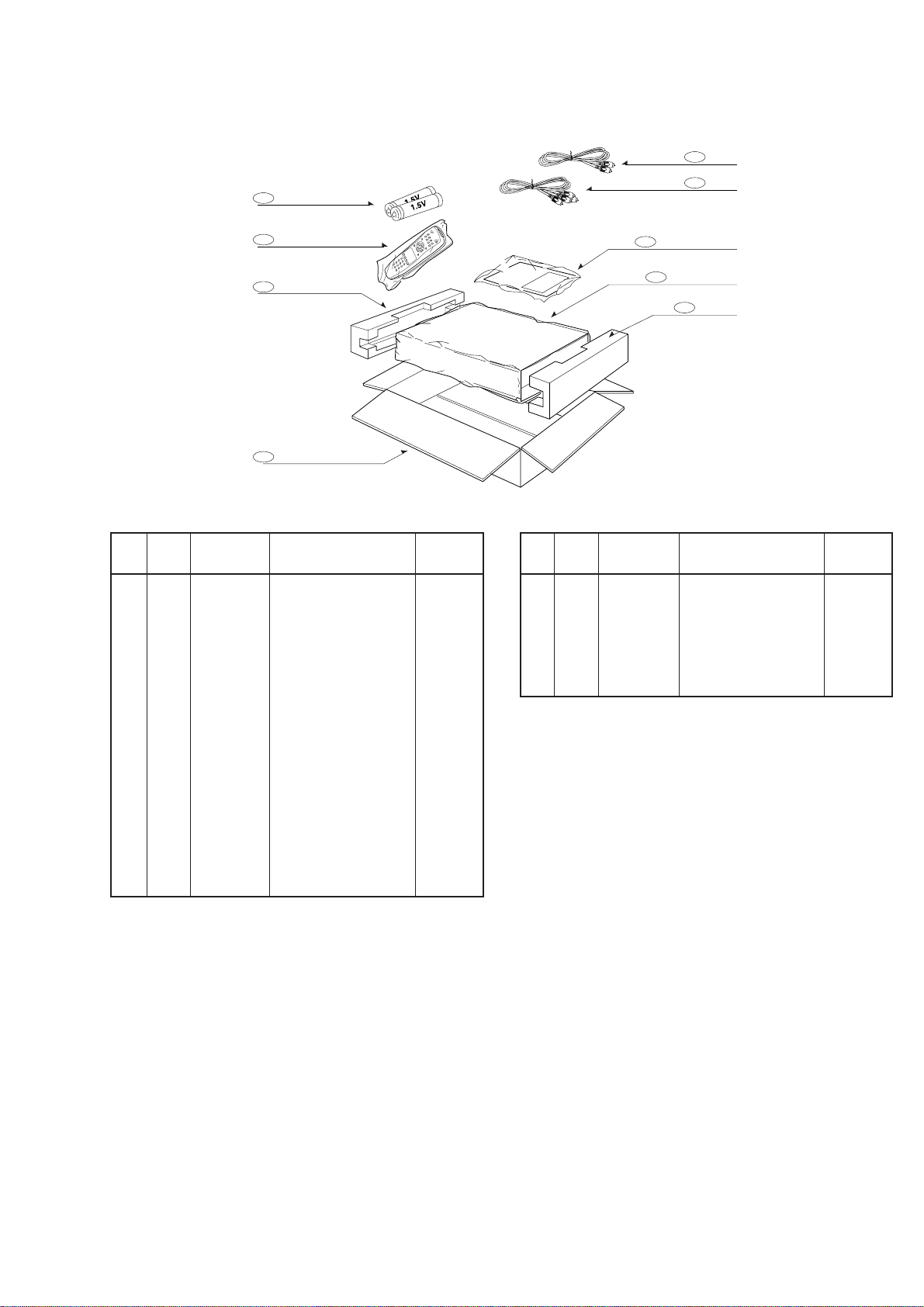

2. Packing Accessory Section....................................................................................................2-5

Page 12

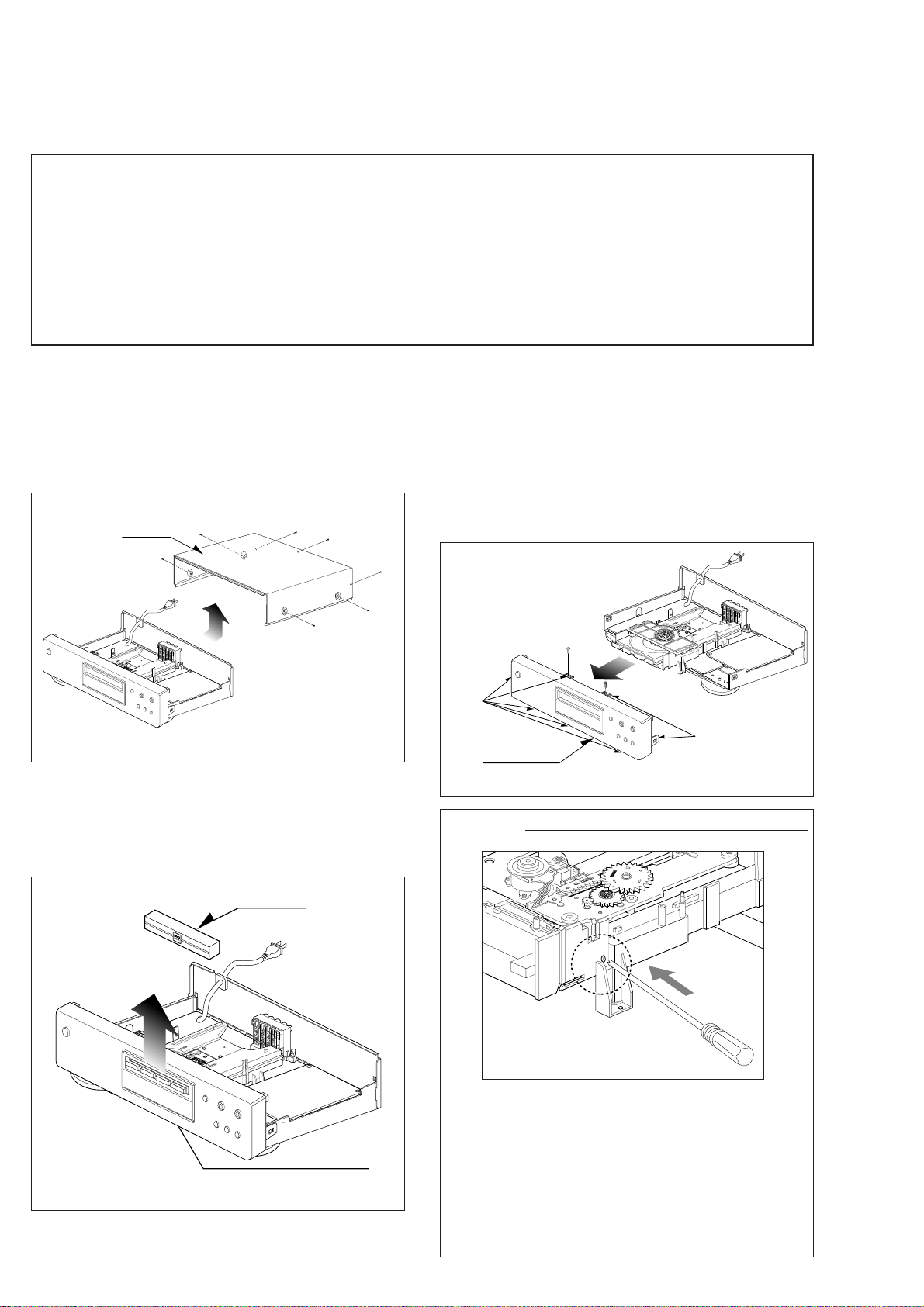

2-2

DISASSEMBLY

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded patrs and fine pitch screws used to secure

metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can not be fixed.

Top Case

(A)

(A)

(A)

(A)

(A)

(A)

(A)

Tray Door

Disc Tray

Front Panel

Stopper

Stopper

(B)

(B)

CABINET DISASSEMBLY

1. Top Case

1. Release 7 screws (A). (See Fig. 2-1)

2. Lift the top case with holding the back of it,

and remove it in the direction of the arrow

Fig. 2-1

Fig. 2-2

Fig. 2-3

3. Front Panel

1. Eject the disc tray. (See Fig. 2-2)

2. Remove the tray door. (See Fig. 2-2)

3. Release 2 screws (B).

4. Pull the front panel toward you while pressing

7 stoppers to disengage, and remove the front

panel. (See Fig. 2-3)

(A)

Press open/close button to open the tray. If the

tray doesn't work, insert and push a small screwdriver in the emergency eject hole (A) at the right

side. Then the tray comes out. After the first

centimeter it is possible to pull the tray out by

hand. Release the door cover of the tray.

REMARK: Before disassemble the front panel.

2.Tray Door

1.Eject the disc tray.

2.Lift up the tray door in the direction of the

arrow.

Page 13

2-3

Main Circuit Board

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

(C)

Power Code

Interface

Circuit

Board

(D)

(D)

Key

Circuit Board

(E)

(E)

(E)

(E)

Fig. 2-4

Fig. 2-5

1. Disassembling of Main Circuit Board

and Interface Board

1. Remove the top case.(See Fig. 2-1)

2. Remove 12 screw (C).

3. Remove the deck from Main Circuit Board.

4. Remove Main Circuit Board from Interface

Board.

5. Remove 2 screw (D).

6. Remove Interface Board from the chassis.

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure to shortcircuit the laserdiode output land.

After replacing the main circuit board, open the land after inserting the flexible connector.

(Refer to Mechanism Disassembly)

2. Digitron and Key Circuit Board

1. Remove the front panel.(See Fig. 2-3)

2. Release 4 screws (E), and remove the digitron

circuit board.

Page 14

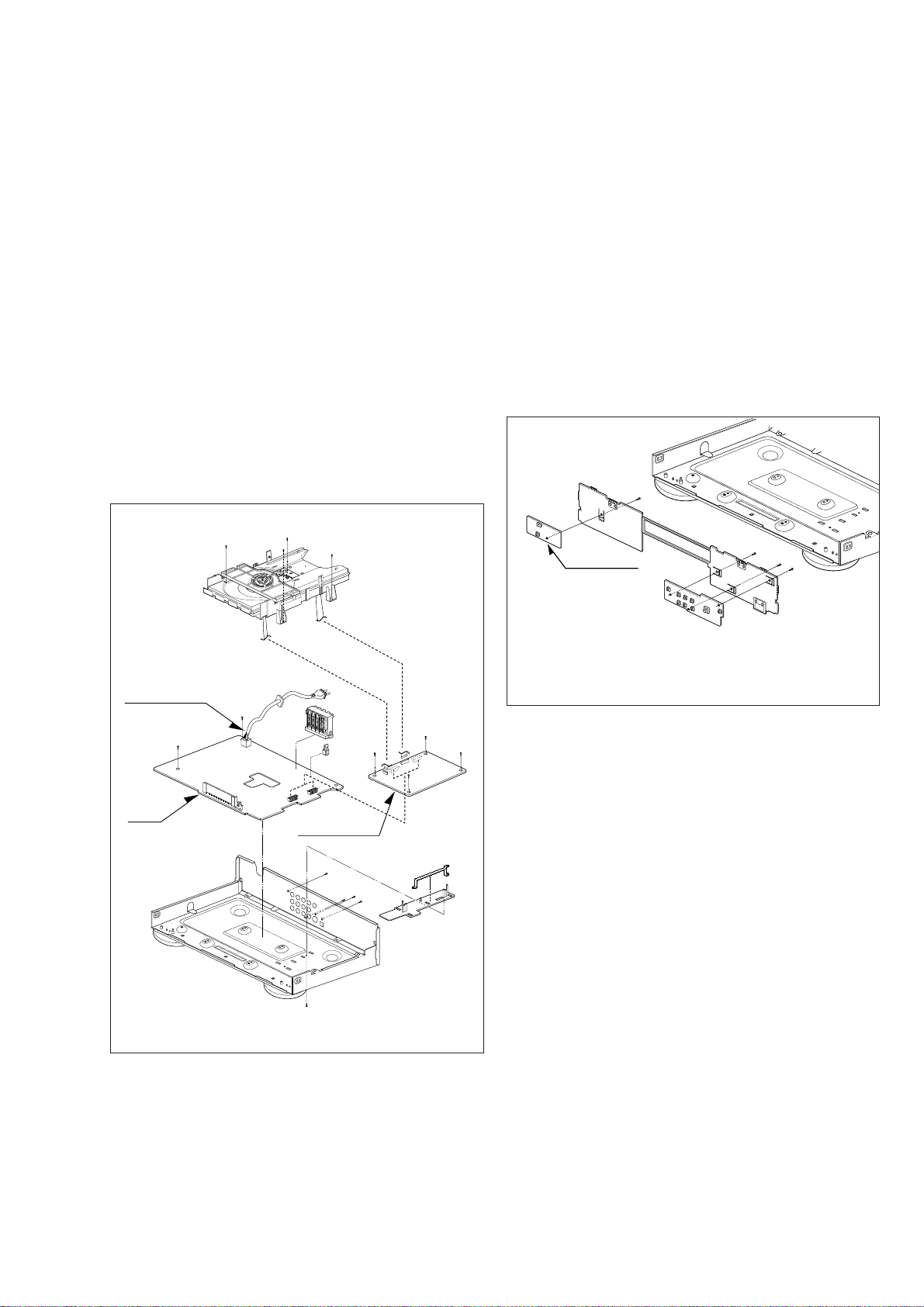

2-4

EXPLODED VIEWS

1. Cabinet and Main Frame Section

280

465

467

465

465

463

A46

463

463

279

275

332

PBP00

PBT00

283

260

467

300

467

A48

A43

250

462

462

463

463

452

452

285

Jack

Scart

A

5

4

3

2

1

BCD

Page 15

2-5

2.Packing Accessory Section

BATTERY

808

PACKING SHEET

804

PACKING

803

811

812

OWNER'S MANUAL

VIDEO

AUDIO

801

REMOTE CONTROLLER

900

BOX CARTON

802

PACKING

803

POS. VERS. PART NO. DESCRIPTON PART NO.

NO. COLOR (ANAM)

(MJI)

250 nsp TOP COVER (BLACK) nsp

260 /N1B nsp CHASSIS ASSY MAIN (/N1B) nsp

275 nsp HOLDER MAIN PCB nsp

279 nsp HOLDER CONNECTOR nsp

280 /N1B 9965 000 06951 PANEL ASSY FRONT (/N1B) 304W248510

283 /N1B 9965 000 06952 DOOR ASSY (BLACK) 304W063500

300 /N1B 9965 000 06953 MAINS CORD (/N1B) *YC000510R

332 nsp PLATE MAIN GND nsp

429 nsp SCREW B-TITE nsp

430 nsp SCREW +D2.0 6MM nsp

SWRCH16A/NIY 4.5MM

430 nsp SCREW +D2.0 6MM nsp

SWRCH16A/NIY 4.5MM

431 nsp SCREW +D2.0 6MM

SWRCH16A/ZNBK 4MM 1 nsp

432 nsp SCREW MACHINE nsp

432 nsp SCREW MACHINE nsp

452 nsp SCREW SPECIAL nsp

462 nsp SCREW DECORATION nsp

463 nsp SCREW SPECIAL nsp

465 nsp SCREW SPECIAL (3X10 BK) nsp

467 nsp SCREW SPECIAL (3X8 BK) nsp

POS. VERS. PART NO. DESCRIPTON PART NO.

NO. COLOR (ANAM)

(MJI)

801 /N1B 9965 000 06954 USER GUIDE (/N1B) 304W851310

802 nsp BOX nsp

803 nsp PACKING nsp

804 nsp SHEE nsp

808 nsp BATTERY AAA(R03) nsp

811 nsp PHONO CORD (YL) nsp

812 nsp PHONO CORD (RD/WH) nsp

900 9965 000 06955 REMOTE CONTROLLER ZK304W0010

Page 16

3-1

SECTION 3

ELECTRICAL

CONTENTS

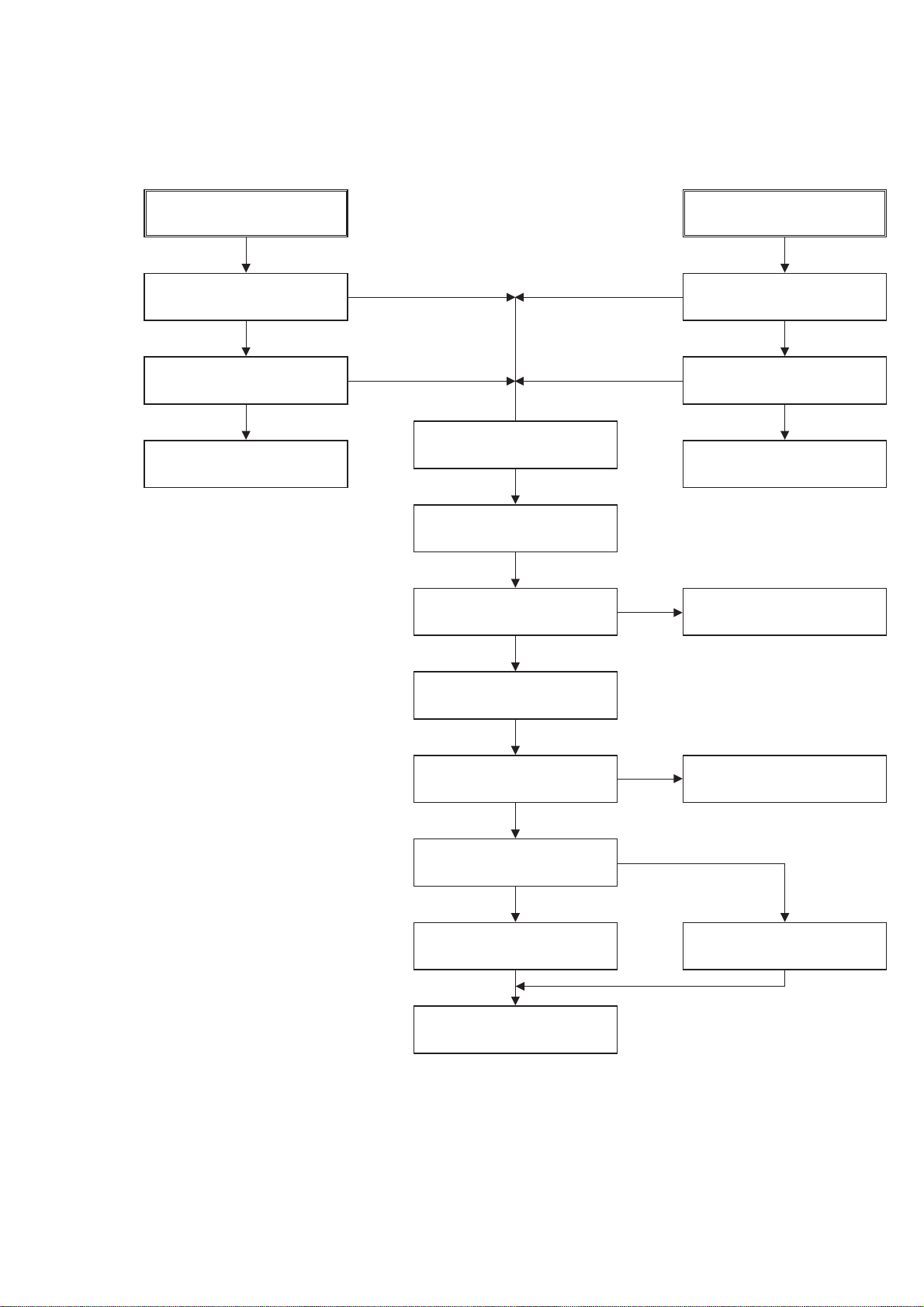

ELECTRICAL TROUBLESHOOTING GUIDE......................................................................3-2

1. Power(SMPS) Circuit...............................................................................................................3-2

2. µ-com Circuit...........................................................................................................................3-3

3. MPEG Circuit ...........................................................................................................................3-6

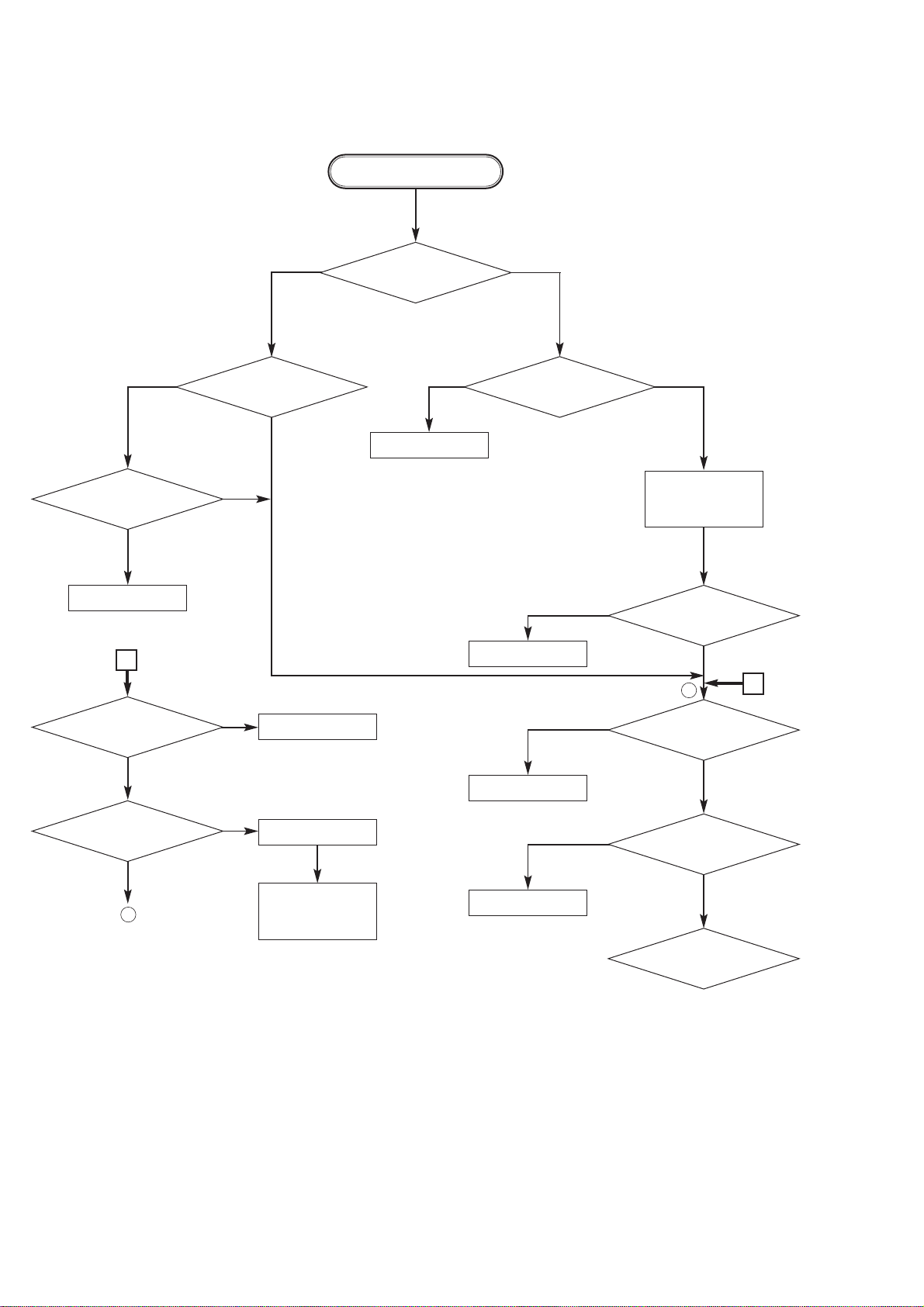

4. Front Circuit(Digitron & Key) .................................................................................................3-7

5. RF/Servo Circuit ......................................................................................................................3-8

BLOCK DIAGRAMS..................................................................................................................3-12

1. Overall Block Diagram ..........................................................................................................3-12

2. Power (SMPS) Block Diagram..............................................................................................3-13

3. RF/CD DSP/DVD DSP/DVD servo Block Diagram..............................................................3-14

4. Audio Block Diagram ............................................................................................................3-15

5. MPEG Block Diagram ..........................................................................................................3-16

6. µ-COM Block Diagram..........................................................................................................3-17

CIRCUIT DIAGRAMS ...............................................................................................................3-18

1. Power (SMPS) Circuit Diagram ............................................................................................3-18

2. DVD DSP Circuit Diagram.....................................................................................................3-20

3. Drive & RF Circuit Diagram...................................................................................................3-22

4. MPEG Circuit Diagram..........................................................................................................3-24

• WAVEFORMS...........................................................................................................................3-26

5. Audio DM & 5.1CH Circuit Diagram.....................................................................................3-28

6. µ-COM/Expander...................................................................................................................3-30

7. DIGITRON & Key Circuit Diagram........................................................................................3-32

8. Jack Circuit Diagram.............................................................................................................3-34

PRINTED CIRCUIT DIAGRAMS ...........................................................................................3-36

1. MAIN P.C.BOARD...................................................................................................................3-36

2. POWER,A/V,FRONT P.C.BOARD...........................................................................................3-38

3. KEY P.C.BOARD ....................................................................................................................3-40

4. POWER LED P.C.BOARD ......................................................................................................3-41

Page 17

3-2

ELECTRICAL TROUBLESHOOTING GUIDE

No 5V_D

or 5V_A .

No 5.2VA.

Is 5.2VA section working?

Is oscillation present at the

Base of Q108?

Replace Q108.

Check L103, C116, 117.

Replace R111.

Replace BD101.

(Bridge rectifier)

Check Fuse(F101).

Is R111 1Ω?

Check D105.

Replace Q101, 102.

Is 5.2V applied to IC102

Pin 1?

Is there a DC voltage at the

(+) terminal of BD101?

Check R127, 128.

(SHUTDOWN CKT)

1. Power(SMPS) Circuit

No VF+

Is 5.2VA section working?

Replace D109.

Is oscillation present at the

anode of D109?

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

A. B.

NO

NO

NO

Page 18

3-3

Replace IC506.

Refer to Front Part

Check short

Reconnect it.

2. µ-COM Circuit

A. No Power

Does Logo appear

on the screen?

Is oscillation of

X501 normal?

Are IC503 Pins 14, 288

and 29 normal?

Do all five Bars appear?

Does Bar appear at FLD?

Is P5901

connected normally?

Is P5901 Pin 24 normal?

The

waveform on A[00:21]

and D[00:15] of IC501

normal?

Are IC506 Pins 7, 8 normal?

Replace Main B/D.

Check the oscillation

Check short.

OK

Replace IC501

or IC503.

Check power.

(Refer to power)

If power is

normal

OK

POWER ON

1

1

YES

YES

YES

YES

YES

YES

YES

YES

A

NO

NO

NO

NO

NO

NO

NO

NONO

NO

A

Page 19

3-4

B. Audio abnormal

D. Open/Close abnormal

Check the

connection of P5901.

Check IC501 Pins 13, 14.

Check Audio jack.

YES (If OK)

YES

NO

NO

YES

YES (If OK)

YES

YES (If OK)

YES (If OK)

YES (If OK)

Check PLL FC of MPEG part.

Refer to Audio part.

Refer to MPEG part.

Replace B/D.

Check Front.

Reconnect it.

Refer to SERVO part.

Check the connection of MD.

AUDIO ABNORMAL

OPEN/CLOSE ABNORMAL

C. Video abnormal

Check Video jack.

YES (If OK)

YES (If OK)

YES (If OK)

YES (If OK)

Refer to Video part.

Refer to Encoder part.

Refer to MPEG part.

Replace B/D.

VIDEO ABNORMAL

Page 20

3-5

E. Picture abnormal

Check the disc.

If OK

YES (If OK)

YES (If OK)

Refer to Servo part

Check PLL IC of MPEG part

Check DSP

Check MPEG

YES (If OK)

Replace B/D

PICTURE ABNORMAL

F. Disc Error

Check Disc

YES (If OK)

YES (If OK)

Refer to Servo part

Replace B/D

DISC ERROR

Page 21

3-6

Power is on

Does LG Logo appear

on the screen?

Does the

moving picture of the DVD Disc

play on the screen

normally?

Is MPEG data signal normal?

Is error signal normal?

Is MPEG data signal normal?

Is Clock normal?

Does the audio

sound output from MPEG

decoder?

Does the

moving picture of the video

CD play on the screen

normally?

Does the audio sound

output normally?

END

Check power & clock.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check clock signal

Check clock signal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

OK

OK

OK

OK

NO

NO

NO

NO

NO

3. MPEG Circuit

_ OPTION

_ If included VCD function.

Page 22

3-7

NO

NO

NO

START

Does remote control

work normally?

Do all the

buttons work

normally?

Check waveform of

IC901 Pin 13.

Check waveform

of IC901 Pin 2.

Is Digitron on normally?

LED ON?

Check waveform

of IC901 Pin 6.

Is oscillation of

X901 normal?

Is waveform of IC901

Pin 76 normal?

Check waveform

of IC901 Pin 13.

Does pulse

waveform of RC901 Pin 1

appear?

Is IC901

Pin 24 connected to

RC901 Pin 1 ?

Is RC901 Pin 2 5V?

Power on.

Check and replace

R903,R912, R904, R905,

R941, R906, R907.

Solder defective parts again.

Solder defective parts

Replace Q901.

Solder Key part.

Check Power.

Replace IC902.

Replace IC901.

Replace LED901.

Replace RC901.

Re-solder.

Recheck

Replace IC901.Complete repairing Front B/D.

NO

NO

NO

NO

NO

NONONO

NO

YES

YES YES

YES

YES YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

CD

4. Front Circuit (Digitron & key)

Page 23

3-8

Does signal pulse

input to IC201 Pins 58, 59 when

the power is on?

Does signal goes

"High" to IC201 Pin194 when the

power is on?

Does

TTL pulse output to

IC201 Pins 140, 142?

Does

33.8688MHz clock input

to IC201 Pin 63?

Is IC201

Pins 83, 84, 88, 89 voltage

about 2.2V?

Replace IC201

(IC206 soldering or IC defect).

Check power circuit.

Check "2.µ-COM Part".

Replace X301 or IC304

(30MHz clock defect)

CHECK POINT(General)

5. RF/Servo Circuit

A.

END

NO

NO

NO NO

NO

YES

YES

YESYES

YES

Page 24

3-9

Does tray open or close?

Does the pick-up

slide inner or outer

track?

Fig.1. SLED Driver waveform

Fig.2. Focus Driver waveform

Does

the voltage change

at PMD04 Pins 1, 2 more than

2V on the basis of

3.8V?

Pressing

the open/close key

repeatedly, check the voltage of IC2M1

Pins 13, 14 change

0V to 5V

Does

PMD03 Pin 7 change

high to low?

Does

the pick-up lens move up

and down?

Check Focus Driver output.

(IC201 Pin 83, IC2M1 Pins 37, 38)

Check SLED Driver output.

IC201 Pin 88 IC2M1 Pins 28, 29.

IC201 Pin 88 no output : IC201 is defective

IC2M1 Pin 18 no output : IC2M1 is defective

IC201 Pin 83 no output : IC201 is defective

IC2M1 Pins 1, 2 no output : IC2M1 is defective

DECK assembly is defective.

Slide the pick-up to

inner track.

.Power on

Check loading Part.

Push Pick-up to inner track to

the end by hand.

DECK assembly is defective.

(Limit sw)

check µ-COM Part.

Replace IC2M1.

No disc

B.

END

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 25

3-10

FOCUS ON?

Check

the focus error moving the

lens up and down.

(IC2A1 Pin 42)

Does the

TTL level change at IC201

Pin 78 and 132 moving

the lens?

Does the disc turn?

IC201 Pin169 is "High"?

Is OK the track jump.

Does the signal

pulse appear at IC2A1 Pins

39, 29?

Does the screen appear?

OPEN/CLOSE

Replace µ-COM or IC201.

Replace IC201.

Check IC2A1 Pin 11,12,13,14

in DVD Mode

Fig.3. FOCUS ERROR waveform

IC201 no output : Pick-up is defective.

Check IC201 and IC2M1 when PMD03 Pin 6 is abnormal

Check IC2M1 Pin 21, PMD03

Pin 6 turn when the IC2M1

Pin 21 is less than 2.2V.

Check A

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

Replace µ-COM part.

IC2A1 is defective.

DISC IN

C.

END

NO

NO

NO

NO NO

NO

NO

NO

YES

YES

YES

YES

YES

YES YES

YES

Page 26

3-11

Is the eye-pattern vivid?

Does the

sawtooth waveform emit

at IC2A1 Pin 41?

Does the 1.6V emit?

Check RF Eye-Pattern.

RF : 1.5-1.6V(IC2A1 Pin 57)

Fig.5. RF

waveform

Check IC2A1 Pins 5, 6, 7, 8.

No signal: Pick-up is defective

Replace IC201.

Check IC201 Pin84.

No signal at IC201 : IC201 is defective

• Check IC201 Pin 162.

• Check the clock at the IC201 Pins 28, 30.

• Both are normal : IC201 is defective

Replace IC2A1.

CHECK A

D.

END

NO

NO NO NO

YES

YES YES YES

Page 27

3-12

BLOCK DIAGRAMS

1. Overall Block Diagram

DISC

SPINDLE

MOTOR

LOADING

MOTOR

Focus, tracking sled

VF+

VF-

-24V8V5.2VA

5V_A

5V_D

3.3V_M

3.3V

2.5V8VA.GND,D.NGD,M.GND

loading drive

spindle

loading

CD,DVD:A,B,C,D,E,F

MIRR,TZC

DVD_LDQM,DVD_SD,CSI

DVD_MA[0:11]

DVD_MD[0:15]

DVD_SD_CAS,

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

DVD_DATA[0:7]

DVD_SD_CSO,

DVD_UDQM

ICADDR[0:8]

ICDATA[00:15]

SDCLKI, ZISENB

REQZI

3.38688MHz

DA_DATA,

DA_LRCK,

DA_BCK

D[00:07]

S_CLK,S_DATA,

DPLL_L

IIC_DATA,

IIC_CLK

A[00:02]

DA_XCK

CVBS,

Y,C

Y(G),

PB(B)

PR(R)

CVBS,Y,C

Y(G)PB(B),PR(R)

27MHz

FE,TE,RFRP,SBADD,DVD/CD RF

TEBAL,FEBAL,

DPOCTL,EQF,EQB

MON,SPINDLE_DRV

FDO,TDO,

FMO

AC100-

240V,

50~

60Hz

FL DISPLAY

REMOCON

RECEIVER

KEY Input

SPINDLE_FG

POWER CONTROL

SENS,FOK,MIRR

MSDATO,DEFECT,DSP_SENSE,

SQSO,SQCK,SCOR,AO[0:5]

XLAT,S_CLK,S_DATA,DO[0:7]

PICK

UP

IC2A1

33P3721

RF Signal

Processor

IC205

DRAM

256K x 16bit

IC201

DVDSP-3301

CD/DVD DSP

DVD SERVO

IC501

SH7034

MAIN

u-COM

IC301

ZiVA-3

MPEG A/V

Decoder

IC305

SAA7126/8

VIDEO

Encoder

IC302

GM72V1621

1M x 16bit

SDRAM

IC303

GM72V1621

1M x 16bit

SDRAM

IC304

PLL1700

CLOCK

GENERATROR

IC2M1

KA3032

Motor Driver

POWER

BOARD

IC901

LC866112

OPEN S/W

CD DECK MECHANISM

CLOSE S/W

LIMIT S/W

M

M

DAC_LO,

S_CLK,

S_DATA

DA_DATA,

DA_LRCK,

DA_BCK

27MHz

X-TAL

L/R

VDATA[0:7]

Hsync

Vsync

IC306/307

BA7660

6dB AMP

AMP

VIDEO

'OUT

L/R

CVBS

Y

C

Y(G) PB(B) PR(R)

IC401/451

PCM1723E

AUDIO

DAC

Page 28

3-13

2. Power(SMPS) Block Diagram

RECTIFIER(FLD)

RECTIFIER LINE FILTER

SWITCHING TR

RECTIFIER(14V) LPF

REG(8V)

REG(3.3V)

REG(3.3V)

PWR ON/OFF

F+

F-

-24VA

12VA

8V

5.2VA

5V_D

5V_A

3.3V

3.3V_M

2.5V

LPF

RECTIFIER(9V)

RECTIFIER(5.2V)

TRANS

LPF

FEED B.

Page 29

3-14

IC2A1

33P3721

RF Signal

Processdr

IC206

DVDSP-3301

CD/DVD DSP

DVD SERVO

DRAM

256K x 16bit

IC2M1

KA3032

SpindleMotor,LoadingMotor,

Actuator Driver

PICK

UP

DVD:A,B,C,D,

FE,TE,PI,SBADD

SENS,FOK,SLD_FG,

MSDATO,DEFECT,DSP_SENSE

SQSO,SQCK,SCOR

XLAT,S_CLK,S_DATA

DSP_CS,/WR,/RD

DO[0:7]

AO[0:5]

DVD_DATA[0:7]

MCK

UCOM

I/F

MPEG

I/F

UCOM

I/F

M/D

DVD/CD RF

MIRR,TZC

ICADDR[0:8]

ICDATA[00:15]

MON,MDP

FDO,TDO,FMO

Spindle

focus,tracking,loading,sled

SPINDLE_FG

Load open/close(loading control)

CD:A,B,C,D/E,F

4

4

5

3

3

3

8

6

8

8

2

4

9

16

3. RF/CD DSP/DVD DSP/DVD SERVO Block Diagram

Page 30

3-15

4. Audio Block Diagram

IC402

LPF &Buffer

NJM4580M

OP AMP

IC401

PCM1716

Audio DAC

U-COM

I/F

DAC_RST

S_DATA

S_CLK

DAC_L0

DA_LRCK

DA_BCK

DA_XCK

DA_DATA0

MPEG

I/F

A/V

JACK

I/F

L

R

L

R

Page 31

3-16

5. MPEG Block Diagram

DSP

I/F

IC301

ZiVA-3

MPEG A/V

Decoder

IC303

GM72V1621

1M x 16bit

SDRAM

IC302

GM72V1621

1M x 16bit

SDRAM

IC304

PLL1700

CLOCK

GENERATROR

IC305

SAA7126/8

NTSC/PAL

Encoder

IC306

BA7660FS

6dB AMP

IC307

BA7660FS

6dB AMP

27MHz

X-TAL

U-COM

I/F

DVD_DATA[0:7]

DAI_DATA

DA_DATA[0:3]

DA_BCK,DA_XCK,DA_LRCK

SPDIF

HSYNC,VSYNC

CVBS

Y

C

Y

PB

PR

CVBS

AUDIO

I/F

A/V

JACK

I/F

U-COM

I/F

U-COM

I/F

SERVO

I/F

Y

C

Y

PB

PR

VDATA[0:7]

DA_XCK

MPEG_CLK

IIC_DATA,IIC_CLKIIC_DATA,IIC_CLK

DAC_RST

8

SDCLK1,ZISENB

REQZ1

2

2

A[00:02]

D[00:07]

MPEG_ERROR

MPEG_RST

DVD_SD_CS0,DVD_UDQM

DVD_MD[0:15]

DVD_MA[0:11]

DVD_SD_CAS

DVD_SD_RAS

DVD_SD_CLK

DVD_MWE

DVD_LDQM

DVD_SD_CS1

S_CLK,S_DATA<DPLL_L

MCK

8

8

4

4

2

2

21216

3

Page 32

3-17

6. µ-COM Block Diagram

AV JACK

I/F

IC506

XC9536

IC502

FLASH

ROM

FRONT

I/F

IC503

DRAM

IC505

74HC374

IC501

SH6417034

MPEG

I/F

SERVO

I/F

DSP

I/F

IC504

EEPROM

2402/2416

16:9,SYSTEM_SW

LD_ON,LOAD CLOSE,MIRR,ACT_MUTE

LOAD_OPEN,SPINDLE_FG,SLD_FG,

D[00:07],A[00:02],IIC_CLK,IIC_DATA,SCLK0, MPEG_RST

,MPEG_INT,V_MUTE,A_MUTE,DAC_RST,Y_SEL

MPEG_ERROR

,DAC_L0

,RF_LAT

,/DSP_CS

,/MPEG_CS

,/PP_CS 16:,

,Y_SEL

,,MPEG_RST

PWR_CTL

,SENS,LIMIT_SW

,MIC_ON,CLOSE_SW

,OPEN_SW,MPEG_WAIT

,16:9,,MPEG_RST

,M_RESET

M_RESET

,RXD0

,TXD0

,SCK0

,F_REQ

,MODE_SW

,M_REQ,

,ECHO

IIC_CLK

,IIC_DATA

SENS_MCOM

, MICOM_WAIT

/IOCS1,/WR

D[00:04]

A[19:21]

A[01:19]

D[00:15]

A[01:09]

D[00:15]

A[01:21]21 D[00:15]

D[00:07]

DAC_RST

,E_DR

,/S_XRST

,XLAT

,ACT_MUTE

,LOAD_OPEN

,LOAD CLOSE

,/PWR_RST

EXP_W2

,/PWR_CTL

2

2

2

88

8

10

2

2

2

19

16

9

16

16

21

D[00:07],A[00:05], ,E_SIN,E_CLK

LOAD_FR,F/R,LOCK,DEFECT,FOK

DSP_SENSE,

Page 33

3-18 3-19

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

'00. 04. 17 R10542A

MARANTZ(NARROW)

CIRCUIT DIAGRAM

1. POWER(SMPS) CIRCUIT DIAGRAM (DV3100/U1B,/F1N)

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE MARANTZ ELECTRONICS CORPORATION.

ALL COMPONENTS SHOULD BE REPLACED ONLY

WITH TYPES IDENTICAL TO THOSE IN THE ORIGINAL

CIRCUIT. SPECIAL COMPONENTS ARE SHADED ON

THE SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO THE

SET IS NOT DELAYED UNTIL THE NEW SERVICE LIT-

ERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

Power oscillator dead.

Q101 is defective

Q101 failure caused D101 failure.

D101 is defective.

VF+ power dead.

D107 is defective.

-24VA power dead.

D108 is defective.

3.3V power dead.

IC106 and IC107 are defective.

Power control is abnormal.

Q107 and Q108 are defective.

8V Power dead.

IC105 is defective.

Power dead.

IC104 is defective.

Power dead.

IC108 is defective.

If fuse fails atstarup.

Q101 and Q102 are defective.

Page 34

3-20 3-21

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

'00. 04. 17 R10542B

MARANTZ(WIDE)

1. POWER(SMPS) CIRCUIT DIAGRAM (DV3100/A1B,/N1B)

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE MARANTZ ELECTRONICS CORPORATION. ALL COMPONENTS SHOULD BE REPLACED

ONLY WITH TYPES IDENTICAL TO THOSE IN THE

ORIGINAL CIRCUIT. SPECIAL COMPONENTS ARE

SHADED ON THE SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SER-

VICE LITERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

FLD power dead.

D107, D108, F102 are defective.

3.3V power dead.

IC106 and IC107 are defective.

Power control is abnormal.

Q107 and Q108 are defective.

8V Power dead.

IC105 is defective.

Power dead.

IC102 is defective.

Power dead.

IC104 is defective.

Power dead.

IC101 is defective.

Page 35

3-22 3-23

5

56

TRACKING LOOP

FOCUS LOOP

SLED LOOP

SPINDLE LOOP

WAVEFORM

'00. 04. 17 R10536A

MARANTZ

IC204 is defective.

Scratched CD Audio abnormal.

IC203 is defective.

AD Converter Error

- No tracking/Focus control

2. DVD DSP CIRCUIT DIAGRAM

Page 36

3-24 3-25

3. DRIVE & RF CIRCUIT DIAGRAM

4

1

1

6

2

3

TRACKING LOOP

FOCUS LOOP

SLED LOOP

SPINDLE LOOP

WAVEFORM

'00. 04. 17. R10535A

MARANTZ

OPEN

OPEN

Q2M3 is defective.

Spindle rotates in high speed.

IC2A2 is defective.

No fucus & tracking control.

Q2A1, Q2A2 are defective.

CD/DVD LD will not be on.

Page 37

3-26 3-27

5

6

7

8

1

2

4

3

9

• NO DVD SCREEN DISPLAY

• NO VCD SCREEN DISPLAY.

• NO CD SOUND OUT.

• NO SCREEN DISPLAY.

• NO SOUND OUT.

• NO 2CH AUDIO OUT

NO SCREEN

NO SCREEN

• NO 2CH AUDIO OUT

11

10

WAVEFORM

'00. 04. 17 R10538A

MARANTZ

"B"

C/No DV3100/N1B ect.

R3B1 0 ohm x

R3C1 x 0 ohm

"B" x 0

*OPTION Table

4. MPEG CIRCUIT DIAGRAM

IC302, IC303 are defective.

A/V out bad.

X301 is defective.

No power on.

Q302, 303 are defective.

Component Y out defective.

Q301, 304 are defective.

Y/C out is defective.

IC306 is defective.

CVBS/Y/C out bad.

IC305 is defective.

Video out bad.

IC307 is defective.

Component out bad.

Page 38

3-28 3-29

• WAVEFORMS

(VIDEO ENCODER)(RF/SERVO)

IC2A1 Pin 42, Focus Error

IC2A1 Pin 36, Pi

IC2A1 Pin 41

Tracking Error

Tek

Stop :

1 00kS/s

3290 Acqs

M 500µs

CH1

280/mV

Record

Length

Fit to Screen

OFF

Time Base

Main

Trigger

Position

50%

Horiz

Scale

(/div)

Horiz

Pos

FastFrame

Setup

more

1 of 3

3

Ch3

1.00V

[ T ]

Record

Length

2500

T

2500

points in

50divs

1000

points in

20divs

500

points in

10divs

IC305 Pins 9~16, MPEG Data IC305 Pin 30, Composite

IC305 Pin 24, Chrominance

Tek

Stop :

2.50MS/s

4 Acqs

M20.0µs

2 Apr 1999

14:47:27

Glitch

Ch1

Ch3

500mV

[T ]

T

3

IC305 Pin 27, Luminance IC305 Pins 40, 41 SDA/SCL

Tek

Stop :

1 00kS/s

3290 Acqs

M 500µs

CH1

280/mV

Edge Slope

Type

<Edge>

Source

Ch1

Coupling

DC

Level

280mV

Mode

&

Holdoff

3

Ch3

1.00V

[ T ][ T ]

Slope

T

IC305 Pin 4, MPEG Clock(27MHz)

Tek

Stop :

10.0kS/s

13 Acqs

M 5 .00ms

CH1

280/mV

Edge Slope

Type

<Edge>

Source

Ch1

Coupling

DC

Level

280mV

Mode

&

Holdoff

3

Ch3

1.00V

[ T ]

Slope

T

IC305 Pin 7, Vertical SYNC

Tek

Stop :

2.50MS/s

7 Acqs

M 20.0µs

CH1

280/mV

Edge Slope

Type

<Edge>

Source

Ch1

Coupling

DC

Level

280mV

Mode

&

Holdoff

3

Ch3

1.00V

[ T ]

Slope

T

IC305 Pin 8 Horizontal SYNC IC305 Pin 29 Component Pb

IC305 Pin 23 Component Pr IC305 Pin 27 Component Y

IC2A1 Pin 41

VBR TRACKING Error

IC2A1 Pin 57,

RF

IC201 Pin 88, SLED Drive(FMO)

IC201 Pin 18, SLED FG

IC2A1 Pin42, Focus Error(in Focus Search)

IC201 Pin 83, Focus Drive(FDO)

Page 39

3-30 3-31

5. AUDIO DM & 5.1CH CIRCUIT DIAGRAM

2CH L SIGNAL

2CH R SIGNAL

'00. 04. 17 R10539A

MARANTZ

Q401 is defective.

2CH Audio out bad.

IC404 is defective.

Audio bad

IC403, Q404 are defective.

Digital data out bad.

IC402 is defective.

2CH Audio out bad.

IC401 is defective

2CH Audio out bad

Page 40

3-32 3-33

6. µ-COM/EXPANDER CIRCUIT DIAGRAM

FLASH ROM SDRAM

MAIN CPU

E

X

P

A

N

D

E

R

EEPROM

CPLD

'00. 04. 17 R10537A

MARANTZ

Audio output is unstable

Servo will not operate

X501 No Power on

Video output level is unstable

Open, Close Error

Servo will not operate

FLD Error

DV3100/K1G(ASIA) : IC502(FLASH ROM) 16M

DV3100/U1B, F1N, N1B, A1B : IC502(FlASH ROM) 8M

Page 41

3-34 3-35

7. DIGITRON(TIMER) & KEY CIRCUIT DIAGRAM

RESET

REMOCON

RECEIVE

FRONT CONTROL

'00. 04. 17 R10540A

MARANTZ

MIC OPTION

IC902 is defective.

Reset Error.

RC901 is defective.

R/C Error.

DIG901 is defective.

FLD is distorted.

Q901, Q902 are defective.

LED will not operate.

Page 42

3-36 3-37

8. JACK CIRCUIT DIAGRAM

SCART OPTION

(DV3100/N1B OPTION)

DV3100/N1B, K1G, A1B ONLY

S VIDEO (C)

AUDIO (L)

AUDIO (R)

OPTICAL

COMP.VIDEO

S VIDEO (Y)

'00. 04. 17 R10541A

MARANTZ

/U1B, /A1B, /F1N ONLY

16:9 can’t be changed

Page 43

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD

LOCATION GUIDE

(TOP SIDE)

(BOTTOM SIDE)

3-38 3-39

Page 44

2. Power, A/V, Front P.C.BOARD

LOCATION GUIDE

3-40 3-41

Page 45

3-42

3. KEY P.C.BOARD

4. Power LED P.C.BOARD

Page 46

3-43

ELECTRICAL PARTS LIST

ASSIGNMENT OF COMMON PARTS CODES.

RESISTORS

R : 1) GD05 x x x 140, Carbon film fixed resistor, ±5% 1/4W

R : 2) GD05 x x x 160, Carbon film fixed resistor, ±5% 1/6W

Examples ;

1 Resistance value

0.1 Ω....... 001 10 Ω.......100 1k Ω...102 100k Ω..... 104

0.5 Ω....... 005 18 Ω.......180 2.7k Ω...272 680k Ω..... 684

1 Ω ....... 010 100 Ω....... 101 10k Ω...103 1M Ω ..... 105

6.8 Ω....... 068 390 Ω....... 391 22k Ω...223 4.7M Ω ..... 475

Note : Please distinguish 1/4W from 1/6W by the shape of parts

used actually.

CAPACITORS

C : CERAMIC CAP.

Examples

2 ATolerance (Capacity deviation)

Tolerance of COMMON PARTS handled here are as follows :

3 Capacity value

C : CERAMIC CAP.

Examples

4 Capacity value

C

Examples

5 Capacity value

6 Working voltage

Examples

7 Capacity valu

3) DD1 x x x x 370, Ceramic capacitor

2 Tolerance

± 0. 2 5 p F .......0

± 0.5 pF ....... 1

± 5 % .......5

0.5 pF - 5 p ......... ± 0,25 pF

6 pF - 10 p F ..... ± 0.5 pF

12 F - 560 pF... ± 5 %

0.5 pF .... 00 5 3 pF .... 030 100 pF ..... 101

1 pF .... 010 1 0 p F .... 100 220 pF ..... 221

1.5 p .... 01 5 4 7 p F .... 470 560 pF ..... .561

4) DK16 x x x 300, High dielectric constant ceramic

4 Capacity value

100 pF.....101 1000 pF.... 102 10000 pF .... 103

470 pF.....471 2200 pF.... 222

5)ELECTR0LY CAP.( ), 6)FILM CAP ( )

5) EA x x x x x x 10, Electrolytic capacitor

5 Capacity value

0.1µ F .... 04 4.7µ F .... 475 100µ F ..... 107

0.33µ F .... 334 10µ F .... 106 330µ F ..... 337

1µ F .... 105 22µ F .... 226 1100µ F .....118

6.3 V. . .006 25 V. . .025

10 V. . .010 35 V. . .035

16 V. . .016 50 V. . .050

6) DF15 x x x 350 Plastic film capacitor

DF15 x x x 310 One-way type, Mylar ±5% 50V

DF16 x x x 310 Plastic film capacitor

0.001µ F (1000pF) ....... 102 0. 1µ F......104

0.0018µ F........................ 182 0.56µ F......564

0.01µ F........................ 103 1µ F......105

0.015µ F........................ 151

1 Resistance value

Disc type

Temp.coeff. P350~N1000, 50V

3 Capacity value

capacitor

Disc type

Temp.chara. 2B4, 50V

One-way lead typeTolerance ±20%

6 Working voltage

2200µ F ..... 228

One-way type, Mylar ±10% 50V

7 Capacity value

NOTE ON SAFETY FOR FUSIBLE RESISTOR :

The suppliers and their type numbers of fusible resistors are as

follows ;

1 . KOA Corporation

Part No.(MJI) Type No.(KOA) Descr iption

NH05 x x x 140 RF25S x x x x Ω J(±5% 1/4W)

NH05 x x x 120 RF50S x x x x Ω J(±5% 1/2W)

NH85 x x x 110 RF73B2A x x x x Ω J(±5% 1/10W)

NH95 x x x 140 RF73B2E x x x x Ω J(±5% 1/4W)

Resistance value Resistance value(0.1 Ω- 10k Ω)

2. Matsushita Electronic Components Co., Ltd

Part No.(MJI) Type No.(MEC) Description

NF05 x x x 140 ERD-2FCJ x x x (±5% 1/4W)

RF05 x x x 140

NF02 x x x 140 ERD-2FCG x x x (±2% 1/4W)

RF02 x x x 140

Examples :

Resistance value

0.1 Ω....... 001 10 Ω...... 100 1k Ω.. 102 100k Ω .... 104

0.5 Ω....... 005 18 Ω...... 180 2.7k Ω.. 272 680k Ω .... 684

1 Ω.......010 100 Ω...... 101 10k Ω.. 103 1M Ω .... 105

6.8 Ω....... 068 390 Ω...... 391 22k Ω.. 23 4.7M Ω .... 475

Resistance value

ABBREVIATION AND MARKS

ANT. : ANTENNA BATT. : BATTERY

CAP. : CAPACITOR CER. : CERAMIC

CONN. : CONNECTING DIG. : DIGITAL

HP : HEADPHONE MIC. : MICROPHONE

µ -PRO : MICROPROCESSOR REC. : RECORDING

RES. : RESISTOR SPK : SPEAKER

SW : SWITCH TRANSF. : TRANSFORMER

TRIM. : TRIMMING TRS. : TRANSISTOR

VAR. : VARIABLE X ‘ T AL : CRYSTAL

NOTE ON SAFETY:

Symbol

Fire or electrical shock hazard.

Only original parts should be used to replaced

any part marked with symbol

. Any other

component substitution ( other than original

type), may increase risk of fire or electrical shock

hazard.

:

1) The above CODES(R , R , C ,C

NOTE

and C ) are omitted on the schematic diagram in

some case.

2) On the occasion, be confirmed the common par ts on the

parts list.

3) Refer to “Common Parts List” for the other common

parts(Rl05, DD4, DK4).

Page 47

3-44

5. ELECTRICAL PARTS LIST

BC101 /N1B 9965 000 06959 BEAD CORE BFS3550R2FD8 *FC900210R

BD101 4822 130 81248 S1WBA60 (1A 600V) *HD201400R

C100 /N1B 9965 000 00393 CE 47µF/50V KME (SMPS) EA47605020

C101 nsp PCX2 275V 0.1µF M nsp

C102 /N1B nsp PCX2 275V 0.1µF M nsp

C103 /N1B 9965 000 07003 68µF SHL SD 400V M FL BK7.5 *EA000980R

C104 nsp 0.022µF 50V Z F TA26 S nsp

C105 nsp 0.01µF D 630V K PE NI nsp

C106 nsp HIGH-VOL 100P/1KV SMPS nsp

C109 /N1B nsp 0.047µF S 50V J PE nsp

C114 /N1B nsp 3300PF 400V M E R(NK AD SD) nsp

C116 9965 000 07004 470µF KME 25V M FM5 EA47702520

C118 nsp 100M SMS 16V M FM5 nsp

C119 9965 000 00393 CE 47µF/50V EA47605020

C121 nsp 220U SMS 16V M FM5 nsp

C122 nsp 330PF 400V K B R nsp

C123 4822 124 23111 1000µF KME TYPE 16V M FM5 EA10801620

C124 4822 124 23111 1000µF KME TYPE 16V M FM5 EA10801620

C125 nsp 330µF SMS 10V M FM5 nsp

C126 9965 000 07004 470µF KME 25V M FM5 EA47702520

C127 /N1B nsp 220µF SMS 25V M FM5 nsp

C128 nsp 0.047µF S 50V J PE nsp

C129 nsp 470µF SHL_SD 10V M FM5 nsp

C130 nsp 100M SMS 16V M FM5 nsp

C131 nsp 100M SMS 16V M FM5 nsp

C134 nsp 100M SMS 16V M FM5 nsp

C137 nsp 470µF SHL_SD 10V M FM5 nsp

C140 nsp 470µF SHL_SD 10V M FM5 nsp

C201 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C203 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C205

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C207

C210 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C221 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C223 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C224 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C226 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C227 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C228 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C229 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C232 4822 124 11383 10µF 6.3V M 3216 EY10600650

C237

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C239

C240 nsp 2200PF 50V K X7R(X) 1608 nsp

C241 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C242 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C245 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C250 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C255

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C260

C270 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C271 4822 124 11383 10µF 6.3V M 3216 EY10600650

C272 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C273 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C274 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C275 4822 124 11383 10µF 6.3V M 3216 EY10600650

C276 4822 124 11383 10µF 6.3V M 3216 EY10600650

C277 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C278

4822 124 11383 10µF 6.3V M 3216 EY10600650

C281

C284 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C285 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2A0 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2A1 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2A2 nsp 2200PF 50V K X7R(X) 1608 nsp

C2A3

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2A8

C2A9 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2B0 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2B1 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2B2 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

POS. VERS. PART NO. DESCRIPTON PART NO.

NO. COLOR (ANAM) (MJI)

C2B3 /N1B nsp GRM39Y5V473Z25C500 PT266 nsp

C2B4 nsp 560PF 50V K NP0 1608 nsp

C2B5 nsp 560PF 50V K NP0 1608 nsp

C2B6 nsp 0.033µF 50V K X7R(X) 1508 nsp

C2B7 nsp 0.033µF 50V K X7R(X) 1508 nsp

C2B8 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2B9 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2C0 nsp 220P 50V J COG 1.6X0.8 nsp

C2C1

nsp 2200PF 50V K X7R(X) 1608 nsp

C2C4

C2C5 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2C8 nsp 33P 50V J COG 1.6X0.8 nsp

C2C9 nsp 33P 50V J COG 1.6X0.8 nsp

C2D2

4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C2D4

C2D5 4822 124 11383 10µF 6.3V M 3216 EY10600650

C2D6 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2D7 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2D9 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2E1 nsp 3900PF 50V K Z5U(E) 1608 nsp

C2M1 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C2M2 nsp 6800P 50V K X7R 1.6X0.8 nsp

C2M3 nsp 4700PF 50V K X7R(X) 1608 nsp

C2M4

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2M9

C2N1 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C2N2 /N1B nsp GRM39X7R103K50C500 PT266 nsp

C2N3 nsp 0.022µF 50V Z Y5V(F) 1508 nsp

C2N4 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C301 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C302 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C303 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C304 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C305

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C330

C331 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C332

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C338

C340 /N1B nsp 10µF 10V M 3216 TP(-) nsp

C341 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C342 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C343 nsp 22P 50V J COG 1.6X0.8 nsp

C344 nsp 22P 50V J COG 1.6X0.8 nsp

C346 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C347 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C348 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C349

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C355

C356 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C357

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C359

C360 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C361 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C362 4822 124 11435 22µF 6.3V M 3528 EY22600650

C363 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C364 4822 124 11435 22µF 6.3V M 3528 EY22600650

C365 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C366 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C367 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C368 4822 124 11435 22µF 6.3V M 3528 EY22600650

C369 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C370 4822 124 11435 22µF 6.3V M 3528 EY22600650

C371 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C372 4822 124 11435 22µF 6.3V M 3528 EY22600650

C373 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C401 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C402

nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C404

C406 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C407 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

POS. VERS. PART NO. DESCRIPTON PART NO.

NO. COLOR (ANAM) (MJI)

Page 48

3-45

C408 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C409 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C410 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C411 /N1B nsp GRM39X7R102K50-500 PT266 nsp

C412 nsp 100P 50V J COG 1.6X0.8 nsp

C413 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C415 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C416 /N1B nsp GRM39X7R102K50-500 PT266 nsp

C417 nsp 100P 50V J COG 1.6X0.8 nsp

C418 nsp 3900PF 50V K Z5U(E) 1608 nsp

C419 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C420 nsp 3900PF 50V K Z5U(E) 1608 nsp

C421 4822 124 11131 47µF 6.3V M 85STD(CYL) EY47600620

C423 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C424 /N1B nsp GRM39X7R103K50C500 PT266 nsp

C427 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C428 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C429 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C430 9965 000 07005 100µF 16V M 85STD(CYL) EY10701660

C501

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C504

C506

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C509

C512

nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C514

C515

nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C517

C518 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C519 nsp 2.2000µF 16V Z Y5V(F) 3216 nsp

C520 nsp 220P 50V J COG 1.6X0.8 nsp

C521 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C522

nsp 220P 50V J COG 1.6X0.8 nsp

C527

C529 nsp 220P 50V J COG 1.6X0.8 nsp

C531 nsp 220P 50V J COG 1.6X0.8 nsp

C532 nsp 220P 50V J COG 1.6X0.8 nsp

C534 nsp 56P 50V J COG 1.6X0.8 nsp

C535 nsp 0.1µF 50V Z Y5V(F) 1508 nsp

C536 9965 000 03911 10µF 16V M 3528MM TP(-) EY10601670

C606 nsp 0.01M 16V M Y TA26 nsp

C608 /N1B nsp 0.047M 50V Z F TA26 nsp

C901 nsp 0.1µF 50V Z F TA26 D nsp

C902 nsp 10µF SMS 16V M FM5 nsp

C903 nsp 33P 50V J SL TA26 nsp

C904 nsp 33P 50V J SL TA26 nsp

C906 nsp 47M SMS 50V M FM5 nsp

C907 nsp 10µF SMS 16V M FM5 nsp

C909 nsp 0.1µF 50V Z F TA26 D nsp

C910 nsp 0.1µF 50V Z F TA26 D nsp

C912

nsp 47M SMS 16V M FM5 nsp

C914

D101 /N1B 4822 130 81244 ERA22-10 *HD201480R

D102 /N1B 9965 000 06965 EU01W *HD201390R

D106 9965 000 06966 RU3YXLF-C1 *HD201470R

D107 /N1B 9965 000 06965 EU01W *HD201390R

D108 /N1B 9965 000 06965 EU01W *HD201390R

D109 9965 000 06968 B10A45V1 *HD201440R

D110 9965 000 06971 ERA18-02KFRB *HD201460R

D113 4822 130 33765 1N5402 *HD201450R

D114 9965 000 06973 RL104 *HD201430R

D2A1 4822 130 33944 DAN202K HZ20002210

D601 /N1B 4822 130 32778 1SS133 HD20015210

D909 4822 130 32778 1SS133 HD20015210

DIG901

9965 000 06975 7-BT-273GN *HQ300420R

F101 /N1B 4822 070 31602

1600MA 250 V 5.2X20 CY/GL SEMK

*FS000740R

F102 /N1B 4822 252 51025 ICP-N10 T104 FU40115020

F103 nsp D=0.6 ROLL nsp

F603 nsp CFI06B1H101MF 2.5K/T nsp

F604 nsp CFI06B1H101MF 2.5K/T nsp

POS. VERS. PART NO. DESCRIPTON PART NO.

NO. COLOR (ANAM) (MJI)

FH101

nsp FUSE CLIP nsp

FH102

nsp FUSE CLIP nsp

IC101 9965 000 06978

STR-G6153T 5PIN FM CUT BK PWM

*HC106630R

IC102 /N1B 4822 130 11545

PC123Y PHOTO-COUPLER(SARPH)

*HC200110R

IC104 4822 209 81397 KA431AZ *HC105750R

IC105 9965 000 06979 KA78R08 *HC300250R

IC106 9965 000 06980 PQ3RD13 *HC105730R

IC107 9965 000 06980 PQ3RD13 *HC105730R

IC201 9965 000 06984 GDC25D801C *HC105650R

IC203 4822 209 90472 NJM3414AM-TE1_3K HC10179090

IC204 9322 119 37685 TC4W53FU *HC105800R

IC205 /N1B 9965 000 06985

GLT440L16-40J4 40P SOJ TP 4M(2

*HC106620R

IC2A1 9965 000 06986 SSI33P3721(VER.2) *HC105760R

IC2A2 4822 209 90472 NJM3414AM-TE1_3K HC10179090

IC2A3 5322 209 12918 AD8011AR *HC105540R

IC2M1 9965 000 06987 KA3032 *HC105610R

IC301 9965 000 06988 ZIVA3-PE0 *HC105590R

IC302 9965 000 06989 GM72V161621ET-7 *HC105630R

IC303 9965 000 06989 GM72V161621ET-7 *HC105630R

IC304 9965 000 06990 PLL1700E *HC105570R

IC305 9965 000 06991 SAA7128 *HC105690R

IC306 9965 000 04716 BA7660FS *HC105700R

IC307 9965 000 04716 BA7660FS *HC105700R

IC401 8203 303 11278 PCM1716E *HC105580R

IC402 9965 000 04714 NJM4580M *HC105660R

IC403 4822 209 33521 TC7W04FU HC10382050

IC404 9965 000 06992 PQ20WZ5U *HC105720R

IC501 9965 000 06993 HD6417034AFI20 *HC105640R

IC502 /N1B 9965 000 06994 AT49F8192A-90TC (/N1B) *HC106600R

IC503 /N1B 9965 000 06995

M11B416256A-35J ELITE 4M(256K)

*HC106610R

IC504 9965 000 06996 KS24C021CS *HC105740R

IC505 9965 000 06997 SN74AHC374PWLE *HC105770R

IC506 9965 000 06292 XC9536-15VQ44C-PROGRAM HC10102990

IC901 9965 000 06998 LC866112B-5R54 *HC105710R

IC902 9965 000 06999 KIA7042P *HC105670R

JK602 /N1B 9965 000 07000

RCA DIN-09G YUQIU D.GND R4P+DI

*YT002250R

JK603 /N1B 9965 000 07001 1F-21P 3.81 ANGLE(BLACK) *YT002260R

L101 9965 000 07002 SHT LFS2020V4-04350 *FN000110R

L102 nsp CHOCK(22MH) 5MM nsp

L103 nsp CHOCK 20UH nsp

L201

nsp HB-1M2012-102JT 3K nsp

L204

L207 nsp HB-1M2012-102JT 3K nsp

L208 nsp HB-1M2012-102JT 3K nsp