Marantz DR-6000 Service Manual

Service

DR6000 /F1N, /K1G, /N1G

/K1B, /N1B, /U1B

Manual

STANDBY

ON/OFF

POWER

REMARK : This service manual explains them by extracting specifications

designed for the model DR6000 only. The explanation for CD-R module

"MAR770" (Loader : CDL4009' + CD-R Main board) is not mentioned on this

service manual.

The CD-R module information is described in the service manual of CD-R

modules <MAR770/MAR775>.

CD RECORDER DR6000

Recordable

ReWritable

DISPLAY SCROLL

OPEN/CLOSE

SOURCE ERASE

Compact Disc Recorder

REC TYPE REW FF

EASY JOG

CANCEL

STORE

FINALIZE

DELETE

MENU

PUSH ENTER

REC

PLAY/PAUSESTOP

LEVEL PHONES

-+

DR6000

TABLE OF CONTENTS

SECTION PAGE

MAIN UNIT

1. Servicing the DR6000 ................................................................................................................................ 1

2. TECHNICAL SPECIFICATIONS ............................................................................................................... 3

3. WARNINGS .............................................................................................................................................. 4

4. SERVICE HINTS AND TOOLS ................................................................................................................. 5

5. SIAGNOSTIC SOFTWARE ....................................................................................................................... 6

6. FAULTFINDING TREES ......................................................................................................................... 11

7. FAULTFINDING GUIDE .......................................................................................................................... 15

8. WIRING DIAGRAM ................................................................................................................................. 25

9. BLOCK DIAGRAM ................................................................................................................................... 27

10. SCHEMATIC DIAGRAM AND PARTS LOCATION ................................................................................. 29

11. EXPLODED VIEW AND PARTS LIST ..................................................................................................... 37

12. ELECTRICAL PARTS LIST ..................................................................................................................... 40

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

R

Printed in Japan

DR6000

385K855010 MIT

3120 785 22360

First Issue 2000.08

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

WILDASH AUDIO SYSTEMS NZ

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIP DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

991207MIT

1.Servicing the DR6000

1.1 INTRODUCTION:

The DR6000 is the consumer version of a CD recorder, this means that the SCMS (Serial Copy Management System) is

included. The DR6000 can only record on the Audio CDRs (Consumer Use).

The DR6000 is suitable for recording and playback of CD-RW discs (CD-Re Writable disc).

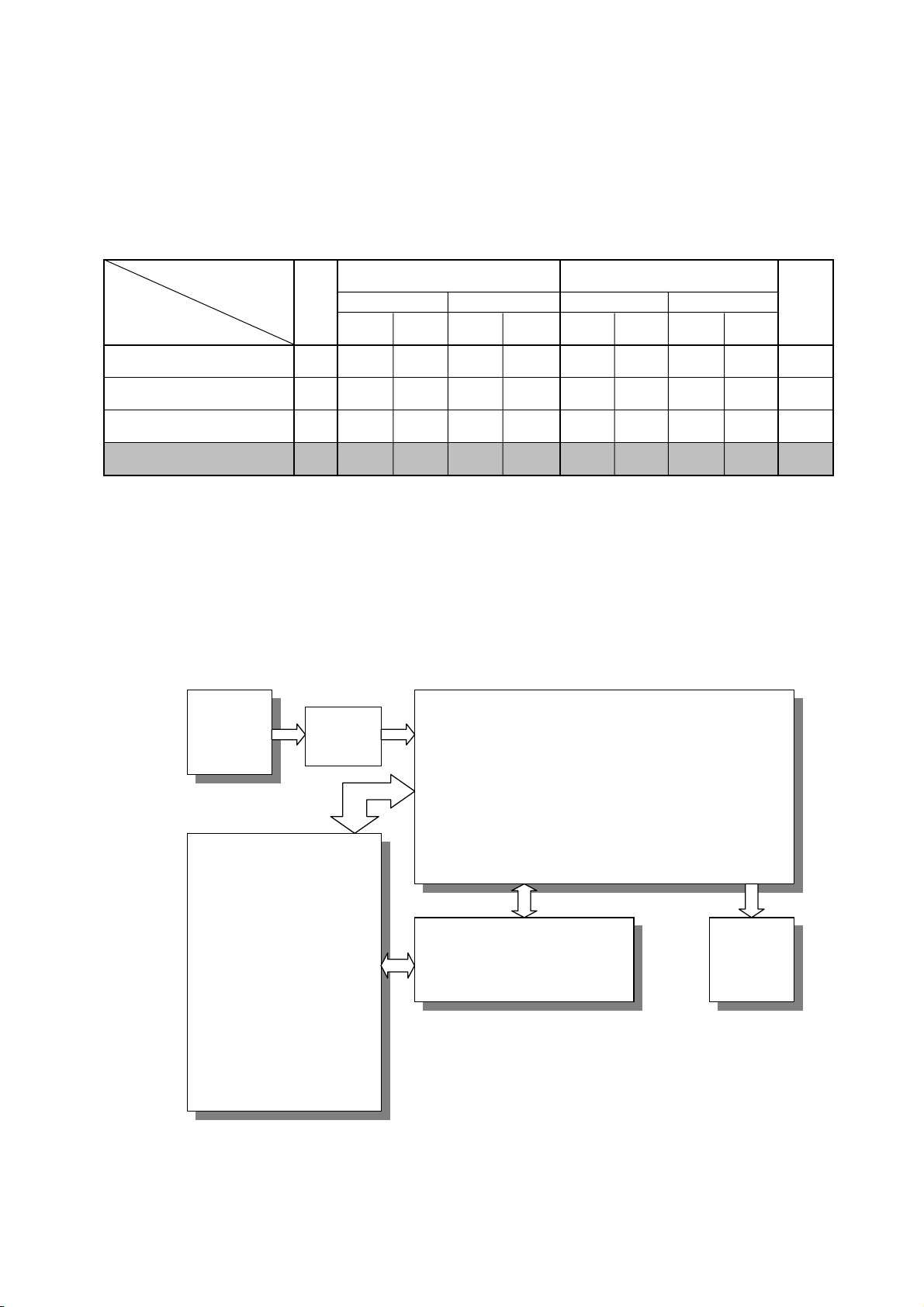

Playback & Recording and Disc

Disc

Player/Recorder

Audio CD Player

Current products Ex:CD-17

Audio CD Player

CD-RW playback Ex:CD-17MK II

CD-RW Recorder

For Professional Ex:CDR630/640

CD-RW Recorder

For Consumer Ex:DR6000

CDR

CD

Consumer Disc

Finalized

non

Finalized

Professional Disc

Finalized Finalized

non

Finalized

Consumer Disc

Finalized

PP no P no no no no no -

PP no P no P no P no -

P P P/R P P/R P/R P/R P/R P/R no

P P P/R P no P/R P/R no no YES

CD-RW

non

Finalized

Professional Disc

non

Finalized

SCMS

Consumer : For Digital Audio

Professional : For General use (Including PC)

P : Playback

R : Recording

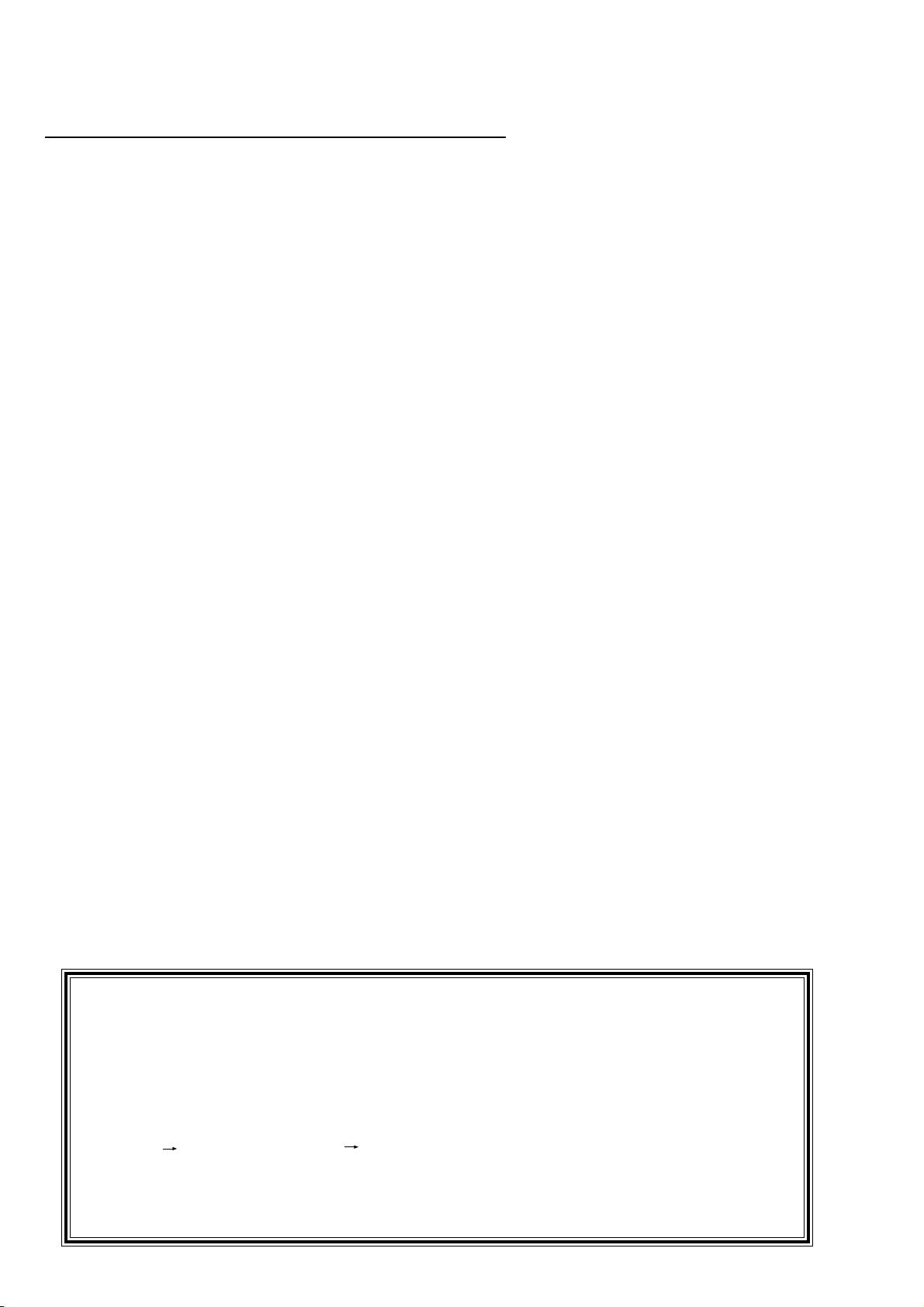

1.2 OPENING THE PRODUCT :

The product can be opened by removing the top cover (6 screws). Once the product is opened one can have access to the

several PCB's and the main module. To have access to the Display PCB, the Headphone PCB first the front cover has to

be removed (See dismantling instructions on page1-7).

POWER

SW

BOARD

Trans-

former

POWER SUPPPLY

and

AUDIO

BOARD

MOTER

BOARD

CDR LOADER

DISPLAY BOARD

Below the several PCB's and it function and service policy will be discussed:

1

HEAD

PHONE

BOARD

1.2.1 CDR loader (CDR main module CDL4009 or MAR770):

This complete CDR loader is considered as not repairable in the field. therefore this module will be repaired centrally. A

module exchange procedure will be set up for this purpose. The module can be removed from the product by removing 4

screws and the transformer (see demounting the CDR module on page 1-7), and loosing the connectors.

This module is the complete CD recorder, it contains the following parts:

CD Mechanism (CDM4009'). Underneath this mechanism a PCB is mounted which is adjusted to the mechanism (laser

current settings are stored in EEPROM).

Loader Assy. This mechanical assy takes care for the tray control.

Main PCB. This PCB takes care that the (analog or digital) signal to be recorded is converted into a suitable signal which

can be recorded on the disc.

Digital signals with an other sampling frequency then 44.1kHz will be converted in the sample rate converter (DASP) to

44.1kHz.

Analog signals will be first converted into a digital converter by the AD converter.

This PCB also takes care that the signal from the CD (playback) is converted into a suitable digital signal (or analog via

the DA converter).

The main microprocessor controls the several functions of this PCB.

1.2.2 Power SW Board.

This PCB contains the Power SW, which is jointed the Power bottom on the front panel. All parts are available as spare

parts.

1.2.3 Power Supply and Audio Board.

This PCB consists of power supply part and audio part. The power suppluy part delivers the several voltages for the diffrent

PCB in the DR6000. On this power supply sevel fuses (secondary side) are mounted on this PCB. The audio part takes care

that the signal from CDR main module is converted into an analog signal via DA converter and outputs the analog signal.

This PCB contains the output and input connectors also. All parts are available as spare parts.

1.2.4 Display Board.

This PCB contains the Display, which informs the user about the status of the recording/playback process and it also takes

care for scanning the keys on the front panel. The information from the keys is fed via a I C connection to the main

microprocessor on the CDR loader module. Information which needs to be displayed is also fed via this I C line from the

main microprocessor on the CDR loader module to the display controller.

The parts for this PCB are available as service parts so this PCB can be repairable up to component level.

2

2

1.2.5 Headphone Board.

This PCB contains the headphone socket and potentiometer which controls the headphone volume. All parts are available

as spare parts.

IMPORTANT

In case of replace the CD-R module "MAR770", the initialization is necessary.

Please initialize the CD-R module with following orders.

1. Press the POWER button (POWER ON) while depressing FINALIZE button and REC

TYPE button together.

2. FL Display shows;

WAIT

PGM PROTOCOL

PGM PORT END

3. Press the POWER button (POWER OFF).

Then the CD-R module set up to DR6000 own status.

2

2 TECHNICAL SPECIFICATIONS

GENERAL

System .................................................................................................... Compact disc digital audio

Number of channels ................................................................................ 2 (stereo)

Applicable discs ...................................................................................... CD, CD-R (digital audio), CD-RW (digital audio)

Power Requirement

F version ........................................................................................... AC 100 V 50 / 60 Hz

K version ........................................................................................... AC 110 V / 220 V 50 /60 Hz

N version ........................................................................................... AC 230 V 50 Hz

U version. .......................................................................................... AC 120 V 60 Hz

Power Consumption ................................................................................ 24 W

Operating Temperature . ......................................................................... 5 °C - 35 °C

Dimension (MAX)

Width ................................................................................................. 440 mm

Height ................................................................................................ 87 mm

Depth ................................................................................................ 317 mm

Weight ................................................................................................ 4.6 kg

AUDIO

Frequency Response ............................................................................. 20 Hz - 20 kHz

Playback S/N .......................................................................................... 105 dB

Playback Dynamic Range ....................................................................... 96 dB

Playback Total Harmonic Distortion ........................................................ 90 dB

Recording S/N (analog) .......................................................................... 90 dB

Recording Dynamic Range (analog) ....................................................... 92 dB

Recording Total Harmonic Distortion (analog) ........................................ 84 dB

Analog Output Voltage ............................................................................. 2 Vrms

Digital Coaxial Output ............................................................................. 0.5 V (p-p) / 75 ohms

Digital Optical Output .............................................................................. - 20 dB

Headphones ............................................................................................ 0 - 5 Vrms / 8 - 2000 ohms

Recording values for line input

Digital Coaxial Input (automatic sample rate conversion) ....................... 32 - 48 kHz

Digital Optical Input (automatic sample rate conversion) ........................ 32 - 48 kHz

Analog Input ............................................................................................ 560 mVrms / 50 kohms

Specifications subject to change without prior notice.

3

3. WARNINGS

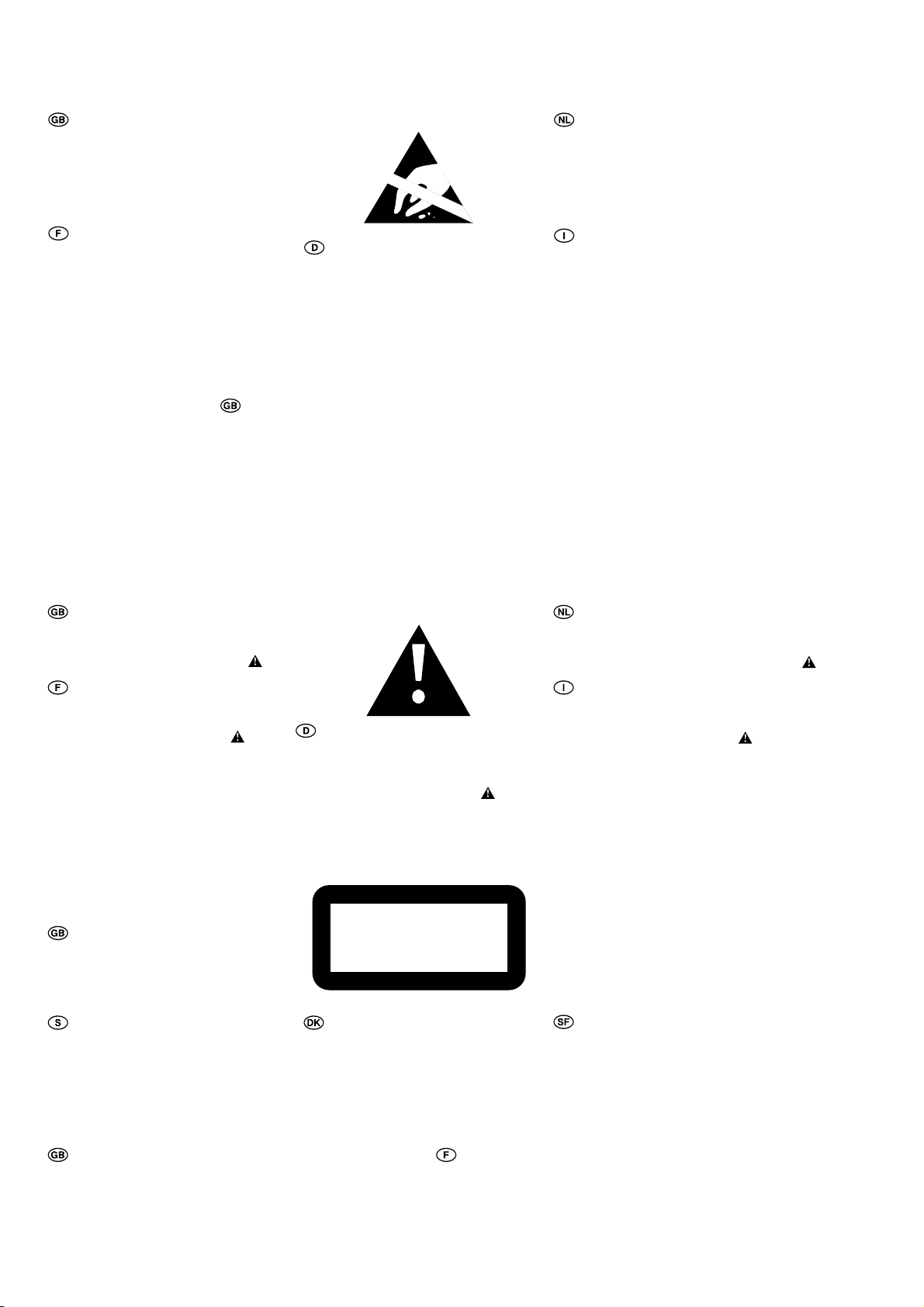

WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1M ) 4822 320 11307

extendible cable (2m, 2M , to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2M , to connect table mat to connection box) 4822 320 11306

earth cable (1M , to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

ESD

WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

small 600x650x1.25mm 4822 466 10958

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

DANGER: Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Varning !

Advarsel !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

LASER PRODUCT

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

SAFETY

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

CLASS 1

Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

4

4. SERVICE HINTS AND TOOLS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

Hexagon socket screw button (No. 1.5)

5

5. Diagnostic Software

5.1 Dealer mode

The purpose of the dealer mode is to prevent people taking out

the CD inside the player at exhibitions, showrooms etc.. This

mode disables the open/close function of the player.

The dealer mode can be switched on and off pressing keys

[OPEN/CLOSE] and [STOP] of the CDR player simultaneously

while switching on the unit. The dealer mode is stored in the

flash memory and can only be changed by executing the above

actions.

5.2 Dealer diagnostics

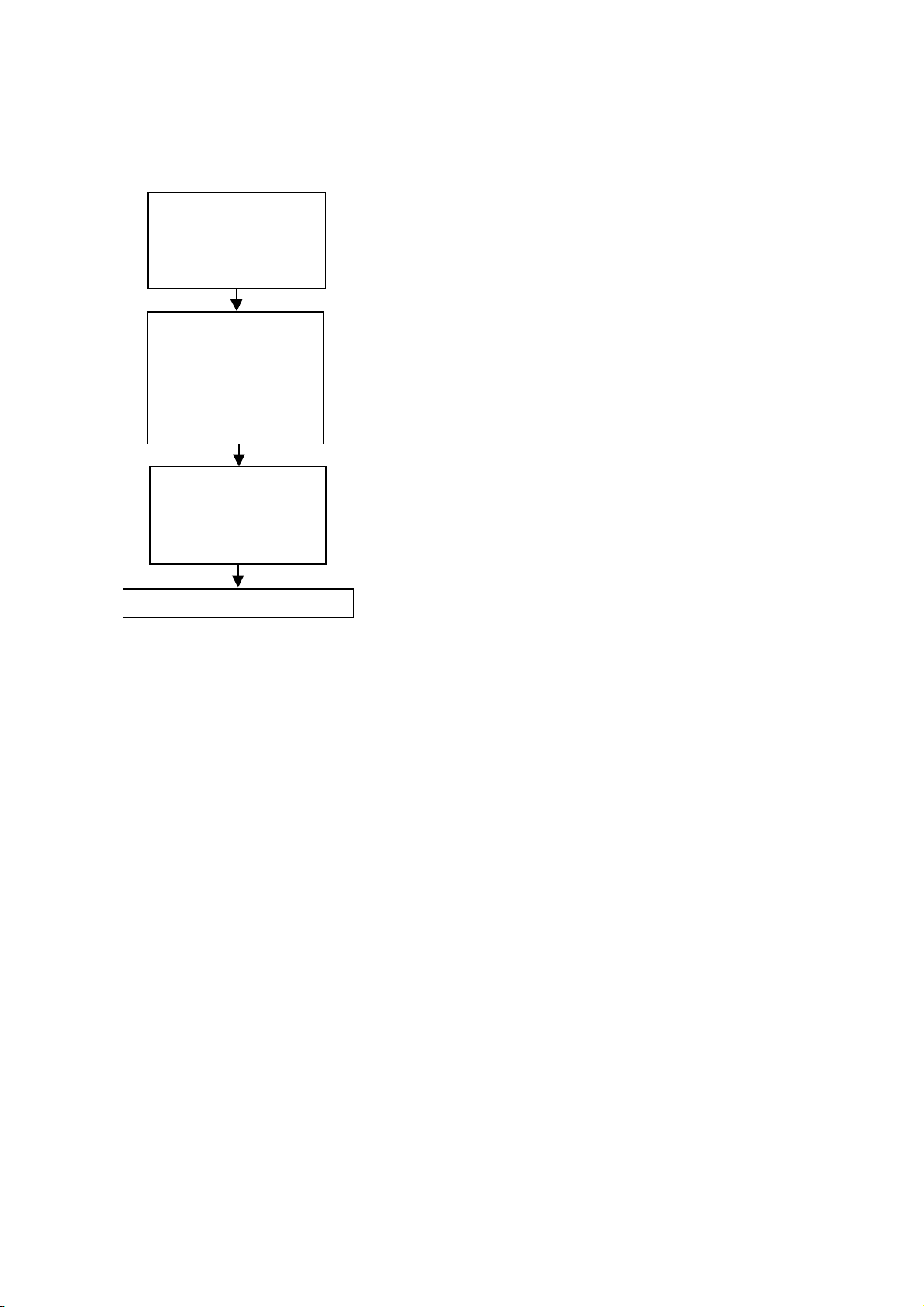

Press <REWIND> + <FFWD>

simultaneously and switch

ON unit

Display blinks

“BUSY”

during test

NO

Set OK?

YES

Set displays

“

PASSED

To end test, switch OFF unit

”

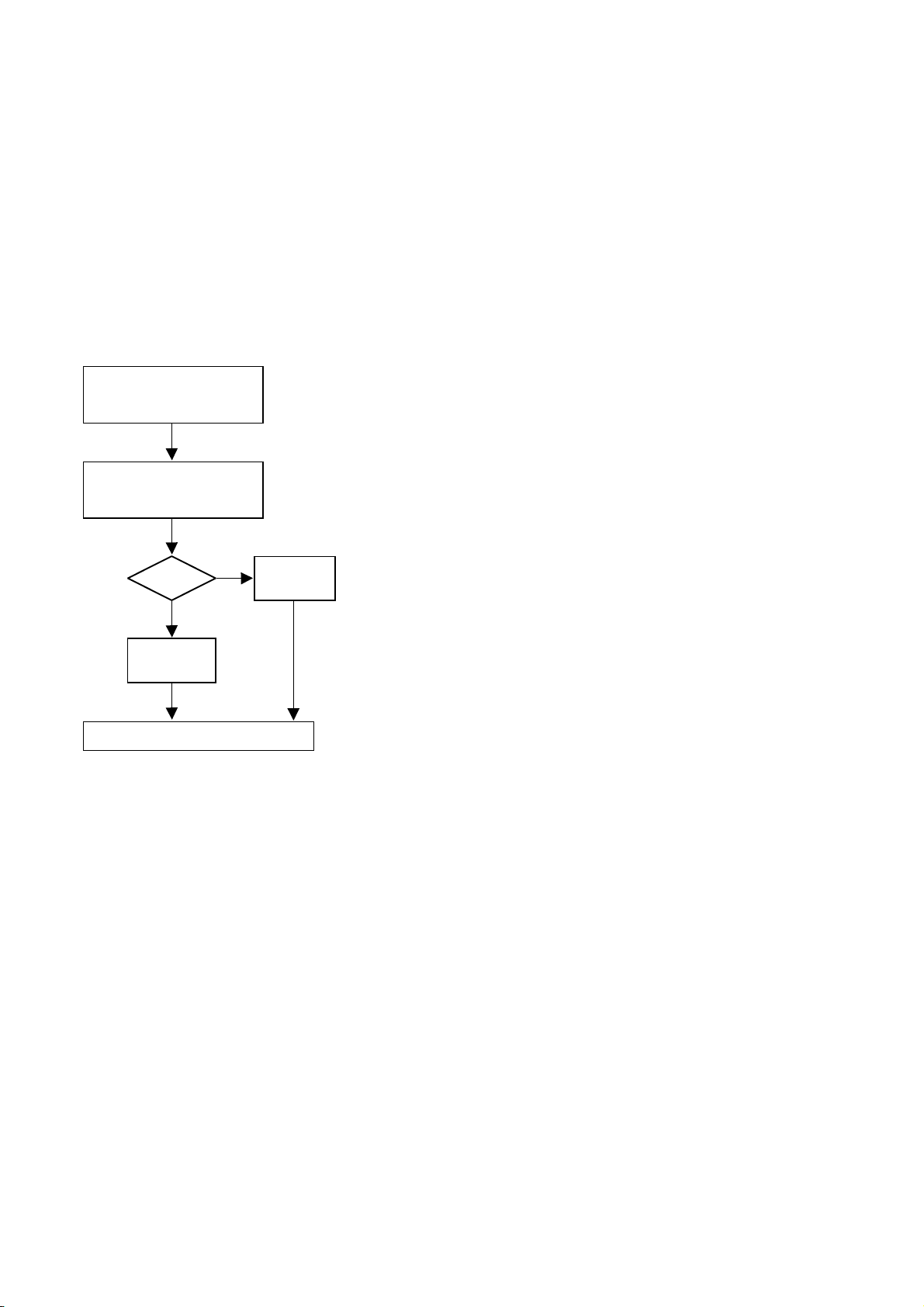

Figure 5-1

Set displays

“ERROR”

5.2.1 Description

The intention of the dealer diagnostics is to give an indication

of the CDR player status. An inexperienced, even non-technical

dealer will/can perform the test. Tests are executed

automatically without need for external tools or disassembly of

the unit. This test checks the CDR main board using the same

tests as the electrical service diagnostics program. Only the

result of the test, "PASSED" or "ERROR", will be shown on the

display. Pressing keys [F FWD] and [REWIND] simultaneously

while switching on the unit, starts the test. Switching off the unit

ends the test.

5.2.2 Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

6

5.3 Electrical service diagnostics

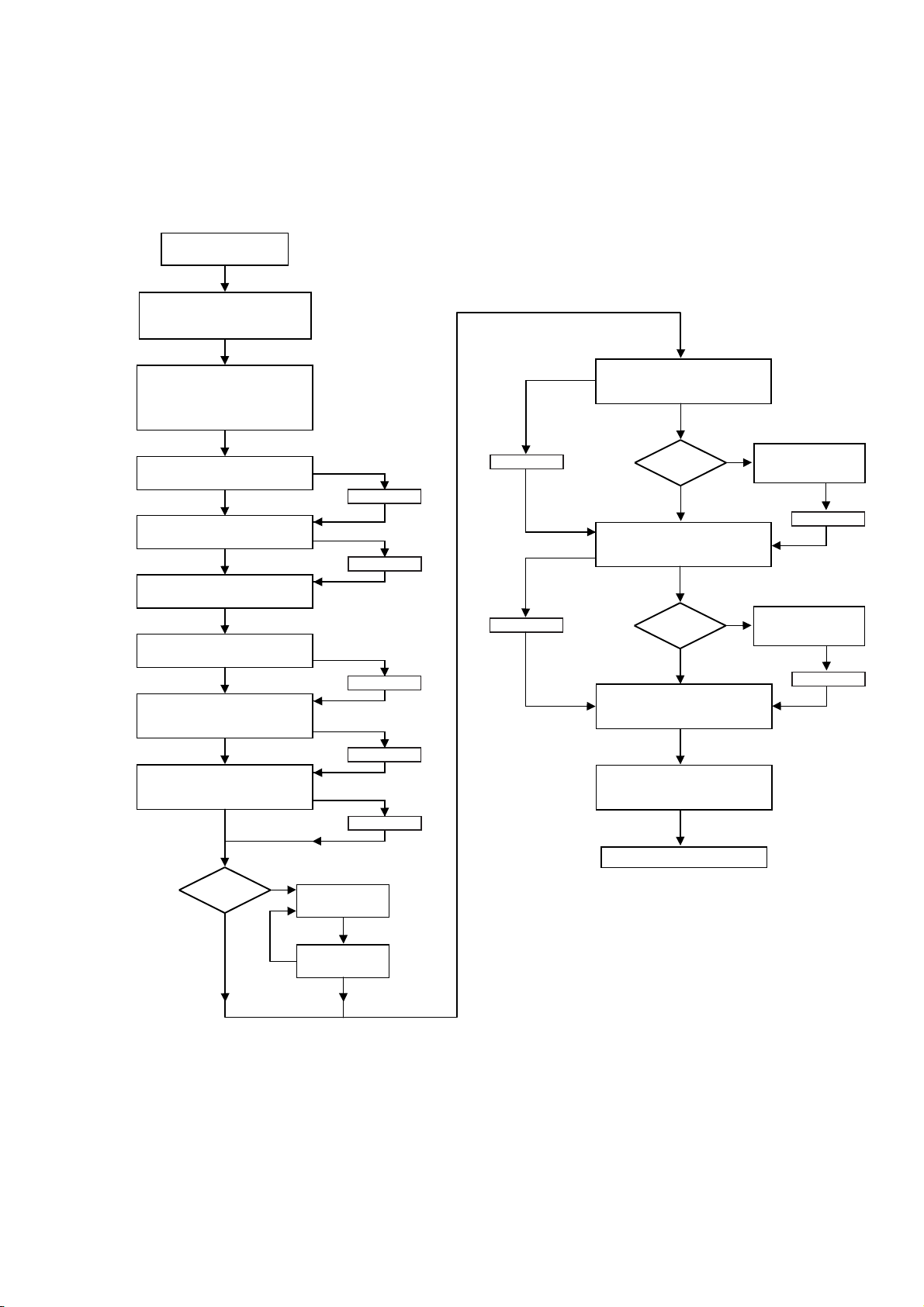

ELECTRICAL SERVICE DIAGNOSTICS

(software versions, test for defective components)

If power ON,

switch power OFF

Load CD-DA disc (SBC444A)

Press <PLAY> + <F FWD>

simultaneously and switch ON unit

PLAYER

INFORMATION

Display :

"PLAYER ID"

"SW VERSION BACK END"

"SW VERSION CDR LOADER"

(DR6050

CDR MAIN

BOARD TEST

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

Display :

PASS OR FAIL

"SW VERSION CD LOADER"

"DTST1"

DRAM test (7702)

"DTST2"

FLASH CHECKSUM test (7702)

"DTST3"

FLASH ERASE test (7702)

"DTST4" *

CODEC test (7702)

"DTST5"

CDR LOADER

COMMUNICATION test

"DTST5"

*

CD LOADER

COMMUNICATION test

* FOR DR6050 ONLY

)

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

LOADER TESTS

CDR LOADER TEST

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

CD LOADER TEST *

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

DISPLAY TEST

DISPLAY TEST

Display segments blink at f=1Hz

KEYBOARD &

RC TEST

KEYBOARD & RC TEST

Display shows name of pressed keys

Press <F FWD>

NO

Display :

or

or

* FOR DR6050 ONLY

NO

Display :

or

or

"BERR1"

"NO CDDA"

"NO DISC"

Press <F FWD>

"BERR2"

"NO CDDA"

"NO DISC"

Press <F FWD>

Tests OK?

YES

NO

Display :

"DERRn"

n = failed test

Display next

failed test

To end test, switch OFF unit

Figure 5-2

7

5.3.1 Description

The intention of the electrical service diagnostics is to show the

software versions present in the player and to direct the dealer

towards defective internal units. The units are : the CDR main

board, the CDR loader, the CD loader in case of a DR6050 and

the keyboard/display board. A sequence of tests is executed

automatically. Some of the tests can be aborted or skipped

without the result being taken into account. External tools or

disassembly of the unit is not necessary to get the diagnostic

information. Pressing keys [PLAY/PAUSE] and [F FWD]

simultaneously while switching on the unit, starts the test.

Switching off the unit ends the test.

Loader tests

These tests determine if the CDR loader and the CD loader in

case of a DR6050 work correctly. A CD-DA disc with a

minimum of 3 tracks needs to be inserted in both loaders. A

disc test is executed to check focus control, disc motor control,

radial control and jump grooves control. The disc test is

performed by audio play-back of 5 seconds at the beginning,

middle and end of the disc.

CDR loader test

During the test, the current disc time is shown. In case of an

error the message "BERR1" will be displayed and the [F FWD]

key must be pressed to continue with the following test.

Pressing the [F FWD] key also aborts this test.

5.3.2 Requirements to perform the test

• Working keyboard to start up the test.

• Working local display to check the output messages.

• A CD-DA disc with a minimum of 3 tracks in all trays to

perform the disc test.

5.3.3 Description of the tests

Player information

In this part of the test the following important information can be

checked without removing the cover :

• Recorder ID.

• SW-version back end of player.

• SW-version CDR loader.

• SW-version CD loader (only for DR6050).

CDR main board test

As soon as the CDR main board tests are finished, all failure

messages (if any) will be displayed sequentially by pressing the

[F FWD] key. The message "DERRn" will be displayed with n

indicating the faulty test number.

If one of the tests is aborted with the [F FWD] key, no error

message will be displayed for this test. The flash data erase

test ("DTST3") can not be aborted !

The CDR main board test consists out of :

DRAM test

Display : "DTST1". The DRAM used for buffer management is

tested by writing, reading and verifying test patterns.

CD loader test

For CDR775 only. During the test, the current disc time is

shown. In case of an error the message "BERR2" will be

displayed and the [F FWD] key must be pressed to continue

with the following test. Pressing the [F FWD] key also aborts

this test.

Display test

All segments will blink at a frequency of 1 Hz. Pressing the [F

FWD] key will start the next test because the user has to check

for himself if all segments work properly.

Keyboard and remote control tests

The test will give the user the ability to test every key without

executing the function assigned to it. Therefore, the user needs

to press every key on the keyboard and the remote control. The

display will show the name of the key being pressed. Pressing

more than one key at once will give an unpredictable result

except for the service combinations : [PLAY/PAUSE] + [STOP],

[PLAY/PAUSE] + [F FWD], [F FWD] + [REWIND], [ERASE] +

[RECORD], [PLAY/PAUSE] + [RECORD].

Flash checksum test

Display : "DTST2". This test checks the checksum of the

player's SW stored in the flash.

Flash data erase

Display : "DTST3". During this test, all temporary information

(CDtxt) in the flash is erased.

CODEC (ADC/DAC) test

Display : "DTST4". This test checks the CODEC IC by writing,

reading and verifying test patterns. The test is not applicable for

CDR950.

CDR communication test

Display : "DTST5". The communication between the host

processor (DASP) and the CDR loader via the DSA-R-bus is

tested.

CD communication test

Display : "DTST6"). The communication between the host

processor (DASP) and the CD loader is tested. The test is only

applicable for DR6050.

8

5.4 Mechanical service diagnostics

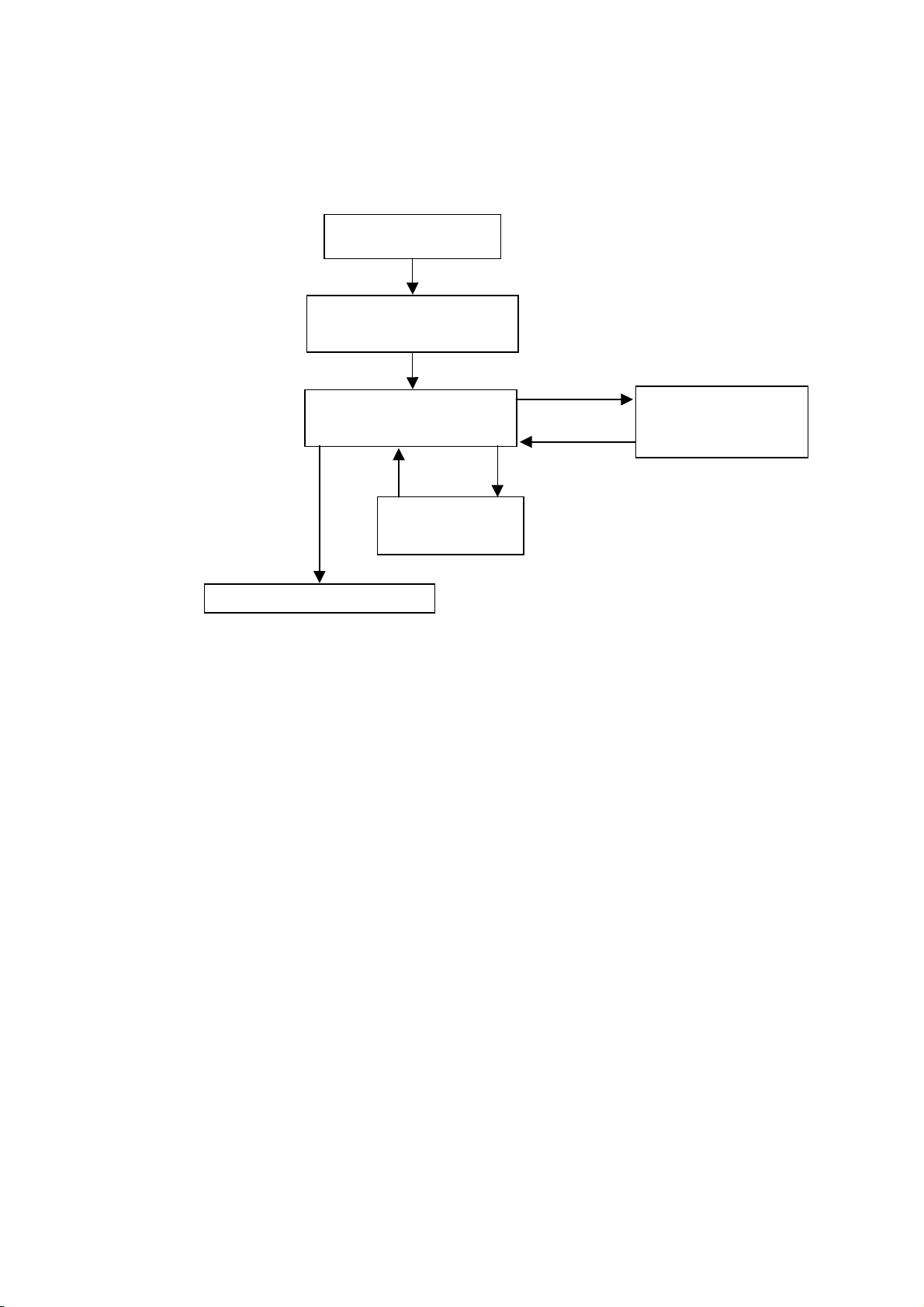

MECHANICAL SERVICE DIAGNOSTICS

(test for defective components)

If power ON,

switch power OFF

Press <PLAY/PAUSE> + <STOP>

simultaneously and switch

To end test, switch OFF unit

ON unit

FOCUS TEST

Display shows

Visual inspection

SLEDGE TEST

Visual inspection

Display shows

“BUSY”

“BUSY”

<

OPEN

>

<

CLOSE

>

<FWD><REWIND>

TRAY TEST

Visual inspection

Display shows

even if tray is blocked

“OPENED”

5.4.1 Description

No external tools are required to perform this test. The cover

needs to be removed because the user has to check the

movements of the tray, focus and sledge visually. Pressing

keys [PLAY/PAUSE] and [STOP] simultaneously while

switching on the unit, starts the test. Switching off the unit ends

the test. In case of a DR6050, one can check the CD loader

mechanics in the same way by pressing the above key

combination on the CD player keys.

5.4.2 Requirements to perform the test

• Working keyboard to cycle through the tests and to start up

the test.

• Working local display to check the output messages.

5.4.3 Description of the tests

Focus control test

The focussing lens is continuously moving up and down. The

display reads "BUSY".

Sledge control test

After pressing [F FWD] the sledge continuously moves up and

down. Pressing [REWIND] stops the sledge at the position it is

in and the focus control test resumes. The display reads

"BUSY".

Figure 5-3

pressing [F FWD]. One has to stop these tests pressing

[REWIND] before it is possible to close the tray again.

Depending on the action the display reads "OPEN",

"OPENED", "CLOSE" or "BUSY".

Tray control test

This test starts from within the focus control test routine.

Pressing [OPEN/CLOSE] moves the tray in or out. In the tray

open position one can initiate focus and sledge tests by

9

5.5 DC-erase service mode

DC ERASE SERVICE MODE

(erasement of complete CD-RW)

Load CD-RW disc

<ERASE> + <RECORD>

simultaneously and switch

Display shows:

“

ER mm:ss

Press

ON unit

”

mm

ss :remaining seconds

TOTAL

illuminated

To end test, switch OFF unit

:remaining minutes

and

REM

are also

Display shows:

“

when the erase function is

PASSED

completed

ERROR

“

if DC ERASE fails

Figure 5-4

”

”

5.5.1 Description

This test is initiated by pressing [ERASE] and [RECORD]

simultaneously while switching on the unit. The player will

erase a complete CD-RW disc (including PMA and ATIP lead

out area) at speed N=2. The display shows the countdown of

the remaining time required for the operation to complete. The

format is "ER mm:ss", where "mm" are the remaining minutes

and "ss" the remaining seconds. After completion the message

"PASSED" is shown, and the player has to be switched off and

on again to start up in normal operating mode. Switching off the

unit before completion of the test, leaves the disc in an

unpredictable state. In such case only a complete DC-erase

procedure can recover the CD-RW disc.

5.5.2 Requirements to perform the test

• Functional CDR player.

• A CD-RW audio disc must be present in the tray.

10

Loading...

Loading...