Marantz DR-4160 Service Manual

Service

DR4160 /F1N, /U1B

Manual

PLAY/PAUSE

CD RECORDER DR4160

REPEAT

CD TEXT

CD1

DISPLAY

SHUFFLE

/

+

–

LEVEL

CD CHANGE

CD2

CD3

MULTI

DISC

CHANGER

AUTO LEVEL CONTROL

PHONES

LEVEL

CD-TEXT EDITING

RECORD

CD→CD

REC

CDR

AUX

LEVEL

COMPLE CD

NO

REC TYPE

FINALIZE

ERASE

4822 725 25242

3104 125 40100

ON/OFF

STOP

OPEN/

CLOSE

MIC

SERVICING

For servicing DR4160, the sets can be divided into two parts:

1. Except for the Power board (Switched Mode Power Supply) and the CD-R/W module the set has to

be repaired on component level.

2. The Power board and the CD-R/W module will be exchanged completely in case of a failure.

The defective CD-R/W module has to be returned for central repair.

Available circuit descriptions:

The Basics of Compact Disc Recordable/Rewritable

3rd generation Compact Disc Recording

CD Recorder

TEXT

PROG

BALANCE

N

O

T

C

R

TR EDIT

O

G

L

O

J

+–

YES

OPEN/

CLOSE

DR4160

TABLE OF CONTENTS

chapter

Technical Specification and Measurement setup................1-1, 1-2

Location of printed circuit boards............................................1-3

Warnings & Safety..................................................................2-1

Dismantling Instructions.....................................................4-1 to 4-5

Service hints......................................................................5-1 to 5-3

Service Test Program........................................................5-4 to 5-6

BLOCK DIAGRAMS ..........................................................6-1 to 6-5

WIRING DIAGRAM.................................................................6-6

POWER BOARD (for orientation only) ..............................7-3 to 7-4

FRONT BOARD.................................................................7-5 to 7-6

KEY BOARD left.....................................................................7-7

KEY BOARD right...................................................................7-8

Please use this service manual with referring to the user guide (D.F.U) without fail.

修理の際は、必ず取り扱い説明書を準備し操作方法を確認の上作業を行ってください。

HEADPHONE/MICROPHONE BOARD ...........................7-9 to 7-10

chapter

INTERFACE BOARD......................................................7-11 to 7-13

3CDC MODULE................................................................8-1 to 8-9

EXPLODED VIEWS

apparatus..........................................................................10-1

3CDC module...............................................................8-8 to 8-9

MECHANICAL PARTSLIST see Exploded views

ELECTRICAL PARTSLIST...................................................10-2 ff

R

DR4160

437W855010 SIG

First Issue:2000.12

1-1

TECHNICAL SPECIFICATION

General:

Mains voltage:

120V / 60Hz for DR4160/U1B

Power consumption:≤16W

≤ 1W in stand by

Input / Output:

Analog in:

input sensitivity : ≤500mV

rms

max. input voltage : 2,8Vrms

input impedance : 47kΩ

Analog out:

output level : 2V

rms±2dB at no load

output impedance : 200Ω

Microphone in:

input sensitivity : ≤1mV

rms

max. input voltage : 50mVrms

input impedance : 2kΩ

Digital in (acc. IEC958):

input level : 0,5V

pp

input impedance : 75Ω

Digital out (acc. IEC958):

output level : 0,5V

pp

output impedance : 75Ω

Headphone:

output level : 4,4V

pp at no load

output impedance:120Ω

frequency response: 20 - 20.000 Hz ±3dB

distortion : 0,01% at 1 kHz and -6dB output level at 120Ω

channel difference : ≤ 3dB at 1 kHz

channel crosstalk : -50dB at 1kHz

AUDIO PERFORMANCE

3CDC module:

To be measured on ANALOG OUT socket.

frequency response : 20 - 20.000 Hz ±0,6dB

signal/noise ratio : ≥ 115dB (120dB A-weighted)

distortion : -88dB at 1 kHz (-91dB typ.)

channel difference : ≤ 0,5dB at 1 kHz

channel crosstalk : -115dB at 1kHz(-120dB typ.)

de emphasis : 0 or 15/50µs switched automatically by subcode on the disc

laser

output power : 500µW

wave length : 780 ±20nm

CD-RW module:

To be measured on ANALOG OUT socket.

frequency response : 20 - 20.000 Hz ±0,3dB (±1dB recording)

signal/noise ratio : ≥ 95dB (98dB A-weighted)

distortion : -86dB at 1 kHz (-83dB recording)

channel difference : ≤ 0,5dB at 1 kHz

channel crosstalk : -86dB at 1kHz (-74dB recording)

de emphasis : 0 or 15/50µs switched automatically by subcode on the disc

laser (laser class 3B)

output power : 1mW max. during reading

20mW max. during writing

wave length : 780 ±20nm

100V / 50-60Hz for DR4160/F1N

1-2

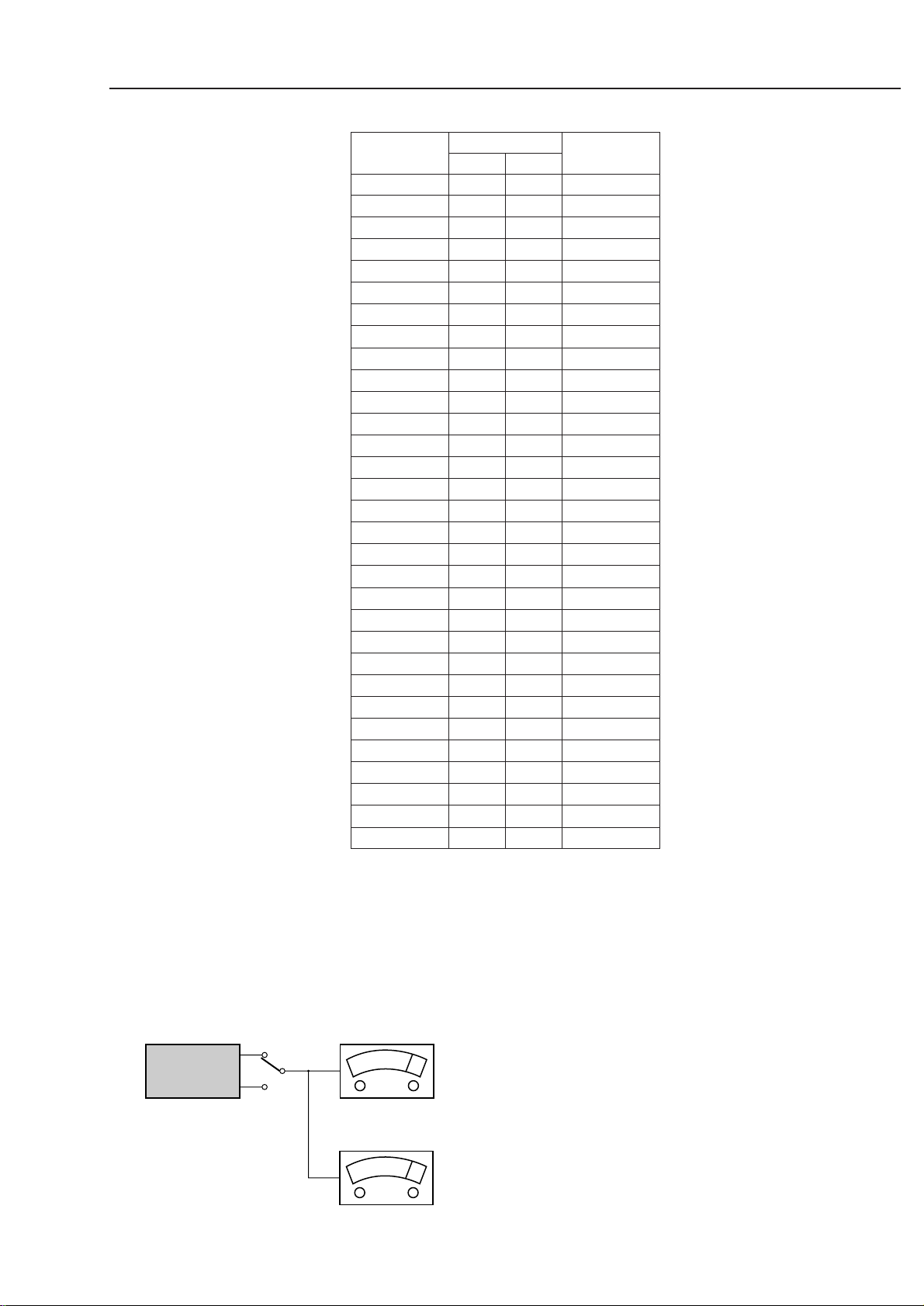

SYSTEM CODE

RC KEY

y

COMMAND CODE

CD

20 26 12

CDR

BRIGHTNESS

Standby

20 26 71

TRACK INCR.

- 26 114

CD TEXT

20 26 88

1

20 26 01

2

20 26 02

3

20 26 03

4

20 26 04

5

20 26 05

6

20 26 06

7

20 26 07

8

20 26 08

9

20 26 09

TEXT EDIT

20 26 82

0

20 26 00

PROGRAM

20 26 36

NO

20 26 49

YES

20 26 87

PLAY

20 26 53

¡

2

9

20 26 33

™

20 26 32

STOP

20 26 54

5

20 26 50

6

;

20 26 52

PAUSE

20 26 48

SHUFFLE

20 26 28

REPEAT

20 26 29

CD1

20 20 55

CD2

20 20 56

CD3

20 20 57

CDR

26 26 63

RC5 code RC283505, 130300

Remote Control:

RC5 commands

RC283521

TECHNICAL SPECIFICATION

L

R

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

S/N and distortion meter

e.g. Sound Technology ST1700B

DUT

CD

Use Audio Signal Disc SBC429 4822 397 30184

(replaces test disc 3)

MEASUREMENT SETUP

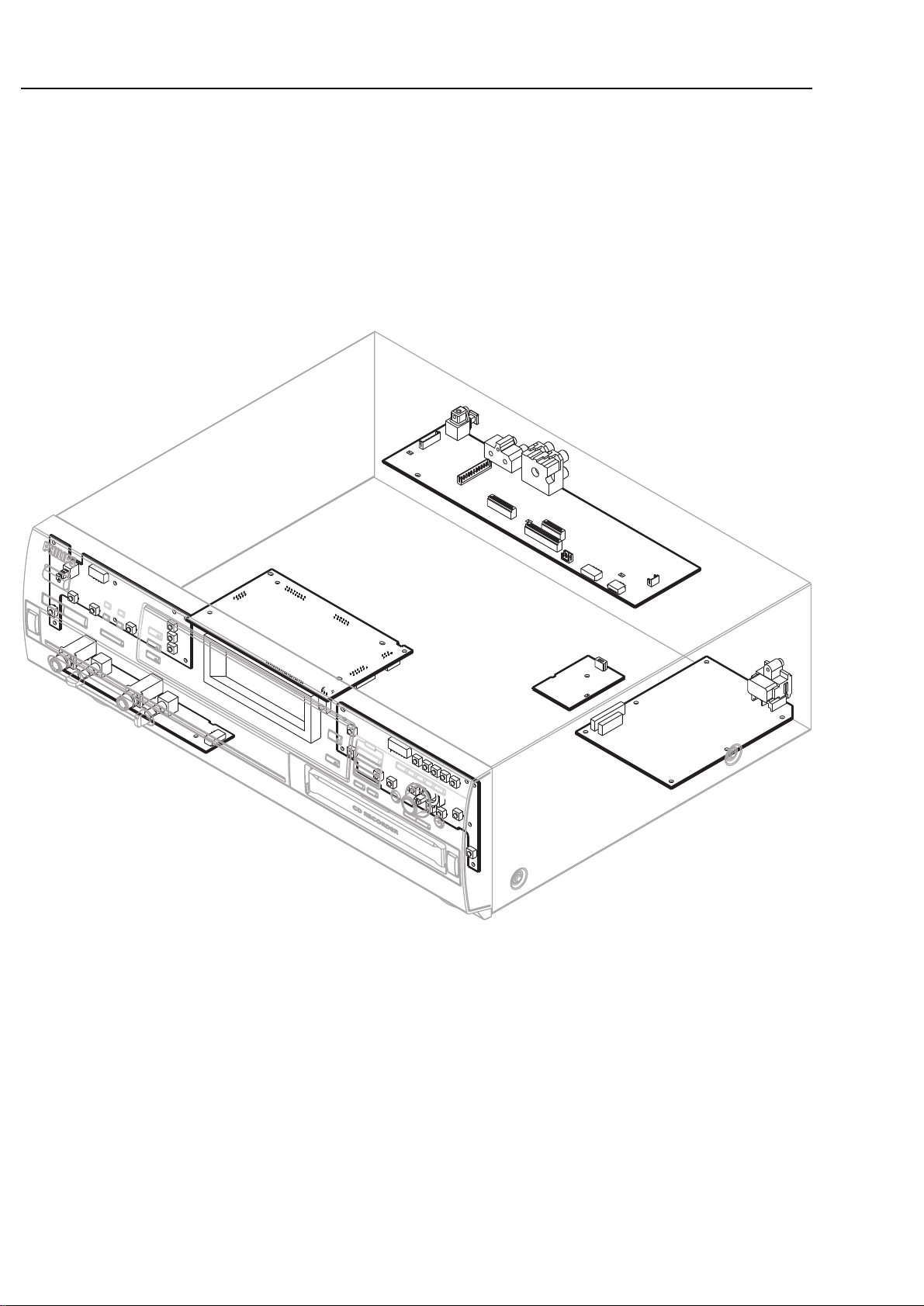

1-3

FRONT BOARD

INTERFACE BOARD

HEADPHONE/MIC BOARD

SWITCHED MODE

POWER SUPPLY

NTC

loccation of pcb´s, 240200

KEY BOARD RIGHT

KEY BOARD LEFT

LOCATION OF PRINTED BOARDS

picture 1

2-1

© WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

f ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

d WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß Sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

ñ WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

i AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

©

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

i

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

ñ

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

s Varning !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

∂ Advarsel !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

ß Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

f

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

ESD

SAFETY

d

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

f

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

CLASS 1

LASER PRODUCT

©

DANGER: Invisible laser radiation when open.

©

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

AVOID DIRECT EXPOSURE TO BEAM.

©

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1MΩ) 4822 320 11307

extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

WARNINGS & SAFETY

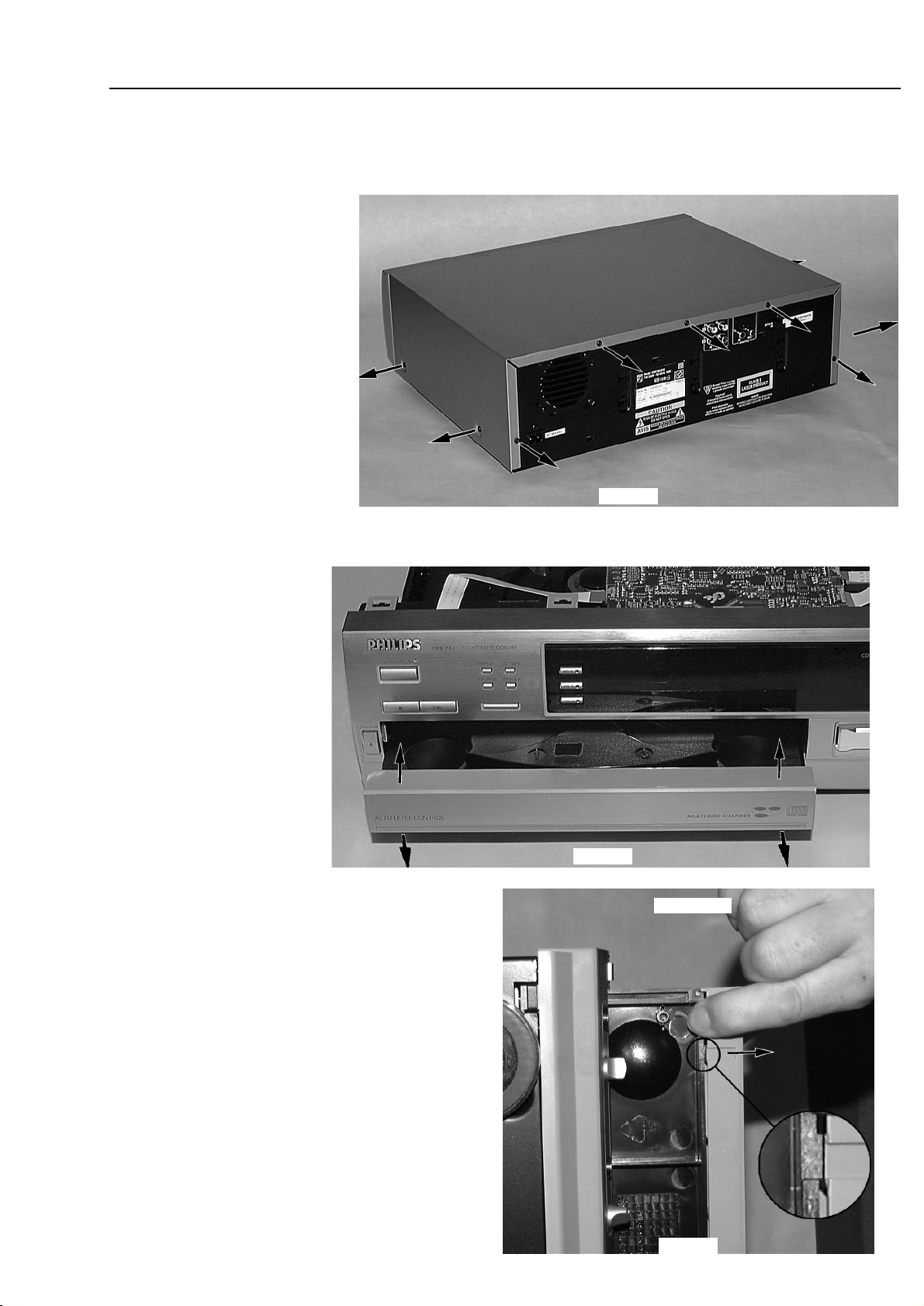

4-1

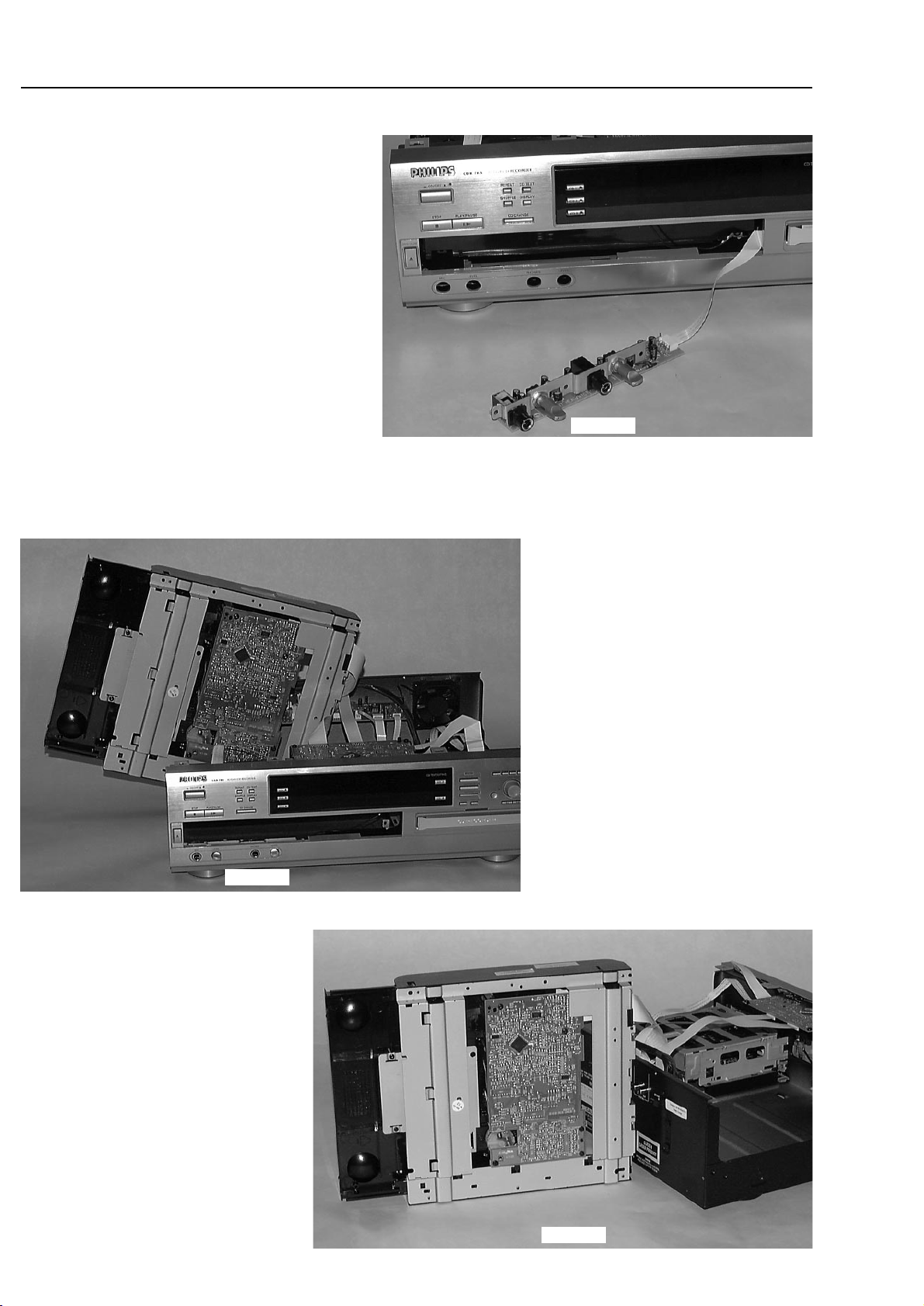

DISMANTLING INSTRUCTIONS

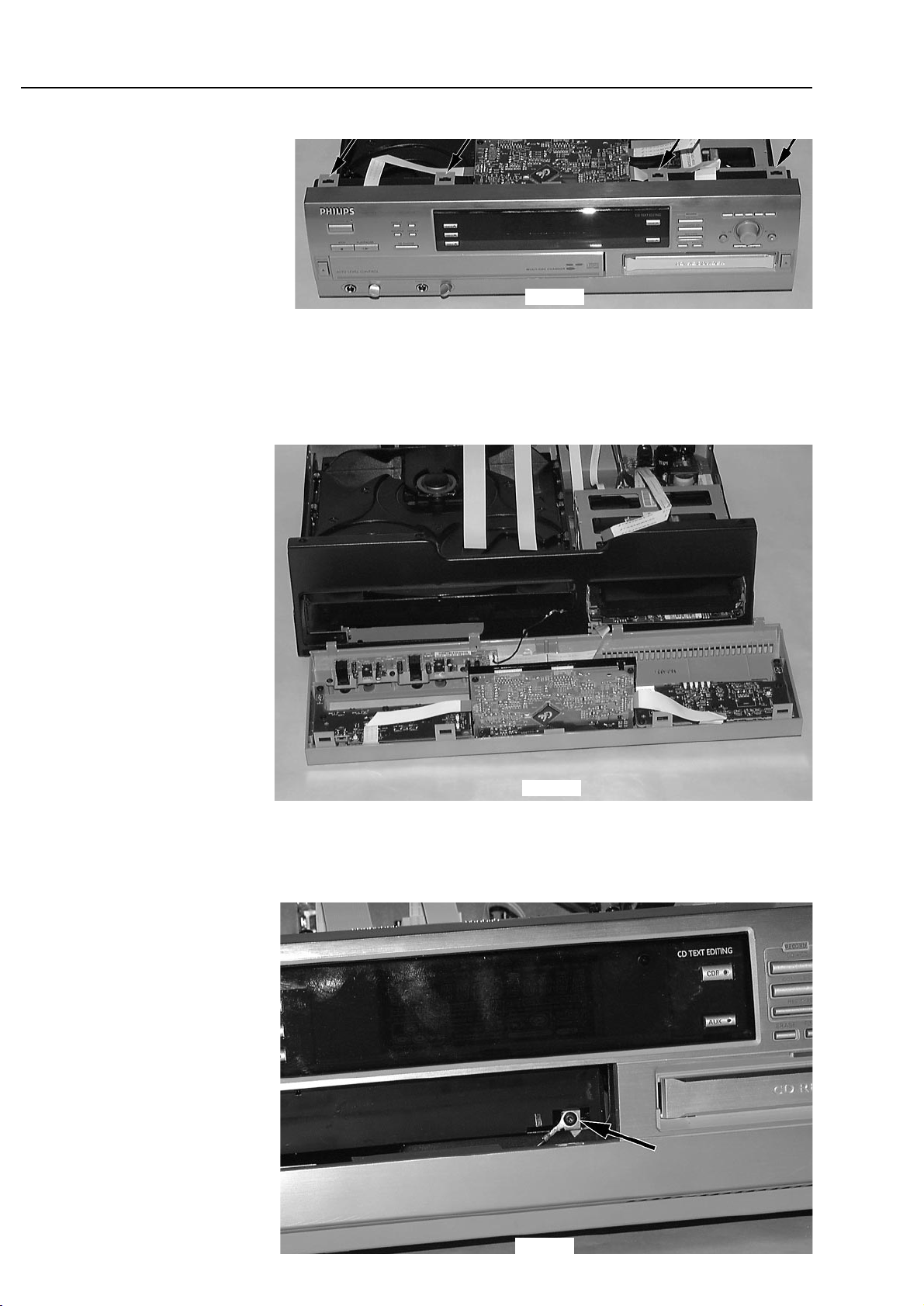

Dismantling the

Top Cover

picture 2

• Remove 9 screws as shown in picture 2.

• Raise top cover at the rear and pull it backwards.

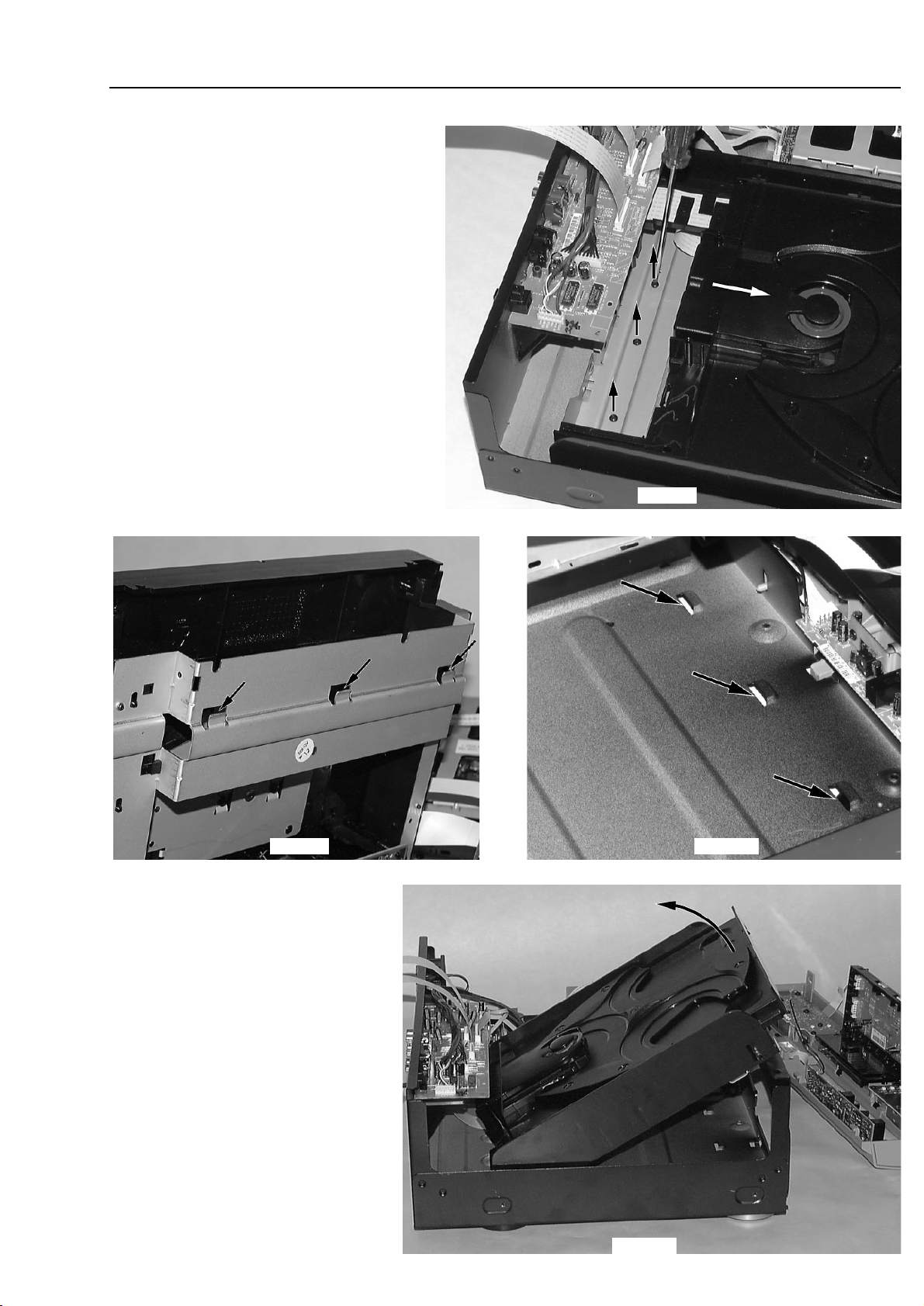

Dismantling the

Tray Cover

picture 3

picture 4

bottom view

• To release the cover from the catch on the tray pull it

frontwards on bottom side as shown in picture 4.

• Pull the cover up.

4-2

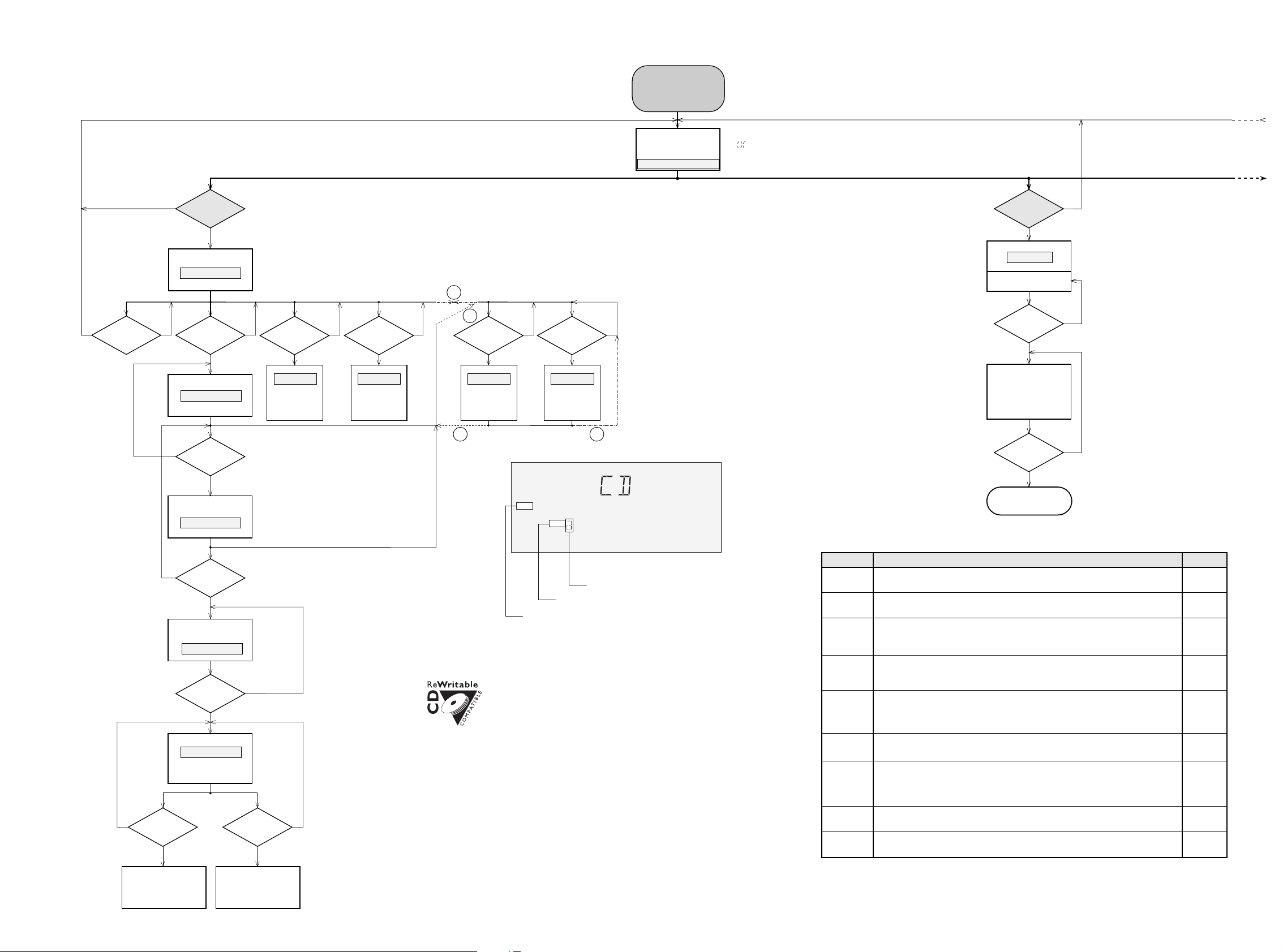

DISMANTLING INSTRUCTIONS

Dismantling the

Front Cabinet

Dismantling the

3CDC module

picture 5

picture 6

• Remove tray cover first →see description before.

• Disconnect flexfoil cables to interface board and CDR module.

• Release catches on top as shown in picture 5 and turn

front cabinet away.

Take care of the flexfoil cables connecting the key boards!

• Place front cabinet as shown in picture 6.

• Remove 2 screws on front side first

→ see pictures 7.

picture 7

4-3

Dismantling the

CDC module

continued

DISMANTLING INSTRUCTIONS

• Dismantle front cabinet as described before.

• Move the tray a few centimetres out to get access

to the fastening screws at the rear.

• Remove the 3 screws as shown in picture 8.

• Put the tray back and move the complete module

backwards to release catches on bottom cabinet.

→ for orientation see picture 9 and 10.

picture 8

picture 9

picture 11

• Pull the module on front side up and turn it

out as shown in picture 11.

• Put the module to a proper service position.

→ see also chapter SERVICE HINTS

• To get the set operating mount front cabinet

and connect flexfoil cables to front board

again.

picture 10

4-4

DISMANTLING INSTRUCTIONS

Dismantling the

CDR module

• Remove 3 screws as as indicated in picture 12.

• Disconnect all cables.

• Move the module backwards to release the catch on

pos. 205 (see exploded view)

• Raise the module on the rear and turn it out.

picture 12

picture 13

Fixation by a catch on

right front-side

4-5

DISMANTLING INSTRUCTIONS

Dismantling the

Power board

• Disconnect all cables.

• Remove 3 screws as as indicated in picture 14.

• Release the catches on the plastic supports.

• Move the board backwards to release the catch on

left front-side.

• Lift the module on the rear and turn it out.

remark: space to CDR module will be very tight

picture 14

picture 15

Fixation by a catch on left

rear-side

5-1

SERVICE HINTS

SERVICE TOOLS

TORX T10 screwdriver with shaftlength 150mm ......................................4822 395 50423

TORX screwdriver set SBC 163..............................................................4822 295 50145

Audio signal disc SBC 429......................................................................4822 397 30184

Playability test disc SBC444...................................................................4822 397 30245

Test disc 5 (disc without errors) +

Test disc 5A (disc with dropout errors, black spots and fingerprints)

SBC 426/426A ....................................................................4822 397 30096

Burn in test disc (65 min. 1kHz signal at -30dB level without "pause")...4822 397 30155

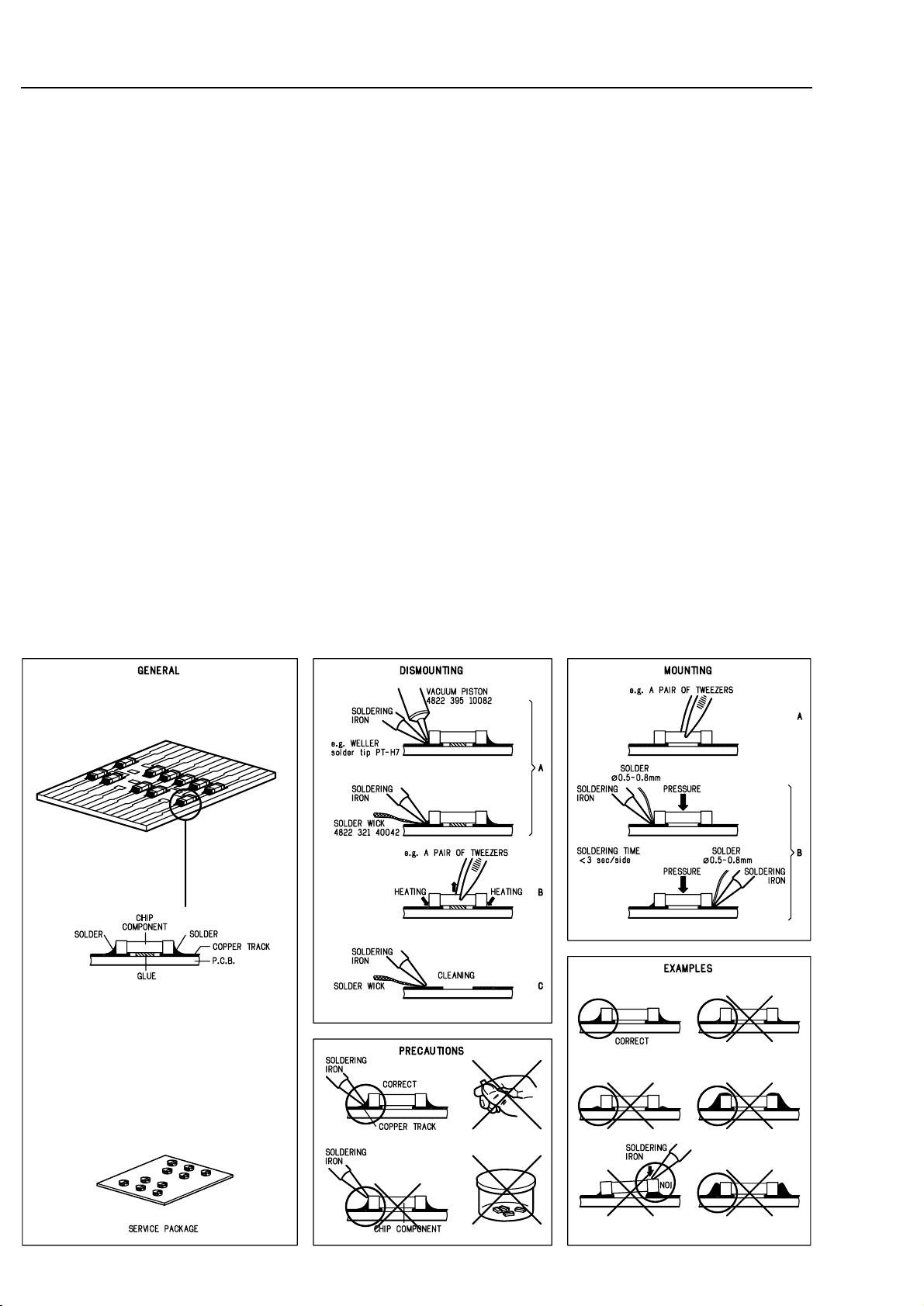

HANDLING CHIP COMPONENTS

5-2

SERVICE HINTS

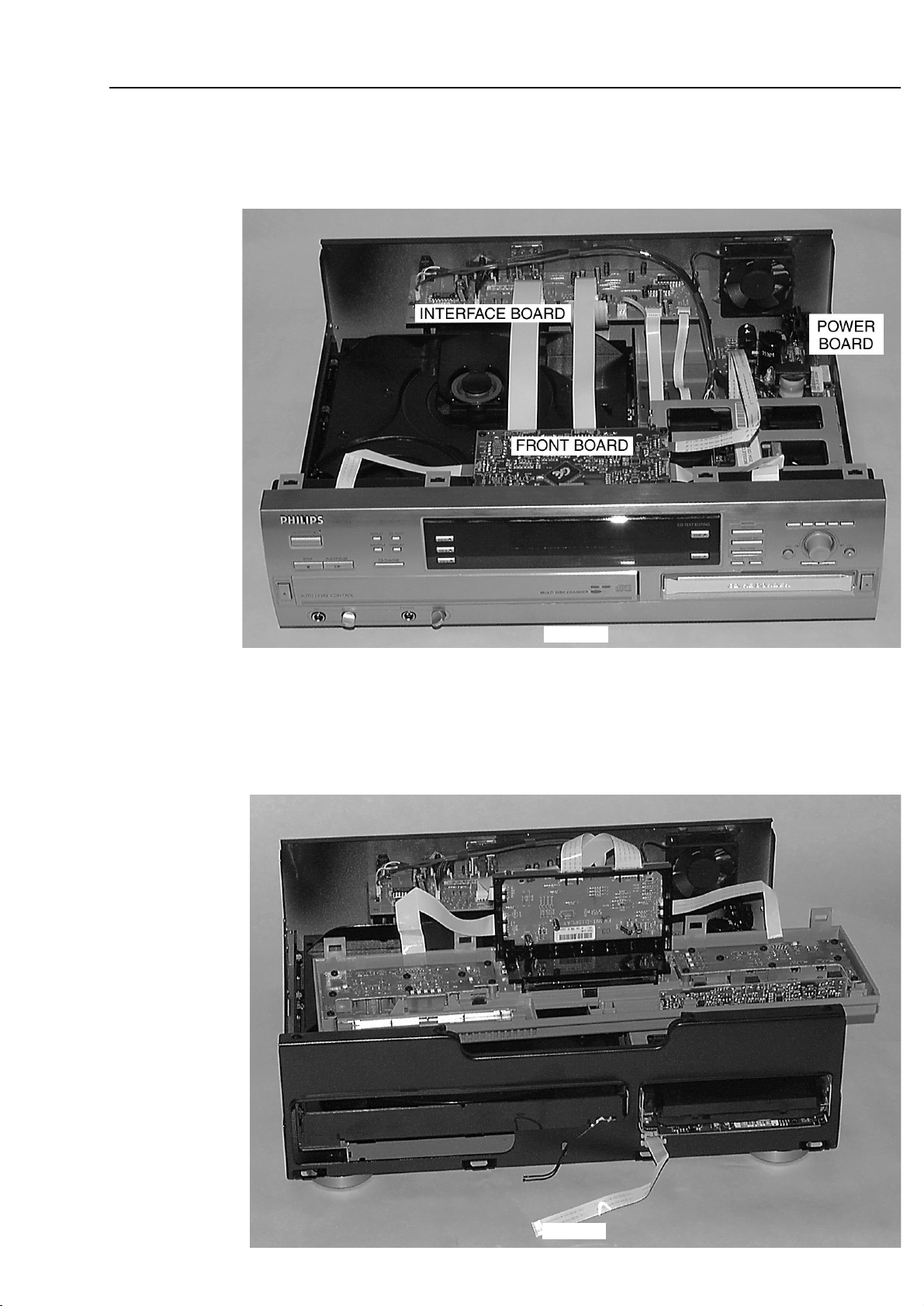

General Service position

For repairs on: Front Board

Power Board

Interface Board

Service position

Key Boards

After dismantling the front cabinet as described in

chapter 4-2 the front unit can be placed on 3CDC- and

CDR module and be re-connected again.

picture 16

picture 17

5-3

SERVICE HINTS

Service position

3CDC Module

Service position

Headphone/Microphone Board

picture 18

picture 20

picture 19

• Dismantle front cabinet as described in chapter 4-2.

• Dismantle Headphone/Microphone Board and put it

through the opening for the 3CDC-tray in front

cabinet.

• Mount front cabinet provisional and re-connect

flexfoil cables to Front Board.

Dismantle the 3CDC module as described

in chapter 4-2 to 4-3 and place it in the

desired service position.

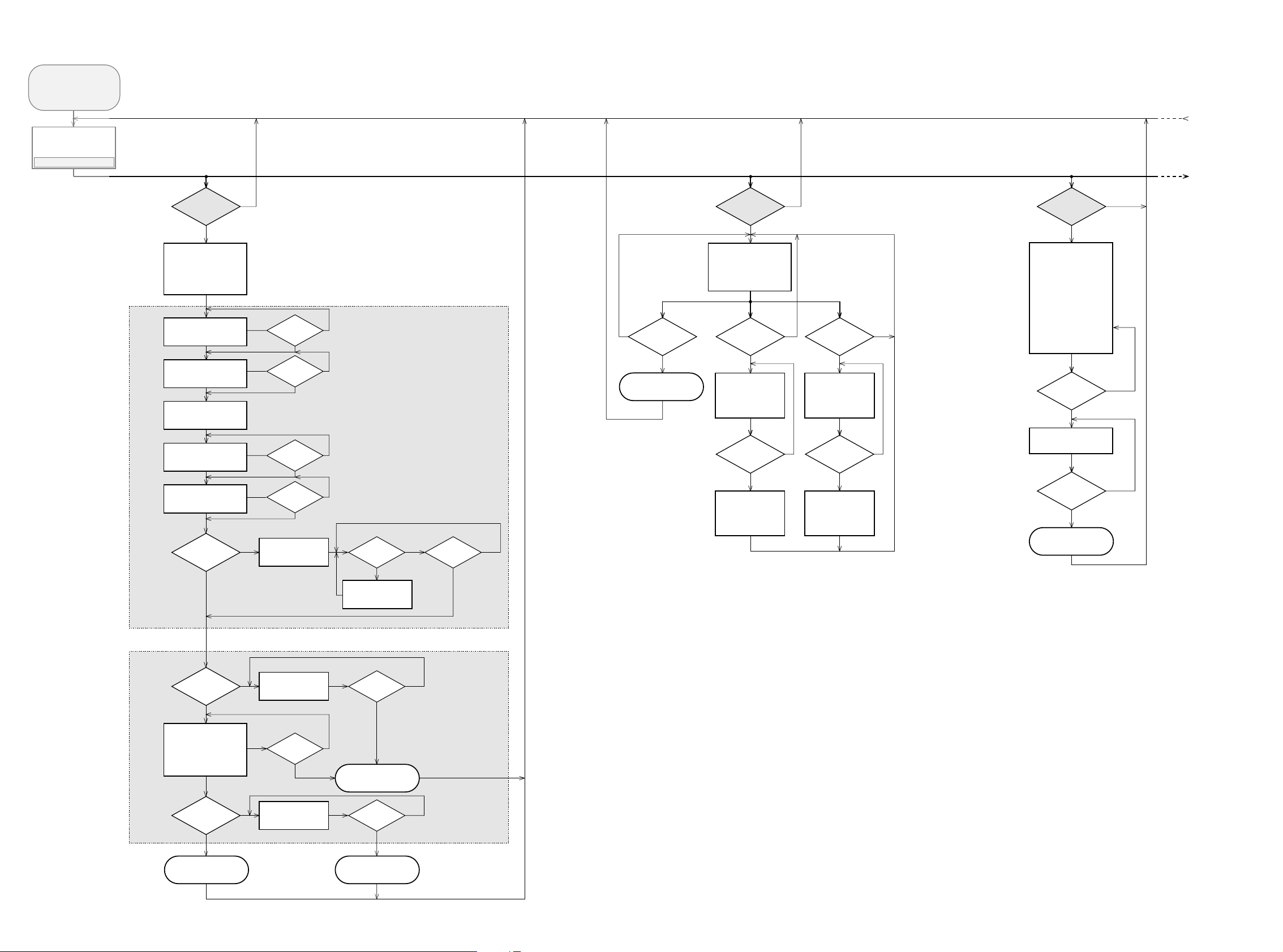

5-45-4

Display shows

version number

of the µP - software.

CDR785 servtest CDC, 070400

*

To leave Service Testprogram plug mains cord off.

SERVICE TESTPROGRAM

CD-CHANGER MODULE

The

CD PLAY TEST

is intended to be used

for continuously playing a disc in order to

detect intermittent or not reproducible

failures. The error code indicates where

the failure can be found.

1)

Y

CD PLAY TEST

1)

N

CD is in normal

PLAY

mode.

In case of failures

error codes acc. table 1

will be indicated

on the display.

MAINS CORD

plugged off?

N

Y

Display shows:

STANDBY

for 5s.

Set is switched to

Standby mode.

PLAY

button

pressed?

N

Y

Exit Service Testprogram

CD3

button

pressed?

stands for Service mode

stands for version number

of the software used in the

front µP.

To enter Service

Testprogram hold

CD yCD & NO

buttons

depressed while

plugging mainscord in.

On/Off switch in pos.

ON

VXX

S

S-CDR785-VXX

Y

Display shows

see also fig. 1

PLAY

button

pressed?

STOP

button

pressed?

NEXT

6 button

pressed?

PREV

5 button

pressed?

REC LEVEL

button

pressed?

PROG

button

pressed?

Slide moves

outside as long as

button is held

depressed.

Slide moves

inside as long as

button is held

depressed.

Disc motor turns

counter clockwise

as long as button

is held depressed.

(brake)

Disc motor turns

clockwise

as long as button

is held depressed.

(accelerate )

Y

Y

YY

YY

N

N

NN

N

NN

A

FOCUS found?

Y

N

Display shows

objective moves up&down

Display shows

NEXT

6 button

pressed?

Y

N

Display shows

→ Play mode

MUTE is switched off

(single speed)

PREV

5 button

pressed?

Y

N

CUE - mode

jumps in steps of

16 tracks forwards

as long as button

is hold depressed.

FOCUS search

RADIAL test

DISC SERVO

REVIEW - mode

jumps in steps of

16 tracks backwards

as long as button

is hold depressed.

SLIDE testDISC MOTOR test

SERVO test

Slide can be activated in FOCUS test too:

check if Focus functions over the whole disc area

PLAY

button

pressed?

Y

N

B

B A

Purpose of RADIAL test:

To check if the Audio signal is reproduced.

Subcode info is ignored during this test →

If the CD player functions well in this testmode,

but not in the normal Play mode check quality

of the eye-pattern signal.

Display shows absolute playing time of the disc

in order one can determine position of the slide.

If the playing time is not shown (display flickers)

the pickup is possibly out of the program area of

the disc. Press

Next

or

Prev

to move slide inside.

Tray (open/close button) and Carousel

(CD1, 2, 3 buttons)

work as in normal mode.

After activation of the tray or the carousel

program returns to SERVO test.

STOP

button pressed in

FOCUS- or RADIAL-test

returns to SERVO-test

Since the CD-RW reflects much less light than an ordinary CD-DA

the gain of the HF-amplifier stage and the sensitivity of the ADC inside

the Signal Processor must be increased to find the focus point.

In normal play mode high/low - gain is switched automatically.

In Service Test Mode, with the

TRACK EDIT

button, the gain/sensitivity can be

toggled manually between high or low as soon as the SERVO test has been entered.

When the set is switched to high gain, RW flag is indicated on the display.

NOTE: If sensitivity is switched to

CDRW

the set

might not work with normal Audio CDs!

In the steps

SERVO test

and

FOCUS search

the disc speed can be toggled manually

between single speed (1x) and double speed (2x) with the

TEXT

button.

Flag 1 or 2 of the music calendar indicates the actual speed.

indicates speed -

single speed

or

double speed

note: when

double speed

is set output is muted in RADIAL test

indicates sensitivity -

CD

or

CDRW

indicates the chosen disc - 1, 2 or 3

Y

N

Disc speeds up.

Display shows

CD SERVO TEST

CD1

button

pressed?

N

PLAY

button

pressed?

Single/double speed

Display shows: Display shows: Display shows: Display shows:

CD

FOC ERR

CCW CW SLD O SLD I

FOC OK

DISC OK

RDL

fig. 1

CD

RW

1 2

set continues operation, message remains on the display until next error occurs

or any key is pressed.

Error number Error type

Error type:

Error description

E1000 Focus Error

Triggered when the focus is lost for more than 250ms while playing the CD.

E1006 Subcode Error

No valid subcode for 300ms during

PLAY

.

Slide-out error

Generated when the inner-switch did not open within approx. 250ms when the pick up is

moved from the inner position outside. Inner-switch or slide motor problems.

E1002

E1003

Slide-in error

Generated when the inner-switch did not close within approx. 6s when the pick up is

moved inside. Inner-switch or slide motor problems.

W

E1020 Focus Search Error

Triggered when the focus could not be found within 4s when starting up the CD.

F

W

W

E1001 Radial error

Triggered when the radial servo is not on track for a certain time during playing the CD.

W

W

W

W

W = Warning →

F = Fatal Error

→ set stops operation, message remains on the display.

CD ERROR CODES

table 1

E1005 Jump error.

Triggered when the servo processor counts too less tracks in a defined time during JUMPS.

This can be caused by a disturbed HF-signal (the tracks cannot be recognized exactly),

slide motor problems, track servo problems or scratched discs.

E1008 Disc motor error

Generated when the CD could not reach 75% of speed during startup within 1,2s.

W

E1007 PLL lock error

When no valid subcode was found within 300ms PLL is checked. If PLL is locked E1006

will be indicated else E1007 and the servo is stopped and restarted once again to recover

(as if the user would have pressed

STOP

and then

PLAY

immediately).

5-5 5-5

*

To leave Service Testprogram plug mains cord off.

Display shows

version number

of the µP - software.

OPEN/CLOSE

button

pressed?

FINALIZE

button

pressed?

N

Y

N

Y

NEXT

6

button

pressed?

N

Y

PREV

5

button

pressed?

N

Y

STOP

button

pressed?

N

Y

CDR MECHANICAL TEST CDR DC-ERASE MODE

FOCUS TEST

Objective moves

continuously up/down.

SLIDE TEST TRAY TEST

Display shows:

BUSY

Display shows:

BUSY

for visual inspection only

OPEN/CLOSE

button

pressed?

N

Y

Slide moves

continuously in/out.

Display shows:

OPENED

(even when tray is blocked)

Tray opens.

Display shows:

CLOSE

(even when tray is blocked)

Tray closes.

Dependent on the

moving direction,

slide moves to inner

or outer end position.

Exit Mech. Testprogram

SERVICE TESTPROGRAM

CDR MODULE

stands for Service mode

stands for version number

of the software used in the

front µP.

To enter Service

Testprogram hold

CD yCD & NO

buttons

depressed while

plugging mainscord in.

On/Off switch in pos.

ON

CDR785 servtest CDR,160200

CDR

button

pressed?

TEST O.K.?

NN

N

Y

Y

N

Y

Y

Y

Display shows for 2s each:

• Software version of DASP

(flash ROM 7703)

• Software version of

basic engine processor

(flash EPROM 7208)

CDR ELECTRICAL TEST

ERASE

button

pressed?

N

Y

Disc erased?

N

Y

N

Y

Insert CD-DA disc

before starting the test

MODULE

INFORMATION

MAIN BOARD DIAGNOSTIC

CDR - LOADER TEST

DRAM TEST 7702

Display shows:

DTST1

CHECKSUM TEST 7703

Display shows:

DTST2

ERASE TEST 7208

Display shows:

DTST3

ADC/DAC TEST 7406

Display shows:

DTST4

COMMUNICATION TEST

(DSA-BUS)

Display shows:

DTST5

Display shows:

DERR

n

n=number of failed test

Display shows next error

FFWD

6 button

pressed?

N

Y

FFWD

6 button

pressed?

Y

FFWD

6 button

pressed?

Y

FFWD

6 button

pressed?

Y

FFWD

6 button

pressed?

all errors shown?

N

N

N

N

FFWD

6 button

pressed?

Y

N

TEST O.K.?

NN

Y

Y

Display shows:

BERR 1

FFWD

6 button

pressed?

CD-DA disc

inserted?

Display shows actual

playing time.

The test is performed by

playing 5s at beginning,

5s in the middle and 5s at

the end of the disc.

N

Y

Display shows:

NO DISC

FFWD

6 button

pressed?

Exit CDR electrical Test

Complete disc will be

erased with double speed.

(starting from PMA-area

up to and including

ATIP leadout area)

The display shows the

countdown of the

remaining time required

to complete the operation:

ER mm ss

Display shows:

PASSED

mm: remaining minutes

ss: remaining seconds

STOP

button

pressed?

Exit DC-ERASE Mode

Note: With the DC-Erase mode the CD-RW can be

changed back in its original state, like a new disc.

Stopping the erase-function by switching power off

will leave the disc in an unpredictable status!

Exit CDR electrical Test Exit CDR electrical Test

S-CDR785-VXX

VXX

S

Loading...

Loading...