Page 1

Service

DR4050/F1N, /N1G, /N1B, /U1B

Manual

OPEN/CLOSE

PLAY/PAUSE OPEN/CLOSESTOP

ON/OFF

REMARK : This service manual explains them by extracting specifications

designed for the model DR4050 only. The explanation for CD-R module

(Loader : CDL4009’ + CD-R Main board) is not mentioned on this service

manual.

The CD-R module information is described in the service manual of CD-R

modules < 2nd line Service Manual : 3104 125 40110 >.

CD RECORDER DR4050

REC TYPE

REC FINALIZE ERASE SOURCE CD-R

STANDBY

CD Recorder

EASY JOG

+–

CANCEL

STORE

PUSH ENTER

/MENU

CD

DJ MODE

REPEATSCROLL

DISPLAYSHUFFLE

PROG

STOP

PLAY/PAUSE

/DELETE

PHONES

DR4050

TABLE OF CONTENTS

1. TECHNICAL SPECIFICATIONS .............................................................................1

2. WARNINGS AND SERVICING HINTS ...................................................................2

3. MECHANICAL INSTRUCTIONS.............................................................................5

4. ELECTRICAL AND CIRCUIT DIAGRAMS............................................................10

5. DIAGNOSTIC SOFTWARE ..................................................................................25

6. FAULTFINDING TREES ....................................................................................... 29

7. FAULTFINDING GUIDE........................................................................................35

8. LIST OF ADDREVIATIONS...................................................................................51

9. ELECTRICAL PARTS LIST...................................................................................57

Please use this service manual with referring to the user guide (D.F.U) without fail.

Printed in Japan

DR4050

435W855010 AO

3120 785 22470

First Issue:2000.12

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

001120 A.O

Page 3

GB 1 1.

1. Technical Specifications

1.1 General

Mains voltage : 220 - 240V/60Hz (/N1B,/N1G)

: 100V/50-60Hz

: 120V/60Hz (/U1B)

Power consumption : 20W

1.2 Input/output

1.2.1 Line output (CDR & CD)

Output level\ : 2Vrms at 0dB

Output resistance : 200

1.2.2 Line input

Input sensitivity : 500mVrms

Input impedance : 50k

Max. input voltage : 2.5Vrms

1.2.3 Digital output (CDR & CD)

Format : AES/EBU format

according IEC958

(consumer format)

Sampling frequency : 44.1kHz

Output resistance : 75

1.2.4 Digital input

Format : AES/EBU format

according IEC958

(consumer format)

Sampling frequency : 32 to 48kHz

Input resistance : 75

1.2.5 Optical input

Format : AES/EBU format

according IEC958

(consumer format)

Sampling frequency : 32 to 48kHz

1.3 Audio performance

1.3.1 Cinch analog output (CDR play-back)

Output voltage : 2Vrms 2dB (0dB

signal)

Frequency range F.R. : 20Hz < F.R.< 20kHz

Amplitude linearity :

0.3dB (typical

0.1dB)

Channel unbalance : < 0.3dB at 1kHz

(typical

0.2dB)

Output resistance : 200

Phase non-linearity : < 0.2 deg at 1kHz

Outband attenuation : 50dB above 30kHz

Channel separation : > 90dB at 1kHz

(typical 110dB),

>85dB between 20Hz

and 20kHz (typical

>93dB)

S/N-ratio A-weighted : > 98dB (typical

100dB)

S/N-ratio unweighted : > 95dB (typical 98dB)

Dynamic range : > 92dB at 1kHz

(typical 96dB), > 90dB

between 20Hz and

20kHz (typical 96dB)

THD+N : >85dB between 20Hz

and 20kHz (typical

91dB)

1.3.2 Cinch analog input/output (monitor path CDR)

Measured with Audio precision system one.

Input voltage is 1Vrms.

Output voltage : 2Vrms

2dB (0dB

signal)

Frequency range F.R. : 20Hz < F.R.< 20kHz

Amplitude linearity :

0.3dB (typical

0.1dB)

Channel unbalance : < 0.3dB at 1kHz

(typical

0.2dB)

Output resistance : 200

Phase non-linearity : < 0.2 deg at 1kHz

Outband attenuation : 50dB above 30kHz

Channel separation : > 90dB at 1kHz

(typical 98dB), > 85dB

between 20Hz and

20kHz (typical >92dB)

S/N-ratio A-weighted : > 90dB (typical 88dB)

Dynamic range : > 85dB at 1kHz

(typical 90dB)

THD+N : > 80dB between 20Hz

and 20kHz (typical

82dB)

Intermodulation THD : > 80dB

1.3.3 Cinch analog output (CD play-back)

Output voltage : 2Vrms 2dB (0dB

signal)

Frequency range F.R. : 20Hz < F.R.< 20kHz

Amplitude linearity :

0.3dB (typical

0.1dB)

Channel unbalance : < 0.3dB at 1kHz

(typical

0.2dB)

Output resistance : 200

Phase non-linearity : < 0.2 deg at 1kHz

Outband attenuation : 50dB above 30kHz

Channel separation : > 90dB at 1kHz

(typical 100dB),

>85dB between 20Hz

and 20kHz (typical

>93dB)

S/N-ratio A-weighted : > 98dB (typical

100dB)

S/N-ratio unweighted : > 94dB (typical 98dB)

Dynamic range : > 92dB at 1kHz

(typical 96dB), > 90dB

between 20Hz and

20kHz (typical 96dB)

THD+N : > 82dB between 20Hz

and 20kHz (typical

85dB)

1.3.4 Headphone output (all functions)

Output voltage : 3Vrms (0dB)/8-2000

S/N : > 80dB

THD+N : > 78dB

Channel separation : > 60dB between 20Hz

and 20kHz

1.4 Laser device

Material : GaAlAs

Wave length : between 780 and

C)

Laser output : 1mW max. during

reading, 20mW max.

during writing

Class : 3B

1.5 Dimensions and weight

Number and height of feet : 4x13mm foiled

Apparatus tray closed (WxDxH) : 440x305x75mm

(without feet)

Weight without packaging : 3.8kg

Weight with packaging : 6.0kg

800nm (at 25

(/F1N)

Page 4

GB 2 2.

2. Warnings and Servicing Hints

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d'autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu'aucune précaution

n'est prise a leur manipulation.

Lors de réparations, s'assurer de bien être

relié au même potentiel que la masse de

l'appareil et enfiler le bracelet serti d'une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l'on utilise soient également a ce

potentiel.

D

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

F

Les normes de sécurité exigent que l'appareil soit remis a l'état d'origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

WARNUNG

NL

Alle IC's en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell'apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

WAARSCHUWING

I

AVVERTIMENTO

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l'apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

SHOCK, FIRE HAZARD SERVICE TEST:

CAUTION: After servicing this appliance and prior to returning to customer, measure the resistance between

either primary AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the

face or Front Panel of product and controls and chassis bottom,

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC

power is applied, and verified before return to user/customer.

Ref.UL Standard NO.1492.

NOTE ON SAFETY:

Symbol

: Fire or electrical shock hazard. Only original parts should be used to replace any part with symbol

Any other component substitution(other than original type), may increase risk or fire or electrical shock hazard.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

Page 5

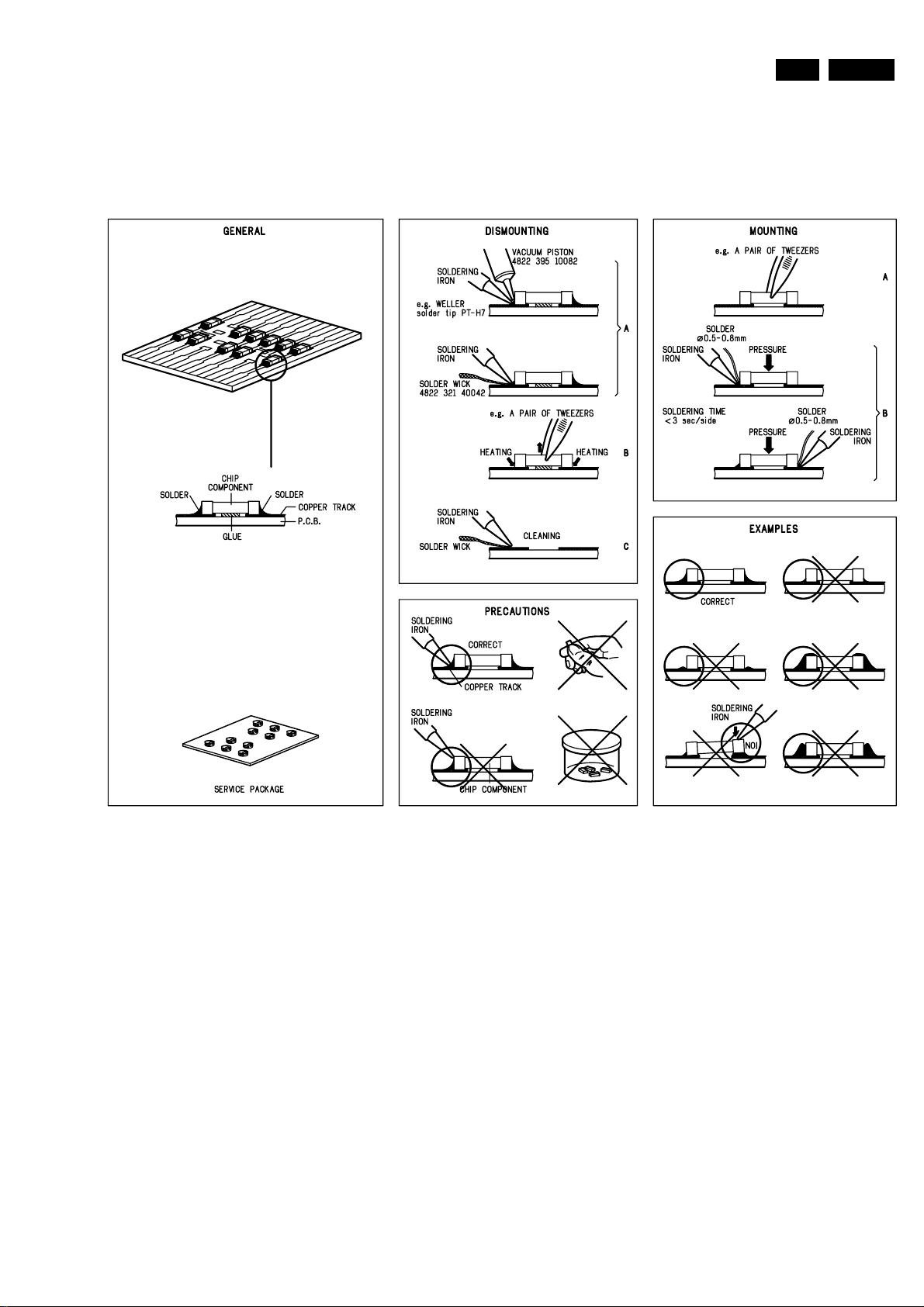

SERVICING HINTS

In the set, chip components have been applied. For disassembly and assembly check the figure below.

GB 32.

Page 6

GB 4 2.

Page 7

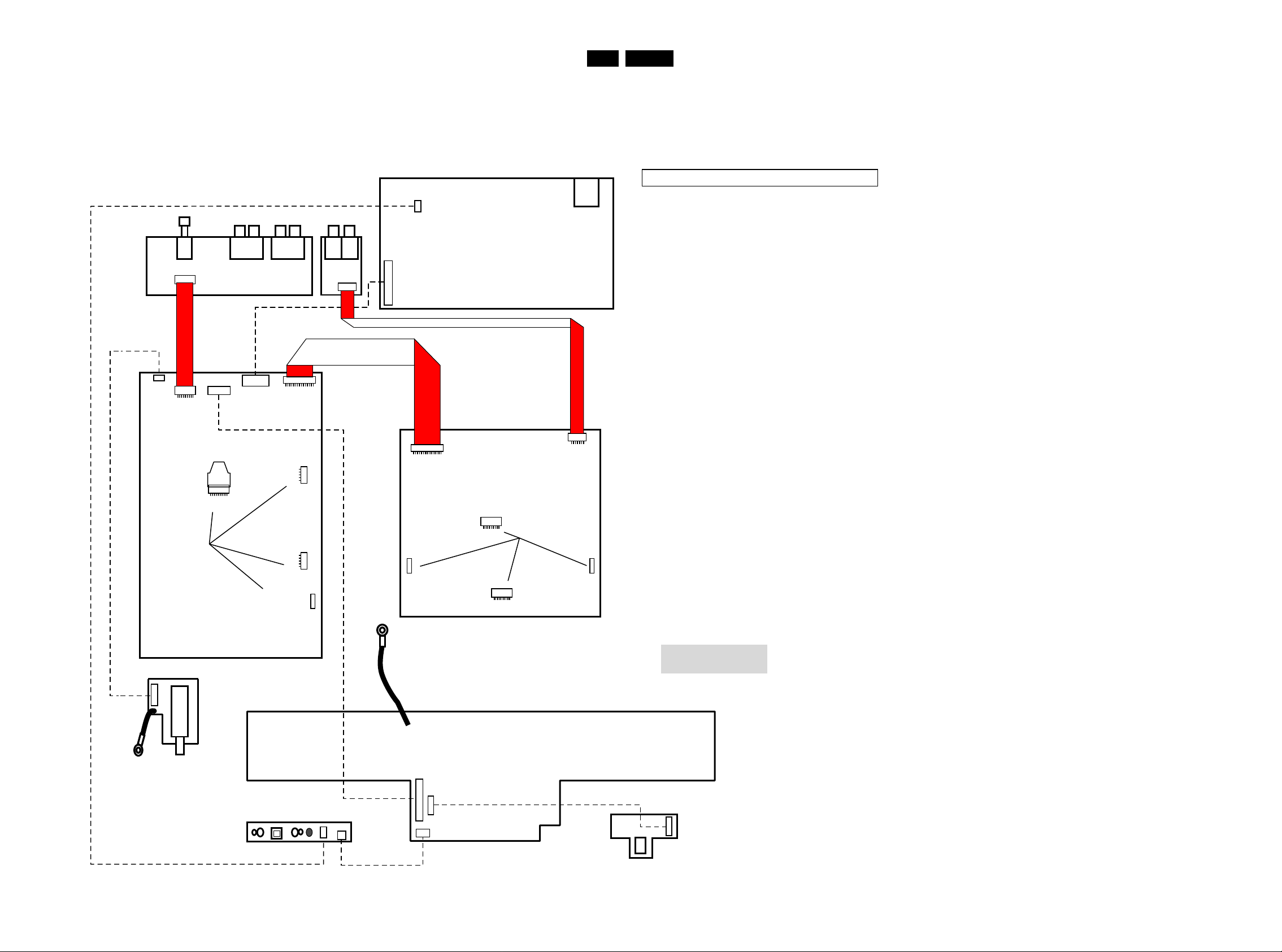

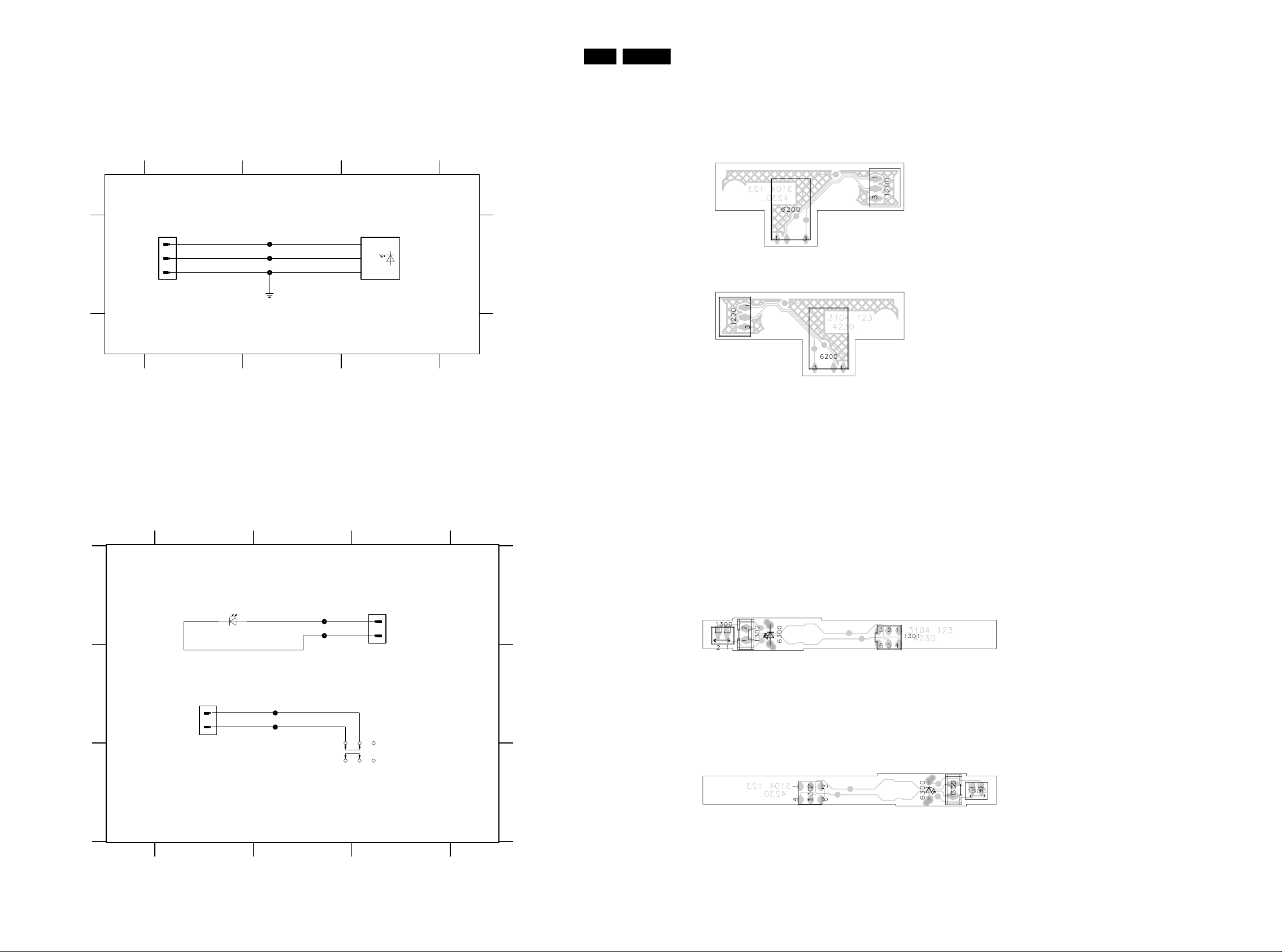

3. Mechanical instructions

Wiring diagram

8006

3104 157 1099

1000

114

8001

3104 157 1124

I/O BOARD

3104 128 0599

8002

3104 157 10962

CD OUT

3104 128 0590

17

1502

11

0205

1

GB 53.

Pin 1 indicated by All Wires are 1/1, except flex 8001, 8005 and 8007

2

0206

1

POWER SUPPLY UNIT

8007

3104 157 1129

0101

8001 (at conn. 1400

of CDR main board)

1 GROUND

2 DIG_OUT_C

3 GROUND

4 EXT_DIG_IN

5 EXT_OPT_IN

6 GROUND

7D5V

8KILL

9LEFT_IN

10 GROUND

11 RIGHT_IN

12 RIGHT_OUT

13 GROUND

14 LEFT_OUT

8002

1 VDC2

2VFTD

3

VDC1

4 GROUND

5+5V

6+5V

7 GROUND

8 GROUND

9 GROUND

10 +12V

11 -8V

8003 (at conn. F934

of CDR main board)

1 VDC2

2 VFTD

3 VDC1

4 SYS_RESET

5IIC_DATA

6 GROUND

7IIC_CLK

8 DISPL_INT

9 GROUND

10 D5V

8004

3104 157 11002

13

1410

Connections delivered

with CDR-loader assy

114

1400

Flex connected

to CDM

F934

1000

130

MAIN BOARD CDR

3104 128 0586

1

3

1400

1

110

1500

11

1708

Flex connected

to sledge motor

Flex connected

to turn table motor

Cable connected

to tray switch and

tray motor

10

1

11

1

4

1

1220

1330

1200

122

8005

3104 157 1123

8003

3104 157 1122

1208

1

4

1002

Cable connected

to tray switch and

tray motor

122

MAIN BOARD CD

3104 128 0598

Flex connected

to CDM panel

1000

116

Connections delivered

with CD-loader assy

111

Flex connected

1006

to turn table motor

17

1209

1001

Cable connected

to sledge motor

8004

1 LEFT_HP_OUT

2 GROUND

8006

1 ON!

2 OFF!

8009

1LED_ON

2 GROUND

3 RIGHT_HP_OUT

8008

1+5V

2

IR_IN

3 GROUND

8007 (at conn. 1209

of CD main board)

1 RIGHT_CD

2 GND

3 LEFT_CD

4 GND

5 DOBM_CD

6 GROUND

1

4

7 KILL

8005 (at conn. 1708

of CDR main board)

1 GROUND

2 DSA_DATA_CD

3 GROUND

4 DSA_STR_CD

5 DSA_ACK_CD

6 GROUND

7 D5V

8 12V_CD

9 GROUND

10 IIS_DATA_CD

11 IIS_WS_CD

12 GROUND

13 IIS_BCLK_CD

14 GROUND

15 DOBM_CD

TO FRAME

Texture indicates text on flex.

16 SYS-RESET

17 LEFT_IN_CD

18 GROUND

19 RIGHT_IN_CD

20 KILL

21 SYS_CLK_8W

22 GROUND

TO FRAME

HEADPHONE BOARD

3104 128 0590

ON/OFF & STBY LED

3104 128 0590

1302

2

1300

12

1

8009

3104 157 03881

1

1119

10

112

DISPLAY BOARD

3104 128 0590

1122

3

1121

8008

3104 157 11281

1200

1

3

IR BOARD

3104 128 0590

Page 8

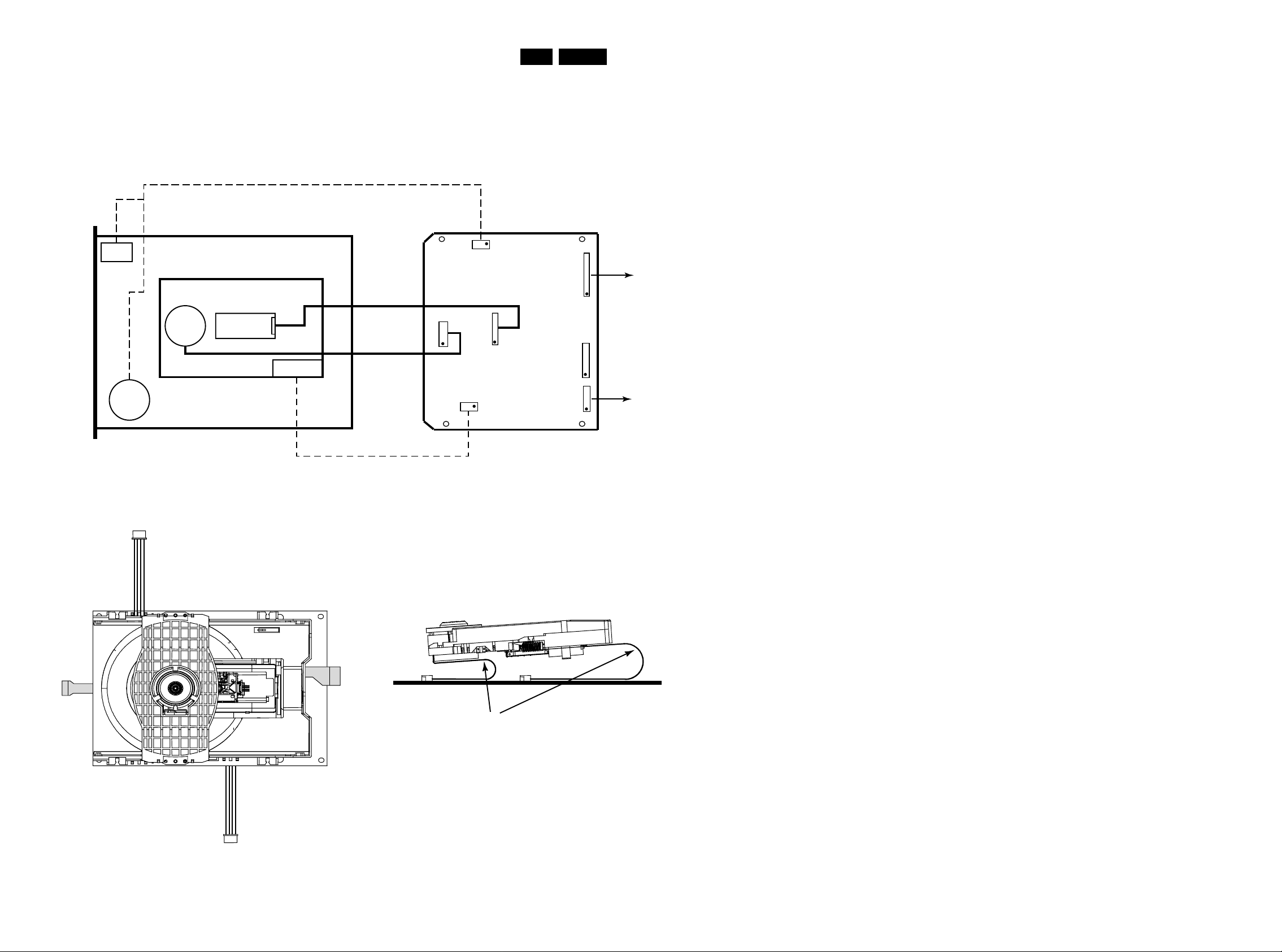

Wiri

ng CD

WIRING DIAGRAM CD LOADER VAL1250

GB 63.

Flex from

turn table motor

Tray

switch

Turn table

motor

Tray motor

Connector from tray motor

and tray switch

Connection tray motor

and tray switch

LOADER VAL1250

CDM VAM1250

OPU

LOADER VAL1250

Sledge motor

and switch

Flex from OPU

Flex from

turn table motor

Connection sledge motor

and sledge switch

Flex from OPU

1002

11

1006

1

MAIN BOARD CD

1001

14

16

1000

1

14

CDM VAM1250

22

1208

1

16

1210

1

7

1209

1

MAIN BOARD CD

To main board CDR

To CD out board

CONNECTOR 1006

1 HALL +

2 W3 W+

4 V+

5 HALL6 U+

7 V8 U9 UCOIL

10 VCOIL

11 WCOIL

CONNECTOR 1000

1 VSUB

2 HFGND

3 VDD

4 RF

5 LDON

6 R2

7 R1

8 D4/D3

9 D2

10 D1

11 FTC

12 RW

13 FOC+

14 FOC15 RAD+

16 RAD-

CONNECTOR 1002

1 HOMESW

2 SGND

3 TRAY+

4 TRAY-

CONNECTOR 1001

1 HOMESW

2 SGND

3 SL4 SL+

CONNECTOR 1209

1 AUDIO R (RIGHT_CD)

2 GND

3 AUDIO L (LEFT_CD)

4 GND

5 DOBM5_CD (DOBM_CD)

6 GND

7 KILL

CONNECTOR 1208

1 GND

2 CRIN (SYS_CLK_8W)

3 KILL

4 AUDIO R (RIGHT_IN_CD)

5 GND

6 AUDIO L (LEFT_IN_CD)

7 DSA_RST (SYS_RESET)

8 DOBM (DOBM_CD)

9 GND

10 SCLK (I2S_BCLK_CD)

11 GND

12 WCLK (I2S_WS_CD)

13 DATA (I2S_DATA_CD)

14 GND

15 +12V

16 +5V

17 GND

18 DSA_ACK (DSA_ACK_CD)

19 DSA_STROBE (DSA_STR_CD)

20 GND

21 DSA_DATA (DSA_DATA_CD)

22 GND

Connector from sledge motor

and sledge switch

POSITION OF FLEX CONNECTIONS

Page 9

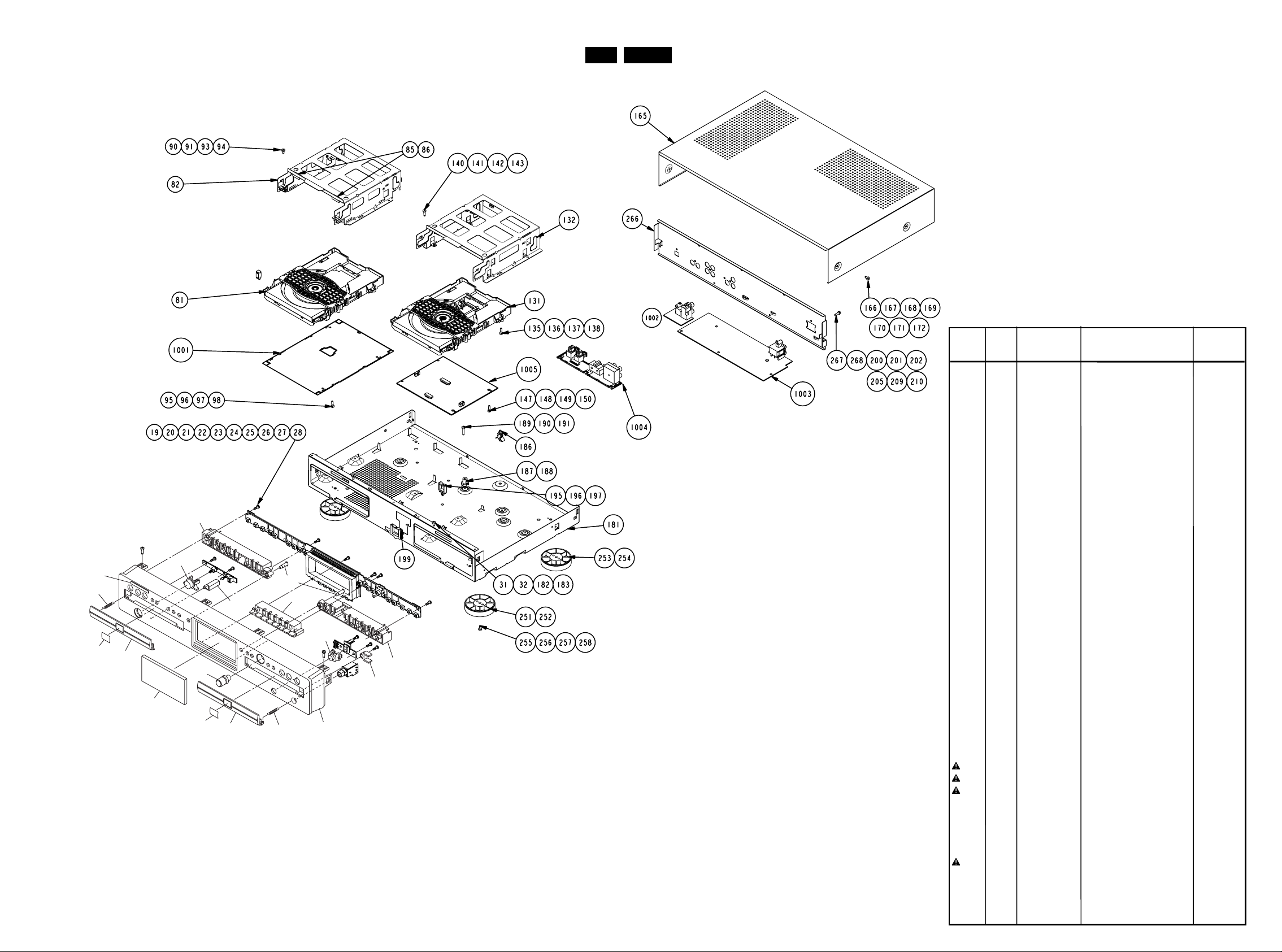

Exploded view

GB 73.

012B

018B

014B

004B

003B

065B

007B

040B

016B

005B

085B

018B

070B

020B

010B

002B

090B

009B

POS.

NO

VERS.

COLOR

PART NO.

(PCS)

DESCRIPTION

PART NO.

(MJI)

002B GLD 9965 000 07435 FRONT PANEL (GOLD) 435W248110

002B BLK 9965 000 07436 FRONT PANEL (BLACK) 435W248010

003B 9965 000 07447 WINDOW 435W158010

004B GLD 9965 000 07448 ESCUTCHEON CDR (GOLD) 435W063110

004B BLK 9965 000 07449 ESCUTCHEON CDR (BLACK) 435W063010

005B GLD 9965 000 07450 ESCUTCHEON CD (GOLD) 435W063120

005B BLK 9965 000 07451 ESCUTCHEON CD (BLACK) 435W063020

007B GLD 9965 000 07452 BUTTON CDR (GOLD) 435W270110

007B BLK 9965 000 07453 BUTTON CDR (BLACK) 435W270010

009B GLD 9965 000 07454 BUTTON CD (GOLD) 435W270120

009B BLK 9965 000 07458 BUTTON CD (BLACK) 435W270020

010B GLD 9965 000 07459 LENS IR (GOLD) 435W355110

010B BLK 9965 000 07460 LENS IR (BLACK) 435W355010

012B 9965 000 07461 BADGE MARANTZ 185J251010

014B GLD 9965 000 07462 LABEL CDR (GOLD) 435W861110

014B BLK 9965 000 07463 LABEL CDR (BLACK) 435W861010

016B GLD 9965 000 07464 LABEL CD (GOLD) 435W861120

016B BLK 9965 000 07465 LABEL CD (BLACK) 435W861020

018B 9965 000 07466 SPRING FOR ESCUTCHEON 435W115010

020B 9965 000 07470 BUTTON MODE 435W270050

040B GLD 9965 000 07471 JOG KNOB (GOLD) 435W154110

040B BLK 9965 000 07472 JOG KNOB (BLACK) 435W154010

065B GLD 9965 000 07473 BUTTON POWER (GOLD) 435W270130

065B BLK 9965 000 07474 BUTTON POWER (BLACK) 435W270030

070B 9965 000 07475 BUTTON LENS 435W270040

085B 9965 000 07476 LENS FOR LED 435W355030

090B nsp HOLDER FOR HEADPHONE 435W271010

251 4822 462 42129 FOOT QP46242129

252 4822 462 42129 FOOT QP46242129

253 4822 462 42129 FOOT QP46242129

254 4822 462 42129 FOOT QP46242129

301 /N 4622 004 50290 MAINS CORD (EURO) 462200450290

301 /U 3104 128 92560 MAINS CORD (NAFTA) QW12892560

301 /F 3104 128 92620 MAINS CORD (JPN) QW12892620

318 /N, /U 3139 228 86260 REMOTE CONTROL ASSY

QT22886260

RC282924/02

309 /N 3104 125 23840 USER GUIDE(N) 435W851310

309 /U 3104 125 23850 USER GUIDE(U) 435W851250

309 /F 3104 125 23860 USER GUIDE(F) 435W851110

1003 3122 427 22020 POWER SUPPLY UNIT 312242722020

8001 3104 157 11240 CWAS FLEX 1MM 14 100 32S QW15711240

8005 3104 157 11230 CWAS FLEX 1MM 22 320 32S QW15711230

8007 3104 157 11320 CWAS FLEX 1.25MM 7 300

QW15711320

32S

Page 10

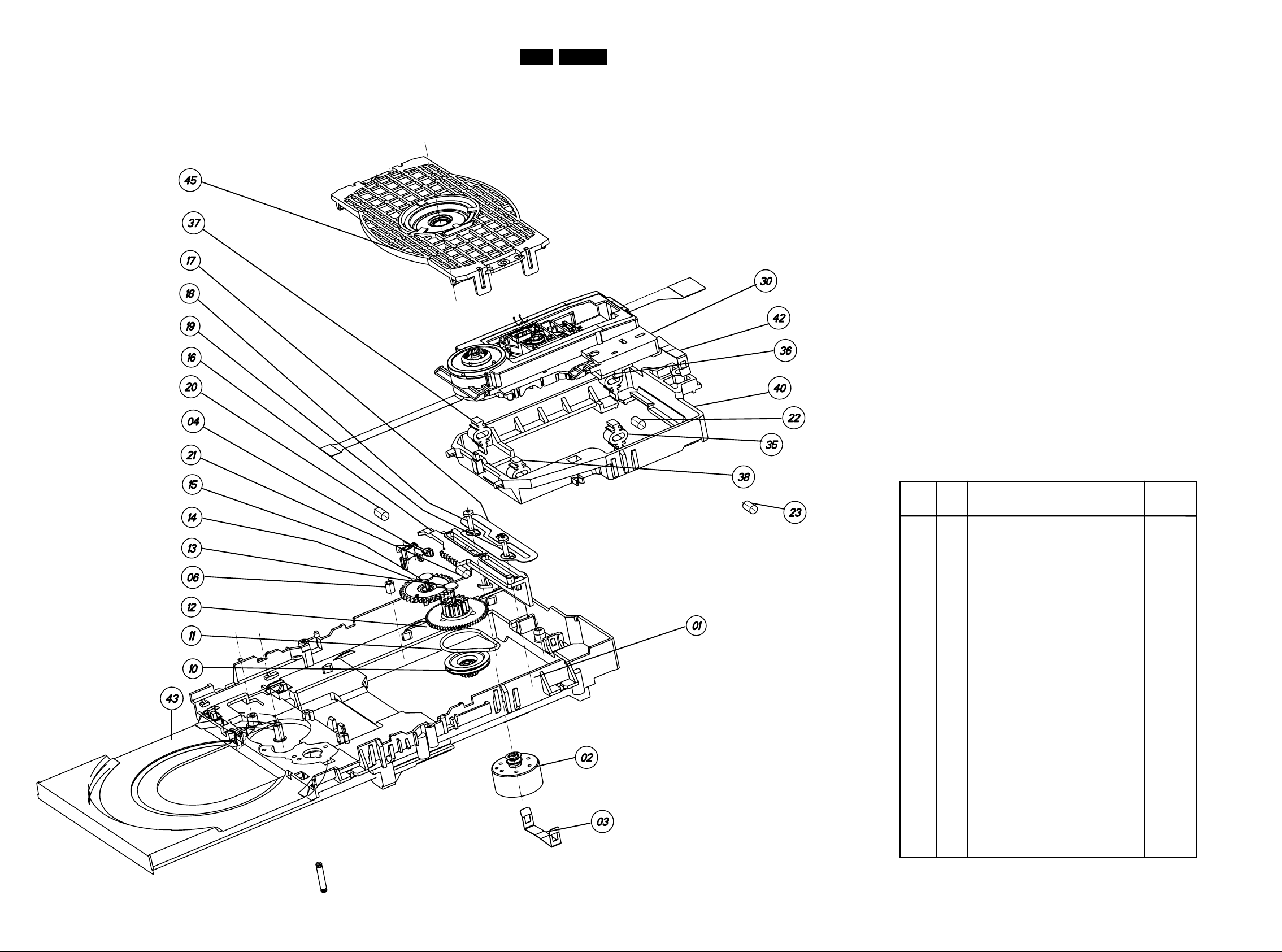

Exploded view CD

EXPLODED VIEW CD LOADER VAL1250

CLAMPER ASSY

SUSPENSION

RACK SPRING

SCREW

GB 83.

CDM VAM1250

SCREW

RUBBER

SWITCH

RUBBER

TRAY GEARWHEEL

RACK GEARWHEEL

PULLEY WHEEL

TRAY HORIZONTAL

RACK

PLUG

PLUG

TULE

BELT

TRAY MOTOR ASSY

MOTORSPRING

MOTORSPRING

SUSPENSION

SUB CHASSIS

RUBBER

SUSPENSION

SUSPENSION

RUBBER

CHASSIS ASSY VAL1250

VERS.

POS.

COLOR

NO

01 3104 147 14100 CHASSIS ASSY LOADER

02 4822 361 11131 TRAY MOTOR ASSY QP36111131

03 4822 492 11709 MOTOR SPRING QP49211709

04 3139 198 80010 SWITCH QT19880010

06 4822 532 13097 TULE QP53213097

10 4822 528 11295 PULLEY, WHEEL QP52811295

11 4822 358 10266 BELT, DRIVING QP35810266

12 4822 522 10739 RACK GEAR WHEEL QP52210739

13 4822 535 10588 PIN, PLASTIC QP53510588

14 4822 522 10741 TRAY GEAR WHEEL QP52210741

15 4822 535 10588 PIN, PLASTIC QP53510588

16 4822 402 11221 RACK QP40211221

17 4822 492 11711 RACK, SPRING QP49211711

20 4822 466 12131 CUSHION RUBBER QP46612131

21 4822 466 12131 CUSHION RUBBER QP46612131

22 4822 466 12131 CUSHION RUBBER QP46612131

23 4822 466 12131 CUSHION RUBBER QP46612131

30 9305 022 25001 CDM VAM 1250 QE02225001

35 3104 144 02030 SUSPENSION Q W14402030

36 3104 144 02030 SUSPENSION Q W14402030

37 3104 144 02030 SUSPENSION Q W14402030

38 3104 144 02030 SUSPENSION Q W14402030

40 3104 144 05870 SUB-CHASIS QW14405870

42 4822 492 11709 MOTOR SPRING QP49211709

43 4822 418 10421 TRAY HORIZONTAL QP41810421

45 3104 147 13910 CLAMPER ASSY VAL 1250 QW14713910

8001 3104 148 01310 LED ASSY 4P QW14801310

PART NO.

(PCS)

VAL 1250

DESCRIPTION

PART NO.

(MJI)

QW14714100

Page 11

Dismantling

DISMANTLING INSTRUCTIONS

See exploded views for item numbers

GB 93.

Cover 165

Remove 7 screws 166 172,

2 at each side and 3 at rear side.

Lift cover at rear side to remove.

assembling

disassembling

CDR module includes :

Loader 81

CDR main board 1001

Loader bracket 82

Put the CDR player's rear side facing you.

Undo the 3 wire connections on the CDR

main board 1001.

Undo the 2 flex connections on CDR main board.

Remove 4 screws 90,91,93,94

(loader bracket 82 frame 181).

Lift CDR module at rear side to remove.

Attention : flexes are not part of the CDR module

and have to stay with CDR player in case

of CDR module exchange !

CD module includes :

Loader 131

CD main board 1005

Loader bracket 132

Put the CDR player's rear side facing you.

Remove 4 screws 140 143

(loader bracket 132 frame 181).

Lift CD module at rear side to remove.

Undo the 2 flex connections on CD main board.

Attention : flexes are not part of the CD module

and have to stay with CDR player in case

of CD module exchange !

CD main board 1005

Remove 4 screws 147 150

(CD main board loader bracket 132).

Undo 2 flex and 2 wire connections

on CD main board.

Remove board.

CD loader assy 131

Remove 4 screws 135 138

(CD loader loader bracket 132).

Remove loader.

CDM VAM1250

Remove clamper assy 45 by releasing 4 snaps

(2 on left 2 on right side) on chassis assy 1.

Open tray 43 by unlocking rack 16.

Undo wires of CDM VAM1250 from

wire retainers on sub chassis 40.

Unlock suspensions 35 38 from sub chassis 40.

Remove CDM VAM1250.

CD out board 1002

Put CDR player's rear side facing you.

Undo flex connection to CD main board 1005.

Remove 2 screws 209, 210 connecting

the 2 I/O sockets to back plate 266.

Remove board.

Attention : flex is not part of the CD out board

and has to stay with CDR player in case

of CD out board exchange !

I/O board 1004 Power suppl y unit 1003

Put CDR player's rear side facing you.

Undo flex connection to CDR main board 1001.

Remove 3 screws 200 202, connecting

the 3 I/O sockets to back plate 266.

Remove board.

Attention : flex is not part of the I/O board

and has to stay with CDR player in case

of I/O board exchange !

IR board 1002

Remove 2 screws 36 and 37

(IR board

Undo wire connection on board.

Remove board.

front assy 1).

Put the CDR player's rear side facing you.

Undo the 2 wire connections on PSU.

Remove screw 205

(mains connector back plate 266).

Remove 3 screws 189 191

(PSU board frame 181).

Unlock snap on spacer 186.

Remove PSU.

WARNING: POSSIBILITY OF HIGH

VOLTAGE (300V) ON HEAT SINK,

EVEN AFTER REMOUNTING OF

PCB. DISCHARGE ELCAP 2121.

Display board 1002

Remove easy jog knob 51 pulling it forward.

Remove 11 screws 19

(display board front assy 1).

Release 2 snaps (1 on left and 1 on right side)

Undo the 3 wire connections on display board.

Remove display board.

Attention : when reassembling make sure

the wiring from display board to IR board is

positioned between FTD display and

middle key assy 3 !

29

Headphone board 1002

Pull board out of front assy 1.

Slide board out of middle key assy 3.

Undo wire connection on board.

Remove board.

Front assy 1

Put the CDR player's front side facing you.

Remove 2 screws 31, 32

(ground wires

Remove 2 screws 182, 183

(front assy 1

Unlock front assy from frame by releasing 7 snaps :

start with 2 on the top and two on the sides

and end with 3 at the bottom.

After disassembly put in front of the set (servi c e position).

frame 181).

frame 181).

On/Off & Stby LED board 1002

Remove 2 screws 33 and 34

(on/off switch

Undo the 2 wire connections on board.

Remove power button 9 from on/off switch.

Remove board.

front assy 1).

Page 12

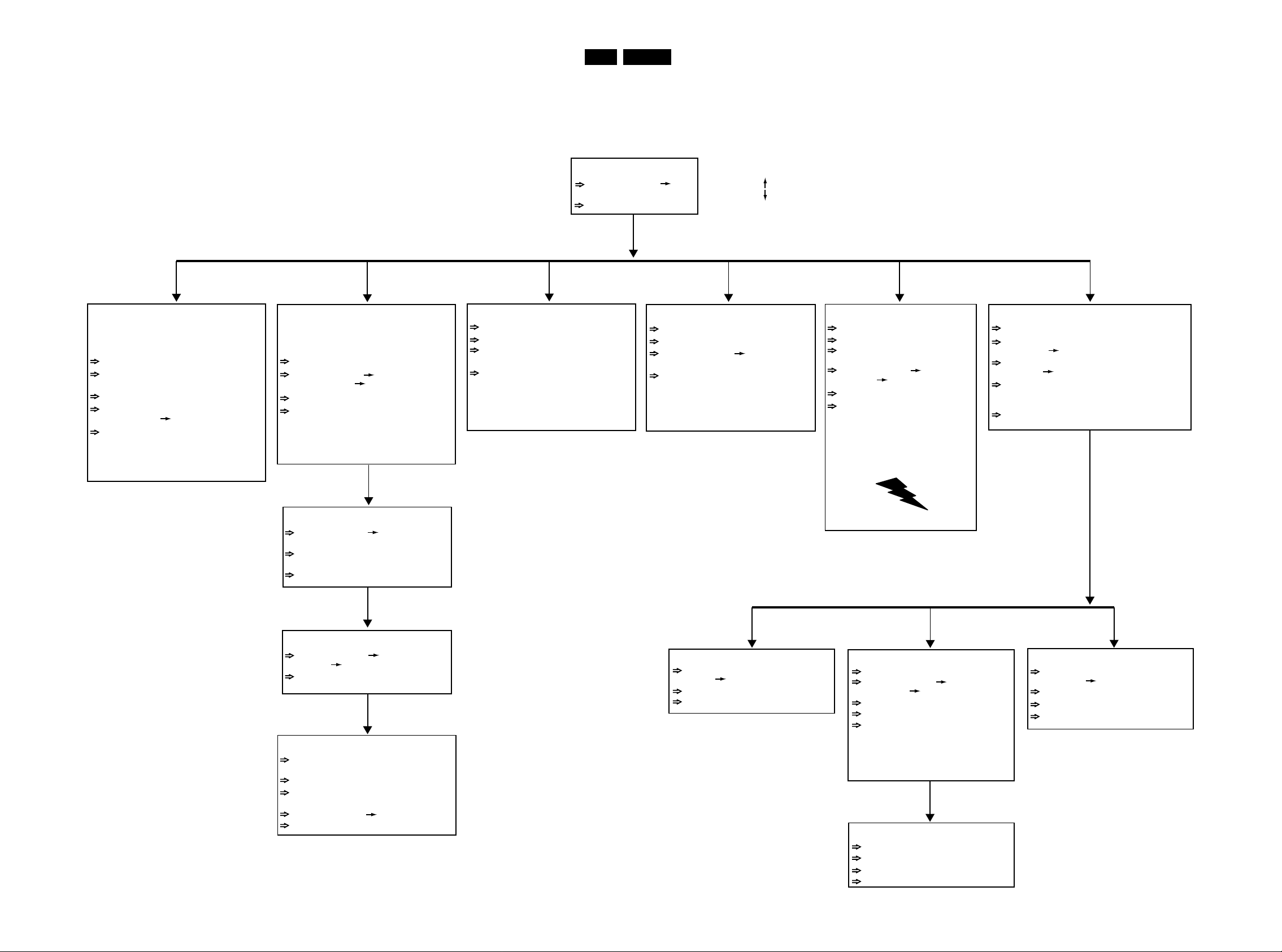

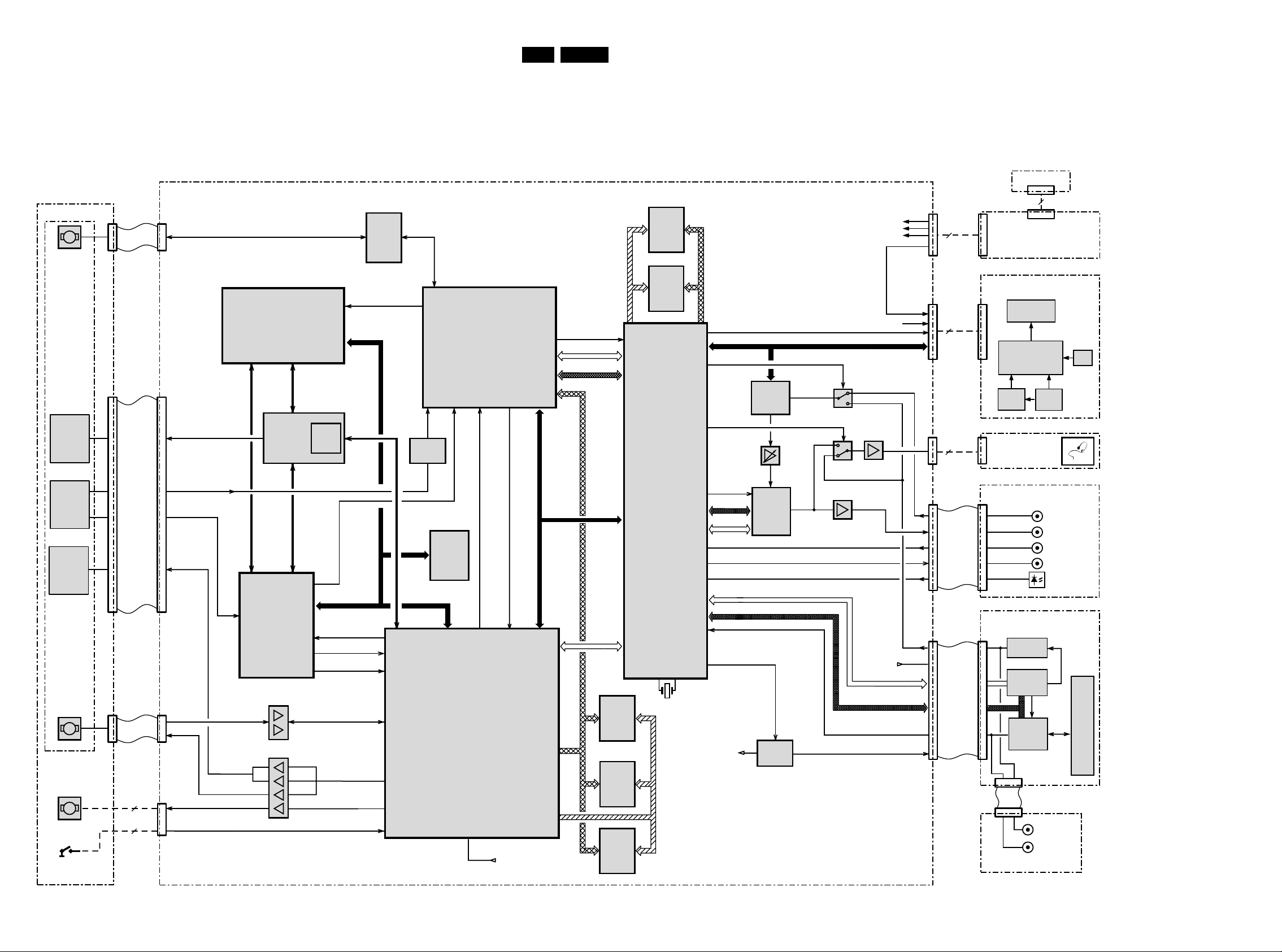

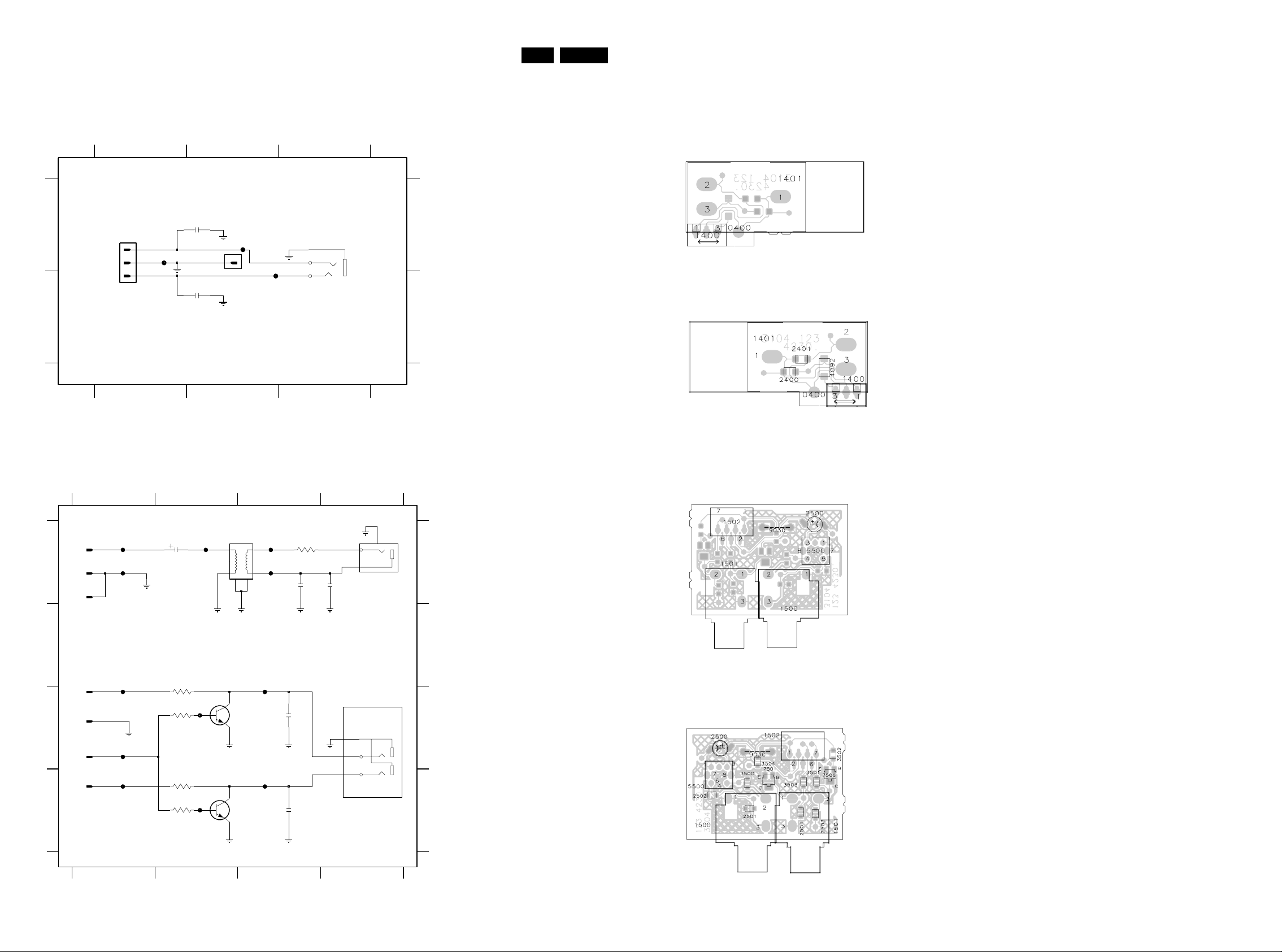

4. Electrical and circuit diagrams

Blockdiagram

OVERALL BLOCK DIAGRAM

GB 104.

CDL 4009

LOADER ASSY

CDM3800

M

TURN

TABLE

LASER

&

FORWARD

SENSE

PHOTO

DIODES

RADIAL

FOCUS

M

SLEDGE

M

TRAY

TRAY

SWITCH

FLEX 11P

FLEX 30P

1220

FLEX 10P

2 WIRES

2 WIRES

CDR MAIN BOARD

1330

DRIVE, HALL FEEDBACK

1000

IR, IW, IE

CAHF

A1LF, A2LF, B1LF, B2LF

C1LF, C4LF

PCS PRE-AMP

SIN+, SINCOS+, COS-

SL+, SL-

1200

TR+, TR-

TRAYSW

NE532D

POWER

DRIVER

BA5938FM

7330

HALL

MOTOR

DRIVER

BA6856FP

7008

EFMTIM3 CDR60

LO9805

EFM TIMING

GENERATOR

EFMDATA,EFMCLK,LWRT

SAA7392

LO9805

DECODER

ENCODER

MOTOR CONTROL

CONTROL

LINES

CONTROL

LINES

AEGER

TZA1020

CONTROL

LINES

LASER

CONTROL

CONTROL

LINES

7010

7016

XDAC

M62364

CONTROL

LINES

2

I C BUS

HIN

HF AMP

FILTER

1 C

EEPROM

M24C08

WOBBLE

7207

2

ANALOG

ERROR SIGNAL

GENERATOR

FOR

RECORDABLE

7225

ALPHA0

A1, A2, CALF

TLN,MAIN,FEN,REN,RE

REFSIN,SINPHI,REFCOS,COSPHI

MACE2

SAA7399

BASIC ENGINE

PROCESSOR

7240

RAD

FOCUS

SLEDGE

TRAY

VRA, VFO, VSL

TRAYIN, TRAYOUT

TRAYSWF

OFFTRACK

LLP

CDR60PLL

ATIPSYNC

SYS-CLK-BE

(8.4672 Mhz)

7300

CONTROL

LINES

7270

ADDRESS

BUS

DOBM-CDR

SUBCODE BUS

2

I S BUS 1

DATA

BUS

DSA-CDR

FLASH

EPROM

DEMUX

A1-A20

DIGITAL AUDIO

SIGNAL

PROCESSOR

7802

RAM

7208

7209

7703

FLASH

ROM

7702

DRAM

DASP

MCF5244

33.8688 MHz

ADDRESS

BUS

%

7701

D16-D31

1707

DATA

BUS

INT-COPY-ANAA

SEL-HP-OUT

SYS-CLK-11W

2

I S BUS 2/4

L3 BUS

EXT-DIG-IN

DIG-OUT-C

EXT-OPT-IN

SYS-CLK-16W (16.9344Mhz)

SYS-CLK-BE

(8.4672 Mhz)

SYS-RESET

2

I S BUS

7801

DIGITAL

POT

DS1807

7405

7406

CODEC

UDA1341TS

ADC/DAC

DSA-CD

2

I S BUS 3-CD

DOBM-CD

/2

74F74D

ANALOG

IN

ANALOG

OUT

7706A

ANA-OUT

CD-ANA-OUT

+5V

+12V

-8V

VDC1,VDC2,VFTD

D5V

7401

EXT-ANA-IN

CD-ANA-OUT

7407 7408

7409

SYS-RESET

SYS-CLK-8W (8.4672Mhz)

1500

F934

1410

1400

1708

11 WIRES

10 WIRES

3 WIRES

FLEX 14P

FLEX 22P

ON/OFF

0205

POWER SUPPLY

UNIT

DISPLAY ASSY

1119

DISPLAY

15-BT-60GNK

SLAVE DISPLAY

CONTROLLER

TMP87CH74F

KEYS

1400

HEADPHONE

I/O BOARD

1000

CD PLAYER

UDA1320

DECODER

FLEX

7P

7309

DAC

uP

S87C654

SAA7324

1209

1502

1208

CD OUT

1302

2 WIRES

0206

1113

7104

1050

EASY

JOG

EXTERNAL

ANALOG IN

ANALOG OUT

COMMON

EXTERNAL

DIGITAL IN

DIGITAL OUT

COMMON

EXTERNAL

OPTICAL IN

7207

7000

CD

ANALOG OUT

CD

DIGITAL OUT

RC5

CD

DRIVE

Page 13

Display

GB 114.

123

DISPLAY BOARD LAYOUT .5 - CIRCUIT DIAGRAM

A

V13

B

C

V14

D

V15

E

F

H

I

3104 123 4230.5

+5V

7203

BC847B

3122

82K

VFTD

+5V

7204

BC847B

3124

82K

VFTD

+5V

7100

BC847B

3106

82K

VFTD

1 11

F101

VDC2

F102

7104

TMP87CH74F

F127

F128

F129

F131

F134

F136

F139

F142

VFTD

2101

100n

GNDA

TO ON/OFF &

STBY LED BOARD

F140

F143

F145

F147

F149

F174

F152

F153

GNDA

1

2

234567

1113

15-BT-60GNK

REM REC

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SYNC MANUAL

DIGITAL ||

OPTICAL||

ANALOG

1F+

2F+

3F+

47

46

45

F100

F114

65

V23

V24

66

V25

V26

67

68

V27

V28

69

V29

70

V30

71

V31

72

V32

73

V33

74

V34

75

76

V35

77

V36

VKK

78

-SCK1

79

SI1

SO1

GNDA

1121

PH-B

1

F159

F166

GNDA

45678

TIME TRACK TOTAL REM TRACK TIME FADE STEP

1G

2G

403G394G385G376G367G358G34

42

41

F103

F115

F116

V21

V20

V22

8-Bit h. break. v.

80k pull

down

8-Bit h. breakdown v.

out. port w. latch P9

source open

drain 80k p.d.

5-Bit h. breakd. v.

out w. latch PD

8-Bit Input/Output

(tri-state)

P03

P04

P05

3

4

F170

F171

CDLED

3109

560R

F164

CD

RW

9G

10G3211G3112G3013G2914G2815G

V15

F104

V19

P06

CDRLED

F117

P0

F106

F105

F118

585966061626364

V16

V15

V17

V18

80k pull down

VFT driver circuit (automatic display)

XIN

XOUT

VSS

P07

8809

7

GNDA

F162

3112

39K

1110

GNDA

CD

P9

F110

V7

TC2

3113

10K

F167

F123

V6

-DV0

+5V

PROG A-B

SHUFFLE ALL

REPEAT DISC

SCAN TRACK

P2

P1

7

8P39P410P511P612P713P814

6

F112

F111

F124

V4

V3

V5

80k pull down80k pull down

8-Bit A/D

Converter

3-B. I/O P3

P1

sink o.drain

INT2

TC1

TC4

B

3114

10K

F168

4344454647484955051525354555657

RECORD

CHANGER

L

R

P2026P21

NC

25

27

V13

V14

F107

F119

V14

8-Bit high breakdown voltage 8-Bit high breakdown v.

output port with latch output port with latchout w. latch P8

F108

F120

V11

V12

V13

P6-P9 source open drain

ROMRAM

RW

P1622P1723P1824P19

P1016P1117P1218P1319P1420P15

15

2133

F109

F122

F121

V8

V9

V10

Program

Counter

CPU

sink open

-RESET

10 11 12

RESETN

drain

3-Bit In/Output

with latch P2

XTIN

XTOUT

F157

2102

22n

GNDA

8-Bit Input/Output

(tri state)

TEST

-STOP

-INT0

F158

INTERRUPT

-INT1

A

13 14 15 16 17 18 19220 21 22 23 24

GNDA

+

3F-

1F-

2F-

1

2

3

F113

F125

4142

V1

V2

VAREF

P6P7

VASS

AIN13

AIN12

AIN11

AIN10

4-Bit In/Output

(tri-state) P5

P4

8-Bit Input/Output

(tri-state)

-SCKO

INT4

SCL

1050

5

3

MT16MT2

GNDA

F165

V0

VDD

AIN7

AIN6

AIN5

AIN4

AIN3

AIN2

AIN1

AIN0

SCA

27

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

F155

F161

VFTD

6100

BZX284-C3V3

VDC1

3125

3K3

+5V

GNDA

5100

BLM21

F126

2100

100n

3107

4K7

B

A

GNDA

GNDA

3108

100R

3111

100R

2111

100n

F130

F132

F135

F137

F141

F144

F146

F148

F150

F151

F154

F163

4

1

89

+5V

+5V

GNDAGNDA

1101

EVQ21

PLAY /

PAUSE

1109

EVQ21

ERASE

1117

EVQ21

SCROLL

F138

B

F133

A

1122

1

EH-B

2

3

TO IR BOARD

9

+5V

3100

4K7

SOURCE

REPEAT

2106

22p

GNDA

2104

22p

GNDA

10 11 12 13

1114

EVQ21

REC.

START

1111

EVQ21

EXT.

1120

EVQ21

1115

EVQ21

MENU

4K7

F160

3101

F172

1131-A

3115

560R

0100

10

1105

EVQ21

STOP

1131-B

SKHQ

CD SELECT

SKHQ

CDRLED

1125

EVQ21

DJ

MODE

1118

EVQ21

CANC /

DEL

F156

INTERRUPT

1

GND WIRE

GNDA

+5V

VDC2

VFTD

VDC1

RESETN

IIC_DATA

IIC_CLK

+5V

3102

4K7

GNDA

GNDA

1130-B

F173

SKHQ

CD SELECT

1130-A

3116

560R

F169

1106

EVQ21

OPEN/

CLOSE

1103

EVQ21

PROG

SKHQ

1126

EVQ21

PLAY

CD

1

2

3

4

5

6

7

8

9

10

CDLED

+5V+5V

GNDA

1119

EH-B

3103

4K7

TO MAINBORD

1107

EVQ21

REC.

TYPE

1102

EVQ21

SHUFFLE

1104

EVQ21

PREV

1127

EVQ21

STOP

CD

+5V

12

3104

4K7

1108

EVQ21

FINALIZE

1116

EVQ21

DISPLAY

1112

EVQ21

NEXT

1128

EVQ21

O / C

CD

+5V

3105

4K7

13

0100 G10

1050 H7

1101 B9

1102 C12

1103 C11

1104 C12

1105 B10

1106 B11

1107 B12

1108 B12

A

1109 C9

1110 G4

1111 C10

1112 C12

1113 A3

1114 B10

1115 D10

1116 C12

1117 C9

1118 D10

1119 F11

1120 C10

B

1121 G3

1122 H9

1125 C10

1126 D11

1127 D12

1128 D12

1130-A D11

1130-B C11

1131-A C10

1131-B B10

2100 D7

C

2101 F2

2102 G5

2104 G10

2106 G10

2111 H8

3100 B9

3101 B10

3102 B11

3103 B11

3104 B12

3105 B13

3106 E1

D

3107 F8

3108 G8

3109 G4

3111 G8

3112 G4

3113 G6

3114 G6

3115 C10

3116 D11

3122 B1

3124 C1

3125 C8

E

5100 D7

6100 B8

7100 E1

7104 D3

7203 A1

7204 C1

F100 C3

F101 B2

F102 C2

F103 D4

F104 D4

F

F105 D4

F106 D5

F107 D5

F108 D5

F109 D5

F110 D6

F111 D6

F112 D6

F113 D7

F114 D3

F115 D4

F116 D4

GG

F117 D4

F118 D4

F119 D5

F120 D5

F121 D5

F122 D6

F123 D6

F124 D6

F125 D6

F126 D7

F127 D3

F128 D3

H

F129 D3

F130 D7

F131 D3

F132 D7

F133 E9

F134 E3

F135 E7

F136 E3

F137 E7

F138 E9

F139 E3

I

F140 E3

F141 E7

F142 E2

F143 E3

F144 E7

F145 E3

F146 E7

F147 E3

F148 E7

F149 F3

F150 F7

F151 F7

F152 F3

F153 F3

F154 F7

F155 G7

F156 G10

F157 G5

F158 G5

F159 G3

F160 G10

F161 G7

F162 G5

F163 H7

F164 G4

F165 C7

F166 G3

F167 H6

F168 H6

F169 G11

F170 G4

F171 G4

F172 B10

F173 C11

F174 F3

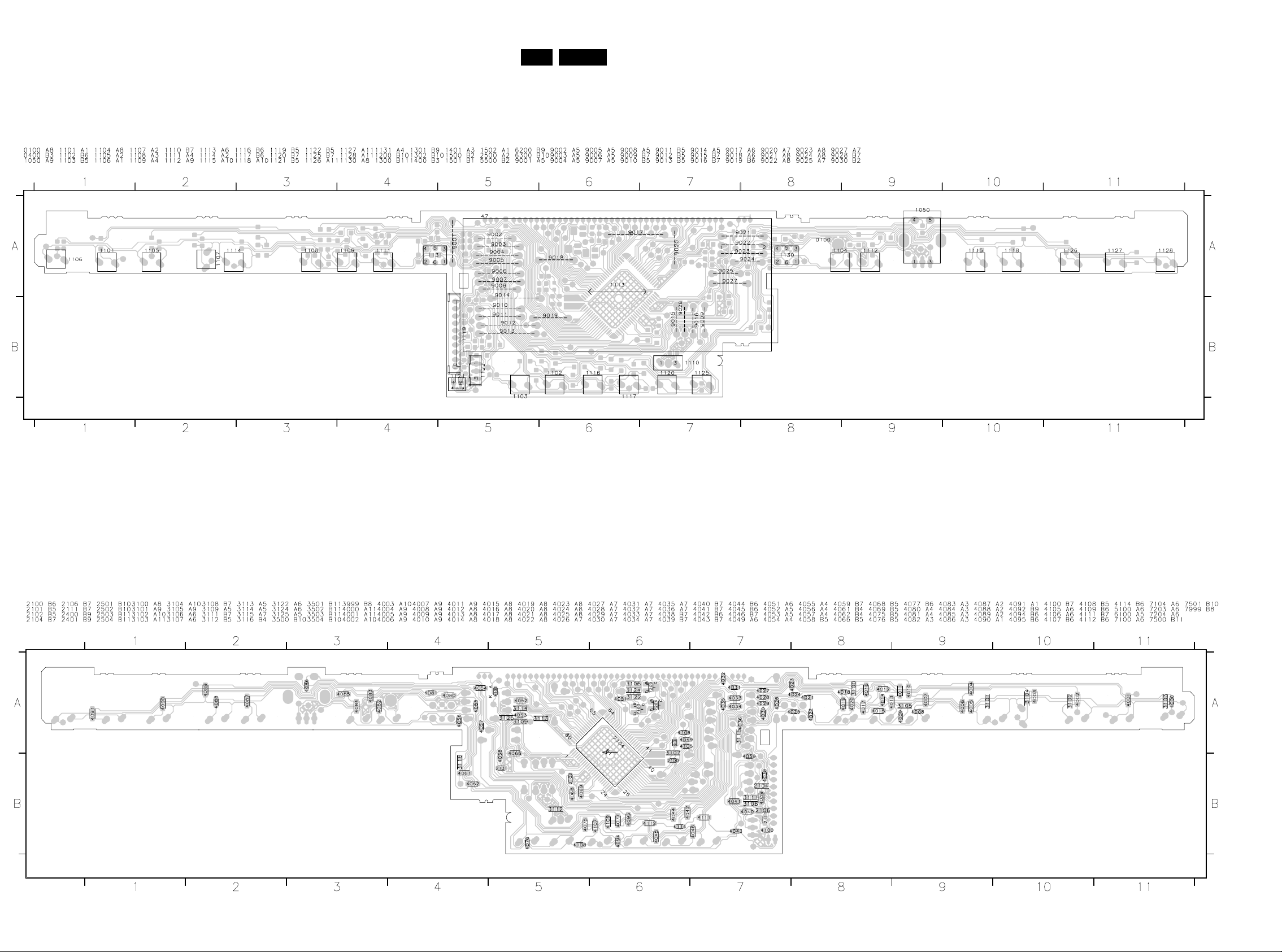

Page 14

Display

DISPLAY BOARD CDR775 LAYOUT.5 TOP VIEW

GB 124.

PB DISPLAY 4230

3104 123 4230.5

DISPLAY BOARD CDR775 LAYOUT.5 BOTTOM VIEW

PB DISPLAY 4230

3104 123 4230.5

Page 15

R on/off

IR BOARD CDR775 - CIRCUIT DIAGRAM

123

1200 A1

6200 A3

F200 A2

F201 A2

F202 A2

GB 135 4.

IR BOARD - FRONT VIEW

1200

EH-S

AA

1

2

3

F200

F201

F202

2

VS

3

OUT

1

GND

6200

TSOP1736

TO DISPLAY

BOARD

12

GNDB

3

PB DISPLAY - 4230

CDR 775

3104 123 4230

ON/OFF & STBY LED BOARD CDR775 - CIRCUIT DIAGRAM

123

A

6300

LTL-1CHPE

F300

F301

1

1300

PH-B

2

TO DISPLAY

BOARD

A

1300 A3

1301 C3

1302 B1

6300 A1

F300 A2

F301 A2

F302 B2

F303 B2

IR BOARD - BACK VIEW

ON/OFF & STBY LED BOARD - FRONT VIEW

B

C

TO PSU

1302

EH-B

1

2

F302

F303

4

6

1301

SPPH23

251

3

PB DISPLAY - 4230

CDR 775

3104 123 4230

123

B

ON/OFF & STBY LED BOARD - BACK VIEW

C

Page 16

HPCD out

HEADPHONE BOARD CDR775 - CIRCUIT DIAGRAM

123

F401

2400

1n

GND WIRE

GNDC

2401

1n

GNDC

GNDC

0400

1

F400

GNDC

F402

HLJ1540

1

3

2

1401

A

1400

PH-B

TO CDR MAIN

BOARD

3

2

1

B

PB DISPLAY - 4230

CDR 775

3104 123 4230

A

B

0400 A2

1400 A1

1401 A3

2400 A2

2401 B2

F400 A2

F401 A1

F402 B2

GB 144.

HEADPHONE BOARD - TOP VIEW

HEADPHONE BOARD - BOTTOM VIEW

123

CD OUT BOARD CDR775 - CIRCUIT DIAGRAM

52044

A

52044 4

52044

TO CD MAIN BOARD

B

52044

52044

C

52044 1

52044 5

D

12

GNDD

2500

10u

F502

GNDD GNDD

3501

180R

F508

3502

2K2

3503

180R

F509

3504

2K2

1502-3

3

1502-4

1502-2

2

1502-7

7

1502-6

6

1502-1

1502-5

F500

DIGININT

F501

F505

RIGHT2

GNDD

F506

KILL

F507

LEFT2

5500

7CHA

DIGOUTCOIL

34

2

1

78

GNDD

7500

BC847B

GNDD

7501

BC847B

34

F503

F504

6

F510

2503

220p

GNDD

F511

2504

220p

3500

68R

33n

2501

GNDD

GNDD

2502

33n

GNDD

1

2

3

1500

YKC21-3416

DIGITAL OUT CD

ANALOG OUT CD

1501

YKC21-3613

3

2

1

CD OUT BOARD - TOP VIEW

1500 A4

1501 C4

1502 A1

1502 A1

1502 A1

1502 C1

1502 C1

A

1502 C1

1502 D1

2500 A2

2501 A3

2502 A4

2503 C3

2504 D3

3500 A3

3501 C2

3502 C2

B

3503 D2

3504 D2

5500 A2

7500 C2

7501 D2

F500 A1

F501 A1

F502 A2

F503 A3

F504 A3

F505 C1

F506 C1

F507 D1

F508 C2

F509 D2

F510 C3

F511 D3

CD OUT BOARD - BOTTOM VIEW

C

D

GNDD GNDD

12

PB DISPLAY - 4230

CDR 775

3104 123 4230

34

Page 17

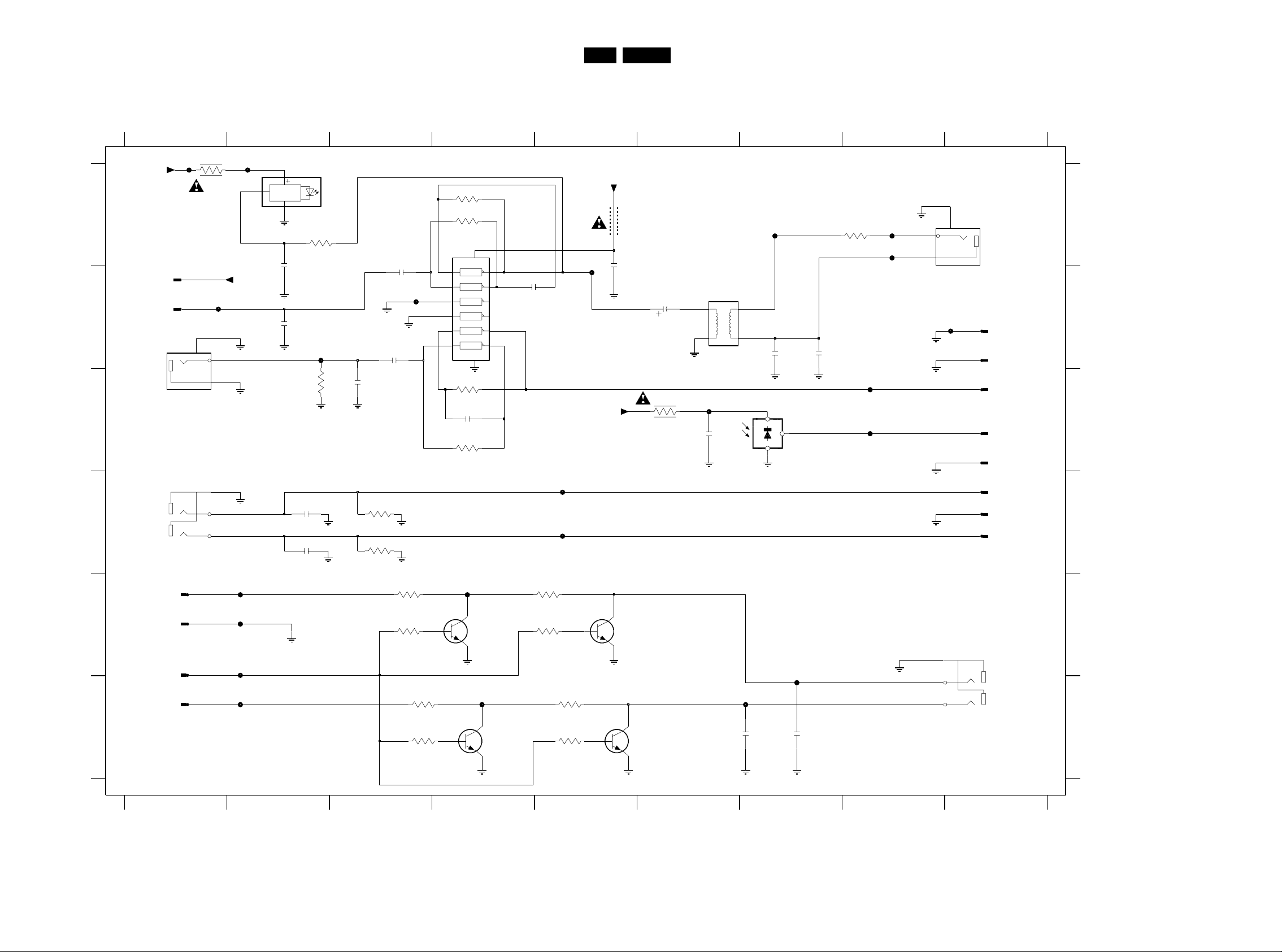

I/O board

I/O BOARD - CIRCUIT DIAGRAM

1

3025

+5VDS

F100 F101

4R7

1

A

1000-8

B

+5V

DIGOUT

1001-B

YKC21-3421

DIGITAL INPUT

8

1000-13

13

5

+5VDS

F108

3

4

C

1002-B

YKC21-3699

5

1000-3

3

1000-2

2

1000-7

7

1000-1

1

6

4

F115

F117

F119

F120

INPUT RIGHT

D

INPUT LEFT

RIGHTOUT

E

KILL

LEFTOUT

F

GB 154.

23456789

2

DRIVER

3

2015

33p

2030

33p

2026

100p

2027

100p

GP1F32T

7010

3023

100R

F105

3029

75R

2025

150p

3030

100K

3031

100K

2017

2020

22n

22n

F107

3032

100R

3034

2K2

3036

100R

3038

2K2

3021

3024

7005

74HCU04D

1A

1

2A

3

3A

5

4A

9

5A

11

6A

13

3026

2023

3027

F116

3K3

3K3

VCC

GND

3K3

22n

3K3

7006

BC847B

14

1Y

2Y

3Y

4Y

5Y

6Y

7

F121

7008

BC847B

2

4

6

8

10

12

2018

22n

F113

F114

3033

100R

3035

2K2

3037

100R

3039

2K2

F106

+5VDS

+5VDS

5002

BLM21

2016

22n

7007

BC847B

7009

BC847B

2019

10u

3028

4R7

5001

7CHA

34

2

1

78

F110

2024

22n

GP1F32R

6000

F102 F103

6

2029

33p

2022

33n

F122

2028

33p

2021

33n

1

3

IR

2

F118

3020

68R

F111

F112

F104

1

2

5

F109

1000-12

1000-11

1000-10

1000-14

1002-A

YKC21-3699

2

3

1

1001-A

YKC21-3421

DIGITAL OUTPUT

1000-9

9

12

DIGIN

11

OPTIN

10

14

1000-4

RIGHTIN

4

1000-5

5

1000-6

LEFTIN

6

A

B

C

D

E

OUTPUT RIGHT

OUTPUT LEFT

F

1000-1 F1

1000-10 C9

1000-11 C9

1000-12 B9

1000-13 B1

1000-14 C9

1000-2 E1

1000-3 E1

1000-4 D9

1000-5 D9

1000-6 D9

1000-7 E1

1000-8 B1

1000-9 B9

1001-A A9

1001-B B1

1002-A E9

1002-B D1

2015 A2

2016 A5

2017 B3

2018 B4

2019 B6

2020 B3

2021 B7

2022 B7

2023 C4

2024 C6

2025 C3

2026 D2

2027 D2

2028 F7

2029 F7

2030 B2

3020 A8

3021 A4

3023 A2

3024 A4

3025 A1

3026 C4

3027 C4

3028 C6

3029 C3

3030 D3

3031 D3

3032 E3

3033 E5

3034 E3

3035 E5

3036 F3

3037 F5

3038 F3

3039 F5

3999 F9

5001 B6

5002 A5

6000 C7

7005 A4

7006 E4

7007 E5

7008 F4

7009 F5

7010 A2

PB AUDIO-I/O CDR99

3104_123_4239

123456789

Page 18

I/O board

I/O BOARD - TOP VIEW

GB 164.

I/O BOARD - BOTTOM VIEW

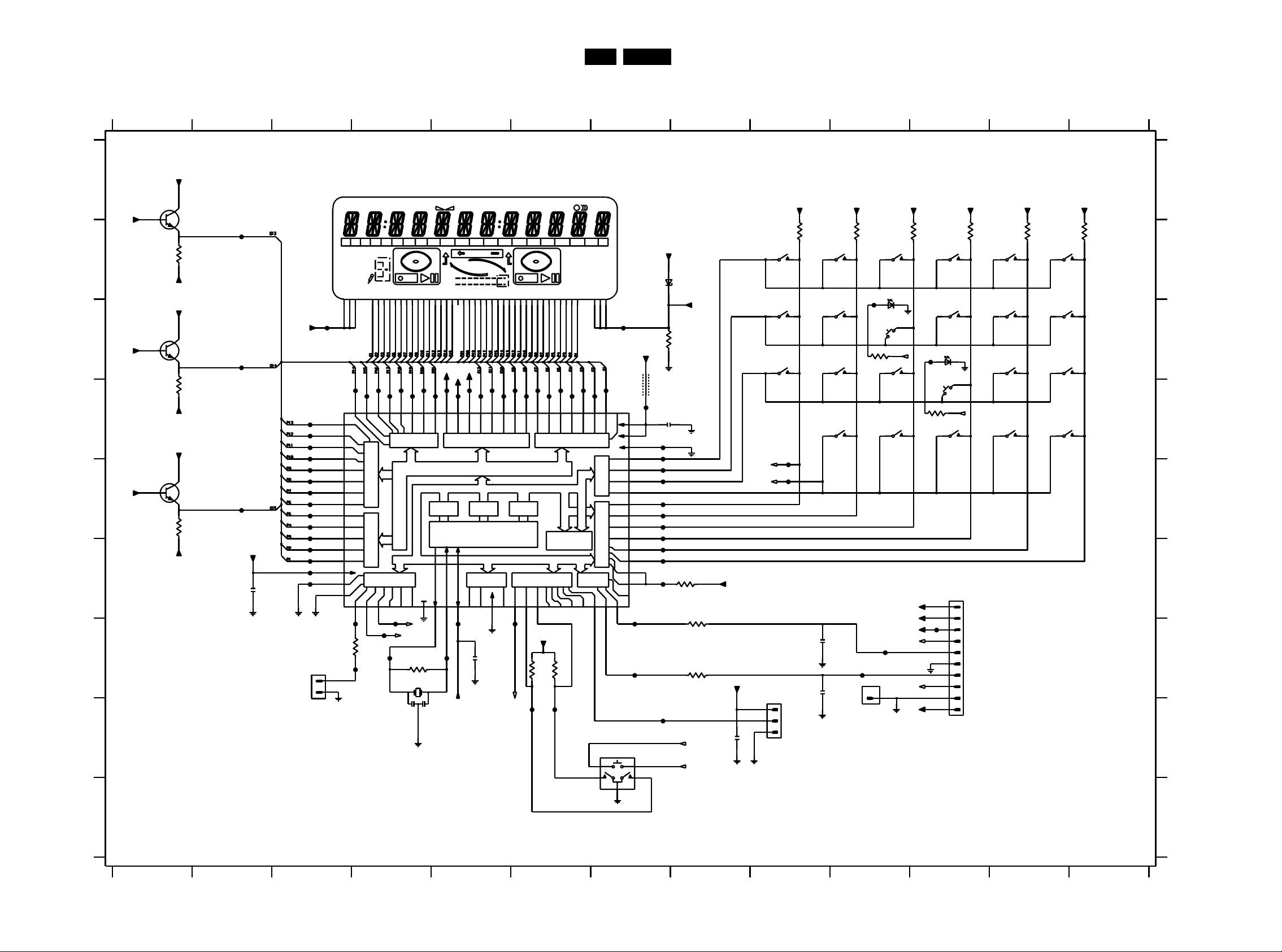

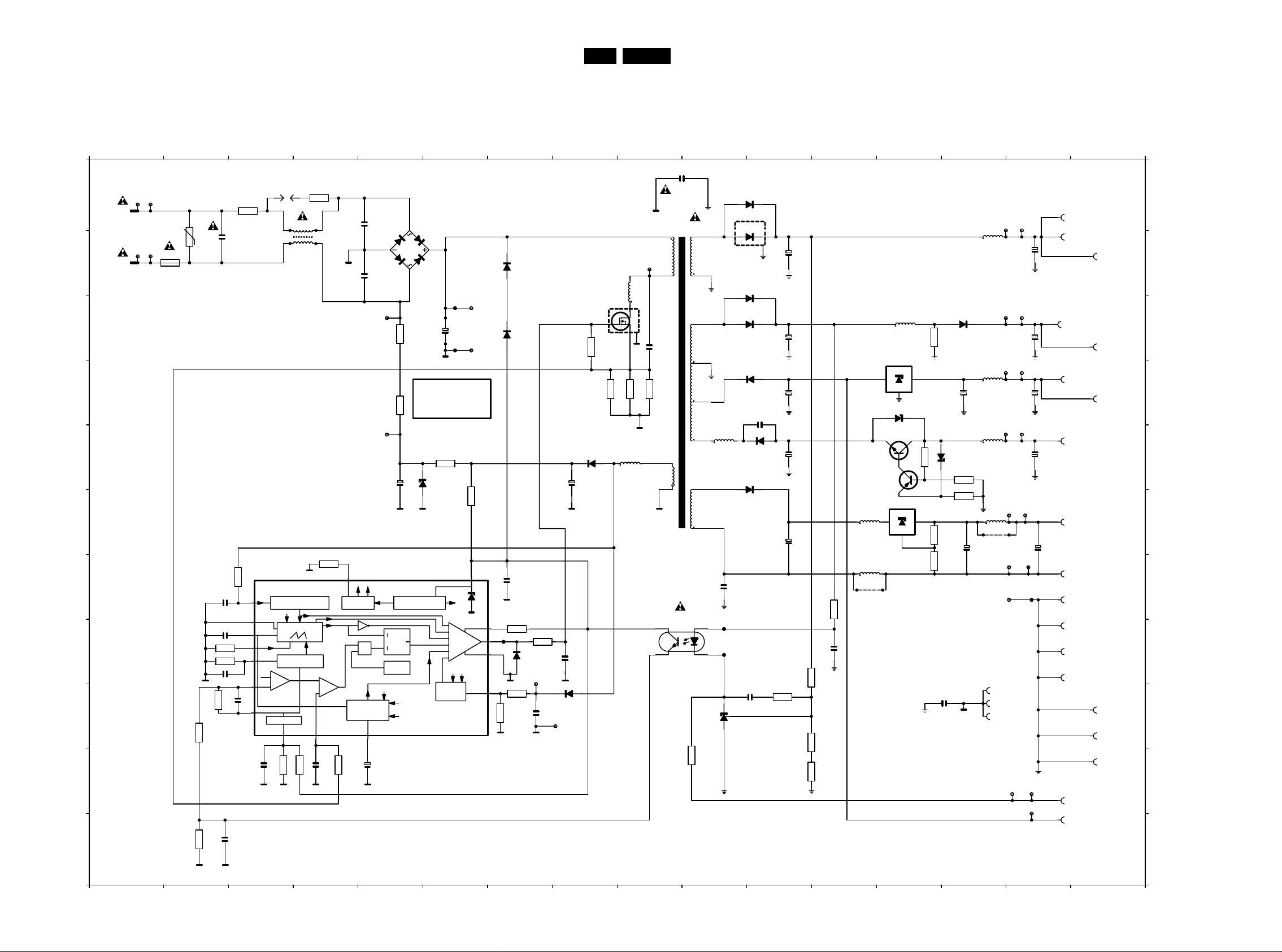

Page 19

PSU 99

GB 174.

0101 A 1

0101 B 1

0125 C 8

0205 F15

0205 E15

0205 G15

A

B

C

D

E

F

G

H

I

J

K

0101

0101

0205 G15

0205 A15

0205 A15

0205 G15

0205 H15

0205 H15

TP1 TP2

TP3 TP4

T2.0AL250V

1120

0205 C15

0205 D15

0206 J15

0206 J15

0207 I16

0207 C16

3120

3102

3103

3105

3106

0207 I16

0207 B16

0207 J16

0207 D16

0208 H14

0210 B11

"$

2120

330nF

385V

2101

82pF

2102

820pF

22K

8K2

2103

470pF

15K

3104

15K

*

1K

2106

3101

2104

3122

1R5

82K

8

9

10

15

12

14

4.7nF

13

1120 B 2

1125 A 3

2101 G 2

2102 H 2

2103 H 2

2104 I 3

1125

5120

7110

MC44603AP

DEMAGNETIZATION

DETECT

DEMAGNETISATION

MANAGEMENT

iref

SYNC INPUT

OSCILLATOR

CT

RF

STANDBY

RP

STANDBY

STANDBY

(reduced frequency)

2.5V

ERROR

AMP

VOLTAGE

FEEDBACK

E/A OUT

FOLDBACK

FOLDBACK

INPUT

5

*

18K

2107

3108

3107

2106 K 2

2107 J 3

2109 J 4

2110 J 5

2111 G 7

2113 H 8

3124

220R

Vstby

VSB OUT

2109

180K

4561 7 8 9 101112131415 1623

3110

10K

16

reference

VOSC PROT

VOSC

CURRENT

SENSE

SOFT-START

CONTROL

CURRENT

SENSE INPUT

7

1.5nF

3109

330R

2114 I 7

2120 B 3

2121 C 6

2125 A 5

2126 B 5

2127 C 9

2125

2126

Vref iref

block

=1

Dmax &

SOFT START

& DMAX

11

2110

2129 E 5

2131 A 9

2133 E 8

2201 H12

2202 I11

2210 B11

2.2nF/400V

2.2nF/400V

TP27

18K

3123

18K

3134

TP28

2129

Vref enable

initialization block

Set

LATCH

Reset

THERMAL

SHUTDOWN

iref

UVL01

Vref

2.2uF/50V

2213 B15

2220 F11

2221 G10

2222 F14

2223 F15

2230 C11

6102

SINB80

TP32

TP25

@

2121

TP33

TP26

@ ITEM 2121

110V 220uF/200V

Wide Range 100uF/400V

Euro 47uF/400V

3129

10K

6129

4.7uF/50V

supply

Q

BZX84-C24

UVL01

BUFFER

Vref Voc

OVER

VOLTAGE

MANAGEMENT

3111

22R

1

VC

OUT

GND

OVER

VOLTAGE

PROTECT

2233 C15

2240 D11

2242 D14

2243 D15

2250 E11

2251 D11

6106

6107

2111

2

TP29

3

4

6

3116

180R

BYD33J

BYD33J

100nF

3112

100R

6113

3115

910R

2252 E15

2260 I14

3101 G 3

3102 H 2

3103 H 2

3104 I 2

3113

15R

*

TP21

2114

TP22

100nF

3105 I 2

3106 K 2

3107 J 4

3108 J 3

3109 J 4

3110 G 4

STP5NB60FI

2133

2113

2.2nF

6114

BYD33D

7125

10K

3125

3126

6132

BYD33J

100uF/25V

3111 F 6

3112 H 7

3113 H 7

3115 I 7

3116 I 7

3120 B 2

0125

1R

3127

5132

10uH

5125

1R5

TP30

BEAD

2127

3128

3122 A 3

3123 C 5

3124 A 4

3125 C 8

3126 D 8

3127 D 9

2

5

470pF/1KV

1R5

7

9

CQY80NG

5

4

2131

2.2nF

5131

CT296F

7200

3203

3128 D 9

3129 E 6

3134 D 5

3201 G12

3202 H11

3203 J10

2

100R

17

15

11

13

10

14

16

18

1

TP23

TP24

7201

PBYR1060F

BYW98-200

5255

1uH

2221

47nF

TL431

3204 I11

3205 J11

3206 I11

3221 G13

3222 F13

3230 C13

6211

SB360

6210

6232

6230

BYW29F

6240

BYD33D

2251

6250

BYD33J

6220

BYD33D

2202

22nF

0210

*

3204

2210

2230

2240

2250

2220

1K8

3232 E13

3233 E14

3234 F14

5120 A 4

5125 B 9

5131 A 9

2200uF/10V

1000uF/16V

220uF/16V

10uF/50V

330uF/16V

3K3

3202

3K

3206

150R

3205

5132 E 9

5210 B14

5220 F14

5225 F12

5226 G12

5230 C13

10R

3201

2201

100nF

5240 D14

5250 E14

5255 E10

6102 A 6

6106 B 7

6107 C 7

BZX284-C6V8

7251

BC847

7252

BC857

5225

4.7uH

5226

*

9226

5230

2u2

6113 H 7

6114 I 8

6129 E 5

6132 E 8

6201 E14

6210 B11

3230

1K

6211 A11

6220 E11

6230 C11

6231 C14

6232 B11

6240 D11

6231

1N4006G

7249

L7908

2242

6251

3232

11K

BZX84-B20

6201

3233

10K

3234

10K

100uF/10V

7221

LM317T

240R

3222

2222

3221

470R

100uF/6V3

0208

2260

1nF

FRAME

* = RESERVED ITEM NUMBER

5210

6.8uH

5240

10uH

5250

10uH

5220

*

9220

1

2

3

6250 E11

6251 D13

7110 G 3

7125 C 8

7200 G10

7201 I10

TP5 TP6

*

TP7 TP8

*

TP9 TP10

TP11 TP12

TP13 TP14

TP15 TP16

TP17 TP18

TP19 TP20

TP31

2213

2233

*

2243

2252

*

2223

7221 F13

7249 D13

7251 E12

7252 E12

9220 F14

9226 G12

0205

5

0205

6

0205

10

0205

11

0205

2

220uF/50V

0205

1

0205

3

0205

4

0205

7

0205

8

0205

9

0206

1

0206

2

+5V

+5V

+12V

-8V

VFTD

VDC2

VDC1

GND

GND

GND

GND

0207

+5V

4

0207

+12V

2

0207

-8V

6

0207

GND

1

0207

GND

3

0207

GND

5

"

"

A

B

C

D

E

F

G

H

I

J

K

4561 7 8 9 101112131415 1623

CL 96532086_013.eps

080999

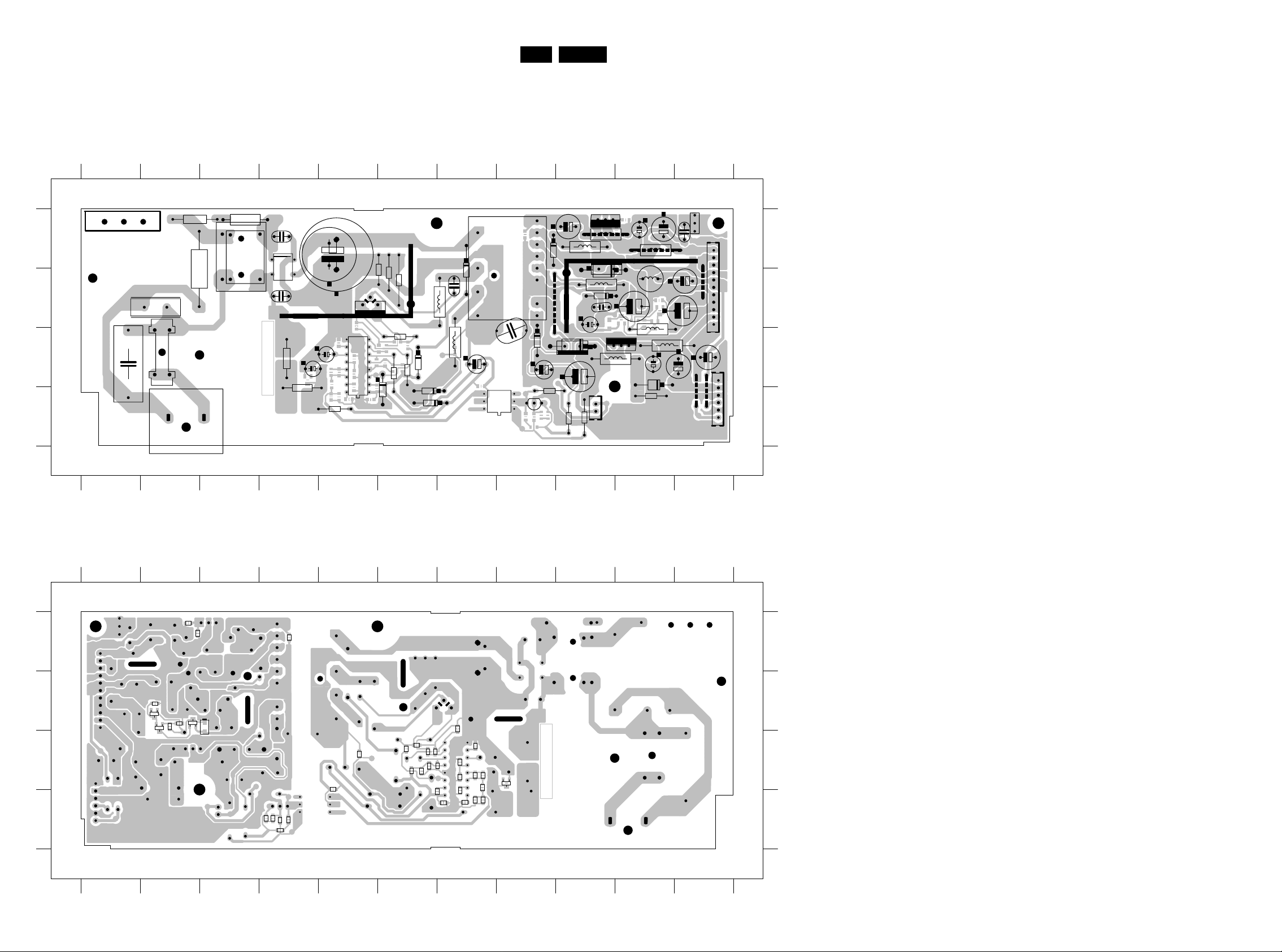

Page 20

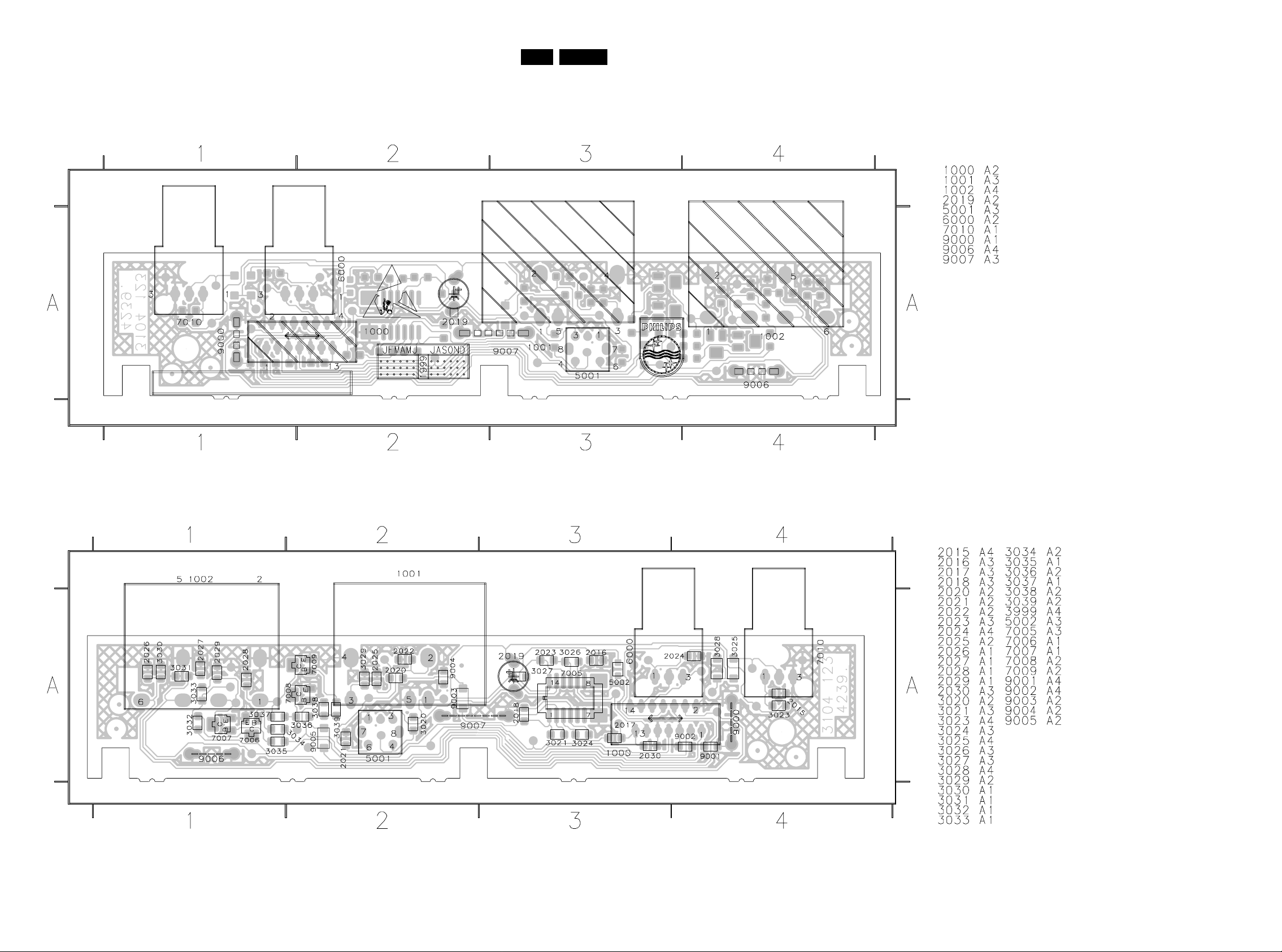

PSU 99

POWER SUPPLY UNIT 20PS317 - COMPONENT SIDE

3126 B 6

0101 D 2

0125 B 5

0205 B 11

0206 D 9

0207 D 11

0208 A 11

0210 A 10

1120 C 2

1125 A 2

2110 C 5

2120 C 1

2121 A 5

2121a A 5

2125 A 4

2126 B 4

2127 B 7

2129 C 4

2131 C 8

2133 C 7

2210 B 10

2213 B 11

2220 A 9

2222 A 10

2223 A 10

2230 C 9

2233 C 11

2240 C 8

2242 C 10

2243 C 11

2250 B 9

2251 B 9

2252 B 11

2260 A 11

3101 C 6

3115 C 6

1234567891011

3120 B 2

3122 B 2

3123 C 4

3124 A 3

3125 C 6

3127 B 6

3128 B 6

3129 D 5

3134 D 4

3201 D 9

3202 D 9

3203 D 8

3230 D 10

5120 A 3

5120a A 3

5125 B 7

5131 B 8

5132 C 7

5210 B 10

5220 A 10

5225 A 9

5226 A 9

5230 C 10

5240 C 10

5250 C 10

5255 B 9

6102 A 4

6106 B 7

6107 C 6

6113 D 6

6114 D 6

6132 D 6

6210 B 9

6211 B 9

6220 A 8

6230 C 9

6231 C 10

6232 C 9

6240 C 8

GB 184.

6250 B 9

7110 C 5

7125 B 5

7200 D 8

7201 D 8

7221 A 9

7249 C 10

9208 B 11

9210 B 8

9214 D 11

9215 D 11

9220 A 10

9226 A 9

1125

3124

2125

A

_

3122

B

3120

5120a

+

2126

6102

0125

5120

T2.0AE 250V

2110

C

2120

D

1120

0101

2129

3123

UL-LOGO

3122 423 30443

CAUTION:

RISK OF FIRE REPLACE ONLY

WITH SAME TYPE OF FUSE.

ATTENTION:

UTILISER UN FUSIBLE

DE RECHANGE DE MEME TYPE

3134

3129

1234567891011

POWER SUPPLY UNIT 20PS317 - SOLDERING SIDE

7125

7110

5131

2121

3126

3128

31273115

2121a

6106

5125

2127

3125

1

3

21

2240

7200

6113

5132

2133

6107

3101

6114

6132

6220

9210

6240

3203

7201

3202

2220

6211

6250

6230

2251

3201

2250

9226

6232

2230

7221

5225

0208

2223

2222

A

B

7249

5226

6210

5255

2210

9220

5220

5210

5250

5240

2213

0210

2252

2260

0205

9208

2243

C

5230

2242

2233

6231

9214

0206

3230

9215

0207

D

A

B

C

D

2101 B 5

2102 C 5

2103 C 5

2104 C 5

2106 D 5

2107 C 6

2109 C 6

2111 D 5

2113 C 6

2114 C 7

2201 D 8

2202 D 8

2221 A 8

3102 D 5

3103 C 5

3104 C 5

3234

7252

6201

3105 C 5

3106 D 5

3107 C 6

3108 C 6

3233

3232

3221

7251

3222

3109 C 6

3110 D 5

3111 C 7

3112 D 5

6251

3113 C 6

3116 C 5

3204 D 8

3205 D 8

3206

3205

2201

3206 D 8

3221 A 10

3222 A 10

3232 B 10

3204

2202

2221

3233 B 10

3234 B 10

6129 C 4

6201 B 10

3111

6251 B 9

7251 B 10

7252 B 10

TP1 D 2

TP2 D 2

TP3 D 3

TP4 C 2

TP5 B 11

2114

TP6 C 11

TP7 C 11

TP8 D 11

TP9 C 11

2113

3109

3113

3107

TP10 D 11

TP14 A 11

TP18 B 11

TP22 B 7

TP26 B 5

TP11 A 11

TP12 B 11

TP13 A 10

TP15 A 11

TP16 A 11

TP17 B 10

TP19 C 9

TP20 D 9

TP21 C 7

TP23 D 8

TP24 D 8

TP25 A 5

TP27 C 4

TP28 C 5

TP29 C 5

TP30 B 7

TP31 D 9

TP32 A 4

TP33 B 5

1234567891011

A

B

2101

2109

3116

3108

2107

3112

2111

2102

2104

3103

3104

2103

3105

3102

3110

6129

2106

3106

UL-LOGO

3122 423 30443

CL 96532086_014.eps

C

D

080999

1234567891011

Page 21

CD Diagram 1A

GB 194.

A

B

C

D

CD-DA, CD-R : 5V

CD-RW : 0V

8

F

G

1000-10

H

1000-1 C1

1000-11 G1

1000-12 D1

1000-2 E1

1000-3 B1

1000-4 E1

1000-5 A1

1000-6 H1

1000-7 H1

1000-8 H1

1000-9 H1

1003 F7

1004 G9

1009 C15

1010 C15

1011 C15

1012 C15

1021 G10

1022 G11

1023 G11

1028 B2

1029 B3

1050-1 G1

1050-2 G1

2128 B12

12345

CD MAIN BOARD - CIRCUIT DIAGRAM 1A

DECODER & SERVO PROCESSOR PA

CONN. 1000 : TO CDM VAM1250

F147

100n

3179

1K

4u7

RW

1

HFGND

2135

HFGND

F155

2174

22u

22n

2175

HFGND

F146

+5VHF

2156

HFGND

3198

47R

1028

1

7008

BFS20

47u

1

+5VHF

3177

3182

47u

3187

3201

HFGND HFGND

+5VHF

2

LDON

1000-5

5

VDD

1000-3

3

2133

HFGND

VSUB

1000-1

1

2147

HFGND

F160

RW

1000-12

12

RF

F170

1000-4

4

HFGND

F173

1000-2

2

HFGND

F177

+5V

F180

FTC

1000-11

11

1

1050-1

2

1050-2

10

1000-9

9

1000-8

8

1000-7

7

1000-6

6

PB CD MAIN 4236

CDR99

3104 123 4236

2134

470n

HFGND

F154

2148

470n

HFGND

47n

2159

HFGND

2163

33n

3208

4R7

12345

2130 B6

2131 B12

2132 B11

2133 B1

2134 B1

2135 B1

2137 B8

2138 B8

3279

1R

1R

390R

390R

7011

BFS20

1K2

7311-A

TDA1308T

1

9

3183

3202

10K

22K

+5VHF

100R

8

4

1029

HFGND

3213

1

2151

2166

2182

3

2

2139 B11

2140 C4

2141 C6

2142 C9

2143 C4

2145 C9

2146 C6

2147 C1

+5VHF

47u

47n

HFGNDHFGND

HFGND

7006

BFS20

1K5

3199

10u

100n

2148 C1

2149 C6

2150 C9

2151 D3

2152 D3

2155 D9

2156 D2

2157 D8

3173

430R

F157

100n

2152

3191

430R

2183

eyepattern

2159 D1

2160 D6

2161 D6

2162 E4

2163 E1

2166 E3

2167 E14

2168 F8

2.5V

0,5us/DIV

3174

430R

2143

330p

2

3192

430R

2164

180p

1n5

2201

HFGND

2140

HFGND

2162

HFGND

180p

100p

2200

HFGND

2170 F81000-10 G1

2172 F9

2173 F9

2174 F1

2175 F2

2178 G10

2182 F3

T

+5VHF

3188

7009

BFS20

3203

HFGND

560p

2183 F3

2184 G9

2185 G9

2186 G10

2189 G9

2191 H9

2200 H4

2201 H4

2230 H14

eyepattern

>800mVpp

+5VHF

2K7

3169

7023

BFS20

2K7

3180

HFGND

2K7

2K7

HFGND

V4

61V462

60

MOTO2

MOTOR

CONTROL

DEMOD

CONTROL

FUNCTION

PRE-

PROCESSING

VNEG21VPOS

20

2178

100n

2186

47u

F324

3225

+3V3

DIG.

PLL

EFM

3282 G11

3283 G123168 B12

3285 H13

3286 H13

3287 H133173 B4

7000 C93176 C14

3172

100R

F303

59

MOTO1

22RN23

2286

1n5

1

1022

2R2

7006 D3

7007 E7

7008 E2

7009 D5

7010 E6

7011 E2

7023 B5

7024 F6

7025 B7

+3V3

2R2

3162

2132

3273

3276

100R

47u

2139

100n

58

VSSD3

ADDR

PROCESSOR

RP

1

100R

6

5

4

F305

F304

F308

57

56

55

SL

FO

VDDD2C

OUTPUT

STAGES

SRAM

AUDIO

SELPLL

TEST1

CL16

24

25 31

26

F184

10K

10K

3220

3282

1023

+3V3

F191

7130 H15

7131 H14

7132 H13

7311-A G2

F139 A12

F143 A13

F146 A23193 D7

F147 B1

F149 B13

3274

100R

F306

54

RA

ERROR

CORR.

SER. DATA

INTERFACE

DATA

27

3275

CFLG

WCLK

100R

53

INTERF.

PEAK

DET.

28

+3V3

3161

F302

VDDD1P

EBU

SCLK

52

29

F151 C13

F154 C1

F155 C2

F156 C8

F157 C3

F159 C9

F160 D13202 E2

F162 D7

F163 D14

F139

2R2

2128

47u

2131

100n

3168

100R

51

DOEM

SUBCODE

MICROCONTROLLER

SER. DATA

LOOPBACK

INTERF.

VERSAT.

KILL

INTERF.

EF

30

F318

F321

F322

F164 D7

F165 D133206 E8

F166 E7

F167 E143211 F6

F168 E14

F170 E1

F171 E7

F172 E14

F173 E1

13 14

+5V

10K

50

49

CL11|4

SBSY

SFSY

SUB

RCK

TEST3

STATUS

SILD

RAB

SCL

SDA

RESETn

SCLI

SDI

WCLI

V2|V3

VSSD1

KILL

32

F182

3219-D

3219-B

+5VHF +5VHF

10K

3286

150K

47K

3287

HFGND

F149

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

47R

47R

3171

VSSD2

PROCESSOR

INTERFACE

TEST2

F183

3283

2232

100n

F311

F315

F181

3219-C

3219-A

3285

3267

HFGND

F143

+5V

3284

0R

F165

VPROC

47R

47R

4K7

2233

1n5

7132

BC848B

1K

F151

3280

F163

F167

F168

F172

10K

2280

100n

+5VHF

3268

F190

F174 E7

F175 E7

F177 F1

F178 F9

F180 G1

F181 F13

F182 G13

F183 G12

F184 G11

7005-B

74HCT08D

+5V

3185

SCLK_IN

DATA_IN

WCLK_IN

+5VHF

100K

HFGND

4

5

10

3269

BC858B

7131

1K

+5VY

4K7

3214

0R

100R

BAS216

3266

F190 H14

F191 H11

F192 H143273 B11

F302 B12

F303 B11

F304 B11

F305 B11

F306 B12

F308 B11

14

7

3176

100R

11.2896MHz

+5V

4K7

3186

6003

HFGND

2232 H131020 G10

2236 F6

2280 F14

2285 G10

2286 G11

3160 A9

3161 B12

3162 B11

3164 B15

3169 B5

3171 B13

3172 B11

3174 B4

3177 C2

3178 C8

3179 C1

3180 C5

3181 C9

3182 D2

3183 D2

3184 D8

3185 D14

3186 D14

3187 D2

3188 D5

3189 D7

3190 D9

3191 D4

3192 D42154 D9

3194 D8

3195 E8

3196 E6

3197 E8

3198 E2

3199 E3

3200 E8

3201 E22164 E4

3203 E5

3204 E8

3205 E72169 F8

3208 F12171 F9

3212 F9

3213 F3

3214 F14

3219-A G13

3219-B G13

3219-C G13

3219-D G13

3220 G11

3225 H10

3229 H9

3265 H15

3266 H14

3267 H13

3268 H14

3269 H14

3270 H152233 H13

3274 B12

3275 B12

3276 B11

3279 B2

3280 F13

3281 F6

6 7 8 9 10 11 12 15

4

6

5

HFGND

390p

2149

680p

BF824

7024

2130

100n

2141

2146

HFGND

BC848B

+5VHF

HFGND

2n2

1n5

22n

7010

HFGND

HFGND

HFGND

+12V

3281

3211

16

7

8

1

5

2

4

12

14

15

11

2160

1K

HFGND

3

47u

3196

2R2

HFGND

74HCT4052D

VCC

4x

VEE

GND

0

1

2

3

+5VHF

3189

2161

3193

1K

BC858B

7007

3205

HFGND

2236

7025

0

3

100n

G4

1003

1

2

0

1

390R

180R

10K

10

9

6

HFGND

3

13

F313

F162

F164

F166

F171

PULSE DENSITY MODULATION

S1

S2

22n

22n

2137

2138

HFGND

HFGND

2142

2145

F156

3178

9

F174

F175

+3V3

3194

10K

3195

10K

3197

10K

3200

10K

3204

10K

3206

10K

3184

2R2

2168

8.4672MHz

22n

HFGND

F310

47p

2150

47n

F312

220p

HFGND

CRIN

7

2171

47u

3190

220p

F178

30K

2172

33p

2184

3181

22K

2154

220p

CX-5F

8M4672

HFGND

1K

HFGND

HFGND

100n

2157

HFGND

2170

2169

220p

220p

2155

2173

3212

1M

1004

F309

F314

F159

7000

SAA7324

100n

220p

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

LDON

HFREF

HFIN

ISLICE

VSSA1

VDDA1

IREF

VRIN

D1

D2

D3

D4

R1

R2

VSSA2

CROUT

CRIN

33p

2185

2189

100n

2191

47u

+5VHF

3160

VDDA2

F319

3229

10K

63

64

V1

VERSATILE

INTERFACE

VREF GEN.

ADC

TIMING

LN19LP

17

18

1

1020

2R2

+3V3

FRONT

END

2285

1n5

V5

BITSTREAM DAC

1

1021

13 14 156789101112

6

F192

2230

3164

47R

3265

100K

4n7

2167

F309 C9

F310 C9

F311 D133284 D13

F312 D9

F313 D7

F314 D9

F315 D136003 H14

F318 G12

F319 G97005-B B14

DOBM5_CD

DOBM5_CD

100n

+5VHF

3270

7130

BC848B

HFGND

F321 G12

F322 G12

F324 G10

SL

FO

RA

V4

MOT1

CFLG

A

B

CL11

1009

1

1010

1

1011

1

1012

1

C

D

SILD

SCL

SDA

RESET

EE

F

MUTE

EF

SCLK

WCLK

DATA

CL16

10K

HFDET

G

H

2.5V

0,5us/DIV

Page 22

CD diagram 1B

GB 204.

123456

789

10 11

CD MAIN BOARD - CIRCUIT DIAGRAM 1B

SERVO DRIVERS PART

1002

A

B

HOMESW

SGND

TRAY+

TRAY-

HOMESW

SGND

SL+

1001

SL-

C

RAD+

1000-15

WCOIL

VCOIL

UCOIL

2113

V+

V-

W+

W-

1000-16

1000-14

1000-13

BC858B

7019

3102

47R

3117

F114

100n

PGND

47R

2112

RAD-

FOC-

FOC+

PGND

F120

F123

F124

F125

F129

F132

F116

+5V

100n

15

16

14

13

PGND

F113

2111

PGND

D

E

1006-1

F101

1

F

11

12

G

13

14

15

H

16

17

18

19

I

HALL+

F106

5

HALL-

1006-5

1006-11

11

1006-10

10

9

1006-9

1006-6

U+

6

U-

8

1006-8

1006-4

4

7

1006-7

1006-3

3

2

1006-2

PB CD MAIN 4236

CDR99

3104 123 4236

1

1

2

1

2

+5V

3 A3

5

1

2

100n

9

10 H1-

4

6

11 H2+

12 H2-

15

13 H3+

14 H3-

F103

3

4

3

4

3100

PH-B

PH-B

7020

A2

A17

NC1

NC2

H1+

NC3

NC4

NC5

SGND

SGND

22K

3101

22K

F112

F133

F136

F138

F145

DRIVER

GAIN

CONTROL

+

-

+

-

+

-

+

-

+

-

+

-

TRAYSW

F107

F109

HOMESW

F115

F117

GND

+5V

VCC

8

PGND

SGND

3148

0R

3152

0R

3155

0R

3159

0R

47u

PGND PGND

25

-+

H BIAS

MT1

16

5V8

SGND

14

13

5V8

5V8

12

10

5V8

5V8

SGND

5V8

5V8

SGND

5V8

F100

100n

2105

BA6856FB

RNF

VM1

REV

PS

+

-

FG3

MT2

29 30

PGNDPGND

TDA7073A

3

4

9

TDA7073A

16

3

14

13

12

4

10

9

2104

28

27VM2

26

24REV

23PS

22EC

21ECR

20CNF

19VH

18FG1

17FG2

16

PGND

F300

F301

F118

100K

PGND

1008

1

1R

3135

3146

F131

VDD

100n

PGND

7021

+

+

-

1V6

1V6

VDD

F104

PGND

1R

3134

6002

BYG50D

3107

560R

+3V3

7022

+

+

-

PH-B

2119

PGND

BC847B

15

11

100n

7031

10n

1

2

5

6

7

8

1