Page 1

Guidelines to fi tting bodies

TRUCKNOLOGY

(TGA)

Edition 2011 Version 1.0

®

GENERATION A

Page 2

PUBLISHER

MAN Truck & Bus AG

(mentioned in the text below “MAN“)

ESC Department

Engineering Services

Consultation

Dachauer Str. 667

D - 80995 Munich

E-Mail:

esc@man.eu

Fax:

+ 49 (0) 89 1580 4264

We reserve the right to make changes in the course of technical development.

© 2011 MAN Truck & Bus Aktiengesellschaft

Reprinting, reproduction or translation, even of excerpts, is not permitted without the written permission of MAN.

All rights, in particular under copyright, are strictly reserved by MAN.

Trucknology

Where designations are trademarks they are, even without the

®

and MANTED® are registered trademarks of MAN Truck & Bus AG

®

or ™ sign, acknowledged as the proprietor‘s protected marks.

Page 3

TRUCKNOLOGY

®

GENERATION A (TGA)

1. Applicability and legal agreements

1.1 Applicability

1.2 Legal agreements and approval procedure

1.2.1 Preconditions

1.2.2 Responsibility

1.2.3 Quality assurance

1.2.4 Approval

1.2.5 Submission of documents

1.2.6 Liability for defects

1.2.7 Product liability

1.2.8 Safety

1.2.9 Manuals from body and conversion companies

1.2.10 Limitation of liability for accessories/spare parts

2. Product designations

2.1 Vehicle designation and wheel formula

2.1.1 Door designation

2.1.2 Variant descriptor

2.1.3 Wheel formula

2.1.4 Suffi x

2.2 Model number, vehicle identifi cation number, vehicle number, basic vehicle number

2.3 Use of logos

2.4 Cabs

2.5 Engine variants

3. General

3.1 Axle overload, one-sided loading

3.2 Minimum front axle load

3.3 Wheels, rolling circumference

3.4 Permissible overhang

3.5 Theoretical wheelbase, overhang, theoretical axle centreline

3.6 Calculating the axle load and weighing procedure

3.7 Checking and adjustment procedures once body has been fi tted

3.8 Notes on MAN Hydrodrive

®

1

1

1

1

2

2

3

3

4

5

5

6

7

7

7

7

7

8

9

10

13

14

16

17

17

19

20

20

21

23

24

25

TRUCKNOLOGY® GENERATION A (TGA) I

Page 4

4. Modifying the chassis

4.1 Frame material

4.2 Corrosion protection

4.3 Drill holes, riveted joints and screw connections on the frame

4.4 Modifying the frame

4.4.1 Welding the frame

4.4.2 Modifying the frame overhang

4.4.3 Modifi cations to the wheelbase

4.5 Retrofi tting additional equipment add-on components or accessories

4.5.1 Retrofi tting additional or larger fuel tanks after factory delivery

4.6 Propshafts

4.6.1 Single joint

4.6.2 Jointed shaft with two joints

4.6.3 Three-dimensional propshaft layout

4.6.3.1 Propshaft train

4.6.3.2 Forces in the propshaft system

4.6.4 Modifying the propshaft layout in the driveline of MAN chassis

4.7 Modifying the wheel formula

4.8 Coupling devices

4.8.1 Basics

4.8.2 Trailer coupling, D value

4.9 Tractor units and converting the vehicle type - truck / tractor

4.9.1 Articulated vehicles

4.9.2 Converting trucks into tractor units or tractor units into trucks

4.10 Modifying the cab

4.10.1 General

4.10.2 Spoilers, roof extensions, roofwalk

4.10.3 Roof sleeper cabs

4.11 Add-on frame components

4.11.1 Rear underride guard

4.11.2 FUP - front underride protection

4.11.3 Sideguards

4.12 Modifi cations to engine systems

4.12.1 Modifi cations to the air intake and exhaust gas routing for engines up to and

including Euro4 with On Board Diagnosis

4.12.2 Additional requirements if changes are made to the AdBlue

®

system/exhaust

system on Euro5 vehicles

4.12.3 Engine cooling

4.12.4 Engine encapsulation, noise insulation

4.13 Fitting other manual gearboxes, automatic transmissions and transfer boxes

25

25

30

30

33

33

35

37

43

44

45

45

46

47

48

48

49

49

51

51

52

52

52

55

55

55

55

58

59

59

61

62

64

64

64

66

66

74

74

74

TRUCKNOLOGY® GENERATION A (TGA) II

Page 5

5. Bodies

5.1 General

5.2 Corrosion protection

5.3 Subframes

5.3.1 General

5.3.2 Permissible materials, yield points

5.3.3 Subframe design

5.3.4 Attaching subframes and bodies

5.3.5 Screw connections and riveted joints

5.3.6 Flexible connection

5.3.7 Rigid connection

5.4 Bodies

5.4.1 Testing of bodies

5.4.2 Platform and box bodies

5.4.3 Tail-lifts

5.4.4 Interchangeable containers

5.4.5 Self-supporting bodies without subframe

5.4.6 Single-pivot body

5.4.7 Tank and container bodies

5.4.8 Tippers

5.4.9 Set-down, sliding set-down and sliding roll-off tippers

5.4.10 Propping air-sprung vehicles

5.4.11 Loading cranes

5.4.12 Cable winches

5.4.13 Transport mixers

5.4.14 Car transporter

74

74

76

76

76

77

79

80

81

84

87

87

87

88

96

97

98

98

101

103

104

105

106

116

116

117

TRUCKNOLOGY® GENERATION A (TGA) III

Page 6

6. Electrics, electronics, wiring

6.1 General

6.2 Routing cables, earth cable

6.3 Handling batteries

6.3.1 Handling and maintaining the batteries

6.3.2 Handling and maintaining batteries with PAG technology

6.4 Additional wiring diagrams and wiring harness drawings

6.5 Fuses, additional power consumers

6.6 Lighting installations

6.7 Electromagnetic compatibility

6.8 Radio equipment and aerials

6.9 Interfaces on the vehicle, preparations for the body

6.9.1 Electrical connections for tail-lifts

6.9.2 Start-stop control on frame end

6.10 Electronics

6.10.1 Display and instrumentation concept

6.10.2 Diagnostics concept and parameterisation using MAN-cats

6.10.3 Parameterisation of the vehicle electronics

118

118

118

118

118

119

120

120

123

123

124

126

126

126

127

127

®

127

127

TRUCKNOLOGY® GENERATION A (TGA) IV

Page 7

7. Power take-off (See separate booklet)

8. Brakes, lines

8.1 ALB, EBS braking system

8.2 Brake and compressed air lines

8.2.1 Basic principles

8.2.2 Voss 232 system plug connectors

8.2.3 Installing and attaching lines

8.2.4 Compressed air loss

8.3 Connecting additional air consumers

8.4 Retrofi tting continuous brakes not manufactured by MAN

9. Calculations

9.1 Speed

9.2 Effi ciency

9.3 Tractive force

9.4 Gradeability

9.4.1 Distance travelled on uphill or downhill gradients

9.4.2 Angle of uphill or downhill gradient

9.4.3 Calculating the gradeability

9.5 Torque

9.6 Power output

9.7 Rotational speeds for power take-offs at the transfer case

9.8 Driving resistances

9.9 Turning circle

9.10 Axle load calculation

9.10.1 Performing an axle load calculation

9.10.2 Calculation of weight with trailing axle lifted

9.11 Support length for bodies without subframes

9.12 Coupling devices

9.12.1 Trailer coupling

9.12.2 Rigid drawbar trailers / central axle trailers

9.12.3 Fifth-wheel coupling

127

128

128

128

128

129

130

132

132

134

134

134

135

136

137

137

137

138

142

143

145

146

149

151

151

154

156

157

157

157

159

The ESC numbers stated in the illustrations are purely for internal reference.

They are of no consequence to the reader.

If not otherwise stated: all dimensions in mm, all weights and loads in kg

TRUCKNOLOGY® GENERATION A (TGA) V

Page 8

1. Applicability and legal agreements

1.1 Applicability

The statements in this guide are binding. If technically feasible, exceptions will be approved only if a written request has been submitted

to the ESC department at MAN, (see „Publisher“ above).

1.2 Legal agreements and approval procedure

1.2.1 Preconditions

In addition to this Guide, the company carrying out the work must observe all

• laws and decrees

• accident prevention regulations

• operating instructions

relating to the operation and construction of the vehicle. Standards are technical standards; they are therefore minimum requirements.

Anyone who does not endeavour to observe these minimum requirements is regarded as operating negligently.

Standards are binding when they form part of regulations.

Information given by MAN in reply to telephone enquiries is not binding unless confi rmed in writing. Enquiries are to be directed to

the relevant MAN department. Information refers to conditions of use that are usual within Europe. Dimensions, weights and other basic

data that differ from these must be taken into consideration when designing the body, mounting the body and designing the subframe.

The company carrying out the work must ensure that the entire vehicle can withstand the conditions of use that it is expected

to experience.

For certain types of equipment, such as loading cranes, tail-lifts, cable winches etc, the respective manufacturers have developed

their own body regulations. If, when compared with this MAN Guide, they impose further conditions, then these too must be observed.

References to

• legal stipulations

• accident prevention regulations

• decrees from professional associations

• work regulations

• other guidelines and sources of information

are not in any way complete and are only intended as ideas for further information.

They do not replace the company’s obligation to carry out its own checks.

Fuel consumption is considerably affected by modifi cations to the vehicle, by the body and its design and by the operation of equipment

driven by the vehicle’s engine. It is therefore expected that the company carrying out the work implements a design that facilitates

the lowest possible fuel consumption.

TRUCKNOLOGY® GENERATION A (TGA) 1

Page 9

1.2.2 Responsibility

The responsibility for proper

• design

• production

• installation of bodies

• modifi cation to the chassis

always lies fully with the company that is manufacturing the body, installing it or carrying out modifi cations (manufacturer’s liability).

This also applies if MAN has expressly approved the body or the modifi cation. Bodies/conversions that have been approved in writing

by MAN do not release the body manufacturer from his responsibility for the product. Should the company carrying out the work detect

a mistake either in the planning stage or in the intentions of

• the customer

• the user

• its own personnel

• the vehicle manufacturer

then that mistake must be brought to the attention of the respective party.

The company is responsible for seeing that the vehicle’s

• operational safety

• traffi c safety

• maintenance possibilities and

• handling characteristics

do not exhibit any disadvantageous properties.

With regard to traffi c safety, the company must operate in accordance with the state of the art and in line with the recognised rules in

the fi eld in matters relating to

• the design

• the production of bodies

• the installation of bodies

• the modifi cation of chassis

• instructions and

• operating instructions.

Diffi cult conditions of use must also be taken into account.

1.2.3 Quality assurance

In order to meet our customers’ high quality expectations and in view of international product/manufacturer liability legislation an

on-going quality monitoring programme is also required for conversions and body manufacture/installation. This requires a functioning

quality assurance system. It is recommended that the body manufacturer sets up and provides evidence of a quality system that

complies with the general requirements and recognised rules (e.g. DIN EN ISO 9000 et seq. or VDA 8).

Evidence of a qualifi ed system can be provided for example by:

TRUCKNOLOGY® GENERATION A (TGA) 2

Page 10

If MAN is the party awarding the contract for the body or conversion evidence of qualifi cation will be requested.

MAN Truck & Bus AG reserves the right to carry out its own system audit in accordance with VDA 8 or a corresponding process check at

the supplier’s premises. VDA volume 8 has been agreed with the following body manufacturers’ associations:

ZKF (Zentralverband Karosserie- und Fahrzeugtechnik – Central Association of Body and Vehicle Engineering) and

BVM (Bundesverband Metall Vereinigung Deutscher Metallhandwerke – Federation of German Metal Trades Associations).

It has also been agreed with the ZDH (Zentralverband des Deutschen Handwerks – Central Association of German Craft Trades).

Documents:

VDA Volume 8

„Minimum quality assurance requirements for trailer, body manufacturers“, obtainable from the Verband der Automobilindustrie e.V

(VDA) (German Engine Industry Association), http://www.vda-qmc.de.

1.2.4 Approval

Approval from MAN for a body or a chassis modifi cation is not required if the bodies or modifi cations are carried out in accordance with

this Guide. If MAN approves a body or a chassis modifi cation, then this approval refers

• In the case of bodies only to the body’s fundamental compatibility with the respective chassis and the interfaces to the body

(e.g. dimensions and mounting of the subframe)

• In the case of chassis modifi cations only to the fact that, from a design point of view, the modifi cations to the chassis in

question are fundamentally permissible.

The approval note that MAN enters on the submitted technical documents does not indicate a check on the

• Function

• Design

• Equipment of the body or the modifi cation.

Observance of this Guide does not free the user from responsibility to perform modifi cations and manufacture bodies properly from

a technical point of view. The approval note only refers to such measures or components as are to be found in the submitted technical

documents.

MAN reserves the right to refuse to issue approvals for bodies or modifi cations, even if a comparable approval has already been issued.

Later submissions for approval are not automatically treated the same as earlier ones, because technical advances achieved in

the interim period have to be taken into account.

MAN also reserves the right to change this Guide at any time or to issue instructions that differ from this Guide for individual chassis.

If several identical chassis have the same bodies or modifi cations MAN can, to simplify matters, issue a collective approval.

1.2.5 Submission of documents

Documents should only be sent to MAN if bodies/conversions diverge from this Guide. Before work begins on the vehicle, technical

documents that require approval or inspection must be sent to the ESC Department at MAN (see „Publisher“ above).

For an approval process to proceed swiftly, the following are required:

• Documents should be submitted in duplicate

• The number of individual documents should be kept to a minimum

• All the technical data and documents must be submitted.

TRUCKNOLOGY® GENERATION A (TGA) 3

Page 11

The following information should be included:

• Vehicle model (see Chapter 2.2 for model code) with

- cab design

- wheelbase

- frame overhang

• · Vehicle identifi cation number or vehicle number (if already available, see Chapter 2.2)

Identifi cation of deviations from this Guide to Fitting Bodies in all documentation!

• Loads and their load application points:

- Forces from the body

- Axle load calculation

• Special conditions of use:

• Subframe:

- Material and cross-sectional data

- Dimensions

- Type of section

- Arrangement of cross members in the subframe

- Special features of the subframe design

- Cross-section modifi cations

- Additional reinforcements

- Upsweeps, etc.

• Means of connection:

- Positioning (in relation to the chassis)

- Type

- Size

- Number.

The following are not suffi cient for inspection or approval:

• Parts lists

• Brochures

• Photographs

• Other not binding information.

Drawings are only valid if they bear the number that has been assigned to them. It is therefore not permitted to draw in the bodies or

modifi cations on chassis drawings that have been provided by MAN and to submit these for approval.

1.2.6 Liability for defects

Liability claims in respect of defects only exist within the framework of the purchasing contract between buyer and seller.

In accordance with this, liability for defects lies with the respective seller of the goods.

Claims against MAN are not valid if the fault that is the subject of the complaint was due to the fact that

• This Guide was not observed

• In view of the purpose for which the vehicle is used, an unsuitable chassis has been selected

• The damage to the chassis has been caused by

- the body

- the type of body mounting or how the body has been mounted

- the modifi cation to the chassis

- improper use.

TRUCKNOLOGY® GENERATION A (TGA) 4

Page 12

1.2.7 Product liability

Any faults in the work that are identifi ed by MAN are to be corrected. Insofar as is legally permissible, MAN disclaims all liability,

in particular for consequential damage.

Product liability regulates:

• The liability of the manufacturer for its product or component

• The compensation claim made by the manufacturer against whom a claim has been made against the manufacturer of

an integral component, if the damage that has occurred is due to a fault in that component.

The company that has made the body or carried out the modifi cation is to relieve MAN of any liability to its customer or other third party

if the damage that has occurred is due to the fact that

• The company did not observe this Guide

• The body or chassis modifi cation has caused damage on account of its faulty

- design

- manufacture

- installation

- instructions

• The fundamental rules that are laid down have not been complied with in any other way.

1.2.8 Safety

Companies carrying out work on the chassis/vehicle are liable for any damage that may be caused by poor functional and operational

safety or inadequate operating instructions. Therefore, MAN requires the body manufacturer or vehicle conversion company to:

• Ensure the highest possible safety, in line with the state of the art

• Provide comprehensible, suffi cient operating instructions

• Provide permanent, easily visible instruction plates on hazardous points for operators and/or third parties

• Observe the necessary protection measures (e.g. fi re and explosion prevention)

• Provide full toxicological information

• Provide full environmental information.

Safety is top priority! All available technical means of avoiding incidents that will undermine operational safety are to be implemented.

This applies equally to

• Active safety = prevention of accidents. This includes:

- Driving safety achieved by the overall vehicle design, including the body

- Safety as a consequence of the driver’s well-being achieved by keeping occupant stress caused by vibrations,

noise, climatic conditions etc. to a minimum

- Safety as a consequence of observation and perception, in particular through the correct design of lighting systems,

warning equipment, providing suffi cient direct and indirect visibility

- Safety as a consequence of operating equipment and controls this includes optimising the ease of operation of all

equipment, including that of the body.

• Passive safety = avoidance and reduction of the consequences of accidents. This includes:

- Exterior safety such as the design of the outside of the vehicle and body with respect to deformation behaviour and

the installation of protective devices

- Interior safety including the protection of occupants of vehicles and cabs that are installed by the body builders.

TRUCKNOLOGY® GENERATION A (TGA) 5

Page 13

Climatic and environmental conditions have effects on:

• Operational safety

• Readiness for use

• Operational performance

• Service life

• Cost-effectiveness.

Climatic and environmental conditions are, for example:

• The effects of temperature

• Humidity

• Aggressive substances

• Sand and dust

• Radiation.

Suffi cient space for all parts required to carry out a movement, including all pipes and cables, must be guaranteed. The operating

instructions for MAN trucks provide information about the maintenance points on the vehicle. Regardless of what type of body is fi tted,

good access to the maintenance points must be ensured in all cases. It must be possible to carry out maintenance unhindered and

without having to remove any components. Suffi cient ventilation and/or cooling of the components is to be guaranteed.

1.2.9 Manuals from body and conversion companies

In the event of a body being added or modifi cations to the vehicle being carried out, the operator of the vehicle is also entitled to receive

operating instructions from the conversion company. All specifi c advantages offered by the product are of no use if the customer is

not able to:

• Handle the product safely and properly

• Use it rationally and effortlessly

• Maintain it properly

• Master all of its functions.

As a result, every vehicle body builder and converter must check his technical instructions for:

• Clarity

• Completeness

• Accuracy

• Comprehensibility

• Product-specifi c safety instructions.

Inadequate or incomplete operating instructions carry considerable risks for the user. Possible effects are:

• Reduced benefi t, because the advantages of the product remain unknown

• Complaints and annoyance

• Faults and damage, which are normally blamed on the chassis

• Unexpected and unnecessary additional cost through repairs and time lost

• A negative image and thereby less inclination to buy the same product or brand again.

Depending on the vehicle body or modifi cation, the operating personnel must be instructed about operation and maintenance.

Such instruction must also include the possible effects on the static and dynamic performance of the vehicle.

TRUCKNOLOGY® GENERATION A (TGA) 6

Page 14

1.2.10 Limitation of liability for accessories/spare parts

Accessories and spare parts that MAN has not manufactured or approved for use in its products may affect the traffi c safety and

operational safety of the vehicle and create hazardous situations. MAN Truck & Bus AG (or the seller) accepts

no liability for claims of any kind resulting from a combination of the vehicle together with an accessory that was made by another

manufacturer, regardless of whether MAN Truck & Bus AG (or the seller) has sold the accessory itself or fi tted it to the vehicle

(or the subject of the contract).

2. Product designations

2.1 Vehicle designation and wheel formula

To enable unique and easily comprehensible identifi cation of the different variants new vehicle designations have been systematically introduced. The vehicle designation system is based on three levels:

- Door designation

- Variant descriptor (in the sales and technical documentation e.g. data sheets, chassis drawings)

- Model code.

2.1.1 Door designation

The door designation comprises:

Model range + permissible weight + engine power

TGA 18.400

Model range + Permissible weight + Engine power

TGA 18 .400

Abbreviated notation of model range TGA = Trucknology® Generation A,

technically permissible weight in [t],

engine power [DIN-hp] rounded to the nearest 10hp

2.1.2 Variant descriptor

The variant descriptor = vehicle designation which comprises the door designation + wheel formula + suffi x.

The terms ‘wheel formula’ and ‘suffi x’ are defi ned in the following sections.

Model range + permissible weight + engine power + wheel formula + suffi x

TGA 25.480 6x2-2 LL-U

Model range + Permissible weight + Engine power

TGA 25 .480 6x2-2 LL-U

Wheel formula Suffi x

TRUCKNOLOGY® GENERATION A (TGA) 7

Page 15

2.1.3 Wheel formula

The wheel formula stipulates the number of axles and provides additional identifi cation of drive, steered and leading/trailing axles.

Wheel formula is a commonly used, but not standardised term. It is “wheel locations” that are counted and not the individual wheels.

Twin tyres are therefore regarded as one wheel.

The following two examples illustrate the wheel formula:

Tabl e 1: Wheel formula examples

6 x 2 - 4

6 x 2 / 4

6 = Total number of wheel locations, i.e. 3 axles

x = No function

2 = Number of driven wheels

- = Trailing axle behind the rear drive-axle assembly

/ = Leading axle ahead of the rear drive-axle assembly

4 = Number of steered wheels

The number of steered wheels is only stated if, aside from steered front wheels, leading axles or trailing axles are also involved.

A leading axle is located “ahead of” a rear drive-axle assembly and a trailing axle is “behind” the rear drive-axle assembly.

A slash “/” represents a leading axle and a hyphen “-” represents a trailing axle.

If a chassis is fi tted with both leading and trailing axles the number of steered wheels follows the hyphen “-”.

If the vehicle is fi tted with MAN HydroDrive

e.g. 6x4H = a front axle with MAN HydroDrive

®

hydrostatic front axle drive then the wheel formula receives an additional H,

®

, 2 rear axles, one of which is driven.

Currently the following wheel formulae are available ex-works:

Tabl e 2: TGA wheel formulae

4x2 Two-axle vehicle with one drive axle

4x4 Two-axle vehicle with two drive axles “All-wheel drive”

4x4H Two-axle vehicle with two drive axles, front axle with MAN HydroDrive

®

6x2/2 Three-axle vehicle with non-steered “Pusher” leading axle

6x2/4 Three-axle vehicle with steered leading axle

6x2-2 Three-axle vehicle with non-steered trailing axle

6x2-4 Three-axle vehicle with steered trailing axle

6x4 Three-axle vehicle with two driven non-steered rear axles

6x4/4 Three-axle vehicle with 2 driven axles (fi rst and last axles), steered leading axle

6x4-4 Three-axle vehicle with 2 driven axles, (fi rst and second axles), steered trailing axle

®

6x4H/2 Three-axle vehicle with MAN HydroDrive

6x4H/4 Three-axle vehicle with MAN HydroDrive

6x4H-2 Three-axle vehicle with MAN HydroDrive

front axle drive, one driven rear axle, non-steered leading axle

®

front axle drive, one driven rear axle, steered leading axle

®

front axle drive, one driven rear axle, non-steered trailing axle

6x4H-4 Three-axle vehicle with MAN HydroDrive® front axle drive, one driven rear axle, steered trailing axle

TRUCKNOLOGY® GENERATION A (TGA) 8

Page 16

Tabl e 2: TGA wheel formulae (continuation)

6x6 Three-axle vehicle with all-wheel drive

6x6-4 Three-axle vehicle with all-wheel drive, steered and driven trailing axle

6x6H Three-axle vehicle with all-wheel drive, front axle with MAN HydroDrive

8x2-4 Four-axle vehicle with one drive axle, two steered front axles, non steered trailing axle or four-axle vehicle with three rear

axles with front and trailing axles steered

8x2-6 Four-axle vehicle with one drive axle, two steered front axles, steered trailing axle

8x4 Four-axle vehicle with two steered front axles and two driven rear axles

8x4/4 Four-axle vehicle with one front axle, one steered leading axle and two driven rear axles

8x4-4 Four-axle vehicle with one front axle, two driven rear axles and one steered trailing axle

8x4H-4 Four-axle vehicle with two steered front axles (2nd front axle with MAN HydroDrive

a non-steered trailing axle

8x4H-6 Four-axle vehicle with two steered front axles (2nd front axle with MAN HydroDrive®), one driven rear axle and

a steered trailing axle

8x6 Four-axle vehicle “All wheel drive” with two front axles (2nd driven) and two driven rear axles

8x6H Four-axle vehicle “All wheel drive” with two front axles (2nd front axle with MAN HydroDrive

8x8 Four-axle vehicle “All wheel drive” with two front axles and two rear axles, all driven

®

®

), one driven rear axle and

®

) and two driven rear axles

2.1.4 Suffi x

The suffi x to the vehicle designation defi nes the type of suspension, differentiates trucks from tractor units and describes special

product features.

TGA 25.480 6x2-2 LL-U

Suffi x

Types of suspension (Digits 1 and 2 of suffi x)

Tabl e 3: Types of s u s p e n s i o n

BB Leaf suspension on front axle(s), leaf suspension on rear axle(s)

BL Leaf suspension on front axle(s), air suspension on rear axle(s)

LL Air suspension on front axle(s), air suspension on rear axle(s)

BH Leaf suspension on front axle(s), hydropneumatic on rear axle(s)

Semitrailer tractor units are designated with an ‘S’ suffi x. Trucks have no special designation.

Example for semitrailer tractor:

TGA 33.440 6x6 BBS

S = Semitrailer tractor

TRUCKNOLOGY® GENERATION A (TGA) 9

Page 17

Special product (design) features are added separately following a hyphen ‘-’ after the fi rst section of the suffi x:

Example for special product features:

TGA 18.350 4x2 BLS -TS

-TS = Weight optimised version for silo tanker

Table 4: Designations for special designs produced to-date (to be supplemented with further designs)

-U For low design ‘Ultra’ e.g.: TGA 18.410 4x2 LLS-U

-TS Weight optimised version for silo tanker, e.g.: TGA 18.400 4x2 BLS-TS

-WW “World wide” variant, eligible for licensing outside Europe only, e.g. TGA 40.460 6x6 BB-WW

-LE “Low entry” cab with lowered entry, e.g.: TGA 28.310 6x2-4 LL-LE

-CKD “Completely knocked down”, for assembly in MAN factory of the recipient country, e.g.: TGA 40.480 6x4-4 WW-CKD

2.2 Model number, vehicle identifi cation number, vehicle number, basic vehicle number

The three-digit model number, also called model code, provides a technical identifi cation of the MAN chassis and also identifi es

to which vehicle range it belongs. This number is part of the 17-digit vehicle identifi cation number (VIN) and is located at digits 4 to 6 in

the VIN. The basic vehicle number, formulated for sales purposes, also contains the model number at digits 2 to 4.

The seven-fi gure vehicle number describes the technical equipment on a vehicle; it contains the model number at digits 1 to 3, followed

by a four-digit sequential number. The vehicle number is to be found in the vehicle papers and on the vehicle’s manufacturing plate.

The vehicle number can be quoted instead of the 17-digit vehicle identifi cation number in the event of any technical queries regarding

conversions and bodies. Table 5 gives some examples of the model number, vehicle identifi cation number, basic vehicle number and

vehicle number.

Tabl e 5: Example vehicle designation, model number, vehicle identifi cation number, basic vehicle number and vehicle number

Vehicle designation Model number

Model code

TGA 18.440 4x2 BLS

TGA 26.410 6x2-4 LL

TGA 33.540 6x4 BB

Up to the date of going to press (03/2007) the Trucknology

H06

H21

H26

Vehicle identifi cation number

(VIN)

WMAH06ZZ14M000479

WMAH21ZZ94G144924

WMAH26ZZ75M350354

®

Generation A or TGA for short, comprises the following model numbers:

Basic vehicle

number

LH06AG53

LH21E 05

LH26LR04

Vehicle number

H060057

H210058

H261158

TRUCKNOLOGY® GENERATION A (TGA) 10

Page 18

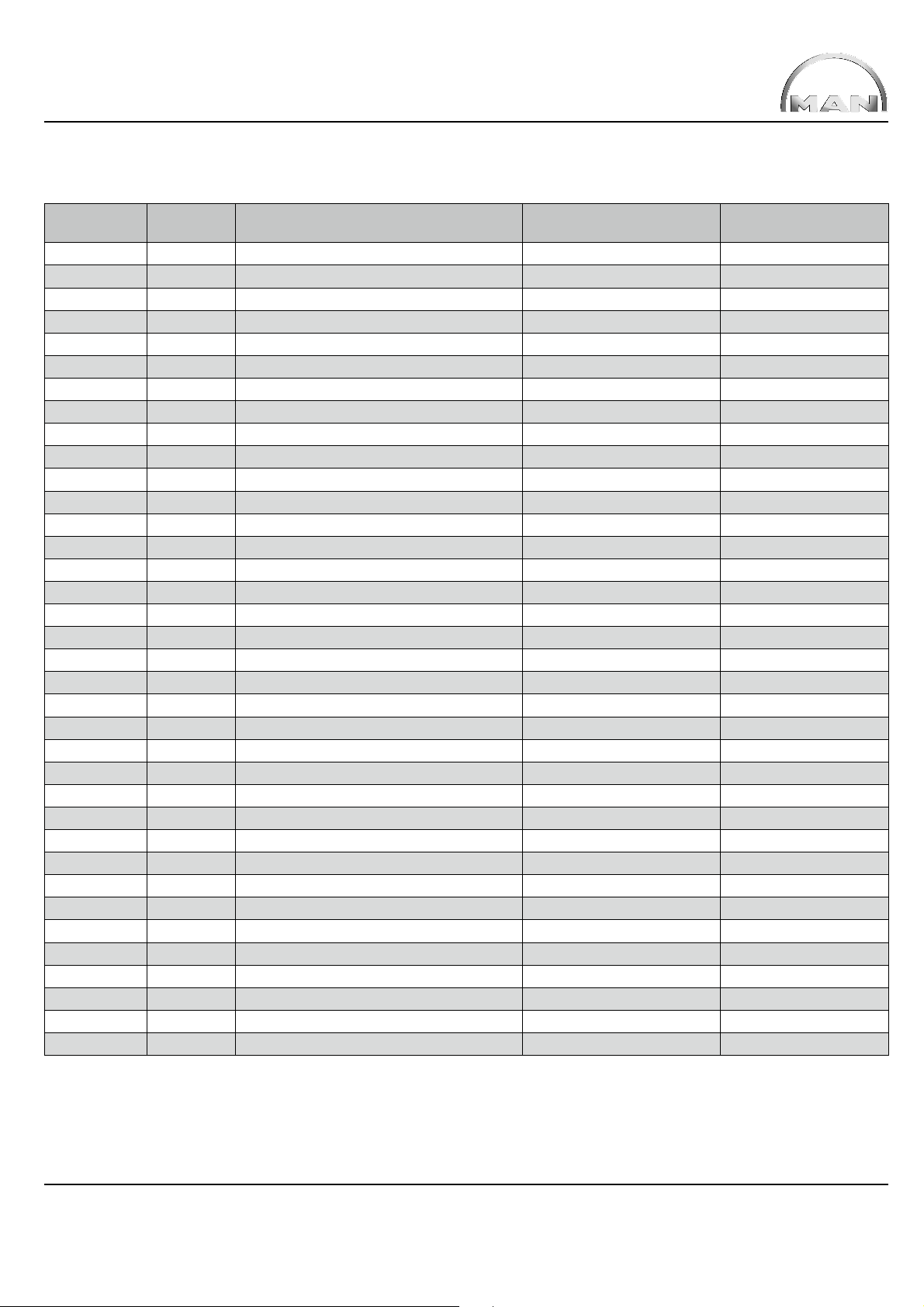

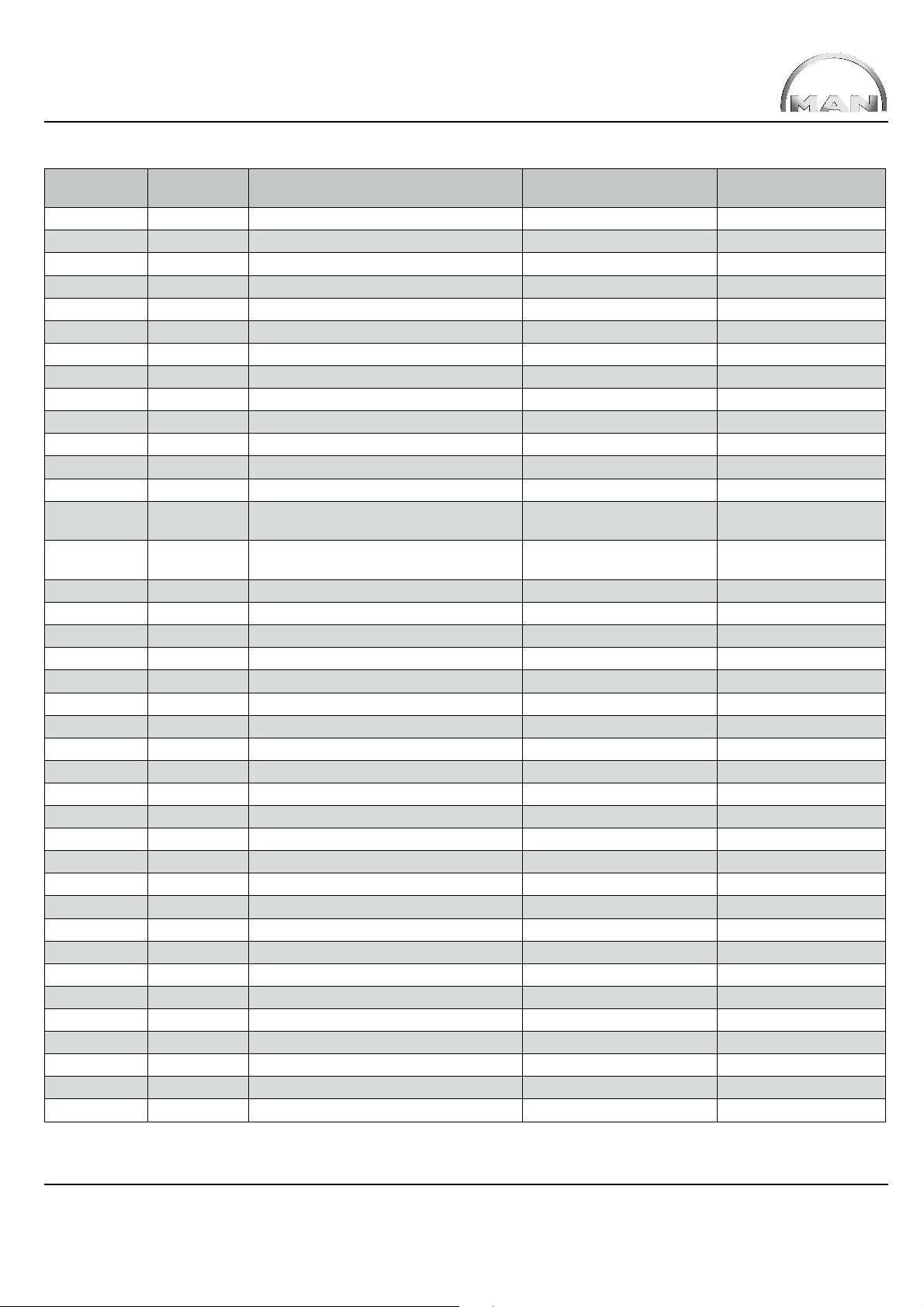

Table 6: Model numbers, tonnage class, vehicle designation and suspension on the TGA

Model number Tonnage Designation , xxx stands for

Engine Suspension

various engine powers

H01 18 t TGA 18.xxx 4x2 BLS-TS D28 R6 BL

H02 18 t TGA 18.xxx 4x2 BB D28 R6 BB

H03 18 t TGA 18.xxx 4x2 BB D20/D26 R6 BB

H05 18 t TGA 18.xxx 4x2 BL D28 R6 BL

H06 18 t TGA 18.xxx 4x2 BL D20/D26 R6 BL

H07 18 t ECT 18.ISM 4x2 BL ISM

e

H08 18 t TGA 18.xxx 4x2 BLS-TS D20/D26 R6 BL

H09 18 t TGA 18.xxx 4x2 LL D28 R6 LL

H10 18 t TGA 18.xxx 4x2 LL D20/D26 R6 LL

H11 40 t TGA 40.xxx 6x4 BB-WW-CKD D20/D26 R6 BBB

H12 18 t TGA 18.xxx 4x2 LLS-U D28 R6 LL

H13 18 t TGA 18.xxx 4x2 LLS-U D20/D26 R6 LL

H14 18 t TGA 18.xxx 4x2 LL-U D28 R6 LL

H15 18 t TGA 18.xxx 4x2 LL-U DD20/D26 R6 LL

H16 26 t TGA 26.xxx 6x2-4 BL D08 R6 BLL

H17 26 t TGA 26.xxx 6x2-2, 6x2-4 BL D28 R6 BLL

H18 26 t TGA 26.xxx 6x2-2, 6x2-4 BL D20/D26 R6 BLL

H19 26 t TGA 26.xxx 6x2-4 LL D08 R6 LLL

H20 26 t TGA 26.xxx 6x2-2, 6x2-4 LL D28 R6 LLL

H21 26 t TGA 26.xxx 6x2-2, 6x2-4 LL D20/D26 R6 LLL

H22 18 t TGA 18.xxx 4x4H BL D20/D26 R6 BL

H23 26 t TGA 26.xxx 6x2/2, 6x2/4 BL D28 R6 BLL

H24 26 t TGA 26.xxx 6x2/2, 6x2/4 BL D20/D26 R6 BLL

H25 26/33 t TGA 26/33.xxx 6x4 BB D28 R6 BBB

H26 26/33 t TGA 26/33.xxx 6x4 BB D20/D26 R6 BBB

H27 26 t ECT 26.ISM 6x2-2, 6x2-4 BL ISM

e

H28 33 t TGA 33.xxx 6x4 BB-WW D28 R6 BBB

H29 26/33 t TGA 26/33.xxx 6x4 BL D28 R6 BLL

H30 26/33 t TGA 26/33.xxx 6x4 BL D20/D26 R6 BLL

H31 26 t ECT 26.ISM 6x2-2 LL ISM

H32 26 t ECT 26.ISM 6x2/2 BL ISM

e

e

H33 40 t TGA 40.xxx 6x4 BB-WW D28 R6 BBB

H34 40 t TGA 40.xxx 6x4 BB-WW D20/D26 R6 BBB

H35 26 t TGA 26.xxx 6x4H-2 BL, 6x4H-4 BL D20/D26 R6 BLL

H36 35 t TGA 35.xxx 8x4 BB D28 R6 BBBB

H37 35 t TGA 35.xxx 8x4 BB D20/D26 R6 BBBB

BL

BLL

LLL

BLL

TRUCKNOLOGY® GENERATION A (TGA) 11

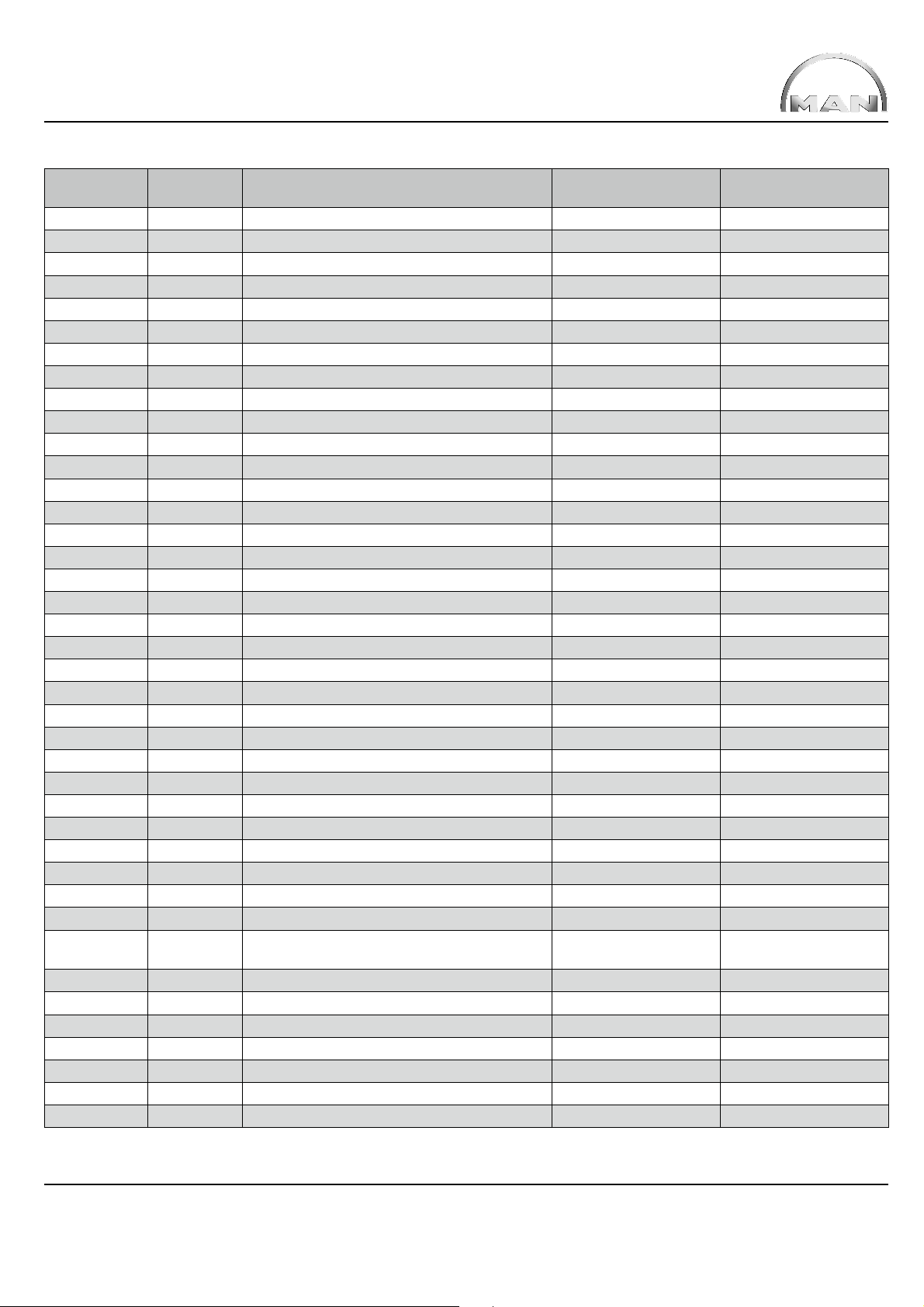

Page 19

Model number Tonnage Designation , xxx stands for

various engine powers

H38 41 t TGA 41.xxx 8x4 BB D28 R6 BBBB

H39 41 t TGA 41.xxx 8x4 BB D20/D26 R6 BBBB

H40 35 t TGA 35.xxx 8x4 BL D28 R6 BBLL

H41 35 t TGA 35.xxx 8x4 BL D20/D26 R6 BBLL

H42 26 t TGA 26.xxx 6x4H/2 BL, 6x4H/4 BL D20/D26 R6 BLL

H43 19 t TGA 19.xxx 4x2 BBS-WW D28 R6 BB

H44 25 t TGA 25.xxx 6x2-2 LL-U D28 R6 LLL

H45 25 t TGA 25.xxx 6x2-2 LL-U D20/D26 R6 LLL

H46 41 t TGA 41.xxx 8x4 BB-WW D28 R6 BBBB

H47 26/33 t TGA 26/33.xxx 6x6H BB D20/D26 R6 BBB

H48 32 t TGA 32.xxx 8x4 BB D28 R6 BBBB

H49 32 t TGA 32.xxx 8x4 BB D20/D26 R6 BBBB

H50 35 t TGA 35.xxx 8x6H BB D20/D26 R6 BBBB

H51 18 t TGA 18.xxx 4x4 BB D28 R6 BB

H52 18 t TGA 18.xxx 4x4 BB D20/D26 R6 BB

H54 33 t TGA 33.xxx 6x6 BB-WW D28 R6 BBB

H55 26/33 t TGA 26/33.xxx 6x6 BB D28 R6 BBB

H56 26/33 t TGA 26/33.xxx 6x6 BB D20/D26 R6 BBB

H57 40 t TGA 40.xxx 6x6 BB-WW D28 R6 BBB

H58 40 t TGA 40.xxx 6x6 BB-WW D20/D26 R6 BBB

H59 35 t TGA 35.xxx 8x6H BL D20/D26 R6 BBLL

H60 19 t TGA 19.xxx 4x2 BBS-WW-CKD D28 R6 BB

H61 18 t TGA 18.xxx 4x2 BLS-WW-CKD D28 R6 BL

H62 33 t TGA 33.xxx 6x4 BB-WW-CKD D28 R6 BBB

H63 26 t TGA 26.xxx 6x4 BL-WW-CKD D28 R6 BLL

H64 19 t TGA 19.xxx 4x2 BBS-WW-CKD D20/D26 R6 BB

H65 18 t TGA 18.xxx 4x2 BLS-WW-CKD D20/D26 R6 BL

H66 33 t TGA 33.xxx 6x4 BB-WW-CKD D20/D26 R6 BBB

H67 26 t TGA 26.xxx 6x4 BL-WW-CKD D20/D26 R6 BLL

H68 40 t TGA 40.xxx 6x4 BB-WW-CKD D28 R6 BBB

H69 39 t TGA 39.xxx 8x2-4 BL D20/D26 R6 BBLL

H70 18 t TGA 18.xxx 4x4 BL D28 R6 BL

H71 28 t TGA 28.xxx 6x2-4 BL

TGA 28.xxx 6x2-4 LL

H72 26/33 t TGA 26/33.xxx 6x6 BL D28 R6 BLL

H73 35/41 t TGA 35/41.xxx 8x6 BB D28 R6 BBBB

H74 28 t TGA 28.xxx 6x2-4 BL D20/D26 R6 BLL

H75 28 t TGA 28.xxx 6x2-4 LL D20/D26 R6 LLL

H76 35/41 t TGA 35/41.xxx 8x8 BB D28 R6 BBBB

H77 28 t TGA 28.xxx 6x4-4 BL D20/D26 R6 BLL

H80 18 t TGA 18.xxx 4x4 BL D20/D26 R6 BL

Engine Suspension

D28 R6 BLLLLL

TRUCKNOLOGY® GENERATION A (TGA) 12

Page 20

Model number Tonnage Designation , xxx stands for

various engine powers

H81 28 t TGA 28.xxx 6x4-4 BL D28 R6 BLL

H82 26/33 t TGA 26/33.xxx 6x6 BL D20/D26 R6 BLL

H83 28 t TGA 28.xxx 6x6-4 BL D20/D26 R6 BLL

H84 28 t TGA 28.xxx 6x4-4 BL D20/D26 R6 BLL

H85 28 t TGA 28.xxx 6x2-2 LL D20/D26 R6 LLL

H86 28 t TGA 28.xxx 6x2-2 BL D28 R6 BLL

H87 28 t TGA 28.xxx 6x2-2 LL D28 R6 LLL

H88 35 t TGA 35.xxx 8x2-4, 8x2-6 BL D28 R6 BBLL

H89 28 t TGA 28.xxx 6x2-2 BL D20/D26 R6 BLL

H90 35 t TGA 35.xxx 8x2-4, 8x2-6 BL D20/D26 R6 BBLL

H91 35 t TGA 35.xxx 8x4-4 BL D28 R6 BLLL

H92 35 t TGA 35.xxx 8x4-4 BL D20/D26 R6 BLLL

H93 35/41 t TGA 35/41.xxx 8x6 BB D20/D26 R6 BBBB

H94 41 t TGA 41.xxx 8x4/4 BB

TGA 41.xxx 8x4/4 BL

H95 41 t TGA 41.xxx 8x4/4 BB

TGA 41.xxx 8x4/4 BL

H96 35/41 t TGA 35/41.xxx 8x8 BB D20/D26 R6 BBBB

H97 18 t TGA 18.xxx 4x2 LL-LE D20/D26 R6 LL

H98 26 t TGA 26.xxx 6x2/4 LL-LE D20/D26 R6 LLL

H99 28 t TGA 28.xxx 6x2-4 LL-LE D20/D26 R6 LLL

HH1 26/33 t TGA 26/33.xxx 6x6H BL D20/D26 R6 BLL

HH2 28 t TGA 28.xxx 6x4H-4 D20/D26 R6 BLL

HH4 35 t TGA 35.xxx 8x4H-4, 8x4H-6 BL D20/D26 R6 BBLL

HV1 26 t TGA 26.xxx 6X2-2, 6X2-4 BL-WW D20/D26 R6 BLL

HV2 26/33 t TGA 26/33.xxx 6X4 BL-WW D20/D26 R6 BLL

HV3 39 t TGA 39.xxx 8X2-4 BL-WW D20 R6 BBLL

HV4 28 t TGA 28.xxx 6X2-2 BL-WW D20/D26 R6 BLL

HV5 18 t TGA 18.xxx 4X4 BB-WW D20 R6 BB

HV6 35/41 t TGA 35/41.xxx 8X8 BB-WW D20 R6 BBBB

HV7 28 t TGA 28.xxx 6X2-2 BL-WW-CKD D20/D26 R6 BLL

HV8 32 t TGA 32.xxx 8X4 BB-WW D20 R6 BBBB

HW1 19 t TGA 19.xxx 4x2 BBS-WW D20/D26 R6 BB

HW2 33 t TGA 33.xxx 6x4 BB-WW D20/D26 R6 BBB

HW3 41 t TGA 41.xxx 8x4 BB-WW D20/D26 R6 BBBB

HW4 33 t TGA 33.xxx 6x6 BB-WW D20/D26 R6 BBB

HW5 19 t TGA 19.xxx 4x2 BLS-WW-CKD D20/D26 R6 BL

HW6 41 t TGA 41.xxx 8x4 BB-WW-CKD D20/D26 R6 BBBB

HW7 19 t TGA 19.xxx 4x2 BLS-WW D20/D26 R6 BL

HW8 33 t TGA 33.xxx 6x4 BBS-WW D20/D26 R6 BBB

HW9 33 t TGA 33.xxx 6x4 BBS-WW-CKD D20/D26 R6 BBB

Engine Suspension

D28 R6 BLBB

D28 V10 BLBB

BLLL

BLLL

TRUCKNOLOGY® GENERATION A (TGA) 13

Page 21

2.3 Use of logos

MAN logos on the chassis may not be removed or modifi ed in any way without prior approval from MAN.

Modifi cations to the chassis or body that do not conform with this Guide to Fitting Bodies and that have not received MAN approval by

the ESC department (for address see „Publisher“ above) must receive a new vehicle identifi cation number (VIN) from the manufacturer

responsible for the modifi cation (normally the vehicle conversion company).

In such cases where the chassis/vehicle has received a new VIN, the logos on the radiator grille (MAN lettering, lion emblem) and

the doors (door designation – see Section 2.1.1) must be removed.

TRUCKNOLOGY® GENERATION A (TGA) 14

Page 22

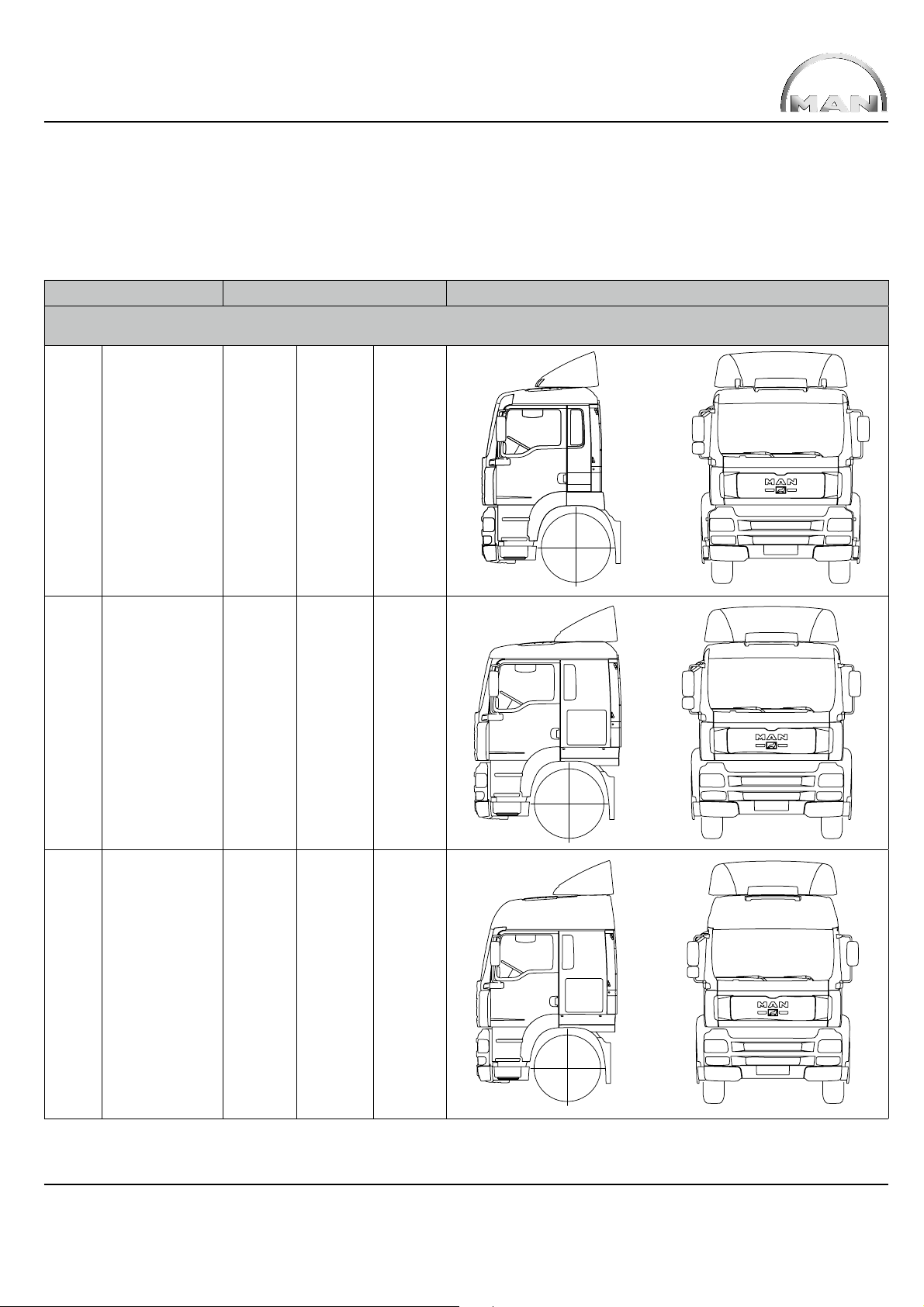

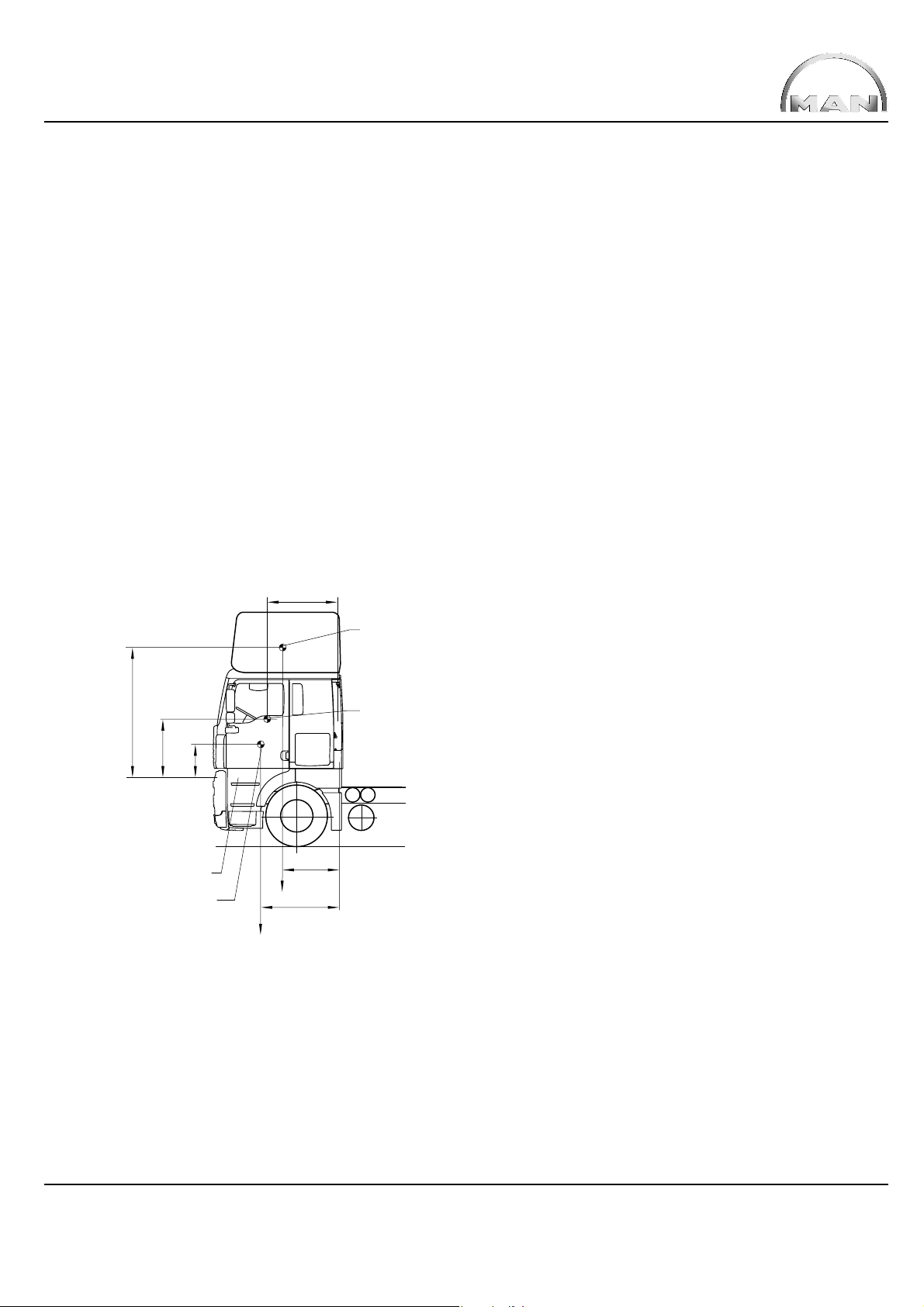

2.4 Cabs

There are 6 different Trucknology® Generation A cabs:

®

Table 7: Trucknology

Description Dimensions* Views

Name Technical Length Width High roof Side Front

description

M LHD

F99L15S

RHD

F99R15S

Generation A cabs

1.880 2.240

L LHD

F99L32S

RHD

F99R32S

LX LHD

F99L37S

RHD

F99R37S

2.280 2.240

2.280 2.240 yes

*) Dimensions refer to the cab without attachments such as mudguards, front spoiler, mirrors, roof spoiler etc.

TRUCKNOLOGY® GENERATION A (TGA) 15

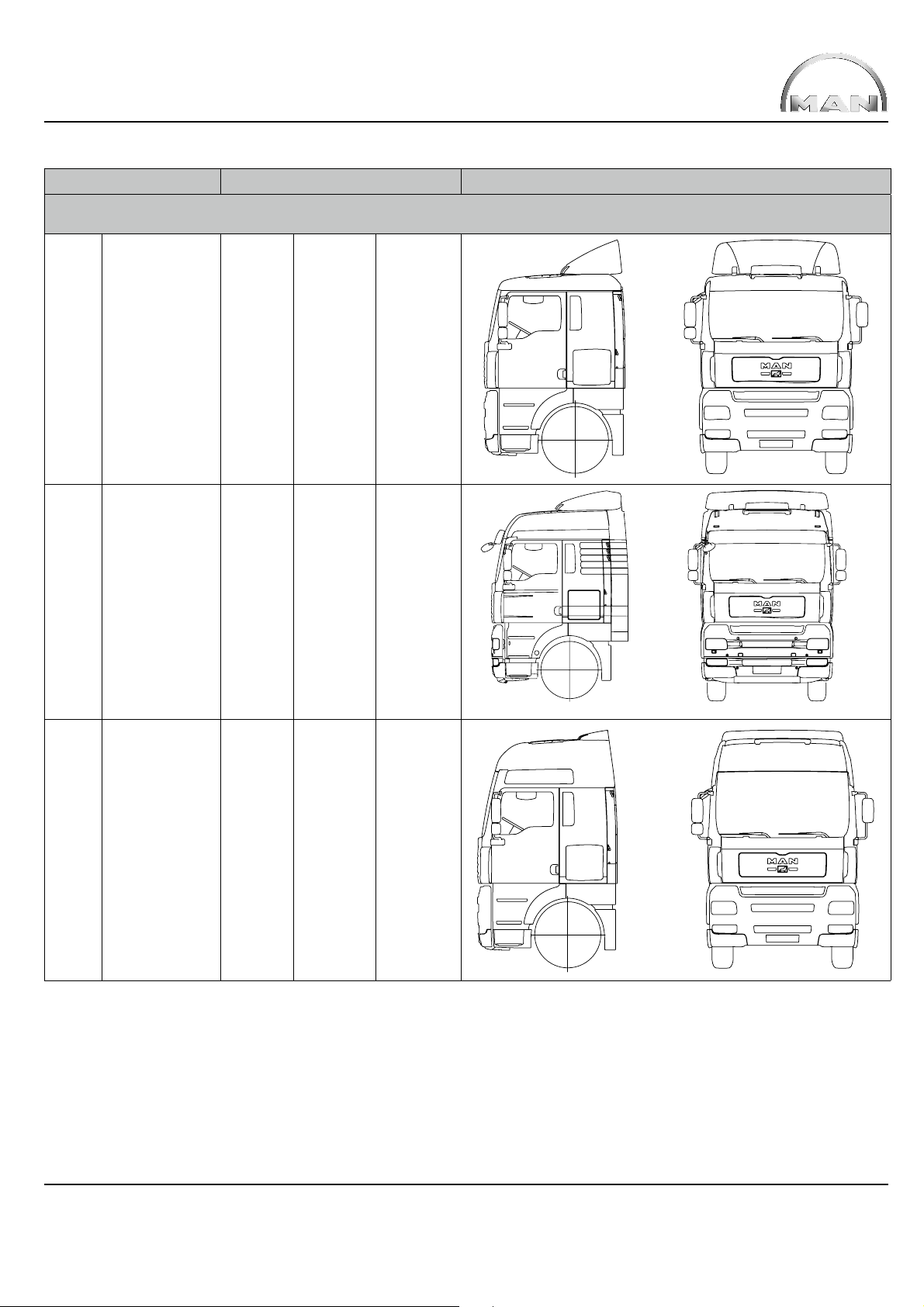

Page 23

Description Dimensions* Views

Name Technical Length Width High roof Side Front

description

XL LHD

F99L40S

RHD

F99R40S

2.280 2.440

XLX LHD

F99 L47 S

RHD

F99 R47 S

XXL LHD

F99L41S

RHD

F99R41S

2.280 2.440 yes, low

2.280 2.440 yes

*) Dimensions refer to the cab without attachments such as mudguards, front spoiler, mirrors, roof spoiler etc.

TRUCKNOLOGY® GENERATION A (TGA) 16

Page 24

2.5 Engine variants

In-line six-cylinder Diesel engines (R6) and a V10 with 4-valve technology from the D28 family of engines are installed in the TGA

(D28 = 1st – 3rd digits of the engine designation). Engines with common rail injection are new additions to the range.

The engine programme has been extended since 2004 with two further engine ranges – the well known engines from the D08 range and

the new D20 Common Rail range that are also available as Euro 4 engines with the PM-Kat

only installed in ERF brand trucks (see table 6, model numbers).

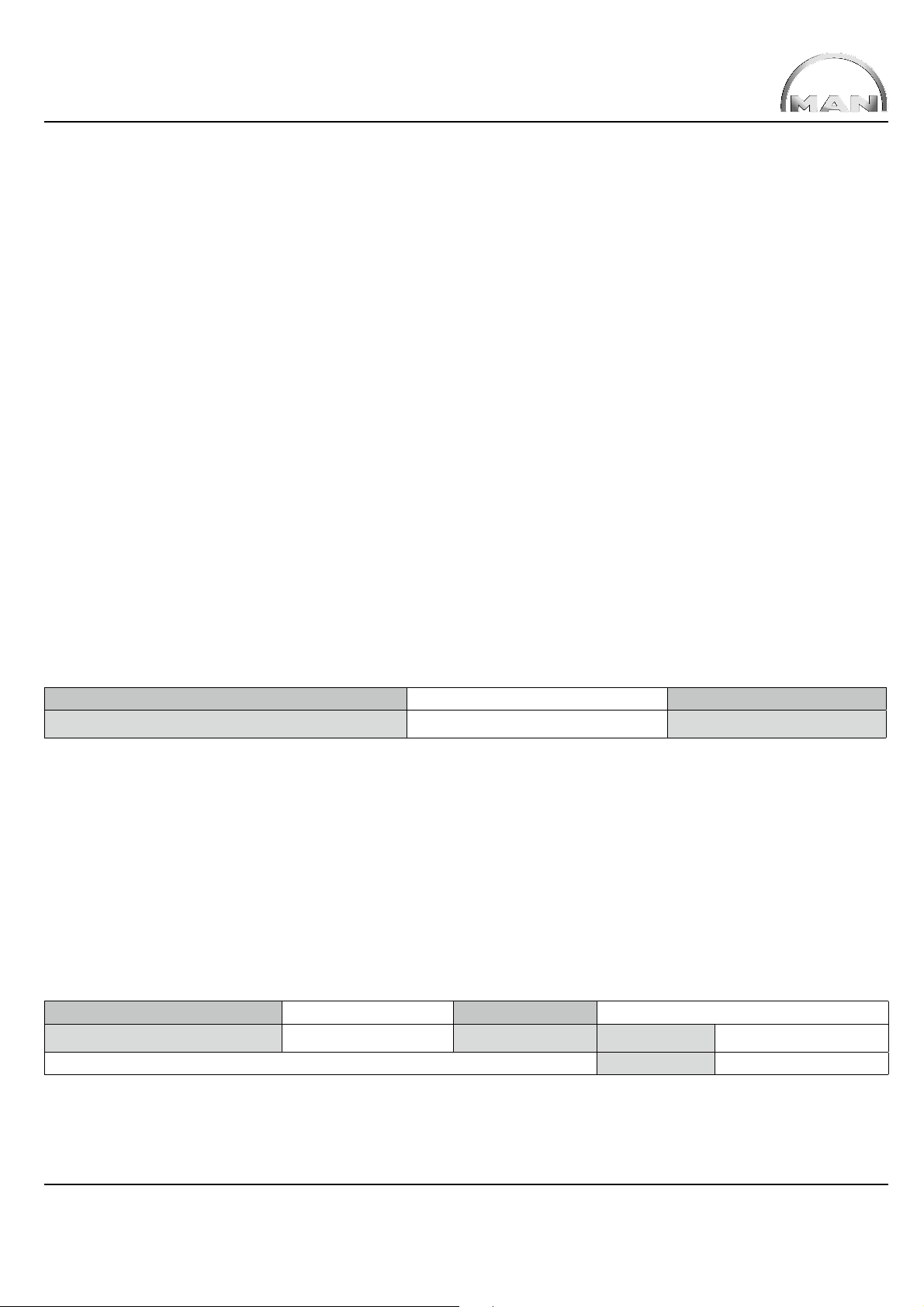

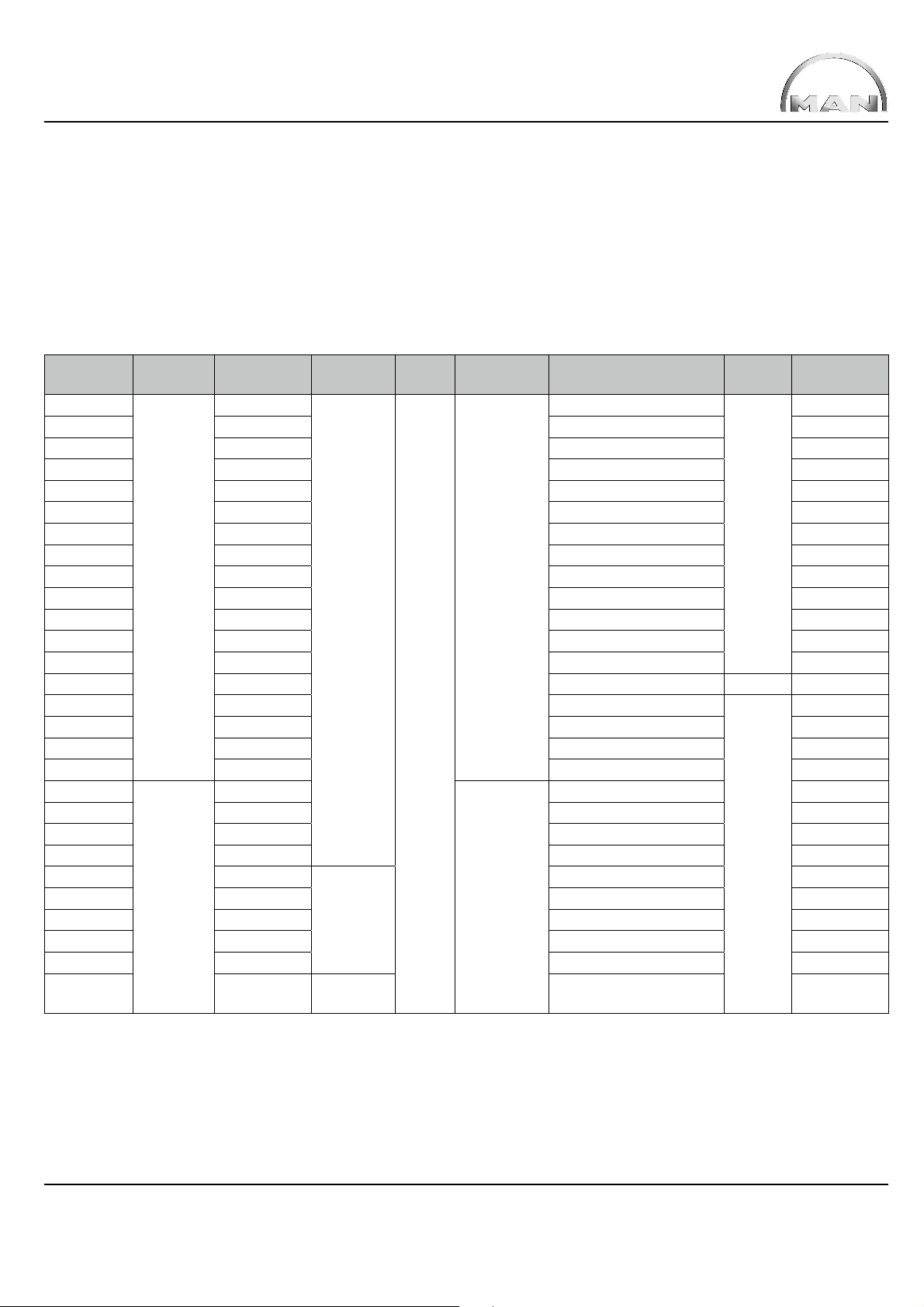

Table 8: TGA engines/engine designations D08D08 / D20 / D26 / D28

®

. Cummins engines of the ISMe range are

Vehicle

designation

xx.280

xx.330 240 kW / 2.400 1.250 at 1.200 - 1.800 rpm D0836LF44

xx.310 228 kW / 1.900 1.500 at 900 - 1.300 rpm D2866LF26

xx.310 228 kW / 1.900 1.550 at 1.000 - 1.300 rpm D2066LF04

xx.360 265 kW / 1.900 1.700 at 900 - 1.400 rpm D2866LF27

xx.350 257 kW / 1.900 1.750 at 1.000 - 1.300 rpm D2066LF03

xx.410 301 kW / 1.900 1.850 at 900 - 1.300 rpm D2866LF28

xx.390 287 kW / 1.900 1.900 at 1.000 - 1.300 rpm D2066LF02

xx.430 316 kW / 1.900 2.100 at 1.000 - 1.300 rpm D2066LF01

xx.460 338 kW / 1.900 2.100 at 900 - 1.300 rpm D2876LF04

xx.510 375 kW / 1.900 2.300 at 1.000 - 1.300 rpm D2876LF05

xx.480 353 kW / 1.900 2.300 at 1.000 - 1.400 rpm D2876LF12

xx.530 390 kW / 1.900 2.400 at 1.000 - 1.400 rpm D2876LF13

xx.660 485 kW / 1.900 2.700 at 1.000 - 1.600 rpm V10 D2840LF25

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF49

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF50

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF31

xx.310

xx.350 257 kW / 1.900 1.750 at 1.000 - 1.400 rpm D2066LF13

xx.390 287 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF12

xx.430 316 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF11

xx.320 235 kW / 1.900

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF33

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF32

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF31

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF01

xx.320 235 kW / 1.900 OBD 1 +

Emission

class

Euro 3

Euro 4

Power [kW]

at [rpm]

206 kW / 2.400

228 kW / 1.900

OBD

generation

No OBD

OBD 1

NO

control

X

EGR Exhaust gas

after treatment

None

With

AGR

®

PM-Kat

Max. torque

[Nm] / at [rpm]

1.100 at 1.200 - 1.800 rpm

1.550 at 1.000 - 1.400 rpm D2066LF14

1.600 at 1.000 - 1.400 rpm D2066LF35

1.600 at 1.000 - 1.400 rpm D2066LF39

Engine

type

R6

R6

Engine

designation

D0836LF41

D2066LF48

TRUCKNOLOGY® GENERATION A (TGA) 17

Page 25

Vehicle

designation

xx.360 Euro 4 265 kW / 1.900 OBD 1 +

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF37

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF36

xx.480 353 kW / 1.9 00 2.300 at 1.050 - 1.400 rpm D2676LF05

xx.400

xx.440 321 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF21

xx.400 294 kW / 1.900

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF23

xx.480 353 kW / 1.9 00 2.300 at 1.050 - 1.400 rpm D2676LF12

xx.5 40 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF11

xx.320 235 kW / 1.900

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF27

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF26

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF25

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF14

xx.5 40 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF13

xx.320* 235 kW / 1.900 1.600 at 1.000 - 1.400 rpm D2066LF20

xx.360* 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF19

xx.400* 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF18

xx.440* 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF17

xx.480* 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF16

xx.540* 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF15

* = In case of NO

rescue services and military vehicles in accordance with Annex I.6558 of Directive 2005/55/EC, version 2006/81/EC

Emission

class

Euro 5

system failure, engines fi tted with OBD 1b or OBD 2 are without torque reduction (TR). Only applies to engines for fi re services,

X

Power [kW]

at [rpm]

294 kW / 1.900

OBD

generation

NOX control

NO OBD

OBD 1

OBD 1 +

NO

control

X

EGR Exhaust gas

after treatment

With

EGR

No

EGR

PM-Kat

SCR

®

Max. torque

[Nm] / at [rpm]

1.800 at 1.000 - 1.400 rpm

1.900 at 1.000 - 1.400 rpm D2066LF22

1.900 at 1.000 - 1.400 rpm D2066LF24

1.600 at 1.000 - 1.400 rpm D2066LF28

Engine

type

R6

Engine

designation

D2066LF38

3. General

National and international regulations take priority over technically permissible dimensions and weights if they limit the technically

permissible dimensions and weights. The following data can be obtained from the quotation documents and documents contained in

MANTED

• Dimensions

• Weights

• Centre of gravity position for payload and body (minimum and maximum position for body) for the production standard

chassis / tractor unit.

The data contained in these documents may vary depending on what technical features the vehicle is actually fi tted with upon delivery.

The critical factor is the vehicle’s actual confi guration and condition at the time delivery.

To achieve optimum payload carrying capability the chassis must be weighed before work starts on the body.

Calculations can then be made to determine the best centre of gravity position for payload and body as well as the optimum body

length. As a result of component tolerances the weight of the standard chassis is allowed to vary by ± 5%, in accordance with

DIN 70020. Any deviations from the standard equipment level will have a greater or lesser effect on dimensions and weights.

Changes in equipment may result in deviations in the dimensions and weights, particularly if different tyres are fi tted that then also lead

to a change in the permissible loads.

®

at www.manted.de:

TRUCKNOLOGY® GENERATION A (TGA) 18

Page 26

In each individual case when a body is fi tted care needs to be taken to ensure the following

• Under no circumstances may the permissible axle weights be exceeded

• A suffi cient minimum front axle load is achieved

• The position of the centre of gravity and loading must not be one-sided

• The permissible overhang (vehicle overhang) is not exceeded.

3.1 Axle overload, one-sided loading

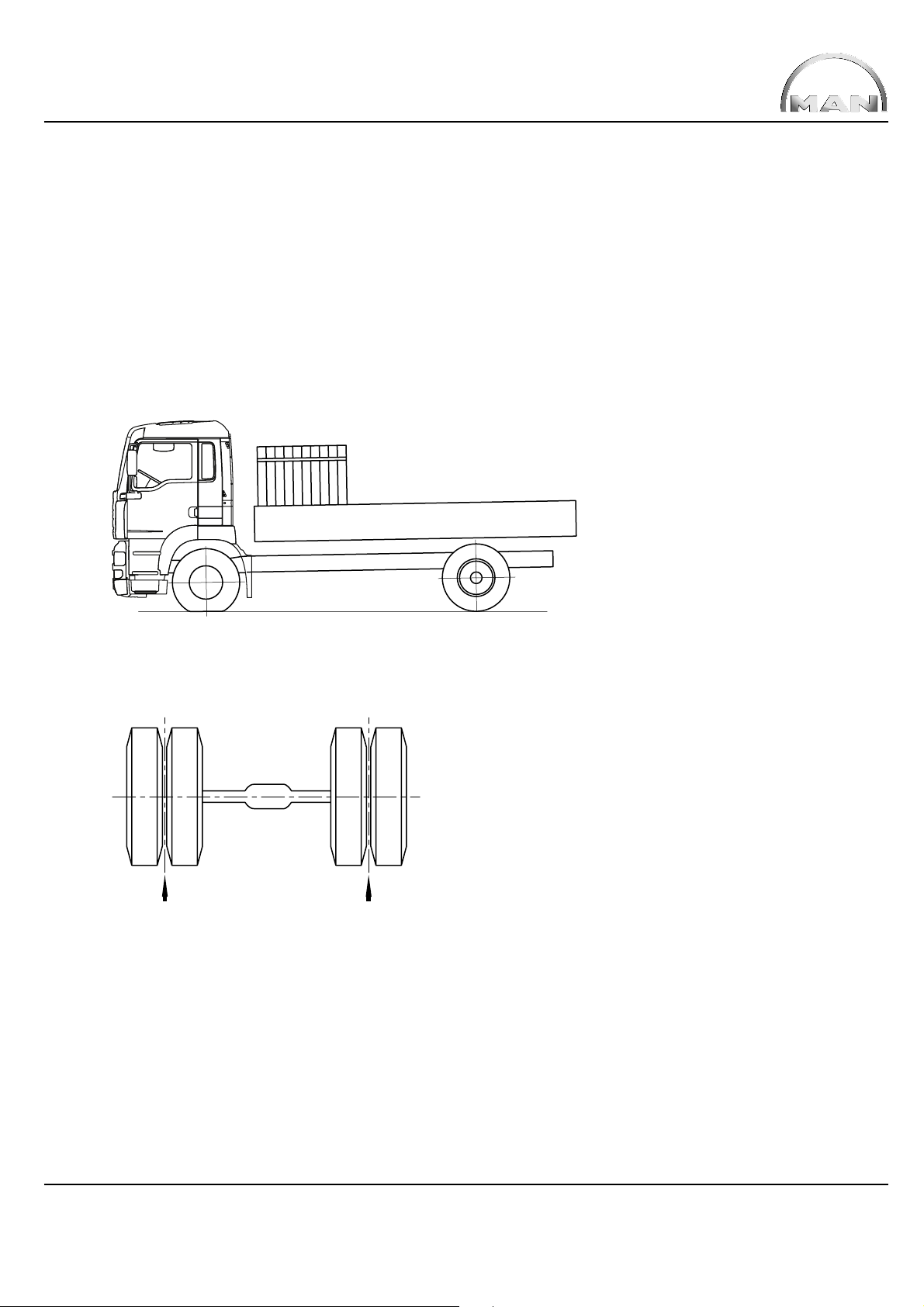

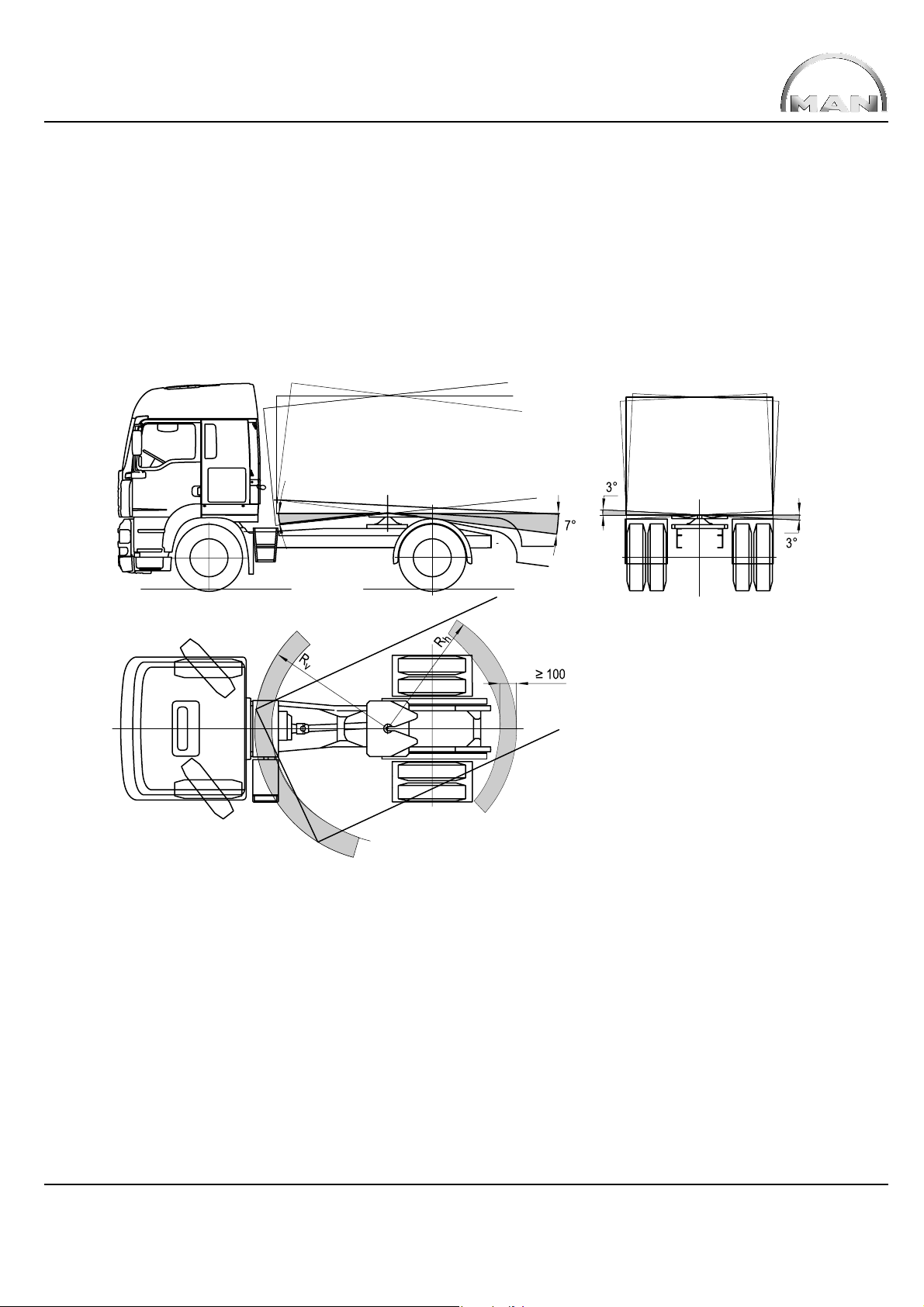

Fig. 1: Overloading the front axle ESC-052

Fig. 2: Difference in wheel load ESC-126

G G

Formula 1: Difference in wheel load

∆G ≤ 0,05 • G

tat

The body must be designed such that one-sided wheel loads do not occur. Following checks, a maximum wheel load difference of 5 %

is permitted (where 100 % represents the actual axle load and not the permissible axle load).

TRUCKNOLOGY® GENERATION A (TGA) 19

Page 27

Example:

Actual axle load G

= 11.000kg

tat

Therefore, the permissible wheel load difference is:

∆G = 0,05 G

= 0,05 · 11.000 kg

tat

∆G = 550 kg

This means for example that the wheel load on one side is 5,225 kg and 5,775 kg on the other.

The calculated maximum wheel load provides no information on the permissible individual wheel load for the tyres fi tted.

Information on this can be found in the technical manuals supplied by the tyre manufacturers.

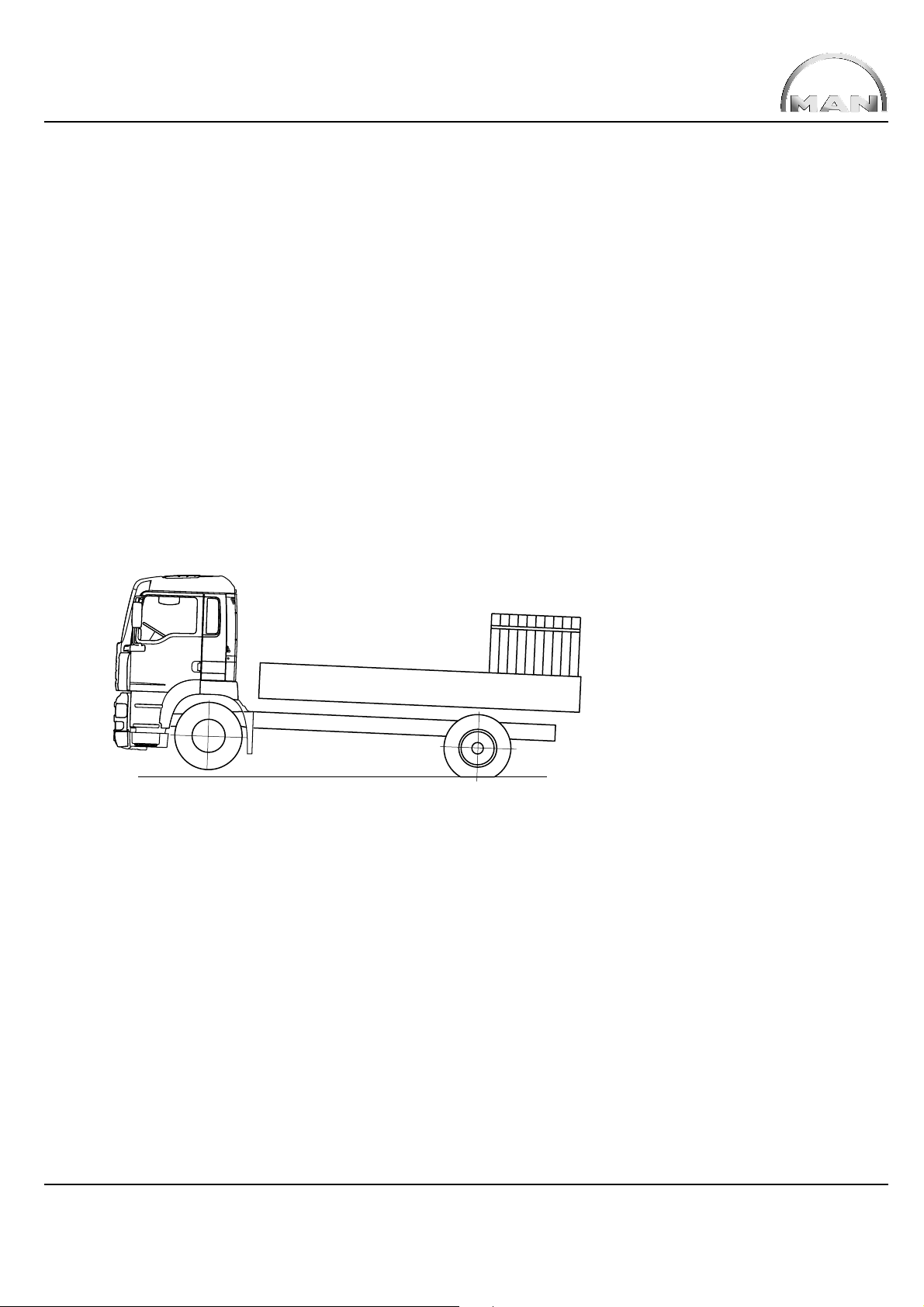

3.2 Minimum front axle load

In order to maintain steerability, the stipulated minimum front axle load must be ensured under all vehicle load conditions, see table 11.

Fig. 3: Minimum front axle loading ESC-051

TRUCKNOLOGY® GENERATION A (TGA) 20

Page 28

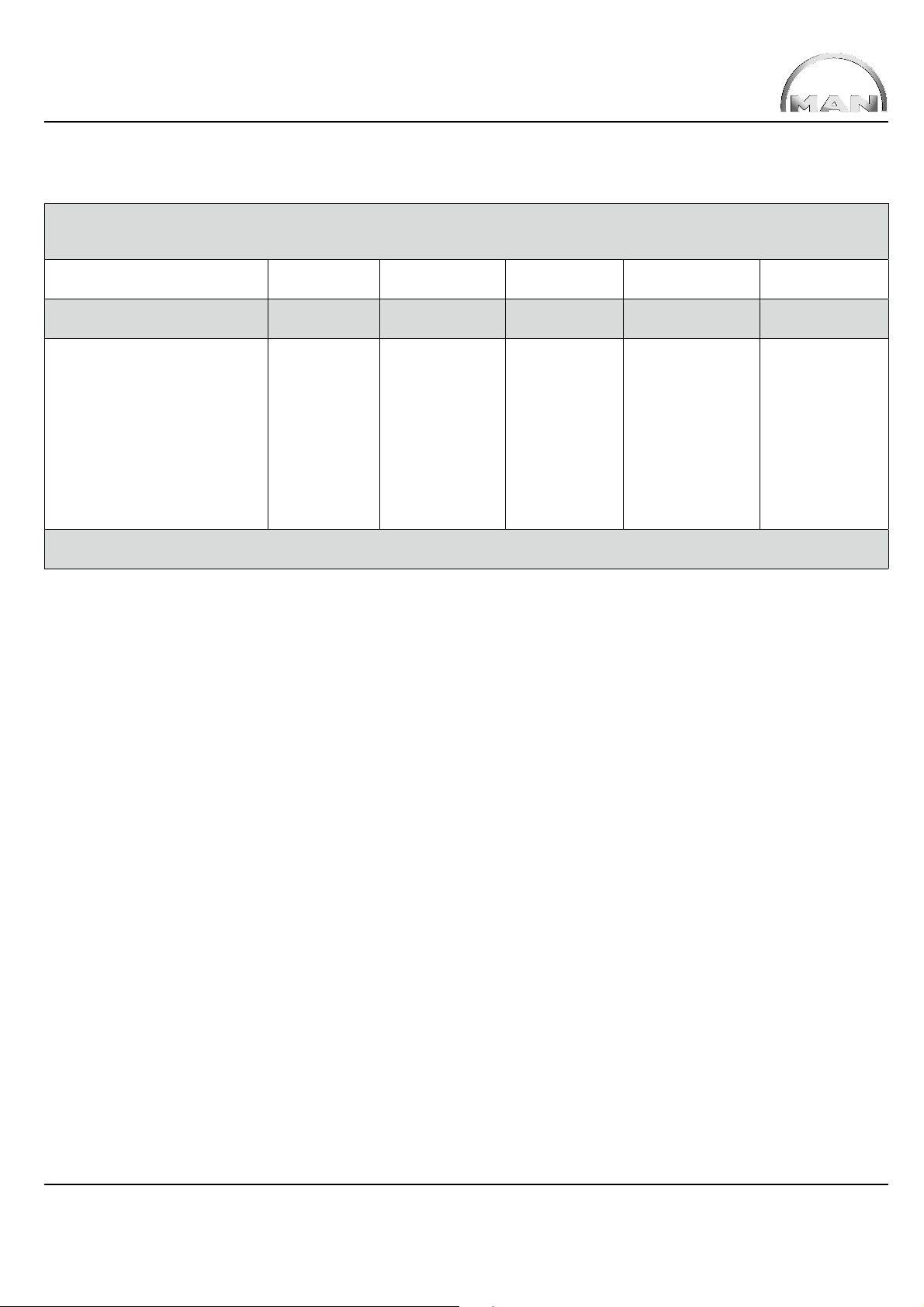

Tabl e 9: Minimum front axle loading for any load condition as a % of the respective actual vehicle weight

Minimum front axle loading for any load condition as a % of the respective actual vehicle weight

SDAH = Rigid drawbar trailer ZAA = Centre-axle trailer

GVW = Gross vehicle weight (vehicle/trailer)

Number of axles Wheel formula Without SDAH

/ZAA

Two-axle vehicle 4x2, 4x4H

25 % 25 % 30 % 30 %

With SDAH /ZAA

GG ≤ 18 t

Tridem SDAH /ZAA

GG > 18 t

Other rear load

e.g. crane

4x4

More than 2 axles

Three axle vehicles with lifting

leading or trailing axles must be

treated as having two axles when

the lifting axles are raised. In this

condition the higher minimum

front axle load for two axle vehicles applies.

6x2/2, 6x2/4

6x2-2, 6x2-4

6x4, 6x4-4

6x4H/2, 6x4H/4

6x4H-2, 6x4H-4

6x6, 6x6H

8x2-4, 8x2-6

8x4, 8x4/4,

20 %* 25 %* 30 %* 25 %*

8x4-4

8x4H-6, 8x6,

8x6H, 8x8

If more than one front axle is fi tted the % value is the total of the front axle loads. When operating with rigid drawbar trailers / centreaxle trailers + additional rear loads (e.g. tail-lift, crane) the higher value should be applied *= -2 % for steered leading/trailing axles

These values are inclusive of any additional rear loads such as: Nose weights exerted by a centre-axle trailer

• loading cranes

• tail lifts

• fork lift trucks.

3.3 Wheels, rolling circumference

Different tyre sizes on the front and rear axle(s) can only be fi tted to all-wheel-drive vehicles if the difference in rolling circumference of

the tyres used does not exceed 2% or 1.5% if the MAN HydroDrive

anti-skid chains, load rating and clearance must be observed.

®

system is installed. The notes in Chapter 5 “Body” relating to

3.4 Permissible overhang

The permissible overhang length is defi ned as the distance between the rear axle centreline (resulting from the theoretical wheelbase) and

the end of the vehicle (including the bodywork). For defi nition see the following the following paragraph 3.5.

The following maximum values are permitted, expressed as a percentage of the theoretical wheelbase

- Two-axle vehicles 65 %

- all other vehicles 70 %.

If the vehicle is not equipped to tow trailers the above values may be exceeded by 5 %.

The basic requirement is that the minimum front axle loads given in table 9 (par. 3.2.) must be observed for every operating condition.

TRUCKNOLOGY® GENERATION A (TGA) 21

Page 29

3.5 Theoretical wheelbase, overhang, theoretical axle centreline

The theoretical wheelbase is an aid for calculating the position of the centre of gravity and the axle loads.

The defi nition is given in the following fi gures.

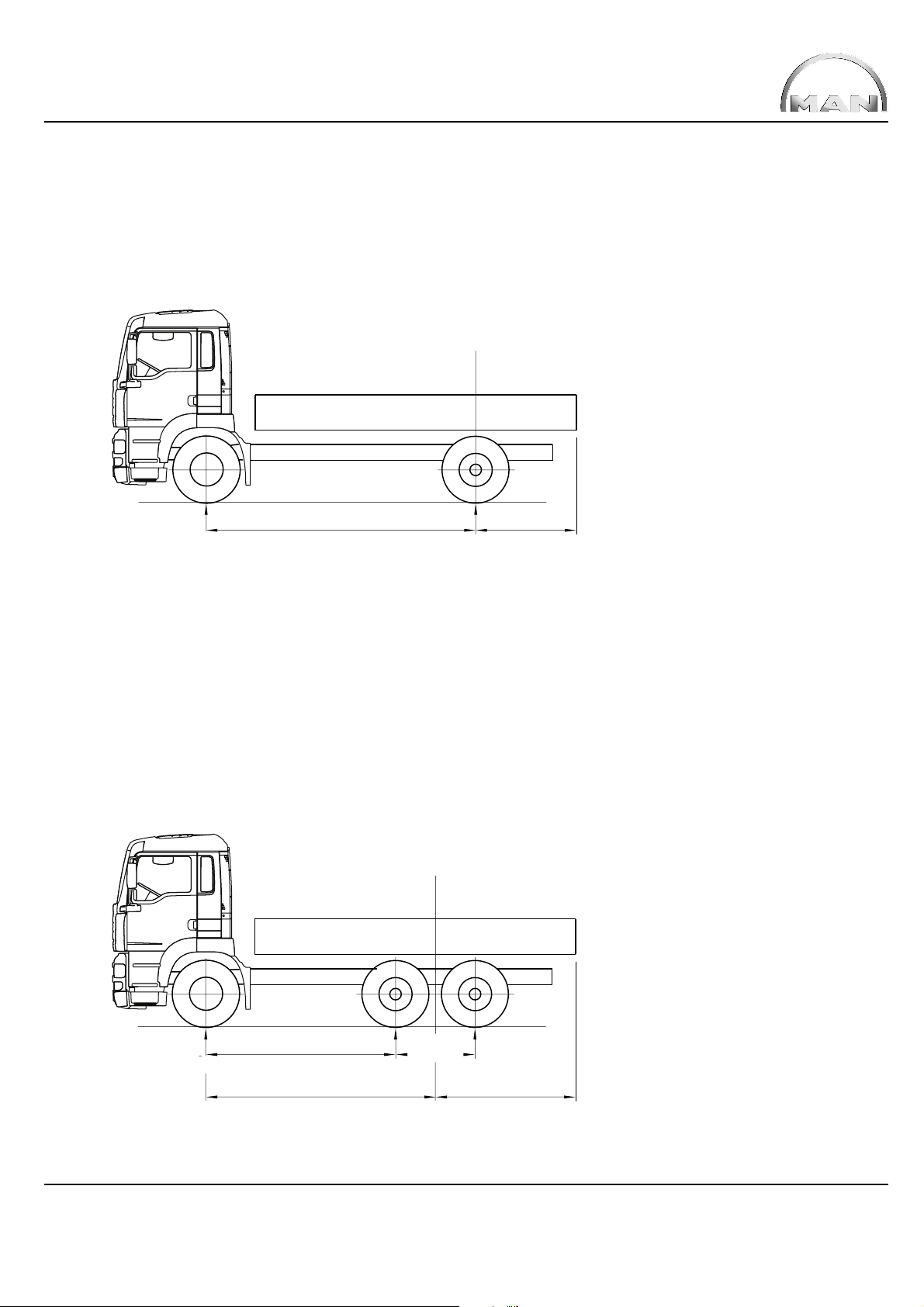

Fig. 4: Theoretical wheelbase and overhang – two-axle vehicle ESC-046

Theoretical rear

axle centreline

u

t

G

zul2

G

G

permissible1

zul1

l12= l

t

G

permissible2

Formula 2: Theoretical wheelbase for a two-axle vehicle

l

= l

t

12

Formula 3: Permissible overhang for a two-axle vehicle

U

≤ 0,65 • l

t

t

Fig. 5: Theoretical wheelbase and overhang for a three-axle vehicle with two rear axles and identical rear axle loads ESC-047

Theoretical rear

axle centreline

G

G

permissible1

zul1

l

12

G

l

t

permissible2

l

23

G

zul2

G

G

permissible3

zul3

u

t

TRUCKNOLOGY® GENERATION A (TGA) 22

Page 30

Formula 4: Theoretical wheelbase for a three-axle vehicle with two rear axles and identical rear axle loads

l

= l12 + 0,5 • l

t

23

Formula 5: Permissible overhang for a three-axle vehicle with two rear axles and identical rear axle loads

U

≤ 0,70 • l

t

t

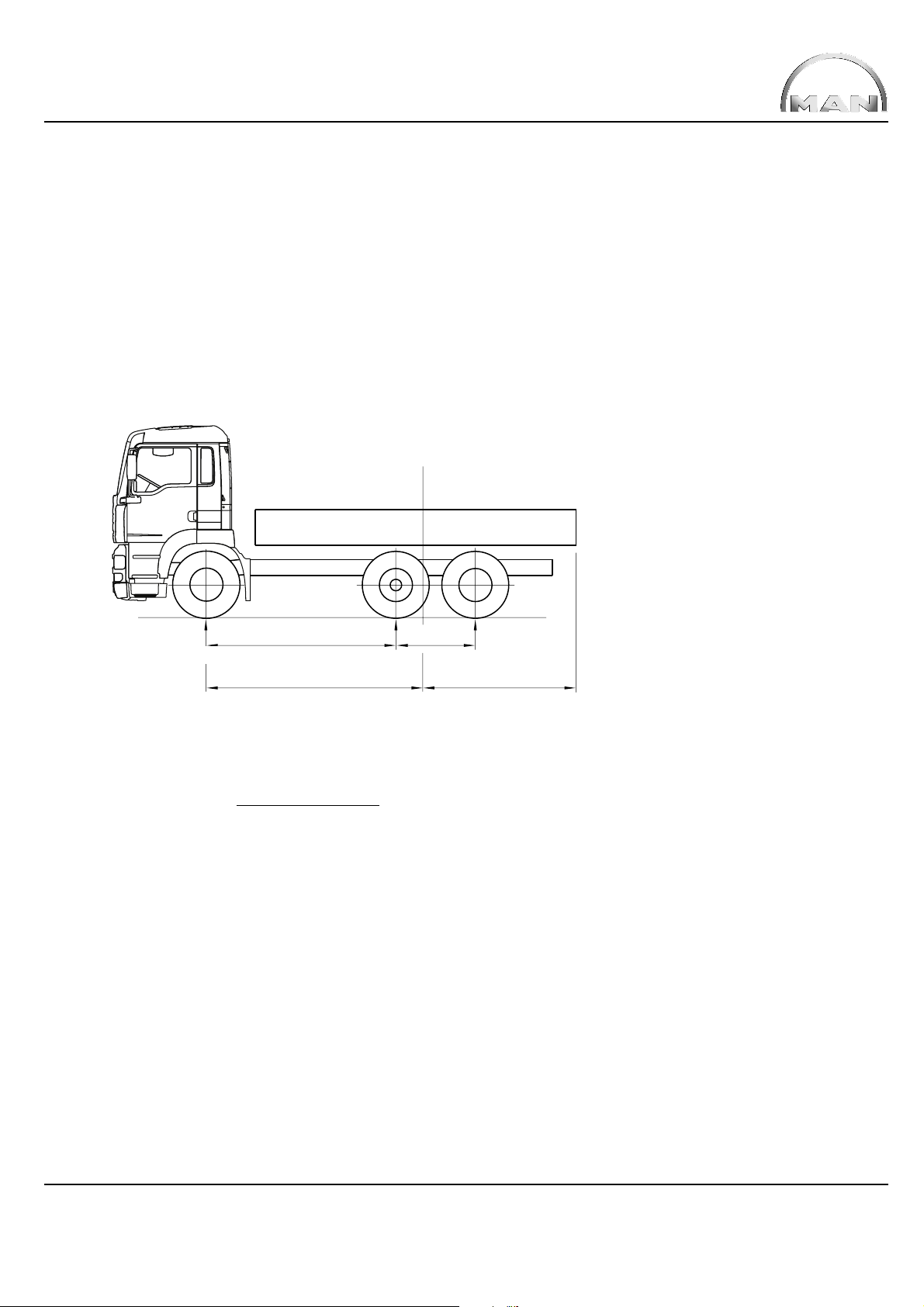

Fig. 6: Theoretical wheelbase and overhang for a three-axle vehicle with two rear axles and different rear axle

loads (e.g. in the MAN vehicle range all 6x2’s) ESC-048

Theoretical rear

axle centreline

G

permissible1

l

G

zul1

12

G

G

permissible2

l

t

zul2

l

23

G

G

permissible3

zul3

u

t

Formula 6: Theoretical wheelbase for a three-axle vehicle with two rear axles and different rear axle loads

G

permissible3

• l

23

lt = l12 +

G

permissible2

+ G

permissible3

Formula 7: Permissible overhang length three-axle vehicle with two rear axles and unequal rear axle loads

U

≤ 0,70 • l

t

t

TRUCKNOLOGY® GENERATION A (TGA) 23

Page 31

Fig. 7: Theoretical wheelbase and overhang for a four-axle vehicle with two front and two rear axles

(any axle load distribution) ESC-050

Theoretical front

axle centreline

Theoretical rear

axle centreline

G

permissible1

l

12

G

permissible2

l

23

G

l

t

l

34

permissible3Gpermissible4

U

t

Formula 8: Theoretical wheelbase for a four-axle vehicle with two front and two rear axles (any axle load distribution)

G

• l12 G

permissible1

permissible4

• l

34

lt = l23 + +

G

permissible1

+ G

permissible2

G

permissible3

+ G

permissible4

Formula 9: Permissible overhang length for a four-axle vehicle with two front and two rear axles

U

≤ 0,70 • l

t

t

3.6 Calculating the axle load and weighing procedure

It is essential that an axle load calculation be completed in order to ensure correct design of the body.

Achieving optimum compatibility between bodywork and truck is only possible if the vehicle is weighed before any work on the body

is commenced. The weights thus obtained are then taken as a basis for an axle load calculation. The weights given in the sales

documents only apply to production standard vehicles. Manufacturing inaccuracies (within tolerances) may occur.

The vehicle must be weighed:

• Without the driver

• With a full fuel tank

• With the handbrake released and the vehicle secured with chocks

• If fi tted with air suspension, raise the vehicle to normal driving position

• Lower any liftable axles

• Do not actuate any moving-off aid.

TRUCKNOLOGY® GENERATION A (TGA) 24

Page 32

Observe the following sequence when weighing a vehicle:

Two-axle vehicles

st

• 1

• 2

axle

nd

axle

• whole vehicle as a check

Three-axle vehicles with two rear axles

st

• 1

• 2

axle

nd

together with 3rd axle

• whole vehicle as a check

Four axle vehicle with two front and two rear axles

st

• 1

• 3

together with 2nd axle

rd

together with 4th axle

• whole vehicle as a check

Four-axle vehicle with one front and three rear axles

st

• 1

• 2

axle

nd

together with 3rd and 4th axles

• whole vehicle as a check.

3.7 Checking and adjustment procedures once body has been fi tted

On the TGA do not check or adjust:

• ALB settings: No adjustments necessary once bodywork has been fi tted

• Tachograph ‘MTCO’ – this has already been calibrated at the factory

• Digital tachograph ‘DTCO’ – this has also been calibrated at the factory.

According to EU Directives however, a person authorised to carry out tests must enter the registration number

(normally this has not been issued when the vehicle leaves the MAN factory).

Checking and adjustment procedures that must be completed by the bodybuilder once the body has been fi tted:

• Basic beam alignment of the headlamps, see also Section 6.6 in this booklet for details

• Check battery charge status according to the charging schedule, sign battery charging log.

See also the Chapter “Electrics, electronics, wiring”

• Check rear underride protection for compliance with statutory regulations, see Section 4.11.1” and adjust as necessary.

• Check sideguards for compliance with statutory regulations (for dimensions see the Chapter “Modifying the chassis”)

and adjust as necessary.

TRUCKNOLOGY® GENERATION A (TGA) 25

Page 33

3.8 Notes on MAN Hydrodrive

®

MAN Hydrodrive® is a hydrostatic front axle drive that employs wheel hub motors. The system is selectable and operates in the speed

range between 0 and 28 km/h. Vehicles fi tted with Hydrodrive

®

are legally regarded as off-road vehicles as defi ned by 70/156 EEC

(as last amended by 2005/64/EU and 2005/66/EG).

The Hydrodrive® hydraulic circuit is solely approved for the regulated drive of the front axle and may not be used to supply other

hydraulic systems. Modifi cations to the Hydrodrive

®

hydraulic system (including relocating pipework) may only be carried out by

specifi cally authorised companies.

In the case of semi-trailer tippers and other bodies where there is a risk of the cargo falling into the area around the oil cooler an oil

cooler cover must be fi tted. This is available fi tted ex-works or as a retrofi t solution under the name ‚Protective cover for oil cooler/fan

for HydroDrive

®

’. (Installation no. 81.36000.8134).

4. Modifying the chassis

To provide customers with the products they want, additional components sometimes need to be installed, attached or modifi ed.

For uniformity of design and ease of maintenance, we recommend that original MAN components be used as long as these comply with

the vehicle’s structural design. To keep maintenance work to a minimum, we recommend the use of components that have the same

maintenance intervals as the MAN chassis.

Modifi cations to safety-critical components of wheel/axle guides, steering and brakes are not allowed. Existing anti-roll bars may

neither be removed nor modifi ed.

Installation and/or modifi cation of components frequently requires intervention in the control unit’s CAN architecture (e.g. when

extending the EBS electronic braking system). The necessary modifi cations and/or expansion of the vehicle programming are

described under the corresponding topic in these guidelines.

Such modifi cations may only be undertaken with assistance from the electronics experts at MAN service centres and the programming

must be approved by the ESC department (for address see “Publisher” above). Retrofi tted systems may, under certain circumstances,

not be assimilated into the vehicles’ on-board Trucknology

For this reason it is not possible to achieve the same degree of maintenance convenience as is possible with original equipment.

®

systems “Time maintenance system” of “Flexible maintenance system”.

4.1 Frame material

When carrying out modifi cations to the chassis longitudinal and cross-members only use of the original frame material S500MC

(QStE 500TM) is approved.

Exception: For profi le 33, the longitudinal members are made of S420MC = QStE420TM.

Table 10: Steel for TGA frame

Material

number

1.0980 QStE420TM SEW 092 ≥ 420 480-620 S420MC DIN EN

1.0984 QStE500TM SEW 092 ≥ 500 550-700 S500MC DIN EN

For subframe longitudinal and cross-members only steels with a yield point of σ

subframes see the Subframe Chapter 5.3.3.

For the TGA the following longitudinal frame members are used, depending on the model.

Previous

material

designation

Previous

standard

σ

0,2

N/mm

σ

2

B

N/mm

2

New material

designation

New

standard

Profi le codes as

per table 11

33

10149-2

31 32 34

10149-2

≥ 350 N/mm2 may be used. For additional details on

0,2

TRUCKNOLOGY® GENERATION A (TGA) 26

Page 34

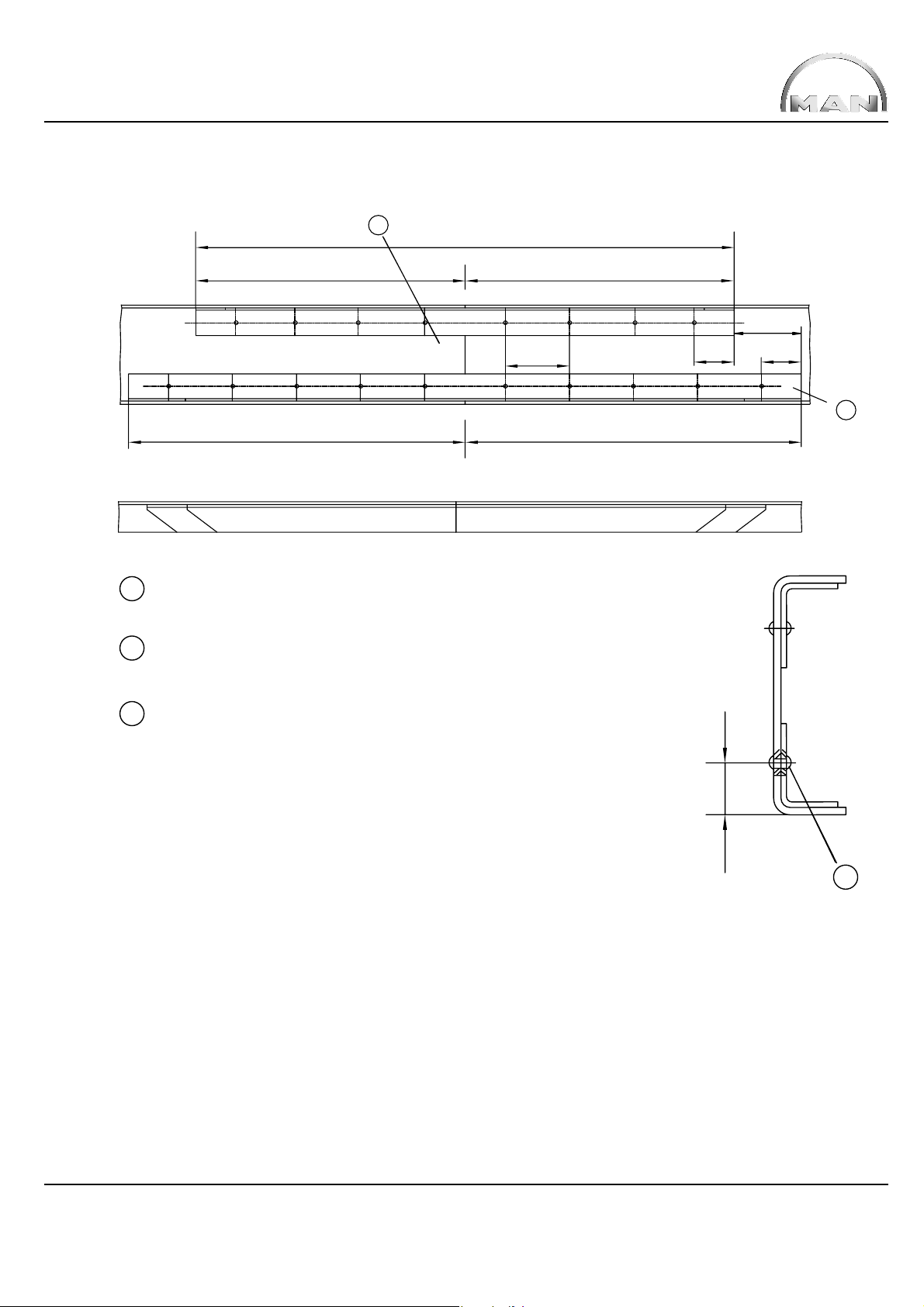

Fig. 8: Profi le data for longitudinal frame members ESC-112

Bo

t

h

y

e

e

x

R

B

u

Surface centre of gravity S

H

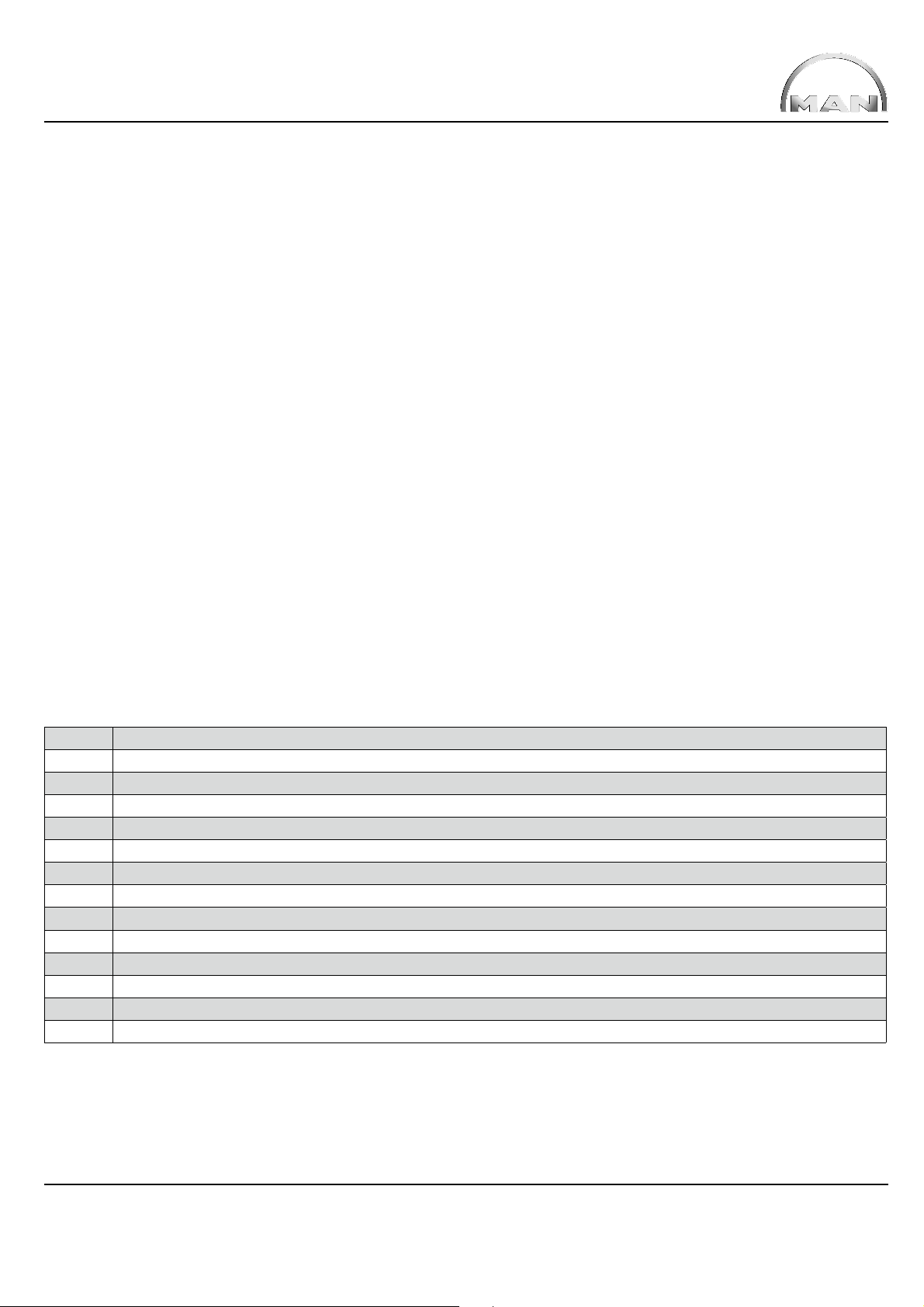

Table 11: Profile data for longitudinal frame members, profi les in bold are used for the TGA range

No H

mmhmm

B

B

o

mm

u

mmtmmRmmGkg/m

σ

0,2

N/mm

σ

2

B

N/mm

A

e

e

x

2

Mm

2

mm

mm

y

cm

W

cm

W

x1

3

cm

l

x

4

l

cm

W

y

y1

4

3

cm

x2

3

1 220 208 80 85 6 10 17 420 480..620 2.171 21 110 1.503 138 135 135 64 21

2 222 208 80 80 7 10 20 420 480..620 2.495 20 111 1.722 155 155 142 71 24

3 222 208 75 75 7 10 19 420 480..620 2.425 18 111 1.641 148 148 118 66 21

4 224 208 75 75 8 10 22 420 480..620 2.768 19 112 1.883 168 168 133 70 24

5 220 208 70 70 6 10 16 420 480..620 2.021 16 110 1.332 121 121 85 53 16

6 322 306 80 80 8 10 29 420 480..620 3.632 17 161 4.821 299 299 176 104 28

7 262 246 78 78 8 10 24 420 480..620 3.120 18 131 2.845 217 217 155 86 26

8 260 246 78 78 7 10 21 420 480..620 2.733 18 130 2.481 191 191 138 77 23

9 224 208 80 80 8 10 22 420 480..620 2.848 20 112 1.976 176 176 160 80 27

10 262 246 80 80 8 10 25 420 480..620 3.152 19 131 2.896 221 221 167 88 27

11 273 247 85 85 7

1)62)

31 355 510 3.836 26 136 4.463 327 327 278 108 47

12 209 200 65 65 4,5 8 11 260 420 1.445 15 105 868 83 83 52 35 10

13 210 200 65 65 5 8 13 260 420 1.605 15 105 967 92 92 58 39 12

14 220 208 70 80 6 10 16 420 480..620 2.081 18 107 1.399 131 124 105 58 17

15 222 208 70 80 7 10 19 420 480..620 2.425 18 108 1.638 152 144 120 67 19

16 234 220 65 65 7 8 19 420 480..620 2.381 15 117 1.701 145 145 80 53 16

17 220 208 75 75 6 10 16 420 480..620 2.081 18 110 1.400 127 127 103 57 18

18 218 208 70 70 5 10 13 420 480..620 1.686 16 109 1.105 101 101 72 45 13

19 222 208 70 70 7 10 18 420 480..620 2.355 17 111 1.560 141 141 97 57 18

20 260 246 70 70 7 10 21 420 480..620 2.621 15 130 2.302 177 177 101 67 18

21 210 200 65 65 5 8 13 420 480..620 1.605 15 105 967 92 92 58 39 12

22 330 314 80 80 8 10 29 420 480..620 3.696 17 165 5.125 311 311 177 104 28

23 270 254 80 80 8 10 25 420 480..620 3.216 18 135 3.118 231 231 168 93 27

24 274 254 80 80 10 10 31 420 480..620 4.011 19 137 3.919 286 286 204 107 33

25 266 254 80 80 6 10 19 420 480..620 2.417 18 133 2.325 175 175 130 72 21

26 224 208 70 70 8 10 21 420 480..620 2.688 17 112 1.789 160 160 109 64 21

27 268 254 70 70 7 10 21 420 480..620 2.677 15 134 2.482 185 185 102 68 19

28 270 254 70 70 8 10 24 420 480..620 3.056 15 135 2.843 211 211 114 76 21

W

cm

y2

3

TRUCKNOLOGY® GENERATION A (TGA) 27

Page 35

Table 11: Profile data for longitudinal frame members, profi les in bold are used for the TGA range

No H

mmhmm

B

B

o

mm

u

mmtmmRmmGkg/m

σ

0,2

N/mm

σ

2

B

N/mm

A

e

e

x

2

Mm

2

mm

mm

y

cm

W

cm

W

x1

3

cm

l

x

4

l

cm

W

y

y1

4

3

cm

x2

3

29 334 314 80 80 10 10 36 420 480..620 4.611 17 167 6.429 385 385 215 126 34

30 328 314 80 80 7 10 25 420 480..620 3.237 16 164 4.476 273 273 158 99 25

31 270 254 85 85 8 10 26 500 550..700 3.296 20 135 3.255 241 241 201 101 31

32 270 251 85 85 9,5 10 30 500 550..700 3.879 21 135 3.779 280 280 232 110 36

33 334 314 85 85 10 10 37 420 480..620 4.711 19 167 6.691 401 401 257 135 39

34 270 256 85 85 6,8 10 22 500 550..700 2.821 19 135 2.816 209 209 174 92 26

35 220 212 70 70 4 10 11 420 480..620 1.367 16 110 921 84 84 59 37 11

36 220 211 70 70 4,5 10 12 420 480..620 1.532 16 110 1.026 93 93 65 41 12

37 220 206 70 70 7 10 18 420 480..620 2.341 17 110 1.526 139 139 97 57 18

38 220 204 70 70 8 10 21 420 480..620 2.656 17 110 1.712 156 156 108 64 20

39 270 256 70 70 7 10 21 420 480..620 2.691 15 135 2.528 187 187 102 68 19

40 270 256 70 70 7 10 21 500 550..700 2.691 15 135 2.528 187 187 102 68 19

41 270 254 70 70 8 10 24 420 480...620 3.056 15 135 2.843 211 211 114 76 21

42 270 254 85 85 8 10 26 500 480...620 3.296 20 135 3.255 241 241 201 101 31

3

270 254 85 85 8 10 26 500 560...700 3.296 20 135 3.255 241 241 201 101 31

43

1)

Upper and lower fl ange 13 mm thick

2)

Outside radius 10 mm

3)

LNE500 in accordance with Brazilian Standard NBR 6656:2008, for TGX in Latin America (status 03 2010: CKD types 28X. 88X)

W

cm

y2

3

Table 12 gives the standard model-related allocation of longitudinal frame members valid on the date of publication of this guide.

No guarantee is given or implied as to the currentness or completeness of this data.

Up-to-date and binding instructions on the longitudinal frame member profi le to be used can be found in:

• the chassis drawing

• the technical data sheet

which can be found for the corresponding vehicle at www.manted.de under “Chassis”.

TRUCKNOLOGY® GENERATION A (TGA) 28

Page 36

Table 12: Model-related allocation of longitudinal frame member profi les for TGA

Tonnage Vehicle Suffi x Model Profi le code Specifi cs

18 t TGA 18.xxx 4x2 BLS-TS

TGA 18.xxx 4x4

TGA 18.xxx 4x4H

19 t TGA 19.xxx 4x2 BBS-WW

25 t TGA 25.xxx 6x2-2, 6x2-4 LL-U

26 t TGA 26.xxx 6x2-2, 6x2-4

TGA 26.xxx 6x4H

26 t TGA 26.xxx 6x2/2, 6x2/4

TGA 26.xxx 6x4H

26 t TGA 26.xxx 6x4 BB

26 t TGA 26.xxx 6x6

TGA 26.xxx 6x6H

BLS-TS

BLS-TS

BB

BB

BL

BL

BL

LL

LL

LLS-U

LLS-U

LL-U

LL-U

BL-WW

BB

BB

BL

BL

BL

BB-WW

LL-U

BL

BL

BL

LL

LL

LL

BL

BL

LL

BL

BL

BL

BL

BB

BL

BL

BL-WW

BB

BB

BB

BL

BL

H01

H08

H11

H02

H03

H05

H06

H07

H09

H10

H12

H13

H14

H15

H61

H51

H52

H22

H70

H80

H43

H60

H44

H45

H16

H17

H18

H19

H20

H21

H35

H27

H31

H23

H24

H32

H42

H25

H26

H29

H30

H63

H55

H47

H56

H72

H82

34 Tractor unit for tanker /Silo

31

42

31

31

32

32

31

31

31

31/32 Profi le 31 for wheelbase ≤ 3.900+1.400

Profi le 32 for wheelbase > 3.900+1.400

31

31/32 Profi le 31 for wheelbase ≤ 3.900+1.400

Profi le 32 for wheelbase > 3.900+1.400

TRUCKNOLOGY® GENERATION A (TGA) 29

Page 37

Tonnage Vehicle Suffi x Model Profi le code Specifi cs

28 t TGA 28.xxx 6x2-4

TGA 28.xxx 6x2-2

28 t TGA 28.xxx 6x4-4 BL H81 31 TA steered

28 t TGA 28.xxx 6x6-4 BL H83 31 TA steered and driven

32 t TGA 32.xxx 8x4 BB

33 t TGA 33.xxx 6x4 BB

33 t TGA 33.xxx 6x6

TGA 33.xxx 6x6H

35 t TGA 35.xxx 8x2-4,

8x2-6

TGA 35.xxx 8x4 BB

TGA 35.xxx 8x4-4 BL

35 t TGA 35.xxx 8x6 BB

35 t TGA 35.xxx 8x8 BB

40 t TGA 40.xxx 6x4 BB-WW

40 t TGA 40.xxx 6x6 BB-WW

41 t TGA 41.xxx 8x4 BB

41 t TGA 41.xxx 8x4/4 BB, BLBB,

41 t TGA 41.xxx 8x6 FFDA

TGA 41.xxx 8x8 FFDA

BL, LL

LL

BL

LL

BL

BB

BB

BB-WW

BB-WW

BLBL H29

BB

BB-WW

BB

BB

BL

BL

BL

BL

BB

BL

BL

BL

BB

BB

BB

BB

BB

BB-WW

BL

FFDA

FFDA

H71

H85

H86

H87

H89

H48

H49

H25

H26

H28

H62

H30

H47

H54

H55

H56

H72

H82

H88

H90

H36

H37

H40

H41

H91

H92

H73

H93

H76

H96

H33

H34

H57

H58

H38

H39

H46

H94

H95

H73

H93

H76

H96

31 TA steered

TA with twin tyres

TA with twin tyres

TA with twin tyres

TA with twin tyres

34 Only transport mixers and rear tippers

31/32 Profi le 31 for wheelbase ≤ 3.900+1.400

Profi le 32 for wheelbase > 3.900+1.400

31

31/32 Profi le 31 for wheelbase ≤ 3.900+1.400

Profi le 32 for wheelbase > 3.900+1.400

31

31

31

31 At permissible gross weights ≤ 35 t

31 At permissible gross weights ≤ 35 t

32

32

32

33

32 At permissible gross weights > 35 t

32 At permissible gross weights > 35 t

TRUCKNOLOGY® GENERATION A (TGA) 30

Page 38

4.2 Corrosion protection

Surface and corrosion protection affects the service life and appearance of the product. In general, the quality of the coatings on body

components should be equal to that of the chassis.

In order to fulfi l this requirement, the MAN Works Standard M 3297 “Corrosion protection and coating systems for non-MAN

bodies” is binding for bodies that are ordered by MAN. If the customer commissions the body, this standard becomes a

recommendation only. Should the standard not be observed, MAN provides no guarantee for any consequences.

MAN-works standards may be sourced via www.normen.man-nutzfahrzeuge.de, registration required.

Series production MAN chassis are coated with environmentally friendly, water-based 2-component chassis top-coat paints at approx.

80°C. To guarantee uniform coating, the following coating structure is required for all metal component assemblies on the body and

subframe:

• Bare metal or blasted component surface (SA 2.5)

• Primer coat: 2-component epoxy primer, approved in accordance with MAN works standard M 3162-C or, if possible,

cathodic dip painting to MAN works standard M 3078-2, with zinc phosphate pre-treatment

• Top coat: 2-component top-coat paint to MAN works standard M 3094, preferably water-based; if there are no

facilities for this, then solvent-based paint is also permitted. (www.normen.man-nutzfahrzeuge.de, registration required).

Instead of priming and painting the vehicle with a top coat, the substructure of the body (e.g. longitudinal and cross-members, corner

plates) may also be galvanised. See the relevant paint manufacturer’s data sheets for information on tolerances for drying and curing

times and temperatures. When selecting and combining materials the compatibility of the different metals (e.g. aluminium and steel)

must be taken into consideration as must the effects of the ‘electrochemical series’ (cause of contact corrosion).

After all work on the chassis has been completed:

• Remove any drilling swarf

• Remove burrs from the edges

• Apply wax preservative to any cavities

Mechanical connections (e.g. bolts, nuts, washers, pins) that have not been painted over must be given optimum corrosion protection.

To prevent the occurrence of salt corrosion whilst the vehicle is stationary during the body-building phase, all chassis must be washed

with clean water to remove any salt residues as soon as they arrive at the body manufacturer’s premises.

4.3 Drill holes, riveted joints and screw connections on the frame

If possible, use the holes already drilled in the frame. No drilling should be carried out in the fl anges of the longitudinal frame member

profi les, i.e. in the upper and lower fl anges (see Fig. 9). The only exception to this is at the rear end of the frame, outside the area of all

the parts fi tted to the frame that have a load-bearing function for the rearmost axle (see Fig. 10).

This also applies to the subframe.

TRUCKNOLOGY® GENERATION A (TGA) 31

Page 39

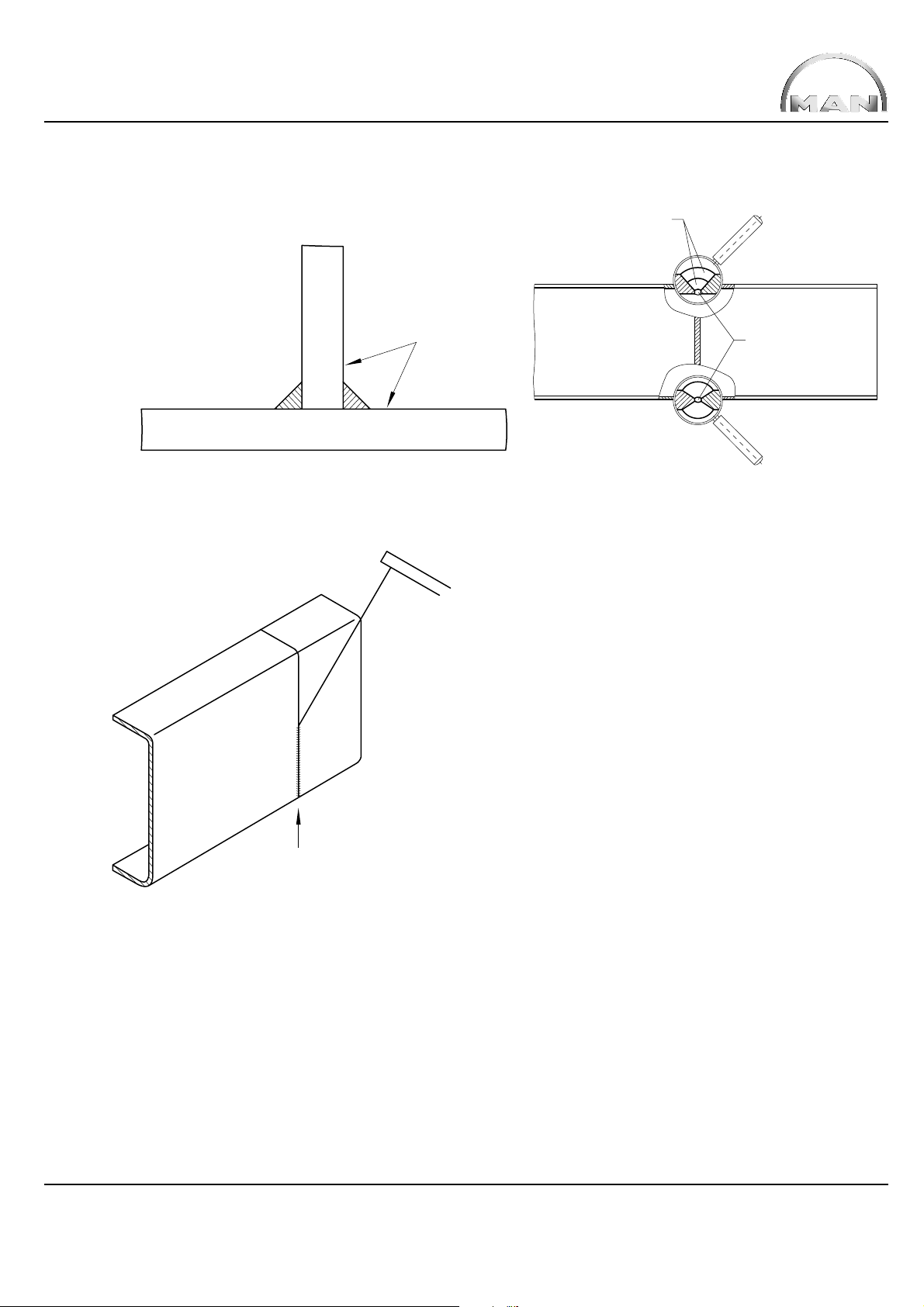

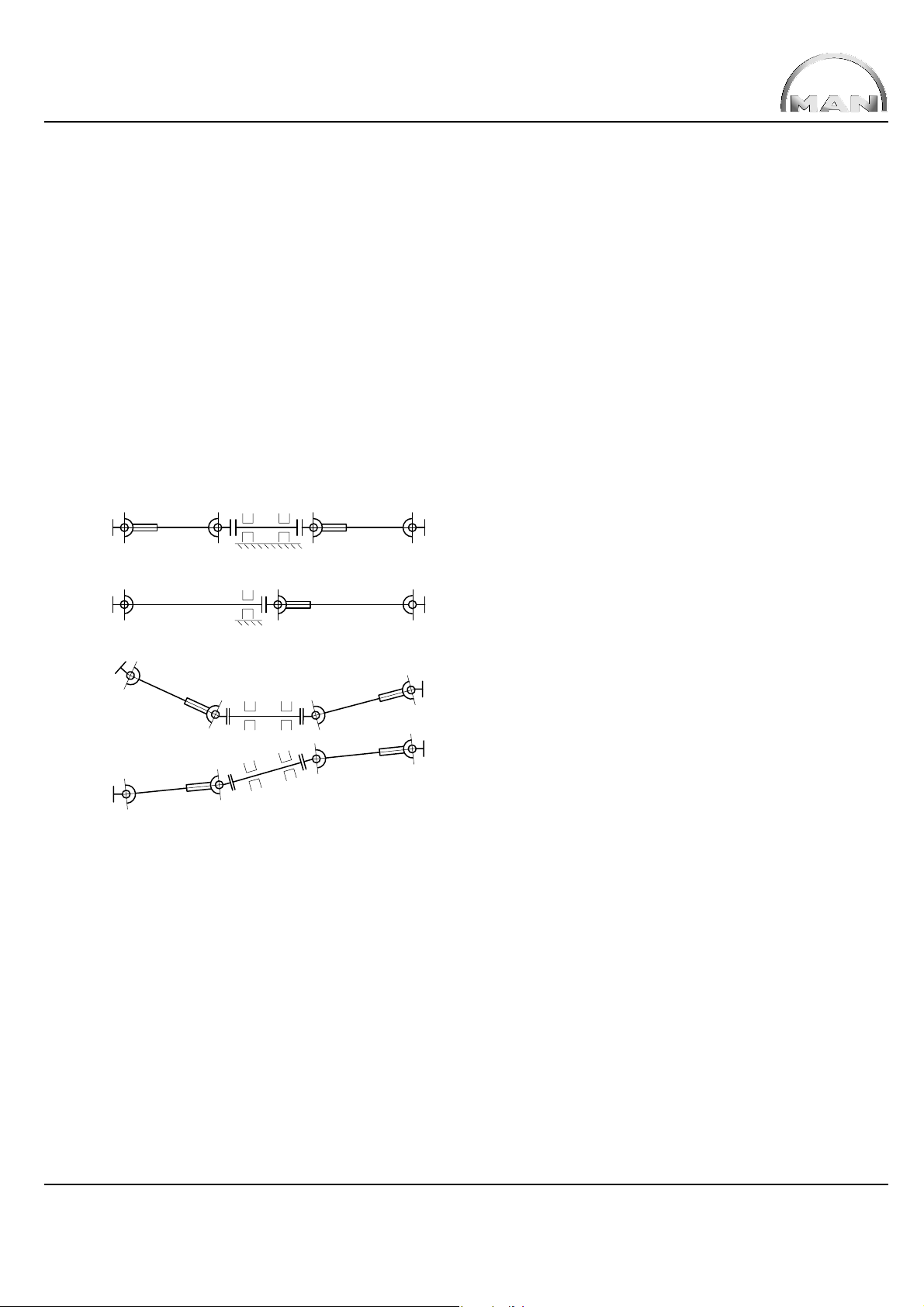

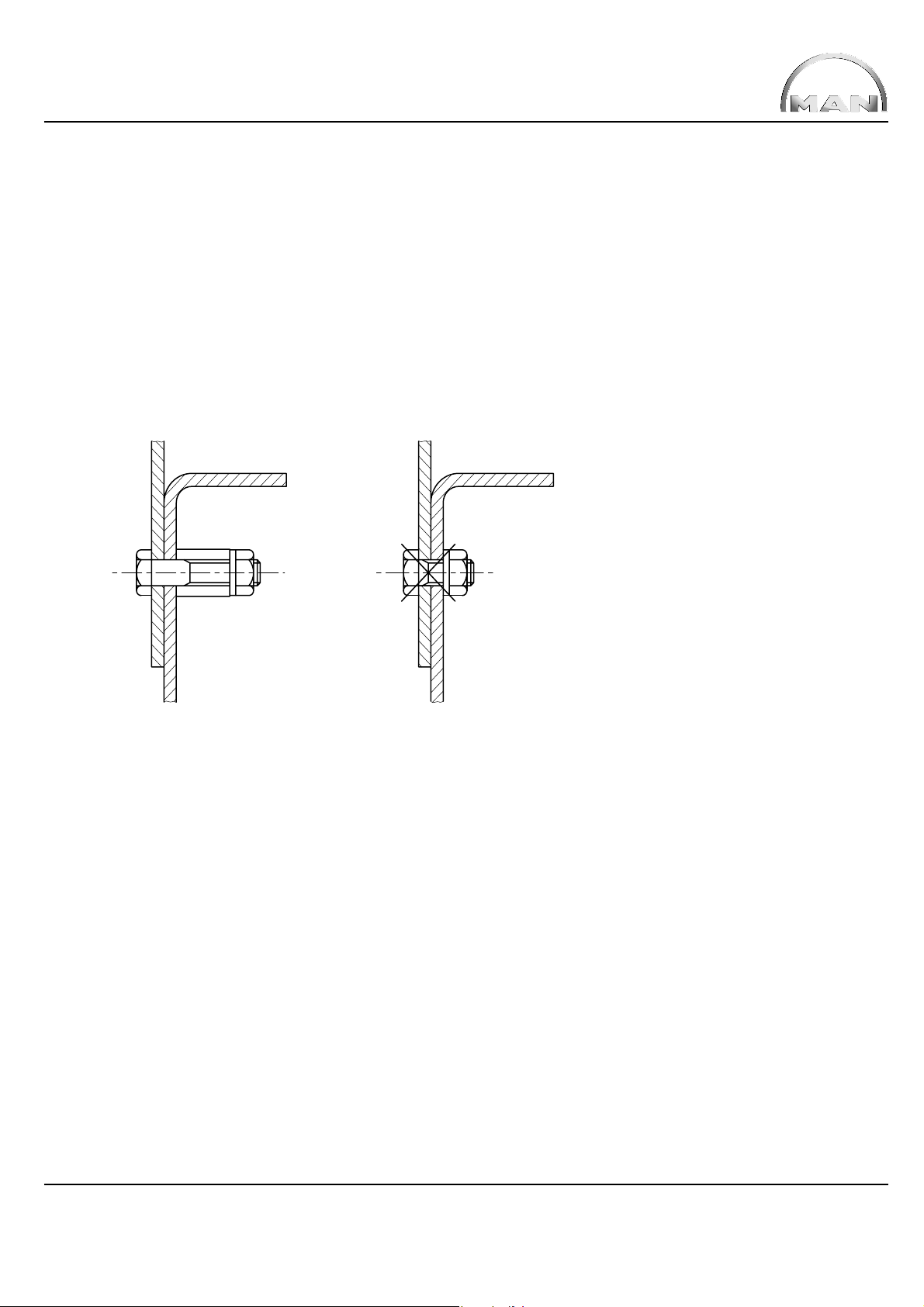

Fig. 9: Frame drill holes in the upper and lower fl ange ESC-155 Fig. 10: Drill holes at frame end ESC-032

It is allowable to make drillings in the frame along its total useable length. However, the permissible distances between holes must be

observed (see Fig. 11). After drilling, rub down all holes and remove any burrs.

Fig. 11: Distances between drill holes ESC-021

Ød

b b

b b

b b a a

a ≥ 40

b ≥ 50

c

c ≥ 25

TGA: d ≤ 16

TRUCKNOLOGY® GENERATION A (TGA) 32

Page 40

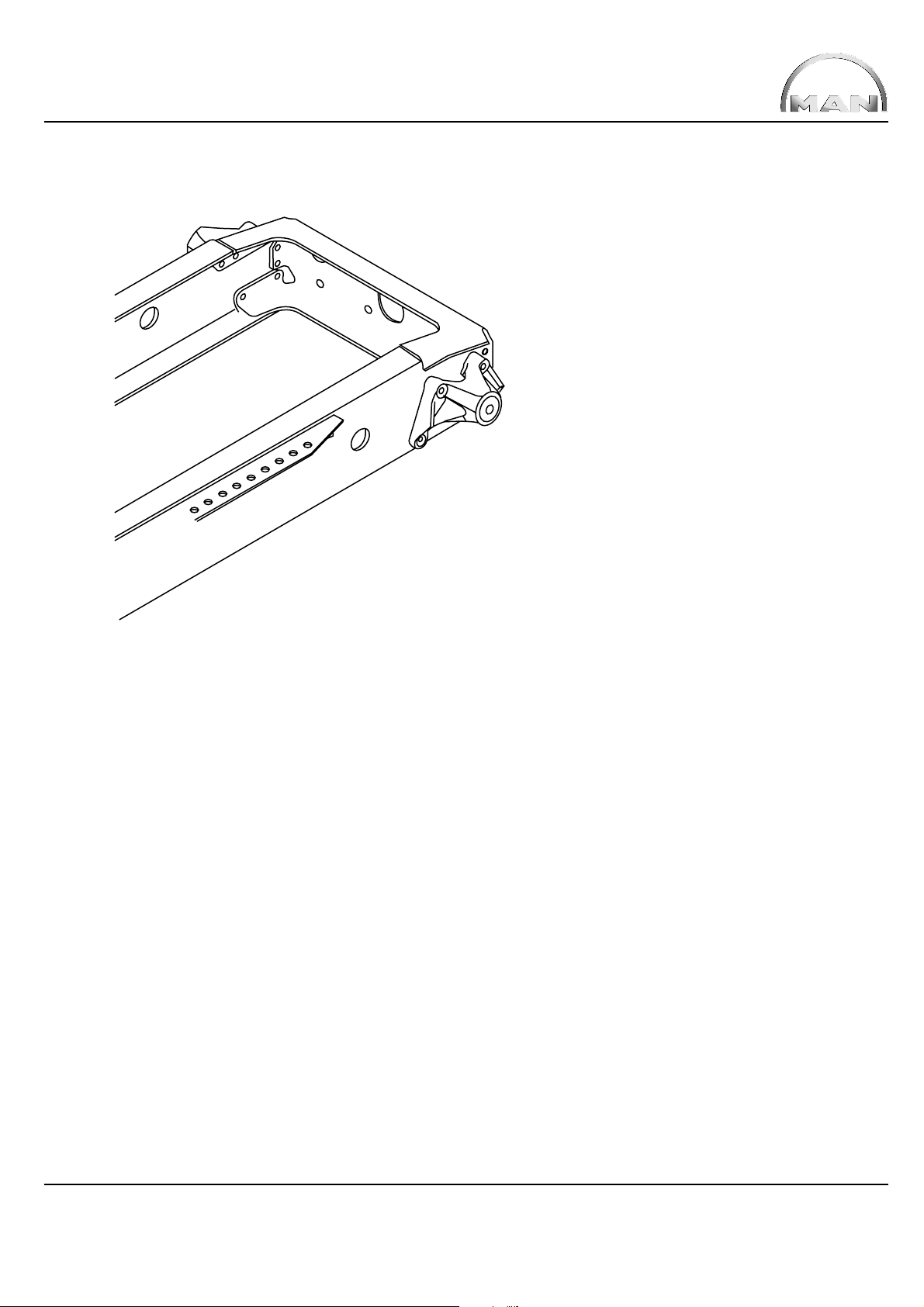

Several frame components and add-on components (e.g. corner plates with cross member, shear plates, platform corner pieces) are

riveted to the frame during production. If modifi cations to these components need to be carried out afterwards, screw connections with

a minimum strength class of 10.9 and mechanical locking device are permitted. MAN recommends double nip countersunk bolts/nuts to

MAN standard M 7.012.04 (may be sourced via www.normen.man-nutzfahrzeuge.de). The manufacturer’s stipulated tightening torque

must be observed. If double nip countersunk bolts are reinstalled then new bolts/nuts must be used on the tightening side.

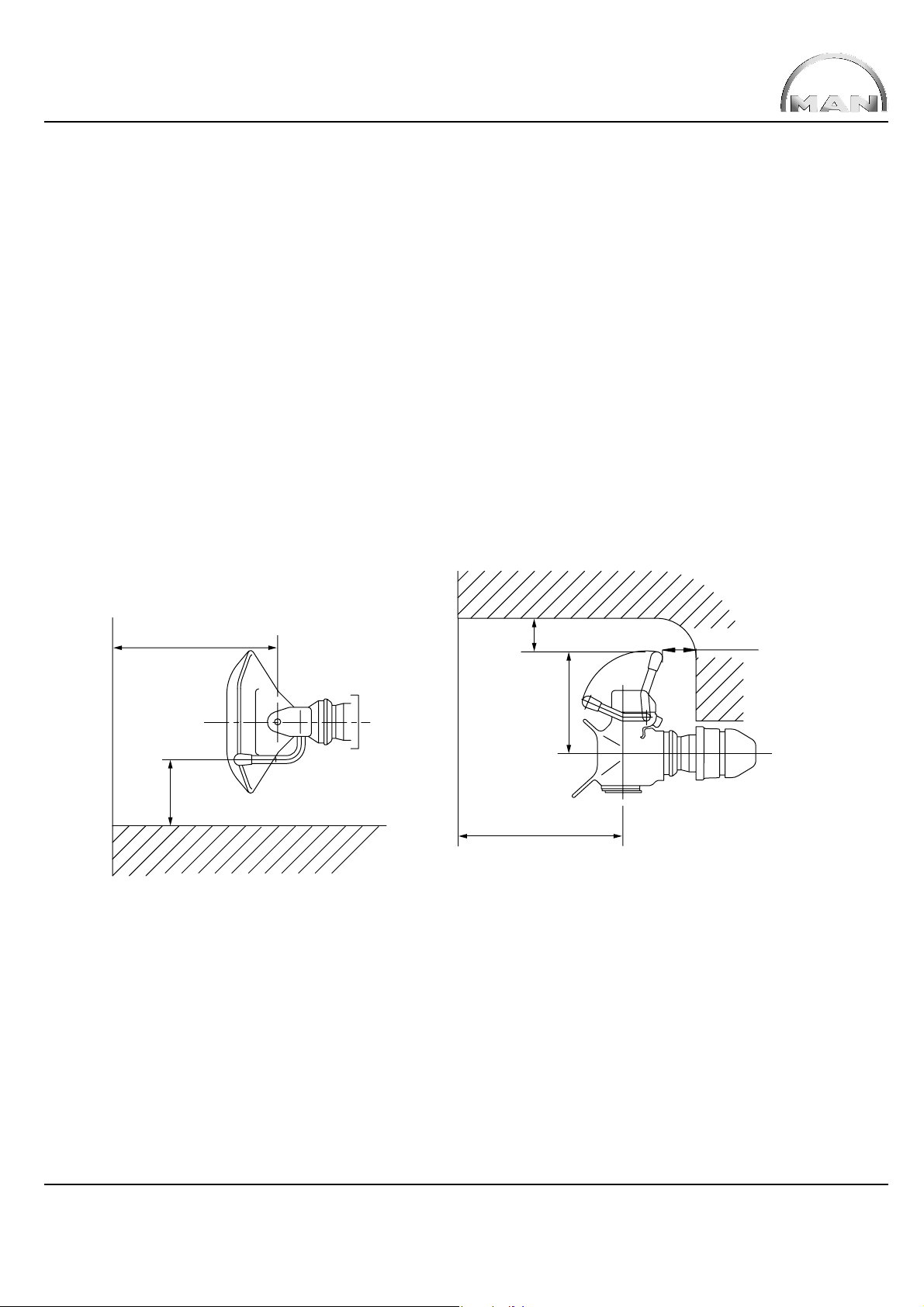

The tightening side can be recognised by slight marks on the bolt’s nips or nut fl ange (see Fig. 12).

Fig. 12: Marks on the bolt’s nips on the tightening side ESC-216

Alternatively, it is possible to use high-strength rivets (e.g. Huck

®

-BOM, blind fasteners) – manufacturers’ installation instructions

must be followed. The riveted joint must be at least equivalent to the screw connection in terms of design and strength.

In principle it is also possible to use fl ange bolts. MAN draws your attention to the fact that such fl ange bolts place high requirements on

installation accuracy. This applies particularly when the grip length is short.

TRUCKNOLOGY® GENERATION A (TGA) 33

Page 41

4.4 Modifying the frame

4.4.1 Welding the frame

As a rule, no welding work is to be carried out on the frame and axle mountings other than that described in these guidelines or in

the MAN repair instructions. Welding work on components and assemblies that are subject to design approval (e.g. coupling devices,

underride protection) may only be carried out by the design approval holder. Welding work on these components will otherwise lead to

the withdrawal of the design approval!

Welders must have specialist knowledge in chassis welding. The workshop must therefore employ suitably trained and qualifi ed

personnel to carry out the required welding work (e.g. in Germany, according to the DVS leafl ets 2510 – 2512 “Carrying out repair

welding work on commercial vehicles”, available from the DVS publishing house).