Page 1

Page 2

2 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

MALAGUTI S.p.A.

Via Emilia 498, 40068 - San Lazzaro di Savena (BO) - ITALY

Tel. 051.62.24.811 - Fax 051.69.47.782

e-mail: info@malaguti.com - http: // www.malaguti.com

FOREWORD

• This manual specifically addresses to specialised technical personnel (MALAGUTI authorised service centres and single motor mechanics) and contains all the

service interventions indicated by the Manufacturer until the publishing of this document.

• Some basic technical information has been intentionally omitted as it is considered to be common knowledge.

• Additional information is available in the SPARE PARTS CATALOGUES of each model.

• It is important to read all the general information before going through the manual to the specific topics and the maintenance operations to be carried out on the motor-bike in

order to make sure the topics, the technical and safety concepts are clearly understood and the manual can be used as a sure reference text.

• All checks, maintenance, repairs or replacements of spare parts in our motor-bikes are to be performed by skilled and expert technical personnel with specific experience

in state-of-the-art technology and full knowledge of the quickest and most rational procedures, technical characteristics, setting values, tightening torques and information as

to which may only be properly and exhaustively provided by the manufacturer.

• It is important to adhere strictly to the following instructions. Any operation carried out carelessly or not carried out at all may lead to personal injury, damage to the motorcycle

or simply to complaints.

MALAGUTI S.p.A. reserves the right to make any changes and modifications hereto it deems necessary without prior notice.

For further information and details, please contact MALAGUTI S.p.A. Servicing or Engineering Division.

Page 3

3 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

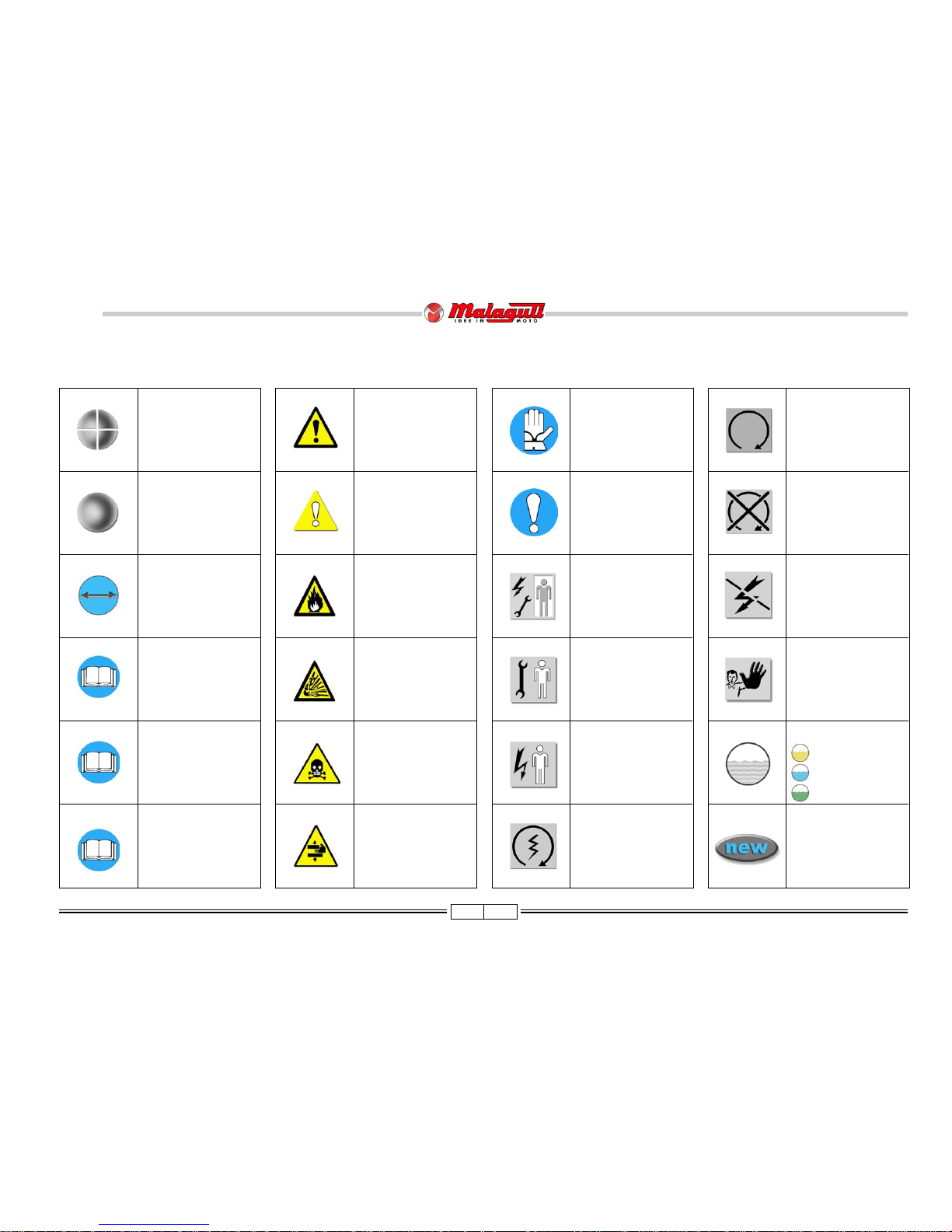

NOTES FOR EASY CONSULTATION

ABBREVIATIONS

EDITING SYMBOLS:

• Symbols have been provided for quick and easy reference, identifying situations requiring utmost attention or providing practical suggestions or simple information.

• These symbols may appear next to a text (in which case they refer solely to the text itself), next to a figure (in which case they refer to the topic illustrated in the figure and

to the relative text), or at the top of the page (in which case they refer to all the topics dealt with in the page).

NOTE - The meaning of the symbols should be duly memorised as their scope is to avoid having to repeat basic technical concepts or safety recommendations.

Cs Torque wrench setting

D Nut

Dx Right

F Picture

G Gasket

P Page

R Washer

Sx Left

T Ta b l e

V Screw

TECHNICAL DICTIONARY

V = (DC) Direct current (battery supply)

V ~ (AC) Alternating current (flywheel supply)

A : Ampere Unit of measurement of the electrical current

W : Watt Unit of measurement of the electrical power (product of Volts and Amperes; A x V = W)

ΩΩ

ΩΩ

Ω : OHM Unit of measurement of the electrical resistance

< Lower

≤≤

≤≤

≤ Lower or equal

> Higher

≥≥

≥≥

≥ Higher or equal

bar Unit of measurement of pressure

N * m Newton/metre Unit of measurement of the tightening torque

Page 4

4 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

SYMBOL LIST

M

R

CAUTION!

Recommendations and

precautions regarding rider

safety and motor vehicle

integrity.

WARNING! Situations

entailing the risk of personal

injury to maintenance or repair

mechanics, other workshop

personnel or third parties, or

damage to environment,

vehicle or equipment

FIRE HAZARD.

Indicates operations which

may constitute a fire

hazard

RISK OF

EXPLOSION

Indicates operations

which may constitute a

risk of explosion

TOXIC FUMES

Indicates a possibility of

intoxication or inflammation

of the upper respiratory

tract

WARNING!

Danger of crashing

arms

SAFETY GLOVES

These operations require

the use of safety gloves

IMPORTANT

This topic requires special

attention

GENERAL SERVICE

PERSONNEL

Skilled electronic or

mechanical technician.

MECHANICAL

MAINTENANCE

Operations to be

performed only by an

expert mechanic

ELECTRICAL

MAINTENANCE

Operations be performed

only by an expert electrical/

electronic technician

IGNITION KEY ON

(ON position)

THIS MANUAL

Information on

this manual

“ENGINE” SERVICE

MANUAL

Indicates information which

may be obtained by

referring to said catalogue

SPARE PARTS

CATALOGUE

Indicates information which

may be obtained by

referring to said catalogue

DISASSEMBLY

OPERATIONS

ASSEMBLY

OPERATIONS

SYMMETRICAL

OPERATIONS

Operations that must be

carried out also on the other

side of the unit or

component.

EMPTY THE CIRCUIT

REPLACE WITH NEW,

ORIGINAL SPARE

PAR TS

IDLING ENGINE

Switch on the engine, at

idling speed, to perfom

these interventions.

ENGINE OFF

Indicates operations to

be performed with

engine off

POWER OFF

Indicates that negative

pole is to be disconnected

from the battery before

performing the operation

NO!

Operations to be

absolutely avoided

OIL

COOLANT

FUEL

Page 5

5 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

GENERAL WORK PROCEDURES

• The recommendations given hereafter are aimed at ensuring maximum work safety as well as at considerably reducing the risk of accidents, personal injury, equipment

damage and idle times, and should therefore be strictly adhered to.

• Always listen with attention to the customer’s opinion and complaints about the motor-bike operation, asking specific questions in order to have a complete understanding of

all the symptoms and identify with good approximation the real causes of the trouble. The present manual provides the technical information and the basic indications on the

intervention procedures but these have to be integrated with the personal expertise.

• We suggest planning the service interventions in order to avoid any waste of time or downtime. Try to reduce as much as possible the operations necessary to reach the

components that needs repairing.

• Prepare the components that are likely to be replaced and all the original spare parts you may need.

• Use only the original spare parts.

• Mark the components that may be mis-placed during re-assembly operations.

• Only use quality tools and equipment.

• Only use equipment conforming to EU Directives for lifting the vehicle.

• During operations, always keep tools and equipment at hand, possibly laying them out according to the sequence in which they are to be used. Absolutely avoid putting them on the

vehicle itself, out-of-sight or in poorly accessible places.

• Always keep the work area neat and clean.

• When tightening screws or nuts, start with the larger diameter or inner fasteners, and tighten them in progressive “pulls” using a “criss-cross” pattern.

• The torque settings specified in the manual refer to the “final torque”, which must be attained progressively by steps.

• Preferably use open-end box wrenches by “pulling” and not “pushing”.

Before any servicing, make sure that the vehicle is perfectly stable.

The front wheel should be anchored to fixture, which is integral with the lift platform.

Page 6

6 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• Before carrying out any operation, wait for all parts to cool down.

• For operations requiring two mechanics, make sure that the various steps to be performed by each of them are clearly defined and co-ordinated beforehand.

• Make sure that each component has been properly mounted before proceeding with assembling the next one.

• Always replace gaskets, O-rings, circlips and split pins at every refitting.

• Only use screwdrivers with sizes suitable to the screws to be loosened or tightened.

Never use open flames for any reason.

Never leave open containers or containers not suitable for holding fuel in passageways, close to heat sources, etc.

Never use petrol to clean the vehicle or the floor of the workshop. Always use low flash point solvents to clean the vehicle components.

When welding, make sure that there are no flammable liquids in the vicinity.

Never suck from or blow into the fuel pipe.

Never leave the engine running in closed or poorly ventilated areas.

Do not use fuses with a higher rated capacity than indicated: this may cause severe damages to the electrical system and burn a fire as a conse-quence of short circuit.

• Make sure that the vehicle is stable and not to have to take on awkward working positions.

• Never reuse old gaskets or circlips.

• Never use a screwdriver as a lever or chisel.

• Never use pincers to loosen or tighten screws or nuts because, in addition to not providing a sufficient clamping force, they may also damage the screw head or nut hexagon.

• Never tap the wrench with a hammer or other similar tool to loosen or tighten screws and nuts.

• Never attempt to increase the lever arm by fitting a tube into the wrench.

Page 7

7 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

CONTENTS

DESCRIPTION P.

SEAT 36

CENTRAL SECTION UNDER THE SEAT 36

HELMET CASE 38

ACCESS (after removing the helmet compartment) 40

FUEL LEVEL SENSOR 41

FUEL PUMP SENSOR 41

FOOTBAR 42

REAR FAIRING 45

REAR HANDLE 45

TAIL LIGHTS 46

FULL REAR FAIRING- FAIRING BREAKDOWN 47

SEAT LOCK UNIT 48

FUEL TANK 51

ELECTRIC FAN AND RADIATOR 52

DISASSEMBLING RADIATOR UNIT - COOLING SYSTEM DRAINAGE 53

FRONT WHEEL 54

FRONT BRAKE DISC 54

FRONT BRAKE CALIPER 55

FRONT MUD GUARD 55

HANDELBAR CONTROL - BRAKE PUMP 56

KEYSWITCH 56

HANDLEBAR 57

FORK 57

FORK LEG 57

COMPLETE FORK 58

MUFFLER 58

MANIFOLD EXHAUST 59

REASSEMBLY OF EXHAUST SYSTEM 59

SHOCK ABSORBERS 60

REAR MUDGUARD - REAR BRAKE CALIPER 61

REAR WHEEL 62

REAR BRAKE DISK 63

STARTER 63

FILTER BOX UNIT 64

AIR FILTER 66

SIDE STAND - CENTRAL STAND 67

ENGINE 67

FRAME SIZE CHECK 68

POSITION OF INJECTION SYSTEM PARTS 69

CABLE POSITIONING, "PIPE SYSTEM" AND ANCHORING TIES 72

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

DESCRIPTION P.

TECHNICAL DATA 8

IDENTIFICATION INFORMATION: FRAME N°/ ENGINE N° 9

ANTI-TAMPERING PLATE 9

TIRES 10

MAINTENANCE CHART 11

LUBRICANT CHART 12

FUEL TANK 13

COOLANT RESERVOIR 13

MOTOR OIL 14

TRANSMISSION OIL 15

BRAKE FLUID 15

BLEEDING THE BRAKE SYSTEM 16

CHECK FRONT/BACK BRAKE PADS AND DISKS 17

REPLACE PADS 17

FORK 18

SHOCK ABSORBER ADJUSTMENTS 18

DASHBOARD - DIGITAL CLOCK 19

KEY SWITCH 20

HANDLEBAR CONTROLS - LEFT CONTROL - RIGHT CONTROL 20

ENGINE STARTER 20

LIGHTS 21

LIGHT BULB REPLACEMENT - LIGHT BEAM ADJUSTMENT 22

FUSES 23

BATTERY 24

SPARK PLUG 25

DISMANTLING AND REMOVAL PROCEDURES FOR COMPONENTS 26

REASSEMBLY NOTES 26

WINDSCREEN SUPPORTS 26

WINDSCREEN 26

REAR-VIEW MIRROR 26

UPPER HANDLEBAR COVERS 27

DASHBOARD 28

LOWER HANDLEBAR COVERS 29

UPPER SHIELD 30

FRONT SHIELD 31

ACCESS (motorbike parts - shield parts) 32

CHANGE LIGHT BULB 33

FRONT FAIRING 34

SIDE STRUTS 35

LEGSHIELD 35

Page 8

8 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

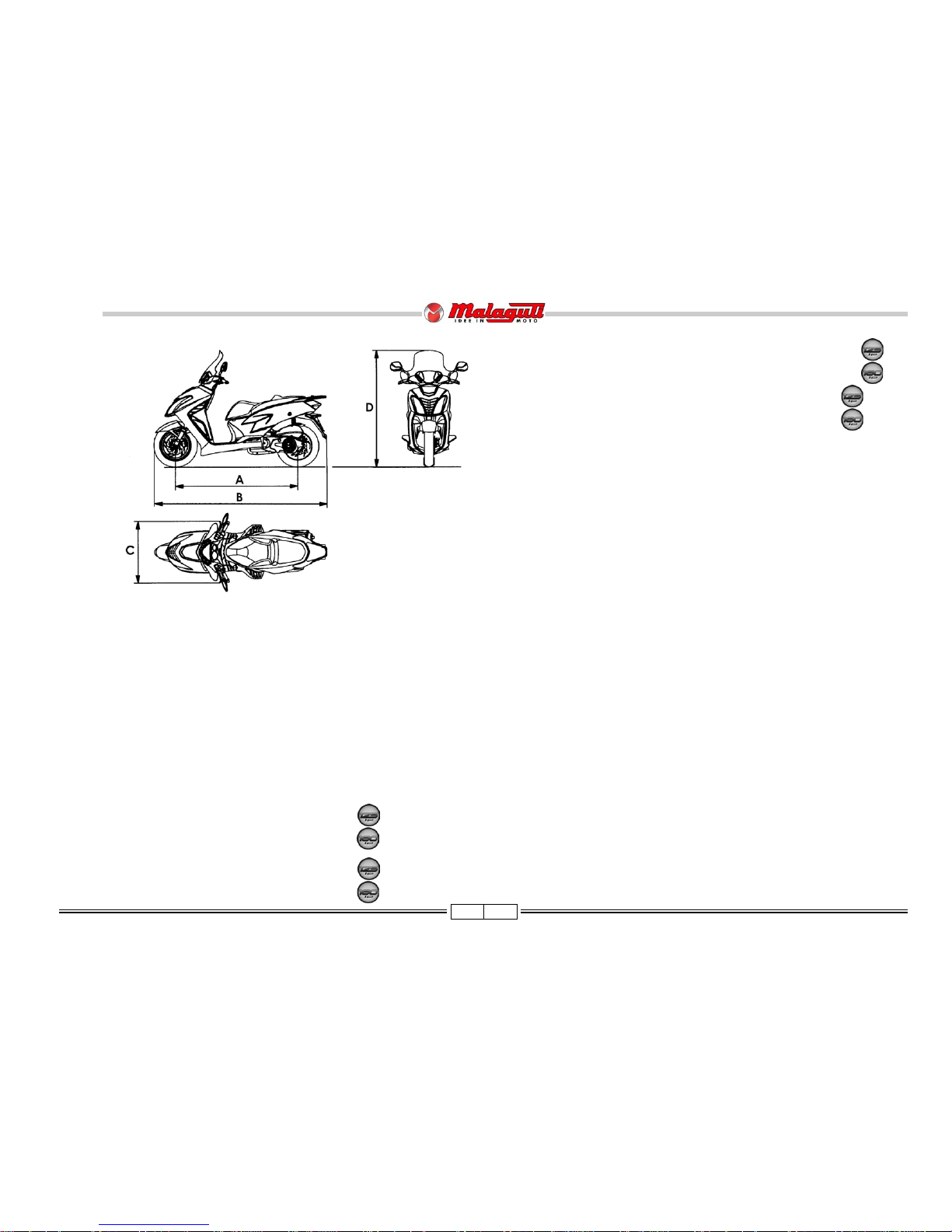

DIMENSIONS

Wheel base (A) m .......................................................................................1,470

Max. length (B) m........................................................................................ 2,090

Max. width (C) m .........................................................................................0,750

Max. height (D) m........................................................................................ 1,330

Kerb weight kg ...............................................................................................155

Max. load with rider, passenger and luggage kg ..............................................180

CAPACITY

Engine oil cm3 ........................................................................................... 1000*

Transmission oil cm3 ................................................................................... 150*

Fuel tank (total) l ................................................................................. 8,0* (3,0*)

ENGINE: 2 valve - 4 stroke single cylinder:

Type ............................................................................................. MALAGUTI 03

MALAGUTI 04

n° Cylinders ...................................................................................................... 1

Bore x stroke mm ......................................................................... Ø 52,4 x 57,8

Ø 58,0 x 57,8

Capacity cm3 .................................................................................................125

153

Compression Ratio ...................................................................................10,6 : 1

11,3 : 1

Cooling ........................................................................................................ liquid

Starting system ............................................................................ electric starter

lubrication system ................................................................................ wet sump

SPARK PLUG

Type ............................................................................................ NGK DPR7EA9

TRANSMISSION

Primary drive: automatic transmission by V-belt speed change gear

Final: by gears.

Automatic centrifugal dry clutch.

FUEL SYSTEM

Electronic fuel injection with electric fuel pump.

Fuel: unleaded petrol.

IGNITION

Digital

BRAKES

Front brake: disk type Ø 225 mm double piston hydraulic caliper Ø 25 mm

Rear brake: disk type Ø 220 mm piston hydraulic caliper Ø 34 mm

CHASSIS

High-tensile steel tubes

SUSPENSIONS

Front: hydraulically fork Ø 35 mm; Stroke: 87,5 mm.

Rear: Swinging engine with double hydraulic shock absorber. Stroke: 74 mm.

BATTERY

Type 12V, 7Ah, no maintenance.

TIRES

Front: 110/90 - 13 56P M/C (tubeless)

Rear: 130/70 - 13 63P M/C (tubeless)

* Indicative Value

F. 1

SPECIFICATIONS

Page 9

9 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

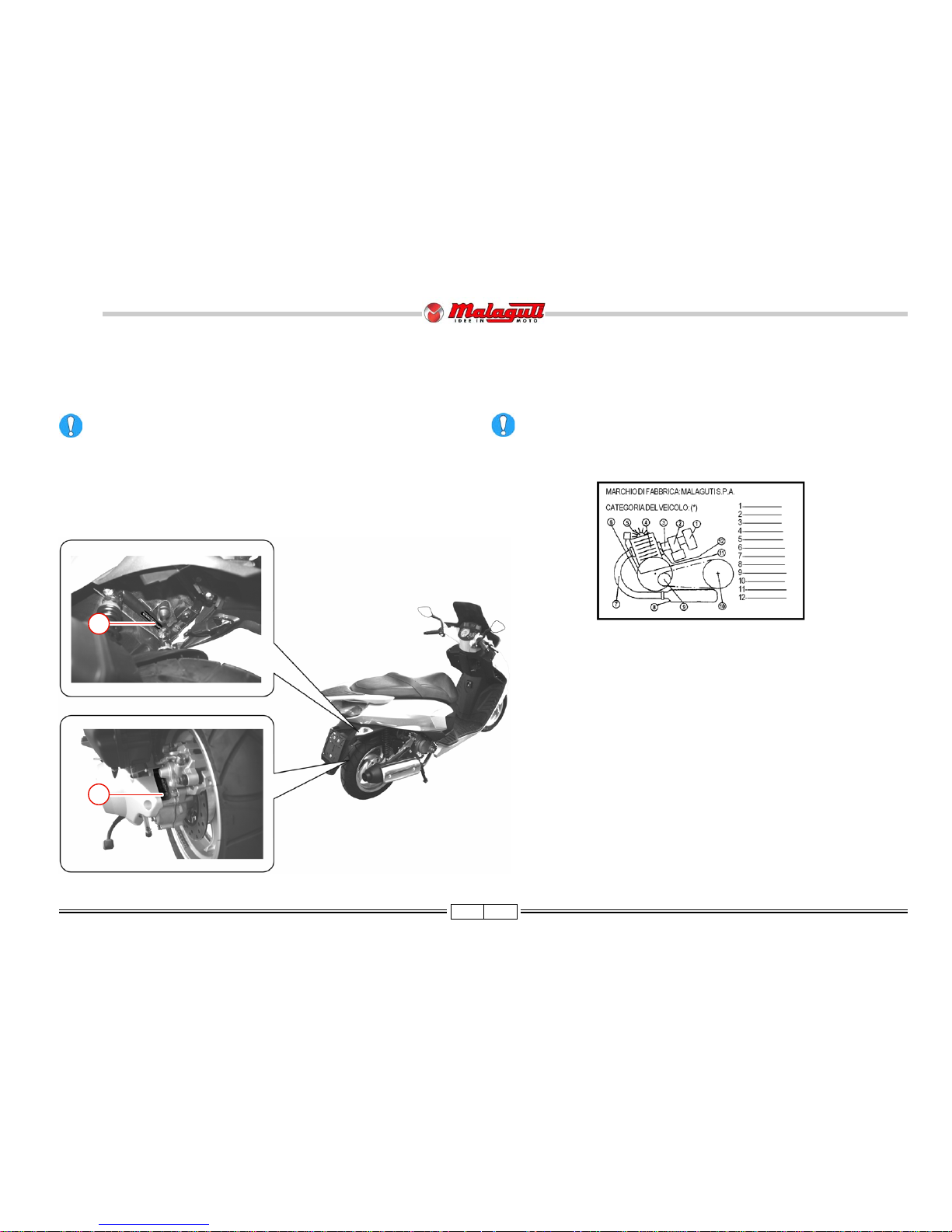

IDENTIFICATION DATA: FRAME N° / ENGINE N°

• The vehicle’s identification number (VIN) (A) is located on the rear side of the chas-

sis, under the helmet compartment.

• Engine identification data are located on the left-hand engine crankcase (B).

Any alteration to the vehicle identification data is pursued by the Law.

• When ordering spare parts, also quote the vehicle identification data.

ANTI-TAMPERING PLATE

• An anti-tampering plate, bearing all vehicle identification data required by Directive

97/24/CE. Is fitted inside the helmet compartment. If you have the helmet compartment

replaced, make sure the plate is fitted too.

Do not remove or alter this plate.

F. 4

A

B

F. 3

F. 2

Page 10

10 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

1.9 1.9 1.9

(27.6) (27.6) (27.6)

2.0 2.1 2.1

(29.0) (30.5) (30.5)

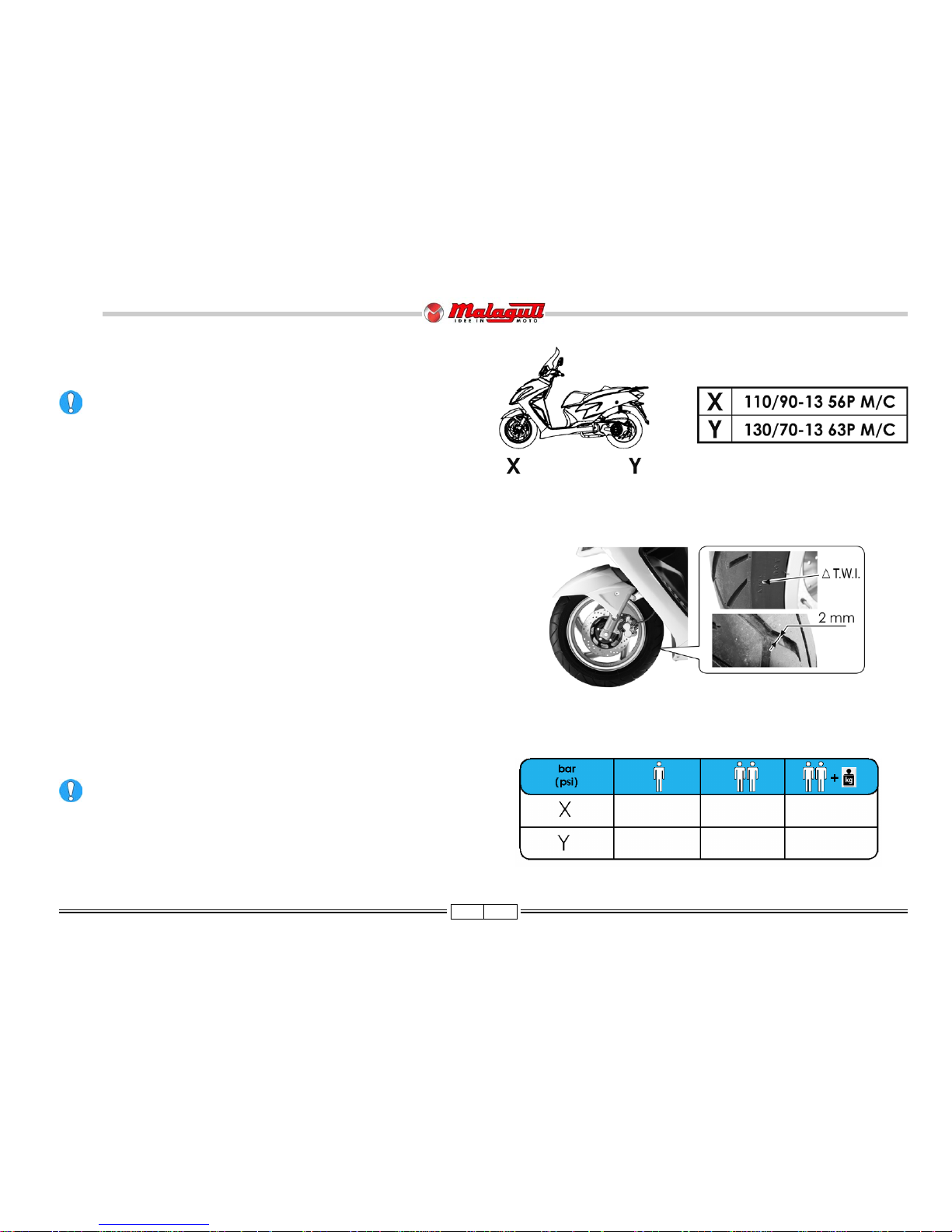

TYRES

Type: Tubeless (without inner tube)

It is possible to use tyres with load and speed indexes that are higher than

or identical to those indicated.

It is however necessary for speed indexes to be identical for both tyres.

USE ONLY TYRES WITH THE RELEVANT TYPE APPROVAL.

• There are T.W.I. marks all around the tyre sides. These correspond to tyre wear

indicators situated in the tyre’s tread; if there is no difference between the thickness

of the tyre wear indicators and the tread depth, the tyre must be replaced.

F. 6

F. 5

Minimum tread depth (front and rear) is 2 mm (F. 6).

Tyre inflation pressure must be adjusted while the tyre is at ambient

temperature.

Pressure differing from that indicated can lead to higher fuel

consumption, irregular wear of the tire, impaired vehicle performance

and riding conditions.

PRESSURE

Page 11

11 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

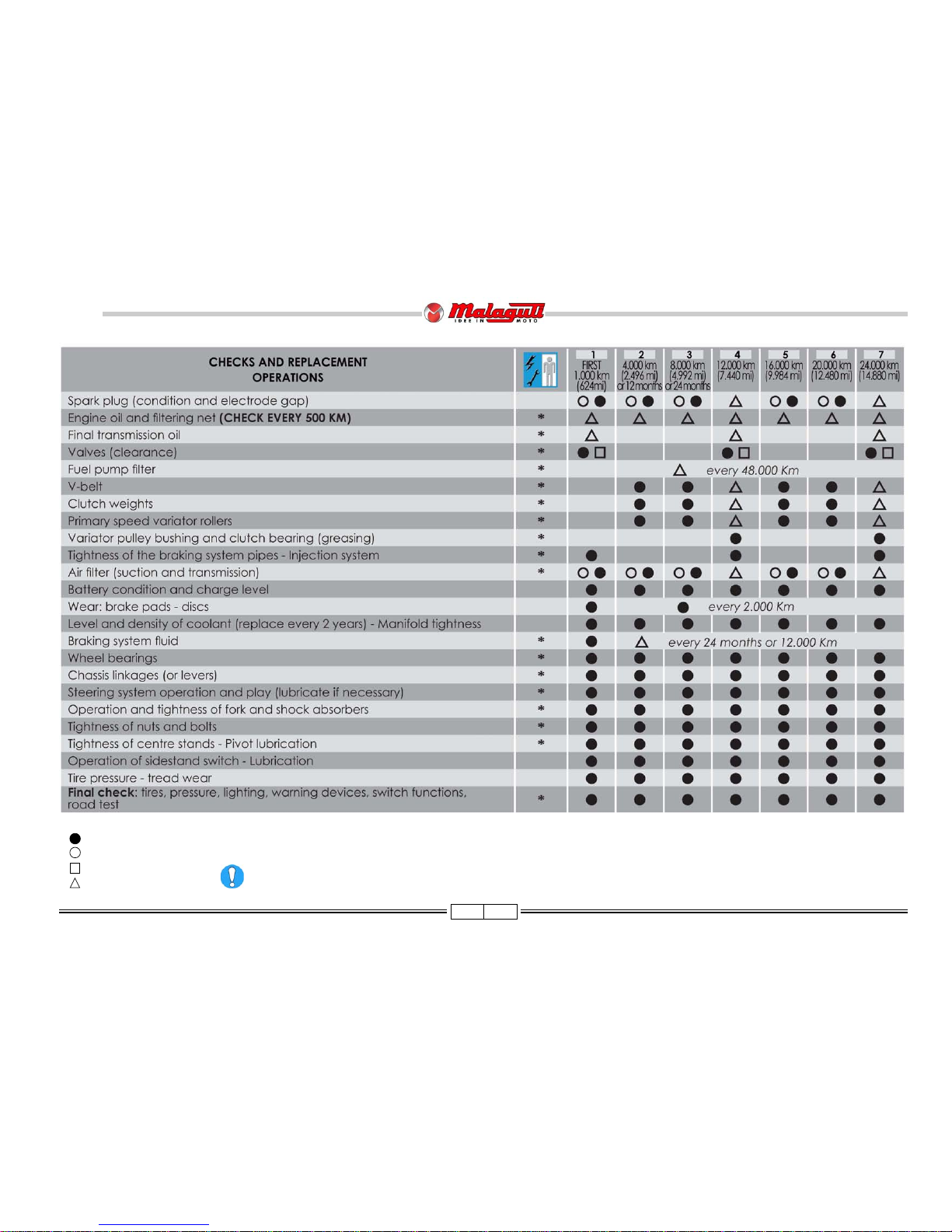

NOTE - Maintenance operations should be performed more frequently if the vehicle is used in rainy weather, in dusty places or on rough

terrain.

Due to their simplicity, checks with no asterisk CAN also be carried out by technicians not authorised by MALAGUTI, but under

their direct responsibility.

Nr. : coupon

: check

: clean

: adjust

: replace

MAINTENANCE TABLE

Page 12

12 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

LUBRICANT TABLE

NOTE - Use only recommended products.

LUBRICANTS

ENGINE OIL (4 STROKE) CLASS 10W 40

ENGINE TRANSMISSION OIL CLASS 10W 40

AIR FILTER LUBRICANT AIR FILTER OIL

RADIATOR FLUID TOP FLUID

BRAKE CIRCUIT FLUID BRAKE FLUID DOT 4

FORK ROD OIL FORK OIL

Page 13

13 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FUEL TANK Liters

TOTAL TANK CAPACITY 8,0

RESERVE 3,0

FUEL TANK

• Inser t the ignition key in the switch block and it into the lock on the left hand side of the seat (B).

• Open seat by turning ignition key clockwise.

• The quantity of fuel, as well as a low fuel level, are displayed by the corresponding indicator on the right hand side of

the instrument board.

Petrol is extremely inflammable; avoid approaching the fuel filler - also during filling - with lit cigarettes or

naked flames (for instance matches). Danger of fire!

COOLANT TANK

• To gain access to the tank containing the coolant, loosen the two screws (A) next to the handlebar

and remove the front fairing.

• Check the level of coolant with respect to the “MIN” and “MAX” notches, next to the tank, by

checking through the sight glass located under front fairing on the right hand side.

F. 7

B

If it needs to be topped up, use the product

specified in the lubricants chart.

Do not remove the cap when the engine is hot.

F. 8

Use UNLEADED PETROL.

A

Page 14

14 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

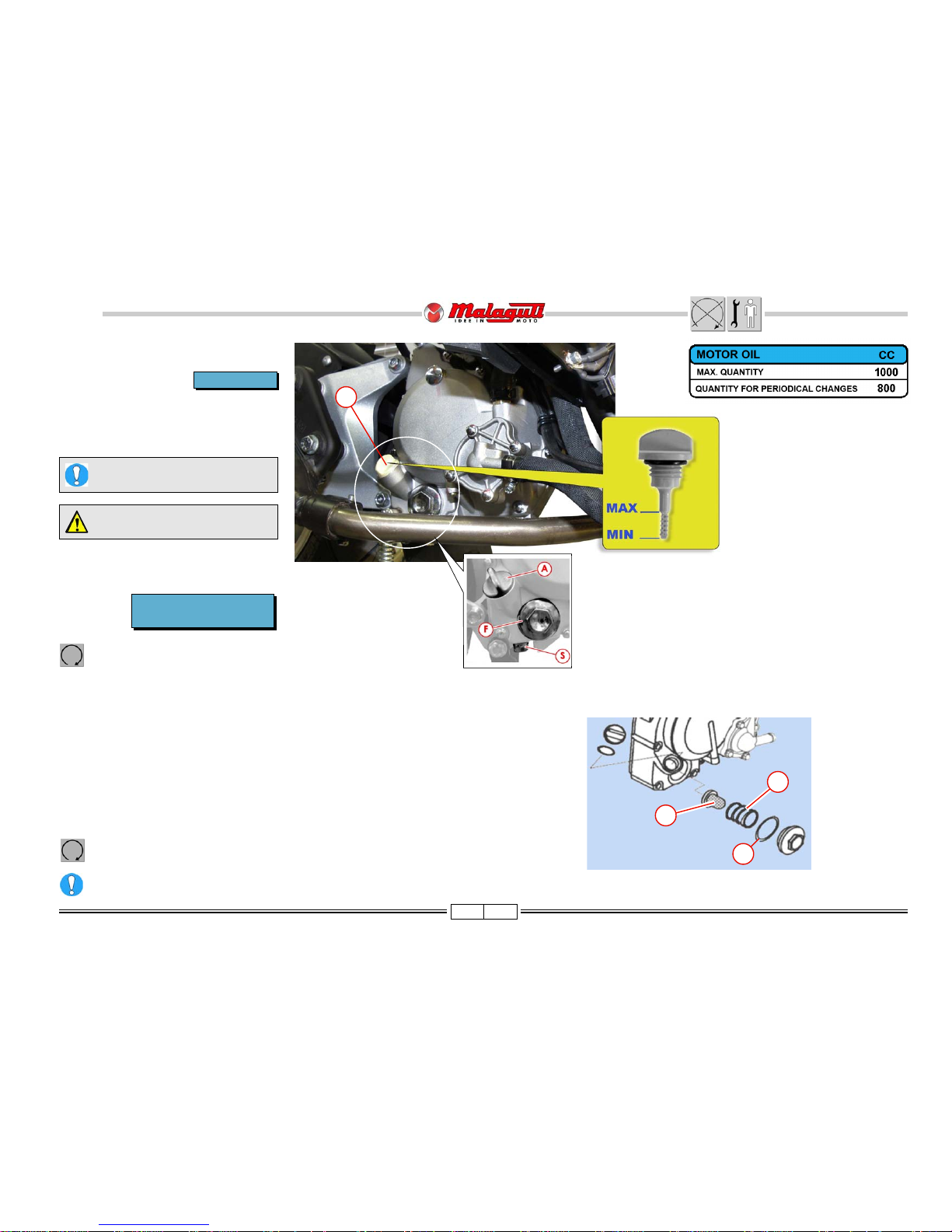

F. 1 0

F. 9

A

1

3

2

Check the level with the plug

tightened.

every 2,000 km

CHECK LEVEL

• The engine must be cold and the vehicle

on level ground.

• The level is shown on the cap/ dipstick

(A).

Top with the oil specified in the

lubricant chart.

ENGINE OIL

• Place an appropriate drain pan under the engine (with the vehicle on flat

ground).

• Pull out the cap/ dipstick (A).

• Unscrew the drain plug (S) and let all the used oil drain out.

• Remove the filter/plug (F).

• Wash the screen (1) with solvent or if it is damaged, replace it.

• Check the wear conditions of the O-Ring (3) and replace if necessary.

• Reassembly: O-Ring (3)- Spring (2)- Screen (1) and tighten the filter/plug.

• Screw on and tighten the drain plug (S).

• Top up the engine with 800 cc of Q8 CLASS 10W40 oil and replace the cap/

dipstick.

Start the engine; leave it running for a few minutes, and check that there

are no leaks.

Dispose of used oil in accordance with current laws in force.

CHANGE

Warm up the engine for a few minutes and then shut it off.

• After the first 1,000 Km

• Every 4,000 KM

Page 15

15 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 1 1

S S

F. 1 2

B

A

CHECK LEVEL/ TOP UP

• Cold engine

• Vehicle on level ground.

• Place a drip pan under the engine.

• Unscrew the oil filler screw (A).

• If necessary, top up with oil specified in the lubricant

chart until the oil starts to overflow.

• Screw on the screw (A).

TRANSMISSION OIL

CHANGE

If there is any debris or water in the brake fluid, it is essential that it be completely changed and the brake system must be bled. Excessive elasticity in the

brake lever is usually an indication that air is in the system.

CHANGE

• After the first 1,000 Km

• Every 12,000 Km

• Cold engine

• Vehicle on level ground

• Place a drip pan under the engine.

• Unscrew the oil filler screw (A).

• Unscrew the drain screw (B)

• Drain out all the used oil.

• Clean the threads of the drain screw and screw back on.

• Refill the crankcase with oil specified in the lubricant

chart until the oil starts to overflow.

• Screw back on the screw (A).

CHECK

• Visually check by way of the warning signal (S) located on the front and back

brake reservoir, with the vehicle on level ground and perfectly straight.

• The fluid level must be 3mm from the lower limit of the warning signal.

BRAKE FLUID

every 30 days

Every 12,000 Km or 24 months

Do not mix different oil types when topping off.

Page 16

16 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

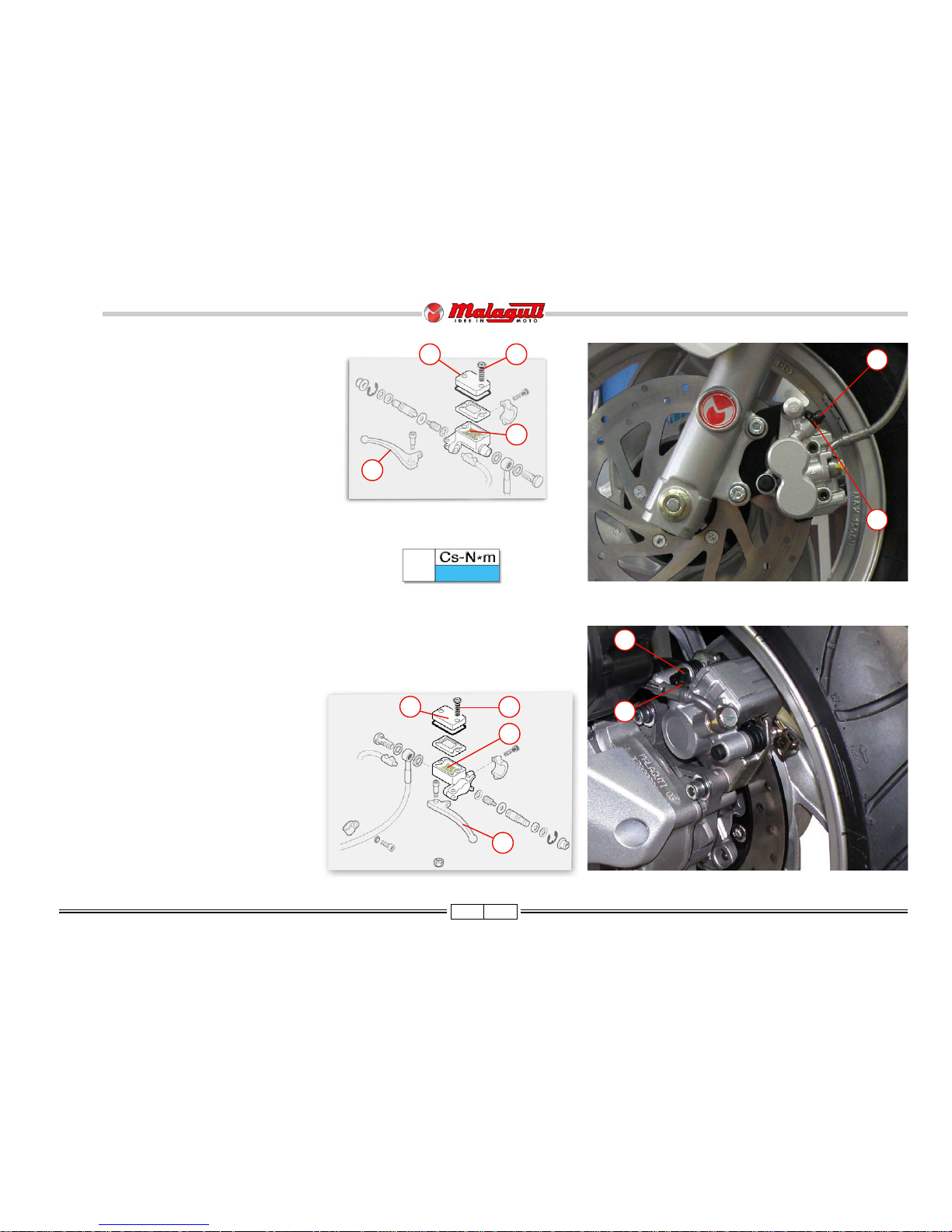

F. 1 3

F. 1 4

F. 1 6

V

12 ± 16%

B

D

V2A

C

V

C

V

F. 1 5

A

V2

B

S

BLEED BRAKE SYSTEM

FRONT CALIPER

NOTE - Position the vehicle in a stabile manner and

perfectly on level ground.

• Remove the (right side) oil pump reservoir cover

(A), unscrewing the relative screws (V"), in order to

be able to top off the fluid.

• Fill the right brake fluid reservoir (B) to the highest

level.

• Remove the rubber hood (C) of the bleeder screw

(V) and insert a rubber tube to recover the brake

fluid.

• Pump the right brake lever (D), prime it and bring

the system in pressure.

• Keeping the brake lever pumped, loosen the bleeder screws (V), to allow air to escape. Then, tighten

the bleeder screw (V).

REAR CALIPER

• To bleed the rear caliper, follow the same operation

above, but pump the left brake lever (S).

• Repeat the operation, until only liquid comes out of

the rubber tube.

• Top up the brake fluid level in the reservoir (B).

Page 17

17 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

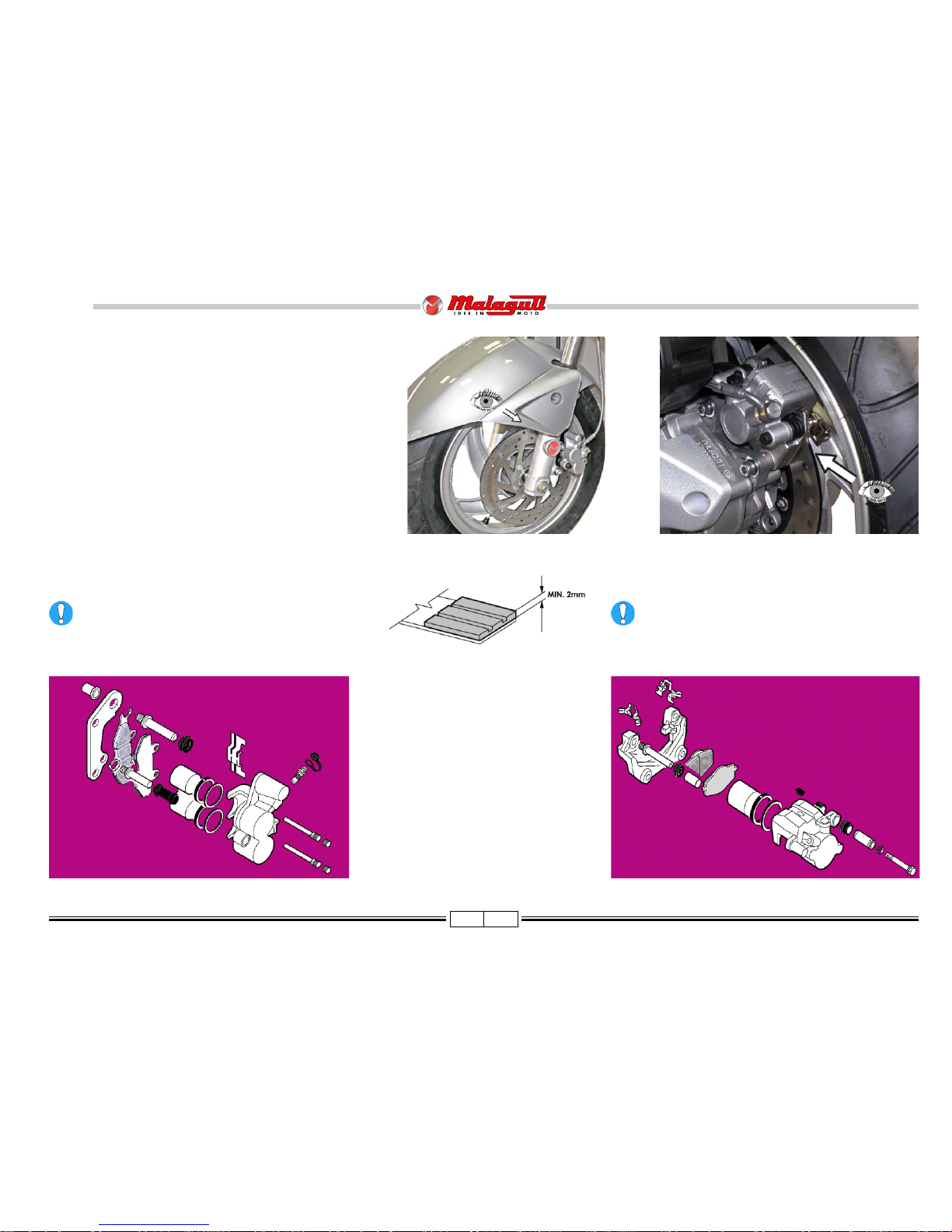

F. 2 0 F. 2 1

F. 1 7

F. 1 8

CHECK FRONT/BACK BRAKE PADS AND DISKS

• Check the condition of front and back brake pads and discs

every 2,000 Km.

• Carry out a visual check on the thickness of the brake pads as

shown in the illustration.The minimum thickness of the brake

pad friction material must not be less than 2mm.

• Replace the pads if they are close to the allowed limit, or if they

are damaged.

REPLACING PADS

REAR BRAKE

FRONT BRAKE

The procedures for replacing front and back brake pads

can be deduced from the illustration shown below.

(M/N table bill of materials).

F. 1 9

To remove back brake pads, see Rear brake caliper

removal (page 61).

Page 18

18 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

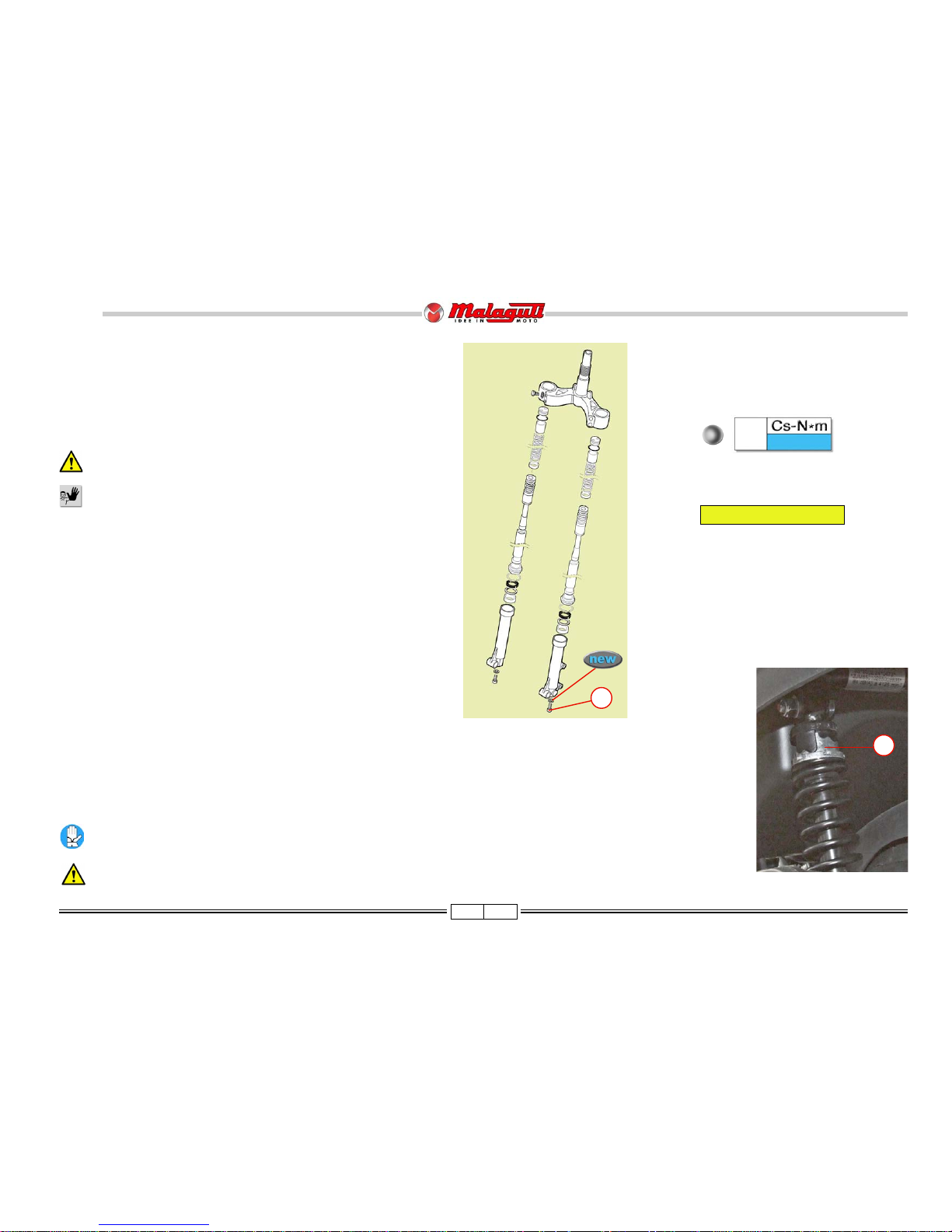

Adjust both shock absorbers using these instructions.

Uneven adjustment can compromise the stability of the vehicle.

Perform adjustments using the special key equipped on the ring nut (A), located on the upper part of the shock absorbers; turning

it anti- clockwise will increase the strength of the spring (increase in load)

SHOCK ABSORBER ADJUSTMENTS

5 adjustment positions are included:

1) driver only (to 75 kg)

2) driver only (over 75 kg)

3) driver and case

4) driver and passenger

5) driver, passenger, and case.

CHANGE FORK OIL

• Place an appropriate drip pan under the slider and remove the screws (V).

• Drain out as much oil as possible.

• Proceed to dismantle the fork legs, as described p. 57.

• Turn the fork legs upside-down, to let the remaining oil drain out.

Hydraulic oil is corrosive and may cause personal injury.

Do not improperly dispose of used oil in the environment.

• Reassemble the fork components and the fork on the

motorcycle.

• Carefully pour the "new" oil in the fork.

V

17 ± 15%

FORK

F. 2 3

A

F. 2 2

V

• Remount the drain screw (V).

NOTE - When remounting, replace the copper washer

located under the screw (V).

Quantity per fork: 98 cc.

Page 19

19 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

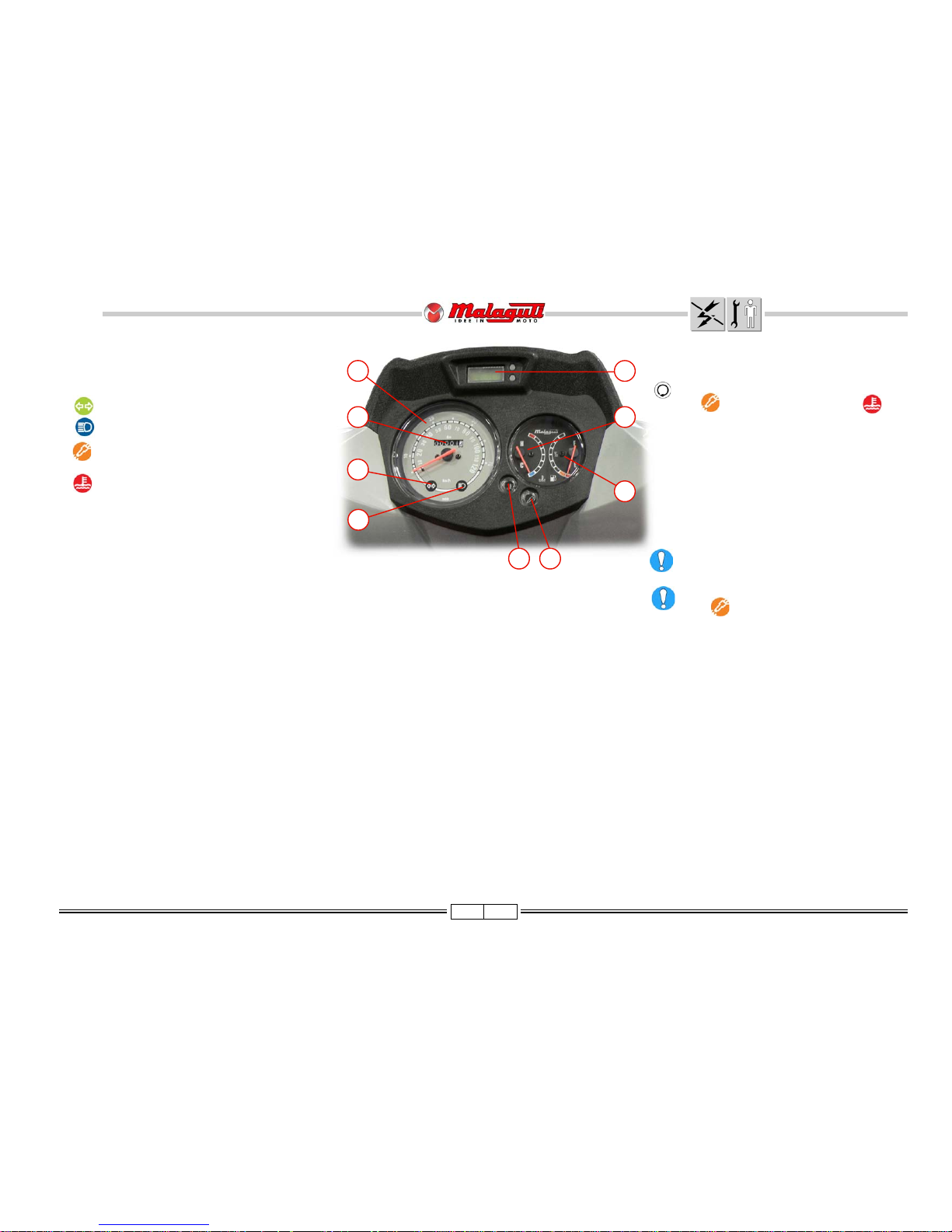

F. 2 4

9

8

7

6

2

1

3

4

5

ELECTRIC/SERVICE MALFUNCTION WARNING

LIGHT

When the starter key is turned in the switch in the

position, without starting the engine, the warning light (as well as the warning light ) will

remain on for a few seconds to verify the functioning,

and it will normally shut off after this.

If it stays on longer (fully and/or flickering) it means:

• Electrical Malfunction (blinking light): indicates a

malfunction in the electrical system.

• SERVICE (15 short blinking lights): indicates the

need to perform programmed maintenance (see the

Maintenance Chart on page 11).

In both cases, reset the signal after performing

the necessary operations.

The warning light interval of the SERVICE

sign of the may have different meanings as shown in the Maintenance Chart, depending on the vehicles conditions of use.

DIGITAL CLOCK

• Date and month readout

Press the top button once (after a few seconds the clock will automatically reappear).

• Seconds readout

Press the top button twice; to restore the initial configuration, press the button again.

To set the clock and calendar, use the two buttons on the right hand side of the dial, starting with the time display.

• Setting the month

Press the lower button twice; and then with the top button select the exact number.

• Setting the date

Press the lower button three times; and then using the top button select the exact number.

• Setting the time

Press the lower button four times, and then using the top button select the exact number.

• Setting the minutes

Press the lower button four times, and then using the top button select the exact number.

Press the lower button once again to return to the time display. Confirm modifications by pressing the top button.

DASHBOARD

1) Speedometer

2) Odometer

3) Turn signal warning light (green)

4) High beams warning light (blue)

5) Electric/SERVICE Malfunction warning

light (orange)

6) coolant temperature too high warning light

(red)

7) Fuel gauge indicator

8) Coolant temperature indicator (red zone:

temperature too high)

9) Digital clock

Page 20

20 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

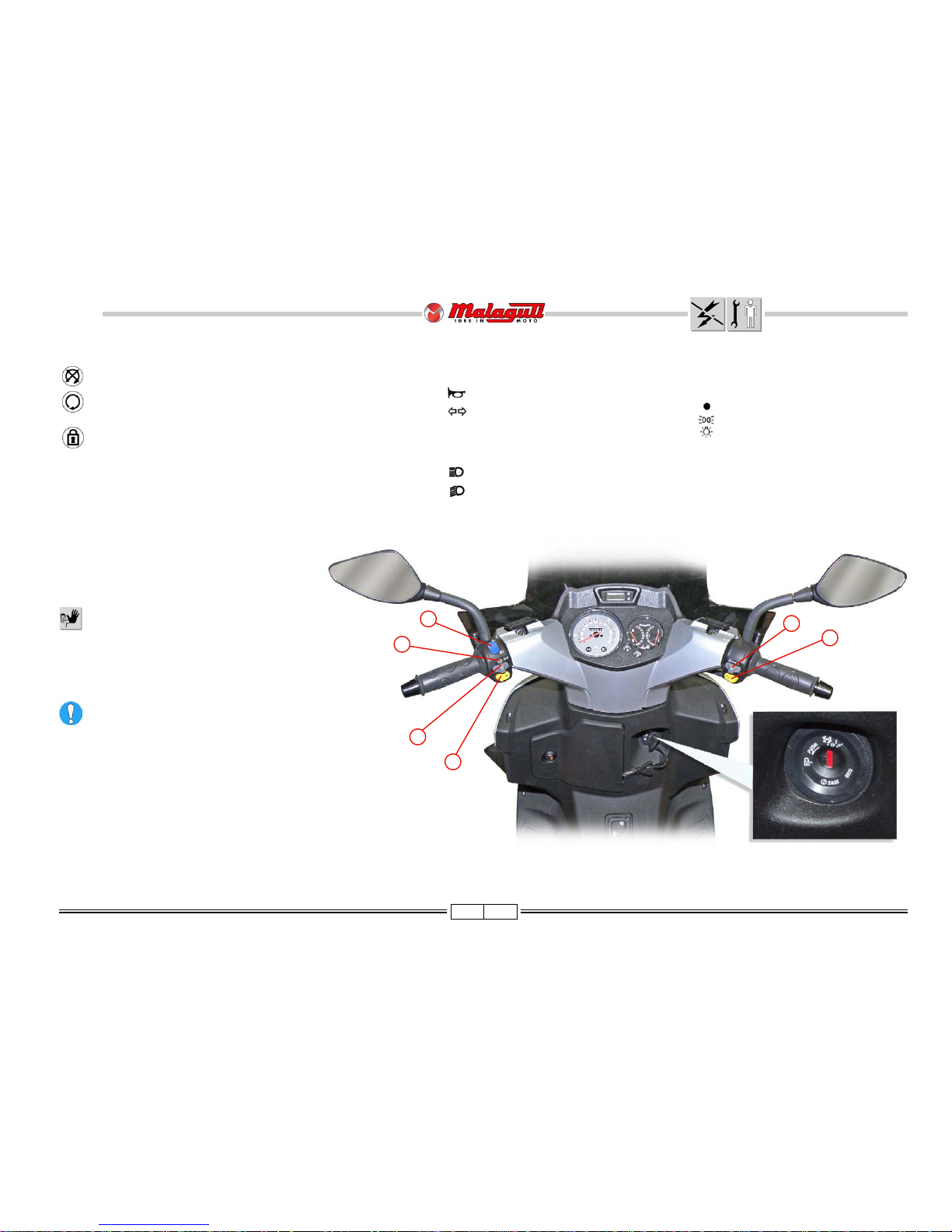

F. 2 5

B

A

1

2

3

4

KEY SWITCH

Ignition inhibited (extractable key)

Preset starting position (non extractable key)

Steering lock insert (Ignition inhibited: extractable key).

In case both of the equipped keys are lost the entire

locking kit must be replaced.

STARTING THE ENGINE

Before pushing the starter button to start the motor,

first pull the front or rear brake lever and keep it

pulled.

Do not start the engine in a closed ambient,

because the exhaust is highly toxic.

To not damage the injection system, never

operate the "START" button if the fuel tank

is empty, or turn the key switch to "ON".

If the engine does not start, release the starter switch, wait a moment, and then press it

again. In order not to drain the battery, do not

operate the starter for more than 10 seconds

on each try. Do not rev the engine to its limit

when it is cold.

Start the engine with the headlights off.

HANDLEBAR CONTROLS

RIGHT CONTROLS

A) light switch:

right= off

center= tail and dashboard lights

left= high/low beams

B) Electric starter button

LEFT CONTROLS

1) Horn button

2) Turn signals switch.

3) Turn signals shutoff switch

4) Turn on lights:

high beam

low beam

Page 21

21 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

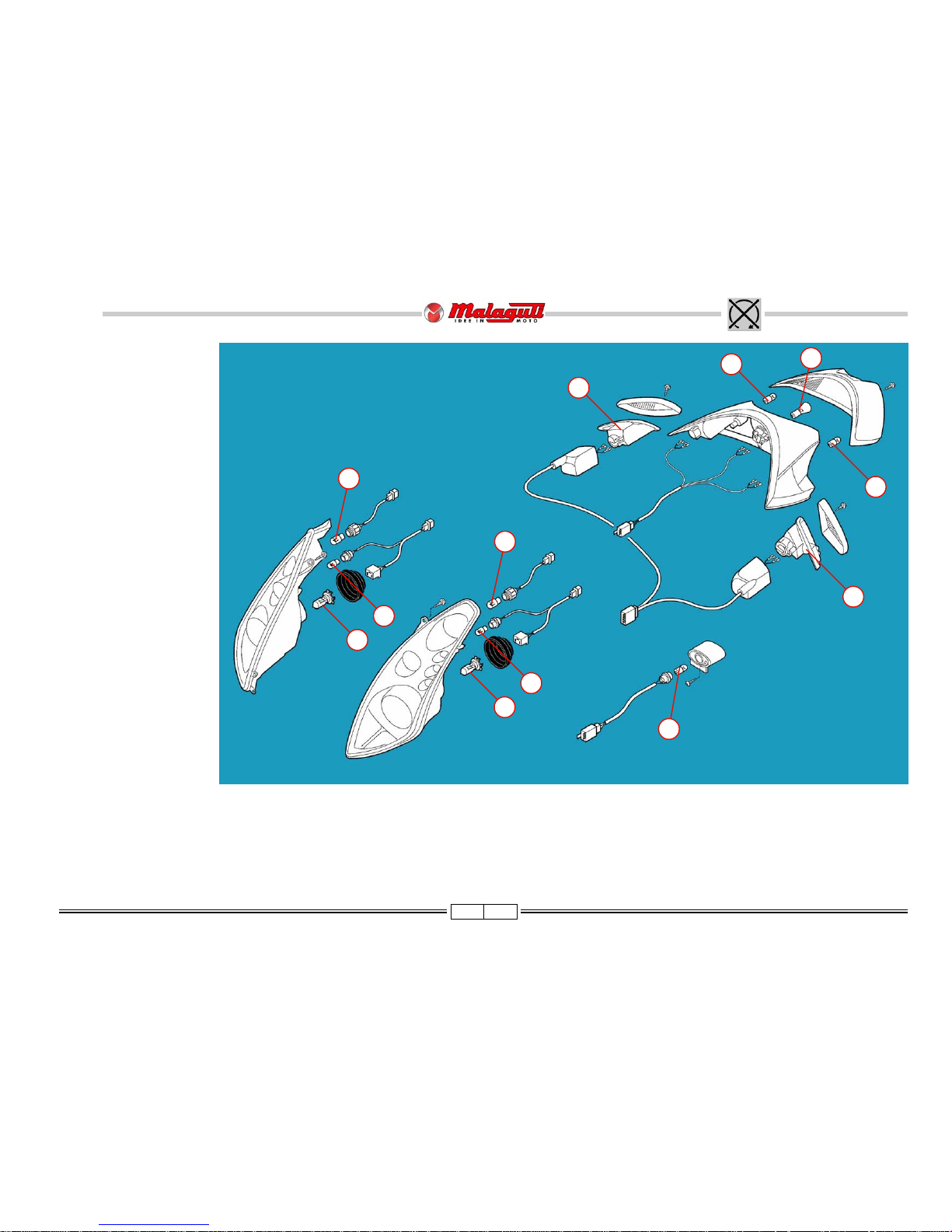

LIGHTS (12 V)

HEADLIGHT

(Quartz halogen lamps)

A) High/Low beam lights:

55W (H7).

B) Tail lights:

5W (W7y5).

TURN SIGNALS

FRONT

C) Bulbs: 10W (RY10W).

TAIL LIGHTS

D) Tail lights:

5W (R5W).

E) Stop lights:

21/25W (P21/5W).

TURN SIGNALS

REAR

F) 10W (W10W).

NUMBER PLATE LIGHT

G) 5W (W5W).

A

E

B

F

C

G

D

C

A

B

F

D

F. 2 6

Page 22

22 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

LIGHT BULB REPLACEMENT

HEADLIGHT

• In order to access the headlight bulbs, refer to the topics at page (33).

TURN SIGNALS

FRONT: See page (33).

REAR: Undo the screws (V) and remove the rear reflectors. Turn the bulb anti-clockwise and replace it by a new

identical one.

TAIL LIGHTS

• Undo the screws (V”) and remove he tail light cover. This operation will allow releasing the whole light unit (body +

cover).

LIGHT BEAM ADJUSTMENTS

To check/adjust the beam, proceed as follows:

• Put the vehicle in running conditions at 10 metres from a wall.

• Turn the low beams on and keep the vehicle vertical, without stand or driver.

• Using an adjustable spanner, turn the projector screw (R), bearing in mind that turning anti-

clockwise raises the beam and vice versa.

F. 2 7

V

V

V2

F

F. 2 8

F

W

NUMBER PLATE LIGHT

• Undo the screw (W) and remove the tail light cover (F).

• Remove the rubber bulb holder from the plastic cover and

replace the bulb.

NOTE - Before reassembling any component removed to

replace one or more bulbs, check the light operation.

F. 2 9

R

Page 23

23 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

REPLACING THE FUSES

• Extract the blown fuse and replace it with one of the same capacity. Inside the compartment, you will find some spare fuses (S).

• Check that the fuse you are using has the same amperage of the fuse you are replacing.

F. 3 0

FUSES

The electrical wiring includes 9 fuses, protecting the main components against faults.

8 are located in the glove compartment.

Do not replace fuses with others that have a higher capacity, as it could seriously damage the electrical system and cause the vehicle to catch fire if there is a

short circuit.

It is important to identify the cause of blown fuses.

S

• A 5A fuse (I) below the helmet compartment is installed to protect the recharge plug.

F. 30/a

I

Page 24

24 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 3 2

F. 3 3

F. 3 4

P

A

F. 3 1

W

S

V3

B

• Replace the previously removed 30 A general protection fuse

in its place.

• Check that the battery and cables are properly positioned;

then remount the battery fastening cover.

• Remount the central panel under the seat.

NEVER invert the cable connections.

Do not use the battery without the battery

inserted and connected to wires of the main

harness. This could cause breakdowns and

short circuits in the electrical system and

components.

It is advisable to use gloves and protective

eyewear, when the battery must be removed

from its housing; for example, when it needs to

be recharged.

Make sure that the tilt sensor (B) is perfectly

horizontal.

Danger of explosion! Do not use open flames

(lighters, matchsticks, etc.).

The battery contains highly toxic sulphuric acid.

Avoid contact with the eyes, skin, and clothes.

Keep the battery out of reach from children.

If for charging/maintenance of the battery the

special electrical outlet connection is used,

open the battery case to permit proper

ventilation.

CHARGE BATTERY

• To carry out this operation, it is advisable to remove the

battery from its housing, unless the special electrical outlet is

used.

• Disconnect cables.

• It is a good rule to recharge using amperage that is equal to

1/10 of the power of the battery.

• Remount the battery, paying attention to connect the positive

cable (red/blue) to the + pole and the negative cable to the pole.

• Properly tighten the battery clamps.

• It is important that the battery always remains fully charged;

therefore, during the winter months or when the vehicle remains unused, it should be recharged at least once a month.

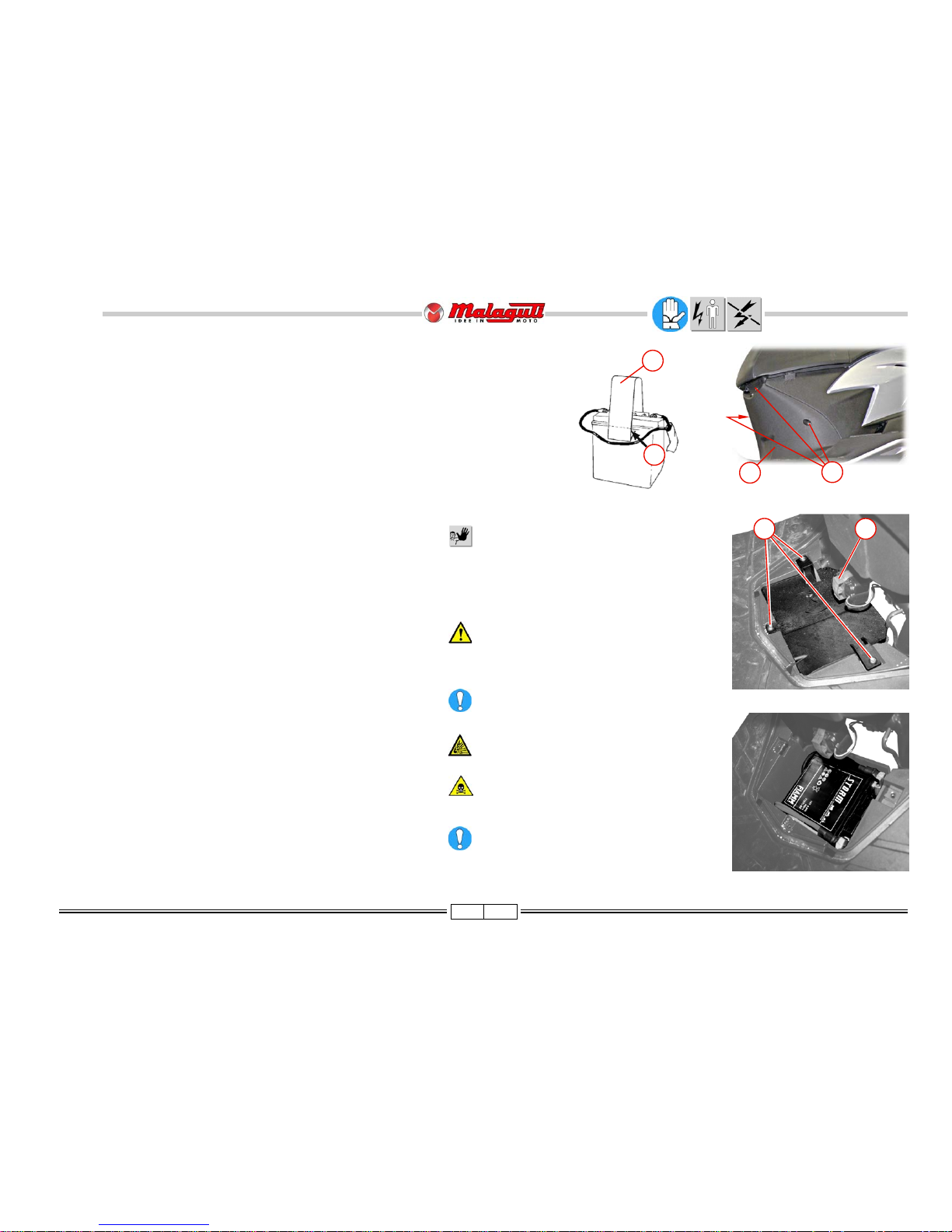

BATTERY (12V - 9Ah)

The battery housing is located in the central tunnel.

BATTERY ASSEMBLY (PRE-DELIVERY OPERATION)

• Take the battery that has been previously charged

• Apply the adhesive strip (A) supplied in the kit, by removing

the protective film located on the end of the adhesive area,

shown by the arrows (P).

• Remove the 30 A general protection fuse.

• Unscrew the three screws (V3) and remove the central panel

under the seat (S).

• Remove the battery fastening cover by removing the 3

screws (W).

• Inser t the battery, ensuring it fits in its housing.

• Connect the battery to the cables

- positive pole (+) RED/BLUE wires

- negative pole (-) BLACK wires

• Properly tighten the battery clamps.

• Properly position the battery clamps.

Page 25

25 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 3 6

F. 3 5

C

P

V3

Spark plugs with a thermal grade that is different than that deduced by the advised

symbols may seriously damage the engine.

Replace all spark plug with cracks on the insulator or corroded electrodes.

SPARK PLUG

REPLACEMENT

Remove the spark plug when the engine is cold.

Type of spark plug to be used: NGK DPR7EA9

• For maintenance, disassemble the central panel under the seat (P), remove the

fastening screws (V3) and lift the internal profile (with the help of a screwdriver)

that is held on two lugs in the foot rest board, carefully extract the hood (C ),

with small clockwise and anti clockwise movements; then unscrew the spark

plug.

• Examine the condition of the sparkplug. Deposits and colorations of the insulator provide useful information on the thermal grade, on the carburetion, on the

lubrication and on the general condition of the engine. If there is a light brownish

color on the insulator around the central electrodes, it means that it functions properly.

• After removing the sparkplug, proceed to clean thoroughly the electrodes and insulators, using a

metallic brush. Adjust the electrode gap, using a laminar feeler gauge: the gap must be 0,6 ÷ 0,7 mm

• Remove any residue, using jets of compressed air.

• Grease the sparkplug threads with motor oil and manually rescrew it.

• Tightening the spark plugs:

every 12,000 km

17,5

Page 26

26 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

PROCEDURES FOR DISMANTLING AND

REMOVING COMPONENTS

REASSEMBLY NOTE

WINDSCREEN

SUPPORTS

• V2.

• Supports (A).

F. 3 7

F. 3 8

V2

A

A

F. 3 9

D

REAR VIEW MIRRORS

RIGHT SIDE MIRROR

• Uncover and loosen the nut (D).

• Unscrew the window holder arm, by turning it clockwise.

LEFT SIDE MIRROR

• After undoing the nut (D), unscrew the mirror holder, anti-clockwise.

V4

WINDSCREEN

• V4.

• Windscreen.

Page 27

27 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• W2.

• V2.

• Release the upper

handlebar cover,

paying attention not

to damage the

anchoring teeth (A).

• Undo the odometer

cable ring nut from

the instrument panel

coupling.

F. 4 0

F. 4 1

F. 4 2

V2

W2

A

UPPER

HANDLEBAR

COVERS

• Disconnect the

connectors (C - D).

F. 4 3

C

D

Page 28

28 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• V2.

F. 4 4

F. 4 7F. 4 6

DASHBOARD

• V4.

• V2/a.

V4

V4

V2

V2a

• Disconnect the

connector (A).

F. 4 5

A

Page 29

29 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ACCESS

(after removing the upper handlebar cover)

1) Front brake pump

2) Hydraulic front brake union

3) Front brake "stop" switch

4) Rear brake "stop" switch

5) Rear brake pump

6) Hydraulic rear brake pump union

7) Right switch connector

8) Left switch connector

LOWER HANDLEBAR COVER

• V2.

•V.

• Release the gas transmission (G).

• Remove the lower handlebar cover (C) pushing it backwards.

V

3 ± 10%

F. 4 8

1

3

2

6

5

4

7

F. 4 9

8

7

V2

V

V2

G

C

Page 30

30 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

UPPER

SHIELD

• V2.

• Tapping slightly with

the hand palm,

release the upper

cover.

When reassembling, make sure

the shield lower teeth are properly

engaged into the slots.

ACCESS

1) Steering adjusting nut.

2) Radiator cap

3) Connector electric fan

4) Connector diagnosis socket

5) Front headlight connector

6) Expansion reservoir plug

7) Handlebar screw

V2

F. 5 0

F. 5 1

V

1 ± 10%

F. 5 2

6

5

A

4

1

2

3

7

Page 31

31 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FRONT

SHIELD

• V2.

V2

1 ± 10%

W

1 ± 10%

•W.

A

V2

F. 5 3 F. 5 4

F. 5 5

W

• Unplug the

connector (B) and

remove the front

shield completely.

F. 5 6

B

• Remove the shield with

moderation, being careful

to not damage the

hooking elements (A).

Page 32

32 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 5 8

(shield parts)

1) Turn signals

2) Tail lights

3) High/Low beam lights

F. 5 7

2

1

2

1

3

2

1

ACCESS

(motorbike parts)

1) Radiator

2) Electric fan

3) Fork stem screw

3

Page 33

33 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

CHANGE LIGHT BULB

TURN SIGNALS

• Turn the bulb holder (A) anti-clockwise and remove the bulb (B).

TAIL LIGHTS

• Extract the bulb holder (C) and remove the bulb (D).

HIGH/LOW BEAM LIGHTS

• Release the bulb holder from the clips (E).

• Replace the bulb, paying attention not to touch the bulb glass with bare fingers.

NOTE - We recommend to test the new bulbs before reassembling the removed

components.

F. 5 9

B

A

D

C

E

Page 34

34 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• V4.

• W2.

• Remove the front wheel

and mud guard.

FRONT

FAIRING

• Remove the front fairing with

care.

•V.

• V1.

• V3.

• V2.

ACCESS

1) Electronic

control unit

2) Horn

F. 6 1

F. 6 2 F. 6 3

F. 6 0

V

V1

W2

V4 V4

2

1

V2

V3

V4

2 ± 10%

V2

2 ± 10%

V

V3

1 ± 10%

V1

3 ± 10%

W2

3 ± 10%

Page 35

35 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

SIDE

STRUTS

• V4.

• V3.

•V.

LEGSHIELD

(After removing the front shield)

• V2/b.

F. 67 F. 67/a

V2

B

A

V2b

V3

V

1 ± 10%

V4

1 ± 10%

V2

5 ± 10%

• V2.

• Bag hook (A)

• Key swith lid (B).

• V2/a.

V2a

F. 6 6

F. 6 5

V

V3

F. 6 4

V4

Page 36

36 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

SEAT

• V4.

•V. • Release the leg-fender

with care, paying

attention not to damage

the sides (A).

V4

3 ± 20%

V

1 ± 10%

CENTRAL

SECTION

UNDER THE

SEAT

• V3.

F. 6 8 F. 6 9

F. 7 0

V

V4

A

F. 7 1

V3

Page 37

37 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ACCESS

• Rollover sensor (A).

When reassembling the removed components, make sure that the tilt sensor is

horizontal.

An inclination of approximately 45° would prevent the engine from starting.

• V3.

• Battery cover (C).

• Battery compartment (B).

F. 7 3

F. 7 2

V3

B

A

C

Page 38

38 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• V3.

• Cap (T).

V3

5 ± 20%

F. 7 6 F. 7 7

T

V3

V2

F. 7 5

A

V4

F. 7 4

• After undoing

the screws

(V2), open up

the fairing, as

shown in the

figure.

• V4.

• V1.

HELMET CASE

V2

V1

P

• V2.

• Remove the seat

fastening plate (P).

• Remove the cover (A).

V2

5 ± 20%

Page 39

39 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• V2. • Lift the helmet

compartment.

• Remove the seat

lock unit (A).

• Disconnect the

connector (B).

• Remove the

helmet

compartment.

• In case you need

to release the

cable (C) follow

the instructions

below:

F. 8 0

V2

3 ± 20%

F. 7 8 F. 7 9

V2

A

B

C

• Move the clip (D)

sideways to

release the cable

(C).

F. 8 1

D

D

C

Page 40

40 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ACCESS

(after removing the helmet compartment)

A) Fuel level gauge

B) Fuel Pump

C) Pump connector

D) Fuel tank

1) Injector connector

2) Temperature gauge (coolant)

3) Throttle body

4) Coolant drainage hose

5) T.P.S. connector

6) Thermal expansion valve

4

3

2

1

B

C

A

F. 8 2

5

D

6

Page 41

41 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 8 3

F. 8 5

H

P

I

FUEL LEVEL

SENSOR

Do not smoke or use open flames,

during operations on the fuel tank.

• During operations, screw the tank cap

(A), to avoid that any foreign matter

falls inside.

• Remove the sheaths (B) and disconnect

the connector located below.

• V4.

• Remove the sensor (D).

V4

2 ± 10%

F. 8 4

D

E

F

FUEL PUMP

• Disconnect the connector (G).

• Disconnect the gas hose (H), pressing on the fitting

with one finger (R). Keep a rag close by to swab up any

leaking fuel.

• Unscrew the ring nut (I).

• Take out the pump (P).

V4

V4

When reassembling, insert the

floater (E) so that the base (D)

remains as it was originally. It is

advisable to mark the correct

position before removal. Check the

condition of the gaskets (F) and

replace them if necessary.

A

B

H

R

D

G

I

Page 42

42 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

In the ending part, the

footbar is linked to the

rear fairing by coupling

teeth.

• In order to release the

footbar from the rear

fairing, move the rear

fairing backwards, with

care, and lift it

simultaneously in order to

release the coupling teeth

(B).

F. 8 7

F. 8 8 F. 8 9

V

1 ± 10%

•V.

FOOTBAR

• Remove the

lids (A) by

means of a

screwdriver.

• V3.

V3

5 ± 10%

F. 8 6

V3

A

V

B

Page 43

43 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 9 0

ACCESS

1) Ignition coil

2) Horn

3) Voltage regulator

4) Rollover sensor

5) Regulator connector

System connector

6) Electronic control unit

6

2

3

4

1

5

Page 44

44 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ELECTRONIC CONTROL UNIT

• Connector (L).

• W2.

VOLTAGE REGULATOR

• V2.

• Disconnect the connector (G) (see 1 - F. 107), cut the clamp

(H), remove the sheaths (I) and disconnect the inside

connector.

ROLLOVER SENSOR

• Connector (F).

• Free the sensor (D) from its housing.

HORN

• Faston (D).

• Screw (V1).

IGNITION COIL

• Connector (A).

• Screw (V).

• H.T. cable (C)

• Remove the coil complete with the support staff.

V2

C

A

V

F

F. 9 1

D

G

L

W2

IH

V1

Page 45

45 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

REAR

FAIRING

REAR HANDLE

•V.

• By means of a screwdriver,

release and remove the

upper cover (A).

• V3. • Rear handle (B).

F. 9 3

F. 9 4 F. 9 5

V3

A

B

V3

43 ± 15%

F. 9 2

V

Page 46

46 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

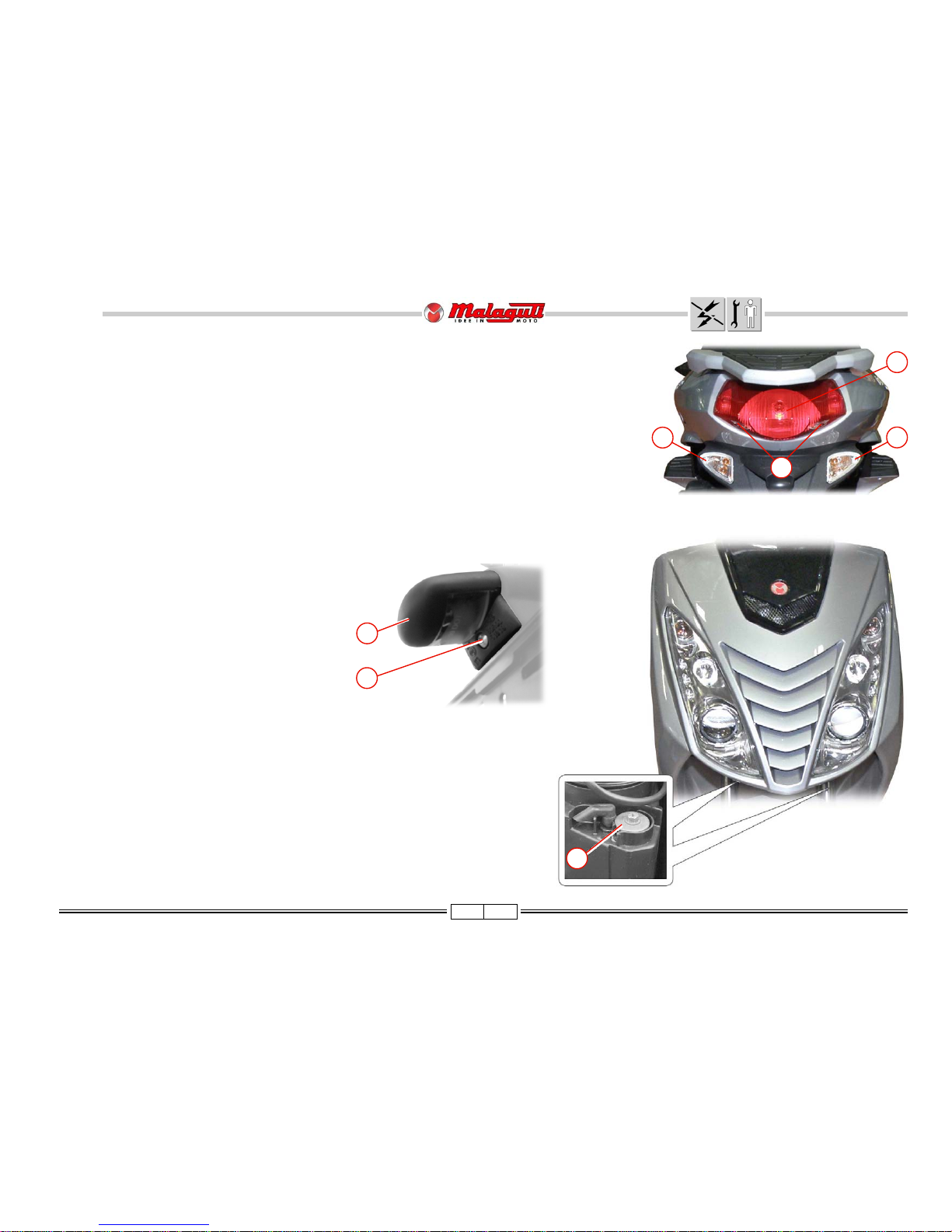

TAIL LIGHTS

• V2.

F. 9 6

V2

F. 9 7

F. 98/a

• Disconnect the faston

connectors and remove the

complete tail light.

• In order to replace the bulbs,

it is not necessary to remove

the complete tail light unit.

FULL REAR FAIRING

After removing the seat, the helmet

compartment, the rear handhold

and the tail light and after releasing

the footbar, proceed as follows:

• V2.

• Lift, while moving backwards,

the fairing with care.

F. 9 8

V2

Page 47

47 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 9 9

F. 100 F. 101

•Ve. • Vi.

A

B

A

B

V5

Ve

Vi

FAIRING BREAKDOWN

• V2.

• Release the electric cables

from the hose rings (A).

• V5.

• Split the two fairing halves

from the coupling teeth (B).

V2

Page 48

48 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

SEAT LOCK

UNIT

• V3.

• Lid (A).

• Lift and remove the key

switch block lock clip.

F. 102 F. 103

• Release the cable.

F. 104

• Remove the cable holder bracket.

F. 105

• Remove the key switch block.

F. 106

V3

A

Page 49

49 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

1

F. 107

7

2

3

5

4

6

8

The reassembly stage of any interventions

on the wiring involves repositioning these as

illustrated, and fastening them with new

clamps that must be placed in the original

points.

NOTE - Access to the various

mechanical components can be deduced from

the illustrations.

ACCESS

1) Three-phase stator

connectors

Regulator connector

2) Connector pick-up

3) Intermittence

4) Mass assembly

5) Electric fan relay

6) Injection system relay

7) Starter relay

8) Idle control valve

Page 50

50 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

9) O2 sensor

10) Thermal unit

15) Fuel hose fastening

clamp

14) O2 sensor connector

NOTE - To reach the indica-

ted components

disassemble only

the helmet

compartment.

F. 109

11 1312

F. 108

9

10

F. 110

14

F. 111

15

11) Exhaust manifold

12) Spark plugs cap

13) Starter motor

ground cable

Page 51

51 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FUEL TANK

F. 112

V4

CD

E

A

M

I

Do not smoke or use open flames,

while operating on the fuel tank.

• During the operation, screw the tank cap

(A), to avoid that any foreign matter falls

inside.

• Disconnect the gas hose (C), pressing on

the fitting with one finger ( D). Keep a rag

close by to swab up any leaking fuel.

• Start the engine and let it run until the pipe

(C) is completely empty.

• Disconnect the connector (B).

• Cut the clamp (I).

• Disconnect the connector (L) inside the

sheaths (E).

• Unscrew the screws (V4), being careful not

to lose the anti-vibration pads, bushings

and clamp (M).

• When reassembling, put the clamp back

(M),

V4

Remove the tank and place it far from heat sources and sparks and/or open flames.

L

B

V4

5 ± 10%

Page 52

52 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ELECTRIC FAN AND RADIATOR

• Position the engine

in a container

suitable for collecting the used

coolant.

• Loosen the clamps

(F) and slide the

tube off (T) of the

water pump.

Before any operations on the cooling

system, check that

the fluid is below

50°C.

• Remove the front shield

(page 31).

• Cut the cable and tube

holding ties.

• Unscrew the radiator

cap (A).

• Disconnect the

connector (B) electric

fan.

• Release the clamps

and the hoses (M)

connected to the

radiator.

F. 114

T

F

F. 115/a

V2

T

F. 115

M

F. 113

A

B

• Remove the hose

(T).

• V2.

• Remove the

radiator unit, along

with the frame, the

expansion reservoir

and the electric

fan.

Page 53

53 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

DISASSEMBLING RADIATOR UNIT

• Disassemble the radiator unit, as shown in the figure.

COOLING SYSTEM DRAINAGE

The cooling system is "self-bleeding".

But if, after the radiator is reassembled, filled with fluid and tested with

the engine idling for a few minutes, an abnormal rise in temperature is

found, manually bleed it by following these steps:

F. 117

F. 116

T

• Partially lift and rotate the helmet case sideways (page 38).

• Wait until the fluid has cooled down, unscrew the cap and completely fill the radiator.

• Slide off the tube (T) (after freeing it from the clamps); Liquid should come out from the

union, in abundance.

• Insert the tube (T) and the cap radiator.

• Before replacing the helmet case, start the engine and check that there is no abnormal

rise in temperature.

Page 54

54 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FRONT WHEEL

• Unscrew the nut (D), holding the wheel pin with a wrench (P).

FRONT BRAKE DISC

• When removing the front wheel, check the condition of the brake disc. In case of deep scoring or if

the thickness is below the minimum limit of 3.5 mm,

remove it by unscrewing the screws (V5) and replace it.

V5

11 ± 10%

• Extract the wheel pin (P)

paying attention not to

damage the spacers

(B - B1), the odometer

unit (A) and the washer (R).

D

53 ± 10%

F. 118

F. 119

F. 120

D

D

A

P

V5

P

R

A

B1

• Remove the wheel pin (P).

• Take off the wheel.

Do not use the brake

lever, with the wheel

removed.

Apply Loctite threadlocker (Strong type) on

the screw threading.

B

Page 55

55 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FRONT BRAKE CALIPER

• Place an appropriate drain pan under the brake calliper.

• Unscrew the hydraulic fitting (A).

Empty the hydraulic circuit completely, pouring the fluid in a special container for

proper disposal in accordance with specific waste disposal laws.

• V2.

• Remove the calliper.

Hydraulic oil is corrosive and may cause personal injury.

Remove the calliper, taking care that fluid line does not get damaged and

the disc and pads do not get dirty. At the end of removal and replacement

operations, check that there are no losses, dry up any traces of fluid and

bleed the system.

A

G

FRONT

MUDGUARD

• V2.

• W (with inside nuts).

V2

3 ± 10%

W

3 ± 10%

F. 121

F. 122 F. 123

A

V2

• Release the odometer

cable (A) and extract the

cable ring (B).

• Mud guard (P).

V2 W

V2

W

P

A

B

V2

A

20 ± 20%

V2

30 ± 20%

Page 56

56 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 124

A

HANDLEBAR CONTROLS

ANDBRAKE PUMP

• Disconnect the throttle transmission (A).

• Disconnect

the "faston"

(F).

F. 125

• V2/a

• Brackets (B).

• Remove the brake pump

and place it in a vertical

position on a dry cloth.

Brake fluid is corrosive.

F

F

KEY SWITCH

• Disconnect the connector (A).

• Tamperproof screws (V2).

F. 127F. 126

V2/a

V

V

B

V2/a

B

V2

10 ± 15%

V2

A

Page 57

57 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 128

HANDLEBAR

• Remove beforehand:

- Upper handlebar covers (page 27)

- Front shield (page 31).

- Brake pump (page 56).

- Right switch and left switch (M).

- Counterweights (P).

- Handlebars (N)

- Cut the cable and tube holding ties.

- Remove the throttle cable (A)

• Loosen the nuts (D) and slide the pin off (H), taking care not to damage the cables

and tubes.

• Slide off the grips.

D

50 ± 20%

FORK

NOTE - When removing the fork leg, as well as the full fork, the

following should be removed beforehand:

- Front wheel (page 54)

- Front mudguard (page 55)

- Front brake calliper (page 55) (only for the left stem).

For the full fork, also remove the:

- Front shield (page 31)

- Handlebar

•To check the oil level and to change oil, see page 18.

FORK LEG

• Loosen the screws (V2)

• Raise the fork leg a few millimetres (A) and

tighten only the lower screw.

• Unscrew the cap (B) and undo the lower

screw.

• Slide out the fork leg (A) downwards.

V2

30 ± 20%

D

PNM

P

N

L

M

D

H

A

F. 129

V2

B

A

Page 58

58 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 131

FULL FORK

• Upper ring nut (A)

• Lower ring nut (A)

NOTE - When extracting the fork unit, take care with the bearings (S) spilling out.

• Remove grease the seat of the caps (C). Check the usage conditions and if necessary replace

them.

Grease and remount the fork unit.

Top bearings (Ø 3/16") n° 22

Lower bearings (Ø 1/4") n° 19

C

C

B

A

S

S

F. 132

MUFFLER

Before operating on the muffler and the exhaust

pipe, ensure that the components are cool.

• Loosen the clamp fixing screws (V)

of the muffler/exhaust pipe.

• V3.

• Remove the muffler.

V

24 ± 10%

V

A

B

F. 130

B

140 ± 15%

A

12 ± 10%

V3

Page 59

59 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

EXHAUST

MANIFOLD

• Disconnect the O2 sensor

connector (A).

REMOUNTING THE EXHAUST SYSTEM

• Screw the O2 sensor (D) on the exhaust connector (1).

• Position the collector (1) in correspondence with the engine, inserting

the gasket (2) that should be replaced if they are deteriorated.

• Screw and tighten the nuts (D2).

• Insert the gasket (3).

• Insert the muffler (4) on the manifold exhaust.

• Screw and tighten the screws (V3), after having inserted the washers

(R ).

• Tighten the clamps (F).

D

45 ± 10%

D2

30 ± 10%

V3

42 ± 15%

2

D2

1

D

V3

F

R

4

R

V3

3

F. 134

D

D2

F. 135

• Loosen the O2 sensor (D).

• D2.

• Remove the exhaust manifold

and related gaskets.

A

F. 133

Page 60

60 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 136

Vs

45 ± 15%

Vi

24 ± 15%

Support the scooter

on the central part of

the chassis.

• Lower screws (Vi)

SHOCK ABSORBERS

• Nuts (D).

• Top screws (Vs)

• Remove the shock

absorbers.

F. 137

Vi

Vi

DD

Vs

Page 61

61 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

REAR

MUDGUARD

Right side

• V2.

Left side

•V.

V2

3,5 ± 20%

V

3,5 ± 20%

V

F. 139

F. 140

REAR BRAKE CALIPER

Remove rear wheel beforehand as follows: unscrew the screws (V4) fixing the wheel to the hub, then

move the rear wheel until it hits the slider arm (B).

• Place an appropriate drain pan under the brake calliper.

• Unscrew the hydraulic fitting (R).

Empty out the hydraulic circuit, pouring the fluid in a special container for disposal in accordance

with specific waste disposal laws.

• Unscrew the screws (V2) and remove the caliper, taking care not to damage the rim previously removed

from the hub.

Brake fluid is corrosive and can cause personal injury.

Remove the calliper, taking care that fluid line does not get damaged and the disc and pads

do not get dirty. When the removal and replacement operations are finished, check that there

are no losses, dry up any traces of fluid and bleed the system as indicated in page 16.

R

20 ± 10%

During reassembly, change the gaskets.

V2

30 ± 20%

V2

R

V2

F. 138

V4

B

Page 62

62 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

REAR

WHEEL

• Position the motorcycle on the

stand and place a suitable support under the engine.

• Remove beforehand:

- Muffler (page 58)

- Rear mudguard (page 61)

- Rear brake calliper (page 61)

• Unscrew the lower screws (V)

of the right shock absorber. Rotate and anchor the shock absorber up high.

• Unscrew the wheel nut (D).

• Unscrew the fixing screws (V2) of the slider arm (B).

• Extract the external spacer (A).

• Remove the slider arm (B).

• Slide off the wheel pin the internal spacer (C).

• Check the wear conditions of the oil seals (E- F) and replace it if necessary.

• Check the condition of the silent-block (G).

• A appropriate puller must be used for bearing (H) replacement operations, after having removed the Seeger ring (l).

• Slide off the wheel with care, ensuring that the vehicle is stable.

F. 142

H

E

C

I

B

G

FA

V2

F. 141

F. 143

D

V

V2

D

100 ± 20%

V2

45 ± 15%

C

Page 63

63 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 146

F. 144

F. 145

REAR BRAKE

CALIPER

• When removing the back

wheel, check the state of

use of the brake disc. In

case of scoring or thickness below the minimum

limit of 3.5 mm, remove it

by unscrewing the screws

(V4) and replace it.

V4

11 ± 10%

REAR

WHEEL

• Before remounting the rear

wheel, grease the shaft in

points A-B.

Apply Loctite threadlocker (Strong type)

on the screw threading.

B

A

STARTER

• Disconnect the "faston" from the connector (A).

• Unscrew the screws (V2).

V2

10 ± 10%

A

V2

V4

Page 64

64 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

FILTER BOX UNIT

• Unhook the clamp (A).

• Disconnect the tube (C ) "IDLE" valve- filter box sleeve.

• Remove the clamps (B).

• Disconnect the vapour recovery tube (C).

• Cut the ties (E).

• Disconnect the connector (F) (Inlet air temperature sensor)

• Loosen the clamps (G).

F. 147

F. 148

C

E

F

A

G

E

The ties that have been cut in order to remove various components must be replaced with identical ones, and placed in the original position.

C1

B

Page 65

65 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

• Remove the whole air intake system.

• To remove the intake air sensor (A), unscrew the screws (V2A).

• Unscrew the fixing screws (V1) of the filter box- rear

mudguard.

• Unscrew the fixing screws (V) of the flexible air

intake tube.

• Unscrew the screws (V2).

V

V1

V2

5 ± 10%

F. 150

V2a

A

F. 149

V

V1

V2

When remounting the inlet air

sensor, check the condition of

the O-ring (B); replace if necessary.

B

F. 151

Page 66

66 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

Position the cover and fasten it with screws (V5).

AIR FILTER MAINTENANCE

• Soak the filtering element (A) in a special solvent solution for filters, for a few

minutes.

• Squeeze the filter (wearing rubber gloves) until all traces of the solvent are

eliminated.

• Apply oil for air filters on the entire surface of the filter, eliminating any extra oil;

the result should be a uniformly impregnated filter without excess oil dripping off.

• If the filter element is damaged, replace it with a new original one.

When remounting the air filter unit, check that the filter casing seals (B)

and the filter cover are correctly inserted in the appropriate housing.

B

A

C

V5

F. 153

AIR FILTER

• Unscrew the screws (V5), remove the cover and take out the filtering element.

F. 152

V5

Page 67

67 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

ENGINE

• Remove beforehand:

- Rear fairing (page 45)

- Rear mudguard (page 61)

- Lower fixing screws, shock absorbers (page 60)

- Air filter unit (page 64)

- Slider arm (page 62)

• Nut (D).

The removal of parts and components that allow the engine to be separated from the frame includes a certain number of bands being cut. These must be replaced and

positioned as they were originally. For this purpose, consult the illustrations on the following pages.

Removing the engine from the frame is a task that should be performed with care and the utmost attention.

Raise the rear part of the motorcycle before sliding off the engine pin (A). It is advisable to have a second operator available to help carry out this operation.

SIDE

STAND

• Springs (A - B).

•V.

It is essential that all the tube and cable ties

are cut from the engine and all relevant connectors are disconnected.

After remounting the previously removed components, all cables, pipelines and ties should result as they were originally; in concern to this, carefully consult

the following pages.

CENTRAL

STAND

• Springs (A - B).

• Seeger (C).

•V.

V

40 ± 10%

V

B

A

V

B

A

V

40 ± 10%

F. 154 F. 155

F. 157

D

45 ± 15%

F. 156

A

D

C

After having

tightened screws (V) ,

insert seeger (C).

Page 68

68 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 158

FRAME SIZE CHECK

• In case of suspected deformation (even slight) of the frame following an accident, perform a size check of the frame.

Check that the distance A = 1168 mm ( ± 2mm tolerance)

• If it results to be outside of the tolerance, replace the frame.

It is absolutely forbidden to deform the frame to restore the original

distance (A).

Page 69

69 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

POSITION OF INJECTION SYSTEM PARTS

F. 159

Battery

H.T. coil

Tilt sensor

Inlet air temperature sensor

Side stand switch

Starter motor ground cable

O2 sensor (Lambda sensor)

Idle control valve

Ignition spark plug

Page 70

70 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 160

Wiring ground cables

Injection system relay (red)

Fuel pump

ECU (engine control unit)

Injection warnig light (orange)

Diagnosis plug

RPM connector (Pick up)

Regulator

Water temperature sensor

Page 71

71 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 161

Fuel injector

Stator three-phase connector regulator

TPS sensor

Regulator connector system

Radiator fan

Fan relay (yellow)

Page 72

72 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

CABLE POSITIONING, "PIPE SYSTEM" AND ANCHORING TIES

F. 162

Page 73

73 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 163

Page 74

74 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 1 6 4

Page 75

75 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 165

Page 76

76 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 166

Page 77

77 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 167

Page 78

78 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 168

Page 79

79 03/09

125 - 160 cc

BlogBlog

BlogBlog

Blog

F. 1 92

Loading...

Loading...