Page 1

T

ECHNICAL INFORMATION

Models No.

Description

EM4350UH, EM4350LH

EM4351UH

Petrol Brushcutter

CONCEPT AND MAIN APPLICATIONS

These models are 43.0cm³ 4-stroke petrol brushcutters developed

in compliance with well-known exhaust emission regulations.

Their main features are:

• Powerful 4-stroke engine for working in larger open area, and

for easily cutting through thick weeds and longer grass

• Newly designed throttle assembly with wide-grip throttle trigger

• Universal guard for both metal blade and nylon cutting head

• Toolless quick fastening handle holder for easy handling and

angle adjustment of handle(for EM4350UH, EM4351UH only)

• Floating structure with four rubber buffers absorbs vibration

transmitted from engine to bike handle. (for EM4351UH only)

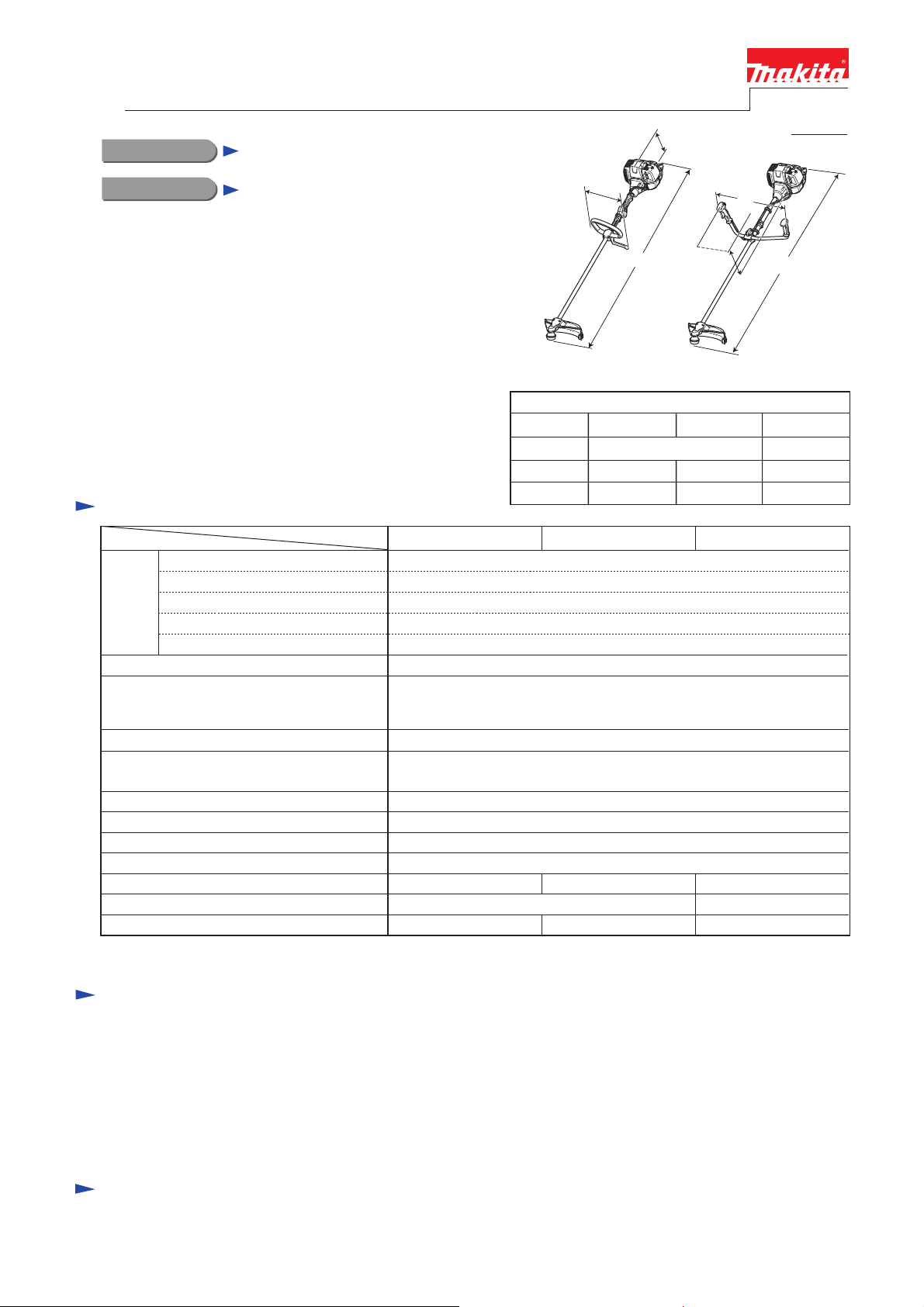

Specification

EM4350LH

Length (L)

Width (W)

Height (H)

PRODUCT

H

W

L

EM4350UH

EM4351UH

Dimensions: mm (")

EM4350UH EM4350LH EM4351UH

1,812 (71-1/2)

635 (25) 339 (13-3/8) 618 (24-1/4)

460 (18-1/8) 528 (20-3/4)250 (9-7/8)

W

H

P 1/ 2

L

The drawing

above is

EM4350UH.

1,812 (71-1/2)

2

Specifications

Type

Displacement: cm³ (cu.in.)

Engine

Max. spindle speed at no load: min.ˉ¹ = rpm

Engine oil

Carburetor

Engine start assist

Primer pump

Clutch

Anti-vibration system

Net weight*1: kg (lbs) 7.9 (17.3)

*1 Dry weight, without universal guard, cutting tool and shoulder harness

Fuel

Max. output: kW (PS)

Max. torque: N.m

Model

in the Class SF or higher of API Classification

(Automotive 4-stroke engine oil)

(by automatic mechanical decompression valve)

Bike handle

Conventional low-vibration structure

8.3 (18.2)

EM4350LH

4-stroke

43.0 (2.6)

Straight unleaded gasoline

1.50 (2.1) at 7,500 rpm

2.1 at 5,500 rpm

7,200

SAE10W-30 oil

Diaphragm

Yes

Yes

Yes

0.62 (21.0)Fuel tank capacity: L (US oz)

M10x1.25, Left-handedSpindle thread size

Loop handleHandle style

EM4351UHEM4350UH

Bike handle

Floating structure

8.6 (18.9)

Standard equipment

Blade or Nylon cutting head ..................... 1

Universal guard (=Protector) .................... 1

Blade cover ............................................... 1 (for the model with blade)

Double shoulder straps with waist pad ..... 1 (for EM4350UH)

Double shoulder straps with waist pad

for Loop handle model...... 1 (for EM4350LH)

Double shoulder straps with waist belt ..... 1 (for EM4351UH)

Note: The standard equipment for the tool shown above may vary by country.

Tool set (Hex wrench 4, Hex wrench 5,

Socket wrench 16-17,

Socket driver 16-10) .................. 1

Accessory bag ............................................ 1

Oil bottle without oil or

Oil bottle containing 100mL engine oil ..... 1

Optional accessories

255mm Triple blade, 300mmTriple blade, 255mm Star blade, 200mm Chisel blade, 225mm Chisel blade,

Nylon cutting heads (UltraAuto 6), Protector, Protector extension, Protector 200 set, Protector 225 set,

Double shoulder straps, Oil bottle

Page 2

P 2/ 22

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

---

---

---

1R219

Retaining ring pliers ST-2 for External ring1R004

Retaining ring pliers RT-2N for Internal ring1R005 removing/ installing Cotter by using 1R389

Retaining ring pliers RT-2E for Internal ring1R006 removing/ installing Retaining rings

Bearing setting pipe 20-12.21R028

Bearing setting pipe 28-20.21R031

Air density tester1R127 diagnosing Carburetor

Round bar for arbor 20-1001R247 removing Clutch drum complete from Clutch case

Round bar for arbor 8-501R282

Round bar for arbor 12-501R286 press-fitting Clutch drum complete into Clutch case

Retaining ring S and R pliers1R291 removing/ installing Retaining rings

Flywheel puller1R364 removing Flywheel

Feeler gauge set1R366 adjusting Ignition coil, Spark plug

Cotter removal attachment1R389 removing/ installing Cotter by using 1R005

10mm Hex socket bit

14mm Hex socket bit

Wire brush

Torque wrench shaft 7-23N.m

Torque wrench shaft 2-6N.m1R254

removing/ installing Retaining rings

press-fitting Cutter shaft set into Ball bearing 6000DDU

removing Spiral bevel gear 14 from Ball bearing 609ZZ

press-fitting Clutch drum into Ball bearing 6004LLU/6003LLU

removing Ball bearing 6000DDU from Cutter shaft completeBearing setting plate 10.21R033

removing Ball bearingsGear extractor (Large)1R045

removing Spiral bevel gear 14 from Ball bearing 6000ZZ and

6000

removing Piston pin

removing/ installing Flywheel

removing/ installing Clutch

cleaning Spark plug

tightening Bolts to specified torque

[2] HANDLING OF GASKET

Once Gasket is removed:

(1) Clean up the mating surface where the gasket was installed to maintain its sealing performance.

(2) Replace it with a new one.

[3] LUBRICANT / ADHESIVE APPLICATION

(1) Apply a little amount of Makita grease N No. 2 to Spiral spring in Recoil starter and the spline ends of Shaft in

Shaft pipe complete.

(2) When the inside of Gear case is cleaned, supply 11g of Makita grease N No. 2 from the grease inlet.

(3) Apply 4g of Makita grease N No. 1 to the entire portion of Shaft in Shaft pipe complete.

(4) Once Engine is disassembled, remove oil/grease from the mating surface of Cylinder and Crankcase complete,

then apply ThreeBond 1215/1216 to the mating surface for the reassembly.

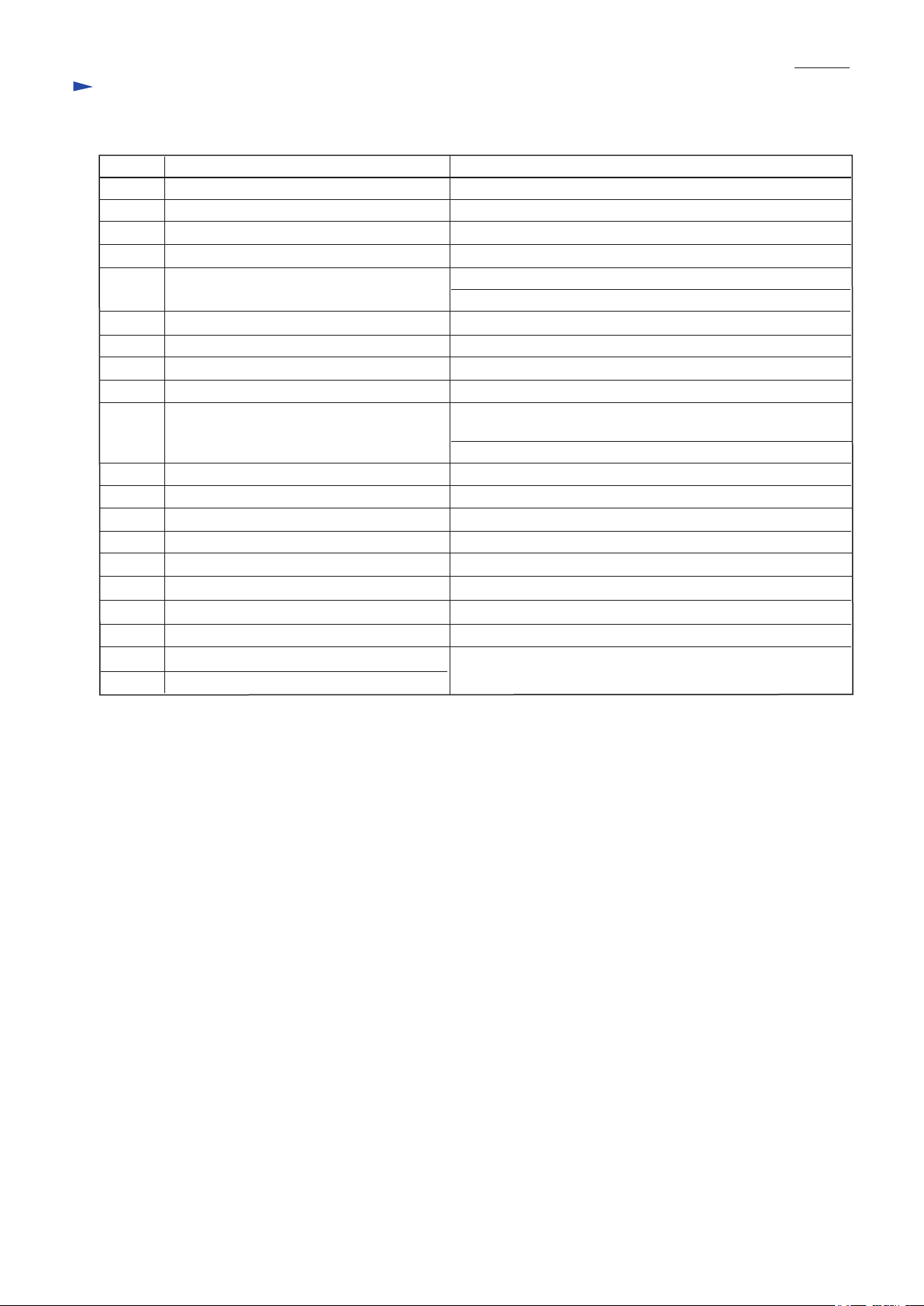

[4] DISASSEMBLY/ASSEMBLY

[4]-1. Warning

Follow the instructions described below in advance before repairing:

• Wear gloves.

• Remove the cutting tool from the unit, and if it is a saw blade, attach the blade cover to the blade.

• When the engine is hot from use, cool down the engine enough or you can get burned.

• Remove remaining fuel from Fuel tank and Carburetor completely. [FLAMMABLE MATERIAL KEEP FIRE AWAY]

• Remove Spark plug cap from Spark plug.

• Repair the engine on a stable workbench and in a clean workplace kept as free of dust and debris as possible.

• In order to avoid wrong reassembly, draw or write down where and how the parts are assembled, and what are the parts.

It is also recommended to have boxes ready to keep disassembled parts by group.

• Handle the disassembled parts carefully. Clean and wash them properly.

• If some bolts and screws are too tight, use an impact driver.

• Tighten the bolts and the screws to the specified torque as shown in "[4]-15. Tightening torque specifications".

• Each time after you mounted a main part of the engine such as the piston, check if it moves smoothly

without abnormal noise by manually turning the crankshaft.

• After completion of reassembly, check for loose parts or abnormal noise and vibration

by manually turning the crankshaft.

Page 3

P 3/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

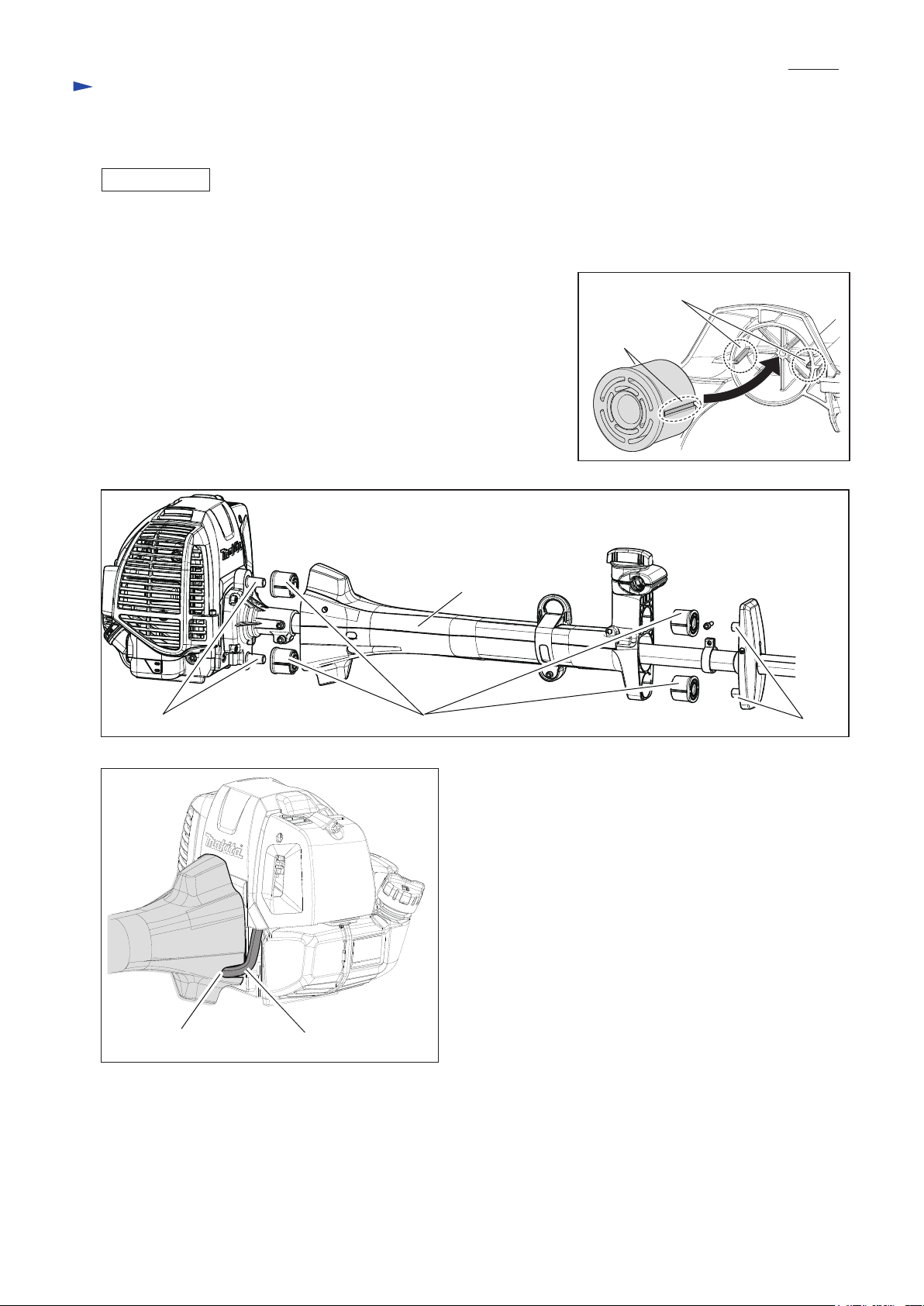

[4]-2. Engine and Shaft

(1) Press down the tab of Cleaner plate assembly gently and separate Cleaner cover assembly from Cleaner plate assembly

by loosening M5x20 Hex socket head bolt. (Fig. 1)

(2) Loosen 5x16 Tapping screw and loosen Clamp that holds Bullet terminals near Cleaner plate assembly. (Fig. 2)

(3) Disconnect Bullet terminals of Earth wire and Primary wire of Ignition coil from the wires of Stop switch. (Fig. 2)

(4) Remove Control cable from Swivel of Carburetor; loosen the three nuts on Control cable to release the tension

between Swivel and Cable bracket of Insulator, then remove the stopper on Inner cable end from Swivel. (Fig. 3)

(5) For EM4351UH: Remove M5x8 Hex socket head bolt and M6x30 Hex socket head bolt in the holes of Pipe housing.

(Fig. 4)

For EM4350UH and EM4350LH: Remove M5x8 Hex socket head bolt and M6x30 Hex socket head bolt from

the threaded holes of Clutch case. (Fig. 5)

(6) Grab Shaft pipe complete by hand, then pull it off from Clutch case.

If Shaft sticks in Clutch case, use water pump pliers or the like to pull it off.

Note: Be sure to wrap Shaft with a rag or the like to protect it from water pump pliers. (Fig. 6)

Fig. 1

Fig. 2

M5x20 Hex socket

head bolt

Inner cable

Clamp

Control cable

Cleaner cover

assembly

Fig. 3 Fig. 4

Stopper on Inner cable end

Cable bracket of Insulator

Nut on Control cable end

(3 pcs.)

Cleaner plate assembly

Tab of

Swivel of Carburetor

5x16

Tapping

screw

Holes of

Pipe housing

M5x8

Hex socket

head bolt

M6x20

Hex socket

head bolt

Cleaner plate assemblySwivel of Carburetor

Bullet terminals

Fig. 5 Fig. 6

M5x8 Hex socket

head bolt

Threaded holes

of Clutch case

M6x20 Hex

socket head bolt

Shaft pipe complete

ShaftRag

Water pump

pliers

Page 4

P 4/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

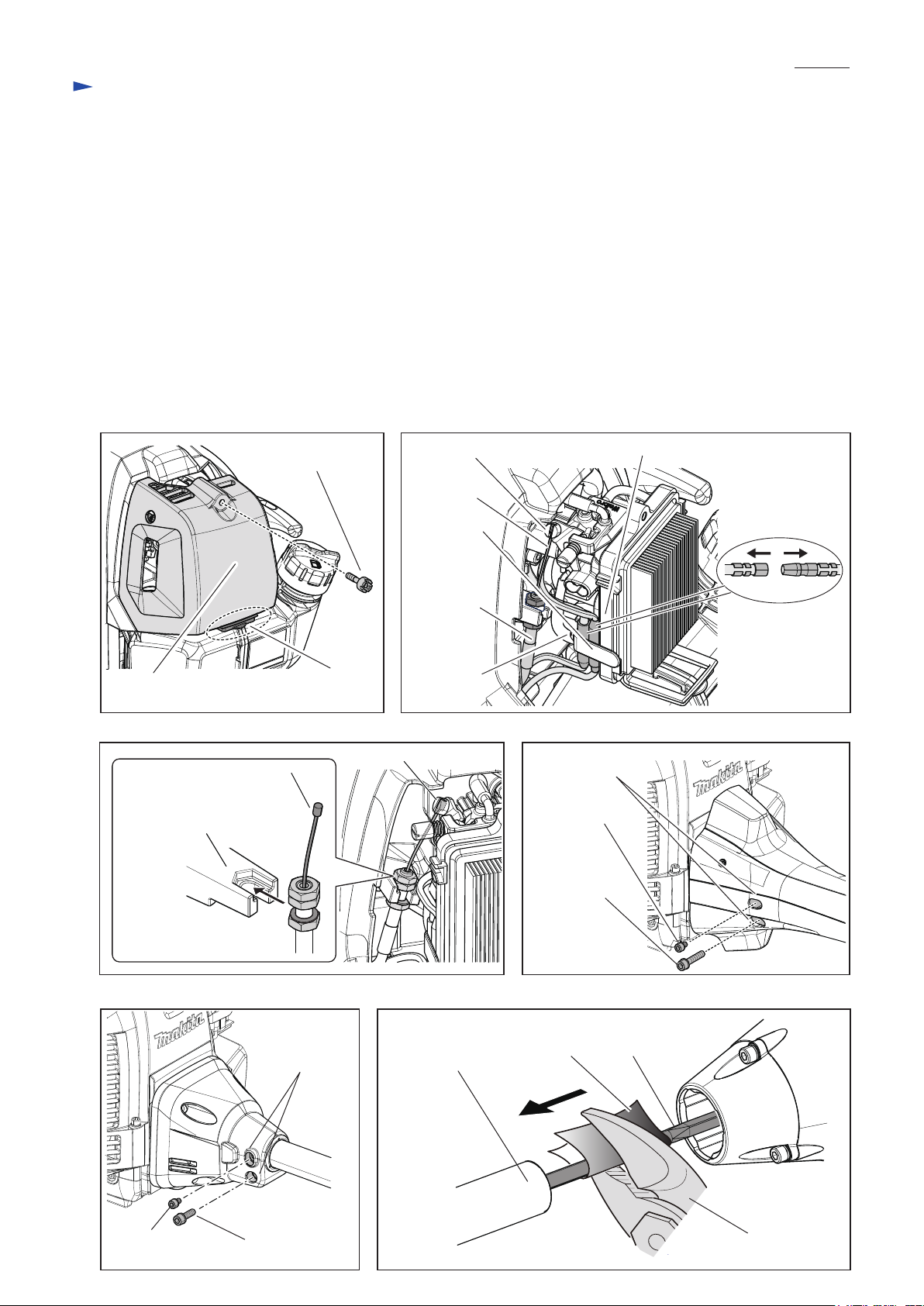

[4]-2. Engine and Shaft (cont.)

ASSEMBLING

Assemble by reversing the disassembly procedure.

(1) Put Cable bracket between Flat washer 6 and middle Nut, and tighten them by turning lower nut, upper nut and

the middle nut. (Fig. 7)

(2) Put Stopper on Inner cable end into Swivel, then adjust the above nuts so that 3mm to 4mm of play is left inside of

Swivel under condition that Throttle lever is not pulled. (Fig. 7)

Note: Adjust the tension of Inner cable to prevent the stopper from being removed . (Fig. 7)

Fig. 7

Stopper on Inner cable end

Cable bracket of Insulator

complete

Nut (upper)

Nut (middle)

Flat washer 6

Nut (lower)

Play: 3mm to 4mm

Swivel

[4]-3. Shaft pipe complete

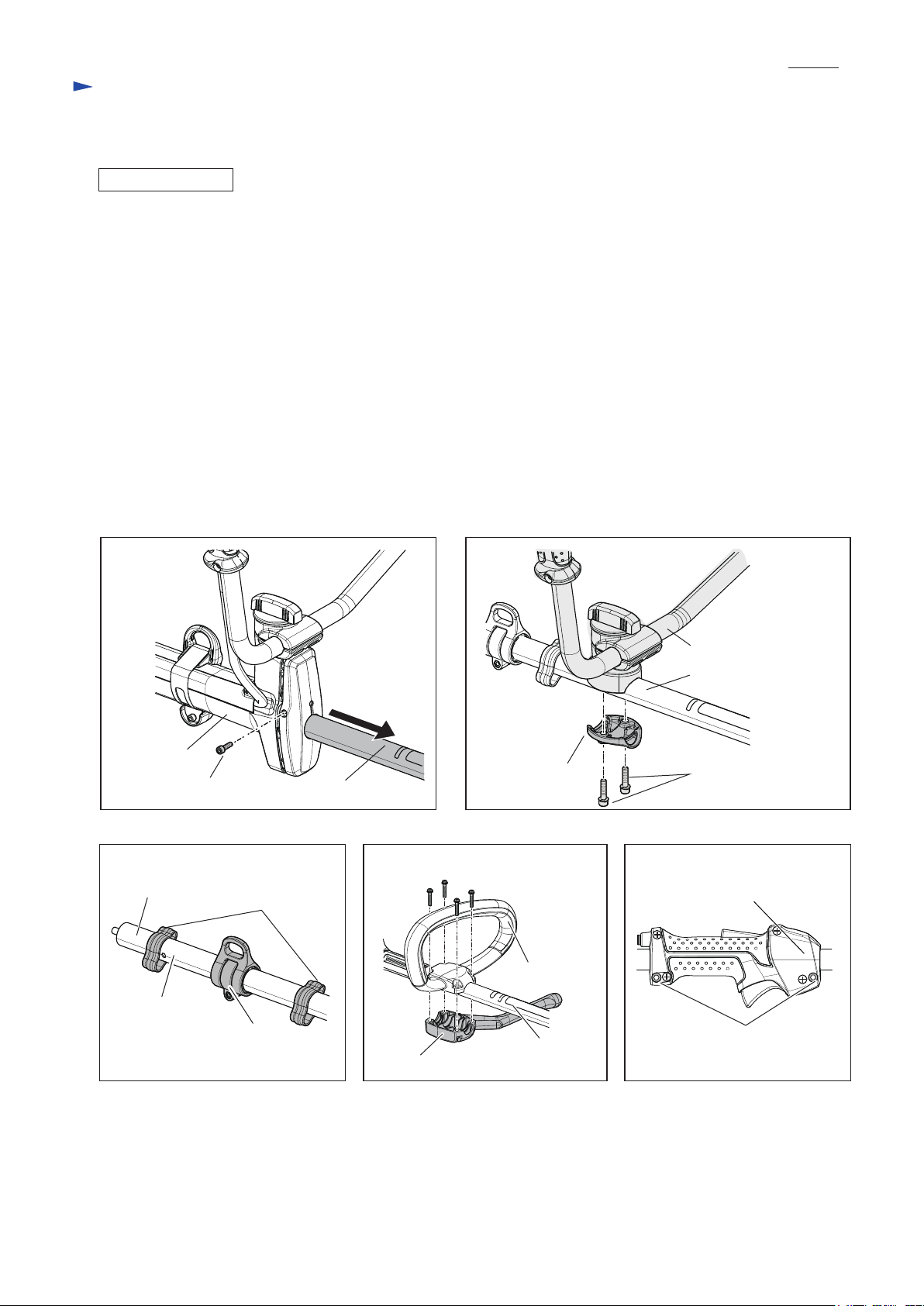

DISASSEMBLING

(1) Loosen two M6x30 Hex. socket head bolt (2pcs.) and remove Protector with Protector extension attached. (Fig. 8)

(2) Enlarge the space between the side wall of Protector cover and M5x14 Hex socket head bolt, and remove Protector cover

from Shaft pipe complete. (Fig. 9)

(3) Remove two M5x14 Hex socket head bolts then remove Protector clamp.

(4) Loosen M6x30 Hex socket head bolt then remove Gear case assembly. (Fig. 10)

Fig. 8

M6x30 Hex. socket

head bolt (2 pcs.)

Fig. 9

M5x14 Hex socket head bolt (2 pcs.)

Shaft pipe

complete

Protector

Protector extension

Fig. 10

M6x30 Hex

socket head bolt

Protector clamp

The side wall of

Protector cover

Gear case assembly

M5x14 Hex socket

head bolt (2 pcs.)

Gear case

assembly

Page 5

P 5/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-3. Shaft pipe complete (cont.)

DISASSEMBLING

For 4351UH:

(5A) Loosen M5x18 Hex socket head bolt and remove Shaft pipe complete from Pipe housing. (Fig. 11)

(6A) Pull out Shaft from Shaft pipe complete.

For 4350UH:

(5B) Remove two M6x25 Hex socket head bolts and Pipe clamp, then separate Bike handle section from Shaft pipe

complete. (Fig. 12)

(6B) Remove the following parts from Shaft pipe complete.

• Wire clamp (2 pcs.) • Hanger set • Shaft (Fig. 13)

For 4350LH:

(5C) Remove four M5x30 Hex socket head screws, then remove Handle clamp 28 and then remove Loop handle 28.

(Fig. 14)

(6C) Loosen two M5x14 Hex socket head bolts, then separate Lever case set from Pipe shaft complete. (Fig. 15)

(7C) Remove the following parts from Pipe shaft complete.

• Hanger set • Spacer • Shaft

Fig. 11

Pipe housing

M5x18 Hex socket head bolt

Fig. 13 Fig. 14 Fig. 15

Shaft

Wire clamp (2 pcs.)

Shaft pipe

Fig. 12

Pipe clamp

M5x30 Hex socket

head screw (4 pcs.)

Loop handle 28

Bike handle section

Shaft pipe complete

M6x25 Hex

socket head bolt

Control lever assembly

Shaft pipe

complete

Hanger set

Handle clamp 28

Shaft pipe

complete

M5x14 Hex socket

head bolt (2 pcs.)

Page 6

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-3. Shaft pipe complete (cont.)

ASSEMBLING

For 4351UH:

(1A) Insert Buffer rubber into Pipe housing so as to align the two grooves

with the two ribs (Fig. 16) Set the four Buffer rubbers in place of

Pipe housing. (Fig. 17)

(2A) Insert two projections of Clutch case into Buffer rubbers.

Insert two projections of Housing holder into the other Buffer rubbers,

then tighten M5x18 Hex socket head bolt while holding Housing

holder by hand. (Fig. 17)

Note: Make sure that Corrugate tube is put in the groove of Pipe housing.

(Fig. 18)

(3A) Assemble by reversing the disassembly procedure.

For 4350UH and 4350LH:

Assemble by reversing the disassembly procedure.

Fig. 17

P 6/ 22

Fig. 16

Ribs of Pipe housing

Grooves of

Buffer rubber

Projections of Clutch case

Fig. 18

Pipe housing

Buffer rubber (4 pcs.) Housing holder

Groove of Pipe housing

Corrugate tube

Page 7

P 7/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

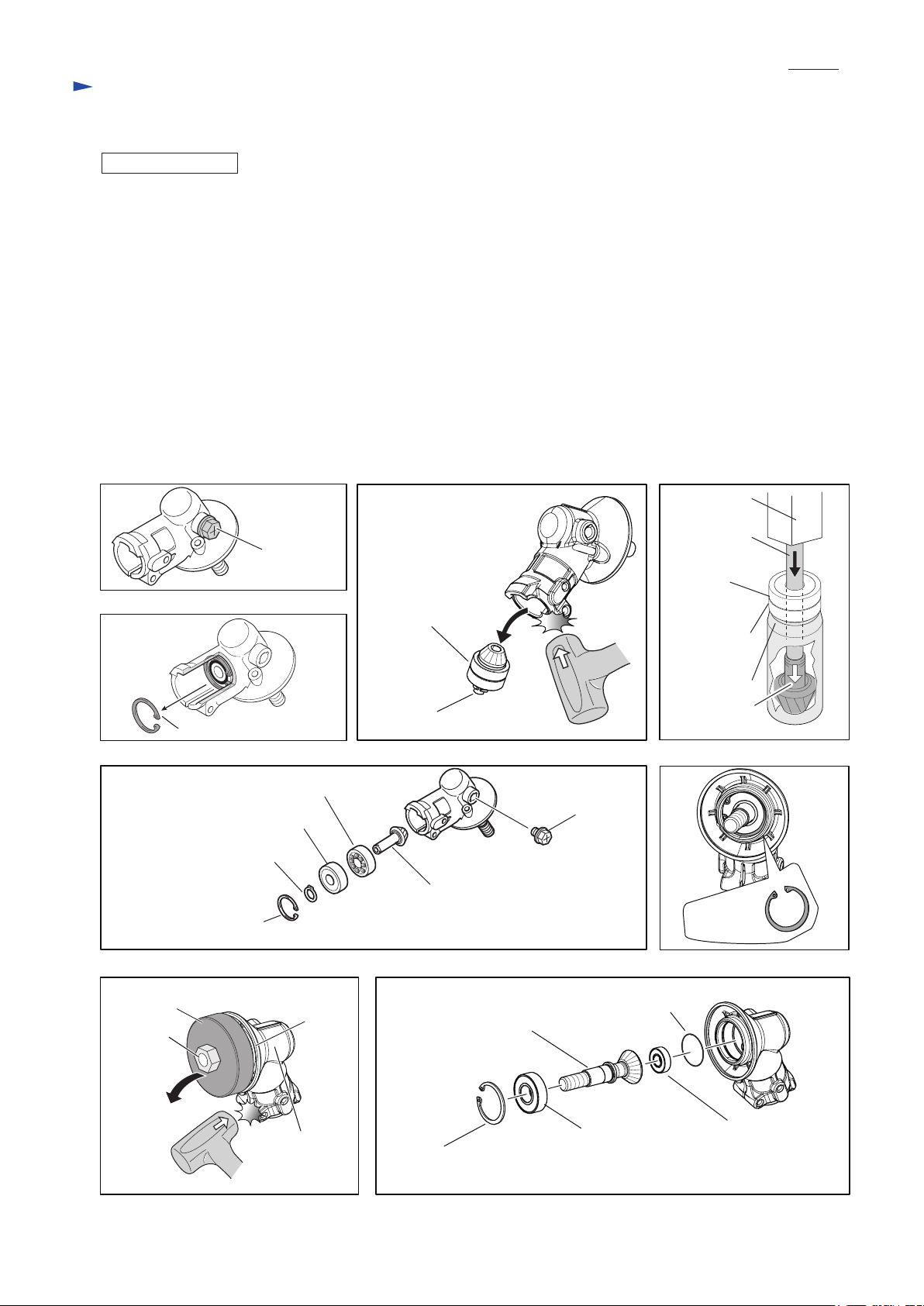

[4]-4. Gear case assembly

DISASSEMBLING

(1) According to the clause of [4]-3, Remove Gear case assembly. (Refer to Figs. 8, 9 and 10)

(2) Remove M8x10 + Hex bolt from the grease inlet of Gear case assembly. (Fig. 19)

(3) Remove Retaining ring R-26 with 1R006. (Fig. 20)

(4) Remove an assembled part of Spiral bevel gear 13*, Ball bearing 6000ZZ, Ball bearing 6000 and Retaining ring S-10

by tapping Gear case assembly with Plastic hammer. (Fig. 21)

Note: If the assembled part cannot be removed, use a heat gun or hair dryer to warm Gear case assembly.

(5) Remove Retaining ring S-10 with 1R291. (Fig. 21)

(6) Receive Ball bearing 6000 with 1R031, then press down the shaft end of Spiral bevel gear 13 using 1R282 with

Arbor press. (Fig. 22) Refer to Fig. 23 for the components.

(7) Remove Retaining ring R-32 with 1R291. (Fig. 24)

(8) Preset Receive washer and 1R033 with M10-17 Hex nut to Cutter shaft complete* as drawn in Fig. 25, and give

the impacts using the plastic hammer. An assembled part of Cutter shaft complete* and Ball bearing 6201LLU is

removed. Refer to Fig. 26 for the components.

(9) Remove Ball bearing 6201LLU with 1R045.

*Neither Spiral bevel gear 13 or Cutter shaft set is supplied individually. It is supplied as a set “Cutter shaft set”.

Fig. 19

Fig. 21 Fig. 22

Arbor press

M8x10

+ Hex bolt

Fig. 20

Retaining ring R-26

Fig. 23

Ball bearing 6000

Ball bearing 6000ZZ

Retaining ring S-10

Retaining ring R-26

It was removed by the previous step (3).

Fig. 25 Fig. 26

Assembled part

Retaining ring S-10

1R282

Ball bearing

6000ZZ

Ball bearing

6000

1R031

Spiral bevel

gear 13*

Fig. 24

M8x10

+ Hex bolt

Spiral bevel gear 13*

Retaining

ring R-32

M10-17

Hex nut

1R033

Receive

washer

Gear case

assembly

Cutter shaft complete*

Ball bearing 6201LLU

Retaining ring R-32

It was removed by the previous step (7).

O ring 32

Ball bearing 629ZZ

Page 8

Repair

P 8/ 22

[4] DISASSEMBLY/ASSEMBLY

Fig. 27

[4]-4. Gear case assembly (cont.)

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note:

• Make sure that O ring 32 is put into the inner groove of

Gear case assembly in advance.

• When mounting Cutter shaft complete into Gear case

assembly, press-fit them together using arbor press and

1R028 as shown in Fig. 27.

The components of

Cutter shaft complete

Gear case assembly

1R028

Ball bearing

6000DDU

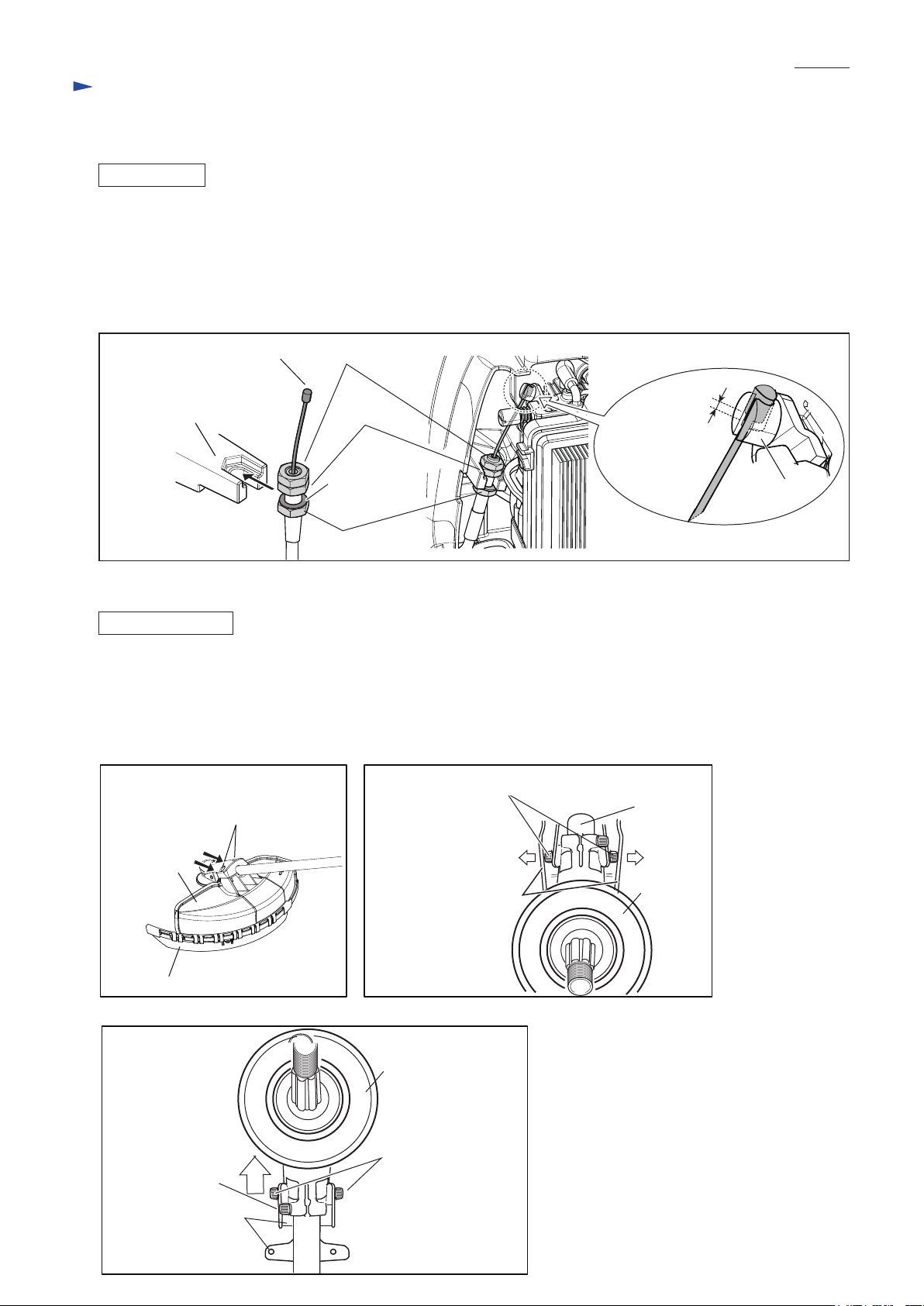

[4]-5. Clutch shoe

DISASSEMBLING

Warning: Remove Spark plug cap from Spark plug to prevent accidental engine starting.

Note: Clutch can be easily removed with a cordless impact driver without locking Piston, because it is locked in a position

due to the compressed air resistance in Cylinder.

Therefore, do not remove Spark plug, or the air in Cylinder cannot be compressed.

(1) Remove two Clutch shoes and Tension springs 5 by loosening each M8 Shoulder hex bolt counterclockwise. (Fig. 28)

(2) Remove Clutch base by turning the hex portion counterclockwise. (Fig. 29)

Fig. 28 Fig. 29

Clutch shoe (2 pcs.)

Hex portion of

Clutch base

M8 Shoulder hex bolt

(2 pcs.)

Tension spring 5 (2 pcs.)

ASSEMBLING

(1) Set Clutch base in place by turning the hex portion clockwise.

(2) Set two Clutch shoes and Tension springs 5 in place by tightening each M8 Shoulder hex bolt clockwise; first by hand,

then with a cordless impact driver*

*This is because the M8 Shoulder hex bolt is a shoulder bolt. Therefore, tighten by hand until the shoulder of the shaft portion contacts the upper end

surface of Clutch shoe, then tighten fully with a cordless impact driver. (Fig. 30)

Note:

• Face the arrow marks on Clutch shoes toward the upper side. (Fig. 31)

• Put Clutch shoe between Wave washer 10 and Flat washer 8, then tighten M8 Shoulder hex bolt.

Refer to Figs. 30 and 31.

Fig. 30 Fig. 31

M8 Shoulder hex bolt

Wave washer 10

shaft portion

shoulder

Clutch shoe

Flat washer 8

Clutch base

Clutch base

Flat washer 8

(2 pcs.)

Wave washer 10 (2 pcs.)

M8 Shoulder hex bolt (2 pcs.)

Arrow marks on

Clutch shoes

(2 pcs.)

Page 9

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-6. Clutch drum

DISASSEMBLING

For 4351UH: Refer to Parts breakdown in Fig. 35.

(1A) Remove four M6x20 Hex socket head bolts, then separate Clutch case from Engine. (Fig. 33)

(2A) Remove Retaining ring (INT) R-42 in Clutch case with 1R006. (Fig. 33)

(3A) Put 1R247 on Clutch drum in Clutch case, press down Clutch drum using Arbor press. (Fig. 34)

Note: If it is difficult to remove Clutch drum from Clutch case, warm Clutch case with a heat gun.

(4A) Remove Retaining ring (EXT) WR-20 from Clutch drum with 1R004.

(5A) Remove Ball bearing 6004LLU from Clutch drum with 1R045.

Fig. 35Fig. 34Fig. 32

Engine

Clutch case

M6x20 Hex

socket head screw

(4 pcs.)

Fig. 33

Arbor

press

1R247

Clutch

case

P 9/ 22

Clutch case

Retaining ring

(EXT) WR-20

Inside view of

Clutch case

For 4350UH and 4350LH: Refer to Parts breakdown in Fig. 39.

(1B) Remove four M6x20 Hex socket head bolts, then separate Clutch case from Engine. (Fig. 36)

(2B) Remove three M5x20 Hex socket head bolts, then separate Pipe retainer from Clutch case. (Fig. 36)

(3B) Remove Retaining ring R-35 in Clutch case with 1R006. (Fig. 37)

(3B) Put 1R247 on Clutch drum in Clutch case, press down Clutch drum using Arbor press. (Fig. 38)

Note: If it is difficult to remove Clutch drum from Clutch case, warm Clutch case with a heat gun.

(4B) Remove Retaining ring S-17 from Clutch drum with 1R004.

(5B) Remove Ball bearing 6003LLU from Clutch drum with 1R045.

M6x20 Hex socket head

screw (4 pcs.)

M5x20 Hex

socket head

screw (3 pcs.)

Clutch drum

Holes for

access to

Retaining ring

(INT) WR-42

Clutch case

Clutch drum

Arbor

press

1R247

Ball bearing

6004LLU

Retaining ring

(INT) WR-42

Clutch drum

Fig. 39Fig. 38Fig. 36

Clutch

case

Clutch case

Fig. 37

Inside view of

Clutch case

Holes for

access to

Retaining ring R-35

Pipe retainer Clutch case

Clutch drum

Clutch case

Spacer

Retaining ring

S-17

Ball bearing

6003LLU

Clutch drum

Retaining ring

R-35

Clutch drum

Page 10

P 10/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-6. Clutch drum (cont.)

ASSEMBLING

For 4351UH:

(1) Press-fit Ball bearing 6004LLU to Clutch drum with 1R031 in Fig. 40.

Note: Put Retaining ring (INT) R-42 between Ball bearing 6004LLU and Clutch drum in advance.

(2) Set Retaining ring (EXT) WR-20 in the groove on Clutch drum.

(3) Put Clutch case on the table of Arbor press horizontally without tilt, and press-fit Clutch drum into Clutch case with

1R286. (Fig. 41)

(4) Set Retaining ring (INT) R-42 to the inner groove of Clutch case.

(5) Assemble by reversing the disassembly procedure.

Fig. 40

Arbor press

Clutch drum

Fig. 41

1R286

Retaining ring (INT)

R-42

Ball bearing 6004LLU

1R031

For 4350LH and 4350UH:

(1) Press-fit Ball bearing 6003LLU to Clutch drum with 1R031 in Fig. 42.

Note: Put Retaining ring R-35 between Ball bearing 6003LLU and Clutch drum in advance.

(2) Set Retaining ring S-17 in the groove on Clutch drum.

(3) Put Clutch case on the table of Arbor press horizontally without tilt, and press-fit Spacer and Clutch drum into

Clutch case with 1R286. (Fig. 43)

(4) Set Retaining ring R-35 to the inner groove of Clutch case.

(5) Assemble by reversing the disassembly procedure.

Arbor press

Clutch drum

Clutch case

Fig. 43Fig. 42

1R286

Retaining ring R-35

Ball bearing 6003LLU

1R031

Clutch case

Spacer

(Refer to Fig. 39 of

the previous page.)

Page 11

P 11/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-7. Ignition system

CHECKING PLUG CAP

(1) Remove Plug cap from Spark plug, then check the continuity between Plug cap spring and the ground (earth) terminal

of Ignition coil with a circuit tester. If there is normal continuity, the resistance value will be 2.0kΩ±0.5kΩ. (Fig. 44)

(2) If there is no or intermittent continuity, check the continuity between Ignition cable and Plug cap spring by following

the procedure described below.

1. Apply spray lubricant in Plug cap, then pull out Plug cap spring together with Ignition cable from Plug cap using

small pliers. (Fig. 45)

2. Check if Plug cap spring is properly connected to Ignition cable. If not, connect them properly.

Also check Plug cap for any crack. If Plug cap is cracked, replace it with a new one.

3. Insert Plug cap spring in the center of Ignition cable. Then using small pliers, put them back into Plug cap while

taking care not to disconnect Plug cap spring from Ignition cable.

4. Make sure that Plug cap spring is firmly connected to Ignition cable by doing the same as you did in step (1) with

a circuit tester.

Note: Poor continuity between Plug spring cap and Ignition cable will result in no or weak spark.

Fig. 44

Plug cap

Plug cap spring

Fig. 45

Small pliers

Plug cap spring

Ignition coil

Circuit tester

Primary wire of

Ignition coil

CHECKING SPARK PLUG

WARNING !!

• When a spark is produced, high-voltage current is delivered from Ignition coil to Spark plug.

It is, therefore, very dangerous to pull Recoil starter knob with your hand on Ignition cable.

Be sure to keep your hands off from Ignition cable when checking for spark.

• Fuel is extremely flammable and fuel vapors are explosive.

Therefore, clean up spilled fuel before starting to check for spark.

Also, be careful not to do the check near Carburetor.

(1) Remove Plug cap from Spark plug, then Spark plug from Cylinder with the supplied socket wrench.

Note: If the electrodes of Spark plug are wet, wipe them with a rag then dry them with an air blower.

(2) Using a wire brush, carefully clean up carbon deposits (if any) from the electrodes and the ceramic insulator

around the center electrode.

(3) Adjust the electrode gap to 0.7 to 0.8mm by carefully bending the side electrode.

Use Feeler gauge set (1R366) to check the gap width:

between the center electrode and the side electrode, insert 0.8mm leaf

of Feeler gauge set. (Fig. 45)

(4) Install another Spark plug into spark plug hole to prevent air/fuel

mixture from leaking outside of engine.

(5) Connect the removed Spark plug with Plug cap, then ground the threads

of Spark plug to a proper metal part of the engine.

(6) With Stop switch on, pull Recoil starter knob gently and check for spark.

Note: • It is hard to see the spark in a bright location. Therefore, be sure to

do the check in a shady but well-ventilated place.

• Sparks do not happen at without exceeding 500 rpm.

(7) If spark is not produced, replace Spark plug with a new one,

then check for spark by following the procedure (1) to (6) once again.

Fig. 46

side electrode

Electrode gap

must be

0.7 to 0.8mm.

center electrode

Page 12

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-7. Ignition system (cont.)

REMOVING IGNITION COIL

(1) Before removing Ignition coil, separate Cylinder cover

from Engine, and pull out Primary wire from Ignition coil

in advance. (Fig. 47)

(2) Remove two M4x20 Hex socket head bolts and Ignition coil

from Engine. (Fig. 47)

Note: Be careful to the torque to loosen the bolts because

adhesive is applied on the threads under our quality

control.

Once removing their bolts, do not fail to apply adhesive

to the threads.

Fig. 47

Female terminal of

Primary wire

P 12/ 22

M4x20 Hex socket

head bolt (2 pcs.)

Ignition coil

Spacer (2 pcs.)

MOUNTING IGNITION COIL

(1) Insert 0.3mm leaf of 1R366 between Ignition coil and

the magnet of Flywheel. (Fig. 48)

Ignition coil will be attracted to the magnet through 1R366.

Then, without removing 1R366, fasten Ignition coil to

Engine with two M4x20 Socket head bolts. (Fig. 47)

(2) Remove 1R366. Then make sure that Flywheel does not

touch Ignition coil by turning it by hand.

Fig. 48

[4]-8. Flywheel

Warning: Remove Spark plug cap from Spark plug to prevent accidental

engine starting.

Note: Flywheel can be easily removed with a cordless impact driver without

using any locking tool, because Piston is locked in a position due to

the compressed air resistance in Cylinder.

Therefore, do not remove Spark plug, or the air in Cylinder cannot be

compressed.

DISASSEMBLING

(1) Turn M8 Collared Hex nut in the center of Flywheel counterclockwise

using a cordless impact driver. (Fig. 49)

(2) Mount 1R364 on Flywheel, then screw two M5 bolts of 1R364 into

Flywheel as drawn in Fig. 50.

Flywheel can now be removed from Crankshaft complete by turning

the center bolt of 1R364 clockwise using a screwdriver or the like.

Important: Screw two M5 bolts evenly.

Ignition coil

0.3mm thick leaf

of 1R366

Flywheel

Fig. 49

M8 Collared

Hex nut

Fig. 50

ASSEMBLING

(1) Wipe off grease and oil from Crankshaft complete.

(2) Aligning the key way of Crankshaft complete with Woodruff key 3 on

Flywheel, install Flywheel onto Crankshaft complete. (Fig. 51)

(3) Screw M8 Collared Hex nut to Crankshaft complete by turning it clockwise

by hand.

(4) Tighten M8 Collared Hex nut firmly using an impact driver.

1R364

M5 bolt

of 1R364

(2 pcs.)

Fig. 51

Keyway in

the hole of

Flywheel

Woodruff key 3 on

Crankshaft complete

Page 13

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-9. Recoil starter

DISASSEMBLING

(1) Remove Starter cover assembly by loosening

four M5x20 Hex socket head bolts. (Fig. 52)

(2) Pull Starter rope out of Starter cover assembly

approximately one winding long.

Then hook Starter rope on the U-shaped notch of

Reel, and then turn Reel clockwise until Spiral

spring is unwound. (Fig. 53)

Note: Be careful with Reel because it will turn very

fast.

(3) Remove Reel from Starter cover by loosening

5x10 Tapping screw.

Note: Be careful with Spiral spring that can suddenly

pop out of Starter cover.

(4) Unite the knot of Starter rope to remove the rope

from Reel.

ASSEMBLING

Fig. 52 Fig. 53

Starter cover assembly

M5x20 Hex socket

head bolt

(4 pcs.)

Reverse side of

Starter cover assembly

U-shaped

notch of Reel

P 13/ 22

Starter rope

(1) If Spiral spring has popped out of Reel, put it back in place; hook the outer end of Spiral spring onto the spring hook

of Reel first, then by winding Spiral spring counterclockwise towards the center of Reel. (Fig. 54)

(2) Apply a little amount of Makita grease N No.2 to the whole surface of Spiral spring.

(3) Put a new Starter rope through Starter cover.

Then tie one end to Starter knob and the other to Reel by making

a knot. (Fig. 55)

(4) Make sure that the inner end of Spiral spring is positioned close to

the shaft portion of Starter cover for the step (6). Then put Reel in

Starter cover.

(5) Wind Starter rope around Reel two or three times.

(6) While turning Reel counterclockwise, mount it in Starter cover.

The inner end of Spiral spring will be engaged with the spring hook

of Shaft portion in Starter cover by the counterclockwise rotation of

Reel. (Figs. 54 and 55)

Note: You do not need force to mount Reel in place.

(7) Fasten Reel to the shaft portion of Starter cover with

M6x20 Set screw. (Fig. 56)

Note: Reel is not properly set in place if the rotation of

Reel is slow after the screw is fastened.

In this case, repeat steps (5) and (6) until normal

rotation of Reel is obtained.

(7) Hook Starter rope on the U-shaped notch of Reel.

Then, while pulling Starter rope, turn Reel counter clockwise. (Fig. 57)

Release Starter rope from the U-shaped notch and

Starter rope will be wound around Reel due to the

rotational force of Spiral spring. Repeat this operation

until the slack is completely removed from Starter rope.

Fig. 56 Fig. 57

Reel

M6x20 Set screw

Fig. 55

Spring hook of Shaft portion

in Starter cover

Starter rope

Fig. 54

Reel viewed from Starter cover side

Reel

Inner end of

Spiral spring

Outer end of

Spiral spring

Spring hook

of Reel

Starter rope

about

10mm

about

10mm

Starter cover

Starter rope

U-shaped notch of Reel

Page 14

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-10. Carburetor section

P 14/ 22

DISASSEMBLING

(1) Press down the tab of Cleaner plate assembly gently and separate

Air cleaner cover from Cleaner plate assembly by loosening

M5x20 Hex socket button head screw. (Fig. 1 of [4]-2.)

(2) Remove Air cleaner element. (Fig. 58)

(3) Remove two M5x60 Hex socket head bolts that fasten

Carburetor assembly and Cleaner plate assembly to Insulator

complete. (Fig. 59)

Note: Remove the bolts completely, or Carburetor cannot be

removed from Insulator complete.

(4) Remove three tubes from Carburetor assembly, then separate

Carburetor assembly from Engine.

DISASSEMBLING/ CLEANING CARBURETOR

(1) Remove four Pan head screws, then separate Metering cover, Metering diaphragm and Metering diaphragm gasket

from Carburetor. (Fig. 60)

Note: If Metering diaphragm gasket is sticking on the adjacent part, remove it with care because it is easily broken.

(2) Check Metering diaphragm for shrinkage, hardening or breakage due to aged deterioration. If any, replace it with

a new one.

(3) The inner parts of Pump body assembly can be removed by separating the pan head screw designated in Fig. 61.

(4) Before mounting the inner parts of Pump body assembly in place, make sure that the tip of Inlet needle is neither

worn nor deformed. (Fig. 62)

Note: The inner parts are not available individually. If you need any of the inner parts, order Pump body assembly.

(5) When mounting Control lever, make sure that the upper end of Spring is firmly held in place under the projection of

Control lever. (Fig. 63)

(6) Remove the pan head screw of Pump cover. (Fig. 64)

(7) Make sure that Inlet screen is not clogged, then set it back in place. (Fig. 65)

(8) Spray Carburetor cleaner in all the fuel lines of Carburetor, then after several minutes, wash out dirt and debris with

clean gasoline.

Fig. 60 Fig. 61

Fig. 58 Fig. 59

Air cleaner element M5x60 Hex socket

head bolt (2 pcs.)

Pan head screw (4 pcs.)

Carburetor

Fig. 62

with good tip with worn tip

An Inlet needle with

worn tip can cause

a pressure leak.

Fig. 64

Pan head screwPump cover

Inner parts of Pump body assembly

Pan head screw Pin

Inlet needle

Control lever

Fig. 63

Correct assembling

of the inner parts of

Pump body assembly

Metering diaphragm

Control lever

Spring

Inlet needle

Fig. 65

Inlet screen

Spring

Pump body assembly

Wrong examples

Debris in valve seat can

cause a pressure leak.

Control lever is not parallel

to Pump body assembly.

The upper end of Spring

is out of place.

Carburetor body

Page 15

P 15/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-10. Carburetor section (cont.)

ASSEMBLING CARBURETOR

Assemble by reversing the disassembly procedure.

Note: Make sure that the assembling direction of each part is correct.

VACUUM LEAK TEST OF CARBURETOR

Connect 1R127 with the fuel inlet of Carburetor, then increase the testing

pressure up to 0.05Mpa. The pressure will stay the same about 10 seconds

if there is no vacuum leak. (Fig. 66)

MOUNTING CARBURETOR

(1) Fasten the following parts to Cylinder block assembly with two M5x60 Pan head screws. (Fig. 67)

Carburetor gasket (2 pcs: small and large) , Carburetor, Cleaner plate assembly, Insulator complete

(2) Connect three Tubes to Carburetor as drawn in Fig. 68.

Then connect Tube 5-160 and Pipe to Cleaner plate assembly as drawn in Fig. 69.

(3) Mount Air cleaner element onto Cleaner plate assembly.

(4) Mount Air cleaner cover complete onto Air cleaner plate, then secure with M5x20 Hex socket head bolt. (Fig. 1 of [4]-2.)

Note: Be sure to fit the tab of Cleaner plate assembly into the slot of Cleaner cover assembly.

Fig. 67

Carburetor

Carburetor

gasket (small)

Carburetor gasket (large)

behind Carburetor

Fig. 68

Tube 3-120 (blue)

between Primer pump

and Carburetor

Tube 3-35 between Carburetor

and Insulator complete

Fig. 66

Carburetor

1R127

Tube 3-250 (black)*

between Carburetor

and Fuel tank

*The component of

Tube complete

Cleaner plate

assembly

M5x70 Pan head

screw (2 pcs.)

Fig. 69

Tube 5-160 and Pipe are connected as follows:

Cylinder

block

assembly

Rocker cover outer

Carburetor

gasket (large)

Carburetor

gasket (small)

Primer pump

Fuel tank

CarburetorInsulator complete

Clamp on Insulator completeClamp on

Tube 5-160 (black) for Rocker cover outer

and Cleaner plate assembly

(Corrugate tube)

(Spiral tube 6-100 to

protect Tube 3-120)

Cleaner plate assembly

Tube 5-160

(black)

Cleaner plate

assembly

Pipe

Pipe for Cleaner plate assembly and the nipple of Cylinder block assembly

Page 16

Repair

[4] DISASSEMBLY/ ASSEMBLY

[4]-11.

Stop switch section

P 16/ 22

CHECKING STOP SWITCH

Check the continuity between the bullet terminals on the two lead wires

extending from Control lever with a circuit tester. (Fig. 70)

If Stop switch functions properly, there will be no continuity with

the switch ON and there will be continuity with the switch OFF.

Fig. 70

[4]-12. Fuel tube section

FUEL TUBE ROUTING

Set Tube complete* in place as shown in Fig. 71.

• Connect Tube 3-260 to Carburetor and Gasoline filter with Hose clamp.

• Connect Tube 3-150 to the long pipe of Primer pump.

• Connect Tube 3-120 to the short pipe of Primer pump.

Also refer to Fig. 72.

(3) Put Coil spring 8 and Clamp on Tube 3-150. (Fig. 71)

(4) Route Tube 3-150 as drawn in Fig. 72.

Route Tube 3-120 between Tube 3-150 and Cleaner plate assembly. (Fig. 73)

Fig. 71

Holders of

Cleaner plate assembly

Tube 3-260 (black)

Breather (to intake air into Tank)

Gasoline filter

(to Carburetor)

Hose clamp

Tube 3-260

(black)

Tube complete

Breather

long pipe of

Primer pump

Clamp

Coil

spring 8

Tube 3-150 (blue)

Fuel tank

Fig. 72 Fig. 73

Nipple of Carburetor

Tube 3-120

(blue)

Spiral tube

6-100

(to intake air into Tank)

Tube 3-260

(black)

Tube 3-150

(blue)

Fuel tank

Tube

3-150

(blue)

Tube 3-120

(blue)

Grommet

short pipe of Primer pump

to connect Tube 3-120

(Refer to Figs. 68 and 69.)

Tube 3-150 (blue)

Spiral tube 6-80

Pipe

Breather

Page 17

P 17/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-13. Engine block

DISASSEMBLING

(1) It is highly recommended to drain the oil system of Engine block before starting disassembling

because the oil remaining there will drip out to delay your operation.

(2) From the engine section, remove the following parts):

Ignition coil, Flywheel complete, Rocker cover inner, Rocker cover outer, Rocker arm assembly (2 pcs),

Rod 2.5 (2 pcs), Cam lifter (2 pcs), Cam gear assembly, Insulator complete, Cleaner plate assembly, Carburetor,

Spark plug, Exhaust muffler.

(3) Remove the assembly of Cylinder head and Cylinder block. (Fig. 74)

(4) Remove Clip (2 pcs. in total) from each end of Piston pin with a pointed tool such as an awl as shown in Fig. 75.

Note: • Be careful with Clip because it can pop out unexpectedly during removal operation.

• Do not use removed Clip. Be sure to replace it with new one.

(5) Remove Piston pin with 1R171 or the like as shown in Fig. 76.

(6) Remove Piston from Crankshaft complete, then separate Top ring, Second ring and Oil ring from Piston.

Note: Mark on one of Top or Second ring to distinguish the original position for reassembling.

Fig. 74

Cylinder head

Cylinder block

Crank case

Piston

Crank shaft

complete

Fig. 75

Fig. 76

Piston pin

Awl

Piston

Clip

1R171

Page 18

P 18/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-13. Engine block (cont.)

ASSEMBLING

(1) Connect Piston with Crank shaft complete by inserting Piston pin into place; there is no front/back to Piston.

Note: Be sure to apply a little amount of Makita grease N No.2 to Needle roller bearing.

(2) Secure Piston pin by mounting Clip onto each end of Piston pin. Any setting direction is allowed.

(3) Install Oil ring in the grooves of Piston; Side rail first, Spacer next, then the other Side rail.

Important: Be sure to fit the three rings with the ring gaps at 120 degrees to one another as shown in the left of Fig. 77.

(4) Install Second ring first then Top ring in the groove of Piston.

Important 1: Be sure to fit the two rings with the ring gaps at 180 degrees to each other as shown in the right of Fig. 77.

Important 2: Second ring has a taper face and must be installed with the large diameter facing Oil ring. (Fig. 78)

Distinguishing between Top ring and Second ring & Discriminating the larger diameter of Second ring:

If both of the two rings are new and unused,

• You can distinguish from their appearances; there is a T marking on the right upper end of Second ring as shown in

Fig. 75 while not on the upper end of Top ring.

• You can face the large diameter of Second ring by placing Second ring with the T marking on your right and

with the ring gap near you as shown in Fig. 79.

If both of the two rings are used and the T marking of Second ring is rubbed off, carefully press the side face of

the two rings to the inner wall surface of Cylinder. You will be able to distinguish the two rings or to discriminate

the large diameter of Second ring through the differences in contact feelings that the different side faces make.

Fig. 77

Oil ring

ring gap

Side rail

Spacer

Side rail

ring gap

ring gap

Fig. 78 Fig. 79

Second ring

Top ring, with barrel face

Second ring, with taper face

Side rail

Spacer Oil ring

Side rail

ring gap

Top ring

Second ring

ring gap

Note: Makita genuine second ring

has T marking on the right

upper end if it is not worn out.

Face the T marking toward

upward for assembly.

T

T marking

(5) Apply 4-cycle engine oil to the following portions:

Oil ring, Needle roller bearing that holds Piston pin,

Needle roller bearing of Crank shaft complete.

(6) Remove oil/grease from the mating surface of

Cylinder block and Crank case.

Then apply ThreeBond 1215/ 1216 carefully to

the mating surface of Crank case as shown in Fig. 80.

Note: Do not apply the adhesive to the area

designated by the enlarged view.

Apply 4-cycle engine oil to the sliding surface of

Piston section and Cylinder block assembly, and then

while compressing Piston rings, mount Cylinder block

onto Crank case.

(7) Tighten eight M6x25 Hex socket head bolts in

a crisscross pattern.

Fig. 80

Crank case viewed

from the upper side

Gray colored portions:

where the adhesive should

be applied

Do not apply the adhesive

to the designated area.

Page 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-13. Engine block (cont.)

DISASSEMBLING

(8) Adjust Valve clearance as follows:

1. Align the marks on the following parts:

• Ignition coil and Flywheel complete (Fig. 81)

• Cam gear assembly and Cylinder block (Fig. 82)

2. Set two Cam lifters and two Rods 2.5 in place, then assemble two Rocker arm

assemblies to them.

Note: The ends of two Rods 2.5 have to be fit into the holes on Rocker arm assemblies

and Cam lifters. (Fig. 83)

3. Assemble Cam gear cover gasket and Cam gear cover to Cylinder block assembly by

tightening four M5x16 Hex socket head bolts firmly.

4. Revolve Flywheel assembly two turns clockwise (Fig. 84) and align the marks on

Flywheel complete and Ignition coil to move Piston to the upper dead point. (Fig. 81)

Fig. 81

Fig. 82

P 19/ 22

Fig. 83

Hole on

Rocker arm

assembly

Rod 2.5

Mark on Ignition coil

Mark on Flywheel

5. Tighten Hex nuts of Rocker arm assemblies, then loosen Adjusting screws of Rocker arm assembly.

Insert 0.08mm thick leaf of 1R366 into the clearance between Rocker arm and Valve section (Re: Fig. 85), then

adjust the valve clearance.

6. After checking the feeler gauge can be passed through the clearance and the clearance itself is not more than

0.12mm, tighten Hex nuts of Rocker arm assembly securely, and then remove the gauge from the clearance.

Note: While making two Rocker arms close to the center (Fig. 86), adjust the valve clearance with Hex nuts pushing

down by hand slightly (Fig. 87) and check the valve clearance.

After setting Spark plug in place and turning Flywheel left and right to 45

checking

Fig. 84

of the valve clearance.

Fig. 85 Fig. 86

0.08 mm thick leaf

of 1R366

Mark on

Cam gear assembly

Mark on

Cylinder block

Hex bit

Hole on

Cam lifter

° two or tree times (Fig. 88), retry

Rocker arm (2 pcs.)

1R170

M5 Hex nut (2 pcs.)

Adjusting screw (2 pcs.)

Fig. 87 Fig. 88

Rocker arm

Valve section

Push down Hex nut of

Rocker arm

Rod 2.5

Refer to Fig. 81 for

the cross section.

Page 20

P 20/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-13. Engine block (cont.)

ASSEMBLING

Assemble by reversing the disassembly procedure.

[4]-14. Valve section

DISASSEMBLING

(1) Remove two Rocker arm assemblies and Pin 5 from Cylinder block assembly. (Fig. 89)

(2) Push a rag into Cylinder block assembly from the bottom side so as not to fall off Intake valve and Exhaust valve.

The rag works as protection of the inside of Cylinder block assembly.

(3) Remove Cotters, Retainers and Compression springs 11 from Intake valve and Exhaust valve with 1R389 and 1R005.

(Figs. 90 and 91)

Fig. 89

Fig. 91

Rocker arm assembly

(2 pcs.)

Pin 5

Fig. 90

Cotter

(4 pcs.)

1R389

1R005

Cotter (4 pcs.)

Retainer (2 pcs.)

Compression spring 11 (2 pcs.)

Exhaust

valve

Intake

valve

Page 21

P 21/ 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-14. Valve section (cont.)

ASSEMBLING

(1) Apply 0.05cc of 4-cycle engine oil to Exhaust valve and Intake valve as drawn in Fig. 92, then insert them into

the holes in Cylinder block assembly. (Fig. 93)

(2) Push a rag into Cylinder block assembly so as not to fall off Intake valve and Exhaust valve.

(3) Assemble Retainers, Cotters and Compression spring 11 to Cylinder block assembly as drawn in Figs. 91 and 90,

then while pushing Compression springs 11, pass the valve tops through the holes of Retainers, (Figs. 94 and 95)

Then assemble Retainers, cotters and valves each other.

Note: If it is difficult to assemble them, use 1R389 with 1R005.

(4) Set Pin 5 and two Rocker arm assemblies in place of Cylinder block assembly. (Fig. 89)

Fig. 92 Fig. 93

10mm up to

15mm

Cotters

Intake valve

10mm up to

15mm

4-cycle engine oil

Holes in Cylinder

block assembly

Fig. 95Fig. 94

Exhaust valve

Rag to prevent Valves from falling

Page 22

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-15. Tightening torque specifications

P 22/ 22

Application

(for fastening A and B)

Fastener

A B

Cylinder block Crank case M6x25 Hex socket head bolt (8 pcs.) 11.0

Crank case Retainer plate

Crank case Oil case

Flywheel Crank shaft

RatchetFlywheel

Ignition coil

Cam gear cover

Rocker arm adjusting screw M5 Hex nut

Rocker cover outer Cylinder block

Clutch shoe Clutch base

Muffler Cylinder block

Engine base

Spark plug

Insulator complete

Starter cover assembly M5x20 Hex socket head bolt (4 pcs.) 5.0

Cylinder block

Crank caseClutch base

Cylinder block, Crank case

Cylinder block

Cylinder block

M5x12 Hex socket button head bolt (2 pcs.) 4.0

M5x18 Hex socket head bolt 6.0

M5x18 Hex socket head bolt (4 pcs.) 6.0

M8 Collared hex nut 16.0

M4x20 Hex socket head bolt (2 pcs.) 4.0

M5x16 Hex socket head bolt

M5 Hex nut (2 pcs.)

M5x18 Hex socket head bolt (4 pcs.) 6.0

M8 Hex portion of Clutch base

M8 Shoulder hex bolt (2 pcs.) 10.0

M6x20 Hex socket head bolt

M6x20 Hex socket head bolt (4 pcs.)

Spark plug (M10-pitch 1.0)

M5x20 Hex socket head bolt (2 pcs.)

Tightening torque

(N.m)

6.0

6.0

16.0

11.0

11.0

12.0

6.0

Muffler plate

Cleaner cover assembly Cleaner plate assembly M5x20 Hex socket head bolt 0.5

Cylinder cover Engine base M5x20 Hex socket head bolt (4 pcs.) 2.5

Cylinder cover Starter cover assembly M5x20 Hex socket head bolt 2.5

Gear case assembly Shaft pipe complete

Control cable

Pipe bracket

EM4351UH

Housing holder Shaft pipe complete M5x18 Hex socket head bolt 5.0

EM4350UH

Pipe clamp Pipe holder M6x25Hex socket head bolt 6.0

EM4350LH

Control lever assembly Shaft pipe complete M5x14 Hex socket head bolt 2.5

Crank case

Insulator M6 Nut 1.5

Shaft pipe complete M5x18 Hex socket head bolt 5.0

Cleaner plate M6x30 Hex socket head bolt 9.0

M5x18 Hex socket head bolt (3 pcs.) 5.0

M5x18 Hex socket head bolt

M5x14 Hex socket head bolt (2 pcs.) 5.0

M6x30 Hex socket head bolt 13.0

5.0Oil pipe Oil case

4.0Cleaner plate assembly Insulator M5x60 Hex socket head bolt

Loading...

Loading...