Page 1

T

ECHNICAL INFORMATION

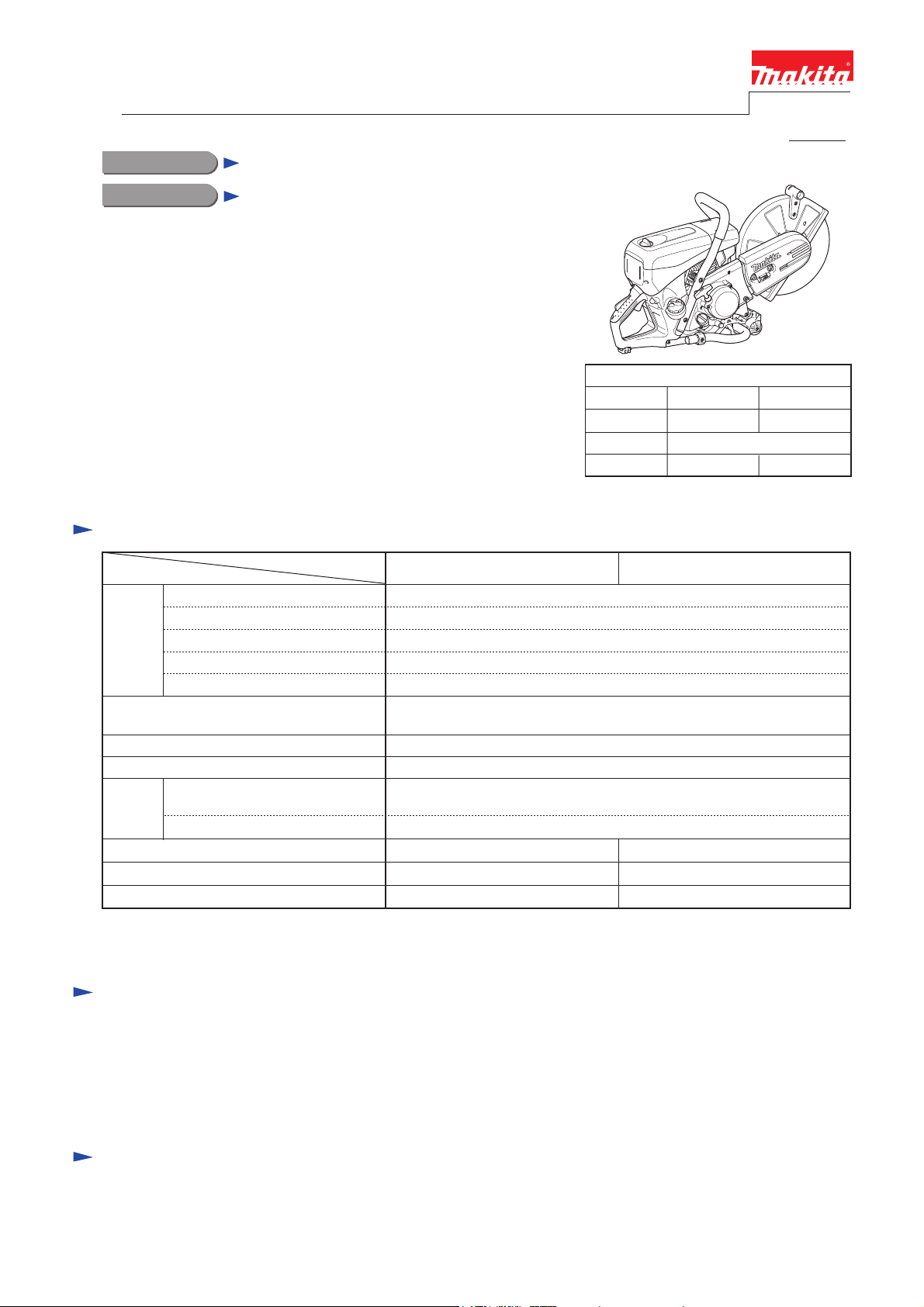

Models No. EK7650H, EK7651H

PRODUCT

P 1/ 19

Description

Power Cutters 305mm (12"), 355mm (14")

CONCEPT AND MAIN APPLICATIONS

Models EK7650H and EK7651H are the world’s first 4-stroke power cutters.

Their main features are:

• Low fuel consumption, low noise and clean exhaust emission achieved

by 4-stroke engine

• Easy start-up with Automatic decompression, Primer pump and

On/off choke combination switch with automatic half-throttle lock

• Low-vibration system with damper springs to absorb vibration from

engine to integrated front and rear handles.

Each wheel diameter is:

305mm (12") for model EK7650H

355mm (14") for model EK7651H

Specification

Specifications

Type

Displacement: cm³ (cu.in)

Engine

Engine oil

Fuel consumption: L/h (US oz/h)

Fuel tank capacity: L (US oz)

Starting

system

Wheel diameter:

Dry weight*2: kg (lbs)

*1 Some countries: E10 or E25 gasoline

*2 without cutting wheel

Fuel Straight unleaded gasoline*

Max. output: kW

Rapid start

(Spring-assisted recoil starter)

Decompression valve

mm (")

mm (")

EK7650H

in the class SF or higher of API Classification

305 (12)

97 (3-13/16)

Dimensions: mm (")

EK7650H

Length (L)

Width (W)

Height (H)

4-stroke

75.6 (4.6)

3.0 (at 7,500 min.

4.6 (at 5,500 min.

SAE10W-30 oil

1.7 (57.5)

1.1 (37.2)

No

Automatic (Mechanical)

435 (17-1/8) 455 (17-7/8)

ˉ¹)

ˉ¹)Max. torque: N.m

761 (30)

310 (12-1/4)

EK7651HModel

1

355 (14)

122 (4-13/16)Max. cutting depth:

12.9 (28.4)12.7 (28.0)

EK7651H

780 (30-3/4)

Standard equipment

Tool kit (Socket wrench 13-16, Hexalobular wrench, Slotted screwdriver and Tool bag)

Oil bottle (containing 220ml engine oil)

Water supply kit

Adapter ring (for some countries only)

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

Filter set

Trolley kit

Oil bottle set (10 bottles of 220ml engine oil)

Diamond wheel

Abrasive cut-off wheel

Page 2

P 2/ 19

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Warning:

• Wear gloves.

• Remove the cutting tool from the unit.

• When the engine is hot from use, cool down the engine enough or you can get burned.

• Remove remaining fuel from Fuel tank and Carburetor completely. [FLAMMABLE MATERIAL KEEP FIRE AWAY]

• Remove Spark plug cap from Spark plug.

• Repair the engine on a stable workbench and in a clean workplace kept as free of dust and debris as possible.

• In order to avoid wrong reassembly, draw or write down where and how the parts are assembled, and what are the parts.

It is also recommended to have boxes ready to keep disassembled parts by group.

• Handle the disassembled parts carefully. Clean and wash them properly.

• If some bolts and screws are too tight, use Impact driver.

• Tighten the bolts and the screws to the specified torque as shown in "[5] Tightening torque specifications".

• Each time after you mounted a main part of the engine such as the piston, check if it moves smoothly

without abnormal noise by manually turning the crankshaft.

• After completion of reassembly, check for loose parts or abnormal noise and vibration

by manually turning the crankshaft.

[1] NECESSARY REPAIRING TOOLS

1R291

1R372

Follow the instructions described below in advance before repairing:

DescriptionCode No. Use for

Retaining ring pliers ST-2N for External ring1R003

Retaining ring pliers RT-2N for Internal ring1R005 removing Cotter

Torque wrench shaft 20-90N·m1R223

Ratchet head 12.7 (for 1R223)1R224

Hexalobular bit VT-27 (6.35mm)1R290

Retaining ring S and R pliers removing/ installing Retaining ring R-40

Retaining ring pliers1R311 removing Tubes

Flywheel puller1R364 removing Flywheel

Feeler gauge set1R366

Crank shaft lock bolt M10

Cotter removal attachment1R389 removing Exhaust / Intake valve system

Socket/ Socket bit 17--- removing/ installing Clutch

Socket/ Socket bit 24--- removing/ installing Clutch

Wire brush--- cleaning Spark plug

Hex wrench 2.5--- assembling/ removing / adjusting M5 Hex socket head bolt

Wrench 8--- holding M5x9 Hex nut

removing Lock off lever

press-fitting Ball bearing 6203LLU into Cutting deviceBearing setting pipe 25-17.21R030

assembling Clutch complete to Crankshaft

removing/ assembling CotterScrewdriver magnetizer1R288

removing/ assembling Hexalobular bolt

removing Pin 5 from Rocker arm assemblySpring pin extractor 4.01R308

adjusting the gap between Ignition coil and Flywheel,

Rocker arm assembly and Valve section, Spark plug

holding the position of Piston/ preventing Crankshaft from

being rotated

[2] GASKET

Once Gasket is removed:

(1) Clean up the mating surface where the gasket was installed to maintain its sealing performance.

(2) Replace it with a new one.

Page 3

P 3/ 19

Repair

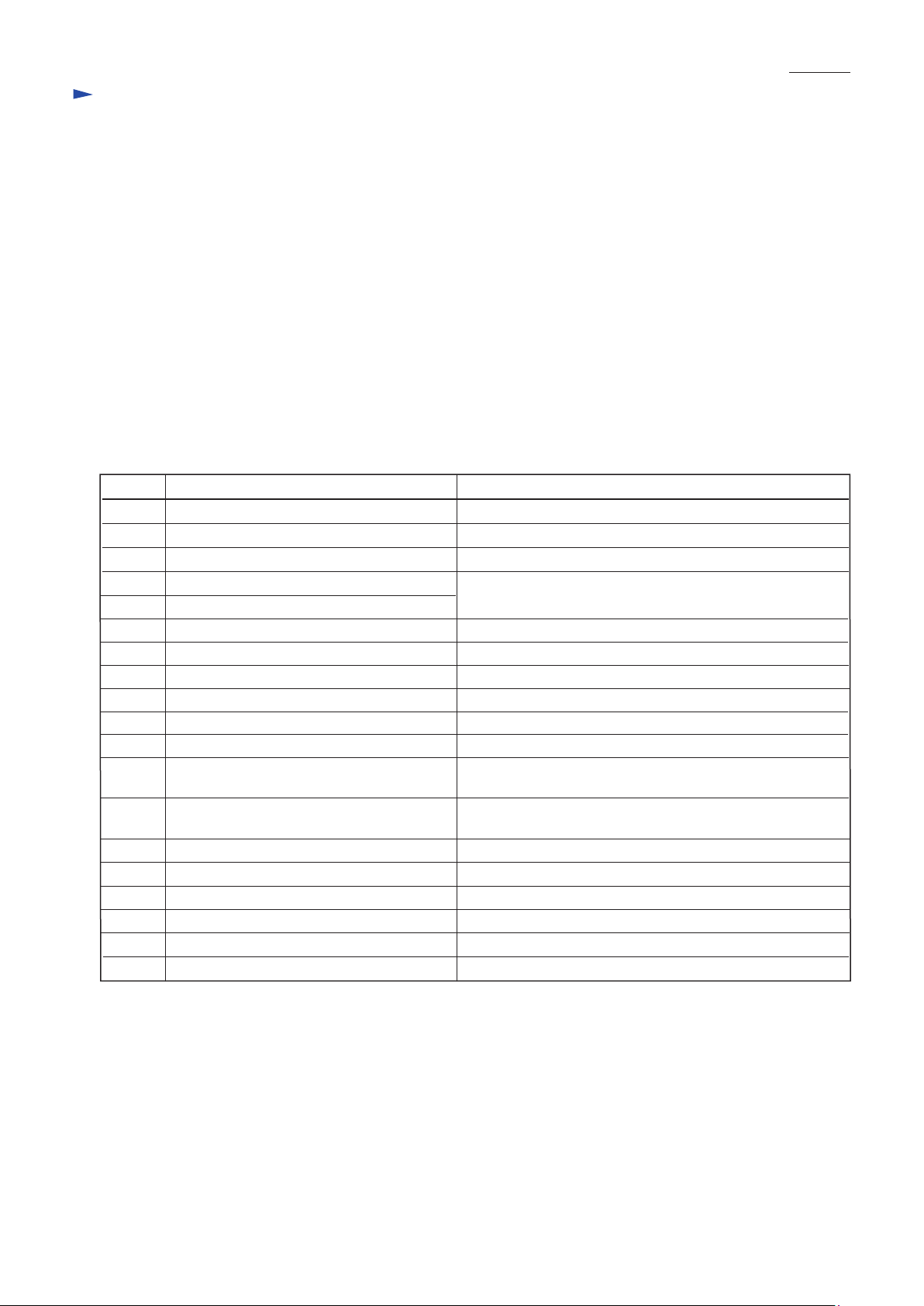

[3] LUBRICANT/ ADHESIVE APPLICATION

Apply the following grease/ oil to protect parts and product from unusual abrasion.

Note: After assembly, supply 220cc of 4-cycle engine oil from the inlet of machine before trial run.

When disassembling the engine, put ThreeBond 1215 to the matching surface of Crank case and Cylinder block. (Fig. 66)

DescriptionItem No. Use for Amount

Retainer (2 pcs.)

109

Pin 5 Contact surface with the holes of Cylinder head assembly

112

Push rod (2 pcs.)

117

Exhaust valve

119

Intake valve

120

Cylinder block

123

complete

Cam lifter L

133

Cam lifter R

134

Oil seal 17

138

Crankshaft

140

complete

Oil seal L

185

Spiral spring Entire surface

208

Contact surface with 119 and 120

Contact surface with the holes of Rocker arm assembly

Contact surface with the inner periphery of Valve guide

Contact surface with Piston

• Contact surface with Push rod

• Contact surface with Cam gear complete

Inner periphery

• Steel balls in Ball bearings 6204LU and 6204

• Hole of Connection rod to pass Piston pin in Piston

• Needle cage in the other hole of Connection rod

Inner periphery

4-cycle Engine oil

(API grade SM class)

Makita grease N No. 2

4-cycle Engine oil

(API grade SM class)

Lubricant

a little

a little

a little

a littleMakita grease N No. 2

Fig. 1

134

133

Cylinder block complete

123

(It consists of Cylinder block

and Crankcase)

112

109

Valve

guide

117

Cylinder head

complete

119

120

Cylinder block

Crankcase

140

138

Connecting

rod

Ball bearing

6204LU

Starter assembly

185

Ball bearing

6204

208

Page 4

P 4/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

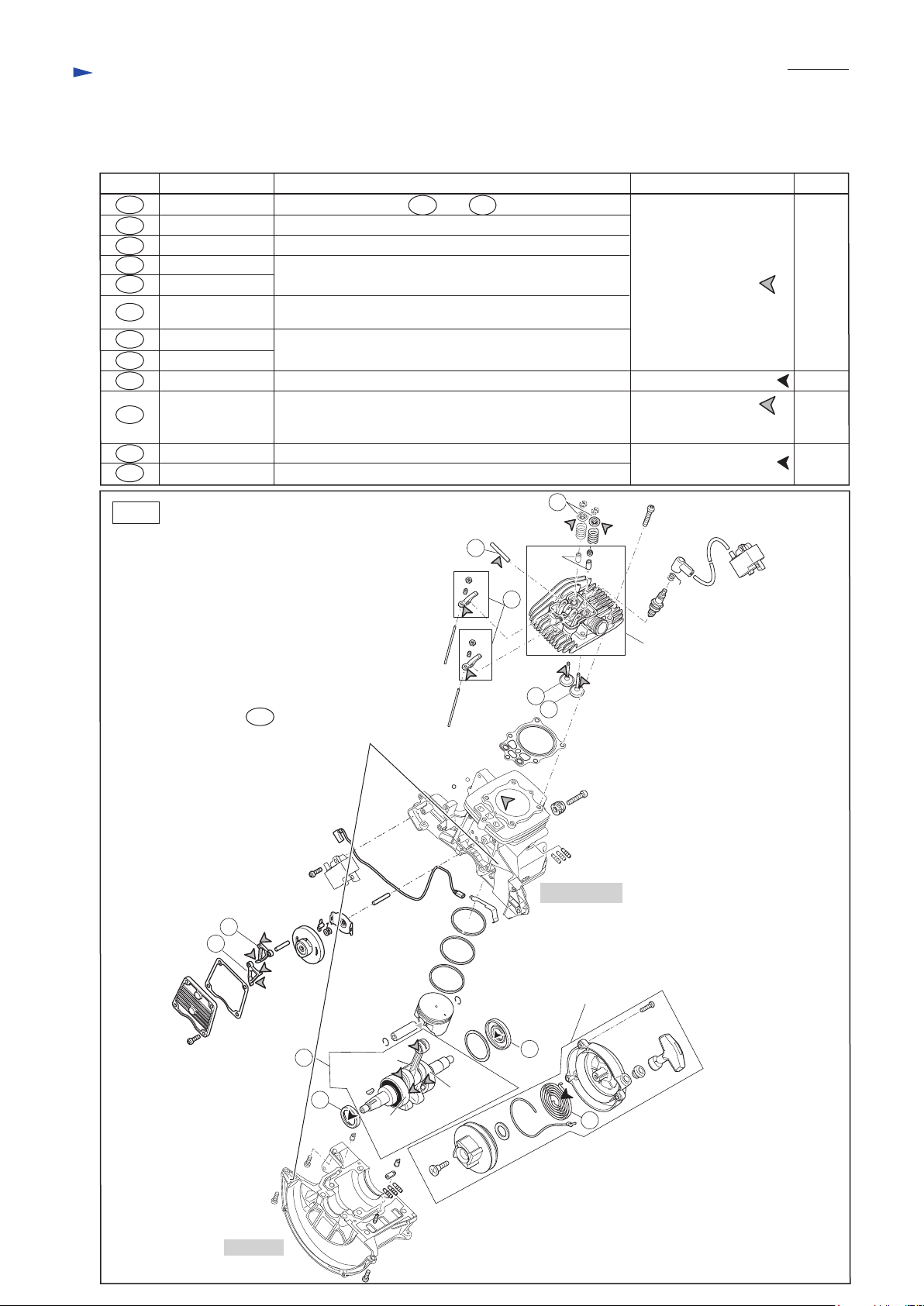

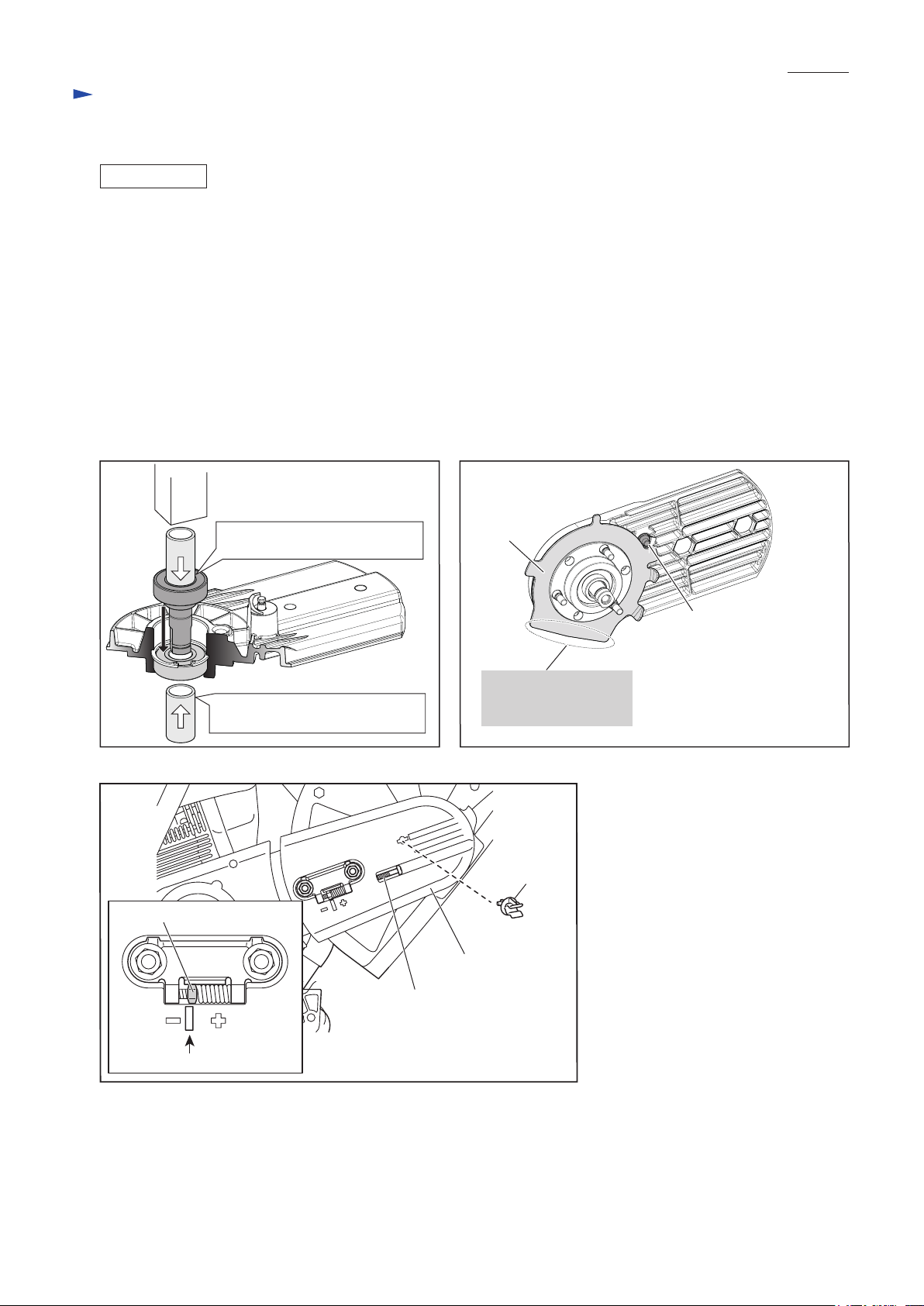

[4]-1. V-belt 5-800, Cutting device

DISASSEMBLING

(1) Loosen two M8 Hex nuts slightly with Wrench 13-16 of a standard accessory. (Fig. 2)

(2) Release the tension on V-belt 5-800 by turning M6 Tensioning screw counterclockwise with Screwdriver.

The position of M6 square nut shows the tension level; as it comes close to the minus mark, the belt tension is

relieved. (Fig. 2)

(3) When Water supply set is on the machine, remove it. (Fig. 3)

Holder (Fig. 2) can be removed from Belt cover by turning clockwise/ counterclockwise to 90° .

(4) Remove two M8 Hex nuts, then separate Belt cover and Hood section from the machine. (Fig. 4)

(5) When Hood section is disassembled:

1. Face the blade installation side of Spindle toward the ram of Arbor press.

2. Press Spindle out of Cutting device. Ball bearing 6203LLU is removed together with Spindle. (Fig. 5)

(6) Remove Retaining ring R-40 from Cutting device with 1R291, and then press the other 6203LLU out of

Cutting device. (Fig. 6)

Fig. 2 Fig. 3

Water supply set

M6 Square nut

Fig. 4

Cutting device

M8 Hex nut (2 pcs.)Minus mark

Hood section

V belt 5-800

Belt cover

M8 Hex nut

(2 pcs.)

Holder

Belt cover

M6 Tension screw

Fig. 5

Arbor press

Spindle

Cutting device

Note: Another Ball bearing 6203LLU

and Retaining ring R-40 are left

in Cutting device as drawn

in Fig. 6.

One of Ball bearing 6203LLU

Fig. 6

Cutting device viewed

from Belt cover side

Ball bearing

6203LLU

Retaining ring R-40

Page 5

P 5/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-1. V-belt 5-800, Cutting device (cont.)

ASSEMBLING

Assemble their parts by reversing the disassembly procedure.

(1) Assemble one of Ball bearing 6203LLU to Cutting holder, then snap Retaining ring R-40 into the groove of

Cutting device to secure the bearing.

(2) Insert Spindle into the other Ball bearing 6203LLU, then assemble them to Cutting device until they stop.

Note: Use two 1R030 as drawn in Fig. 7 so that their inner retainers of Ball bearings 6203LLU can be held without load

to the other portions.

This retains the proper tensions to their inner retainers.

(3) Insert Lock shaft into the place of Cutting device, then set Sliding disc and Impact plate. Push Lock shaft from

Belt cover side toward Blade installation side until the top bumps against Impact plate. (Fig. 8)

(4) Belt tension must be adjusted by turning M6 Tension screw clockwise until M6 Hex nut is aligned to a line between

plus mark and minus mark. (Fig. 9.)

(5) Holder of Water supply set can be set to Belt cover by turning clockwise/ counterclockwise to 90° .

Fig. 7

Fig. 8

[Belt cover side]

Fig. 9

M6 Square nut

1R030 to hold the inner retainer

of Ball bearing 6203LLU

1R030 to hold the inner retainer

of Ball bearing 6203LLU

Impact plate

Belt cover

Align the flat end of

Impact plate to that of

Hood complete.

Holder

Lock shaft

[Blade installation side]

Line

M6 Tension screw

Page 6

Repair

[4] DISASSEMBLY/ASSEMBLY

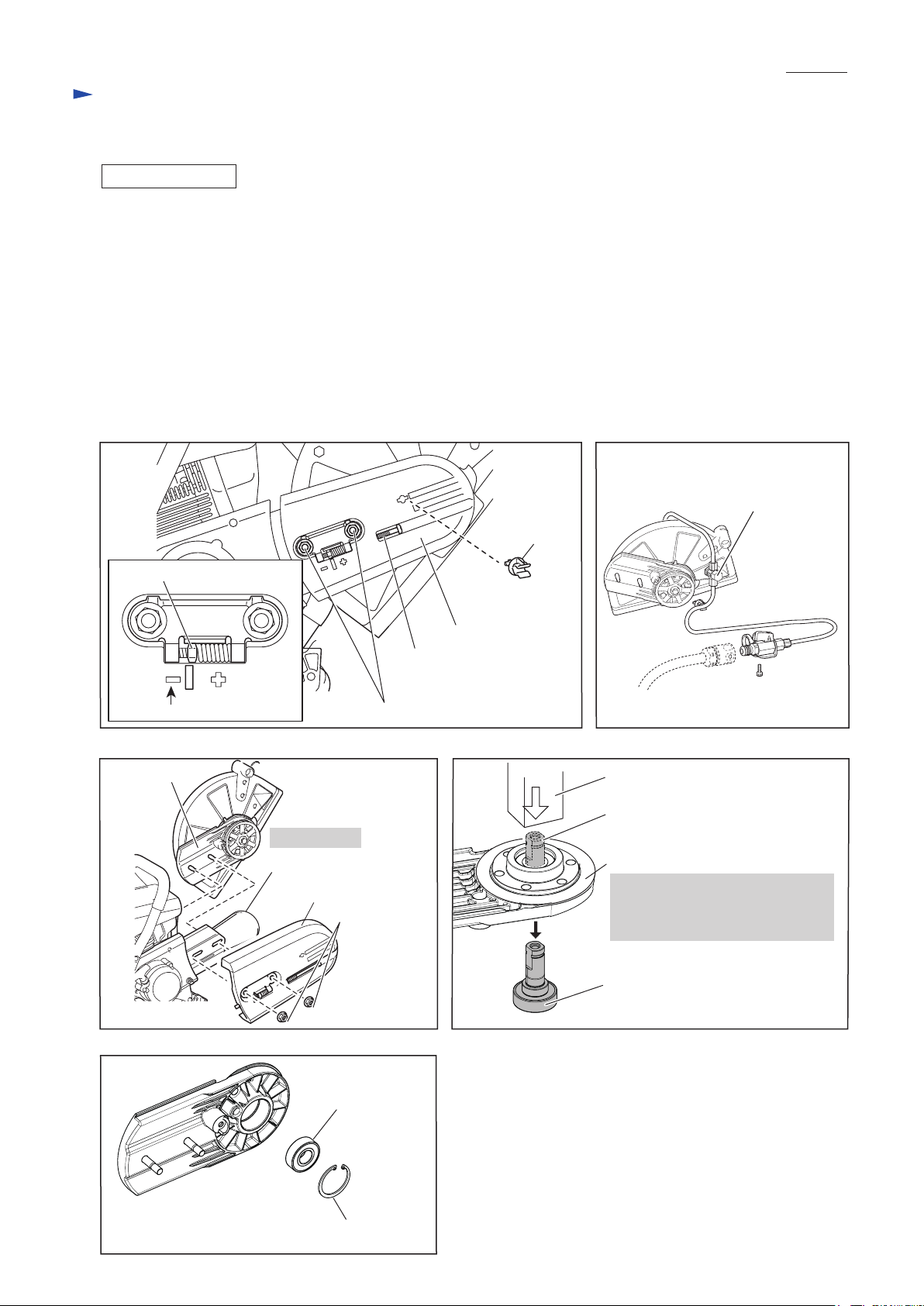

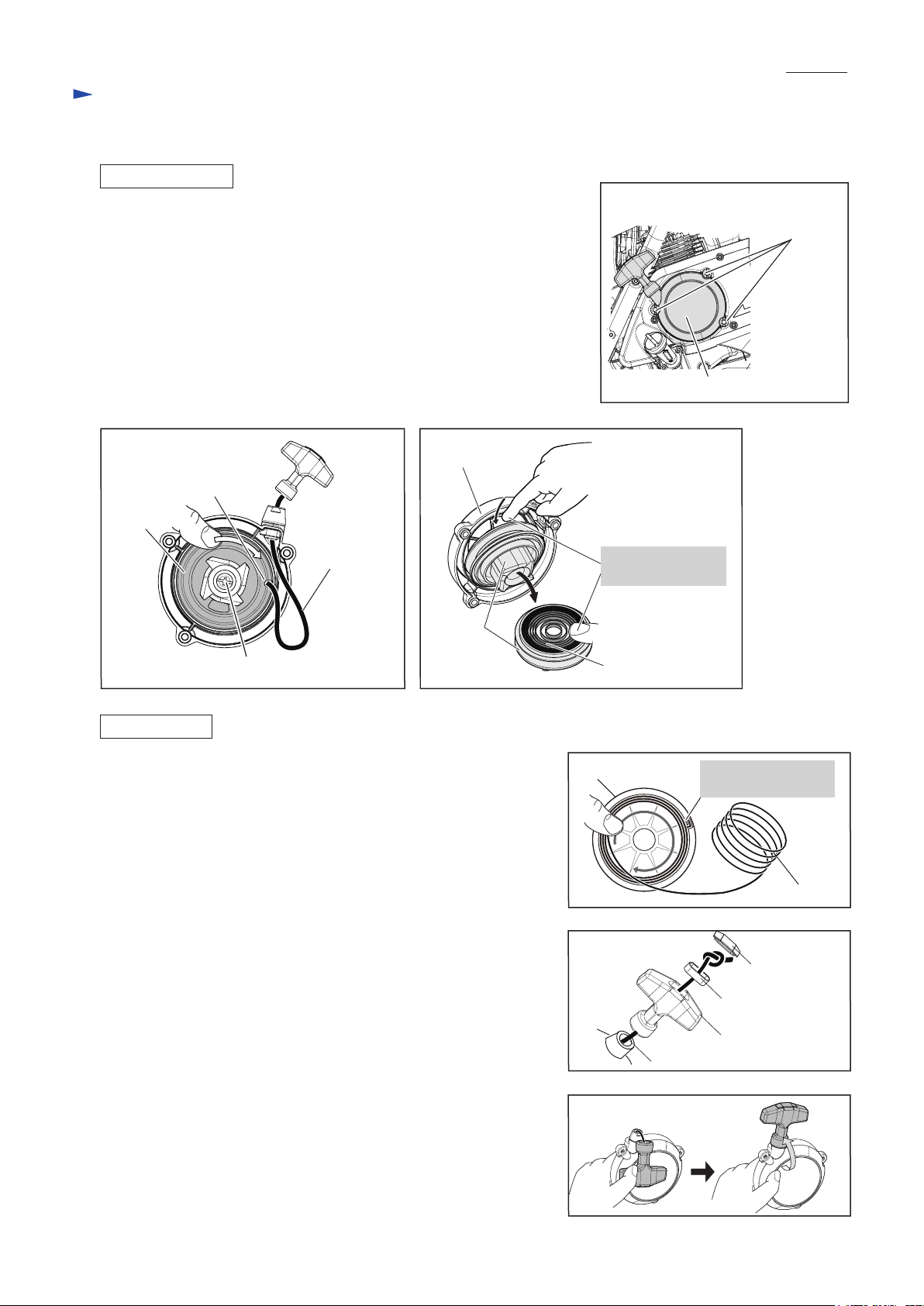

[4]-2. Starter assembly

P 6/ 19

DISASSEMBLING

(1) Loosen three M5x19 - Hexalobular socket head bolts, then remove

Starter assembly. (Fig. 10)

(2) When Starter rope is not broken;

1. Make a slack of Starter rope then hook it on U-shaped notch of Reel.

(Fig. 11)

2. Be sure to loosen the spiral spring force by turn Reel clockwise to spin

Starter rope around Reel before the step (3). (Fig. 11)

(3) Loosen M6x20 Set screw with Phillips screwdriver No. 3. (Fig. 11)

(4) When Reel is removed from Starter case, insert a index finger carefully to

the reverse side of Reel and then remove Reel from Starter case with

Spiral spring attached. (Fig. 12.)

Fig. 11

U-shaped

notch of Reel

Reel

Starter rope

Fig. 12

Starter case

Fig. 10

M5x19 - Hexalobular

socket head bolt

(3 pcs.)

Starter assembly (gray portion)

Hold Spiral spring

by an index finger.

Reel

M6x20 Set screw

ASSEMBLING

(1) If Spiral spring pops out of Reel, put it back in place by setting

the outer end of Spiral spring in place in Reel first, then by winding

Spiral spring counterclockwise towards the center of Reel. (Fig. 13)

(2) Apply a little amount of Makita grease N No.2 to the whole surface

of Spiral spring.

(3) Put Starter rope through Starter case complete.

After passing the one end through Starter knob and Rope stopper,

tie the end as drawn in Fig. 14. Then cover the top of Starter knob

with Cap.

After passing the other end from the hole of Starter case to Reel,

tie the end in Reel.

(4) Wind Starter rope around Reel for the 2/3 length (When the whole

length is 1m, wind 66cm.)

(5) While setting the inner end of Spiral spring into the center slot of

Starter case, assemble Reel to Starter case properly.

(6) Tighten M6x20 Set screw with Phillips screwdriver No. 3. (Fig. 11)

(7) Make a slack of Starter rope then hook it on U-shaped notch of

Reel. (Fig. 11) Turn Reel counterclockwise to spin Starter rope

around Reel.

Important: Make sure that the proper spring force is effective to Starter

assembly by turning Starter knob by hand and it can be

returned back to the original position. (Fig. 15)

Even if Starter rope is pulled to the full, there is room to

rotate Reel because of Spiral spring performance.

Fig. 13

Reel

Fig. 14

Fig. 15

Spiral spring

Set the outer end of

Spiral spring here.

Spiral spring

Cap

Rope stopper

Starter knob

Hole of Starter case

Page 7

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-3. Clutch, Ratchet

P 7/ 19

DISASSEMBLING

(1) Remove Cutting device. Refer to the clause of [4]-1.

(2) Loosen three M5x12 Hexalobular socket head bolts, then remove

Clutch cover together with Starter assembly. (Fig. 16)

(3) Loosen three M5x16 Hexalobular socket head bolts with 1R290

and Cordless impact driver, and remove Ratchet complete. (Fig. 17)

(4) Remove M10-17 Hex lock nut by turning it counterclockwise by

using Cordless impact driver with Socket bit.

(5) Turn the hexagonal portion of Clutch holder clockwise by using

Cordless impact driver with Socket bit.

Clutch complete is removed.

Note: Clutch holder has a left hand thread.

(6) Remove Clutch drum assembly by hand. No tools are required.

Remove Retaining ring R-35 from Clutch drum with 1R005.

Press down Ball bearing 6003LLU in Clutch drum.

Fig. 17

Ratchet complete

Fig. 18 Fig. 19

M10-17

Hex lock

nut

Fig. 16

Clutch cover

Starter

assembly

U-shaped notch

of Reel

M5x12 Hexalobular socket

head bolt (3 pcs.)

Hexagonal

portion (M16-24)

of Clutch holder

M5x16 Hexalobular

socket head bolt (3 pcs.)

ASSEMBLING

(1) Put Spacer 17 and Clutch drum assembly to Crankshaft, then put

the other Spacer 17 on Clutch drum assembly. (Fig. 20)

(2) Remove Spark plug and assemble 1R372 carefully to Cylinder

block by hand to prevents Crankshaft from being rotated. (Fig. 21)

(3) Turn Flywheel slowly and carefully by hand until the top of

1R372 contacts Piston.

Note: Do not damage Piston.

(4) Turn the hexagonal portion of Clutch holder counterclockwise

with 1R223, 1R224 and 17mm flat width Socket in order to

tighten Clutch complete to the fastening torque 38N.m. (Fig. 20)

Note: • Do not use Cordless impact driver.

• Do not turn the hexagonal portion with 1R372 taken

apart from Piston.

(5) Assemble M10-17 Hex lock nut to Crankshaft by reversing

the disassembling procedure shown in Fig. 18.

(6) Set Ratchet complete and three M5x16 Hexalobular socket head

bolts in place by reversing the disassembling procedure shown in

Fig. 17.

(7) Assemble the rest in accordance with the clause of [4]-1.

17mm flats width

Socket bit

24mm flats width

Socket bit

Fig. 20

Crankshaft

Spacer 17

Clutch drum

assembly

Spacer 17

Clutch complete

24mm flats width Socket

(Square drive: 12.7mm)

1R224 1R223

Fig. 21

Cylinder block

1R372

Piston

Page 8

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-4. Flywheel, Ignition coil

DISASSEMBLING FLYWHEEL COMPLETE

(1) Loosen four M5x30 - Hexalobular socket head bolts, then remove

Fan cover. (Fig. 22)

(2) Remove M10 Flange nut from Crankshaft by turning counterclockwise

by using Cordless impact driver with 14mm flats width Socket bit.

(Fig. 23)

(3) Mount 1R364 on Flywheel complete, then put Screwdriver through

the center shaft of IR364. (Fig. 24)

(4) While holding the one of M6 bolts and center bolt with Water pump pliers

to prevent 1R364 from being rotated, turn Screwdriver clockwise.

When Flywheel is removed from Crankshaft, a snap sound is heard

because of their tapered fit.

Fig. 23

Fig. 24

P 8/ 19

Fig. 22

M5x30 - Hexalobular socket

head bolt (4 pcs.)

14mm flats width

Socket bit

M10 Flange nut

Crankshaft

Flywheel

ASSEMBLING FLYWHEEL COMPLETE

(1) Remove grease from Crankshaft complete.

(2) After aligning the key slot of Flywheel complete with

Woodruff key in the keyway of Crankshaft complete,

mount Flywheel complete onto Crankshaft complete.

(Fig. 25)

(3) Assemble the rest by reversing the disassembly procedure.

Screwdriver

M6 bolt of 1R364Center bolt of 1R364

Water pump

pliers

Fig. 25

Woodruff key

in key way of

Crankshaft complete

ADJUSTMENT THE GAP BETWEEN IGNITION COIL AND FLYWHEEL

0.3 up to 0.4mm is the proper gap between Ignition coil and Flywheel.

Refer to Fig. 26 and the following steps.

(1) Loosen two M5x16 Hexalobular socket head bolts on Ignition coil.

(2) Insert 0.3mm leaf of 1R366 between Ignition coil and the magnet of

Flywheel complete.

Ignition coil will be attracted to the magnet through the Feeler gauge.

Then, without removing the Feeler gauge, fasten Ignition coil to

the engine with two M5x16 Hexalobular socket head bolts.

First tighten 1 , the next, tighten 2 . The order is easy to keep

the proper gap.

(2) Remove 1R366. Then make sure that Flywheel complete does not

touch Ignition coil by turning it by hand.

Fig. 26

Key slot of

Flywheel complete

M5x16 Hexalobular socket head bolt

(2 pcs.)

1

2

0.3mm leaf of 1R366

0.3 up to

0.4mm

Page 9

P 9/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-4. Flywheel, Ignition coil (cont.)

DISASSEMBLING IGNITION COIL

(1) Loosen M6x15 Thumb screw, then remove Top cover. (Fig. 27)

(2) Loosen four M5x40 Hexalobular socket head bolts, then remove Filter cover complete (Fig. 28)

and Air filter. (Fig. 29)

(3) Loosen M5x16 Hexalobular socket head bolt, then remove Cylinder cover.

Remove Plug cord of Ignition coil assembly from Cylinder cover. (Fig. 30)

(4) Remove Flag terminal on Lead unit end from Ignition coil with care to the breaking of Lead unit.

Note: It is recommend to apply “the principle of leverage.” Without being forced to pull, put the long noses of Pliers

on the edge of Ignition coil and lever up the flag terminal. (Fig. 31)

(5) Loosen two M5x16 Hexalobular socket head bolts, and then remove Ignition coil. Refer to Fig. 26.

Important: Unless the disassembling is necessary for repair, do not touch the bolts of Ignition coil.

In case of disassembling them, the hard work “ADJUSTMENT THE GAP BETWEEN

IGNITION COIL AND FLYWHEEL” will be required.

Fig. 27

M6x15 Thumb screw

Top cover

Fig. 30 Fig. 31

Fig. 28 Fig. 29

Filter cover

complete

M5x40

Hexalobular

socket head

bolt (4 pcs.)

Cylinder cover

M5x16

Hexalobular

socket head

bolt

Air filter

Lead unit

Flag terminal

Ignition coil

Plug cord of

Ignition coil assembly

Ignition coil

Long noses of Pliers

put on the edge of Ignition coil

Page 10

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-5. Carburetor

Fig. 32

(1) After completion of the steps (1) and (2) on [4]-4, remove Grip cover by loosening

5.5x20 Hexalobular tapping screw. (Fig. 32)

(2) Loosen two M5x45 Hexalobular socket head bolts, then remove Carburetor and

Filter gasket from Carburetor mount. (Figs. 33 and 34)

Note: Use 1R311 to hold/ pinch Tubes to lever it up for easy removing.

Do not use the sharp edged Pliers that causes damage to Tubes. (Fig. 35)

(3) Remove Contact spring. (Fig. 36)

(4) Carburetor WT can be disassembled as shown in Fig. 37.

Note: • Check the components’ shrinkage, hardening or breakage due to aged

deterioration. If any, replace it with a new one.

• Carburetor for some countries is different from Carburetor WT. (Fig. 37)

The components cannot be supplied individually because of the regulation

for compliance with standards.

(5) Before mounting the inner parts of Pump body assembly in place, make sure that

the tip of Inlet needle valve is neither worn nor deformed.

Note: The inner parts are not available individually. If you need some of the inner parts,

order Pump body assembly.

(6) Make sure that Inlet screen is not clogged, then set it back in place.

(7) Spray carburetor cleaner in all the fuel lines of Carburetor, then after several minutes,

wash out dirt and debris with clean gasoline.

Fig. 33 Fig. 34

P 10/ 19

Grip cover

5.5x20 Hexalobular tapping

screw

Filter bracket

M5x45

Hexalobular

socket head bolt

Fig. 35 Fig. 37

Inner parts of Pump

body assembly

Metering lever pin

1R311

Tube

Fig. 36

The shape edges

damage Tubes.

Carburetor WT

Throttle linkage

(2 pcs.)

Screw

Filter bracket

Carburetor gasket

M5x45 Hexalobular socket head

bolt (2 pcs.)

Screw assembly (4 pcs.)

Metering cover

assembly

Metering diaphragm

assembly

Metering diaphragm

gasket

Inlet screen

Tank complete

Contact spring

Metering

lever

Inlet needle valve

Spring

Limiter cap

Pump body assembly

Pump diaphragm

Pump gasket

Pump body assembly

Spring

Idle adjust screw

Screw

Page 11

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-5. Carburetor (cont.)

ADJUSTMENT OF CARBURETOR AFTER REPLACEMENT

P 11/ 19

Pull throttle lever fully after a while engine running at idle position. When there is

a problem with the engine quick acceleration, adjust H needle (Fig. 38) as follows:

(1) Warm up the engine by pulling the throttle lever fully for one minute.

(2) Keep engine idling and do fine adjustment of the idling speed by turning

H needle (Fig. 38) with a thin slotted screwdriver.

(3) Pull the throttle lever quickly. If Engine stall happens/ Engine does not reach

the maximum rpm, do step (4). If there are no problems with the engine quick

acceleration, go ahead to step (5).

(4) Unscrew H needle 1/8 turn (45

After pulling the throttle lever fully with no load, retry the step (3).

(5) Push two Limiter caps (Fig. 37) into Carburetor with a flat top of rod.

Note: It is not necessary to touch L needle.

ASSEMBLING

Assemble by reversing the disassembly procedure. Be careful to the following points.

• Align the ends of Sponge sleeve 9 and Breather on Tube 3-190. (Fig. 39)

• Set Breather in place so that Tube 3-190 is fixed to the rib in Tank complete. (Fig. 40)

• Set Tubes, Choke linkage and Throttle linkage in place. (Fig. 41) Be careful to each

direction of the linkages.

Fig. 40

°)

with a thin slotted screwdriver.

Fix the assembled part

drawn in Fig. 39 with

Lead wire holder in

Tank complete

Fig. 38

Adjust H needle through the hole

near H mark with a thin slotted

screwdriver.

Fig. 39

Sponge

sleeve 9

Breather

Tube 3-190

Fig. 41

Lead unit (A)

Lead unit (A) must be routed

under these ribs.

Contact spring on Lead unit

(B) end must be inserted

into these notches of ribs.

Perspective view

Lead unit (B) between Contact

spring and Ignition oil

Plate on Switch lever

Tube 3-45 between Hose joint

and Carburetor

Carburetor

Choke linkage

Throttle linkage

Hose joint

Tube 3-35 from

Hose joint to

Filter bracket

Tube 3-300 between

Carburetor and

Gasoline filter in

Tank complete

Tube 3-190

(Refer to Fig. 39.)

Tube 3-120 between

Primer pump and

Grommet on

Tank complete

Tube 3-190 between

Primer pump and

Carburetor

(Refer to Fig. 39.)

Page 12

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-6. Throttle lever

DISASSEMBLING

(1) Remove Pin 5 from the grooves on Tank complete by levering it up with a

slotted screwdriver. (Fig. 42)

(2) Expand the hinge portion for Throttle lever on Tank complete with 1R003.

(Fig. 43)

Throttle lever section can be removed as drawn in Fig. 44.

Fig. 43 Fig. 44

P 12/ 19

Fig. 42

Pin 5

1R003

Expand the hinge portion carefully.

Throttle lever

Torsion

spring 12

Pin 5

Lock off lever

[4]-7. Engine block

DISASSEMBLING

Note: • It is highly recommended to drain the oil system of Engine block before starting disassembling

because the oil remaining there will drip out to delay your operation.

• When Piston section is repaired, it is necessary to remove Engine from Tank complete.

(1) Remove Hood section. Refer to Fig. 4 of [4]-1.

(2) Remove Carburetor. Refer to [4]-5.

Refer to Fig. 45 and do the following steps (3), (4), (5).

(3) Remove three Tubes’ ends that come from Cylinder block complete as follows:

• Tube 3-170 with Clamp to Rocker cover

• Tube 3-130 to Hose joint in Seal

• Tube 3-75 to Hose joint in Seal

(4) Remove Tube 5-70 with Clamp from Rocker cover.

(5) Loosen Hose clamp 30 then remove Suction line from Cylinder block complete.

Fig. 45

Tube 3-170

with Clamp

Tube 5-70

with Clamp

Tube 3-130

Seal with Joints

Tube 3-75

Rocker cover

Suction line

Hose clamp 30Cylinder block

Page 13

P 13/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-7. Engine block (cont.)

DISASSEMBLING

(6) Remove four M6x30 Hexalobular socket head bolts that fasten Front handle, Tank complete and Engine. (Fig. 46)

Engine block can be removed. (Fig. 47)

Fig. 46

[Viewed from Blade installation side] [Viewed from Starter assembly installation side]

M6x30 Hexalobular socket

head bolt (3 pcs.)

Fig. 47

Tank complete

M6x30 Hexalobular socket

head bolt

Front handle

Engine block

Page 14

P 14/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine

DISASSEMBLING

(1) Remove Clutch complete and Clutch drum. Refer to [4]-3.

(2) Remove Flywheel. Refer to [4]-4. If necessary, remove Ignition coil.

(3) Loosen five M6x25 Hexalobular socket head bolts, then remove Cutting arm from Cylinder block complete. (Fig. 48)

(4) Remove Exhaust muffler from Cylinder block complete.

Note: Although Spark arrester can be removed from Exhaust muffler, it is not permitted to replace Spark arrester only

because it functions as the integrated part with Exhaust muffler.

(5) Remove Oil case from Cylinder block complete. (Fig. 49)

Fig. 48 Fig. 49

Exhaust

Cylinder block complete

muffler

Spark arrester

Crank case

Oil case

Cylinder head

complete

Cylinder block

Cylinder

block

complete

M6x25 Hexalobular

socket head bolt (5 pcs.)

Note: Unless you repair Exhaust valves, Cam lifters, and Rocker arms, do the following steps. It is not necessary to

remove Cylinder block from Crank case (Fig. 49)/ Carburetor from Cylinder block complete (Refer to Fig. 34.)

(6) Remove two M6x20 Hexalobular socket head bolts on the upper side of Exhaust muffler.

Remove two M5x25 Hexalobular socket head bolts then separate Rocker cover complete from Cylinder head

complete. (Fig. 50)

(7) Loosen Hose clamp then remove Suction line from Cylinder head complete. (Refer to Fig. 41)

(8) Remove Cylinder head complete from Cylinder block, then pull out two Push rods. (Fig. 51)

Note: Do not failure to mix them up. It is recommend to distinguish Exhaust push-rod and Intake push-rod.

(9) Remove Cam gear cover (Fig. 52).

(10) Remove Cam lifter L and Cam lifter R. Then, remove Cam gear complete by pulling out Pin 5. (Fig. 53)

Fig. 50 Fig. 51

Rocker cover

complete

M5x25 Hexalobular

socket head bolt

(2 pcs.)

M6x20 Hexalobular

socket head bolt

(2 pcs.)

Do not touch this M6x20

Hexalobular socket

head bolt.

Cutting arm

Cylinder head complete

Push rod (for exhaust system)

Push rod (for intake system)

Cylinder block

M5x16 Hexalobular

socket head bolt (4 pcs.)

M6x35 Hexalobular socket

head bolt (4 pcs.)

Fig. 52 Fig. 53

Cam lifter L

Cam gear cover

M5x16

Hexalobular

socket head

bolt (4 pcs.)

Pin 5

Cam lifter R Cam gear assembly

Cam gear

complete

Fly weight

Cam gear plate

Torsion spring 9

Page 15

P 15/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

DISASSEMBLING

Note: Cam gear assembly functions as automatic decompression valve system.

Valve is slightly open to release the compressed air in Engine at the starting time, before moving fly weight

by centrifugal effects. It means the insufficient setting of Cam gear assembly will cause engine stall/ extreme

reaction force at engine running due to too much load by the compressed air.

(11) Remove Pin 5 that sets Rocker arm assembly in place on Cylinder head complete. (Fig. 54)

Use 1R308 to push out Pin 5.

The distinction of Rocker arm assembly and Push rods (for use of the exhaust system/ intake system) enables you

shortens the repair process (Gap adjustment between Rocker arms and Retainers is even difficult, however, you can

adjust it by using 1R366. Refer to Fig. 68.

Fig. 54

the hole of Cylinder head complete

Pin 5

Cylinder head

complete

Important: Disassemble the parts in the room on Cylinder head complete before removing it and

clean the clogged portions in the following steps. You may repair successfully without

doing the step (5) and later in the next page.

(1) Remove Rocker cover complete, then push out Pin 5 on hinge for Rocker arms with 1R308 and remove Rocker arms.

(Refer to Figs. 50 and 54)

(2) Remove Spark plug. Turn Flywheel until Piston comes to the upper dead point by looking through Spark plug hole

on Cylinder head complete.

Note: Align the rib as a mark on Flywheel with the rib on Cylinder block as drawn in Fig. 55.

(3) Insert a bent Lead wire #16 into Combustion chamber through Spark plug hole so that Valves do not fall into

Combustion chamber. (Fig. 56)

(4) While compressing Compression spring 11 by pushing Retainer with 1R003 attached with 1R389, remove Cotter by

a thin bit magnetized by 1R288.

Routes in Cylinder head complete, the upper surface on Valves and the room on Cylinder head complete can be clean

through removal of four Cotters, two Retainers, and two Compression springs 11.

Fig. 55 Fig. 57

Rocker arm assembly

Exhaust

system

Exhaust

push-rod

Intake

push-rod

Intake

system

Note: Intake system of Rocker

arm has to be close to

the hole of Cylinder head

complete.

Fig. 56

Use Cotter removal

attachment to push

Retainer.

[viewed from the upper side of the room]

Rib on Cylinder block

Rib on Flywheel

1R389

1R003

Retainer (2 pcs.)

Cotter (4 pcs.)

Compression

spring 11 (2 pcs.)

Cylinder head complete

Note: Intake valve has to

be close to this hole

of Cylinder head

complete.

Intake valve Exhaust valve

Page 16

P 16/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

DISASSEMBLING

Important: When Intake/ Exhaust valves have to be replaced, remove Cylinder head complete.

(Refer to previous page.)

(5) Loosen eleven Hexalobular socket head bolts on the bottom of Crank case (Fig. 58), then remove Crank case from

Cylinder block. As Liquid gasket makes Cylinder block stick on Crank case, insert and twist a slotted screwdriver

between the clearance. (Fig. 59)

Scrape away Liquid gasket on the mating surface.

(6) Pull out the assembled part of Crank shaft and Piston from Cylinder block. (Fig. 60)

(7) Remove one of Ring spring 12 with a thin slotted screwdriver, then push Piston pin from the opposite with care

so as not to damage the other Ring spring 12. (Fig. 61)

The following parts mentioned in Fig. 62 can be replaced individually. When the rest parts have to be replaced,

Crankshaft complete is required.

Fig. 58

M5x16

Hexalobular

socket head

bolt (3 pcs.)

Crank case viewed

from the bottom

side

Fig. 60

M6x30 Hexalobular

socket head bolt (8 pcs.)

Cylinder block

Fig. 59

Fig. 62

Top ring

Second ring

Oil ring

Piston

Crank case viewed from the bottom side

Slotted

screwdriver

Cylinder block

screwdriver

Ring spring 12

Oil seal L

Slotted

Fig. 61

Piston pin

Insert a thin slotted screwdriver

from the depression on the rib

around Piston pin hole.

Ring spring 12

Piston

Piston pin

Ring spring 12

Woodruff key 4

Oil seal 17

Flat washer 41

Crankshaft

complete*

*The components cannot be

supplied individually.

Page 17

P 17/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

ASSEMBLING ENGINE BLOCK

Note: Be sure to apply Makita grease N No.2/ 4-cycle engine oil in accordance with [3] LUBRICANT APPLICATION.

(1) Connect Piston with Crankshaft complete by inserting Piston pin into place; there is no front/back to Piston.

(2) Secure Piston pin by mounting Ring spring 12 onto each end of Piston pin.

Note: The ring gap of Ring spring 12 can be positioned at any angle to Piston pin.

(3) Install Oil ring in the grooves of Piston; Side rail first, Spacer next, then the other Side rail.

Important: Be sure to fit the three rings with the ring gaps at 120 degrees to one another as shown in the left of Fig. 63.

(4) Install Second ring first then Top ring in the groove of Piston.

Important 1: Be sure to fit the two rings with the ring gaps at 180 degrees to each other as shown in the right of Fig. 63.

Important 2: Second ring has a taper face and must be installed with the large diameter facing Oil ring. (Fig. 64)

Distinguishing between Top ring and Second ring & Discriminating the larger diameter of Second ring:

If both of the two rings are new and unused,

• You can distinguish from their appearances; there is a red marking on the side face of Second ring as shown in

Fig. 65 while not on the side face of Top ring.

• You can face the large diameter of Second ring by placing Second ring with the red marking on your right and

with the ring gap near you as shown in Fig. 65.

If both of the two rings are used and the white marking of Second ring is rubbed off, carefully press the side face of

the two rings to the inner wall surface of Cylinder. You will be able to distinguish the two rings or to discriminate the

large diameter of Second ring through the differences in contact feelings that the different side faces make.

(4) Remove oil/grease from the mating surface of Cylinder block and Crankcase.

Then apply ThreeBond 1215 to the mating surface of Crankcase as shown in Fig. 66.

Note: ThreeBond 1215 must not be applied to Oil supply routes.

Apply 4-cycle engine oil to the cylinder portion of Cylinder block, and then while compressing Piston rings, mount

Cylinder block onto Crankcase.

(6) Tighten eleven Hexalobular socket head bolts in a crisscross pattern. (Refer to Fig. 58.)

(7) Do not forget to set Exhaust port spacer in place on Muffler installation side of Cylinder head complete. (Fig. 67)

Fig. 63

Oil ring

ring gap

Side rail

ring gap

Top ring

Second ring

Spacer

Side rail

ring gap

Fig. 64

Top ring,

with barrel face

Second ring,

with taper face

Side rail

Spacer Oil ring

Side rail

Fig. 66 [Crankcase viewed from top]

ring gap

Fig. 65

ring gap

Second ring

red marking

Portion to apply

ThreeBond:

indicated in gray

Oil supply routes

This mark can be

ignored for

assembling

EK7650H/ EK7651H.

Fig. 67

Cylinder head complete

Exhaust port spacer

Page 18

P 18/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-8. Engine (cont.)

DISASSEMBLING

(8) Assemble Cam gear section by reversing the disassembly procedure. (Refer to Fig. 53 and 52.)

(9) Move Piston to the upper dead point in Cylinder block by turning Crankshaft slowly and carefully by hand.

(10) Adjust the gap between Rocker arms and Exhaust valve section/ Intake valve section as follows:

A. Put 0.1mm or 0.15mm leaf of 1R366 on Valve section. (Fig. 68)

B. While holding M5x9 Hex nut by Wrench 8, turn M5 Hex socket head bolt with Hex wrench 2.5. (Fig. 68)

C. Check the gap.

(11) After pretightening the nuts and bolts, turn Crankshaft complete by hand to move Crank portion two or three turns,

check the gap again, if the proper gap is obtained, tighten the nuts and bolts firmly.

(12) Lead unit that comes from Stop switch has to be fastened to Cylinder block with 6x30 Hexalobular socket head

bolt. (Fig. 69)

(13) Plug cord and Tube have to be fixed with Lead wire holders on Cylinder cover. (Fig. 70) And then, Plug cord has to

be fixed with Lead wire holders on Cylinder cover to route it without slacking toward Flywheel. (Fig. 71)

Lead unit connected with Ignition coil has to be fixed with the Lead wire holders as drawn in Fig. 71.

Fig. 68

Hex wrench 2.5

Wrench 8

M5 Hex

socket

head bolt

M5x9

Hex nut

Fig. 69

1R366

Lead unit

M6x30

Hexalobular

socket head

bolt

Fig. 71Fig. 70

Plug cord

Lead unit

Lead wire holders

on Cylinder cover

Plug cord and

Tube

Terminal of Ignition coil

Lead wire holders

on Cylinder cover

Page 19

P 19/ 19

Repair

[4] DISASSEMBLY/ASSEMBLY

[4]-9. Ignition system (cont.)

CHECKING SPARK PLUG

WARNING !!

• When a spark is produced, high-voltage current is delivered from Ignition coil to Spark plug.

It is, therefore, very dangerous to pull Recoil starter knob with your hand on Ignition cable.

Be sure to keep your hands off from Ignition cable when checking for spark.

• Fuel is extremely flammable and fuel vapors are explosive.

Therefore, clean up spilled fuel before starting to check for spark.

Also, be careful not to do the check near Carburetor.

(1) Remove Plug cap from Spark plug, then Spark plug from Cylinder head complete with the supplied socket wrench.

Note: If the electrodes of Spark plug are wet, wipe them with a rag then dry them with an air blower.

(2) Using a wire brush, carefully clean up carbon deposits (if any) from the electrodes and the ceramic insulator around

the center electrode.

(3) Adjust the electrode gap to 0.5mm by carefully bending the side electrode.

Use Feeler gauge set (1R366) to check the gap width:

between the center electrode and the side electrode, insert 0.5mm leaf

of Feeler gauge set. (Fig. 42)

(4) Install another Spark plug into spark plug hole to prevent air/fuel mixture

from leaking outside of engine.

(5) Connect the removed Spark plug with Plug cap, then ground the threads

of Spark plug to a proper metal part of the engine.

(6) With Stop switch on, pull Recoil starter knob gently and check for spark.

Note: It is hard to see the spark in a bright location.

Therefore, be sure to do the check in a shady but well-ventilated place.

(7) If spark is not produced, replace Spark plug with a new one,

then check for spark by following the procedure (1) to (6) once again.

Fig. 42

side electrode

Electrode gap

must be 0.5mm.

center electrode

[5] Tightening torque specifications

Application

(for fastening A to B)

Fastener

A B

Cushion Tank complete M6x30 Hexalobular socket head bolt

1

Cutting arm Cylinder block complete M6x25 Hexalobular socket head bolt

2

3

4

5

6

7

8

9

10 6

Rocker arm M5x9 Hex nutM5 Hex socket head bolt

Hexagonal portion (M16-24) of Clutch holder

M10-17 Hex lock nutClutch assembly Crankshaft

Tightening

torque (N.m)

7

30Cutting arm Belt cover M8 Hex nut

3Front inner holder M6x30 Hexalobular socket head bolt

12Crank case Cylinder block M6x30 Hexalobular socket head bolt

12Cylinder head complete Cylinder block M6x35 Hexalobular socket head bolt

40Flywheel Crankshaft M10 Flange nut

38Clutch holder Crankshaft

18

Loading...

Loading...