Page 1

Operator’s and Safety Manual

for Gasoline Power Cuts (page 2 - 27)

Manuel d’instructions et de sécurité

de découpeuse thermiques (page 28 - 53)

EK6100

EK6101

WARNING!

Read and understand this Manual. Always follow safety precautions in the Operator’s and Safety Manual. Improper use can cause serious injury! Preserve this Manual carefully!

WARNING!

FUELS WITH MORE THAN 10% ETHANOL ARE NOT APPROVED FOR USE IN MAKITA 2-STROKE ENGINES!

Use of alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting MAKITA requirements are not approved for use in MAKITA 2-stroke gasoline engines!

USE OF ALTERNATIVE FUELS CAN CAUSE THE FOLLOWING PROBLEMS:

Poor engine performance, loss of power, overheating, fuel vapor lock, improper clutch engagement, premature deterioration of fuel lines, premature deterioration of gaskets,

premature deterioration of carburetors.

USING ALTERNATIVE FUELS AND/OR 2-STROKE OILS NOT ACCORDING TO JASO FC OR ISO-L-EGD IN MAKITA 2-STROKE ENGINES WILL VOID YOUR ENGINE WARRANTY!

ATTENTION!

Suivez toujours les conseils de sécurité du présent manuel d’emploi et de sécurité. Une utilisation incorrecte de la tronçonneuse peut entraîner des blessures graves!

Lisez et comprenez ce manuel. Conservez avec soin ce manuel!

ATTENTION!

LES CARBURANTS CONTENANT PLUS DE 10 % D’ÉTHANOL NE SONT PAS AUTORISÉS POUR L’UTILISATION DANS LES MOTEURS 2 TEMPS!

Les carburants alternatifs, tels que E-20 (20 % d‘éthanol), E-85 (85 % d’éthanol) ou tout autre carburant n’étant pas conformes aux exigences MAKITA ne sont pas autorisés

pour l’utilisation dans les moteurs essence à 2 temps MAKITA!

L’UTILISATION DE CARBURANTS ALTERNATIFS PEUT CAUSER LES PROBLÈMES SUIVANTS:

Faible performance moteur, Perte de puissance, Surchauffe, Bouchons de vapeur dans la conduite d’essence, Embrayage incorrect, Détérioration prématurée des conduites

d’essence, Détérioration prématurée des joints d’étanchéité, Détérioration prématurée des carburateurs.

L’UTILISATION DE CARBURANTS ALTERNATIFS ET/OU D’HUILES 2 TEMPS NON-CONFORMES À LA NORME JASO FC OU ISO-L-EGD DANS LES MOTEURS À 2 TEMPS

MAKITA ANNULERA VOTRE GARANTIE MOTEUR!

Page 2

Thank you for purchasing a MAKITA product!

Congratulations on choosing a MAKITA Power Cut cutoff saw!

Like our chain saws, the MAKITA Power Cuts feature specially

designed high-performance engines with outstanding power-to-weight ratios, for heavy-duty yet lightweight tools.

Other advantages of the MAKITA Power Cuts:

• Sturdy construction and high reliability.

• Maintenance-free electronic ignition, hermetically sealed to

protect against dust and moisture.

• Vibration damping with the MAKITA 2-mass system (D2M) for

tireless working even when guiding the Power Cut by hand.

• Multilevel air lter system with turbo-cyclone lter for dependa-

ble function even under very dusty conditions.

• The Featherlight-Start system lets you start the cutter effortlessly with a spring-loaded starting assist.

• Extensive range of resin-bonded and diamond grit cutting

discs.

We want you to be satised with your MAKITA product.

In order to guarantee the optimal function and performance of

your Power Cut and to ensure your personal safety we would

request you to perform the following:

Read this operator’s manual carefully before putting the

Power Cut into operation for the rst time, and strictly

observe the safety regulations! Failure to observe these

precautions can lead to severe injury or death!

WARNING

The ignition system of this equipment produces an electromagnetic eld. This eld may interfere with some medical

devices such as a pacemaker. To reduce the risk of serious

or fatal injury, persons with a medical device should consult

with their physician and the manufacturer of the device before

operating this equipment.

Only for EK6100, EK6101: The Emissions Compliance Period

referred to on the emission Compliance label indicates the

number of operating hours for which the engine has been shown

to meet federal emissions requirements.

Category C= 50 hours, B= 125 hours, and A= 300 hours.

Table of contents Page

Packing ................................................................................ 2

Delivery inventory .............................................................. 3

Symbols ............................................................................... 3

SAFETY PRECAUTIONS

Intended use ................................................................... 4

General precautions ....................................................... 4

Protective equipment ................................................... 4-5

Fuels / Refuelling ............................................................ 5

Putting into operation ...................................................... 5

Cutting discs ................................................................... 6

Kickback and lock-in ....................................................... 7

Working behavior / Method of working ............................7

Always observe the following when using

synthetic resin cutting discs ............................................. 8

Cutting metal ................................................................... 8

Cutting masonry and concrete ..................................... 8-9

Transport and storage .....................................................9

Maintenance ................................................................. 10

First aid ......................................................................... 10

Disposal and environmental protection ......................... 10

Technical data ................................................................... 11

Denomination of components ......................................... 12

PUTTING INTO OPERATION

Mounting the cutting disc ............................................... 13

Fuels / Refuelling .....................................................14-15

Starting the engine ........................................................ 16

Cold-starting ................................................................. 16

Warm-starting ...............................................................16

Stop engine ................................................................... 16

Adjusting the carburetor .................................................. 17

MAINTENANCE

Changing the V-belt ......................................................18

Cleaning the protection hood ........................................ 19

Cleaning / changing the air lter ................................... 19

Replacing the spark plug .............................................. 20

Checking the ignition spark ............................................ 20

Replacing the suction head .......................................... 20

Replacing the starter cable ........................................... 21

Replacing the return spring ........................................... 22

Replacing the start spring ............................................. 22

Instructions for periodic maintenance ........................... 23

Replacing/cleaning the spark arrester screen ............... 23

Service, spare parts and guarantee ................................ 24

Troubleshooting ...............................................................25

SPECIAL ACCESSORIES

Diamond cutting discs, water tank ................................. 25

Extract from spare parts list ....................................... 26-27

2

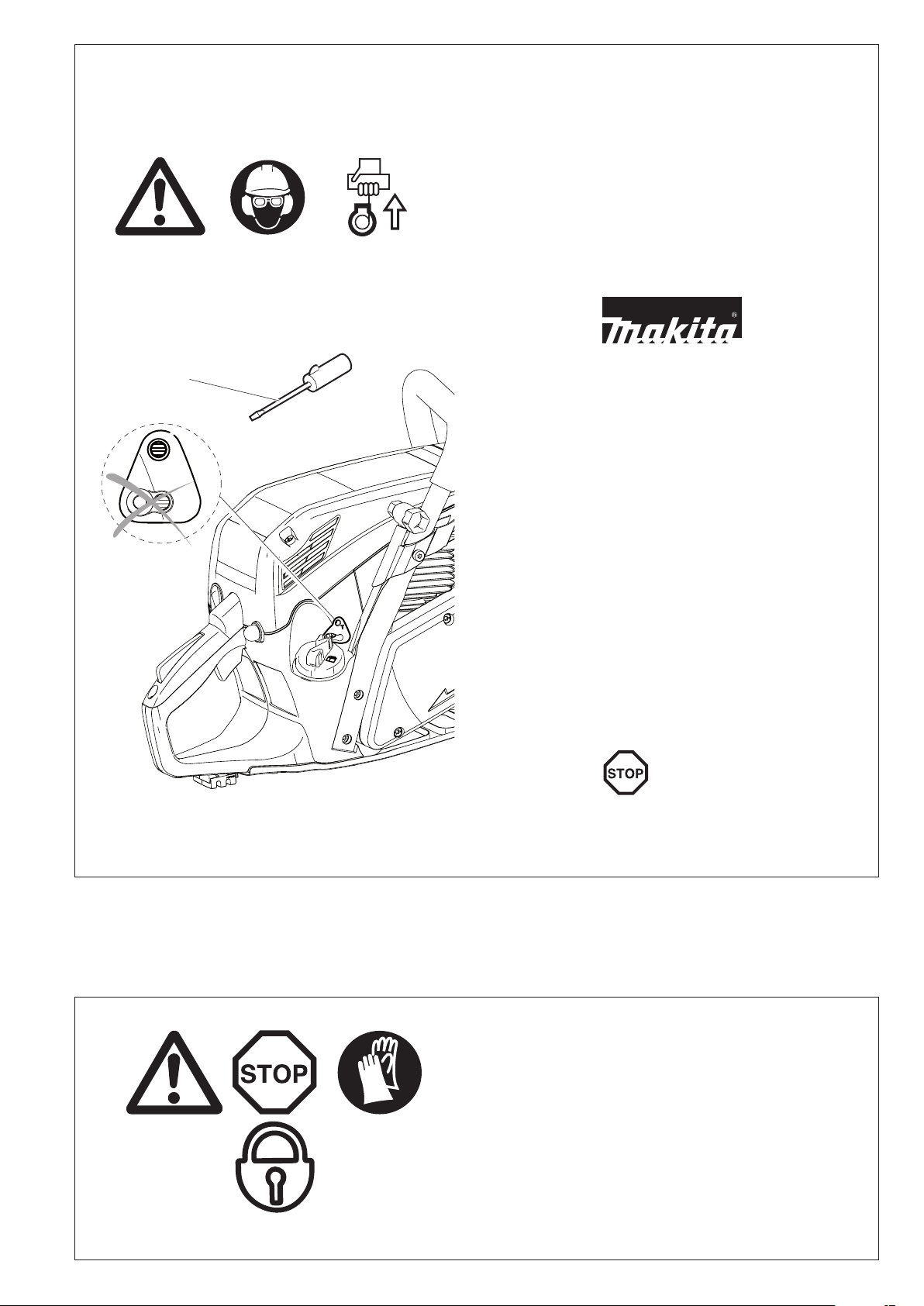

Page 3

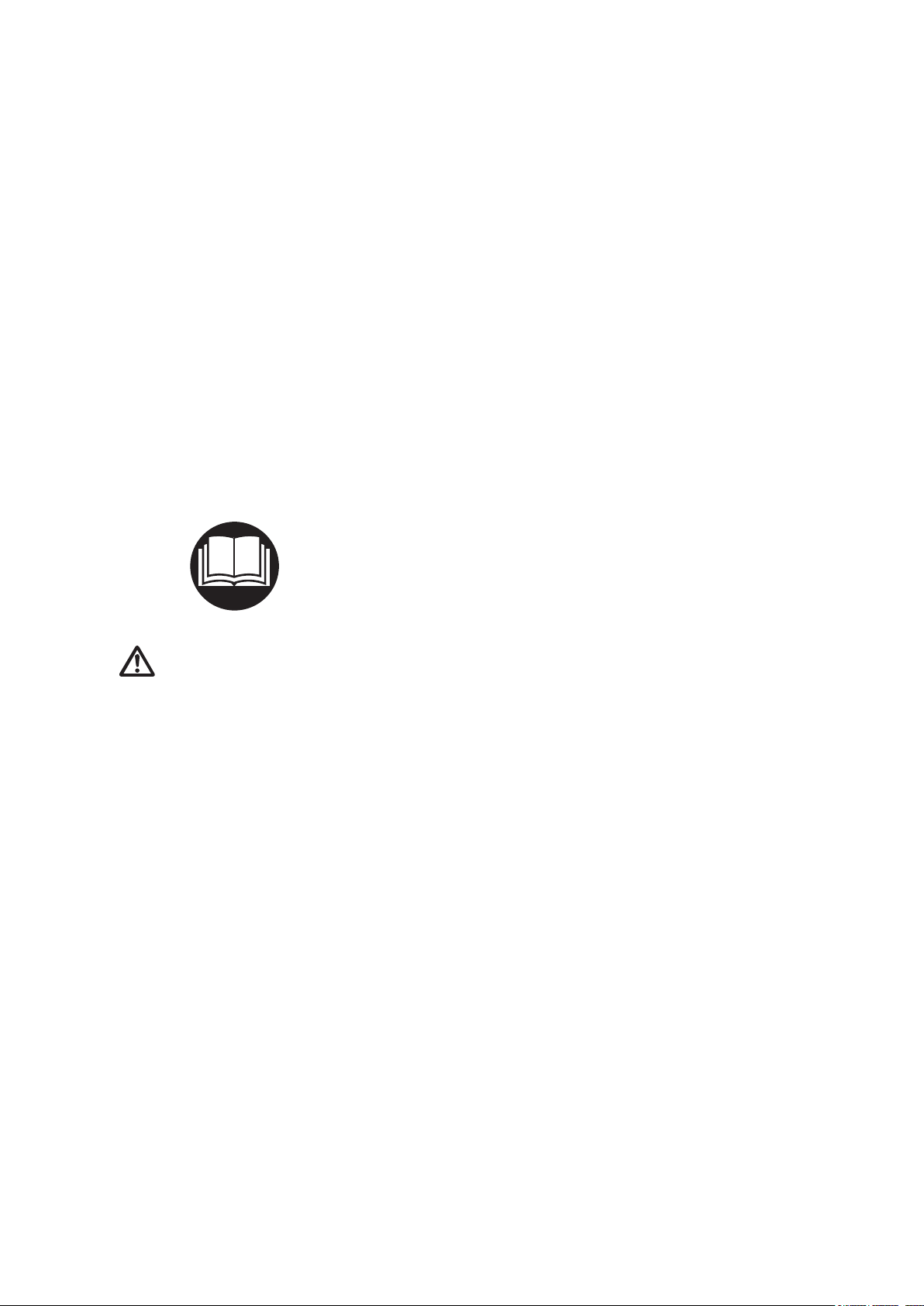

Delivery inventory

5

1. Power Cut

2. Cutting disc (not in the general scope of delivery. Country-specic)

3. Screwdriver (for carburetor adjustment)

4. Offset screwdriver

5. Universal wrench 13/19

6. Operator’s and safety manual (not shown)

4

3

2

1

In case one of the parts listed should not be included in the

delivery inventory, please consult your sales agent.

Symbols

You will notice the following symbols on the Power Cut and in the operator’s and safety manual:

Read operator’s and safety manual

and follow the warning- and safety

precautions!

Particular care and caution!

Forbidden!

Never use circular saw blades!

Never use damaged cutting discs!

Wear helmet and eye, respiratory

and hearing protection!

Wear protective gloves!

Wear respiratory protection!

Hazardous dust and/or

gas emission!

Fire hazard from ying sparks!

No smoking!

No open re!

Direction of cutting wheel rotation

Warning: the max. peripheral

speed of the cutting disc is 80 m/s!

Combination switch

Choke, On/Stop

Safety position

Start engine

Stop engine!

Warning!

Kickback!

Fuel and oil mixture

First aid

Recycling

Cutting disc dimensions

Do not touch hot surfaces!

3

Page 4

SAFETY PRECAUTIONS

Note: The illustrations in the safety precautions are not identical

with the product!

Intended use

Power Cut

Use the Power Cut cutoff saw outdoors only, for trimming and cutting suitable materials, using cutting discs rated for this machine.

Improper use:

Never use the cutoff saw cutting discs for grinding or sanding (using

the side of the cutting disc to remove material). The disc can break!

Never use the Power Cut with saw blades, cutter blades, brushes,

carbide tipped, wood cutting blades etc.

Unauthorised users:

Persons unfamiliar with the operator’s manual, children, young

people, and persons under the inuence of alcohol, drugs or med-

ications must not use the Power Cut.

General precautions

- The operator MUST read this operator’s manual to ensure

safe operation (even if you already have experience in using

cutoff saws). It is important to be familiar with the operation of

this particular cutoff saw. Users insufciently informed will endanger themselves as well as others due to improper handling.

- Let only persons who have experience in using cutoff saws work

with this unit. When letting another person use the Power Cut,

this operator’s manual must be provided along with it.

- First-time operators should ask a specialist to instruct them in

working with gasoline-powered cutoff saws.

- Children and persons under 18 years of age must not be allowed

to use this Power Cut. Persons over the age of 16 years may,

however, use the Power Cut for the purpose of being trained

as long as they are under the supervision of a qualied trainer.

- Working with the Power Cut requires high concentration.

- Operate the Power Cut only if you are in good physical condition.

If you are tired, your attention will be reduced. Be especially

careful at the end of a working day. Perform all work calmly and

carefully. The user has to accept liability for others.

- Never work while under the inuence of alcohol, drugs, medi-

cation or other substances which may impair vision, dexterity

or judgement.

- A re extinguisher must be available in the immediate vicinity

when working in easily inammable vegetation or when it has

not rained for a long time (danger of re).

- Asbestos and other materials that can release toxins may be cut

only with the necessary safety precautions and after notication

of the proper authorities and under their supervision or that of

a person appointed by them.

- The use of dust-reduction devices is urgently recommended

(see Accessories, pressure water tank, water tank).

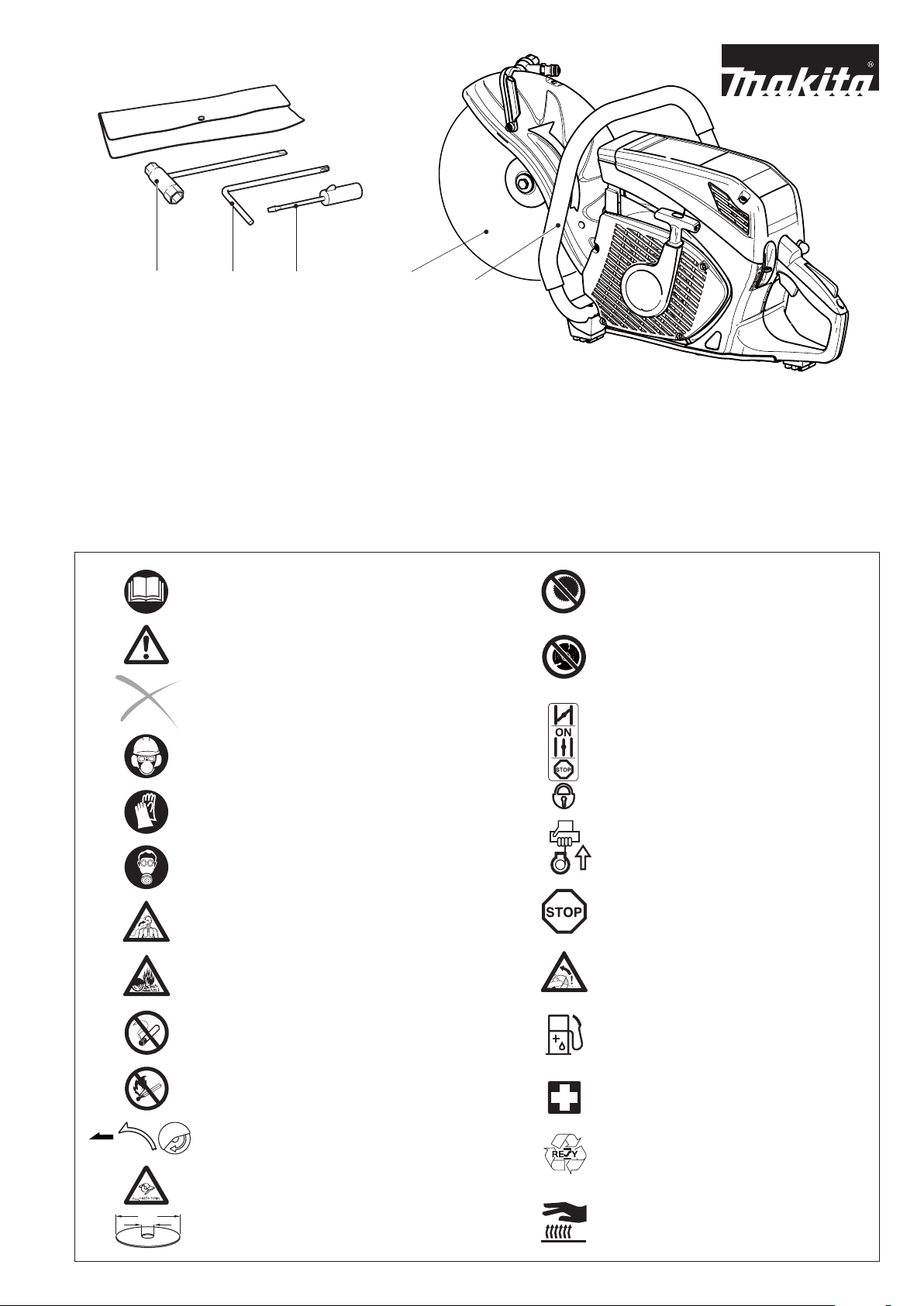

- The helmet visor (B) protects the face from dust and material

grains. In order to prevent injuries to eyes and face, always

wear protective goggles (C) or visor when using the Power

Cut.

- To prevent hearing damage, always wear suitable personal

hearing protection. (ear muffs (D), ear plugs, etc.). Octave

brand analysis upon request.

- When dry-cutting dust-producing materials such as stone

or concrete, always wear approved respiratory protection

(E).

- Work gloves (F) of tough leather are part of the required

work kit of the Power Cut and must always be worn when

working with the Power Cut.

1

2

Protective equipment

- In order to avoid head, eye, hand or foot injuries as well

as to protect your hearing the following protective equipment must be used during operation of the Power Cut:

When using personal protective equipment, ensure compliance with ANSI Z87.1!

- The kind of clothing should be appropriate, i. e. it should be

tight-tting but not be a hindrance. Clothing in which grains of

material can accumulate (trousers with cuffs, jackets and trousers with wide-open pockets, etc.) must not be worn, particularly

when cutting metal.

- Do not wear any jewellery or clothing that can get caught or

distract from the operation of the Power Cut.

- It is necessary to wear a protective helmet whenever working

with the Power Cut. The protective helmet (A) is to be checked

in regular intervals for damage and is to be replaced after 5

years at the latest. Use only approved protective helmets.

4

3

4

Page 5

- Always wear safety shoes or boots (G) with steel toes, non-skid

soles, and leg protectors when working with the Power Cut.

Safety shoes equipped with a protective layer provide protection

against cuts and ensure a secure footing.

- Always wear a work suit (H) of tough material with sufcient

ame-retardant qualities whenever working with the cutoff saw.

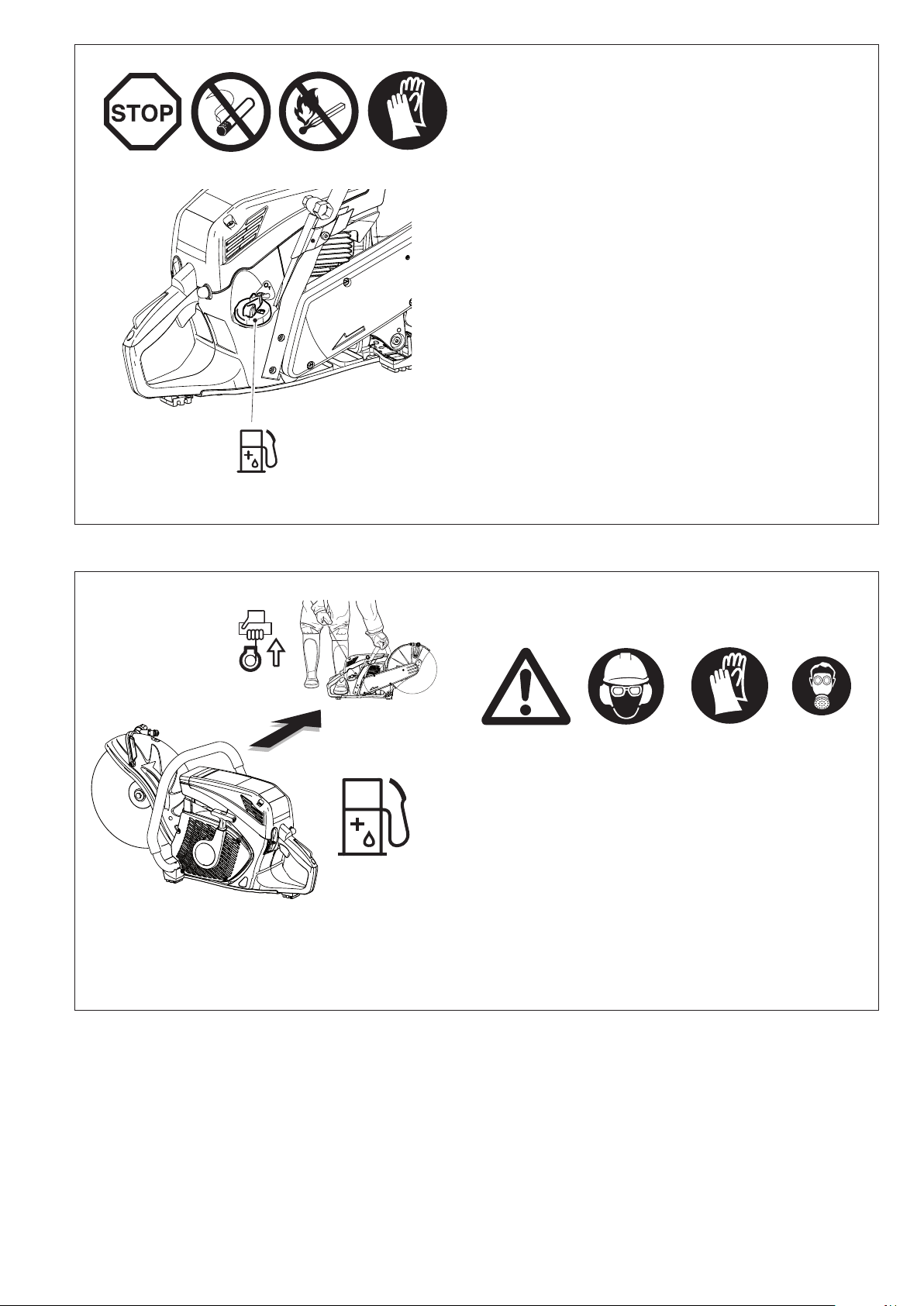

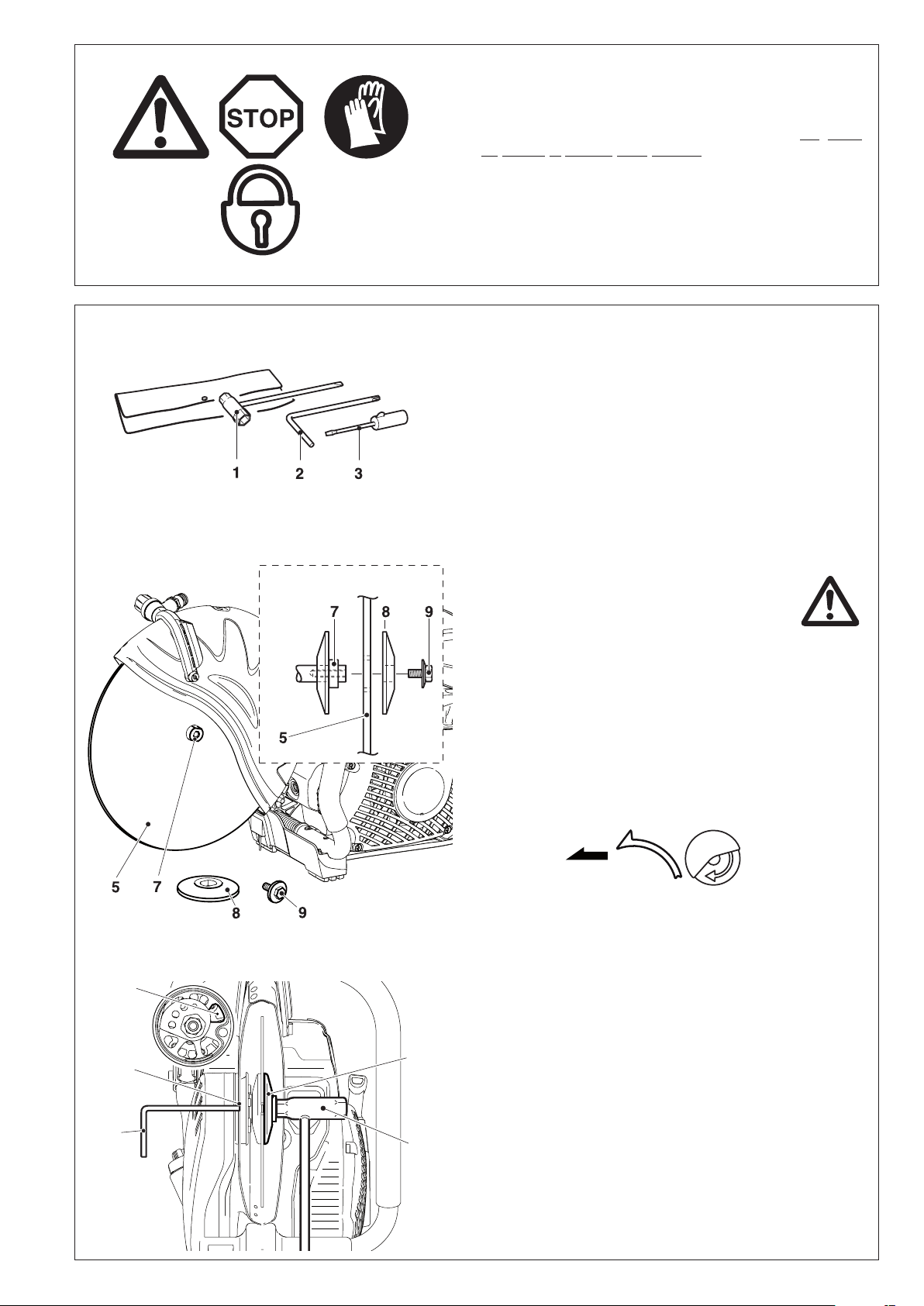

Fuels / Refuelling

- Go to a safe, level place before refuelling. Never refuel while

on scaffolding, on heaps of material, or in similar places!

- Switch off the engine before refuelling the Power Cut.

- Do not smoke or work near open res (6).

- Let the engine cool down before refuelling.

- Fuels can contain substances similar to solvents. Eyes and skin

should not come in contact with mineral oil products. Always wear

protective gloves when refuelling (not the regular work gloves!).

Frequently clean and change protective clothes. Do not breathe

in fuel vapors. Inhalation of fuel vapours can be hazardous to

your health.

- Do not spill fuel. If a spill occurs, clean off the Power Cut immediately. Fuel should not come in contact with clothes. If your

clothes have come in contact with fuel, change them at once.

- Ensure that no fuel oozes into the soil (environmental protection).

Use an appropriate base.

- Refuelling is not allowed in closed rooms. Fuel vapors will ac-

cumulate near the oor (explosion hazard).

- Ensure to rmly tighten the screw cap of the fuel tank.

- Before starting the engine, move to a location at least 3 meters

(approx. 10 feet) from where you fuelled the Power Cut (7), but

not within the extended swing range of the cutting disc (direction

of sparks).

- Fuel cannot be stored for an unlimited period of time. Buy only

as much as will be consumed in the near future.

- When making up the gasoline/oil mixture, always put the oil in

the mixing container rst, and then the gasoline.

- Use only approved and marked containers for the transport and

storage of fuel.

- Keep fuel away from children!

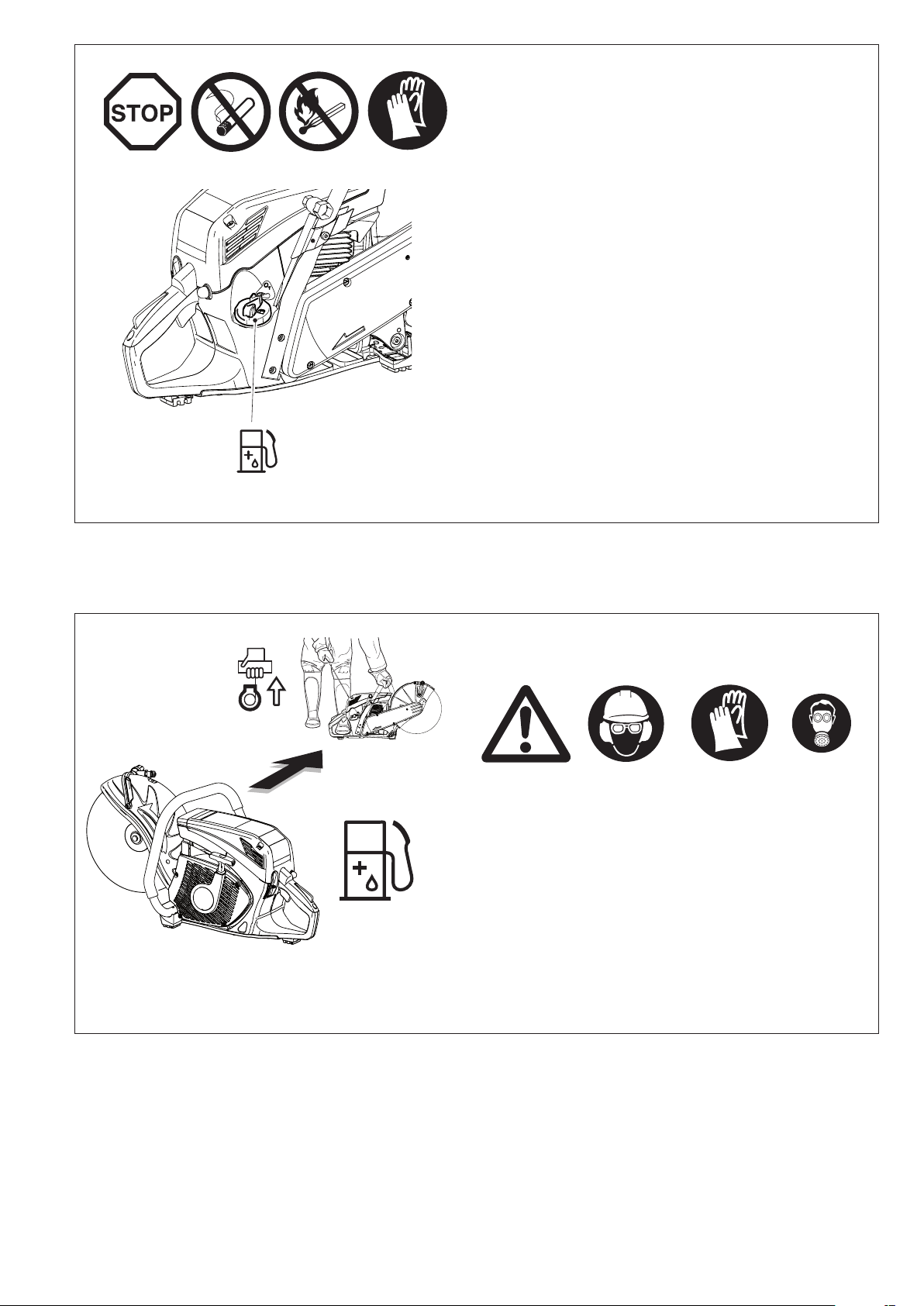

Putting into operation

- Do not work on your own. There must be someone around

in case of an emergency (within shouting distance).

- Observe all anti-noise regulations when working in residential

areas.

- Never use the Power Cut near inammable materials or

explosive gases! The Power Cut can create sparks leading

to re or explosion!

- Make sure that all persons within 30 meters (100 feet), such

as other workers, are wearing protective gear (see "Protective

Equipment") (8). Children and other unauthorized persons must

remain more than 30 meters away from the working area. Keep

an eye out for animals as well (9).

- Before starting work the Power Cut must be checked for

perfect function and operating safety according to the prescriptions. In particular, make sure that the cutting wheel is in

good condition(replace immediately if torn, damaged or bent), the

cutting wheel is properly mounted, the protective hood is locked

in place, the hand guard is properly mounted, the V-belt has the

proper tension, the throttle moves easily and the half-throttle lock

button functions properly, the grips are clean and dry, and the

combination switch functions properly (Start/Stop (I/O) switch,

choke). Visually inspect the mufer for damage and possible dirt

in the mufer area.

- Start the Power Cut only after complete assembly and inspection.

Never use the Power Cut when it is not completely assembled.

5

6

3 meters

7

30 m

=

8

wearing Protective Equipment

9

5

Page 6

Cutoff discs

- The protection hood must always be on! Change discs only

with the engine off!

- There are two basic types of cutoff discs:

- For metal (hot cutting)

- For masonry (cold cutting)

WARNING!

Never use carbide tipped, circular saw blades or any kind of wood

cutting blades. Never cut any type of wood. Reactive forces can

cause severe personal injury from blade contact or thrown tips.

NOTE: When using diamond cutoff discs, always make sure to observe

the "direction of rotation" markings. Diamond discs should only be

used for cutting masonry/brick/ concrete etc.

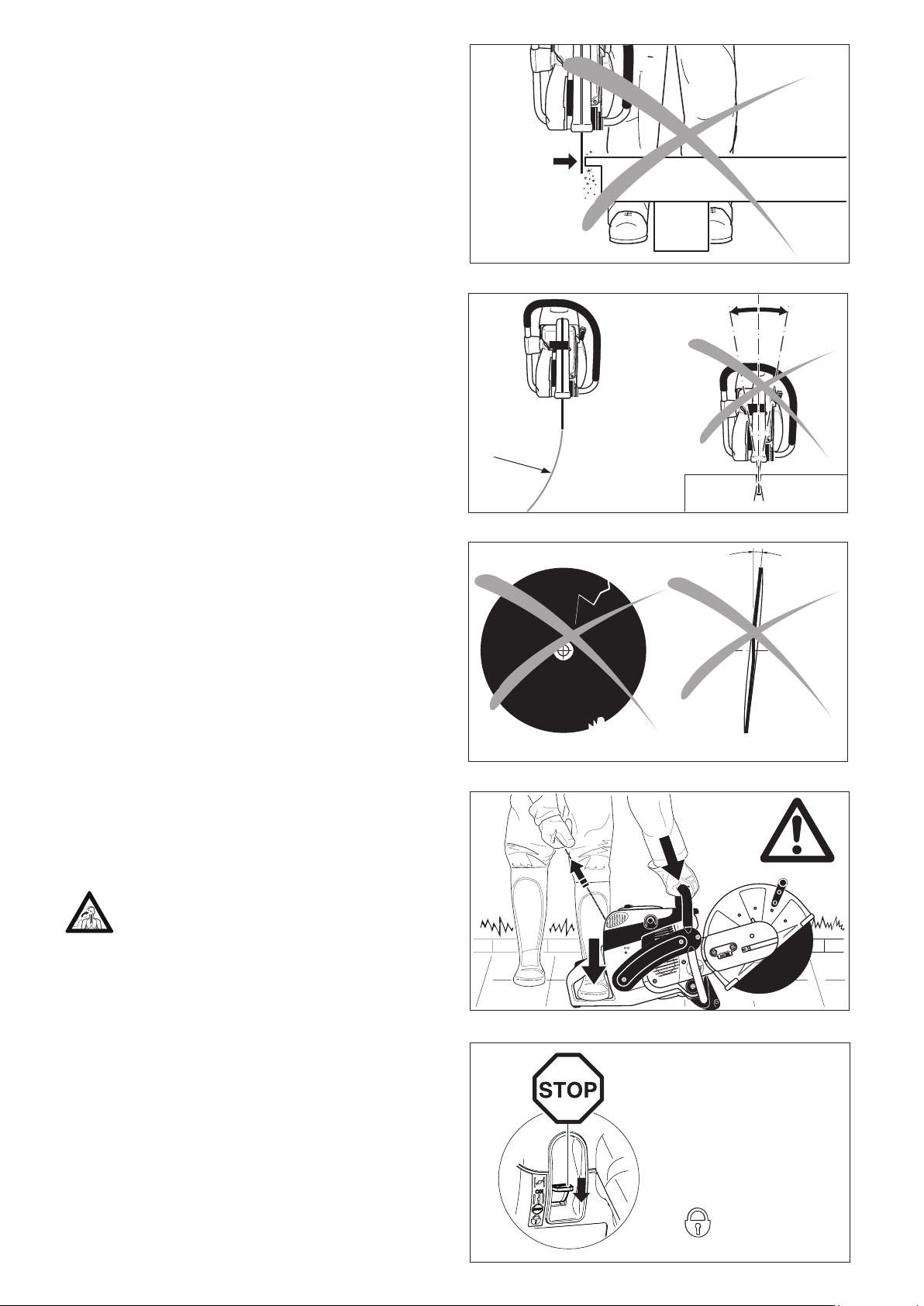

- Cutoff discs are intended only for radial loading, i.e. for cutting. Do

not grind with the sides of the cutting disc! This will break the disc

(10)!

Caution!

Never change direction (turning radius less than 5 meters (16

feet), exert lateral (sideways) pressure, or tip the Power Cut during

cutting (11)!

- Use a cutting disc only for cutting the materials it is intended for.

The proper type of disc must be used, for either metals or masonry.

- The arbor hole of the cutting disc must be an exact t with the arbor

or shaft. If the arbor hole is larger, it must be tted with an adapter

ring (available as an accessory).

- The cutting disc must be rated for freehand cutting at up to 4370

rpm or 80 m/sec for 350 mm discs, or up to 5100 rpm or 80 m/s

for 300 mm discs. Use only cutting discs that comply with EN

12413, EN 13236.

- The disc must be free of defects (12). Do not use defective cutting

discs.

Always tighten the cutting disc mounting bolt to a torque of 30

Nm. Otherwise, the cutting disc can twist.

- Before starting the cutting disc, make sure you have a steady footing.

- Put the Power Cut into operation only as described in this oper-

ator’s manual (13). Always place your left foot in the rear handle

and grasp the other handle rmly (with thumb and ngers). Other

starting methods are not allowed.

- When starting the Power Cut it must be well supported and securely

held. The cutting disc must not be touching anything.

- If the cutting disc is new, test it by running it at least 60 seconds at

top speed. When doing this, make sure that no persons or body parts

are in the extended swing range of the disc, in case it is defective

and ies apart.

- When working with the Power Cut always hold it with both

hands. Take the back handle with the right hand and the tubular

handle with the left hand. Hold the handles tightly with your thumbs

facing your ngers.

- CAUTION: When you release the throttle lever the disc will

keep spinning for a short period of time (free-wheeling effect).

- Continuously ensure that you have a safe footing.

- Hold the Power Cut such that you will not breathe in the

exhaust gas. Do not work in closed rooms or in deep holes

or ditches (danger of poisoning by fumes).

- WARNING – CARBON MONOXIDE PRODUCED DURING USE

CAN KILL – DO NOT USE POWER CUTTER INDOORS – MAKE

SURE THERE IS PROPER VENTILATION WHEN USING POWER

CUTTER IN TRENCHES OR OTHER CONFINED SPACES.

- Switch off the Power Cut immediately if you observe any

changes in its operating behavior.

- Switch off the engine before inspecting the V-belt tension or

tightening it, replacing the cutting wheel or eliminating faults

(14).

- Turn off the engine immediately and check the disc if you hear or

feel any change in cutting behaviour.

- Turn off the Power Cut when taking a break or stopping work (14).

Place the unit in such a way that the disc is not touching anything

and cannot endanger anyone.

- Do not put the overheated Power Cut in dry grass or on any inammable objects. The mufer is very hot (danger of re).

- IMPORTANT: After wet cutting, rst turn off the water feed and then

let the disc run at least 30 seconds, to ing off the remaining water

and prevent corrosion.

10

min. 5 m

11

12

13

● Refuelling

● Changing cutoff discs

● Stopping work

● Transport

● Putting out of function

● Maintenance

14

6

Page 7

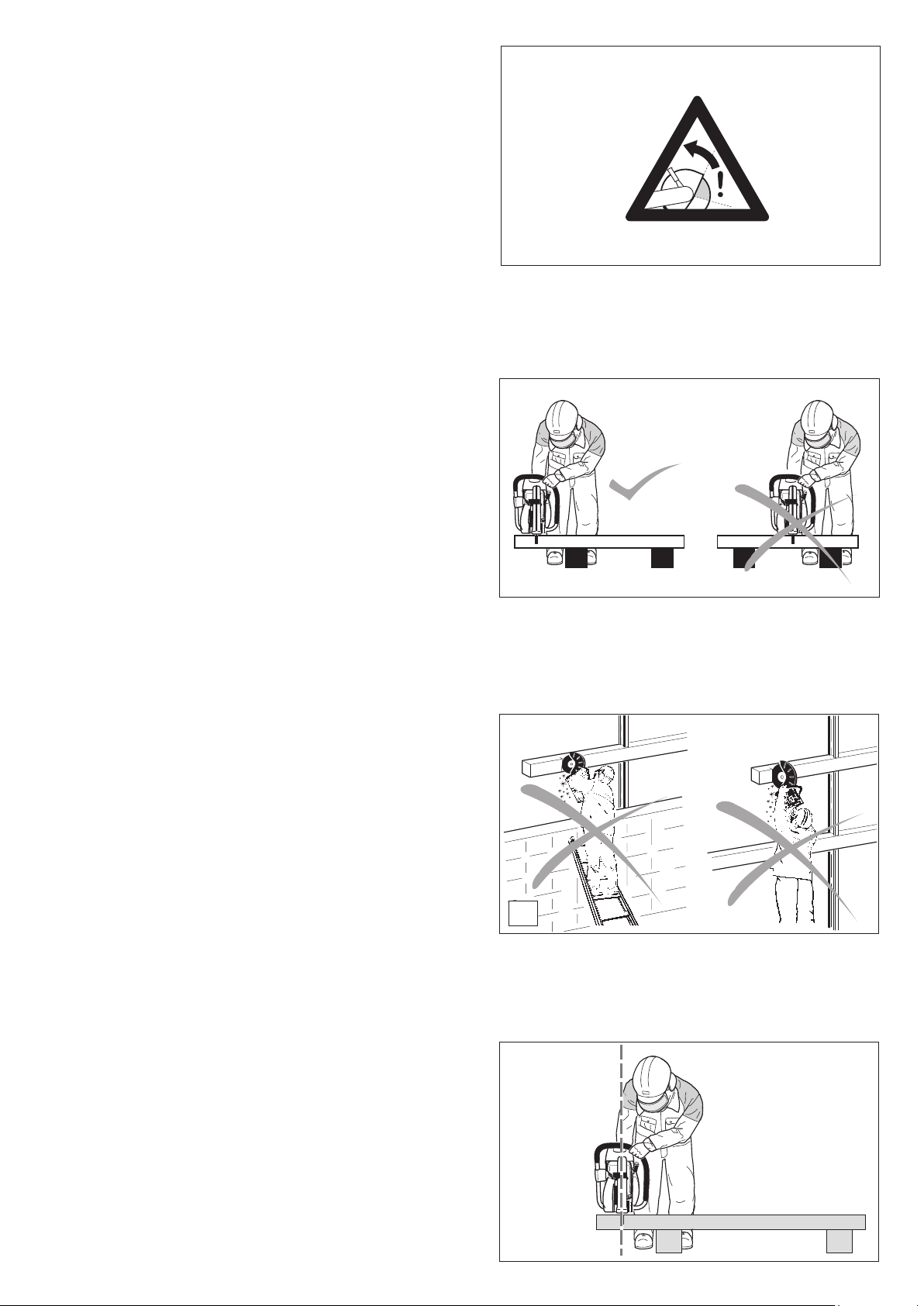

Kickback, lock-in and gyroscopic forces

- When working with the Power Cut there is a danger of kickback

and lock-in.

- Kickback occurs when the top of the cutting disc is used for

cutting (15).

- This causes the Power Cut to be thrown back toward the user

with great force and out of control. Risk of injury!

To prevent kickback, observe the following:

- Never cut with the section of the cutting disc shown in gure 15.

Be especially careful when reinserting the disc into cuts

that have already been started!

- Lock-in occurs when the cut narrows (crack, or workpiece under

stress).

- This causes the Power Cut to suddenly jump forward, out of

control and with great force. Risk of injury!

To prevent lock-in, observe the following:

- When reinserting the disc into previous cuts, have the Power

Cut running at top speed. Always cut at top speed.

- Always support the workpiece so that the cut is under tension

(16), so that the cut does not press together and jam the cutting

disc as it proceeds through the material.

- When starting a cut, apply the disc to the workpiece with care.

Do not just shove it into the material.

- Never cut more than one piece at a time! When cutting, make

sure that no other workpiece comes into contact.

- Gyroscopic forces come into play when handling a power cutter

with a rapidly rotating composite wheel.

- The power cut will react in an uncontrolled manner. There is a

danger that injuries may occur.

In order to prevent gyroscopic forces developing, please

note the following: Do not rotate the machine rapidly about

its longitudinal axis!

15

16

Working behavior / Method of working

- Check the integrity of the composite wheel both before and after

tting it to the machine.

- Before starting work, check the work area for any hazards

(electrical wires, inammable substances). Clearly mark the

work area (for example with warning signs or by cordoning off

the area).

- When working with the Power Cut hold it rmly by the front and

rear handles. Never leave the Power Cut unattended!

- Use the Power Cut at high speed as far as possible (see “Technical Data”).

- Only use the Power Cut during good light and visibility periods.

Be aware of slippery or wet areas, and of ice and snow (risk of

slipping).

- Never work on unstable surfaces. Make sure that there are no

obstacles in the working area, risk of stumbling. Always ensure

that you have a safe footing.

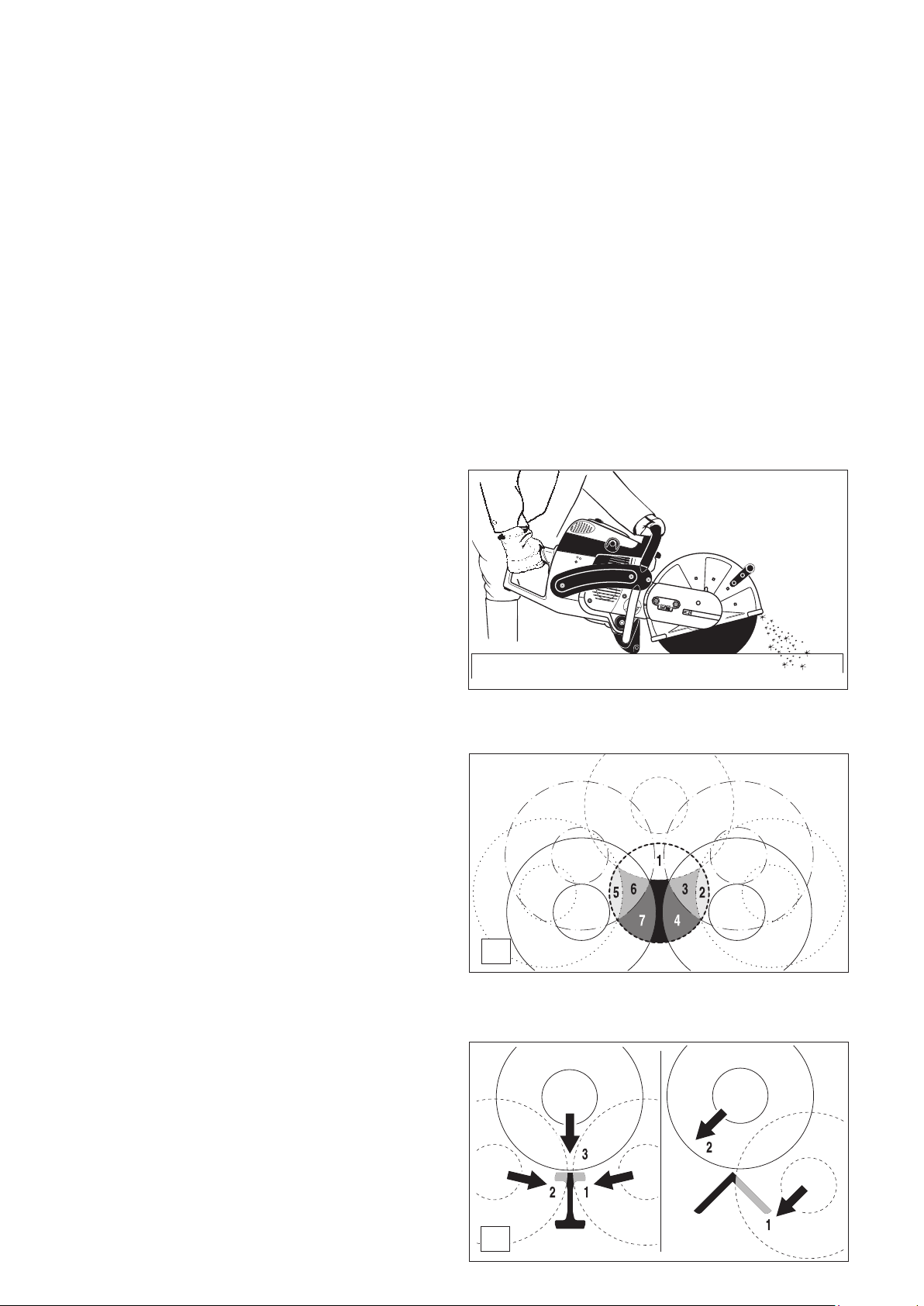

- Never cut above your shoulder height (17).

- Never stand on a ladder to cut (17).

- Never use the Power Cut while standing on scaffolding.

- Do not lean over too far when working. When putting down and

picking up the Power Cut, do not bend over from the waist, but

instead bend in the knees. Save your back!

- Guide the Power Cut in such a way that no part of your body

is within the extended swing range of the disc (18).

- Use cutting discs only for the materials for which they are designed!

- Use cutting discs only for the materials for which they are designed. Do not use the Power Cut to lift up and shovel away

pieces of material and other objects.

Important! Before cutting, remove all foreign objects, such as

rocks, gravel, nails etc. from the cutting area. Otherwise, such

objects can be ung away by the disc with great speed. Injury

hazard!

- When cutting workpieces down to length use a rm support.

If necessary, secure the workpiece from slipping, but do not

steady it with your foot or allow another person to hold it.

- When cutting round items, always secure them against rotation.

17

18

7

Page 8

When using synthetic resin cutting discs, always observe the following:

CAUTION:

- Synthetic resin cutting discs can absorb moisture. This

moisture can cause the disc to become unbalanced at high

speed. This imbalance can cause the disc to break.

- Do not cool resin cutting discs with water or other uids.

- Do not expose resin cutting discs to high humidity or rain!

Do not use resin cutting discs past their use-by date (expiration date)! The date (quarter and year) is stamped on the disc’s

arbor ring.

EXAMPLE: 04 / 2018

This cutting disc can be used through the end of the fourth quarter

of 2018, if properly stored and correctly used.

Cutting metals

IMPORTANT!

Always wear approved respiratory protection!

Materials that can release toxic substances may be cut only

after notifying the proper authorities and under their supervision or that of a person appointed by them.

CAUTION!

The rapid rotation of the cutting disc heats metal and melts it at

the point of contact. Swing the guard as far down as possible

(19) in order to direct the stream of sparks forward, away from

the operator (re hazard).

- Determine the cut line, mark the cut and apply the disc to the

material at moderate speed, to cut a guide groove before going

to top speed and applying more pressure to the Power Cut.

- Keep the disc straight and vertical. Do not tip it, as this can

break it.

- The best way to get a good, clean cut is to pull or move the

Power Cut back and forth. Do not simply press the disc into

the material.

- Thick round stock is best cut in stages (20).

- Thin tubing and pipes can be cut with a simple downward cut.

- Cut large-diameter pipes as for round stock. To prevent tipping

and for better control, do not let the disc sink too deeply into the

material. Instead, always cut shallow around the whole piece.

- Worn discs have a smaller diameter than new discs, so that at

the same engine speed they have a lower effective circumferential speed and therefore do not cut as well.

- Cut I-beams and L-bars in steps; see Figure 21.

- Cut bands and plates like pipes: along the wide side with a long

cut.

- When cutting material under stress (supported material or material in structures), always make a notch in the thrust (pressure)

side, and then cut from the tension side, so that the disc does

not lock in. Secure cutoff material from falling!

Cutting masonry and concrete

IMPORTANT!

Always wear approved respiratory protection!

Asbestos and other materials that can release toxic sub-

stances may be cut only after notifying the proper authorities

and under their supervision or that of a person appointed

by them. When cutting prestressed and reinforced concrete

piles, follow the instructions and standards of the responsible authorities or the builder of the structural member.

Reinforcement rods must be cut in the prescribed sequence

and in accordance with applicable safety regulations.

NOTE:

Mortar, stone, and concrete develop large quantities of dust during

cutting. To increase the lifetime of the cutting disc (by cooling),

to improve visibility, and to avoid excessive dust creation, we

strongly recommend wet cutting instead of dry cutting.

19

20

CAUTION!

If there is a chance that the material is under stress, be pre-

pared for it to kick back. Make sure you can get out of the

way if you have to!

Be particularly careful in scrap-metal yards, junkyards, at accident sites, and with haphazard piles of material. Precariously

balanced pieces or pieces under stress can act in unpredictable

ways, and may slide, jump out, or burst. Secure cutoff material

from falling! Always exercise extreme caution and use only

equipment that is in perfect working order.

Observe the accident-prevention rules and regulations of your

employer and/or insurance organization.

8

21

Page 9

In wet cutting, the disc is wetted at an equal rate on both sides

by a trickle of water. MAKITA offers the right accessories for all

wet cutting applications (see also "SPECIAL ACCESSORIES").

- Remove foreign objects such as sand, stones and nails found

within the working area. Caution: Watch out for electric wires

and cables!

The rapid rotation of the cutting disc at the point of contact

throws fragments out of the cut groove at high speed. For

your safety, swing the protection hood down as far as possible (23), so that material fragments are thrown forward, away

from the operator.

- Mark the cut, and then make a groove about 5 mm (just under

1/5") along the entire length of the planned cut. This groove will

then guide the Power Cut accurately guring the actual cutoff.

- Perform the cut with a steady back-and-forth motion.

- When cutting slabs to size, you need not cut through the entire

material thickness (creating unnecessary dust). Instead, simply

make a shallow groove, and then knock off the excess material

cleanly on a at surface (25).

CAREFUL!

When cutting into lengths, cutting through material, making cutouts, etc., always make sure to plan the direction and sequence

of cuts in such a way that the disc does not get jammed by the

cut-off piece, and that no persons can be injured by falling pieces.

23

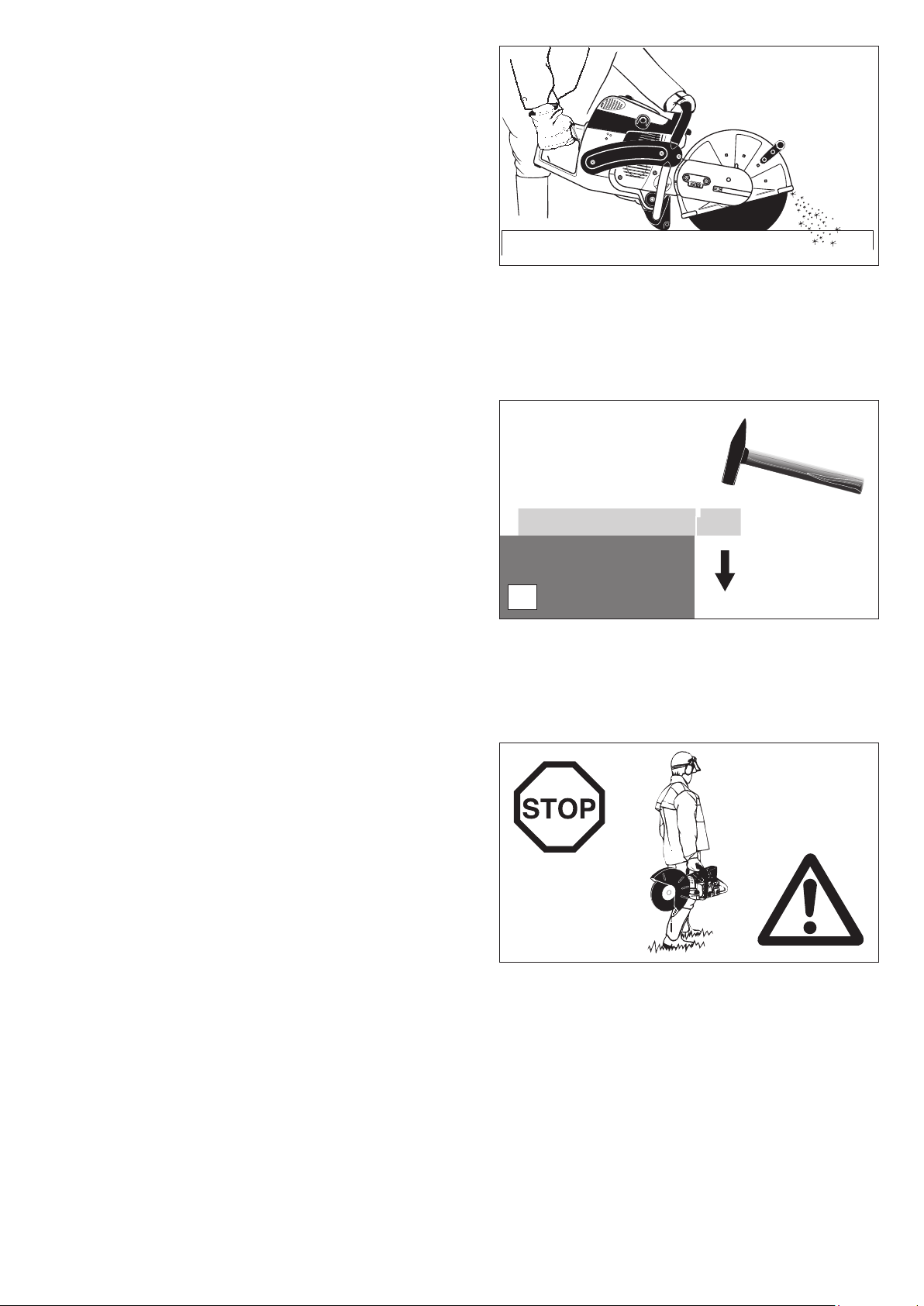

Transport and storage

- Always turn off the Power Cut when transporting it or

moving it from place to place on a site (26).

- Never carry or move the unit with the engine on or the

disc moving!

- Carry the unit only by the tubular (middle) handle with the cutting disc pointing behind you (26). Avoid touching the exhaust

mufer (burn hazard!)

- When moving the Power Cut over longer distances, use a

wheelbarrow or wagon.

- When transporting the Power Cut in a vehicle, make sure it is

securely positioned in such a way that no fuel can leak out.

Always remove the cutting disc before transporting the unit in

a vehicle.

- The Power Cut should be stored safely in a dry place. It must

not be left outdoors! Always dismount the cutting disc before

storage. Keep the Power Cut away from children.

- Before long-term storage and before shipping the Power

Cut, follow the instructions in the chapter on "Periodic

care and maintenance". ALWAYS empty the fuel tank and

run the carburetor dry.

- When putting cutting discs in storage, be careful to:

• Clean and dry them well. CAUTION: Do NOT clean synthetic

resin cutting discs with water or other uids!

• Store them lying down at.

• Avoid dampness, freezing temperatures, direct sunshine,

high temperatures and temperature uctuations, as these

can cause breakage and splintering.

• Before re-using a resin cutting disc, make sure of the use-by

(expiration) date (quarter and year, stamped on the arbor ring).

If this date has been exceeded, do NOT use the cutting disc.

- Always check new cutting discs or cutting discs that have

been in storage to make sure that they are free of defects

and before the rst cut test-run the tool at top speed for at

least 60 seconds. Keep body parts and people well away out

of range of the direction of the cutting disc during this test.

25

26

9

Page 10

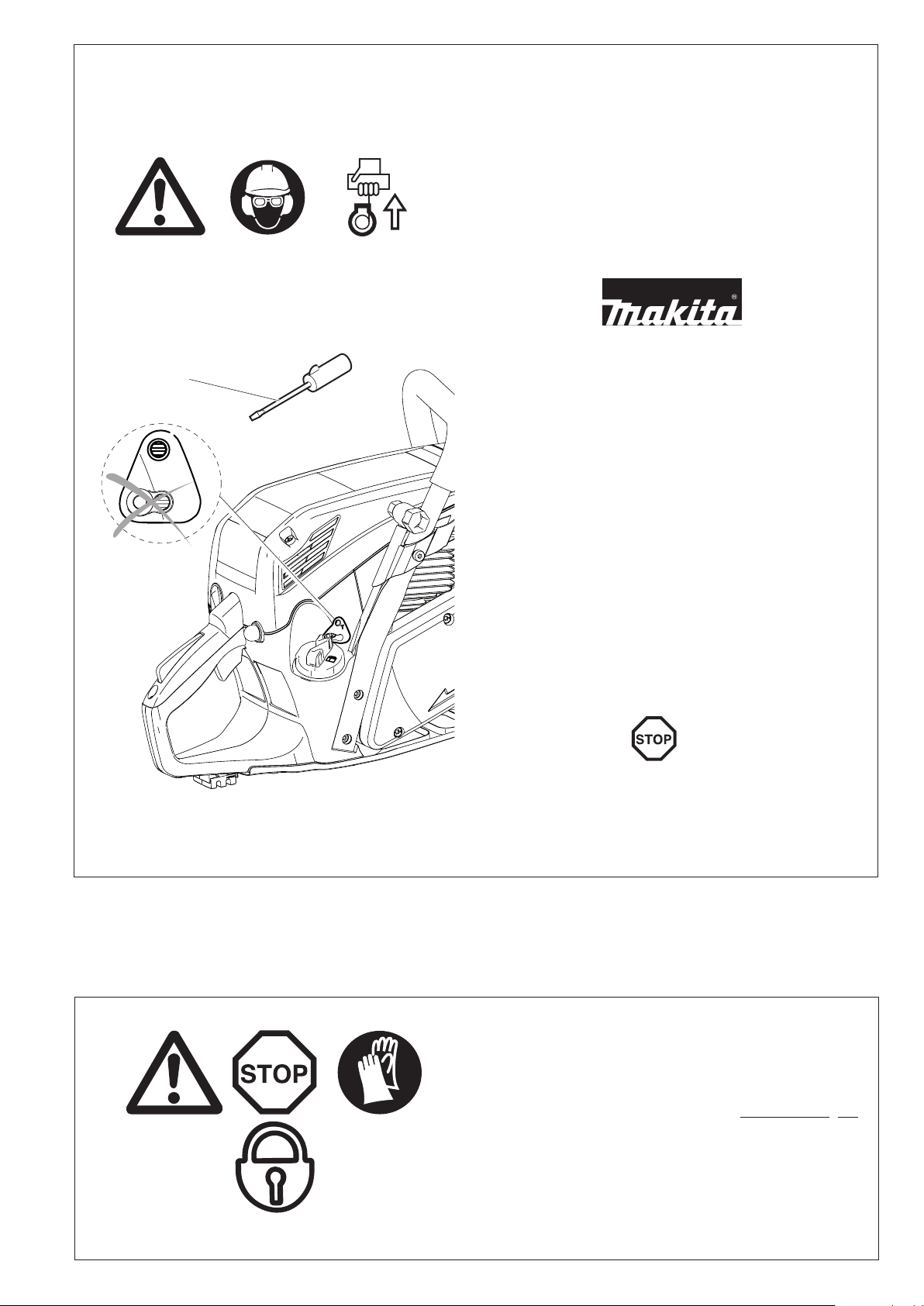

Maintenance

- Before performing maintenance work switch off the Power

Cut (27) and pull out the plug cap.

- Allow the Power Cut to cool off before doing any maintenance work (burn hazard)!

- Always check the Power Cut before using it to make sure that

it is in good working order. In particular, make sure that the

cutting disc is properly mounted. Make sure that the cutting

wheel is undamaged and suitable for the job it will be used for.

- Operate the Power Cut only at a low noise and emission level.

For this ensure the carburetor is adjusted correctly.

- Clean the Power Cut regularly.

- Check the fuel tank cap regularly for good sealing.

Observe the accident prevention instructions issued by

trade associations and insurance companies. NEVER

make any modications to the Power Cut! You will only

be putting your own safety at risk!

Perform only the maintenance and repair works described in

the operator’s manual. All other work must be carried out by

MAKITA Service.

Use only original MAKITA spares and accessories.

The use of non-MAKITA spares, accessories, or cutting discs

increases the risk of accident. We cannot accept any responsibility for accidents or damage occurring in association with the

use of cutting discs or accessories other than original MAKITA.

27

SERVICE

28

First aid

For the event of a possible accident, please make sure that a

rst aid kit is always immediately available close by. Immediately

replace any items used from the rst aid box.

When calling for help, give the following information:

- Place of the accident

- What happened

- Number of injured people

- Kind of injuries

- Your name!

NOTE

Individuals with poor circulation who are exposed to excessive

vibration may experience injury to blood vessels or the nervous

system.

Vibration may cause the following symptoms to occur in the ngers, hands or wrists: ”Falling asleep” (numbness), tingling, pain,

stabbing sensation, alteration of skin colour or of the skin. If any

of these symptoms occur, see a physician!

Disposal and environmental protection

Be mindful of the environment!

Dispose of worn-out or defective cutting discs in accordance with

your local disposal regulations. To protect unusable cutting discs

from misuse, destroy them before disposal.

When the Power Cut is worn out or damaged beyond repair, have

it disposed of or recycled in an environmentally sound manner. If

necessary, consult your local authorities.

29

10

Page 11

Technical data

Displacement cu in (cm3)

EK6100 EK6101

3.7 (60.7) 3.7 (60.7)

Bore in (mm) 1.85 (47) 1.85 (47)

Stroke in (mm) 1.38 (35) 1.38 (35)

Max. power / operating speed

hp (kW)/1/min

4.4 (3.2) / 9.500 4.4 (3.2) / 9.500

Max. torque Nm 3.9 3.9

Idling speed 1/min 2.600 2.600

Clutch engagement speed 1/min 3.900 3.900

Engine speed limitation 1/min 9.850 ± 150 9.850 ± 150

Max. spindle speed 1/min 5.100 4.400

Sound pressure level at the operators ear dB(A) 100 100

Sound pressure level at the bystander’s position (50 ft) dB(A) 79 80

Vibration acceleration a

- Tubular handle (rated speed) m/s

per ANSI.175.4

h,w

2

5.6 5.6

- Rear handle (rated speed) m/s2 5.1 5.1

Carburetor (diaphragm carburetor) Type ZAMA

Ignition system (with speed limitation) Type electronic

Spark plug Type

NGK BPMR 7A

Electrode gap in (mm) .020 (0.5) .020 (0.5)

Fuel consumption at max. load per ISO 8893 kg/h 1.42 1.42

Specic consumption at max. load per ISO 8893 g/kWh 430 430

Fuel tank capacity oz (l) 23.6 (0.7) 23.6 (0.7)

Mixture ratio (fuel/two-stroke oil)

- when using MAKITA Synthetic oil 50:1 50:1

- when using other synthetic oil (quality grade: JASO FC or ISO EGD) 50:1 50:1

Cutting disc for 80 m/sec.

Cutting disc for 80 m/sec.

1)

in 12" / 0.8" / 0.2"

1) 3)

in --

2)

14" / 1" / 0.2"

14" / 0.8" / 0.2" 2)

2)

Arbor diameter in 0.8" 0.8"

Overall weight (tanks empty, without cutting disc) lb (kg) 18.7 (8,5) 19.6 (8,9)

1)

Circumference speed at max. engine speed.

2)

Outside diameter / arbor hole / maximum permissible thickness of the composite wheels.

3)

Country-specic.

11

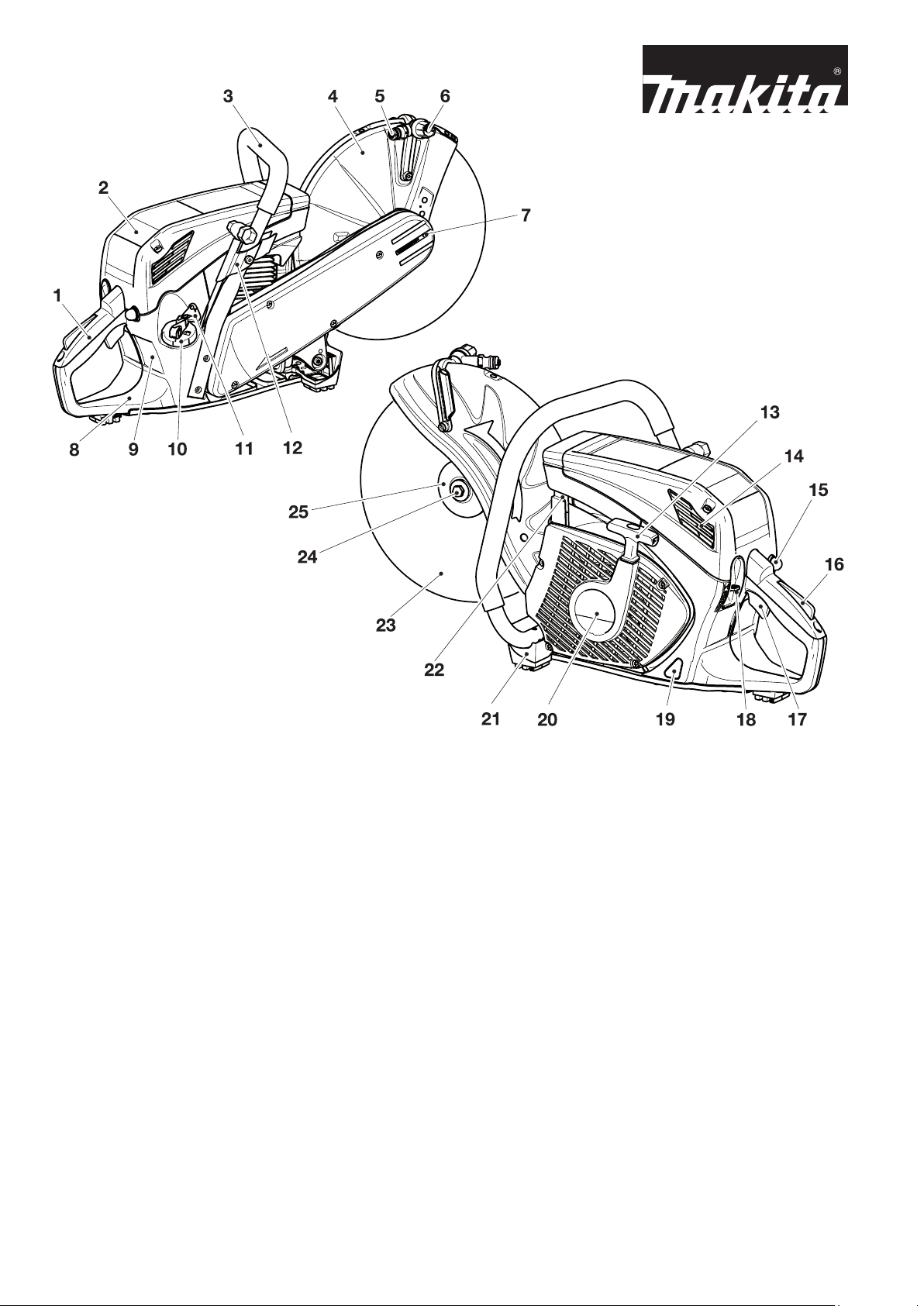

Page 12

Denomination of components

1 Handle

2 Air lter cover

3 Tubular handle

4 Protection hood

5 Water set

6 Adjusting screw

7 Hold opening

8 Fuel tank with handle

9 Identication plate

10 Tank cap (fuel)

11 Carburetor adjustment opening

12 Holder for combination tool and 1/2" hose

13 Starter grip

12

14 Air intake

15 Fuel pump (Primer)

16 Safety locking button

17 Throttle lever

18 Combination switch „Choke, On/Stop (I/O)”

19 Fuel tank ll-level window

20 Starter housing with starter

21 Stand

22 Mufer

23 Cutting disc

24 Disc bolt

25 Spring washer

Page 13

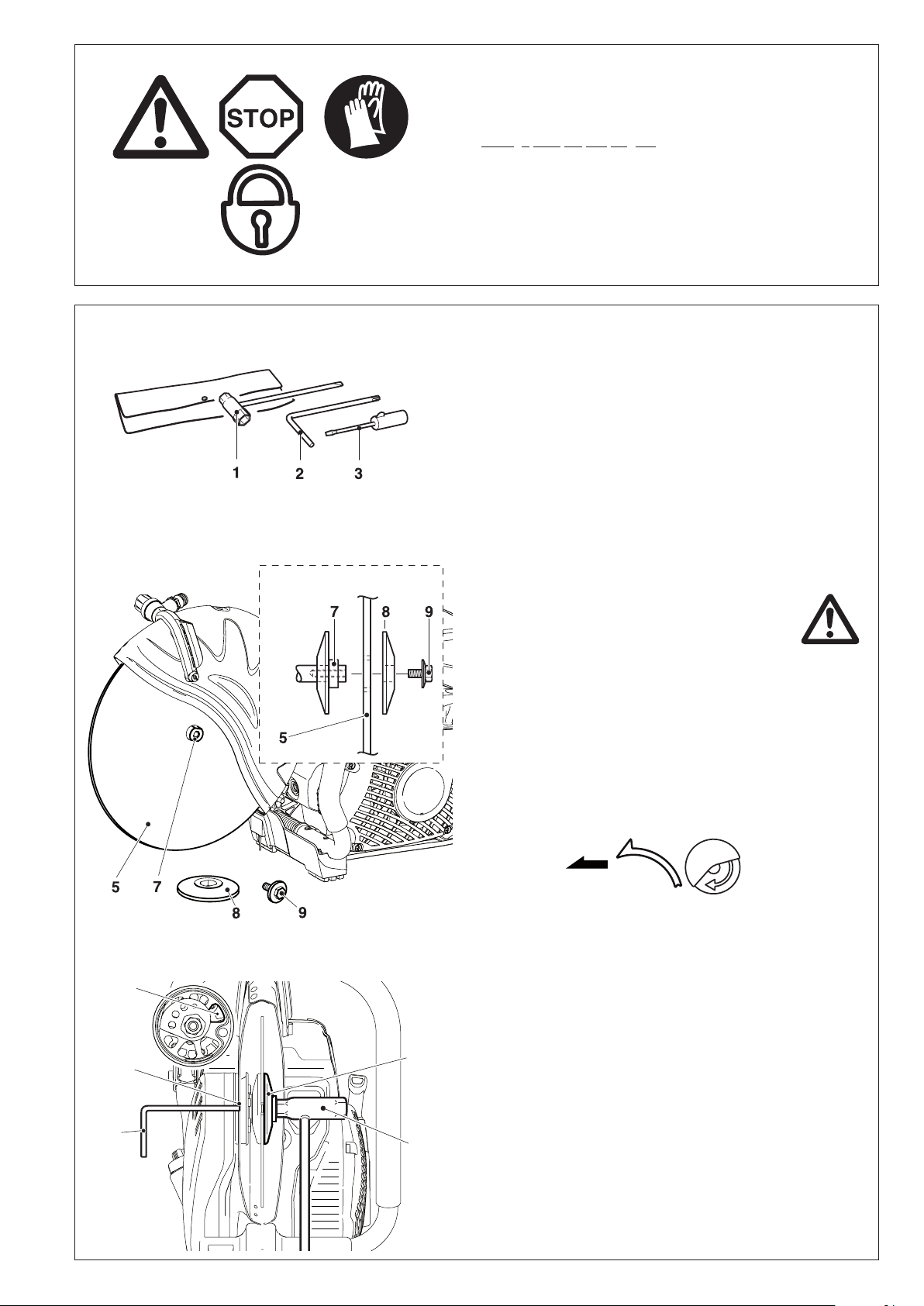

PUTTING INTO OPERATION

CAUTION:

Always turn off the engine and pull off the spark plug cap

before doing any work on the Power Cut! Always wear

protective gloves!

CAUTION:

Start the Power Cut only after complete assembly and

inspection.

For the the following work, use the assembly tools included

with delivery:

1. 13/19 AF combination wrench

2. Allen key

3. Carburetor adjustment screwdriver

Place the Power Cut on a stable surface and carry out the

following assembly steps:

11

Sequence

Mounting the cutting disc

Check the integrity of the composite wheel both

before and after tting it to the machine.

See SAFETY INSTRUCTIONS, Page 6.

Unscrew screw (9) and remove the spring washer (8).

Place the cutting disc (5) on the arbour (7).

NOTE:

The arbor hole of the cutting disc must be an exact t with the

arbor or shaft. Ensure that the composite wheel is seated correctly!

For cutoff discs with 25.4 mm (1”) arbor holes, use the correct size disc holder (supplied only with cutoff discs with 25.4

mm (1”) arbor holes). Non-compliance can cause serious

injury!

Make sure the cutting disc is installed so it turns in the right

direction, if a direction is marked on the disc.

2

10

Place the spring washer (8) on the arbour and insert the screw

(9) and tighten by hand.

8

Slowly turn the cutoff disc until a hole (11) in the V-belt pulley

is visible in the counter-holding opening (10) of the cutting arm.

Insert the Allen key (2) as far as it will go. The shaft is now blocked.

Tighten the screw with the combination wrench (1).

1

NOTE: Tighten the screw rmly (30 ± 2 Nm), as otherwise

the cutting wheel may slip during cutting.

Remove the Allen key and combination tool.

13

Page 14

Fuels

Caution:

This tool uses petroleum products (gasoline and oil).

Be especially careful when handling gasoline.

Do not smoke. Do not allow gasoline to come near ames,

sparks or re (explosion hazard).

Fuel mixture

This tool is powered by a high-performance air-cooled two-stroke

engine. It runs on a mixture of gasoline and two-stroke engine oil.

The engine is designed for unleaded regular gasoline with a

min. octane value of 89 (R+M)/2. In case no such fuel is available, you can use fuel with a higher octane value. This will not

affect the engine.

In order to obtain an optimum engine output and to protect

your health and the environment use unleaded fuel only.

To lubricate the engine, use a synthetic oil for two-stroke air-cooled engines (quality grade JASO FC or ISO-L-EGD), which has

to be added to the fuel.

The correct mixture ratio:

50:1 When using MAKITA synthetic two-stroke engine oil, i.

e. 50 parts gasoline to 1 part oil.

50:1 When using other synthetic two-stroke engine

oil (quality grade JASO FC or ISO -L -EGD), i. e. 50

parts gasoline to 1 part oil.

Gasoline

50:1

OIL

+

50:1

1.0 Us-gal. (3.7 l) 2.6 oz. (75 cm3)

2.5 Us-gal. (9.4 l) 6.4 oz. (189 cm3)

5.0 Us-gal. (18.9 l) 12.8 oz. (378 cm3)

The Storage of Fuel

Fuels have a limited storage life. Fuel and fuel mixtures

age through evaporation, especially at high temperatures. Aged fuel and fuel mixtures can cause starting

problems and damage the engine.

Purchase only that amount of fuel, which will be consumed over the next few months. At high temperatures,

once fuel has been mixed it should be used up in 6-8

weeks.

Store fuel only in proper containers, in dry, cool,

secure locations!

MAKITA synthetic two-stroke engine oil (50:1) is available in the

following sizes to suit your individual requirements:

2.6 oz. order number T-00745

6.4 oz. order number T-00739

NOTE: For preparing the fuel-oil mixture rst mix the entire oil

quantity with half of the fuel required, then add the remaining fuel.

Thoroughly shake the mixture before lling it into the tank.

Caution: Open the tank cap carefully, as pressure might have

built up inside!

It is not wise to add more engine oil than specied to ensure

safe operation. This will only result in a higher production of

combustion residues which will pollute the environment and

clog the exhaust channel in the cylinder as well as the mufer.

In addition, fuel consumption will rise and performance will

decrease.

AVOID SKIN AND EYE CONTACT

Mineral oil products degrease your skin. If your skin

comes in contact with these substances repeatedly and

for an extended period of time, it will desiccate. Various

skin deseases may result. In addition, allergic reactions

are known to occur.

Eyes can be irritated by contact with oil. If oil comes into

your eyes, immediately wash them with clear water. If

your eyes are still irritated, see a doctor immediately!

14

Page 15

Fuel mixture

Refuelling

IMPORTANT:

FOLLOW THE SAFETY PRECAUTIONS!

Be careful and cautious when handling fuels.

The engine must be turned off and cooled down!

Carefully clean the area around the fuel-tank ller neck to keep

dirt from getting in the tank.

Place the Power Cut on an even surface.

Unscrew the tank cap and ll tank with fuel mixture. Take care

to avoid spilling.

Screw the tank cap back on hand-tight.

Clean screw cap and tank after refuelling. Never start or

operate the Power Cut in the same place as it was fuelled!

If fuel gets on your clothing, change clothes immediately.

3 meters

Starting the engine

if

necessary

CAUTION:

Observe the SAFETY INSTRUCTIONS on page 5 and 6!

Start the Power Cut only after complete assembly and

inspection!

Move at least 3m (10 feet) away from the place where you

fuelled the Power Cut.

Make sure you have a good footing, and place the Power

Cut on the ground in such a way that the cutting disc is

not touching anything.

15

Page 16

2

2a

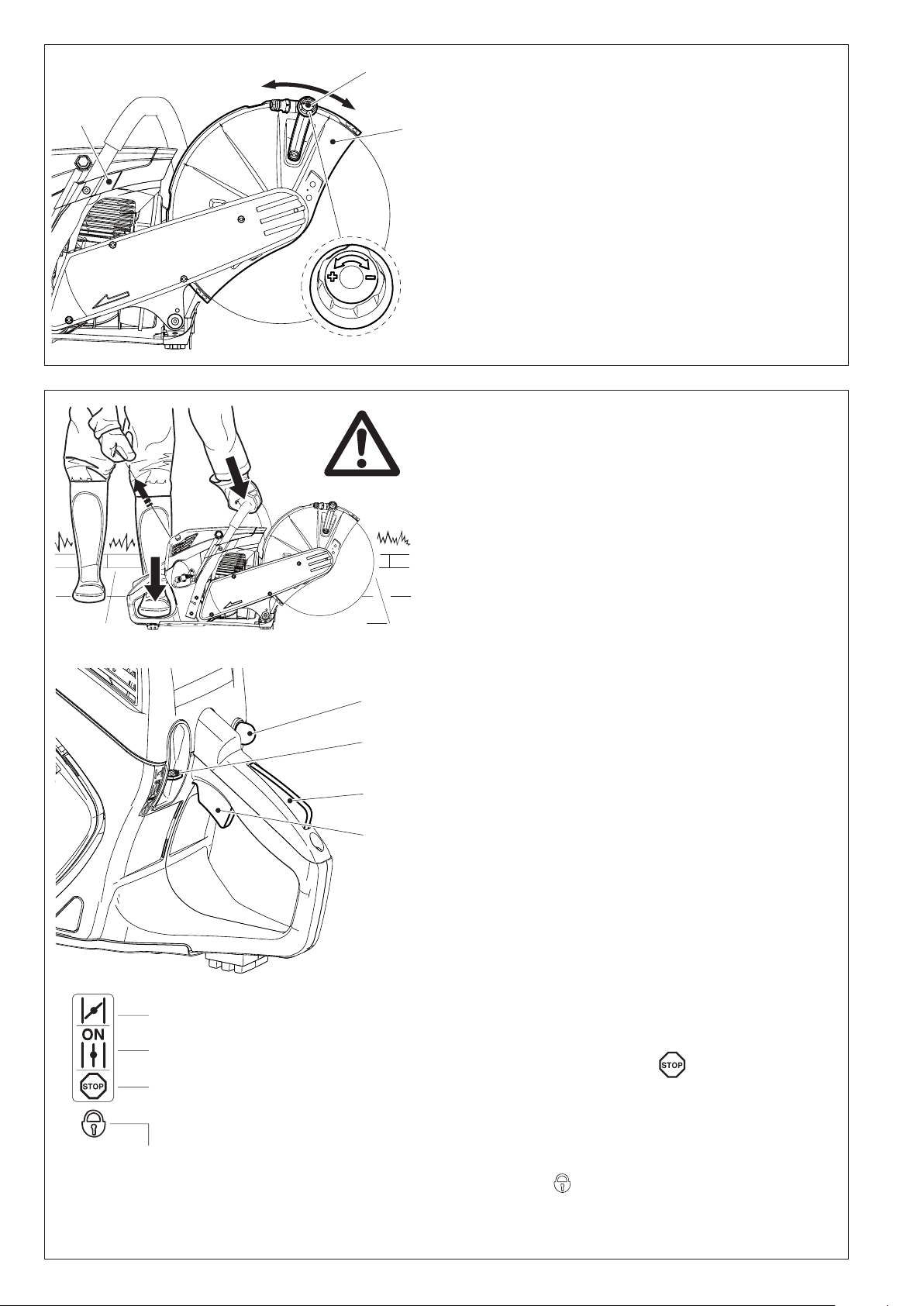

Move the protective hood (1) into the proper position for the

work you intend to do (see illustration).

The protective hood (1) can be moved between the stops in

1

both directions.

Note: A water supply line (from a pressurized water tank or

other source) is connected by the water set on the protective

hood. The water ow rate can be adjusted with the adjusting

screw (2). Press the 1/2" hose into the holder (2a).

For a slower ow, turn the adjusting screw clockwise.

For a faster ow, turn it counter-clockwise.

Cold starting:

Grasp front handle rmly with one hand and press the Power

Cut against the ground.

Place left toe in the rear handguard.

Prime the fuel pump (4) by pressing it several times until you

can see fuel in the pump.

Move the combination switch (3) up (choke position). This also

actuates the half-throttle lock.

Pull starter handle smoothly and evenly, until you hear the

rst ignition (but max. 3-5 pulls).

CAUTION: Do not pull the starter cable more than about 50

cm/20” out, and let it back in slowly by hand.

Move the combination switch (3) to the central “ON” position.

Pull the starter handle smoothly and evenly again.

4

3

As soon as the engine is running, grasp the rear handle (the

safety lock button (5) is actuated by the palm of the hand) and

press the throttle trigger (6). The half-throttle lock will disengage

and the engine will now idle.

Cold start (Choke)

Warm start (ON)

Engine off

Combination switch in safety position

(ignition current cut off, necessary for all

maintenance, repair, and installation work)

5

6

Warmstart:

As described above for cold starting, but before starting push

the combination switch (3) up (Choke position) and

then right away back to the middle “ON” position. This is only

to engage the half-throttle lock. If the engine doesn’t start after

2 or 3 pulls, repeat the entire starting procedure as described

for cold starting.

NOTE: If the engine was switched off only for a short time, the

saw can be started without using the combination switch.

Important: If the fuel tank has been completely emptied and the

engine has stopped due to lack of fuel prime the fuel pump (4)

by pressing it several times until you can see fuel in the pump.

Stopping the engine

Depress the combination switch (3).

NOTE: After being pressed down, the combination switch will

revert to the ”ON” position again. The engine is switched off, but

can be turned on again without moving the combination switch.

IMPORTANT: To cut off the ignition current, push the combination switch all the way down past the resistance point to the

safety position (

).

16

Page 17

Adjusting the carburetor

NOTE: The grinding parts are equipped with an electronic

ignition to limit the speed.

At the factory the idling speed has been set to approx.

2600 rpm, but the running-in process of a new engine may

require slight readjustment of the idling speed.

Adjustments to the adjusting screws (L) and (H) may only

be made by an authorised MAKITA service center.

SERVICE

7

For correct adjustment of the idling speed the following

steps must be carried out:

T

L

Start the engine and run it until it is warm (about 3 - 5 minutes).

Adjust the carburetor with the screwdriver (7) included with the

Power Cut. It has a lug that helps with adjustment.

Readjust the idling speed.

If the cutoff disc turns when the engine is idling, turn the throttle

stop screw (T) counter-clockwise in small increments until the

disc no longer turns.

If the engine suddenly stops in idle, turn the screw back slightly

clockwise.

Switch off the engine.

MAINTENANCE

CAUTION:

Before doing any work on the Power Cut turn off the engine,

remove the cutting disc, pull the plug cap off the spark plug

and wear protective gloves!

CAUTION:

Start the Power Cut only after complete assembly and

inspection.

17

Page 18

SERVICE

IMPORTANT:

Because many of the parts and assemblies not mentioned

in this Operator’s manual are vital to the safety of the unit,

and because all parts are subject to a certain amount of

wear and tear, it is important for your own safety that

you have the unit checked and maintained regularly by a

MAKITA service center.

IMPORTANT:

If the cutting wheel breaks during cutting, the

Power Cut must be repaired by a MAKITA service

center before being used again!

Changing the V-belt

Loosen bolts (1) and remove belt cover (2).

2

1

Move the V-belt pulley into the position shown.

Insert the Allen key into the hole (3) to block the V-belt pulley

(5).

Note: Make sure that the V-belt pulley remains blocked.

Use the combination tool to turn the nut (4) about one turn

counter-clockwise.

Use the combination tool to turn the eccentric (6) forcefully

counter-clockwise to the position shown.

Remove the old V-belt (7) or belt fragments.

5

4

3

Clean out the interior with a brush.

Insert a new V-belt.

Use the combination tool to turn the eccentric (6) forcefully

clockwise to its original position (V-belt is now tight).

Tighten the nut (4).

Remove Allen key from hole (3).

Put the belt cover (2) on and tighten the bolts (1).

18

Note: The V-belt is highly elastic, so it is not necessary to

7

6

retighten it.

A worn V-belt causes the cutoff disc turns at the lowest idle

speed. In this case, the V-belt must be replaced!

Page 19

Cleaning the protection hood

Over time, the inside of the protective hood can become caked

with material residue (especially from wet cutting), which if

allowed to accumulate can hinder the free rotation of the cutting disc. For this reason the hood must be cleaned out from

time to time.

Take off the cutting wheel with spring washer and remove the

accumulated material from inside the hood with a strip of wood

or similar implement.

Clean the shaft and all removed parts.

Cleaning / changing the air lter

CAUTION:

Turn off the engine before cleaning the air lter! Never clean

out the air lter with compressed air! Do not use fuel to

clean the air lter insert (3) and inner lter (6).

The service life of the engine depends on the condition

and regular maintenance of the lter elements. Failure

to perform maintenance and cleaning at the prescribed

intervals will cause increased wear inside the engine!

If the air lter becomes damaged, replace immediately!

Pieces of cloth or large dirt particles can destroy the engine!

Do not work in dusty conditions when it can be avoided!

The ne dust generated when dry-cutting concrete and

stone is hazardous to the health of the operator and also

shortens the service life of the engine. Whenever possible,

wet-cut with water when working in concrete and stone,

to bind the dust.

NOTE: To install the cutting wheel see ”Mounting the

cutting wheel”.

Loosen both bolts (1) and remove the lter cover (2).

Take the air lter cover (3) out of the cover (5).

Loosen the six bolts (4) on the cover and remove the cover.

Remove the inner lter (6).

When reassembling, make sure that the two lugs (7) of the

lter cover engage in the cover (5).

Inner lter

Wash out the dirty inner lter (6) in lukewarm soapy water with

regular dishwashing liquid.

Let the inner lter dry thoroughly.

Air lter insert (paper cartridge)

The air lter insert (3) lters the intake air through a very ne

paper lter lamella system. For this reason the cartridge must

never be washed or cleaned with compressed air. Check the

air lter insert once per month and clean if necessary.

To clean the air lter insert, spread it out slightly and carefully

tap it against a clean surface.

Replace the air lter insert every 500 operating hours. Replace it immediately if there is a drop in power, drop in speed,

or smoke in the exhaust.

Before installing the lter system, check the intake opening to

make sure no dirt particles have fallen in. If they have, remove

them.

7

2

1

3

4

5

6

19

Page 20

0,5 mm

Replacing the spark plug

CAUTION:

Do not touch the spark plug or plug cap if the engine is

running (high voltage).

Switch off the engine before starting any maintenance work.

A hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced in case of damage to the

insulator, electrode erosion (burn) or if the electrodes are very

dirty or oily.

Remove the lter cover and hood. See Cleaning / changing

the air lter.

Pull the plug cap (1) off the spark plug. Use only the combination

wrench supplied with the saw to remove the spark plug.

CAUTION: To prevent damage to the decompression valve

(8), when unscrewing the spark plug position the combination tool in such a way that it does not impact the valve.

Electrode gap

The electrode gap must be .020" (0.5 mm).

1

CAUTION: Use only NGK BPMR 7A

spark plug.

Other spark plugs can damage the

ignition system!

Checking the ignition spark

Insert the combination tool (2) between the ventilation hood and

cylinder only as shown in the illustration.

CAUTION!

Do not insert the combination tool into the spark plug hole,

but make contact only with the cylinder (otherwise you may

damage the engine).

Using insulated pliers, hold the spark plug (3) (unscrewed but

with the plug cap on) against the combination tool (away from

the spark plug hole!).

Switch the combination switch (4) to ”ON”.

Pull the starter cable hard.

If the function is correct, an ignition spark must be visible near

the electrodes.

Replacing the suction head

The felt lter (5) of the suction head can become clogged. It

is recommended to replace the suction head once every three

months in order to ensure unimpeded fuel ow to the carburetor.

Unscrew the tank cap (6), pull the retainer out of the opening.

Empty fuel tank.

Use a wire hook to pull the suction out of the tank opening for

replacement.

Caution: Do not allow fuel to come into contact with skin!

4

3

2

20

5

6

Page 21

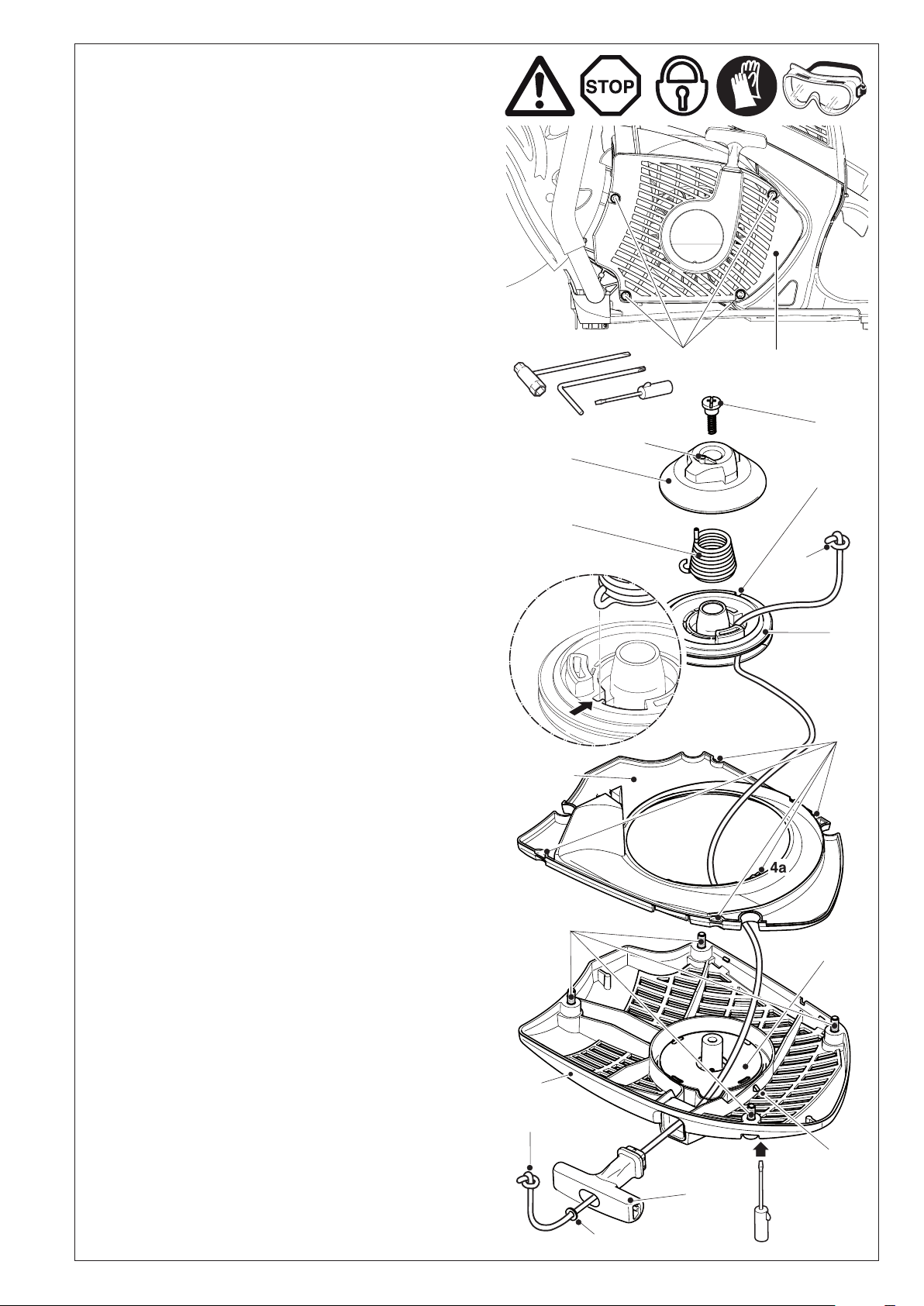

Replacing the starter cable

10

Unscrew four screws (1).

Remove fan housing (2).

Insert a small screwdriver through the ventilation slit on the back

of the fan housing (2) near the holder (15).

Bend the air guide tab (4a) slightly to the side and carefully

remove the air guide (3) from the fan housing.

CAREFUL! Injury hazard! Do not unscrew screw (7) if the

return spring is under tension.

If the starter cable is to be replaced although it is not broken,

it will be necessary to rst de-tension the cable drum return

spring (13).

To do this, use the grip to pull the cable all the way out of the

fan housing.

Hold the cable drum with one hand, and with the other push the

cable into the space (14).

Carefully let the drum turn until the return spring is no longer

under tension.

Unscrew screw (7) and remove the carrier (8).

Remove any pieces of old line and take out the spring (6).

Carefully remove the cable drum (5).

Put the spring (6) back in the cable drum (so that its lower end

ts in the notch, see the arrow in the close-up).

Thread a new cable (dia. 4 mm, length 1000 mm) as shown

in the illustration (don’t forget the washer (10)) and knot both

ends as shown.

Pull the knot (11) into the cable drum (5) and press it into the

space.

Pull knot (12) into the starter grip (9).

Put the cable drum and spring back on, and turn it slightly until

the return spring catches.

Guide the hole (16) in the carrier (8) over the end of the spring,

press down the carrier and turn it slightly counter-clockwise until

it is ush on the cable drum.

Insert screw (7) and tighten.

Guide the cable into the slot (14) on the cable drum and turn

the drum with the cable clockwise three times.

Hold the cable drum with your left hand and with your right hand

untwist the cable, pull it tight and hold it.

Carefully release the cable drum. The spring will wind the cable

around the drum.

Repeat the procedure once. The starter grip should now stand

straight up on the fan housing.

NOTE: With the cable pulled all the way out, it must still be possible to turn the pulley another 1/4 turn against the return spring.

CAUTION: Danger of injury! Secure the cable grip when

pulled out! It will whip back if the cable pulley is released

by accident.

12

7

16

8

14

6

11

5

4

3

1

13

Mounting the fan housing

Insert the air guide (3) in the fan housing so that the ve re-

cesses (4) engage.

Position the fan housing on the machine, apply slight counter-pressure, and pull the starter grip until the starter mechanism engages.

Tighten screws (1).

2

12

15

9

21

Page 22

Replacing the return spring pack/Replacing the

7

starter spring

Remove the fan housing (see “Replacing the starter cable”).

Remove the air guide from the fan housing (see “Replacing

the starter cable”).

Detension the return spring on the cable drum and remove the

cable drum (see “Replacing the starter cable”).

Note: Unspool the starter cable from the drum only. Do not pull

it out of the cable drum or the starter grip!

CAREFUL! Injury hazard! The return spring can pop out!

Always wear eye protection and protective gloves!

Lightly tap the fan housing on a wooden surface with the entire

surface of the hollow side, and hold it down. Now lift the fan

housing carefully and in small steps. This will allow the return

spring pack (13), which should now have fallen out, to relax in

a controlled manner if the return spring has popped out of the

plastic pack.

If the return spring pops out, it can be wound back into the cassette

as shown (15). Make sure the direction of winding is correct.

Carefully insert a new return spring cassette and press down

until it engages.

Put the cable drum (5) and spring back on, and turn it slightly

until the return spring catches.

Put on the carrier (8) and bolt it on with bolt (7).

Tension the return spring (see “Replacing the starter cable”).

8

5

13

6

4

3

Replacing the starter spring

NOTE: If the spring (6) in the Featherlight-Starting system is

broken, more effort will be required to start the engine and you

will notice some resistance when pulling the starter cable.

If you notice this, check the spring (6) and replace if necessary.

Mounting the fan housing

Insert the air guide (3) in the fan housing so that the ve re-

cesses (4) engage.

Position the fan housing on the machine, apply slight counter-pressure, and pull the starter grip until the starter mechanism catches.

Tighten screws (1).

1

15

22

Page 23

Replacing/cleaning the spark arrester screen

CAUTION:

Do not use sharp or pointed objects for screen cleaning.

Damaged or misformed screen wires may result.

The spark arrester screen should be checked and cleaned

regularly.

Let cool the engine down for sure!

Unscrew and remove screw (1). Remove the spark

arrester screen (2).

Cleaning or replacing the spark arrester screen.

Reassembly the spark arrester screen and tighten the screw.

1

2

Instructions for periodic maintenance

To ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform the

prescribed maintenance work can lead to accidents!

Users of the Power Cut must not perform any maintenance work not described in this Operator’s manual. All such work must be

carried out by a MAKITA service center.

General Entire Power Cut Clean exterior, check for damage. In case of damage,

have repaired by a qualied service center immediately

Cutting disc Inspect regularly for damage and wear. 6

Clutch Have inspected at a service center.

Protection hood Clean 19

Before each start Cutting disc Inspect for damage and make sure the cutting wheel is 6

right for the job

Protective hood Adjust position 16

Combination switch, Functional check

Safety locking button, Functional check

Throttle lever Functional check 16

Tank cap Check for tightness

Page

Every day Idle speed Check (cutting disc must not turn on idle) 17

Every week Starter housing Clean to ensure proper air cooling 12

Starter cable Check for damage 21

V-belt Inspect for damage and wear 18

Spark plug Check and replace if necessary 20

Mufer Check tightness of mounting 12

Spark arrester screen Clean or replace if necessary 24

Screws and nuts Check their condition and that they are rmly secured.

Monthly Air lter insert Check the air lter insert, clean as needed,

replace after 500 operating hours 19

Every 3 months Suction head Replace 20

Fuel tank Clean

Annually Entire Power Cut Check at an authorized service center

Storage Entire Power Cut Clean exterior, check for damage. In case of damage,

have repaired by a qualied service center immediately

Cutting disc Remove and clean 13

Fuel tank Empty and clean

Carburetor Run empty

23

Page 24

Service, spare parts and guarantee

Maintenance and repair

The maintenance and repair of modern cutoff saws and their safety-related components requires qualied technical training and a

workshop equipped with special tools and testing devices.

We therefore recommend that you consult a MAKITA service center for all work not described in this operator’s manual.

The MAKITA service centers have all the necessary equipment and skilled and experienced personnel, who can work out cost-effective

solutions and advise you in all matters.

Please contact your nearest service center or the general trading company or importer (see last page), who will gladly provide you

with the address of your nearest MAKITA service center.

Spare parts

Reliable long-term operation, as well as the safety of your Power Cut, depend among other things on the quality of the spare parts

used. Use only original MAKITA parts, marked

Only original parts are from the same production line as the original unit and therefore ensure the highest possible quality of materials, dimensions, functioning and safety.

Only original spare parts and accessories guarantee the highest quality in material, dimensions and function.

Original spare parts and accessories can be obtained from your local dealer. He will also have the spare part lists to determine the

required spare part numbers, and will be constantly informed about the latest improvements and spare part innovations.

Please bear in mind that if parts other than original MAKITA spare parts are used, this will automatically invalidate the MAKITA

product guarantee.

We will furthermore not accept any liability damages arising from the use of non-MAKITA spare parts.

Guarantee

MAKITA guarantees the highest quality and will therefore reimburse all costs for repair by replacement of damaged parts resulting

from material or production faults occurring within the guarantee period after purchase. Please note that in some countries particular

guarantee conditions may exist. If you have any questions, please contact your salesman, who is responsible for the guarantee of

the product.

Please note that we cannot accept any responsibility for damage caused by:

• Disregard of the operator’s manual.

• Non-performance of the required maintenance and cleaning.

• Incorrect carburetor adjustment.

• Normal wear and tear.

• Obvious overloading due to permanent exceeding of the upper performance limits.

• The use of other than original MAKITA cutting discs.

• Use of force, improper use, misuse or accidents.

• Damage from overheating due to dirt on the fan housing.

• Work on the Power Cut by unskilled persons or inappropriate repairs.

• Use of unsuitable spare parts or parts which are not original MAKITA parts, insofar as they have caused the damage.

• Use of unsuitable or old oil.

• Damage related to conditions arising from lease or rent contracts.

• Damages caused by disregarding loose outer bolted connections.

Cleaning, servicing and adjustment work is not covered by the guarantee. All repairs covered by the guarantee must be performed

by a MAKITA service center.

24

Page 25

Troubleshooting

Malfunction System Observation Cause

Cutting disc does not

start turning Clutch Engine runs Damage to clutch

Cutting disc runs in idle Carburetor, Cutting disc runs Incorrect idle speed,

clutch blocked clutch

V-belt Belt has insufcient tension, V-belt is worn

Engine does not start or Ignition system Ignition spark Malfunction in fuel supply system, com-

only with difculty pression system, mechanical malfunction.

No ignition spark Switch on STOP, fault or short-circuit in the

wiring, plug cap or spark plug defective.

Fuel supply Fuel tank is lled Choke in wrong position, carburetor defective,

suction head dirty, fuel line bent or interrupted.

Compression Inside Cylinder base packing ring defective, radial

system shaft packings defective, cylinder or piston rings

defective

Outside Spark plug does not seal.

Mechanical Starter does not engage Spring in starter broken, broken parts

malfunction inside the engine.

Warm start difculties Carburetor Fuel tank is lled Wrong carburetor adjustment.

Ignition spark

Engine starts, but Fuel supply Fuel tank is lled Wrong idling adjustment, suction head or

dies immediately carburetor dirty.

Tank venting defective, fuel line interrupted,

cable defective, STOP switch defective.

Decompression valve dirty

Insufcient power Several systems Engine is idling Air lter dirty, wrong carburetor adjustment,

may be involved mufer clogged, exhaust channel in cylinder

simultaneously clogged, spark arrester screen clogged.

SPECIAL ACCESSORIES

Diamond cutting discs

MAKITA diamond cutting discs meet the highest demands

in working safety, ease of operation, and economical cutting performance. They can be used for cutting all materials

except metal.

The high durability of the diamond grains ensures low wear

and thereby a very long service life with almost no change in

disc diameter over the lifetime of the disc. This gives consistent

cutting performance and thus high economy. The outstanding

cutting qualities of the discs make cutting easier.

The metal disc plates give highly concentric running for minimal

vibration during use.

The use of diamond cutting discs reduces cutting time signicantly. This in turn leads to lower operating costs (fuel consumption,

wear on parts, repairs, and last but not least environmental

damage).

Pressurized water tank

To keep down dust and for better cutting-disc cooling, MAKITA

offers several options for wetting the disc during operation.

The pressurized water tank is connected to the Power Cut by

the water set on the protective hood.

25

Page 26

Extract from the spare parts list

Use only original MAKITA parts. For repairs and

replacement of other parts, see your MAKITA service center.

EK6100

EK6101

14

17 18

20

15

16

9

8

19

26

5

6

22

Page 27

Extract from the spare parts list

Use only original MAKITA parts. For repairs and

replacement of other parts, see your MAKITA service center.

Pos. Qty. Denomination

Synthetic resin cutting disc (not in the general scope of delivery. Country-specic)

1 1 Cutting disc for steel, dia. 300/20 mm

1 Cutting disc for steel, dia. 350/20 mm

1 Cutting disc for steel, dia. 350/25,4 mm

1 1 Cutting disc for masonry, dia. 300/20 mm

1 Cutting disc for masonry, dia. 350/20 mm

1 Cutting disc for masonry, dia. 350/25,4 mm

Diamond cutting disc

22 1 Cutting disc for masonry, dia. 350/25,4 mm

3 1 Hex screw M8x25

4 1 V-belt (EK6100)

1 V-belt (EK6101)

5 1 Suction head

6 1 Tank cap, compl. (fuel)

8 1 Inner lter

9 1 Air lter insert (paper cartridge)

10 1 Disk 5

11 1 Spark plug

12 1 Starter cable ø 4x1000 mm

13 1 Starter grip

14 1 Return spring in housing

15 1 Spring

16 1 Driver

EK6100

EK6101

17 1 Universal wrench SW 13/19

18 1 Offset screwdriver T27

19 1 Screwdriver (carburetor)

20 1 Spark arrester screen

Accessories (not delivered with the Power Cut)

Diamond cutting disc

22 1 Please consult your MAKITA dealer!

26 1 Pressure water tank, cpl.

- 1 Combined can (for 5l fuel, 3l oil)

27

Page 28

Nous vous remercions de votre conance!

La découpeuse moderne de MAKITA vous a convaincu à l’achat.

Comme des tronçonneuses MAKITA, les découpeuses MAKITA sont équipées de moteurs haute puissance spécialement

construits à cet effet présentant un rapport puissance / poids

excellent, donc une puissance moteur élevée pour un poids

faible.Autres avantages des découpeuses MAKITA:

• construction robuste et haute abilité.

• allumage électronique nécessitant aucun entretien, protégé

hermétiquement contre la poussière et l’humidité.

• amortissement des vibrations selon le système 2 masses

MAKITA (D2M) garantissant un travail sans fatigue même

pour un appareil portatif.

• Système de ltre à air multi-niveaux avec turbo-ltre cyclone

pour un fonctionnement able même en cas de fort dégagement de poussières.

• Le système de démarrage facile à ressorts permet un dé-

marrage sans grands efforts. Un accumulateur à ressorts

soutient ici le lancement.

• Vastes accessoires sur les disques à découper revêtues

diamant et liés par résine synthétique.

Notre plus grande attente est que vous soyez un client

MAKITA satisfait.

An de garantir en permanence un fonctionnement optimal de

votre découpeuse MAKITA et d’assurer votre sécurité person-

nelle, nous vous demandons de:

Lire attentivement cette notice avant la première mise en

route et veuillez observer avant tout les prescriptions de

sécurité! La non-observation de ces instructions risque

d’entraîner des blessures mortelles!

ATTENTION !

Le système d’allumage de cette machine génère un champ

électromagnétique qui peut perturber le fonctionnement de

certains dispositifs médicaux, comme les stimulateurs cardiaques,

par exemple. An de réduire le risque de blessures graves ou

mortelles, les personnes portant un dispositif médical doivent

contacter leur médecin et le fabricant du dispositif avant de mettre

la machine en service.

Seulement pour EK6100, EK6101 : La période de conformité

relative aux émissions indiquée sur le label de conformité à

la réglementation relative aux émissions indique le nombre

d’heures de service pendant lesquelles le moteur s’est avéré

répondre aux exigences d’émissions nationales. Catégorie C=50

heures, B=125 heures, et A=300 heures.pacemaker ou votre

médecin avant de mettre l‘appareil en service.

Sommaire Page

Emballage .......................................................................... 28

Etendue de la fourniture .................................................. 29

Symboles ........................................................................... 29

INSTRUCTIONS DE SÉCURITÉ

Utilisation conforme aux prescriptions .......................... 30

Instructions générales ................................................... 30

Equipement de protection personnel ....................... 30-31

Produits de fonctionnement /Remplissage des

réservoirs ...................................................................... 31

Mise en route ................................................................ 31

Disques à découper ...................................................... 32

Rebond (klickback) et freinage ..................................... 33

Comportement et technique de travail .......................... 33

A observer impérativement en cas d’utilisation

de disques à découper en résine synthétique ............... 34

Découper les métaux .................................................... 34

Découper pierre, béton, amiante ou asphalte .......... 34-35

Transport et stockage ...................................................35

Maintenance ................................................................. 36

Premier secours ............................................................ 36

Elimination des déchets et protection de l’environnement .. 36

Caractéristiques techniques ........................................... 37

Désignation des pièces .................................................... 38

MISE EN ROUTE

Montage du disque à découper ..................................... 39

Carburants / ravitaillement ....................................... 40-41

Démarrer le moteur ....................................................... 41

Démarrage à froid ......................................................... 42

Démarrage à chaud ...................................................... 42

Arrêter le moteur ........................................................... 42

Réglage du carburateur ................................................... 43

TRAVAUX DE MAINTENANCE

Remplacer la courroie ................................................... 44

Nettoyer le capot de protection ..................................... 45

Nettoyer / remplacer le ltre à air .................................. 45

Remplacement de bougie ............................................. 46

Vérication de l’étincelle d’allumage ............................. 46

Remplacement de la crépine d’aspiration ..................... 46

Remplacement du cordon de lancement ...................... 47

Remplacement du ressort de rappel ............................. 48

Remplacement du ressort de rappel Easy-Start ........... 48

Changement / nettoyage du pare-étincelles .................. 49

Indications de maintenance et d’entretien périodiques ...49

Service d’atelier, pièces de rechange et garantie ..........50

Recherche de pannes ...................................................... 51

ACCESSOIRES SPECIAUX

Disques à découper au diamant,

réservoir à eau .............................................................. 51

Extrait de la liste des pièces de rechange ................52-53

28

Page 29

Etendue de la fourniture

5

1. Découpeuse

2. Disque à découper (pas toujours fournie, en fonction du pays)

3. Tournevis (pour carburateur)

4. Tournevis coudé

5. Outillage de montage 13/19

6. Notice d’emploi (sans illustration)

4

3

2

1

Si un des composants indiqués ici ne devait pas être dans la

fourniture, veuillez vous adresser à votre vendeur!

Symboles

Vous rencontrerez les symboles suivants sur l’appareil et dans le instructions d’emploi:

Lire instructions d'emploi et