Page 1

T

Model No.

ECHNICAL INFORMATION

EH7500S

PRODUCT

P 1/ 25

Description

Petrol Hedge Trimmer

CONCEPT AND MAIN APPLICATIONS

Model EH7500S is a 22.2cm³ 2-stroke petrol hedge trimmer

with single-sided blade in compliance with all known exhaust

emission regulations, featuring extra light design with further

improvements in noise, vibration and handling compared with

our current models.

Especially, the lightweight design is outstanding.

4.7kg (10.4lbs) dry weight is the world’s lightest among all petrol

hedge trimmers in compliance with any exhaust emission regulation

as of February, 2010.

Specification

Specifications

Type

Engine Displacement: cm³

Fuel

In compliance with main exhaust emission regulations;

CARB Tier 3, EPA Phase 2, EU Stage 2

Max. output power: kW (PS) 0.68 (1.0) [at 7,500 min.ˉ¹]

Max. torque: N.m

Stroke rate at No load: min.

Max. cutting capacity: mm (") 728 (25-5/8)

Carburetor

Clutch Yes

Rotation limiter Yes

Type

Length: mm (")

Blade

Max. branch diameter

Net weight*2: kg (lbs)

*1: Indicates maximum diameter of the branch that can be received

between adjacent two blade teeth. (See the figure on right.)

*2: Dry weight

Cutting teeth

Thickness: mm (")

Blade drive mechanism

Tooth spacing: mm (")

ˉ¹ = spm (stroke pre minute)

*1: mm (")

Model

EH7500S

2-stroke

22.2

Mixed gasoline

Yes

0.9 [at 6,000 min.ˉ¹]

4,390

0.4 (13.5)Fuel tank capacity: L (US oz)

Diaphragm

Recoil starterStarting system

YesPrimer pump

Single-sided

750 (29-1/2)

with 3 sharpened edges

2.3 (3/32)

Connecting rod drive

35 (1-3/8)

21.5 (7/8)

4.7 (10.4)

Dimensions: mm (")

Length (L) 1,150 (45-1/4)

Width (W)

Height (H)

323 (12-3/4)

212 (8-3/8)

Standard equipment

Blade cover .................... 1

Socket wrench ................ 1

Hex wrench .................... 1

Note: The standard equipment for the tool

shown above may vary by country.

Optional accessories

Chip receiver set

Page 2

P 2/ 25

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

< Note in repair>

* Repair the tool always with gloved hand

* Blades must be covered by Blade cover

* Cool down the engin first before repairing to avoid a skin burn.

* Remove all fuels from fuel tank and carburetor. Avoid any fire from the work shop.

* Repair the tool on the stable work table and keep dust out.

* Record where and how the parts were assembled to avoid mis-assembling.

Assort and reserve the dismantled parts in the box by section.

* The dismantled parts must be treated carefully and washed clean before reassembling.

* Use Impact driver in case bolts or screws can not be loosen by hand.

* The bolts or screws must be tightened to the designated fastening torque.

* Check the movement, sound and alignment of the main parts just after assembled.

* Replace the removed gasket with the new one.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Used for

1R024 Press tool removing Spur gear 9

1R127 Air density tester checking air leakage in Carburetor

1R170 T type hex wrench 3-127 removing / tightening M4 Hex socket head bolt

1R171 T type hex wrench 4-130 removing / tightening M5 Hex socket head bolt

1R229 1/4” hex shank bit removing / tightening Engine section

1R364 Fly wheel puller removing Fly wheel

1R366 Feeler gauge set adjusting a proper gap of ignition coil, Spark plug, Shear blade assembly

1R371 Clutch removing tool removing Clutch

1R373

1R374

Clutch drum removing tool

Pinion gear holding Jig

Hex socket bit 10

Wire brush cleaning Spark plug

removing Clutch drum

fixing Spur gear 9

removing Fly wheel

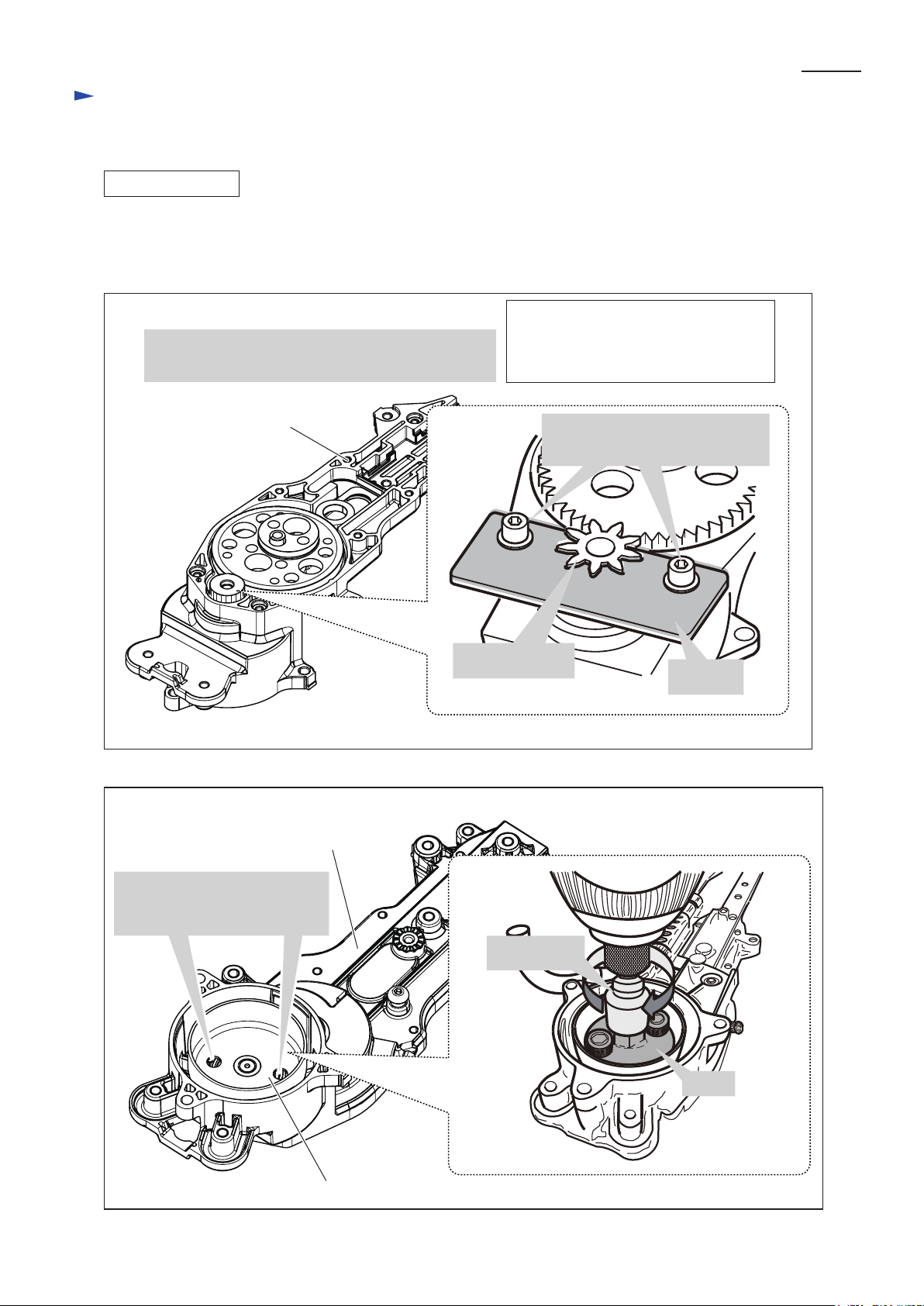

[2] LUBRICATION

Apply Makita Grease N. No.2 to Spiral spring for recoil starter (approx. 2g) and Gear room (approx. 40g).

Page 3

P 3/ 25

Repair

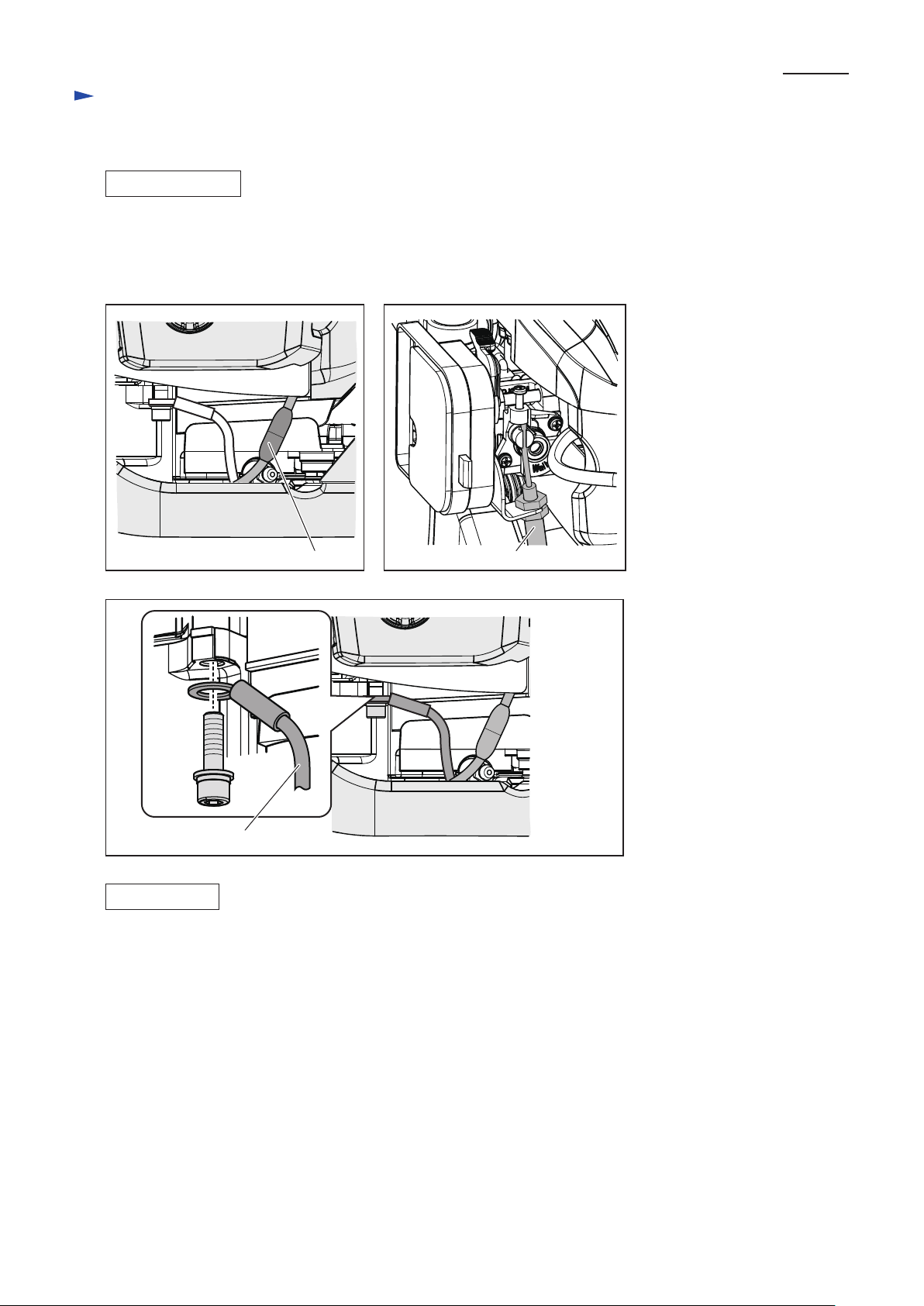

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Engine section

DISASSEMBLING

(1) Disconnect Bullet terminal from the Lead wire of Ignition coil. (Fig. 1)

(2) Remove Air cleaner cover and disconnect control cable from the swivel of carburetor.

Remove Control cable from cable bracket. (Fig. 2)

(3) Remove three bolts to separate engine section. Grounding lead wire is fastened with one of the three bolts. (Fig. 3)

Fig. 1 Fig. 2

Bullet terminal

Fig. 3

Grounding lead wire

ASSEMBLING

(1) Assemble engine section to the Gear housing.

Note: • Do not to pinch the Lead wires between Engine section and Gear housing.

• Make sure to fasten the terminal of Grounding lead wire with one of three Hex socket head bolts.

(2) Fix Control cable along with Adjust screw in the Cable bracket by clamping it with a Nut.

Hook the Control cable end on the Swivel of Carburetor.

Note: Adjust the Cable tension with a 1 - 2 mm play.

(3) Connect Bullet terminals. (Fig. 1)

Control cable

Page 4

Repair

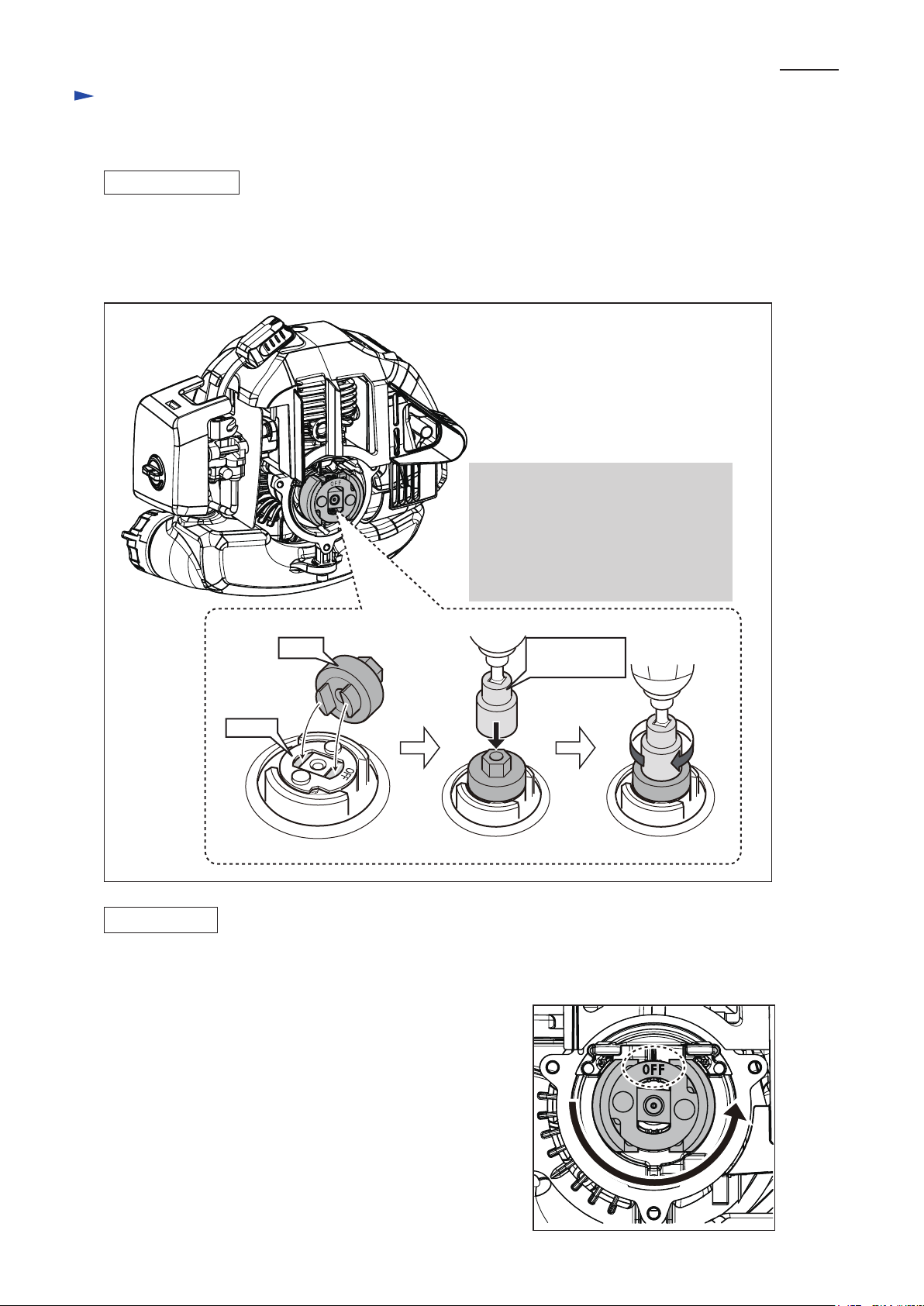

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Clutch Section

DISASSEMBLING

By using impact driver, Clutch can be loosened without holding Piston by utilizing air pressure in the cylinder.

In order to utilize this air pressure resistant, do not remove Spark plug in this step.

(1) Separate Engine section from Gear housing. (Figs. 1, 2 and 3)

(2) Remove Clutch. (Fig. 4)

Fig. 4

Caution:

Remove Plug cap to avoid

an accidental start of engine.

1. Fit 1R371 to Clutch.

2. Fix 19mm Hex socket bit to

Impact driver.

3. Turn the Clutch clockwise

with Impact driver.

4. Now, the Clutch is removed

from Crankshaft.

P 4/ 25

1R371

Clutch

ASSEMBLING

(1) Drive the Clutch to Crankshaft counterclockwise by hand so that the “ OFF” mark

can face the upper position. (Fig. 5)

(2) Set 1R371 and fasten it counterclockwise by Impact driver

with 19mm Hex socket bit for approx. 2 seconds. (Fig. 4)

19 mm Hex

socket bit

Fig. 5

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Clutch Drum

DISASSEMBLING

(1) Separate Gear case from Engine section. (Figs. 1, 2 and 3)

(2) Remove Gear case cover from Gear case.

(3) Disassemble Clutch drum. (Figs. 6 and 7)

Fig. 6

Lock Spur gear 9 with 1R374 for disassembling

Clutch drum located on the reverse side of Spur gear 9.

P 5/ 25

Note:

Hex socket head bolts removed from

Gear case cover can be used for

fixing1R374.

Fig. 7

Gear case

Gear case

(reverse side view)

Hex socket head bolts for fastening

Gear case cover to Gear case

Spur gear 9

1R374

Fix 1R373 to these holes and

remove Clutch drum by turning

1R373 clockwise.

Clutch drum

13 mm Hex

socket bit

1R373

Page 6

P 6/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Clutch Drum (cont.)

ASSEMBLING

(1) Lock Spur gear 9 with 1R374. (Fig. 6)

(2) Drive Clutch drum to the shaft of Spur gear 9 counterclockwise by hand.

(3) Mount 1R373 to Clutch drum and fasten it counterclockwise with impact driver and 13 mm Hex socket bit. (Fig. 7)

Note 1: Do not lose Friction plate next to Rod when mounting Clutch drum.

Note 2: Replace Gear case gasket to the new one.

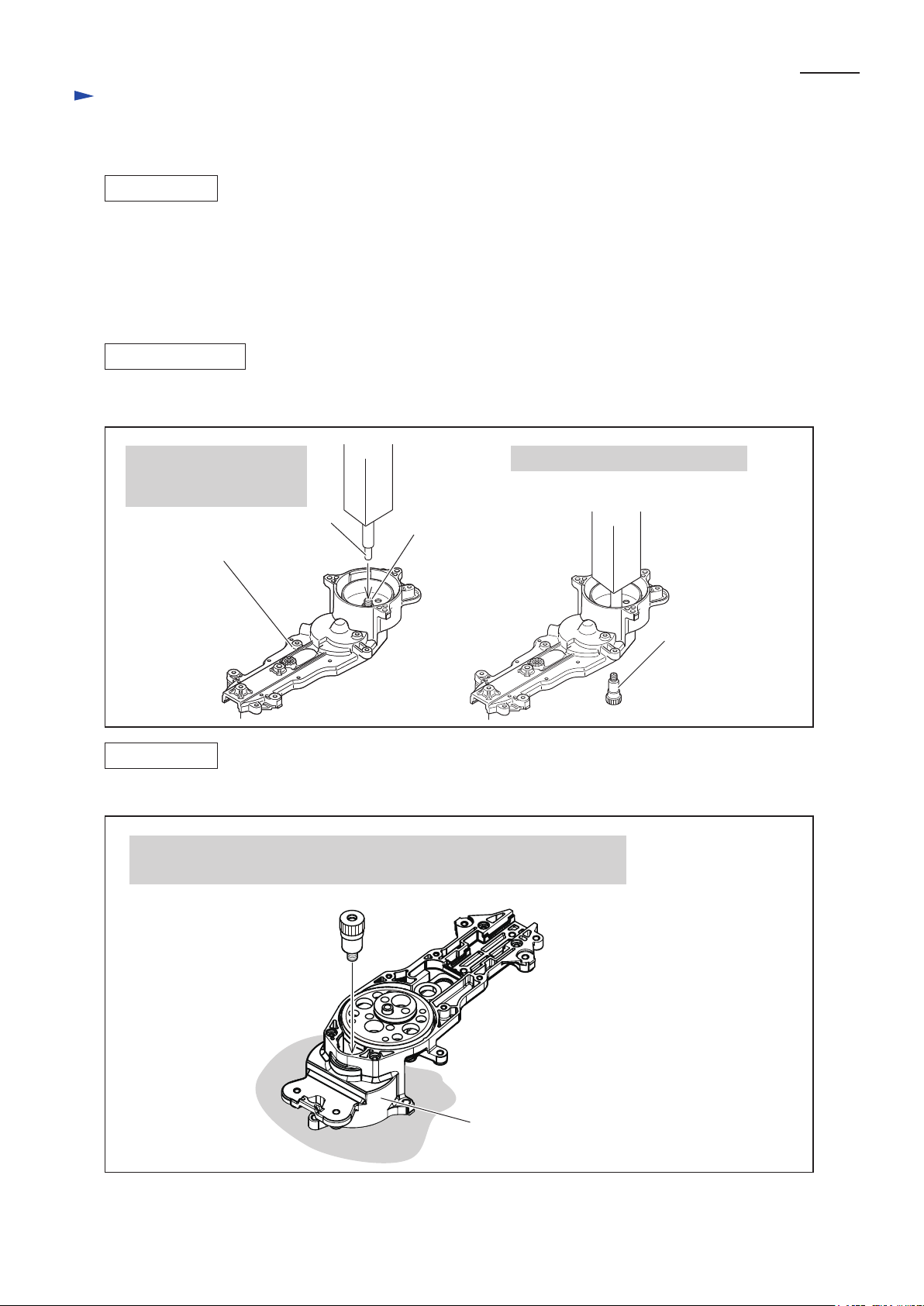

[3] -4. Spur Gear 9

DISASSEMBLING

Remove Spur gear 9. (Fig. 8)

Fig. 8

1. Apply 1R024 to Shaft of

Spur gear 9 and press it

with Arbor press.

1R024

Gear case

ASSEMBLING

Assemble Spur gear 9. (Fig. 9)

Fig. 9

Put Gear housing on the turn base of Arbor press horizontally.

Insert Spur gear 9 into Ball bearing in Gear case and press it with Arbor press.

Shaft of

Spur gear 9

2. Now, Spur gear 9 is disassembled.

Spur gear 9

Gear case complete

Page 7

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Shear Blade

DISASSEMBLING

Remove Holder and Shear blade assembly by unscrewing two Hex socket head bolts. (Fig. 10)

Note: 2 pcs. of Sleeve 5 are mounted under Plate. Do not lose them. (Fig. 12)

Fig. 10

Spur gear 43

P 7/ 25

Holder

Gear case

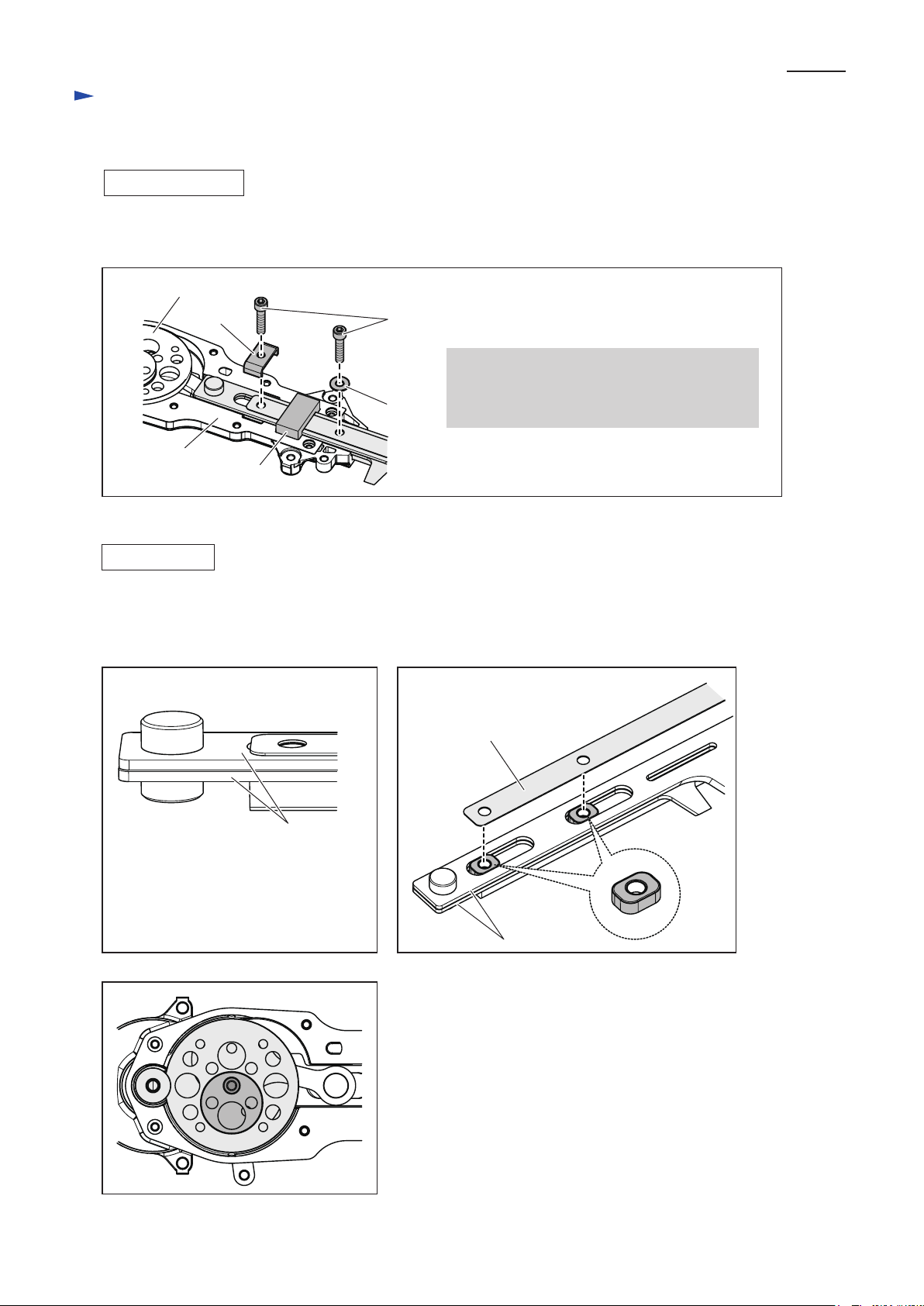

ASSEMBLING

(1) Align the Shear blade (upper) with the lower one. (Fig. 11)

(2) Set 2 pcs. of Sleeve 5 under Plate of Shear blade assembly. (Fig. 12)

(3) Set the position of Spur gear 43 as drawn in Fig. 13.

Fig. 11

Seal

Hex socket head bolt

Note:

Holder and Washer are fastened with Hex socket

Washer

Fig. 12

head bolts. Do not lose them when removing

Shear blade assembly.

Plate

Fig. 13

Shear blades

Sleeve 5

Shear blades

Page 8

P 8/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Shear Blade (cont.)

ASSEMBLING

(4) Mount Shear blade assembly in the Gear case while fitting Shear blade’ boss into the hole of Connecting rod.

Fix the Shear blade assembly to Gear case by driving Hex socket head bolt through the Holder and

each Sleeve 5.

Note: • Do not forget to mount Seal. (Fig. 14)

• Apply Makita grease N. No.2 to the portion designated with black triangle. (Fig. 15)

Fig. 14

Spur gear 43

SealHolder

Boss

Gear case

ADJUSTMENT

(1) Loosen Hex lock nut.

(2) After tightening Hex socket button head bolt, turn it back by 1/4 to 3/8 counterclockwise.

(3) Tighten Hex lock nut fully while locking Hex socket button head bolt with Hex wrench. (Fig. 16)

Fig. 16

Lock Hex socket button

head bolt.

Fig. 15

Connecting rod

Cam portion

Apply the both of Cam portions

which accept Connecting rods.

Connecting rod

Tighten Hex lock nut.

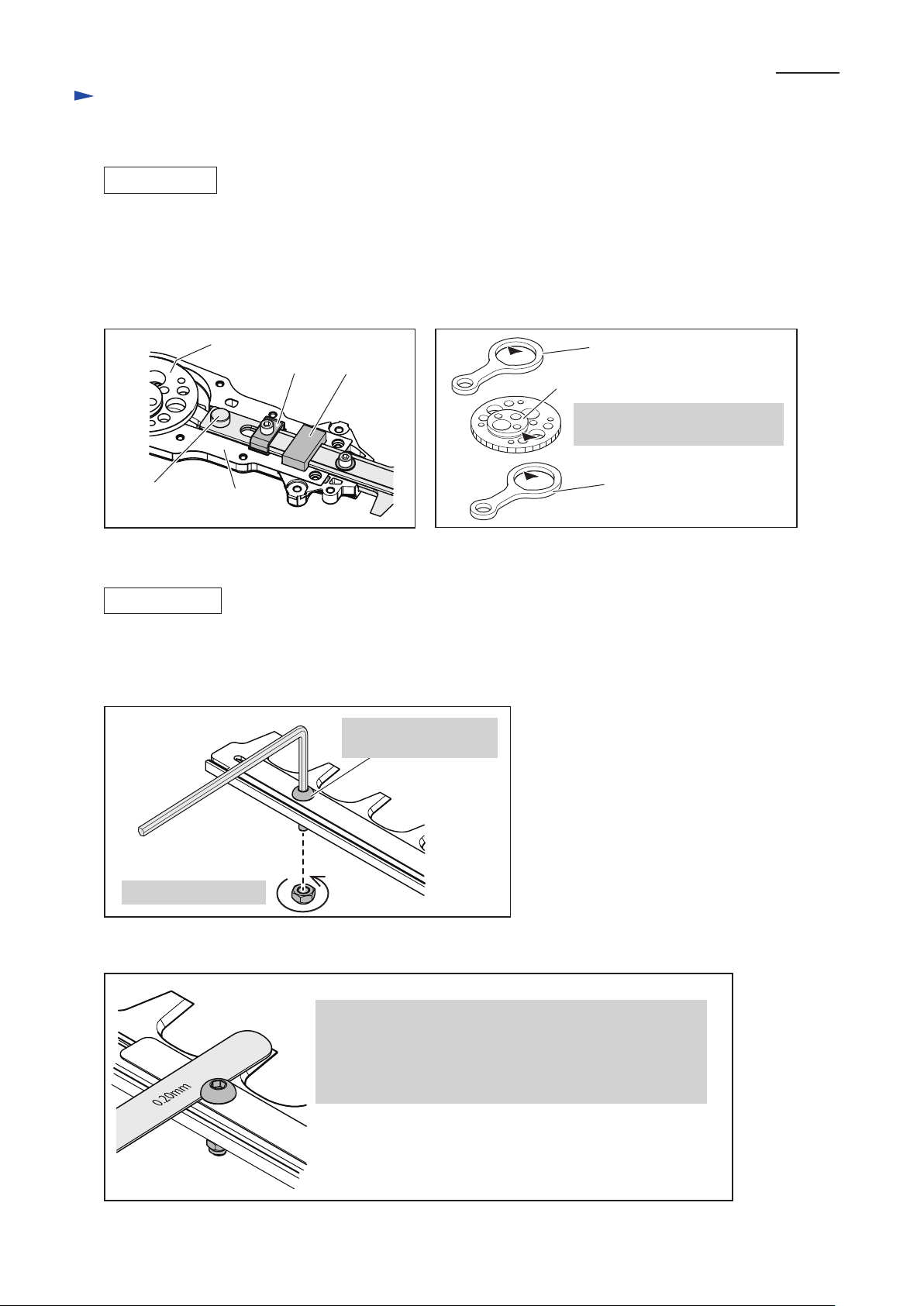

(4) Check the clearance by inserting 1R366 into the gaps of all Hex socket button head bolts. (Fig. 17)

Fig. 17

• If 0.4 gauge can be inserted, the clearance is too big.

It causes poor cutting performance.

• If 0.2 gauge can not be inserted, the clearance is too tight.

It causes over consumption of fuel due to high friction load

and heavy load on gears.

Page 9

P 9/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Ignition

MAINTENANCE

Plug Cap

(1) Remove Plug cap from Spark plug and check the resistance between Plug cap spring and Ignition coil with circuit

tester. (Fig. 18)

Fig. 18

Spark plug

Grounding terminal

of Ignition coil

If the Circuit tester shows 2.0 ± 0.5 kΩ,

the connection is in order.

(2) Check the connection of Plug cap spring with Ignition cable if Pointer of Circuit tester does not move or

does not steadily indicate 2.0 ± 0.5 caw.

Spray lubricant into the Plug cap and pull out Plug cap spring together with Ignition cable. (Fig. 19)

Fig. 19

Plug cap spring

Ignition cable

Plug cap

Circuit tester

Plug cap

(3) Check Plug cap if there is any crack, damage or disconnection. Re-fix them or replace the damaged one

with the new one if there is any disorder.

(4) Stick a Plug cap spring end into the center of Ignition cable and put them back into Plug cap while holding

Plug cap spring with pliers.

(5) Incomplete connection of Plug cap spring with Ignition cable causes the feeble sparking or no sparking from

Spark plug. Check the connection by taking the same procedure of (1) to (4).

Page 10

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Ignition (cont.)

MAINTENANCE

Spark Plug

(1) Remove Plug cap with Socket wrench 10-16. Clean the spark terminals of the removed Plug. (Fig. 20)

And adjust the gap of Spark terminals to 0.6 - 0.7 mm.

Fig. 20

P 10/ 25

1. Remove the remaining Fuel and

Carbon deposits stuck in the gap

with wire brush and air duster.

(2) Mount Plug cap on the Plug and contact the Plug’s thread portion to the metal portion of engine, and then,

pull Starter rope gently. The plug is in order if its terminals have sparking constantly.

In case of no sparking at the terminals, return to “MAINTENANCE in [3]-6. Ignition” and replace the Plug with

the new one if the plug is out of order.

DISASSEMBLING

Ignition Coil

(1) Remove Blower housing, Cylinder cover, Muffler cover and Ignition coil.

Note: Do not lose Spacer for insulating Cylinder’s heat when removing Cylinder cover.

(2) Remove Rubber from Insulator. (Fig. 21)

0.6 - 0.7 mm

0.7 mm Feeler

gauge of 1R366

2. Adjust the gap between

Spark terminals to 0.7 mm

by inserting 0.7 mm

Feeler gauge of 1R366.

Fig. 21

Rubber

Page 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Ignition (cont.)

ASSEMBLING

Ignition Coil

(1) Set Spacer on Cylinder and assemble Ignition coil on Spacer while inserting 0.3 mm feeler gauge of

1R366 between Fly wheel’s magnetized portion and Ignition coil. (Fig. 22)

Keep the inserted feeler gauge in this step till the Ignition coil is fully tightened

in order to fix the 0.3 mm gap precisely.

Fig. 22

Ignition coil

0.3 mm

P 11/ 25

Magnetized

portion of

Flywheel

(2) Remove the feeler gauge after Ignition coil is fixed. Make sure that Fly wheel can be turned smoothly by hand

without interference by Ignition coil.

Note: Make sure to fix Ignition coil through the Spacer. High voltage cable and Lead wire must be fixed

into Rubber. Locate high voltage cable to Cylinder side.

(3) Fix Rubber to Insulator.

Note: Make sure that the assembled High voltage cable does not interfere with Throttle in action.

(4) Assemble Cylinder cover.

Note: Tighten Cylinder cover together with Spacer to Cylinder.

Thread locker must be applied to the thread of Hex socket head bolt which tightens that parts.

Apply “ThreeBond 1342” or “Loctite 242” as a thread locker.

(5) Assemble Muffler cover.

Note: Apply “ThreeBond 1342” or “Loctite 242” as a thread locker.

Page 12

P 12/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Ignition (cont.)

DISASSEMBLING

Fly Wheel

Note: Plug cap has to be removed in order to avoid accidental start of engine.

Do not remove Plug when the nut for tightening Fly wheel is loosened to utilize air resistant in Cylinder.

(1) Attach 10 mm Hex socket bit to Impact driver. Turn M6 Hex nut counterclockwise with a Impact driver

(Clutch is removed by turning clockwise). (Fig. 23)

Fig. 23

1. Turn Hex nut counterclockwise.

So the Hex nut can be removed.

Piston

Clutch

2. Clutch is removed by

Clutch side

(2) Set 1R364 to Fly wheel with two M6 bolts. Tighten Both of two M6 bolts to the same depth.

Fig. 24

turning clockwise.

1R364

Hex Nut

Fly wheel

M6 Bolt

Page 13

P 13/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Ignition (cont.)

ASSEMBLING

Fly Wheel

(1) Remove oil completely from Crankshaft.

(2) Align Woodruff key on Crank shaft to the key groove of Fly wheel and mount Fly wheel to Crankshaft.

(3) Turn M6 Hex nut to Crankshaft clockwise by hand and tighten it with Impact driver with 10 mm Socket bit

clockwise for 2 second.

Fig. 25

1. Remove Oil completely

from Crankshaft.

Woodruff Key

2. Align this Key to the groove

in the Fly wheel.

[3] -7. Recoil Starter

DISASSEMBLING

(1) Remove Recoil starter assembly from Blower housing.

Note: Record the position and the pulling direction of Starter knob before disassembling. (Fig. 26)

Fig. 26

Recoil starter assembly

Blade sideLever case side

Starter knob

Pulling direction

Page 14

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Recoil Starter (cont.)

DISASSEMBLING

(2) Disassemble Recoil starter. (Fig. 27)

Fig. 27

P 14/ 25

1. Pull out Rope by the length of one or two times

turn of the Reel and hold the Reel.

Reel

Notch

Starter knob

Rope

3. Remove Set screw, Cam and Torsion spring.

2. Release Starter knob while holding the Reel with

your finger and pull the slack Rope inside.

Hook the Rope in the notch and turn the Reel

counterclockwise while braking the Reel and

holding the Rope. Turn Reel until

Spiral spring recoil force is gone.

Reel

Notch

Starter

case

Rope

4. Remove Reel from Starter case.

Note: Do not let Spiral spring leap out

in this step.

Set screw

Cam

Reel Torsion spring

Reel

Spiral spring

Page 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Recoil Starter (cont.)

ASSEMBLING

Assemble the Recoil starter. (Figs. 28 and 29)

Fig. 28

P 15/ 25

Spiral spring

2. Pass the new Starter rope through Starter case and

tie the both Rope ends in Starter knob and Reel.

And wind the Rope around Reel two or three times.

Starter case

Starter knob

Reel

1. Set the outer end of Spiral spring here firstly and wind it

clockwise till it is completely installed in the Starter case.

Note: Apply Makita grease N. No.2 a little on

the Spiral spring (Red grease was applied

to it at ex-factory condition).

3. Fit the projection of Reel to the hook of Spiral spring

while turning Reel clockwise.

Projection of Reel

Hook of Spiral spring

Note: Precisely fit the projection of Reel to the hook of

Spiral spring by repeating the step 3.

Set screw

Cam

Torsion spring

Mounted Reel

Fig. 29

6. Hold the rope near by the notch and turn it

with the Reel clockwise to let Spiral spring

have recoil force for driving Reel.

Reel

4. Fix Torsion spring and Cam

on the Reel with Set screw.

Notch

5. Pull the slack rope in the Starter case

and hook it in the notch of Reel.

Reel

Rope

7. Remove the rope from the notch and release your finger from Reel.

The Reel turns counterclockwise. Repeat the actions of 5, 6, 7,

until the Rope is wound by the Reel completely.

Notch

Starter case

RopeReel

Rope

Page 16

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Carburetor

DISASSEMBLING, CLEANING

(1) Remove Air cleaner cover. (Fig. 30)

(2) Remove Elements, Sponge and Felt. (Fig. 31)

Fig. 30 Fig. 31

P 16/ 25

Air cleaner

cover

(3) Remove two Hex socket head bolts fixing Air cleaner plate and Carburetor assembly. (Fig. 32)

Note: Take off the Hex socket head bolts completely from the machine,

otherwise, it’s impossible to disassemble Carburetor.

(4) Remove two tubes and disassemble Carburetor assembly. (Fig. 32)

Fig. 32

Element

(Felt made)

Element

(Sponge made)

Clear Tube

Carburetor

assembly

Hex socket

head bolt

Black

Air cleaner plate

Hex socket

head bolt

(5) Remove Diaphragm cover, Metaling diaphragm, Gasket set by unscrewing four Pan head screws. (Fig. 33)

Note: Carefully separate Gasket from Metaling diaphragm in case they stick each other as they are fragile.

(6) Replace Metaling diaphragm to the new one if it has any curing, deformation or breakage.

Fig. 33

Throttle valve

assembly

Pan head screw (small) Pan head screw (4pcs.)

Pump diaphragm

Gasket

Carburetor

body assembly

Tube

Inlet

screen

Pump body assembly

Metaling

diaphragm

Gasket

Diaphragm

cover

Page 17

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Carburetor (cont.)

DISASSEMBLING, CLEANING

(7) Check Inlet needle in the Pump body assembly if its tip is intact. Replace Controller set including Inlet needle

to the new set if Inlet needle tip is damaged. It can be removed by unscrewing M3x4 Set screw.

Check if there is any foreign material stuck on Fuel inlet before fixing Inlet needle. (Figs. 33, 34 and 35)

(8) Fully loosen idling screw, then, remove Pan head screws (small) for fixing Throttle valve assembly

to Carburetor body.

(9) Spray carburetor cleaner on the Inlet screen, all fuel inlets, outlets and internal routes. And then, wash them

with gasoline. (Fig. 35)

Fig. 34 Fig. 35

P 17/ 25

Component Parts of Controller set

Countersunk

head screw

Compression spring

Note:

The above parts are not supplied individually.

In case of replacement of any of the above parts,

it has to be replaced as a Pump body assembly.

(10) Make sure that Compression spring fits to the protrusion of Control lever when assembled. (Fig. 36R)

Metaling diaphragm

Inlet needle

Pin

Control lever

Inlet needle

in normal condition

Carbureted air leaks out

if foreign material sticks

at inlet hole.

Fig. 36FFig. 36R

Wrong Assembling of Compression spring

Carbureted air leaks out

if Inlet needle is worn out.

worn out

Control lever

Inlet needle

Compression spring

fits to the projection

of Control lever.

Compression spring

Projection of

Control lever

Page 18

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Carburetor (cont.)

ASSEMBLING

Assemble by reversing the disassembly, cleaning procedure.

AIR-TIGHT TEST

See Fig. 37.

Fig. 37

P 18/ 25

Carburetor

Nipple for

fuel intake

1R127

ASSEMBLING CARBURETOR TO ENGINE

(1) Connect two Tubes to Carburetor. (Fig. 38)

Fig. 38

1. Connect 1R127 to Carburetor.

2. Push up the air pressure until

the pressure gauge indicates

0.05 Mpa.

3. The Carburetor is in order

if the air pressure of 0.05 Mpa

can be kept for 10 seconds.

Push

Nipple for

fuel intake

Clear Tube

Black Tube

Page 19

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Carburetor (cont.)

ASSEMBLING CARBURETOR TO ENGINE

(2) Fasten the following parts with two Hex socket head bolts. (Fig. 39)

* Plate

* Air cleaner plate

* Gasket

* Cable bracket

* Gasket

* Carburetor assembly

* Carburetor gasket

Fig. 39

P 19/ 25

Starter case

Air cleaner plate

Hex socket

head bolt

(2pcs.)

Plate

Note 1:

Assemble plate to Air cleaner plate

while facing its triangle side to

Starter case side.

Gasket

Cable bracket

Gasket

Carburetor gasket

Carburetor

assembly

Note 3:

Make sure that Gaskets

are mounted to the both

side of Cable bracket.

Note 2:

Assemble Carburetor gasket

while facing its cut portion

to Loop handle side.

(3) Assemble Elements. (Fig. 40)

Fig. 40

1. First, assemble Felt element, and then, Sponge element.

2. Fit the tab of Air cleaner plate with the square hole of

Air cleaner cover and fasten Air cleaner cover

with a screw.

Air cleaner plate

Element (felt)

Element (sponge)

Air cleaner cover

Tab of

Air cleaner plate

Square hole

for tab

Page 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -9. Stop Switch

MAINTENANCE

(1) Connect Circuit tester for checking Stop switch. (Fig. 41)

Fig. 41

Connecting terminal

P 20/ 25

Bullet terminal

Stop switch is in order if it works as followings:

* Circuit tester shows no connectivity

when Engine ON

* Circuit tester shows a connectivity

when Engine OFF

Page 21

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -10. Fuel Tube

TUBING

Connect Fuel tank, Primer pump, Carburetor with Tubes. (Fig. 42)

Fig. 42

1. Mount Tube complete (equipped with black Tube and clear Tube) to Fuel tank.

The black Tube is for Fuel inlet. Insert Fuel filter to the black one with Hose clamp.

And then, put Fuel filter into the Tank.

Fuel filter

P 21/ 25

Fuel tank

Tube complete

2. Connect the clear tube to the longer nipple of Primer pump.

Fuel tank

3. Connect the black tube to the nipple for fuel inlet of Carburetor.

4. Connect the outlet nipple of Carburetor and shorter nipple of

Primer pump with another clear Tube.

Hose clamp

Fuel tank

Page 22

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -11. Spark Arrestor

DISASSEMBLING, CLEANING

(1) Separate Engine from the product. (Figs. 1, 2 and 3)

(2) Disassemble Muffler section. (Fig. 43)

Fig. 43

P 22/ 25

1. Remove Muffler cover (outer). And remove two Hex socket

head bolts. So, Muffler and Inner muffler cover (metal made)

are removed.

Inner muffler cover

(metal made)

Hex socket

head bolt

Muffler

3. Unscrew three Pan head screws

and remove Tail pipe, Gasket and

Spark arrestor from Muffler.

Muffler cover (outer)

4. Remove the carbon deposits and dust from Spark arrestor if any.

Replace the Arrestor if it has any deformation or breakage.

Spark arrestor

Muffler

2. Remove Inner muffler cover (metal)

and Muffler gasket from Muffler.

Muffler gasket

Muffler

Tail pipe

Pan head screw (3 pcs.)

Inner muffler cover

(metal made)

Gasket

ASSEMBLING

(1) Set Spark arrestor to Muffler.

(2) Put Gasket on the Spark arrestor while facing its cut corner to the hill formed portion of Muffler. (Fig. 44)

(3) Assemble Tail pipe through Gasket to Muffler with three Pan head screws. (Fig. 44)

Fig. 44

2. The Gasket has convex portion

on the reverse side for pressing

1. The hole comes under

the Hill formed portion of

Muffler when assembled.

Mount Gasket while facing this cut corner to the Hill formed portion of Muffler

so that the convex side of Gasket presses the Spark arrestor.

Muffler gasket

Hill formed portion

Spark arrestor

Spark arrestor to Muffler surface.

Gasket

Tail pipe

(4) Mount Inner muffler cover. (Fig. 43)

(5) Fix the assembled muffler section to Engine with Hex socket head bolts. (Fig. 43)

Note: Apply “Loctite 242” or “ThreeBond 1342” to the thread of Hex socket head bolts.

Page 23

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -12. Engine Block

DISASSEMBLING

(1) Disassemble the following parts from Engine.

* Blower housing * Muffler cover (out side) * Muffler * Cylinder cover

* Plug cap * Spark plug * Ignition coil * Carburetor

* Clutch * Fly wheel

(2) Remove Fuel tank while paying attention not to lose Spacer which is fixed in between the Tank and Engine.

(3) Remove Insulator with Insulator gasket from Cylinder.

(4) Separate Cylinder from Crankcase assembly and remove Piston. (Fig. 45)

Fig. 45

P 23/ 25

Cylinder

Cylinder gasket

Piston

Crankcase

assembly

1. Remove Piston clips from the both

side of Piston with the awl.

Note: Do not reuse the removed

Piston clip.

2. Remove Piston pin by pushing it

with 1R171.

Now, Piston can be removed

Crankshaft

from Crankshaft.

Fly wheel

side

Piston

Piston pin

Piston clip

Awl

Piston pin

Piston clip

1R171

ASSEMBLING

(1) Before assembling Piston, apply one or two drops 2 stroke engine oil to Needle bearing on Crank shaft.

(2) Assemble Piston to Crank shaft. (Fig. 46)

Fig. 46

Assemble Piston at the direction described below.

Left

Cavity

Right

Fly wheel

side

Page 24

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -12. Engine Block (cont.)

ASSEMBLING

(3) Assemble the new Piston clip with Awl. (Fig. 47)

Fig. 47

Piston clip opening must face to either the top side or

Skirt side of Piston when assembled.

Groove on Piston Groove on Piston

Top Side

P 24/ 25

Top Side

Skirt Side

(4) Assemble Piston rings (Fig. 48).

Fig. 48

The first nock pin

in the lower groove

1. Mount Piston ring to

the lower groove while

aligning its opening gap

to the first nock pin.

Piston clip

Top view of Piston

The second nock pin

in the upper groove

Skirt Side

Note 1:

Carefully open Piston ring when fixed

so as not to break it.

Note 2:

Face cut surface to the top

when Piston ring is assembled.

2. Mount another Piston ring

to the upper groove while

aligning its opening gap

to the second nock pin.

(5) Assemble Cylinder gasket to Cylinder. (Fig. 49)

Fig. 49

1. Apply 2 stroke engine oil to the internal

surface of Cylinder before assembling it

to Crankcase assembly.

2. Assemble Cylinder gasket

while aligning its square

hole to that of Cylinder.

Cylinder

Cylinder gasket

Page 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -12. Engine Block (cont.)

ASSEMBLIG

(6) Mount Cylinder to Crankcase assembly. (Fig. 50)

Fig. 50

P 25/ 25

Cylinder

1. Insert Cylinder over Piston

while pressing Piston rings

toward the Piston’s center.

Note:

Pay attention not to let Piston

rings to move onto Nock pins

when it’s assembled to Cylinder

(Fig. 48).

Piston rings will break

if Cylinder is mounted by force

over Piston rings that are

moved onto Nock pins.

(7) Assemble Insulator to Cylinder.

Note: Apply “ThreeBond 1342” or “Loctite 242” to the thread of Hex socket head bolt.

(8) Assemble Fuel tank.

Note: • Do not forget to mount Spacer between Fuel tank and Clutch case assembly.

• Apply “ThreeBond 1342” or “Loctite 242” to the thread of Hex socket head bolt.

2. Tighten four Hex socket

head bolts in diagonal

order.

Piston

Crankcase assembly

[3] -13. Fastening Torque

Part description

Crankcase 1 Crankcase 2 M5x18 Hex Socket Head Bolt

Cylinder Crankcase M5x18 Hex Socket Head Bolt 8

Fly wheel Crankshaft 1 M6 Nut 12

Coil Cylinder M4x20 Hex Socket Head Bolt 4

Muffler Cylinder M5x50 Hex Socket Head Bolt 8

Muffler cover Muffler M5x5 Screw 4

Clutch Crankshaft 2 M8 Screw (Left Hand Thread) 12

Recoil starter Blower housing 4.5x14 Tapping Screw 2.5

Plug Cylinder M10 10

Spur gear 9 Clutch drum M8 Screw (Left Hand Thread) 8

Grease nipple Gear case M6 4

Gear case cover Gear case M4x16 Hex Socket Head Bolt 4

Blade guard Guide bar M5x6 Screw 3.5

Plate Guide bar M5x8 Screw 3.5

Bolt and Screw

Fastening

Torque (N. m)

8

Loading...

Loading...