Page 1

Installation and Parts Manual

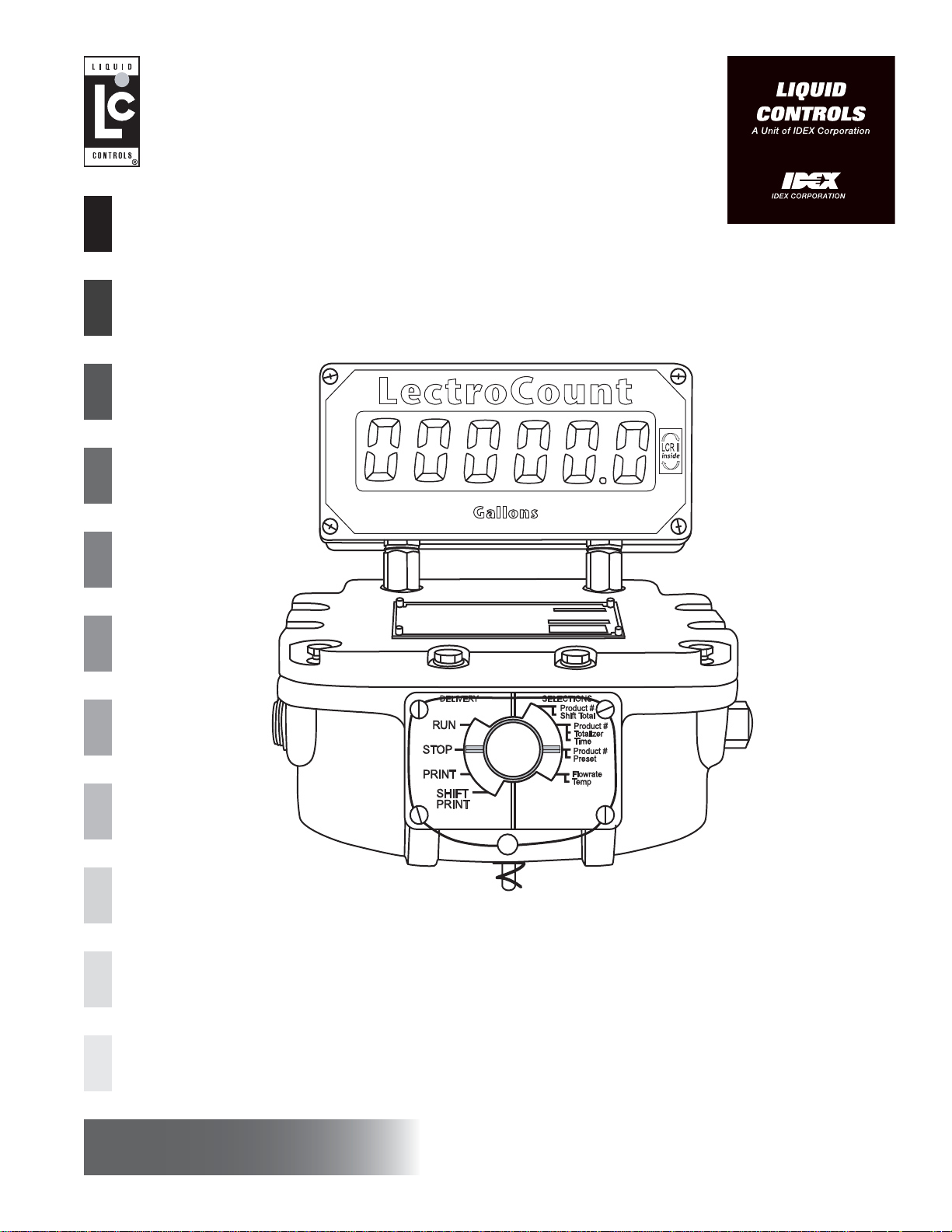

LectroCount LCR

Installation: EM100-20

www.lcmeter.com

Page 2

Table of Contents

!!

!!

!

WARNING WARNING

WARNING WARNING

WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this puclication could result in property damage, personal injury,

or death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

Description Page Number

Sytstem Overview ........................................................................ 3

Installation Overview .................................................................... 4

Specifications ............................................................................... 5

Regulatory Specifications ............................................................ 6

Parts Requirements ..................................................................... 7

LCR Register Mounting................................................................ 8

Valve Installation .......................................................................... 9

Wiring the LCR ............................................................................. 11

Guidelines for Environmental Sealing .......................................... 16

System Startup............................................................................. 17

Wiring Schematic ......................................................................... 19

Wire Connection Tables ............................................................... 21

Illustrated Parts Breakdown ......................................................... 23

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our website, www.lcmeter.com.

It is the responsibility of the Local Distributor to provide the most current version of LC Manuals, Instructions, and

Specification Sheets in the required language of the country, or the language of the end user to which the products are

shipping . If there are questions about the language of any LC Manuals, Instructions, or Specification Sheets, please

contact your Local Distributor.

2

Page 3

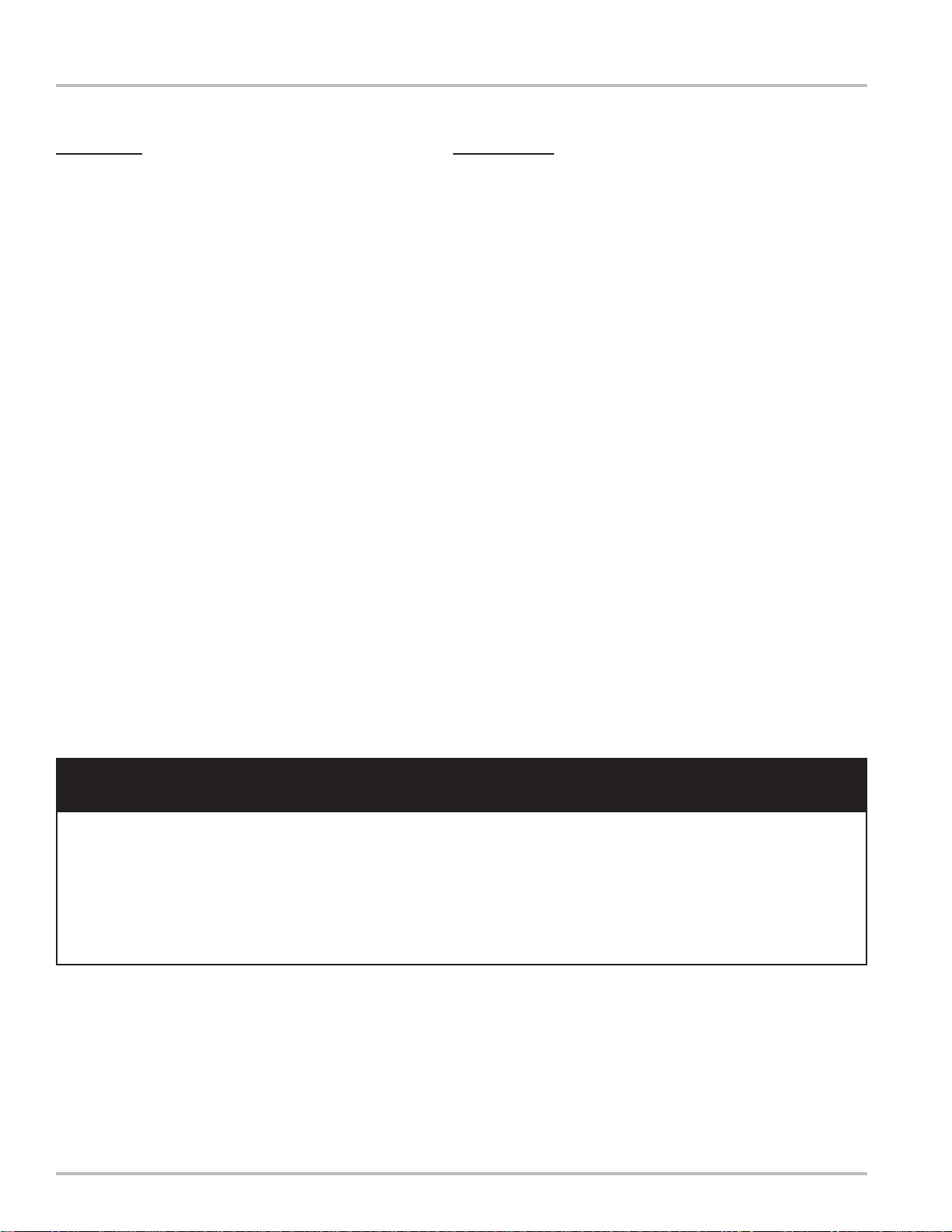

Sytstem Overview

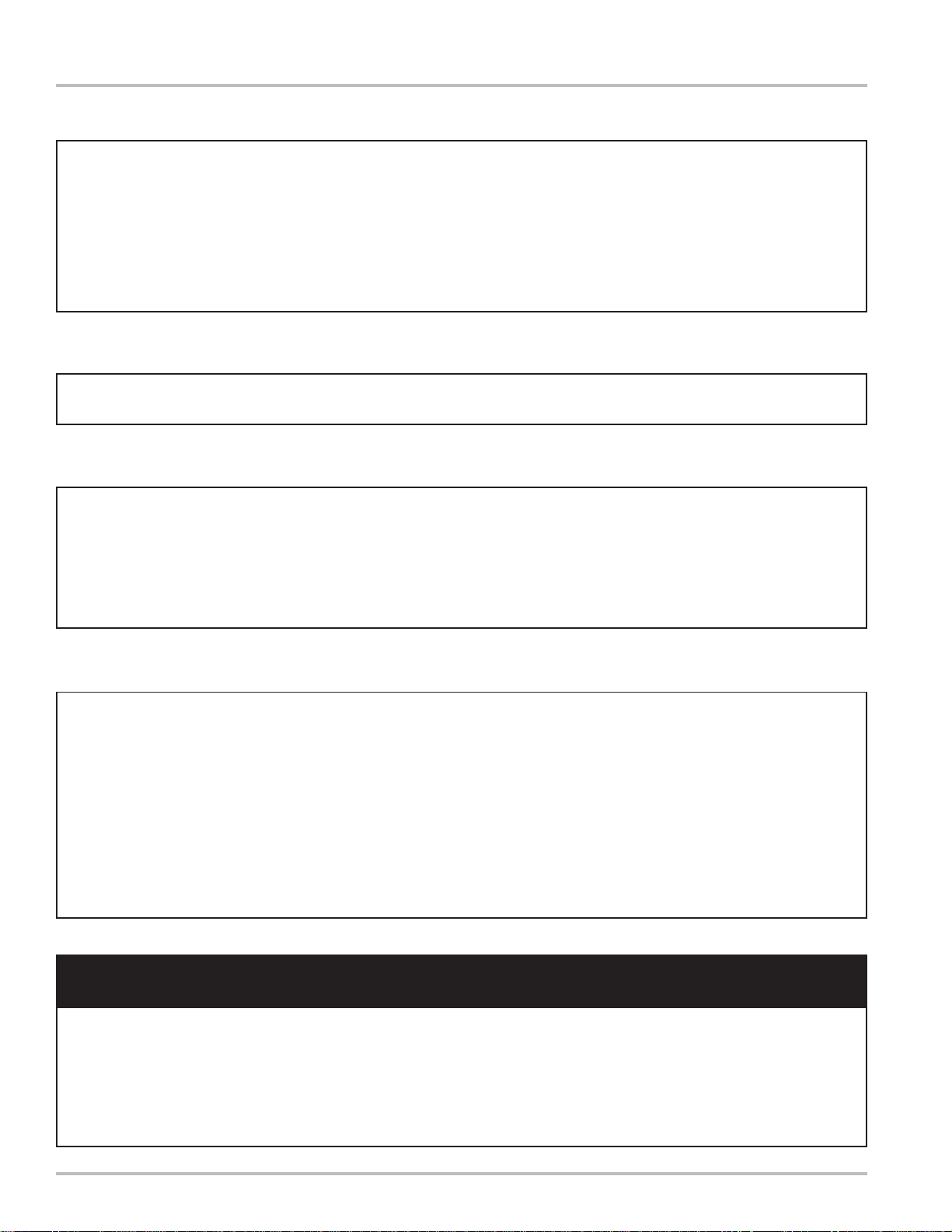

General

The LectroCount LCR is an electronic meter register that

can be used to calibrate a flow meter, control a security

valve, output delivery information via an LCD display and

printer, and, optionally, perform electronic temperature

volume compensation. The LCR receives its flow input

signal from either an external pulser, a meter output, or

an internally mounted quadrature pulser that is

mechanically connected to the flow meter. LCR is housed

in a weather and explosion proof enclosure that can be

mounted directly atop many common positive

displacement meters. Alternatively, the LCR may be

mounted remotely from meters utilizing external pulsers.

A backlit remote electronic counter with a six digit display

on top of the LCR housing provides a real time readout

of product delivered.

Operation

The LCR can be operated as a stand-alone system, as a

stand-alone system with electronic presetting, and as a

slave to a host controller such as a hand held computer,

process controller, or vehicle mounted data terminal. It

can be used in mobile and fixed installations. When

installed with the proper system accessories the LCR

can be used for Weights & Measures approved custody

transfer transactions.

Outputs

Information from the LCR can be output via an RS-232

printer port, RS-485 or RS-232 communication port, a

scaled pulse output,and a counter output.

Installation

This manual describes the installation and operation of

the LCR and its optional accessories. Read this entire

manual before beginning the installation to make sure

that you understand the total scope of the project.

Specific installation requirements will vary with the model

of truck, the physical layout of a fixed installation, the

configuration of any existing metering equipment, the

options that are selected, and the type of fluid being

metered. Make sure that the LCR, and accessories such

as the Electronic Temperature Volume Compensation kit

and the control valves can be installed in such a manner

so as to not interfere with routine service of the meter

and strainer. The conduit and wiring for the above

components need to be routed with similar concerns in

mind.

This manual applies to LCR’s equipped with SR 200

Series software.

3

Page 4

Installation Overview

Meters with LCR (factory installed)

In many instances, the LCR will be factory installed on a

Liquid Controls meter, along with a strainer/air eliminator

and security valve. In such cases, the user may proceed

to page 10 of this manual “Wiring the LCR” after verifying

that the truck electrical system meets the specifications

listed below.

Field retrofit of LCR to existing meters

For field installation of the LCR to a meter the steps listed

below, and described in this manual, should be followed.

A typical truck installation includes the following steps:

• Ensure that the truck electrical system meets

specifications

• Remove existing mechanical registration equipment

• Remove manual preset valve

• Install an electronically controlled security/preset

valve

• Mount LCR to the meter

• Install optional peripheral accessories including

electronic temperature/volume

compensation (ETVC) kit, odometer pulser, remote

START/STOP switch, etc…

• Route factory supplied cables from LCR to truck cab

• Mount printer in cab

• Connect printer and LCR to truck’s

accessory circuit (12 VDC)

Electrical check for Truck Installations

Before beginning the installation, make sure that the truck

electrical system meets the minimum requirements to

correctly power the LCR. The truck system should

produce at least 12.6 VDC to reliably power the LCR

and the valve control solenoids. Truck systems that do

not meet this requirement need to be serviced to ensure

that the LCR will be reliably powered. The LCR computer

will power down if the voltage drops below 9 VDC.

The truck system must meet the following requirements:

• Make sure that, with the truck running at low idle

and ALL accessories on (including the hose reel),

the voltage does not drop below 9 volts.

• Be sure that all radio antennas have been installed

in accordance with the manufacturer’s specifications

to prevent RF interference.

NOTE: The LCR power cable kit includes a fuse holder

and a 5 Amp fuse to protect the truck system in the event

of a short circuit in the cable. Liquid Controls

recommends that this fuse be used in all installations

not having a fused accessory block to protect the truck

in the event of cable faults. A 5 Amp fuse is required.

4

Page 5

Specifications

Power Requirements

+9 to 28 Volts DC @ less than 3 Amps for entire register

including solenoid valves. The system can operate with

either a positive or negative ground.

Pulse Input

5 to 28 volt peak to peak square wave from an open

collector with pull-up resistor greater than 750 ohms.

Quadrature or single channel with a direction logic line.

Frequency not to exceed 2500 Hz.

Scaled Pulse Output

The scaled pulse output reflects net volume if temperature

compensation is being employed or gross volume if

temperature compensation is NOT employed. One pulse

will be output per least significant digit of the display, i.e.,

a system set to read in 1/10 gallon will provide one pulse

per 1/10 gallon (10 pulses per gallon).

Open drain output common to the negative power input

line. Sinking capability up to 150 mA. Maximum open

circuit voltage is 28 VDC.

Auxiliary Outputs

This output can be used to add features such as pump

control or additive injection.

Aux 1: Open drain output common to the negative power

input line. Sinking capability up to 1 Amp. Maximum

circuit voltage is 28 VDC.

Aux 2: Open drain output common to the negative power

input line. Sinking capability up to 150 ma. Maximum

open circuit voltage is 28 VDC.

Solenoid Outputs

Open drain transistor common to the negative power

input line. Sinking capability up to 1 Amp. Maximum

open circuit voltage is 28 VDC.

Up/Down/Reset pulse to Remote electronic counter

Open drain transistor capable of sinking 1 Amp.

Maximum open circuit voltage is 28 VDC.

Pulses are active low and are approximately 10 μsec in

duration. The LCD counter is reset by turning on both

outputs for 0.01 second.

RS-232 I/O Port

Meets EIA -232E standard but only incorporates four

signaling lines:

• Transmit data

• Receive data

• Request to Send or Data Set Ready

• Clear to Send or Data Terminal Ready

The printer output port is compatible with the Epson TM

TM 290 II, TM 295, TM 300, TMU 200D, TMU 295

printers, Axiohm Blaster, and Okidata™ ML184 printer.

RS-485 I/O Port

Line terminations are SAE J1708 standard compatible

which allows up to 20 units per network.

RTD

Four-wire platinum sensor with 100 ohms resistance at

0°C and 138.5 ohms resistance at 100°C.

Accuracy per IEC 751 Class B.

Printer (Epson Model 295)

Operating temperature: -22° to 104°F (-30° to 40°C).

Printer must use multi-part NCR forms and operate

without a ribbon (impact image on form) to operate in the

low end of the temperature range.

5

Page 6

Regulatory Specifications

!!

!!

!

IMPOR IMPOR

IMPOR IMPOR

IMPOR

TT

TT

T

ANTANT

ANTANT

ANT

For North American Installations, the installation must be fully in accordance with the National Electrical Code (US)

or the Canadian Electrical Code respectively to maintain the hazaardous location ratings on the product. This may

involve using rigid conduit for all connections.

For European installations, the installation must be fully in accordance with EN60079-14 to maintain the hazardous

location ratings on the product. This may involve using special cable gands for all connections.

Weights & Measures - Custody Transfer

United States

Canada

International

NTEP Certificate of Conformance #86-022. Complies with requirements in NIST handbooks

44 and NCWM Publication 24 for use with any approved meter.

Measurements Canada Notice of Approval #AV-2342. Complies with Weights & Measures

Acts, Regulations, Specifications, Bulletins, and Rulings/Interpretations including specifications SVM-1 and SVM-2 for use with any approved meter.

OIML R117 Report through Nederlands Meetinstituut (NHMi)

Safety Approvals

United States/

Canada

Class I, Division 2, Groups C & D (non-incendive), IP66

Class I, Division 2, Groups C & D (non-incendive), IP66

EMC

United States

Canada

International

Cispr A

SVM 1

ISO 7637, EN 50081-1, EN 50081-2, EN 50082-1, and EN50082-2. Also complies with OIML

R117 for Class I

(Mobile instruments, in particular measuring systems on trucks). Self-declared CE Mark.

Mechanical/Climatic Suitability

Ratings

IP 66

NEMA 4X

OIML R117

Operating Temperature: -40° to 158°F (-40° to 70°C)

Relative Humidity: 0 to 100%

Dust tight, dust will not enter.

Protection against a powerful jet of water from all practical directions.

Either indoor or outdoor use to provide against falling rain, splashing water, and hose-directed

water; undamaged by the formation of ice on the enclosure; resists corrosion. Plastic lens is

resistance to UV and water immersion. Gaskets are resistant to aging.

Includes testing for Dry Heat, Cold, Damp Heat Cyclic, and Vibration (sinusoidal)

6

Page 7

Parts Requirements

!!

!!

!

WARNING WARNING

WARNING WARNING

WARNING

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST BE RELIEVED

AND ALL LIQUID DRAINED FROM THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the meter and liquid or gas pressure source.

For Safety Rules regarding LPG, refer to NFPA Pamphlet 58 and local authorities.

Failure to follow this warning could result in property damage, personal injury, or death from fire and/or explosion, or

other hazards that may be associated with this type of product.

Liquid Controls Supplied Components

LCR register, and LC-supplied options including; printer,

Lap Pad, control valve or solenoid, ETVC kit, glandless

pulse output device (POD), odometer kit, preset switch,

remote START/STOP switch, communication protocol

selector switch (RS232/485), power cable, and printer/

Lap Pad cable.

Installer Supplied Parts

• All conduit/cable glands

• All fittings

• Hardware for printer mounting brackets

• Non-standard cables or cable extensions

Removing Existing Mechanical Registration Equipment

Liquid Controls Meters

Remove the mechanical register components by

removing the four bolts that attach the register “stack” to

the meter. (See illustration below).

Neptune Fuel Oil Meters

Remove the mechanical register from the meter, leaving

just the star shaped gear and two square headed studs.

Neptune LPG Meters with Mechanical TVC’s

Remove the mechanical register and the mechanical

automatic temperature compensator from the meter

leaving just the star shaped gear.

Removing mechanical register stack from Liquid Controls meter (typical).

7

Page 8

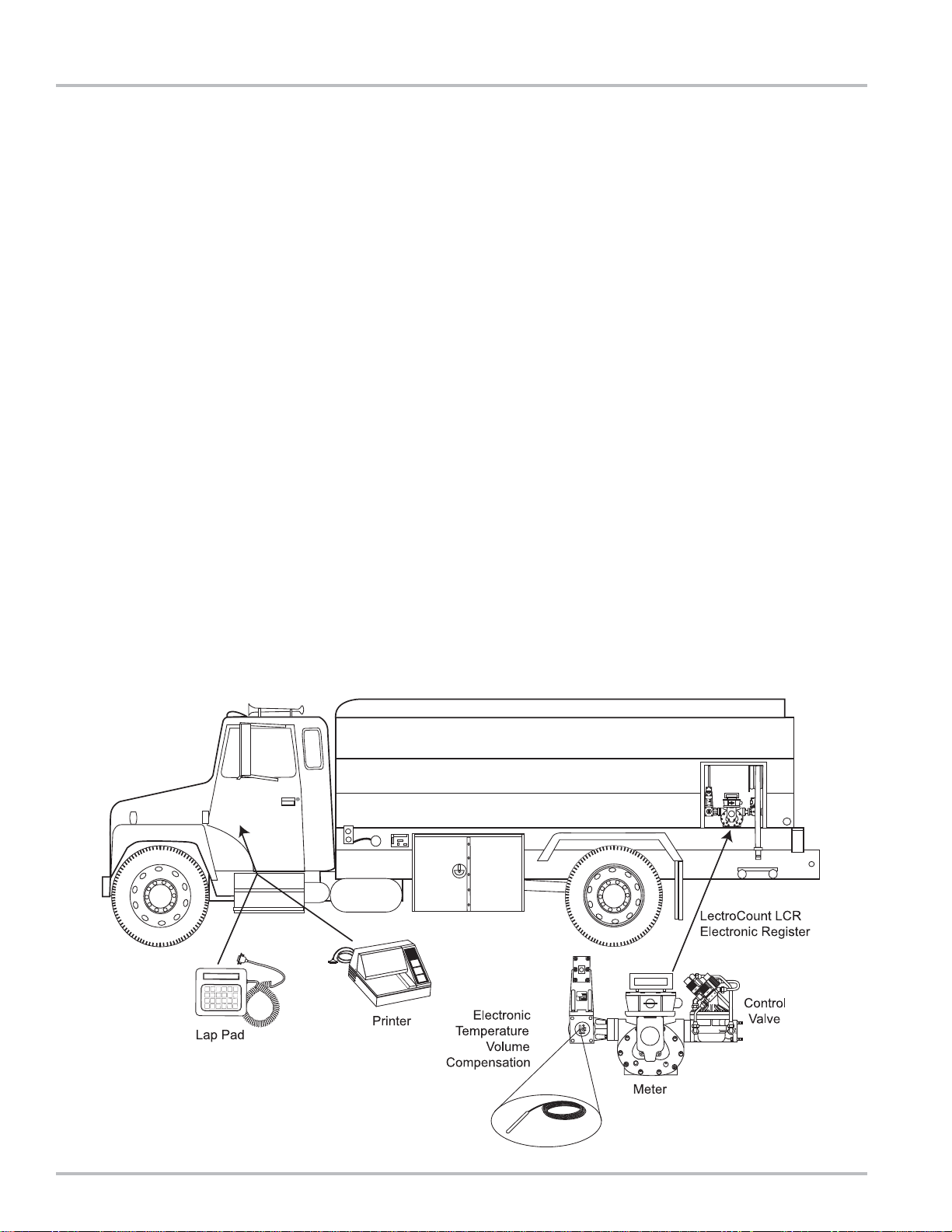

LCR Register Mounting

The LCR register is usually mounted on the liquid flow

meter, though for fixed installations it can be mounted

up to 1000 wire feet (304.0 meters) away from the meter

if the meter is equipped with an external pulser. The

actual distance depends on the pulser specifications and

the type of wire used to install it. Contact the factory if

your installation requires pulser or RTD cable lengths

greater than 1000 feet.

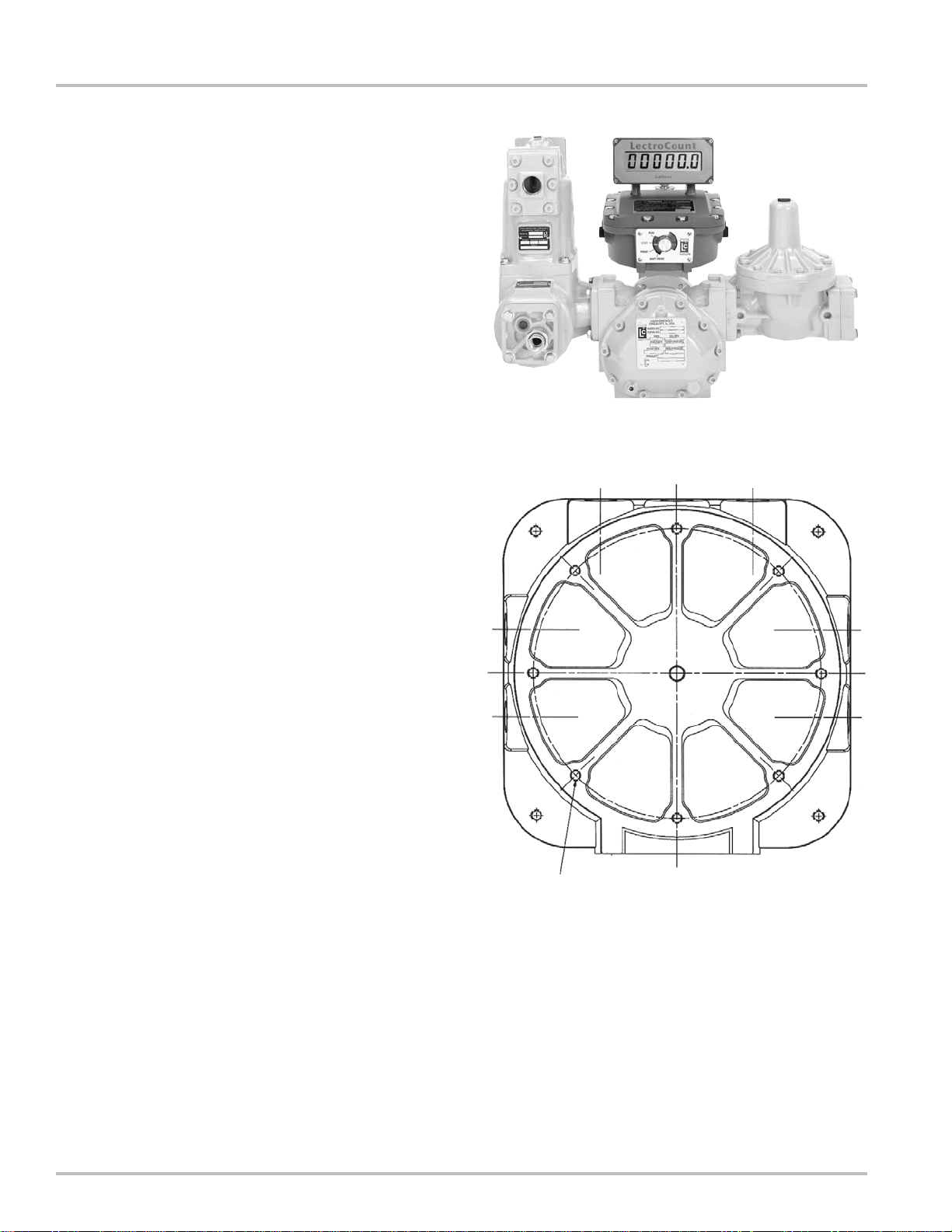

LCR Mounting Bolt Pattern

The LCR base casting contains eight mounting holes in

an industry standard bolt pattern that allows it to be easily

attached to a number of common meters. All of the holes

are 1/2” deep and will require 1/4 - 20” screws.

Refer to the drawing below if you will need to fabricate a

mounting bracket for the LCR. Brackets and adapters

are available from Liquid Controls for many common

meters. Installation instructions are packed with the

mounting or adapter kit. When mounting the LCR, leave

the cover assembly fastened to the base to protect the

internal components. As the LCR is placed on top of the

meter, make sure the vertical drive shaft from the meter

is attached to the pulser drive shaft using the kit provided.

Before securely fastening the LCR to the meter or

bracket, make sure that the counter is visible and that

the selector switch can be easily operated.

NOTE: If the LCR will be exposed to the elements before

the installation is complete, make sure that the cover

gasket is in place and that all (12) M8 mounting bolts

and washers are snugly installed. Also, remove all of

the pipe plugs from the LCR’s seven 1/2” NPT conduit

hubs, apply pipe sealant or Teflon tape to the threads,

then re-install the plugs in the ports.

NOTE: When removing/installing cover screws, switch

plate screws, or display cover screws, apply antiseize

compound to the screws upon reassembly to ensure easy

removal at later date.

Mounting Holes:

.250-20 UNC -2B .50 Deep

8 Holes Equally Spaced on a 6.65 Dia. Circle.

8

Page 9

Valve Installation

General

The LCR can provide security valve and preset control

capabilities via the Solenoid 1 and 2 outputs. Singlestage and two-stage solenoid actuated valves and threeway solenoids can be controlled. Valves should be

installed in accordance with accepted industry practice

and Weights & Measures regulations. NOTE: The

modulated two-solenoid valves designed for use with the

LectroCount3 cannot be used with the LCR.

LPG and NH3 Truck Installations

The differential valve used on many LPG trucks can be

used in conjunction with Liquid Controls 3-way solenoid

kit as a security valve. Since the differential valve is

installed after the meter, little of the piping has to be

modified.

The 3-way solenoid mounts to the LCR via the rear middle

port using the short 1/2” NPT nipple and explosion proof

union supplied with the kit. Port A is connected to the

vapor eliminator’s vapor port. Port B is connected to the

differential valve’s diaphragm. Port C is connected to

upstream system pressure. See illustration below.

If the solenoid is not energized by the LCR, upstream

high pressure liquid is directed to the valve diaphragm

and the valve closes, preventing product from being

delivered.

When the solenoid is energized by the LCR’s SOL-2

signal, the vapor eliminator’s control port is connected

to the differential valve. This allows the valve to function

normally: if the vapor eliminator is filled with liquid, the

pressure on the valve (bonnet) is low and the valve opens,

allowing product to be delivered. If the fluid level in the

vapor eliminator drops, high pressure gas will be directed

to the valve bonnet, and the valve will close.

NOTE: Liquid Controls’ supplied 3-way solenoids can

have either of two labeling schemes. Check to determine

which 3-way solenoid has been supplied with your kit.

Install as indicated below.

Port Connections:

A (or R) - connected to air eliminator vapor port.

B (or B) - connected to valve diaphragm.

C (or P)- connected to upstream system pressure.

9

Page 10

Valve Installation

Fuel Oil Trucks Preset/Security Valve Installation

Installing an LCR on a refined fuel truck typically requires

the removal of the system’s mechanical valve. Those

trucks equipped with air check valves should retain them

as part of the air elimination system. However, an air

check valve will not perform well as a preset/security valve

on fuel trucks.

Liquid Controls can provide two-stage or single-stage

valves that provide the security and accurate presetting

functions. The valve control software in LCR compares

the volume delivered to the preset amount and

automatically adjusts itself to deliver the correct preset

quantity.

Two-Stage Valves

Two-stage valve solenoids should be connected to the

LCR’s valve control outputs (SOL-1 and SOL-2). When

both of the solenoids are energized, the valve will be

operating at full flow. When SOL-1 is turned off, the valve

will operate at a reduced or dwell flow rate. If neither of

the solenoids is energized, the valve will close, stopping

product flow.

NOTE: A 2-inch Preset Valve can be used with a 3-inch

meter system if the flow rate does not exceed 160 GPM.

Single-Stage Valves

Single-stage solenoids should be connected to the SOL2 control. When the solenoid is energized, the valve will

open to the maximum flow rate.

On certain applications, trucks equipped with LC V-7

mechanical valves can be retrofitted with LC air valve

actuators to provide single-stage shut-down and solenoid

block functions. These systems require truck system

compressed air to function. Consult Liquid Controls for

more information.

Special Note for Canadian Installations

Canadian Weights & Measures regulations require that

the preset valve on truck systems be located after the

meter. In addition they require that a manual ball type

valve be located between the meter and the hose reel.

Liquid Controls recommends that the manual ball valve

be located after the preset valve and before the hose

reel.

Install the preset valve in the pipe between the meter

and the hose reel or manual shut-off valve. If an air check

valve is present in the system, leave it in place.

Make sure that the preset valve is installed in the correct

orientation with respect to fluid flow. On many valves

the flow direction is indicated by an arrow on the valve

body.

10

Page 11

Wiring the LCR

!!

!!

!

WARNINGWARNING

WARNINGWARNING

WARNING

Power, input and output (I/O) wiring must be in

accordance with the area classification for which it is

used (Class I, Div 2). For North America, installations

must be per the U. S. National Electrical Code, NFPA

70, or the Canadian Electrical Code in order to maintain

Class I, Division 2 ratings. This may require using

connections or other adaptations in accordance with

the requirements of the authority having jurisdiction.

General

Once the LCR, and optional equipment such as control valve and ETVC kit have been installed in accordance with

instructions supplied with the units, wiring connections need to be made from those components to the LCR. The user

supplied wiring for all connected equipment must be routed through suitable conduit to the LCR. Threaded pipe

conduit, Liquid Tight, and Synflex are among some choices. If plastic Synflex fittings are used, make sure that they are

rated for outdoor use, temperature and gas/oil service. The conduit hubs on the LCR are all 1/2” - 14 NPT. Recommended

conduit routings are shown to the right. For your convenience in wiring, all terminal blocks on the LCR are removable

by pulling straight up. CAUTION: The conduit/cable entrances must be sealed inside and out using appropriate cable

glands to prevent moisture from entering in the LCR.

WARNING: Explosion Hazard - Substitution of

components may impair suitability for Class I, Division

2 applications.

WARNING: Explosion Hazard - When in hazardous

locations, turn power OFF before replacing or wiring

modules.

WARNING: Explosion Hazard - Do NOT disconnect

equipment unless power has been switched OFF or

the area is known to be Non-Hazardous.

11

Page 12

Wiring the LCR

Wiring of Valve Solenoids to LCR

When wiring valve solenoids to the LCR, the wires may

have to be spliced in order to reach the appropriate

terminal strip location. Use stranded 18 GA wire. It is

recommended that red wire be used for the main

connections, though black can be used as a substitute.

Green 18 GA stranded wire should be used for the

solenoid case ground. Leave a small amount of excess

wire to allow for future servicing of the junction box wiring.

Single-Stage Valve and Three-Way Solenoid Wiring

Single-stage (security) valve solenoid (S2) or three-way

solenoid (LPG service) should be wired into terminal block

J13, Pins 17, 18, and 19, as shown on page 14. Solenoid

operates when the LCR pulls SOL-2 (Pin 18) signal low.

Two-Stage Valve Solenoid Wiring

The S1 and S2 solenoids are connected to terminal block

J13, Pins 14, 15, 16, and 17, 18, and 19, respectively, as

shown on page 14. The SOL-1 signal is connected to

the bonnet solenoid (S1). The SOL-2 signal is connected

to the bypass solenoid (S2). Each solenoid will be turned

on when the LCR pulls its respective signal low (SOL-1;

SOL-2).

Wiring RTD Temperature Probe to LCR (Optional)

Make sure that there is enough slack in the conduit

leading from the LCR to the strainer mounted RTD to

allow the strainer cover to be removed. Feed the cable

from the back of the RTD through the conduit to the LCR.

Cut the cable on the LCR end, leaving enough to expose

a few inches of the wires inside. Strip the insulation from

the wires and connect them to terminal block J14, Pins

20, 21, 22, and 23, as shown on page 14. The two white

wires are connected to Pins 20 and 21, and the two red

wires to Pins 22 and 23.

Connecting Lap Pad to LCR (optional)

The optional Liquid Controls Lap Pad is connected to

the printer in the cab of the truck. Each Lap Pad is

provided with a 3-terminal Lap Pad Adapter that provides

a junction for the Lap Pad, the printer, and the LCR printer

cable. The Lap Pad adapter is inserted in the port at the

back of the printer. Then, the printer cable from the LCR

is installed in the back of the adapter. Refer to page 14.

NOTE: The jumper on terminal J10 on LCR circuit board

must be in the RS-232 position for operation of the Lap

Pad (factory set position). See page 14.

12

Page 13

Installing factory-supplied printer Power cable, LCR

Power Cable, and printer data cable

Your LCR includes an electrical black-sheathed10conductor printer data cable for connecting the LCR at

the rear of the vehicle to the printer located in the vehicle

cab, and a separate gray-sheathed 3-wire power cable

for connecting the LCR to the accessory circuit in the

vehicle cab. For your convenience, the cables have been

factory pre-wired to the LCR, and are ready for routing

to the vehicle cab. The cable assemblies should be run

in 3/4” automotive black plastic corrugated split loom to

protect the cables from the elements. Make sure the

loom is securely fastened to the truck. NOTE: Be

especially careful to keep the cables away from hot

surfaces, rotating shafts, and moving linkages.

Printer Data Cable (P/N 81513040)

Connect the D-connector on the free end of the black

printer data cable to the receptacle on the back of the

printer in the vehicle cab. NOTE: The socket labeled

“KD”(telephone style connector) on the back of the printer

is NOT used. Printer may be located a maximum of 50

feet from LCR.

Printer Power Cable (24 VDC)

Printer power is supplied through the socket labeled “24

VDC” on the back of the printer. The 82500 DC/DC

converter plugs into this socket. The pigtail end of the

82500 must be connected to the accessory circuit (red)

to 12 VDC and (black) to system ground. See page 14.

Wiring the LCR

Wiring the pod pulser to lcr (optional)

LCR is most commonly supplied with an internal pulser

for the convenience of the customer. In such cases, the

optional external POD pulser is not used. If the LCR is

located remotely from the meter, the POD pulser is

required to supply pulse outputs to the LCR.

The POD pulser should be installed in accordance with

the installation instructions supplied with the POD (Series

E200 Installation, and Operation Manual). Wire the POD

to terminal block J8, Pins 31, 33, 34, and 37, as shown

on page 15. Route wires from the POD into the LCR

through Port 6.

NOTE: For connection of other design pulsers, refer to

page 19 of this manual.

LCR Power Cable (P/N 81512)

Connect the black lead of the power cable for the LCR to

a suitable grounding point in the cab. Connect the red

lead to a source of 12 VDC power that is on the vehicle

“accessory” circuit (the LCR is designed to be “OFF”

when the vehicle is turned off). Typically the ignition

switch and the fuse panel are sources of 12-volt power.

If power is drawn from a fuse tap, make sure the cable

connection is on the load side of the fuse. The power to

the LCR should be “OFF” when the truck ignition switch

is in the “OFF” position. NOTE: The LCR Power Cable

Kit includes a 5 Amp fuse holder and fuse to protect the

truck system in the event of a short circuit in the cable.

Liquid Controls recommends that this fuse be used in all

installations not having a fused accessory panel already

in the truck. See page 14. A 5 Amp fuse is required.

CAUTION: Electrical Power must be off until all wiring

operations have been completed.

Wiring odometer PULSER to lcr (optional)

The Odometer pulser is mechanically installed on the

vehicle in accordance with the installation manual

provided with the odometer kit. The 3-wire cable from

the odometer pulser is wired to terminal block J8, Pins

31, 36, and 38, as shown on page 15. Route wires from

the odometer pulser into the LCR through Port 6.

13

Page 14

Wiring the LCR

Wiring Customer-Furnished Remote START/Stop

Switch to LCR (Optional)

A user-supplied momentary remote START/STOP Switch

can be connected to terminal block J8, Pins 36 and 38 in

lieu of the odometer pulser. For programming instructions

to activate the user supplied remote START/STOP

Switch, refer to the LCR Set-up Manual (Bulletin No.

500050).

Preset/product Selector switch (optional)

LCR can be provided with a factory installed optional

preset switch for setting a preset delivery quantity from

the back of the vehicle. The preset switch is connected

to terminal block J8, Pins 35 and 38, as shown on page

15. For instructions on the operation of the preset switch,

refer to the LCR Set-up Manual (Bulletin No. 500050).

NOTE: The preset switch can also be used to select

one of four different products. Refer to the LCR Set-up

Manual for details.

Communication protocol selector switch (optional)

LCR can be provided with a factory installed optional

communication protocol selector switch. This optional

switch, which is housed in Port No. 1 on the LCR, allows

the user to select the RS-232 communication protocol

for use with the Liquid Controls Lap Pad terminal (switch

in “up” position), or the RS-485 protocol for use with a

handheld computer (switch in “down” position). This

protocol selection can be made without breaking Weights

& Measures seals on the LCR. Without this switch, any

change in protocol selection requires breaking Weights

& Measures seals to gain access to jumper switches on

the LCR circuit board (terminal J10).

CAUTION: This switch must only be activated with power

to the LCR “OFF”. If the protocol selector switch position

is changed with power supplied to the unit, the

microprocessor memory contents may be destroyed and

data will be lost. If this switch is installed or replaced in

the field, the wiringharness MUST be attached to the

circuit board as shown on page 15, with the notched side

of the connector facing in.

connecting handheld or lap top computer

The LCR is capable of interfacing to a handheld or lap

top computer. In such cases, the optional RS-232 to

RS-485 Converter is connected to terminal block J2, Pins

24 and 25, as shown on page 15. The computer, in turn,

is connected to the D-connector in the Converter.

NOTE: When a handheld or lap top computer is used to

interface to the LCR, the LCR must be configured for the

RS-485 communication protocol. This can be

accomplished either by means of the selector switch

(described above), or by means of selecting the

appropriate jumper setting at terminal J10 on the LCR

circuit board. Refer to the figure on page 14 for details.

connecting auxiliary outputs (optional)

Aux 1, terminal block J12, Pin 44: This signal can be

turned OFF, ON, or ON when the LCR enters the RUN

state. It remains OFF, ON, or ON until the LCR ends the

delivery. See LCR Set-up Manual for programming

options.

Aux 2, terminal block J12, Pin 43: This signal can be

turned on when the LCR enters the reverse flow state. It

remains off during forward flow. Optionally, it can can

function like Auxiliary Output 1. See LCR Set-up Manual

for programming options.

Pulse, terminal block J12, Pin 42: This output

represents the gross delivery quantity if the LCR is making

an uncompensated delivery. The output represents net

delivery quantity if the LCR is equipped with the

temperature compensation option and the system has

been configured for net delivery. This is a real time 50/

50 duty cycle output representing the least significant

digit of LCR totalizers.

DN/UP Counts, Terminal Block J12, Pins 39 and 40:

These signals are duplicates of the signals sent to the

LCR counter via connector J7. They can be used to

integrate an additional counter into the system. These

outputs are used to control the 6-digit LCD local display.

The up and down counters are pulsed so that the counter

displays the gross delivery quantity, or net delivery

quantity if compensated. Pulses are active low and are

approximately 5 μsec in duration. The LCD counter is

reset by turning on both outputs for 0.01 second. Refer

to table on page 18 for wiring connection instructions for

Auxiliary outputs, pulse outputs, and DN/UP count

outputs.

14

Page 15

Wiring the LCR

Installing a Valve with 110VAC Solenoids

This step applies only to configurations that will be using

a two-stage valve with 110VAC solenoids.

Using a two-stage valve with solenoids operating on

110VAC requires the use of two relays. These relays

must operate at +12VDC and the contact rating must be

greater than the current draw for the device being

switched. The relays must be SPST (single pole, single

throw) and be normally open.

For installation of the valve the following parts will be

need:

• Cable, 2 conductor, stranded 20 GA

• Flexible liquid-tight conduit, ½" diameter and ½" NPT

conduit connectors or cable glands

• Teflon tape or pipe sealant

• 2 SPST, normally open relays

Installation Procedure

1. Install the valve between the meter and the hose reel.

If there is a manual ball valve installed in the system,

make sure it is after the two-stage valve and before

the hose reel. If an air check valve is present in the

system, leave it in place.

6. Run the cables through the conduit or cable gland

between the solenoids and relays and then connect

the conduit to the solenoid valve and the relays.

7. Wire the solenoids to the relays as shown in the figure

to the right.

8. Run the cables through the conduit or cable gland

between the relays and register and then connect

the conduit to the relays and the register.

9. Wire the relays to the register as shown in Figure 9.

10. Wire the 110VAC source to the solenoids according

the solenoid manufacturer’s instructions.

2. Install the relays in an appropriate location based on

the requirements of the environment. Follow all

applicable codes.

3. Install cable glands or conduit connectors on each

solenoid valve and on the LCR ports. Use Teflon

based pipe sealant or Teflon tape on the threads.

4. Cut the conduit to the length required between the

port on the register and the relays, and between the

relays and the corresponding valve solenoids.

5. Cut the cable 6" longer than the lengths of conduit or

the cable run.

6. Using wire strippers, strip-off the insulation (approx.

1¼") on each end of the cable and off the tip of the

conductors (approx. ¼").

15

Page 16

Guidelines for Environmental Sealing

The LCR contains a printed circuit board with sensitive

electronic components that can be damaged by the

presence of moisture. Conformal coating on the board

and a moisture-absorbing desiccant inside the enclosure

mitigates the problem of moisture corroding the LCR

board. These measures protect the board from small

amounts of moisture trapped inside when the lid is closed

in humid conditions, but are not adequate in protecting

the unit over time if a continuing leak in the enclosure is

present. Therefore, it is necessary to adequately seal

all openings to the unit during installation. The LCR is

rated NEMA 4x making it capable of pressure washing

when seals are adequately applied, as described below.

1. Conduit Entrances

The LCR has seven conduit entrances each with 1/2 14 NPT female threads. Use only 1/2 - 14 NPT male

threaded fittings on all conduit entrances. Pressed in

Caplugs are inadequate as seals for these entrances.

Straight rather than tapered threads are also inadequate.

Acceptable fittings are either metal or plastic conduit, pipe

plugs, or cable glands. Threads should be treated with

a Teflon based “pipe dope” or taped using a minimum of

two revolutions of Teflon tape prior to installation. Threads

should be engaged a minimum of four full turns. When

using cable glands be sure that the gland is sized properly

for the outside diameter of the cable being sealed and

that the elastometric seal around the cable sheath is

compressed onto the cable. Use only one cable per cable

gland unless the gland is designed for multiple cables.

When using conduit or Liquid-Tite make sure that the

opposite end is going into an environmentally sealed

device as well. For example, some solenoid valves are

rated for hazardous locations but may not be sealed

environmentally. If the conduit is not sealed on the other

device, fill the interior of the conduit at the LCR with a

silicone rubber sealant such as RTV to prevent moisture

from running down the conduit into the LCR

enclosure.Refer to “Wiring The LCR” notes on page 10

for code requirements.

2. Cover Seals

The covers on both the LCR and its Remote Electronic

Counter (REC) are provided with 0-ring seals to prevent

moisture ingress. The LCR O-ring must be inserted in

the groove of the cast housing

prior to the cover being attached. All twelve bolts must

be tightened to compress the cover O-ring adequately.

The O-ring on the REC is integral to the REC cover. All

four cover screws must be tightened to effect a seal on

the REC cover.

3. Shaft Seals

Units with internal pulsers have an O-ring seal around

the pulse encoder drive shaft emanating from the bottom

of the LCR. Various drivers can be attached to this shaft

to adapt to industry standard PD flow meters. When

installing a driver make sure not to remove the O-ring

that is around the drive shaft embedded in the base

casting. The O-ring should be seated in the counter bore

in the casting and covered with the flat washer provided

before attaching a driver using the cotter pin. The control

switch on the front of the LCR is also sealed with an Oring that is held in place by a bushing secured with three

socket head cap screws. In the event that a control switch

is replaced in the field, make sure that the O-ring is in

place on the switch shaft before reinstalling the switch

bushing.

16

Page 17

After the LCR has been installed, check to make sure

that it will power up correctly. The back light on the LCR

display should go on when the truck’s ignition key is

turned to the “ON” or the “accessory” position. At this

point, you need to attach a compatible data terminal to

the LCR to initialize system values, set the clock, enter

ticket headers, calibrate the meter, etc. The user can

use a Liquid Controls Lap Pad, handheld computer, or

lap top computer.

Lap Pads and computers emulating a VT-100 terminal

must be connected to the RS-232 terminal port (J3

Terminal Block). The LCR must be configured for RS232 operation by proper positioning of the jumper on the

J10 terminal block, as shown on page 14.

Refer to the Liquid Controls LectroCount LCR Setup

Manual (Bulletin #500050) if you will be using a Lap Pad

or VT-100 compatible terminal to set up the LCR.

System Startup

17

Page 18

Wiring Schematic

18

Page 19

Wiring Schematic

19

Page 20

Wire ConnectionTables

This appendix provides a tabular description of the wiring connections made to each LCR-II terminal block. It should

be referenced in the event wiring inadvertently mis-routed in the field, or for general troubleshooting in the event of a

problem.

PRINTER CONNECTION (J1)

Connector/

Pin

J1-30 GN D Printer, Pin 7

29 CT S Printer, Pin 20

28 RXD Printer, Pin 2

27 TXD Printer, Pin 3

26 RT S Printer, Pin 6

Signal Route To:

Wire Color

Cab le #81513

Black

Blue

Yello w

Orange

Brown

TERMINAL CONNECTION RS-485 (J2)

Connector/

Pin

J2-25 485-B Black Viloet Terminal

24 485+A Red Red Terminal

Signal

Wire Color

Cable

#81572

Cable

#81513

Route To:

POWER CONNECTION (J6)

Connector/

Pin

J6-13 Earth Drain/Green Wire No Connection*

12 GND Black DC Ground

11

*On free-end of cable, cut off foil shield and drain wire,

then insulate by taping.

NOTE: The LCR-II Power cable kit includes a fuse holder

and 5 Amp fuse to protect the system in the event of a

short circuit in the cable. Liquid Controls recommends

that this fuse be used in all installations not having a

fused accessory block to protect the truck in the event of

cable faults. A 5 Amp fuse is required.

Signal Wire Color Route To:

+12V In

(or +24V In)

Red

+12VDC (or +24VDC)

(accessory truck circuit)

NOTE: Jumper J10 on LCR circuit board must be set for

RS-485 communication protocol.

LAP PAD CONNECTION RS-232 (J3)

Connector/

Pin

J3-51 GND Ground, Pin 5

50 CTS RTS Terminal, Pin 4

49 RXD TXD Terminal, Pin 3

48 TXD RXD Terminal, Pin 2

47 RTS CTS Terminal, Pin 8

46 +Vo Lap Pad +12, Pin 8

Signal

NOTE: Jumper J10 on LCR-II circuit board must be set

for RS-232 communication protocol.

* For a standard RS-232 terminal (other than the Lap

Pad), the black wire is connected to J3-47.

Wire Color

Cable #81513

White

Green

Gray

Violet

*

Red

Route To:

ODOMETER, PRESET/PRODUCT

SELECTOR SWITCH, START/STOP

SWITCH, AND INTERNAL PULSER

CONNECTIONS (J8)

Connector/

Pin

J8-38 GND Black

37 GND Black

36 In1 Violet

35 In2 Gray Preset switch

34 In3 Green Int. Pulser "B"

33 In4 White Int. Pulser "A"

32 +5V Out Red Int. Pulser "+"

31 +Vo Odometer +12V

Signal Wire Color Route To:

Preset switch or Remote

Start/Stop sw itch

Internal pulser and

Odometer ground

Odometer pulser or

remote Start/Stop switch

20

Page 21

Wire Connection Tables

LIQUID CONTROLS POD (J8)

Connector/

Pin

J8-38 - - -

37 GND Black Pulser Signal GND

36 - - 35 - - 34 In 3 Green Channel B Output

33 In 4 White Channel A Output

32 - - 31 +Vo Red +V Input

Signal Wire Color Route To:

SINGLE CHANNEL PULSER (J8)

Connector/

Pin

J8-38 - - -

37 GND N/A Pulser Signal GND

36 - - 35 - - 34 33 In 4 N/A Pulse Output

32 - - 31 +Vo Red +V Input

Signal Wire Color Route To:

AUXILIARY OUTPUTS (J12)

Connector/

Pin

J12-45 +Vo N/A

44

43

42 Out 3 N/A

41 GND N/A

40 Out 4 N/A Display Input

39 Out 5 N/A Display Input

Signal Wire Color Route To:

Out 1

(Aux. 1)

Out 2

(Aux. 2)

N/A

N/A Flow Direction

Pump or

Aux. Control

Pulse Input for

Aux. System

VALVE SOLENOID CONNECTION (J13)

Connector/

Pin

J13-19 Earth Green

18 Out 6 Black or Red Solenoid 2

17 +Vo Black or Red Solenoid 2

16 Earth Green

15 Out 7 Black or Red Solenoid 1

14 +Vo Black or Red Solenoid 1

Signal Wire Color Route To:

Solenoid 2

Case Ground

Solenoid 1

Case Ground

NOTE: To operate a single channel pulser, a jumper is

required between pins 2 and 3 on J4.

VEEDER ROOT SOLID STATE QUAD

PULSER (J8)

Connector/

Pin

J8-38 - - -

37 GND White Pulser Signal GND

36 - - 35 - - 34 In 3 Orange Channel B Output

33 In 4 Black Channel A Output

32 - - 31 +Vo Red +V Input

NOTE: Pull-down resistors of 300 Ω needs to be

connected between CHAN B and GND, and CHAN A and

GND.

Signal Wire Color Route To:

RTD TEMP. PROBE CONNECTION (J14)

Connector/

Pin

J14-23 RTD-D White RTD

22 RTD-S White RTD

21 RTD+D Red RTD

20 RTD+S Red RTD

Signal Wire Color Route To:

21

Page 22

Illustrated Parts Breakdown

22

Page 23

Illustrated Parts Breakdown

23

Page 24

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2007 Liquid Controls

Pub. No. 500049

(05/07)

Loading...

Loading...