Page 1

Installation & Parts Manual

K-7, K-15, & K-30

Air Actuated & Differential Check Valves

Installation: M400-30

www.lcmeter.com

Page 2

Table of Contents

!!

!!

! WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance

of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury, or

death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

Description Page Number

General Information ..................................................2

Specifications ............................................................3

K-7 Valves .................................................................4-5

Installation .................................................................4

New Installations .......................................................4

Retrofit Installations...................................................4

Disassembly and Reassembly ..................................5

K-15 Valves ...............................................................6-7

Installation .................................................................6

New Installations .......................................................6

Retrofit Installations...................................................6

Description Page Number

Disassembly and Reassembly ..................................7

K-30 Valves ...............................................................8

Installation .................................................................8

New Installations .......................................................8

Retrofit Installations...................................................8

Illustrated Parts Breakdown ......................................9-11

K-7 Valves .................................................................9

K-15 Valves ...............................................................10

K-30 Valves ...............................................................11

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our website, www.lcmeter.com.

It is the responsibility of the Local Distributor to provide the most current version of LC Manuals, Instructions, and

Specification Sheet s in the required language of the country, or the language of the end user to which the products are

shipping . If there are questions about the language of any LC Manuals, Instructions, or Specification Sheets, please

contact your Local Distributor.

General Information

Liquid Controls Air Actuated/Differential Check V alves

are designed to prevent flow whenever air or vapor is

present, thereby assuring accurate measurement.

Check Valves are normally closed, spring loaded valves

installed on the meter outlet. When fluid enters the valve

from the inlet side, and the pressure is greater than the

back pressure combined with the force of the spring, the

spring will compress, opening the valve and allowing fluid

K-7 Valve Operation

to pass through (as shown in the figure below).

When back pressure plus spring strength is greater than

the fluid pressure entering the meter, the valve will remain

closed.

These meters are used in conjunction with the air/vapor

eliminator to prevent air/vapor from being metered. This

is important when split compartment testing.

2

Page 3

Model/Applications

K-7 Valves:

Model No. Material Spring Seals Applications

A2811 Cast Iron Standard Viton Chlorinated Solvents

A2817 Aluminum Standard Viton Petroleum Products

A28171 Aluminum Medium Viton Petroleum Products

A28172 Aluminum Heavy Duty Viton Petroleum Products

A2821 Aluminum Standard PTFE Liquid Sweeteners, Methanol

A2826 Aluminum Standard Viton Liquid Sweeteners

A2831 Cast Iron Standard PTFE Caustics

A2851 Aluminum Standard EPT NH3 Applications.

A2862 Stainless Steel Standard PTFE Acidic PH Liquids

K-15 Valves:

Model No. Material Spring Seals Applications

A3830

Aluminum,

Aluminum Guide

Standard Viton Aviation Fuels

A3845

Aluminum,

Bronze Guide

Standard Viton Petroleum Products

K-30 Valve:

Model No. Material Spring Seals Applications

A4845 Aluminum Standard Viton Petroleum Products

Used on M-5 & M-7 - 1½" & 2" Meters

Maximum Flow Rate = 150 gpm (568 lpm)

Working Pressure: 150 psi (10.5 bar)

Used on M-15 & M-25 - 3" Meters

Maximum Flow Rate = 300 gpm (1,136 lpm)

Working Pressure = 150 psi (10.5 bar)

Used on M-30 - 3" Meters

Maximum Flow Rate = 300 gpm (1,136 lpm)

Working Pressure = 150 psi (10.5 bar)

Specifications

K-7 Valves

3

K-15 & K-30 Valves

Page 4

K-7 Valves

!!

!!

!WARNING!

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST

BE RELIEVED. Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the

meter and liquid or gas pressure source (such as the supply tank, discharge lines and supply

lines).

New Installations

When ordered with a new metering system, the Check

Valve is supplied mounted to the metering system as

shown to the right. A line must be connected to the flange

on the outlet side of the 2-stage, preset valve. This flange

connection is 2” NPT.

Finally, install a vent line from one port of the check valve

to the air eliminator. Plug the other side of the check

valve.

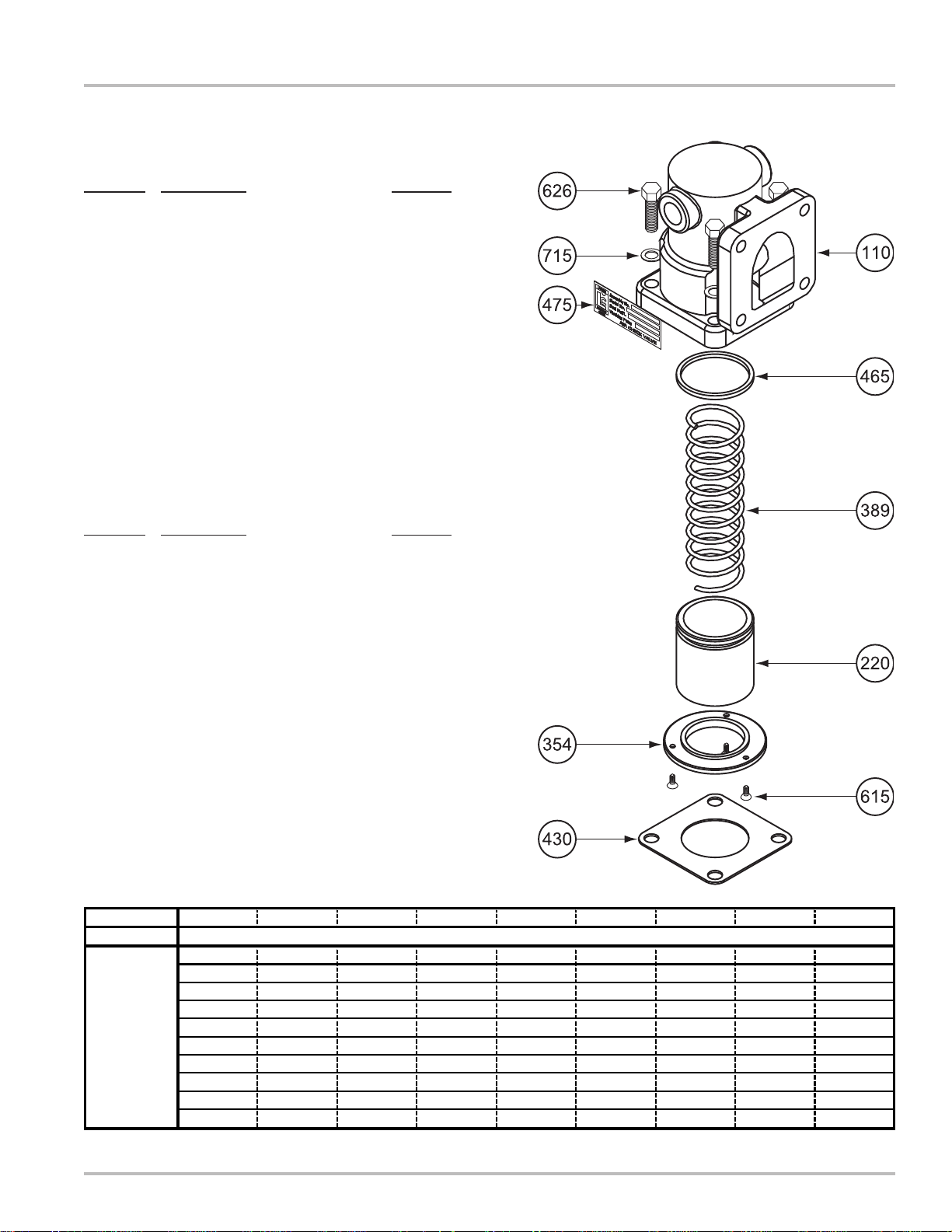

Retrofit Installations

Depending on the existing configuration, adding a Check

V alve may require modification of the outlet piping.

After the internal pressure is relieved from the system,

the output line can be disconnected from the output side

of the meter. If the system includes an electronic, 2stage, preset valve, remove it from the meter. The check

valve assembly can then be connected to the output side

of the meter.

Use the four bolts and washers to fasten the valve

assembly to the meter. The valve has an arrow showing

the direction of flow. Ensure that the valve is properly

oriented.

Tighten the bolts in a crossing pattern. Once the check

valve is secure, the electronic, 2-stage, preset valve can

be connected to the back check valve as shown to the

right. Once this is complete, the output piping may be

reconnected to the electronic, 2-stage, preset valve. The

preset valve output fitting is 2” NPT.

Run a line from one port of the check valve to the air

eliminator. Plug the other side of the check valve.

4

Page 5

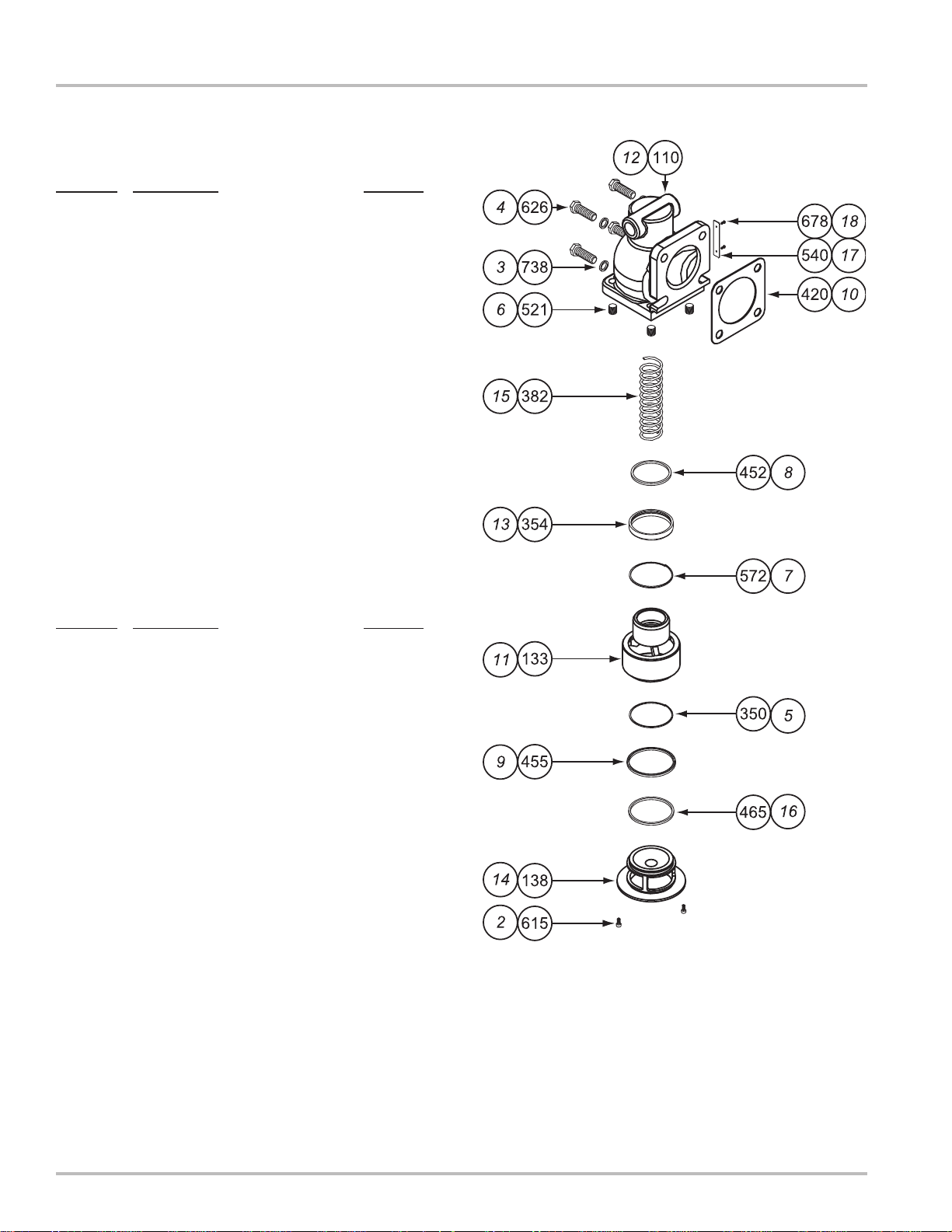

Disassembling the K-7 Valve

NOTE: Refer to the illustrated parts breakdown to the right

for Item Numbers referenced in these instructions. Item

Numbers appear in circles in the drawing.

1 Use a fixture to press and hold the piston (Item 220)

in place with the compression spring (Item 389)

compressed.

2 Loosen the three screws (Item 615) that hold the seal

ring (Item 354).

3 Slowly remove the fixture holding the piston (Item 220)

and compression spring (Item 389) until the spring

exerts NO pressure.

4 Remove the seal ring (Item 354), piston (Item 220)

and compression spring (Item 389).

5 Remove the Quad Ring (Item 465) from the piston

(Item 220). Replace necessary components and

reassemble.

K-7 Valves

Reassembling the K-7 Valve

1 Place the compression spring (Item 389) over the

valve stem in the valve housing (Item 110).

2 Place the Quad Ring (Item 465) on the piston (Item

220).

3 Place the piston (Item 220) over the compression

spring (Item 389).

4 Place the seal ring (Item 354) on the piston (Item 220).

5 Place the piston (Item 220) and seal ring (Item 354)

on top of the compression spring (Item 389) and

compress using a fixture to hold the assembly in

place, leaving the seal ring (Item 354) free to rotate.

6 Line up the holes of the seal ring assembly (Item 354)

with the holes of the housing assembly (Item 110)

and screw in the three screws (Item 615). Tighten

the screws.

7 When the screws are tight, remove the fixture used

to hold the piston and spring in compression.

5

Page 6

K-15 Valves

!!

!!

!WARNING!

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST

BE RELIEVED. Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the

meter and liquid or gas pressure source (such as the supply tank, discharge lines and supply

lines).

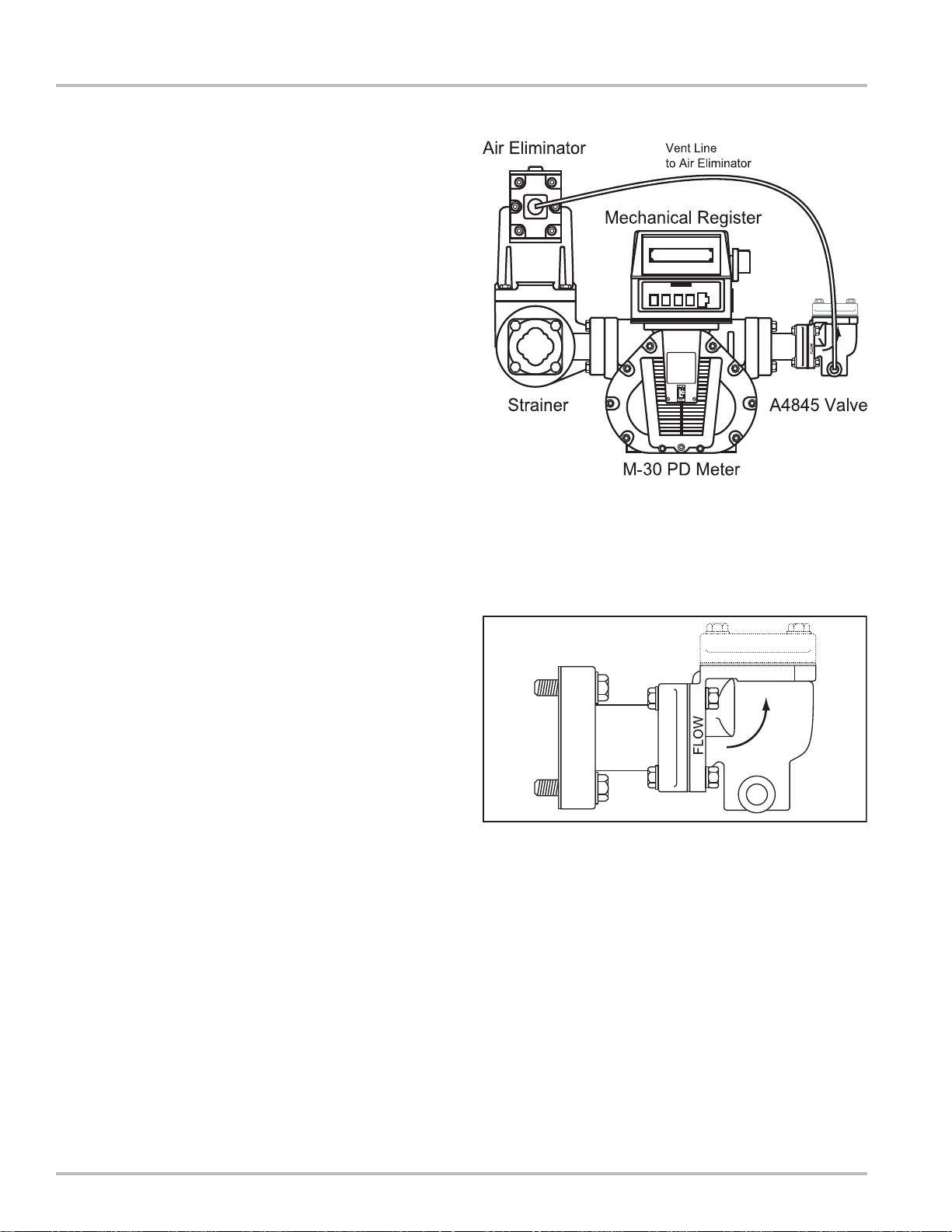

New Installations

When ordered with a new metering system, the Check

Valve is supplied mounted to the metering system as

shown in the example to the right. A line must be

connected to the flange on the outlet side of the check

valve. This flange connection is 3” NPT.

Mechanical Register

Air Eliminator

Finally, install a vent line from one port of the check valve

to the air eliminator. Plug the other side of the check

valve.

Retrofit Installations

Depending on the existing configuration, adding a Check

V alve may require modification of the outlet piping.

After the internal pressure is relieved from the system,

the output line can be disconnected from the output side

of the meter. In the example to the right, the output line

would be connected to the V-15 valve. The check valve

assembly can then be connected to the output side of the

V-15 valve.

Use the four bolts and washers to fasten the check valve

assembly to the V-15 valve. The check valve has an arrow

showing the direction of flow. Ensure that the valve is

properly oriented.

Tighten the bolts in a crossing pattern. Once the check

valve is secure, the output line may be reconnected to

the output side of the check valve. The output fitting is 3”

NPT .

V-15

Valve

Strainer

K-15 Check Valve

M-25 PD Meter

A vent line must be connected from one side of the check

valve to the air eliminator. Plug the other side of the check

valve.

6

Page 7

Disassembling the K-15 Valve

NOTE: Refer to the illustrated parts breakdown to the right

for Item Numbers referenced in these instructions. Item

Numbers appear in circles in the drawing.

1 Use a fixture to press and hold the valve check guide

(Item 14) in place with the compression spring (Item

15) compressed.

2 Remove the two screws (Item 2).

3 Release the pressure from the check valve guide (Item

14) until the spring (Item 15) exerts NO pressure.

4 Remove the check valve guide (Item 14), Quad Ring

(Item 16), O-Ring (Item 9) , lock ring (Item 5),

compression spring (Item 15) and piston (Item 11).

5 Remove the retainer seal and retaining ring (Items

13 & 7), and the spring seal (Item 8).

6 Leave the Heli-Coil inserts in place.

K-15 Valves

Reassembling the K-15 Valve

1 Insert the four Heli-Coil Inserts (Item 6) into the air

check housing (if they were removed).

2 Place the Quad Ring (Item 16) onto the large end of

the piston (Item 11).

3 Place the check valve guide (Item 14) into the piston

(Item 11).

4 Slide the Quad Ring (Item 16) onto the check valve

guide (Item 14) and into the groove at the flanged

end.

5 Insert the O-Ring (Item 9) with the spring facing up

onto the step on the check valve guide (Item 14).

6 Insert the lock ring (Item 5) over the O-Ring (Item 9).

7 Place the check valve guide (Item 14) into the piston

(Item 11).

8 Place the seal (Item 8) into the retainer seal (Item

13) from the end with the large chamfer and the spring

(Item 15) in the seal (Item 8).

9 Insert the retaining ring (Item 7) into the groove of

the retainer seal (Item 13) and place them into the air

check housing (Item 12) with the chamfered end

down. Carefully press in while visually inspecting

alignment. Once alignment is adjusted, press in until

seated.

10 Insert the compression spring (Item 15) into the

bottom of the air check housing (Item 12).

11 Place the piston (Item 1 1) over the compression spring

(Item 15).

12 Carefully align the piston (Item 11) with the retainer

seal (Item 13) and press down until the flange of the

check valve guide (Item 14) is flush with the housing.

This will require the use of a fixture to overcome the

pressure of the spring (Item 15).

13 While holding the check valve guide in place, insert

the two screws (Item 2) and tighten.

14 Remove the assembly from the fixture.

7

Page 8

K-30 Valves

The K-30 check valve is used on M-30 3” meters. The K30 check valve is a combination of the K-15 check valve

Model A3845 and a pipe nipple assembly. The nipple

assembly includes two flanges. One flange is 6” square

with a 3” NPT thread, the other is 4.75” square with a 3”

NPT thread. The pipe nipple is 3” in diameter and 4” in

length.

The pipe nipple assembly is included in order to mount

the check valve to the meter as the meter connection is

larger than the check valve connection.

New Installations

When ordered with a new metering system, the K-30

Check V alve is supplied mounted to the metering system.

A line must be connected to the flange on the outlet side

of the check valve. This flange connection is 3” NPT.

Finally, install a vent line from one port of the check valve

to the air eliminator. Plug the other side of the check

valve.

Retrofit Installations

Depending on the existing configuration, adding a Check

V alve may require modification of the outlet piping.

After the internal pressure is relieved from the system,

the output line can be disconnected from the output side

of the meter. In the example to the right, the output line

would be connected to the M-30 PD Meter. The check

valve assembly can then be connected to the output side

of the meter using the nipple assembly.

Use the four bolts and washers to fasten the nipple

assembly to the M-30 PD Meter. Tighten the bolts in a

crossing pattern.

Use the four bolts and washers to fasten the check valve

to the other end of the nipple assembly . The check valve

has an arrow showing the direction of flow. Ensure that

the valve is properly oriented.

Tighten the bolts in a crossing pattern. Once the check

valve is secure, the output line may be reconnected to

the output side of the check valve. The output fitting is 3”

NPT .

A vent line must be connected from one side of the check

valve to one side of the air eliminator. Plug the other side

of the check valve.

8

Page 9

Model A2817: K-7 Valve

Model No: A2811 A2817 A28171 A28172 A2821 A2826 A2831 A2851 A2862

Item No:

110 44672 49624 49624 49624 49624 49624 44672 49624 N/S

220 44674 44676 44676 44676 44677 44676 N/S 44676 45330

354 N/S* 44669 44669 44669 44669 44669 N/S 47648 N/S

389 42954 41190 45597 45598 42954 42954 42954 42954 42954

430

40430 40430 40430 40430 45818 40430 40430 N/A 45818

465 07253 07253 07253 07253 07832 07253 07832 07928 07832

572 N/A** N/A N/A N/A 06044 N/A 06044 N/A 06044

615 07364 07364 07364 07364 07364 07364 07364 07364 07364

626 07319 06991 06991 06991 06991 06991 07319 06991 07497

715 04607 04607 04607 04607 04607 04607 04607 04607 06166

Part No:

*N/S = Not for Sale **N/A = Not Applicable

Used with M-5 & M-7, 1½” & 2” meters.

Item No. Description Part No.

110 Air Check Housing 49624

220 Piston 44676

354 Seal Ring 44669

389 Compression Spring (A2817) 41190

Compression Spring (A28171) 45597

Compression Spring (A28172) 45598

430 Flange Gasket 40430

465 Quad Ring 07253

475 Name Plate N/S*

615 Screw, #6-32-3A (3) 07364

626 Screw, .375-16 x 1.25 (4) 06991

715 Flat Washer (4) 04607

Illustrated Parts Breakdown

Model A2851: K-7 Valve for NH

Used with M-5 & M-7, 1½” & 2” meters.

Item No. Description Part No.

110 Air Check Housing 49624

220 Piston 44676

354 Seal Ring Assembly 47648

389 Compression Spring 42954

465 Quad Ring 07928

475 Name Plate N/S*

615 Screw, #6-32-3A (3) 07364

626 Screw, .375-16 (4) 06991

715 Flat Washer (4) 04607

NOTE: Item 572 listed below is a retaining ring used with

Models A2821, A2831, and A2862. It is used to secure

the PTFE Seal (Item 465) on the Piston (Item 220).

3

K-7 Valve Part Numbers

9

Page 10

Illustrated Parts Breakdown

Model A3830: K-15 Valve

Used with M-15 & M-25, 3” meters.

Item No. Description Part No.

110 Air Check Housing 44118

133 Cup & Piston 41702

138 Guide 49924

350 Lock Ring 07207

354 Seal Retainer 44128

382 Compression Spring 44062

420 Flange Gasket 40871

452 Seal 07392

455 U-Cup 09014

465 Quad Ring 09158

521 Heli-Coil Insert, .5-13 x .5 (4) N/S*

540 Plate N/S

572 Retaining Ring 07391

615 Screw, #10-14 x .375 (2) 06819

626 Screw, .5-13 x 1.5 (4) 06057

678 Screw N/S

738 Flat Washer (4) 04685

Model A3845: K-15 Valve

Used with M-15 & M-25, 3” meters. (Item No. Italic)

Item No. Description Part No.

2 Screw, #10-14 x .375 (2) 06819

3 Flat Washer (4) 04685

4 Screw, .5-13 x 1.5 (4) 06057

5 Lock Ring 07207

6 Heli-Coil Insert, .5-13 x .5 (4) N/S

7 Retaining Ring 07391

8 Seal 07392

9 U-Cup 09014

10 Flange Gasket 40871

11 Cup & Piston 41702

12 Air Check Housing 44118

13 Seal Retainer 44128

14 Guide 46036

15 Compression Spring 46047

16 Quad Ring 09158

17 Plate N/S

18 Screw N/S

*N/S = Not for Sale

10

Page 11

Model A4845: K-30 Valve

Used with M-30, 3” meters.

Item No. Description Part No.

1 K-15 Air Check Valve Assy A3845

(See Page 9 for A3845 Parts.)

2 Flange, 3” N/S*

3 Pipe Nipple 07150

5 Flange, 3” NPT N/S

6 Screw, .5-13 x 2.75 (4) 06052

7 Hex Nut, .5-13 (4) 06707

8 Flange Gasket 40871

9 Flange Gasket 40704

11 Screw, .625-11 x 2.5 (4) 06466

12 Flat Washer (6) 04685

13 Flat Washer (4) 04764

14 Lock Washer (2) 06070

Illustrated Parts Breakdown

*N/S = Not for Sale

11

Page 12

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2005 Liquid Controls

Pub. No. 500322

(7/13)

Loading...

Loading...