Page 1

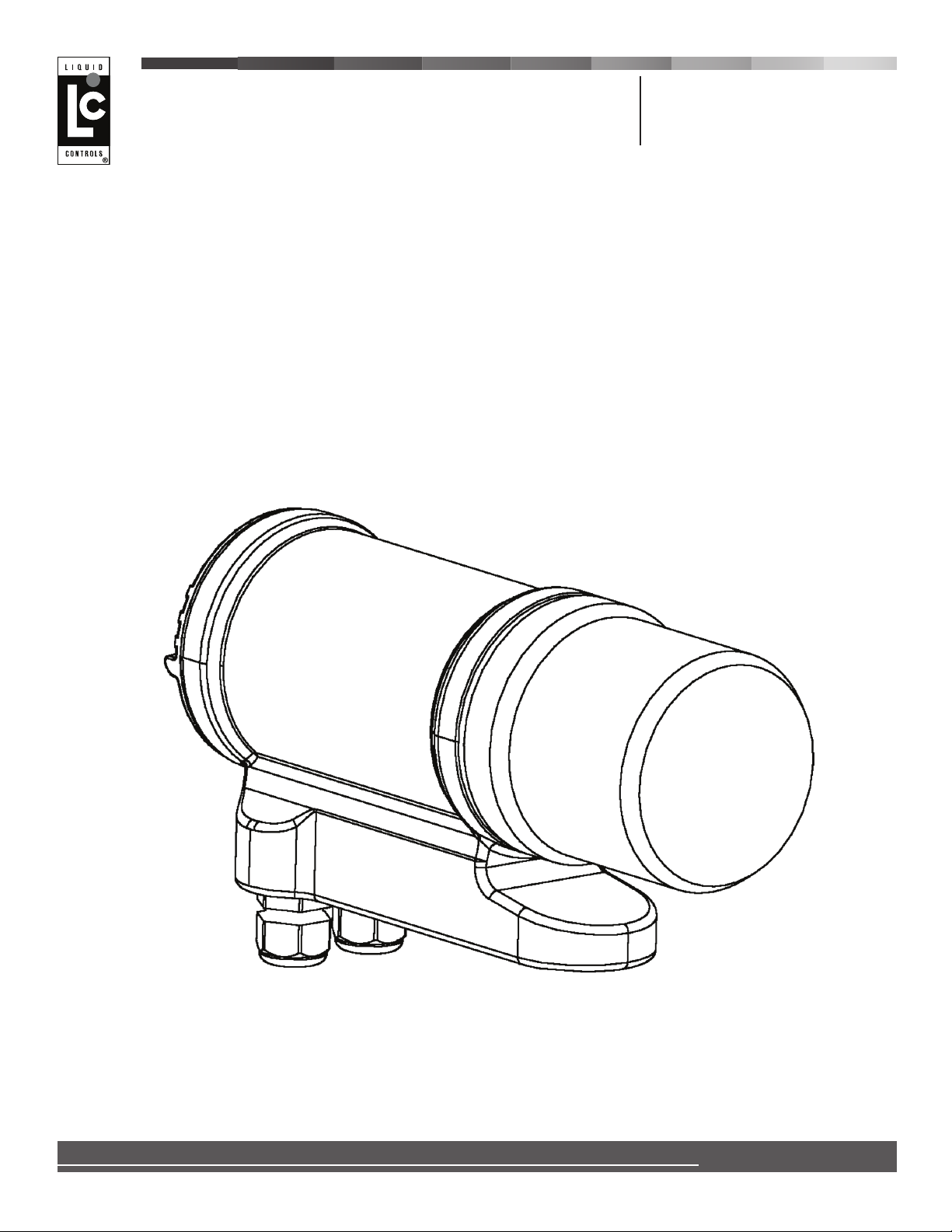

HML4-F1 Converter

LCMag Electromagnetic Flowmeters

Installation &

Operation

Release number: 4F1_EN_LC_R1_3_9X

The last three digits of le name identify the software version which the manual refers to;

it is visualized at the instrument start up, or by specic function on DIAGNOSTIC menu.

Liquid ControLs Group

An IDEX Fluid & Metering Business

IOM: IEM200-20

Page 2

HML4-F1

2

INDEX

q

Introduction _______________________________________________ pag.3

q Safety informations ___________________________________ pag.3

§ Safety conventions __________________________________________ pag.4

q Technical characteristics ____________________________________ pag.5

§ Electrical characteristics ______________________________________ pag.5

§ Environmental use conditions _________________________________ pag.5

§ Ambient temperature ________________________________________ pag.5

§ Data plate _________________________________________________ pag.5

§ Overall dimensions __________________________________________ pag.6

q Electrical connections __________________________________ pag.7

§ Grounding instructions _______________________________________ pag.7

§ Power supply converter ______________________________________ pag.7

§ Input/output cables _________________________________________ pag.8

§ Sensor cables ______________________________________________ pag.9

q Inputs/outputs ______________________________________

pag.10

§ Optional expansion modules __________________________________ pag.11

§ Digital Input _______________________________________________ pag.12

q Flags and led interpretation ____________________________

pag.16

q Flow rate visualization ________________________________ pag.1

7

q Access codes ________________________________________

pag.17

q Access to the configuration menu________________________

pag.18

q Visualization pages ___________________________________

pag.19

q Quick start menu ____________________________________

pag.20

q Examples __________________________________________

pag.21

q Programming functions _______________________________ pag.2

3

q Functions description _________________________________

pag.25

q Batch _____________________________________________ pag.3

3

§ Enable batch _______________________________________________ pag.33

§ Programming batch _________________________________________ pag.33

§ Start/stop batch ____________________________________________ pag.34

§ Important notes ____________________________________________ pag.34

q Alarm messages _____________________________________ pag.3

5

§ Causes and action to be taken _________________________________ pag.35

§ Anomalies codes ____________________________________________ pag.35

q Conformity declaration ________________________________ pag.3

9

Page 3

HML4-F1

3

INTRODUCTION

These operating instructions and description of device functions are provided as part of the

scope of supply. They could be modified without prior notice. The improper use, possible

tampering of the instrument or parts of it and substitutions of any components not original,

renders the warranty automatically void.

The converter is to be used only to be coupled directly with a sensor device to realize a

measuring device, flow meter, that is to be used for measuring the flow of conductive

liquids in closed pipes with conductivity greater than 5µS/cm.

The reproduction of this manual and any supplied software is strictly forbidd

en.

S

AFETY INFORMATIONS

Any

use other than described in this manual affects the protection provided by the

manufacturer and compromises the safety of people and the entire measuring system and

is, therefore, not permitted.

The manufacturer is not liable for damaged caused by improper or non-designated use.

1) Transport the measuring device to the measuring point in the original packaging. Do

not remove covers or caps until immediately before installation. In case of cartons

packaging it is possible to place one above the other but no more than three cartons.

In case of wooden packaging do not place one above the other.

2) Disposal of this product or parts of it must be carried out according to the local

public or private waste collection service regulations.

3) The converter must only be installed, connected and maintained by qualified and

authorized specialists (e.g. electrical technicians) in full compliance with the

instructions in these Operating Instructions, the applicable norms, legal regulations

and certificates (depending on the application).

4) The specialists must have read and understood these Operating Instructions and

must follow the instructions it contains. The Operating Instructions provide detailed

information about the converter. If you are unclear on anything in these Operating

Instructions, you must call the service.

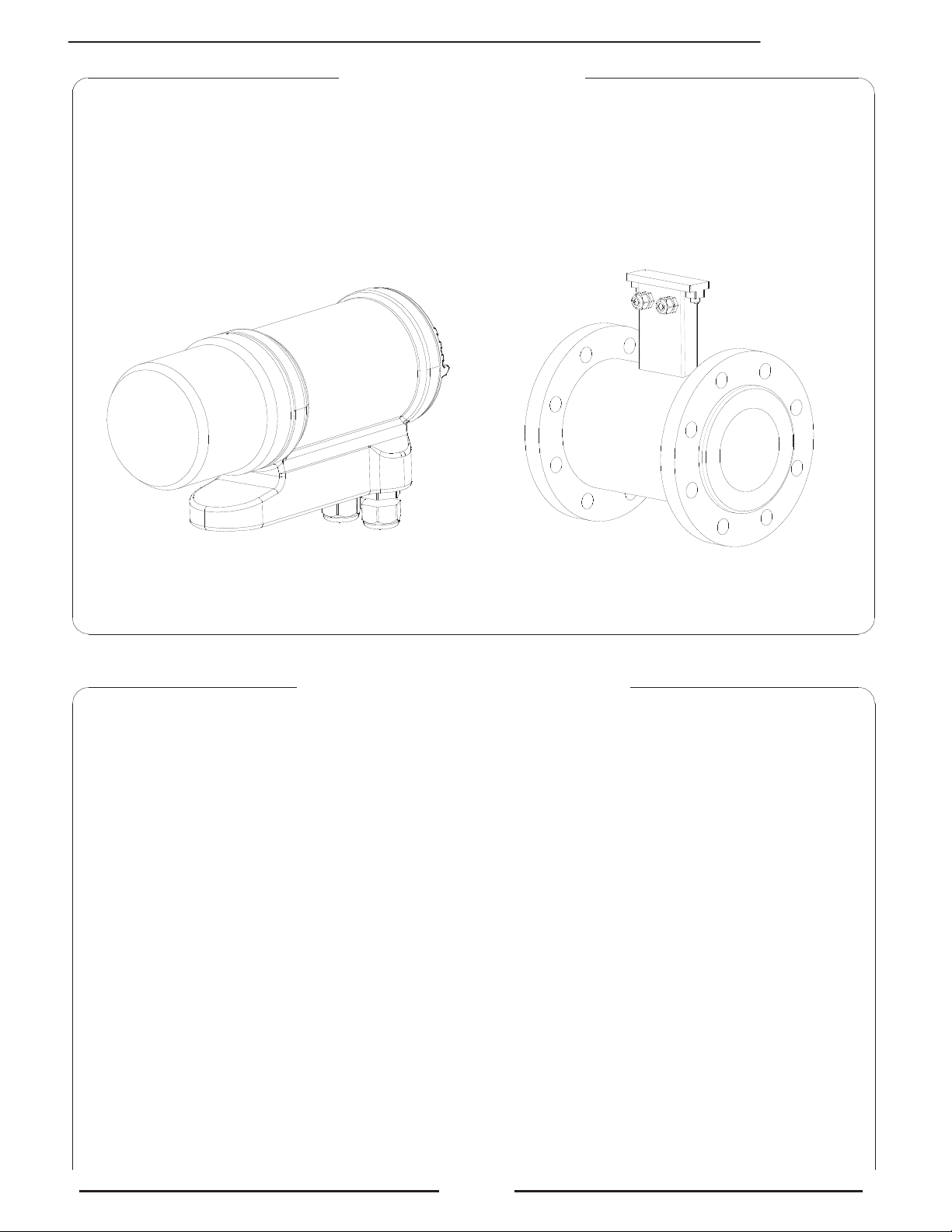

CONVERTER

SENSOR

Page 4

HML4-F1

4

5) The converter should only be installed after have verified technical data provided in

these operating instructions and on the data plate.

6) Specialists must take care during installation and use personal protective equipment

as provided by any related security plan or risk assessment.

7) Never mount or wire the converter while it is connected to the power supply and

avoid any liquid contact with the instrument’s internal components. To connect

remove the terminals from the terminal block.

8) Before connecting the power supply check the functionality of the safety equipment.

9) Repairs may only be performed if a genuine spare parts kit is available and this

repair work is expressly permitted.

10) For the cleaning of the device use only a damp cloth, and for the

maintenance/repairs contact the service center.

Before starting up the equipment please verify the following:

q Power supply voltage must correspond to that specified on the data plate

q Electric connections must be completed as described

q Ground (earth) connections must be completed as specified

Verify periodically (every 3-4 months):

q The power supply cables integrity, wiring and other connected electrical parts

q The converter housing integrity

q The suitable tightness of the sealing elements

q The mechanical fixing of the converter to the pipe or wall stand.

SAFETY CONVENTIONS

DANGER

W

arning indicates an action or procedure which, if not performed correctly,

can result in injury or a safety hazard. Comply strictly with the instructions

and proceed with care.

WARNING

Caution indicates an action or procedure which, if not performed correctly,

can result in incorrect operation or destruction of the device. Comply strictly

with the instructions.

NOTES

Note indicates an action or procedure which, if not performed correctly, can

have an indirect effect on operation or trigger an unexpected response on

the part of the device.

Page 5

HML4-F1

5

TECHNICAL CHARACTERISTICS

ENVIRONMENTAL USE CONDITIONS

AMBIENT TEMPERATURE

Da

ta plate

On the data plate there is some technical information:

Conv. Mod.: converter Model

Conv. s/n: converter Serial Number

P.S.: power supply

Power: maximum power consumption

Sensor Mod.: serial number of sensor coupled

Sens s/n: serial Number of the sensor

DN: sensor nominal diameter

PN: sensor nominal pressure

IP: Protection grade

Fittings: process connections

Lining: sensor lining

Max Temp: maximum sensor temperature

Electrodes: sensor electrodes

KA: sensor KA

ITEM: free for user

Min. *

Max. 1

°C

-20

60

°F

-4

140

ELECTRICAL CHARACTERISTICS

Converter classification: class I, IP 67,

installation category (overvoltage) II, rated

pollution degree 2.

Power supply

versions

Power supply

voltage

Max

power

LLV

18-30V

10W

q Voltage variations must not exceed ±10% of the nominal one.

q Input/output are insulated up to 500V

q The output 4-20 mA (optional) is electrically connected

q

The converter can be installed inside or outside buildings

q Altitude: from –200 to 2000m (from -656 to 6560 feet)

q Humidity range: 0-100% (IP 67)

Consider the ambient temperatures more restrictive between converter and sensor.

*

= For discontinuous use, the installation of a heating resistance is necessary.

1

= For liquid temperature > 60°C , ambient temperature max 40°C

130°C Cip (cleaning in place) is allowed up to 30’ (unlimited time if converter switch off)

Page 6

HML4-F1

6

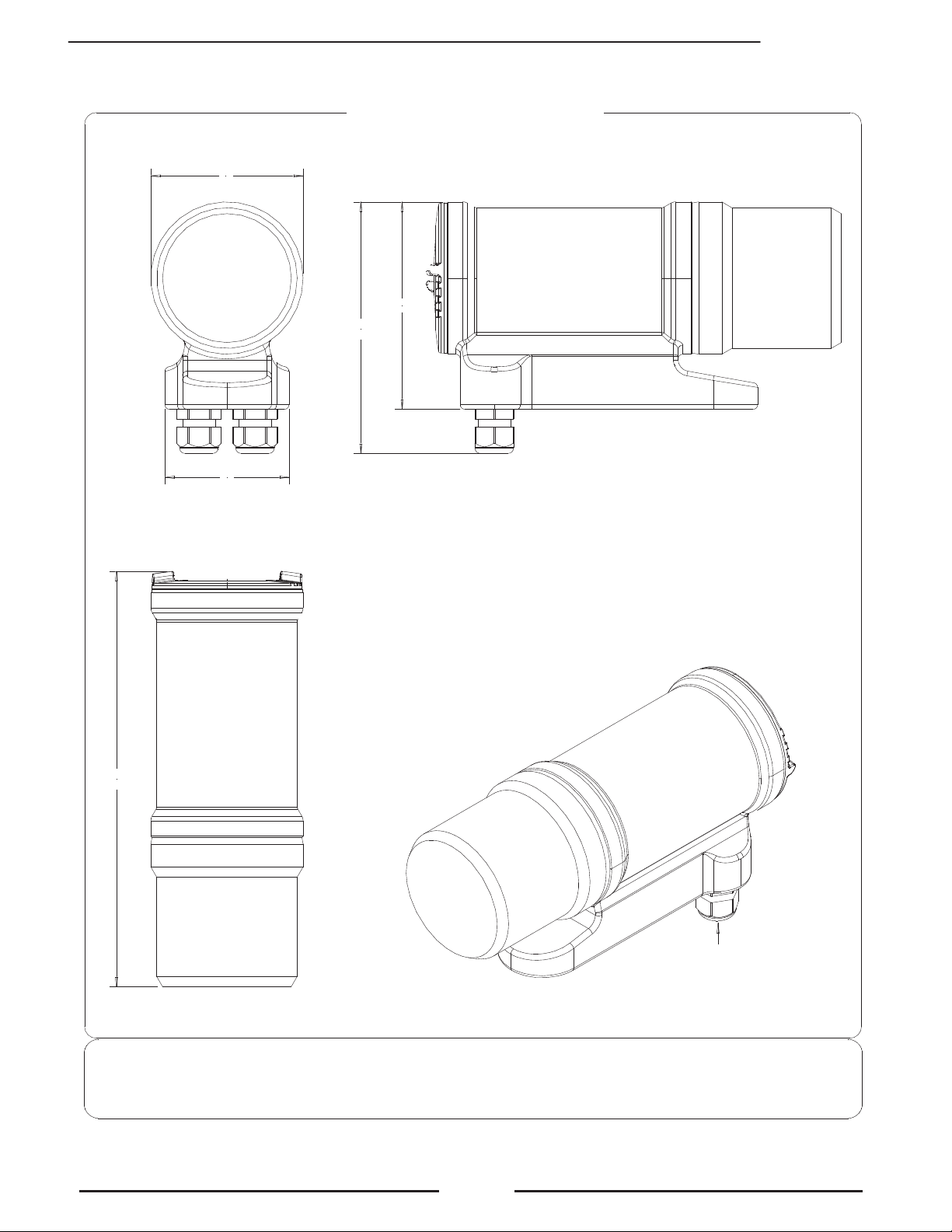

65

53

107

89

177

OVERALL DIMENSIONS

Weight: 2kg

CABLE GLAND

TORQUES

To guarantee the housing’s IP degree the following torques are required

:

q cable glands: 1.8Nm (in reference conditions)

Page 7

HML4-F1

7

-

+

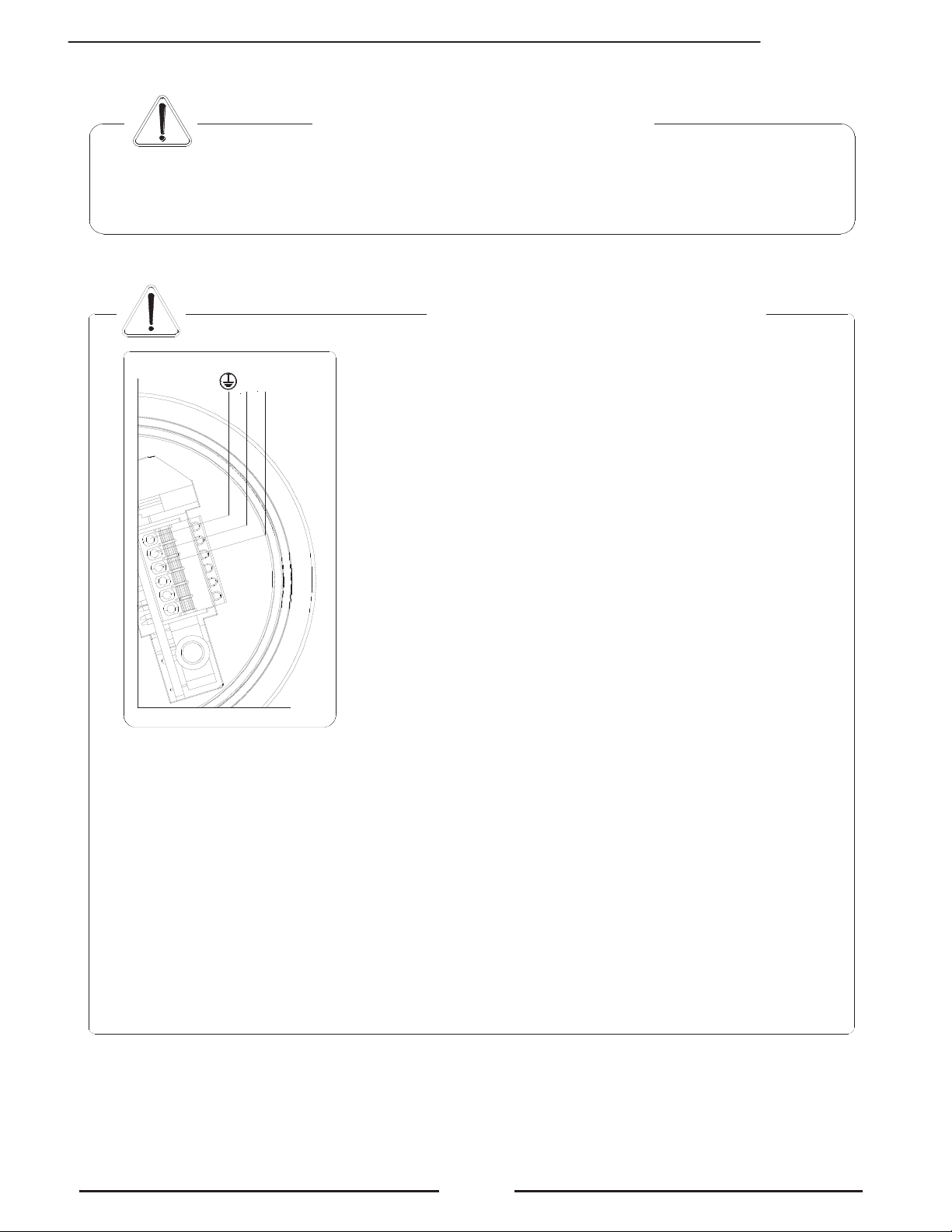

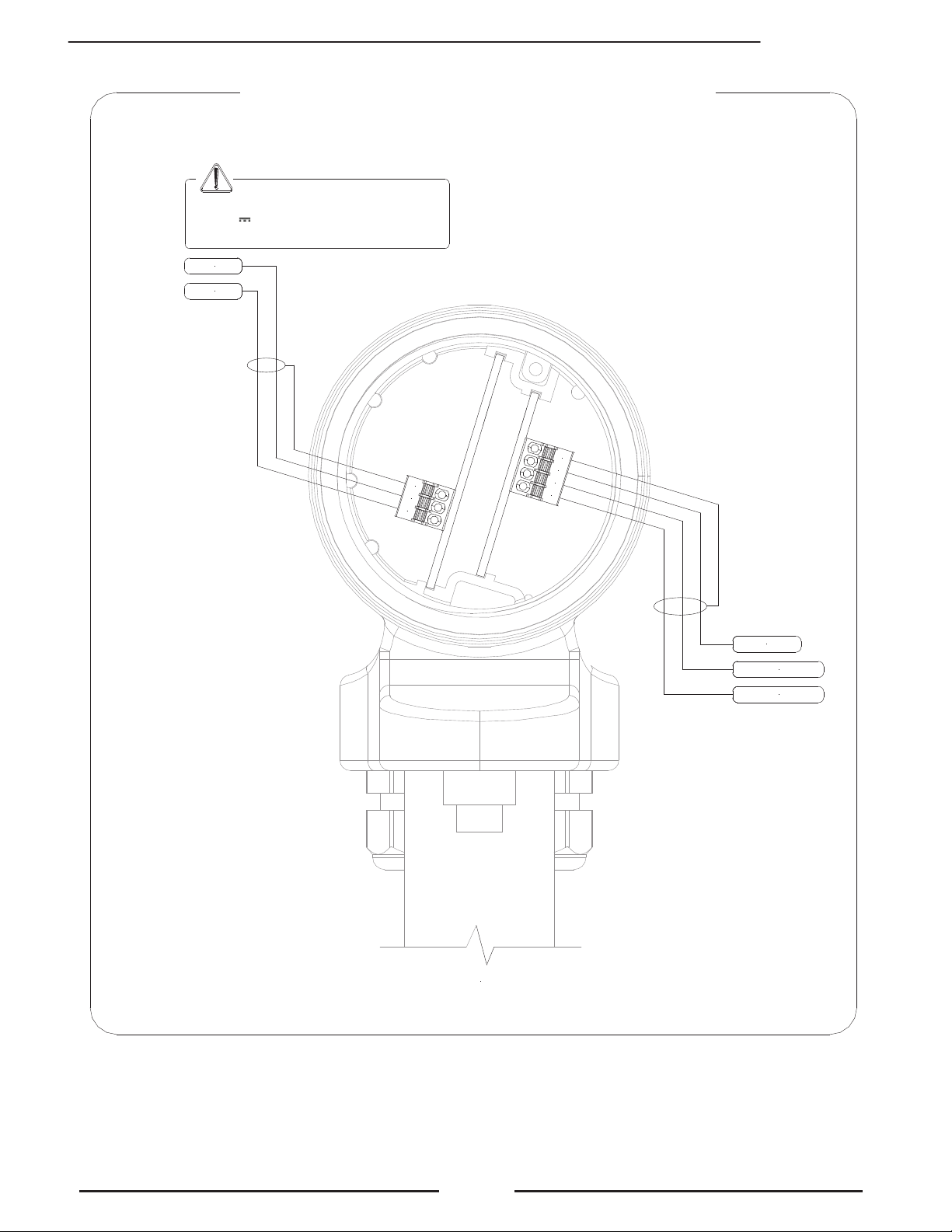

GROUNDING INSTRUCTIONS

ELECTRICAL CONNECTIONS

ALWAYS ensure that the converter and the sensor are grounded (earthed) correctly. The

grounding of the sensor and converter ensures that the equipment and liquid are

equipotential.

CONVERTER POWER SUPPLY

q

Before connecting the power supply, verify that the

mains voltage is

within the limits indicated on data

plate.

q ATTENTION:

the converters on dc power supply line

are not protected against the inversions of polarity.

q

For the connections use only approved conductors, with

fire-

proof properties, whose section varies from

0.25mm2 to 2.50mm

2

, based on distance/power;

additionally fix the

power supply wires with a additional

fastening system located close to the terminal.

q

The power supply line must be equipped with an

external protection for overload current (fuse or

automatic line breaker).

q Provide in close proximity the converter

a circuit

breaker easily accessible for the operator and clearly

identified;

whose symbols must conform to the

electrical safety and local electrical requirements.

q

Ensure that the component complies with the requirements of the standard for

electrical safety distance.

q Check chemical compatibility of

materials used in the connection security systems in

order to minimize electrochemical corrosion.

q

The sensor, hardwired inputs and outputs are connected to the converter through a

terminal blocks located inside the converter.

q To locate terminal blocks loosen the 2 covers, front and

back. The terminal block is

the hardwire connection of the converter to external equipment, including the

sensor.

The following pages give informations on the terminal block numbering, and the

respective connecting of the sensor cables, and inputs/outputs.

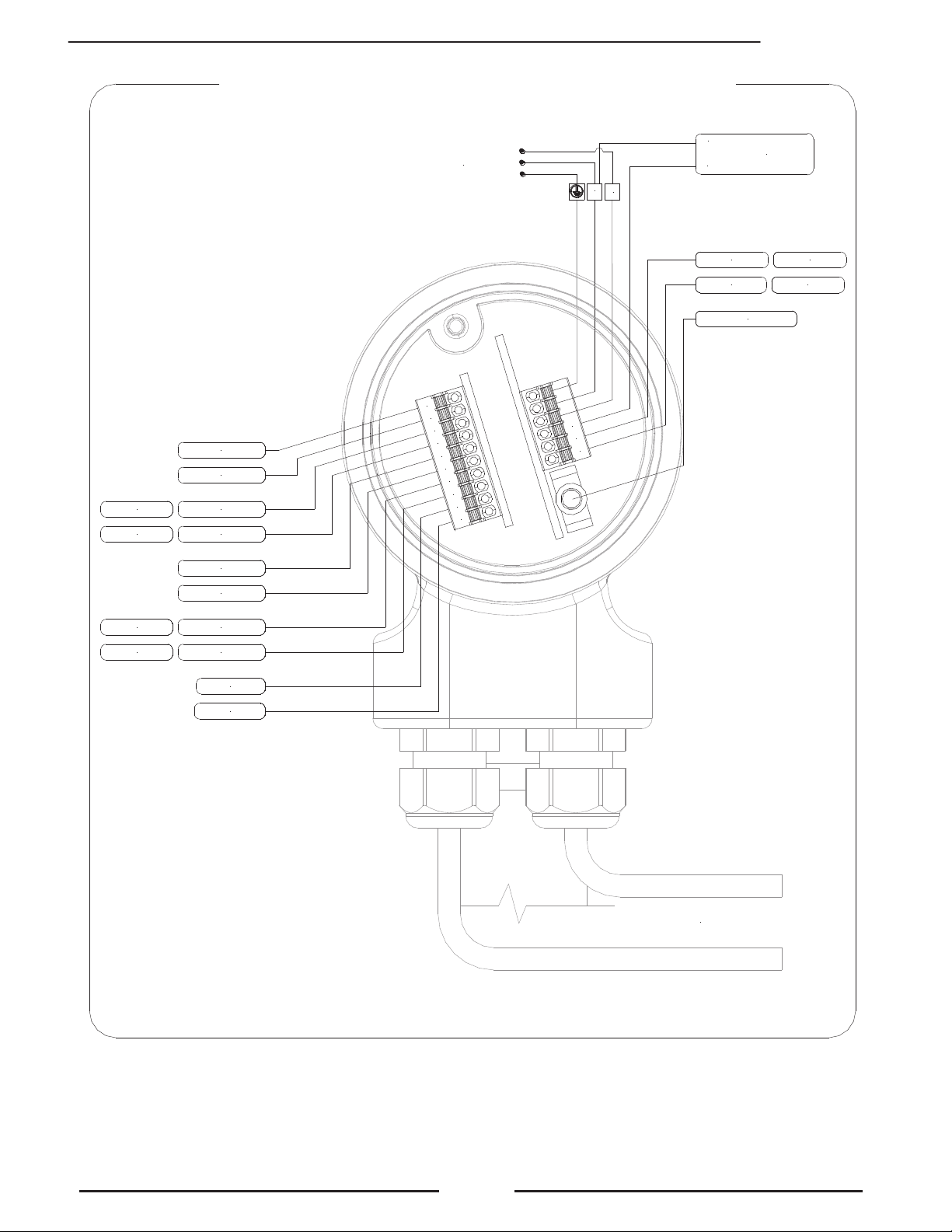

Page 8

HML4-F1

8

+

-

OUTPUT 4-20

"A" RS485

"B" RS485

JACK FOR IF2X

PROFIBUS

PROFIBUS

IN / OUT CABLES

15

16

14

17

18

19

20

21

22

23

24

25

26

- INPUT 1

+ INPUT 1

E. OUTPUT 4- INPUT 3

C. OUTPUT 4+ INPUT 3

E. OUTPUT 2

C. OUTPUT 2

E. OUTPUT 3

C. OUTPUT 3

- INPUT 2

+ INPUT 2

E. OUTPUT 1

C. OUTPUT 1

MAIN POWER

+

-

NOTE: shielded cables are recommended for inputs and outputs wiring.

INPUT/OUTPUT CABLES

Page 9

HML4-F1

9

CABLES FROM SENSOR

13

12

11

1

2

3

4

COMMON

ELECTRODE 2

ELECTRODE 1

COIL 1

COIL 2

SENSOR CABLES

Dangers voltage:

- 60V max

- 250V max commutation coils circuit

Page 10

HML4-F1

10

17 (Out 1)

21 (Out 2)

18 (Out 1)

22 (Out 2)

+

-

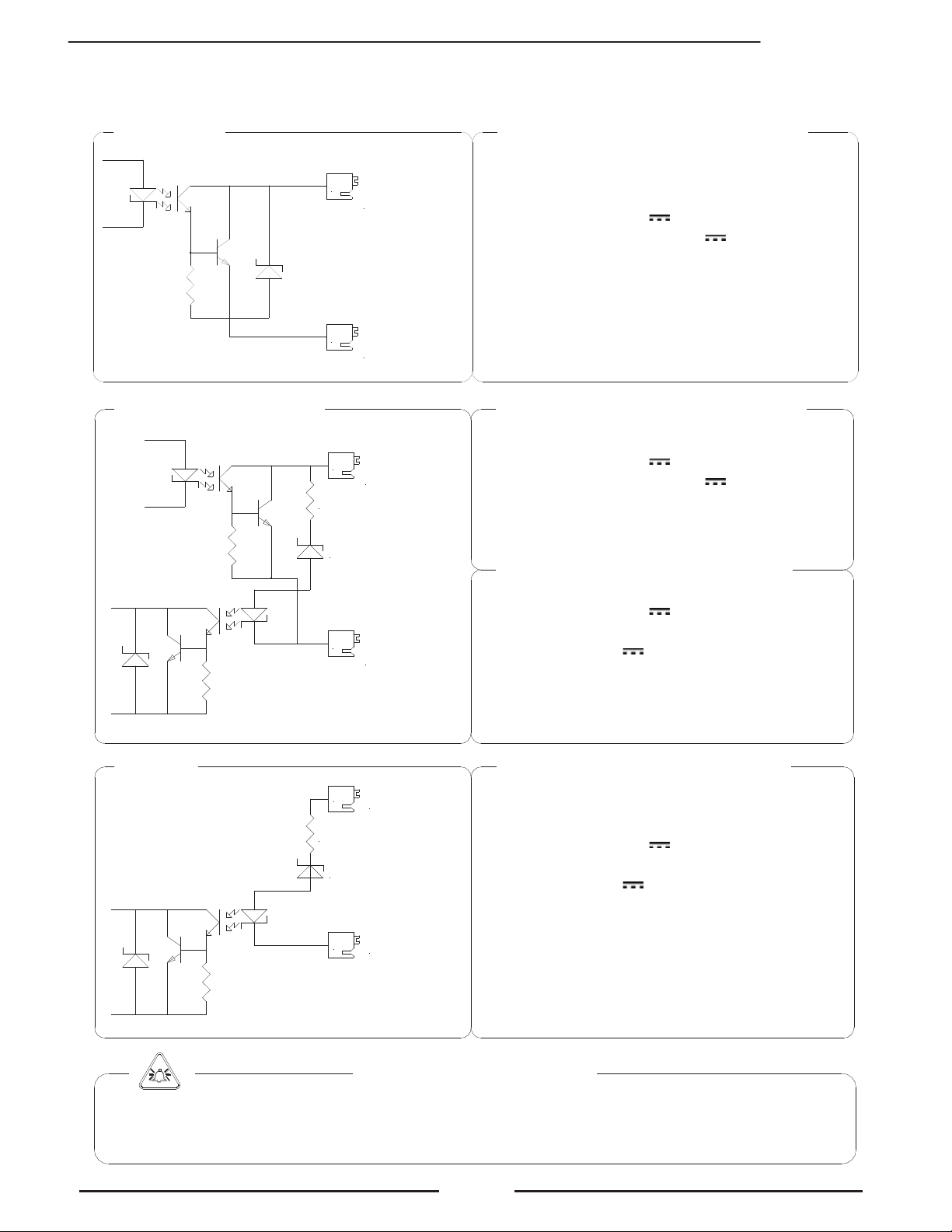

INPUTS/OUTPUTS

Output 1-2

20 (Out 3)

24 (Out 4)

19 (Out 3)

23 (Out 4)

47K

5V1-1/2 W

+

-

Output 3-4/Input 2-3

OUTPUTS technical characteristics

INPUTS technical characteristics

OUTPUTS technical characteristics

25

47K

5V1-1/2 W

26

+

-

Input 1

INPUTS technical characteristics

PROTECTIONS

The terminals are protected for the

accidental polarity inversion; the output is protected

from the extra voltage due to the inductive loads (connections of coils or relay).

q Max voltage 30V

q Max load: 100mA @24V ,

q Max frequency: 1250Hz.

q Max voltage 30V

q Min voltage for recognized logical state

enables: 18V

q Entry resistance of the circuit: 47kΩ

q Max voltage 30V

q Max load: 100mA @24V ,

q Max frequency: 1250Hz.

q Max voltage 30V

q Min voltage for recognized logical state

enables: 18V

q Entry resistance of the circuit: 47kΩ

Page 11

HML4-F1

11

4-20mA OUT

mA

14

I

external supply

+

-

Output 4-20mA

14 15 16

A B

RS 485

or

PROFIBUS DP

+

-

MODULE ME35/36

OPTIONAL

FOR COMMUNICATION MODULE SEE THE SPECIFIC MANUALS

OPTIONAL EXPANSION MODULES

q Power supply 18-30V

q Max load resistive to the output: 800Ω

with 24V of power supply

q Minimum load recommended 500Ω

q Setting time: 5ms

ATTENTION: The power supply of

communication module is the same of

that of entire instruments, therefore is

not insulated from it.

Terminal block M2

ATTENTION: The power supply of 420mA is the same of that of entire

instruments, therefore is not insulated

from it.

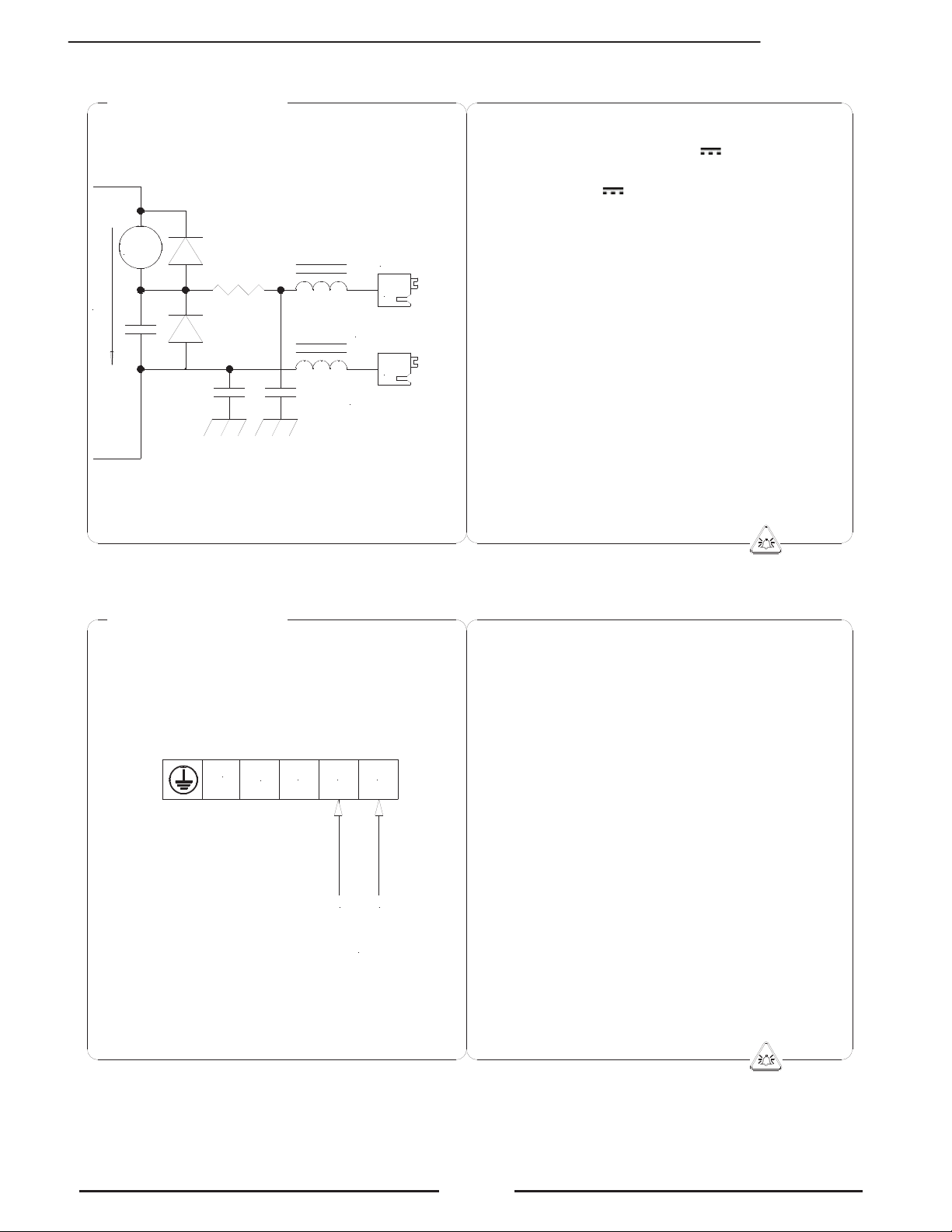

Page 12

HML4-F1

12

DIGITAL INPUT

The functions refer to the inputs could be substantially divided in three groups:

1.

only assignable functions to the input 1

2.

functions that act directly on the inputs independently from the select input

3. only assignable functions to the input 2 and only to the input 3 which they

interact between them

Remember that the activation of any functions of batch automatically disable the

operation o

f other.

The list of such functions is suitable in the table of the batch

function configuration section.

5/33 VDC (ON)

0/1.5 VDC (OFF)

25 (+)

26 (-)

10 K

Input electric wiring

ATTENTION: where not specified the time T

must be to Tmin

Speed rate

Tmin

20 Hz

50 Hz

80 Hz

150 Hz

110 ms

45 ms

30 ms

15 ms

60 Hz 40 ms

Page 13

HML4-F1

13

0-1.5 V

3-40 V

AUTOCALIB. OFF

T

RESET

0-1.5 V

3-40 V

Tmin = 100ms

BLOCK

0-1.5 V

3-40 V

T

0-1.5 V

3-40 V

INPUT OPERATION STAGE (GENERIC FUNCTIONS)

Auto-calibration

Reset totalizers

Block totalizers

Block totalizers

Totalizers active

Necessary conditions for enable the function

Necessary conditions for enable the function

Necessary conditions for enable the function

Tmin<T<1sec. = autocalibration

T > 1 sec. = Autozero

POS. 5.5 ENABLED

POS. 5.7-8-9 batch functions assign to input 1-2-3

(optional) DISABLED

(op

POS. 6.1-2-3-4 batch functions assign to output 1-2-

3-4 DISABLED

POS. 5.1-2 ENABLED at least one

POS. 5.4 ENABLED

POS. 9.5 (auto-batch) DISABLED

POS. 9.7 (cons. mode) DISABLED

POS. 5.6 ENABLE

POS. 5.7 (batch on input 1) DISABLED

POS. 5.8-9 batch functions assign to input 2-3

(optional) DISABLED

Necessary conditions for enable the function

Range change

THE FUNCTIONS POINT OUT ABOVE ARE ENABLED ONLY ON INPUT 1

Scale 2

Scale 1

Page 14

HML4-F1

14

T

T

OPERATION STAGE ON INPUT 1 OR 2 OR 3 (BATCH FUNCTION)

Start batch from remote input

Start batch from consent (remote)

Start batch from remote input with auto-

batch enabled

POS. 5.7 ENABLE or POS. 5.8 or 5.9 on

batch

POS. 6.1-4 on end batch

Start batch from remote input with

automatic selection of formula 00/03

N.B.: THE ACTIVATION OF BATCH FUNCTIONS ON INPUT 2

PREVENTS THE ACTIVATION OF BATCH FUNCTIONS ON INPUT 1

Necessary conditions for enable the function

Necessary conditions for enable the function

POS. 5.7 ENABLE or POS. 5.8 or 5.9 on

batch

POS. 6.1-4 on end batch

POS. 9.7 (CONSENT MODE) ENABLED

POS. 5.7 ENABLE or POS. 5.8 or 5.9 on

batch

POS. 6.1-4 on end batch

POS. 9.5 (auto-batch) ENABLED

POS. 9.7 (consent mode) DISABLED

Necessary conditions for enable the function

T= 100ms ±50ms for select the formula 00

T= 200ms ±50ms for select the formula 01

T= 300ms ±50ms for select the formula 02

T= 400ms ±50ms for select the formula 03

In case of stop batch from remote input the

time of input pulse must be > 50ms

POS. 5.7 ENABLE or POS. 5.8 or 5.9 on

batch

POS. 6.1-2 on end batch

POS. 9.6 (BM auto sel) ENABLED

POS. 9.7 (consent mode) DISABLED

POS. 5.8-9 functions assigned to BM

SELECT

Necessary conditions for enable the function

Start batch from remote input 1 reset p+

enabled on remote input 1

T BEETWEEN 1 E 4 = RESET TOTALIZER

T<1 = START E RESET TOTALIZER

Necessary conditions for enable the function

POS. 5.7 (batch on input 1) ENABLED

POS. 6.1-2 on AND BATCH

POS. 5.2 (reset T2) ENABLED

0-1.5 V

3-40 V

INPUT

OUTPUT

Closing

valve

Opening

valve

BATCH

INPUT

OUTPUT

0-1.5 V

3-40 V

Opening

valve

Opening

valve

Closing

valve

BATCH

3-40 V

0-1.5 V

5 Sec.

<5 Sec.

INPUT

OUTPUT

Closing valve

quantity to batch

memorized

Opening

valve

Closing

valve

AUTO-BATCH

BATCH

3-40 V

0-1.5 V

Formula selection

Start

INPUT

OUTPUT

Opening

valve

Closing

valve

BATCH

INPUT

OUTPUT

3-40 V

0-1.5 V

Start

Opening

valve

Closing

valve

BATCH

Start

Page 15

HML4-F1

15

T

T T

OPERATION STAGE ON INPUT 1 and 2 or 1 and 3 (BATCH FUNCTION)

Start batch on remote input 1 stop from output

selection formula 00 o 01 from remote input 2

Block totalizer from remote input 1 start

batch from remote input 2

Block and reset totalizer from remote input 1

start batch from remote input 2 consent mode

to batch enable

Necessary conditions for enable the function

POS. 5.7 ENABLED

POS. 6.1 or 6.3 on END BATCH

POS. 5.8 or/and 5.9 on BM SELECT

The block of totalizer always determine

the interruption of the batch. Exciting

again the input 2 or 3 is been able to

get 2 results:

1) T< 1Sec = restart interrupted

batch

2) T between 1 e 4 Sec = reset

interrupted batch. N.B.: will be

necessary give a new impulse

of start to the input 2 (T< 1Sec)

for begin a new batch

Necessary conditions for enable the

function

POS. 5.4 (Count lock) ENABLE

POS. 6.1 or 6.3 on END BATCH

POS. 5.8 or 5.9 on BATCH

POS. 5.2 (T2) ENABLE

The block of the totalize always determines

the stop of batch. With the function of reset

T2 enable on descent front of input 1 comes

reset the totalize of the batch in course.

therefore the presence of the consent or a

new pulse on the input 2 or 3 they will

determine the start of a new batch

Necessary conditions for enable the function

POS. 5.4 (Cout lock) ENABLE

POS. 5.8 or 5.9 on BATCH

POS. 9.7 (consent mode) ENABLE

POS. 5.2 (T2) ENABLE

3-40 V

0-1.5 V

Start

Opening

valve

Closing

valve

Opening

valve

Closing

valve

BATCH FORMULA 00

BATCH FORMULA 01

BATCH FORMULA 00

BATCH FORMULA 01

3-40 V

INPUT 2

OUTPUT

INPUT 1

3-40 V

0-1.5 V

Start

Start

Opening

valve

Closing

valve

Opening

valve

Closing

valve

NEW BATCH

RESTART INTERRUPTED

BATCH

OUTPUT

OUTPUT

INPUT 2

INPUT 2

INPUT 1

T<1 Sec.

T compreso tra 1 e 4 Sec.

3-40 V

0-1.5 V

Start

RESET

T<1 Sec.

Start

Opening

valve

Closing

valve

Opening

valve

Closing

valve

INTERRUPTED BATCH

0-1.5 V

3-40 V

BLOCK

0-1.5 V

3-40 V

Start

INPUT 2

Opening

valve

Closing

valve

Opening

valve

Closing

valve

0-1.5 V

3-40 V

BLOCK

RESET T2

INPUT 1

OUTPUT

INTERRUPTED BATCH

NEW BATCH

INTERRUPTED BATCH

Page 16

HML4-F1

16

15

16

14

17

18

19

20

21

22

23

24

25

26

FLAGS INTERPRETATION

FLAG

DESCRIPTION

Alarm max/min activated

!

- Interruption coils circuit

- Signal error

- Empty pipe

C

Calibration running

S

Simulation

Pulse output saturation (reduce

TIME PULSE)

FLAGS AND LED INTERPRETATION

FLAGS

LED

LED INTERPRETATION

PERMANENT LIGHT:

initialization

FLASHING

LIGHT ( 1 sec.): normal function

FLASHING

LIGHT (<1 SEC.): alarm on

The LED signals the real alarm status only if the display visualizes

one of the visualization pages

Page 17

HML4-F1

17

Functions in the converter main menu are enabled by the access codes. The information of

this manual is related to all the functions available with the L2 level. All the functions

available through higher level are protected and reserved to the service.

Description of the L2 access code

(menu “11 Internal data” pos. 11.1)

q with code L2 = 00000 (only with this code) you can disable the L2 code request

q * with L2 customized

(freely chosen by the user) you can program all the functions

up to L2 security level, entering the code whenever you need enter the Main menu.

* ATTENTION:

take careful note of the customized code, since

there is no way for the

user to retrieve or reset it if lost.

Factory preset access codes

The converter is delivered with the

default L2 (level 2) access code:

11111

The instrument can show a 5 digit character display for flow rate units; this mean the

maximum flow rate value that can be represented on the display is

99999

(no matter the

positioning of the decimal point). The minimum is

0.0025.

The representable measure unit depends from sensor flow rate and diameter; the

permitted units are those, set the instrument full scale value, allow to be represented with

a numerical field which the maximum value do not exceed

99999.

Example for DN 300:

- Full scale value: 3m/s

- PERMITTED measure unit (example): l/s (216.00); m3/h (777.60); m3/s (0.2160)

- NOT PERMITTED measure unit (example): l/h (777600)..

FLOW RATE VISUALIZATION

ACCESS CODES

Page 18

HML4-F1

18

Functions can be accessed in two different ways:

q The Quick start menu makes direct access

possible to a range of principal

functions for setting the scale reading and display characteristics of the sensor.

Quick start menu can be enabled by function 8.4 (menu display)

q Through the Main menu

it is possible to access functions with the access code

level 2. These control the sensor’s monitoring, data processing, inpu

t/output as

well further options.

E

xamples in the next pages show how to change the Full scale by Quick Start menu

and

by the Main menu.

The converter configuration menu can be accessed ONLY using ISOCON interface

(

cable and software needed).

Isocon is a Windows® software that

allows to set all the converter

functions and personalize the menu

(IF2X is required), see suitable

manual for details.

THE CONFIGURATION MENU

Factory pre-setting:

QUICK START MENU=ON

ACCESS TO THE CONFIGURATION MENU

ISOCON INTERFACE

Page 19

HML4-F1

19

* The maximum digits by from the totalizer is 999999999 independently from the number of

selected decimal. Beyond this value the totalizers are reset.

Flow rate value

% full scale

Direct/reverse totalizer

Sampling rate

Three vertical bars

Flow direction +/-

See: anomalies codes and

flags interpretation

C=Calibration

S=Simulation

Flow speed

Scale (1=low); (2=high)

Flow rate value

% full scale

Measure units

Flow direction

Time scale

% full scale

Active scale

The three vertical bars represent the filters behaviors: first

bar, “F”, is the FAST filter, second bar, “S”, is the “SLOW”

filter and the third bar represents

the variation of the new

measure samples respect to the averaged value. It can give

an indication about the total noise of the measure.

*

VISUALIZATION PAGES

Push to change

visualization

Page 20

HML4-F1

20

The set up functions (batching, regulation, flow and SMART measure) configure

automatically the instrument (filters) for the operation set modifying optimally the

parameters related to the function chosen.

To enable one of

four types operation press the key Enter while the function is

highlighted, to confirm the changes press the key Del/Canc or Esc.

Fi

lters settings for different S.rate (sensor menu, not user modifiable):

Batching

Regulation

Flow measure

SMART measure

MFSLN

MFFLN

MFSLN

MFFLN

MFSLN

MFFLN

MFSLN

MFFLN

20Hz 0 0 5 0

10 0 50

5

50Hz 0 0 2 0 4 0

20

2

60Hz 0 0

1.7 0 3.3

0

16.7

1.67

80Hz 0 0

1.3 0 2.5

0

12.5

1.25

150Hz 0 0

0.7 0 1.3 0 6.7

0.67

See the functions description section for more details regarding filters.

QUICK START MENU

The user has immediate access to the Quick Start menu when the converter is powered up

by pressing the key Enter. If access to the quick start menu does not occur, then it has

been disabled through the function 8.4

See function menu section

Automatic parameters optimization (see below)

Access to all functions

Page 21

HML4-F1

21

EXAMPLE: modifying the full scale value from 4dm³/s to 5dm³/s,

from the “Quick start menu”

Enter in the

Quick start menu

Access to the

function “Fs1”

Push

repeatedly

Change

the value

Confirm

the new value

Main page

Page 22

HML4-F1

22

EXAMPLE: modifying the full scale value from 4dm³/s to 5dm³/s,

from the “Main Menu” (quick start menu enabled)

Enter in the

Quick start menu

Access to the

Main Menu

Access to the

Scale menu

Access to the

function “Fs1”

Change the value

Confirm

the new value

X 5 TIMES

Push

repeatedly

Confirm the

keycode

Main page

Page 23

HML4-F1

23

1.1 Insert the Nominal Diameter of the sensor (0-3000mm)

1.2 Calibration data of sensor visualized on sensor label

1.3 Sensor model: enter the first two characters of the sensor serial number

1.4 Factory parameters

1.5 Enables the empty pipe detection feature

1.7* Value of empty pipe sensibility detection

1.8* Enables the automatic zero calibration system

1.6* Electrodes cleaning

2.1* Full scale value set for range N.1

2.2* Full scale value set for range N.2

2.3* Unit of measure and number of decimal totalizes

2.4* Pulse value on output 1

2.6* Duration of the pulse generated on output 1

2.7* Duration of the pulse generated on output 2

2.8 Specific gravity set in kg/dm³ (enable only if FS1 or FS2 are weigh/time)

2.5* Pulse value on output 2

3.3* Main frequency filter

3.5 Enable every hour an internal cycle of calibration. The measure is stopped for 8-15 sec.

3.6* Automatic change of scale

3.1 Low flow zero threshold: 0-25% of full scale value

3.2* Measure filter

3.4 Only for service purposes

4.1 Maximum value alarm set for direct flow rate

4.2 Maximum value alarm set for reverse flow rate

4.3 Minimum value alarm set for direct flow rate

4.4 Minimum value alarm set for reverse flow rate

4.5 Hysteresis threshold set for the minimum and maximum flow rate alarms

4.6* Current output value in case of failure

4.7* Batch safety timer

5.8* Functions assigned to input 2 (automatically disabled if OUT3 is enabled)

5.9* Functions assigned to input 3 (automatically disabled if OUT4 is enabled)

5.1* Total direct (positive) flow totalizer reset enable

5.2* Partial direct (positive) flow totalizer reset enable

5.3 Reset totalizer of pulse from digital input (see page 13)

5.4 Totalizer counting lock command (see page 13)

5.5* Autozero calibration external command

5.7 Batch start/stop external command (see batch functions)

5.6 Range change external command (see pos. 3.6)

Functions assigned

on input 1

PROGRAMMING FUNCTIONS

(functions with access code < 3, those with symbol “*” see next section)

Functions in grey colour are visualized on display only with other active functions or with optional modules

Page 24

HML4-F1

24

6.1* Output 1 functions

6.2* Output 2 functions

6.3* Output 2 functions

6.4* Output 4 functions

6.5* Choice of the function and the range of current output n.1

8.1 Choice of the language: EN= English, IT=italian, FR= French, SP= Spanish

8.2 Display totilizer mode

8.3 Updating frequency on the display: 1-2-5-10 Hz

8.4 Quick start menu visualization

8.5* Volume totalizer 1 reset

8.6* Volume totalizer 2 reset

9.1* Number of batch cycles to be done to define the value of compensation.

9.2* % limit of compensation threshold

9.3* Compensation value

9.4* Prebatch value

9.5* Auto-batch

9.7* Static consent of batch

9.6* Automatic selection of batch formula

7.1 Choice of the communication protocol for the IF2 device

7.2 Address value of the converter

7.3 Speed of the RS485 output (possible choices: 4800, 9600, 19200, 38400 bps)

7.4 Instrument answer delay

11.1 Level 2 access code enter

11.2 Load factory data pre-set

11.3 Load user data saved

11.4 Save user data

11.6 Ks coefficient (only for service purposes)

11.5 Ignore the calibration error during the switch on test

10.1* Enable the calibration of the converter

10.2* Converter autotest

10.3* Flow rate simulation enabling

10.4 Stand-by of converter to reduce the consumption during service operation

10.5 Firmware revision/version

Menu 9 visualized only IF batch is active

Page 25

HML4-F1

25

MENU 1.SENSOR

(POS. 1.1) Nominal diameter of sensor

[ND= XXXX]

FUNCTIONS DESCRIPTION

(description of the functions with access code< 3)

The following pages give a description of the most important functions and how they can be changed or

enabled/disabled by the user.

MENU 1 - SENSOR

(POS. 1.6) Electrodes cleaning [E. cleaning=MIN]

Selectable options: OFF, minimum, average and maximum. It is not recommended the use of this

function (let OFF) when the liquid has a conductivity less than 100µS/cm.

(POS. 1.7) Empty pipe threshold [E.p. thr.=XXX]

This value represents the threshold of measure block to zero in empty pipe condition; the span

function is 20-250. Since the sensibility of empty pipe detection could be changed by the liquid

conductivity, ground connections, type of lining, in case of needed it is possible to adjust manually

the preset threshold. It is recommended to check periodically its proper functioning. Value

increasing means sensibility decreasing.

(POS. 1.8) Autozero calibration [Autozero cal.]

This function activates the zero calibration automatic system. To perform this operation, it is

necessary for the sensor to be full of liquid, and the liquid be perfectly still. Even minimal

movement of the liquid may affect the result, and consequently, the accuracy of the system. Once

you are sure the above conditions have been fulfilled (and the percentage flow rate value is stable)

press the key and automatically activates the zeroing procedure, after which it is necessary to

check that the percentage value showed goes to zero, repeat the operation otherwise. When the

value is stable at zero, then press the key Enter.

MENU 2 - SCALES

(POS. 2.1-2) Full scale n° 1-2 [FS1-2=

dm³/S

X.XXXX]

The full scale is used to indicate to the maximum meter’s flow rate; a volume per time is required.

The full scale should be chosen carefully as it’s parameters are used for several other parameters.

There are four fields to fill in order to set this parameter, from left to right: 1) volume unit of

measure, 2) type of unit, 3) time unit of measure and 4) numeric value. The selection is made by

positioning the cursor on the field to modify. To change the type of unit of measure (metric, British

or American, mass or volume) the cursor has to be positioned on the symbol “/” (field N. 2). When

the nominal diameter is set to zero it is possible to modify only the numeric field, since the unit of

measure stays at m/sec. The following tables show the units of measure available and the

conversion factor by comparison with 1 dm3 and 1 kg. The converter accepts any kind of

co

mbination of units of measure satisfying both the following conditions:

1. Numeric field value

99999

2. 1/25 fs

max

numeric field value fs

max

.

Menu visualized on the converter (from 1 to 11)

Synthetic description of the function

Identification of the function (not visualized on display)

Converter request

Page 26

HML4-F1

26

Where fs

max

is the maximum full scale value corresponding to the sensor, equal to a 10 m/sec liquid

speed. The units of measure are shown as appear on the display. The British and American units

are diversified by using capital and small characters. Available units of mass and volume:

When a mass unit of measure is set, the specific gravity function is automatically enabled by the

system. The units of measure of time may be chosen among the values: s=second, m=minute,

h=hour, d=day.

(POS. 2.3) Measure unit and number decimal totalizers [MU.tot:dm³X.XXX]

Setting the unit of measure and number of decimals for visualized the totalizers or the volumes to

batch. For set the unit of measure, position the cursor on field of the actual unit of measure; to set

the type of unit, position the cursor on the blank space between the unit of measure and the

numeric value; to set the number of decimal totalizers position the cursor on numeric field and

choose one of the possible combinations: 1000-01.00-001.0-00001.

(POS. 2.4-5) Pulse value output 1-2 and unit of measure of tot. [Imp1-2=

dm³

X.XXXXX]

Setting of the pulse volume corresponding to output 1-2 and of the totalizers measure units. There

are three fields to fill in to set this parameter, from left to right: 1) measure unit, 2) unit type and

3) numeric value. The selection is performed by positioning the cursor on the field to be modified.

To change the unit type (metric, British or American, mass or volume) just position the cursor on

the blank space between the measure unit and the numeric value. When the nominal diameter is

set to zero it is possible to modify only the numeric field since the measure unit stays at meter (m)

or feet (ft). The possible measure units are those above described

(POS. 2.6-7) Pulse duration on output 1-2 [Tpul1-2=msXXXX.XX]

Setting of the duration of the pulse generated on output 1-2. Its value is expressed in milliseconds

and has to be between 0.4 and 9999.99. When the high frequency output is present, then the

minimum value can go down to 0.04 milliseconds.

ATTENTION

: since the instrument cannot detect which type of device it is connected to, it is up to

the user to verify the set pulse duration is compatible with the external device processing such

pulses. If, for example, an electro-mechanical pulse counter is connected, then two kind of

problems may occur: if the pulse is too long than the coil may burn or, if it is too short, the counter

may not be able to count and eventually even cause the damaging of the output itself.

cm3

Cubic centimetre

ml

Millilitre

l

Liter

dm3

Cubic decimeter

dal

Decalitre

hl

Hectolitre

m3

Cubic metre

in3

Cubic inch

Gal

American gallon

GAL

British gallon

ft3

Cubic foot

Bbl

Standard barrel

BBL

Oil barrel

yd3

Cubic yard

kgl

KAmerican gallon

KGL

KBritish gallon

G

Gram

Kg

Kilogram

T

Ton

Oz

Ounce

Lb

Pound

Ton

short tons

Page 27

HML4-F1

27

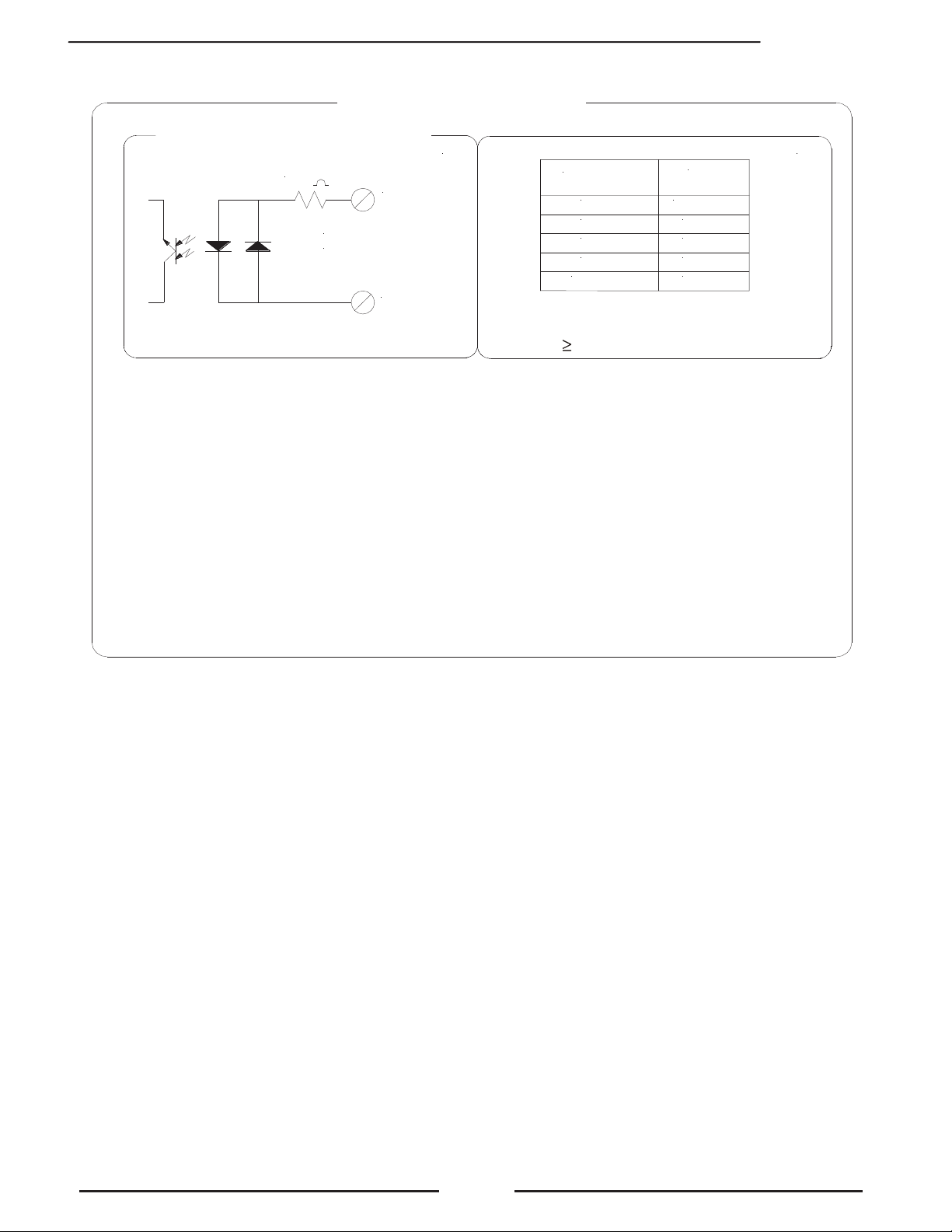

MENU 3 – MEASURE

(POS. 3.2) Measure filter [M. filter=s XXX.X]

This section of the manual is extremely important because the right settings of filters allow to get a

proper meter reaction according to the flow rate behaviour.

WORKING PRINCIPLE

There are two filters:

MFSLN (Measure Filter Slow LeNght): available via ETP and through the display, in menu

3. Measure, function “M. filter”

The M. filter function effects the converter response time while measuring (it is like LOW PASS

filter); the value needs to be chosen carefully as it effects the meter behaviours. A smaller value

with a fluctuating flow will lead to unstable flow readings as the integration filter will be measuring

over very short periods. A higher value corresponds to a more stable but slower measure, a smaller

value gives a faster measure but is more unstable.

MFFLN (Measure Filter Fast LeNght): is available ONLY via ETP

The MFFLN must be set by the user in accordance with the MFSLN (M. filter) to meet the required

meter behaviour.

How the system functions: If the period of flow rate variation is over the MFFLN time (i.e. a slow

flow variation), the outputs (display/4-20mA/Alarms) are refreshed according to MFSLN (M. filter);

as soon as the flow rate variation is within MFFLN time, the output will be set immediately at the

new value.

The combination of MFSLN & MFFLN is useful as it allows the converter to react quickly to large

flow rate variations, regardless of the MFSLN (M. filter) set, therefore delaying (dampening) smaller

fluctuations in flow, resulting in very stable measures.

The value of those parameters has to be within the range from 0 (filter disabled) to the maximum

value defined on below table:

Sampling rate

M Filter (MFSLN)

F Filter (MFFLN)

20

50.0

7.50

50

20.0

3.00

60

16.7

2.50

80

12.5

1.88

150

6.7

1

Page 28

HML4-F1

28

10

20

30

40

50

60

0

0 2 4 6 8 10 12 14 16 18 20 22

MFSLN: 0,0s

MFFLN: 0,0s

FLOW RATE MEASURE

FILTERS

>>>>

>>>>

10

20

30

40

50

60

0

0 2 4 6 8 10 12 14 16 18 20 22

10

20

30

40

50

60

0

0 2 4 6 8 10 12 14 16 18 20 22

1,0sec.

1,0sec.

1,0sec.

1,0sec.

1,0sec.

5,0sec.

IN

OU T

MFSLN: 5,0s

MFFLN: 1,0s

FLOW RATE MEASURE

FILTERS

>>>>

>>>>

IN

OU T

MFSLN: 5,0s

MFFLN: 0,0s

FLOW RATE MEASURE

FILTERS

>>>>

>>>>

IN

OU T

FLOW RATE (%)

TIME (Sec)

TIME (Sec)

FLOW RATE (%)

TIME (Sec)

FLOW RATE (%)

The following diagrams show the response of the instrument for a flow rate variation from 0 to

100% of full scale set using different settings of filters.

Both filters to zero

(batching setup)

: the

measure quickly

follows the flow rate

behaviour

Both filters are used

(Smart mode): prompt

reaction to quick flow

variation (based on

the MFFLN value);

smoothing the

measure result to slow

flow variations (based

on MFSLN value)

Only M. filter (MFSLN)

is u

sed (regulation

and flow measure

setup)

: smoothing the

measure result (based

on MFSLN value) in

reaction to quick and

slow flow variation

(MFFLN does no

t

work).

Page 29

HML4-F1

29

(POS. 3.3) Measure filter AC enable [AC Line fil.=ON/OFF]

This function allow to filter electrical noise on the liquid coming from the main frequency.

(POS. 3.6) Automatic scale change enable [Autorange=ON/OFF]

Enables the automatic change of scale. The meter may have two different working ranges in order

to suit to the variable process conditions. In order to get the best results out of this function it is

important range N.2 is bigger than N.1. When the flow rate increases and reaches the 100% of the

full scale 1, then the meter automatically switches to scale 2. When the flow rate decreases again

reaching a value on scale 2 equal to the 90% of full scale N.1, then the active scale is 1 again.

Allowed values for this parameter: ON/OFF. N.B.: the autorange does not allow using the manual

change of range (pos. 5.6)

MENU 4 - ALARMS

(POS. 4.6) Current output value in case of failure [mA v.fault =% XXX]

Setting of the value the 4-20mA current output has to be in one of the following cases:

empty pipe; coils interrupted; ADC error

The allowed range is from 0 to 120% of the 0-20 mA scale, 120% corresponds to 24mA and does

not depend on the selected range (0-20/4-20mA). The NAMUR NE43 recommendation asks for a

alarms signalling value for the current output lower than 3.6mA (<18%) or bigger than 21mA

(>105%). It would then be preferable to set the value of this function at the 10%, so that the

current value in case of the a.m. cases would be 2mA, allowing the following diagnostics:

1. current < 2 mA - 5%: line interrupted, power supply failure or faulty converter;

2. 2mA -5%

current 2mA + 5%: hardware alarm;

3. 4mA current 20mA: normal working range;

4. 20mA < current 22mA: out of range, measure above 100% f.s.

N.B.: To set this parameter to zero corresponds to disable the alarm

(POS. 4.7) Batch safety timer [Timeout=s XX.X]

With this function is possible to set a maximum time for the batch; over this time will be generate

an alarm.

This function is useful when you need control one or both of the followings condition:

q batch valve open and flow rate is zero

q batch valve closed and flow rate different to zero

When this alarm is activated, they are aborted the batch operation and the power supply of the

valve. The values of function are from 0 to 25.5 seconds and is active only if one or more of the

batch functions are enable.

MENU 5 - INPUTS

(POS. 5.1-2) Modify/reset totalizer enable [T1/2 reset=ON/OFF]

When one of this function is enabled, the related totalizer may be reset through the on/off input.

(POS. 5.5) Autozero calibration external command enable [Calibration=ON/OFF]

When this function is active, applying a voltage on the on/off input terminals the meter performs a

autozero calibration cycle. ATTENTION: if the voltage pulse is less 1 sec., the meter performs a

calibration cycle for compensate possible thermal drifts. If the voltage pulse is more 1 sec, the

meter performs a zero calibration of measure. This function enables/disables the automatic zero

calibration system. To perform the sensor it is absolutely necessary the sensor is full of liquid and

that the liquid is perfectly staying still. Even very small movement of the liquid may affect the result

of this function, and, consequently, the accuracy of the system.

(POS. 5.8-9) Functions assigned to input 2-3 [INP.2-3=XXXXXX]

Choice of the function to associate the input 2 The functions are listed in the table below.

FUNCTIONS FOR INPUTS 2-3

OFF:

DISABLE

BATCH

: START/STOP BATCH

BM SELECT:

STATIC SELECTION OF FORMULA

VALV.

OPEN: OPEN VALVE COMMAND

STAND

-BY: STAND-BY COMMAND (see function 10.4)

Page 30

HML4-F1

30

MENU 6 - OUTPUTS

(POS. 6.1-4) Function corresponding to on/off output 1-2-3-4 [OUT1=XXXXXX]

Choice of the function corresponding to digital Output 1. The functions are listed in the table below:

(POS. 6.5) Function and the range of current output n.1 [OUT.mA1=X÷XX+]

Choice of function and range of current output N.1. There are three fields to modify:

q Scale zero: 4 or 0 mA; Full scale: 20 or 22 mA

q Field: + = positive, - = negative, blank = both, -0+ = central zero scale

The values corresponding to the scale points are shown in the following chart:

In hardware alarm conditions “HW ALARM” (interrupted coils, empty pipe, measure error) the

current value is programmed by the function “mA v. fault” (pos. 4.6) and it is expressed as

percentage of a fixed current range, where: 0% = 0mA e 110% = 22mA.

CURRENT VALUES IN mA ASSOCIATE TO THE % VALUE OF FULL SCALE

POSSIBLE FIELD

REVERSE FLOW VALUE

ZERO

DIRECT FLOW VALUE

-110%

-100%

0%

+100%

+110%

OutmA = 0 ÷ 20 +

0 0 0

20

20

OutmA = 0 ÷ 22 +

0 0 0

20

22

OutmA = 4 ÷ 20 +

4 4 4

20

20

* OutmA = 4 ÷ 22 +

4 4 4

20

22

OutmA = 0 ÷ 20 -

20

20 0 0

0

OutmA = 0 ÷ 22 -

22

20 0 0

0

OutmA = 4 ÷ 20 -

20

20 4 4

4

OutmA = 4 ÷ 22 -

22

20 4 4

4

OutmA = 0 ÷ 20

20

20 0 20

20

OutmA = 0 ÷ 22

22

20 0 20

22

OutmA = 4 ÷ 20

20

20 4 20

20

OutmA = 4 ÷ 22

22

20 4 20

22

OutmA = 0 ÷ 20 –0+

0 0 10

20

20

OutmA = 0 ÷ 22 –0+

0 1 11

21

22

** OutmA = 4 ÷ 20 –0+

4 4 12

20

20

OutmA = 4 ÷ 22 –0+

4

4.8

12.8

20.8

22

22 mA

20 mA

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

zero

4 mA

I (mA)

I (mA)

20 mA

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

zero

12 mA

4 mA

FUNCTIONS FOR OUTPUTS 1, 2, 3, 4

OFF: DISABLED

PLS+: PULSE FOR POSITIVE FLOW RATE (ONLY OUTPUT 1-2)

PLS-: PULSE FOR NEGATIVE FLOW RATE (ONLY OUTPUT 1-2)

PLS: PULSE FOR POSITIVE AND NEGATIVE FLOW RATE (ONLY OUTPUT 1-2)

SIGN: FLOW DIRECTION OUTPUT (ENERGIZED = -)

RANGE: RANGE INDICATION OUTPUT (ENERGIZED = SCALE 2)

MAX AL+: MAX DIRECT FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MAX AL-: MAX REVERSE FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MAX AL: MAX DIRECT/REVERSE FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MIN AL+: MIN DIRECT FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MIN AL-: MIN REVERSE FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MIN AL: MIN DIRECT/REVERSE FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MAX+MIN±: MAX AND MIN FLOW RATE ALARM OUTPUT (ENERGIZED = AL. OFF)

P.EMPTY: EMPTY PIPE ALARM OUTPUT (ENERGIZED = FULL PIPE)

OVERFLOW.: OUT OF RANGE ALARM OUTPUT (ENERGIZED = FLOW RATE OK)

HARDW AL.: CUMULATIVE ALARM OUTPUT interrupt coils, empty pipe, measure error (ENERGIZED = NO ALARMS

EXT. COMM.: ONLY AVAILABLE WITH DATA LOGGER MODULE

BATCH AL: BATCH ALARM

BATCH SYN.: AT THE AND OF BATCH THE OUTPUT CHANGE STATUS

END BATCH.: END BATCH OUTPUT (ENERGIZED =BATCH IN PROGRESS)

PREBATCH.: PREBATCH OUTPUT (ENERGIZED = PREBATCH IN PROGRESS)

* Example 1: out 4÷22 +

** Example 2: out 4÷20 –0+

Page 31

HML4-F1

31

MENU 8 - DISPLAY

(POS. 8.5-6) Totalizer 1-2 reset [T1/2 reset]

These functions are activated pressing the key Enter during the function visualization. When

"EXECUTE?" is required, press Esc/Del/Canc to proceed; or any other key to delete the operation.

MENU 9 - BATCH

Visualized only with batch active (output on batch and/or pos. 5.8 enable or pos. 5.9 on

batch)

(POS. 9.1) Number of batch samples [N.SAMPLES=XXX]

Number of batch cycles to be done to define the value of compensation. This function allows to

automatically determine the average value for automatic compensation of system delay (pos. 9.3).

Set to ZERO this function for manually introduction of the compensation value.

(POS. 9.2) % limit of compensation [HYST.=%XXX]

This value defines the percentage of maximum difference between the compensation value set

(pos. 9.3) and the average compensation value defined with the function 9.1. Over this threshold

the new compensation value will be automatically set (if number of batch samples is not zero)

(POS. 9.3) Compensation value [V.COM.=XX.XXX]

This value, expressed in the same selected volume unit of measure, is the result of the difference

between the batch value set and the quantity of product really supplied due to the system delays:

closing valves, stop pumps, stop motors, etc. Attention: if you need to set manually the value of

compensation, preset to ZERO the Number of batch samples (pos. 9.1)

(POS. 9.4) Prebatch value [V.PRE.=XX.XXX]

set the volume of liquid at which you want to enable the pre-batch. When the pre-batch volume “V

Pre” is reached the output (if enabled) is de-activated. This value is constant for all quantities to be

batched and must be set in current volume unit of measure. The pre-batch function is useful when

you need fast and accurate fillings.

(POS. 9.5) Enable/disable auto-batch function [AUTO BATCH=ON/OFF]

Applying a voltage on the on/off input terminals for more than 5 second the valve controlled by the

meter stands open while the voltage is applied on the input. When the product has reached the

desired volume/level, removing the voltage from the input, the meter closes the valve and

memorizes the supplied product volume in the current memory batch (see BATCH FUNTIONS); the

value obtained with this procedure will be the volume supplied in every following batch. In order to

modify this value, repeat the operations above. This procedure set the safety timer at a value 1.25

times greater than the time used to reach the batched quantity; after that the counter will be reset.

(POS. 9.6) Automatic selection of batch formula [BM AUTO SEL=ON/OFF]

The function allows the automatic selection of the first 4 formulas depending on the duration of the

pulse of the batch start (see section Input operation stage). This function is active only if the

function cons. mode (pos. 9.7) has not enabled. Besides, activating this function, the automatic

compensation of the batch volume is also excluded (the value of the parameter "N.samples" (pos.

9.1) will be automatically set to zero). However the manual compensation is possible introducing

the opportune value on the parameter "V.com" (pos. 9.3)

(POS. 9.7) Static consent of batch [CONS. MODE=ON/OFF]

The function enable the dosing start and stop using a static signal, instead of an impulsive, applied

to the input (see Digital input section), this signal will have to stand applied all through the batch.

The function automatically disables functions BM AUTO SEL (pos. 9.6) and AUTO BATCH (pos. 9.5).

Page 32

HML4-F1

32

MENU 10 - DIAGNOSTIC

(POS. 10.1) Meter calibration [CALIBRATION]

Enable the calibration of the meter. The activation of this function happens pressing the key Enter

during the function visualization. Will be visualized the following question: "EXECUTE?" press the

key Esc/Del/Canc to proceed. Press any other key to delete the operation

(POS. 10.2) Autotest function enable [SELF TEST]

Meter autotest function. This function stops the normal functions of the meter and performs a

complete test cycle on the measure input circuits and on the excitation generator. To activate this

function, after select it, push key Enter, at the question: “EXECUTE?” push the key

Esc/Del/Canc.

For start autotest, or any other key for delete operation. The result of the test is shown on the

display. At the end of operation will have visualized one of visualization page. This function is

automatically performed when switching on the device.

(POS. 10.3) Flow rate simulation [SIMULATION=ON/OFF]

Flow rate simulation enabling. With this function it is possible to generate an internal signal that

simulates the flow rate, allowing the outputs and all the connected instruments test. After enabling

it, a ‘S’ appears in the top left of the screen and the flow rate simulation can be:

q set: by pushing the key Enter from one of visualization pages, to set the required flow rate

(Fl.rate=) and the same key to confirm the value;

q finished: by pushing the key Enter from visualization pages and then by the key Esc/Del/Canc.

Page 33

HML4-F1

33

BATCH FUNCTION

For each formula you can

associate:

q Product quantity

q Product name

q

Maximum time for

batch (safety time for

each formula)

After activating the batch

function from visualization

page, proceed as in the

aside example.

VISUALIZATION PAGE WITH BATCH FUNCTION ENABLE

PROGRAMMING BATCH

Programming formula n°

product Name

Batch in progress

Visualizations:

1) batch off: n° batch effected

2) batch on: decrease safety timer

3) programming: programming safety timer

indefinite if timer=0 timer disabled

Programming batch quantity

Visualization batched product

Input key code

Choose the formula number for associate

quantity batch (between 00 and 15)

Input quantity product for each batch

Input product name for batch (max 8 characters.)

Input maximum time for batch

If timer = 0, safety timer disabled max time set

= 6000 sec.

N.B. if to one output is assigned the function of

batch alarm, to the attainment of the maximum

time, beyond to the interruption of the batch,

will have activated also the alarm output

From the visualization pages

ENABLE BATCH

Enable one of the following functions to enable and program the batch on the converter:

q POS. 5.7-8-9: START/STOP batch from input

q POS. 6.1-2-3-4: assign one of the functions to one of two output

Some examples of operation of such functions are visualized from page 14

Page 34

HML4-F1

34

START STOP BATCH

START: it is possible activate the start of batch in two different way:

1. from remote input: assigning the

functions of start/stop batch to the input 1 (POS.

5.7) or input 2-3 (POS. 5.8-9) and using the input/s like visualized from page 14.

2. from keyboard: pressing of the key

N.B.:

the start of batch from keyboard is always on the descent front (release of the

key) and is not available with the function of batch consent (POS. 9.7)

STOP: the stop of batch can be due to three events:

1. keyboard or remote input (manual stop): pressing of the key

2. end of batch:

in this case the stop of batch will have activated from a output signal to

the attainment of the batch quantity

3. maximum time of batch:

if a maximum batch time has been set and this is exceeded,

the batch in progress is stopped independently from the batched quantity

Notes:

q

during the batch the symbol of the active batch

and the name of the

formula are visualized on video.

q When the batch outputs are enable, pushing the key , the outputs will remai

n

energized till the key is released. On the display, in place of the CT and ST totalises the

following messages will appear:

!! VALVE !!

!! OPENED !!

IMPORTANT NOTES

Cross of relation between functions assigned to the input and automatic settin

gs of IN/OUT:

THEN

IF

POS 9.5

POS 9.6

POS 5.4 POS 9.1

POS

3.6-

5.6

POS 5.5

POS 5.7

POS 5.8

POS

5.9

AUTO BATCH

BM AUTO SEL

COUNT LOCK

N. SAMPLES

AUTO RANGE

CHANGE OR FROM

INPUT

CALIBRATION

INPUT 1

(BATCH)

INPUT 2

INPUT 3

POS 9.5

AUTO BATCH

*DISABLE

POS 9.6 BM AUTO SEL ** DISABLE

POS 9.7

CONS. MODE

DISABLE

DISABLE

* DISABLE

POS 5.7 INPUT 1 ON BATCH

DISABLE

DISABLE

POS 5.8

INPUT 2 ON BATCH

DISABLE

DISABLE

DISABLE

POS 5.9

INPUT 3 ON BATCH

DISABLE

DISABLE DISABLE

DISABLE

POS 6.1-2-3-4

OUTPUT 1-2-3-

4 ON BATCH

FUNCTIONS

DISABLE

DISABLE

DISABLE

POS 6.3-4

OUTPUT 3-4 ON ANY

FUNCTION

DISABLE

DISABLE

POS 5.8-9

INPUT 2-3 ON BM SELECT

DISABLE

** DISABLE

* IF IMPUT 1 USED

** SET VALUE TO ZERO

To

optimize the performances of the meter used as a batch instrument (batch time < 5s), it is

recommended to set it as prompt as possible according to the plant requirements, choosing the

batching setup for the automatic parameter optimization of the quick start menu. It is also

reccomended to disactivate the function 3.3, AC line filter.

Page 35

HML4-F1

35

CODES

ANOMALIE DESCRIPTIONS

ACTION TO TAKE

0001

problem with watch-dog circuit

ADDRESS TO SERVICE

0002

wrong configuration work data in eeprom

0004

wrong configuration safety data in eeprom

0008

defective eeprom

0010

defective keyboard (one or more key are pushed during the test)

0020

Power supply voltage (+3.3) is out of range

0040

Power supply voltage (+13) is too low (<10V)

0080

Power supply voltage (+13) it’s too high (>14V)

0200

timeout calibration input (input circuit is broken)

0400 Input stage gaining is out of range

Check the status of the cables connecting the sensor to

the converter, the grounding connections of the devices

or the possible presence of strong and anomalous noise

sources

0800 Interruption on the coils circuit

Check the status of the cables connecting the sensor to

the converter

0C00 Cumulative alarm 0800 + 0400

see single code

ALARMS

Messages ANOMALIES ACTION TO TAKE

NO ALARMS

All works regularly

-----

MAX ALARM

The flow rate is higher than the maximum threshold set

Check the maximum flow rate threshold set and the

process conditions

MIN ALARM

The flow rate is lower than the minimum threshold set

Check the minimum flow rate threshold set and the

process conditions

FLOW RATE >FS

The flow rate is higher than the full scale value set on the

instrument

Check the full scale value set on the instrument and

the process conditions

PULSE/FREQ>FS

The pulse generation output of the device is saturated and cannot

generate the sufficient number of impulses

Set a bigger unit of volume or, if the connected

counting device allows it, reduce the pulse duration

value

EMPTY PIPE

The measuring pipe is empty or the detection system has not

been properly calibrated

Check whether the pipe is empty or perform again

the empty pipe calibration procedure

BATCH ALARM

Batch interrupted for the followings

condition:

q Timer batch expired before the end of the

batch

q Batch valve open and flow rate to zero for a

time longer to the safety timer set

q

batch valve closed and flow rate different from

zero for a time longer to the safety timer set

Verify:

q presetting

q system condition

INPUT NOISY

The measure is strongly effected by external noise or the cable

connected the converter to the sensor is broken

Check the status of the cables connecting the sensor,

the grounding connections of the devices or the

possible presence of noise sources

EXCITATION FAIL

The coils or the cable connecting the sensor are interrupted

Check the connecting cables to the sensor

CURR. LOOP

OPEN

The 0/4...20mA output on board or the optional one are not

correctly closed on a valid load

Verify the load is applied to the output (max 1000

ohm).

To disable the alarm,set the “mA VAL.FAULT” value (

menu alarm ) to 0.

P.SUPPLY FAIL

Power supply different from that suitable in the label.

Verify that the power supply is that suitable on label

Causes and actions to be taken

Anomalies codes

Page 36

Page 37

Page 38

Page 39

CONFORMITY DECLARATION

it declares under the own responsibility that the product:

Converter model:

HML 110

Sensors model:

HMS 501 – HMS 600 – HMS 1000 – HMS 2410 – HMS 2500 – HMS 377

0

– HMS 3800 – HMS 5000

to which this declaration refers, is in compliance with the following

Harmonized

European Norms:

§ EN 61010-1:2010

§ EN 61326-1:2006

and therefore answering to essential requirement of CE directives:

§ 2006/95/CE (Low voltage directive – LVD)

§ 2004/108/CE (Electromagnetic compatibility Directive – EMC)

04/03/2011

Page 40

Liqui d c onT roL S

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

Liqui d c onT roL S e uro pe/ SAm pi

Via Amerigo Vespucci 1

55011 Altopascio (Lucca), Italy

+39 0583 24751

ideX FLu id And me Ter ing pv T. LTd.

Survey No. 256, Alindra

Savli GIDC, Manjusar

Dist. Vadodara 391 770

Gujarat, India

+91 265 2631855

Liqui d c onT roL S S pon SLe r

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

TopTe ch SySTe mS

1124 Florida Central Parkway

Longwood, FL 32750

(407) 332-1774

Nateus Business Park

Nieuwe Weg 1-Haven 1053

B-2070 Zwijndrecht (Antwerp), Belguim

+32 (0)3 250 60 60

FAu re her mAn

Route de Bonnetable

B.P. 20154

72406 La Ferté-Bernard Cedex, France

+33 (0)2 43 60 28 60

6961 Brookhollow West Drive

Houston, TX 77040

(713) 623-0808

corke n

3805 Northwest 36th St.

Oklahoma City, OK 73112

(405) 946-5576

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2012 Liquid Controls

Pub. No. 502062

(6/12)

Loading...

Loading...