Page 1

HML110 Converter

LCMag Electromagnetic Flowmeters

Installation &

Operation

Release number: 110_EN_LC_5_3_6X

The last three digits of le name identify the software version which the manual refers to;

it is visualized at the instrument start up, or by specic function on DIAGNOSTIC menu.

Liquid ControLs Group

An IDEX Fluid & Metering Business

IEM200-11

Page 2

HML 110

CONTENTS

INTRODUCTION ............................................................................................ 3

SYMBOLS USED IN THIS MANUAL .................................................................. 3

TECHNICAL CHARACTERISTICS....................................................................... 4

INPUT/OUTPUT ISOLATION ............................................................................ 4

ENVIRONMENTAL COND ITIONS OF USE .......................................................... 4

OPERATING TEMPERATURE ............................................................................ 4

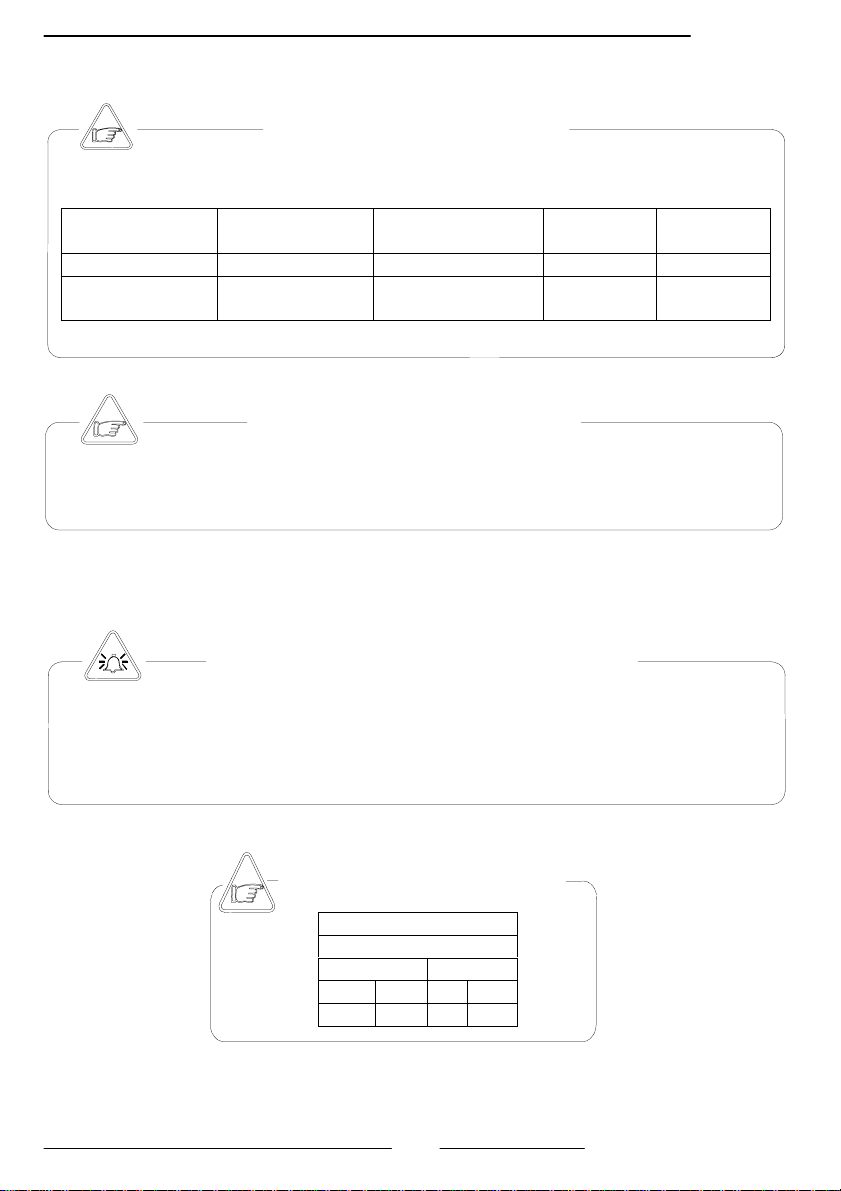

DIMENSIONS ( HOUSING IN NYLON ).............................................................. 5

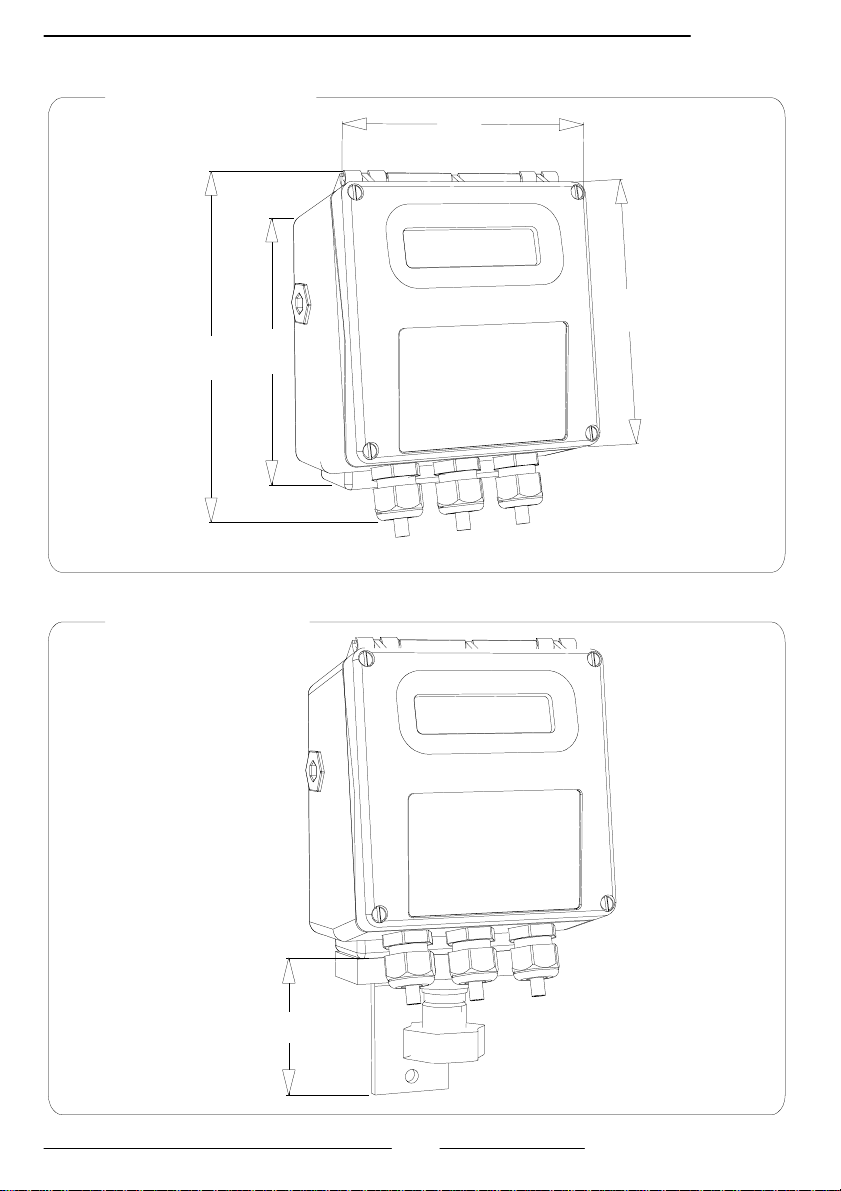

DIMENSIONS ( HOUSING IN ALUMINUM ) ....................................................... 6

ELECTRICAL CONNECTIONS............................................................................ 7

GROUNDING INSTRUCT IONS .......................................................................... 7

CONVERTER POWER SUPPLY........................................................................... 7

INTERNAL VIEW OF CONVERTER .................................................................... 8

CONVERTER TO SENSOR E LECTRICAL CONNECTIONS...................................... 8

DIGITAL INPUT ............................................................................................ 10

OPERATION ON INPUT ON/OFF.................................................................... 10

OUTPUTS WIRING ........................................................................................ 11

DISPLAY FLAGS AND LED WARNING INTERPRETATION.................................. 12

ACCESS TO THE CONVERTER KEYPAD........................................................... 13

ACCESSING THE CONVERT FUNCTIONS AT START- UP (Powe r On).................. 14

Example of visualized display pages at start-up............................................... 14

FLOW RATE VISUALIZATION......................................................................... 15

CONVERTER FUNCTION SETTING ACCESS CODES.......................................... 16

ACCESS TO THE CONFIGURATION MENUES................................................... 16

EXAMPLE: “Quick start menu” function modification. Full scale value 1 (Fs1) from

4dm³/s to 5dm³/s......................................................................................... 17

EXAMPLE: “Main menu” function modification. Full scale value 1 (Fs1) from 4dm³/s

to 5dm³/s. (Quick start menu enabled) .......................................................... 18

MAIN MENU GROUPS AND FUNCTION DESCRIPTIO NS .................................... 19

MAIN MENU FUNCTION PRGRAMMING .......................................................... 22

ALARM MESSAGES, CAUSES AND CORRECTIVE ACTIONS................................. 28

ANOMOLY CODES......................................................................................... 28

2

110_EN_LC_5_3_6X.doc

Page 3

INTRODUCTION

A

K

This manual is an integral part of the product. Read carefully the instructions contained,

they give important indications for it’s safe use and maintenance. Technical information

and related products in this manual may undergo modifications without prior notice.

The flow meter must be used within the specified limits. The improper use, possible

tampering, or substitutions of one or any of the original components renders the

manufacturers warranty void with immediate effect. The manufacturer accepts

responsibility only if the instrument it’s used within the published or prior agreed

specification.

Reproduction of this manual and any software supplied with this

converter is strictly forbidden.

SYMBOLS USED IN THIS MANUAL

TTENTION

DANGER ELECTRIC SHOC

WARNING

PRECAUTIONS

HML 110

3

110_EN_LC_5_3_6X.doc

Page 4

g

)

TECHNICAL CHARACTERIST ICS

ELECTRIC CHARACTERISTICS

Classification of the converter: class I, IP 65, category of installation II

Power supply

versions

HV 90-265 Vac 44 - 66 Hz 3W/5VA 35 mA

LV

Power supply

voltage

12-60 Vdc

18-45 Vac

INPUT/OUTPUT ISOLATION

Input/output insulated up to 500V

The output 4-20 mA and output 24 Vdc are electrically connected

The converter can be installed internally or externally with in the following specification

Altitude: from –200 to 6000 m (from -656 to 19685 feet)

Humidity range: 0 - 98%

Line volta

ENVIRONMENTAL CONDITIONS OF USE

e range: (see table of Electrical Characteristics above

OPERATING TEMPERATURE

Ambient Temp.

Min. Max

°C °F °C °F

-10* -14* 50 122

* In situations of discontinuous use in cold ambient temperatures, the

installation of an additional heat source may be necessary.

Power supply

frequency

Pmax

0 - 44 - 66 Hz 3W/5VA 300 mA

CONVERTER

current

max

HML 110

4

110_EN_LC_5_3_6X.doc

Page 5

HML 110

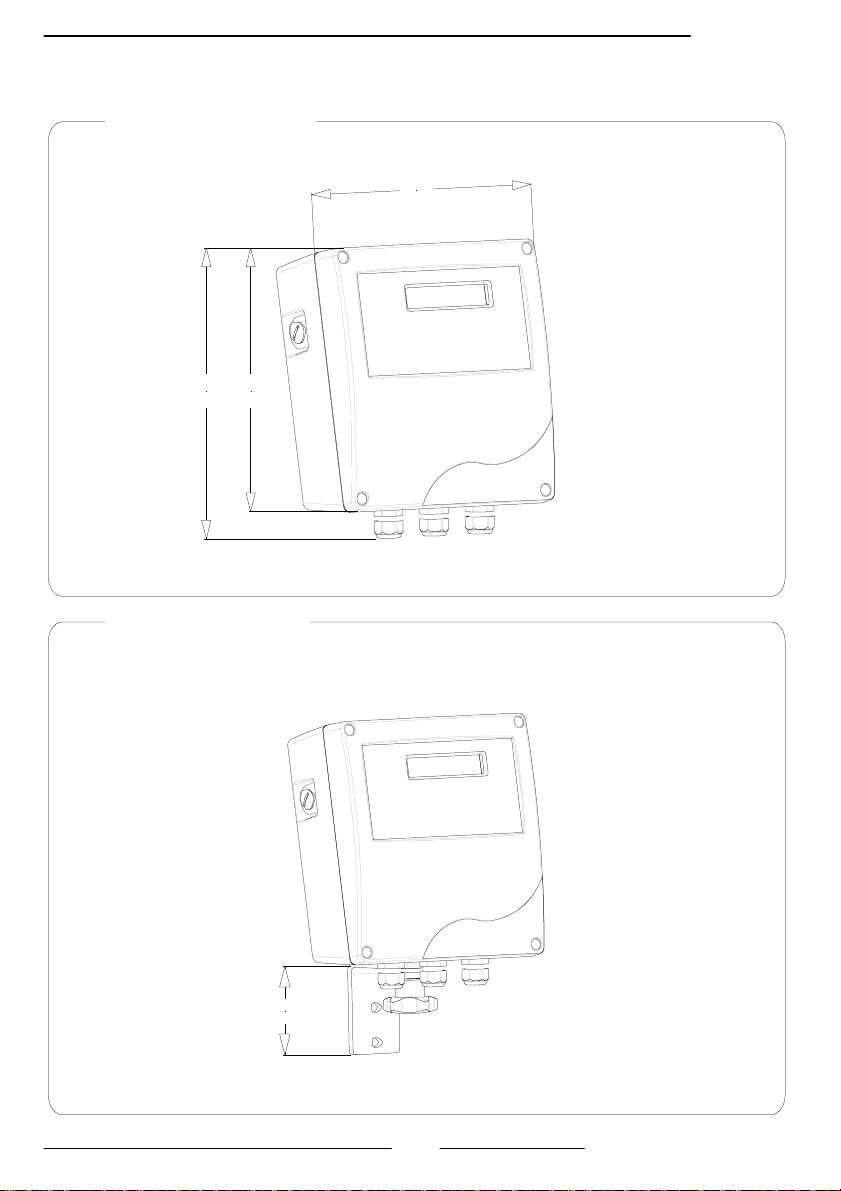

DIMENSIONS ( HOUSING IN NYLON )

COMPACT VERSION

168

SEPARATE VERSION

129

78

1

2

7

4

2

1

5

110_EN_LC_5_3_6X.doc

Page 6

HML 110

DIMENSIONS ( HOUSING IN ALUMINUM )

COMPACT VERSION

0

6

1

193

169

SEPARATE VERSION

78

6

110_EN_LC_5_3_6X.doc

Page 7

ELECTRICAL CONNECTIONS

GROUNDING INSTRUCTIONS

ALWAYS ensure that the Converter and the Sensor are grounded (earthed) correctly.

The grounding of t he sensor and converter ensures th at the equipment and liquid are

equipotential.

CONVERTER POWER SUPPLY

L

(-)

N

(+)

Before connecting the power supply, verify that the

mains voltage falls between the limits indicated on

the tag plate.

ATTENTION: Converters on a dc power supply line

are not protected against the inversions of p o larity.

When wiring the converter and sensor equipme nt use

only approved conductors, with fire- proof p r op erties.

The power supply line must be equipped with an

external protection for current overload (fuse or

automatic line breaker, limiting current to less than

10 A).

Provide in close proximity to the converter a circuit

breaker that must be easily accessible to the operator

and clearly identified.

NOTE: For characteristics of the converter’s power

supply, see page 4

The sensor, hardwired inputs and outputs are connected to the converter

through a terminal block locate inside the converter.

To locate the terminal block loosen the 4 screws on the front cover. Lift the

front panel. With the front cover lifted, the terminal block is visible. The

terminal block is the hardwire connection of the converter to external

equipment, including the sensor.

The following pages give information on the terminal block numbering, and the

respective connecting of the senor cables, and input/outputs.

HML 110

7

110_EN_LC_5_3_6X.doc

Page 8

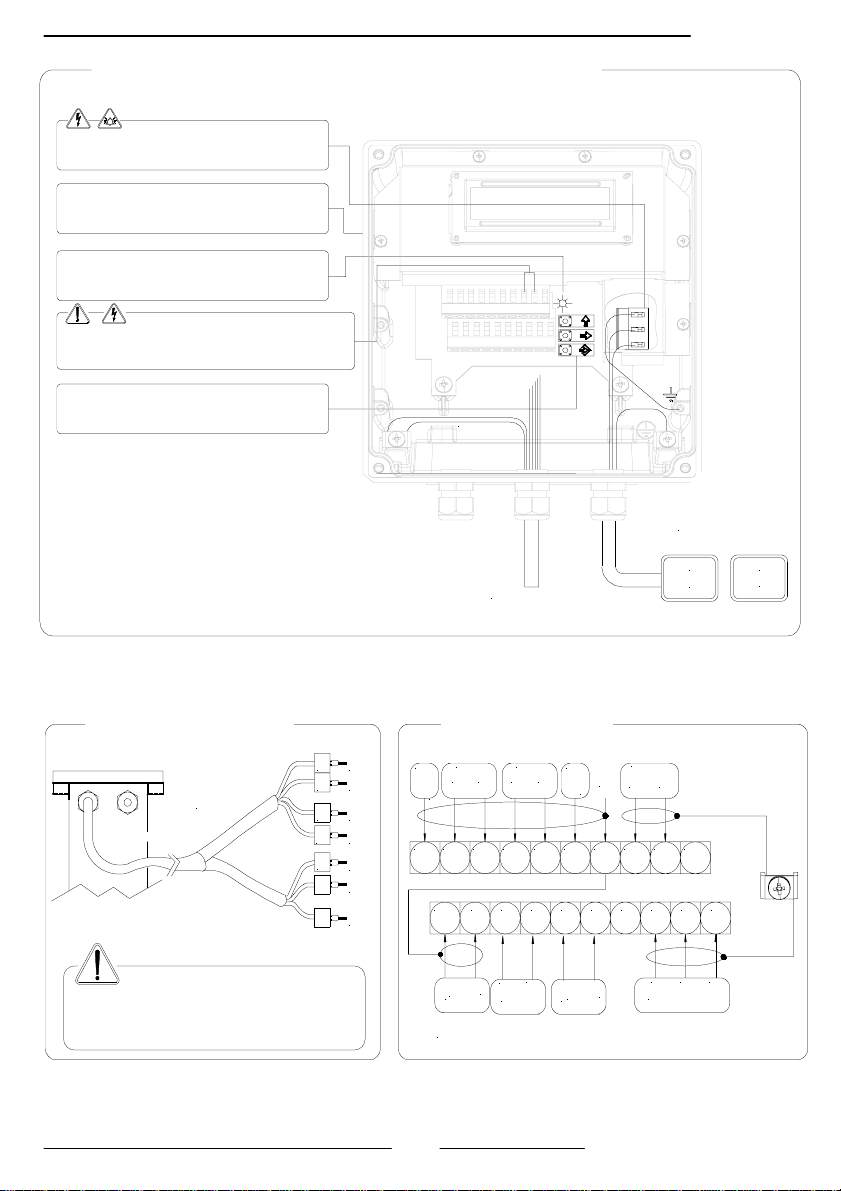

INTERNAL VIEW OF CONVERTER

Power supply

IF2 socket

Signalling LED:

See interpretation notes page 12

Dangerous voltage on block 12-13:

- 60 Vdc Max

- 250 V Max on commutation coils (switching )

Keyboard

CONVERTER TO SENSOR ELECTRICAL CONNECTIONS

SEPARATE VERSION

C018 CABLE

1

2

3

4

11

12

13

E1

E2

C

SH

B1

B2

Sudden movements to the electrodes

cable can cause noise during

measurement Max length of

electrodes cable: 20 m

11 12 13 14 15 16 17 18 19 20

TERMINAL BLOCK

OUT2

24V

-

E C

E C

10

-

+

A

4-20mA

RS 485* : OPTIONAL

RS 485* INPUT

12345678910

OUT1

B

24V

-

+

Power supply

>HV<

90..265VAC

SC

B2

+

SC

HML 110

>LV<

15...45VAC

10...63VDC

COILS

SC

B1

11121314151617181920

C

E2

ELECTRODES

123456789

E1

8

110_EN_LC_5_3_6X.doc

Page 9

R

INTERNAL VIEW OF THE ALUMINUM CONVERTE

Power supply

IF2 socket

Signalling LED:

See interpretation notes page 10

Dangerous voltage on block 12-13:

- 60 Vdc Max

- 250 V Max on commutation coils (switching )

Keyboard

Shield

C018 cable

ALUMINIUM CONVERTER TO SENSOR, ELECTRICAL CONNECTIONS

SEPARATE VERSION TERMINAL BLOCK M1

1

C018 CABLE

2

3

S

S

12

13

E1

E2

C

SH

SH

B1

B2

24V

-

10

OUT2

E

OUT1

24V

+

E

C

C

SC

Sudden movements to the

electrodes cable can cause noise during

measurement Max length of

electrodes cable: 20 m

-

+

A

4-20mA

RS 485* INPUT

RS 485* : OPTIONAL

-

B

+

>HV<

90..265VAC

COILS

B1

B2

C

ELECTRODES

HML 110

Power supply

>LV<

15...45VAC

10...63VDC

11121314151617181920

123456789

E1

E2

9

110_EN_LC_5_3_6X.doc

Page 10

DIGITAL INPUT

A

External power supply Internal power supply

10 K

5 (+)

3/40 Vdc (ON)

0/1,5 Vdc (OFF)

6 (-)

10 K

+24

15

5

6

0

20

OPERATION ON INPUT ON/OFF

uto-calibration

AUTOCALIB. OFF

3-40 V

Tmin<T<1sec. = autocalibr ation

T > 1 sec. = Auto zero

Necessary conditions for enabling the function

POS. 5.7 ENABLED (Autozero calibration external command)

0-1,5 V

T

Reset totalizes

3-40 V

0-1,5 V

BLOCK

T

RESET

Tmin = 100ms

Necessary conditions f or en abling the function

POS. 5.1 to 5.4 ENABLED (partial positive or reverse

flow totalise reset enable).

Block totalizes

Block totalizes

3-40 V

Necessary conditions f or en abling the function

POS. 5.6 ENABLED (totalise counting lock command)

0-1,5 V

Totalizers active

Range change

3-40 V

Scale 2

0-1,5 V

Scale 1

Necessary conditions f or en abling the function

POS. 5.8 ENABLED (range change)

SAMPLE RAT E

10 Hz

20 Hz

50 Hz

Tmin

220 ms

110 ms

45 ms

SAMPLE RATE

80 Hz

150 Hz

Tmin

30 ms

T must be > to Tmin

15 ms

HML 110

10

110_EN_LC_5_3_6X.doc

Page 11

A

OUTPUTS WIRING

Output on/off 1250

16 (out1)

18 (out2)

43V

17 (out1)

19 (out2)

Output 0/4-20mA

+24V INTERNAL

m

I

9 (+)

0/4..20mA OUT

10 (-)

24V COMMON

There is a Converter load CHECK on the 4 - 20mA output; to disable this

function set the value "mA Val. Fault" to 0 (Pos. 4.5, see page 15)

CONVERTER START UP AND MAINTENANCE INSTRUCTIONS

Before starting up the equipment please verify the following:

Power supply voltage must correspond to that speci f ied on the data plate

Electric connections must be completed as described at page 7-8

Ground (earthed) connections must be comp leted as specified on page 7

Verify periodically:

The integrity of the pow er supply cables, w iring and other con nected electrical

parts

The integrity of the converter’s housing (this must not have dents or other

damage that may compromises it’s hermetical sealing)

The tightening of the sealing elements (cable glands, covers, etc.)

The integrity of the front panel (display and keyboard), any damage may

compromise the equipment sealing

The mechanical fixing of the converter to the pipe or wall stand

11

HML 110

Opto-insulated output with floating collector and

emitter terminals freely connectable

Maximum switching v o lt age: 40 Vdc

Maximum switching current : 100m A

Maximum saturation voltage between collector and

emitter @100mA: 1,2V

Maximum switching frequency (load on the

collector or emitter, RL=470Ω, VOUT=24Vdc):

1250Hz

Maximum reverse current bearable on the input

during and accidental polarity reversion (VEC):

100mA

Insulation from other secondary circu it s: 500 Vdc

Opto-insulated output

Maximum load: 1000 ohm

Maximum voltage without load: 27 Vdc

Refresh frequency is the same of the sample

frequency of the connected sensor

Protected against persistent over voltages to

maximum 30 Vdc

110_EN_LC_5_3_6X.doc

Page 12

HML 110

DISPLAY FLAGS AND LED WARNING INTERPRETATION

At ‘Power on’ of the converter, the user will see the following display screen. In the top right

hand corner there may be a range of symbols. The symbols can be interpreted from the table

below. Interpretation of the flashing LED can be made from the LED Interpretation table at the

bottom of this page

FLAGS

FLAG INTERPRETATION

FLAG DESCRIPTION

M Alarm max activated

m Alarm min activated

C Calibration running

S Simulation

- Interruption coils circuit

!

- Segnal error

- Empty pipe

Pulse output saturation (reduce

TIME PULSE )

LED

PERMANENT LIGHT: initialisation

FLASHING LIGHT ( 1 sec.): normal function

FLASHING LIGHT (<1 SEC.): alarm on

The LED signals the alarm status only if the display shows one of the

suitable visualisation screens as shown on page 14

LED INTERPRETATION

12

110_EN_LC_5_3_6X.doc

Page 13

HML 110

ACCESS TO THE CONVERTER KEYPAD

M3

KEYBOARD

The keypad is accessible by loosening the 4 cover screws,

and opening the front cover of the converter. Three KEYS

are set aside of the M1 terminal block allowing the user to

change screen display visualizations and select functions.

Key pad function

SHORT PRESSING (< 1 SECOND):

Increases the numeric figure or the parameter selected by the cursor

Accesses the previous subject when in the Quick start or Main menus

Batch start/stop (when enabled)

LONG PRESSING (> 1 SECOND):

Decreases the numeric figure or the parameter selected by the cursor

Accesses the next subject in the Quick start or Main menus

SHORT PRESSING (< 1 SECOND):

Moves the cursor rightwards on the input field

Accesses to the following subject in the Quick start or Main menus

Changes the display of the process data

LONG PRESSING (> 1 SECOND):

Moves the cursor leftwards on the input field

Accesses the previous subject in the Quick start or Main menus

SHORT PRESSING (< 1 SECOND):

Enters/leaves the selected function

Enables the main menu for the converter configuration

Cancels the selected function under progress

LONG PRESSING (> 1 SECOND):

Leaves the current function, in the Quick start or Main menus.

Enables the ‘EXECUTE?’ prompt in the Main menu functions, and total reset

request (when enabled) from the required function

Confirms the selected function

Blind converters

For converters without a keyboard (blind version),

functions are programmed utilizing the IF2 device:

13

110_EN_LC_5_3_6X.doc

Page 14

A

A

A

A

y

HML 110

ACCESSING THE CONVERT FUNCTIONS AT START-UP (Power On)

Example of visualized display pages at start-up

ctive scale

larm on

Flow rate visualization

The direct exposure of the converter to the solar rays, could damage

the liquid crystals display.

Note: The user will see the

screen displayed (left) at

power on of the converter.

Use the keys on the keypad

as indicated centrally on

this page to move

between the screens

shown (not all shown).

* Direct/Reverse totalizer

visualization

lternate visualization

Push keypad button

indicated to move

between pages

CURRENCY FUNTION ENABLE

* Direct totalizer

Reverse totalizer

Currency value

If the user dwells on this screen the converter

will automatically scr oll through the rest o f the

initial visualizatio n pages. If the user presses t h e

lower key on the keypad they will access the

Quick start menu . Pressing the middle key will

move to the next initial visu alization screen.

Flow rate visualization Flow rate visualization

Push keypad button

indicated to move

between pages

* Direct Reverse totalizer Flow speed

larm description

Push keypad button

indicated to view the

Flow rate Alarm

Sampling frequenc

* The maximum number shown on the totalizer is 999999999 regardless of the number of user selected

decimals (see page 19 Pos 2.3) . Beyond this value the totalizers are reset to zero.

Note: if the converter is not connected to the

sensor then an ‘Excitation Fail’ will be shown

14

110_EN_LC_5_3_6X.doc

Page 15

FLOW RATE VISUALIZATION

The ML110 allow showing 5 digit character display for flow rate units. This mean

the maximum flow rate value that can be represent on the display i s 19999* (no

matter the positioning of the decimal point ) and the minimum is 0.025.

The converter’s calculation are based on the following formula :

- DN x DN x 0,008

The results of above calc ulat io n give th e m aximum f low rat e at 10 m/s of speed

according to sensor’s diameter; the permitted units for the display are the unit

measure that, in reference to this calculated value, do not exceed the number

19999 ( higher limit ) and 0,25 ( lower limit )

Example for DN 100 :

- Full scale value : 100 x 100 x 0,008 = 80 l/s

- PERMITTED unit of measure ( example ) : l/s ( 80.00 ) ; mc/h ( 288.0 ) …

- NOT PERMITTED unit of measure ( example ) : cm3/s ( 0,08 ) ….

The not permitted example has a unit of measure greater than 5 character digits in

length including the ‘/’, cm3/s.

HML 110

15

110_EN_LC_5_3_6X.doc

Page 16

CONVERTER FUNCTION SETTING ACCESS CODES

Factory preset access

The converter is delivered with the default

L2 (level 2) access code. The code if

required for accessing ‘Main menu’

functions from the ‘Quick start menu’.

11111

The first level configuration "Quick start

menu" can be automatically a cces sed with

out the access code by pressing the key

from one of the visualization pages at start

up (power on) of the converter. See page

14 to see the screens from which the Quick

start menu can be accessed

User defined acces s codes

Functions in the converter’s ‘Main menu’ are

enabled by the a ccess codes. The

information of this manual is related to all the

functions available with in the L2 level. All

higher level functions are reserved for

servicing and not available.

Description of the L2 access code

(menu “11 Internal data” pos. 11.1, see page

21)

with code L2 = 00000 (with this code

only) you can disable the request of code

L2

*with L2 customized (freely chosen by

the user) you can program all the

functions up to L2 security level, entering

this code whenever you enter the Main

menu.

*ATTENTION: take careful note of the

customized code you have ch osen, t here is no

way for the user to retrieve or reset it if lost.

ACCESS TO THE CONFIGURATION MENUES

The converter’s configuration menus can be acce ssed in two different modes:

Through the “Quick start menu” it is possible to access directly a

range of principal functions for setting the scale reading and display

characteristics of the sensor (see function explanations pages 18-19)

Through the “Main menu” it is possible to access functions with an

access code ≤ 2, which control more of the sensor’s monitoring, data

processing and output, as well further disp lay options.

The following example (page 17) illustrates how to change some of the values

in the Fs1 display field of the Quick Start menu. The second example (page 18)

illustrates how to change a function parameter in the ‘Main menu’.

HML 110

16

110_EN_LC_5_3_6X.doc

Page 17

HML 110

EXAMPLE: “Quick start menu” function modification. Full scale value 1 (Fs1)

from 4dm³/s to 5dm³/s.

Enter in the “Quick start menu”

The keypad button to be pressed at

each step is indicated by the icon

symbol place on one of the three

keys of the keypad (here lower key)

Access the function “Fs1” by

pressing the button indicated for less

than 1 second

Push the key repeatedly and rapidly

to move the cursor to the value to

modify

To increase the value press

the upper key for short

periods of less than 1 second,

to reduce the value press t h e

upper key for more than 1

second repeatedly

Confirm the new value with a

short press of the key (less

than 1 second)

Long push to leave the quick

start menu and return to the

initial visualizati on page

Initial visualizat io n page

17

110_EN_LC_5_3_6X.doc

Page 18

HML 110

EXAMPLE: “Main menu” function modification. Full scale value 1 (Fs1) from

4dm³/s to 5dm³/s. (Quick start menu enabled)

Enter in the “Quick start menu”

From any of the start-up

(power on) screens

Press the button indicated

to enter the Main menu

page screen from the Quick

menu page

Access to the “Main Menu”

by pressing the key

indicated

To enter the main menu

input the key code (11111

as default) by increasing

the ‘0’ to ‘1’ and moving to

the next ‘0’ until the key

code is entered

To enter the key code press

the lower key

To move between main

menu function groups press

the arrow key indicated

Access the “Scale” menu

with a short key press.

Access the function “Fs1”

with a short key press

Move between the

modifiable options by short

pressing the key indicated

on the key pad

Change the value by pushing

the button rapidly as many

times as required

Confirm the new value with

a short press of the key

indicated on the keypad

Long push to return to

the main menu groups

Initialization page

Long push to return to

the initialization pag es

18

110_EN_LC_5_3_6X.doc

Page 19

HML 110

MAIN MENU GROUPS AND FUNCTION DESCRIPTIONS.

The main menu is selected from the Quick Start Menu by pressing the key) and entering the factory

code(11111). Functions denoted in grey are displayed only with other acti ve functions, or with optional

modules.

displayed on the converter are shown below are reserved for serving purposes only and not configurable.

(for details of the func tions with the symbol “*” refer to pages 22-27) .

Not all the functions

1.1 Nominal Diameter (ND) of sensor, (enter input value 0-3000 mm )

1.2 Sensor calibration data (En ter value as specified on sensor label)

1.3 Type of sensor: Enter the first two characters of the sensor serial number

1.4 Position of insertion sensor: 0=1/8DN, 1=1/2DN, 2=7/8DN

1.5 Factory parameters

1.6 Enables the empty pipe detection featu re

1.7 Value of empty pipe sensibility detection

1.8 Enables the automatic calibration procedure of zero calibration

2.1* Full scale value set for range N.1 (function info & modification pa ge 22)

2.2* Full scale value set for range N.2

2.3* Unit of measure and number of decimal place (Info & modification page 23)

2.4* Pulse value on channel 1 (Function Info & modification page 23)

2.5* Pulse value on channel 2 (Function Info & modification page 23)

2.6* Duration of the pulse generated on channe l 1 (Info & mo di fic ation page 23)

2.7* Duration of the pulse generated on channel 2 (Info & modification page 23)

2.8 Full scale frequency for channel 1 (0.1Hz-1000.0H z)

2.9 Full scale frequency for channel 2 (0.1Hz-1000.0H z)

3.1* Time constant (function info & modification page 23)

3.2* Acceleration threshold (function info & modification page 23)

3.3* Anomalous signal peak cut off threshold (Info & modification page 24)

3.4 Low flow zero threshold: 0-25% of full scale value

3.5 Filter on the power supply: 0.1s="ready" measure; 0.5s=filter of noise on the liquid

3.6 Enable automatic hourly internal calibration cycle. Measurement stopped for 8-15s.

3.7* Automatic change of scale (function info & modification page 24)

3.8* Energy saving function (function info & modification page 24)

4.1 Maximum flow rate value alarm setting

4.2 Minimum flow rate value alarm setting

4.3 Hysteresis threshold setting for the minimum and maximum flow rate alarms

4.4 Empty pipe detection threshold. Automatically set by the function 1.9

4.5*Current output value in case of failure (function info & modification page 24)

4.6* Frequency output value in case of failure (function info & modification page 25)

19

110_EN_LC_5_3_6X.doc

Page 20

HML 110

5.1* Total direct (positive) flow totalise reset enable

5.2* Partial direct (positive) flow totalise reset enable

5.3* Total reverse (negative) flow totalise reset enable

5.4* Partial reverse (negative) flow totalise reset enable

5.6 Totalise counting lock command (see page 10)

5.7* Autozero calibration external command

5.9 Range change external command

6.1* Output 1 functions (function info & modification page 25)

6.2* Output 2 functions (function info & modification page 25)

6.3* Duty cycle value for pulses/frequency output (Info & modification page 26)

6.4* Choice of function the range of current output n.1 (Info & modification page 26)

7.1 Choice of the communication protocol for the IF2 device

7.2 Address value of converter (range 0 - 255)

7.3 Speed of the RS485 output (possible choices: 2400, 9600, 19200, 38400 bps)

7.4 *********************

8.1 Choice of the language: EN= English, IT=Italian, FR= French, SP= Spanish

8.2 Display update frequency: 1-2-5-10 Hz

8.3 Display contrast

8.4 Quick start menu visualization

8.5* Enable the change value of the totalises (info & modification page 27)

8.6 Enable the page of net totalizer

8.7* Total direct (positive) flow totalise reset (info & modification page 27)

8.8* Partial direct (positive) flow totalise reset (info & modification page 27)

8.9* Total reverse (negative) flow totalise reset (info & modifi cation page 27)

8.10*Partial reverse (negative) flow totalise res et (in fo & modifi cat ion page 27)

8.11 Visualizes the values of the partial totalise in the unit of selected cu rrency

8.12 Choice of the numbers of decimals for the visualization currency value: From 0 to 3

8.13*Value of conversion/currency for direct totalizer (info & modification page 27)

8.14*Value of conversion/currency for reverse totalizer (info & modificati on page 27)

20

110_EN_LC_5_3_6X.doc

Page 21

HML 110

10.1* Calibration of the converter (single occurrence each time function is selected)

10.2* Converter auto test (single occurrence each time function is selected)

10.3* Flow rate simulation enabling

11.1 Level 2 access code enter (user choice and setting of access code if required)

11.2 Load factory data pre-set

11.3 Load user data saved

11.4 Save user data

11.5 Visualisation of the total operation hours of the converte r ( func ti on no t ed it abl e)

11.6 Ignore the calibration error during th e switch on test (ena bl e/di sable)

11.7 KS Coefficient

21

110_EN_LC_5_3_6X.doc

Page 22

R

HML 110

MAIN MENU FUNCTION PRGRAMMING

(description of the functions with access code< 3)

MENU 1 - SENSO

(POS. 1) Nominal diameter of sensor [ND= XXXX]

The following pages give a description of the most important functions and how they can be changed or

enabled/disabled by the user.

MENU 1 - SENSOR

(POS. 1.7) “Autozero” calibration [Autozero cal.]

This function allow to zeroing the meter . To perform the zero calibration, it is necessary for t he

sensor to be full of liquid, and the liquid be perfectly still.

Even very small movement of the liquid may affect the result, and, c onsequently, the acc uracy of the

system.

Once you are sure the above conditions have been fulfilled (and the percentage flow rate value is

stable) press the key for one second or more. Check the percentage flow rate value goes to zero.

If this does not occur repeat the o peration again . When the value is stable at zero, then press the

key.

(POS. 1.7) “Empty pipe” threshold [E.P. thr.]

Value of empty pipe threshold detection. The span of this function is 0-255.

Since the sensibility of empty pipe detection could be change by the liquid conductivity, ground

connections, type of lining, in case of needed it’s possible to adjust manually the preset threshold.

It’s recommended to check periodically its proper functioning.

Increasing of value means decreasing the sensibility.

MENU 2 - SCALES

(POS. 2.1-2.2) Full scale N. 1-2 [Fs1-2=dm³/s X.XXXX]

The Full scale range N.1.-2 is the corresponding output signal (20mA) to the meters maximum flow

rate (max 10m/s). There are four fields to fill in order to set this parameter, from left to right: 1)

volume unit of measure, 2) type of unit, 3 ) time unit of measure and 4) numeric value. The select ion

is made by positioning the cursor on the field to modify. To change the type of unit of measure

(metric, British or American, mass or volume) the cursor has to be positioned on the symbol “/” ( field

N. 2). When the nominal diameter is set to zero it is possible to modify only the n umeric field, since

the unit of measure stays at m/sec.

The following tables show the units of measure available and the conversion factor by comparison

with 1 dm3 and 1 kg. The converter accepts any kind of combination of uni ts of measure satisfying

both the following conditions:

Numeric field value ≤ 9999

1

/25 fs

≤ numeric field value ≤ fs

max

max

.

where fsmax is the maximum full scale value corresponding to the sens or, equal to a 10 m/ sec liquid

speed. The units of measure are shown as appear on the display. The British and American units are

diversified by using capital and small characters.

Identification of the function (not visualized on display)

Converter request

Menu visualized on the convert er ( from 1 to 11)

Synthetic description of the function

22

110_EN_LC_5_3_6X.doc

Page 23

cm3 Cubic centimeter

Ml Milliliter

L Liter

dm3 Cubic decimeter

Dal Decalitre

Hl Hectolitre

m3 Cubic meter

in3 Cubic inch

Gal American gallon

GAL British gallon

ft3 Cubic foot

Bbl Standard barrel

BBL Oil barrel

yd3 Cubic yard

kgl KAmerican gallon

KGL KBritish gallon

Oz Ounce

Lb Pound

Ton Short tons

G Gram

Kg Kilogram

T Ton

When a mass unit of measure is set, the specific gravity function is automatica lly enabled by the

system. Please, note that the mass measure is heavily affected by the temperature. With certain

liquids this may cause significant measurement errors. The following measure of time units can be

selected: s = second, m = minute, h = hour, d = day.

(POS. 2.3) Unit of measure and number of decimal places [Tot.MU=dm³ X.XXX]

Setting the unit of measure and number of decimals places dis pla ye d for the vol umes. To se t the uni t

of measure, position the cursor on field of the unit of measure. To s et the type of unit, position the

cursor on the blank space between the unit of measure and the numeric value; The number of

decimal places can be selected by placing the cursor on numeric field and choosing one of the

possible combinations: 1000-01.00-001.0-00001.

(POS. 2.4-2.5) Pulse value channel 1-2 and unit of total measure. [Pls1-2=dm³ X.XXXXX]

Setting of a flow volume by which a corresponding pulse wil l be emitted on channel 1-2. (units mus t

be identical to ‘Full scale’(POS 2.1 and 8) and ‘Totalizer’ functions. To set the parameter, complete the

three fields, from left to right: 1) unit of measure , 2) unit type and 3) numeric value. The selection is

performed by positioning the cursor in the field to be modified. To change the unit type (metric,

British or American, mass or volume) position the cursor on the blank space betw een the measure

unit and the numeric value. When the nom inal diam eter is s e t to z ero it is pos sible to modify only the

numeric field since the measure unit stays a t meters(m) or feet(ft) . Only t hose units des cribed above

are available to be selected. This function is active only if the pulse emission on channel 1 is enabled.

(POS. 2.6-2.7) Pulse duration channel 1-2 [Tpls1-2=ms XXXX.XX]

Setting of the duration of the pulse generated on channel 1-2 as set in (POS 2.4-2.5). This value is

expressed in milliseconds and has to be between 0,4 and 9999,99. When the high frequency output is

present, then the minimum value can be set to a minimum of 0,04 milliseconds. ATTENTION: since

the converter cannot detect which type of device is connected to the converter, the user must verify

that the set pulse duration is compatible with the external device processing such pulses. If, for

example, an electro-mechanical pulse counter is c onnected, one of tw o problems may oc cur; firs t ly, i f

the pulse is too long the coils may burn out, secondly, if the pulse is too short, the c ounter may not

be able to function, with the possibility of causing damage of the output.

MENU 3 - MEASURE

(POS. 3.1) Time constant [Tconst=s XXXX.X]

This parameter affects the integrating filter, setting a quicker or s lower response time, according to

the value set. A higher value corresponds to a more stable but slower measure, a smaller gives and

faster measure but is more unstable. The most common values are f rom 1 to 5 sec onds. The value of

this parameter has to be within the range fr om 0 (integral filter disabled) to 6000.0 seconds. The

following diagram shows the response of the instrument for a flow rate variation from 0 to 100%

within the T time constant period.

(POS. 3.2) Acceleration threshold [Skip thr=% XXX]

Acceleration threshold set. The acceleration threshold is the lim it beyond which a flow rate variation

gives an immediate response at the output, withou t being filtered b y the time constant . This func tion

allows the converter to have an immediate response in cases of big flow rate variations, while filtering

(and delaying) the response to small variations, resulting in a very s table measure. The set valu e is a

percentage of the full scale value (from 0 to 125%). If such a value is set to zero any flow rate

variation bigger than 0.5% of the full scale value will immediately activate an output response. The

following graphs show the instrument response in two cases: Firstly, a flow rate variation from 0 to

10% completely absorbed by the time constant effect

HML 110

23

110_EN_LC_5_3_6X.doc

Page 24

HML 110

Secondly a variation form 10% to 100%, exceeding the acceleration threshold and then immedia tely

sent to the output. In reality there is always a minimum time between the measure acquisition and

the outputs update.

(POS. 3.3) Peak cut off threshold [Peak thr=% XXX]

Anomalous signal peak cut off threshold set. This parameter al lows for setti ng the maximum va lue of

deviation of the measured sample in comparison to the average. If a successive value is higher than

the set limit, than such a value is “cut” to the limiting value. This function is used to make the meter

less sensitive to big perturbations of the flow rate measure. This may happen when there are solids

suspended in the liquid in contact with the electrodes resulting in higher electrical noise. The

permitted values of this function range from 0 to 125 % in reference to the full scale value. I f this

parameter is set to zero the peak detection function is disabled and any subsequent measured sample

will be accepted and processed by the converter.

(POS. 3.7) Automatic scale change enable [Autorange=ON/OFF]

Enables/disables the automatic change of scale. The meter may have two different w orking ranges in

order to suit variable process conditions. In order to get the best results out of this function it is

important that range N.2 is greater than N.1. When the flow rate increases and reaches the 100% of

the scale N.1, the meter automatically switches to scale N.2. When the flow rate subsequently

decreases to an equivalent value on scale N.2 (equal to the 9 0% of full scale N.1), scale N.1 will

assume the active scale. Allowed values for this parameter: ON / OFF.

(POS. 3.8) Energy saving enable [E.saving=ON/OFF]

Automatic energy saving function enables. This funct ion is us ed whe n the instr ument is powered by a

battery or solar cells, allowing an energy saving up the 6 0-80%. The energy saving function contr ols

the powering cycles ratio of the coils while the measuring cycling remain unaffected. When the

energy saving function is enabled and the flow rate is stable the number of “off” cycles is greater

than the “on” cycles, reducing the average power consumption. If the flow rate suddenly changes,

the meter switches to a higher number of measuring cycles, achieving a higher respons e time. Once

the flow rate resumes stability the number of powering cycles is reduced. If the flow rate varies below

the “acceleration threshold” percentage value, th e meter assumes the “off” cycles. When the flow

rate exceeds such a threshold, the meter incr eases the measuring cycles. The speed at which the

meter will switch between the increased and reduced powering cycles are different. From a constant

to a variable flow rate is a very fast process, while from variable to a stable flow rate is much slower.

The allowed values for this parameter: ON/OFF. N.B.: to optimize this function, a value for the

acceleration threshold between 10 – 15 is recommended

MENU 4 - ALARMS

(POS. 4.5) Current output value in case of failure [mA v.fault =% XXX]

Setting of the value of the 0/4...20 mA current output in one or more of the following cas es; empty

pipe , ADC error, and coils interrupted.

The permitted range is from 0 to 120% of the 0 - 20 mA scales, 120% corresponds to 24 mA and

does not depend on the selected range (0…20 / 4…20 mA).

24

110_EN_LC_5_3_6X.doc

Page 25

The NAMUR NE43 recommendations requires alarms signaling value for a current output lower than

HML 110

3.6 mA (<18%) or greater than 21 mA (>105%). It is preferable to set the val ue of this function at

10%, so that the current value in cases of a.m. would be 2 mA, allowing the following diagnostics:

current < 2 mA - 5%: line interrupted, power supply failure or faulty converter;

2 mA -5% ≤ current ≤ 2 mA + 5%: hardware alarm;

4 mA ≤ current ≤ 20 mA: normal working range;

20 mA < current ≤ 22 mA: out of range, measure above 100% full scale (f.s.).

(POS. 4.6) Frequency output value in case of failure [Hz v.fault=% XXX]

To set the frequency value assigned to the on/off output in one or more of the following cases:

Empty pipe; Coils interrupted ; ADC error

Allowable range from 0 to 125% of the frequency full scale value.

Although there are no specific rules regulating cases such as these, i t would be c onvenien t to use t he

failure information as follows:

0% Hz ≤ frequency ≤ 100% f.s.: normal working range;

100% f.s. < frequency ≤ 110% f.s.: overflow, measure above the 100% of the f.s.;

115% f.s. ≤ frequency ≤ 125% f.s.: hardware alarm condition.

MENU 5. INPUT

( POS. 5.1-5.2-5.3-5.4) Enable reset partial/total totalizers [T+-/P+- reset= ON/OFF]

When this function is active, the totalizers may be reset applying a voltage on the on/off input or

from keyboard.

(POS.5.7) Autozero” calibration external command enable [Calibration=ON/OFF]

This function enables/disables the automatic z ero calibration system. When this function is active,

applying a voltage on the meter’s on/off input terminals performs an autozero calibration cycle.

ATTENTION: if the voltage pulse is less 1 sec., the meter performs an Auto calibration cycle to

compensate for possible thermal drifts. If the voltage pulse is more 1 sec, the meter performs a

Autozero calibration of measure.

MENU 6 - OUTPUTS

(POS. 6.1) Choice of the function corresponding to on/off output 1 [Out1=XXXXXX]

Function choice corresponding to digital Output 1. The functions are listed in the table below.

(POS. 6.2) Choice of the function corresponding to on/off output 2 [Out2=XXXXXX]

Function choice corresponding to digital Output 2. The functions are listed in the table below.

OFF: DISABLED

#1PULS+: PULSE ON CHANNEL 1 FOR POSITIVE FLOW RATE

#1PULS-: PULSE ON CHANNEL 1 FOR NEGATIVE FLOW RATE

#1PULS±: PULSE ON CHANNEL 1 FOR POSITIVE AND NEGATIVE FLOW RATE

#2PULS+: PULSE ON CHANNEL 2 FOR POSITIVE FLOW RATE

#2PULS-: PULSE ON CHANNEL 2 FOR NEGATIVE FLOW RATE

#2PULS±: PULSE ON CHANNEL 2 FOR POSITIVE AND NEGATIVE FLOW RATE

#1FREQ+: FREQUENCY CHANNEL 1 FOR POSITIVE FLOW RATE

#1FREQ-: FREQUENCY CHANNEL 1 FOR NEGATIVE FLOW RATE

#1FREQ±: FREQUENCY CHANNEL 1 FOR P OSITIVE AND NEGATIVE FLOW RATE

#2FREQ+: FREQUENCY CHANNEL 2 FOR POSITIVE FLOW RATE

#2FREQ-: FREQUENCY CHANNEL 2 FOR NEGATIVE FLOW RATE

#2FREQ±: FREQUENCY CHANNEL 2 FOR P OSITIVE AND NEGATIVE FLOW RATE

SIGN: FLOW DIRECT ION OUTPUT (ENERGISED = -)

RANGE: RANGE INDICATION OUTPUT (ENERGISED = SCALE 2)

MAX AL: MAX FLOW RATE OUTPUT(ENERGISED = AL. OFF)

MIN AL: MIN FLOW RATE OUTPUT(ENERGISED = AL. OFF)

MAX+MIN: MAX AND MIN FLOW RATE ALARM OUTPUT (ENERGISED = AL. OFF)

EMPTY PIPE: EMPTY PIPE ALARM OUTPUT (ENERGISED = FULL PIPE)

OVERFLOW.: OUT OF RANGE ALARM OUTPUT (ENERGISED = FLOW RATE OK)

HW ALARM: CUMULATIVE ALARM OUT interrupt coils, empty pipe, measure error (ENERGISED=NO ALARMS)

FUNCTION FOR OUTPUT 1, 2.

25

110_EN_LC_5_3_6X.doc

Page 26

(POS. 6.3) Duty cycle value for pulses/frequency output [Duty cycle=% XX]

HML 110

The duty cycle function defines t he time ratio between ON and O FF state when frequency output is

used: 50% means that the ON phase will equal that of the OFF phase, 60% means that the ON phase

will be 60 % and the OFF phase will be 40% of the total cycle time. When the pulse outputs are used,

the duty cycle defines the OFF phase, this is because the ON phase is already set with the "PULSE

DURATION" function ( see Main menu “2 - SCALE” ). In this case, for example, the duty cycle is set at

50% and the pulse duration at 50ms, the OFF phase w ill be the same of th e ON phase. The formula

to calculate the minimum time of the OFF phase and the time of total cycle is the following:

T. total cycle= 100 x (pulse duration in ms)/ (duty cycle)

T. OFF phase = T. total cycle - pulse duration

N.B.: When using the function in frequency mode, DO NOT set the duty cycle to 0. If the value of the

function is set to 0 the emission of the pulses occ urs in synchronous mode with the flow rate. The

function is active only if one of the outputs is set on pulse and/or frequency function.

(POS. 6.4) Current output option and range [Out mA=X_XX±XXX]

This function sets the current output N .1. This function is optional and will not appear unless the

option has been requested. There are three fields to modify for this function:

• Scale zero: 4 or 0 mA

• Full scale: 20 or 22 mA

• Field: + = positive, - = negative, ± = both, -0+ = central zero scale

The values corresponding to the scale points are shown in the following chart:

POSSIBLE FIELD

OutmA = 0 - 20 + 0 0 0 20 20

OutmA = 0 - 22 + 0 0 0 20 22

OutmA = 4 - 20 + 4 4 4 20 20

* OutmA = 4 - 22 + 4 4 4 20 22

OutmA = 0 - 20 - 20 20 0 0 0

OutmA = 0 - 22 - 22 20 0 0 0

OutmA = 4 - 20 - 20 20 4 4 4

OutmA = 4 - 22 - 22 20 4 4 4

OutmA = 0 - 20 ± 20 20 0 20 20

OutmA = 0 - 22 ± 22 20 0 20 22

OutmA = 4 - 20 ± 20 20 4 20 20

OutmA = 4 - 22 ± 22 20 4 20 22

OutmA = 0 - 20 –0+ 0 0 10 20 20

OutmA = 0 - 22 –0+ 0 1 11 21 22

** OutmA = 4 - 20 –0+ 4 4 12 20 20

OutmA = 4 - 22 –0+ 4 4.8 12.8 20 .8 22

CURRENT VALUES IN mA ASSOCIATE TO THE % VALUE OF FULL SCALE

REVERSE FLOW VA L UE ZERO DIRECT FLOW VALUE

≤ -110%

-100% 0% +100%

≥+110%

In hardware alarm conditions “HW ALARM” (interrupted coils, empty pipe, measure error) the current

value is programmed by the function “mA v.fault” (pos. 4 .5) and it is expressed as percentage of a

fixed current range, where: 0% = 0 mA and 110% = 22 mA.

* Example 1: out 4-22 +

I (mA)

22 mA

20 mA

** Example 2: out 4-20 –0+

I (mA)

20 mA

12 mA

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

4 mA

4 mA

zero

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

zero

26

110_EN_LC_5_3_6X.doc

Page 27

MENU 8 - DISPLAY

HML 110

(POS. 8.5) Totalizer modify enable [Tot.modif.=ON/OFF]

Enable this function to modify the totalizer. From visualization pages, proceed in the following mode:

1) Push the key , Set the L2 CODE if required (otherwise go to step 2) and then push the key

2) Positioning by the key to modify the numerical value push the key to access and then to

confirm the modified value

3) Positioning the cursor on “RESET TOTALIZ.?” Push the key and then the key to confirm

or any other key to cancel this operation.

With the function 8.5 disabled it’s possible reset the totalizer by pushing the key from

visualization page, at the required “RESET TOTALIZ.?” Push the key and then the key to

confirm or any other key to cancel this operation

(POS. 8.7-8.8-8.9-8.10) Total/Partial – totalizer reset enable [T/P/-/+ reset]

Activates the reset of Total and partial flow totalizer.

Functions 8.7-8.8-8.9-8.10 are activated by pressing the key during the visualization of the

function itself. When " EXE CUTE?" is required, press the key to proceed. Press any other key to

delete the operation

N.B.: The PARTIAL totalizers reset can also be achieved in the following way:

From one of the visualization page press the key .

Set the L2 code and press the key . The following prompt will be visualized: "EXECUTE?"

Press the key to proceed . Press any other key to delete the operation.

(POS. 8.13-8.14) Conversion factor for direct flow rate totalizers [EUR/dm³+/- =X]

Setting of the conversion/currency value for direct flow to talizers (positive). There are three setting

fields for this parameter, from le ft to right: 1) monetary symbol, 2 ) default/personalized monetary

symbol, 3 ) conversion coefficient. To select, s et the cursor over the field to be modified. Sett ing the

monetary symbol can be achieved in two ways:

1. Choosing one of the 7 predetermined monetary symbols (standard ISO 4217REV81):EUR=Euro; USD=USA dollar; CAD=Canadian dollar; AUD=Australian dollar;

GPB=English pound; CHF=Swissfranc; JPY=Japanese yen.

2. Entering a three character (numbers or letters) personalized currency. To change the

characters, the cursor must be set on the symbol “/” (second field)

MENU 10 - DIAGNOST IC

(POS. 10.1) Meter “calibration” [Calibration]

Enables the calibration function of the meter. The activati on of this function happens by pressing the

key during the visualization of the function. The following question will be visualized: "

EXECUTE?". Press the key to proceed . Press any other key to delete the operation.

(POS. 10.2) “Self test” function [Self test]

Meter auto test function. This function stops the normal functions of the meter and performs a

complete test cycle on the measuring input circuits and the excitation generator. To activate this

function, selecting it, by pressing the key , at the prompt: “EXECUTE?” press the key to start

the test, any other key will delete the operation. The result of the tes t is shown on the dis play, the

display will return to one of the visualiz ation pages at the test end. The function is automatically

performed when the device is switched on. For any errors see page 28 for corrective actions.

(POS. 10.3) Flow rate simulation [Simulation = ON/OFF]

Flow rate simulation enabling. This function a llows for the possible generation of an internal s ignal

that simulates the flow rate, allowing the outputs and all the connected instruments to be tested.

After enabling it, the flow rate simulation can be:

- set: by pushing the key from one of the four visualization pages

- started: by pushing the key after setting it

- finished: by pushing the key from the visualization pages and then by pushing the key .

(see page 12 for description of key symbols)

27

110_EN_LC_5_3_6X.doc

Page 28

HML 110

ALARM MESSAGES, CAUSES AND CORRECTIVE ACTIONS

Messages ANOMALIES ACTION TO TAKE

NO ALARMS All works regularly -----

MAX ALARM The flow rate is higher than the maximum threshold set

MIN ALARM The flow rate is lower than the minimum threshold set

FLOW RATE >FS

PULSE/FREQ>FS

EMPTY PIPE

INPUT NOISY

EXCITATION

FAIL

CURR. LOOP

OPEN

P.SUPPLY FAIL Power supply different from that indicated on the label.

The flow rate is higher than th e f u ll scale v alue set on the

instrument

The pulse generation output of the device is saturated and

cannot generate the sufficient number of impulses

The measuring pipe is empty or the detection system has not

been properly calibrated

The measure is strongly effect ed by external noise or the

connecting cable from converter to the sensor may be broken

The coils or the cable connecting the sensor are interrupted Check the connect in g cables to the sensor

The 0/4...20mA output on board or the optional one are not

correctly closed on a v a lid load

Check the maximum flow rate threshold set and

the process condition s

Check the minimum flow rate threshold set and

the process condition s

Check the full scale value set on the instrument

and the process conditions

Set a bigger unit of vo lu m e o r , if the connected

counting device allows it, reduce the pulse

duration value

Check whether the pipe is empt y , or rep eat t he

empty pipe calibration procedure

Check the status of the cables connecting t h e

sensor, the grounding connections of the devices

or the possible presence of nois e sou r ces

Verify the load is applied to the output (max 1000

ohm).

To disable the alarm, set the “mA VAL.FAULT”

value ( menu alarm ) to 0.

Verify that the power supply is as indicated on the

label

ANOMOLY CODES

CODES ANOMALIE DESCRIPTIONS ACTION TO TAKE

0001 problem with watch-dog circu i t

0002 wrong configuration work data in eeprom

0004 wrong configuration safety data in eeprom

0008 defective eeprom

defective keyboard (one or more key are pushed

0010

during the test)

0020 Power supply voltage (+3.3) is out of range

0040 Power supply voltage (+13) is too low (<10V)

0080 Power supply voltage (+13) it’s too high (>14V)

0200 timeout calibration input (input circuit is broken)

0400 Input stage gaining is out of range

0800 Interruption on the coils circuit

0C00 Cumulative alarm 0800 + 0400

ADDRESS TO SERVICE

Check the status of the cables connecting the sensor to the

converter, the grounding connections or the possible presence of

strong and anomalous noise sources

Check the status of the cables connecting the sensor to the

converter

see single code

28

110_EN_LC_5_3_6X.doc

Page 29

it declares under the own responsibility that the product:

MS 500 – MS 501 – MS 600 – MS 1000 – MS 2410- MS 2500 – MS

3700 MS 3770 – MS 5000

to which this declaration refers, is in compliance with the following

Harmonized European Norms:

CEI EN 61010-1(2001)

CEI EN 61326-1 (2007)

and therefore answering to essential requirement of CE directives:

2006/95/CE (Low voltage directive – LVD)

2004/108/CE (Electromagnetic compatibilità Directive – EMC)

25/11/2007

DECLARATION OF CONFORMITY

Model converters

HML110

Model sensors

HML 110

29

110_EN_LC_5_3_6X.doc

Page 30

HML 110

30

110_EN_LC_5_3_6X.doc

Page 31

Liquid conTroLS

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

Liquid conTroLS europe/SAmpi

Via Amerigo Vespucci 1

55011 Altopascio (Lucca), Italy

+39 0583 24751

ideX FLuid And meTering pvT. LTd.

Survey No. 256, Alindra

Savli GIDC, Manjusar

Dist. Vadodara 391 770

Gujarat, India

+91 265 2631855

Liquid conTroLS SponSLer

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

TopTech SySTemS

1124 Florida Central Parkway

Longwood, FL 32750

(407) 332-1774

Nateus Business Park

Nieuwe Weg 1-Haven 1053

B-2070 Zwijndrecht (Antwerp), Belguim

+32 (0)3 250 60 60

FAure hermAn

Route de Bonnetable

B.P. 20154

72406 La Ferté-Bernard Cedex, France

+33 (0)2 43 60 28 60

4702 North Sam Houston Parkway West

Suite 100

Houston, TX 77086

(713) 623-0808

corken

3805 Northwest 36th St.

Oklahoma City, OK 73112

(405) 946-5576

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2005 Liquid Controls

Pub. No. 500375

(7/13)

Loading...

Loading...