LINDE H40D, H45D, H50D operations manual

Dieseltruck

Originalinstructions

H40D,H45D,H50D

3948071001EN–07/2011

Preface

Linde− YourPartner

With over 100,000 fork lift trucks and warehousemachinessoldannually,Lindeisoneof theworld’sleadingmanufacturersofmaterial handlingequipment. Therearemanyreasons forthissuccess: Lindeproductsarerenowned notonlyfortheirinnovative,cutting-edgetech- nology,butalsofortheirlowenergyandoperatingcosts,whichareupto 40percentlower thanthoseoftheircompetitors.

The high quality of Linde products is also matchedbythequalityofourservice. Withten productionplantsworldwideandanextensive network of sales partners, we are at your serviceroundtheclockandaroundtheworld.

Your local Linde partner can offer you a complete package from a single source; ranging from expert advice on all aspects of sales and service through, of course, to appropriatefinanceoptions. Ourleasing,hire or lease-purchase agreements provide you with the flexibilityto tailordecision-making to yourindividualbusinessrequirements.

LindeMaterialHandlingGmbH Carl-von-Linde-Platz

63743Aschaffenburg Telephone+49(0)602199-0 Fax+49(0)602199-1570 Mail: info@linde-mh.com Web: http://www.linde-mh.com

OperatingInstructions–3948071001EN–07/2011 |

I |

|

|

Table of contents |

1 |

Introduction |

|

|

Yourforklifttruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 2 |

|

Properuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 3 |

|

Impermissibleuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 3 |

|

Descriptionofuseandclimaticconditions . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 3 |

|

Symbolsused . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 4 |

|

Technicaldescription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 4 |

|

Truckoperationwhenusingashovel . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 6 |

|

Receivingtheindustrialtruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 6 |

|

Legalrequirementsformarketing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 7 |

2 |

Safety |

|

|

Safetyguidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 10 |

|

Residualrisks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 11 |

|

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 12 |

|

Inthecaseoftip-over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 12 |

|

Handlingconsumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 12 |

|

Competentperson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 13 |

|

Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 13 |

|

Instructionsforfittingattachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 14 |

|

Forkcarriageemergencylowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 15 |

|

Emergencyexitwithattachedrearwindow . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 16 |

3 |

Overview |

|

|

Identificationplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 18 |

|

Generalview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 20 |

|

Operatingdevices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 21 |

|

Displayunit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 22 |

|

Switchpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 28 |

4 |

Operation |

|

|

Serviceplanbeforeinitialcommissioning . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 30 |

|

Running-ininstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 30 |

OperatingInstructions–3948071001EN–07/2011 |

III |

|

Tableofcontents

|

Pre-shift-checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Standardequipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

Enteringandexitingthetruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

Adjustingthestandarddriver’sseatandcomfortdriver’sseat . . . . . . . . . . . . . . . . . . . . |

32 |

|

Adjustingtheheight-adjustablecomfortdriver’sseat . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

Adjustingtheluxurydriver’sseat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

|

Adjustingthearmrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

|

Adjustingthesteeringcolumn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

Settingtheclock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

Seatbelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

Driveengine(dual-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

Driving(dual-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

Driveengine(single-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

Driving(single-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

Steeringsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

Brakesystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

Signalhorn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

Joystickwithcentralleveroperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

|

Joystickwithsingleleveroperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

Specialequipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Depressurisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Driver’scab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

|

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

|

Windscreenwiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

Windowheater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

|

Heatingsystem,airconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

LindeForkliftDataManagement(LFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

|

Adjustingthedriver’sseatwithrotatingdevice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Liftmastpositioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

Workingunderload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Beforetakingupaload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Adjustingtheforkspread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

|

Takingupload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

|

Travellingwithload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

95 |

|

Settingdownloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

|

Towcoupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

|

Beforeleavingthelifttruckunattended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

Beforeleavingthetruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

Loading/Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

|

Securingthehosepulleyagainstrollingup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

|

Removingtheliftmast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

99 |

IV |

OperatingInstructions–3948071001EN–07/2011 |

|

|

Table of contents |

Drivingwithouttheliftmast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 100 |

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 100 |

Transportationbylorryorlowloadingtrucks . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 102 |

5Maintenance

Generalinformation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Inspectionandmaintenancedata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

Recommendationsforconsumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

Inspectionandmaintenanceoverview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

108 |

Serviceplanasrequired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

108 |

1000hserviceplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

3000hserviceplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

6000hserviceplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

114 |

9000hServiceplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

117 |

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

Checkingtheengineoillevel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

Changeengineoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

Changingtheengineoilfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

123 |

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

Drainingwaterfromthefuelfilter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 |

|

Changingthefuelfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

Cleanthefueltankventilationhose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

Checkingthecoolantlevel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

Changingthecoolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

Checkingthecoolantconcentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

Cleaningthewatercoolerandhydraulicoilcooler,andcheckingthemforleaks . . . . . . |

133 |

Checking the condition and secure positioning of the engine support and engine |

|

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

134 |

Checkconditionoftheribbedveebelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

ReplacingribbedV-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

136 |

Checkingtheconditionandtensionoftoothedbelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

Renewthetoothedbeltandidlerpulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

Changethewaterpump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

Changingtheairfiltercartridge,checkingthevacuum-operatedswitch . . . . . . . . . . . . |

139 |

Changingtheairfiltersafetycartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

Checkthedustdischargevalve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

Changingthebreatherfilterforthechargeairpressureregulator . . . . . . . . . . . . . . . . . |

142 |

Cleaningtheprefilter(specialequipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

Cleaningtheoilbathairfilter(specialequipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

Changetheoilintheoilbathaircleaner(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

144 |

OperatingInstructions–3948071001EN–07/2011 |

V |

Tableofcontents

|

Checksuctionandexhaustpipesforleaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

145 |

|

Regeneratingtheparticlefilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

|

Regeneratingthechangingparticlefilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

149 |

|

Checkingtheparticlefiltersystem(specialequipment) . . . . . . . . . . . . . . . . . . . . . . . . |

151 |

|

Draining water from the water trap at the changing particle filter (special equip- |

|

|

ment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

152 |

|

Cleaningthewatertrapatthechangingparticlefilter(specialequipment) . . . . . . . . . . . |

152 |

|

Cleaning the pressure control device at the changing particle filter (special equip- |

|

|

ment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

153 |

|

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

154 |

|

Axleclampsandwheelmotors: checkingthemountings . . . . . . . . . . . . . . . . . . . . . . . |

154 |

|

Checkingandadjustingthesidestopsonthedriveaxle . . . . . . . . . . . . . . . . . . . . . . . . |

154 |

|

Checkingthedriveaxlebearingsforwear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

|

Checkingthehydraulicpump’smountingontheengine . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

|

Chassis,bodyworkandfittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

Cleaningthetruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

Floorplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

158 |

|

Maintainingtheheatingsystemandairconditioning(specialequipment) . . . . . . . . . . . |

159 |

|

Checkingtheconditionandcorrectfunctionoftheseatbelt . . . . . . . . . . . . . . . . . . . . . |

160 |

|

Checkfasteningforframe,tiltcylindersandsteeringaxle . . . . . . . . . . . . . . . . . . . . . . . |

162 |

|

Checkingandoilingotherbearingpointsandjoints . . . . . . . . . . . . . . . . . . . . . . . . . . . |

162 |

|

Toppingupthewashersystemwatertank(specialequipment) . . . . . . . . . . . . . . . . . . |

163 |

|

Chassisframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

Changingawheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

Tightenthewheelnuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

165 |

|

Checkthetyresfordamageandforeignobjects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

165 |

|

Checkingthetyrepressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

166 |

|

Checkingtheconditionoftheantistaticbelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

|

Cleaningandgreasingthesteeringaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

|

Checkingthemountingsofthesteeringcylinderandsteeringpivotpin . . . . . . . . . . . . . |

168 |

|

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

|

Checkingtheparkingbrakeforcorrectoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

|

Checkingthepedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

|

Checkingthebellowsattheactuatinglever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

170 |

|

Electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

171 |

|

Check the condition and secure positioning ofelectric cables, cable connectors and |

|

|

connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

171 |

|

Battery: Checkcondition,levelanddensityofacid . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

171 |

|

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

174 |

|

Changehydraulicoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

174 |

VI |

OperatingInstructions–3948071001EN–07/2011 |

|

|

Table of contents |

Hydraulicsystem: Checktheoillevel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 |

|

Hydraulicsystem: changingthefilter . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 176 |

Checkthebleedervalveonthehydraulicoiltankforcorrectoperation . . |

. . . . . . . . . . . 179 |

Checkthehydraulicsystemforleaks . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 180 |

Checktiltcylinderbearingsforwear . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 180 |

Checkthetensionofdoublehoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 181 |

Loadliftsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 182 |

Workingontheliftmastandatthefrontofthetruck . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 182 |

Cleaningandsprayingtheliftmastchain . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 185 |

Liftmast,liftmastchains,liftcylinderand endstops: Checkmounting, condition and |

|

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 186 |

Adjustingtheliftmastchain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 186 |

Checktheforksandforkquick-releases . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 188 |

Cleansideshift(specialequipment)andgrease,checkfastening . . . . . . |

. . . . . . . . . . . 189 |

Checkingtheslideguidesonthesideshift(specialequipment)forwear . |

. . . . . . . . . . . 190 |

Self-help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 191 |

Openingthecovertotheelectricalsystem . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 191 |

Fusesforbasicandspecialequipment . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 192 |

Mainfusesinenginecompartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 192 |

Diagnosticconnector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 193 |

Malfunctionsduringoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 194 |

Malfunctions,CausesandRemedies(dieselengine) . . . . . . . . . . . . . . . |

. . . . . . . . . . . 196 |

Malfunctions,causesandremedies(hydraulicsystem) . . . . . . . . . . . . . |

. . . . . . . . . . . 199 |

Jumpstart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 201 |

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 202 |

Shuttingdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 205 |

Shuttingdownthetruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 205 |

Disposalofoldtrucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 206 |

OperatingInstructions–3948071001EN–07/2011 |

VII |

Tableofcontents

6Technical data

TypesheetH40,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

TypesheetH45,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

TypesheetH50/500,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

TypesheetH50/600,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

TypesheetH40elevateddriver’scompartment,asat07/2011 . . . . . . . . . . . . . . . . . . |

220 |

TypesheetH45elevateddriver’scompartment,asat07/2011 . . . . . . . . . . . . . . . . . . |

223 |

TypesheetH50/500elevateddriver’scompartment,asat07/2011 . . . . . . . . . . . . . . . |

226 |

TypesheetH40container,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

229 |

TypesheetH45container,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

232 |

TypesheetH50/500container,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

235 |

TypesheetH50/600container,asat07/2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

238 |

Truckconfiguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

241 |

Tyrevariantsandrimsizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

242 |

Loadcapacitydiagramsandliftmastdataasat07/2011 . . . . . . . . . . . . . . . . . . . . . . . |

244 |

Additionalcapacityratingplateforattachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

247 |

Noiseemissionvalues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

248 |

Vibrationcharacteristicvaluesforbodilyvibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . |

249 |

Annex

7Circuitdiagrams

|

Wiringdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

264 |

|

Basicequipmentfordieselwithpumpinjectionengine—Sheet01 . . . . . . . . . . . . . . . . |

264 |

|

Basicequipmentfordieselwithpumpinjectionengine—sheet02 . . . . . . . . . . . . . . . . |

266 |

|

Basicequipmentfordieselwithpumpinjectionengine—sheet03 . . . . . . . . . . . . . . . . |

268 |

|

Specialequipmentsheet01—workingspotlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

270 |

|

Specialequipmentsheet02—Windscreenwipers,seatheater,seatwithairsuspen- |

|

|

sion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

272 |

|

Special equipment sheet 03 — Heating system, air conditioning, flashing/rotating |

|

|

beacon,reversingsignal,interiorlighting/clipboardlighting . . . . . . . . . . . . . . . . . . . |

274 |

|

Specialequipmentsheet04—hazardwarningsystemforreversetravel,truckdeacti- |

|

|

vation,mastpositioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

276 |

|

Specialequipmentsheet05—particlefilter,radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

278 |

|

Special equipment sheet 06 — Higher lighting, 12 V socket, diesel filter water trap |

|

|

warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

280 |

VIII |

OperatingInstructions–3948071001EN–07/2011 |

|

Table of contents |

|

Specialequipmentsheet07–Truckdatamanagement,LPGvolumedisplay . . . . . . . . |

282 |

Special equipmentsheet08 – LPG volume display for volumetric filling withshut-off |

|

valve,changingparticlefilter,camerasystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

284 |

Specialequipmentsheet09—batterymainswitchwithdisplayunitpowersupply,rear |

|

centrebrake/taillight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

286 |

Specialequipmentsheet10—thirdauxiliaryhydraulicswiththirdjoystick . . . . . . . . . . |

288 |

Special equipmentsheet11 — Lighting, direction indicator and hazard warning sys- |

|

tem,brakelight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

290 |

Special equipmentsheet12 — single leverforlifting/lowering, tilting, single auxiliary |

|

hydraulicsanddoubleauxiliaryhydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

292 |

Hydrauliccircuitdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

294 |

Traction,workingandsteeringhydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

294 |

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

296 |

OperatingInstructions–3948071001EN–07/2011 |

IX |

1

Introduction

1 Introduction

Your forklift truck

Yourforklift truck

offers optimum economic efficiency, safety and driving comfort. It is primarily down to you to maintain these characteristics for a longtimeandtakeadvantageoftheresulting benefits.

During manufacture:

•all safety requirements ofthe relevant EC directiveswereobserved

•all conformity assessment procedures stipulatedin theapplicable directiveswere carried out

ThisisattestedbytheCEmarkshownon the nameplate.

These operating instructions contain everythingyouneedtoknowaboutcommissioning, drivingandmaintenance.

Theattachmentoperatinginstructionsareenclosed for trucks that are delivered from the factory with an attachment. Before commissioning a truckwith an attachment,you must check that loads are handled securely. Depending on the type ofattachment,itmay be necessary to make adjustments, e.g. pressuresettingsoradjustingstopsandoperating speeds. See the attachment operating instructionsforthe corresponding instructions. The instructions for operation of the attachmentmustalsobeobserved.

Carry outthe specified work regularly, atthe due times and using the consumablesenvisaged for thispurpose in accordance with the inspectionandmaintenanceoverview. Please make sure you record the work performed in the registration document for the industrial truck;thisisessentialforanywarrantyclaims.

Thedesignationsusedinthetext(front,back, left, right) always refer to the installation position ofthe partsdescribed,with forwards as the drive direction for the truck (fork arms forwards).

Servicingworknotdescribedherewillrequire specialistknowledge,measuringdevicesand frequentlyalsospecialtools. Pleaseaskyour authoriseddealertocarryoutthiswork.

Servicing should only be carried outbyqualified personnel approved by Linde (specialists).

With orders for parts, please specify the followingalongwiththepartsnumbers:

Truckmodel:

Chassis number/year of manufacture:

Handoverdate:

Theproductionnumbermustalsobespecified for parts from the following units: engine, lift mast,hydraulicvariable displacementpump, driveaxleandsteeringaxle.

Enginenumber:

Liftmastnumber:

Liftmastlift:

Hydraulic variable displacementpump number:

Driveaxlenumber:

Steering axle number:

When taking over the truck, this data should becopiedfromtheidentification platesofthe unitsintotheseoperatinginstructions.

NOTE

NOTE

Intheeventofrepairs,onlyusegenuineLinde spareparts. Thisistheonlywaytoguarantee thatyourtruckremainsinthe sametechnical conditionasatthetimeofreception.

Please address all queries and orders for spare parts relating to your truck only to your authorised dealer, stating your mailing address.

Linde is constantly engaged in the further developmentofitsproducts. We askforyour understandingthatfiguresandtechnicaldata aresubjecttotechnicalmodificationintermsof

2 |

OperatingInstructions–3948071001EN–07/2011 |

Introduction 1

Descriptionofuseandclimaticconditions

form,equipmentandexpertise in theinterest ofprogress.

For this reason, no claims can be asserted onthe basisofthefollowingdata,figuresand descriptionsintheseoperatinginstructions.

These operating instructions must not be reproduced,translatedormadeaccessibleto third parties—including as excerpts—except with the express written approval of the manufacturer.

Proper use

The truck is used for moving and lifting the loadsindicatedonthecapacityratingplate.

Pleasepayparticularattentionto:

•The VDMA brochure on "Rules for proper useofindustrialtrucks",suppliedwiththese operatinginstructions

•Regulationsfordriving on public roads,as wellasanycountry-specificrestrictionson winterroadconditions

•Specific measures for using the industrial truckinoperatingareaswithmagneticfields

that have magnetic flux densities greater than 5 mT

• Otherspecificnationalregulations.

It is essential that operating personnel and repair personnel observe the rules for the properuseofindustrialtrucks.

Modifications, in particular attachments or conversions,arenotpermittedto bemadeto theindustrialtruckwithoutthemanufacturer’s approval.

The user, and notthe manufacturer, isliable foranyhazardscausedbyimproperuse.

Impermissible use

Theoperatingcompanyordriver,andnotthe manufacturer,isliableifthetruckisusedina mannerthatisnotpermitted.

Itisnotpermittedtousethetruck:

• fortakingpassengers

•for stacking/unstacking operations on slopes

•Forsteppingontotheforkarmswhenthelift mastisraised

•Ifthemaximumloadcapacityisexceeded

•in areas where there is a risk of fire of explosion

Descriptionofuseandclimaticconditions

Normaluse

•Indoorandoutdooruse

•AmbienttemperatureintropicalandNordic regionsrangingfrom-15°Cto50°C

•Startcapabilityat-15°Cto50°C

•Maximumstarttimeof20seconds

•Useatupto2000metresabovesealevel.

Special use (partly with special measures)

•Use,e.g. intheeventofabrasivedust(such asAL203),lint,acid,leach,salt,corundum, incombustiblesubstances

•Ambienttemperatureintropicalregionsup to 55 °C

•Startcapabilityto-25 °C

•Useatupto3500metresabovesealevel.

OperatingInstructions–3948071001EN–07/2011 |

3 |

1 Introduction

Technicaldescription

Symbols used

ThetermsDANGER,WARNING,CAUTION, NOTE and ENVIRONMENTNOTE are used in these operating instructions for notes on particularhazards orforunusual information thatneedstobehighlighted:

DANGER

DANGER

Meansthat failure to complycan cause riskto life and/ormajordamagetoproperty.

WARNING

WARNING

Means that failure to comply can cause risk of seriousinjuryand/ormajordamagetoproperty.

CAUTION

CAUTION

Means that failure to comply can cause risk of materialdamageordestruction.

NOTE

NOTE

Means that particular attention is drawn to combinations oftechnicalfactors which may notbeevidenteventoaspecialist.

ENVIRONMENT NOTE

ENVIRONMENT NOTE

Theinstructionslistedheremustbecomplied withasotherwiseenvironmentaldamagemay result.

CAUTION

CAUTION

This label is found on the truck in theareaswhere particularcare and attentionarerequired.

You should refer to the appropriate section in these operating instructions.

For your safety, additional symbols are also used. Pleaseheedthevarioussymbols.

Technicaldescription

The forklift trucks in the 394 series allow loading and palletising to be performed for loadsupto 4 t with H40, up to4.5 t with H 45 andupto5twithH50-500,ataloaddistance of500 mm.

Details on the exact lift-height-specificmaxi- mum loadsare available in the load capacity diagram.

The trucks are eco-friendly and their quiet operational noise and low emission levels benefit both the driver and the environment. Theirdistinguishingfeaturesarethecompact design and small turning radius. For this reason,thetrucksareparticularlywell-suited to narrow entrances and operational areas wherespaceisatapremium.

Engine

The drive engine is a 4-cylinder, four-stroke dieselenginewithturbochargingandstate-of-

the-artpump injection technology. Itpowers the truck’s hydraulic pumps and varies its speed depending on the load. The engine is cooled by means of a closed coolant circuit with expansiontank.

Forcedcirculationlubricationwithanoilpump in the oil sump is used forengine lubrication. The combustion airiscleanedby meansofa dryairfilterwithapaperinsert. Dieselengines with state-of-the-art engine technology are used for:

•High torque

•Low fuelconsumption

•Lowexhaustemissions

•Lowparticulateemissions

•Low noiselevels

Hydraulicsystem

Thedriveunitconsistsofa hydraulicvariable displacement pump, two hydraulic fixed

4 |

OperatingInstructions–3948071001EN–07/2011 |

Introduction 1

Technicaldescription

displacement wheel motors (assembled as adriveaxleunit),aswellasahydraulicpump (fixed displacement pump) for the working and steering hydraulics. Drive direction and driving speed are regulated by means oftwo accelerator pedals via the hydraulicvariable displacementpump.

The hydraulic fixed displacement wheel motors in the drive axle are supplied by the hydraulicvariabledisplacementpumpandare used to power the drive wheels via two side gearboxes.

Operation

Oneacceleratorpedaleachforforwardtravel and reverse travel (dual pedal operation) is usedtosimultaneouslyregulatethehydraulic variable displacementpump and the engine speed. The hydrostatic drive enables the driving speed to be continuously varied in both directions,ranging fromstandstillto the maximum speed. The dual-pedal control means that operation of the truck is simple, safe,non-fatiguingandefficient.

The driver always has both hands free for steering and controlling operational movements. Thisresultsin fastreversing andefficientstacking.

Anoptionalversionisalsoavailablewhereby the driving speed is regulated byan accelerator pedal (single pedal operation) and the drivedirection controlledbymeansofadrive direction switch.

To control the operational movements oflifting,loweringandtilting,thereisonlyoneactuatinglever(joystick). Anotherjoystickisfitted for actuation of additional attachments. Operational movements can also be controlled usingtwoorfourjoysticks(singleleveroperation version).

LindeLoadControl

Thetruck’sLinde Load Control(LLC)control electronicssystemenables:

•Millimetre-preciseandsecureloadhandling

•Effortless finger-tip control of all lift mast functions

•Drive and lifting functions are entirely separate.

LindeTruckControl

The truck’s Linde Truck Control control electronicssystem(LTC)offers:

•Reliablecontrolunit

•A high level of safety thanks to multiple monitoring systems

•Automatic, load-dependent control of engine speed

•Protection fromdustanddirtthoughuseof afullyenclosedhousing.

Brakes

The hydrostatic drive is used as the service brake. This means that the service brake is maintenance-free. Two multi-disc brakes incorporated in the wheel motors are used as the parking brake. When the engine is switched off, the multi-disc brakes engage, meaningthatthetruckhasanautomaticbrake function. Always apply the parking brake when parkingthe truck.

Steering

Thesteeringisahydrostaticsteeringsystem, under which the steering wheel acts on the steering cylinder to actuate the rear wheels. If the power applied to the steering wheel is increased,the steering can also be operated whentheenginehasbeenswitchedoff.

Liftmast

Thefree-viewliftmastenables:

•Idealvisibilityduetoslimliftmastprofiles

•Fullloadcapacityuptomaximumliftheights

•Enormousresidualloadcapacity

OperatingInstructions–3948071001EN–07/2011 |

5 |

1 |

Introduction |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Receivingtheindustrialtruck |

|

|

|

|

|

||

• |

Maintenance-free storage of the lift mast |

Electricalsystem |

|||||

|

and tilt cylinder via rubber-cushioned |

The electrical system is powered by the |

|||||

|

linkage points |

||||||

|

three-phasealternatorwith12VDCvoltage. A |

||||||

• |

Electrictiltanglelimitation. |

||||||

12Vbatterywith88Ahisinstalledforstarting |

|||||||

theengine. Itislocatedunderthedriver’sseat intheenginecompartment.

Truckoperationwhenusingashovel

When operating the truck with a shovel, stall protectioncanbeactivatedbyyourauthorised dealer.

In this case, extreme loading of the drive engine due to the associated engine speed decrease leads to a slight delayin executing theworking hydraulics.

NOTE

NOTE

For a period of extended loading of the engine, the joystick mustbe switched to the zero position in order to release the working hydraulicsagain.

Receivingtheindustrialtruck

Before the industrialtruckleaves ourfactory, itundergoesathoroughinspectionprocessin ordertoguaranteethatitisinperfectcondition and that it contains all of the equipment specifiedinthe order.

Inorderto preventcomplaintsfromoccurring further down the line, the exact condition of the industrial truck and the integrity of the equipment are checked and the proper

handover/acceptanceofthetruckisconfirmed bythe dealer.

NOTE

NOTE

In trucks that leave our factory without a lift mast, an additional stop screw for speed limitationislocatedunderthereverseaccelera- torpedal(dual-pedal operation)or underthe

accelerator pedal (single-pedal operation). This must be removed after installing the lift mast;seethe section entitled Drivingwithout a liftmast.

The following technicaldocumentsbelong to each industrialtruck:

•Operatinginstructionsforthetruck

•Operating instructions for the attachment (only applies to trucks delivered from the factorywithanattachment)

•ECdeclarationofcompliance

•Safety rules forthe use ofindustrialtrucks (VDMA)

•Registration document for the industrial truck,whichisissuedbyauthoriseddealers aspartofthehandover.

6 |

OperatingInstructions–3948071001EN–07/2011 |

Introduction 1

Legalrequirementsformarketing

Legalrequirementsformarketing

|

Declaration |

Linde MaterialHandling GmbH |

|

Carl-von-Linde-Platz |

|

D-63743 Aschaffenburg,Germany |

|

We declare thatthe machine |

|

Industrial truck |

accordingtotheseoperatinginstructions |

Model |

accordingtotheseoperatinginstructions |

complieswiththemostrecentversionofmachinerydirective2006/42/EC. Personnelauthorisedtocompilethetechnicaldocuments:

see EC declaration ofconformity Linde MaterialHandling GmbH

ECdeclarationofconformity

ThemanufacturerdeclaresthatthetruckcomplieswiththerequirementsoftheECmachinery directive and any other EC directives, if applicable,thatarevalidatthetimeofmarketing. This is confirmed by the EC declaration of conformity and by the CE labelling on the nameplate.

The EC declaration of conformity document is delivered with the truck. The declaration

shown explains the conformity with the requirementsoftheECmachinerydirective.

Anindependentstructuralchangeoraddition to the truck can compromise safety, thus invalidatingtheECdeclarationofconformity.

The EC declaration of conformity must be carefully stored and made available to the responsible authorities if applicable. It must also be handed over to the new owner if the truck is sold on.

OperatingInstructions–3948071001EN–07/2011 |

7 |

1Introduction

Legalrequirementsfor marketing

8 |

OperatingInstructions–3948071001EN–07/2011 |

2

Safety

2 Safety

Safety guidelines

Safety guidelines

It is essential that operating personnel and repair personnel observe the" rules for the properuse ofindustrialtrucks"enclosedwith theseoperatinginstructions.

Examplesofthoselistedare:

•Operatingindustrialtrucks

•Driving licence

•Drivewaysandworkingareas

•Rights,dutiesandrulesofbehaviourforthe driver

•Specialoperatingareas

•Information regarding setting off, driving and braking

•Informationformaintenanceandrepair

•Regular tests

•Disposalofgreases,oilsandbatteries

The operating company or the person it has commissioned must ensure that the driver understands all safety information and that all guidelines and safety regulations are observed.

During training, the driver must familiarise themselveswiththefollowing:

•The operating conditions of the working areas

•Thespecifictechnicalcharacteristicsofthe industrialtruck

•Theoperationofattachments

Practise driving, control and steering operations with an unloaded truck until they are completelymastered. Onlythencanaloaded industrialtruckbeusedforpractice.

Safetyinformation

DANGER

DANGER

Theindustrialtruckmustnotbeusedbyunauthorised persons.

Only trained persons and those authorised for operationmayhaveaccesstotheindustrialtruck.

DANGER

DANGER

Inoperatingareaswithmagneticfieldsthathavea magneticfluxdensitygreaterthan5mT,unintentionaltruckandliftmastmovementscannotbeentirely excludedunderunfavourablecircumstances.

For magnetic fields with magnetic flux densities greater than 5 mT, components developed especiallyforthispurposemustbeused.

Contactyourauthoriseddealer.

DANGER

DANGER

Safetysystems(e.g. theseatswitch)arethere for safety.

Safetysystemsmustneverbedisabled,regardless of the kind.

DANGER

DANGER

Any additional bores or welding to the overhead guardwillcompromiseitsrigidity.

Itistherefore strictlyprohibited to drillholesin the overheadguardortoweldtoit.

CAUTION

CAUTION

Welding operations on other parts of the vehicle cancausedamagetotheelectronics.

Therefore, beforeperforming anywelding,always disconnect the battery and all connections to the electroniccontrol units.

CAUTION

CAUTION

Different functions are supported by gas springs. Gas springsare undera high internalpressure of up to 300 bar.

Theymust onlybe removedwhen notundercompressionandmustnotbeopenedwithoutinstructions. Anykindofdamage,lateralforces, buckling, temperaturesinexcessof80°Candheavycontaminationmustbeavoidedunderallcircumstances.

Damagedordefective gasspringsmustbe replaced immediately.

Contactyourauthoriseddealer.

10 |

OperatingInstructions–3948071001EN–07/2011 |

Safety 2

Residualrisks

WARNING

WARNING

In truckswithan accumulator,seriousinjuriescan occuriftheaccumulatorisnotproperlyhandled.

Beforestartingworkontheaccumulatoritmustbe depressurised.

Contactyourauthoriseddealer.

WARNING

WARNING

Dependingonthedurationofuseand operatingtime,componentscarrying exhaustgasesand exhaustairmay become hot.

Protectiveequipmentmusttherefore be worn.

CAUTION

CAUTION

Variouspiecesofspecialequipmentareconnected to the special "speed reduction" function. This is simplyan assistance function, on whichthe driver mustnotsolelyrelyduringoperation.

Thedriverisalwaysresponsibleforsafeoperation.

CAUTION

CAUTION

Ifdrivershaveactivemedicalequipment,e.g. pace makersorhearingaids,thesemaybeimpaired.

Check with a doctor or the medical equipment manufacturerwhethertheequipmentissufficiently protectedagainstelectromagneticinterference.

NOTE

NOTE

WARNING

WARNING

Thetruckworkingareamustbesufficientlylit.

If it is insufficiently lit, working spotlights must be installedtoensurethatthedrivercanseeproperly.

Residualrisks

Despite careful work and compliance with allapplicable standards and regulations,the possibility of other dangers when using the industrialtruckcannotbeentirelyexcluded.

The industrial truck and its possible attachmentscomplywithcurrentsafetyregulations. Nevertheless,evenwhenthetruckisusedfor itsproperpurposeandallinstructionsarefollowed,someresidualriskcannotbeexcluded.

Evenbeyondthenarrow dangerareasofthe industrial truck itself, a residual risk cannot be excluded. Personsin the areaaround the industrial truck must exercise a heightened degree ofawareness, so thatthey can react immediately in the event ofany malfunction, incidentorbreakdown.

Ifyourtruck isequipped with a fire extinguisher, make sure that you familiarise yourself with itin case ofan emergency. Handling informationisprovidedonthefireextinguisher.

DANGER

DANGER

Persons in the vicinity of the industrial truck must beinstructedwith regard to thedangersthatarise through use ofthe truck.

Theseoperatinginstructionsalsocontainadditional safetyregulations.

Residualdangerscaninclude:

•Escapeofconsumablesduetoleakagesor theruptureoflines,hosesorcontainers,

•Riskofaccidentwhen driving overdifficult ground such as gradients, smooth or irregularsurfaces,orwithpoorvisibility,

•Riskoffalling,tripping,slippingetc. during movementoftheindustrialtruck,especially inthe wet,with leaking consumablesoron icy surfaces,

•Riskoffireandexplosionduetothebattery and electricalvoltages,

•Human error,

•Disregardingthesafetyregulations,

•Riskcausedbyunrepaireddamage,

OperatingInstructions–3948071001EN–07/2011 |

11 |

2Safety

Handlingconsumables

•Riskcausedbyinsufficientmaintenanceor testing,

•Risk caused by using the wrong consumables.

Stability

Stabilityisguaranteedifyourindustrialtruckis usedaccordingtoitsintendedpurpose.

Stabilitywillnotbeguaranteedintheeventof:

•corneringatexcessivespeeds,

•movingwiththeloadraised,

•movingwith a loadthatisprotruding to the side (e.g. sideshift),

•turning and driving diagonally across descentsorascents,

•drivingondescentsorascentswiththeload onthedownhillside,

•loadsthataretoowide,

•drivingwithaswingingload,

•ramp edgesorsteps.

In thecase oftip-over

•Staybuckled up

•Don’tjump

•Hold on tight

•Brace feet

•Lean away

Thestabilityofyourindustrialtruckisensured ifused properlyand asintended. Should the industrialtrucktipoverduringanunapproved application or due to incorrect operation, alwaysfollowtheinstructionsdepictedabove.

Handlingconsumables

ENVIRONMENTNOTE

ENVIRONMENTNOTE

Consumables must be handled properly and in accordance with the manufacturer’s instructions.

•Consumables should only be stored in containers complying with applicable regulationsandatthelocationsstipulated.

•Do notbring flammable consumablesinto contactwithhotobjectsoranakedflame.

•When topping up consumables, use only cleancontainers.

•Observe the manufacturer’s instructions relatingtosafetyanddisposal.

•Avoid spilling.

•Removeanyspilledfluidimmediatelywitha suitable binderand dispose ofitaccording toapplicableregulations.

•Old and contaminated operating materials should be disposed of according to the regulations.

•Complywiththestatutoryprovisions.

•Before performinggreasing,filterchanges or any work on the hydraulic system,

12 |

OperatingInstructions–3948071001EN–07/2011 |

Safety 2

Regulations

carefully clean the area around the part involved.

•Disposeofusedsparepartsinan environmentallyfriendlymanner.

WARNING

WARNING

The penetration of pressurisedhydraulicfluid into the skin, e.g. due to leakage, is hazardous. If an injuryofthistypeoccurs,alwaysconsultadoctor.

Protectiveequipmentmustbeworn.

WARNING

WARNING

Theimproperhandlingofcoolantandcoolantadditivespresentsarisktohealthandtheenvironment.

Observe the manufacturer’s instructions without fail.

Competentperson

Acompetentpersonisaspecialistinthefield ofindustrialtruckswhohas:

•Successfullycompletedtraining,asatleast aserviceengineerforindustrialtrucks

•Manyyearsofprofessionalexperiencewith industrialtrucks

•Knowledge of the accident prevention regulations

•Knowledgeofthe relevantnationaltechnicalregulations

Regulations

Periodicsafetyinspection

Periodic safety inspections are required in orderto maintainthe function andsecurityof the industrialtruck.

Complywith the nationalregulationsforyour country.

In Europe, the national laws are based on the directives 95/63/EC, 99/92/EC and 2001/45/EC. These stipulate that periodic

safetyinspectionsofthe industrialtruckmust be carriedoutbycompetentpersonnel,inordertoensurepropercondition.

The competent person is able to assess the conditionofindustrialtrucksintermsofhealth and safety.

OperatingInstructions–3948071001EN–07/2011 |

13 |

2Safety

Instructions forfittingattachments

There is a recommendation setting out the scopeoftheperiodicsafetyinspection—FEM 4.004 ofthe EuropeanIndustrialTruckAsso- ciation—whichdefinesatestlogtodocument thecurrentsafetyinspectionandaninspection stickerforthenextsafetyinspection. Thenext safety inspection date is shown by the year number (3) on an adhesive label (2), which changes colour every yearand is found on a label(1).

The scope of the safety inspection is added by the manufacturer in accordance with the specific truck type. Please ask your authoriseddealertocarryoutthiswork.

Dieselengineemissions

Dieselengineemissionsincludecarcinogenic hazardous materials. These should not be allowedtoinfiltratetheairinworkplaces.

Iftrucks with diesel engines are used in fully orpartiallyenclosedspaces,thismustfirstbe reported to the relevant occupational health andsafetyauthorities. Operatinginstructions mustbedisplayedintheworkingareas.

The national regulations must be observed withoutfail.

Checkingtheparticlefiltersystem

Particle filter systems must be maintained and tested every 6 months by a competent person. Thetestresultsmustberecordedand enclosed with the report book. Observe the nationalregulationsforyourcountry.

Instructionsforfittingattachments

To depressurise the oil in the lines before fitting an attachment, the hydraulic system forthe auxiliaryhydraulicscanbeconnected using an accumulator (Special equipment) depressurised

Seethesectionentitled"Depressurisation".

WARNING

WARNING

Improperhandlingoftheaccumulatormayleadto seriousinjuries.

Beforestartingworkontheaccumulator,itmustbe depressurised. Contactyourauthoriseddealer.

14 |

OperatingInstructions–3948071001EN–07/2011 |

Safety 2 Forkcarriageemergencylowering

Fork carriage emergency lowering

Ifthereisamalfunction,the forkcarriagecan be lowered manually.

¾ Removefloormat.

DANGER

DANGER

Risk of accident or danger to life when loweringtheforkcarriagewith forkarms.

Peoplearenotallowedtostandinthe vicinityoftheforkarmswhentheyare beinglowered.

During lowering, leave the socket wrench on the threaded stud (1)on thevalveblock(3)toenablelowering tobeinterruptedatanytime.

¾Insert the 8 mm WAF socket wrench throughtheopeninginthebottomplate.

¾Using the socket wrench slowly rotate the threaded stud (1) approx. 3 turns anti-clockwise until the fork carriage has beencompletelylowered.

¾Open the bonnet.

¾Open the bottom plate and secure it in place.

¾Undotheself-lockingnut(2)about2turns.

OperatingInstructions–3948071001EN–07/2011 |

15 |

2Safety

Emergencyexitwithattachedrearwindow

¾Screw the threaded stud (1) back in clockwise. Otherwiseitwillnotbepossibletolift theforkcarriageusingthejoystick.

Tighteningtorque10 Nm.

¾ Retightentheselflockingnut(2). Tighteningtorque9.5Nm

NOTE

NOTE

After emergency lowering has been performedthreetimes,anewthreadedstudwithself locking nutmustbeused.

¾Closethebottomplateandbonnet.

¾Insertthe floormat.

1

1

3 |

2 |

d3941386 |

Emergencyexitwithattached rearwindow

If a truck with an attached front and rear window breaks down in a narrow aisle, the drivermaypossiblybeunabletoexitthetruck atthe side. In the eventofacute danger, the driver can exit the truck via the rear window. For this purpose, the rear window must be brokenwithanemergencyhammer.

¾Bend open split pin (1) from the support mounting(2)undertherearwipermotor.

WARNING

WARNING

Glasssplintersmaycauseinjuries.

Removeglasssplinterscarefully.

¾Taketheemergencyhammer(3)outofthe support mounting and carefully break the rearwindow.

¾Climboutcarefully.

3 |

|

2 |

1 |

|

t3921371 |

16 |

OperatingInstructions–3948071001EN–07/2011 |

3

Overview

3 Overview

Identification plates

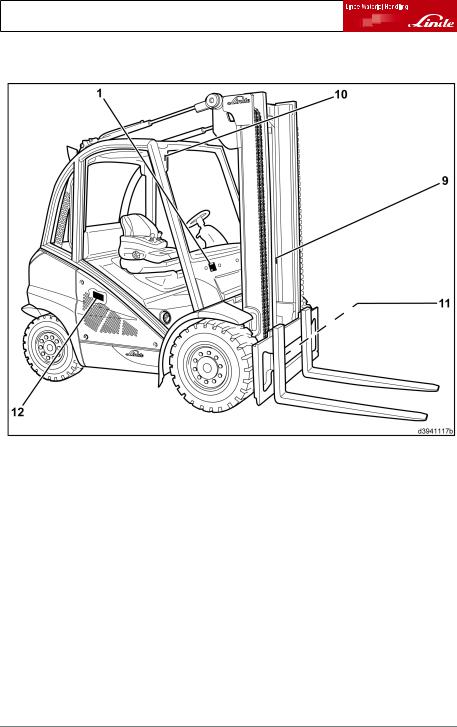

Identificationplates

1Nameplate

9Liftmastnumber(adhesivelabel)

10Serial number (stamped into the front right of the junction plate on theoverheadguard)

11Driveaxleidentificationplate

12Engineidentificationplate

18 |

OperatingInstructions–3948071001EN–07/2011 |

Loading...

Loading...