LINDE H25D, H30D, H35D User Manual

OperatingInstructions

Dieselforklifttruck

H25D,H30D,H35D

3938071001EN–06/2006

Preface

Linde -Your Partner

With over 100,000 fork lift trucks and warehousemachinessoldannually,Lindeisoneof theworld’sleadingmanufacturersofmaterial handlingequipment. Therearemanyreasons forthissuccess: Lindeproductsarerenowned notonlyfortheirinnovative,cutting-edgetech- nology,butalsofortheirlowenergyandoperatingcosts, whichareupto 40percentlower thanthoseoftheircompetitors.

The high quality of Linde products is also matchedbythequalityofourservice. Withten productionplantsworldwideandanextensive network of sales partners, we are at your serviceroundtheclockandaroundtheworld.

Your local Linde partner can offer you a complete package from a single source;

ranging from expert advice on all aspects of sales and service through, of course, to appropriatefinanceoptions. Ourleasing,hire or lease-purchase agreements provide you with the flexibilityto tailordecision-making to yourindividualbusinessrequirements.

LindeMaterialHandlingGmbH&Co. KG Schweinheimerstraße34

63743Aschaffenburg Telephone+49(0)602199-0 Fax+49(0)602199-1570 Mail: info@linde-mh.com Web: http://www.linde-mh.com

OperatingInstructions–3938071001EN–06/2006 |

I |

|

|

Table of contents |

1 |

Introduction |

|

|

Yourforklifttruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 2 |

|

Intendeduse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 2 |

|

Symbolsused . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 2 |

|

Technicalspecification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 4 |

|

Truckoperationwithabucket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 5 |

|

Trucktakeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 5 |

|

Initialoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 6 |

2 |

Safety |

|

|

Safetyregulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 8 |

|

Inthecaseoftip-over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 9 |

|

Handlingfluidsandlubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 9 |

|

Experts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 10 |

|

Operationofindustrialtrucksinplantarea . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 10 |

|

Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 10 |

|

Determinationandassessmentofhazardsfromuseofindustrialtrucks . |

. . . . . . . . . . . 11 |

|

Instructionsforfittingattachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 12 |

3 |

Overview |

|

|

Ratingplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 14 |

|

Generalview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 16 |

|

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 17 |

|

Indicatorunit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 18 |

4 |

Operation |

|

|

Running-ininstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 22 |

|

Checksbeforestartingwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 22 |

|

Standardequipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 22 |

|

Adjustingthedriver’sseat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 22 |

|

Adjustthesteeringcolumn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 25 |

|

Settingtheclock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 26 |

|

Lapseatbelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 26 |

|

Drivemotor(two-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 28 |

OperatingInstructions–3938071001EN–06/2006 |

III |

|

Table ofcontents |

|

|

|

Driving(double-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Drivemotor(single-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

Driving(single-pedaloperation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

Steeringsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

Brakingsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

Liftingsystemandattachments(centralleveroperation) . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

Liftingsystemandattachments(singleleveroperation) . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

Specialequipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

Lifting system and attachments (single lever operation with 3rd additional hy- |

|

|

draulics) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

Adjustingtheswivelseat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

Adjustthedriver’sair-sprungseat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

|

Mastpositioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

Windscreenwiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

60 |

|

Heating,airconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

|

TruckDataManagement(LFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

|

Workingunderload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

Beforetakingupaload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

Adjustingtheforkspread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

70 |

|

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Transportingaload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

|

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

73 |

|

Towcoupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

Loading/Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

Securingthehosereelagainstrewinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

Dismantlingtheliftmast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

|

Drivingwithoutamast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

76 |

|

loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

|

Transportwithlorryorlow-bedtrailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

79 |

|

Beforeleavingthetruckunattended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

79 |

5 |

Servicing |

|

|

Inspectionandmaintenanceoverview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Generalinformation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Workonthemastandfrontpartofthetruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

|

Initialoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

Checksbeforestartingwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

Maintenanceafterthefirst50hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

IV |

OperatingInstructions–3938071001EN–06/2006 |

|

Table of contents |

|

Inspectionandmaintenanceasrequired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

Inspection and maintenance work every 500 to 1000 operating hours * or every |

|

year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

Inspectionandmaintenanceevery3,000operatinghoursorevery2years . . . . . . . . . . |

87 |

Inspectionandmaintenanceevery6000hoursorevery3years . . . . . . . . . . . . . . . . . . |

88 |

Inspectionandmaintenanceevery9000hoursorevery4years . . . . . . . . . . . . . . . . . . |

88 |

Inspectionandmaintenancedata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

Consumablematerialsrecommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

Checkspriortostartingwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

Engineoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

95 |

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

Tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

Checkthethirdauxiliaryhydraulicfunctionandsafetysystem(option) . . . . . . . . . . . . . |

99 |

Inspectionandmaintenanceasrequired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

101 |

Baseplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

101 |

Changingwheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

102 |

Tightenthewheelbolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

103 |

Cleanthelifttruck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

103 |

Cleantheventhosetothetank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

104 |

Cleanandlubricatetheliftchainsl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

Changetheairfilterelement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

Changetheairfiltersafetyelement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

106 |

Checkthedustdischargevalve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

106 |

Cleantheprefilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

Cleanandchecktheradiatorandhydraulicoilcoolerforleaks . . . . . . . . . . . . . . . . . . . |

107 |

Regeneratethesootfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

Changetheoilintheoilbathaircleaner(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

Toppingupwashersystemwatertank(specialequipment) . . . . . . . . . . . . . . . . . . . . . |

111 |

Drainthefuelfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

112 |

Lubricatethesteeringaxlebearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

Checkthetyresfordamageandforeignobjects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

Checktheseatbeltforconditionandproperoperation . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

Servicingtheairconditioning(specialequipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

114 |

Inspectionandmaintenanceevery500to1000operatinghoursoronceayear . . . . . . |

116 |

Changingmotoroil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

116 |

Cleantheradiatorandhydraulicoilcooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

118 |

Cleanwettypeaircleaner(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

118 |

Checkcoolantconcentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

119 |

Hydraulicsystem: Checktheoillevel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

OperatingInstructions–3938071001EN–06/2006 |

V |

Table ofcontents |

|

|

|

Checkcorrectoperationofbreathervalveonthehydraulicoiltank . . . . . . . . . . . . . . . . |

121 |

|

Battery: checkcondition,acidlevelandacidspecificgravity . . . . . . . . . . . . . . . . . . . . |

122 |

|

Changethefuelfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

|

Engineoilfilterchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

|

Checkconditionoftheribbedveebelt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

|

Checktoothedbeltconditionandtension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

|

Checkthesootfiltersystem(option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

|

Checkelectricalcables,cableconnectorsandcableterminalsforconditionandsecure |

|

|

attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

|

Checkthepedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

130 |

|

Checkandoilotherpivotsandjoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

130 |

|

Checkthecontrolunitforproperoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

|

Renewtheairfilterelement,checkthevacuumswitch . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

|

Cleanandgreasethesteeringaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

132 |

|

Cleansideshift(specialequipment)andgrease,checkfastening . . . . . . . . . . . . . . . . . |

133 |

|

Clean and lubricate fork arm adjuster (special equipment), check fastenings Clean |

|

|

andlubricate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

133 |

|

Mast,liftchains,liftcylindersandendstops: Checkforsecurity,conditionandproper |

|

|

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

|

Adjusttheliftchainlength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

|

Checkthetensionofdoublehoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

Checktheforksandforkquick-releases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

|

Checktheenginemountingforconditionandsecurity . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

|

Checkingfasteningforframe,tiltcylindersandsteeringaxle . . . . . . . . . . . . . . . . . . . . |

139 |

|

Axleclampsandwheelmotors,checkingfastening . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

|

Checkthesteeringcylinderandkingpinforsecurity . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

|

Check,adjustthedriveaxlelateralstops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

|

Checkthecombustionairintakeandexhaustpipesforleaks . . . . . . . . . . . . . . . . . . . . |

141 |

|

Checkthehydraulicsystemforleaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

|

Checktheoperationoftheparkingbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

|

Inspectionandmaintenanceevery3000operatinghoursorevery2years . . . . . . . . . . |

143 |

|

Hydraulicsystem: renewthefilters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

|

Changetheairfiltersafetyelement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

145 |

|

RenewtheribbedV-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

|

Renewthetoothedbeltandidlerpulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

147 |

|

Checkthedriveaxlemountingforwear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

147 |

|

Checktiltcylinderbearingsforwear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

|

Checkthehydraulicpumpsecurityattheengine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

|

Checkslideguidesonsideshift(specialequipment)forwear . . . . . . . . . . . . . . . . . . . . |

148 |

|

Inspectionandmaintenanceevery6000operatinghoursorevery3years . . . . . . . . . . |

150 |

|

Changehydraulicoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

150 |

VI |

OperatingInstructions–3938071001EN–06/2006 |

|

Table of contents |

|

Inspectionandmaintenanceevery9000operatinghoursorevery4years . . . . . . . . . . |

152 |

Replacethewaterpump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

152 |

Changingcoolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

152 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

Openingtheelectricalsystemcover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

Fusesforbasic-andspecialequipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

Mainfuseintheenginecompartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

Diagnosticconnector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

157 |

Jumpstart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

157 |

Emergencyloweringofforkcarriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

158 |

Emergencyexitfortruckswithrearscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

159 |

Towinginstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

Placingtheforklifttruckintostorage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

162 |

Disposalofoldvehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

163 |

Malfunctionsduringoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

Faults,causes,remedies(dieselengine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

166 |

Hydraulicsystemtroubleshootingguide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

6Technical data

Technicaldata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

TypesheetH25,Edition12/2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

TypesheetH30,Edition12/2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

TypesheetH35,Edition12/2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

LoaddiagramsandliftmastdataEdition12/2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Noiseemissiondata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Frequencycharacteristicsforhumanbodyvibrations . . . . . . . . . . . . . . . . . . . . . . . . . . 184

OperatingInstructions–3938071001EN–06/2006 |

VII |

Table ofcontents |

|

Annex |

|

7 Wiring diagrams |

|

Wiringdiagram(standardequipment)sheet1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

196 |

Wiringdiagram(standardequipment)sheet2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

198 |

Wiringdiagram(standardequipment)sheet3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

200 |

Wiringdiagram(option)sheet1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

202 |

Wiringdiagram(option)sheet2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

204 |

Wiringdiagram(option)sheet3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

206 |

Wiringdiagram(option)sheet4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

208 |

Wiringdiagram(option)sheet5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

210 |

Wiringdiagram(specialequipment)page6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

212 |

Wiringdiagram(specialequipment)page7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

214 |

Hydrauliccircuitdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

216 |

VIII |

OperatingInstructions–3938071001EN–06/2006 |

1

Introduction

1 Introduction

Symbols used

Your forklift truck

offers optimum efficiency, safety, reliability and comfort. It is now up to you to maintain these characteristics for as long as possible andtotakeadvantageoftheresultingbenefits.

During manufacture:

•all safety requirements of the relevant EC directiveswereobserved

•all conformity assessment procedures stipulatedin theapplicable directiveswere carried out.

ThisisattestedbytheCEmarkshownon the nameplate.

This operating manual contains everything you need to know about commissioning, drivingandmaintenance.

A number of special equipment items have theirown operating manuals, which are supplied along with this equipment. Please observetheinformationforoperationdepending

on the version of your forklift truck and carry out the specified work regularly, at the due times and using the workingmaterialsenvisagedforthispurposeaccordingtotheinspection and maintenance overview programme. Please make sure you record the work performed in the registration document for the industrial truck; only in this manner will you retainyourwarrantyclaims.

Thedesignationsusedinthetext: front-back - left - right - always refer to the installation position of the parts described with forwards asthe direction oftravel(forkarmsforwards) fortheforklift truck.

In the case of servicing work not described here,specialistknowledge,measuringinstruments and frequently also special tools are required. Please askyour authorised dealer tocarryoutthiswork.

Servicingshouldonlybecarriedout byqualifiedstaffauthorisedbyLinde(specialists).

Intended use

The lift truck is designed fortransporting and stackingthe loadsstated in the load capacity diagram. In particular

•we refer to the VDMA "Guidelines for the normalandproperuseofindustrialtrucks" (orBITAforUKmarket),

•thesafetyrulesofyourtradeassociation,

•thespecialmeasuresrequiredfordrivingon publicroadsinaccordancewiththeC.U.R.,

•otherlocalregulations.

Symbols used

The precautionsWARNING, CAUTION, AT-

TENTION, NOTE and ENVIRONMENTAL

NOTEinthismanualareprovidedto indicate

The rules forthe intended and approved use ofindustrialmustbefollowedunderallcircumstances by the responsible persons, especiallybytheoperatorandservicepersonnel.

The user, and not Linde, is responsible for any danger arising from applications not authorisedbythemanufacturer.

If you desire to use the truck for applications not mentioned in the manual and convert or supplement it for this purpose, please first contactyourauthoriseddealer.

Nochanges,particularlynomodificationsand additions, may be made to the truck without theapprovalofthemanufacturer.

specialhazardsorunusualinformationrequiringspecialidentification:

2 |

OperatingInstructions–3938071001EN–06/2006 |

Introduction 1

Symbols used

DANGER

DANGER

indicateshazardsthatmayresultinpersonalinjury ordeathand/orsubstantialdamagetotheproduct.

ENVIRONMENTNOTE

ENVIRONMENTNOTE

The information contained herein must be observed, otherwise environmental damage may occur.

WARNING

WARNING

indicateshazardsthatmayresultinpersonalinjury and/orsubstantialdamagetotheproduct.

CAUTION

CAUTION

indicates hazards that may result in damage to or destructionoftheproduct.

NOTE

NOTE

Identifies technical information requiring specialattentionbecausetheconnectionmay notevenbeobvioustoskilledpersonnel.

CAUTION

CAUTION

This label is affixed on the truck at the places needing your special attention.

Read the related material in this manual.

For yoursafetyothersymbolsare also used.

Pleasenotethedifferentsymbols.

OperatingInstructions–3938071001EN–06/2006 |

3 |

1 Introduction Technical specification

Technicalspecification

Forklifttrucksinthe393seriesaredesignedto handle loading and palletising operations for loadsup to 2.5 t with H 25, up to 3 t with H 30 andup to3.5t withH35.

Details on the exact lifting height-specific maximum loads are available in the load diagram.

The forklift trucks are eco-friendly and their quiet operational noise and low level of emissions benefit both the driver and the environment. Theyexcel on account of their compact design and a small turning radius, and they are fully container compatible. For this reason, the forklift trucks are particularly well-suited fornarrow alleysand operational areaswherespaceisatapremium.

Motor

A 4-cylinder, four-stroke diesel motor with turbocharging is installed as the drive motor. It drives the forklift truck’s hydraulic pump at a speed to match the load. The motor is cooled by means of a closed coolant circuit withremoteexpansionreservoir.

Pressure circulation lubrication with an oil pump in the oil sump is used to lubricate the motor. The combustion air is cleaned by means of a dry air filter with a paper insert. Dieselmotorswithstate-of-the-arttechnology are used for:

•high torque

•lowfuelconsumption

•lowexhaustemissions

•lowparticulateemissions

•low noise values

Hydraulicsystem

The travel drive consists of a hydraulic vari- able-displacement pump, two hydraulic constantwheelmotors(assembledasadriveaxle unit) as well as a hydraulic pump (fixed-dis- placementpump)fortheoperatingandsteering hydraulics. The direction of travel and

speed are regulated by means of two accelerator pedals via the hydraulic variable-dis- placement pump.

The hydraulic constant wheel motors in the drive axle are supplied by the hydraulic variable-displacement pump and theypower thedrive wheels.

Operation

One accelerator pedal each for forward travel and reversing (two-pedal operation) isusedtoregulateboththehydraulicvariabledisplacement pump and simultaneously the motor speed. The hydrostatic drive enables the speed to be continuously varied in both directions, ranging from standstill up to maximum speed. The dual-pedal control means that operation of the forklift truck is bothsimpleandreliable.

The driver always has both hands free for steeringand controlofthework movements. Fastreversing andenergy-saving stackingis the result.

An optionalversionisalsoavailable whereby thespeedisregulatedbyanacceleratorpedal (single-pedal operation) and the direction of travelcontrolledbymeansofatraveldirection switch.

To control the work movements, lifting, loweringandtilting,thereisonlyoneoperating lever (joystick). Another joystick is fitted to operate additional attachments. Working movementscan also be controlled using two joysticks(single-leveroperationversion).

LindeTruckControl

The forklift truck’sLinde TruckControl (LTC) enables:

•sensitive,smoothdrivingandreversing,

•automatic regulation of motor speed to match respective power required by the hydraulics,

•fasterservicethroughselfdiagnosis,

•maximumoperationalreliability.

4 |

OperatingInstructions–3938071001EN–06/2006 |

Introduction 1

Truck takeover

Brakes |

Steering |

The hydrostatic drive is used as a service brake. This in turn means that the service brake is maintenance free. Two multi-disc brakes integrated into the wheel motors are used as a parking brake. When the motor is switched off the multi-disc brakes engage, thisinturnmeansthattheforklifttruckhasan automatic braking function. To operate the parking brake when switching off the forklift trucktheparkingbrakehandlemustalwaysbe engaged.

Thesteeringisahydrostaticsteeringsystem, with which the steering wheel acts on the steering cylinder to actuate the rear wheels. If the power applied to the steering wheel is increased, the steering system can also be operated when the motorhasbeen switched off.

Electricalsystem

The electrical system is powered through the alternator with 12 V d.c. voltage. A 12 V battery with 88 Ah has been installed for starting the motor. It is located under the driver’sseatinthemotorcompartment.

Truckoperationwithabucket

If the truck is operated with a bucket, the anti-stall device can be activated by your authorised dealer.

In this case the working hydraulics will operate with a slight delay due to the drop in engine speed when the engine experiences extremelyheavyloads.

NOTE

NOTE

With a longer sustained load on the engine, thejoystickmustbeputtotheneutralposition toreleasetheworkinghydraulicsagain.

Truck takeover

Every Linde lift truck undergoes careful inspection before leaving the factory in order to make sure that it will be in good condition andfullyequippedasorderedwhendelivered. YourauthorisedLindedealerisunderobliga- tiontore-inspectthetruckbeforedeliveryand tohanditoverinfullworkingorder.

In orderto avoid later complaints and inconvenience to customers, youare requested to ascertainthatthetruckisinsatisfactorycondition and fully equipped at the time of delivery and to acknowledge the correct installation ofthetruckinthemanufacturerscertificateof conformity.

Lindepursuesapolicyofcontinuousimprovement in the design and manufacture of its

products. The illustrations and technicaldetailsreferringtodesign,fittingsandengineeringoflifttrucksaresubjecttochangeormodification asa result of technologicalprogress by Linde.

Linde is therefore unable to consider any claims based on the specifications, illustrationsanddescriptionscontainedinthisOperatingInstructionsmanual.

Please submit allenquiriesconcerning Linde fork truckorders forspare parts to your local Linderepresentative,makingsuretogivethe correctdeliveryaddress.

ForrepairsuseonlyoriginalLindespareparts. Only in this way can it be guaranteed that yourLinde forklift truckmaintains its original technicalstandard.

OperatingInstructions–3938071001EN–06/2006 |

5 |

1 Introduction

Initial operation

These operating instructions or excerpts thereof may only be copied, translated or transmitted to third parties after prior written approvalbythemanufacturer.

Whenorderingspareparts,pleasespecifythe partnumberandstatethefollowingtruckdata:

Lifttruckmodel:

Serial number/year ofmanufacture:

Handoverdate:

Additionally, specify the serial numberof the engine, mast, hydrostatic hydraulic pump and drive axle when ordering parts for these assemblies.

Enginenumber:

Mastnumber:

Maststroke:

Hydraulic pump number:

Driveaxlenumber:

This information can be found on the type plateson the truck. We recommend that you

transfer this information to this manual for ease offuturereference.

NOTE

NOTE

Whenaforklifttruckwithoutamastisdelivered from our factory, it is fitted with an additional stopscrewtolimitthespeed. Thisstopscrew islocatedunderthereverseacceleratorpedal (twopedaloperation)orundertheaccelerator pedal (one pedal operation). This additional screw must be removed when the mast is mounted. To do this, loosen the hexagonal screwandunscrewitalongwiththehexagonal nut(seealso: Drivingwithoutmast).

The following technicaldocumentsbelong to each forklift truck:

•OperatingInstructionsmanualforthetruck

•EC Declaration of Conformity (The manufacturer certifies that the industrial truck conformstoECdirectivesformachines.)

•Rules for the Normal and Proper use of Industrial Trucks or Booklet for Users of IndustrialandRoughTerrainTrucks(VDMA

•orBITAforUKmarket)

Initial operation

¾ Checktheengineoillevel |

¾ Checkthehydraulicoillevel |

|

¾ Check the coolant level in the expansion |

¾ Checkthebrake system |

|

reservoir |

¾ Checkthesteeringsystem |

|

¾ Refuelling |

||

¾ Checktheliftingdeviceandattachments |

||

¾ Checkcondition, electrolyte leveland acid |

||

¾ Regeneratethesootfilter(option) |

||

densityofthe battery |

||

¾ Checkthethirdauxiliaryhydraulicfunction |

||

¾ Checkthetyreinflationpressure |

||

and safetysystem |

||

¾ Tightenthewheelnuts |

||

|

6 |

OperatingInstructions–3938071001EN–06/2006 |

2

Safety

2Safety

Safety regulations

Safety regulations

This "rules enclosed with this operating manual refer to the correct use of industrial trucks."Theymustbebroughttotheattention of the persons responsible, in particular to thosepersonsconcernedwith operatingand maintainingthetrucks,beforeworkingwithor on the trucks.

Theoperatingcompanymustensurethat the driverunderstandsallthesafetyinformation.

Pleasecomplywiththeregulationsandrules, e. g.

•Operationofindustrialtrucks,

•Rulesfordrivewaysandtheareaofoperation,

•Right, dutiesandrulesofbehaviourforthe driver,

•Specialoperatingareas,

•Information regarding setting in motion, drivingand braking,

•Informationformaintenanceandrepair,

•Periodicchecks,

•UVV inspections,

•Disposalofoils,greasesandbatteries,

•Otherhazards.

As the operating company or responsible person, ensurethatallregulationsandsafety rules that are applicable to your industrial trucksarecompliedwith.

When training a fork-lift truck driver who has alreadybeentrainedtoBGVD27,the

•special features of the Linde fork lift truck (dual-pedal control, central joystick, stop pedal),

•andanyspecialattachments,

•special features of operation and working area,

must be practised sufficiently by training, driving, switching and steering, so that they are fullymastered.

Onlythenshouldtrainingonforkliftaccessto therackingcommence.

Safetyinformation

DANGER

DANGER

Safety devices (e.g. the seatswitch) are there for your safety.

Safety devices - of whatever kind - must never be disconnected.

DANGER

DANGER

Whenretrofittinga3rdadditionalhydraulicsystem, usingsolutionsotherthanthoserecommendedby the truck manufacturer will render EC conformity nullandvoidandisthereforeexpresslyforbidden.

Trucksmayonlyberetrofittedwitha3rdadditional hydraulic system with the approval of the truck manufacturer.

DANGER

DANGER

It is forbidden to connect any safety-critical functions such as a ball clamp or swivel of a fluid container to any thirdadditionalhydraulic systemthat may be fitted.

Soastopreventinadvertentopeningoftheclampor swivel,theadditionalfunctionshouldbeconnected tothefirstadditionalhydraulicsystem.

DANGER

DANGER

Anyadditionaldrilledholesorweldingtothedriver’s protectiveroofwillcompromiseitsstrength.

It is therefore strictly forbidden to drill holes in the driver’sprotectiveroofortoweldtoit.

CAUTION

CAUTION

Welding operations on other parts of the vehicle cancausedamagetotheelectronics.

Therefore before performing any welding, always disconnect the battery and all connections to the electroniccontrol units.

8 |

OperatingInstructions–3938071001EN–06/2006 |

Safety 2

Handling fluids and lubricants

WARNING

WARNING

Itis thecoolanttemperaturethatdetermineswhen thefanonthecoolerstartsup. Thismeansthatthe fancanevenstartupautomatically iftheignitionis switched off.

Whenperformingworkintheenginecompartment, waituntiltheenginehascooleddown.

WARNING

WARNING

Depending on the duration of operation and use, components carryingexhaustgasesandexhaust aircanbecomehot.

Thereforewearprotectiveclothing

WARNING

WARNING

Theforklifttruckworkingareamustbeadequately lit.

If it is insufficiently lit, floodlights mustbe installed toensurethatthedrivercanseeproperly

Inthe case oftip-over

•Stay buckled up

•Don’t jump

•Hold on tight

•Brace feet

•Lean away

The stability of your truck is ensured if used properly and as intended. Should the truck tip overduring an unapproved application or due to incorrect operation, always follow the instructionsdepictedbelow.

Handlingfluidsandlubricants

ENVIRONMENTNOTE

ENVIRONMENTNOTE

Always handle fluids and lubricants as requiredandasspecifiedbythemanufacturer.

•Onlystorefluidsandlubricantsinapproved containersatspecifiedstorageplaces.

•Astheycouldbe inflammable,donotallow contactwithhotobjectsoranakedflame.

•Onlyusecleancontainerswhenreplenishingfluidsandlubricants.

•Follow the manufacturer’s safety and disposalinstructions.

•Do not spillfluids.

•Remove any spillage immediately with a suitable binding agent and dispose of as specified.

•Alsodisposeofusedorcontaminatedfuels andlubricantsasspecified.

•Followlawsandregulations.

•Clean the area surrounding the part in question before lubrication, filter renewal orrepairsinthehydraulicsystem.

•Discard replaced parts in a way friendly to the environment.

OperatingInstructions–3938071001EN–06/2006 |

9 |

2 Safety

Regulations

WARNING |

|

WARNING |

Do not allow hydraulic oil under pressure, for |

|

Improperhandlingofcoolantsandcoolantadditives |

example at a leak, to penetrate the skin. Medical |

|

putsyourhealthandtheenvironmentatrisk. |

aidisrequiredifsuchaninjuryoccurs. |

|

Observemanufacturer´sdirections. |

Wear protectivegear. |

|

|

|

|

|

|

|

|

|

|

|

Experts

Expertsarepersonswithaspecialtrainingand experience in servicing and testing industrial trucksandfamiliarwiththeapplicableworker’s protectionrules,safetyregulations,directives and generally recognised rules of the art

(DIN and VDE standards, technical rules of members of the EU or EEA agreements) so that they can give a qualified assessment of the safe operating condition of industrial trucks.

Operationofindustrialtrucksinplantarea

Manyplant areasare so-called limited public traffic areas. In this sense, we would like to advise you to check your company liability insurance coverage, to ensure that possible

claims for damages caused by your truck in limited public traffic areas in relation to third parties are included in the insurance coverage.

Regulations

Safetyinspection

The accidentprevention rulesin somecountries require that the fork lift truck must be checked periodically for properoperation by trainedpersonnel. Pleasecontactyourauthoriseddealerforthisinspection.

Dieselengineemissions

InGermany, fork trucksequipped withdiesel engines must conform to TRGS 554. Accordingtothisregulation,dieselengineemissions are hazardous materials causing cancer. They should not get into the air at the workplace,ifpossible. Iftrucksequippedwith

diesel engines are used in totally or partially enclosed spaces, the labour protection authority must first be notified. Appropriate notices must be posted in the work areas(refer toTRGS554foranexample).

Sootfilterinspection

The responsible authorities specify that soot filters must be inspected and serviced every six months by an expert. The results of the inspection must be recorded in a "Diesel EngineEmissionsInspectionCertificate"and attached to the log book (eg truck’s safety inspectionlogbook).

10 |

OperatingInstructions–3938071001EN–06/2006 |

Safety 2 Determinationandassessmentofhazardsfromuseofindustrialtrucks

Safety 2 Determinationandassessmentofhazardsfromuseofindustrialtrucks

Determinationandassessmentofhazardsfromuseofindustrial trucks

|

|

Checknote |

|

Hazard |

Action |

X=actioned |

Notes |

|

|

- = not |

|

|

|

concerned |

|

Industrial truck |

|

|

If in doubt, consult |

|

|

competent factory |

|

equipment does not |

|

|

|

Check |

|

inspectorate or |

|

comply with local |

|

||

|

|

employers’ liability |

|

provisions |

|

|

|

|

|

insuranceassociation |

|

|

|

|

|

Lack of skills and |

Driver training (sit-on |

|

UVV-BGV D 27 - § 7, |

and stand-on industrial |

|

BGG 925 driver permit |

|

qualificationofdriver |

|

||

trucks) |

|

VDI3313 |

|

|

|

||

|

|

|

|

Lack of skills and |

Instructionforpedestrian- |

|

|

qualificationofdriver |

controlledtrucks |

|

|

Usage by unauthorised |

Access with keyonly for |

|

|

persons |

appointedstaff |

|

|

Industrial truck not in a |

Recurrent testing and |

|

UVV-BGV D 27 - §§ 9, |

safecondition |

rectificationofdefects |

|

37,BGG 918 |

Impaired visibility |

Deploymentplanning |

|

UVV-BGVD27-§12 |

throughload |

|

||

|

|

|

|

Contamination of |

Assessment of diesel |

|

TRGS554 |

respiratoryair |

exhaustgases |

|

|

|

|

||

Contamination of |

Assessment of fuel gas |

|

MAKlist(maximumwork- |

respiratoryair |

exhaustgases |

|

placeconcentrationslist) |

Impermissible usage |

Issue of operating |

|

UVV-BGVD27-§5 |

(improperusage) |

instructions |

|

|

|

|

||

Impermissible usage |

Written notice of |

|

UVV-BGVD27-§7 |

(improperusage) |

instructiontodriver |

|

|

|

|

||

Impermissible usage |

UVV-BGVD27,observe |

|

|

operating manual and |

|

|

|

(improperusage) |

|

|

|

VDMAleaflet |

|

|

|

|

|

|

|

When filling up with a) |

UVV-BGVD27,observe |

|

|

operating manual and |

|

|

|

diesel |

|

|

|

VDMAleaflet |

|

|

|

|

|

|

|

When filling up with b) |

UVV-BGVD27,observe |

|

|

operating manual and |

|

|

|

fuel gas |

|

|

|

VDMAleaflet |

|

|

|

|

|

|

|

When charging traction |

UVV-BGVD27,observe |

|

VDE 0510: In particular |

batteries |

operatingmanual,VDMA |

|

a)ventilationb)insulation |

leafletandVDE0510 |

|

value |

|

|

|

OperatingInstructions–3938071001EN–06/2006 |

11 |

2Safety

Instructions forfittingattachments

IntheFederalRepublicof Germanythe GermanLawonHealth and Safetyat Work(ArbSchG) states that it is up to the Employer to assess which hazards are associated with theworkofemployeesandwhichHealth and Safetymeasuresarerequired(§5ArbSchG). The result must be documented (§ 6 ArbSchG). In the case of industrial truck deploymentsinvolving similarhazard situationsitis permitted tosummarisethe results. IncountriesoutsidetheFederalRepublicofGermany the country-specific regulations must be observed. With the list we are helping you to complywiththeseregulations. Theconstructionandequipmentofindustrialtruckscomply with the Machinery Directive 98/37/EC and are identified by the CE mark accordingly. This means that they do not fall under the scopeinvolvedintheassessmentofhazards, and nordo attachments due to their own CE marking . The operator must however select thetypeandequipmentofindustrialtrucksso as to comply with the local provisions for deployment.

Inordertoensurethesafeusageofindustrial trucks we not only supply every industrial truckwitha copyof theoperating manualbut also with the leaflet of the VDMA (German Engineering Federation)specifying the rules fortheproperusageofindustrialtrucks"Rules fortheProperUseofIndustrialTrucks".

Thelistspecifieskeyhazardswhicharemost frequentlythecauseofaccidentsintheevent ofnon-compliance. Ifothermajorhazardsare involvedataspecificplant,theymustbelisted additionally.

In many plants the conditions of use for industrial trucks are by and large similar so that the hazards can be summarised in one list. The pronouncements of the employers’ liability insurance association competent in eachcaseasregardsthistopicshouldalsobe taken into account.

Instructionsforfittingattachments

To depressurise the oil in the pipes be- |

For this consult the section "Operate attach- |

forefitting an additionalhydraulicattachment |

ments". |

to the hydraulic system, a pressure receiver |

|

(specialequipment)canbeused. |

|

12 |

OperatingInstructions–3938071001EN–06/2006 |

3

Overview

3 Overview

Rating plates

Rating plates

1Nameplate

9Liftmastnumber(stick-onlabel)

10Chassisnumber(stampedintotherearwall ofthedriver’sprotectiveroof)

11Ratingplatefordriveaxle

12Ratingplateforengine

14 |

OperatingInstructions–3938071001EN–06/2006 |

Overview 3

Rating plates

NOTE

NOTE

TheCEmarkconfirmscompliancewiththeEC machinery directive and with all regulations applicabletoforklifttrucks.

1 |

Nameplate |

2 |

Manufacturer |

3 |

CE mark |

4 |

SerialNo. /buildyear) |

5 |

Tareweight |

6 |

Batteryvoltage |

7 |

Nominalloadcapacity |

8 |

Type |

OperatingInstructions–3938071001EN–06/2006 |

15 |

3 Overview

General view

General view

1 |

Mast |

13 |

Maintenanceaccesscovers |

2 |

Lift cylinder |

14 |

Chassisandoverheadguard |

3 |

Compositeinstrument |

15 |

Enginebonnet |

4 |

Tiltcylinders |

16 |

Stepformountinganddismounting |

5 |

Toggle switch for auxiliary functions (op- |

17 |

Fuses(intheenginecompartment) |

|

tional) |

18 |

Wheelmotor, left |

6 |

Steeringwheel/hydrostaticpowersteering |

19 |

Handwheelforadjustingsteeringcolumn |

7 |

Controllever(joystick) |

20 |

Fork carriage |

8 |

Operator’sseat |

21 |

Fuses, forks |

9 |

Electricalsystemcover |

22 |

Forks |

10 |

Fuses(behindtheelectricalsystemcover) |

23 |

Forks, locking |

11 |

Counterweight |

24 |

Liftchain(onlyforduplexortriplexmast) |

12 |

Steeringaxle |

|

|

16 |

OperatingInstructions–3938071001EN–06/2006 |

Overview 3

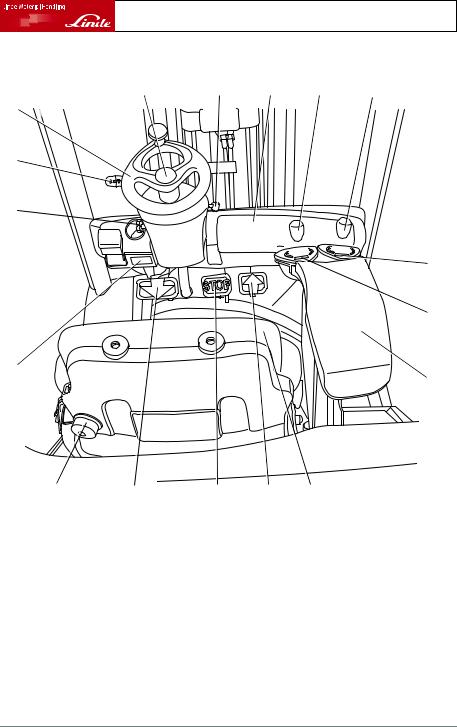

Controls

Controls

5 |

6 |

7 |

8 |

9 |

4

3

2

1

10

11

18

12

d3921508

|

17 |

16 |

15 |

14 |

13 |

1 |

Parkingbrakehandle |

|

10 |

Symbollabelforauxiliaryhydraulics(attach- |

|

2 |

Handwheelforadjustingsteeringcolumn |

|

ments)(option) |

||

3 |

Combined lever for wiper/washer and |

11 |

Symbollabelforworkinghydraulics |

||

|

blinker(option) |

|

12 |

Operator’sseatarmrest |

|

4 |

Steeringwheel/hydrostaticpowersteering |

13 |

Operator’sseat |

||

5 |

Signalbutton |

|

14 |

Forwardaccelerator |

|

6 |

Ignitionswitchwithignitionkey |

15 |

Brakepedal |

||

7 |

Cubbyhole |

|

16 |

Reverseaccelerator |

|

8 |

Control lever (joystick) for working hy- |

17 |

Backrestcushionadjuster(option) |

||

|

draulics |

|

18 |

Plate"Guaranteedacousticpowerlevel" |

|

9Control lever (joystick) for auxiliary hydraulics(attachments)(option)

OperatingInstructions–3938071001EN–06/2006 |

17 |

3 Overview

Indicator unit

Indicator unit

1Indicatorunit

2Hydraulicoiltemperatureindicator

3Batterychargeindicator

4Engine oil pressure indicator / Engine oil levelindicator(specialequipment)

5Electricalcontrolsystemfault

6Enginetemperatureindicator

7Load / overload indicator (special equipment)

8not assigned

9Leveldisplay(specialequipment)

10Hydraulic oil micro-filter indicator (special equipment)

11Fueltankleveldisplay

12Display

13not assigned

14Displayoperatinghours

(2)Hydraulicoiltemperatureindicator(colour red)

Lights up when the specified temperature limit is reached. A buzzer sounds when the permissibletemperaturelimitisreached.

•Insufficientoilinthehydraulicsystem

•Incorrectoilused

•Oil filterclogged

•Oilcoolerclogged

•Switchbuzzeroffwiththeresetbutton(19).

(3)Batterychargeindicator(colourred)

15Symboloperatinghours

16Display time

17Symbolserviceintervalexceeded

18Functionpush-button

19Resetbutton

20Symbolparkingbrakeapplied

21Symbol"donotstarttheengine"

22Symbol operating hours (until next service shownforonly4secondisplayfield(14))

23Symbolliftmastpositionsensing

24Text field

25Glowplugindicator

26Airfilterinductionpressureindicator

27Coolant water leveldisplay(special equipment)

28not assigned

Lights up when there is a fault in the battery chargersystem.

•Ribbed vee belt broken or ribbed vee belt tensiontoo slack

•Ribbedveebelttensionerdefective

•Cable defective

•Alternatordefective

•Charge controller or controller switch defective.

(4) Engine oil pressure indicator / Engine oil level indicator (special equipment) (colour red)

18 |

OperatingInstructions–3938071001EN–06/2006 |

Overview 3

Indicator unit

When engine lubricating oil pressure is too low this indicator lights up, and also a buzzersounds. In addition the text field (24)

displaysthetextOil Adoublearrowpointing downwardsindicatesthatthe engineoillevel istoo low.

•Insufficientoilinthecrankcase

•Engine too hot

•Incorrect oilused

•Internalleakageinthelubricatingoilcircuit

•Topup withengine oil

•Switchbuzzeroffwiththeresetbutton(19).

(5)Electricalcontrolsystemfault(colourred)

Lights up when an electrical control system fault is present, and displays a fault code in text field (24).

(6)Enginetemperatureindicator(colourred)

Lights up when the specified temperature limit is reached. A buzzer sounds when the permissibletemperaturelimitisreached.

•Fanmotordefective

•Thermostaticswitchdefective

•Radiatorclogged

•Leakageinthecoolantcircuit

•Coolantleveltoolow

•Switchbuzzeroffwiththeresetbutton(19).

(7) Load / overload display (special equipment)

Symbollightsuporangewhenloadisnormal.

Pleasecontactyourauthoriseddealer.

(10)Hydraulicoilmicro-filterindicator (colour yellow)(specialequipment)

Lights up when the micro-filter requires maintenance.

• Micro-filterclogged,exchangeit.

(11)Fueltankleveldisplay(colourdepending onthelevel,greenorred

• Showsthecurrentfueltanklevel.

(13)not assigned

(14)Displayoperatinghours

Showstheoperatinghoursoftheforklifttruck. This indicator is an shows the forklift truck’s operating hours and indicatesthe inspection andmaintenanceworktobeperformed.

NOTE

NOTE

If a defective indicator unit is exchanged, the operating hours up to that point must be recorded.Notethedataonanembossedstrip attachedneartheindicatorunit. Thereisalso the option of subsequentlyupdating the new indicatorunit. Pleasecontactyourauthorised dealer.

(15)Symboloperatinghours

Flashes when operating hours are being counted (only when the ignition is on and the enginespeedexceeds500rpm)

(16)Displayclock

DANGER

DANGER

Symbollightsupredwhenoverloaded.

Setdownloadimmediately.

• Consult load diagram.

(8)not assigned

(9)Level display (colour yellow) (special equipment)

Lightsup when the coolant level is below the minimum.

• Topupthe coolant.

24-hour clockdisplay

Canbeadjustedusingbuttons(18)and(19.)

Resettingto12-hourclockdisplayispossible usingadiagnostictester. Pleasecontactyour authorised dealer.

(17)Symbolserviceintervalexceeded

Ifthenumberofoperatinghoursuntilthenext service is less than or equal to 0, the symbol flashes for 10 sec every time the vehicle is started,andthenlightsupcontinuously.

Adjustment and reset of the intervals can be performed only using the diagnostic tester

OperatingInstructions–3938071001EN–06/2006 |

19 |

3 Overview

Indicator unit

providedforthispurpose. Pleasecontactyour authorised dealer.

(18)Functionpush-button Assignmentdependingonversion.

(19)Resetbutton(specialequipment)

To adjust the time, switch off the warning buzzerand otherfunctionsdependingon the version.

(20)Symbolparkingbrake

Lightsupwhentheparkingbrakeisapplied. (21)Symbol"donotstarttheengine" Lightsupwhentheenginehasstalled.

NOTE

NOTE

Itisessentialtoleavetheignitionswitchedon untilthis symbolhas gone out(depending on the oil temperature this may be between 15 and50seconds). Then attempt torestart the engine.

(22)Symboloperatinghoursuntilnextservice

After the ignition has been switched on, display field (14) shows the operating hours untilthenextservice(countingbackwards).

Symbol(22)lightsup. After5secondssymbol 22 goes out and indicator (14) automatically switches to the operating hours of the forklift truck;theoperatinghourssymbol(15)flashes.

(23)Symbolliftmastpositionsensing(special equipment)

Lightsup whenthefunction "liftmastposition sensing" isenabled.

(24) text field

Servesasadisplayfield. Pleasecontactyour authorised dealer for interpretation of fault codes.

(25)Glowplugindicator(colouryellow)

Lights up whilst the glow plugs are warming up, then goes out.

Flashes if there an engine fault or engine management fault occurs. Please contact yourauthorised dealer.

(26) Air filter induction pressure indicator (colouryellow)

Lights up when the air filter is excessively clogged.

• Airfilterclogged,exchangeit.

(27) Coolant water level display (colour yellow)(specialequipment)

Lightsup whenthe coolant levelisbelow the minimum.

• Top up thecoolant. (28) not assigned

20 |

OperatingInstructions–3938071001EN–06/2006 |

Loading...

Loading...