Page 1

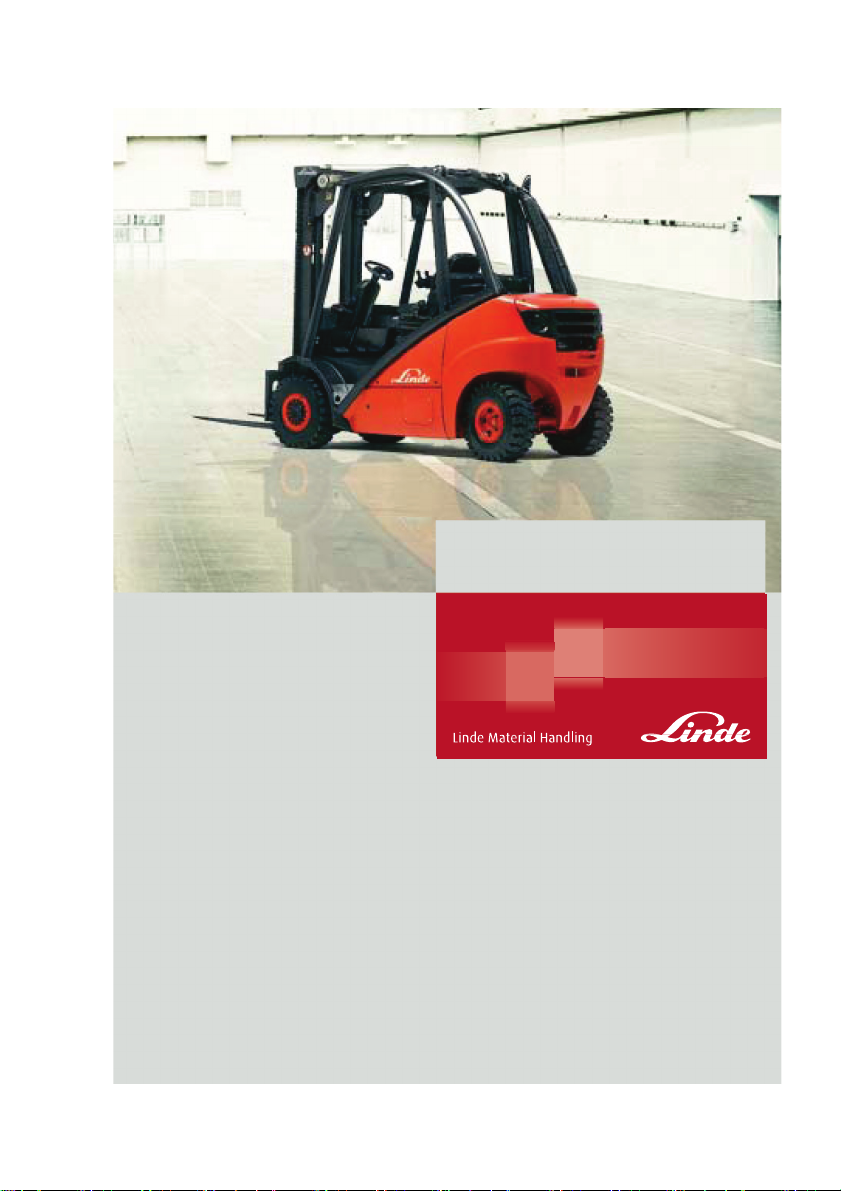

Operating Instructions

Diesel forklift truck

H25D, H30D, H35D

393 807 1001 EN – 06/2006

Page 2

Page 3

Linde - Your Partner

Preface

g

With over 100,000 fork lift trucks and warehouse machines sold annually, Linde is one of

the world’s leading manufacturers of material

handling equipment. There are many reasons

for this success: Linde products are renowned

not only for their innovative, cutting-edge technology, but also for their low energy and operating costs, which are up to 40 per cent lower

than those of their competitors.

Thehighquali

matched by the

production pl

network of sal

service round

Your local Linde partner can offer you a

complete package from a single source;

Operating Instructions – 393 807 1001 EN – 06/2006 I

ty of Linde products is also

quality of our service. With ten

ants worldwide and an extensive

es partners, we are at your

the clock and around the world.

ranging from expert advice on all aspects

of sales and service through, of course, to

appropriate finance options. Our leasing, hire

or lease-purchase agreements provide you

with the flexibility to tailor decision-making to

your individual business requirements.

Linde Materia

Schweinheimer

63743 Aschaffen

Telephone +49 (0)

Fax +49 (0) 6021 99Mail: info@lindeWeb: http://www.li

l Handling GmbH & Co. KG

straße 34

burg

6021 99-0

1570

mh.com

nde-mh.com

Page 4

Page 5

Table of contents

1 Introduction

Your forklift truck ..................................................... 2

Intended use ........................................................ 2

Symbols used ....................................................... 2

Technical specification ................................................. 4

Truck operation with a bucket ............................................ 5

Truck takeover ....................................................... 5

Initial operation ...................................................... 6

2Safety

Safety regulations .................................................... 8

In the case of tip-over .................................................. 9

Handling fluids and lubricants ............................................ 9

Experts ........................................................... 10

Operation of industrial trucks in plant area .................................. 10

Regulations ........................................................ 10

Determination and assessment of haza

Instructions for fitting attachments ....................................... 12

rds from use of industrial trucks ............ 11

g

3Overview

Rating plates ....................................................... 14

General view ....................................................... 16

Controls .......................................................... 17

Indicator unit ....................................................... 18

4 Operation

Running-in instructions ............................................... 22

Checks before starting work ............................................ 22

Standard equipment ................................................. 22

Adjustingthedriver’sseat .............................................. 22

Adjustthesteeringcolumn ............................................. 25

Settingtheclock ..................................................... 26

Lapseatbelt ....................................................... 26

Drive motor (two-pedal operation) ........................................ 28

Operating Instructions – 393 807 1001 EN – 06/2006 III

Page 6

Table of contents

g

Driving (double-pedal operation) ......................................... 31

Drive motor (single-pedal operation) ...................................... 33

Driving (single-pedal operatio

Steeringsystem ................................................. .... 40

Brakingsystem ..................................................... 41

Horn ............................................................. 42

Liftingsystemandattachments(centralleveroperation) ....................... 43

Liftingsystemandattachments(singleleveroperation) ........................ 46

Special equipment ................................................... 50

Lifting system and attachments (single lever operation with 3rd additional hy-

draulics) .......................................................... 50

Adjustingtheswivelseat .............................................. 53

Adjustthedriver’sair-sprungseat ........................................ 54

Mastpositioning ..................................................... 56

Lighting ........................................................... 58

Windscreenwiper ................................................... 60

Heating, air conditioning ............................................... 62

Truck Data Management (LFM) ......................................... 64

Working under load .................................................. 69

Beforetakingupaload ................................................ 69

Adjustingtheforkspread .............................................. 70

Loading ........................................................... 71

Transportingaload .................................................. 72

Unloading ......................................................... 73

Towcoupling ....................................................... 74

Loading / Transport .................................................. 74

Securing the hose reel against rewinding .................................. 74

Dismantlingtheliftmast ............................................... 75

Driving without a mast ................................................ 76

loading . . ......................................................... 77

Transportwithlorryorlow-bedtrailer ..................................... 79

Before leaving the truck unattended ...................................... 79

n) ......................................... 37

5 Servicing

Inspection and maintenance overview .................................... 82

General information .................................................. 82

Workonthemastandfrontpartofthetruck ................................. 83

Initial operation ..................................................... 86

Checksbeforestartingwork ............................................ 86

Maintenance after the first 50 hours ...................................... 86

IV Operating Instructions – 393 807 1001 EN – 06/2006

Page 7

Table of contents

Inspection and maintenance as required . . . ................................ 86

Inspection and maintenance work every 500 to 1000 operating hours * or every

year ........................................................... ... 87

Inspection and maintenance ever

Inspection and maintenance every 6000 hours or every 3 years . ................. 88

Inspection and maintenance every 9000 hours or every 4 years . ................. 88

Inspection and maintenance data ........................................ 8

Consumable materials recommendations . . ................................ 89

Checks prior to starting work ............................................ 92

Fuel ........................................................... ... 92

Bonnet ........................................................... 93

Engineoil ......................................................... 95

Coolant ........................................................... 96

Tyres ............................................................. 98

Check the third auxiliary hydraulic function and safety system (option) . ............ 99

Inspection and maintenance as required ...................................10

Baseplate ....................................................... . . 101

Changing wheels ....................................................102

Tighten the wheel bolts . ...............................................103

Cleanthelifttruck ....................................................103

Cleantheventhosetothetank ..........................................104

Cleanandlubricatetheliftchainsl .......................................105

Change the air filter element ............................................105

Change the air filter safety element .......................................106

Checkthedustdischargevalve .........................................106

Cleantheprefilter ....................................................107

Cleanandchecktheradiatorandhydraulicoilcoolerforleaks ...................107

Regenerate the soot filter ..............................................109

Change the oil in the oil bath air cleaner (Optional) ............................111

Topping up washer system water tank (special equipment) .....................111

Drainthefuelfilter ...................................................112

Lubricate the steering axle bearings ......................................113

Checkthetyresfordamageandforeignobjects ..............................113

Check the seat belt for condition and proper operati

Servicing the air conditioning (special equipment) ............................114

Inspection and maintenance every 500 to 1000 operating hours or once a year ......116

Changing motor oil ...................................................116

Cleantheradiatorandhydraulicoilcooler ..................................118

Clean wet type air cleaner (Optional) ......................................118

Checkcoolantconcentration ...........................................119

Hydraulicsystem:Checktheoillevel .....................................120

y 3,000 operating hours or every 2 years .......... 87

on .........................113

g

8

1

Operating Instructions – 393 807 1001 EN – 06/2006 V

Page 8

Table of contents

g

Check correct operation of breather valve on the hydraulic oil tank ................121

Battery:checkcondition,acidlevelandacidspecificgravity ....................122

Change the fuel filter .................................................124

Engine oil filter change ................................................125

Check condition of the ribbed vee belt .....................................126

Check toothed belt condition and ten

Checkthesootfiltersystem(option) ......................................128

Check electrical cables, cable connectors and cable terminals for condition and secure

attachment ..................................................... ...129

Check the pedals ....................................................130

Checkandoilotherpivotsandjoints ......................................130

Check the control unit for proper operation .................................131

Renew the air filter element, check the

Cleanandgreasethesteeringaxle .......................................132

Clean sideshift (special equipment) and grease, check fastening .................133

Clean and lubricate fork arm adjuster (spe

andlubricate .......................................................133

Mast, lift chains, lift cylinders and end stops: Check for security, condition and proper

operation ..........................................................135

Adjusttheliftchainlength ..............................................135

Check the tension of double hoses .......................................137

Checktheforksandforkquick-releases ...................................138

Check the engine mounting for condition and security .........................138

Checking fastening for frame, tilt cylinders

Axleclampsandwheelmotors,checkingfastening ...........................139

Checkthesteeringcylinderandkingpinforsecurity ..........................140

Check,adjustthedriveaxlelateralstops ...................................140

Checkthecombustionairintakeandexhaustpipesforleaks ....................141

Checkthehydraulicsystemforleaks .....................................141

Check the operation of the parking brake ..................................142

Inspection and maintenance every 3000 operating hours or every 2 years ..........143

Hydraulicsystem:renewthefilters .......................................143

Change the air filter safety element .......................................145

Renew the ribbed V-belt ...............................................146

Renewthetoothedbeltandidlerpulley ....................................147

Check the drive axle mounting for wear ....................................147

Check tilt cylinder bearings for wear ......................................148

Check the hydraulic pump security at the engine . . ...........................148

Check slide guides on sideshift (special equipment) f

Inspection and maintenance every 6000 operating hours or every 3 years ..........150

Change hydraulic oil ..................................................150

sion ..................................127

vacuumswitch .........................131

cial equipment), check fastenings Clean

andsteeringaxle ....................139

orwear ....................148

VI Operating Instructions – 393 807 1001 EN – 06/2006

Page 9

Table of contents

Inspection and maintenance every 9000 operating hours or every 4 years ..........152

Replacethewaterpump ............................................. . . 152

Changing coolant ....................................................152

Troubleshooting .....................................................155

Openingtheelectricalsystemcover ......................................155

Fuses for basic- and special equip

Mainfuseintheenginecompartment .....................................156

Diagnosticconnector .................................................157

Jumpstart ...................................................... . . . 157

Emergency lowering of fork carriage ......................................158

Emergency exit for trucks with rear screen . ................................159

Towinginstructions ..................................................160

Placingtheforklifttruckintostorage ......................................162

Disposalofoldvehicles ...............................................163

Malfunctions during operation ...........................................164

Faults, causes, remedies (diesel engine) . . ................................166

Hydraulic system troubleshooting guide . . . ................................169

ment ....................................155

6 Technical data

Technical data ......................................................172

Type sheet H 25, Edition 12/2005 ........................................172

Type sheet H 30, Edition 12/2005 ........................................175

Type sheet H 35, Edition 12/2005 ........................................178

Load diagrams and lift mast data Edition 12/2005 ............................181

Noiseemissiondata ..................................................183

Frequency characteristics for human body vib

rations ..........................184

g

Operating Instructions – 393 807 1001 EN – 06/2006 VII

Page 10

Table of contents

g

Annex

7 Wiring diagrams

Wiring diagram (standard equipment) sheet 1 ...............................196

Wiring diagram (standard equi

Wiring diagram (standard equipment) sheet 3 ...............................200

Wiring diagram (option) sheet 1 .........................................202

Wiring diagram (option) sheet 2 .........................................2

Wiring diagram (option) sheet 3 .........................................206

Wiring diagram (option) sheet 4 .........................................208

Wiring diagram (option) sheet 5 .........................................21

Wiring diagram (special equipment) page 6 .................................212

Wiring diagram (special equipment) page 7 .................................214

Hydraulic circuit diagram ..............................................216

pment) sheet 2 ...............................198

04

0

VIII Operating Instructions – 393 807 1001 EN – 06/2006

Page 11

1

Introduction

Page 12

1 Introduction

Symbols used

Your forklift truck

offers optimum efficiency, safety, reliability

and comfort. It is now up to you to maintain

these characteristics for as long as possible

and to take advantage of the resulting benefits.

During manufacture:

• all safety requirements of the

directives were observed

• all conformity assessment procedures

stipulated in the applicable directives were

carried out.

This is attested by the CE mark shown on the

nameplate.

This operating manual contains

you need to know about commissio

driving and maintenance.

A number of special equipment items have

their own operating manuals, which are supplied along with this equipment. Please observe the information for operation depending

relevant EC

everything

ning,

Intended use

The lift truck is designed for transporting and

stacking the loads stated in the load capacity

diagram. In particular

• we refer to the VDMA "Guidelines for the

normal and proper use of industrial trucks"

(or BITA for UK market),

• the safety rules of your tr

• the special measures required for driving on

public roads in accordance with the C.U.R.,

• other local regulations.

ade association,

on the version of your forklift truck and carry

out the specified work regularly, at the due

times and using the working materials envisaged for this purpose according to the inspection and maintenance overview programme.

Please make sure you record the work performed in the registration document for the

industrial truck; only in this manner will you

retain your warranty claims.

The designations used in the text: front - back

- left - right - always refer to the installation

position of the parts described with forwards

as the direction of travel (fork arms forwards)

for the forklift truck.

In the case of servicing work

here, specialist knowledge

ments and frequently also sp

required. Please ask your au

to carry out this work.

Servicing should only be carried out by qualified staff authorised by Linde (specialists).

The rules for the intended and approved use

of industrial must be followed under all circumstances by the responsible persons, especially by the operator and service personnel.

The user, and not Linde, is responsible for

any danger arising from applications not

authorised by the manufacturer.

If you desire to use the tru

not mentioned in the manua

supplement it for this pur

contact your authorised

No changes, particularly no modifications and

additions, may be made to the truck without

the approval of the manufacturer.

not described

, measuring instru-

ecial tools are

thorised dealer

ck for applications

l and convert or

pose, please first

dealer.

Symbols used

The precautions WARNING, CAUTION, ATTENTION, NOTE and ENVIRONMENTAL

NOTE in this manual are provided to indicate

2 Operating Instructions – 393 807 1001 EN – 06/2006

special hazards or unusual information requiring special identification:

Page 13

Introduction 1

Symbols used

DANGER

indicates hazards that may result in personal injury

or death and/or substantial damage to the product.

WARNING

indicates hazards that may result in personal injury

and/or substantial damage to the product.

CAUTION

indicates hazards that may result in damage to or

destruction of the product.

NOTE

Identifies technical information requiring

special attention because the connection may

not even be obvious to skilled personnel.

ENVIRONMENT NOTE

The information contained here

observed, otherwise environme

in must be

ntal damage

may occur.

CAUTION

This label is affixed on the truck at

the places needing your special

attention.

Read the related material in this

manual.

For your safety other symbols are also used.

Please note the different symbols.

Operating Instructions – 393 807 1001 EN – 06/2006 3

Page 14

1 Introduction

Technical specification

Technical specification

Forklift trucks in the 393 series are designed to

handle loading and palletising operations for

loads up to 2.5 t with H 25, up to 3 t with H 30

and up to 3.5 t with H 35.

Details on the exact lifting height-specific

maximum loads are available in the load

diagram.

The forklift trucks are eco-fr

quiet operational noise and lo

emissions benefit both the dri

environment. They excel on acc

compact design and a small turn

and they are fully container

this reason, the forklift tr

well-suited for narrow alle

areas where space is at a prem

Motor

A 4-cylinder, four-stroke diesel motor with

turbocharging is installed as the drive motor.

It drives the forklift truck’s hydraulic pump

at a speed to match the load. The motor is

cooled by means of a closed coolant circuit

with remote expansion reservoir.

Pressure circulation lubrication with an oil

pump in the oil sump is used to lubricate the

motor. The combustion air is cleaned by

means of a dry air filter with a paper insert.

Diesel motors with state-of-the-art technology

areusedfor:

• high torque

• low fuel consumption

• low exhaust emissions

• low particulate emissions

• low noise values

Hydraulic system

The travel drive consists of a hydraulic variable-displacement pump, two hydraulic constant wheel motors (assembled as a drive axle

unit) as well as a hydraulic pump (fixed-displacement pump) for the operating and steering hydraulics. The direction of travel and

iendly and their

w level of

ver and the

ount of their

ing radius,

compatible. For

ucks are particularly

ys and operational

ium.

speed are regulated by means of two accelerator pedals via the hydraulic variable-displacement pump.

The hydraulic constant wheel motors in

the drive axle are supplied by the hydraulic

variable-displacement pump and they power

the drive wheels.

Operation

One accelerator pedal each for

travel and reversing (two-ped

is used to regulate both the hyd

displacement pump and simult

motor speed. The hydrostatic

the speed to be continuously v

directions, ranging from sta

maximum speed. The dual-peda

means that operation of the fo

both simple and reliable.

The driver always has both hands free for

steering and control of the work movements.

Fast reversing and energy-saving stacking is

the result.

An optional version is also available whereby

the speed is regulated by an accelerator pedal

(single-pedal operation) and the direction of

travel controlled by means of a travel direction

switch.

To control the work movement

lowering and tilting, there

lever (joystick). Another j

operate additional attachm

movements can also be contro

joysticks (single-lever op

forward

al operation)

raulic variable-

aneously the

drive enables

aried in both

ndstill up to

lcontrol

rklift truck is

s, lifting,

is only one operating

oystickisfittedto

ents. Working

lled using two

eration version).

Linde Truck Control

The forklift truck’s Linde Truck Control (LTC)

enables:

• sensitive, smooth driving and reversing,

• automatic regulation of moto

match respective power requi

hydraulics,

• faster service through self diagnosis,

• maximum operational reliability.

r speed to

red by the

4 Operating Instructions – 393 807 1001 EN – 06/2006

Page 15

Introduction 1

Truck takeover

Brakes

The hydrostatic drive is used as a service

brake. This in turn means that the service

brake is maintenance free. Two multi-disc

brakes integrated into the wheel motors are

used as a parking brake. When the motor is

switched off the multi-disc brakes engage,

this in turn means that the forklift truck has an

automatic braking function. To operate the

parking brake when switching off the forklift

truck the parking brake handle must always be

engaged.

Truck operation with a buck

If the truck is operated wit

anti-stall device can be ac

authorised dealer.

In this case the working hydraulics will operate with a slight delay due to the drop in

engine speed when the engine experiences

extremely heavy loads.

h a bucket, the

tivated by your

et

Steering

The steering is a hydrostatic steering system,

with which the steering wheel acts on the

steering cylinder to actuate the rear wheels.

If the power applied to the steering wheel is

increased, the steering system can also be

operated when the motor has been switched

off.

Electrical system

The electrical system is power

the alternator with 12 V d.c. vo

battery with 88 Ah has been inst

starting the motor. It is loca

driver’s seat in the motor com

NOTE

With a longer sustained loa

the joystick must be put to

to release the working hyd

ed through

ltage. A 12 V

alled for

ted under the

partment.

d on the engine,

the neutral position

raulics again.

Truck takeover

Every Linde lift truck undergoes careful inspection before leaving the factory in order

to make sure that it will be in good condition

and fully equipped as ordered when delivered.

Your authorised Linde dealer is under obligation to re-inspect the truck before delivery and

to hand it over in full working order.

In order to avoid later complaints and inconvenience to customers, you are requested to

ascertain that the truck is in satisfactory condition and fully equipped at the time of delivery

and to acknowledge the correct installation

of the truck in the manufacturers certificate of

conformity.

Linde pursues a policy

ment in the design and m

Operating Instructions – 393 807 1001 EN – 06/2006 5

of continuous improve-

anufacture of its

products. The illustrations and technical details referring to design, fittings and engineering of lift trucks are subject to change or modification as a result of technological progress

by Linde.

Linde is therefore unable to consider any

claims based on the specifications, illustrations and descriptions contained in this Operating Instructions manual.

Please submit all enqui

fork truck orders for sp

Linde representative,

correct delivery addre

For repairs use only original Linde spare parts.

Only in this way can it be guaranteed that

your Linde fork lift truck maintains its original

technical standard.

ries concerning Linde

are parts to your local

making sure to give the

ss.

Page 16

1 Introduction

Initial operation

These operating instructions or excerpts

thereof may only be copied, translated or

transmitted to third parties after prior written

approval by the manufacturer.

When ordering spare parts, please specify the

part number and state the following truck data:

Lift truck model:

Serial number/year

of manufacture:

Handover date:

Additionally, specify the serial number of the

engine, mast, hydrostatic hydraulic pump

and drive axle when ordering parts for these

assemblies.

Engine number:

Mast number:

Mast stroke:

Hydraulic pump

number:

Drive axle number:

This information can be found on the type

plates on the truck. We recommend that you

transfer this information to this manual for

ease of future reference.

NOTE

When a forklift truck without a ma

from our factory, it is fitted wit

stop screw to limit the speed. T

is located under the reverse ac

(two pedal operation) or under

pedal (one pedal operation). T

screw must be removed when the m

mounted. To do this, loosen the

screw and unscrew it along with

nut (see also: Driving without

The following technical documents belong to

each fork lift truck:

• Operating Instructions manua

• EC Declaration of Conformity (The manufacturer certifies that the industrial truck

conforms to EC directives for machines.)

• Rules for the Normal and Proper use of

Industrial Trucks or Booklet for Users of

Industrial and Rough Terrain Trucks (VDMA

• or BITA for UK market)

st is delivered

h an additional

his stop screw

celerator pedal

the accelerator

his additional

ast is

hexagonal

the hexagonal

mast).

lforthetruck

Initial operation

¾ Check the engine oil level

¾ Check the coolant level in the expansion

reservoir

¾ Refuelling

¾ Check condition, electrolyte level and acid

density of the battery

¾ Check the tyre inflation pressure

¾ Tighten the wheel nuts

6 Operating Instructions – 393 807 1001 EN – 06/2006

¾ Check the hydraulic oil level

¾ Check the brake system

¾ Check the steering system

¾ Check the lifting device and attachments

¾ Regenerate the soot filter (option)

¾ Check the third auxiliary hydraulic function

and safety system

Page 17

2

Safety

Page 18

2 Safety

Safety regulations

Safety regulations

This "rules enclosed with this operating

manual refer to the correct use of industrial

trucks." They must be brought to the attention

of the persons responsible, in particular to

those persons concerned with operating and

maintaining the trucks, before working with or

on the trucks.

The operating company must ensure that the

driver understands all the safety information.

Please comply with the regulat

e. g.

• Operation of industrial trucks,

• Rules for driveways and the area of operation,

• Right, duties and rules of behav

driver,

• Special operating areas,

• Information regarding setting in motion,

driving and braking,

• Information for maintenance and

• Periodic checks,

• UVV inspections,

• Disposal of oils, greases and batter

• Other hazards.

As the operating company or responsible

person, ensure that all regulations and safety

rules that are applicable to your industrial

trucks are complied with.

When training a fork-lift truck driv

already been trained to BGV D 27, the

• special features of the Linde fork lift truck

(dual-pedal control, central joystick, stop

pedal),

• and any special attachments,

• special features of operation and wor

area,

must be practised sufficiently by training,

driving, switching and steering, so that they

are fully mastered.

ions and rules,

iour for the

repair,

ies,

er who has

king

Only then should training on fork lift access to

the racking commence.

Safety information

DANGER

Safety devices (e.g. the seat switch) are there for

your safety.

Safety devices - of whatever kind - must never be

disconnected.

DANGER

When retrofitting a 3rd additional hydraulic system,

using solutions other than those recommended by

the truck manufacturer will render EC conformity

null and void and is therefore expressly forbidden.

Trucks may only be retrofitted with a 3rd additional

hydraulic system with the approval of the truck

manufacturer.

DANGER

It is forbidden to connect any safety-critical functions such as a ball clamp or swivel of a fluid container to any third additional hydraulic system that

may be fitted.

So as to prevent inadvertent opening of the clamp or

swivel, the additional function should be connected

to the first additional hydraulic system.

DANGER

Any additional drilled holes or welding to the driver’s

protective roof will compromise its strength.

It is therefore strictly forbidden to drill holes in the

driver’s protective roof or to weld to it.

CAUTION

Welding operations on other parts of the vehicle

can cause damage to the electronics.

Therefore before performing any welding, always

disconnect the battery and all connections to the

electronic control units.

8 Operating Instructions – 393 807 1001 EN – 06/2006

Page 19

Safety 2

Handling fluids and lubricants

WARNING

It is the coolant temperature that determines when

the fan on the cooler starts up. This means that the

fan can even start up automatically if the ignition is

switched off.

When performing work in the engine compartment,

wait until the engine has cooled down.

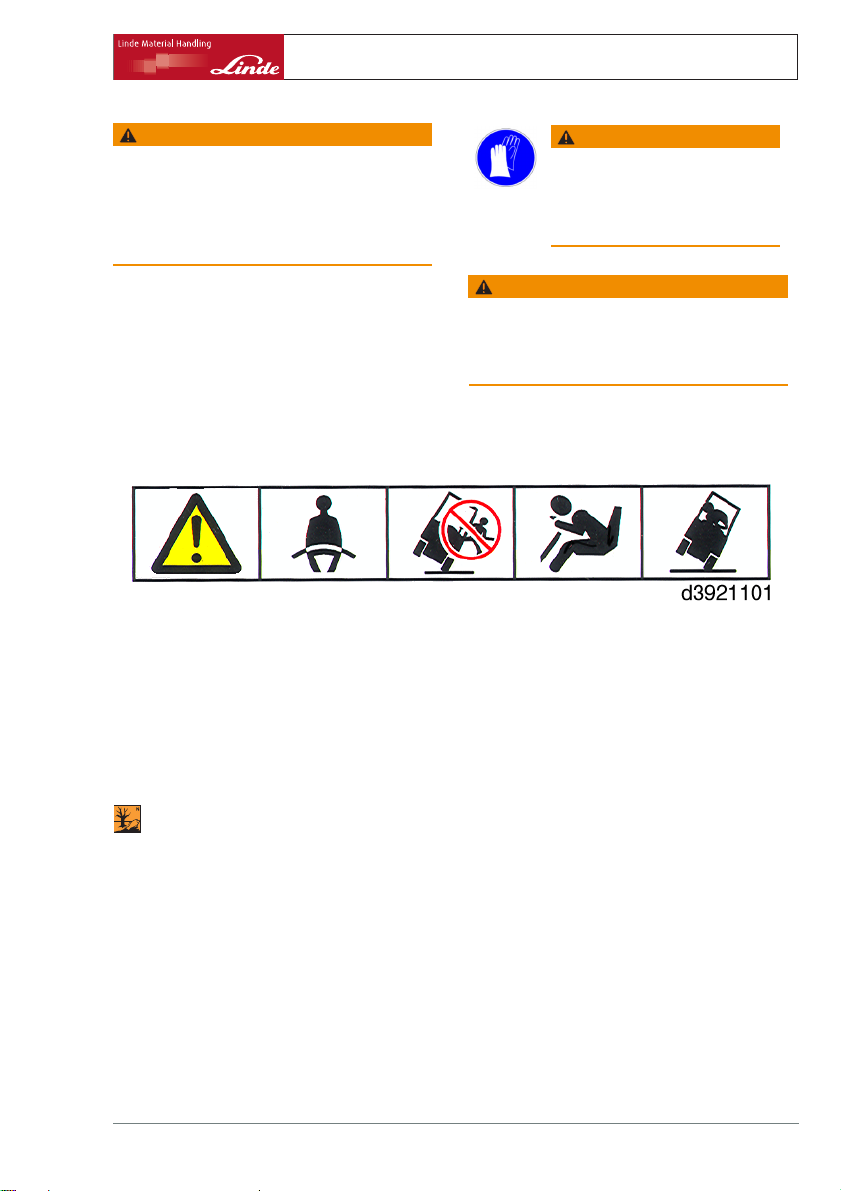

In the case of tip-over

• Stay buckled up

• Don’t jump

• Hold on tight

• Brace feet

•Leanaway

WARNING

Depending on the duration of

operation and use, components

carrying exhaust gases and exhaust

air can become hot.

Therefore wear protective clothing

WARNING

The fork lift truck working area must be adequately

lit.

If it is insufficiently lit, floodlights must be installed

to ensure that the driver can see properly

The stability of your truck is ensured if used

properly and as intended. Should the truck

tip over during an unapproved application or

due to incorrect operation, always follow the

instructions depicted below.

Handling fluids and lubricants

ENVIRONMENT NOTE

Always handle fluids and lubricants as required and as specified by the manufacturer.

• Only store fluids and lubricants in approved

containers at specified storage places.

• As they could be inflammable, do not allow

contact with hot objects or a naked flame.

• Only use clean containers when replenishing fluids and lubricants.

• Follow the manufacturer’s safety and

disposal instructions.

Operating Instructions – 393 807 1001 EN – 06/2006 9

• Do not spill fluids.

• Remove any spillage immediately with a

suitable binding agent and dispose of as

specified.

• Also dispose of used or contaminated fuels

and lubricants as specified.

• Follow laws and regulations.

• Clean the area surrounding the part in

question before lubrication, filter renewal

or repairs in the hydraulic system.

• Discard replaced parts in a way friendly to

the environment.

Page 20

2 Safety

Regulations

WARNING

Do not allow hydraulic oil under pressure, for

example at a leak, to penetrate the skin. Medical

aidisrequiredifsuchaninjuryoccurs.

Wear protective gear.

WARNING

Improper handling of coolants and coolant additives

puts your health and the environment at risk.

Observe manufacturer´s directions.

Experts

Experts are persons with a special training and

experience in servicing and testing industrial

trucks and familiar with the applicable worker’s

protection rules, safety regulations, directives

and generally recognised rules of the art

(DIN and VDE standards, technical rules of

members of the EU or EEA agreements) so

that they can give a qualified assessment

of the safe operating condition of industrial

trucks.

Operation of industrial trucks in plant area

Many plant areas are so-called limited public

traffic areas. In this sense, we would like to

advise you to check your company liability

insurance coverage, to ensure that possible

claims for damages caused by your truck

in limited public traffic areas in relation to

third parties are included in the insurance

coverage.

Regulations

Safety inspection

The accident prevention rules in some countries require that the fork lift truck must be

checked periodically for proper operation by

trained personnel. Please contact your authorised dealer for this inspection.

Diesel engine emissions

In Germany, fork trucks equipped with diesel

engines must conform to TRGS 554. According to this regulation, diesel engine emissions are hazardous materials causing cancer. They should not get into the air at the

workplace, if possible. If trucks equipped with

diesel engines are used in totally or partially

enclosed spaces, the labour protection authority must first be notified. Appropriate notices must be posted in the work areas (refer

to TRGS 554 for an example).

Soot filter inspection

The responsible authorities specify that soot

filters must be inspected and serviced every

six months by an expert. The results of the

inspection must be recorded in a "Diesel

Engine Emissions Inspection Certificate" and

attached to the log book (eg truck’s safety

inspection logbook).

10 Operating Instructions – 393 807 1001 EN – 06/2006

Page 21

Safety 2

Determination and assessment of hazards from use of industrial trucks

Determination and assessment of hazards from use of industrial

trucks

Check note

Hazard Action

Industrial truck

equipment does not

comply with local

provisions

Lack of skills and

qualification of driver

Lack of skills and

qualification of driver

Usage by unauthorised

persons

Industrial truck not in a

safe condition

Impaired visibility

through load

Contamination of

respiratory air

Contamination of

respiratory air

Impermissible usage

(improper usage)

Impermissible usage

(improper usage)

Impermissible usage

(improper usage)

When filling up with a)

diesel

When filling up with b)

fuel gas

When charging traction

batteries

Check

Driver training (sit-on

and stand-on industrial

trucks)

Instruction for pedestriancontrolled trucks

Access with key only for

appointed staff

Recurrent testing and

rectification of defects

Deployment planning

Assessment of diesel

exhaust gases

Assessment of fuel gas

exhaust gases

Issue of operating

instructions

Written notice of

instruction to driver

UVV-BGV D 27, observe

operating manual and

VDMA leaflet

UVV-BGV D 27, observe

operating manual and

VDMA leaflet

UVV-BGV D 27, observe

operating manual and

VDMA leaflet

UVV-BGV D 27, observe

operating manual, VDMA

leaflet and VDE 0510

X = actioned

- = not

concerned

Notes

If in doubt, consult

competent factory

inspectorate or

employers’ liability

insurance association

UVV-BGV D 27 - § 7,

BGG 925 driver permit

VDI 3313

UVV-BGV D 27 - §§ 9,

37, BGG 918

UVV-BGV D 27 - § 12

TRGS 554

MAK list (maximum workplace concentrations list)

UVV-BGV D 27 - § 5

UVV-BGV D 27 - §7

VDE 0510: In particular

a) ventilation b) insulation

value

Operating Instructions – 393 807 1001 EN – 06/2006 11

Page 22

2 Safety

Instructions for fitting attachments

In the Federal Republic of Germany the German Law on Health and Safety at Work (ArbSchG) states that it is up to the Employer to

assess which hazards are associated with

the work of employees and which Health and

Safety measures are required (§ 5 ArbSchG).

The result must be documented (§ 6 ArbSchG). In the case of industrial truck deployments involving similar hazard situations it is

permitted to summarise the results . In countries outside the Federal Republic of Germany

the country-specific regulations must be observed. With the list we are helping you to

comply with these regulations. The construction and equipment of industrial trucks comply

with the Machinery Directive 98/37/EC and

are identified by the CE mark accordingly.

This means that they do not fall under the

scope involved in the assessment of hazards,

and nor do attachments due to their own CE

marking . The operator must however select

the type and equipment of industrial trucks so

as to comply with the local provisions for deployment.

Instructions for fitting attachments

To depressurise the oil in the pipes beforefitting an additional hydraulic attachment

to the hydraulic system, a pressure receiver

(special equipment) can be used.

In order to ensure the safe usage of industrial

trucks we not only supply every industrial

truck with a copy of the operating manual but

also with the leaflet of the VDMA (German

Engineering Federation) specifying the rules

for the proper usage of industrial trucks "Rules

for the Proper Use of Industrial Trucks".

The list specifies key hazards which are most

frequently the cause of accidents in the event

of non-compliance. If other major hazards are

involved at a specific plant , they must be listed

additionally.

In many plants the conditions o

industrial trucks are by and la

that the hazards can be summar

list. The pronouncements of t

liability insurance associa

each case as regards this topi

taken into account.

For this consult the section "Operate attachments".

f use for

rge similar so

ised in one

he employers’

tion competent in

c should also be

12 Operating Instructions – 393 807 1001 EN – 06/2006

Page 23

3

Overview

Page 24

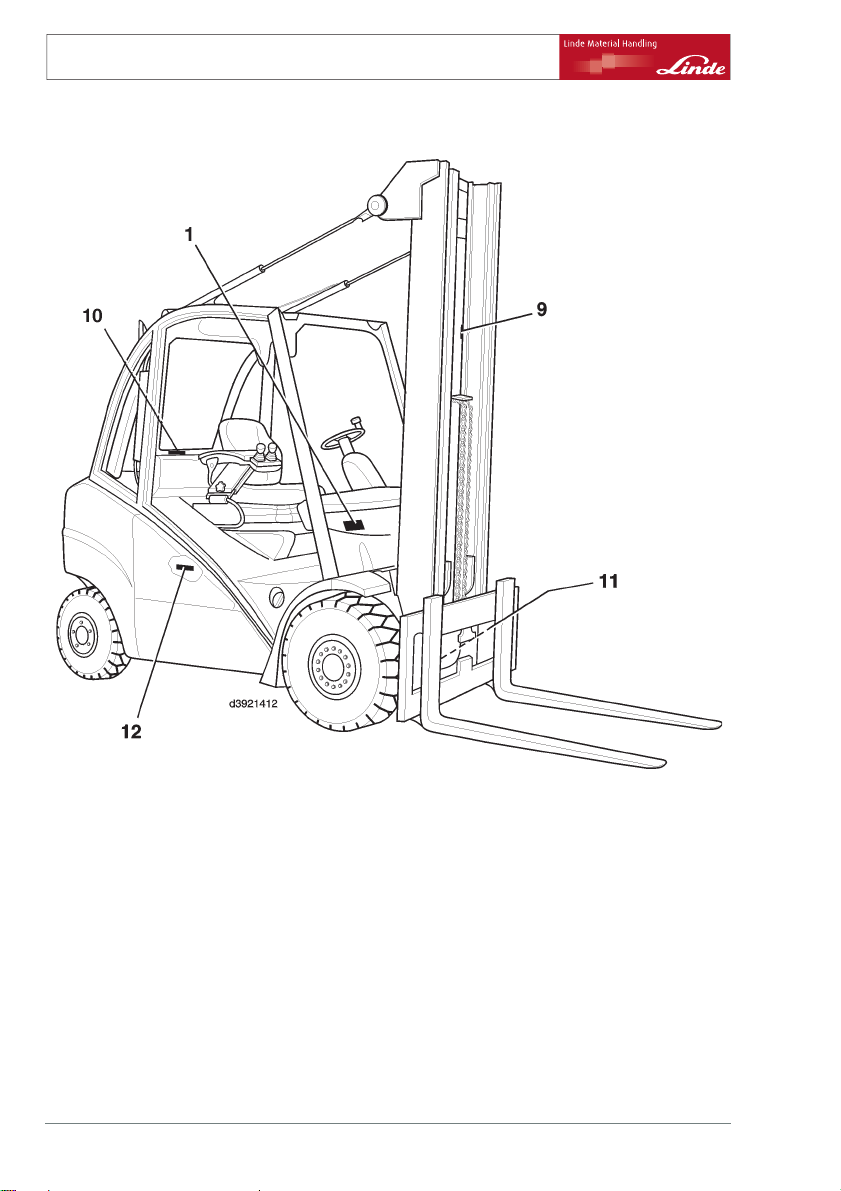

3 Overview

Rating plates

Rating plates

1 Nameplate

9 Lift mast number (stick-on label)

10 Chassis number (stamped into the rear wall

of the driver’s protective roof)

11 Rating plate for drive axle

12 Rating plate for engine

14 Operating Instructions – 393 807 1001 EN – 06/2006

Page 25

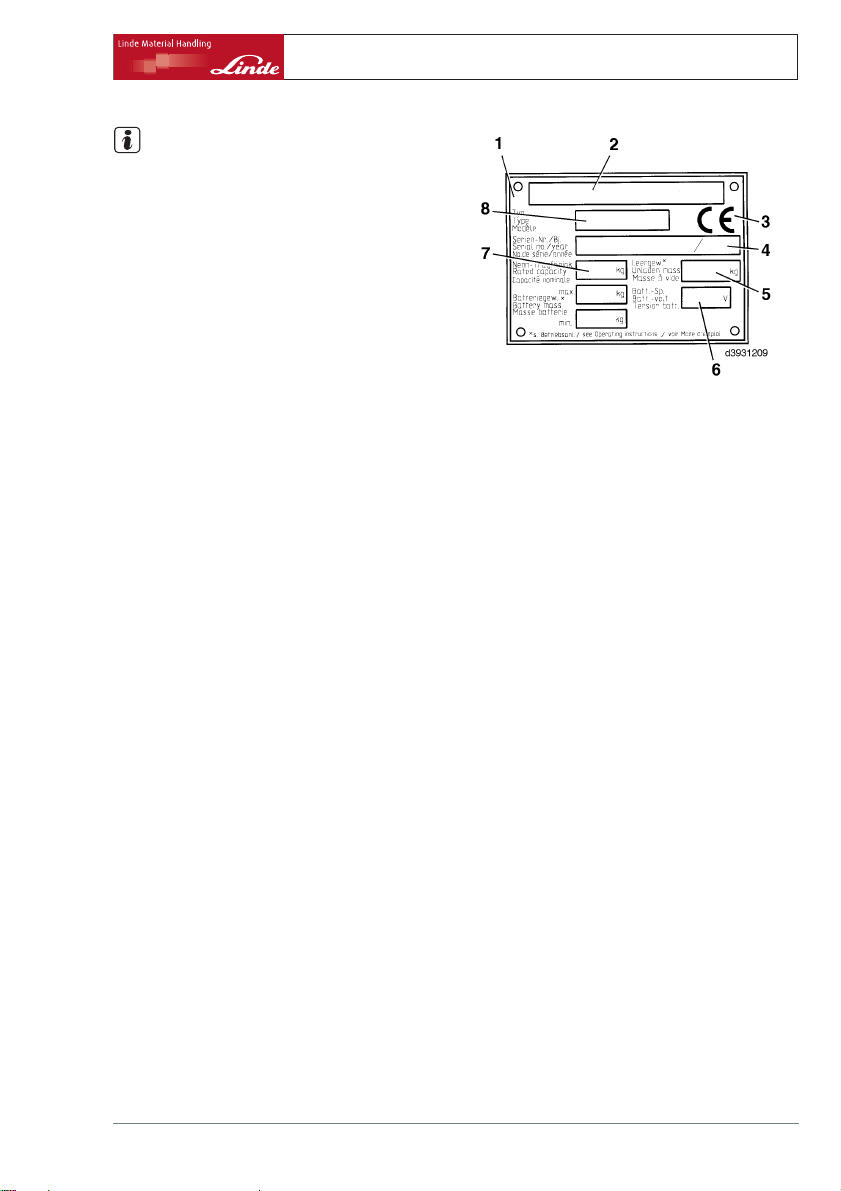

NOTE

The CE mark confirms compliance with the EC

machinery directive and with all regulations

applicable to fork lift trucks .

Overview 3

Rating plates

1 Nameplate

2 Manufacturer

3CEmark

4 Serial No. / build year)

5 Tare weight

6 Battery voltage

7 Nominal load capacity

8 Type

Operating Instructions – 393 807 1001 EN – 06/2006 15

Page 26

3 Overview

General view

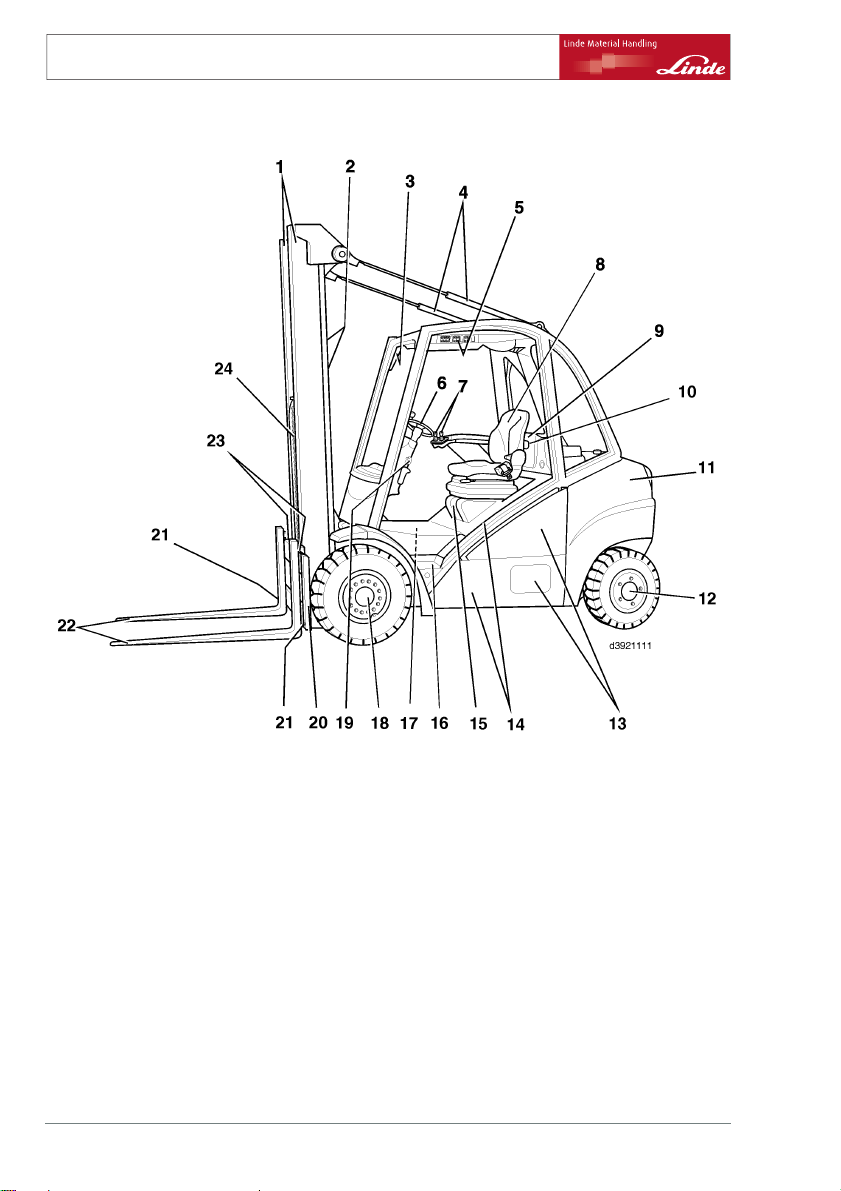

General view

1Mast

2 Lift cylinder

3 Composite instrument

4 Tilt cylinders

5 Toggle switch for auxiliary functions (op-

tional)

6 Steering wheel/hydrostatic power steering

7 Control lever (joystick)

8 Operator’s seat

9 Electrical system cover

10 Fuses (behind the electrical system cover)

11 Counterweight

12 Steering axle

16 Operating Instructions – 393 807 1001 EN – 06/2006

13 Maintenance access covers

14 Chassis and overhead guard

15 Engine bonnet

16 Step for mounting and dismounting

17 Fuses (in the engine compartment)

18 Wheel motor, left

19 Handwheel for adjusting steering column

20 Fork carriage

21 Fuses, forks

22 Forks

23 Forks, locking

24 Lift chain (only for duplex or triplex mast)

Page 27

Controls

4

3

2

1

Overview 3

Controls

56 879

10

11

18

12

d3921508

14151617

1 Parking brake handle

2 Handwheel for adjusting steering column

3 Combined lever for wiper/washer and

blinker (option)

4 Steering wheel/hydrostatic power steering

5 Signal button

6 Ignition switch with ignition key

7 Cubby hole

8 Control lever (joystick) for working hy-

draulics

9 Control lever (joystick) for auxiliary hy-

draulics (attachments) (option)

Operating Instructions – 393 807 1001 EN – 06/2006 17

10 Symbol label for auxiliary hydraulics (attach-

11 Symbol label for working hydraulics

12 Operator’s seat armrest

13 Operator’s seat

14 Forward accelerator

15 Brake pedal

16 Reverse accelerator

17 Backrest cushion adjuster (option)

18 Plate "Guaranteed acoustic power level"

13

ments) (option)

Page 28

3 Overview

Indicator unit

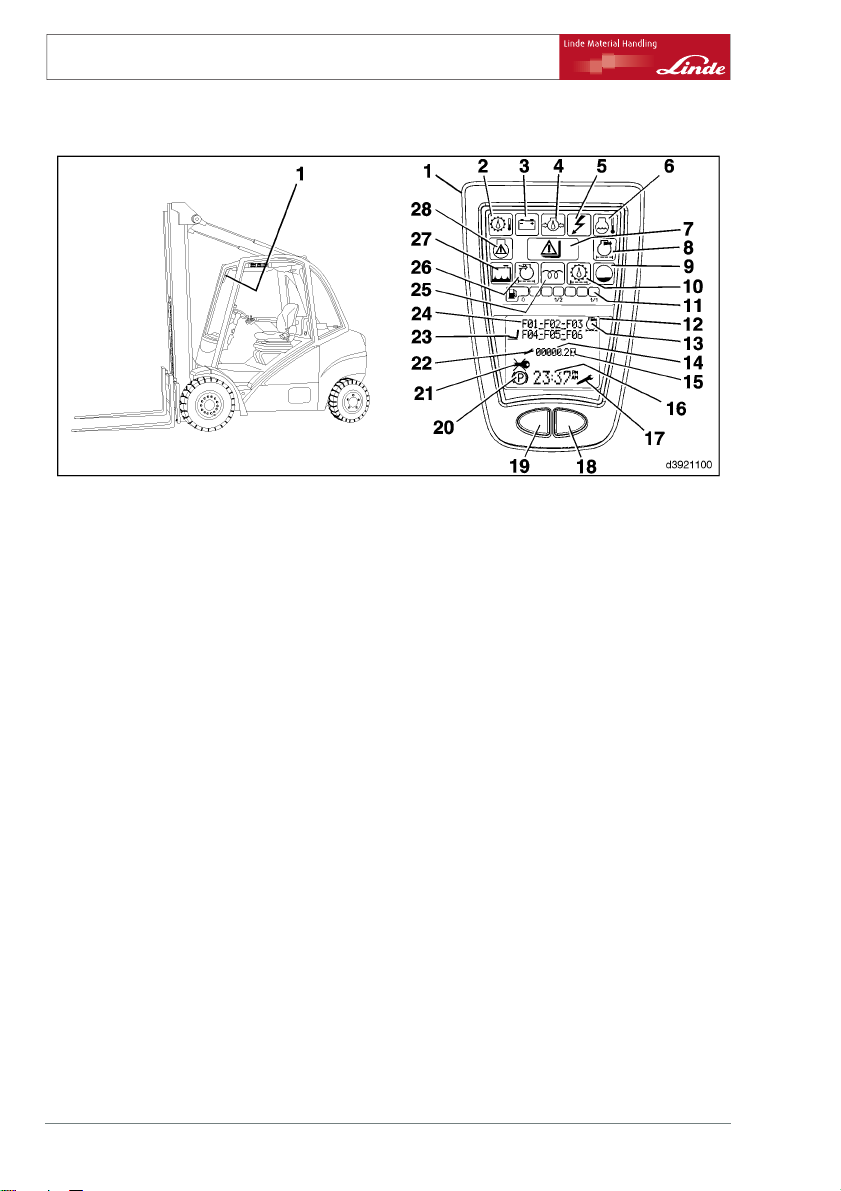

Indicator unit

1 Indicator unit

2 Hydraulic oil temperature indicator

3 Battery charge indicator

4 Engine oil pressure indicator / Engine oil

level indicator (special equipment)

5 Electrical control system fault

6 Engine temperature indicator

7 Load / overload indicator (special equip-

ment)

8 not assigned

9 Level display (special equipment)

10 Hydraulic oil micro-filter indicator (special

equipment)

11 Fuel tank level display

12 Display

13 not assigned

14 Display operating hours

(2) Hydraulic oil temperature indicator (colour

red)

Lights up when the specified temperature

limit is reached. A buzzer sounds when the

permissible temperature limit is reached.

• Insufficient oil in the hydraulic system

• Incorrect oil used

• Oil filter clogged

• Oil cooler clogged

• Switch buzzer off with the reset button (19).

(3) Battery charge indicator (colour red)

15 Symbol operating hours

16 Display time

17 Symbol service interval exceeded

18 Function push-button

19 Reset button

20 Symbol parking brake applied

21 Symbol "do not start the engine"

22 Symbol operating hours (until next service

shown for only 4 sec on display field (14))

23 Symbol lift mast position sensing

24 Text field

25 Glow plug indicator

26 Air filter induction pressure indicator

27 Coolant water level display (special equip-

ment)

28 not assigned

Lights up when there is a fault in the battery

charger system.

• Ribbed vee belt broken or ribbed vee belt

tension too slack

• Ribbed vee belt tensioner defective

• Cable defective

• Alternator defective

• Charge controller or controller switch

defective.

(4) Engine oil pressure indicator / Engine oil

level indicator (special equipment) (colour

red)

18 Operating Instructions – 393 807 1001 EN – 06/2006

Page 29

Overview 3

Indicator unit

When engine lubricating oil pressure is

too low this indicator lights up, and also a

buzzer sounds. In addition the text field (24)

displays the text

downwards indicates that the engine oil level

is too low.

• Insufficient oil in the crankcase

• Engine too hot

• Incorrect oil used

• Internal leakage in the lubricating oil circuit

• Top up with engine oil

• Switch buzzer off with the reset button (19).

(5) Electrical control system fault (colour red)

Lights up when an electrical contro

fault is present, and displays a fau

text field (24).

(6) Engine temperature indicator (colour red)

Lights up when the specified temperature

limit is reached. A buzzer sounds when the

permissible temperature limit is reached.

• Fan motor defective

• Thermostatic switch defective

• Radiator clogged

• Leakage in the coolant circuit

• Coolant level too low

• Switch buzzer off with the reset button (19).

(7) Load / overload display (special equ

ment)

Symbol lights up orange when load is normal.

DANGER

Symbol lights up red when overloaded.

Set down load immediately.

• Consult load diagram.

(8) not assigned

(9) Level display (colour yellow) (special

equipment)

Lights up when the coolant level is below the

minimum.

• Top up the coolant.

Oil A double arrow pointing

l system

lt code in

ip-

Please contact your authorised dealer.

(10) Hydraulic oil micro-filter indicator (colour

yellow) (special equipment)

Lights up when the micro-filter r

maintenance.

• Micro-filter clogged, exchange it.

(11) Fuel tank level display (colour depending

on the level, green or red

• Shows the current fuel tank level.

(13) not assigned

(14) Display operating hours

Shows the operating hours of the fo

This indicator is an shows the fork

operating hours and indicates the

and maintenance work to be perform

NOTE

If a defective indicator unit is exc

the operating hours up to that poi

recorded. Note the data on an embo

attached near the indicator unit

the option of subsequently updat

indicator unit. Please contact y

equires

rklift truck.

lift truck’s

inspection

ed.

hanged,

nt must be

ssed strip

. There is also

ing the new

our authorised

dealer.

(15) Symbol operating hours

Flashes when operating hours are

counted (only when the ignition i

engine speed exceeds 500 rpm

(16) Display clock

24-hour clock display

Can be adjusted using buttons (18) a

Resetting to 12-hour clock display is possible

using a diagnostic tester. Please contact your

authorised dealer.

(17) Symbol service interval exceeded

If the number of operating hours unt

service is less than or equal to 0, th

flashes for 10 sec every time the veh

started, and then lights up contin

Adjustment and reset of the intervals can be

performed only using the diagnostic tester

being

sonandthe

)

nd (19.)

il the next

e symbol

icle is

uously.

Operating Instructions – 393 807 1001 EN – 06/2006 19

Page 30

3 Overview

Indicator unit

provided for this purpose. Please contact your

authorised dealer.

(18) Function push-button

Assignment depending on version

(19) Reset button (special equipment)

To adjust the time, switch off the warning

buzzer and other functions depending on the

version.

(20) Symbol parking brake

Lights up when the parking brake is applied.

(21) Symbol "do not start the engine"

Lights up when the engine has stall

NOTE

.

ed.

It is essential to leave the ignition switched on

until this symbol has gone out (depending on

the oil temperature this may be between 15

and 50 seconds). Then attempt to restart the

engine.

(22) Symbol operating hours until

After the ignition has been switched on,

display field (14) shows the operating hours

until the next service (counting backwards).

Symbol (22) lights up. After 5 seconds symbol

22 goes out and indicator (14) automatically

switches to the operating hours of the forklift

truck; the operating hours symbol (15) flashes.

next service

(23) Symbol lift mast position sensing (special

equipment)

Lights up when the function "lift mast position

sensing" is enabled .

(24) text field

Serves as a display field. Please contact your

authorised dealer for interpretation of fault

codes.

(25) Glow plug indicator (colour yellow)

Lights up whilst the glow plugs are

up, then goes out.

Flashes if there an engine fault or engine

management fault occurs. Please contact

your authorised dealer.

(26) Air filter induction pressure indicator

(colour yellow)

Lights up when the air filter is exc

clogged.

• Air filter clogged, exchange it.

(27) Coolant water level display (colour

yellow) (special equipment)

Lights up when the coolant level is b

minimum.

• Top up the coolant.

(28) not assigned

warming

essively

elow the

20 Operating Instructions – 393 807 1001 EN – 06/2006

Page 31

4

Operation

Page 32

4 Operation

Standard equipment

Running-in instructions

The lift truck can be operated at full speed

directly. Avoid sustained high loads on the

working hydraulic system and the travel

drive in the first 50 hours of operation. The

wheel fasteners must be tightened before the

commissioning and after each wheel change.

Checks before starting work

¾ Check the fuel level

¾ Check the engine oil level

¾ Check the hydraulic oil level

Standard equipment

Adjusting the driver’s seat

WARNING

An incorrect adjustment of the seat can cause back

injury. Do not operate the seat adjusting devices

while operating the truck.

Before each start-up of the truck and with each

change in driver, set the weight setting to the individual weight of the driver and check if all settings are

correctly engaged. Do not place any objects in the

vicinity of the controls.

Thereafter at least every 100 operating hours.

Tighten opposite wheel fasteners to a torque

of

front:

rear:

¾ Check the coolant level

¾ Check the tyre pressures

170 Nm

460 Nm

22 Operating Instructions – 393 807 1001 EN – 06/2006

Page 33

Horizontal adjustment

¾ Lift lever (2) up and pull it.

¾ Move the driver’s seat on the sli

backwards or forwards to give th

the best position in relation to

wheel and the accelerator pedal

¾ Re-engage the lever.

de rails

edriver

the steering

s.

Backrest adjustment

¾ Push up and hold the backrest adjuster (1).

¾ Move the backrest forward and bac

comfortable sitting position fo

found.

¾ Release the backrest adjuster (1).

k until a

r the driver is

Adjusting the lumbar support (option)

¾ Turn knob (3) until a comfortable sitting

position is achieved.

Turning the knob anticlockwise makes the

backrest arch outwards.

Turning the knob clockwise returns the backrest to its original position.

d3921352

Operation 4

Standard equipment

1

2

3

6

Adjusting for the operator’s weight

¾ Turn the adjusting handwheel (5) to set the

cushioning to the weight of the driver.

The adjustment range from 50 kg to 130 kg is

visible at the weight range indicator (4).

To reduce the weight, turn the handwheel

anticlockwise.

To increase the weight, turn the handwheel

clockwise.

Operating Instructions – 393 807 1001 EN – 06/2006 23

5

4

d3921353

Page 34

4 Operation

Standard equipment

Adjusting the seat angle of tilt (option)

¾ Lift the handle (6).

The seat is tilted to the desired

applying or taking off one’s wei

ously.

Adjusting the seat position (

¾ Lift the handle (9).

The desired position is reached by simultaneously sliding the seat forward or back.

Adjusting the backrest extension (option)

¾ Push the backrest extension (7

for an individual adjustment.

Turning the seat heating on/off

¾ Toggle the switch (8) on or off.

NOTE

Long sitting puts excessive strain on the spinal

column. Prevent strain with regular, light exercising.

position by

ght simultane-

option)

)upordown

(option)

7

9

8

d3921354

Adjusting the armrest on the operator’s

seat

NOTE

The armrest on the operator’s s

automatically by spring press

eat is raised

ure after the

handwheel (1) is loosened.

24 Operating Instructions – 393 807 1001 EN – 06/2006

Page 35

Operation 4

Standard equipment

¾ Sit down on the operator’s seat and loosen

the handwheel (1).

¾ Push the armrest (3) down against the force

of the spring until a comfortable position for

the arm is reached.

¾ Tighten the handwheel (1).

¾ Loosen the handwheel (2) and slide the

armrest (3) back and forth until the control

lever (4) is easily accessible.

¾ Tighten the handwheel (2).

Adjust the steering column

DANGER

If the clamping screw is loose, safe driving is not

possible.

The steering column may only be adjusted when

the truck is stationary.

Tilt adjustment

¾ Loosen the clamping screw (2) in counter-

clockwise direction.

¾ Move the steering wheel (1) to the desired

position.

¾ Tighten the clamping screw (2) in clockwise

direction.

4

3

2

1

d3921416

1

Height adjustment (Optional)

¾ Loosen the clamping screw (2) counter-

clockwise.

¾ Pull the steering wheel (1) upwards, or push

it downwards, to the desired position.

¾ Tighten the clamping screw (2) clockwise.

Operating Instructions – 393 807 1001 EN – 06/2006 25

2

t3921369

Page 36

4 Operation

Standard equipment

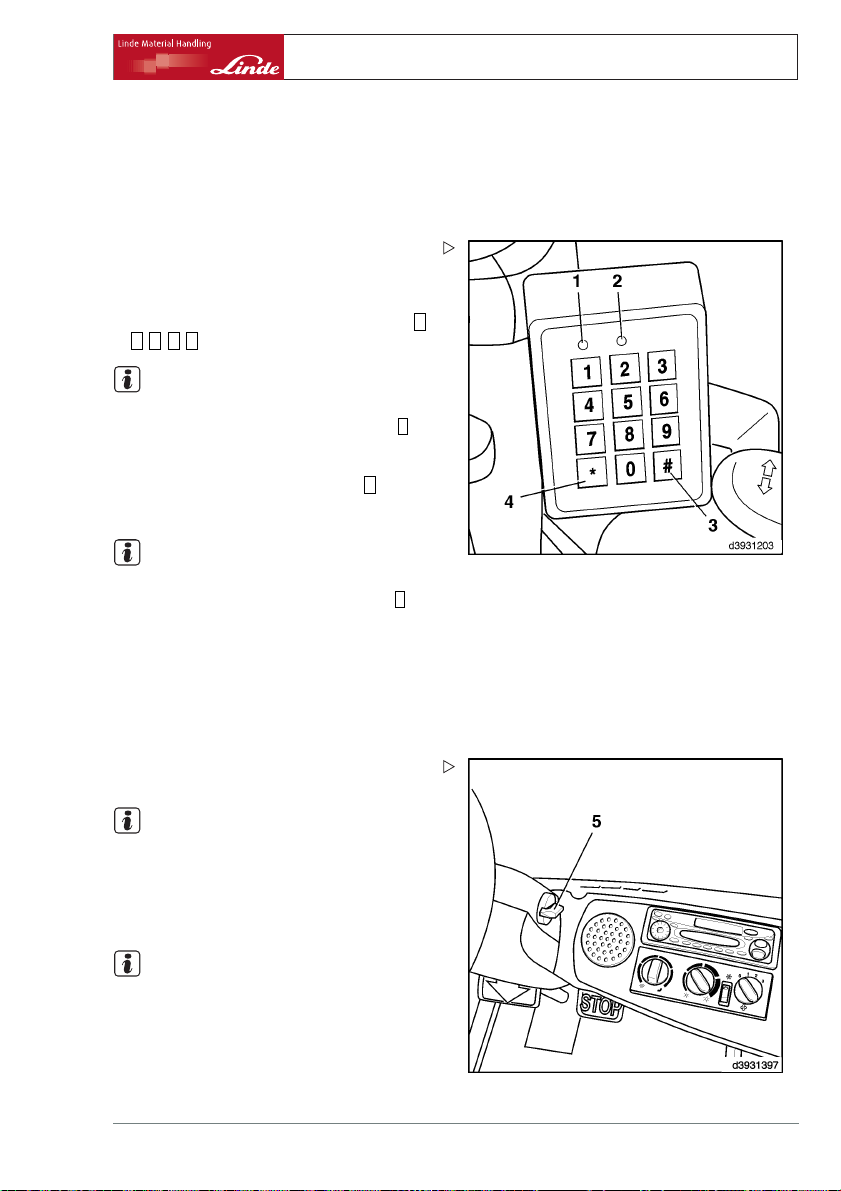

Setting the clock

NOTE

The time is shown in the 24 hour mode.

Change to 12 hour mode with diagnostic unit.

Please contact your authorised dealer for this

service.

¾ Depress both buttons (2) and (3) simultane-

ously for 3 seconds.

The hour readout in the time dis

NOTE

The setting of the hours or minutes can be

adjusted slowly with button (2) by tipping it or

fast by holding it.

¾ Depress button (2) to set the h

¾ Depress button (3) to confirm the hour set-

ting.

Now the minute readout blinks.

¾ Depress button (2) to set the mi

¾ Depress button (3) to confirm the setting of

the minutes.

play (1)blinks.

ours.

nutes

1

3

2

d3921348

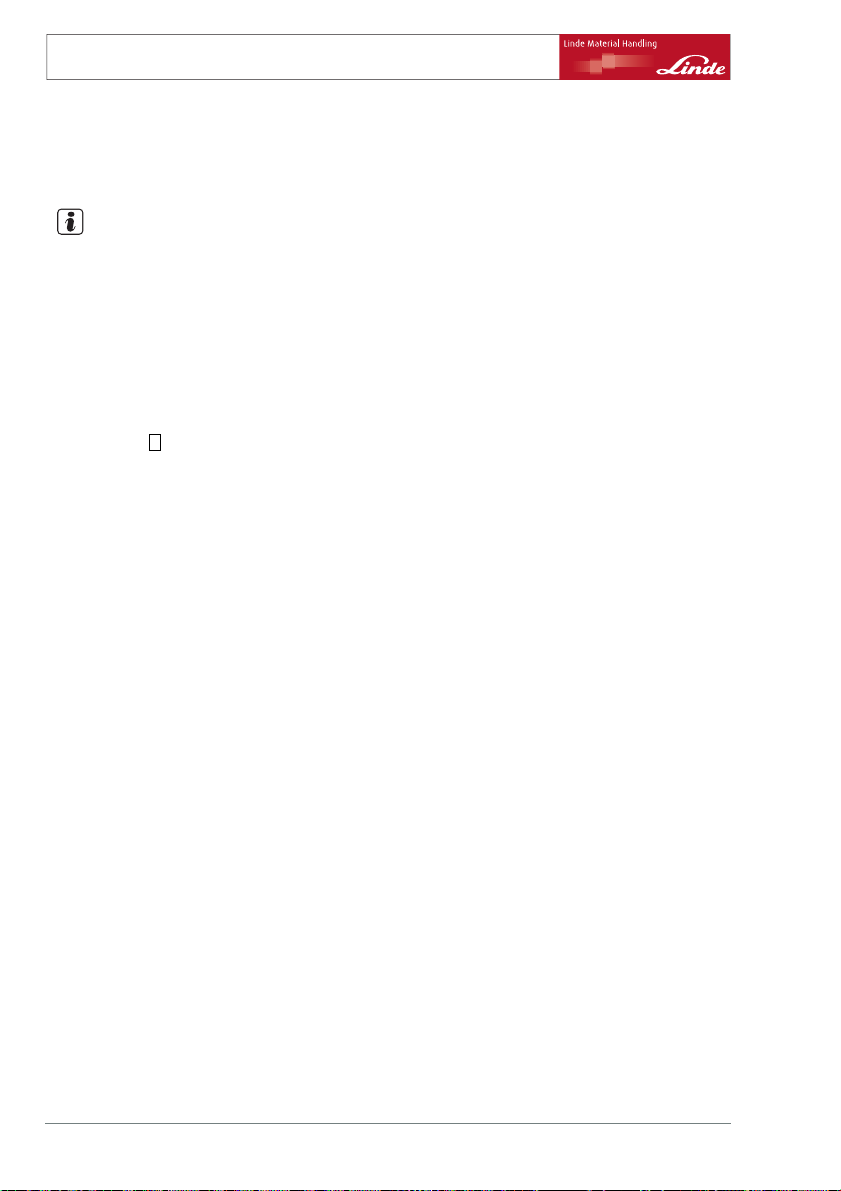

Lap seat belt

Applying the lap seat belt

DANGER

It is dangerous to leave the truck in

an uncontrolled manner.

Therefore always keep buckled up

when operating the truck! Only one

person may be fastened with the

seat belt.

WARNING

The proper operation of the lap belt must be guaranteed.

Therefore do not let the belt get twisted, caught

or tangled. Protect the lock and retractor against

foreign objects, damage and dirt.

26 Operating Instructions – 393 807 1001 EN – 06/2006

Page 37

NOTE

Cabins with closed solid doors or guards comply with the safety requirements for driver

restraint systems. The lap seat belt can be applied optionally. However, it must be applied

when driving with the doors open or removed.

PVC doors are not considered to be an operator restraint system.

The automatic blocking system locks the belt

when the truck tilts heavily. The belt can then

no longer be pulled out of the retractor. To

loosen the automatic blocking system of the

truck, drive off the slope carefully.

During the operation of the truck (eg driving,

operation of the mast, etc), sit as far back as

possible so that the back contacts the backrest. The retractor’s automatic blocking system sufficient freedom of movement during

normal truck operation.

¾ Pull the lap seat belt (1) gent

retractor on the left.

¾ Place the belt over the thighs, not over the

abdomen.

¾ Engage the tongue (2) in belt lock (4).

¾ Check seat belt tension.

The belt should be snug on the body.

ly from the

Operation 4

Standard equipment

5

1

4

Opening the lap seat belt

¾ Press the red button (5) on the lock (4).

¾ Return the tongue (2) to the retr

with the hand.

NOTE

actor (3)

2

3

d3921415

If the belt is retracted too fast the automatic

blocking system can be triggered when the

tongue hits the case. The belt can not be

pulled out with the usual force.

Operating Instructions – 393 807 1001 EN – 06/2006 27

Page 38

4 Operation

Standard equipment

Drive motor (two-pedal operation)

Starting motor

DANGER

Risk of poisoning!

Do not allow motor to run in unventilated rooms.

NOTE

Where possible, avoid starting up the motor

frequently and short service periods to ensure that the combustion engine attains its

operating temperature. Frequent cold-starts

encourage wear.

¾ The joystick must be in neutral.

¾ Sit down on the driver’s seat.

¾ Fasten the seat belt.

¾ Place both feet on the accelerator pedals

(4).

¾ Parking brake handle (1) engaged, (motor

will only start when parking brake handle is

engaged).

¾ Insert switch key (2) into the ignition and

starting switch and turn from the zero position to position "I" .

The electrical system is switched on.

1

2

3

d3921417

28 Operating Instructions – 393 807 1001 EN – 06/2006

4

4

Page 39

Operation 4

Standard equipment

¾ Check the indicator unit (3).

NOTE

After switching on the ignition the indicator unit

will perform a self-test . The displays all light

up for approx. 2 seconds and the operating

hours until the next service are displayed for

5 seconds in the indicator unit (3) display field

(11). During this time symbol (12) remains

lit. After 5 seconds the display reverts automatically to the operating hours. If the buzzer

sounds (particulate filter unit fault), check the

lamps (see Diesel motor faults, cause, remedies). If the buzzer continues to sound, please

contact your local authorised dealer.

The following controls light up:

• Symbol (9) parking brake engaged,

• Motor oil pressure indicator (

• Battery charge indicator (5),

• Glow plug indicator (13).

¾ Wait until the glow plug indicat

out

¾ Turn switch key to position "II".

As soon as the motor starts

¾ release the switch key.

Symbol (7) will flash on and off.

CAUTION

For vehicles with particulate filter units only. If the

exhaust is very smoky and remains so, switch off.

Please contact your authorised dealer.

Every time the engine is started, watch the exhaust

pipe outlet for about 5 seconds.

6),

or (13) goes

13

12

11

10

3

56

7

9

8

d3921349

If motor fails to start

¾ After the glow plugs have heated up, keep

turning the starter motor until the motor runs

at idling speed . Depending on the vehicle,

the temperature and the altitude, this can

take more than 1 minute.

If the motor stalls, the symbol" Do not start the

motor"(10) will appear.

Operating Instructions – 393 807 1001 EN – 06/2006 29

Page 40

4 Operation

Standard equipment

¾ Always leave ignition switched on until sym-

bol extinguishes (between 15 und 50 seconds depending on oil temperature).

¾ Then try to restart.

When trying to start the motor, wa

for min. 1 minute to protect the ba

motor still does not start at th

consult: Malfunctions, Cause

The Charging and Motor oil pressure symbols

must extinguish once the motor starts to run

smoothly.

Motor speed is regulated automatically depending on the load on the motor.

NOTE

Do not allow motor to warm up at id

Under load drive truck at a brisk

motor will warm up quickly.

Switchingoffthemotor

CAUTION

For motors with a turbocharger, the high speed of

the turbocharger shaft (approx. 100 000 rpm at

full load) could cause the shaft bearing to run dry

through lack of lubrication thus damaging it.

Do not switch off motor under full load, but rather

allow to run on for a few minutes at low speed.

it each time

ttery. If the

e third attempt,

s and Remedy.

ling speed.

speed . The

¾ Take your feet off the accelerator pedals

(3).

¾ Move switch key (2) into zero position.

NOTE

1

2

The brake becomes active when the motor is

switched off.

¾ Pull up parking brake handle (1).

¾ Remove the switch key (2) when leaving the

truck.

d3921418

30 Operating Instructions – 393 807 1001 EN – 06/2006

3

3

Page 41

Driving (double-pedal operation)

WARNING

Driving on gradients over 15 % is generally not

allowed due to the specified minimum brake applications and the stability values. Contact your

authorised dealer before driving on steeper gradients. The climbing ability values given in the data

sheet have been derived from the drawbar pull and

apply only for crossing obstacles and short differences in height.

Always adapt your driving style to the conditions

of the roadway (rough surfaces, etc.), especially

hazardous work zones and the load.

WARNING

If mirrors are used, please note the rear-view mirror

is only provided for observing the traffic area to the

rear.

If you are reversing, therefore, always look over the

shoulder in the direction your are reversing.

CAUTION

Possibly fitted side doors must be protected against

damage.

Therefore always ensure both side doors are closed

and locked before driving.

Operation 4

Standard equipment

NOTE

The truck can only be driven with the operator

seated.

¾ Start the engine.

¾ Raise the forks slightly and tilt the mast

back.

Operating Instructions – 393 807 1001 EN – 06/2006 31

Page 42

4 Operation

Standard equipment

¾ Push the parking brake handle (1) down.

Forward travel

¾ Depress the right accelerator (2) gently.

Truck speed depends on how far the

depressed.

NOTE

Flooring the accelerator does n

speed as maximum acceleration i

pedal is

ot increase the

s controlled

automatically.

Reversing

¾ Depress the left accelerator (4) gently.

The truck willreverse slowly or fast, depending

on how far the accelerator is depressed.

Changing the direction of travel

¾ Release the depressed accelerat

The hydrostatic drive will act as service brake.

¾ Depress the accelerator for the opposite

direction of travel.

The truck will now accelerate in th

direction.

¾ Keep both feet on the accelerators to main-

tain easy control over all truck movements.

The accelerators can be operated directly.

The hydrostatic drive will brake the truck to a

full stop and then accelerate it in the opposite

direction of travel.

or.

e selected

d3921419

1

4

3

2

32 Operating Instructions – 393 807 1001 EN – 06/2006

Page 43

Starting on gradients

¾ Fully depress the brake pedal (3).

¾ Push the parking brake handle (1

¾ Release the brake pedal half way.

¾ Depress accelerator (2) or (4).

¾ Slowly release the brake pedal fu

The brake is released and the truck will drive

without rolling back.

) down.

lly.

Stopping

¾ Release the depressed accelerator slowly.

The hydrostatic drive will act as s

¾ When stopping on gradients, keep both feet

on the accelerators and compensate drive

slippage by lightly depressing the accelerator in the "upslope" direction of travel.

¾ Depress the brake pedal (3) for a long stop.

¾ When dismounting form the truck w

engine running, for example, to b

form some actions in close vicini

truck (opening a gate, unhitchin

etc.), always pull the parking br

(1) and release the seat belt. In c

longer stop, shut down the engine

the parking brake handle (1).

¾ Remove the ignition key when leaving the

truck unattended.

ervice brake.

ith the

riefly per-

ty of the

gatrailer,

ake handle

ase of a

and pull

d3921419

Operation 4

Standard equipment

1

4

3

2

1

Drive motor (single-p

edal operation)

d3921419

4

3

2

Starting motor

DANGER

Risk of poisoning!

Do not allow motor to run in unventilated rooms.

Operating Instructions – 393 807 1001 EN – 06/2006 33

Page 44

4 Operation

Standard equipment

NOTE

Where possible, avoid starting up the motor

frequently and short service periods to ensure that the combustion engine attains its

operating temperature. Frequent cold-starts

encourage wear.

¾ Sit down on the driver’s seat.

¾ Fasten the seat belt.

¾ Move the operating lever (hydra

direction of travel (5) into neu

ulics and

tral.

5

d3921361

¾ Place foot on accelerator pedal (4).

¾ Parking brake handle (1) engaged, (motor

will only start with parking brake handle

engaged).

¾ Insert switch key (2) into the ignition and

starting switch and turn from the zero position to position "I".

The electrical system is switched on.

34 Operating Instructions – 393 807 1001 EN – 06/2006

1

d3921420

2

3

4

Page 45

Operation 4

Standard equipment

¾ Check the indicator unit (3).

NOTE

After switching on the ignition the indicator unit

will perform a self-test. The displays all light up

for approx. 2 seconds and the operating hours

until the next service are displayed for 5 seconds in the indicator unit (3) display field (12).

During this time symbol (13) remains lit. After

5 seconds the display reverts automatically

to the operating hours. If the buzzer sounds

(particulate filter unit fault), check the lamps

(see Diesel motor faults, cause, remedy). If

the buzzer continues to sound, please contact

your local authorised dealer.

The following controls light up:

• Symbol (10) Parking brake engaged

• Motor oil pressure indicator (

• Battery charge indicator (6),

• Glow plug indicator (14).

¾ Wait until the glow plug indicat

out

¾ Turn switch key to position "II".

As soon as motor starts,

¾ release switch key.

Symbol (8) flashes on and off.

CAUTION

Only for vehicles with particulate filter units. If the

exhaust is very smoky and remains so, switch off

the motor. Please contact your authorised dealer.

Every time the engine is started, watch the exhaust

pipe outlet for about 5 seconds.

7),

or (14) goes

14

13

12

11

3

67

8

10

9

d3921359

If motor fails to start

After the glow plugs have heated up, keep

turning the starter motor until the motor runs

at idling speed. Depending on the vehicle,

the temperature and the altitude, this can take

more than 1 minute.

If the motor stalls, the symbol " Do not start

motor"(11) will appear.

Operating Instructions – 393 807 1001 EN – 06/2006 35

Page 46

4 Operation

Standard equipment

¾ Always leave ignition switched on until sym-

bol extinguishes (between 15 und 50 seconds depending on oil temperature).

¾ Then try to restart.

When trying to start the motor, wa

for min. 1 minute to protect the ba

motor still does not start at th

consult: Malfunctions, Cause

The Charging and Motor oil pressure symbols

must extinguish once the motor runs smoothly.

Motor speed is regulated automatically depending on the load on the motor.

NOTE

Do not allow motor to warm up at id

Drive truck, under load, at a bri

motor will reach operating stat

quickly.

Switching off motor

CAUTION

For motors with a turbocharger, the high speed of

the turbocharger shaft (approx. 100 000 rpm at

full load) could cause the shaft bearing to run dry

through lack of lubrication thus damaging it.

Do not switch off motor under full load, but rather

allow to run on for a few minutes at low speed.

it each time

ttery. If the

e third attempt,

s and Remedy.

ling speed.

sk speed. The

e temperature

¾ Take foot off accelerator pedal (3).

36 Operating Instructions – 393 807 1001 EN – 06/2006

1

d3921421

2

3

Page 47

¾ Move direction of travel lever (4) into neu-

tral.

¾ Move switch key (2) into zero position.

NOTE

The brake becomes active when the

motor is

switched off.

¾ Pull up parking brake handle (1).

¾ Remove the switch key (2) when le

aving the

truck.

Driving (single-pedal operation)

WARNING

Driving on long gradients over 15 % is generally

not allowed due to the specified minimum brake

applications and the stability values. Contact your

authorised dealer before driving on steeper gradients. The climbing ability values given in the data

sheet have been derived from the drawbar pull and

apply only for crossing obstacles and short differences in height.

Always adapt your driving style to the conditions

of the roadway (rough surfaces, etc.), especially

hazardous work zones and the load.

Operation 4

Standard equipment

4

d3921362

WARNING

If mirrors are used, please note the rear-view mirror

is only provided for observing the traffic area to the

rear.

If you are reversing, therefore, always look over the

shoulder in the direction your are reversing.

CAUTION

Possibly fitted side doors must be protected against

damage.

Therefore always ensure both side doors are closed

and locked before driving.

Operating Instructions – 393 807 1001 EN – 06/2006 37

Page 48

4 Operation

Standard equipment

NOTE

The truck can only be driven with the operator

seated.

¾ Start the engine.

¾ Raise the forks slightly and tilt the mast

back.

¾ Push the parking brake handle (

Forward travel

¾ Push the direction lever (4) forward.

¾ Depress the accelerator (3) gently.

Truck speed depends on how far th

depressed.

NOTE

Flooring the accelerator does no

speed as maximum acceleration is

automatically.

1) down.

e pedal is

t increase the

controlled

1

Reversing

¾ Pull the direction lever (4) back.

¾ Depress the accelerator (3) gently.

The truck willreverse slowly or fa

on how far the accelerator is depre

Changing the direction of trave

¾ Release the accelerator.

The hydrostatic drive will act as service brake.

38 Operating Instructions – 393 807 1001 EN – 06/2006

st, depending

ssed.

l

d3921422

2

3

Page 49

¾ Move the direction lever (4) to the opposite

direction of travel.

The truck will now accelerate in the selected

direction.

The direction lever can be moved d

the opposite direction. The hydr