Page 1

1

DUAL AUXILIARY TROLLEY

MODIFICATION

For Use With Models J, H and GH

659213-XX AND 6592131-XX

APPLICATION

This modification is available for model J, H and GH operators.

For 1/2 HP and lower side mount operators use #48 drive chain.

For 3/4 HP and higher side mount operators use #41 drive chain.

FUNCTIONS

Provides trolley type operation on wide standard lift doors where

a side mount operator is preferred over a draw bar operator.

NOTE: Use the Model "T" owner’s manual for trolley installation,

where appropriate, with the following exceptions:

TRACK ASSEMBLY

1. Assemble both tracks by installing the track spacers (Figure 2).

2. Install the idler assemblies onto the wall end of the tracks. One

idler assembly is set up with a coupling sprocket on each end,

and the other idler is set up with only one coupling sprocket.

3. Slide the slider assembly into both tracks from the open end.

Be sure that the take-up bolt is facing the open end of the track.

4. Install the idler roller assemblies onto the open end of the

tracks.

5. Install the chain, use the take-up bolt to adjust the chain

tension to allow about 3" sag in the center (remove links

if necessary).

6. Determine which side of the door the operator will be mounted

on and install the track with the double idler on that side at the

center of the opening.

7. Install the track assembly with the single idler on the other side

of the center of the opening. Brace the tracks appropriately.

CONNECT TRACKS

1. Determine the length of the shaft needed to couple the two

tracks together and cut the shaft provided to that length. Slide

two bearing assemblies on the end of the shaft.

2. Install a 48B14 sprocket on each end of the shaft using the

(2) 1/4" x 1-1/2" roll pin provided (Figure 1).

3. Use a tape measure to set the slider assemblies the same

distance from the wall.

4. Couple the shaft between the two idler assemblies by butting

the 14 tooth sprockets together and connect with a #40 chain

and master link (Figure 2).

NOTES: 1. Shipped with 1/2 HP and lower side mount operators.

2. Shipped with 3/4 HP and higher side mount

operators.

PART # DESCRIPTION QTY

Model "T" Owner’s Manual 1

10-10203 Curved Arm 2

10-10204 Door Bracket 2

10-10205 Front Bracket 2

12-11438 Bearing 4

15-48B14LXX Sprocket 48B14 1" Bore 3

15-50B35LGH Sprocket 50B35 1" Bore

1/4" KW (2) 5/16-18 SS 1

75-10170 Slider 2

75-10214 Straight Arm 2

K75-10259 Track Spacer See Chart

75-11502 Drive Chain Front Idler #48 See Note 1

75-11503 Drive Chain Front Idler #41 See Note 2

75-11544 Drive Chain Double Idler #41 See Note 2

K75-11545 Chain Double Idler #48 Drive See Note 1

80-10383 Key Ring 1-1/4" See Chart

86-RP08-108 Long Roll Pin 1/4" x 1-1/2" 2

PACKING LIST

VARIABLE PARTS

PART #

K75-10259

80-10383

DESCRIPTION

Track Spacer

Key Ring 1-1/4"

DOORS

12'-14''

0

0

DOORS

16'-20'

2

2

DOORS

22'-24'

4

2

DOORS

TO 26'

6

2

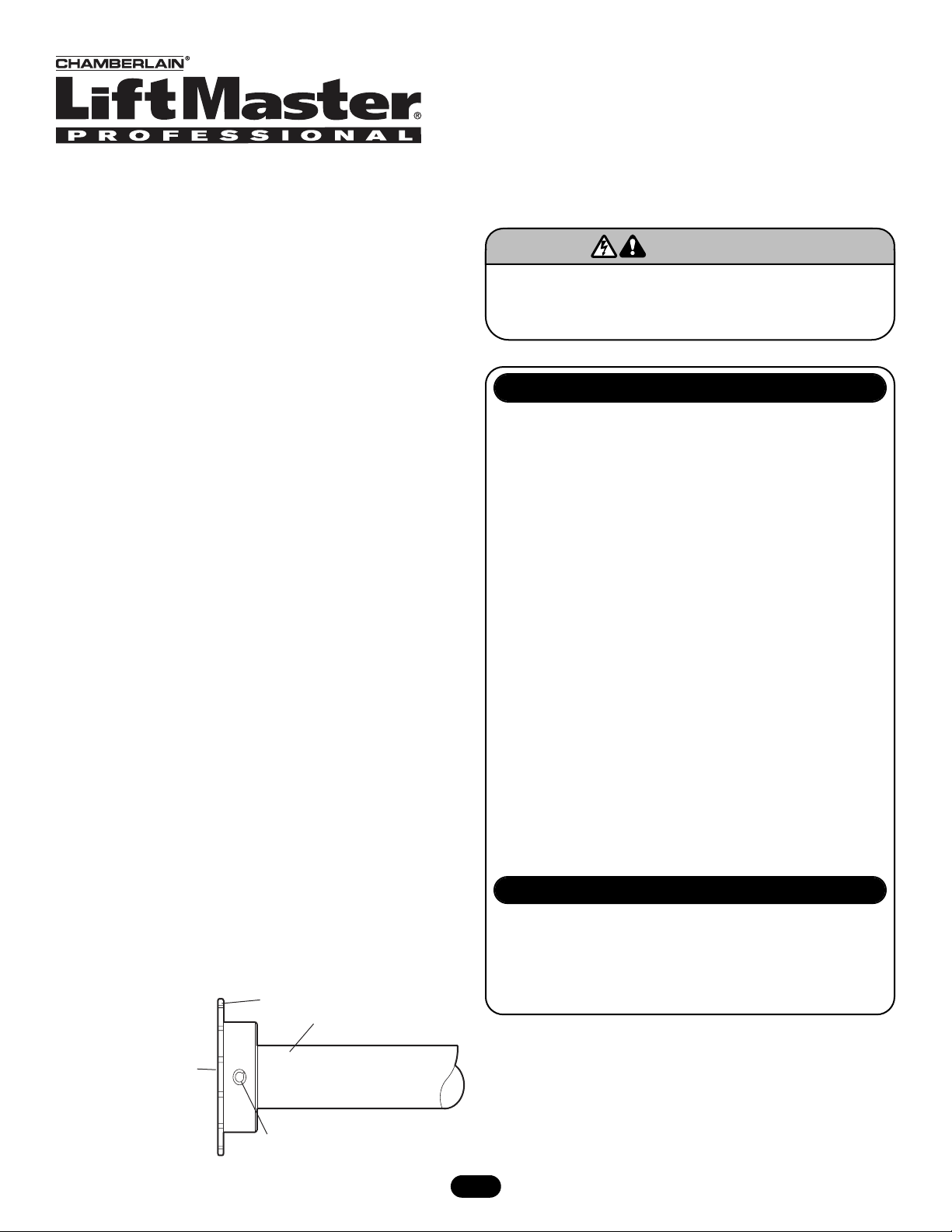

FIGURE 1

To prevent possible SERIOUS INJURY or DEATH, disconnect

electric power to operator BEFORE installing. ALL electrical

connections MUST be made by a qualified individual.

WARNING

WARNING

NOTE: XX is door height.

48B14 Sprocket 1" Bore

1" Diameter Shaft

Be Sure Shaft is Flush With

Sprocket. Do Not Let Shaft

Protrude Beyond Sprocket.

Drill 1/4" Hole - Pin

with 1/4"x1-1/2" Roll Pin

Page 2

INSTALLATION

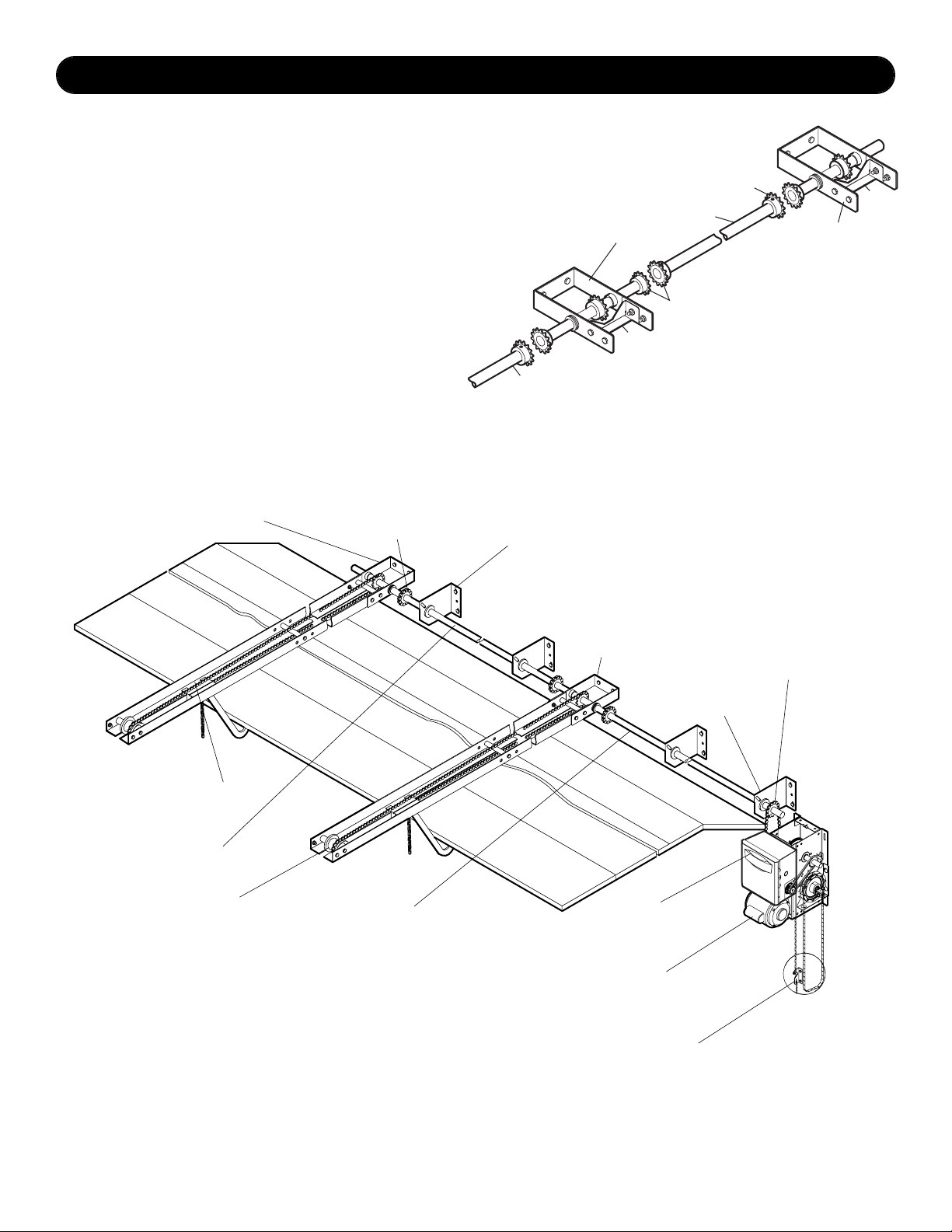

FIGURE 2

© 2005, The Chamberlain Group, Inc.

01-12575E All Rights Reserved Printed in Mexico

NOTES:

1. Smaller sprocket (50B12) is mounted on the extension shaft.

2. Larger sprocket (50B35) is mounted to the operator where the

(50B12) sprocket was removed.

3. Bearing assembly should be mounted as close to the (50B12)

sprocket as possible to prevent shaft flex.

4. Refer to owner’s manual for instructions on reversing limits.

Front Idler Assembly

Chain Coupling

(3 Places)

Bearing Assembly

(4 Places)

Extension Shaft

Sprocket 50B12

(See Note 1)

GH, H, J Operator

(With Reversed Limits

Logic 3 Requires Removal

of Jumper)

Disconnect Bracket

Idler Roller

(2 Places)

Sprocket 50B35

(See Note 2)

See Note 3

Double Idler Assembly

Connecting Shaft

Slider Assembly

(2 Places)

FIGURE 3

INSTALL OPERATOR

1. Install the operator using the appropriate manual.

2. Determine the length of shaft needed to connect the operator

to the double idler assembly and cut the shaft provided to that

length.

3. Install the last 48B14 sprocket to one end of the extension

shaft with the 1/4" x 1-1/2" roll pin provided (Figure 3).

4. Slide the last two bearing assemblies onto the end of the shaft.

Place one of the bearings in the center of the shaft. The other

bearing should be placed as close to where the operator driven

sprocket will be.

5. Remove the 50B12 sprocket from the operator and replace it

with the 50B35 sprocket provided. Install the 50B12 sprocket

on the extension shaft just installed.

Extension Shaft,

Runs to Operator

Connecting Shaft

Double Idler Assembly

Couple Sprockets Together with

#40 Chain and Master Link

Track

Spacer

48B14 Sprocket

Track

Spacer

Single Idler Assembly

Loading...

Loading...