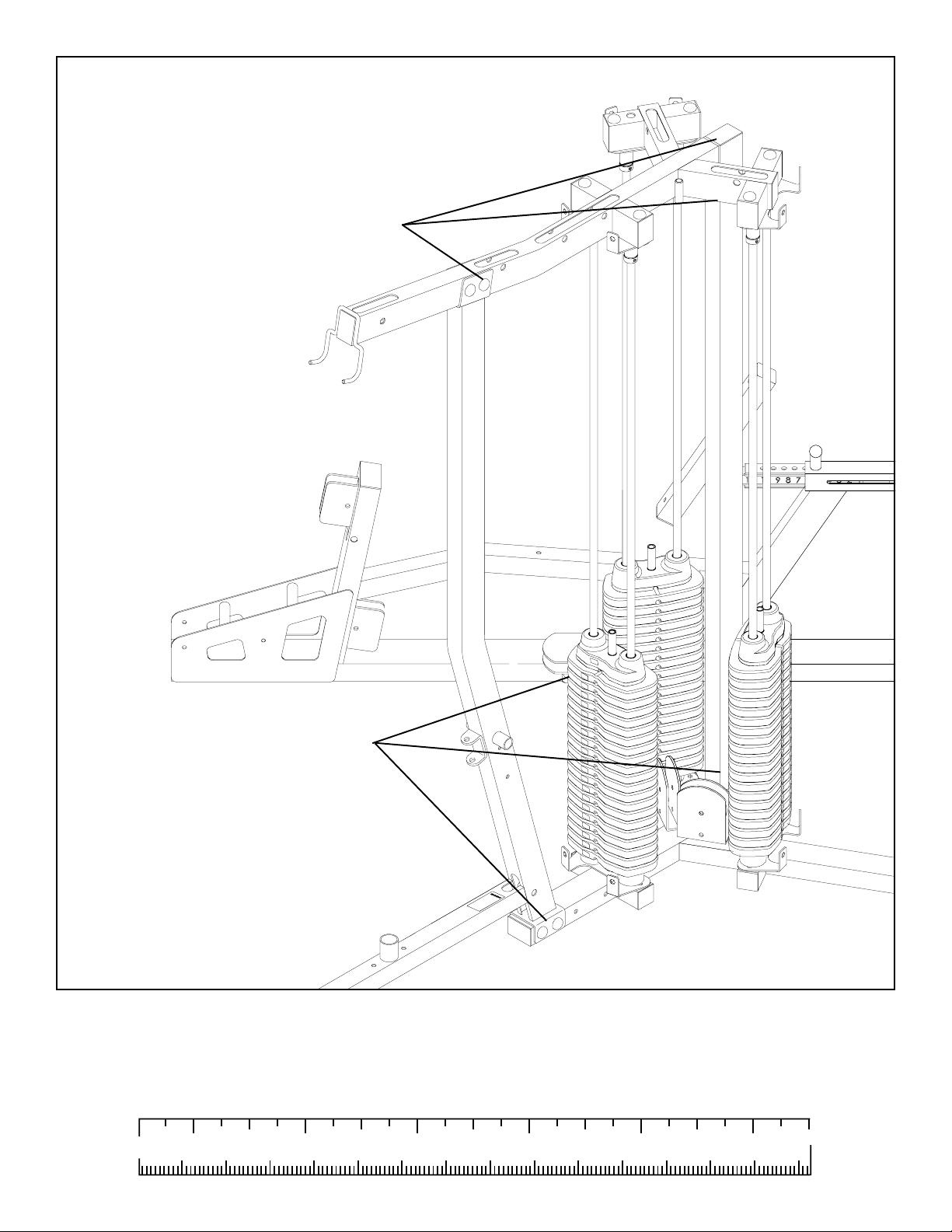

FIT SERIES FIT-3

W/ LEG PRESS

Part # 7348201

Rev C.

ASSEMBLY INSTRUCTIONS

Revision:4/04/031

MAIN UNIT PARTS LIST

KEY

ACU04-1360

1

ACU04-1367

2

ACU04-1361

3

ACU04-1338

4

ACU04-1359

5

ACU04-1358

6

ACU04-1362

7

ACU04-1356

8

ACU04-1355

9

ACU04-1352

10

ACU04-1365

11

ACU04-1364

12

ACU04-1368

13

ACU04-1363

14

ACU04-1354

15

ACU02-1306

16

ACU04-1366

17

ACU02-1294

18

ACU02-1321

19

ACU04-1385

20

ACU02-1320

21

ACU05-0313

22

23

ACU02-1296

24

ACU01-2028

25

ACU05-0351

26

ACU06-0025

27

ACU06-0024

28

ACU02-1304

29

ACU02-0078

30

ACU05-0349

31

ACU06-0371

32

ACU06-0304

33

ACU01-2155

34

35

36

37

38

39

40

41

42

ACU72925

ACU06-0382

ACU10-0204ASY

ACU05-0356

ACU11-0067

ACU05-0212

ACU06-0388

ACU05-0348

ACU07-0157

PART #

DESCRIPTION

COUNTERBALANCE

FOOT REST

SEA T PAD SUPPORT

PRESS ARM

PIVOT ARM

MUL TI PRESS SEA T ADJUST

BACK P AD SUPPOR T

MUL TI PRESS FRAME

TOWER UPRIGHT

TOWER BASE

LA T/LOW BOOM

KNEE HOLD DOWN

LA T/LOW SEAT

LA T/LOW FRAME

SHROUD BRACKET

SHROUD SUPPORT BRACKET

SWIVEL PULLEY

MUL TI PRESS PLA TE

LA T/LOW PLATE

MUL TI-PRESS ADJUST PLA TE

LA T/LOW ADJUST PLA TE

1/2 X 3” SHOULDER BOL T

DUAL PULLEY PLATE

MUL TI PRESS SLIDE TUBE

PILLOW BLOCK

4-1/2” PULLEY

3-1/2” PULLEY

2-7/8 X 2-1/4” CABLE CLIP

3-1/2 X 1” CABLE CLIP

3/4 X 3-1/8” T APPED SHAFT

3” ACCORDIAN SLEEVE

3/4 X 2” WEIGHT ST ACK CUSHION

GUIDE ROD

WEIGHT PLA TE

2-3/8” OD PLASTIC W ASHER

HEAD PLA TE

PILLOW BLOCK SP ACER

WEIGHT ST ACK PIN

13/16” SHAFT COLLAR

1-1/4” SHAFT COLLAR

5-1/2” PIVOT SHAFT

LA T SEAT P AD

QTY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

2

4

1

1

1

2

1

2

14

1

7

1

1

2

6

6

60

4

3

4

3

6

2

7

1

KEY

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

OR

70

71

72

73

74

75

76

77

78

79

80

81

82

83

PART #

ACU07-0156

ACU08-0077

ACU10-0215

ACU08-0085

ACU05-0350

ACU08-0078

ACUDA1C03804316NU

ACUDA1C03803216NU

ACUDA1C03804316NU

ACUDA1C03804316YU

ACUDA1C03805016NU

ACUDA1C03806116NU

ACUDA1C03806716NU

ACUDA1C03807016NU

ACUDA1C03807316NU

ACUDA1C03809016NU

ACUDA1C03809716NU

ACUDA1C03810616NU

ACUDA1C03816416NU

ACUDAEC03802516NB

ACUDAEC03807616NB

ACUDC1250100020B

ACUDB2E03807200U

ACUDC120010510U

ACU05-0310

ACU06-0357

ACU06-0357

ACU06-0357

ACU07-0158

ACU13-0122

ACU13-0123

ACU13-0121

ACU73086

ACU04-1353

ACU03-0340

ACU05-0193

ACUDI1080080U

ACU04-1386

ACU04-0622

ACU10-0205BLK

ACU10-0205BLK

ACU03-0536

DESCRIPTION

MUL TI PRESS BACK P AD

3/8 X 1” FLANGE SP ACER

5 X 8” ROLLER P AD

3/8 X 1/2” FLANGE SP ACER

3/8 X 1/2” SP ACER

3/8 X 3/4” FLANGE SP ACER

3/8 X 25mm BOL T

3/8 X 32mm BOL T

3/8 X 43mm BOL T

3/8 X 43mm BOL T W/LOCTITE

3/8 X 50mm BOL T

3/8 X 61mm BOL T

3/8 X 67mm BOL T

3/8 X 70mm BOL T

3/8 X 73mm BOL T

3/8 X 90mm BOL T

3/8 X 97mm BOL T

3/8 X 106mm BOL T

3/8 X 164mm BOL T

3/8 X 25mm BUTTON HEAD BOL T

3/8 X 76mm BUTTON HD BOL T

3/8” BLACK SAE W ASHER

3/8” LOW HEIGHT LOCK NUT

3/8” SAE W ASHER

3/8” RH WASHER

BLACK RH CAP

WHITE RH CAP

PLA TINUM RH CAP

MUL TI PRESS SEA T PAD

LA T CABLE

ROW CABLE

MUL TI-PRESS CABLE

WEIGHT ST ACK LABEL

STORAGE UPRIGHT

STORAGE PEG

12 LINK CHAIN

SNAP LINK

LA T BAR

LOW ROW BAR

MUL TI PRESS SHROUD

LA T SHROUD

5-1/2” T APPED PIVOT SHAFT

QTY

1

1

2

16

1

1

3

2

10

2

3

4

10

7

5

17

4

2

7

12

4

16

69

145

135

43

92

92

1

1

1

1

3

1

2

1

3

1

1

1

1

1

2

LEG PRESS PARTS LIST

KEY

PART #

ACU10-0205BLK

84

ACU04-1377

85

ACU04-1378

86

ACU04-1379

87

ACU04-1380

88

ACU04-1381

89

90

ACU07-0161

91

ACU07-0159

92

ACU13-0125

93

ACU06-0025

94

ACU02-1304

95

ACU08-0085

96

ACU08-0079

97

ACU05-0352

98

DESCRIPTION

LEG PRESS SHROUD

LEG PRESS FRAME

HANDLE

MAIN PIVOT ARM

SECONDARY PIVOT ARM

FOOT PLA TE

LEG PRESS PLACARD

LEG PRESS SEA T P AD

LEG PRESS BACK P AD

LEG PRESS CABLE

4-1/2” PULLEY

2-7/8 X 2-1/4” CABLE CLIP

3/8 X 1/2” FLANGE SP ACER

3/8 X 1-1/2” FLANGE SP ACER

3/4 X 4” PIVOT SHAFT

QTY

1

1

1

1

1

1

1

1

1

1

7

1

4

2

4

KEY

99

100

101

102

103

104

105

106

107

108

109

OR

110

111

112

PART #

ACUDA1C03804316NU

ACUDA1C03805016NU

ACUDA1C03806716NU

ACUDA1C03807016NU

ACUDA1C03807316NU

ACUDA1CO3811716NU

ACUDB2E03807200B

ACUDC120010510U

ACU05-0310

ACU06-0357

ACU06-0357

ACU06-0357

ACU04-1510

ACU13-0144

ACU04-1382

DESCRIPTION

3/8 X 43mm BOL T

3/8 X 50mm BOL T

3/8 X 67mm BOL T

3/8 X 70mm BOL T

3/8 X 73mm BOL T

3/8 X 117mm BOL T

3/8” LOW HEIGHT LOCK NUT

3/8” SAE WASHER

3/8” RH WASHER

BLACK RH CAP

WHITE RH CAP

PLA TINUM RH CAP

PULLEY BRACKET

FLOA TING PULLEY CABLE

BACK P AD SUPPORT

QTY

4

2

3

1

4

9

15

34

30

5

25

25

1

1

1

T ools Required for Assembly

* 9/16” wrench

* Ratchet with 9/16” socket

* Metric Allen wrench set

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOLT .

BOLT LENGTH

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

3

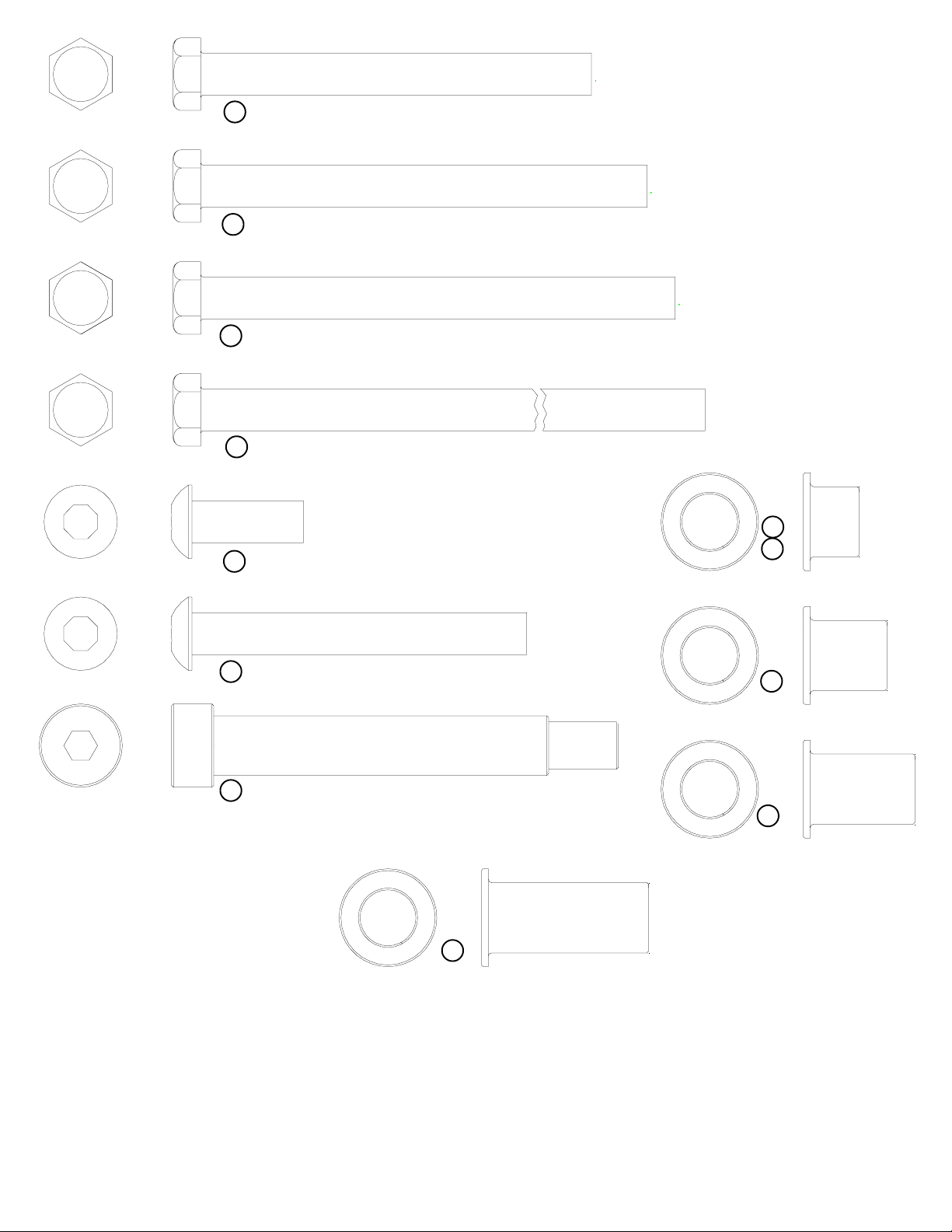

49 3/8 X 25mm BOL T

50 3/8 X 32mm BOL T

99 3/8 X 43mm BOL T

51

105

65

3/8” LOW

HEIGHT LOCK

NUT

106

66

3/8” SAE

WASHER

52 3/8 X 43mm BOL T W/NYLOCK

100 3/8 X 50mm BOL T

53

54 3/8 X 61mm BOL T

101 3/8 X 67mm BOL T

55

64

3/8” BLACK

SAE W ASHER

68

69

109

108

RH CAP

(WHITE/PLATINUM/BLACK)

107

67

RH

WASHER

102 3/8 X 70mm BOL T

56

103 3/8 X 73mm BOL T

57

104 3/8 X 117mm BOL T

4

58 3/8 X 90mm BOL T

59 3/8 X 97mm BOL T

60 3/8 X 106mm BOL T

61 3/8 X 164mm BOL T

62 3/8 X 25mm BUTTON HEAD BOL T

46

96

1/2”

FLANGE SP ACER

63 3/8 X 76mm BUTTON HEAD BOL T

22 1/2 X 3” SHOULDER BOLT

97

1-1/2”

FLANGE SP ACER

48

3/4”

FLANGE SP ACER

44

1”

FLANGE SP ACER

5

14

10

65

67

66

3/8 X 97mm 59

69

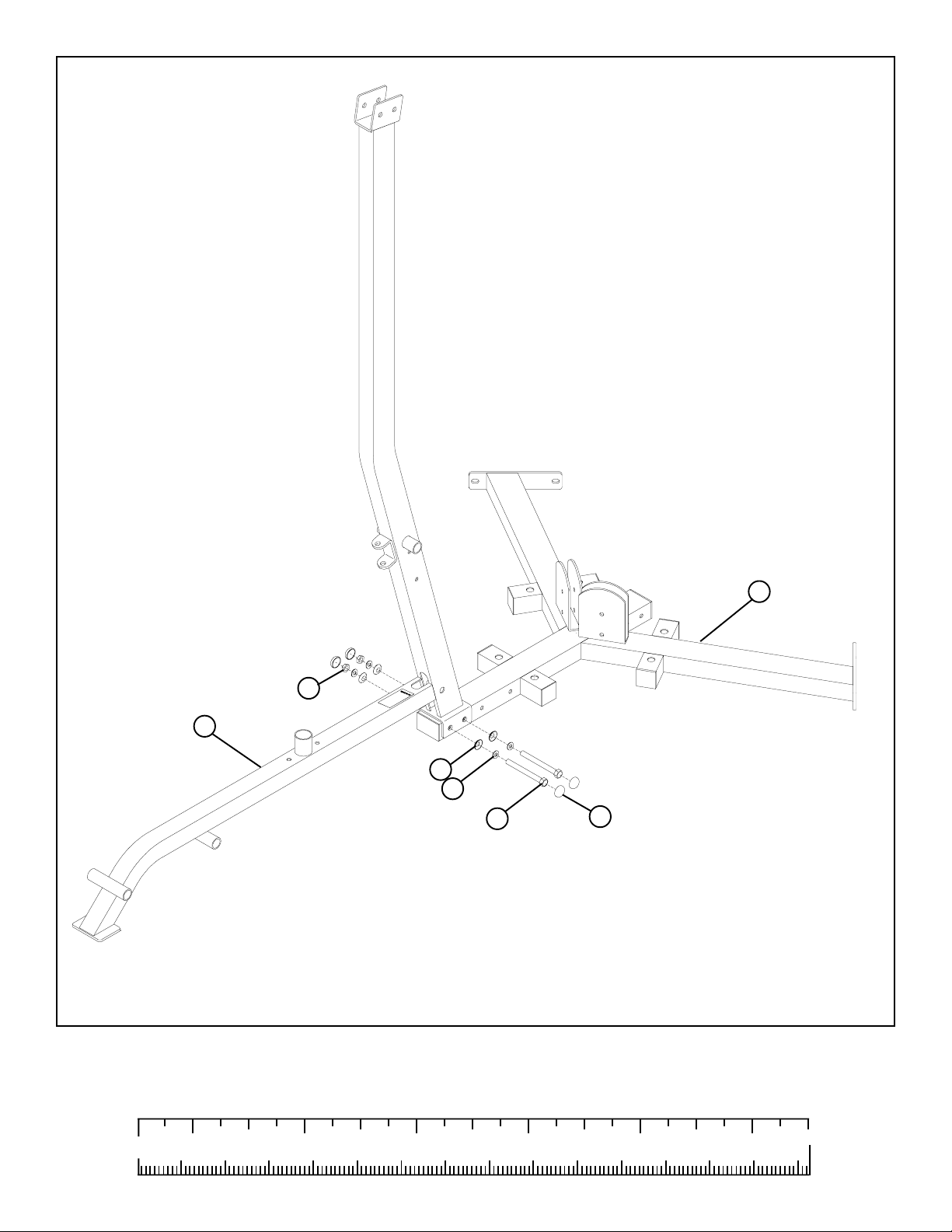

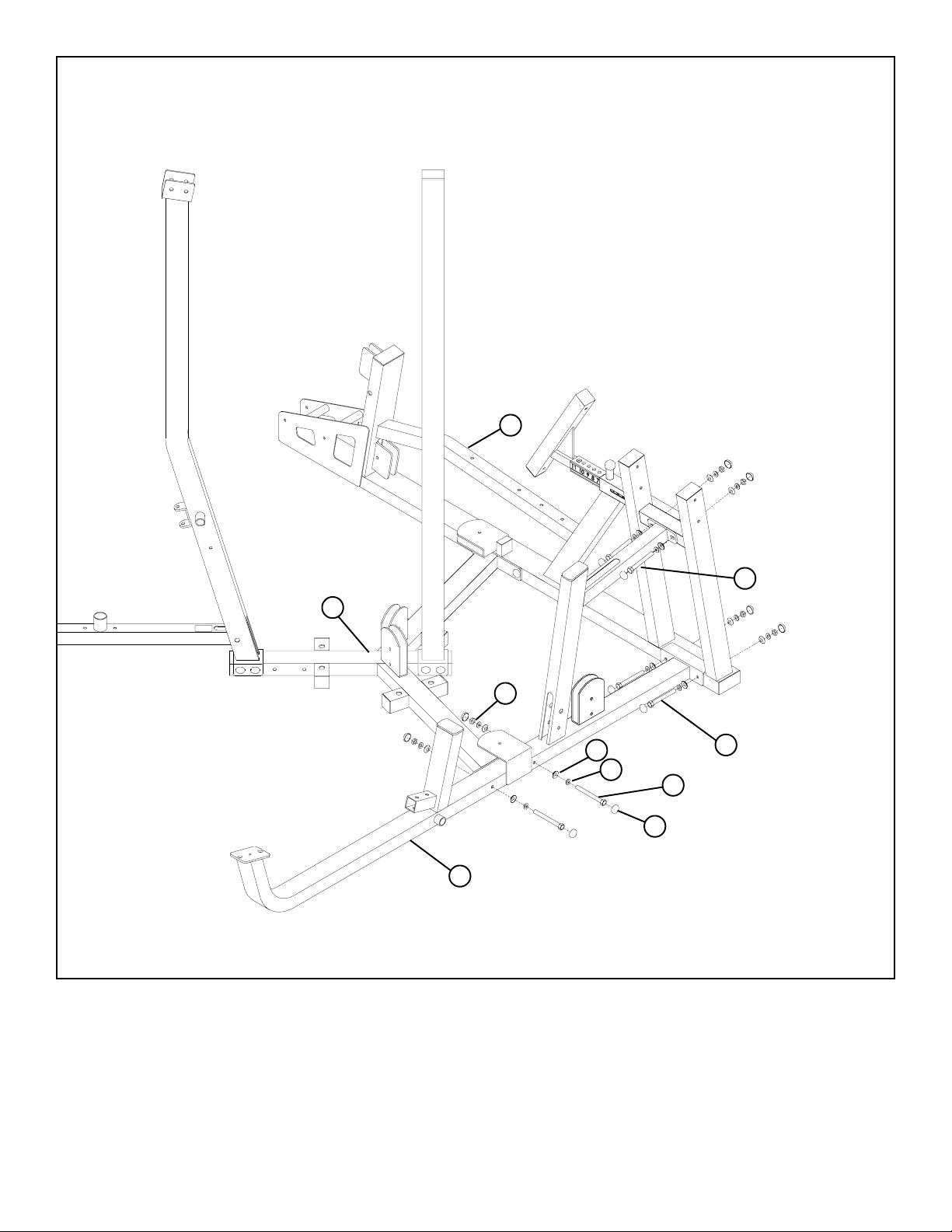

FIGURE 1

STEP 1:

• LOOSELY assemble the LA T/LOW FRAME (14) to the T OWER BASE (10) using four RH CAPS (69), two 3/8 X 97mm BOL TS (59),

four 3/8” SAE W ASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 1.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

6

65

85

67

66

104 3/8 X 117mm

69

10

FIGURE 2

STEP 2:

• LOOSELY assemble the LEG PRESS FRAME (85) to the TOWER BASE (10) using four RH CAPS (69), two 3/8 X 1 17mm BOL TS

(104), four 3/8” SAE W ASHERS (66), four 3/8” RH WASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 2. (NOTE: The two 3/8 X 117mm BOLTS (104) for this step are in the LEG PRESS hardwar e bag.)

7

65

9

REMOVE CAP BEFORE ASSEMBL Y!

67

66

59 3/8 X 97mm

69

10

FIGURE 3

STEP 3:

• LOOSELY assemble the TOWER UPRIGHT (9) to the TOWER BASE (10) using four RH CAPS (69), two 3/8 X 97mm BOL TS (59),

four 3/8” SAE W ASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 3.

(NOTE: REPLACE CAP AFTER ASSEMBL Y .)

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

8

10

85

55 3/8 X 67mm

65

67

66

58 3/8 X 90mm

69

8

104 3/8 X 117mm

FIGURE 4

STEP 4:

• LOOSEL Y assemble the MUL TI PRESS FRAME (8) to the LEG PRESS FRAME (85) using eight RH CAPS (69), two 3/8 X 1 17mm BOL TS

(104), two 3/8 X 67mm BOL TS (55), eight 3/8” SAE WASHERS (66), eight 3/8” RH W ASHERS (67) and four 3/8” LOW HEIGHT LOCK

NUTS (65) as shown in FIGURE 4. (NOTE: The two 3/8 X 1 17mm BOL TS (104) for this step are in the LEG PRESS hardware bag.)

• LOOSELY assemble the MUL TI PRESS FRAME (8) to TOWER BASE (10) using four RH CAPS (69), two 3/8 X 90mm BOLTS (58),

four 3/8” SAE W ASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 4.

9

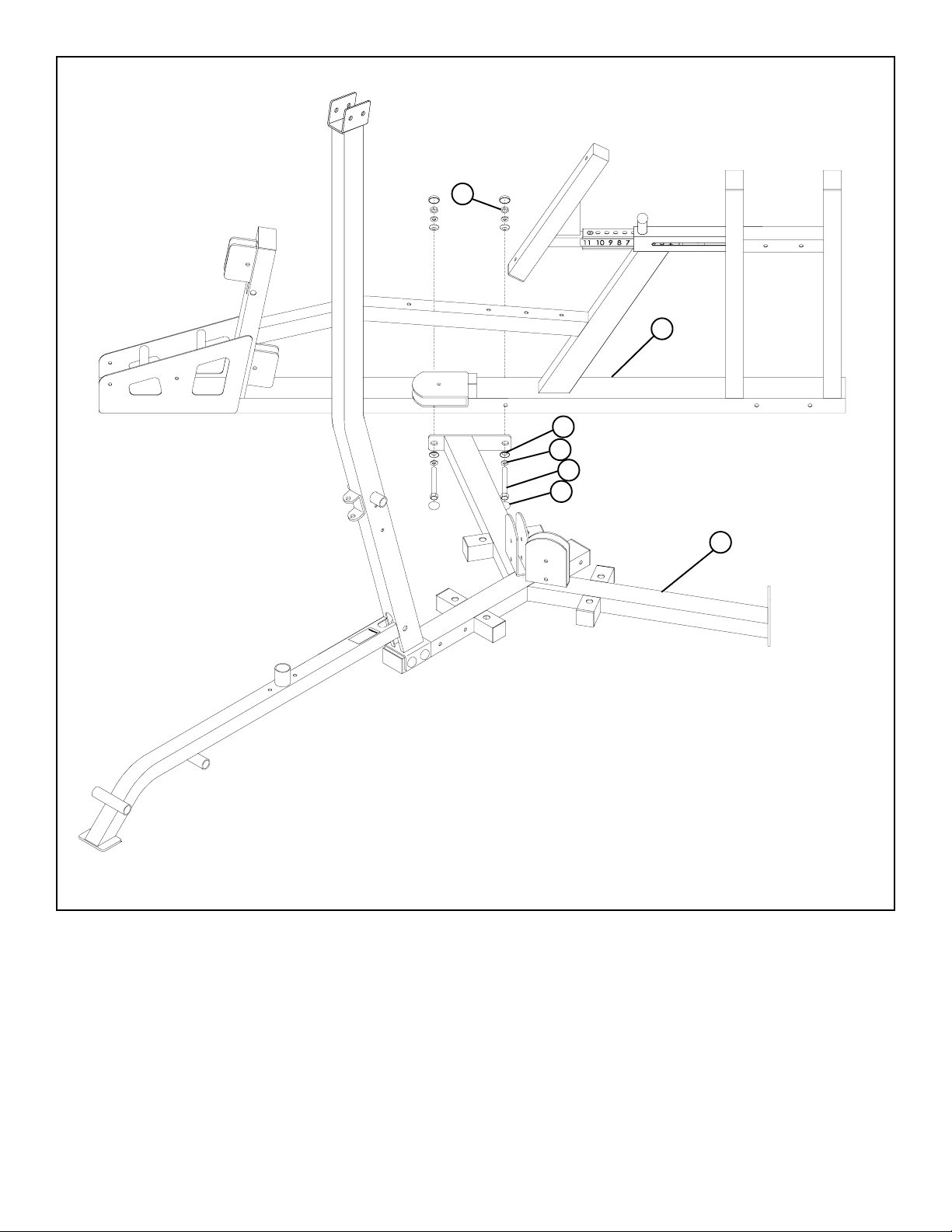

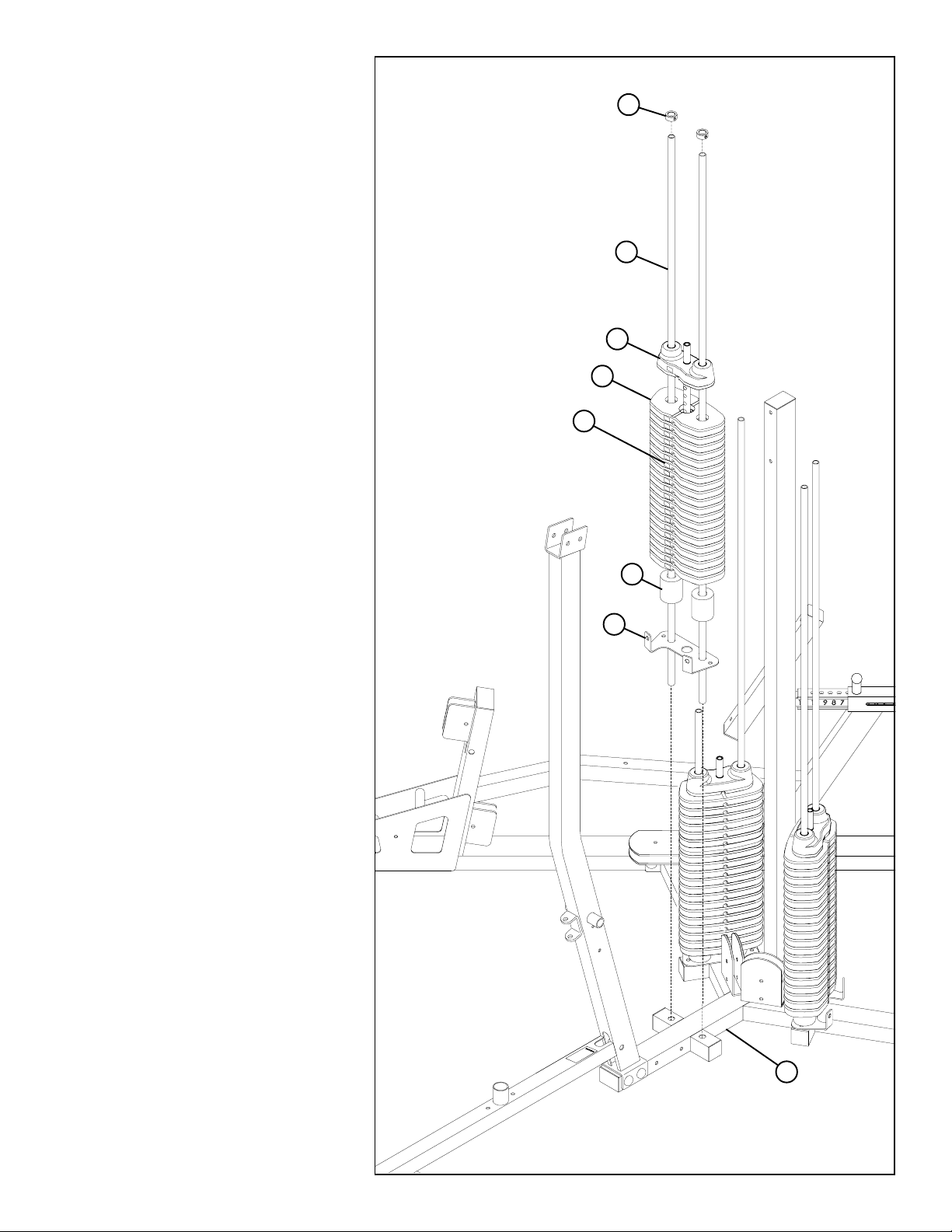

STEP 5:

• Insert two GUIDE RODS (33) through the

SHROUD SUPPORT BRACKET (16) and into

the TOWER BASE (10) as shown on FIGURE

5.

• (NOTE: Lubricate GUIDE RODS (33) with

silicon or teflon spray available at most

hardware stores.)

FIGURE 5

39

• Slide two 3/4 X 2” WEIGHT STACK CUSHIONS (32) down over the GUIDE RODS (33)

as shown in FIGURE 5.

• Using EXTREME CARE slide all twenty

WEIGHT PLATES (34) down over the GUIDE

RODS (33) on to the WEIGHT STACK CUSHIONS (32). Make sure that the WEIGHT

PLATES (34) are all facing as shown.

• Slide the HEAD PLATE ASSEMBLY (36) down

over the GUIDE RODS (33) onto the weight

stack as shown in FIGURE 5.

• Slide two 13/16” SHAFT COLLARS (39)

over the GUIDE RODS (33) as shown in

FIGURE 5.

• Apply WEIGHT STACK LABELS (74) to

WEIGHT PLA TES (34) and HEAD PLATE (36)

as shown in FIGURE 5. Begin with number one

at the HEAD PLATE (36) with larger numbers

in consecutive order towards bottom of weight

stack.

• Repeat STEP 5 to assemble two more weight

stacks to the TOWER BASE (10).

33

36

34

74

32

16

10

10

11

33

15

FIGURE 6

STEP 6:

• CAREFULLY slide three SHROUD BRACKETS (15) over all the GUIDE RODS (33) as shown in FIGURE 6.

• CAREFULLY assemble the LAT/LOW BOOM (11) over all the GUIDE RODS (33) as shown in FIGURE 6.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

11

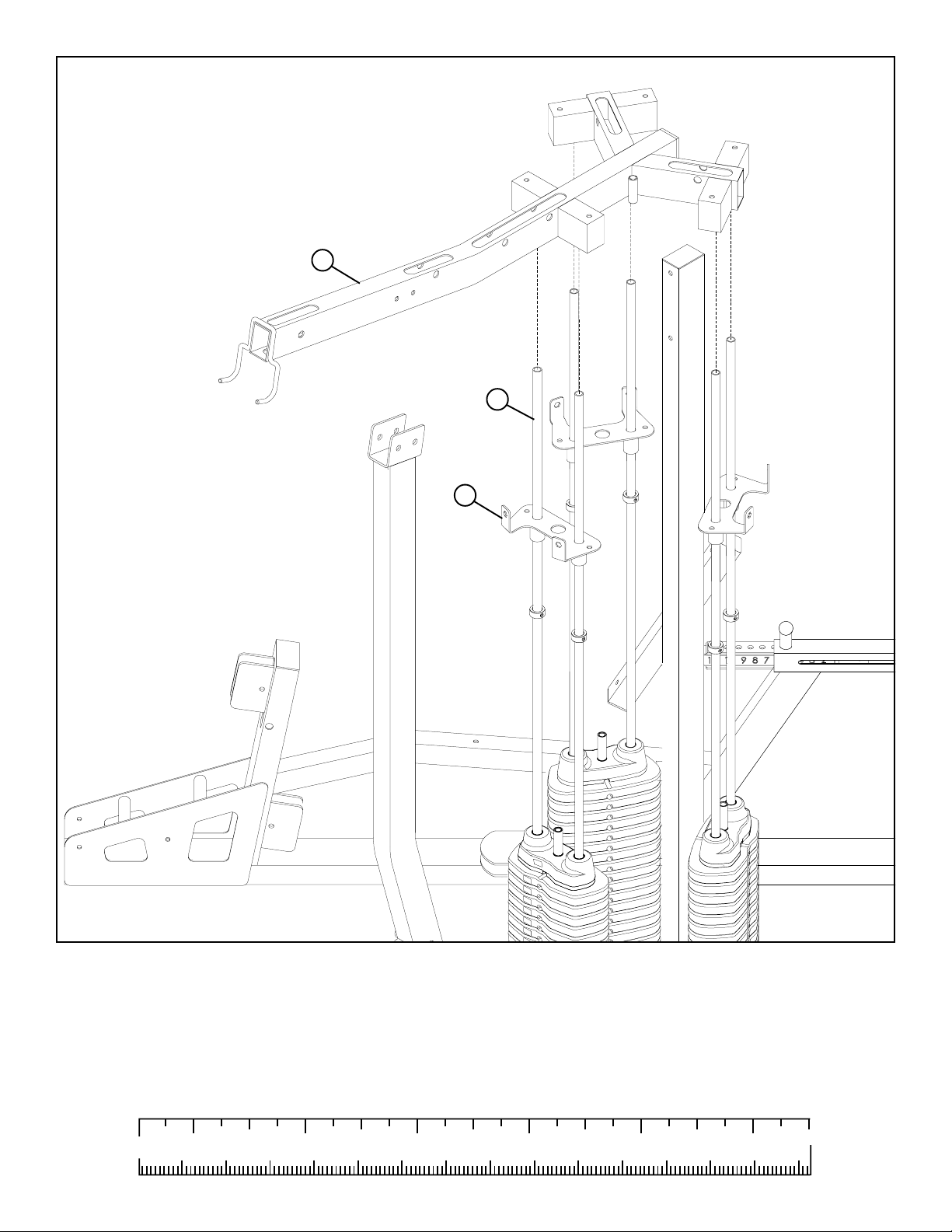

FIGURE 7

14

11

57 3/8 X 73mm

3/8 X 90mm 58

9

67

66

69

65

STEP 7:

• LOOSELY assemble the LAT/LOW BOOM (11) to the LAT/LOW FRAME (14) and the TOWER UPRIGHT (9) using seven RH

CAPS (69), two 3/8 X 73mm BOL TS (57), two 3/8 X 90mm BOL TS (58), seven 3/8” SAE WASHERS (66), seven 3/8” RH W ASHERS

(67) and three 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 7.

69

3/8 X 90mm 58

66

67

11

65

15

39

TIGHTEN!

FIGURE 8

STEP 8:

• SECUREL Y assemble the three SHROUD BRACKETS (15) to the LAT/LOW BOOM (11) using six RH CAPS (69), six 3/8 X 90mm

BOL TS (58), twelve 3/8” SAE WASHERS (66), six 3/8” RH W ASHERS (67) and six 3/8” LOW HEIGHT LOCK NUTS (65) as shown

in FIGURE 8. (NOTE: Use RH W ASHERS and RH CAPS on top only .)

• Slide the 13/16” SHAFT COLLARS (39) up against the SHROUD BRACKETS (15) and SECURELY tighten the set screws on

the SHAFT COLLARS (39). See FIGURE 8.

12

LUBRICATION NOTE:

When finished assembling the W eight Stack, open the lube Pack provided

with this unit and apply a thin film of Lubricant around the first 2 to 3

inches of each Guide Rod above the Head Plate Assembly . After the

cables are installed, use of the machine will spread the lubricant over the

length of the Guide Rods and into the Head Plate

Assemblies bushings

TIGHTEN!

TIGHTEN!

FIGURE 9

STEP 9:

• Securely tighten all loose frame connections made to this point, then proceed to snap RH CAPS

(69) over the RH WASHERS (67) on all tightened connections.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

13

65

13

14

41

FIGURE 10

19

67

66

61 3/8 X 164mm

68 BLACK

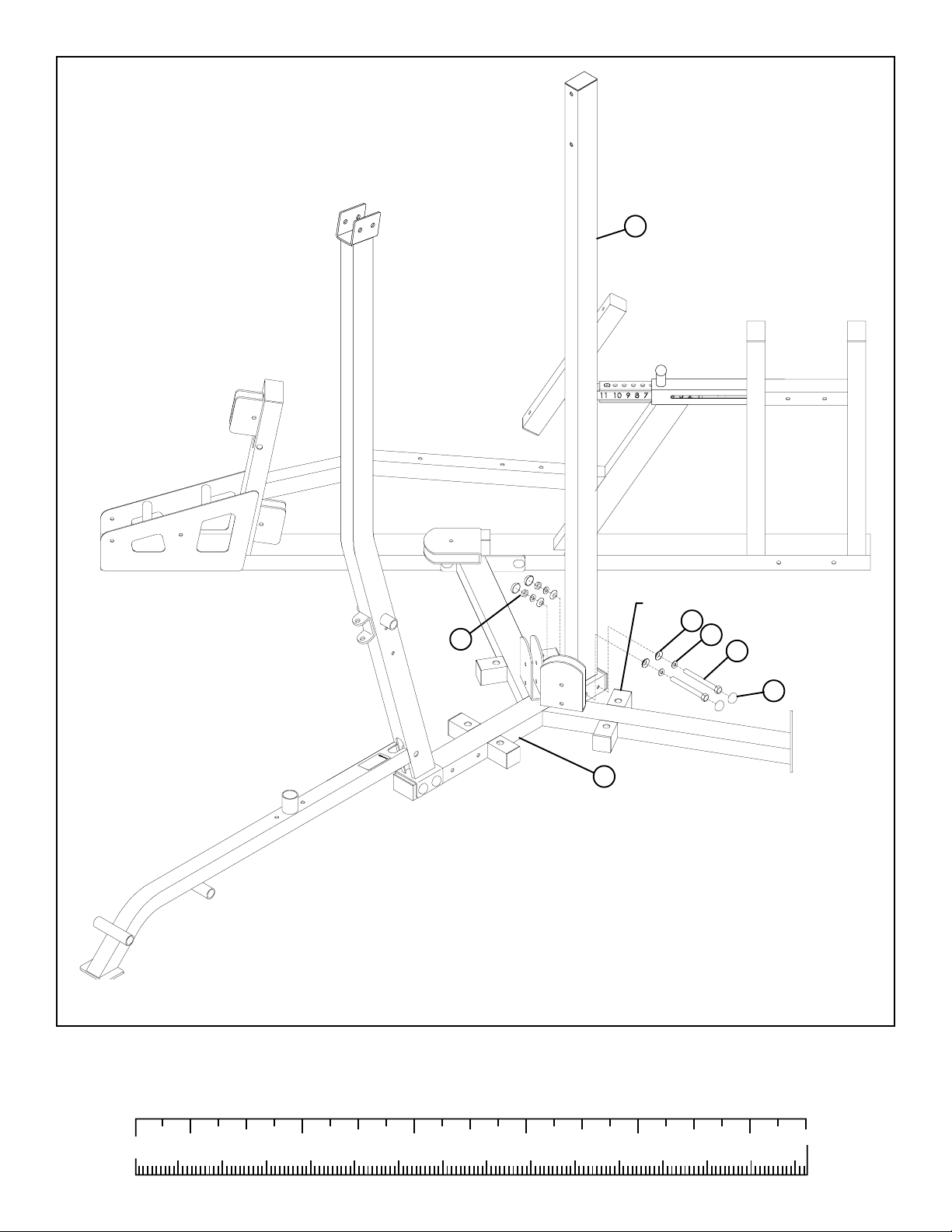

STEP 10:

• Insert four 5-1/2” PIVOT SHAFTS (41) into the LAT/LOW FRAME (14) and the LA T/LOW SEAT (13) as shown in FIGURE 10.

• SECURELY assemble four LA T/LOW PLATES (19) to the LA T/LOW SEA T (13) and to the LAT/LOW FRAME (14) using eight

BLACK RH CAPS (68), four 3/8 X 164mm BOL TS (61), eight 3/8” SAE WASHERS (66), eight 3/8” RH W ASHERS (67) and four 3/8”

LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 10.

69

3/8 X 67mm 55

14

2

67

66

FIGURE 11

65

STEP 11:

• SECUREL Y assemble FOOT REST (2) to the LA T/LOW FRAME (14) using four RH CAPS (69), two 3/8 X 67mm BOLTS (55), four 3/8”

SAE W ASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 11.

14

42

13

67

3/8 X 50mm 53

BLACK 68

66

FIGURE 12

STEP 12:

• SECUREL Y assemble LAT SEA T PAD (42) to the LA T/LOW SEA T (13) using two BLACK RH CAPS (68), two 3/8 X 50mm BOL TS (53),

two 3/8” SAE WASHERS (66) and two 3/8” RH W ASHERS (67) as shown in FIGURE 12.

FIGURE 13

1/2 X 3” 22

17

66

67

14

69

65

STEP 13:

• Assemble the SWIVEL PULLEY (17) to the LAT/LOW FRAME (14) using one 1/2 X 3” SHOULDER BOLT (22), one 3/8” RH

WASHER (67), one 3/8” SAE W ASHER (66) one 3/8” LOW HEIGHT LOCK NUT (65) and one RH CAP (69) as shown in FIGURE

13. (NOTE: Tighten connection enough to remove play, yet allowing SWIVEL PULLEY (17) to rotate freely.)

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

15

68

69

65

3/8 X 67mm 55

14

30

47

21

67

66

53 3/8 X 50mm

68 BLACK

FIGURE 14

STEP 14:

• SECURELY assemble the LAT/LOW ADJUST PLATE (21) to the LAT/LOW FRAME (14) using two BLACK RH CAPS (68),

two RH CAPS (69), two 3/8 X 67mm BOL TS (55), four 3/8” SAE WASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW

HEIGHT LOCK NUTS (65) as shown in FIGURE 14.

• Assemble the 3/4 X 3-1/8” TAPPED SHAFT (30) to the LAT/LOW ADJUST PLATE (21) using two BLACK RH CAPS (68), one

3/8 X 50mm BOL T (53), two 3/8” SAE WASHERS (66), two 3/8” RH WASHERS (67), one 3/8 X 1/2” SPACER (47) and one 3/8” LOW

HEIGHT LOCK NUT (65) as shown in FIGURE 14. (NOTE: T ighten connection enough to remove play, yet allowing T APPED

SHAFT to rotate freely .)

FIGURE 15

69

65

67

66

71

11

69

28

3/8 X 70mm 56

BLACK 68

2646

68

BLACK

51 3/8 X 43mm

69

23

STEP 15:

• Route the LAT CABLE (71) through the LAT/LOW BOOM (11) and assemble two 4-1/2” PULLEYS (26) to the BOOM (11) using two RH CAPS (69), two BLACK RH CAPS (68), two 3/8 X 70mm BOL TS (56), four 3/8” SAE WASHERS (66), four 3/8” RH

W ASHERS (67), two 2-7/8” X 2-1/4” CABLE CLIPS (28), four 3/8 X 1/2” FLANGE SP ACERS (46) and two 3/8” LOW HEIGHT LOCK

NUTS (65) as shown in FIGURE 15.

• Route the LAT CABLE (71) around one 4-1/2” PULLEY (26) and assemble the PULLEY to two DUAL PULLEY PLATES (23)

using two RH CAPS (69), one 3/8 X 43mm BOL T (51), two 3/8” SAE WASHERS (66), two 3/8” RH W ASHERS (67) and one 3/8”

LOW HEIGHT LOCK NUT (65) as shown in FIGURE 15.

16

69

65

26

66

67

46

56 3/8 X 70mm

28

11

68 BLACK

71

36

38

FIGURE 16

STEP 16:

• Route the LAT CABLE (71) through the LAT/LOW BOOM (11) and assemble two 4-1/2” PULLEYS (26) to the BOOM (11) using two BLACK RH CAPS (68), two RH CAPS (69), two 3/8 X 70mm BOL TS (56), four 3/8” SAE WASHERS (66), four 3/8” RH

W ASHERS (67), two 2-7/8 X 2-1/4” CABLE CLIPS (28), four 3/8 X 1/2” FLANGE SP ACERS (46) and two 3/8” LOW HEIGHT LOCK

NUTS (65) as shown in FIGURE 16.

• Slide one WEIGHT STACK PIN (38) over the stem on the HEAD PLATE (36) as shown in FIGURE 16.

• Screw the threaded end of the LAT CABLE (71) all the way onto the end of the stem on the HEAD PLATE (36) and tighten jam

nut securely. See FIGURE 16.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

17

72

17

27

26

69

65

14

51 3/8 X 43mm

46

28

68 BLACK

67

56 3/8 X 70mm

66

68 BLACK

FIGURE 17

STEP 17:

• Route the ROW CABLE (72) around one 4-1/2” PULLEY (26) and assemble the 4-1/2” PULLEY and one 3-1/2” PULLEY (27)

to the SWIVEL PULLEY (17) using six BLACK RH CAPS (68), three 3/8 X 43mm BOL TS (51), six 3/8” SAE WASHERS (66), six 3/8”

RH WASHERS (67) and three 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 17.

• Route the ROW CABLE (72) through the LAT/LOW FRAME (14) and assemble one 4-1/2” PULLEY (26) using one RH CAP

(69), one BLACK RH CAP (68), one 3/8 X 70mm BOL T (56), two 3/8” SAE W ASHERS (66), two 3/8” RH W ASHERS (67), one 2-7/8

X 2-1/4” CABLE CLIP (28), two 3/8 X 1/2” FLANGE SP ACERS (46) and one 3/8” LOW HEIGHT LOCK NUT (65) as shown in FIGURE 17.

18

FIGURE 18

41

65

72

30

23

67

26

51 3/8 X 43mm

66

69

14

STEP 18:

• Route the ROW CABLE (72) around one 4-1/2” PULLEY (26) and assemble the PULLEY to the bottom holes of the DUAL

PULLEY PLA TES (23) using two RH CAPS (69), one 3/8 X 43mm BOL T (51), two 3/8” SAE W ASHERS (66), two 3/8” RH W ASHERS (67)

and one 3/8” LOW HEIGHT LOCK NUT (65) as shown in FIGURE 18.

• Screw the threaded end of the ROW CABLE (72) all the way onto the end of the 3/4 X 3-1/8” TAPPED SHAFT (30) and tighten

jam nut securely. See FIGURE 18.

• Insert one 5-1/2” PIVOT SHAFT (41) into the LAT/LOW ROW FRAME (14) as shown in FIGURE 18.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

19

12

65

14

67

66

45

35

3/8 X 164mm 61

40

69

FIGURE 19

STEP 19:

• SECURELY assemble the KNEE HOLD DOWN (12) to the LA T/LOW FRAME (14) using two RH CAPS (69), one 3/8 X 164mm BOL T

(61), two 3/8” SAE W ASHERS (66), two 3/8” RH W ASHERS (67) and one 3/8” LOW HEIGHT LOCK NUT (65) as shown in FIGURE 19.

• Assemble two ROLLER PADS (45) and four 2-3/8” OD PLASTIC WASHERS (35) to the KNEE HOLD DOWN (12) using two

1-1/4” SHAFT COLLARS (40) as shown in FIGURE 19.

20

8

24

6

SPRING PIN

FIGURE 20

STEP 20:

• Pull back on the SPRING PIN and slide the MUL TI PRESS SEAT ADJUST (6) over the MULTI PRESS SLIDE TUBE (24) as shown

in FIGURE 20.

• Slide the end of the MULTI PRESS SLIDE TUBE (24) over the MULTI PRESS FRAME (8) as shown in FIGURE 20.

8

3/8 X 25mm 49

54 3/8 X 61mm

69

55 3/8 X 67mm

66

67

24

65

FIGURE 21

STEP 21:

• SECURELY assemble the MULTI PRESS SLIDE TUBE (24) to the MULTI PRESS FRAME (8) using seven RH CAPS (69), two

3/8 X 67mm BOL TS (55), one 3/8 X 61mm BOL T (54), one 3/8 X 25mm BOLT (49), seven 3/8” SAE W ASHERS (66), seven 3/8” RH

W ASHERS (67) and three 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 21.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

21

41

7

41

3

FIGURE 22

8

STEP 22:

• Insert one 5-1/2” PIVOT SHAFT (41) into the MULTI PRESS FRAME (8) and one 5-1/2” PIVOT SHAFT (41) into the BACK P AD

SUPPORT (7) as shown in FIGURE 22.

7

8

18

67

65

66

68 BLACK

6

3

68 BLACK

3/8 X 164mm 61

60 3/8 X 106mm

FIGURE 23

STEP 23:

• SECURELY assemble the BACK P AD SUPPORT (7) to the MULTI PRESS SEA T ADJUST (6) using two BLACK RH CAPS (68),

one 3/8 X 106mm BOL T (60), two 3/8” SAE WASHERS (66), two 3/8” RH W ASHERS (67) and one 3/8” LOW HEIGHT LOCK NUT (65)

as shown in FIGURE 23. (NOTE: TIghten connections enough to remove slop, yet allow part to rotate fr eely.)

• SECURELY assemble two MULTI PRESS PLATES (18) to the BACK PAD SUPPORT (7) and to the MULTI PRESS FRAME (8)

using four BLACK RH CAPS (68), two 3/8 X 164mm BOL TS (61), four 3/8” SAE WASHERS (66), four 3/8” RH W ASHERS (67) and two

3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 23.

• SECURELY assemble the SEAT PAD SUPPORT (3) to the MULTI PRESS SEA T ADJUST (6) using two BLACK RH CAPS (68),

one 3/8 X 106mm BOL T (60), two 3/8” SAE WASHERS (66), two 3/8” RH W ASHERS (67) and one 3/8” LOW HEIGHT LOCK NUT (65)

as shown in FIGURE 23. (NOTE: TIghten connections enough to remove slop, yet allow part to rotate fr eely.)

22

3/8 X 73mm 57

7

FIGURE 24

43

STEP 24:

• SECURELY assemble the MULTI PRESS BACK PAD

(43) to the BACK PAD SUPPORT (7) using two

BLACK RH CAPS (68), two 3/8 X 73mm BOL TS (57),

two 3/8” SAE WASHERS (66), two 3/8” RH W ASHERS

(67) as shown in FIGURE 24.

• SECURELY assemble the MUL TI PRESS SEAT P A D

(70) to the SEAT PAD SUPPORT (3) using two

BLACK RH CAPS (68), two 3/8 X 32mm BOL TS (50),

two 3/8” SAE WASHERS (66), two 3/8” RH W ASHERS

(67) as shown in FIGURE 24.

68

BLACK

67

66

3/8 X 32mm 50

STEP 25:

• Slide two 3” ACCORIDIAN SLEEVES

(31) over the shafts on the PIVOT ARM

(5) as shown in FIGURE 25.

• Slide two PILLOW BLOCKS (25) over

the shafts on the PIVOT ARM (5) as

shown in FIGURE 25.

70

3

BLACK 64

31

37

25

• Assemble four 3/8 X 76mm BUTT ON

HEAD BOL TS (63), four 3/8” BLACK

SAE WASHERS (64) and four PILLOW

BLOCK SP ACERS (37) to the the

PILLOW BLOCKS (25)

FIGURE 25.

0

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

as shown in

1/2 1/2 1/2 1/2 1/2 1/2

1

63 3/8 X 76mm

BUTTON HEAD

5

FIGURE 25

23456

23

25

TIGHTEN!

69

65

67

66

92

5

FIGURE 26

STEP 26:

• SECUREL Y assemble the PIVOT ARM (5) to the LEG CURL/EXT FRAME (92) using four previously inserted 3/8 X 76mm BUTTON

HEAD BOL TS (63), four RH W ASHERS (67), four 3/8” SAE W ASHERS (66), four 3/8” LOW HEIGHT LOCK NUTS (65) and four RH

CAPS (69) as shown in FIGURE 26.

• IMPORTANT! When PIVOT ARM (5) is centered and level in the PILLOW BLOCKS (25), tighten the PILLOW BLOCK set

screws.

83

69

44

68 BLACK

5

65

66

67

20

3/8 X 73mm 57

69

48

58 3/8 X 90mm

68 BLACK

73

55 3/8 X67mm

FIGURE 27

STEP 27:

• SECURELY assemble the MULTI PRESS ADJUST PLATE (20) to the PIVOT ARM (5) using three RH CAPS (69), three

BLACK RH CAPS (68), one 3/8 X 67mm BOL TS (55), one 3/8 X 73mm BOL T (57), one 3/8 X 90mm BOL T (58), six 3/8” SAE W ASHERS (66), six 3/8” RH W ASHERS (67), one 3/8 X 3/4” FLANGE SPACER (48), one 3/8 X 1” FLANGE SP ACER (44), one MUL TI

PRESS CABLE (73) and three 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 27. (NOTE: Assemble the MUL TI PRESS

CABLE to the second set of holes.)

• Insert one 5-1/2” TAPPED PIVOT SHAFT (83) into the PIVOT ARM (5).

24

69

1

65

5

67

66

3/8 X 61m 54

3/8 X 43mm 52

W/LOCTITE

4

FIGURE 28

STEP 28:

• SECURELY assemble the PRESS ARM (4) to the PIVOT ARM (5) using two RH CAPS (69), two 3/8 X 43mm BOL TS W/LOCTITE

(52), two 3/8” SAE WASHERS (66) and two 3/8” RH W ASHERS (67) as shown in FIGURE 28.

• SECUREL Y assemble the COUNTERBALANCE (1) to the PIVOT ARM (5) using four RH CAPS (69), two 3/8 X 61mm BOL TS (54), four

3/8” SAE W ASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 28.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

25

28

68 BLACK

3/8 X 70mm 56

FIGURE 29

69

26

5

4

73

65

8

46

3/8 X 67mm 55

69

67

66

54 3/8 X 61mm

26

STEP 29:

• Route the MULTI PRESS CABLE (73) through the MULTI PRESS FRAME (8) and assemble one 4-1/2” PULLEY (26) to the

FRAME (8) using four RH CAPS (69), one 3/8 X 67mm BOL T (55), one 3/8 X 61mm BOLT (54), four 3/8” SAE W ASHERS (66), four

3/8” RH W ASHERS (67), two 3/8 X 1/2” FLANGE SPACERS (46) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 29.

• Route the MULTI PRESS CABLE (73) through the MULTI PRESS FRAME (8) and PIVOT ARM (5) and assemble one 4-1/2”

PULLEY (26) to the PIVOT ARM (5) using one BLACK RH CAP (68), one RH CAP (69), one 3/8 X 70mm BOLT (56), two 3/8” SAE

W ASHERS (66), two 3/8” RH WASHERS (67), one 2-7/8” X 2-1/4” CABLE CLIP (28), two 3/8 X 1/2” FLANGE SP ACERS (46) and one

3/8” LOW HEIGHT LOCK NUT (65) as shown in FIGURE 29.

26

FIGURE 30

8

3/8 X 43mm 51

26

26

73

66

29

67

65

68 BLACK

69

69

51 3/8 X 43mm

STEP 30:

• Route the MULTI PRESS CABLE (73) through the bracket on the MULTI PRESS FRAME (8) and assemble one 4-1/2” PULLEY

(26) to the FRAME (8) using four RH CAPS (69), two 3/8 X 43mm BOL TS (51), four 3/8” SAE WASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 30.

• Route the MULTI PRESS CABLE (73) under the bracket on the MULTI PRESS FRAME (8) and assemble one 4-1/2” PULLEY

(26) to the FRAME (8) using one BLACK RH CAP (68), one RH CAP (69), one 3/8 X 43mm BOL T (51), two 3/8” SAE WASHERS

(66), two 3/8” RH WASHERS (67), one 3-1/2 X 1” CABLE CLIP (29) and one 3/8” LOW HEIGHT LOCK NUT (65) as shown in FIGURE 30.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

27

FIGURE 31

73

65

26

10

66

51 3/8 X 43mm

STEP 31:

• Route the MULTI PRESS CABLE (73) under the weight stack and through the bracket on the TOWER BASE (10) and assemble

one 4-1/2” PULLEY (26) to the T OWER BASE (10) using two 3/8 X 43mm BOL TS (51), four 3/8” SAE WASHERS (66) and two 3/8”

LOW HEIGHT LOCK NUTS (65) as shown in FIGURE 31.

28

FIGURE 32

3/8 X 70mm 56

28

68

BLACK

26

69

66

65

67

46

11

73

38

36

STEP 32:

• Route the MULTI PRESS CABLE (73) through the LAT/LOW BOOM (11) and assemble one 4-1/2” PULLEY (26) to the BOOM

(11) using one BLACK RH CAP (68), one RH CAP (69), one 3/8 X 70mm BOLT (56), two 3/8” SAE W ASHERS (66), two 3/8” RH

W ASHERS (67), one 2-7/8” X 2-1/4” CABLE CLIP (28), two 3/8 X 1/2” FLANGE SP ACERS (46) and one 3/8” LOW HEIGHT LOCK

NUT (65) as shown in FIGURE 32.

• Slide one WEIGHT STACK PIN (38) over the stem on the HEAD PLATE (36) as shown in FIGURE 32.

• Screw the threaded end of the MULTI PRESS CABLE (73) all the way onto the end of the stem on the HEAD PLATE (36) and

tighten jam nut securely. See FIGURE 32.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

29

66

49 3/8 X 25mm

76

75

65

67

69

67

66

3/8 X 90mm 58

10

69

FIGURE 33

STEP 33:

• SECURELY assemble the STORAGE UPRIGHT (75) to the TOWER BASE (10) using four RH CAPS (69), two 3/8 X 90mm BOL TS

(58), four 3/8” SAE WASHERS (66), four 3/8” RH W ASHERS (67) and two 3/8” LOW HEIGHT LOCK NUTS (65) as shown in

FIGURE 33.

• SECUREL Y assemble the ST ORAGE PEGS (76) to the STORAGE UPRIGHT (75) using two RH CAPS (69), two 3/8 X 25mm BOL TS

(49), two 3/8” SAE W ASHERS (66) and two 3/8” RH W ASHERS (67) as shown in FIGURE 33.

• Please refer to the LEG PRESS PARTS LIST to complete the

assembly of the LEG PRESS.

30

STEP 34:

• Slide one WEIGHT STACK SELECTOR PIN (38)

over the shaft on the HEAD PLATE (36) as shown

in FIGURE 34.

• Screw the threaded end of the FLOATING PULLEY CABLE (111) all the way onto the end of the

shaft on the HEAD PLATE (36) and tighten jam

nut securely. See FIGURE 34.

• Route the FLOATING PULLEY CABLE (1 11)

through the LAT/LOW ROW BOOM (11) and

assemble one 4-1/2” PULLEY (94) to the

BOOM (11) using one RH CAP (109), one

BLACK RH CAP (108), one 3/8 X 70mm BOL T

(102), two 3/8” SAE W ASHERS (106), two 3/8”

RH W ASHERS (107), one 2-7/8 X 2-1/4” CABLE

CLIP (95), two 3/8 X 1/2” FLANGE SP ACERS (96)

and one 3/8” LOW HEIGHT LOCK NUT (105) as

shown in FIGURE 34.

FIGURE 34

3/8 X 70mm 102

95

108 BLACK

3/8 X 43mm 99

BLACK 108

11

94

111

110

94

105

109

106

107

96

108

BLACK

• Route the FLOATING PULLEY CABLE (1 11)

around one 4-1/2” PULLEY (94) and assemble

the PULLEY (94) to the PULLEY BRACKET

(110) using two BLACK RH CAPS (108), one

3/8 X 43mm BOL T (99), two 3/8” SAE WASHERS

(106), two 3/8” RH WASHERS (107) and one 3/8”

LOW HEIGHT LOCK NUT (105) as shown in FIGURE 34.

38

36

1/2 1/2 1/2 1/2 1/2 1/2

0

1

2

345

31

6

FIGURE 35

11

111

STEP 35:

• Screw the threaded end of the FLOATING PULLEY CABLE (111) all the way onto the end of the shaft on the LAT/LOW ROW

BOOM (11) and tighten jam nut securely. See FIGURE 35.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

32

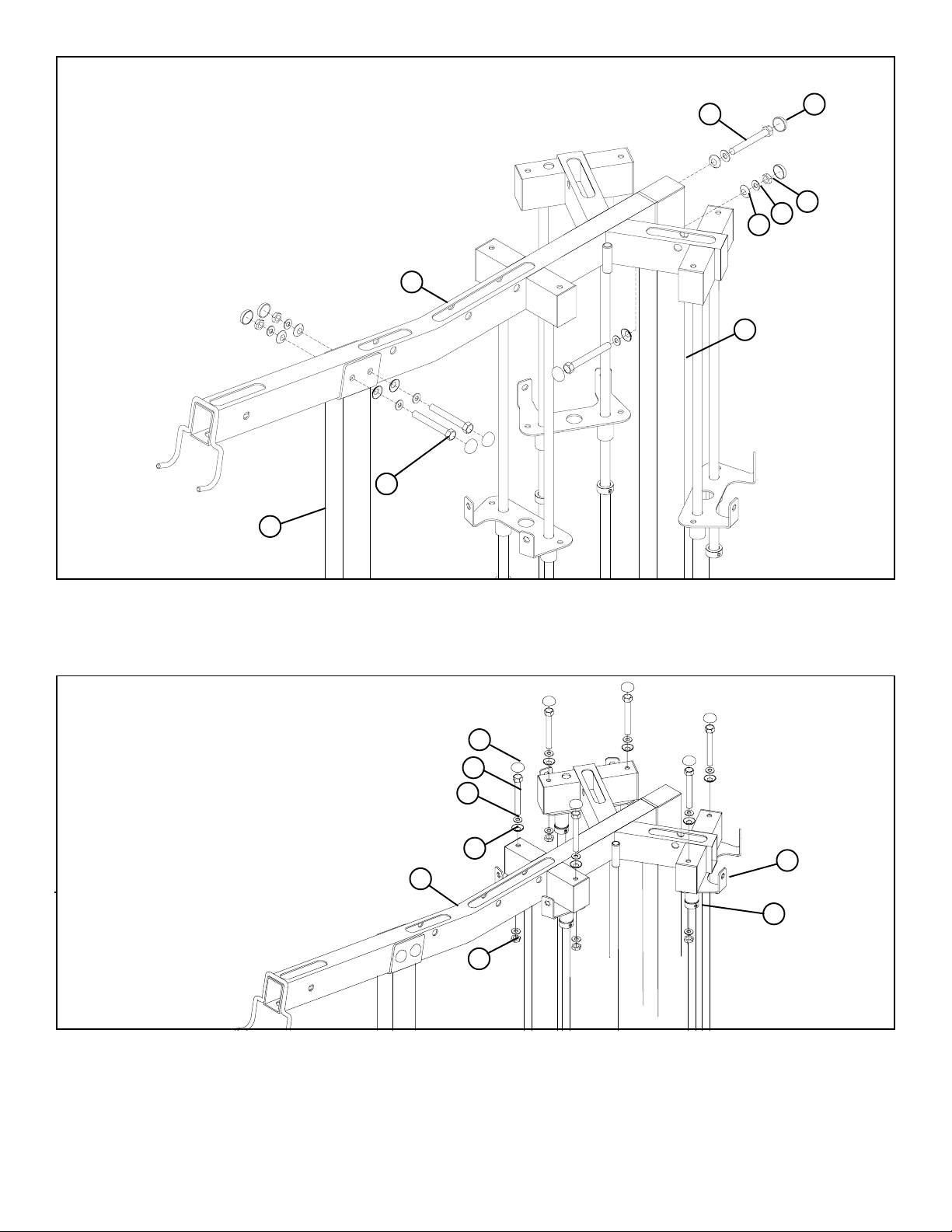

FIGURE 36

3/8 X 67mm 101

86

85

109

106

107

105

STEP 36:

• SECURELY assemble the HANDLE (86) to the LEG PRESS FRAME (85) using four RH CAPS (109), two 3/8 X 67mm BOL TS (101),

four 3/8” SAE WASHERS (106), four 3/8” RH W ASHERS (107) and two 3/8” LOW HEIGHT LOCK NUTS (105) as shown in FIGURE

36.

FIGURE 37

STEP 37:

109

88

105

106

98

107

87

1”

3/8 X 117mm 104

85

13”

• Assemble four 3/4 X 4” PIVOT SHAFTS (98) to the MAIN & SECONDARY PIVOT ARMS (87 & 88) as shown in FIGURE 37.

• SECURELY assemble the MAIN & SECONDARY PIVOT ARMS (87 & 88) to the LEG PRESS FRAME (85) using four RH

CAPS (109), two 3/8 X 117mm BOL TS (104), four 3/8” SAE WASHERS (106), four 3/8” RH WASHERS (107) and two 3/8” LOW

HEIGHT LOCK NUTS (105) as shown in FIGURE 37. (NOTE: Make sure the MAIN PIVOT ARM is assembled as shown.)

33

89

85

105

87

88

107

106

FIGURE 38

3/8 X 117mm 104

109

STEP 38:

• SECURELY assemble the FOOT PLATE (89) to the MAIN & SECONDARY PIVOT ARMS (87 & 88) using four RH CAPS

(109), two 3/8 X 117mm BOL TS (104), four 3/8” SAE W ASHERS (106), four 3/8” RH WASHERS (107), and two 3/8” LOW HEIGHT

LOCK NUTS (105) as shown in FIGURE 38.

103 3/8 X 73mm

106

107

92

112

108 BLACK

FIGURE 39

STEP 39:

• SECURELY assemble the LEG PRESS BACK PAD (92) to the BACK PAD SUPPORT (112) using two BLACK RH CAPS (108),

two 3/8 X 73mm BOL TS (103), two 3/8” SAE WASHERS (106) and two 3/8” RH W ASHERS (107) as shown in FIGURE 39.

34

91

85

107

106

103 3/8 X 73mm

109

FIGURE 40

STEP 40:

• SECUREL Y assemble theLEG PRESS SEA T P AD (91) to the LEG PRESS FRAME (85) using two RH CAPS (109), two 3/8 X 73mm BOL TS

(103),two 3/8” SAE W ASHERS (106) and two 3/8” RH W ASHERS (107) as shown in FIGURE 40.

105

87

FIGURE 41

96

107

94

85

106

101 3/8 X 67mm

93

100 3/8 X 50mm

109

STEP 41:

• Route the LEG PRESS CABLE (93) through the MAIN PIVOT ARM (87) and assemble one 4-1/2” PULLEY (94) to the MAIN

PIVOT ARM (87) using two RH CAPS (109), one 3/8 X 67mm BOL T (101), two 3/8 X 1/2” FLANGE SP ACERS (96), two 3/8” SAE

W ASHERS (106), two 3/8” RH W ASHERS (107) and one 3/8” LOW HEIGHT LOCK NUT (105) as shown in FIGURE 41.

• Route the LEG PRESS CABLE (93) between the upper bracket and through the tube on the LEG PRESS FRAME (85) and assemble

one 4-1/2” PULLEY (94) to the FRAME (85) using two RH CAPS (109), one 3/8 X 50mm BOL T (100), two 3/8” SAE W ASHERS (106),

two 3/8” RH WASHERS (107) and one 3/8” LOW HEIGHT LOCK NUT (105) as shown in FIGURE 41.

• Route the LEG PRESS CABLE (93) between the lower BRACKETS on the LEG PRESS FRAME (85) and assemble one 4-1/2”

PULLEY (94) to the FRAME (85) using two RH CAPS (109), one 3/8 X 50mm BOL T (100), two 3/8” SAE W ASHERS (106), two 3/8” RH

W ASHERS (107) and one 3/8” LOW HEIGHT LOCK NUT (105) as shown in FIGURE 41.

35

85

109

93

105

97

107

106

104 3/8 X 117mm

87

FIGURE 42

STEP 42:

• Assemble the swivel end of the LEG PRESS CABLE (93) to the LEG PRESS FRAME (85) using two RH CAPS (109), one 3/8 X 1 17mm

BOL T (104), two 3/8 X 1-1/2” FLANGE SP ACERS (97), two 3/8” SAE W ASHERS (106), two 3/8” RH W ASHERS (107) and one 3/8” LOW

HEIGHT LOCK NUT (105) as shown in FIGURE 42.

109

85

94

106

107

105

99 3/8 X 43mm

93

FIGURE 43

STEP 43:

• Route the LEG PRESS CABLE (93) through the bracket on the LEG PRESS FRAME (85) and assemble one 4-1/2” PULLEY

(94) to the bracket on the FRAME (85) using two RH CAPS (109), one 3/8 X 43mm BOL T (99), two 3/8” SAE W ASHERS (106), two

3/8” RH WASHERS (107) and one 3/8” LOW HEIGHT LOCK NUT (105) as shown in FIGURE 43.

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

36

94

10

106

99 3/8 X 43mm

93

105

FIGURE 44

STEP 44:

• Route the LEG PRESS CABLE (93) under the weight stack and through the bracket on the TOWER BASE (10) and assemble one

4-1/2” PULLEY (94) to the T OWER BASE (10) using two 3/8 X 43mm BOL TS (99), four 3/8” SAE WASHERS (106) and two 3/8”

LOW HEIGHT LOCK NUTS (105) as shown in FIGURE 44.

37

STEP 45:

• Screw the threaded end of the LEG PRESS

CABLE (93) all the way onto the end of the

shaft on the PULLEY BRACKET (110) and

tighten jam nut securely. See FIGURE 45.

• Please refer back to the MAIN UNIT

P ARTS LIST to complete assembly .

FIGURE 45

110

93

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

38

79

78

71

72

80

78

77

FIGURE 46

STEP 46:

• Assemble the LOW ROW BAR (80) to the ROW CABLE (72) using two SNAP LINKS (78) and one 12-LINK CHAIN (77) as

shown in FIGURE 46.

• Assemble the LAT BAR (79) to the LAT CABLE (71) using one SNAP LINK (78) as shown in FIGURE 46.

39

ADJUSTMENT

FIGURE 47

STEP 47:

• Adjustments can be made in the above locations to set the correct amount of tension in the cables.

• If upon completion of assembly, the HEAD PLATE (36) does not sit on top of the first WEIGHT PLATE (34), push the HEAD

PLATE (36) down, insert the WEIGHT STACK PIN (38) and perform several repetitions. This will relax the cable system and

prevent the HEAD PLATE (36) from lifting up. See FIGURE 47.

• If after completing the previous step, the HEAD PLATE (36) still does not sit on top of the first WEIGHT PLATE (34) or if

there is excess slack in the cable system, adjust the threaded ends of the CABLES attached to the HEAD PLATE (36) and the 3/4

X 3-1/8” TAPPED SHAFT (30) accordingly and retighten the jam nuts. See FIGURE 47.

• For maximum performance, the HEAD PLATE (36) should just barely sit on the top WEIGHT PLATE (34).

40

FIGURE 48

90

84

82

81

SERIAL #

LOCATION

64

62 3/8 X 25mm BUTTON HEAD

STEP 48:

• SECUREL Y assemble the MUL TI-PRESS SHROUD (81), LA T SHROUD (82), and LEG PRESS SHROUD (84) to the SHROUD

BRACKETS (15 & 16) using twelve 3/8 X 25mm BUTTON HEAD BOL TS (62) and twelve 3/8” BLACK SAE WASHERS (64) as

shown in FIGURE 48.

• Assemble the LEG PRESS PLACARD (90) to the LEG PRESS SHROUD (84) as shown in FIGURE 48.

Thank you for purchasing the LifeFitness FIT 3. If unsure of proper use of equipment, call your local

LifeFitness distributor or call the LifeFitness customer service department at

(800) 351-3737.

41

CAUTION-PLEASE READ

There is a risk assumed by individuals who use this type of equipment. To minimize risk, please

follow these rules:

1. Inspect equipment daily . Tighten all loose connections and replace worn parts immediately.

Failure to do so may result in serious injury.

2. Do not allow minors or children to play on or around this equipment.

3. Exercise with care to avoid injury .

4. Consult your physician before beginning any exercise program.

WARRANTY INFORMATION

10 YEARS STRUCTURUAL FRAME

1 YEAR PILLOW BLOCKS, PULLEYS, WEIGHT PLATES AND GUIDE RODS

1 YEAR CABLES

90 DA YS UPHOLSTERY

PREVENTATIVE MAINTENANCE TIPS

Action DAILY WEEKLY QUARTERLY BI-ANNUALLY AS NEEDED

CLEAN

Uphol s tery

Guide Rods

Hand Grips

INSPECT

Visual Overall

Cabl e s

Hardware

Frame

Hand Grips

LUBRICATE

Guide Rods

X

X

X

X

X

X

X

X

X

Clean:

• Upholstery with mild soap and water.

• Guide rods with a cotton cloth.

• Hand grips with mild soap and water.

• Frame damage can be repaired with touch-up paint can be purchased from your LifeFitness customer service representative at

(800) 351-3737

Inspect:

• Cables for wear or damage and proper tension (should not exceed 3/4” deflection.) Pay close attention at bends and attachment

points.

• Hardware should be checked for looseness. Tighten as required.

• Frames should be inspected for wear or damage.

• Hand Grips should be checked for wear or damage

Lubricate:

• Lube the Guide Rods. Apply the lubricant to a cotton cloth, then run the cotton cloth up and down the guide rods as needed. Do not

spray lubricant directly on the Guide Rods.

Thank you for purchasing the LifeFitness CLUB SERIES FIT-3. If unsure of proper use of equipment, call

your local LifeFitness distributor or call the LifeFitness customer service department at

(800) 351-3737.

42

Loading...

Loading...