Page 1

FIT SERIES

BICEPS/TRICEPS

Part # 7489001

Rev A.

ASSEMBLY INSTRUCTIONS

Revision:5/06/031

Page 2

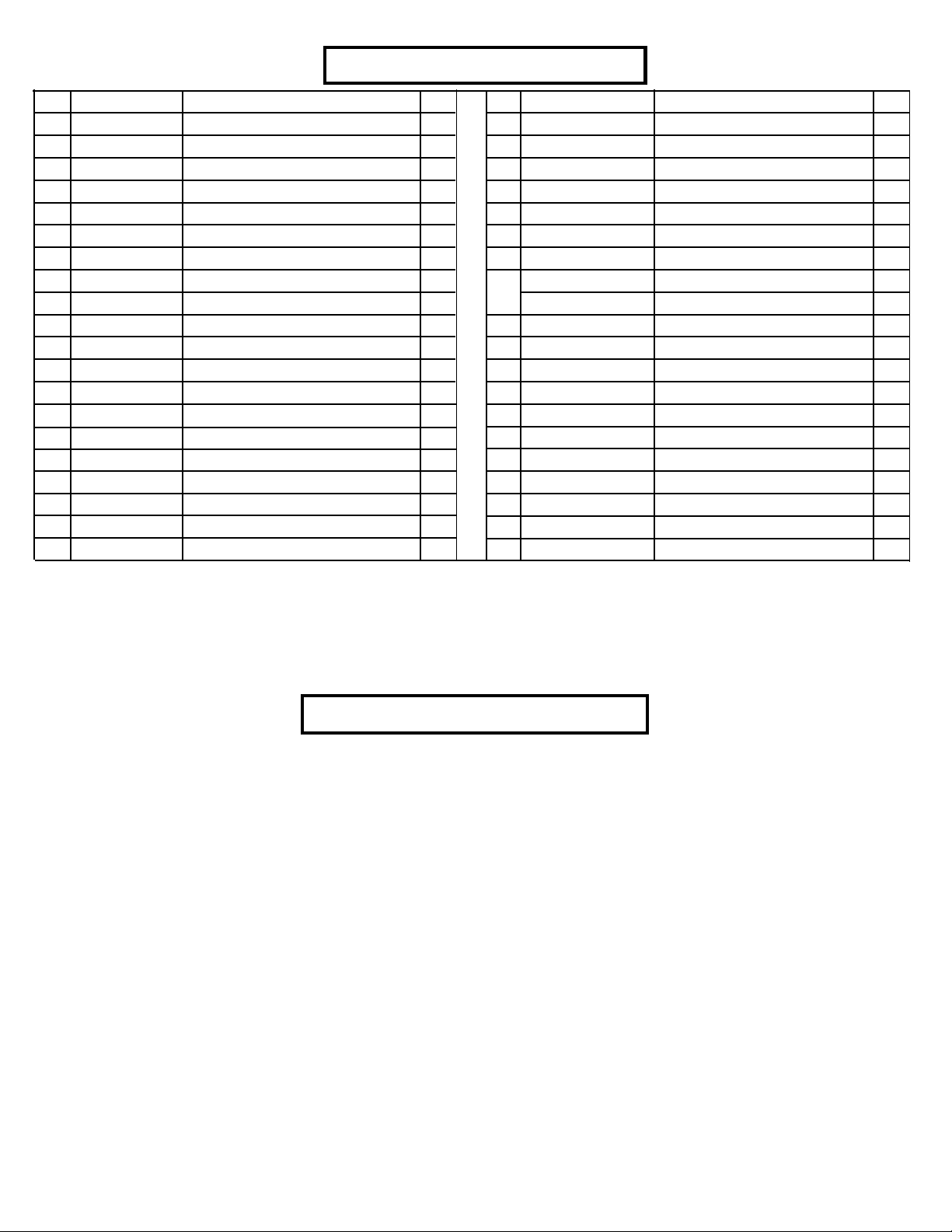

PAR TS LIST

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PART #

ACU04-1661

ACU04-1657

ACU04-1659

ACU04-1660

ACU04-1658

ACU02-1648

ACU06-0025

ACU06-0304

ACU01-2387

ACU72925

ACU73086

ACU10-0204ASY

ACU05-0212

ACU08-0087

ACU08-0073

ACUDA1C03804316NU

ACUDA1C03805016NU

ACUDA1C03807316NU

ACUDA1C03808616NU

ACUDA1C03809016NU

DESCRIPTION

TOWER

BASE FRAME

PULLEY BOOM

REAR UPRIGHT

FOOT PLA TE

BAR SUPPORT

4-1/2” PULLEY

3/4 X 2” WEIGHT ST ACK CUSHION

GUIDE ROD

WEIGHT PLA TE

WEIGHT ST ACK LABEL

HEAD PLA TE ASSEMBL Y

13/16” SHAFT COLLAR

3/8 X 1-1/4” FLANGE SP ACER

3/8 X 1” FLANGE SP ACER

3/8 X 43mm BOL T

3/8 X 50mm BOL T

3/8 X 73mm BOL T

3/8 X 86mm BOL T

3/8 X 90mm BOL T

QTY

1

1

1

1

1

2

7

2

2

20

1

1

2

4

4

6

2

2

1

2

KEY

21

22

23

24

25

26

27

28

OR

29

30

31

32

33

34

35

36

37

38

39

PART #

ACUDA1C03809716NU

ACUDAEC03802516YB

ACUDC1250100020B

ACUDB2E03807200U

ACUDC120010510U

ACU05-0310

ACU06-0357

ACU06-0357

ACU06-0357

ACU13-0169

ACUDI1080080U

ACU04-1662

ACU10-0238

ACU10-0229

ACU10-0231

ACU10-0232

ACUDB9E03813016B

ACUDA1C03810216NU

ACUDAEC03809016NB

ACUDC1250100020U

DESCRIPTION

3/8 X 97mm BOL T

3/8 X 25mm BUTTON HEAD BOL T

3/8” BLACK FLA T W ASHER

3/8” LOW HEIGHT LOCK NUT

3/8” SAE W ASHER

3/8” RH WASHER

BLACK RH CAP

WHITE RH CAP

PLA TINUM RH CAP

BI/TRI CABLE

SNAP LINK

CURL BAR

TRICEPS ROPE

TOP SHROUD

FRONT SHROUD

REAR SHROUD

3/8” ACORN NUT

3/8 X 102mm BOL T

3/8 X 90mm BUTTON HEAD BOL T

3/8” FLA T WASHER

QTY

5

2

22

20

36

36

4

32

32

1

1

1

1

1

1

1

10

2

10

4

T ools Required for Assembly

* 9/16” wrench

* Ratchet with 9/16” socket

* Metric Allen wrench set

2

Page 3

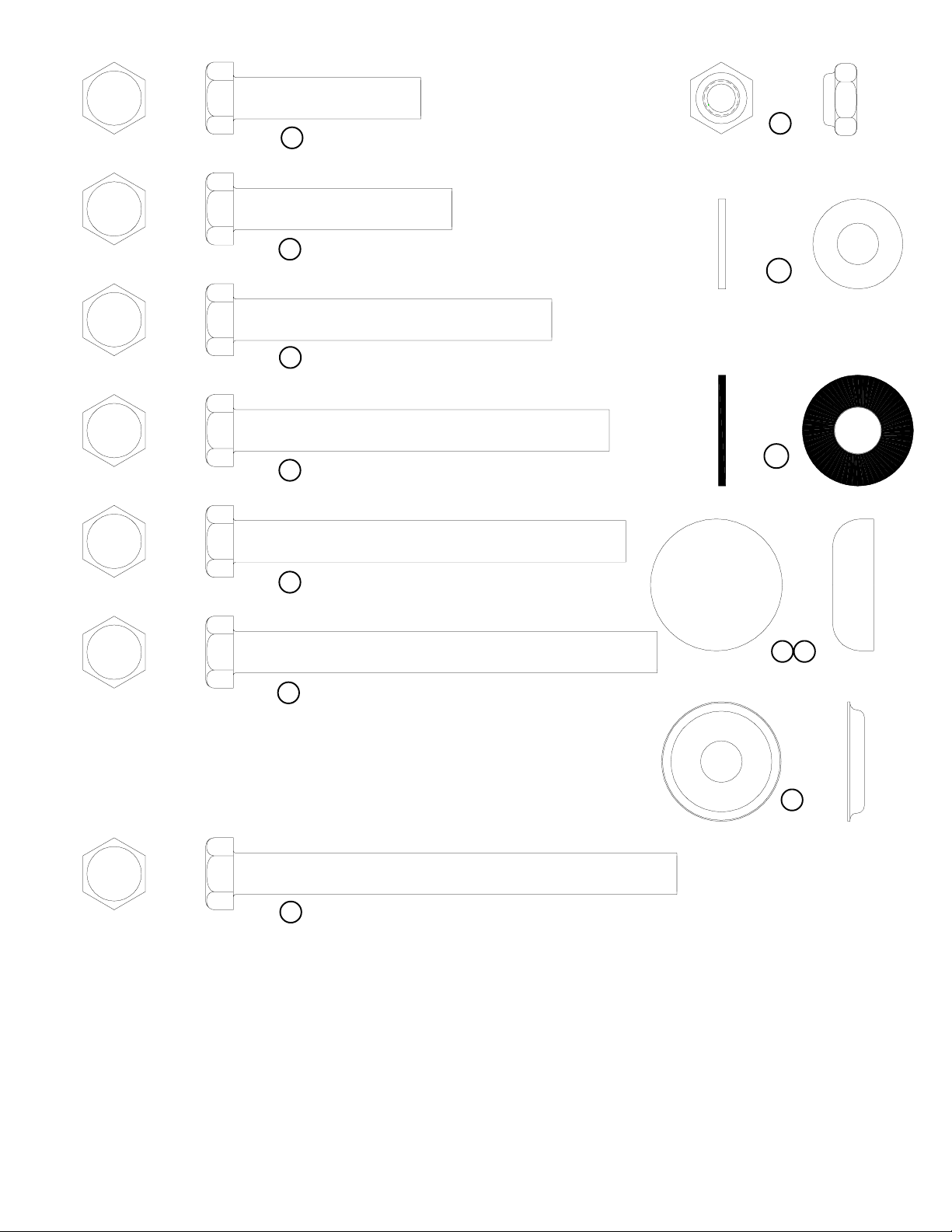

16 3/8 X 43mm BOL T

17 3/8 X 50mm BOL T

18 3/8 X 73mm BOL T

24

3/8” LOW

HEIGHT LOCK

NUT

25

3/8” SAE

WASHER

19 3/8 X 86mm BOL T

20 3/8 X 90mm BOLT

21 3/8 X 97mm BOL T

23

3/8” BLACK

FLA T W ASHER

27

28

RH CAP

(WHITE/PLATINUM/BLACK)

26

RH

WASHER

37 3/8 X 102mm BOL T

3

Page 4

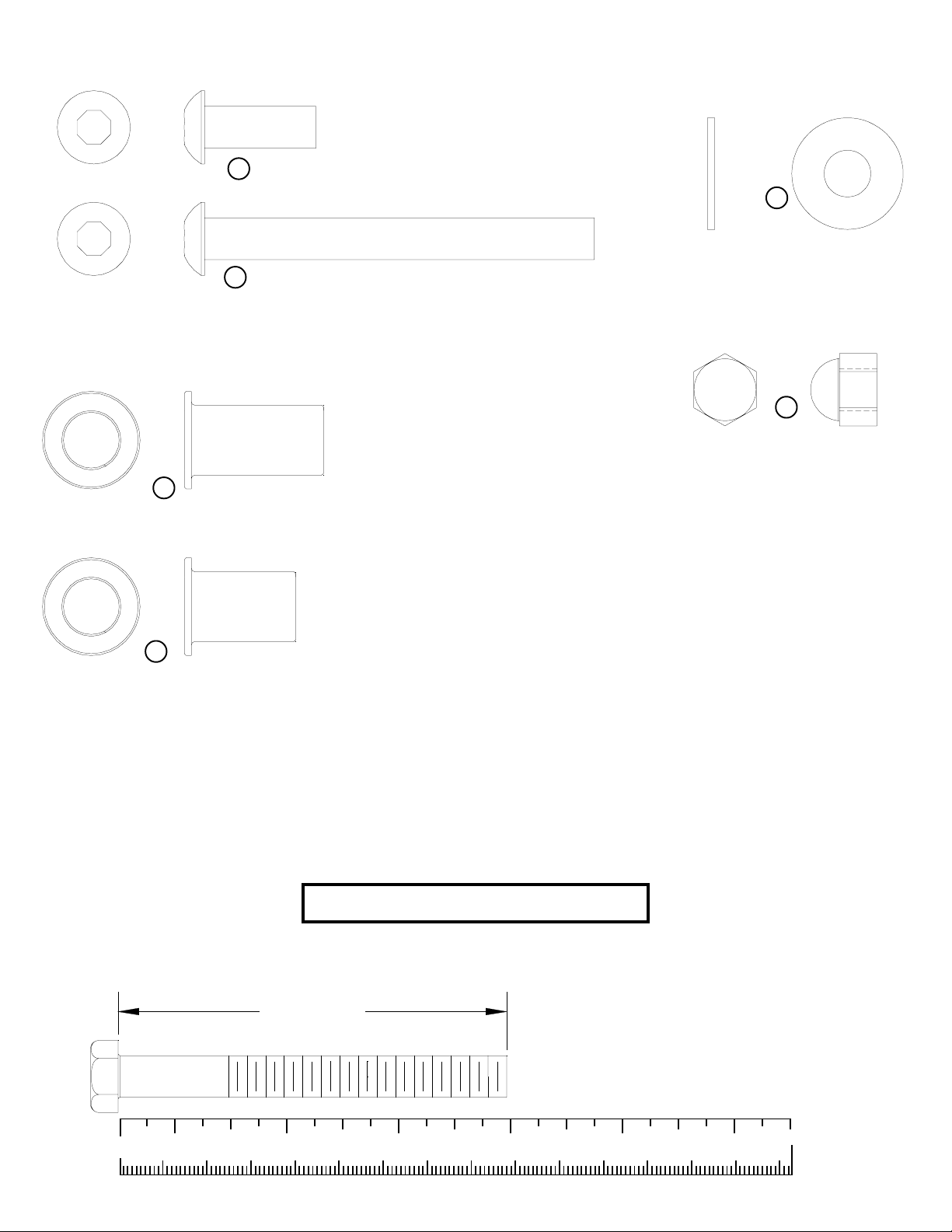

22 3/8 X 25mm BUTTON HEAD BOL T

38 3/8 X 90mm BUTTON HEAD BOL T

14

3/8 X 1-1/4” FLANGE SP ACER

39

3/8”

FLA T WASHER

36

3/8”

ACORN NUT

15

3/8 X 1”

FLANGE SP ACER

Bolt Length Ruler

NOTE: BOL T LENGTH IS MEASURED FROM THE UNDERSIDE OF THE HEAD OF THE BOLT .

BOLT LENGTH

0

1/2 1/2 1/2 1/2 1/2 1/2

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

1

23456

4

Page 5

1

24

2

26

25

28

3/8 X 97mm 21

3/8 X 97mm 21

5

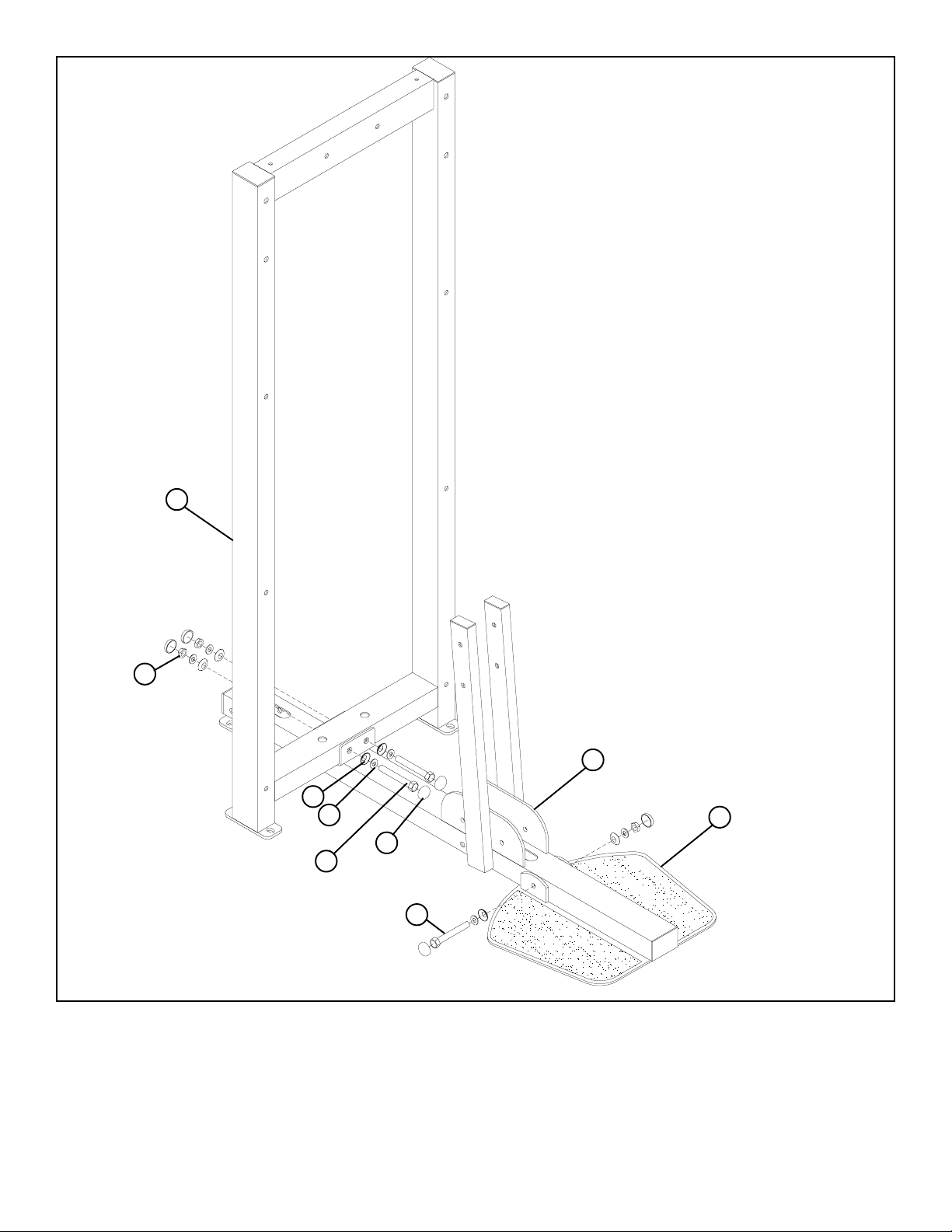

FIGURE 1

STEP 1:

• SECURELY assemble the FOOT PLA TE (5) to the BASE FRAME (2) using two RH CAPS (28), one 3/8 X 97mm BOLT (21), two 3/8”

SAE WASHERS (25), two 3/8” RH W ASHERS (26) and one 3/8” LOW HEIGHT LOCK NUT (24) as shown in FIGURE 1.

• SECURELY assemble the TOWER (1) to the BASE FRAME (2) using four RH CAPS (28), two 3/8 X 97mm BOLTS (21), four 3/8”

SAE W ASHERS (25), four 3/8” RH W ASHERS (26) and two 3/8” LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 1.

5

Page 6

4

24

26

25

3/8 X 97mm 21

28

2

FIGURE 2

STEP 2:

• LOOSELY assemble the REAR UPRIGHT (4) to the BASE FRAME (2) using four RH CAPS (28), two 3/8 X 97mm BOL TS (21), four 3/

8” SAE W ASHERS (25), four 3/8” RH W ASHERS (26) and two 3/8” LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 2.

6

Page 7

3/8 X 43mm 16

28

7

24

29

26

25

12

ADJUSTMENT

FIGURE 3

STEP 3:

• Route the BI/TRI CABLE (29) around one 4-1/2” PULLEY (7) and SECURELY assemble the 4-1/2” PULLEY (7) to the BRACKET on the

HEAD PLA TE (12) using four RH CAPS (28), two 3/8 X 43mm BOL TS (16), four 3/8” SAE W ASHERS (25), four 3/8” RH WASHERS (26)

and two 3/8” LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 2. (NOTE: Make sure CABLE runs over the retaining bolt.)

7

Page 8

3

13

9

12

10

1

8

FIGURE 4

STEP 4:

• Insert two GUIDE RODS (9) into the TOWER (1) as shown on FIGURE 4.

• Slide two 3/4 X 2” WEIGHT ST ACK CUSHIONS (8) down over the GUIDE RODS (9) as shown in FIGURE 4.

• Using EXTREME CARE slide all twenty WEIGHT PLA TES (10) down over the GUIDE RODS (9) on to the WEIGHT ST ACK CUSHIONS

(8). Make sure that the WEIGHT PLATES (10) are all facing as shown.

• Slide the HEAD PLA TE ASSEMBL Y (12) down over the GUIDE RODS (9) onto the weight stack as shown in FIGURE 4.

• Slide two 13/16” SHAFT COLLARS (13) and the PULLEY BOOM (3) over the GUIDE RODS (9) as shown in FIGURE 4.

8

Page 9

FIGURE 5

13

TIGHTEN!

24

39

1

4

3

18 3/8 X 73mm

27 BLACK

28

24

2

6

26

BLACK 27

25

16 3/8 X 43mm

STEP 5:

• SECUREL Y assemble the PULLEY BOOM (3) to the TOWER (1) and the REAR UPRIGHT (4) using two 3/8 X 73mm BOL TS (18),

four 3/8” FLA T W ASHERS (39) and two 3/8” LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 5.

• Slide the 13/16” SHAFT COLLARS (13) up against the PULLEY BOOM (3) and SECURELY tighten the set screws on the SHAFT

COLLARS (13). See FIGURE 5.

• SECURELY assemble the two BAR SUPPOR TS (6) to the BASE FRAME (2) using four BLACK RH CAPS (27), four RH CAPS (28),

four 3/8 X 43mm BOL TS (16), eight 3/8” SAE WASHERS (25), four 3/8” RH W ASHERS (26) and four 3/8” LOW HEIGHT LOCK

NUTS (24) as shown in FIGURE 5.

9

Page 10

LUBRICATION NOTE:

When finished assembling the W eight Stack, open the lube Pack provided

with this unit and apply a thin film of Lubricant around the first 2 to 3

inches of each Guide Rod above the Head Plate Assembly . After the

cables are installed, use of the machine will spread the lubricant over the

length of the Guide Rods and into the Head Plate

bushings

TIGHTEN!

FIGURE 6

STEP 6:

• Securely tighten all loose frame connections made to this point, then proceed to snap RH CAPS

(27)(28) over the RH WASHERS (26) on all tightened connections.

10

Page 11

FIGURE 7

3/8 X 50mm 17

24

3

29

26

25

28

7

STEP 7:

• Route the BI/TRI CABLE (29) through the PULLEY BOOM (3) and SECURELY assemble two 4-1/2” PULLEYS (7) to the BOOM (3)

using four RH CAPS (28), two 3/8 X 50mm BOL TS (17), four 3/8” SAE WASHERS (25), four 3/8” RH W ASHERS (26), and two 3/8”

LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 7.

7

24

4

29

14

26

25

37 3/8 X 102mm

28

FIGURE 8

STEP 8:

• Route the BI/TRI CABLE (29) inside the REAR UPRIGHT (4) and SECURELY assemble one 4-1/2” PULLEY (7) to the REAR UP-

RIGHT (4) using two RH CAPS (28), one 3/8 X 102mm BOL T (37), two 3/8” SAE WASHERS (25), two 3/8” RH WASHERS (26), two

3/8 X 1-1/4” FLANGE SP ACERS (14) and one 3/8” LOW HEIGHT LOCK NUT (24) as shown in FIGURE 8.

11

Page 12

4

2

29

24

7

14

26

25

FIGURE 9

3/8 X 102mm 37

28

STEP 9:

• Continue to route the BI/TRI CABLE (29) inside the REAR UPRIGHT (4) and BASE FRAME(2) and SECURELY assemble one 4-1/2”

PULLEY (7) to the REAR UPRIGHT (4) using two RH CAPS (28), one 3/8 X 102mm BOLT (37), two 3/8” SAE W ASHERS (25), two 3/8”

RH W ASHERS (26), two 3/8 X 1-1/4” FLANGE SPACERS (14) and one 3/8” LOW HEIGHT LOCK NUT (24) as shown in FIGURE 9.

12

Page 13

29

24

7

2

15

26

FIGURE 10

28

3/8 X 90mm 20

25

STEP 10:

• Route the BI/TRI CABLE (29) between two 4-1/2” PULLEYS (7) and SECUREL Y assemble the 4-1/2” PULLEYS (7) to the BASE FRAME

(2) using four RH CAPS (28), two 3/8 X 90mm BOL TS (20), four 3/8” SAE WASHERS (25), four 3/8” RH W ASHERS (26), four 3/8 X 1”

FLANGE SP ACERS (15) and two 3/8” LOW HEIGHT LOCK NUTS (24) as shown in FIGURE 10.

29

24

2

26

25

28

FIGURE 11

3/8 X 86mm 19

STEP 1 1:

• SECUREL Y assemble one 3/8 X 86mm retaining BOL T (19) to the BASE FRAME (2) using two 3/8” SAE WASHERS (25), two 3/8” RH

W ASHERS (26), one 3/8” LOW HEIGHT LOCK NUT (24) and two RH CAPS (28) as shown in FIGURE 11. (NOTE: Make sur e the BI/

TRI CABLE (29) runs in the groove of the PULLEY .)

13

Page 14

29

32

ADJUSTMENT

7

12

10

11

31

30

FIGURE 12

STEP 12:

• Assemble the TRICEPS ROPE (32) to the BI/TRI CABLE (29) as shown in FIGURE 12.

• Assemble the CURL BAR (31) to the BI/TRI CABLE (29) using one SNAP LINK (30) as shown in FIGURE 12.

• To adjust cable tension, disassemble the 4-1/2” PULLEY (7) and loosen both jam nuts under the bracket on the HEAD PLA TE (1 2).

Adjust the bolt accordingly. Retighten jam nuts and reassemble the 4-1/2” PULLEY (7).

• Apply WEIGHT ST ACK LABELS (11) to WEIGHT PLATES (10) and HEAD PLA TE (12) as shown in FIGURE 12. Begin with number

one at the HEAD PLATE (12) with larger numbers in consecutive order towards bottom of weight stack.

14

Page 15

FIGURE 12

22 3/8 X 25mm BUTTON HEAD

33

35

36

23

1

34

38 3/8 X 90mm BUTTON HEAD

SERIAL # LOCA TION

STEP 13:

• SECURELY assemble the TOP SHROUD (33) to the TOWER (1) using two 3/8 X 25mm BUTTON HEAD BOLTS (22) and two 3/8”

BLACK FLA T WASHERS (23) as shown above.

• SECUREL Y assemble the FRONT SHROUD (34) and the REAR SHROUD (35) to the TOWER (1) using ten 3/8 X 90mm BUTTON HEAD

BOL TS (38), twenty 3/8” BLACK FLA T WASHERS (23) and ten 3/8” ACORN NUTS (36) as shown above.

Thank you for purchasing the LifeFitness FIT SERIES BICEPS/TRICEPS. If unsure of proper use of equip-

ment, call your local LifeFitness distributor or call the LifeFitness customer service department at

(800) 351-3737.

15

Page 16

CAUTION-PLEASE READ

There is a risk assumed by individuals who use this type of equipment. To minimize risk, please

follow these rules:

1. Inspect equipment daily . T ighten all loose connections and replace worn parts immediately.

Failure to do so may result in serious injury.

2. Do not allow minors or children to play on or around this equipment.

3. Exercise with care to avoid injury .

4. Consult your physician before beginning any exercise program.

WARRANTY INFORMA TION

10 YEARS STRUCTURUAL FRAME

1 YEAR PILLOW BLOCKS, PULLEYS, WEIGHT PLATES AND GUIDE RODS

1 YEAR CABLES

90 DA YS UPHOLSTERY

PREVENT ATIVE MAINTENANCE TIPS

Action DAILY WEEKLY QUARTERLY BI-ANNUALLY AS NEEDED

CLEAN

Uphol s tery

Guide Rods

Hand Grips

INSPECT

Visual Overall

Cabl e s

Hardware

Frame

Hand Grips

LUBRICATE

Guide Rods

X

X

X

X

X

X

X

X

X

Clean:

• Upholstery with mild soap and water.

• Guide rods with a cotton cloth.

• Hand grips with mild soap and water.

• Frame damage can be repaired with touch-up paint can be purchased from your LifeFitness customer service representative at (800)

351-3737

Inspect:

• Cables for wear or damage and proper tension (should not exceed 3/4” deflection.) Pay close attention at bends and attachment

points.

• Hardware should be checked for looseness. Tighten as required.

• Frames should be inspected for wear or damage.

• Hand Grips should be checked for wear or damage

Lubricate:

• Lube the Guide Rods. Apply the lubricant to a cotton cloth, then run the cotton cloth up and down the guide rods as needed. Do not

spray lubricant directly on the Guide Rods.

Thank you for purchasing the LifeFitness FIT SERIES BICEPS/TRICEPS. If unsure of proper use of equip-

ment, call your local LifeFitness distributor or call the LifeFitness customer service department at

(800) 351-3737.

16

Loading...

Loading...