Page 1

Crawler Excavator R 956

Operating Weight with Backhoe Attachment:

Operating Weight with Shovel Attachment:

Engine Output: 240 kW / 326

Bucket Capacity: 1.25 – 3.30 m³

Shovel Capacity: 3.10 m³

49,600 – 57,100 kg

55,650 – 56,200 kg

HP

Page 2

R 956

Operating Weight with Backhoe Attachment: 49,600 – 57,100 kg

Operating Weight with Shovel Attachment: 55,650 – 56,200 kg

Engine Output: 240 kW / 326 HP

Bucket Capacity: 1.25 – 3.30 m³

Shovel Capacity: 3.10 m³

R 956 Litronic

2

Page 3

Performance

Responsive and precise, the R 956 crawler excavators allow you to perform a large number of mass excavation tasks

in earthmoving sites or in quarries. Thanks to their tested

hydraulic design and their various work modes, Liebherr

excavators will always be there to satisfy your needs.

Reliability

Engineered for difficult operating conditions, the R 956

crawler excavators were designed to meet a list of specifications resulting from our customer’s requirements.

Comfort

The new, more spacious operator’s cab provides the operator with a quiet working environment. What’s more, the

ergonomics, visibility and soundproofing have been improved for increased comfort.

Profitability

The raw performance amounts to maximum effective

working hours. These excavators allow you to target essential operations and reduce operating costs in order to

obtain the best return on investment.

R 956 Litronic

3

Page 4

R 956 Litronic

4

Liebherr Engine

•NewStage3B/Tier4iengine

•Designedspecicallyforconstructionapplications

•LiebherrCommonRailInjectionsystemwith

three times less load losses than a conventional

Common Rail system

•Automaticfuel-savingidlingsystem

•Two-stageturbochargingwithintercooler,

for increased power at low revs and reduced

fuel consumption

Page 5

Performances

Responsive and precise, the R 956 crawler excavators allow you to perform a

large number of mass excavation tasks in earthmoving sites or in quarries. Thanks

to their tested hydraulic design and their various work modes, Liebherr excavators will always be there to satisfy your needs.

Technology serving productivity

Liebherr Integration

Regeneration Plus

Power and speed

Increased

break-out force

Faster cycles

All the major components aredesigned and manufactured within the Liebherr group. This includes

components such as the heat engine, hydraulic

pumps,electroniccomponents (injection mapping,

hydraulic control, control console) and of course the

essential mechanical elements including cylinders,

the slewing ring and work tools, resulting in an overall increase in productivity.

The „Regeneration Plus“ function allows for the

accelerated lowering of the boom, reduced losses

of pressure and an improved work cycle. The optimization and combination of the „zero-pressure

lowering of the boom“ and „Regeneration plus“

functions, together with the increased power of

the hydraulics, provide increased performance and

lower consumption.

Thanks to their kinematics and hydraulic power, the

R 956 crawler excavators develop increased breakout and digging forces. The generously sized cylinders allow you to increase the break-out performance in hard materials.

The mechanical link between the rotation engine

and slewing ring gives the machine a high torque

and swing speed, thus improving your operating

cycles.

Choice of work mode

The different work modes offered allow you to adapt the power

of the excavator to the application

E Mode - Economy: for economical and ecologically-friendly

operation.Minorrestrictionofpowerwithoutaffectingtheload

lifting and excavating capacities. Highly recommended for light

and moderate working conditions

P Mode - Power: for high excavation capacities and difficult

applications.Pumpowandpowerarenotlimited

S Mode -Sensitivity:forprecisionjobsandloadingofmaterials.

Thepumpowandpowerarerestrictedtoattainoptimalsensitivity

P+ Mode - Full Power: especially designed for increased power;

only recommended for extreme applications

Floating Boom Function

•Increasedhydraulicowforthe

other cylinders (stick and/or bucket

for example)

•Morepoweravailable,makingiteasier

to extract materials and reduce work

cycle times

•Increasedservicelifewhenahydraulic

hammer is used

R 956 Litronic

5

Page 6

R 956 Litronic

6

Liebherr particle filter

•DesignedandmanufacturedbyLiebherr,it

eliminates more than 99% (VERT certification)

of fine particle emissions

•Activeregenerationoftheparticlelter,causing no interruption to the operator and without reducing the machine’s performance

•Thecentralmodule(lterunit)isremovable

and easily accessible for maintenance

Page 7

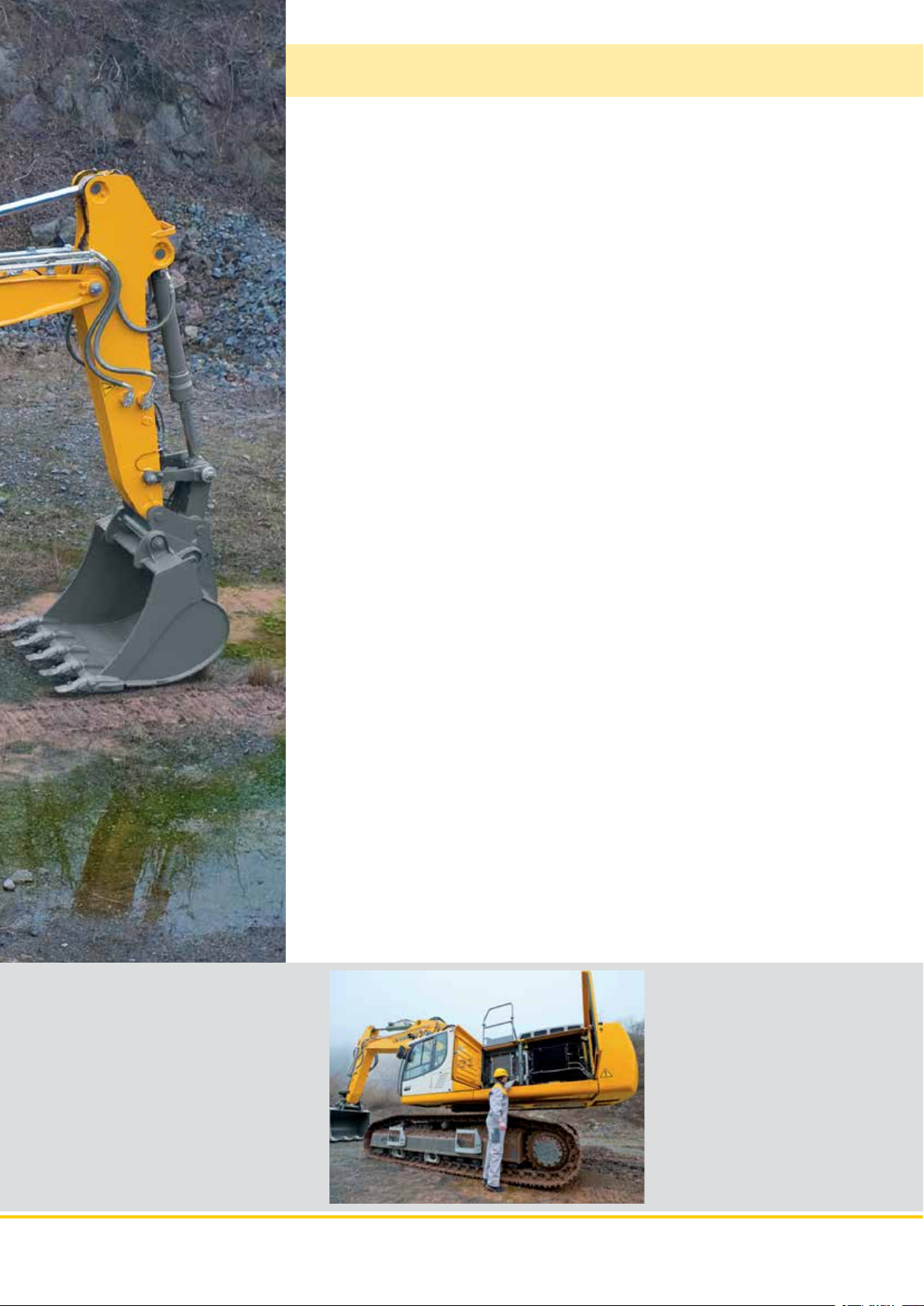

Reliability

Engineered for difficult operating conditions, the R 956 crawler excavators were

designed to meet a list of specifications resulting from our customer’s requirements.

Fully-tested strength

Improved and reinforced

undercarriage

With an X-shaped design and an increased slewing ring diameter, this new undercarriage is characterized by an even distribution of stresses over

the whole structure. This results in increased performance, greater load properties and an increased

service life.

Safe travel

The integration of 3 guiding guards per track as

standard significantly reduces the risk of tracks

comingoff.Inaddition,trackpinsandbearingsare

lubricated for life, which reduces both maintenance

tasks and down time.

Strengthened

uppercarriage

The uppercarriage has been reinforced with heavier

steel to ensure increased strength. The HD boom

and stick are standard - improving resistance to the

impact of materials. Similarly, the system of cast

and welded housings on the boom allows for an

improved distribution of stresses.

Quality serving safety

Finest details

The hydraulic, electric and lubrication lines are laid

out to ensure optimum operating safety and maximum availability. The finish paint applied before

assembly and the appropriate surface treatment of

the components guarantee maximum protection

against corrosion. The integration of the rear camera

in the counter weight elegantly highlights the overall

perception of quality, safety and reliability.

Undercarriage

•Newdesignforincreasedlifeand

improved distribution of forces

•Linearslopebetweentheupperplateof

the central section and the track carriers

for constant cleaning

•Easyandsafetransportthanks

to integrated securing hooks

•3typesofundercarriageavailable,

including one with a variable gauge

for an accurate configuration to suit

thejobsiterequirements

ROPS cab structure

The cab is equipped with an integrated roll over

protection system (ROPS), pursuant to standard

ISO12117-2.

Key components developed by Liebherr

•Perfectharmonizationofthemachine

elements, designed specifically for

earthmoving and quarry applications

•Engine,hydraulicpumps,transferbox,

transmission, rotating mechanism, slewing

ring, cylinders and electronic components

are designed and manufactured by Liebherr

•Purposebuiltoptionssuchasspecialattachment lengths

•Specictoolsandcustomprotectioncan

be added at the factory

R 956 Litronic

7

Page 8

R 956 Litronic

8

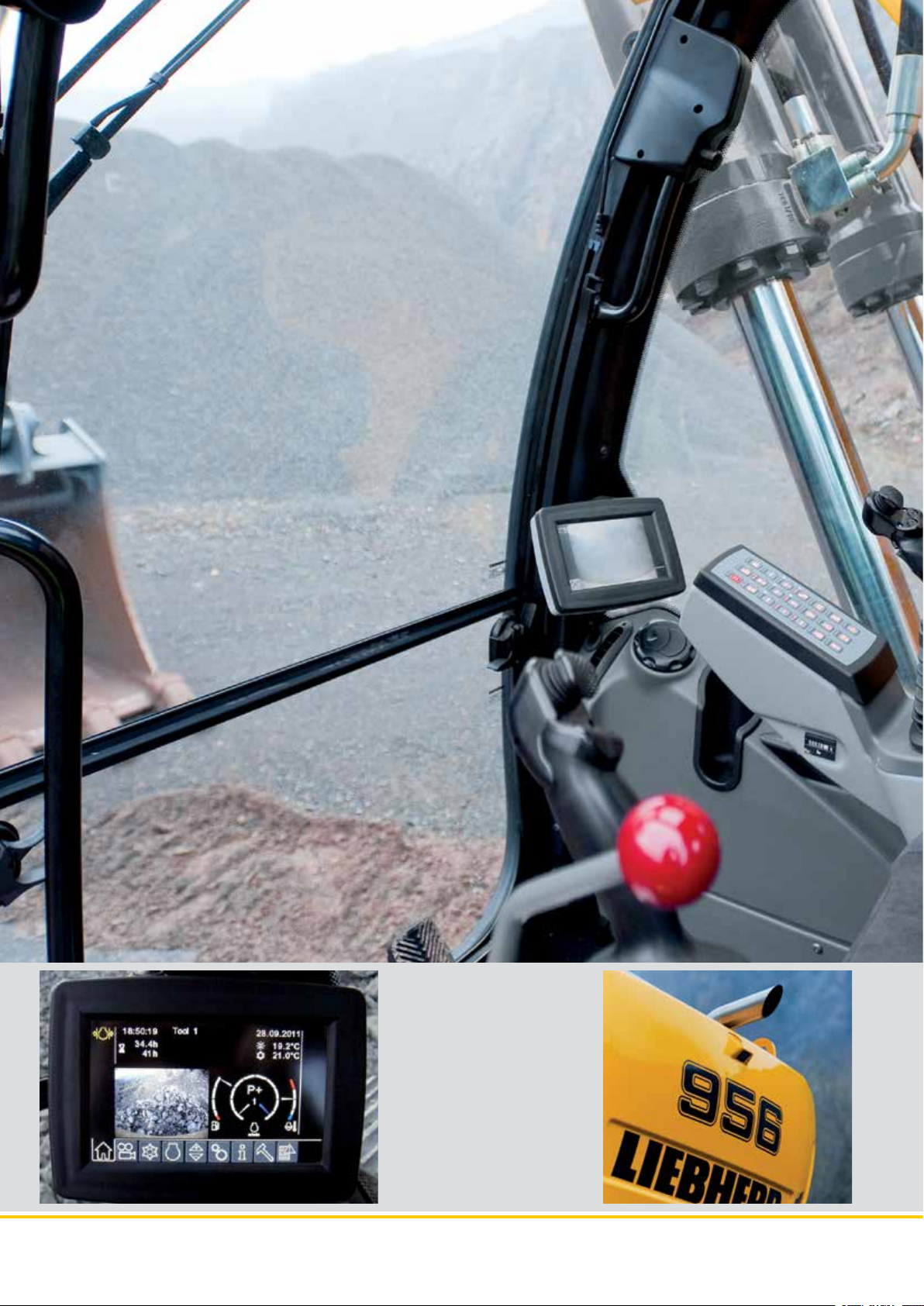

Control screen

•7’’colortouchscreen

•Severalsetting,control

and surveillance options

•Robustandreliabledesign

(IngressProtectionRatingIP65)

•Compatiblehighresolution

video for displaying the rear

camera image

Page 9

Comfort

The new, more spacious operator’s cab provides the operator with a tranquil working environment. What’s more, the ergonomics, visibility and soundproofing have been improved for increased comfort.

It’s just about feeling good

A spacious and ergonomic work station

Fully automatic

air-conditioning

High resolution

color touchscreen

A cab that’s easy

to look after

The cab offers a generous space for maximum comfort. Equipped, among other things, with a pneumatic seat with heater as standard (optional with airconditioning), controls connected to the seat and

high-performance automatic air-conditioning, the

cab creates a pleasant working environment. All the

controls are precisely laid out in an intuitive manner

for greater responsiveness and concentration while

working. The cab is mounted on viscoelastic studs

for significantly lower vibration.

The automatic air-conditioning with touchscreen

controls has several ventilation outlets for optimum

ambient air in the cab.

The color touchscreen is a true human-machine

interface for controlling several comfort functions,

such as the radio, and more operational functions,

such as work modes, tool types and even the

backup camera.

The possibility of working in a clean environment

wasanimportantobjectiveinthedesignofthecab.

Itisparticularlyeasytomaintainthankstoelements

such as a keyboard with soft touch comfort keys

and an easily accessible cab air filter.

Heightened visibility

•Rearcameraintegratedinthecounterweight as standard, for rear visibility

and heightened operating safety

•Optimizeddesignofthewhole

uppercarriage providing the operator

with an improved field of vision

•Retractablelaminatedglassroofpanel

Joystick

•Sensitivejoystickwithproximityswitch

(controlled by approach of the operator’s hand) for greater responsiveness

when resuming operations

•Proportionalergonomiccontrolfor

heightenedjobprecision

R 956 Litronic

9

Page 10

R 956 Litronic

10

Liebherr tools

•Widerangeoftoolssuitableforevery

type of application

•Toolsdesignedformaximum

productivity and durability

•Shapeofbucketsdesignedtoassist

the filling and stability of bulky materials

during the transport stages

•Hydraulicquickcouplersystem

Page 11

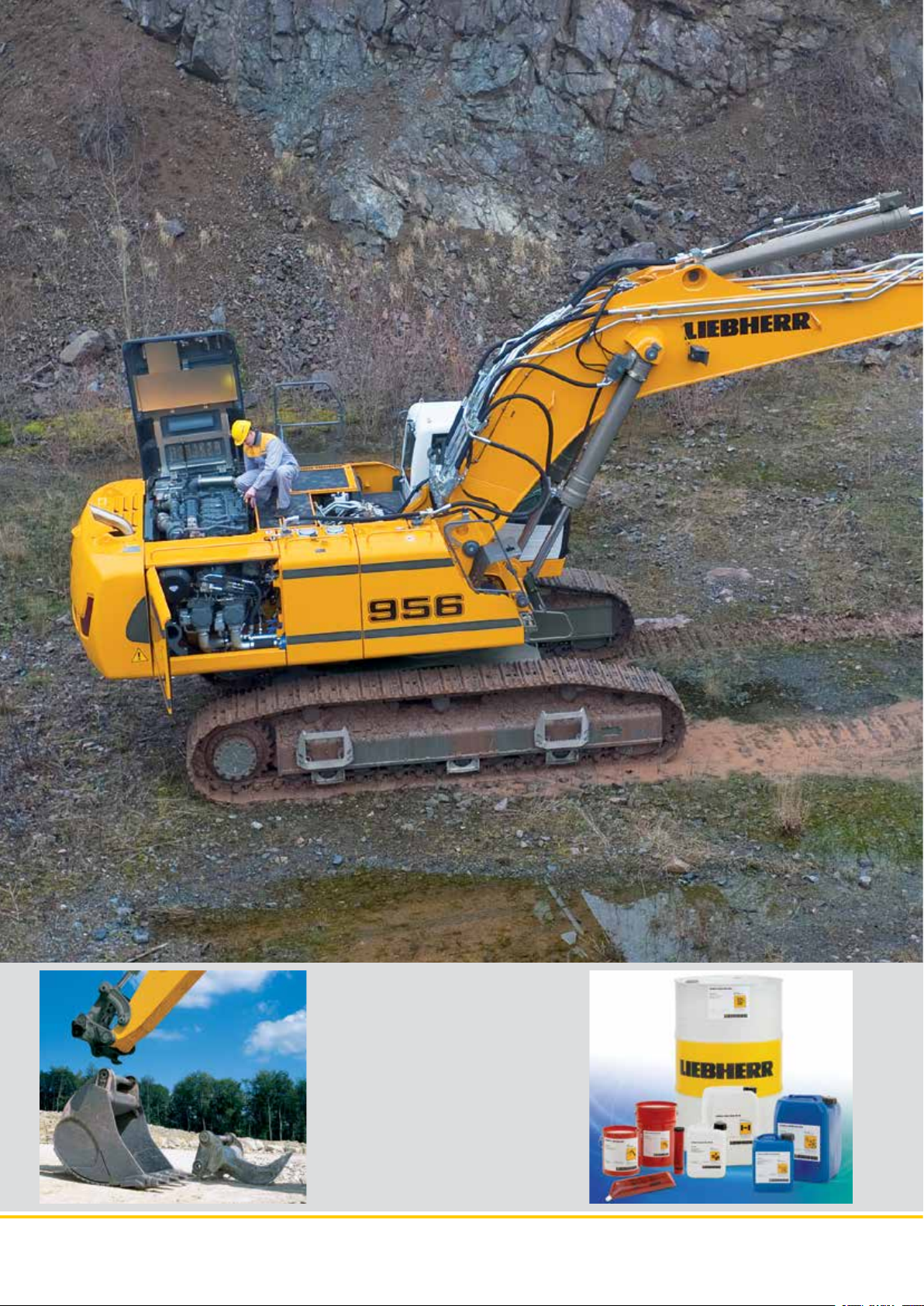

Profitability

The raw performance amounts to maximum effective working hours. These

excavators allow you to target essential operations and reduce operating costs

in order to obtain the best return on investment.

The best choice

Low operating costs

LiDAT fleet and machine

park management tool

Liebherr-Service

An excellent after-sales

service

Thanks to its high technology and its innovation,

the Liebherr France Company increases the performance of its machines while reducing their fuel

consumption. Examples of this are the new diesel

engine, automatic idling, electronic engine speed

sensing control, Regeneration Plus function and the

hydrostatic cooling system (fans operate only when

necessary). Consequently, the reduced fuel consumption means less pollution.

To improve your machine management, Liebherr

has developed its own data transmission system

using the GPRS network. This system allows you

to instantly know the position of your excavator

via a web interface. Thanks to data transmission,

theLIDATsystemdevelopedandmanufacturedby

Liebherr keeps you informed about fuel consump-

tion,numberofservicehoursormachinefaults,just

tonameafew.LIDATallowsyoutobeproactiveand

more responsive: organizing and maintaining your

eetforincreasedproductivity.

The after-sales services can be customized to suit

and respond to your specific needs. Several pro-

grams,suchasReMan,ReBuiltandRepairprovide

the perfect, economical solution, always including

the manufacturer’s quality and guarantee. A team

of technicians, specialized to intervene on your

machines, has all the latest-generation diagnostic

tools, for a reduced down time of the machine. By

following your chosen maintenance program, you

will also obtain a higher resale price.

Liebherr lubricants

•Completerangeoflubricantsand

coolants for your Liebherr engines

•Specialservicewithproductspecialists available to listen to and

advise you

Maintenance

•Automaticcentralizedlubricationas

standard for regular lubrication of critical points and reduced machine down

times accurate lubrication for cutting

costs and increasing the service life of

the elements

•Hydraulictankshutoffvalveforeasily

and quickly cutting off the hydraulic

circuit: complete drainage not required

if it is necessary to repair the system

R 956 Litronic

11

Page 12

R 956 Backhoe –

Experience Progress

Visibility

•Rearcameraintegratedinthecounterweight

• Two boom-mounted lights - standard

• Optimized design of the whole uppercarriage pro-

viding the operator with a better field of vision

Automatic centralized

lubrication - standard

•Reduced maintenance time

• Longer service life thanks

to better lubrication

R 956 Litronic

12

Undercarriage

•RobuststructurethankstotheX-shapedprole

•Improvedself-cleaningcapacity

• Special heat treatment for low wear and tear of drive sprockets

• 3 types of undercarriage available, including a variable gauge one

• 3 guiding guards per track - standard

Page 13

Operator’s cab

•Newdesign

• Comfortable and ergonomic

• 7” high resolution color touchscreen

for heightened readability

• Rear window with improved visibility

Equipment

•Cast steel elements

• Greater resistance to stresses

• Longer service life

Tools

•Z-type Liebherr teeth

for fast replacement

• Wide range of work tools

R 956 Litronic

13

Page 14

R 956 Shovel –

Experience Progress

Equipment

•Parallelkinematicsforpowerfulbreak-out

• Bucket cylinders positioned under the

equipment for better protection

• Optional boom cylinder protection

R 956 Litronic

14

Tools

•Differenttypesofbuckets:

•TypeI:non-abrasivematerials,

suchaslimestonewithoutint

•TypeII:Shotmaterial,oreasilybreakablerock

(classication3to4accordingtoDIN18300)

•TypeIII:Highlyabrasivematerials,suchasrocks

with a high silica content, sandstone, granite, etc.

Page 15

Operator’s cab

•Operator’scabwith2’7”

elevation for improved visibility

• Optionally equipped with a

FOPS and FGPS front guard

• Comfortable and quiet cab

R 956 Litronic

15

Page 16

Technical Data

Engine

Rating per ISO 9249

�����������������������������

Model

�������������������������������

Type

Bore/Stroke

Displacement

Engine operation

Exhaust gas treatment

���������������������������

Cooling

Air cleaner

Fuel tank

Electrical system

Voltage

Batteries

Starter

�����������������������

�������������������������

����������������������

�����������������������

Alternator

Engine idling

Motor management

���������

���������������

�������������

��������������

��������������������

�������������������

��������������

����������

Hydraulic System

Hydraulic pump

for attachment and

travel drive

Max. flow

Max. pressure

Pump regulation

Hydraulic pump

for swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic system

Hydraulic oil filter

Hydraulic oil cooler

MODE selection

RPM adjustment

Tool Control

�����������������

�������������������

������������

���������������

������������

�������������������

������������

������������������

��������������

��������������

�����������

���������������

��������������

���������������������

240 kW (326 HP) at 1,800 RPM

Liebherr D 936 A7

6 cylinder in-line

122/150 mm

10.52 l

4-stroke diesel

Common-Rail, bi-turbo

exhaust-gas recirculation (eagr)

������

particle filter with active regeneration

emission standard stage IIIB / Tier 4i

water-cooled and integrated motor oil

cooler, after-cooled and fuel cooled

dry-type air cleaner with pre-cleaner, pri-

mary and safety elements

800 l

24 V

2 x 180 Ah/12 V

24 V/7.8 kW

three phase current 28 V/100 A

sensor-controlled

connection to the integrated excavator

system controlling via CAN-BUS to the

economical utilisation of the service that

isavailable

two Liebherr variable flow, swash plate

pumps

2 x 350 l/min.

350 bar

electro-hydraulic with electronic engine

speed sensing regulation, pressure com-

pensation, flow compensation, automatic

oil flow optimizer

reversible, variable flow, swash plate pump,

closed-loop circuit

211 l/min.

355 bar

380 l

670 l

2 full flow filters in return line with integrated

fine filter area (5 µm)

compact cooler for water cooler, after-

cooler, fuel cooler and transmission pump

oil, sandwiched with cooler for oil and

condenser of air-conditioning with hydro-

statically controlled fan drives

adjustment of engine and hydraulic perfor-

mance via a mode pre-selector to match

application for especially economical and

environmentally friendly operation or for

maximum digging performance and heavy-

duty jobs

stepless adjustment of engine output via

RPM at each selected mode

10 preadjustable pump flows and pres-

sures for add-on tools

Hydraulic Controls

The controlling is conducted via the integrated

nology, input and output modules, communicated via the CAN-BUS

with the electronic central unit.

Power distribution

������������

Flow summation

Closed-loop circuit

via control valves in single block with inte-

grated safety valves

���������

to boom and stick

�����

for uppercarriage swing drive

Servo circuit

Attachment

and swing

Travel

������������������

������������������������

proportional via joystick levers

– proportional via foot pedals or removable

hand levers

– speed pre-selection

Additional functions

����������

via foot pedals or joystick toggle switch

excavator

system tech-

Swing Drive

���������������������������

Drive by

Transmission

Swing ring

�����������������������

Swing speed

Swing torque

Holding brake

�����������������������������

Option

�������������������

��������������������

�������������������

������������������

Liebherr swash plate motor with integrated

brake valves

Liebherr compact planetary reduction gear

Liebherr, sealed single race ball bearing

swing ring, internal teeth

0 – 6.1 RPM stepless

165 kNm

wet multi-disc (spring applied, pressure

released)

pedal controlled positioning brake

Operator’s Cab

���������������������������������

Cab

Operator’s seat

Control system

����������������

�����������������

Operation and displays

Air-conditioning

Noise emission

ISO 6396

2000/14/EC

����������������

�������������������������

���������������������

ROPS safety cab structure (capable of

sweeping over) with individual windscreens

or featuring a slide-in subpart under the

ceiling, work headlights integrated in the

ceiling, a door with a side window (can be

opened on both sides), large stowing and

depositing possibilities, shock-absorbing

suspension, sounddamping insulating,

tinted laminated safety glass, separate

window shades for the sunroof window

andwindscreen, 12 V plug, storage bins,

lunchbox, cup holder

Liebherr-Comfort seat, airsprung with auto-

matic weight adjustment, vertical and hori-

zontal seat damping including consoles

and joysticks. Seat and armrests adjustable

separately and in combination, seat heating

as standard

arm consoles, swinging with the seat

�����

large high resolution colour display with

selfexplanatory operation via touch screen,

video, versatile adjusting, control and

monitoring facilities, e.g. climate control,

implement and tool parameters

standard automatic air-conditioning, ambi-

ent air function, fast de-icing and demisting

at the press of a button, air vents can be

operated via a menu; ambient air and fresh

air filters can be easily replaced and are

accessible from the outside; heating-

cooling unit, designed for extreme outside

temperatures, sensors for solar radiation,

inside and outside temperatures

LpA (inside cab) = 72 dB(A)

LWA (surround noise) = 106 dB(A)

16 R 956 Litronic

Page 17

Technical Data

Undercarriage

Version

�����������������������������

LC

LC-V

HD

Drive

Transmission

Travel speed

Net drawbar pull

on crawler

Track components

Track rollers/

Carrier rollers

Tracks

Track pads

Digging locks

Brake valves

Lashing eyes

��������������������������

����������������������������

�������������������������������

�������������������

��������������������

������������������������

�������������������

�����������������������������

����������������������

�������������������

��������������������

�������������������

������������

gauge 2,900 mm

gauge 2,890 mm

gauge 2,900 mm

Liebherr swash plate motor with integrated

brake valves

Liebherr planetary reduction gears

LC/LC-V: low range – 3.3 km/h

high range – 4.8 km/h

HD: low range – 2.4 km/h

high range – 3.5 km/h

LC/LC-V: 363 kN

HD: 414 kN

LC/LC-V: D 7 G, maintenance-free

HD: D 8, maintenance-free

LC: 10/2

LC-V: 10/3

HD: 9/2

sealed and greased

triple grouser

wet multi-discs (spring applied, pressure

released)

integrated into travel motor

integrated

Attachment

�������������������������������

Type

Hydraulic cylinders

������������������������������

Pivots

Lubrication

Hydraulic connections

����������������������������

Bucket

�����������

����������������������

combination of resistant steel plates and

cast steel components

Liebherr cylinders with special seal-system,

shock protection

sealed, low maintenance

automatic central lubrication system

(except link and tilt geometry)

������

pipes and hoses equipped with SAE split-

flange connections

standard equipped with Liebherr tooth

system

R 956 Litronic 17

Page 18

Dimensions

E

D

W

H

K

L

U

Z

V

X

E

D

W

N

H

A

C

Q

S

B

G

A

P

R0058

C

K

Q

L

U

Z

V

X

N

S

B

G

P

R0056

18 R 956 Litronic

Page 19

Dimensions

LC mm LC-V mm HD mm

A 2,970 2,970 2,970

C 3,315/3,510** 3,390/3,585** 3,335/3,530**

D 3,830 3,830 3,830

E 3,850 3,850 3,850

H 2,925 3,000 2,945

K 1,335 1,410 1,355

L 4,400 4,400 4,500

P 1,160 1,160 1,225

Q 555 760 575

U 5,365 5,365 5,550

S 2,900 2,390/2,890* 2,900

N 500 600 750 500 600 750 500 600 750

B 3,462 3,500 3,650 2,950 2,990 3,140 3462 3,500 3,650

G 3,715 3,715 3,715 3,200 3,200 3,200 3,715 3,715 3,715

Z 6,515 6,515 6,605

* work position

** with FOPS top guard

LC-Undercarriage

Stick Mono Mono Mono Two-piece

Length Boom Boom Boom Boom

6.70 m 7.60 m 9.20 m 4.70 m

m mm mm mm mm

V 2.35 7,650 7,600 – 8,200

2.90 7,100 8,200 8,750 7,600

3.80 9,300* 7,300 9,000 7,000

5.00 – – 7,750 –

W 2.35 3,900 3,900 – 3,550

2.90 3,950 3,950 4,150 3,650

3.80 3,950* 4,000 4,250 3,950

5.00 – – 4,350 –

X 2.35 12,150 13,200 , – 13,650

2.90 12,200 13,200 14,850 13,550

3.80 12,150* 13,200 14,850 13,550

5.00 – – 14,850 –

HD-Undercarriage

Stick Mono Mono Straight Two-piece

Length Boom Boom Mono Boom

6.70 m 7.60 m Boom 4.70 m

8.00 m

m mm mm mm mm

V 2.35 7,750 7,700 8,350 8,300

2.90 7,200 8,300 7,900 7,700

3.80 9,400* 7,400 8,250 7,100

5.00 – – – –

W 2.35 3,900 3,900 3,550 3,550

2.90 3,950 3,950 3,650 3,650

3.80 3,900* 4,000 3,800 3,950

5.00 – – – –

X 2.35 12,150 13,200 13,750 13,650

2.90 12,200 13,200 13,650 13,550

3.80 12,150* 13,200 13,650 13,550

5.00 – – – –

* without bucket

LC-V-Undercarriage

Stick Mono Mono Mono Two-piece

Length Boom Boom Boom Boom

6.70 m 7.60 m 9.20 m 4.70 m

m mm mm mm mm

V 2.35 7,650 7,600 – 8,050

2.90 7,100 8,200 8,800 7,600

3.80 9,300* 7,300 9,050 6,900

5.00 – – 7,800 –

W 2.35 3,950 3,950 – 3,550

2.90 4,000 4,000 4,200 3,650

3.80 3,950* 4,050 4,300 3,900

5.00 – – 4,400 –

X 2.35 12,150 13,200 – 13,650

2.90 12,200 13,200 14,800 13,550

3.80 12,150* 13,200 14,800 13,550

5.00 – – 14,800 –

R 956 Litronic 19

Page 20

Backhoe Bucket

with Mono Boom 6.70 m

m

ft

12

11

35

10

30

9

8

25

7

20

6

5

15

4

10

3

2

5

1

0

0

-1

-5

-2

-3

-10

-4

-15

-5

-6

-20

-7

-25

-8

-9

-30

-10

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 m

45 40 35 30 25 20 15 10 5 0 ft

1

2

3

R0059

Digging Envelope

1 2 3

Stick length m 2.35 2.90 3.80

Max. digging depth m 7.15 7.70 8.60

Max. reach at ground level m 11.10 11.50 12.40

Max. dump height m 7.05 7.30 7.70

Max. teeth height m 10.55 10.85 11.30

Digging Forces 1 2 3

Digging force ISO kN 248 217 181

t 25.8 22.1 18.6

Breakout force ISO kN 313 313 313

t 31.9 31.9 31.9

Breakout force max. ISO 345 kN (35.2 t)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with mono boom 6.70 m,

stick 2.35 m and bucket 2.35 m

Undercarriage LC LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 49,550 50,150 51,400 51,650 52,250 53,500

Ground pressure kg/cm

Undercarriage HD

3

.

2

1.05 0.88 0.72 1.09 0.92 0.75

Pad width mm 500 600 750

Weight kg 51,650 52,200 53,000

Ground pressure kg/cm

2

1.06 0.89 0.72

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 2,000 kg and

ground pressure by 0.04 kg/cm

2

)

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

LC-Undercarriage LC-V-Undercarriage HD-Undercarriage

Stick length (m) Stick length (m) Stick length (m)

2.35 2.90 3.80 2.35 2.90 3.80 2.35 2.90 3.80

Cutting

width

Capacity

ISO 7451

Weight

mm m

1,350 1.65 2,100

1,550 2.00 2,250

1)

1,750 2.35 2,450

1,950 2.70 2,650

STD

1,950 3.00 2,750

2,100 3.30 3,000

1,350 1.65 2,450

1,550 2.00 2,650

2)

1,750 2.35 2,850

HD

1,950 2.70 3,100

2,100 3.00 3,250

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 70 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)

2)

HD bucket with Liebherr teeth Z 70 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)

Other backhoes available on request

Max. material weight

3

kg

X

X

X

X

Y

V

X

X

X

Y

V

X

= ≤ 2.2 t/m3,

X

X

X

Y

V

y

X

X

X

Y

V

Y

= ≤ 1.8 t/m3,

X

X

Y

V

y

v

X

Y

V

y

v

V

= ≤ 1.5 t/m3,

X

X

X

X

Y

V

X

X

X

Y

V

X

X

X

X

Y

V

X

X

X

Y

V

y

= ≤ 1.2 t/m3,

X

X

Y

V

y

v

X

Y

V

y

v

X

X

X

X

Y

V

X

X

X

Y

V

v

= not authorized

X

X

X

X

Y

V

X

X

X

Y

V

X

X

Y

V

y

v

X

Y

V

y

v

20 R 956 Litronic

Page 21

Lift Capacities

with Mono Boom 6.70 m

Stick 2.35 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

m

10.3* 10.3*

10.2* 10.2*

10.3* 10.3*

10.2* 10.2* 9.3* 9.3*

11.0* 11.0* 9.2* 9.2*

10.5* 10.5* 9.3* 9.3*

13.0* 13.0* 11.0 11.7* 8.9* 8.9*

13.1* 13.1* 11.4 11.7* 8.9* 8.9*

13.0* 13.0* 11.5 11.7* 8.9* 8.9*

21.2* 21.2* 14.7 15.0* 10.6 12.5* 7.9 8.9*

21.5* 21.5* 15.1 15.1* 10.9 12.6* 8.2 9.0* 8.2 8.9*

21.3* 21.3* 15.1* 15.1* 11.0 12.5* 8.3 8.9*

13.6 17.2* 10.0 13.6* 7.7 11.8* 7.4 9.1*

14.1 17.2* 10.4 13.6* 8.0 11.8* 7.7 9.2*

14.3 17.2* 10.5 13.6* 8.1 11.8* 7.8 9.1*

12.9 18.6* 9.6 14.4* 7.5 11.6 7.2 9.7*

13.4 18.6* 10.0 14.5* 7.8 12.1 7.5 9.8*

13.6 18.6* 10.1 14.4* 7.9 12.1* 7.6 9.7*

14.5* 14.5* 12.6 18.9* 9.4 14.8* 7.4 10.8*

15.2* 15.2* 13.1 18.9* 9.7 14.8* 7.7 10.9*

14.7* 14.7* 13.3 18.9* 9.8 14.8* 7.8 10.8*

13.7* 13.7* 19.6 23.7* 12.6 18.3* 9.3 14.4* 8.1 12.4*

14.7* 14.7* 20.3 23.6* 13.1 18.3* 9.7 14.4* 8.4 12.4*

14.0* 14.0* 20.6 23.7* 13.3 18.3* 9.8 14.4* 8.5 12.4*

26.2* 26.2* 20.0 21.2* 12.8 16.6* 9.6 12.5* 9.5 12.4*

26.0* 26.0* 20.7 21.0* 13.4 16.5* 10.0 12.4*

26.2* 26.2* 21.0 21.1* 13.5 16.6* 10.1 12.5* 10.1 12.4*

16.6* 16.6* 12.3* 12.3* 11.9* 11.9*

16.3* 16.3* 11.9* 11.9* 11.8* 11.8*

16.5* 16.5* 12.2* 12.2* 11.9* 11.9*

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

7.8* 7.8*

7.8* 7.8*

7.8* 7.8*

10.4* 10.4* 7.1* 7.1*

10.4* 10.4* 7.1* 7.1*

10.4* 10.4* 7.1* 7.1*

10.8* 10.8* 7.0* 7.0* 6.9* 6.9*

10.9* 10.9* 7.4* 7.4* 6.9* 6.9*

10.8* 10.8* 7.1* 7.1* 6.9* 6.9*

18.9* 18.9* 14.0* 14.0* 10.7 11.8* 8.0 10.7* 6.9* 6.9*

19.1* 19.1* 14.1* 14.1* 11.0 11.9* 8.3 10.7* 6.9* 6.9*

18.9* 18.9* 14.0* 14.0* 11.2 11.8* 8.4 10.7* 6.9* 6.9*

15.3* 15.3* 13.9 16.3* 10.1 13.0* 7.7 11.3* 6.8 7.0*

14.6* 14.6* 14.3 16.4* 10.5 13.1* 8.0 11.3* 7.0 7.1*

15.1* 15.1* 14.5 16.3* 10.6 13.0* 8.1 11.3* 7.0* 7.0*

11.6* 11.6* 13.1 18.0* 9.6 14.0* 7.5 11.5 6.6 7.5*

11.8* 11.8* 13.5 18.1* 10.0 14.1* 7.7 11.8* 6.9 7.5*

11.7* 11.7* 13.7 18.0* 10.1 14.0* 7.8 11.8* 7.0 7.5*

17.6* 17.6* 12.6 18.8* 9.3 14.6* 7.3 11.3 6.8 8.2*

17.9* 17.9* 13.1 18.8* 9.7 14.6* 7.6 11.9 7.1 8.3*

17.7* 17.7* 13.3 18.8* 9.8 14.6* 7.7 12.0* 7.1 8.2*

14.6* 14.6* 19.4 24.7* 12.5 18.6* 9.2 14.5* 7.3 9.5*

15.1* 15.1* 20.1 24.7* 13.0 18.5* 9.6 14.5* 7.6 9.6*

14.7* 14.7* 20.4 24.7* 13.1 18.6* 9.7 14.5* 7.7 9.5*

25.0* 25.0* 19.6 22.6* 12.6 17.3* 9.3 13.4* 8.4 11.8*

25.6* 25.6* 20.4 22.4* 13.1 17.2* 9.7 13.3* 8.8 11.8*

25.2* 25.2* 20.7 22.5* 13.3 17.3* 9.8 13.4* 8.8 11.8*

24.6* 24.6* 18.8* 18.8* 13.1 14.3* 10.9 11.7*

24.2* 24.2* 18.5* 18.5* 13.6 14.1* 11.5 11.6*

24.5* 24.5* 18.7* 18.7* 13.7 14.3* 11.5 11.6*

6.2

7.6

8.4

9.0

9.2

9.2

9.0

8.4

7.5

6.1

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

6.9

8.2

9.0

9.5

9.8

9.8

9.5

9.0

8.2

6.9

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid for the undercarriage

when in the longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 %

of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the lift capacities will increase by 800 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic

safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use of lifting accessories.

5.4* 5.4*

5.4* 5.4*

5.4* 5.4*

6.4* 6.4* 5.0* 5.0*

6.7* 6.7* 5.0* 5.0*

6.5* 6.5* 5.0* 5.0*

9.5* 9.5* 8.4 9.2* 4.8* 4.8*

9.6* 9.6* 8.7 9.2* 4.8* 4.8*

9.5* 9.5* 8.8 9.2* 4.8* 4.8*

12.3* 12.3* 10.6* 10.6* 8.2 9.7* 4.8* 4.8*

12.4* 12.4* 10.7* 10.7* 8.5 9.8* 4.8* 4.8*

12.3* 12.3* 10.7* 10.7* 8.5 9.7* 4.8* 4.8*

20.8* 20.8* 14.4 14.8* 10.4 12.0* 7.8 10.5* 6.1 6.1* 4.9* 4.9*

21.1* 21.1* 14.9 14.9* 10.7 12.1* 8.1 10.5* 6.2* 6.2* 4.9* 4.9*

20.9* 20.9* 14.8* 14.8* 10.8 12.0* 8.2 10.5* 6.1* 6.1* 4.9* 4.9*

19.6* 19.6* 13.4 17.0* 9.8 13.3* 7.5 11.2* 5.9 6.5* 5.2* 5.2*

19.4* 19.4* 13.9 17.1* 10.1 13.3* 7.8 11.2* 6.2 6.4* 5.2* 5.2*

19.5* 19.5* 14.1 17.0* 10.3 13.3* 7.9 11.2* 6.2 6.5* 5.2* 5.2*

7.3* 7.3* 19.4 19.6* 12.8 18.3* 9.4 14.2* 7.2 11.3 5.7* 5.7*

7.6* 7.6* 19.7* 19.7* 13.2 18.4* 9.7 14.2* 7.5 11.7* 5.7* 5.7*

7.4* 7.4* 19.6* 19.6* 13.4 18.3* 9.8 14.2* 7.6 11.7* 5.7* 5.7*

13.4* 13.4* 19.2 24.5* 12.5 18.7* 9.1 14.5* 7.1 11.2 6.3 6.4*

13.8* 13.8* 19.9 24.9* 12.9 18.7* 9.5 14.5* 7.4 11.7 6.4* 6.4*

13.5* 13.5* 20.2 24.6* 13.1 18.7* 9.6 14.5* 7.5 11.8* 6.4* 6.4*

20.2* 20.2* 19.3 24.4* 12.4 18.1* 9.1 14.1* 7.1 10.9* 7.0 7.7*

20.6* 20.6* 20.1 24.3* 12.9 18.1* 9.5 14.1* 7.5 10.1* 7.3 7.8*

20.3* 20.3* 20.3 24.3* 13.1 18.1* 9.6 14.1* 7.5 10.7* 7.4 7.7*

29.0* 29.0* 19.7 21.6* 12.7 16.3* 9.3 12.4* 8.5 10.2*

29.5* 29.5* 20.5 21.4* 13.2 16.2* 9.7 12.3* 9.0 10.4*

29.1* 29.1* 20.7 21.5* 13.3 16.3* 9.8 12.4* 9.0 10.3*

22.4* 22.4* 16.5* 16.5* 12.0* 12.0* 10.6* 10.6*

21.9* 21.9* 16.1* 16.1* 11.6* 11.6* 10.6* 10.6*

22.3* 22.3* 16.4* 16.4* 11.9* 11.9* 10.6* 10.6*

8.1

9.2

9.9

10.4

10.6

10.6

10.4

9.9

9.2

8.1

6.4

R 956 Litronic 21

Page 22

Backhoe Bucket

with Mono Boom 7.60 m

m

ft

13

40

12

11

35

10

30

9

8

25

7

20

6

5

15

4

3

10

2

5

1

0

0

-1

-5

-2

-3

-10

-4

-15

-5

-6

-20

-25

-30

-7

-8

-9

-10

1415 13 12 11 10 9 8 7 6 5 4 3 2 1 0 m

45 40 35 30 25 20 15 10 5 0 ft R0060

1

2

3

Digging Envelope

1 2 3

Stick length m 2.35 2.90 3.80

Max. digging depth m 7.65 8.20 9.10

Max. reach at ground level m 11.95 12.50 13.35

Max. dump height m 8.10 8.40 8.90

Max. teeth height m 11.70 12.05 12.60

Digging Forces 1 2 3

Digging force ISO kN 248 217 181

t 25.8 22.1 18.6

Breakout force ISO kN 313 313 313

t 31.9 31.9 31.9

Breakout force max. ISO 345 kN (35.2 t)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with mono boom 7.60 m,

stick 2.90 m and bucket 2.00 m

Undercarriage LC LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 49 950 50 550 51 800 52 050 52 650 53 900

Ground pressure kg/cm

Undercarriage HD

3

.

2

1,06 0,89 0,73 1,10 0,93 0,76

Pad width mm 500 600 750

Weight kg 52 050 52 600 53 400

Ground pressure kg/cm

2

1,07 0,90 0,73

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 2,000 kg and

ground pressure by 0.04 kg/cm

2

)

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

LC-Undercarriage LC-V-Undercarriage HD-Undercarriage

Stick length (m) Stick length (m) Stick length (m)

2.35 2.90 3.80 2.35 2.90 3.80 2.35 2.90 3.80

Cutting

width

Capacity

ISO 7451

Weight

mm m

1,350 1.65 2,100

1,550 2.00 2,250

1)

1,750 2.35 2,450

STD

1,950 2.70 2,650

1,950 3.00 2,750

1,350 1.65 2,450

2)

1,550 2.00 2,650

1,750 2.35 2,850

HD

1,950 2.70 3,100

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 70 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)

2)

HD bucket with Liebherr teeth Z 70 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)

Other backhoes available on request

Max. material weight

3

kg

X

X

Y

V

y

X

Y

V

y

X

= ≤ 2.2 t/m3,

X

Y

V

y

v

Y

V

y

v

Y

= ≤ 1.8 t/m3,

Y

V

y

v

v

V

y

v

v

V

= ≤ 1.5 t/m3,

X

X

Y

V

y

X

Y

V

y

X

Y

V

y

v

X

Y

V

y

y

= ≤ 1.2 t/m3,

Y

V

y

v

v

Y

V

y

v

X

X

Y

V

y

X

Y

V

y

v

= not authorized

X

X

Y

V

y

X

Y

V

y

Y

V

y

v

v

Y

V

y

v

22 R 956 Litronic

Page 23

Lift Capacities

with Mono Boom 7.60 m

Stick 2.35 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

m

10.4* 10.4* 9.9* 9.9*

10.7* 10.7* 9.9* 9.9*

10.8* 10.8* 9.9* 9.9*

10.6* 10.6* 8.5 9.2*

10.6* 10.6* 8.7 9.2*

10.6* 10.6* 8.9 9.2*

18.2* 18.2* 13.3* 13.3* 10.6 11.2* 7.9 10.2* 7.2 8.9*

13.4* 13.4* 10.9 11.3* 8.2 10.2* 7.4 8.9*

13.4* 13.4* 11.1 11.2* 8.3 10.2* 7.5 8.9*

13.5 15.5* 10.0 12.2* 7.6 10.6* 6.4 8.9*

13.9 15.6* 10.3 12.3* 7.9 10.6* 6.7 8.9*

14.1 15.5* 10.4 12.2* 8.0 10.6* 6.8 8.9*

12.4 17.4* 9.3 13.2* 7.3 11.1* 6.0 9.1*

12.8 17.5* 9.7 13.3* 7.5 11.1* 6.3 9.1*

13.0 17.4* 9.8 13.2* 7.6 11.1* 6.4 9.1*

11.9 16.7* 8.9 13.9* 7.0 11.1 5.9 9.3

12.3 16.9* 9.2 13.9* 7.3 11.5* 6.2 9.6*

12.5 16.8* 9.4 13.9* 7.4 11.4* 6.2 9.5*

11.7 17.8* 8.7 14.1* 6.8 10.9 6.0 9.5

12.2 17.8* 9.0 14.1* 7.1 11.4 6.3 10.0

12.4 17.8* 9.1 14.1* 7.2 11.5* 6.4 10.2

12.9* 12.9* 11.8 17.0* 8.6 13.7* 6.8 10.9 6.5 10.2

13.8* 13.8* 12.3 16.9* 9.0 13.6* 7.1 11.0* 6.8 10.3*

13.1* 13.1* 12.5 17.0* 9.1 13.7* 7.2 11.1* 6.8 10.3*

18.4* 18.4* 12.0 15.5* 8.8 12.5* 7.4 10.2*

18.3* 18.3* 12.5 15.4* 9.2 12.4* 7.8 10.2*

18.4* 18.4* 12.7 15.4* 9.3 12.5* 7.8 10.2*

15.4* 15.4* 12.5 12.9* 9.3 9.6*

15.2* 15.2* 12.7* 12.7* 9.6* 9.6*

15.3* 15.3* 12.8* 12.8* 9.6* 9.6*

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

9.7* 9.7* 7.6* 7.6*

9.7* 9.7* 7.6* 7.6*

9.7* 9.7* 7.6* 7.6*

9.8* 9.8* 8.1 9.4* 7.1* 7.1*

9.8* 9.8* 8.4 9.4* 7.1* 7.1*

9.8* 9.8* 8.5 9.4* 7.1* 7.1*

12.4* 12.4* 10.6* 10.6* 8.0 9.6* 6.5 6.9*

12.5* 12.5* 10.6* 10.6* 8.3 9.6* 6.7 6.9*

12.4* 12.4* 10.6* 10.6* 8.4 9.6* 6.8 6.9*

13.9 14.6* 10.1 11.6* 7.6 10.1* 5.9 6.8*

14.3 14.7* 10.4 11.7* 7.9 10.1* 6.1 7.0* 6.1 6.9*

14.5 14.6* 10.6 11.6* 8.0 10.1* 6.2 6.8*

12.7 16.6* 9.4 12.7* 7.3 10.7* 5.7 9.0 5.5 7.0*

13.1 16.7* 9.8 12.8* 7.6 10.7* 6.0 9.4 5.8 7.0*

13.3 16.6* 9.9 12.8* 7.7 10.7* 6.0 9.5* 5.9 7.0*

12.0 17.8* 8.9 13.6* 7.0 11.0 5.6 8.8 5.4 7.3*

12.4 17.8* 9.3 13.6* 7.2 11.2* 5.8 9.2 5.7 7.4*

12.6 17.8* 9.4 13.6* 7.3 11.2* 5.9 9.4 5.7 7.3*

11.7 17.9* 8.6 14.0* 6.8 10.8 5.5 7.9*

12.2 17.9* 9.0 14.0* 7.0 11.3 5.8 8.0*

12.3 17.9* 9.1 14.0* 7.1 11.4* 5.8 7.9*

14.8* 14.8* 11.7 17.4* 8.5 13.8* 6.7 10.7 5.9 8.9*

15.3* 15.3* 12.2 17.3* 8.9 13.8* 7.0 11.2* 6.2 8.9*

15.0* 15.0* 12.3 17.4* 9.0 13.8* 7.1 11.2* 6.2 8.9*

16.9* 16.9* 18.7 20.1* 11.8 16.1* 8.6 12.9* 6.8 10.2* 6.6 9.6*

17.4* 17.4* 19.5 19.9* 12.3 16.1* 9.0 12.9* 7.1 10.2* 6.9 9.6*

17.1* 17.1* 19.7 20.0* 12.5 16.1* 9.1 12.9* 7.2 10.2* 7.0 9.6*

20.6* 20.6* 17.2* 17.2* 12.2 14.0* 8.9 11.0* 8.0 9.4*

20.3* 20.3* 17.0* 17.0* 12.7 13.8* 9.3 10.8* 8.5 9.3*

20.5* 20.5* 17.1* 17.1* 12.9 13.9* 9.4 11.0* 8.5 9.4*

12.4* 12.4* 9.7* 9.7* 8.2* 8.2*

9.4* 9.4* 8.1* 8.1*

12.3* 12.3* 9.6* 9.6* 8.2* 8.2*

7.5

8.7

9.5

10.0

10.2

10.2

9.9

9.5

8.7

7.5

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

8.2

9.3

10.0

10.5

10.7

10.7

10.5

10.0

9.3

8.2

6.6

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid for the undercarriage

when in the longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 %

of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the lift capacities will increase by 800 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic

safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use of lifting accessories.

5.9* 5.9*

5.8* 5.8*

5.9* 5.9*

7.5* 7.5* 5.3* 5.3*

7.7* 7.7* 5.3* 5.3*

7.5* 7.5* 5.3* 5.3*

8.3* 8.3* 5.0* 5.0*

8.3* 8.3* 5.0* 5.0*

8.3* 8.3* 5.0* 5.0*

9.5* 9.5* 8.2 8.7* 6.2 8.1* 4.8* 4.8*

9.5* 9.5* 8.5 8.7* 6.4 8.3* 4.8* 4.8*

9.5* 9.5* 8.6 8.7* 6.5 8.2* 4.8* 4.8*

18.1* 18.1* 13.0* 13.0* 10.4 10.7* 7.8 9.3* 6.0 8.5* 4.8* 4.8*

18.4* 18.4* 13.2* 13.2* 10.7* 10.7* 8.1 9.4* 6.3 8.5* 4.8* 4.8*

18.2* 18.2* 13.1* 13.1* 10.7* 10.7* 8.2 9.3* 6.3 8.5* 4.8* 4.8*

13.3 15.3* 9.7 11.9* 7.4 10.0* 5.8 8.9* 4.9 4.9*

13.7 15.4* 10.0 12.0* 7.7 10.1* 6.0 8.9* 4.9* 4.9*

13.9 15.3* 10.2 11.9* 7.8 10.1* 6.1 8.9* 4.9* 4.9*

12.3 17.0* 9.1 13.0* 7.0 10.7* 5.6 8.8 4.8 5.1*

12.8 17.1* 9.4 13.0* 7.3 10.7* 5.8 9.2 5.0 5.1*

13.0 17.0* 9.6 13.0* 7.4 10.7* 5.9 9.3* 5.1 5.1*

9.5* 9.5* 11.8 17.8* 8.7 13.7* 6.7 10.8 5.4 8.6 4.8 5.5*

9.7* 9.7* 12.2 17.8* 9.0 13.7* 7.0 11.2* 5.7 9.1 5.1 5.5*

9.6* 9.6* 12.4 17.8* 9.2 13.7* 7.1 11.1* 5.7 9.2 5.1 5.5*

8.1* 8.1* 14.8* 14.8* 11.6 17.8* 8.5 13.8* 6.6 10.6 5.3 8.6 5.1 6.1*

8.4* 8.4* 15.1* 15.1* 12.1 17.7* 8.8 13.8* 6.9 11.2 5.6 9.0 5.3 6.1*

8.2* 8.2* 14.8* 14.8* 12.2 17.7* 8.9 13.8* 7.0 11.2* 5.7 9.2 5.4 6.1*

14.3* 14.3* 18.2 21.5* 11.6 17.0* 8.4 13.4* 6.6 10.6 5.6 7.0*

14.6* 14.6* 19.0 21.9* 12.1 16.9* 8.8 13.4* 6.9 10.8* 5.9 7.0*

14.4* 14.4* 19.2 21.6* 12.3 17.0* 8.9 13.4* 7.0 10.8* 5.9 7.0*

21.3* 21.3* 18.7 19.8* 11.8 15.4* 8.6 12.2* 6.8 9.5* 6.5 8.6*

21.7* 21.7* 19.4 19.6* 12.3 15.3* 9.0 12.1* 7.1 9.4* 6.9 8.7*

21.4* 21.4* 19.7 19.7* 12.5 15.4* 9.1 12.2* 7.2 9.4* 6.9 8.6*

20.6* 20.6* 16.0* 16.0* 12.3 12.6* 9.1 9.5* 8.4* 8.4*

20.2* 20.2* 15.7* 15.7* 12.4* 12.4* 9.3* 9.3* 8.3* 8.3*

20.5* 20.5* 15.9* 15.9* 12.5* 12.5* 9.4* 9.4* 8.4* 8.4*

8.0

9.3

10.3

11.0

11.4

11.6

11.6

11.4

10.9

10.3

9.3

7.9

R 956 Litronic 23

Page 24

Backhoe Bucket

with Straight Mono Boom 8.00 m

m

ft

16

40

15

14

45

13

40

12

11

35

10

30

9

8

25

7

20

6

5

15

4

10

3

2

5

1

0

0

-1

-5

-2

-3

-10

-4

-15

-5

-20

-25

-6

-7

-8

-9

1415 13 12 11 10 9 8 7 6 5 4 3 2 1 0 m

45 40 35 30 25 20 15 10 5 0 ft

1

2

3

R0061

Digging Envelope

1 2 3

Stick length m 2.35 2.90 3.80

Max. digging depth m 6.20 6.75 7.65

Max. reach at ground level m 12.45 13.00 13.90

Max. dump height m 10.05 10.55 12.30

Max. teeth height m 13.95 14.40 15.20

Digging Forces 1 2 3

Digging force ISO kN 248 217 181

t 25.8 22.1 18.6

Breakout force ISO kN 313 313 313

t 31.9 31.9 31.9

Breakout force max. ISO 345 kN (35.2 t)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with straight mono boom

8.00 m, stick 2.90 m and bucket 2.00 m

Undercarriage HD

Pad width mm 500 600 750

Weight kg 52,100 52,650 53,450

Ground pressure kg/cm

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 2,000 kg and

ground pressure by 0.04 kg/cm

3

.

2

1.07 0.90 0.73

2

)

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

HD-Undercarriage

Stick length (m)

2.35 2.90 3.80

Cutting

width

Capacity

ISO 7451

Weight

mm m

1,350 1.65 2,100

1)

1,550 2.00 2,250

1,750 2.35 2,450

STD

1,950 2.70 2,650

1,350 1.65 2,450

2)

1,550 2.00 2,650

1,750 2.35 2,850

HD

1,950 2.70 3,100

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 70 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)

2)

HD bucket with Liebherr teeth Z 70 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)

Other backhoes available on request

Max. material weight

3

kg

X

= ≤ 2.2 t/m3,

X

Y

V

y

X

Y

V

y

Y

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

X

Y

V

y

Y

V

y

v

y

= ≤ 1.2 t/m3,

v

= not authorized

Y

V

y

v

V

y

v

v

24 R 956 Litronic

Page 25

Lift Capacities

with Straight Mono Boom 8.00 m

Stick 2.35 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m

Under-

m

carriage

m

HD

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

15.0* 15.0* 11.9* 11.9* 6.6

14.7* 14.7* 11.4 12.8* 9.6 10.2* 8.2

15.4* 15.4* 11.1 12.9* 8.2 11.3* 7.7 9.4* 9.3

14.7 16.7* 10.6 13.4* 8.0 11.4* 6.6 9.0* 10.0

9.9 13.9* 7.6 11.5* 6.0 8.8* 10.5

9.3 14.1* 7.3 11.6* 5.9 9.4 5.7 8.9* 10.7

9.0 13.8* 7.1 11.3* 5.8 9.2* 5.7 8.8* 10.7

8.8 12.8* 7.0 10.6* 5.8 8.2* 10.4

12.3 12.5* 8.9 11.3* 7.0 9.2* 6.3 7.3* 10.0

9.8* 9.8* 8.9* 8.9* 6.7* 6.7* 5.9* 5.9* 9.2

Stick 2.90 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m

Under-

m

carriage

m

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

HD

0

– 1.5

– 3.0

– 4.5

– 6.0

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

HD

11.7* 11.7* 5.2

14.0* 14.0* 8.9* 8.9* 7.5

14.0* 14.0* 11.6 12.1* 7.8* 7.8* 8.9

15.3* 15.3* 14.7* 14.7* 11.3 12.4* 8.3 10.8* 6.9 7.2* 9.9

15.1 16.0* 10.7 12.9* 8.0 11.0* 6.1 8.6* 6.0 6.9* 10.6

13.7 17.4* 10.0 13.6* 7.7 11.3* 6.0 9.5 5.5 6.8* 11.0

9.4 14.0* 7.3 11.4* 5.8 9.3 5.3 6.9* 11.2

9.0 13.9* 7.0 11.3* 5.7 9.2 5.2 7.1* 11.2

11.9 15.4* 8.8 13.2* 6.9 10.8* 5.6 8.7* 5.3 7.5* 11.0

12.0 13.8* 8.7 11.8* 6.8 9.7* 5.7 7.1* 5.7 7.0* 10.6

11.2* 11.2* 8.9 9.8* 7.0 7.8* 5.9* 5.9* 9.9

7.7* 7.7* 6.7* 6.7* 5.0* 5.0* 8.6

Stick 3.80 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m

Under-

m

carriage

m

HD

12.0

HD

10.5

HD

9.0

HD

7.5

HD

6.0

HD

4.5

HD

3.0

HD

1.5

HD

0

HD

– 1.5

HD

– 3.0

HD

– 4.5

HD

– 6.0

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid for the undercarriage

when in the longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 %

of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the lift capacities will increase by 800 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic

safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use of lifting accessories.

10.9* 10.9* 7.3* 7.3* 6.9

10.3* 10.3* 6.0* 6.0* 8.7

10.6* 10.6* 8.7 9.8* 5.4* 5.4* 10.0

10.6* 10.6* 11.2* 11.2* 8.5 10.2* 6.4 8.2* 5.1* 5.1* 10.9

17.9* 17.9* 14.6* 14.6* 11.1 12.2* 8.2 10.5* 6.3 9.3* 4.9* 4.9* 11.5

14.4 16.4* 10.4 13.0* 7.8 10.9* 6.1 9.4* 4.8* 4.8* 11.9

13.1 17.6* 9.7 13.6* 7.4 11.2* 5.9 9.4 4.7 6.3* 4.6 4.8* 12.1

12.3 17.8* 9.1 13.9* 7.1 11.3* 5.7 9.2 4.6 6.5* 4.6 5.0* 12.1

11.9 17.0* 8.8 13.6* 6.8 11.0* 5.5 9.0 4.7 5.2* 11.9

9.9* 9.9* 11.9 15.4* 8.6 12.6* 6.7 10.3* 5.5 8.3* 4.9 5.6* 11.5

14.7* 14.7* 12.0 13.2* 8.7 11.0* 6.8 9.0* 5.6 6.6* 5.4 5.7* 10.9

10.8* 10.8* 10.2* 10.2* 8.6* 8.6* 6.6* 6.6* 4.5* 4.5* 9.9

R 956 Litronic 25

Page 26

Backhoe Bucket

with Two-piece Boom 4.70 m

ft

m

16

50

15

14

45

13

40

12

11

35

10

30

9

8

25

7

20

6

5

15

4

3

10

2

5

1

0

0

-1

-5

-2

-3

-10

-4

-15

-5

-6

-20

-25

-30

-7

-8

-9

-10

1415 13 12 11 10 9 8 7 6 5 4 3 2 1 0 m

45 40 35 30 25 20 15 10 5 0 ft R0062

1

2

3

Digging Envelope

1 2 3

Stick length m 2.35 2.90 3.80

Max. digging depth m 7.70 8.25 9.15

Max. reach at ground level m 12.35 12.90 13.80

Max. dump height m 10.15 10.65 11.45

Max. teeth height m 14.05 14.50 15.30

Digging Forces 1 2 3

Digging force ISO kN 248 217 181

t 25.8 22.1 18.6

Breakout force ISO kN 313 313 313

t 31.9 31.9 31.9

Breakout force max. ISO 345 kN (35.2 t)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with two-piece boom 4.70 m,

stick 2.90 m and bucket 2.00 m

Undercarriage LC LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 53,150 53,750 55,000 55,250 55,850 57,100

Ground pressure kg/cm

Undercarriage HD

Pad width mm 500 600 750

Weight kg 55,250 55,800 56,600

Ground pressure kg/cm

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 2,000 kg and

ground pressure by 0.04 kg/cm

3

.

2

1.12 0.95 0.77 1.17 0.98 0.80

2

1.14 0.96 0.76

2

)

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

LC-Undercarriage LC-V-Undercarriage HD-Undercarriage

Stick length (m) Stick length (m) Stick length (m)

2.35 2.90 3.80 2.35 2.90 3.80 2.35 2.90 3.80

Cutting

width

Capacity

ISO 7451

Weight

mm m

1,350 1.65 2,100

1)

1,550 2.00 2,250

1,750 2.35 2,450

STD

1,950 2.70 2,650

1,350 1.65 2,450

2)

1,550 2.00 2,650

1,750 2.35 2,850

HD

1,950 2.70 3,100

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 70 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)

2)

HD bucket with Liebherr teeth Z 70 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)

Other backhoes available on request

Max. material weight

3

kg

Y

V

y

v

Y

V

y

v

X

= ≤ 2.2 t/m3,

Y

V

y

v

V

y

v

v

Y

= ≤ 1.8 t/m3,

V

y

v

v

V

y

v

v

V

= ≤ 1.5 t/m3,

X

Y

V

y

Y

V

y

v

Y

V

y

v

Y

V

y

v

y

= ≤ 1.2 t/m3,

V

y

v

v

V

y

v

v

X

Y

V

y

Y

V

y

v

v

= not authorized

X

Y

V

y

Y

V

y

v

Y

V

y

v

V

y

v

v

26 R 956 Litronic

Page 27

Lift Capacities

with Two-piece Boom 4.70 m

Stick 2.35 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

m

11.6* 11.6*

11.5* 11.5*

11.6* 11.6*

13.9* 13.9* 10.8 12.1* 9.9 10.0*

13.9* 13.9* 11.2 12.0* 9.9* 9.9*

13.9* 13.9* 11.3 12.1* 10.0* 10.0*

18.4* 18.4* 14.3* 14.3* 11.0 12.0* 7.6 9.3*

18.5* 18.5* 14.4* 14.4* 11.3* 12.0* 7.8 9.2*

18.5* 18.5* 14.4* 14.4* 11.4* 12.0* 7.9 9.2*

20.3* 20.3* 14.5 15.3* 10.8 12.4* 7.6 10.6* 6.3 8.9*

20.2* 20.2* 14.8* 15.4* 11.0* 12.4* 7.9 10.6* 6.5 8.9*

20.2* 20.2* 15.0 15.4* 11.1* 12.4* 8.0 10.6* 6.7 8.9*

19.6* 19.6* 14.1* 16.4* 10.6 12.8* 7.6 10.7* 5.6 8.9*

19.6* 19.6* 14.3 16.5* 10.8 12.8* 7.9 10.7* 5.8 8.9*

19.6* 19.6* 14.5 16.4* 10.9* 12.8* 8.0 10.7* 5.9 8.9*

20.5 20.8* 13.9* 16.7* 10.6 13.1* 7.3 10.7* 5.2 8.6

20.9* 20.9* 14.2 16.7* 10.8 13.1* 7.6 10.7* 5.4 9.0*

20.8* 20.8* 14.3* 16.7* 10.9 13.1* 7.7 10.7* 5.5 9.0*

20.8* 23.0* 14.1 16.8* 10.3 13.0* 7.0 10.7* 5.1 8.5

21.2 23.1* 14.4 16.8* 10.6 13.0* 7.2 10.8* 5.3 8.6*

21.4 23.1* 14.5 16.8* 10.8 13.0* 7.4 10.7* 5.4 8.6*

29.3* 29.3* 20.9 24.1* 13.8 17.0* 9.5 13.2* 6.6 10.8 5.2 8.0*

30.0* 30.0* 21.6 24.1* 14.3 17.1* 9.8 13.3* 6.9 10.9* 5.4 8.0*

29.5* 29.5* 21.9 24.1* 14.5 17.0* 10.0 13.2* 7.0 10.9* 5.5 8.0*

40.8* 40.8* 20.0 24.7* 13.1 17.8* 8.8 13.8* 6.3 9.9* 5.6 7.3*

40.8* 40.8* 20.7 24.8* 13.6 17.9* 9.1 13.7* 6.6 9.8* 5.9 7.2*

40.8* 40.8* 21.0 24.7* 13.8 17.8* 9.3 13.7* 6.7 9.8* 5.9 7.3*

40.8* 40.8* 19.8 25.7* 12.2 17.7* 8.4 12.1* 6.1* 6.1*

40.8* 40.8* 20.5 25.7* 12.7 17.6* 8.8 12.0* 6.0* 6.0*

40.8* 40.8* 20.8 25.7* 12.9 17.7* 8.9 12.1* 6.1* 6.1*

35.0* 35.0* 19.3 21.0* 12.0 13.0* 5.6* 5.6* 5.1* 5.1*

34.3* 34.3* 20.0 20.6* 12.5 12.6* 5.2* 5.2*

34.8* 34.8* 20.3 20.9* 12.6 12.9* 5.4* 5.4* 5.1* 5.1*

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

13.4* 13.4* 8.7* 8.7*

13.3* 13.3* 8.6* 8.6*

13.4* 13.4* 8.7* 8.7*

13.2* 13.2* 11.2 11.4* 7.6* 7.6*

13.2* 13.2* 11.4* 11.4* 7.6* 7.6*

13.2* 13.2* 11.4* 11.4* 7.6* 7.6*

13.7* 13.7* 11.0 11.5* 7.9 10.1* 6.8 7.1*

13.7* 13.7* 11.3 11.5* 8.2 10.1* 7.0 7.1*

13.7* 13.7* 11.4* 11.5* 8.2 10.1* 7.1 7.1*

19.9* 19.9* 14.7 14.7* 10.8 12.0* 8.0 10.2* 5.7 6.9*

20.1* 20.1* 14.8* 14.8* 11.0 12.0* 8.3 10.2* 6.0 6.9*

20.0* 20.0* 14.7* 14.7* 11.1 12.0* 8.4 10.2* 6.1 6.9*

20.2* 20.2* 14.1* 15.9* 10.5 12.5* 7.9 10.4* 5.4 8.7 5.1 6.9*

20.2* 20.2* 14.4* 16.0* 10.7* 12.5* 8.2 10.4* 5.6 8.9* 5.3 6.9*

20.2* 20.2* 14.5 16.0* 10.8* 12.5* 8.3 10.4* 5.7 8.9* 5.4 6.9*

20.3* 20.6* 13.8 16.6* 10.4 12.9* 7.7 10.6* 5.3 8.6 4.8 7.0*

20.8* 20.8* 20.7* 20.7* 14.1 16.6* 10.6 12.9* 8.0 10.6* 5.5 8.9* 5.0 7.0*

20.4* 20.4* 20.7* 20.7* 14.2 16.6* 10.7 12.9* 8.1 10.6* 5.6 8.9* 5.1 7.0*

23.0* 23.0* 20.5 22.4* 13.9 16.6* 10.6 12.9* 7.3 10.5* 5.1 8.4 4.6 7.3*

23.1* 23.1* 20.9 22.5* 14.2* 16.6* 10.8 12.9* 7.5 10.5* 5.3 8.8* 4.9 7.4*

23.0* 23.0* 21.1* 22.4* 14.2 16.6* 10.8 12.9* 7.6 10.5* 5.4 8.8* 4.9 7.3*

28.3* 28.3* 21.0 23.7* 14.1 16.8* 9.9 13.0* 6.8 10.8* 4.9 8.1* 4.7 7.6*

28.7* 28.7* 21.4 23.8* 14.5 16.8* 10.2 13.0* 7.1 10.8* 5.1 8.1* 5.0 7.6*

28.4* 28.4* 21.6 23.7* 14.6 16.8* 10.4 13.0* 7.2 10.8* 5.2 8.1* 5.0 7.6*

37.8* 37.8* 20.2 24.2* 13.2 17.2* 9.1 13.6* 6.4 10.6* 5.0 7.0*

38.4* 38.4* 20.9 24.3* 13.7 17.3* 9.4 13.6* 6.7 10.6* 5.3 7.0*

38.0* 38.0* 21.2 24.3* 13.9 17.2* 9.5 13.6* 6.8 10.6* 5.4 7.0*

40.8 41.0* 19.7 25.4* 12.5 18.1* 8.5 13.1* 6.2 8.4* 5.7 6.0*

41.0* 41.0* 20.4 25.4* 12.9 18.1* 8.8 13.1* 6.5 8.2* 6.0* 6.0*

41.0* 41.0* 20.7 25.4* 13.1 18.1* 8.9 13.1* 6.6 8.3* 6.0* 6.0*

39.0* 39.0* 19.3 23.5* 11.9 15.4* 8.3 9.3* 4.4* 4.4*

38.6* 38.6* 20.0 23.2* 12.4 15.2* 8.7 8.9* 4.3* 4.3*

38.9* 38.9* 20.3 23.4* 12.6 15.4* 8.8 9.2* 4.4* 4.4*

23.0* 23.0* 13.3* 13.3* 7.9* 7.9*

21.9* 21.9* 12.5* 12.5* 8.5* 8.5*

22.7* 22.7* 13.1* 13.1* 8.1* 8.1*

6.0

7.8

8.9

9.7

10.1

10.4

10.4

10.1

9.7

8.9

7.6

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

6.9

8.5

9.5

10.2

10.7

10.9

10.9

10.7

10.2

9.5

8.4

5.6

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid for the undercarriage

when in the longitudinal position. Capacities are valid for 600 mm wide triple grouser pads with adjusting cylinder in optimal position. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the lift capacities will

increase by 800 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic

safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use of lifting accessories.

8.6* 8.6*

8.7* 8.7*

9.2* 9.2* 5.9* 5.9*

9.3* 9.3* 5.9* 5.9*

9.2* 9.2* 5.9* 5.9*

10.5* 10.5* 8.2 8.4* 5.3* 5.3*

10.5* 10.5* 8.5 8.6* 5.3* 5.3*

10.5* 10.5* 8.5* 8.5* 5.3* 5.3*

11.1* 11.1* 10.7* 10.7* 8.4 9.5* 5.0* 5.0*

11.2* 11.2* 10.8* 10.8* 8.7 9.5* 5.4* 5.4* 5.0* 5.0*

11.2* 11.2* 10.7* 10.7* 8.7 9.5* 5.1* 5.1* 5.0* 5.0*

13.7* 13.7* 10.9 11.3* 8.3 9.7* 5.9 8.6* 4.9* 4.9*

13.8* 13.8* 11.1* 11.3* 8.5* 9.7* 6.2 8.6* 4.9* 4.9*

13.7* 13.7* 11.2 11.3* 8.6 9.7* 6.2 8.6* 4.9* 4.9*

21.1* 21.1* 14.3 15.1* 10.5* 12.0* 8.2* 10.0* 5.9 8.7* 4.5 4.8*

21.3* 21.3* 14.6* 15.1* 10.8* 12.0* 8.4 10.0* 6.1 8.7* 4.7 4.8*

21.2* 21.2* 14.7 15.1* 10.8 12.0* 8.5 10.0* 6.2 8.7* 4.8 4.8*

19.4* 19.4* 20.4 20.7* 13.8 16.2* 10.3* 12.6* 8.2* 10.3* 5.7 8.7 4.2 4.9*

19.7* 19.7* 20.7* 20.7* 14.1* 16.2* 10.5 12.6* 8.3 10.3* 5.9 8.7* 4.4 4.9*

19.5* 19.5* 20.7* 20.7* 14.2 16.2* 10.6 12.6* 8.4* 10.3* 6.0* 8.7* 4.5 4.9*

26.2* 26.2* 20.3* 21.6* 13.7* 16.5* 10.3* 12.8* 7.8 10.4* 5.4 8.7* 4.1 5.1*

26.4* 26.4* 20.7 21.7* 14.0 16.5* 10.5 12.8* 8.1 10.4* 5.7 8.7* 4.3 5.1*

26.3* 26.3* 20.8* 21.7* 14.1 16.5* 10.6* 12.8* 8.2 10.4* 5.8 8.7* 4.3 5.1*

28.6* 28.6* 20.5 23.1* 13.8 16.5* 10.4 12.8* 7.3 10.4* 5.1 8.4 4.1 5.5*

28.7* 28.7* 21.0 23.1* 14.2* 16.6* 10.8 12.8* 7.5 10.4* 5.4 8.8* 4.3 5.5*

28.6* 28.6* 21.1 23.1* 14.2 16.6* 10.8* 12.8* 7.6 10.4* 5.4 8.8* 4.4 5.5*

32.8* 32.8* 20.8 23.7* 13.6 16.8* 9.7 13.0* 6.7 10.7* 4.9 8.2 4.3 6.0*

33.1* 33.1* 21.4 23.7* 14.0 16.8* 10.0 13.0* 7.0 10.7* 5.1 8.2* 4.6 6.0*

32.9* 32.9* 21.8 23.7* 14.2 16.8* 10.2 13.0* 7.1 10.7* 5.2 8.2* 4.6 6.0*

40.2* 40.2* 19.8 24.4* 12.9 17.5* 8.8 13.6* 6.3 10.3* 4.8 5.9*

40.3* 40.3* 20.5 24.5* 13.3 17.6* 9.2 13.6* 6.6 10.2* 5.1 5.8*

40.2* 40.2* 20.8 24.5* 13.5 17.5* 9.3 13.6* 6.7 10.3* 5.1 5.9*

40.8* 40.8* 19.6 25.4* 12.1 17.6* 8.3 12.3* 6.2 7.3* 4.8* 4.8*

40.7* 40.7* 20.3 25.4* 12.6 17.5* 8.7 12.2* 6.5 7.1* 4.7* 4.7*

40.7* 40.7* 20.6 25.4* 12.7 17.5* 8.8 12.3* 6.6 7.3* 4.8* 4.8*

34.0* 34.0* 19.0 20.4* 11.9 12.9* 6.6* 6.6* 4.6* 4.6*

33.3* 33.3* 19.8 19.9* 12.4 12.5* 6.1* 6.1* 4.8* 4.8*

33.8* 33.8* 20.1 20.3* 12.5 12.7* 6.4* 6.4* 4.7* 4.7*

8.2

9.6

10.5

11.1

11.6

11.8

11.8

11.5

11.1

10.5

9.5

7.9

R 956 Litronic 27

Page 28

Lift Capacities

with Mono Boom 6.70 m and Heavy Counterweight

Stick 2.35 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

m

10.3* 10.3*

10.2* 10.2*

10.3* 10.3*

10.2* 10.2* 9.3* 9.3*

11.0* 11.0* 9.2* 9.2*

10.5* 10.5* 9.3* 9.3*

13.0* 13.0* 11.7* 11.7* 8.9* 8.9*

13.1* 13.1* 11.7* 11.7* 8.9* 8.9*

13.0* 13.0* 11.7* 11.7* 8.9* 8.9*

21.2* 21.2* 15.0* 15.0* 11.8 12.5* 8.9* 8.9*

21.5* 21.5* 15.1* 15.1* 12.1 12.6* 9.0* 9.0* 8.9* 8.9*

21.3* 21.3* 15.1* 15.1* 12.3 12.5* 8.9* 8.9*

15.3 17.2* 11.3 13.6* 8.7 11.8* 8.4 9.1*

15.8 17.2* 11.6 13.6* 9.0 11.8* 8.6 9.2*

16.0 17.2* 11.8 13.6* 9.1 11.8* 8.7 9.1*

14.6 18.6* 10.9 14.4* 8.5 12.1* 8.2 9.7*

15.1 18.6* 11.2 14.5* 8.8 12.1* 8.5 9.8*

15.3 18.6* 11.3 14.4* 8.9 12.1* 8.6 9.7*

14.5* 14.5* 14.3 18.9* 10.6 14.8* 8.4 10.8*

15.2* 15.2* 14.8 18.9* 11.0 14.8* 8.7 10.9*

14.7* 14.7* 15.0 18.9* 11.1 14.8* 8.8 10.8*

13.7* 13.7* 22.1 23.7* 14.3 18.3* 10.6 14.4* 9.2 12.4*

14.7* 14.7* 22.9 23.6* 14.8 18.3* 10.9 14.4* 9.5 12.4*

14.0* 14.0* 23.1 23.7* 14.9 18.3* 11.0 14.4* 9.6 12.4*

26.2* 26.2* 21.2* 21.2* 14.5 16.6* 10.8 12.5* 10.8 12.4*

26.0* 26.0* 21.0* 21.0* 15.0 16.5* 11.3 12.4*

26.2* 26.2* 21.1* 21.1* 15.2 16.6* 11.3 12.5* 11.3 12.4*

16.6* 16.6* 12.3* 12.3* 11.9* 11.9*

16.3* 16.3* 11.9* 11.9* 11.8* 11.8*

16.5* 16.5* 12.2* 12.2* 11.9* 11.9*

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

7.8* 7.8*

7.8* 7.8*

7.8* 7.8*

10.4* 10.4* 7.1* 7.1*

10.4* 10.4* 7.1* 7.1*

10.4* 10.4* 7.1* 7.1*

10.8* 10.8* 7.0* 7.0* 6.9* 6.9*

10.9* 10.9* 7.4* 7.4* 6.9* 6.9*

10.8* 10.8* 7.1* 7.1* 6.9* 6.9*

18.9* 18.9* 14.0* 14.0* 11.8* 11.8* 9.0 10.7* 6.9* 6.9*

19.1* 19.1* 14.1* 14.1* 11.9* 11.9* 9.3 10.7* 6.9* 6.9*

18.9* 18.9* 14.0* 14.0* 11.8* 11.8* 9.4 10.7* 6.9* 6.9*

15.3* 15.3* 15.6 16.3* 11.4 13.0* 8.7 11.3* 7.0* 7.0*

14.6* 14.6* 16.0 16.4* 11.7 13.1* 9.0 11.3* 7.1* 7.1*

15.1* 15.1* 16.2 16.3* 11.8 13.0* 9.1 11.3* 7.0* 7.0*

11.6* 11.6* 14.7 18.0* 10.9 14.0* 8.4 11.8* 7.5* 7.5*

11.8* 11.8* 15.2 18.1* 11.2 14.1* 8.7 11.8* 7.5* 7.5*

11.7* 11.7* 15.4 18.0* 11.4 14.0* 8.8 11.8* 7.5* 7.5*

17.6* 17.6* 14.3 18.8* 10.6 14.6* 8.3 12.0* 7.7 8.2*

17.9* 17.9* 14.8 18.8* 10.9 14.6* 8.6 12.0* 8.0 8.3*

17.7* 17.7* 14.9 18.8* 11.0 14.6* 8.7 12.0* 8.1 8.2*

14.6* 14.6* 21.9 24.7* 14.2 18.6* 10.4 14.5* 8.3 9.5*

15.1* 15.1* 22.6 24.7* 14.7 18.5* 10.8 14.5* 8.6 9.6*

14.7* 14.7* 22.9 24.7* 14.8 18.6* 10.9 14.5* 8.7 9.5*

25.0* 25.0* 22.2 22.6* 14.3 17.3* 10.5 13.4* 9.5 11.8*

25.6* 25.6* 22.4* 22.4* 14.8 17.2* 10.9 13.3* 9.9 11.8*

25.2* 25.2* 22.5* 22.5* 15.0 17.3* 11.0 13.4* 10.0 11.8*

24.6* 24.6* 18.8* 18.8* 14.3* 14.3* 11.7* 11.7*

24.2* 24.2* 18.5* 18.5* 14.1* 14.1* 11.6* 11.6*

24.5* 24.5* 18.7* 18.7* 14.3* 14.3* 11.6* 11.6*

6.2

7.6

8.4

9.0

9.2

9.2

9.0

8.4

7.5

6.1

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

6.9

8.2

9.0

9.5

9.8

9.8

9.5

9.0

8.2

6.9

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m

Under-

m

carriage

m

LC

LC-V

12.0

HD

LC

LC-V

10.5

HD

LC

LC-V

9.0

HD

LC

LC-V

7.5

HD

LC

LC-V

6.0

HD

LC

LC-V

4.5

HD

LC

LC-V

3.0

HD

LC

LC-V

1.5

HD

LC

LC-V

0

HD

LC

LC-V

– 1.5

HD

LC

LC-V

– 3.0

HD

LC

LC-V

– 4.5

HD

LC

LC-V

– 6.0

HD

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid for the undercarriage

when in the longitudinal position. Capacities are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 %

of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the lift capacities will increase by 800 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic

safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use of lifting accessories.

5.4* 5.4*

5.4* 5.4*

5.4* 5.4*

6.4* 6.4* 5.0* 5.0*

6.7* 6.7* 5.0* 5.0*

6.5* 6.5* 5.0* 5.0*

9.5* 9.5* 9.2* 9.2* 4.8* 4.8*

9.6* 9.6* 9.2* 9.2* 4.8* 4.8*

9.5* 9.5* 9.2* 9.2* 4.8* 4.8*

12.3* 12.3* 10.6* 10.6* 9.2 9.7* 4.8* 4.8*

12.4* 12.4* 10.7* 10.7* 9.4 9.8* 4.8* 4.8*

12.3* 12.3* 10.7* 10.7* 9.5 9.7* 4.8* 4.8*

20.8* 20.8* 14.8* 14.8* 11.6 12.0* 8.8 10.5* 6.1* 6.1* 4.9* 4.9*

21.1* 21.1* 14.9* 14.9* 11.9 12.1* 9.1 10.5* 6.2* 6.2* 4.9* 4.9*

20.9* 20.9* 14.8* 14.8* 12.0* 12.0* 9.2 10.5* 6.1* 6.1* 4.9* 4.9*

19.6* 19.6* 15.1 17.0* 11.0 13.3* 8.5 11.2* 6.5* 6.5* 5.2* 5.2*

19.4* 19.4* 15.5 17.1* 11.4 13.3* 8.8 11.2* 6.4* 6.4* 5.2* 5.2*

19.5* 19.5* 15.7 17.0* 11.5 13.3* 8.9 11.2* 6.5* 6.5* 5.2* 5.2*

7.3* 7.3* 19.6* 19.6* 14.4 18.3* 10.6 14.2* 8.2 11.7* 5.7* 5.7*

7.6* 7.6* 19.7* 19.7* 14.9 18.4* 11.0 14.2* 8.5 11.7* 5.7* 5.7*

7.4* 7.4* 19.6* 19.6* 15.1 18.3* 11.1 14.2* 8.6 11.7* 5.7* 5.7*

13.4* 13.4* 21.7 24.5* 14.1 18.7* 10.4 14.5* 8.1 11.8* 6.4* 6.4*

13.8* 13.8* 22.4 24.9* 14.6 18.7* 10.7 14.5* 8.4 11.8* 6.4* 6.4*

13.5* 13.5* 22.7 24.6* 14.8 18.7* 10.9 14.5* 8.5 11.8* 6.4* 6.4*

20.2* 20.2* 21.8 24.4* 14.1 18.1* 10.3 14.1* 8.1 10.9* 7.7* 7.7*

20.6* 20.6* 22.6 24.3* 14.6 18.1* 10.7 14.1* 8.5 10.1* 7.8* 7.8*

20.3* 20.3* 22.8 24.3* 14.8 18.1* 10.8 14.1* 8.5 10.7* 7.7* 7.7*

29.0* 29.0* 21.6* 21.6* 14.3 16.3* 10.5 12.4* 9.6 10.2*

29.5* 29.5* 21.4* 21.4* 14.8 16.2* 10.9 12.3* 10.1 10.4*

29.1* 29.1* 21.5* 21.5* 15.0 16.3* 11.0 12.4* 10.1 10.3*

22.4* 22.4* 16.5* 16.5* 12.0* 12.0* 10.6* 10.6*

21.9* 21.9* 16.1* 16.1* 11.6* 11.6* 10.6* 10.6*

22.3* 22.3* 16.4* 16.4* 11.9* 11.9* 10.6* 10.6*

8.1

9.2

9.9

10.4

10.6

10.6

10.4

9.9

9.2

8.1

6.4

28 R 956 Litronic

Page 29

Lift Capacities

with Mono Boom 7.60 m and Heavy Counterweight