Page 1

Crawler Tractors PR 764PR 754

Engine Output (SAE J1349): 250 kW / 335 HP 310 kW / 416 HP

Engine Output

Operating Weight: 35,000 - 40,800 kg 44,220 - 52,685 kg

(ISO 9249): 250 kW / 340 HP 310 kW / 422 HP

77,162 - 89,948 lb 97,488 - 116,150 lb

Page 2

PR 754

PR 764

Engine Output (SAE J1349): 250 KW / 335 HP

Engine Output (ISO 9249): 250 KW / 340 HP

Operating Weight: 35,000 - 40,800 kg

77,162 - 89,948 lb

Blade Capacity: 8.9 - 11.7 m³

11.6 - 15.3 yd³

Hydrostatic travel drive,

electronically controlled

Engine Output (SAE J1349): 310 kW / 416 HP

Engine Output (ISO 9249): 310 KW / 422 HP

Operating Weight: 44,220 - 52,685 kg

97,488 - 116,150 lb

Blade Capacity: 13.6 - 17.0 m³

17.8 - 22.2 yd³

Hydrostatic travel drive,

electronically controlled

PR 754 Litronic PR 764 Litronic

2

Page 3

Performance

Power and innovative technology are features of

Liebherr’s generation 4 crawler tractors. Their excellent

power-to-weight ratio stands for maximum productivity in all operating conditions. Whether ripping hard

ground, moving material or grading surfaces, the outstanding performance of the PR 754 and PR 764 never

fails to impress.

Reliability

Sturdy and strong: Liebherr crawler tractors and the

materials used to build them are designed for long,

trouble-free life. Components subject to severe loads

are made from high-strength materials, and points

exposed to possible damage are well protected.

Liebherr crawler tractors owe their high levels of availability to these stringent reliability standards.

Economy

Liebherr’s economic advantages are undisputed: like all

Liebherr machines, the PR 754 and PR 764 save money by

being easy to service, with shorter down times and lower

maintenance costs. The latest generation of Liebherr diesel engines combines performance with economy, and

with the machines’ efficient drive-train, impressive power

is available at minimum fuel consumption.

Comfort

The operator of a generation 4 Liebherr crawler tractor works in a cab of generous size, with controls laid

out according to the latest ergonomic principles. This

well-designed cab provides an ideal view of the work

area and the working equipment. Intuitive single joystick

control makes for sensitive and accurate dozer operation.

PR 754 Litronic PR 764 Litronic

3

Page 4

PR 754 Litronic PR 764 Litronic

4

Liebherr diesel engines featuring

the latest technologies:

• Electronically controlled, the power

output and torque curves are designed

for outstanding power and tractive force

when ripping or dozing.

• Environmentally responsible and economical: the engines comply with the

latest exhaust emission limits.

• An extra-deep oil sump maintains

engine lubrication at slopes of

up to 45 degrees (PR 754) and

40 degrees (PR 764).

Page 5

Performance

Liebherr has successfully been building crawler tractors with hydrostatic transmission for the past thirty years. The generation 4 models exemplify power, efficiency

and capability in a wide range of applications.

Outstanding productivity

Impressive power

and drawbar pull

High traction and

ripping power

Bogie suspension

Outstanding

maneuverability

Optimized blade

patterns

Low center of gravity

The powerful Liebherr diesel engine, combined with

Liebherr’s innovative driveline, makes ample power

available for every working situation. The hydrostatic

drive requires no gear shifting: engine power reaches

the tracks without interruption, even when turning.

Thanks to the hydrostatic transmission, the operator

simply selects the most suitable working speed. The

system automatically maintains peak engine rpm and

power efficiency. Track slip is kept low and maximum

power is continuously transferred to the tracks.

For work on uneven or rough surfaces, Liebherr offers

different types of bogie undercarriages for increased

traction and pushing power.

The hydrostatic drive is particularly suitable for ripping

work. The machine can be turned quickly, the rear

mounted ripper positioned accurately between hard

rock layers, and the material broken out with the necessary force.

The blades for the PR 754 and PR 764 have had their

penetration and rolling behavior optimized, to increase

their transport capacity.

The driveline assemblies are compact so that the complete machine has a very low center of gravity, thereby

allowing safe operation on steep slopes.

Liebherr hydrostatic transmission

• Automatic speed and torque adjustment

keeps the engine working at optimal

power as the load changes.

• Even at low speeds, for example in

demanding ripping operations, the thermal load of the hydrostatic travel drive

remains low. The efficiency of the drive

remained virtually unchanged.

Generous ground

clearance

The well-planned component layout is designed for

maximum ground clearance. Heavy duty belly pans

prevent damage when working on rough stone or rock.

Oscillating roller tracks

• When working on uneven surfaces,

oscillating bogie undercarriages

increase the ground contact area

and improve traction. In addition, the

resilient mountings effectively absorb

shock loads.

• For work on softer, more yielding

surfaces such as coal or wood chips,

tracks with rigid rollers are used.

PR 754 Litronic PR 764 Litronic

5

Page 6

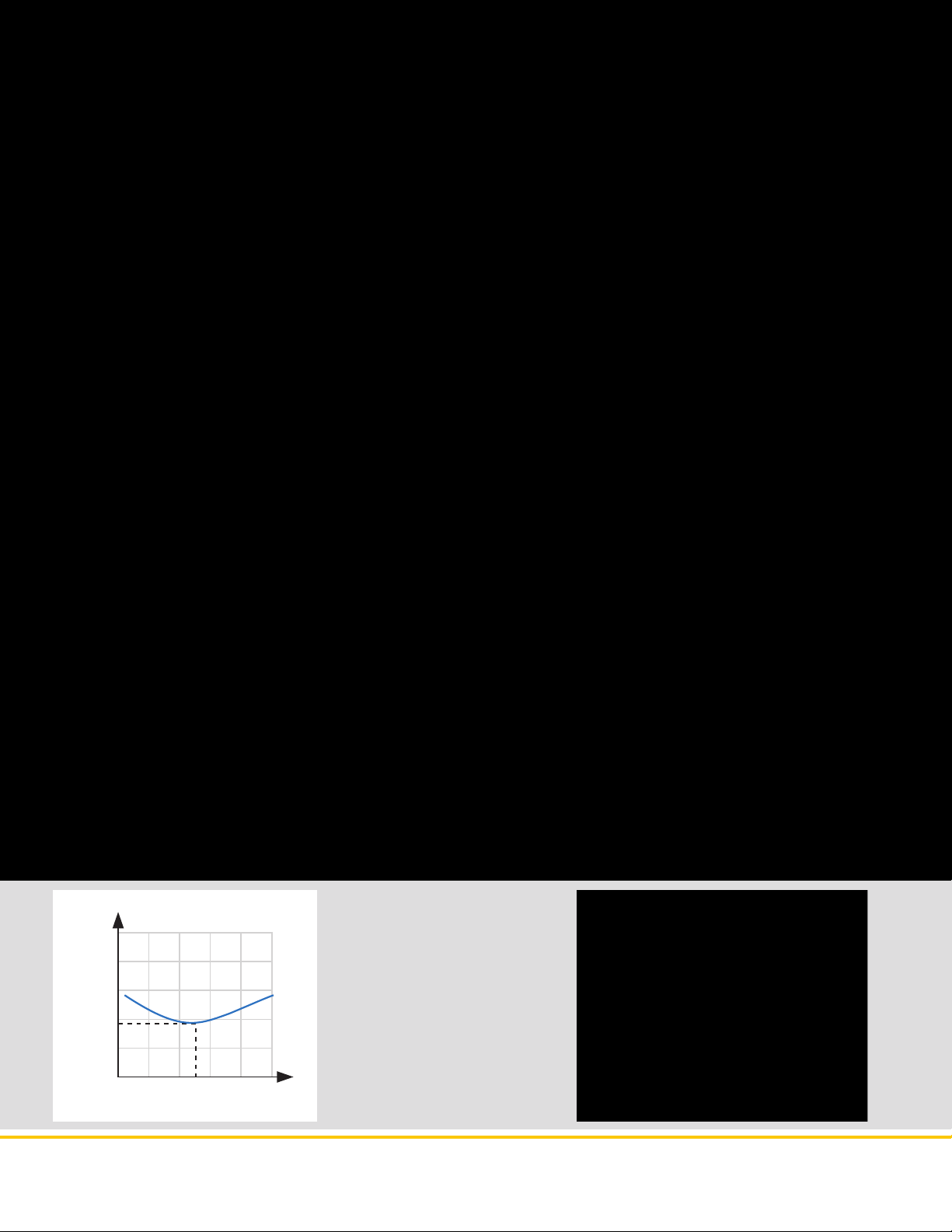

Specific fuel consumption [g/kWh]

Engine rated speed [1/min]

PR 754 Litronic PR 764 Litronic

6

Constant engine speed

keeps fuel consumption low

• Since the engine’s nominal operating speed is in the region of its lowest

specific fuel consumption, maximum

operating economy is assured.

Page 7

Economy

Liebherr crawler tractors are designed with economy in mind, featuring low fuel

consumption, high productivity, extended component life and minimum maintenance costs.

Low fuel consumption

Constant low

engine speeds

The Liebherr diesel engine always operates at a constant speed – in the most economical rpm range –

regardless of the actual travel speed.

A low mean piston speed boosts cylinder filling and leads

to more efficient combustion of the fuel-air mixture.

Efficient driveline

Hydrostatic transmission delivers the best possible

level of efficiency over the full speed range. Even

when peak power at low ground speed is required e.g. when ripping - the oil temperature remains low.

Load-sensing

implement hydraulics

This system keeps energy consumption down to the

level needed by the hydraulics at any given moment. It

saves fuel when the work tools are not being operated.

Low maintenance costs

Good accessibility

Longer maintenance

intervals

All the diesel engine’s servicing points are grouped

together centrally, and can be easily reached. The hydraulic tilt cab makes it even easier to reach the various

mechanical assemblies for quick, effective servicing.

Maintenance intervals are optimally matched to the

various components and assemblies. Where parts are

exposed to dirt and dust, for instance on the pushing

frame, maintenance-free bearings are used.

Tiltable cab

• For easy, quick access to all drivetrain

and hydraulic components.

Simple maintenance

• All the servicing points are located

centrally and are easy to reach,

minimizing the time spent on daily

inspection work.

Long-life tracks

Large track

components

High-quality components with ample dimensions prolong the operating life of the undercarriage.

Liebherr Litronic control system

• Liebherr’s Litronic control system matches

travel speed ideally to the task at hand.

• Track slip is kept to a minimum in pushing as

well as in ripping applications; this improves

power transmission and prolongs track life.

PR 754 Litronic PR 764 Litronic

7

Page 8

PR 754 Litronic PR 764 Litronic

8

The ideal configuration for every task

• For mining or applications in abrasive

materials, optional wear plates increase

machine operating life.

• Liebherr offers special machine configurations for landfill, coal, or woodchip

applications, as well as for low ambient

temperatures.

Page 9

Reliability

Well-proven technologies and high quality are what keeps a machine ready for use.

Liebherr develops and builds its own components and assemblies specifically for

use on construction and civil engineering machinery, so that their strength can be

guaranteed however difficult the application.

Liebherr powertrain

Liebherr engines

Liebherr diesel engines have been developed for the

toughest imaginable operating conditions. A rigid ladder-type frame reduces engine vibration and provides

the strength needed for maximum operating reliability

and long service life.

Wear-free driveline

concept

A tried and tested system: Liebherr’s hydrostatic travel

drive needs no torque converter, manual-shift gearbox,

differential steering or steering clutches. The system’s

hydraulic pumps and motors are standardized, effectively wear-free in operation and exceptionally reliable.

Long-life final drives

Of ample dimensions, Generation 4 final drives are

designed to withstand the most severe loads. Double

transmission seals with automatic leak detection enhance reliability even more.

Robust steel construction

Box-section main frame

Rear-mounted ripper

The main frame is of box-section design – a wellproven principle for maximum torsional stiffness and

optimal absorption of forces. Cast steel is used for

components subject to high stress.

Liebherr rippers are built for heavy-duty tasks, and

have extra protection at all areas exposed to wear.

Component endurance tests

• Even at the design stage, components

are subjected to FE analysis in order to

determine their dimensions in relation to

the loads they will encounter.

• All components undergo long-term laboratory and field testing, and only those

that comply with Liebherr’s high quality

standards are approved for production.

Secrets of long-term reliability

Modern cooling system

Protected electrics

Two hydrostatically driven fans and a wide-meshed radiator guarantee optimal cooling performance, even in

dusty environments.

High quality cable protection prevents mechanical

damage to the cable harness.

Modern cooling system

•

Two electronically controlled fans draw in the volume

of air actually needed to keep the hydraulic fluid and

engine oil temperatures stable as loads vary. All components operate in their most favorable temperature

ranges, thus avoiding unnecessary strain and prolonging their trouble-free operating life.

• Cooling air is drawn in from clean zones around

the machine, to keep dust contamination to a

minimum.

• Optional: a reversible fan for automatic radiator

cleaning when operating in extremely dirty or

dusty conditions.

PR 754 Litronic PR 764 Litronic

9

Page 10

PR 754 Litronic PR 764 Litronic

10

Intuitive single joystick control

• Fingertip speed control: three travel

speed ranges can be preselected and

programmed individually by push-button:

Initial settings Stage 1: 0 – 2.5 mph

Stage 2: 0 – 4.0 mph

Stage 3: 0 – 6.8 mph

• Memory function

Each time the machine is restarted,

all existing settings are retained.

Inching brake pedal

• In addition to the travel

joystick, the operator can

control speed via a pedal

and apply the brakes if

necessary.

1 Inching function

2 Braking function

Page 11

Comfort

The operator’s work area has been redesigned for an exceptionally high level of

comfort and convenience. There is ample space, the controls are laid out ergonomically and the noise level is low. Liebherr cabs provide perfect conditions for

concentrated work without fatigue. The excellent view makes safe, accurate operation much easier.

Outstanding cab design

Ergonomics

The well-planned cab layout makes conditions ideal

for stress-free, efficient operation of the machine. All

instruments and controls are clearly laid out and within

easy reach.

Low noise levels

Thanks to effective sound insulation and the use of

modern, quiet-running diesel engines, the PR 754 and

PR 764 feature exemplary noise levels that are well

below the legal limits.

Outstanding view

Integral ROPS/FOPS protection large window area

provide the operator with the best possible view in

every direction.

Simple, precise control

Single joystick control

Stepless speed control

Safety in every situation

A single joystick controls all travel movements conveniently and accurately, including the ’counter rotation’ function.

Ground speed can be selected without gear changes

and therefore with no interruption to the transmission

of power.

Even on steep gradients, the crawler tractor is always

positively driven. Since the system cannot freewheel

(hydrostatic transmission), the operator controls braking simply by moving back the travel joystick. When

the machine comes to a halt, the parking brake is applied automatically for additional safety.

Well-planned details

• A large storage compartment is standard, and includes a 12 Volt power.

• The seat with its wide range of

adjustments and three-position

armrests helps to provide a

pleasant work area for the operator.

• Many other details, for example

a sliding side window, tinted

glass and a footrest, add to the

operator’s comfort.

Excellent view of

rear-mounted attachments

• ROPS/FOPS protection

is integrated into the cab,

with large window area

• Excellent view of ripper and

surrounding work area

• Direct view of ripper

adjusting pin

PR 754 Litronic PR 764 Litronic

11

Page 12

Basic machine

Engine

Liebherr diesel engine D 946 L A6 D 9508 A7

Rating (SAE J1349) 250 kW / 335 HP 310 kW / 416 HP

Rating (ISO 9249) 250 kW / 340 HP 310 kW / 422 HP

Rated speed 1,600

Displacement 12 l / 733 in

Design 6 cylinder in-line-engine 8 cylinder V-engine

Injection system Direct fuel injection, Direct fuel injection,

pump-line-nozzle Common Rail

system, electronic system, electronic

control control

Lubrication Force-feed lubrication, engine lubrication

Operating voltage 24 V 24 V

Alternator 80 A 80 A

Starter 7.8 kW / 11 HP 7.8 kW / 11 HP

Batteries 2 x 225 Ah / 12 V 2 x 225 Ah / 12 V

Air cleaner Dry-type air cleaner with safety element,

Cooling system Combi radiator, comprising a radiator for water

PR 754 PR 764

Emission regulations according to 97/68/EC,

2004/26/EC Stage IIIA and EPA/CARB Tier 3

1

/min 1,600 1/min

3

16.2 l / 989 in

(wet-sleeve) water-cooled, turbocharged,

intercooled

guaranteed for inclinations up to 45° (PR 754)

and 40° (PR 764)

aspirated pre-cleaner, service gauge in cab

and charge air. Hydrostatic fan drive

3

Travel drive, control

PR 754 PR 764

Transmission system Infinitely variable hydrostatic travel drive,

Travel speed* continuously variable

Speed range 1 (reverse) 0– 4.0 km/h / 2.5 mph (4.8 km/h / 2.9 mph)

Speed range 2 (reverse) 0– 6.5 km/h / 4.0 mph (7.8 km/h / 4.8 mph)

Speed range 3 (reverse) 0–11.0 km/h / 6.8 mph (11.0 km/h / 6.8 mph)

* Pre-adjusted, all speed ranges can be custo-

Drawbar pull at 520 kN 610 kN

1.5 km/h / 0.9 mph 116,901 lbf 137,134 lbf

Electronic control Electronic engine speed sensing control (load

Steering Hydrostatic

Service brake Wear-free, hydrostatic (dynamic braking)

Automatic park brake Wear-free, wet multiple-disc brakes, automa-

Cooling system Separate hydraulic oil cooler, hydrostatically

Filter system Micro cartridge filters in cooling circuit

Final drive Heavy-duty combination spur gear with plane-

Control Single joystick for all travel and steering

independent drive for each track

mized on the travel joystick (memory function)

sensing feature) automatically adjusts travel

speed and drawbar pull to match changing

load conditions

tically applied with neutral joystick position

driven and thermostatically controlled

tary final gear, double sealed with electronic

seal-integrity indicator

motions, as well as for counter rotation

Operator’s cab

PR 754 PR 764

Cab Resiliently mounted cab with positive pressure

Operator’s seat Comfort seat, adjustable to operator’s weight

Monitoring Combined analog / LC display, automatic

ventilation, can be tilted with hand pump 40°

to the rear. With integrated ROPS Rollover Protective Structure (EN ISO 3471) and FOPS Falling Objects Protective Structure (EN ISO 3449)

monitoring of abnormal operating conditions

Undercarriage

PR 754 PR 764

Design Undercarriage with rigid or bogie suspension

Mount Via separate pivot shafts and an oscillating

Chains Lubricated single-bar grouser shoes SESS*,

Links, each side 44 44

Track rollers/carrier

rollers 7/2 each side 7/2 each side

Sprocket segments 5 each side 3 each side

Track shoes standard

Track shoes optional 610 mm / 24” SESS

660 mm / 26” SESS

710 mm / 28” SESS

* SESS Super Extreme Service Shoes

equalizer bar

track chain tensioning via steel spring and

grease tensioner

560 mm / 22” SESS 610 mm / 24” SESS

660 mm / 26” SESS

710 mm / 28” SESS

760 mm / 30” SESS

Drawbar pull PR 754/PR 764

Usable drawbar pull will depend on traction and weight of tractor

Noise emissions

PR 754 PR 764

Operator sound exposure L

ISO 6396 emission at the operator’s position

Exterior sound pressure L

2000/14/EC emission in the environment

12 PR 754 Litronic PR 764 Litronic

= 78 dB(A) LpA = 79 dB(A)

pA

= 113 dB(A) LwA = 114 dB(A)

wA

Page 13

Basic machine

Hydraulic system

PR 754 PR 764

System type Load Sensing proportional pump flow control

Pump type Swash plate variable displacement piston pump

Pump flow max. 261 l/min / 68.9 gpm 352 l/min / 92.9 gpm

Pressure limitation 260 bar / 3,770 PSI 260 bar / 3,770 PSI

Control valve 2 segments, expandable to 4

Filter system Return filter with magnetic rod in the hydraulic

tank

Control Single joystick for all blade functions

Dimensions

Refill capacities in US gallons

PR 754 PR 764

Fuel tank 650 l (171.6 gallons) 860 l (227 gallons)

Cooling system 74 l (19.5 gallons) 85 l (22.4 gallons)

Engine oil with oil filters 43 l (11.4 gallons) 70 l (18.5 gallons)

Splitter box 5.5 l (1.5 gallons) 6.4 l (1.7 gallons)

Hydraulic tank 215 l (56.8 gallons) 281 l (74.2 gallons)

Final drive, each 18.5 l (4.9 gallons) 22.5 l (5.9 gallons)

Dimensions

PR 754 PR 764

Rigid Single bogie Rigid Single bogie Double link

undercarriage suspension undercarriage suspension bogie

suspension

A Height over cab mm 3,630 3,935

ft-in 11’11” 12’11”

B Overall length without attachments mm 4,875 5,280

ft-in 16’0” 17’4”

C Distance idler/sprocket center mm 3,174 3,540

ft-in 10’5” 11’7”

D Height of grousers mm 84 84

in 3.31” 3.31”

E Track gauge mm 2,180 2,240

ft-in 7’2” 7’4”

F Total width over tracks mm 2,749 2,850

ft-in 9’0” 9’4”

G Total width over blade-mounting mm 3,145 3,263

trunnions ft-in 10’4” 10’8”

H Ground clearance mm 630 695

in 25” 27”

Tractor shipping weight

1

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab and track shoes 560 mm/22” for PR 754, track shoes 610 mm/24” for PR 764.

PR 754 Litronic PR 764 Litronic 13

1

kg 28,947 29,842 37,537 38,037 38,437

lb 63,817 65,790 82,755 83,857 84,739

Page 14

Front attachment

Semi-U blade

PR 754 PR 764

Rigid Single bogie Rigid Single bogie Double link

undercarriage suspension undercarriage suspension bogie

suspension

Blade capacity according to m3 8.9 13.6

ISO 9246 yd

A Height of blade mm 1,650 1,950

ft-in 5’5” 6’5”

B Width of blade mm 4,030 4,370

ft-in 13’3” 14’4”

C Lifting height mm 1,400 1,480

ft-in 4’7” 4’10”

D Depth below ground mm 570 647

in 22” 25”

E Max. blade pitch 10° 9.4°

Max. blade tilt mm 972 1,028

ft-in 3’2” 3’4”

H Overall length mm 6,448 7,022

ft-in 21’2” 23’

Operating weight1 with track kg 34,990 35,885 – – –

shoes 560 mm / 22” lb 77,140 79,113

Ground pressure

shoes 560 mm / 22” PSI 13.94 14.36

Operating weight

shoes 610 mm / 24” lb 77,658 79,631 98,591 99,693 100,575

Ground pressure

shoes 610 mm / 24” PSI 12.94 13.22 14.79 14.93 15.09

Operating weight

shoes 710 mm / 28” lb 78,694 80,667 100,090 101,192 102,074

Ground pressure

shoes 710 mm / 28” PSI 11.23 11.52 12.81 12.94 13.08

Operating weight

shoes 760 mm / 30” lb 100,707 101,809 102,691

Ground pressure

shoes 760 mm / 30” PSI 12.09 12.23 12.37

1

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab, semi-U blade, operator

1

with track kg/cm2 0.98 1.01 – – –

1

with track kg 35,225 36,120 44,720 45,220 45,620

1

with track kg/cm2 0.91 0.93 1.04 1.05 1.06

1

with track kg 35,695 36,590 45,400 45,900 46,300

1

with track kg/cm2 0.79 0.81 0.90 0.91 0.92

1

with track kg - - 45,680 46,180 46,580

1

with track kg/cm2 - - 0.85 0.86 0.87

3

11.64 17.79

14 PR 754 Litronic PR 764 Litronic

Page 15

Front attachment

U blade *

PR 754 PR 764

Rigid Single bogie Rigid Single bogie Double link

undercarriage suspension undercarriage suspension bogie

suspension

Blade capacity according to m3 11.7 17.0

ISO 9246 yd

A Height of blade mm 1,650 1,950

ft-in 5’5” 6’5”

B Width of blade mm 4,325 4,650

ft-in 14’2” 15’3”

C Lifting height mm 1,400 1,480

ft-in 4’7” 4’10”

D Depth below ground mm 570 647

in 22” 25”

E Max. blade pitch 10° 9.4°

Max. blade tilt mm 1,043 1,094

ft-in 3’5” 3’7”

H Overall length mm 6,915 7,549

ft-in 22’8” 24’9”

Operating weight

shoes 560 mm / 22”

Ground pressure

shoes 560 mm / 22”

Operating weight

shoes 610 mm / 24”

Ground pressure

shoes 610 mm / 24”

Operating weight

shoes 710 mm / 28”

Ground pressure

shoes 710 mm / 28”

Operating weight

shoes 760 mm / 30”

Ground pressure

shoes 760 mm / 30”

* Counterweight or rear attachment is recommended for improved performance and balance.

1

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab, U blade, operator.

1

with track kg 36,090 36,985 – – –

1

with track kg/cm2 1.02 1.04 – – –

1

with track kg 36,325 37,220 45,570 46,070 46,470

1

with track kg/cm2 0.94 0.96 1.06 1.07 1.08

1

with track kg 36,795 37,690 46,250 46,750 47,150

1

with track kg/cm2 0.82 0.84 0.92 0.93 0.94

1

with track kg – – 46,530 47,030 47,430

1

with track kg/cm2 – – 0.86 0.87 0.88

3

15.3 22.23

lb

79,565 81,538

PSI

14.50 14.79

lb

77,878 82,056 100,465 101,567 102,449

PSI

13.37 13.65 15.07 15.22 15.36

lb

81,119 83,092 101,964 103,066 103,948

PSI

11.66 11.94 13.08 13.22 13.37

lb

102,581 103,683 104,565

PSI 12.23 12.37 12.51

PR 754 Litronic PR 764 Litronic 15

Page 16

Rear attachment

Ripper Parallelogram

single-shank with hydraulic

pitch

adjustment

PR 754 PR 764

A Ripping depth (max./min.) mm 1,201 / 421 1,300 / 476

ft-in 3’11” / 1’5” 4’3” / 1’7”

B Lifting height (max./min.) mm 1,040 / 260 1,000 / 260

ft-in 3’5” / 10” 3’3” / 10”

C Overall length, attachment mm 1,821 1,894

raised ft-in 6’0” 6’3”

D Overall length, attachment mm 2,374 2,494

lowered ft-in 7’9” 8’2”

E Ripper width mm 1,330 1,400

ft-in 4’4” 4’7”

Max. shank pitch 31° 31°

Maximum penetration force kN 118.2 166.9

lb 26,563 37,507

Pryout force kN 208.8 291.5

lb 46,924 65,509

Weight kg 3,631 4,786

lb 8,005 10,551

Drawbar Rigid

A Additional length mm 463 434

in 18” 17”

B Socket pin diameter mm 60 60

in 2.36” 2.36”

C Height of jaw mm 619 678

in 24” 27”

D Ground clearance mm 466 528

in 18” 21”

Jaw opening mm 105 105

in 4.13” 4.13”

Weight kg 660 750

lb 1,455 1,653

PR 754 PR 764

Counterweight PR 754 PR 764

Counterweight kg 4,000 5,000

lb 8,818 11,023

Counterweight with storage kg 3,500 –

compartment lb 7,716

Ripper Parallelogram

multi-shank with hydraulic

pitch

adjustment

PR 754 PR 764

A Ripping depth (max./min.) mm 791 / 476 900 / 520

ft-in 2’7” / 1’7” 2’11” / 1’8”

B Lifting height (max./min.) mm 985 / 670 1,038 / 658

ft-in 3’3” / 2’2” 3’5” / 2’2”

C Overall length, attachment mm 1,821 1,894

raised ft-in 6’0” 6’3”

D Overall length, attachment mm 2,374 2,494

lowered ft-in 7’9” 8’2”

E Toolbar width mm 2,434 2,494

ft-in 8’0” 8’2”

F Distance between shanks mm 1,100 1,130

ft-in 3’7” 3’8”

Max. shank pitch 31° 31°

Maximum penetration force kN 120.4 176.4

lb 27,057 39,642

Pryout force kN 208.8 291.5

lb 46,924 65,509

Weight kg 4,725 6,160

lb 10,417 13,580

PR 754 Litronic PR 764 Litronic 16

Page 17

Equipment

Basic machine

Tow switch •

Towing hitch rear •

Towing lug front •

Battery compartment, lockable •

Belly pans, heavy-duty •

Cold start device, glow plug •

Radiator, wide-meshed •

Radiator guard, heavy-duty •

Radiator guard, hinged •

Liebherr diesel engine •

Fan, hydraulically driven •

Fan guard •

Engine cover, perforated •

Engine doors, perforated •

Engine doors, hinged, lockable •

Lugs for crane lifting •

Fuel water separator •

Air filter, dry-type, dual step •

Pre-cleaner with automatic dust ejector •

Toolkit •

Forestry equipment +

Landfill equipment +

Filling with bio-degradable hydraulic oil +

Tank guard, complete +

Refueling pump, electric +

Diesel particle filter +

Special paint +

Fuel water separator with electric heater +

Travel drive

Parking brake, automatic •

Function control, automatic •

Control, single joystick •

Load limit control, electronic •

Electronic control •

Travel control, 3-speed •

Hydrostatic travel drive •

Inching brake pedal •

Emergency stop •

Oil cooler •

Final drives planetary gear •

Safety lever •

• = Standard

+ = Option

(1) = only PR 754

(2) = only PR 764

Subject to changes.

Undercarriage

Track frame, closed •

Sprocket segments, bolted •

Master link, two-piece •

Tracks oil lubricated •

Undercarriage, rigid •

Track frames, oscillating •

Pivot shaft, separate •

Track guide center part •

Track shoes with mud hole +

Track guard +

Undercarriage with single bogie

suspension +

Undercarriage with double link bogie

suspension (2) +

Sprocket segments with recesses +

Electrical system

Starter motor 7.8 kW •

Working lights, front, 4 units •

Working lights, rear, 2 units •

Batteries, cold start, 2 units •

Battery main switch, mechanical •

On-board system 24 V •

Alternator 80 A •

Horn •

Back-up alarm •

Beacon +

Immobilizer, electronic +

Additional lights, rear +

Additional lights, front, on lift cylinders,

4 units +

Operator’s cab

Storage compartment •

Armrests 3D adjustable •

Ash tray •

Pressurized cab with air filter •

Operator’s seat, 6-way adjustable •

Dome light •

Coat hook •

Air conditioning •

Radio pre installation •

ROPS/FOPS •

Rear mirror, inside •

Safety glass, tinted •

Windshield washer system •

Windshield wipers front, rear and on the

doors, with intermittent function •

Sliding window, left •

Sliding window, right •

Sun visor •

Socket 12 V •

Warm water heating •

Operator’s seat, air-suspended +

Fire extinguisher +

FM radio +

Protective grids for windows +

Extension, seat back +

Control and

warning lights

Display travel speed range (digital) •

Engine coolant temperature gauge

(analog) •

Fuel gauge (analog) •

Hour meter (analog) •

Warning light battery charging •

Warning light diesel engine •

Warning light electronic travel

control system •

Warning light final drive seal,

each side •

Warning light parking brake •

Warning light fuel water separator •

Warning light fan control •

Warning light pump replenishing

pressure •

Warning light float position blade •

Warning light oil return filter •

Warning light air filter •

Warning light diesel engine preheating •

Main warning light •

Warning light hydraulic oil temperature +

Hydraulic system

Variable flow pump, load sensing •

Oil filter in hydraulic tank •

Blade quick drop •

Control valve for 2 circuits •

Float position blade •

Hydraulic servo control •

Hydraulic control ripper +

Hydraulic control winch +

Hydraulic tank oil level warning light +

Attachments

Mounting plate for external tools +

Drawbar rear, rigid +

Counterweight, rear +

Ripper, 1 shank +

Ripper, 3 shanks +

Semi-U blade +

U blade +

Winch +

Spill guard for blade +

Options and/or special attachments, supplied

by vendors other than Liebherr, are only to be

installed with the knowledge and approval of

Liebherr to retain warranty.

PR 754 Litronic PR 764 Litronic 17

Page 18

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s highvalue products and services enjoy a high reputation in

many other fields, too. The wide range includes domestic appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical excellence and acknowledged quality, Liebherr products offer

a maximum of customer benefits in practical application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured inhouse, for instance the entire drive and control technology for construction equipment and mining trucks.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 100 companies with over

32,000 employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

in Bulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.us

Printed in Germany by DWS RG-BK-RP LWT/VM 11003722-1-02.11_enUS

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

+1 (757) 245 5251, Fax +1 (757) 928 8701

www.liebherr.us, E-Mail: info.lce@liebherr.com

Loading...

Loading...