Engineering Specification

LCM ENGINEERING

SPECIFICATION

LC370EUA

Ver. 0.1

*MODEL LC370EUA

SUFFIX AEM1

Update Dec.15, 2011

( ) Preliminary Specification

(

) Final Specification

●

1 /31

Engineering Specification

CONTENTS

LC370EUA

Number ITEM

COVER 1

CONTENTS

RECORD OF REVISIONS

1 GENERAL DESCRIPTION

2 ABSOLUTE MAXIMUM RATINGS

3 ELECTRICAL SPECIFICATIONS

3-1 ELECTRICAL CHARACTERISTICS

3-2 INTERFACE CONNECTIONS

3-3 SIGNAL TIMING SPECIFICATIONS

3-4 Panel Pixel Structure

3-5 POWER SEQUENCE

4 OPTICAL SPECIFICATIONS

5 MECHANICAL CHARACTERISTICS

6 RELIABILITY

Page

2

3

4

5

6

6

9

12

15

16

19

22

25

7 INTERNATIONAL STANDARDS

7-1 SAFETY

7-2 ENVIRONMENT

8 PRECAUTIONS

8-1 MOUNTING PRECAUTIONS

8-2 OPERATING PRECAUTIONS

8-3 ELECTROSTATIC DISCHARGE CONTROL

8-4 PRECAUTIONS FOR STRONG LIGHT EXPOSURE

8-5 STORAGE

Ver. 0.1

26

26

26

27

27

27

28

28

28

2 /31

Engineering Specification

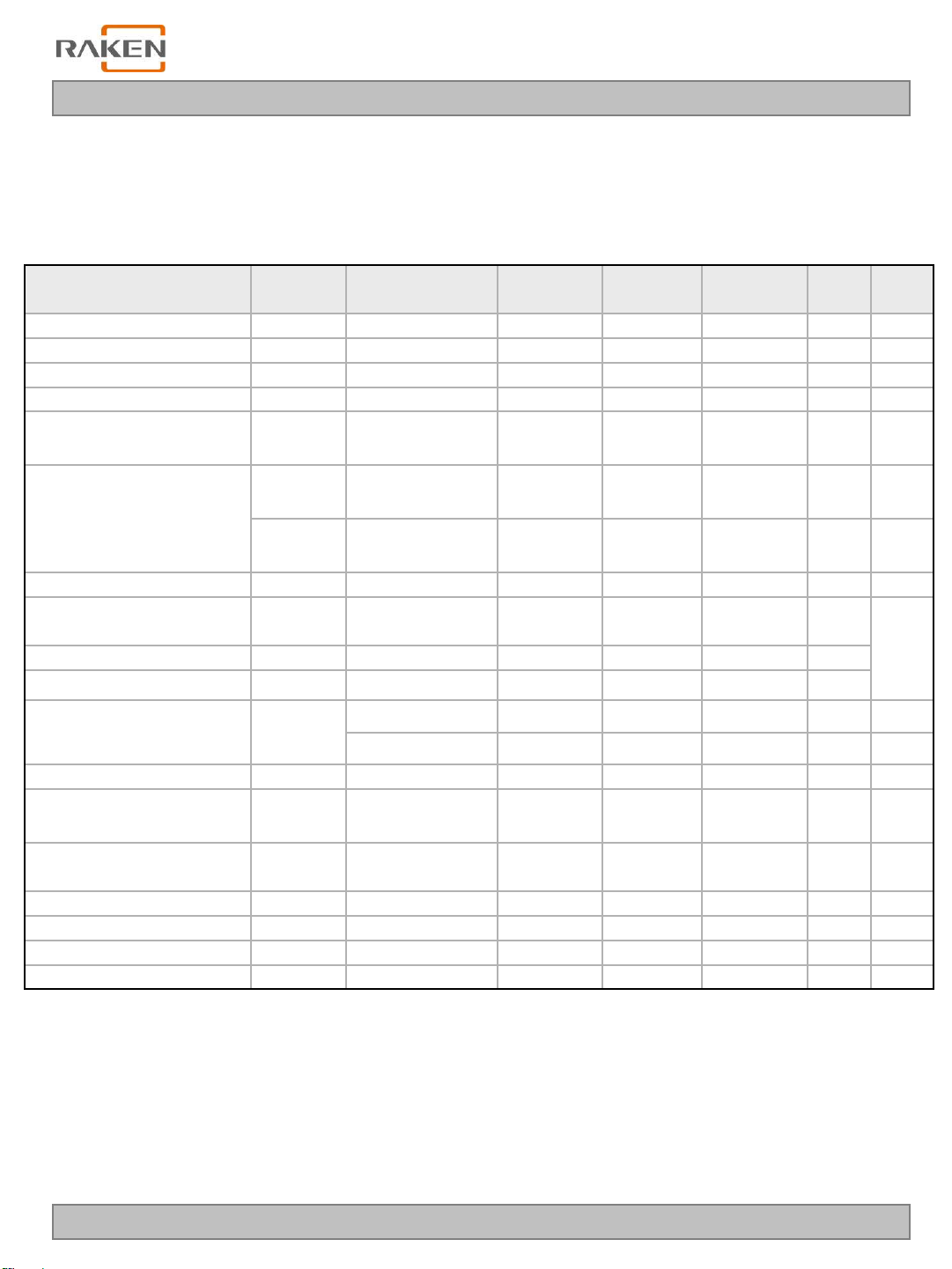

RECORD OF REVISIONS

Revision No. Revision Date Page Description

0.1 Oct 07, 2011 - Preliminary Specification(First Draft)

1.0 Dec.15,2011 6 DC Electrical characteristics are corr ected

8 Electrical characteristics (continue) are corrected

13 . Power On to DLL Lock time is corrected

17 Optical characteristics are corrected

21 Mechanical characteristics are corrected

22,23 Mechanical drawings are corrected

28 Cancel US patent

- Final Specification

LC370EUA

Ver. 0.1

3 /31

LC370EUA

Engineering Specification

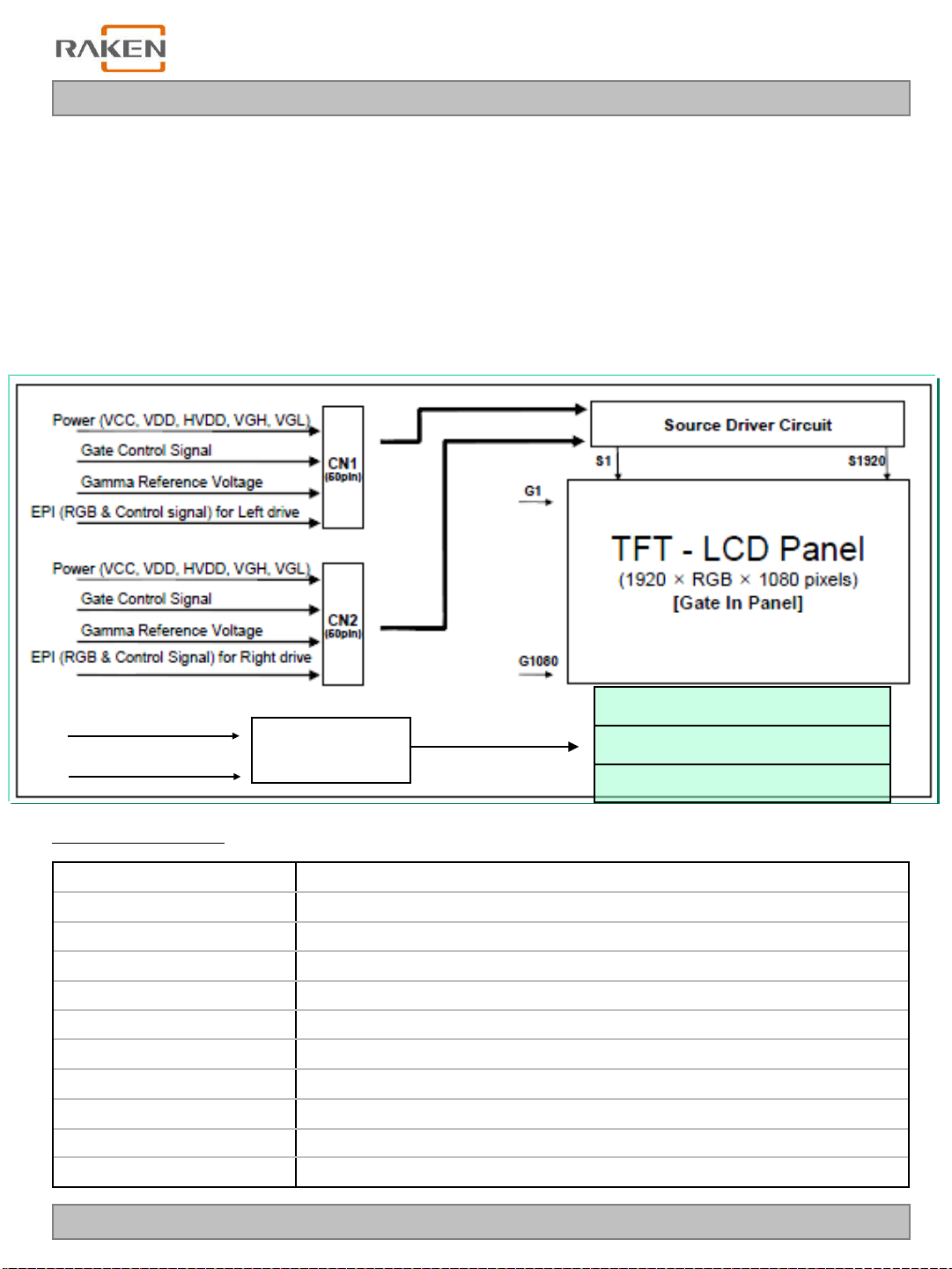

1. General Description

The LC370EUA is a Color Active Matrix Liquid Crystal Display with an integral Light Emitting Diode (LED)

backlight system . The matrix employs a-Si T hin Film Transistor as the active element.

It is a transmissive display type which is operating in the normally black mode. It has a 36.5 inch diagonally

measured active display area with W UX GA resolution (1080 vertical by 1920 horizontal pixel array).

Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arrayed in vertical stripes.

Gray scale or the luminance of the sub-pixel color is determined with a 8-bit gray scale signal for each dot.

Therefore, it can present a palette of more than 1.67M(ture) colors.

It is intended to support LCD TV, PCTV where high brightness, super wide viewing angle, high color gamut,

high color depth and fast response time are important.

PWM_OUT

1~3

LED Driver

+24.0V, GND, On/Off

Scanning Block 1

Scanning Block 2

Scanning Block 3

General Features

Active Screen Size 36.5 inches(927.2mm) diagonal

Outline Dimension

Pixel Pitch 0.4209 mm x 0.4209 mm

Pixel Format 1920 horiz. by 1080 vert. Pixels, RGB stripe arrangement

Color Depth 8bit, 16.7 Million colors

Luminance, White 360 cd/m

Viewing Angle (CR>10) Viewing angle free ( R/L 178 (Min.), U/D 178 (Min.))

Power Consumption Total 46.8W (Typ.) [Logic= 5.8W, LED Driver=41W (ExtVbr_B=100% )]

Weight 7.5 Kg (Typ.)

Display Mode Transmissive mode, Normally black

Surface Treatment Hard coating(2H), Anti-glare treatment of the front polarizer (Haze 10%)

837.2(H) × 490.6(V) X 9.9(B) /22.7 mm(D) (Typ.)

2

(Center 1point ,Typ.)

Ver. 0.1

4 /31

LC370EUA

Engineering Specification

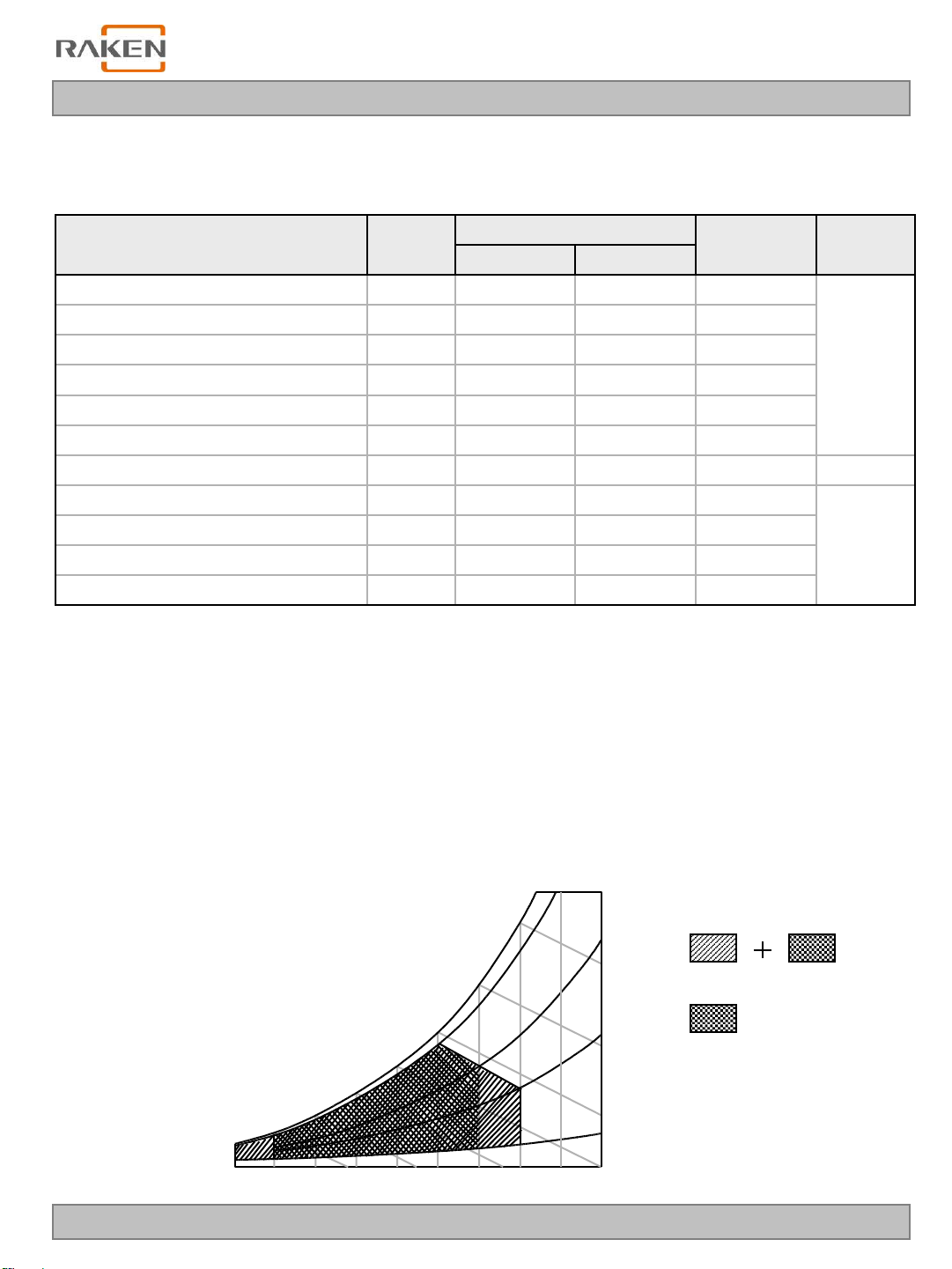

2. Absolute Maximum Ratings

The following items are maximum values which, if exceeded, may cause faulty operation or permanent damage

to the LCD module.

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter Symbol

Value

Min Max

Logic&EPI Power Voltage VCC -0.5 +2.2 V

Gate High Voltage VGH +18.0 +30.0 V

Gate Low Voltage VGL -8.0 -4.0 VDC

Source D-IC Analog Voltage VDD -0.3 +18.0 VDC

Gamma Ref. Voltage (Upper) VGMH ½VDD-0.5 VDD+0.5 VDC

Gamma Ref. Voltage (Low) VGML -0.3 ½ VDD+0.5 VDC

Panel Front Temperature TSUR - +68

Operating Temperature T

Storage Temperature T

Operating Ambient Humidity H

Storage Humidity H

Note

1. Ambient temperature condition (Ta = 25 ± 2 °C )

OP 0 +50

ST -20 +60

OP 10 90 %RH

ST 10 90 %RH

2. Temperature and relative humidity range are shown in the figure below. Wet bulb temperature

should be Max 39 °C and no condensation of water.

3. Gravity mura can be guaranteed below 40℃ condition.

4. The maximum operating temperature is based on the test condition that the surface temperature

of display area is less than or equal to 68 ℃ with LCD module alone in a temperature controlled

chamber. Thermal management should be considered in final product design to prevent the surface

temperature of display area from being over 68 ℃. The range of operating temperature may

degrade in case of improper thermal management in final product design.

5. The storage test condition:-20℃ temperature/90% humidity to 60℃ temperature/40% humidity ;

the operating test condition: 0℃ temperature/90% humidity to 50℃ temperature/60% humidity.

90%

Unit Note

DC

DC

1

°C

4

°C

°C

2,3

Ver. 0.1

Wet Bulb

Temperature [

10

0

10 20 30 40 50 60 70 800-20

Dry Bulb Temperature [

°C]

20

30

40

50

°C]

60

60%

40%

10%

Storage

Operation

Humidity [(%)RH]

5 /31

Engineering Specification

3. Electrical Specifications

It requires two kind of power inputs.

One is employed to power for the LCD circuit. The other Is used for the LED backlight circuit.

3-1. Electrical Characteristics

Table 2. DC ELECTRICAL CHARACTERISTICS

Parameter Symbol Condition MIN TYP MAX Unit Note

LC370EUA

Logic & EPI Power Voltage VCC - 1.62 1.8 1.98 V

Logic High Level Input Voltage VIH - 1.4 - VCC VDC

Logic Low Level Input Voltage VIL - 0 - 0.4 VDC

Source D-IC Analog Voltage VDD - 16.6 16.8 17.0 VDC

Half Source D-IC Analog

Voltage

Gamma Reference Voltage

Common Voltage Vcom Reverse 6.17 6.47 6.77 V

EPI input common voltage VCM LVDS Type 0.8 VCC/2

EPI Input eye diagram

EPI input differential voltage Vdiff - 150 - 500 mV

Gate High Voltage VGH

Gate Low Voltage VGL

GIP Bi-Scan Voltage

H_VDD - 8.2 8.4 8.6 VDC 6

V

GMH

V

GML

Veye

VGI_P

VGI_N

(GMA1 ~ GMA9) H_VDD+0.2 - VDD-0.2 VDC

(GMA10 ~ GMA18) 0.2 - H_VDD-0.2V VDC

VCC-0.6-

Vdiff/2

- 75 - - mV

@ 25℃

@ 0℃

-

- VGL - VGH VDC

27.7 28 28.3 V

29.7 30 30.3 V

-5.2 -5.0 -4.8 VDC

DC

V

DC

DC

5

GIP Refresh Voltage

GIP Start Pulse Voltage

GIP Operating Clock GCLK - VGL - VGH V

Total Power Current

Total Power Consumption

VGH

even/odd

VST - VGL - VGH V

LCD - - 510 663 mA 1

I

CD - - 6.1 8.0 Watt 1

PL

- VGL - VGH V

Note:

1. The specified current and power consumption are under the VLCD=12V., 25 ± 2°C, fV=60Hz

condition whereas mosaic pattern(8 x 6) is displayed and f

is the frame frequency.

V

2. The above spec is based on the basic model.

3. All of the typical gate voltage should be controlled within 1% voltage level

4. Ripple voltage level is recommended under ±5% of typical voltage

5. In case of EPI signal spec, refer to Fig 2 for the more detail.

6. HVDD Voltage level is half of VDD and it should be between Gamma9 and Gamma10.

Ver. 0.1

6 /31

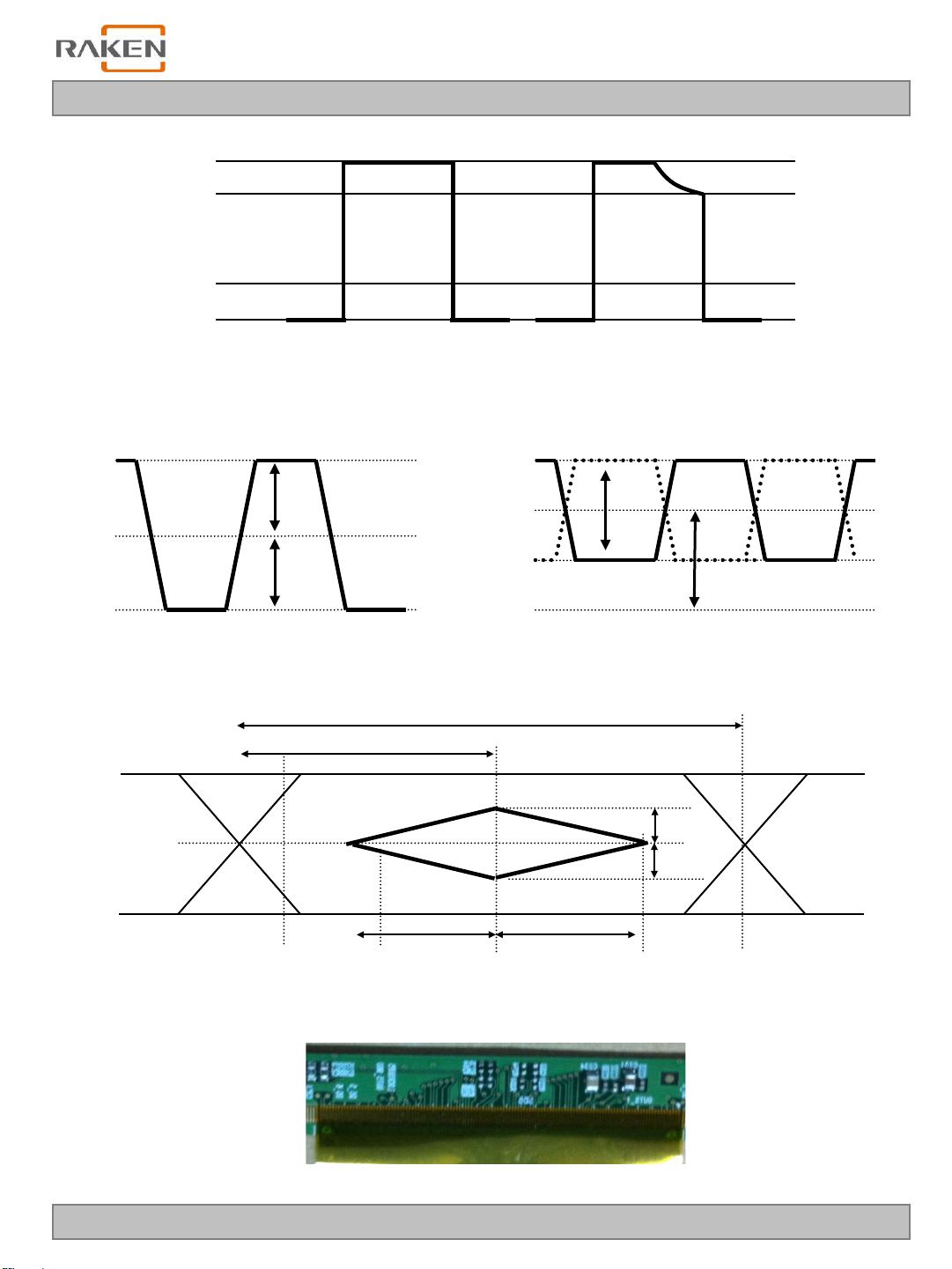

VGH

VGHM

GND

VGL

LC370EUA

Engineering Specification

Without GPM With GPM

FIG. 1 Gate Output Wave form without GPM and with GPM

EPI +

0 V

0 V

Vdiff

Vdiff

(Differential Probe)

FIG. 2-1 EPI Differential signal characteristics

EPI -

0 V

1 UI

0.5 UI

B1

(Differential Probe)

B2

FIG. 2-2 Eye Pattern of EPI Input

Vdiff

Vcm

(Active Probe)

Veye

Veye

Ver. 0.1

FIG. 3 Measure point

7 /26

Engineering Specification

Table 3. ELECTRICAL CHARACTERISTICS (Continue)Table 3. ELECTRICAL CHARACTERISTICS (Continue)

LC370EUA

Parameter Symbol

LED Driver :

Power Supply Input Voltage VBL 22.8 24.0 25.2 Vdc 1

Power Supply Input Current IBL

Power Supply Input Current (In-Rush) In-rush - - 2.5 A

Power Consumption PBL -

Input Voltage for

Control System

Signals

LED :

Life Time 30,000 Hrs 2

On/Off

On V on 2.5 - 5.0 Vdc

Off V off -0.3 0.0 0.7 Vdc

Min Typ Max

Values

-

1.7

41 44.8

1.9

Unit Notes

A 1

VBL = 22.8V

BR-B

= 100%

ExtV

W 1

Notes :

1. Electrical characteristics are determined after the unit has been ‘ON’ and stable for approximately 60

minutes at 25±2°C. The specified current and power consumption are under the typical supply Input voltage

24Vand V

BR (ExtVBR-B : 100%), it is total power consumption.

2. The life time (MTTF) is determined as the time which luminance of the LED is 50% compared to that of initial

value at the typical LED current (ExtVBR-B :100%) on condition of continuous operating in LCM state at

25±2°C.

Ver. 0.1

8 /31

LC370EUA

Engineering Specification

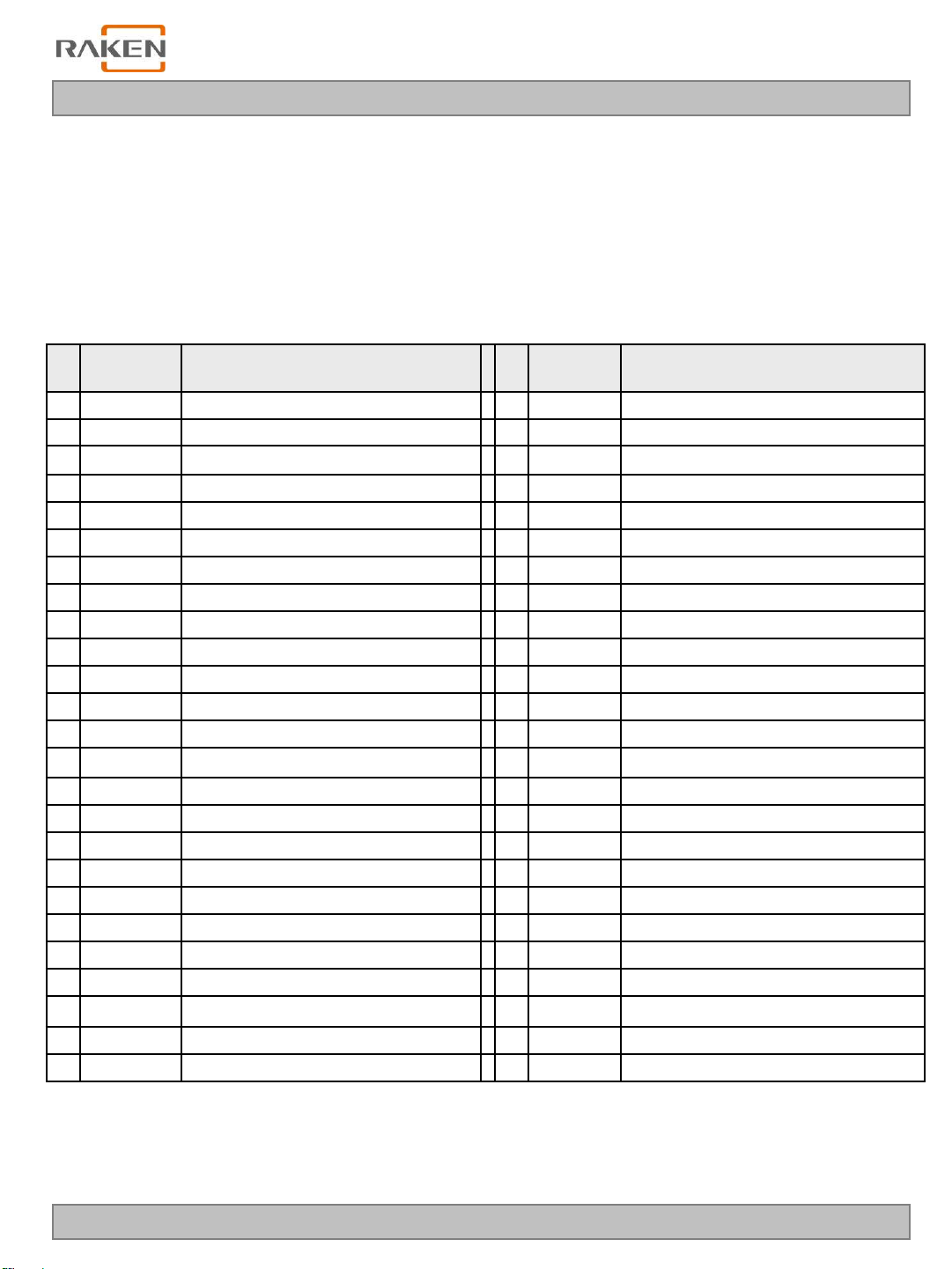

3-2. Interface Connections

This LCD module employs two kinds of interface connection, two 50-pin FFC connector are used for the

module electronics.

3-2-1. LCD Module

-LCD Connector (CN1): TF06L-50S-0.5SH (Manufactured by HRS) or Compatible

Table 3-1. MODULE CONNECTOR(CN1) PIN CONFIGURATION

No Symbol Description No Symbol Description

1 LTD_OUT LTD OUTPUT 26 GND Ground

2 NC No Connection 27 EPI2- EPI Receiver Signal(2-)

3 GCLK1 GIP GATE Clock 1 28 EPI2+ EPI Receiver Signal(2+)

4 GCLK2 GIP GATE Clock 2 29 GND Ground

5 GCLK3 GIP GATE Clock 3 30 GND Ground

6 GCLK4 GIP GATE Clock 4 31 EPI1- EPI Receiver Signal(1-)

7 GCLK5 GIP GATE Clock 5 32 EPI1+ EPI Receiver Signal(1+)

8 GCLK6 GIP GATE Clock 6 33 GND Ground

9 VGI_N GIP Bi-Scan (Normal =VGL Rotate = VGH) 34 VCC Logic & EPI Power Voltage

10 VGI_P GIP Bi-Scan (Normal =VGH Rotate = VGL) 35 NC No Connection

11 VGH_ODD GIP Panel VDD for Odd GATE TFT 36 LOCKOUT3 LOCKOUT3

12 VGH_EVEN GIP Panel VDD for Even GATE TFT 37 NC No Connection

13 VGL GATE Low Voltage 38 GND Ground

14 VST VERTICAL START PULSE 39 GMA 18 GAMMA VOLTAGE 18 (Output From LCD)

15 GIP_Reset GIP Reset 40 GMA 16 GAMMA VOLTAGE 16

16 VCOM_L_FB VCOM Left Feed-B ac k Output 41 GMA 15 GAMM A VO L TAG E 1 5

17 VCOM_L VCOM Left Input 42 GMA 14 GAMMA VOLTAGE 14

18 GND Ground 43 GMA 12 GAMMA VOLTAGE 12

19 VDD Driver Power Supply Voltage 44 GMA 10 GAMMA VOLTAGE 10 (Output From LCD)

20 VDD Driver Power Supply Voltage 45 GMA 9 GAMMA VOLTAGE 9 (Output From LCD)

21 H_VDD Half Driver Power Supply Voltage 46

22 GND Ground 47 GMA 5 GAMMA VOLTAGE 5

23 EPI3- EPI Receiver Signal(3-) 48 GMA 4 GAMMA VOLTAGE 4

24 EPI3+ EPI Receiver Signal(3+) 49 GMA 3 GAMMA VOLTAGE 3

25 GND Ground 50 GMA 1 GAMMA VOLTAGE 1(Output From LCD)

GMA 7 GAMMA VOLTAGE 7

Note :

1. Please refer to application note for details.

(GIP & Half VDD & Gamma Voltage setting)

Ver. 0.1

9 /26

LC370EUA

Engineering Specification

-LCD Connector (CN1): TF06L-50S-0.5SH (Manufactured by HRS) or Compatible

Table 3-2. MODULE CONNECTOR(CN2) PIN CONFIGURATION

No Symbol Description No Symbol Description

1 GMA 1 GAMMA VOLTAGE 1 (Output From LCD) 26 GND Ground

2 GMA 3 GAMMA VOL T AG E 3 27 EPI1- EPI Receiver Signal(4-)

3 GMA 4 GAMMA VOL T AG E 4 28 EPI1+ EPI Receiver Signal(4+)

4 GMA 5 GAMMA VOL T AG E 5 29 GND Ground

5 GMA 7 GAMMA VOL T AG E 7 30 H_VDD Half Driver Power Supply Voltage

6 GMA 9 GAMMA VOLTAGE 9 (Output From LCD) 31 VDD Driver Power Supply Voltage

7 GMA 10 GAMMA VOLTAGE 10 (Output From LCD) 32 VDD Driver Power Supply Voltage

8 GMA 12 GAMMA VO L T AGE 1 2 33 GND Ground

9 GMA 14 GAMMA VO L T AGE 1 4 34 VCOM_R VCOM Right Input

10 GMA 15 GAMMA VOLTAGE 15 35 VCOM_R_FB VCOM Right Feed-Back Output

11 GMA 16 GAMMA VOLTAGE 16 36 GIP_Reset GIP Reset

12 GMA 18 GAMMA VOLTAGE 18 (Output From LCD) 37 VST VERTICAL START PULSE

13 GND Ground 38 VGL GATE Low Voltage

14 LOCKOUT6 LOCKOUT6 39 VGH_EVEN GIP Panel VDD for Even GATE TFT

15 LOCKIN3 LOCKIN3 40 VGH_ODD GIP Panel VDD for Odd GATE TFT

16 NC No Connection 41 VGI_P GIP Bi-Scan (Normal =VGH Rotate = VGL)

17 VCC Logic & EPI Power Voltage 42 VGI_N GIP Bi-Scan (Normal =VGL Rotate = VGH)

18 GND Ground 43 GCLK6 GIP GATE Clock 6

19 EPI6- EPI Receiver Signal(6-) 44 GCLK5 GIP GATE Clock 5

20 EPI6+ EPI Receiver Signal(6+) 45 GCLK4 GIP GATE Clock 4

21 GND Ground 46

22 GND Ground 47 GCLK2 GIP GATE Clock 2

23 EPI5- EPI Receiver Signal(5-) 48 GCLK1 GIP GATE Clock 1

24 EPI5+ EPI Receiver Signal(5+) 49 NC No Connection

25 GND Ground 50 LTD_OUT LTD OUTPUT

GCLK3 GIP GATE Clock 3

Note :

1. Please refer to application note for details.

(GIP & Half VDD & Gamma Voltage setting)

Source Right PCB

Ver. 0.1

CN 2

#1 #50

CN 1

Source Left PCB

#1 #50

10 /26

Engineering Specification

3-2-2. Backlight Module

Master

-LED Driver Connector

: 20022WR - H14B2(Yeonho) or compatible

- Mating Connector

: 20022HS - 14B2 or compatible

Table 5-1. LED DRIVER CONNECTOR PIN CONFIGURATION

Pin No Symbol Description Note

1 VBL Power Supply +24.0V

2 VBL Power Supply +24.0V

3 VBL Power Supply +24.0V

4 VBL Power Supply +24.0V

5 VBL Power Supply +24.0V

LC370EUA

6

7

8

9

10

11

12

13 NC Don’t care

14 NC Don’t care

GND

GND

GND

GND

GND

Status

VON/OFF

Backlight Ground

Backlight Ground

Backlight Ground

Backlight Ground

Backlight Ground

Back Light Status 2

Backlight ON/OFF control

Notes :1. GND should be connected to the LCD module’s metal frame.

2. Normal : Low (under 0.7V) / Abnormal : Open

◆ Rear view of LCM

PCB

1

14

…

1

14

…

1

Ver. 0.1

<Master>

11 /31

Engineering Specification

3-2-2. Backlight Module

LED Driver Connector

: 10031HR-H04L_Black (YEONHO)

Table 5-2. LED DRIVER CONNECTOR PIN CONFIGURATION

Pin No Symbol Description Note

1 GND Ground 1

2 SCAN3 PWM 3

3 SCAN2 PWM 2

4 SCAN1 PWM 1

Notes :1. GND should be connected to the LCD module’s metal frame.

LC370EUA

◆ Rear view of LCM

1

4

…

PCB

1

4

…

Ver. 0.1

12 /31

3-3. Signal Timing Specifications

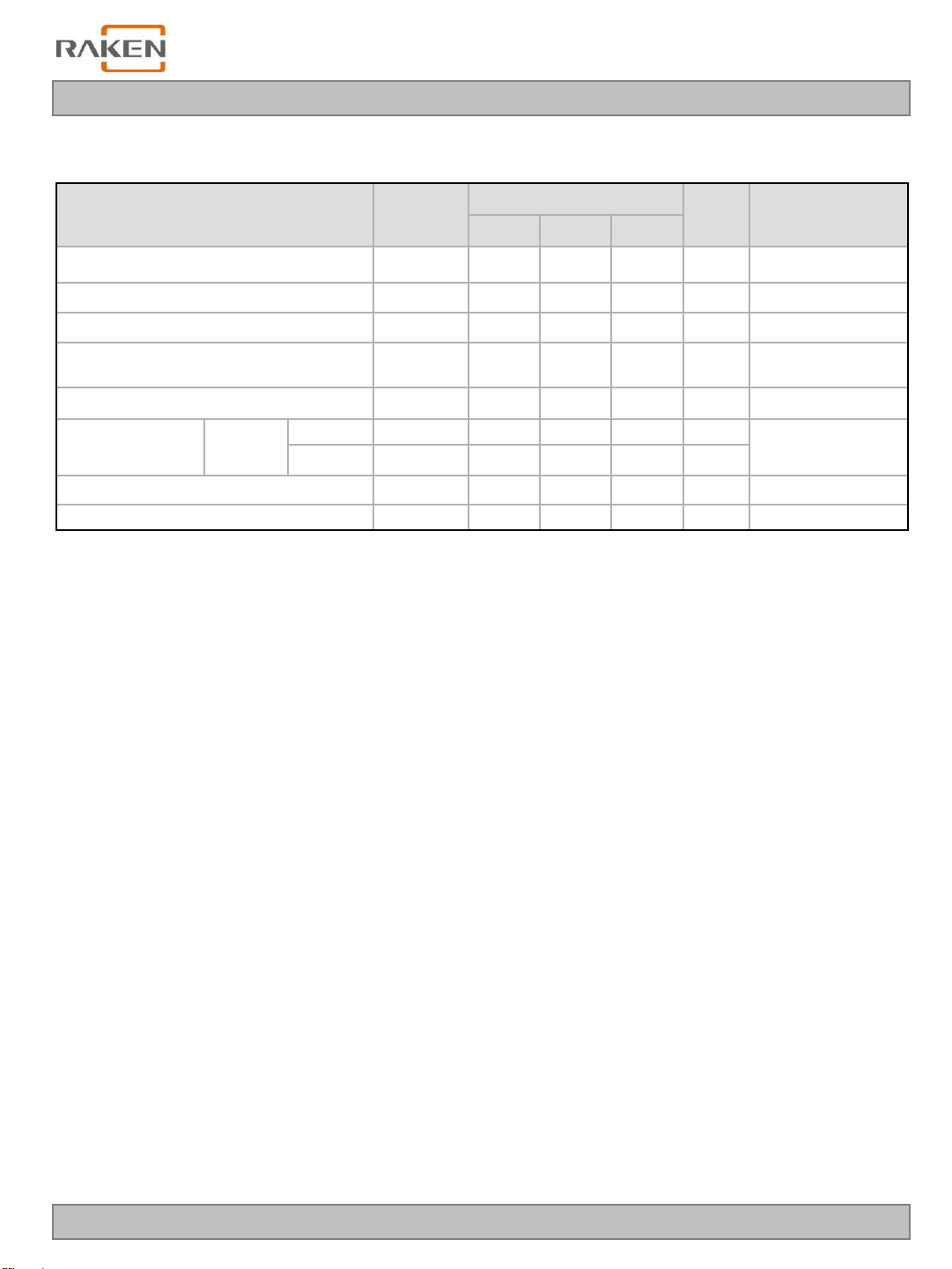

Table 4. Timing Requirements

Parameter Symbol Condition Min Typ Max Unit Note

LC370EUA

Engineering Specification

Unit Interval

DLL Lock time

Effective Veye width time

SSC

Receiver off to SOE rising time

SOE pulse width

SOE rising to 1

EPI Bandwidth - 0.607(TBD) - 0.728(TBD) GBPS

EPI Input

VCC

st

data time

UI

Tlock

B1&B2

Vspread

tSOE_

Rising

tSOE_

Width

tSOE_

DATA

- 0.59(TBD) - - ns

- 1.6(TBD) - 200(TBD) Us Fig 4

- 0.25(TBD) - - UI Fig. 2

@100KHz - - 2(TBD) %

5(TBD) - - Packet Fig.5

- 4(TBD) - - Packet Fig.5

- 5(TBD) - - Packet Fig.5

Tlock

Ver. 0.1

FIG 4. Power On to DL L L o ck time

FIG 5. SOE Width & Timing

13 /26

3-4. Panel Pixel Structure

D1 D2 D3 D4 D5 D1918 D1919 D1920 D1921

G1

G2

G3

G4

G5

G6

LC370EUA

Engineering Specification

G1078

G1079

G1080

FIG. 6 Panel Pixel Structure

Ver. 0.1

14 /26

3-7. Power Sequence

3-7-1. LCD Driving circuit

Power Supply For LCD

VCC

Power Supply For LCD

VDD, HVDD,VGH, GammaRef.

Voltage

Power Supply For LCD

VGL

0V

0V

Engineering Specification

70%

T2

50%

100%

T1

VGH

90%

LC370EUA

T7

GIP Signal For LCD

VGH

even/Odd

T3

T4

VST

GCLK1~6

Power For LED

Table 9. POWER SEQUENCE

Parameter

T1 0.5 - ms

2 0.5

T

T

3 0

T

4 10

5 0 - ms

T

T6 / T6’ 20 - ms 6

T7 2 - sec

Min Typ Max

Value

Note : 1. Power sequence for Source D-IC must follow the Case1 & 2.

※ Please refer to Appendix Ⅲ for more details.

2. VGH Odd signal should be started “High” status and VGH even & odd can not be “High at the

same time.

3. Power Off Sequence order is reverse of Power On Condition including Source D-IC.

4. GCLK On/Off Sequence

Normal : GCLK4 GCLK5 GCLK6 GCLK1 GCLK2 GCLK3.

Reverse :GCLK3 GCLK2 GCLK1 GCLK6 GCLK5 GCLK4.

5. VDD_odd/even transition time should be within V_blank

6. In case of T6’, If there is no abnormal display, no problem

T5

T6

-

-

-

..

..

..

T6’

LED on

Ta= 25±2°C, fV=60Hz

Unit Notes

ms

ms

ms 2

Ver. 0.1

15 /31

3-7. Power Sequence

3-7-2. Sequence for LED Driver

Power Supply For LED Driver

VBL

0V

10%

Engineering Specification

24V (typ.)

90%

LC370EUA

90%

T1 T2

VON/OFF

ExtVBR-B

3-6-3. Dip condition for LED Driver

(Typ.) x 0.8

V

BL

Table 9. Power Sequence for LED Driver

Parameter

T1 20 - - ms 1

T2 500 - - ms

T3 10 - - ms

T4 0 - - ms

T5 - - 10 ms V

T6 500 - - ms 2

Min Typ Max

T4 T6

Values

LED ON

T5

T3

V

: 24V

BL

0 V

Units Remarks

(Typ) x 0.8

BL

Notes : 1. T1 describes rising time of 0V to 24V and this parameter does not applied at restarting time.

Even though T1 is over the specified value, there is no problem if I

2. In T6 section,

Ver. 0.1

ExtVBR-B should be sustained from 5% to 100% .

2

T spec of fuse is satisfied.

16 /31

LC370EUA

Engineering Specification

4. Optical Specification

Optical characteristics are determined after the unit has been ‘ON’ and stable in a dark environment at 25±2°C.

The values are specified at distance 50cm from the LCD surface at a viewing angle of Φ and θ equal to 0 °.

FIG. 8 shows additional information concerning the measurement equipment and method.

Optical Stage(x,y)

LCD Module

FIG. 8 Optical Characteristic Measurement Equipment and Method

Table 10. OPTICAL CHARACTERISTICS

Parameter Symbol

Contrast Ratio CR

Surface Luminance, white L

Luminance Variation δ

Response Time

Color Coordinates

[CIE1931]

Color Temperature

Color Gamut

Viewing

Angle

Gray Scale

2D

(CR>10)

Variation

Gray to Gray (BW)

RED

GREEN

BLUE

WHITE

right(φ=0°)

left (φ=180°)

up (φ=90°)

down (φ=270°)

WH

WHITE

Rising

Falling

θr (x axis) 89 - -

θl (x axis) 89 - θu (y axis) 89 - θd (y axis) 89 - -

Pritchard 880 or

equivalent

50cm

Ta= 25±2°C, V

=12.0V, fV=60Hz, Dclk=74.25MHz ,

LCD

EXTVBR-B =100%

Value

Min Typ Max

1000 1400

2D

5P 1.3 3

Rx

Ry

Gx

Gy

Bx

By

Wx

Wy

290 360

-

-

10 14

0.636(TBD)

0.343(TBD)

0.318(TBD)

Typ

-0.03

0.605(TBD)

0.155(TBD)

0.056(TBD)

0.279

0.292

8 12

10,000

68

- - -

- 1

Typ

+0.03

Unit Note

2

cd/m

ms 4

K

%

degree 6

2

5

7

Ver. 0.1

17 /31

Engineering Specification

Note : 1. Contrast Ratio(CR) is defined mathematically as :

LC370EUA

Contrast Ratio =

Surface Luminance with all white pixels

Surface Luminance with all black pixels

It is measured at center 1-point.

2. Surface luminance are determined after the unit has been ‘ON’ and 1 Hour after lighting the

backlight in a dark environment at 25±2°C. Surface luminance is the luminance value at center

1-point across the LCD surface 50cm from the surface with all pixels displaying white.

For more information see the FIG. 9.

3. The variation in surface luminance , δ WHITE is defined as :

δ WHITE(5P) = Maximum(L

Where L

on1

to L

are the luminance with all pixels displaying white at 5 locations .

on5

on1,Lon2

on3

on4

) / Minimum(L

on5

on1,Lon2

, L

on3

, L

on4

, L

on5

)

, L

, L

, L

For more information, see the FIG. 9.

4. Response time is the time required for the display to transit from G(N) to G(M) (Rise Time, Tr

and from G(M) to G(N) (Decay Time, Tr

). For additional information see the FIG. 10. (N<M)

D

5. Viewing angle is the angle at which the contrast ratio is greater than 10. The angles are

determined for the horizontal or x axis and the vertical or y axis with respect to the z axis which

is normal to the LCD module surface. For more information, see the FIG. 11.

6. Gray scale specification

Gamma Value is approximately 2.2. For more information, see the Table 11.

)

R

Table 11. GRAY SCALE SPECIFICATION

Gray Level Luminance [%] (Typ)

L0 TBD

L15 0.27

L31 1.04

L47 2.49

L63 4.68

L79 7.66

L95 11.5

L111 16.1

L127 21.6

L143 28.1

L159 35.4

L175 43.7

L191 53.0

L207 63.2

L223 74.5

L239 86.7

L255 100

Ver. 0.1

18 /31

Engineering Specification

Measuring point for surface luminance & measuring point for luminance variation.

H

A

③②

LC370EUA

V

①

B

A : H / 4 mm

④

FIG.9 5 Points for Luminance Measu re

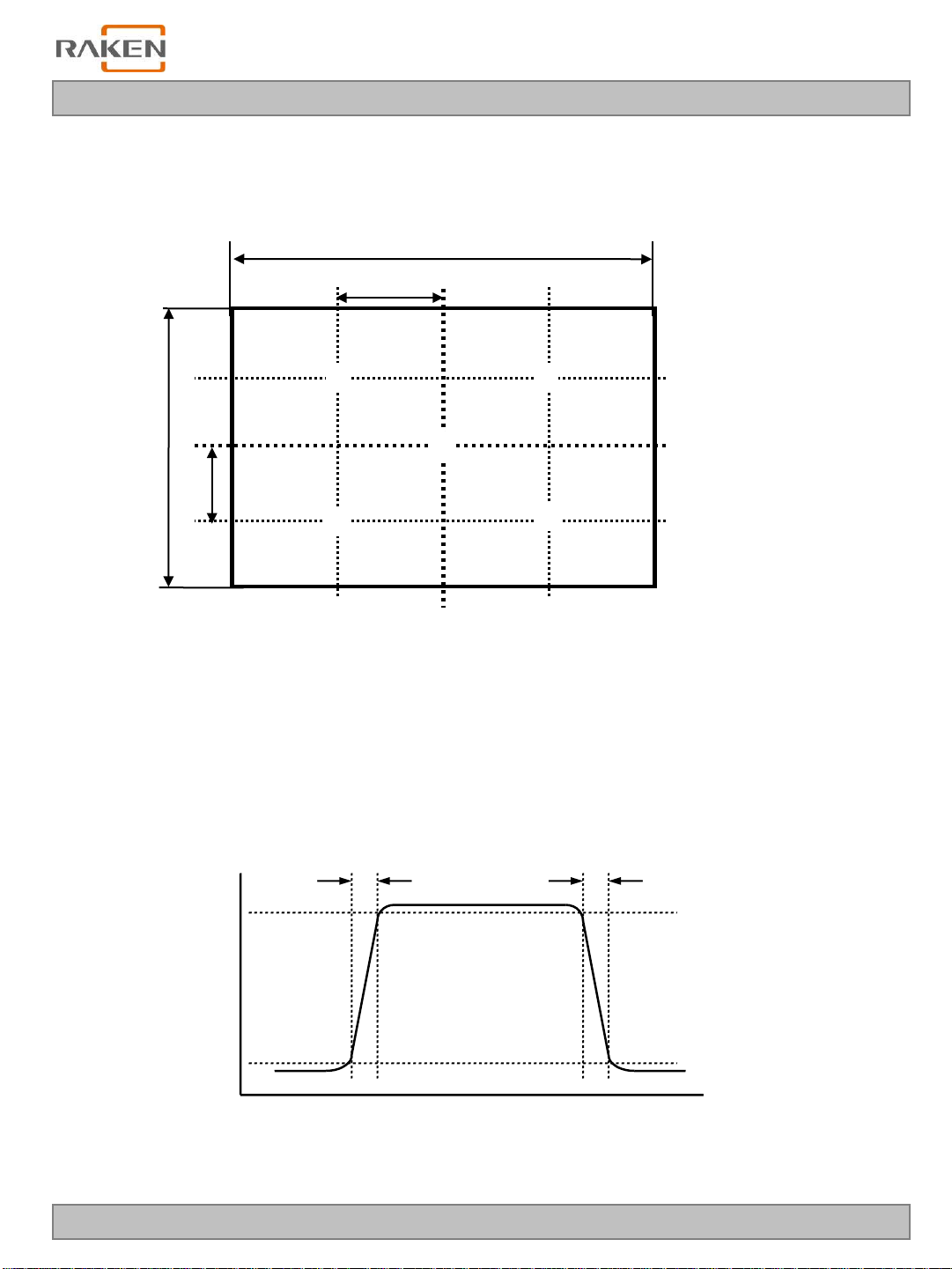

Response time is defined as the following figure and shall be measured by switching the input signal for

“Gray(N)” and “Gray(M)”.

TrR

100

90

⑤

TrD

B : V / 4 mm

@ H,V : Active Area

Ver. 0.1

Optical

Response

10

0

Gray(N)

N,M = Black~White, N<M

FIG. 10 Response Time

Gray(M)

Gray(N)

19 /31

Dimension of viewing angle range

Normal

Y

E

φ

θ

φ

= 0°, Right

φ

= 180°, Left

φ

= 270°, Down

φ

= 90°, Up

LC370EUA

Engineering Specification

FIG. 11 Viewing Angle

Ver. 0.1

20 /39

Engineering Specification

5. Mechanical Characterist ics

Table 12 provides general mechanical characteristics.

Table 12. MECHANICAL CHARACTERISTICS

Item Value

LC370EUA

Outline Dimension

Bezel Area

Active Display Area

Weight

Horizontal

Vertical

Depth

Horizontal

Vertical

Horizontal 808.128 mm

Vertical 454.572 mm

7.5 Kg (Typ.), 7.9 kg (Max.)

837.2 mm

490.6 mm

22.7 mm

815.4 mm

461.7 mm

Ver. 0.1

21 /31

[ FRONT VIEW ]

LC370EUA

Engineering Specification

Set : Top

Set : Down

Ver. 0.1

22 /32

[ REAR VIEW ]

LC370EUA

Engineering Specification

Ver. 0.1

23 /32

Engineering Specification

6. Reliability

Table 13. ENVIRONMENT TEST CONDITION

No. Test Item Condition

LC370EUA

1 High temperature storage test

2 Low temperature storage test

3 High temperature operation test

4 Low temperature operation test

5 Humidity condition Operation

Ta= 60°C 240h

Ta= -20°C 240h

Ta= 50°C 50%RH 240h

Ta= 0°C 240h

Ta= 40 °C ,90%RH

Note : Before and after Reliability test, LCM should be operated with normal function.

Ver. 0.1

24 /32

Engineering Specification

7. International Standards

7-1. LED Array - Safty

1. Laser (LED Backlight) Information

Class 1M LED Product

IEC60825-1 : 2001

Embedded LED Power (Class 1M)

2. Caution

: LED inside.

Class 1M laser (LEDs) radiation when open.

Do not open while operating.

7-2. Environment

a) RoHS, Directive 2002/95 / EC of the European Par lia m ent and of the council of 27 J anua ry 2003

LC370EUA

Ver. 0.1

25 /32

LC370EUA

Engineering Specification

8. Precautions

Please pay attention to the followings when you use this TFT LCD module.

8-1. Mounting Precautions

(1) You must mount a module using specified mounting holes (Details refer to the drawings).

(2) You should consider the mounting structure so that uneven force (ex. Twisted stress) is not applied to

the module. And the case on which a module is mounted should have sufficient strength so that external

force is not transmitted directly to the module.

(3) Please attach the surface transparent protective plate to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to the resist external force.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case are not desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter causes circuit break

by electro-chemical reaction.

(6) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment.

Do not touch the surface of polarizer for bare hand or greasy cloth.(Some cosmetics are detrimental

to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton or other soft materials like

chamois soaks with petroleum benzine. Normal-hexane is recommended for cleaning the adhesives

used to attach front / rear polarizers. Do not use acetone, toluene and alcohol because they cause

chemical damage to the polarizer

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(9) Do not open the case because inside circuits do not have sufficient strength.

8-2. Operating Precautions

(1) The spike noise causes the mis-operation of circuits. It should be lower than following voltage :

V=±200mV(Over and under shoot voltage)

(2) Response time depends on the temperature.(In lower temperature, it becomes longer.)

(3) Brightness depends on the temperature. (In lower temperature, it becomes lower.)

And in lower temperature, response time(required time that brightness is stable after turned on)

becomes longer

(4) Be careful for condensation at sudden temperature change.Condensation makes damage to polarizer or

electrical contacted parts. And after fading condensation, smear or spot will occur.

(5) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(6) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall be

done by system manufacturers. Grounding and shielding methods may be important to minimized the

interference.

(7) Please do not give any mechanical and/or acoustical impact to LCM. Otherwise, LCM can’t be operated

its full characteristics perfectly.

(8) A screw which is fastened up the steels should be a machine screw.

(if not, it can causes conductive particles and deal LCM a fatal blow)

(9) Please do not set LCD on its edge.

(10) The conductive material and signal cables are kept away from LED driver inductor to prevent abnormal

display, sound noise and temperature rising.

Ver. 0.1

26 /31

LC370EUA

Engineering Specification

8-3. Electrostatic Disch arge Co ntr ol

Since a module is composed of electronic circuits, it is not strong to electrostatic discharge. Make certain that

treatment persons are connected to ground through wrist band etc. And don’t touch interface pin directly.

8-4. Precautions for Strong Light Exposure

Strong light exposure causes degradation of polarizer and color filter.

8-5. Storage

When storing modules as spares for a long time, the following precautions are necessary.

(1) Store them in a dark place. Do not expose the module to sunlight or fluorescent light. Keep the temperature

between 5°C and 35°C at normal humidity.

(2) The polarizer surface should not come in contact with any other object.

It is recommended that they be stored in the container in which they were shipped.

(3) Storage condition is guaranteed under packing conditions.

(4) The phase transition of Liquid Crystal could be recovered if the LCM is released at the normal condition

after the low or over the storage temperature.

8-6. Handling Precautions for Protection Film

(1) The protection film is attached to the bezel with a small masking tape.

When the protection film is peeled off, static electricity is generated between the film and polarizer.

This should be peeled off slowly and carefully by people who are electrically grounded and with well ion-

blown equipment or in such a condition, etc.

(2) When the module with protection film attached is stored for a long time, sometimes there remains a very

small amount of glue still on the bezel after the protection film is peeled off.

(3) You can remove the glue easily. When the glue remains on the bezel surface or its vestige is recognized,

please wipe them off with absorbent cotton waste or other soft material like chamois soaked with normal-

hexane.

9-7. Operating condition guide

(1) The LCD product should be operated under normal conditions. Normal condition is defined as below;

- Temperature : 5 ~ 40 ℃

- Display pattern : continually changing pattern (Not stationary)

(2) If the product will be used in extreme conditions such as high temperature, display patterns or operation

time etc..,

It is strongly recommended to contact LGD for Qualification engineering advice. Otherwise, its reliability

and function may not be guaranteed. Extreme conditions are commonly found at Airports, Transit Stations,

Banks, Stock market, and Controlling systems. The LCD product should be applied by global standard

environment. (refer ETSI EN 300, IEC 60721)

Ver. 0.1

27 /31

# APPENDIX- I

■ LCM Label

Model

UL, TUV Mark

LGD Logo

LC370EUA

Engineering Specification

Serial No.

Origin

Ver. 0.1

28 /31

# APPENDIX- I I

■ LCM Source power sequence

< Source power sequence >

LC370EUA

Engineering Specification

- Input Signal : SOE,POL,GSP,H_CONV,OPT_N

Ver. 0.1

29 /31

Loading...

Loading...