LG ARNH963K2A2, ARNH763K3B2, MULTI V ARNH963K2A2, MULTI V ARNH763K3B2 Installation Manual

Hydro Kit Medium Temperature (K2)

Hydro Kit High Temperature (K3)

Installation Manual

Hydro Kit Medium Temperature (K2)

Btu/h 107,500

Hydro Kit High Temperature (K3)

Btu/h 86,000

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information, and

other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc., only in confidence.

This document is for design purposes only.

Do not throw away, destroy, or lose this manual.

Please read carefully and store in a safe place for future reference.

Content familiarity required for proper installation.

The instructions included in this manual must be followed to prevent product malfunction, property damage, injury, or death to the user or

other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the

symbols described below.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in death, serious injury, property

damage or equipment damage.

This symbol indicates additional helpful information such as an explanation, a comment, or a clarication about the subject.

This symbol indicates a tip or recommendation.

Recommendations instruct the user to apply the suggested practice to ensure the best operating results in order to achieve the

maximum benet of the product.

Tips contain practical information that may help the user solve a problem or describe actions that may save time.

For more technical materials such as submittals, engineering

databooks, and catalogs, visit www.lg-vrf.com.

VRF-IM-BT-001-US_014A06

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

This document, as well as all reports, illustrations, data, information, and other materials are the property of LG Electronics U.S.A., Inc.

©LG Electronics U.S.A., Inc.

TABLE OF CONTENTS

SAFETY PRECAUTIONS ....................................................................... 5

Roughing-In ......................................................................................... 5

Power Wiring and Communications Cabling ....................................... 6

Installation ........................................................................................... 7

Wiring Precautions .............................................................................. 7

Operation and Maintenance ................................................................ 8

INTRODUCTION ..................................................................................... 9

Nomenclature ....................................................................................... 10

Unit Features .........................................................................................11

Parts ...................................................................................................... 13

Installation Parts ................................................................................ 13

Optional Accessories ......................................................................... 13

Specications ...................................................................................... 14

Dimensions .......................................................................................... 15

Wiring ................................................................................................... 17

ROUGHING-IN ...................................................................................... 19

Unpack the Indoor Unit / Inspect for Freight Damage ..................... 19

Receiving / Transportation / Storage ................................................. 21

General Mounting / Anchoring ........................................................... 22

Hydro Kit Wall Mounted Controller .................................................... 23

Piping .................................................................................................... 24

Refrigerant Piping ............................................................................... 26

Water Piping ......................................................................................... 27

Strainer Installation ............................................................................ 30

Accessory Installation ................................................................... 41-53

Independent Power Module (K2 Only) .............................................. 41

Hydro Kit Medium Temperature (K2) Control Panel Layout 43

Hydro Kit High Temperature (K3) Control Panel Layout .................... 43

Terminating Group Controlled Hydro Kits .......................................... 46

PRE-COMMISSIONING ........................................................................ 54

Group Control Setup ........................................................................... 54

Plan the Multi V System Central Control Addresses Assignments 54

Hydro Kit/Indoor Unit Central Control Address Assignments 54

Hex Address Assignment Limitations................................................. 54

Multi V System Central Controller Communications Limitations 54

Group Control Setup ........................................................................... 55

DIP Switch Setting - Hydro Kit Medium Temperature ...................... 56

DIP Switch Setting - Hydro Kit High Temperature ............................ 57

Installer Setting Conguration ........................................................... 58

Installer Setting Function Codes ....................................................... 59

Function Codes - Common Settings ................................................. 60

Function Codes - Hydro Kit Medium Temperature ........................... 62

Function Codes - Hydro Kit High Temperature ................................66

UNIT OPERATION ................................................................................ 70

Emergency Operation ......................................................................... 71

Maintenance ......................................................................................... 72

Seasonal (K2, K3) ................................................................................ 72

Hydro Kit Accessories ........................................................................ 73

Solar Heating System Piping .............................................................. 32

Solar Heating System Interface Kit (PHLLA) ..................................... 32

Water Piping Schematic ...................................................................... 33

Water Circuit Preparation ................................................................... 34

Power Wiring ........................................................................................ 35

Dry Contact Wiring .............................................................................. 36

Communications Cables ..................................................................... 37

LG Remote Temperature Sensor ....................................................... 40

FINISH UP ............................................................................................. 41

Troubleshooting .................................................................................. 75

Error Codes .......................................................................................... 76

Troubleshooting .................................................................................. 77

Finishing the Installation .................................................................... 79

Installation Checklist .......................................................................... 80

Device Conguration Worksheet ....................................................... 82

Who to Call for Assistance ................................................................. 83

3

MULTI V Hydro Kit Installation Manual

This page left intentionally blank.

Due to our policy of continuous product innovation, some specications may change without notication.

4

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SAFETY PRECAUTIONS

IMPORTANT!

•Please read this manual completely before installing the product.

•As an installer or service provider, it is your job to install or service the system to operate safety and efficiently. Improper installation, ad-

justment, alteration, service, or maintenance is dangerous to personnel and/or property and can void the warranty.

•Follow the instructions in this manual to prevent product malfunction, property damage, injury or death to the user or other people.

Incorrect operation due to ignoring any instructions will cause harm or damage.

•The level of seriousness is classified by the symbols described below.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in death or serious injury.

This symbol indicates additional helpful information such as an explanation, a comment, or a clarication about the subject.

This symbol indicates a tip or recommendation.

Recommendations instruct the user to apply the suggested practice to ensure the best operating results in order to achieve the

maximum benet of the product.

Tips contain practical information that may help the user solve a problem or describe actions that may save time.

Safety Precautions

Roughing-In

If the air conditioner is installed in a small space, take

measures to prevent the refrigerant concentration from

exceeding safety limits in the event of a refrigerant leak.

Consult the latest edition of ASHRAE (American Society of Heating,

Refrigerating, and Air Conditioning Engineers) Standard 15. If the

refrigerant leaks and safety limits are exceeded, it may result in personal

injuries or death from oxygen depletion.

Do not install, remove, or re-install the unit by yourself

(customer).

There is risk of re, electric shock, physical injury or death.

Ask the dealer or an authorized technician to install the unit.

Improper installation by the user may result in water leaks, re, electric

shock, physical injury or death.

For re-installation, always contact the dealer or an authorized

service provider.

There is risk of re, electric shock, physical injury or death.

Be very careful when transporting the unit.

• Indoor unit weight and size preclude one person carrying the unit.

Use two or more people to transport the unit without the assistance of mechanical transport equipment because there is a risk of

personal injury.

• Some products use polypropylene bands for packaging. Do not use

polypropylene bands to lift the unit.

• Suspend the water source unit from the base at specified positions.

Support the outdoor unit a minimum of four points to avoid slippage

from rigging apparatus.

Do not handle indoor units without the use of gloves and

protective clothing. The unit may have sharp edges.

There is a risk of personal injury.

Dispose the packing materials safely.

Destroy the structure of plastic packaging and boxes to prevent children

from playing with them. There is a risk of injury, suffocation and/or death

to humans, animals and wildlife.

Do not install the unit on an unstable structure.

It may result in the failure of the structure, property damage, equipment

damage, and/or personal injury or death.

Install the unit in a safe location where nobody can step on

or fall onto it.

There is risk of unit damage, physical injury or death.

R410A and R134a refrigerants create toxic gases when

burned. Do not store or use ammable products near the

unit.

There is risk of product failure, re, and physical injury or death.

Replace all control box and panel covers after completing

work.

Failure to do so may result in dust or water inltration, causing re, electric

shock, and physical injury or death.

Always wear safety glasses and work gloves when installing

the unit. A rapid release of R410A and R134a refrigerants may

cause frostbite.

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

5

SAFETY PRECAUTIONS

Roughing-In — Continued

Properly insulate all cold surfaces when installing this product.

Uninsulated cold surfaces may generate condensate that may drip and

cause water damage to wall and oors.

air conditioner to malfunction.

Install the unit considering the potential for earthquakes.

Improper installation may cause the unit to fall over, resulting in physical

injury or death.

This product is engineered to be used for comfort cooling /

heating. It is not to be used in applications that require

precision cooling or heating such as data centers, food

preservation, wine coolers, refrigeration and / or freezer

applications.

There is risk of property damage.

Provide eld-installed electrical isolation devices to protect

sensitive equipment sharing a power source with this product.

Provide sufcient protection against the effects of

electromagnetic elds (EMF) and electrical noise.

Inverter equipment, private power generators, high-frequency

medical equipment, or radio communication equipment may cause the

Power Wiring and Communications Cabling

The information contained in this manual is intended for use

by a qualied, experienced service technician who is familiar

with safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in this manual

may result in equipment malfunction, property damage, personal injury

or death.

Always use lock-out, tag-out procedures!

Ensure the electrical power is off and the disconnect is locked and tagged

prior to working on the Hydro Kit.

MULTI V Hydro Kit Installation Manual

All electric work must be performed by a licensed electrician

and conform to local building codes or, in the absence of local codes, with the National Electrical Code, and the instructions given in this manual.

If the power source capacity is inadequate or the electric work is not

performed properly, it may result in re, electric shock, physical injury or

death.

This equipment uses high voltage electricity. Only a qualied,

experienced electrician should wire this system. Never

assume that the electrical power has been disconnected.

Verify with a meter.

Failure to properly respect electricity, use industry best grounding practices, follow suggested wiring instructions, local, and NEC codes can lead

to electrical shock, physical injury, seizures, and death.

Do not install this product in a location that is noise

sensitive. Provide additional acoustical treatment as needed.

The risk is occupants may be discomforted.

Provide sufcient electrical system protection against

lighting strikes.

The risk is loss of warranty, product damage, and / or complete loss of

this product.

When installing refrigerant piping, consider pipe expansion.

Improper pipe installation may lead to pipe fatigue, failure, and a rapid

release of refrigerant, frostbite, suffocation, physical injury, and or death.

Use a properly sized circuit protective device. Using an undersized protective device will lead to equipment malfunction. In-

stalling an oversized protective device may cause burns, re,

and death.

There is risk of re, electric shock, explosion, physical injury or death.

Always ground the unit following local, state, and NEC codes.

There is risk of re, electric shock, and physical injury or death.

Do not use a eld-provided communications cable between

the Hydro Kit and the Hydro Kit Wall Mounted Controller. Use

only LG provided communications cable. Do not shorten,

modify, lengthen, or remove factory plug-able connectors

from the communications cable provided with the Hydro Kit

Wall Mounted Controller wiring kit.

Verify all power, ground, and communications wires and

cables are properly terminated before applying power to the

product. Securely tighten all wire terminations.

The product will malfunction.

Improper and/or loose wire and communications cable terminations may

cause product malfunction, re, physical injury or death.

Properly secure power wires and communications cables

at connectors, and provide slack in cable to eliminate wire

strain.

Inadequate connections may generate heat or cause a re and result in

physical injury or death.

Refer to local, state, and federal codes, and use power wires

of sufcient current capacity and rating.

Wires that are too small may generate heat and cause a re.

Due to our policy of continuous product innovation, some specications may change without notication.

6

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Turn power off at the unit disconnect before servicing.

Electrical shock can cause physical injury or death.

Installation

SAFETY PRECAUTIONS

Always use lock-out, tag-out procedures!

Ensure the electrical power is off and the disconnect is locked and tagged

prior to working on the Hydro Kit.

Verify the piping system has been properly evacuated

(<500 ppm), and the system’s refrigerant charge is correct

before commissioning and after any repair is made.

Improper system evacuated and/or an improper refrigerant charge may

cause product malfunction.

Do not install the units outside.

There is risk of re, electric shock, explosion, and physical injury or death.

Do not change the settings of the protection devices.

If the pressure switch, thermal switch, or other protection device is

shorted and forced to operate improperly, or parts other than those

specied by LG are used, there is risk of re, electric shock, explosion,

and physical injury or death.

Do not store or use ammable gas or combustibles near the

unit.

There is risk of product failure, re, explosion, and physical injury or death.

Replace all control box and panel covers.

If cover panels are not installed securely, dust, water and animals may

enter the outdoor unit, causing re, electric shock, and physical injury or

death.

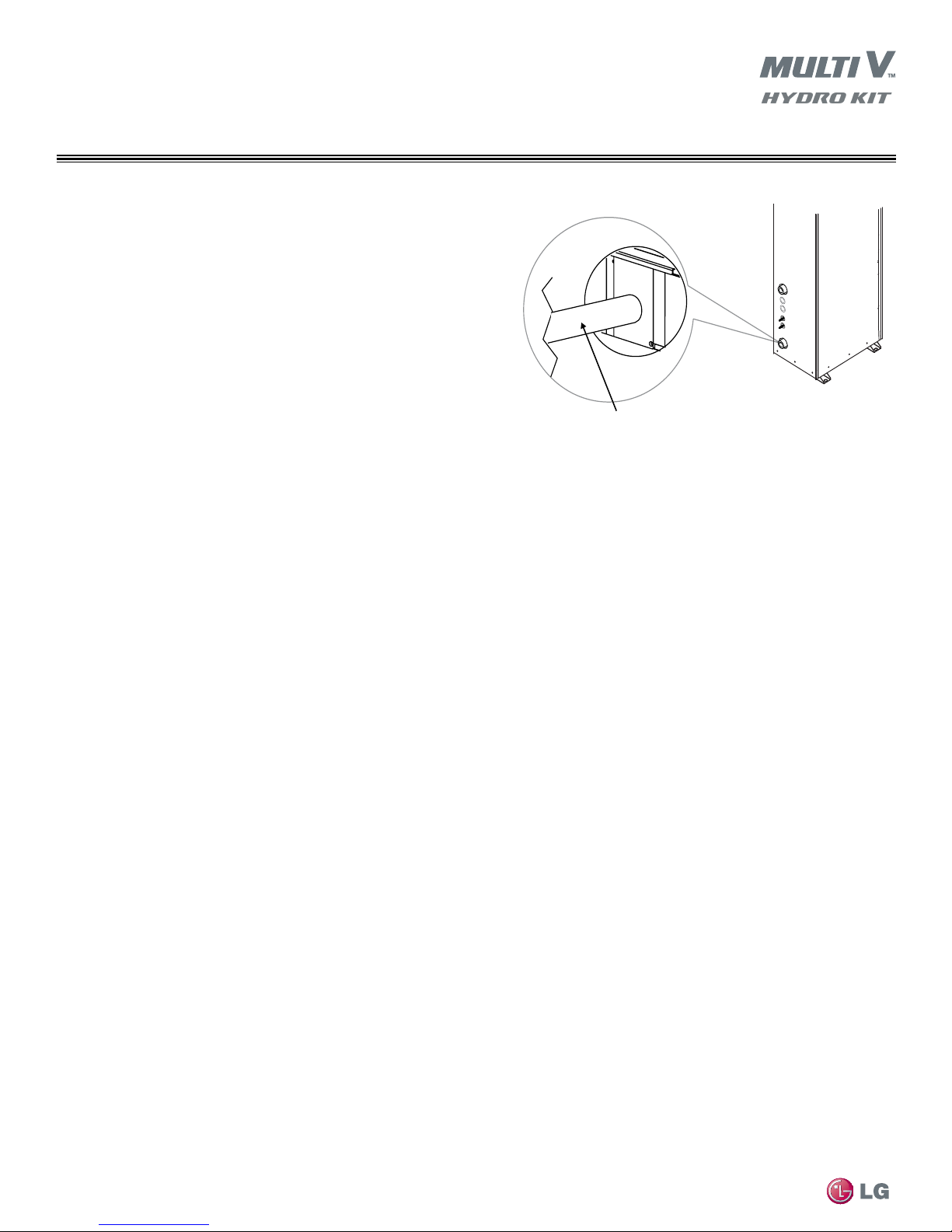

Hydro Kit High Temperature Water Heater (K3) must be kept

in an upright position during installation.

To avoid oil migration from the onboard compressor..

Do not make refrigerant substitutions. Use the refrigerant

listed on the nameplate of the unit.

If a different refrigerant is used, or air mixes with original refrigerant, the

unit will malfunction and be damaged.

Take appropriate actions at the end of HVAC equipment life

to recover, recycle, reclaim or destroy refrigerants

according to applicable U.S. Environmental Protection

Agency (EPA) rules.

Wiring Precautions

Turn the power off at the nearest disconnect before servicing

the equipment.

Electrical shock can cause physical injury or death.

Do not supply power to the unit until all electrical wiring,

controls wiring, piping, installation, and refrigerant system

evacuation are completed AND the commissioning agent has

authorized you to do so.

Safety Precautions

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Low refrigerant levels may cause product failure, and exposure to high

concentration levels of refrigerant gas may lead to illness or death.

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

7

SAFETY PRECAUTIONS

Operation and Maintenance

Do not allow water, dirt, or animals to enter the (Hydro Kit)

unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Do not provide power to or operate the unit if it is ooded or

submerged.

There is risk of re, electric shock, physical injury or death.

Do not operate the disconnect switch with wet hands.

There is risk of re, electric shock, physical injury or death.

Periodically verify the equipment mounts have not

deteriorated.

If the base collapses, the unit could fall and cause property damage, product failure, physical injury or death.

Do not touch the refrigerant piping during or after operation.

It can cause burns or frostbite.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

The rotating, hot, cold, and high-voltage parts of the unit can cause physical injury or death.

If a refrigerant gas leak is detected, leave the room!

Refrigerant gas in sufcient quantity in an enclosed area can cause suffocation and death. Obtain a properly maintained Self Contained Breathing Apparatus (SCBA) and training on how to use it before reentering the

area

For the High Temperature Heating Model (K3), turn on the

power at least six (6) hours before operation begins.

Starting operation immediately after turning on the main power switch can

result in severe damage to the compressor(s). Keep the power switch on

during the operational season.

Clean up the site after servicing is nished, and check that

no metal scraps, screws, or bits of wiring have been left

inside or surrounding the Hydro Kit.

MULTI V Hydro Kit Installation Manual

Due to our policy of continuous product innovation, some specications may change without notication.

8

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

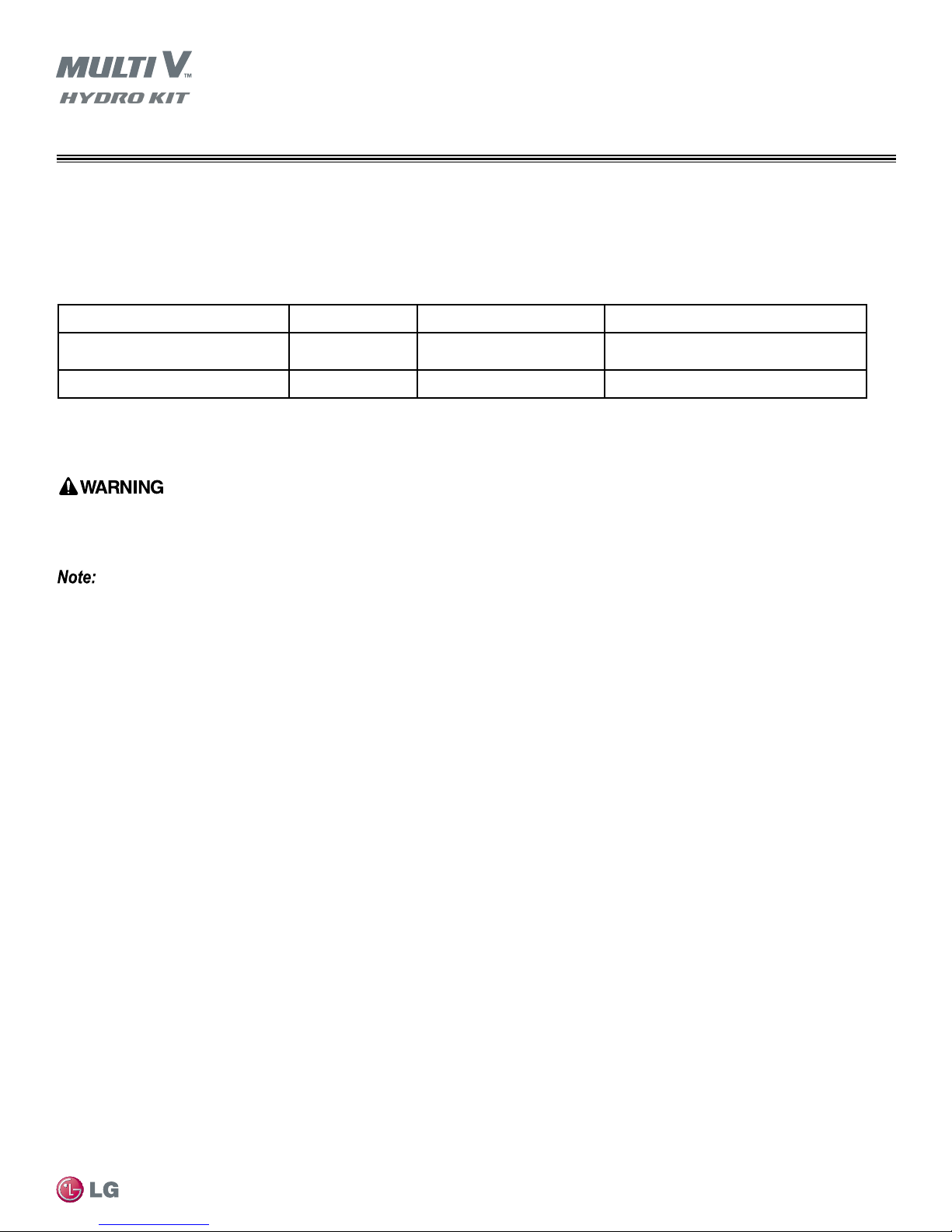

INTRODUCTION

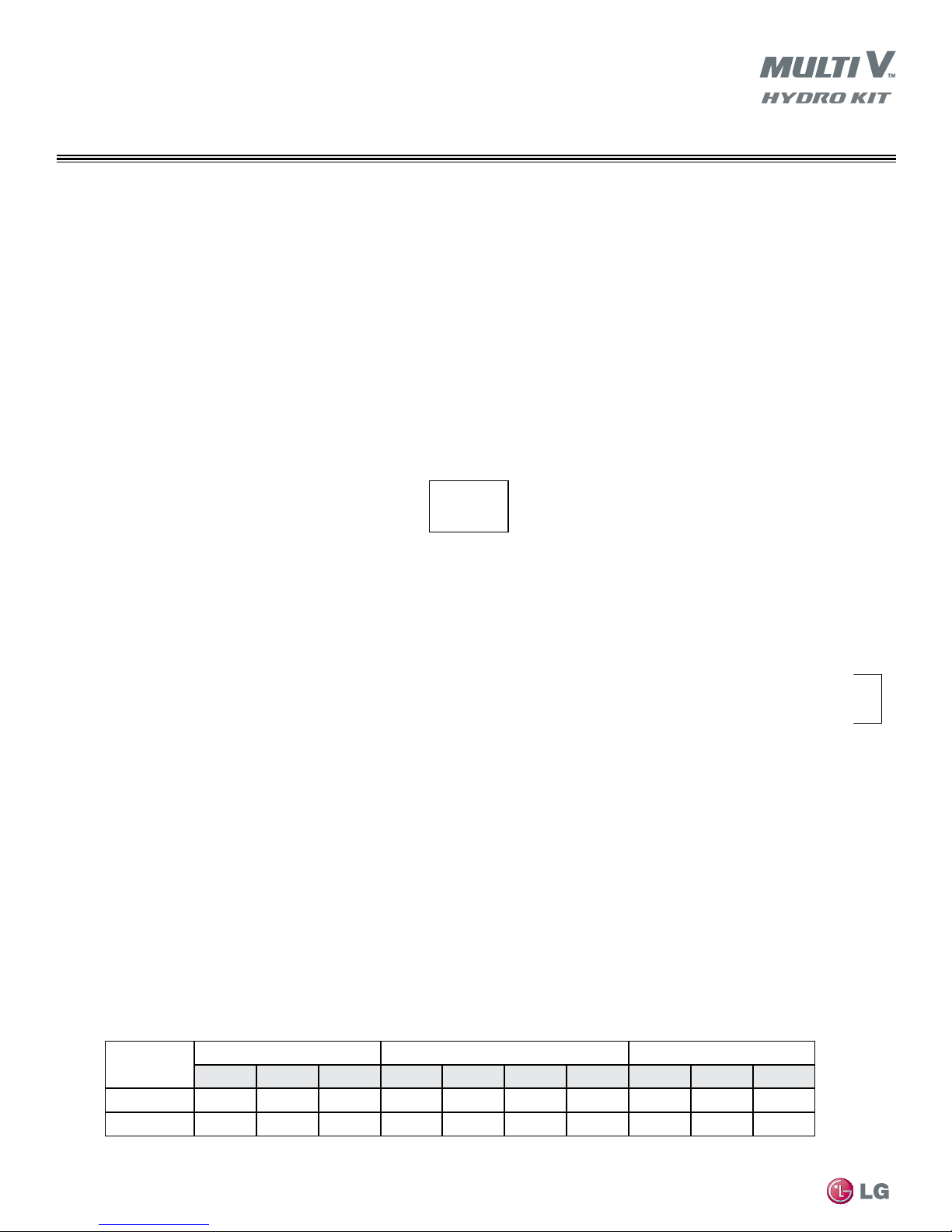

Hydro Kit Models

This manual describes how to install the Multi V™ Hydro Kit. The Hydro Kit is available in two models. Refer to Table 1 for model chassis,

model number and capacities.

Table 1: Hydro Kit Model Numbers and Capacities

Unit Chassis Name Model Number Capacity

Hydro Kit Medium Temperature K2 ARNH963K2A2

Hydro Kit High Temperature K3 ARNH763K3B2 Heating Only: 86,000 Btu/h

These units are to be used in conjunction with LG’s Multi V Variable Refrigerant Flow (VRF) Heating, and Air Conditioning system. Both units

operate on 208–230 V, 60 Hz, 1-phase power.

Install these unit(s) in the location(s) specied by your design engineer, HVAC system layout drawings and project specications. Perform the installation according to the procedures in this manual. Improper installation may result in injury to or death of personnel, equipment malfunction and/or

property damage.

Cooling: 95,900 Btu/h

Heating: 107,500 Btu/h

Introduction

More in-depth technical and performance information on these units is available in the Multi V™ Hydro Kit Engineering Manual available at

http://www.lg-vrf.com.

HydroKit Medium Temperature (K2)

HydroKit High Temperature (K3)

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

9

NOMENCLATURE

HydroKit Nomenclature

ARN H 96 3 K2 A

Family

ARN = Multi V Indoor Unit

(Refrigerant R410A)

Type

H = Hydro Kit

Nominal Capacity

(Total Heating Capacity in Btu/h)

96 = 107,500

76 = 86,000

Electrical Ratings

3 = 208–230V/60Hz/1Ph

Chassis

K2 = Hydro Kit Medium Temperature

K3 = Hydro Kit High Temperature

2

Combination of functions

A = Standard

MULTI V Hydro Kit Installation Manual

B = High Temperature Water Heater

Generation

2 = Second

Due to our policy of continuous product innovation, some specications may change without notication.

10

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

UNIT FEATURES

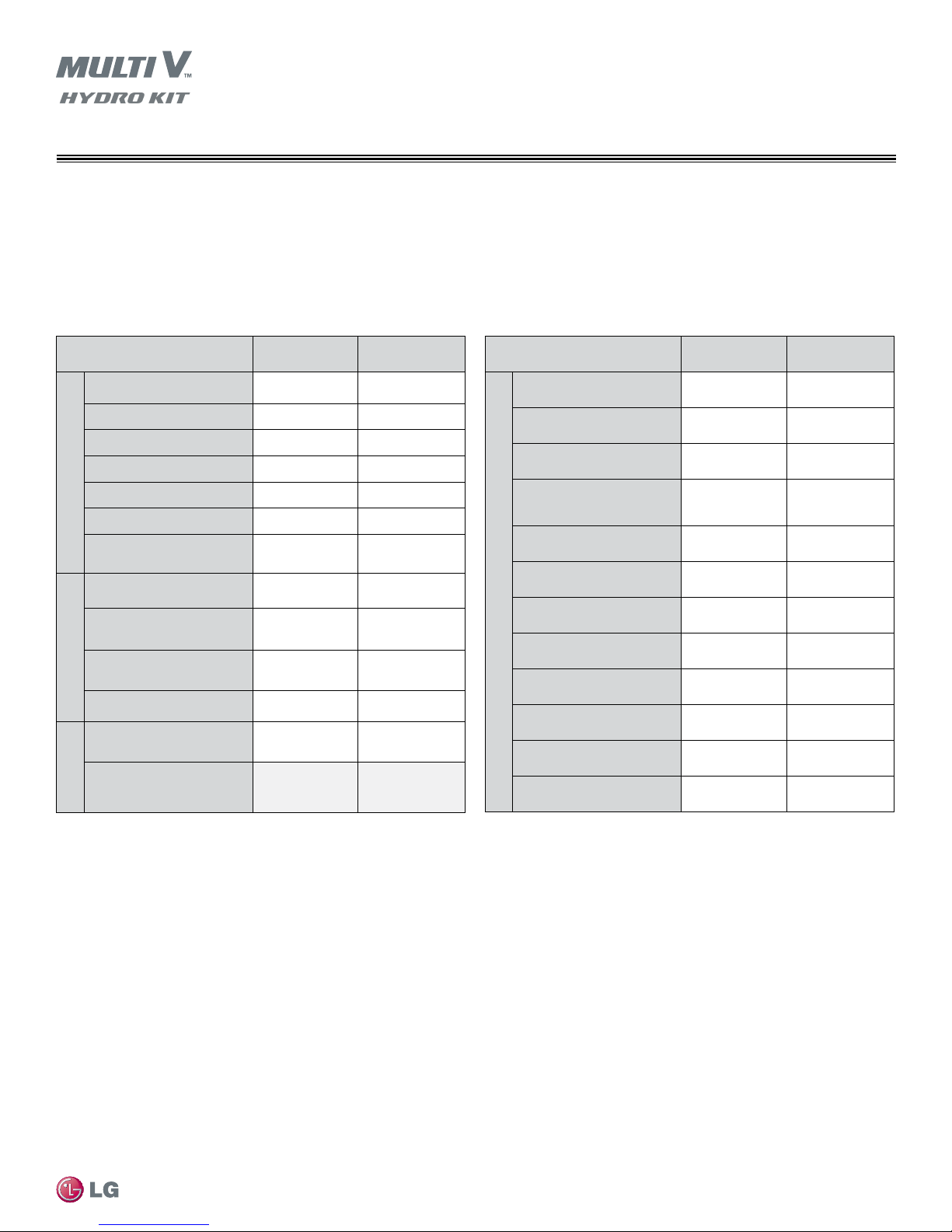

Table 2 compares main features of the two Hydro Kit models.

Hydro Kit Compatibility

The Hydro Kit is fully compatible with Multi V III, Multi V IV and Multi V Water IV units. The Hydro Kit is not compatible with Multi V Mini, Multi

V Plus II, Multi V Sync II, Multi V Space, Multi V Water II, Multi V Water Mini or any duct-free split products.

Table 2: Hydro Kit Product Features.

Features ARNH963K2A2 ARNH763K3B2

Self diagnosis

Auto Start

*Manual or Auto Restart

Child Lock

Group Control

Timer (on/off)

Controller Based Functions

Timer (weekly)

1

2

2

Hydro Kit Wall Mounted

Controller

Network Solution (LGAP)

Remote Enable/Disable via

LG Dry Contact

BMS Integration

Power Distribution

3

Indicator (PDI) Interface

Remote Temperature

Sensor

Solar Heating Circuit

Options

Interface

1

Hydro Kit models (i.e., K2 and K3 chassis) cannot be mixed within the same group. Each Hydro Kit unit group must be connected to the same outdoor unit.

1

√ √

√ √

√ √

√ √

√ √

X √

X √

√ √

√ √

PQDSB-1 PQDSB-1

X √

PQRSTA0 PQRSTA0

PHLLA X

Hydro Kit Based Functions

Features ARNH963K2A2 ARNH763K3B2

Hydronic Circuit Isolation

Water Pump ON/ OFF

Control

Factory Mounted Flow

Switch

√ X

√ √

√ √

Conventional line voltage

(208-230° v) Thermostat

√ √

Interface2

Conventional 24 vac

Thermostat Interface2

Conventional Mechanical

Thermostat Interface

1

Indirect Tank Water

Pre-Heating

3rd Party Solar Heating

System Flow Control

Storage Tank Heating

Operation Timer

Water Temperature Reset

Overheating Protection

Emergency Heating

Operation

√ X

√ √

√ √

√ X

√ √

√ √

√ √

√ √

Hydro Kit units within the same group must have the same DIP switch settings. The only DIP switch that can differ is the group control setting switch, where

one Hydro Kit will be the master and the remaining Hydro Kit units will be slaves.

2

Manual restart is not available when the Hydro Kit is configured for conditioned space control, using a conventional thermostat.

3

Sold separately and field installed.

KEY:

Introduction

√:Available

X: Not available

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

11

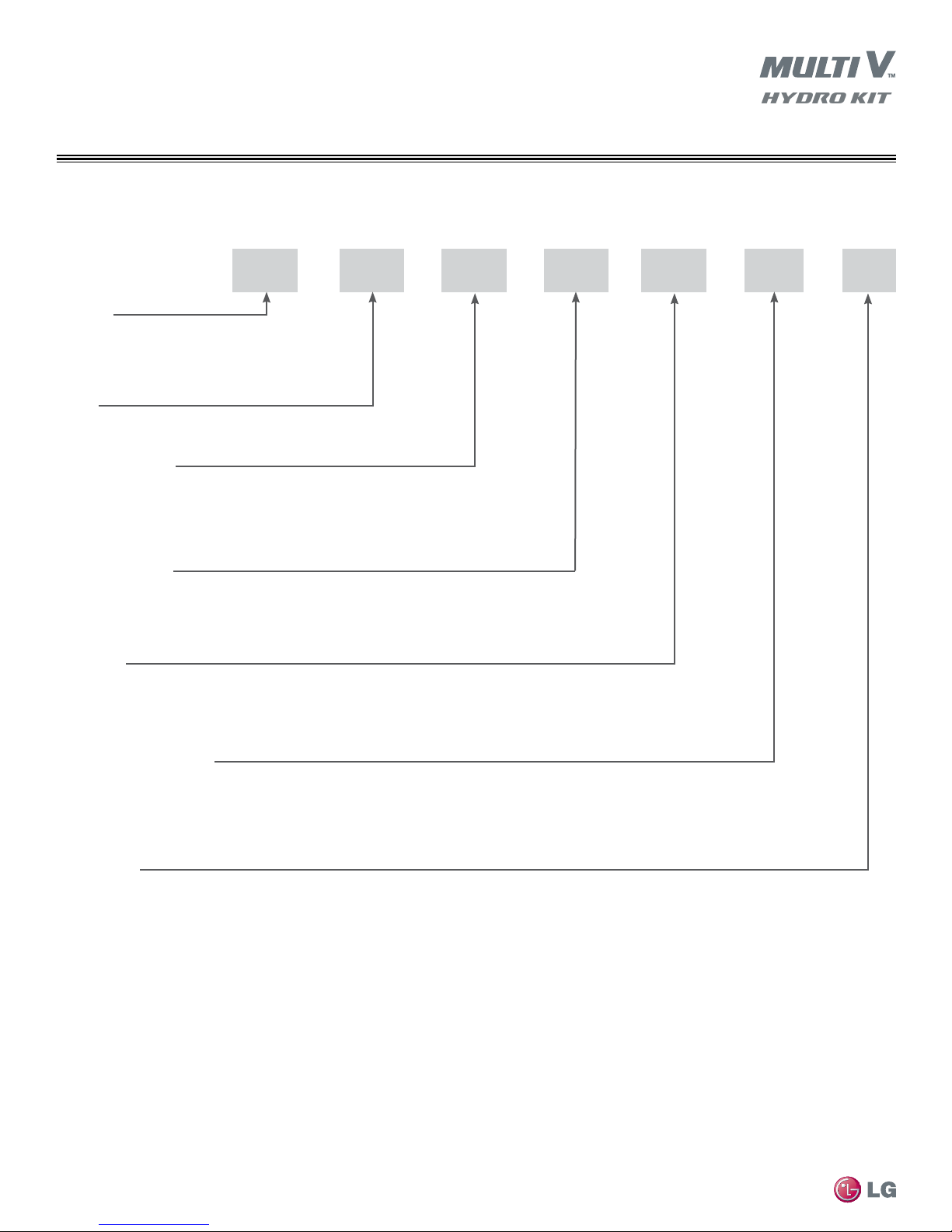

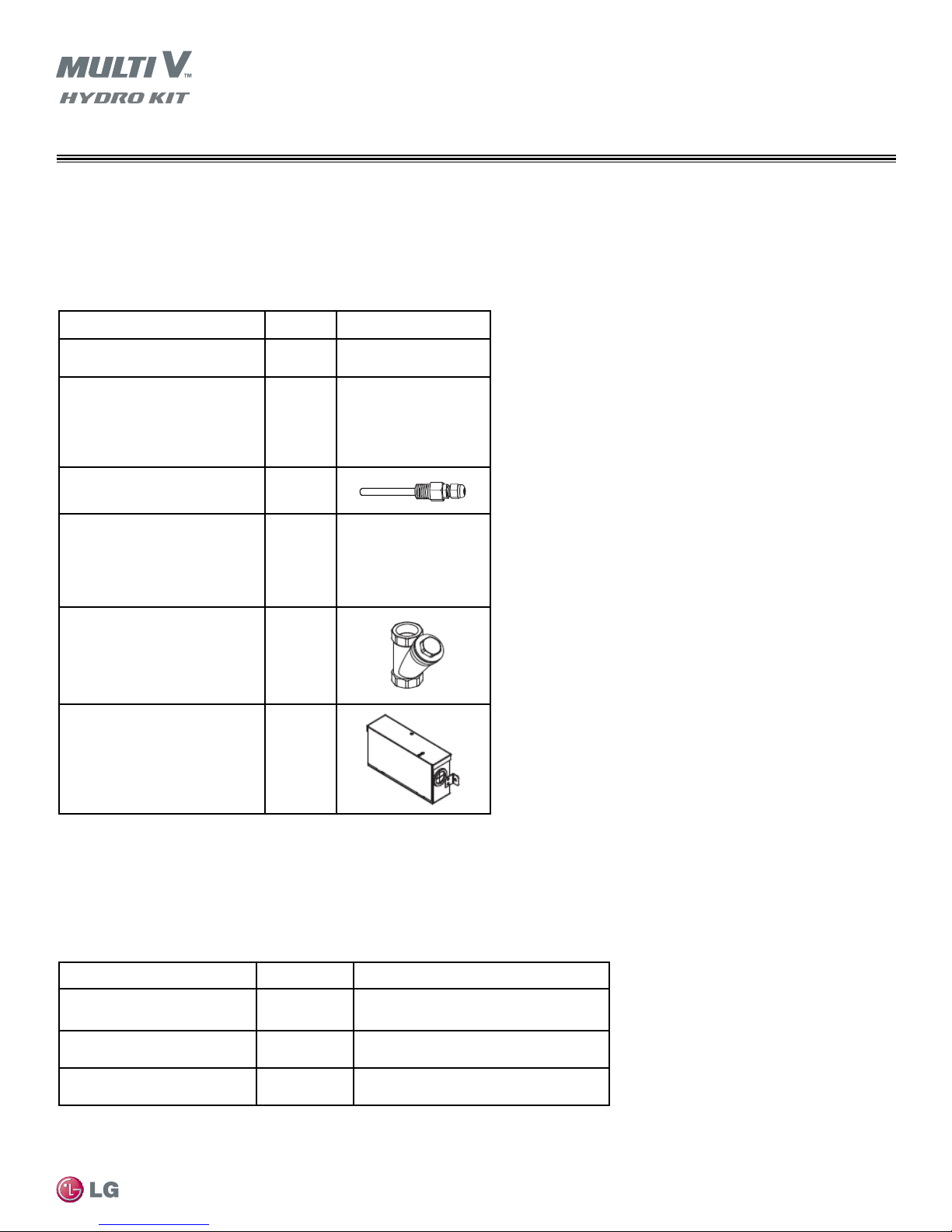

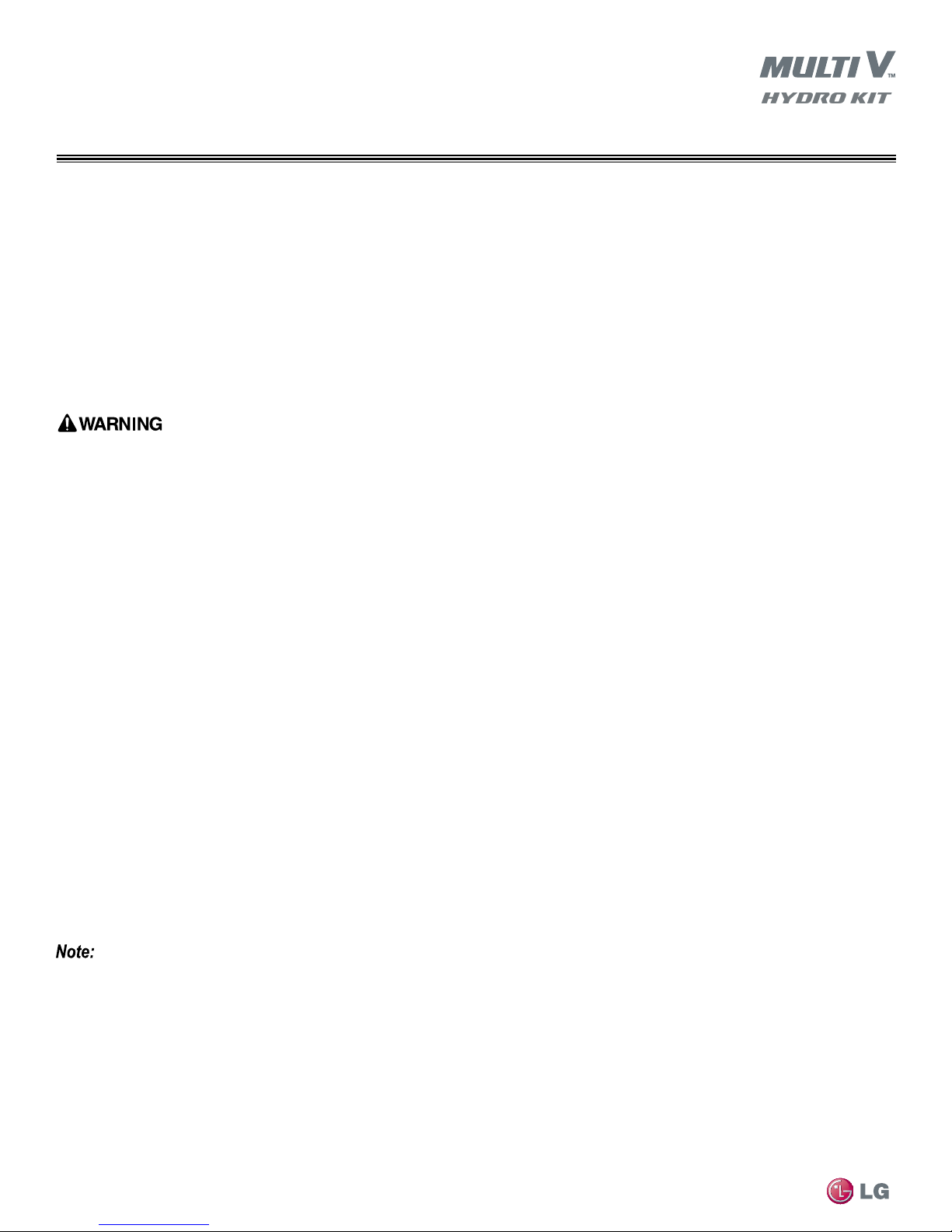

UNIT PIPE, WIRE AND CABLE

CONNECTION

The following diagrams display all piping and cable routing locations on the two chassis.

Hydro Kit Medium Temperature — K2

Power Wire Knock-out

Communication Cable Knock-out

Hydronic Circuit Water Outlet Connection

R-410a Low Pressure Vapor Pipe Connection

R-410a High Pressure Vapor

Liquid Pipe Connection

Condensate Drain Pipe

Hydronic Circuit Water Inlet Connection

Figure 1: Medium Temperature (K2) Unit Connections

Hydro Kit High Temperature — K3

MULTI V Hydro Kit Installation Manual

Heating Circuit Water Outlet Connection

Communication Cable Knock-out

Power Wire Knock-out

R-410a Low Pressure Vapor Pipe

R-410a High Pressure Liquid Pipe

Heating Circuit Water Inlet Connection

Figure 2: High Temperature (K3) Unit Connections

Due to our policy of continuous product innovation, some specications may change without notication.

12

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

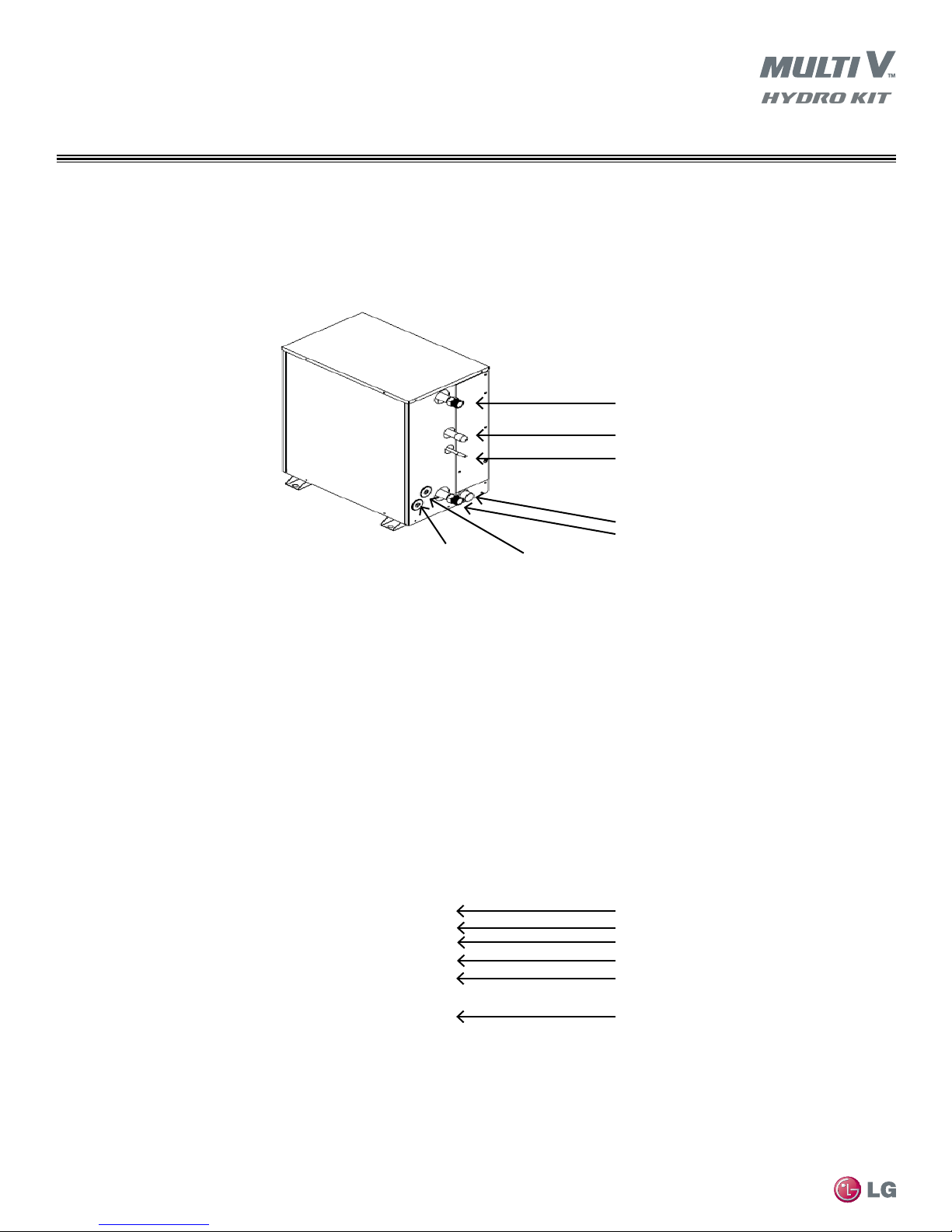

PARTS

Installation Parts

Table 3 lists installation parts for the K2 and K3 models of the Hydro Kit. Be sure all field-provided parts meet appropriate local and national

codes. Quantities are per each unit installed.

Table 3: Parts and Accessories Provided for each Hydro Kit

Part Quantity Part Image

Installation Manual (this manual) 1 n/a

Hydro Kit Remote Control Panel 1

Sensor Well 1

Indirect Hot Water Storage Tank

Sensor

Refrigerant Strainer 1

Independent Power Module 1

1

Optional Accessories

Table 4 lists additional optional accessories available through LG Electronics.

Table 4: Optional Accessories Available from LG Electronics

Part Model Description

Remote Wall Mounted Sensor PQRSTA0

Control via the Hydro Kit based on

conditioned space temperature.

Introduction

Dry Contact PQDSB-1 Binary closure- Remote Enable/Disable.

Solar Heating System

Interface Kit

PHLLA Solar heating system interface.

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

13

SPECIFICATIONS

Table 5 lists specifications for each Hydro Kit chassis (K2 and K3). Note that due to the functionality of each Hydro Kit some types of specs

will not be available on certain unit models.

Table 5: HydroKitSpecications

Type ARNH963K2A2 ARNH763K3B2

Power Supply (V/Hz/Ph) 208-230/60/1 208-230/60/1

Rated Cooling Capacity (Btu/h) 95,900 n/a

Rated Heating Capacity (Btu/h) 107,500 86,000

Nominal Dimensions W x D x H (In) 21 x 25 x 13 21 x 43 x 13

Net Weight (lbs) 78 208

Shipping Weight (lbs) 89 219

Type

Refrigerant

to Water Heat Exhanger

Water Pipe Connections

Refrigerant Pipe

Connections

Drain Connection 1” MPT 1” MPT

Multi V ODU Comm. Cable

(AWG -# Conductors, type)

Hydro Kit Wall Mounted Controller

Communication Cable

Internal Circuit

MULTI V Hydro Kit Installation Manual

Rated Water

Flow (GPM)

Pressure Drop (ft-wg) 23.1 7

Inlet Diameter 1” MPT 1” MPT

Outlet Diameter 1” MPT 1” MPT

Liquid ODU (in) 3/8 3/8

Vapor Gas ODU (in) 7/8 3/4

Refrigerant Type - R410A

Control Device - Electronic Expansion Valve

Brazed Plate Heat

Exchanger

24.3 9.5

18-2 stranded shielded 18-2 stranded shielded

Use LG supplied cable only Use LG supplied cable only

Brazed Plate Heat

Exchanger

Refrigerant Type R410A R134a

Multi V System

14

Refrigerant

Charge (lbs)

Control Device Electronic Expansion Valve Electronic Expansion Valve

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

- 6.6

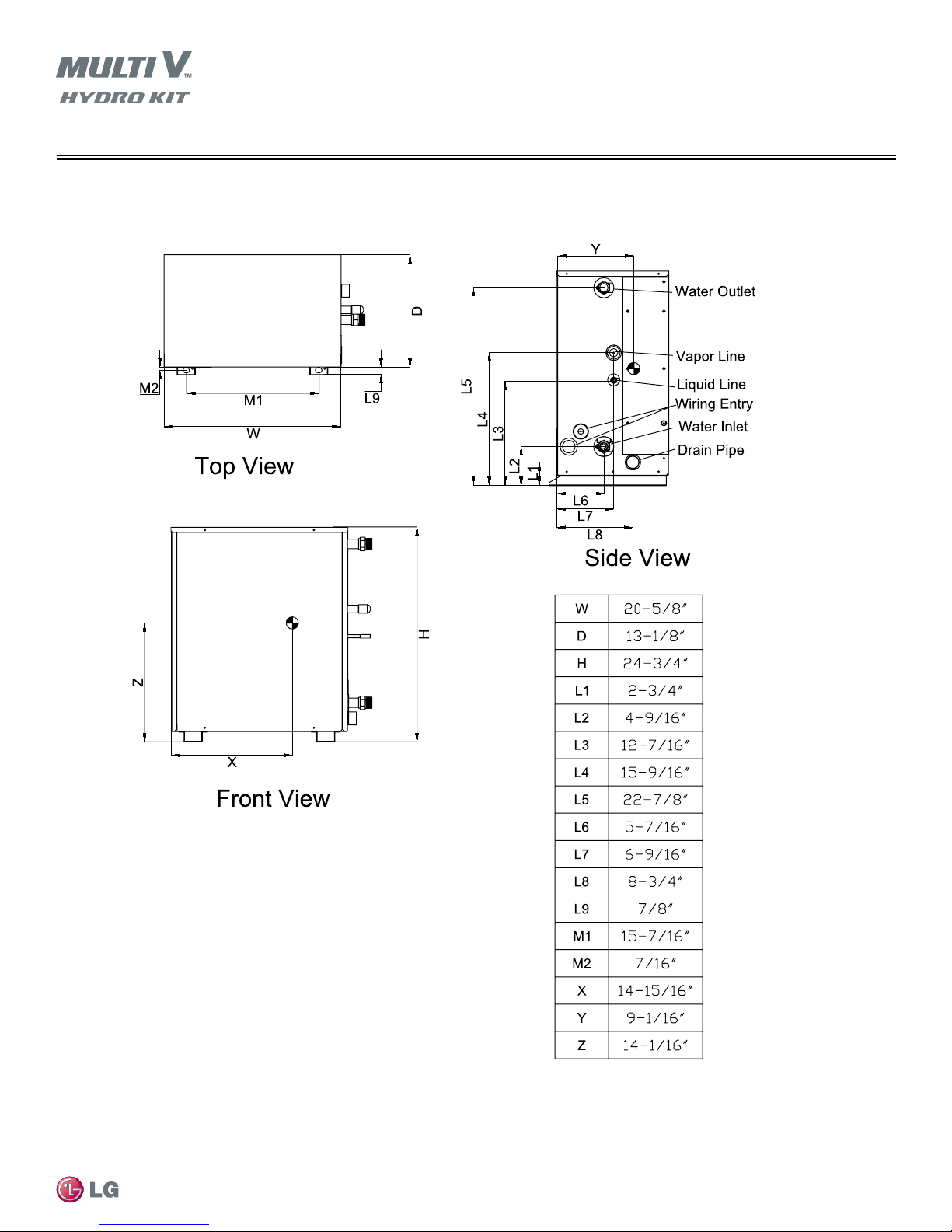

DIMENSIONS

Hydro Kit - K2

Figure 3 shows the dimensional diagram of the Hydro Kit Medium Temperature, along with piping and cabling information.

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 3: Dimensions for Hydro Kit — K2

15

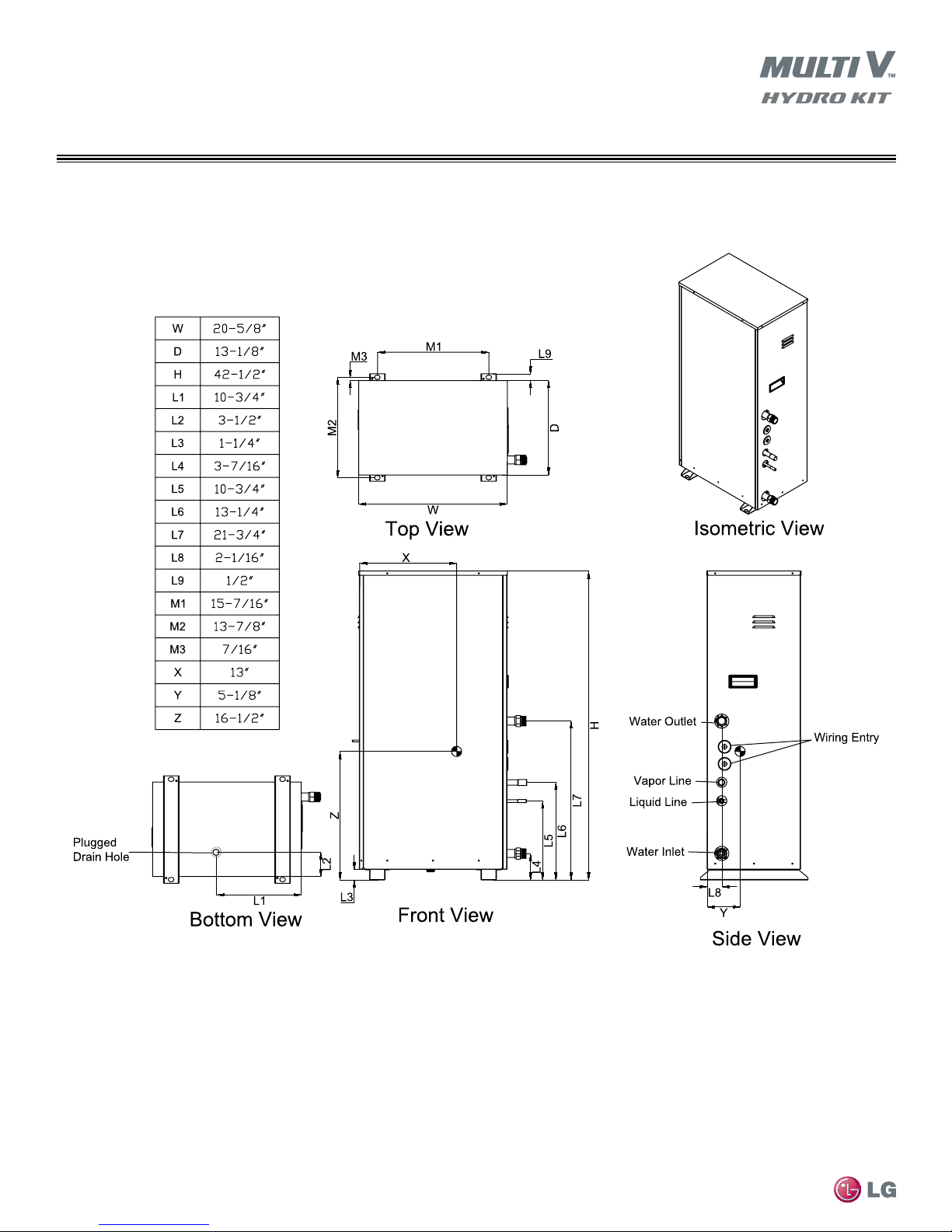

DIMENSIONS

Hydro Kit - K3

Figure 4 shows the dimensional diagram of the Hydro Kit High Temperature, along with piping and cabling information.

MULTI V Hydro Kit Installation Manual

Due to our policy of continuous product innovation, some specications may change without notication.

16

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 4: Dimensions for Hydro Kit (K3)

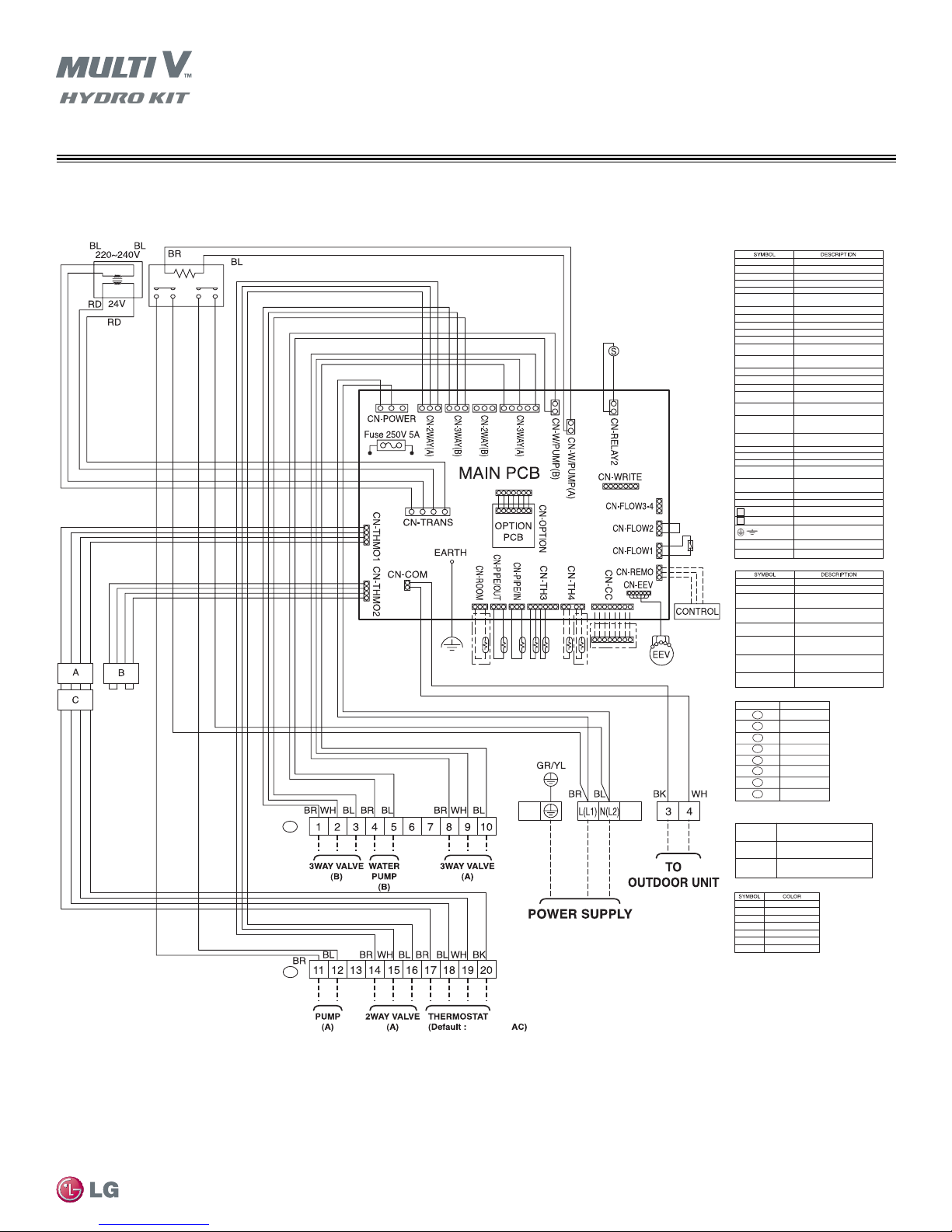

Figure 5 shows the wiring diagram for the Hydro Kit Medium Temperature.

(USE COPPER WIRE ONLY)

208-230V/60/1

208/230V

24V Transformer

Water Pump

Pilot Relay

A

B

*For 24V thermostat disconnect housting A and C then connect housing B and C

*

**

F

Sockets and Connections+

Wi

WH White

WIRING

Hydro Kit - K2

CN-2WAY (A)

CN-2WAY (B)

CN-3WAY (A)

CN-3WAY (B)

CN-CC

CN-COM

CN-EEV

CN-FLOW1

CN-FLOW2

CN-FLOW3-4

CN-OPTION

CN-PIPEIN

CN-PIPEOUT

CN-POWER

CN-REMO

CN-ROOM

CN-TH3(TOP/LEFT)

CN-TH3(BOTTOM/

CENTER)

CN-TH4(TOP)

CN-TH4(BOTTOM)

CN-THM01

CN-THM02

CN-TRANS

CN-W/PUMP (A)

CN-W/PUMP (B)

CN-WRITE

EARTH

L

N

To terminal strip B, screws 14, 15, 16

Not used

To terminal strip A, screws 8, 9, 10

To terminal strip A, screws 1, 2, 3

Optional LG Dry Contact connection

Multi V communication to outdoor or water

source unit

R410A EEV value

Factory mounted ow switch

Not used

Not used

Option card interface

Heat exchanger - refrigerant pipe in

temperature

Heat exchanger - refrigerant pipe out

temperature

AC power to PCB

Hydro Kit unit controller

LG Remote Temperature Sensor (optional)

Heat exchanger-inlet water temperature

sensor

Heat exchanger-outlet water temperature

sensor

Temperature sensor: Solar heating circuit

temperature sensor (optional)

Temperature sensor: Hot water storage tank

sensor (eld mounted)

3rd Party 208-230/60/1 thermostat (option)

3rd Party 24VAC thermostat (option)

24 Volt power to PCB

To terminal strip B, screws 11, 12: Solar

heating system circulating pump

To terminal strip A, screws 4,5: Solar heating

system circulating pump

Not used

Earth Ground

Line (+) power connection 208-230/60/1

Neutral (-) power connection 208-230/60/1

Ground

Thermistor

Fuse

ield Connections - LG Sourced Accessories

CN-ROOM

CN-REMO

CN-CC

CN-TH4 (TOP)

CN-TH4 (BOTTOM)

CN-EEV

CN-WRITE

CN-EEV/LOAD

Field Supplied Connections

TERMINAL STRIP SCREW TERMINALS

NOTE: If a 24 volt thermostat will be used, adjust wiring

harness conguration

Wire Harness A

Wire Harness B

Wire Harness C

LG remote temperature sensor (optional)

Remote mounted Hydro Kit unit controller

LG Dry Contact PCB interface (3rd party

binary signal enabe/disable

LG Solar Kit temperature sensor for

secondary heated water storage tank

LG provided hot water tank temperature

sensor

5-wire harness from power module accessory

CN-EEV/MAIN to CN-EEV on the Hydro Kit

MAIN PCB

Single wire from power module accessory

CN-EEV/MAIN to Hydro Kit MAIN PCB

CN-WRITE

Wire harness from power module accessory

to Hydro Kit EEV valve

A

1, 2, 3

A

4,5

A

6,7

A

8, 9, 10

B

11, 12

B

13

B

14, 15, 16

B

17, 18, 19, 20

PCB interface 208-230/60/1 or

mechanical conventional thermostat

PCB interface for 24VAC conventional

thermostat

Wire harness Plug C to conventional

thermostat terminals 18, 19, 20

re Color Legend

Black

BK

Blue

BL

BrownBR

GR Green

RD Red

Yellow

YL

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 5: Wiring for Hydro Kit (K2 Chassis)

17

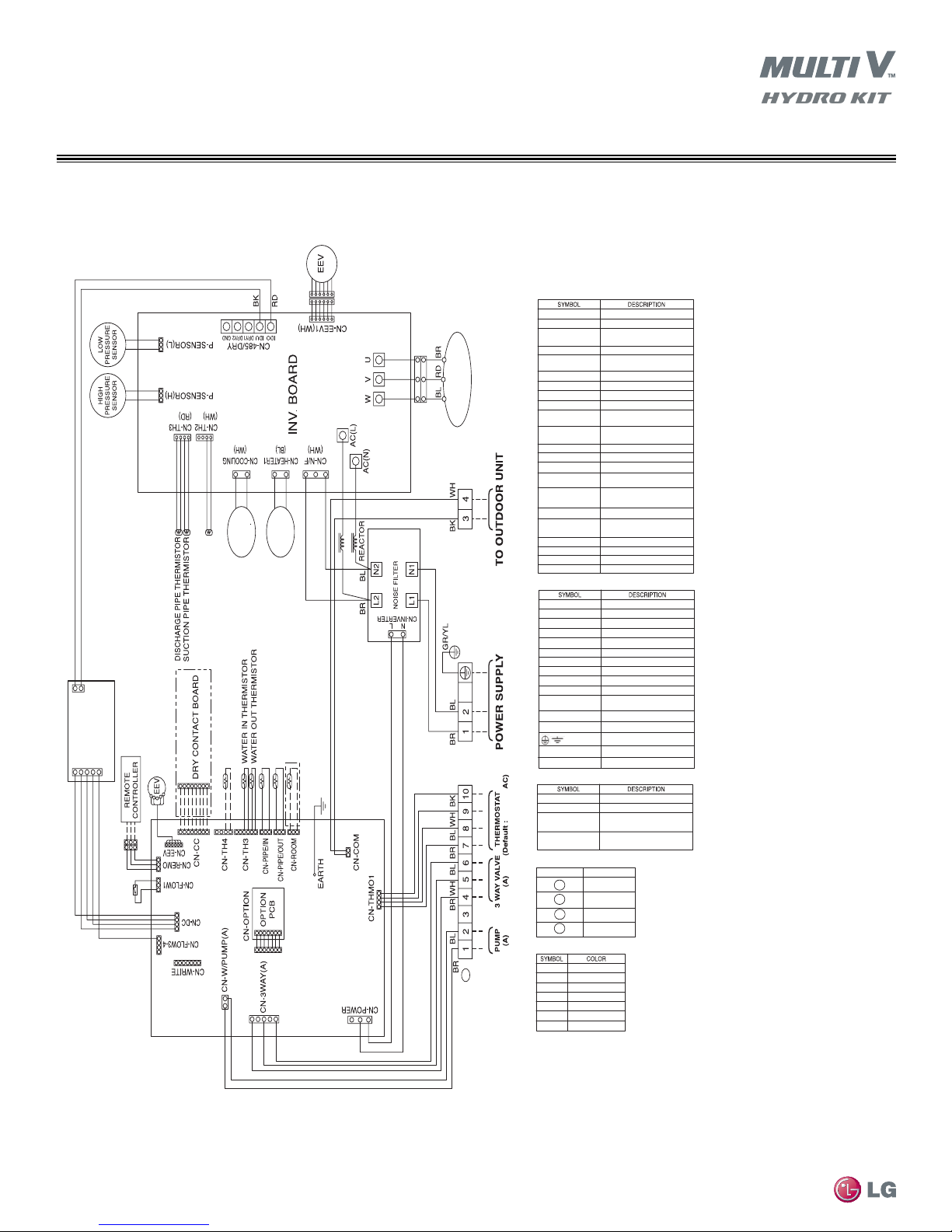

WIRING

(USE COPPER WIRE ONLY)

208-230/60/1

208/230V

R-134A Inverter

Compressor

RS 485

Communication Board

Crankcase

Heater

Inverter PCB

Cooling Fan

MAIN PCB

Field Connections - LG Sourced Accessories

Sockets and Connections - Main PCB

CN-3WAY (A)

CN-CC

CN-COM

CN-CC

CN-COM

CN-EEV

CN-FLOW1

To terminal strip A, screws 4,5,6

Optional LG Dry Contact connection

Multi V communication to outdoor or water

source unit

Optional LG Dry Contact connection

Multi V communication to outdoor or water

source unit

R410A EEV value

Factory mounted ow switch

CN-FLOW3-4

Power to RS-484 communications PCB

CN-OPTION

Option card interface

CN-PIPEIN

Heat exchanger - refrigerant pipe in

temperature

CN-PIPEOUT

Heat exchanger - refrigerant pipe out

temperature

CN-POWER

AC power to PCB

CN-REMO

Hydro Kit unit controller

CN-ROOM

LG Remote Temperature Sensor (optional)

CN-TH3(TOP/LEFT)

Heat exchanger-inlet water temperature

sensor

CN-TH3(BOTTOM/

CENTER)

Heat exchanger-outlet water temperature

sensor

CN-TH4(TOP)

Not used

CN-TH4(BOTTOM)

Hot water storage tank sensor (eld

mounted)

CN-THM01

To terminal strip A, screws 7,8,9,10

CN-WRITE

EARTH

Earth Ground

CN-DC

Communications link with inverter board

TERMINAL STRIP SCREW TERMINALS

A

A

A

A

1, 2

3

4,5,6

7,8, 9, 10

Field Supplied Connections

Wire Color Legend

BK

Black

BL

Blue

BrownBR

GR Green

RD Red

YL

Yellow

WH White

Not used

Sockets and Connections - Inverter and Other PCB’s

CN-COOLING

CN-Heater1

CN-N/F

AC (N)

AC (L)

W, U, V

CN-EEV1

Inverter PCB cooling fan

R134A compressor crankcase heater

Filtered power to inverter

Line power neutral

Line power 208-230/60/1

Inverter compressor connection

R134A circuit EEV

CN-485/DRY

Communications link

P-SENSOR (L)

Power to noise lter

P-SENSOR (H)

R134A high pressure sensor

CN-TH3

R134A compressor discharge pipe

thermistor

CN-TH2

R134A compressor suction pipe thermistor

CN-INVERTER

R134A low pressure sensor

Ground

Thermistor

Fuse

CN-ROOM

CN-REMO

CN-CC

CN-TH4 (BOTTOM)

LG remote temperature sensor (optional)

Remote mounted Hydro Kit Unit Controller

LG Dry Contact PCB interface (3rd party

binary signal enable/disable

Temperature sensor: Hot water storage tank

sensor (eld mounted)

A

Hydro Kit - K3

Figure 6 shows the wiring diagram for the High Temperature Heating Hydro Kit.

MULTI V Hydro Kit Installation Manual

Due to our policy of continuous product innovation, some specications may change without notication.

18

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 6: Wiring for Hydro Kit (K3 Chassis)

ROUGHING-IN

Unpack the Indoor Unit / Inspect for Freight Damage

Choose a location in the vicinity of the installation before removing the protective materials.

After opening, if the unit is damaged, repack the unit as it was shipped to you. RETAIN ALL PACKING MATERIALS. In general, freight damage claims

will be denied if the original packing materials are not retained for the claims adjustor to inspect. Call your supervisor on how to proceed with ling a

freight claim and to order a replacement unit.

1. Before opening, check the unit model number on the box. Verify it is the correct capacity, unit type and voltage. Refer to Nomenclature

Chart on page 10 of this manual.

2. Place the box on a solid surface right side up.

3. Cut the white reinforced nylon straps.

4. Open the top of the box and fold back all four flaps.

5. Remove the protective cardboard.

6. The walls and top panels are not attached to the bottom of the box. Lift the cardboard carton by the flaps and remove the box walls and

top and place it to the side.

7. Remove the moisture barrier plastic bonnet.

8. Check the unit nameplate data and model number. Verify the unit voltage, and capacities are correct before proceeding.

9. Remove and retain the installation manual. It is located under the unit, on top of the unit, or taped and inserted inside the unit cabinet.

10. Lift the unit (but not by refrigerant piping!) and inspect for freight damage. If damage is found, repack the unit as it was received in the

original container.

Installation

DO NOT lift the unit by the refrigerant piping. Use the hanger brackets or the unit case only to lift the unit. Damage to the piping components may occur.

Location Selection

Select a location for installing the unit where:

•The location is indoors in a conditioned space and protected from outdoor weather events.

•The mounting structure will support the weight of the unit(s), piping, and accessories.

•The unit is level.

•Space is allocated for heat exchanger maintenance and draining.

•Space is allocated for the connection of necessary piping.

•Proper electrical panel clearance requirements are satisfied.

•The unit is not exposed to steam, humid air, caustic, and/or acidic

chemical vapors such as but not limited to Chlorine or Muratic acid.

•Provide minimum maintenance clearance and electrical component service areas as shown in Figure 7

•Refer to Table 6 for clearance measurements specific to each chassis.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

19

Match Letter

Clearance Area to

Corresponding

Hydro Kit Chassis

K3 Chassis

ROUGHING-IN

Roughing-In the Hydro Kit Chassis

Figure 7: Minimum Clearance Areas Around Units

K2 Chassis

Match Letter

Clearance Area

to Corresponding

Hydro Kit Chassis

MULTI V Hydro Kit Installation Manual

Table 6: Hydro Kit Minimum Clearance Dimension in Inches

Hydro Kit

Chassis

K2 20-1/2 24 --- --- --- --- 13-1/2 8 25

K3 20-1/2 24 42-1/2 13-1/2 3-1/2 10-1/2 32 13-1/2 14 27

20

Maintenance Ventilation Piping / Heat Exchanger Pull

A B C E F G H I J K

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

ROUGHING-IN

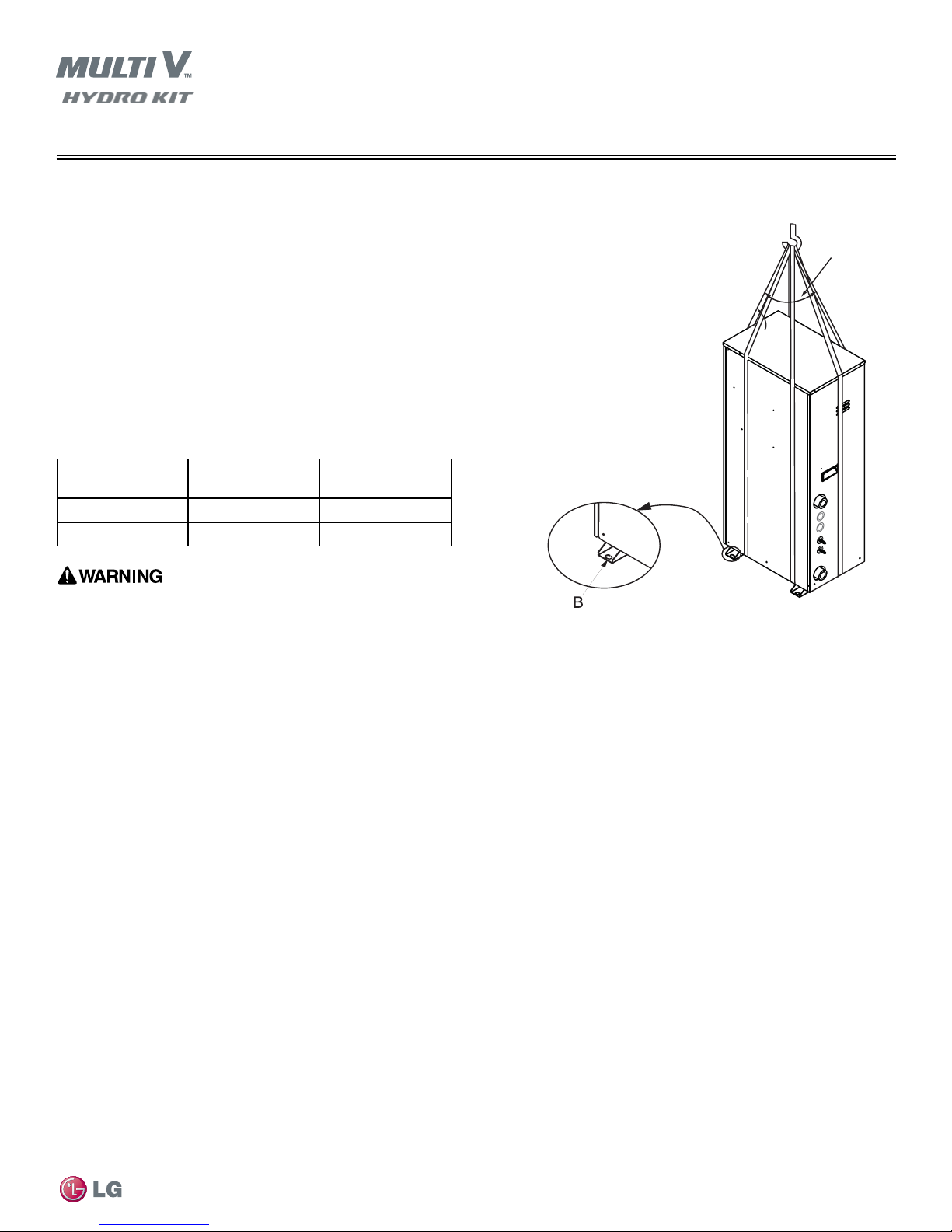

Receiving / Transportation / Storage

Transporting / Lifting

Figure 8: Proper Transportation of Unit

•Refer to Table 7 for accurate weights before transporting or lifting.

•When lifting the unit, use the lifting straps and place around the unit.

A

•Always lift the unit using properly sized lifting straps rated to carry the

unit weight.

•Ensure the straps are long enough to maintain a maximum of a 40°

angle as shown at “A” in Figure 8.

A

•Center of gravity information regarding each Hydro Kit unit can be

found on the dimensional drawings for the specific unit, on Figure 3

and Figure 4 of this installation manual.

A:

≤40°

B:

Mounting Rail

Table 7: Hydro Kit Chassis Net and Shipping Weights

Chassis Net Weight (lbs.) Shipping Weight

(lbs.)

ARNH963K2A2 78 89

ARNH763K3B2 208 219

• One person should not carry the product.

• Some products include polypropylene bands around the unit for packag-

ing. Do not use polypropylene bands to lift the unit.

• Tear apart and throw away plastic packaging bags so that children may not play with them and risk suffocation and death.

• Lift the water source unit from the base at specified locations. Support the water source unit at a minimum of six (6) points to avoid slip-

page from the rigging apparatus.

• Do not drop the unit when carrying it with a forklift.

• Use a minimum of three (3) lifting straps.

• Place a protective cloth or other soft material at the locations where the casing comes in contact with the lifting straps to prevent damage

to painted surfaces.

• Always know where the center of gravity of the water source unit is before lifting. Hoist the unit with the center of gravity centered among

the lifting straps.

• Use caution when using forklift to transport an unpackaged unit. Consider the unit’s center of gravity when lifting. Protect the painted

surfaces as necessary to prevent damage to the unit finish.

Installation

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

21

ROUGHING-IN

General Mounting / Anchoring

General Mounting

Securely attach the Hydro Kit to a concrete pad, base rails, or other mounting platform anchored to the building structure.

Avoid placing the unit in a low lying area where water may accumulate. Refer to dimensional drawing on page 15 and on page 16 of this

manual, and follow the applicable local code for clearance, mounting, anchor, and vibration attenuation requirements.

Place rubber isolation pads between the mounting feet and the base. Secure the feet to the base using washers and nuts. Fix the unit tightly

with bolts as shown below in Figure 9.

• When building a base support for the Hydro Kit, ensure that the floor surface / location has enough strength to support the weight of the unit,

enough space for pipes and wiring, the condensate drain connection, and the floor drain.

• Install the Hydro Kit to a base and in a manner approved by the structural engineer to minimize damage to the unit in the event of an earth-

quake. Any deficiency in installation may cause unit to fall, resulting in physical injury or death.

Anchoring the Hydro Kit Unit

Figure 9 shows the proper location and mounting of the anchor bolts for the Hydro Kit.

Figure 9: Location of the Anchor Bolts

15-1/4

Front

MULTI V Hydro Kit Installation Manual

Plan View

Guidelines

• Securely fasten all four (4) corners to the supporting base.

• If not otherwise directed by the structural engineer or local codes,

Use a 7/16 inch or 1/2 inch diameter J-bolt. Use a hexagon nut with

a spring washer.

• Include anti-vibration material chosen by the acoustics engineer.

• Include enough space for refrigerant piping and electrical wiring

when installing through the bottom of the unit.

• Use an H-beam, concrete support, or other acceptable support

structure designed by a structural engineer.

• All referenced materials are to be field-supplied. Images are not to

scale, are for reference only, and are not intended to be used for design

purposes.

• Always install per mounting instruction and detail provided by the

design or structural engineer.

13-15/16

Unit: Inch

Location of the

anchor bolts

Concrete

Base

Unit: Inch

Anti-vibration

Material

3

Side View

Unit: Inch

Three Threads

Four Bolts

Required

8

Due to our policy of continuous product innovation, some specifications may change without notification.

22

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

ROUGHING-IN

Hydro Kit Wall Mounted Controller

Drip Pan (Optional and Field Supplied)

Depending on the location of the unit an optional drip pan may be necessary underneath the unit. The K2 unit creates condensate and has a

1.0” MPT condensate pipe connection on the right side. The K3 High Temperature Heating model does not create condensate. All cold sur-

faces are insulated from the factory. However, the unit is equipped with a base pan drain hole. This hole is provided to drain water that may

enter the unit during maintenance and service.

Roughing-In the Hydro Kit Unit Controller

• It may be necessary to use a handy box that is sized in metric units, depending on the controller model. Check the mounting hole pattern

and dimensions on of the Hydro Kit Unit Controller subbase before selecting a handy box.

• Use only LG-supplied communications cable. Using field-supplied cable may result in communications problems between the Hydro Kit

Unit Controller and the Hydro Kit unit.

• DO NOT cut the quick-connect plugs off or adjust the length of the cable.

• Keep the communications cable away from high voltage wires and electromagnetic field (EMF) producing equipment.

• Do not route power wiring and communications cables in the same conduit.

• Maintain the minimum distance required between the communications cable and power wiring. The minimum required space between

the two is dependent on the voltage of the power wiring. Refer to the appropriate Multi V Outdoor Unit Engineering Manual for minimum

distance specifications.

1. If the Hydro Kit’s water flow will be controlled by monitoring the conditioned space temperature, proper Hydro Kit operation depends

on the location of the wall mounted sensor or thermostat. A good location will protect the sensor/thermostat from direct sunlight and

local sources of water vapor, heated, and cooled air. If no mounting height was specified by the building designer, place the handy

box approximately fifty-five (55) inches above the finished floor if regulations of the American Disability Act (ADA) do not require a

lower mounting height.

2. Pull LG communications cable between the Hydro Kit controller handy box and the Hydro Kit unit. A 30 foot length of cable will be

found with the Hydro Kit Controller.

3. Store a minimal amount of cable in the handy box. Any additional cable should be coiled and stored near the Hydro Kit unit control

panel.

4. If additional cable length is needed, use a 39 foot LG Wired Remote Extension cable (Model No. PZCWRC-1).

5. If the cable between the Hydro Kit controller and the Hydro Kit unit is too long, do not cut the cable and shorten. Coil any spare communications cable, tie-wrap it, and leave it next to the indoor unit location.

Installation

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

23

ROUGHING-IN

Piping

Refrigerant Piping

Refrigerant Safety

ASHRAE Standards 15-2010 and 34-2010 offer guidelines that address refrigerant safety and the maximum allowable concentration of refrigerant in an occupied space. Refrigerant will dissipate into the atmosphere, but a certain volume of air is required for this to occur safely.

For R410A refrigerant, the maximum allowable concentration of refrigerant is twenty-six (26) lbs. per 1,000 cubic feet of an occupied space.

Buildings with twenty-four (24) hour occupancy allow half of that concentration.

ASHRAE Standards 15 and 34 assume that if a system develops a leak, its entire refrigerant charge will dump into the area where the leak

occurs. To meet ASHRAE Standards 15 and 34, calculate the refrigerant concentration that may occur in the smallest room volume on the

system, and compare the results to the maximum allowable concentration number.1 Also consult state and local codes in regards to refrigerant safety.

Verify that the maximum refrigerant concentration level in the space where the indoor unit will be mounted meets the concentration limit for the

application.

Cutting the Pipes

•Use the accessory piping kit or use pipes purchased locally

(Figure 10).

•Measure the distance between the indoor and outdoor units.

•Cut the pipes a little longer than the measured distance.

1

Removal of Burrs

•Completely remove all burrs from the cut cross section of pipe/tube

(Figure 11).

MULTI V Hydro Kit Installation Manual

•Be sure the end of the copper tubing is pointed downward (toward

the floor) as you remove burrs. This will prevent the burrs from

falling back into the tubing.

Pipe Brazing

Make sure to flow Nitrogen during brazing. If brazing is done without

owing Nitrogen, it can generate a thick oxidized coating within the pipe

which will interfere with the normal operation of valve and compressor

(Figure 12).

Figure 10: Cutting Pipes

Figure 11: Removing Burrs for Piping

Figure 12: Brazing Pipes

1

Information about ASHRAE Standard 15-2010 / 34-2010 and addenda current as of the date of this publication.

Due to our policy of continuous product innovation, some specifications may change without notification.

24

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

No Clearance

Insulation for Indoor Unit Port

Gas pipe 5/8 inch

Liquid pipe 3/8 inch

Gas pipe 7/8 inch

Liquid pipe 3/8 inch

Figure 13: Heat Recovery - Refrigerant Pipe Connections

ROUGHING-IN

Pipe Insulation

Heat Recovery System Unit

Refrigerant Pipe Connections

•When connected to a Heat Recovery Unit, the Hydro Kit requires

the use of two ports. If the capacity of the Hydro Kit and other

IDU’s connected to the Heat Recovery Unit are similar, install the

Hydro Kit on Ports 1 & 2.

•When twinning ports, the “twinned” pipes must be the same diam-

eter, layout, and length to balance the flow between the two

(Figure 13).

Hydro kit

Refrigerant Piping Support

A properly installed pipe system will have sufficient support so that

pipes will not sag during the life of the system. As necessary, place

supports looser for segments where potential sagging could occur.

Maximum spacing of pipe supports shall meet local codes

(Figure 14).

Pipe Insulation

To prevent condensate from forming on the surface of the insulation,

calculate the proper wall thickness required based on the ambient air

conditions of the surrounding area. Use calculation procedures provided

by the pipe insulation manufacturer.

•Use insulation material with high thermal resistance and rated

for the anticipated operating temperature range. If installing in a

humid environment, use thicker insulation material as specified by

system designer.

•Insulate all cold surfaces to prevent moisture/condensate from

forming.

•Insulate and wrap each pipe separately.

•Use field-provided half (1/2) of an inch thick (or better) closed cell

insulation.

Figure 14: Refrigerant Piping Support

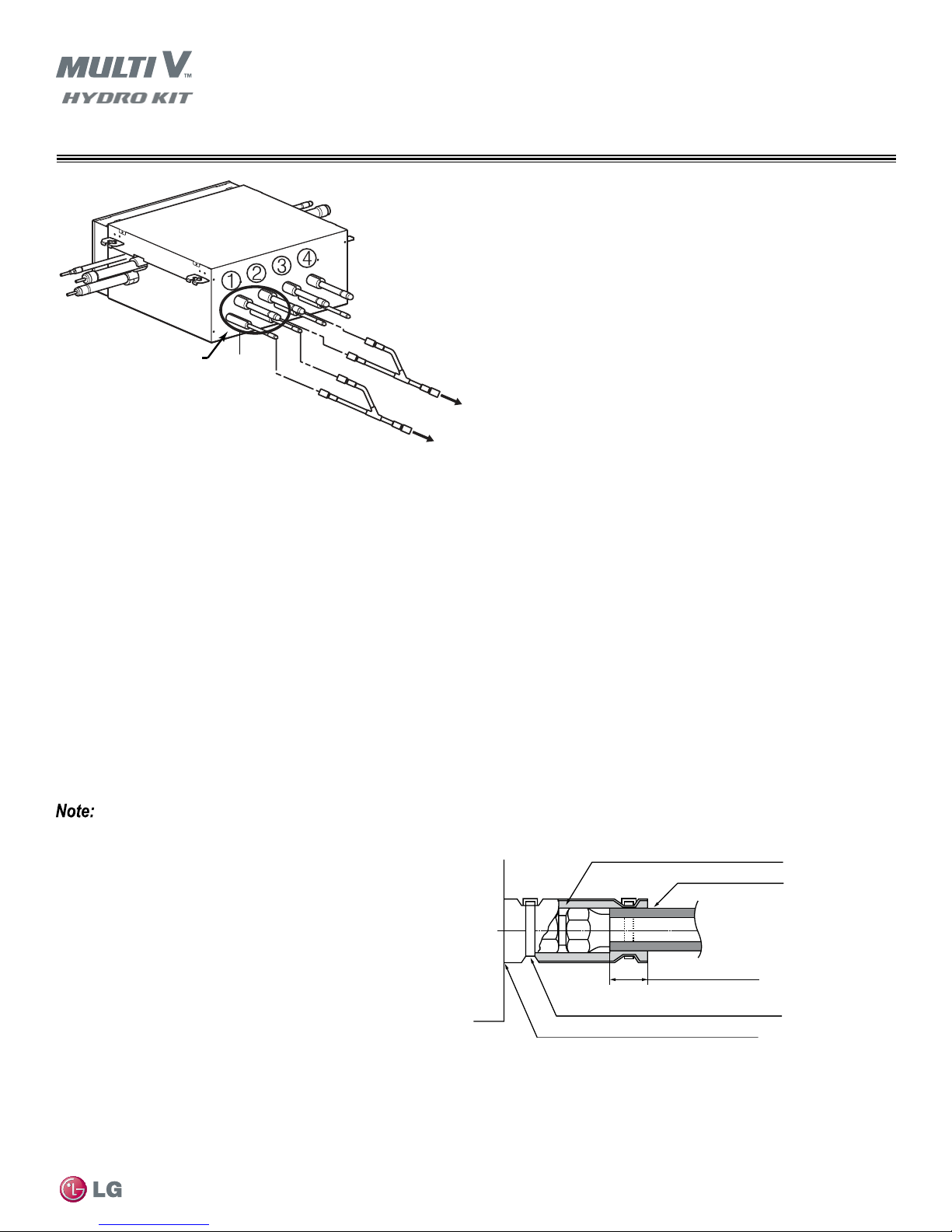

Typical Refrigerant Line Connection

(Field Supplied)

Insulation Clip (Field Supplied)

Figure 15: Typical Refrigerant Line Joint Insulation Detail

Insulation Detail

Insulation for Refrigerant

Piping (Field Supplied)

Overlap Insulation Where the

Port and the Piping Meet

Installation

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

25

ROUGHING-IN

Insulation over Pipe

Hydro Kit

Refrigerant Piping

Pipe Insulation - Continued

— The thickness may need to be increased based on ambient

conditions and local codes.

•Wrap all refrigerant and condensate piping, including field-provided

isolation ball valves and pipe connection kits provided by LG.

•Glue all insulation joints (see Figure 15).

— There should be no air gaps between insulation segments, or

between the insulation segments and the unit case.

— Fit insulation material snugly against refrigeration pipe. There

should be no air space between pipe surface and surrounding

insulation.

•Do not compress the insulation in areas where the piping passes

through pipe hangers, conduit, and/or wall sleeves.

— Protect insulation from compression inside hangers and sup-

ports by wrapping with a second layer.

Figure 16: Hydro Kit Pipe Insulation

Condensate Piping for Hydro Kit High Temperature (K3) Only

•The Hydro Kit condensate line connection is designed to be a gravity drain. If a condensate pump is required, it shall be field provided and

installed external to the unit case.

•Slope drain line a minimum of 1/4” per foot of horizontal run away from the unit case. Properly vent the condensate line per industry standard

practices. See Figure 17.

While making pipe connections, be careful to support pipe to avoid placing lateral force on the drain nipple. Internal damage may occur.

•Condensate pipe connection is 1” male pipe thread.

MULTI V Hydro Kit Installation Manual

Figure 17: Typicalcondensateline(eldprovided-nottoscale)

Due to our policy of continuous product innovation, some specifications may change without notification.

26

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

Loading...

Loading...