LG Multi V, ARNU073CEA4, ARNU093CEA4, ARNU123CEA4, ARNU153CEA4 Installation Manual

...

FLOOR-STANDING INDOOR UNIT

INSTALLATION MANUAL

GEN 4 Floor Standing Cased Models:

• ARNU073CEA4

• ARNU093CEA4

• ARNU123CEA4

• ARNU153CEA4

• ARNU183CFA4

• ARNU243CFA4

GEN 4 Floor Standing Uncased Models:

• ARNU073CEU4

• ARNU093CEU4

• ARNU123CEU4

• ARNU153CEU4

• ARNU183CFU4

• ARNU243CFU4

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information, and other

materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc., only in confidence.

Do not throw away, destroy, or lose this manual.

Please read carefully and store in a safe place for future reference.

Content familiarity required for proper installation.

The instructions included in this manual must be followed to prevent prod-

uct malfunction, property damage, injury, or death to the user or other

people. Incorrect operation due to ignoring any instructions will cause

harm or damage. A summary of safety precautions begins on page 4.

For more technical materials such as submittals, engineering

databooks, and catalogs, visit www.lghvac.com.

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

This document, as well as all reports, illustrations, data, information, and other materials are the property of LG Electronics U.S.A., Inc.

IM_MultiV_IV_FloorStanding_8_17

©LG Electronics U.S.A., Inc.

TABLE OF CONTENTS

CONTENTS

Proprietary Data Notice ................................................................................................................................... 2

Safety Instructions ........................................................................................................................................... 4

Introduction ...................................................................................................................................................... 8

Floor-Standing Indoor Units .......................................................................................................................................... 8

Safety ........................................................................................................................................................................... 8

Required Tools (eld provided) ..................................................................................................................................... 8

Required Parts (eld provided) ..................................................................................................................................... 8

Unit Nomenclature ......................................................................................................................................... 10

R410A Refrigerant ......................................................................................................................................... 11

General Data ................................................................................................................................................. 12

Specications ............................................................................................................................................................. 12

Dimensions ................................................................................................................................................................ 14

Electrical Data ............................................................................................................................................................ 16

Refrigerant Piping Diagram ........................................................................................................................................ 17

Installation Manual

General Installation Guidelines ...................................................................................................................... 18

Location Selection ...................................................................................................................................................... 18

Required Clearances .................................................................................................................................................. 19

Unpack and Inspect for Freight Damage .................................................................................................................... 19

Installation ..................................................................................................................................................... 20

Install Floor-Standing Units ........................................................................................................................................ 20

Refrigerant Piping .......................................................................................................................................... 21

Drilling the Piping Hole in the Wall .............................................................................................................................. 21

Piping Preparations .................................................................................................................................................... 21

Piping Materials and Handling .................................................................................................................................... 23

Refrigerant Safety ....................................................................................................................................................... 23

Brazing ....................................................................................................................................................................... 24

Refrigerant Piping Connections .................................................................................................................................. 25

Insulating the Piping ................................................................................................................................................... 25

Condensate Drain Piping ............................................................................................................................... 26

Install the Condensate Drain Pipe .............................................................................................................................. 26

Wiring ............................................................................................................................................................ 27

Connecting Power and Control Wiring ....................................................................................................................... 27

Indoor Unit Communications Cable Connections ....................................................................................................... 28

Communications and Power Cable Connection ......................................................................................................... 29

DIP Switch Settings for Gen4 Indoor Units ................................................................................................................. 30

Floor-Standing Cassette Cased and Uncased Chassis ............................................................................................ 31

Wall-Mounted Sensor Installation ............................................................................................................................... 33

Wall-Mounted Controller Installation ........................................................................................................................... 33

Controls Setup ............................................................................................................................................... 34

Installation Checklist ...................................................................................................................................... 38

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

SAFETY INSTRUCTIONS

WARNING

DANGER

WARNING

CAUTION

DANGER

The instructions below must be followed to prevent product malfunction, property damage, injury or death to the user or other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the symbols below.

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Note:

This symbol Indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

INSTALLATION

Don’t use or store ammable gas or combustibles near the unit.

There is risk of product failure, re, explosion, and physical injury or death.

Do not install, remove, or re-install the unit by yourself

(customer). Ask the dealer or an authorized technician to

install the unit.

Improper installation by the user may result in water leakage, re,

explosion, electric shock, physical injury or death.

For replacement of an installed unit, always contact a trained

Multi V Floor-Standing Indoor Unit

LG service provider.

There is risk of re, electric shock, explosion, and physical injury or death.

The outdoor unit is shipped with refrigerant and the service

valves closed.

all non-condensibles have been removed from the piping

system and authorization has been obtained from the commissioning agent.

There is a risk of physical injury or death.

Do not run the compressor with the service valves closed.

There is risk of explosion, physical injury, or death.

Periodically check that the outdoor unit is not damaged.

There is risk of explosion, physical injury, or death.

Replace all control box and panel covers.

If cover panels are not installed securely, dust, water and animals may

enter the unit, causing re, electric shock, and physical injury or death.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Exposure to high concentration levels of refrigerant gas may lead to

illness or death.

4

Do not open service valves on the unit until

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Do not install the unit using a defective stand.

There is risk of physical injury or death.

Wear protective gloves when handling equipment.

Sharp edges may cause personal injury.

Dispose the packing materials safely.

• Packing materials, such as nails and other metal or wooden parts

may cause puncture wounds or other injuries.

• Tear apart and throw away plastic packaging bags so that children

may not play with them and risk suffocation and death.

Do not install the unit in any location exposed to open

ame or extreme heat.

hands.

There is risk of re, electric shock, explosion, and physical injury or death.

Install the unit considering the potential for earthquakes.

Improper installation may cause the unit to fall, resulting in physical

injury or death.

Do not change the settings of the protection devices.

If the pressure switch, thermal switch, or other protection device is

shorted and forced to operate improperly, or parts other than those

specied by LG are used, there is risk of re, electric shock, explosion,

and physical injury or death.

If the air conditioner is installed in a small space, take measures to prevent the refrigerant concentration from exceeding safety limits in the event of a refrigerant leak.

Consult the latest edition of ASHRAE (American Society of Heating,

Refrigerating, and Air Conditioning Engineers) Standard 15. If the refrigerant leaks and safety limits are exceeded, it could result in personal

injuries or death from oxygen depletion

Do not touch the unit with wet

CAUTION

SAFETY INSTRUCTIONS

INSTALLATION – CONTINUED

Be very careful when transporting the product.

•

Do not attempt to carry the product without assistance.

• Some products use polypropylene bands for packaging.

• Suspend the unit from the base at specified positions.

• Support the unit a minimum of four points to avoid slippage from rigging apparatus.

Note:

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated pipe can generate condensate that may

drip and cause a slippery oor condition and/or water damage to walls.

When installing the unit in a hospital, mechanical room, or

similar electromagnetic eld (EMF) sensitive environment,

provide sufcient protection against electrical noise.

Inverter equipment, power generators, high-frequency medical equip-

ment, or radio communication equipment may cause the air conditioner to

operate improperly. The unit may also affect such equipment by creating

electrical noise that disturbs medical treatment or image broadcasting.

Do not use the product for special purposes such as preserving foods, works of art, wine coolers, or other precision

air conditioning applications. This equipment is designed to

provide comfort cooling and heating.

There is risk of property damage.

Do not make refrigerant substitutions. Use R410A only.

If a different refrigerant is used, or air mixes with original refrigerant, the

unit will malfunction and be damaged.

Do not install the unit in a noise sensitive area.

When connecting refrigerant tubing, remember to allow for

pipe expansion.

Improper piping may cause refrigerant leaks and system malfunction.

Take appropriate actions at the end of HVAC equipment life

to recover, recycle, reclaim or destroy R410A refrigerant according to applicable U.S. Environmental Protection Agency

(EPA) rules.

Do not use polypropylene bands to lift the unit.

Periodically check that the outdoor unit is not damaged.

There is a risk of equipment damage.

Install the unit in a safe, stable location where no one can

step on or fall onto it.

attaching or mounting hardware.

There is risk of unit and property damage.

Install the drain hose to ensure adequate drainage.

There is a risk of water leakage and property damage.

Don’t store or use ammable gas / combustibles near the

unit.

There is risk of product failure.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Low refrigerant levels may cause product failure

The unit is shipped with refrigerant and the service valves

closed.

non-condensibles have been removed from the piping system and authorization to do so has been obtained from the

commissioning agent.

There is a risk of refrigerant contamination, refrigerant loss and equipment damage.

Do not install the unit with defective

Installation Manual

Do not open service valves on the unit until all

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

5

SAFETY INSTRUCTIONS

DANGER

WARNING

WIRING

High voltage electricity is required to operate this system.

Adhere to the National Electrical Codes and these

instructions when wiring.

Improper connections and inadequate grounding can cause accidental

injury or death.

Always ground the unit following local, state, and National

Electrical Codes.

The information contained in this manual is intended for use

by an industry-qualied, experienced, certied electrician

familiar with the U.S. National Electric Code (NEC) who is

equipped with the proper tools and test instruments.

Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury or

death.

Ensure the unit is connected to a dedicated power source

that provides adequate power.

If the power source capacity is inadequate or the electric work is not per-

formed properly, it may result in re, electric shock, physical injury or death.

Do not turn on the breaker or power under condition if the

front panel, cabinet, top cover, control box cover are removed or opened.

It may result in re, electric shock, physical injury or death.

Turn the power off at the nearest disconnect before servicing

the equipment.

Electric shock can cause physical injury or death.

Properly size all circuit breakers or fuses.

There is risk of re, electric shock, explosion, physical injury or death.

Refer to local, state, and federal codes, and use power wires

of sufcient current capacity and rating.

Wires that are too small may generate heat and cause a re.

Secure all eld wiring connections with appropriate wire

strain relief.

Improperly securing wires will create undue stress on equipment power

lugs. Inadequate connections may generate heat, cause a re and

physical injury or death.

Properly tighten all power connections.

Loose wiring may overheat at connection points, causing a re, physical

injury or death.

Note:

Multi V Floor-Standing Indoor Unit

Do not cut, lengthen or shorten the communications and

power cable between any dry contact unit and its connected

indoor unit.

communications and power cable cannot be safely and easily

connected between the two units.

cable.

Do not install the unit in a location where the

Do not allow strain on this

Poor cable connections can cause equipment malfunction.

6

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

OPERATION

DANGER

WARNING

CAUTION

Do not provide power to or operate the unit if it is ooded

or submerged.

There is risk of re, electric shock, physical injury or death.

Use a dedicated power source for this product.

There is risk of re, electric shock, physical injury or death.

Do not operate the disconnect switch with wet hands.

There is risk of re, electric shock, physical injury or death.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Avoid excessive cooling and periodically perform ventilation

to the unit.

Inadequate ventilation is a health hazard.

Do not touch the refrigerant piping during or after operation.

It can cause burns or frostbite.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

The rotating, hot, cold, and high-voltage parts of the unit can cause

physical injury or death.

Periodically check power cable and connection for damage.

Cable must be replaced by the manufacturer, its service agent, or similar

qualied persons in order to avoid physical injury and/or electric shock.

SAFETY INSTRUCTIONS

Periodically verify the hanging bolts and other hardware

securing the unit have not deteriorated.

If the unit falls from its installed location, it can cause property damage,

product failure, physical injury or death.

If refrigerant gas leaks out, ventilate the area before operating the unit.

If the unit is mounted in an enclosed, low-lying, or poorly ventilated area

and the system develops a refrigerant leak, it may cause re, electric

shock, explosion, physical injury or death.

Do not open the inlet grille of the unit during operation.

Do not operate the unit with the panels or guards removed.

Do not insert hands or other objects through the inlet or

outlet when the unit is powered.

static lter, if the unit includes one.

The unit contains sharp, rotating, hot, and high voltage parts that can

cause personal injury and/or electric shock.

Ensure no power is connected to the unit other than as

directed in this manual. Remove power from the unit before

removing or servicing the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Securely attach the electrical cover to the unit.

Non-secured electrical covers can result in burns or electric shock due to

dust or water in the service panel.

Do not use the remote if the batteries have leaked. If the

liquid from the batteries gets onto skin or clothes, wash it

well with clean water

Battery chemicals could cause burns or other injuries.

Do not touch the electro-

Installation Manual

To avoid physical injury, turn off main power and use caution

when cleaning or servicing the air conditioner.

There is risk of electric shock.

Note:

Clean up the site after installation is nished, and check

that no metal scraps, screws, or bits of wiring have been left

inside or surrounding the unit.

Do not use this equipment in mission critical or specialpurpose applications such as preserving foods, works of art,

wine coolers or refrigeration. This equipment is designed to

provide comfort cooling and heating.

Provide power to the compressor crankcase heaters at least

six (6) hours before operation begins.

Starting operation with a cold compressor sump(s) may result in severe

bearing damage to the compressor(s). Keep the power switch on during

the operational season.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Do not block the inlet or outlet.

Unit may malfunction.

Securely attach the electrical cover to the indoor unit. Non-

secured covers can result in re due to dust or water in the

service panel.

Periodically verify the equipment mounts have not deteriorated.

If the base collapses, the unit could fall and cause property damage or

product failure.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure.

7

INTRODUCTION

WARNING

Floor-Standing Indoor Units

This manual describes how to install LG Cased and Uncased FloorStanding indoor units (IDU) for Multi V Variable Refrigerant Flow

(VRF) heat pump and heat recovery systems. Table 1 lists the available models. Refer to LG’s Multi V Indoor Unit Engineering Manual

for complete detailed engineering data and selection procedures.

Safety

Safety of personnel is the primary concern during all procedures.

Read and understand the safety summary at the front of this manual.

Read and understand this installation procedure before beginning

installation. Use the appropriate tools and accessories during installation. Plan your work and do not work alone, if possible. Know how

to obtain emergency medical and fire fighting assistance.

Installation Personnel

This equipment is intended for installation by personnel trained

in the required construction, mechanical, electrical, and/or other

disciplines.

Applicable Codes

Personnel must be familiar with and follow the applicable national,

state, and/or local codes. In the event of a conflict between any

applicable code and the instructions in this manual, comply with the

applicable code.

Figure 1: Cased Floor-Standing Indoor Unit.

Figure 2: Uncased Floor-Standing Indoor Unit.

Installation work must be performed by trained personnel and in accordance with national wiring standards and all local or other applicable codes.

Improper installation can result in re, electric shock, physical injury, or death.

Note:

Multi V Floor-Standing Indoor Unit

• Installation work must be performed by trained personnel and in accordance with national wiring standards and all local or other applicable

codes. Improper installation can prevent proper operation of the unit.

• Please read all instructions before installing this product. Become familiar with the unit’s components and connections, and the order of

installation. Incorrect installation can degrade or prevent proper operation.

Required Parts (factory provided)

• Drain Hose (One [1] Each)

• Screws (Five [5] Each)

• Insulation (One [1] Each for Vapor Pipe; One [1] Each for Liquid Pipe)

• Cable Ties (Eight [8]) Each)

• Conduit Mounting Plate (One [1] Each)

8

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Required Parts (field provided)

• Connecting cable (power and control)

• Pipes - vapor line and liquid line, with insulation

• Additional drain hose

• Type “A” Screws (Four [4] Each)

Required Tools (field provided)

• Level

• JIS and other screwdrivers

• Electrical lineman pliers

• Electric drill

• Holesaw

• Drill

• Flaring tool set

• Tubing cutter

• Tube/pipe reamer

• Torque wrenches

• Allen wrench

• Gas-leak detector

• Thermometer

INTRODUCTION

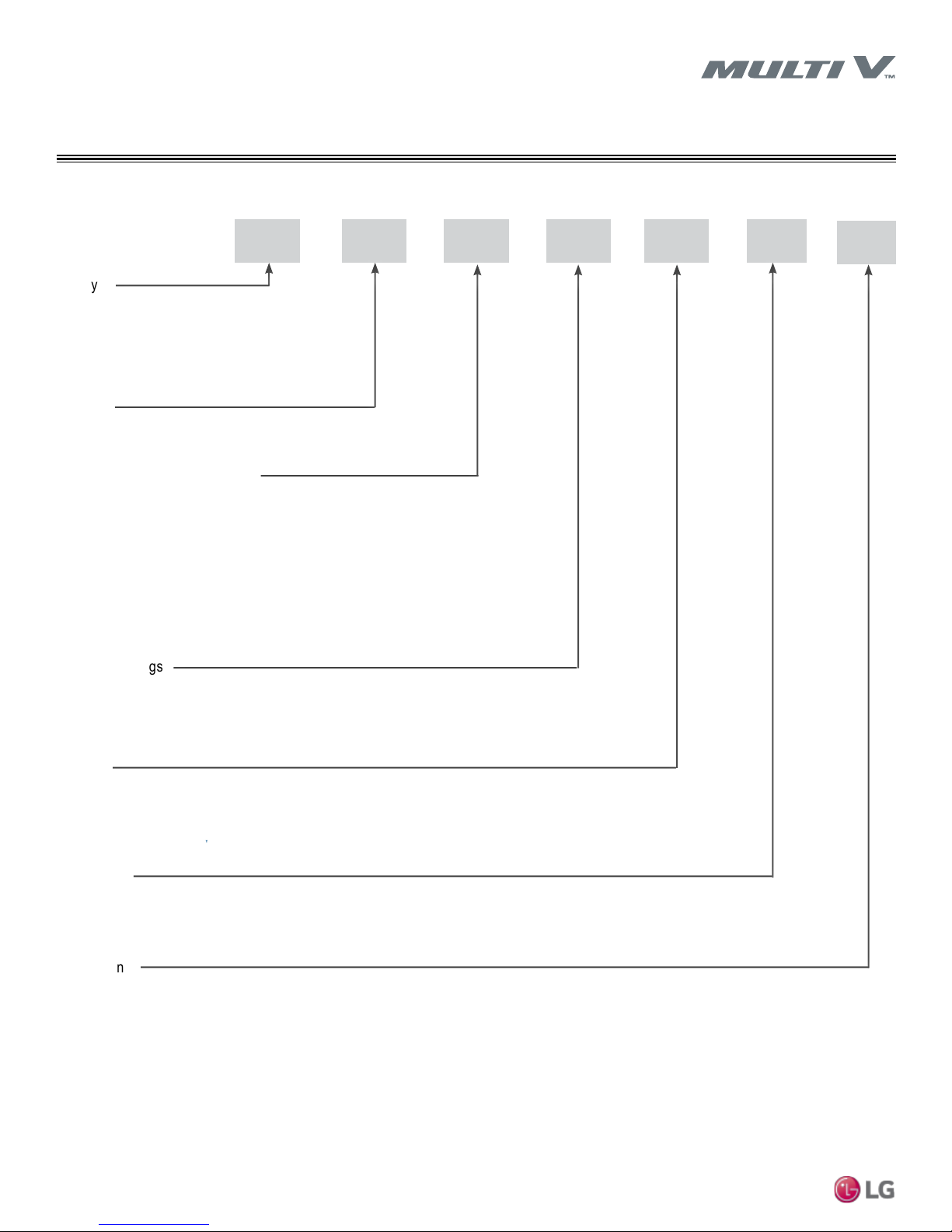

Table 1: Multi V Floor-Standing Indoor Units

Unit Model Number

Cased

Uncased

ARNU073CEA4

ARNU093CEA4

ARNU123CEA4

ARNU153CEA4

ARNU183CFA4

ARNU243CFA4

ARNU073CEU4

ARNU093CEU4

ARNU123CEU4

ARNU153CEU4

ARNU183CFA4

ARNU243CFA4

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

9

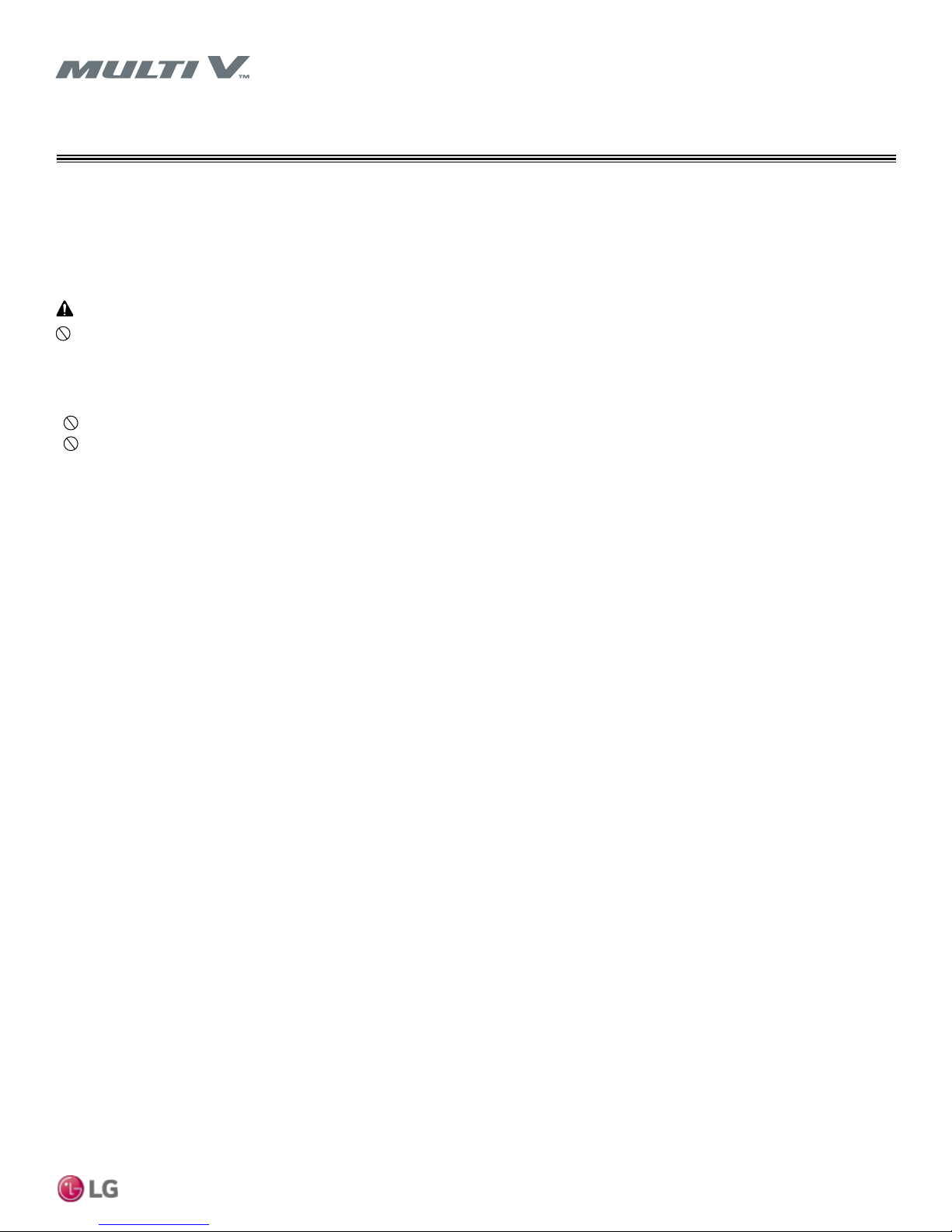

UNIT NOMENCLATURE

Floor Standing Indoor Units Nomenclature

Family

ARN = Multi V Indoor Unit

(Refrigerant R410A)

Type

U = DC Inverter Heat Pump

Indoor Unit Nominal Capacity

05 = 5,000 Btu/h

07 = 7,000 Btu/h

09 = 9,000 Btu/h

12 = 12,000 Btu/h

15 = 15,000 Btu/h

18 = 18,000 Btu/h

24 = 24,000 Btu/h

Electrical Ratings

3 = 208–230V/60Hz/1Ph

ARN U 07 3 TN C

4

Model

Multi V Floor-Standing Indoor Unit

CE = Floor Standing (small frame)

CF = Floor Standing (large frame)

Feature

U = Uncased

Generation

2 = Second

4 = Fourth

A = Second, Revision A

10

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

R410A REFRIGERANT

WARNING

R410A Refrigerant

R410A refrigerant has a higher operating pressure in comparison to R22 refrigerant and, therefore, all piping system materials installed must

have a higher resisting pressure than the materials traditionally used in R22 systems.

R410A refrigerant is an azeotrope of R32 and R125, mixed at 50:50, so the ozone depletion potential (ODP) is 0.

Do not place refrigerant cylinder in direct sunlight. Refrigerant cylinder may explode causing severe injury or death.

Note

• Because R410A is a combination of R32 and R125, the required additional refrigerant must be charged in its liquid state. If the refrigerant is

charged in its gaseous state, its composition changes and the system will not work properly.

• Do not heat piping more than necessary during installation. Piping may become soft and fail when pressurized.

• Do not use any piping that has not been approved for use in high-pressure refrigerant systems. Piping wall thickness must comply with

the applicable local, state, and federal codes for the 551 psi design pressure of R410A. Inadequate piping may fail when pressurized.

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

11

GENERAL DATA

Specications

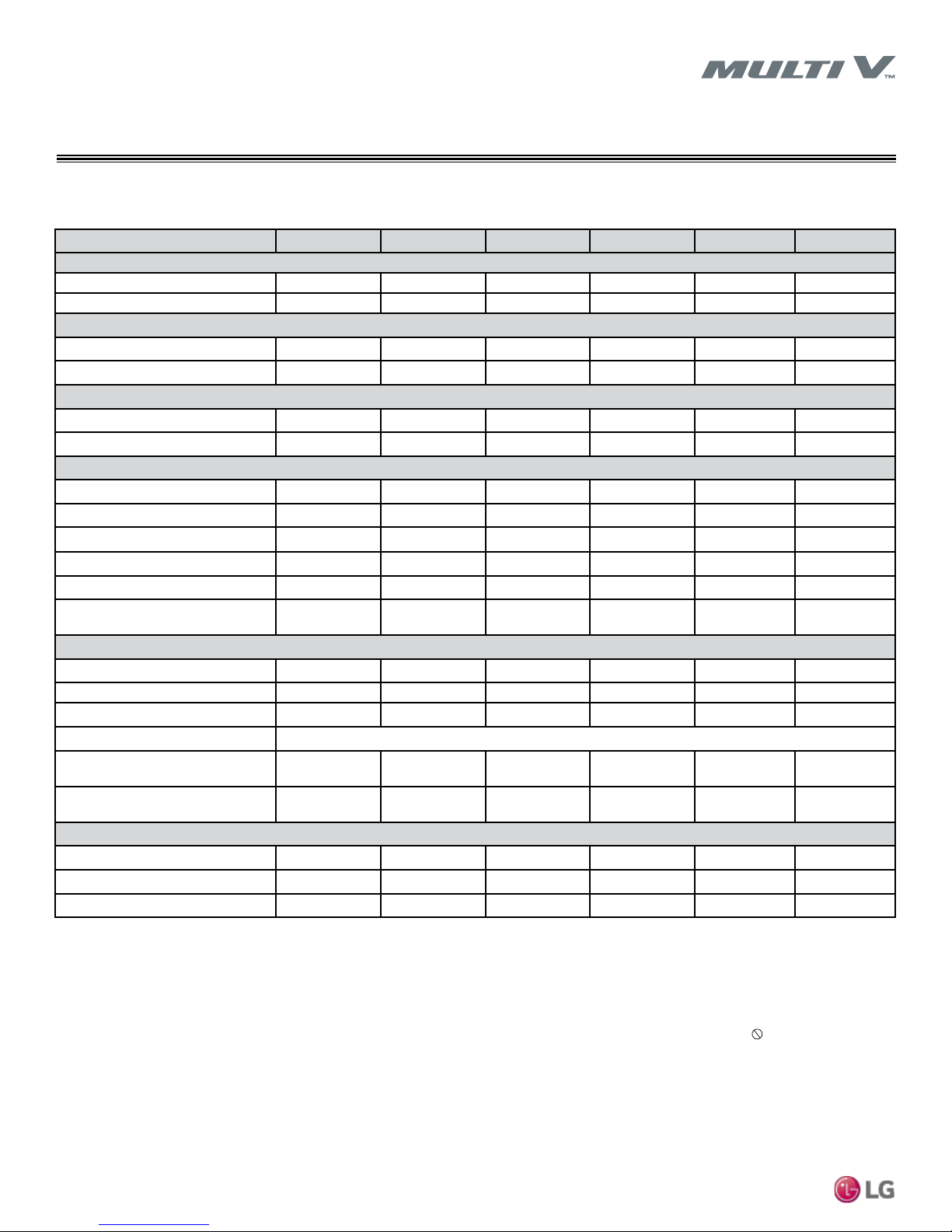

Table 2: Cased Floor-Standing Indoor Units Specications.

Model No. ARNU073CEA4 ARNU093CEA4 ARNU123CEA4 ARNU153CEA4 ARNU183CFA4 ARNU243CFA4

Cooling Mode Performance

Capacity (Btu/h) 7,500 9,600 12,300 15,400 19,100 24,200

Power Input

Heating Mode Performance

Capacity (Btu/h) 8,500 10,900 13,600 17,100 21,500 27,300

Power Input

Entering Mixed Air

Cooling Max. (°F WB) 76 76 76 76 76 76

Heating Min. (°F DB) 59 59 59 59 59 59

Unit Data

Refrigerant Type

Refrigerant Control EEV EEV EEV EEV EEV EEV

Sound Pressure

Net Unit Weight (lbs.) 59.5 59.5 59.5 59.5 75.0 75.0

Shipping Weight (lbs.) 68.3 68.3 68.3 68.3 86.0 86.0

Communication Cable

(No. x AWG)

Fan

Type Sirocco Sirocco Sirocco Sirocco Sirocco Sirocco

Motor 2 2 2 2 2 2

Housing 3 3 3 3 4 4

Motor/Drive Brushless Digitally Controlled / Direct

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

Multi V Floor-Standing Indoor Unit

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.) 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

Vapor Line (in., O.D.) 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

Condensate Line (in., I.D.) 1 1 1 1 1 1

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

1

(W) 85 85 85 85 115 115

1

(W) 85 85 85 85 115 115

2

R410A R410A R410A R410A R410A R410A

3

dB(A) (H/M/L) 35 / 33 / 31 36 / 34 / 32 37 / 35 / 33 38 / 37 / 35 40 / 37 / 34 43 / 40 / 37

4

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

300 / 265 / 229 335 / 300 / 265 371 / 335 / 300 406 / 353 / 335 565 / 494 / 424 635 / 565 / 494

0 0 0 0 0 0

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

Sound Pressure levels are tested in an anechoic chamber under ISO Standard 3745.

4

All communication cable to be minimum 18 AWG, 2-conductor, twisted, stranded, shielded

and must comply with applicable local and national codes. Ensure the communication

cable is properly grounded at the master outdoor unit only. Do not ground the ODU-IDU

communication cable at any other point.

12

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

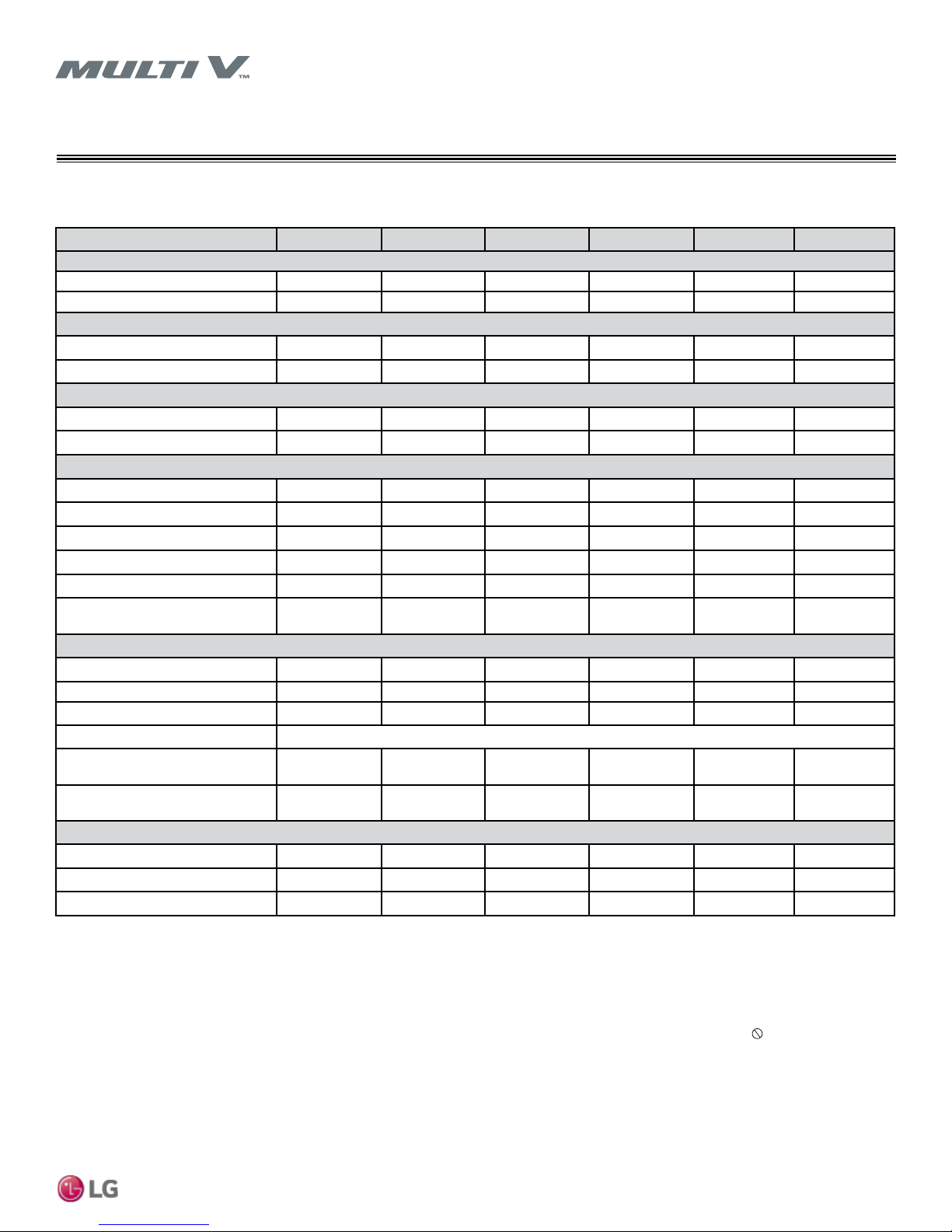

Table 3: Uncased Floor-Standing Indoor Unit Specications.

Model No. ARNU073CEU4 ARNU093CEU4 ARNU123CEU4 ARNU153CEU4 ARNU183CFU4 ARNU243CFU4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

7,500 9,600 12,300 15,400 19,100 24,200

85 85 85 85 11 5 115

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

8,500 10,900 13,600 17,100 21,500 27,300

85 85 85 85 11 5 115

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

76 76 76 76 76 76

59 59 59 59 59 59

Unit Data

2

Refrigerant Type

Refrigerant Control

Sound Pressure3 dB(A) (H/M/L)

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4

(No. x AWG)

R410A R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV EEV

35 / 33 / 31 36 / 34 / 32 37 / 35 / 33 38 / 37 / 35 40 / 37 / 34 43 / 40 / 37

46.3 46.3 46.3 46.3 58.4 58.4

56.2 56.2 56.2 56.2 68.3 68.3

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Fan

Type

Motor

Housing

Sirocco Sirocco Sirocco Sirocco Sirocco Sirocco

2 2 2 2 2 2

3 3 3 3 4 4

Motor/Drive

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

High Mode (Factory Set)

300 / 265 / 229 335 / 300 / 265 371 / 335 / 300 406 / 353 / 335

0 0 0 0 0 0

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

1 1 1 1 1 1

GENERAL DATA

Specications

Brushless Digitally Controlled / Direct

565 / 494 /

424

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

Sound Pressure levels are tested in an anechoic chamber under ISO Standard 3745.

4

All communication cable to be minimum 18 AWG, 2-conductor, twisted, stranded, shielded

and must comply with applicable local and national codes. Ensure the communication

cable is properly grounded at the master outdoor unit only. Do not ground the ODU-IDU

communication cable at any other point.

635 / 565 /

494

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

13

Loading...

Loading...