LG ARNU 243 S8R2, ARNU 073 SBL4, ARNU 093 SER2, ARNU 053 SBL4, ARNU 093 SBL4 Engineering Manual

...

EM-MultiV-WallMounted-IndoorUnits-01-15

WALL-MOUNTED INDOOR UNIT

ENGINEERING MANUAL

Art Cool™ Mirror Wall-Mounted

7,500 to 24,200 Btu/h

Standard Wall-Mounted

5,500 to 24,200 Btu/h

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information,

and other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc. only in confidence.

This document is for design purposes only.

A summary list of safety precautions is on page 3.

For more technical materials such as submittals, catalogs, installation,

owner’s, and service manuals, visit www.lghvac.com.

For continual product development, LG Electronics U.S.A., Inc. reserves the right to change specifications without notice.

© LG Electronics U.S.A., Inc.

TABLE OF CONTENTS

DANGER

CAUTION

Unit Nomenclature ................................................................................. 4

Indoor Unit Overview ............................................................................ 5

Controllers Overview ............................................................................ 8

LATS Overview .................................................................................... 14

Art Cool™ Mirror Wall-Mounted Indoor Units .............................. 15-32

Mechanical Specications ................................................................. 16

General Data ..................................................................................... 17

Electrical Data ................................................................................... 18

External Dimensions ..................................................................... 19-20

Electrical Wiring Diagrams ........................................................... 21-22

Refrigerant Flow Diagrams ................................................................ 23

Acoustic Data ............................................................................... 24-25

Air Velocity / Temperature Distribution .......................................... 26-28

Capacity Tables ............................................................................ 29-32

Standard Wall-Mounted Indoor Units ...........................................33-54

Mechanical Specications ................................................................. 34

General Data ................................................................................ 35-36

Electrical Data ................................................................................... 37

External Dimensions ..................................................................... 38-39

Electrical Wiring Diagrams ................................................................ 40

Refrigerant Flow Diagrams ................................................................ 41

Acoustic Data ............................................................................... 42-45

Air Velocity / Temperature Distribution .......................................... 46-49

Capacity Tables ............................................................................ 50-54

Application Guidelines ................................................................... 55-60

Selecting the Best Location ............................................................... 56

General Mounting .............................................................................. 56

General Drain Piping Information ................................................. 57-58

Wiring Guidelines ......................................................................... 59-60

Wired Remote Controller Location .................................................... 60

Acronyms ............................................................................................. 61

Introduction

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action should not be completed.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

INTRODUCTION | 3

UNIT NOMENCLATURE

ARN U 07 3 TN C

Family

ARN = Multi V Indoor Unit

(Refrigerant R410A)

Type

U = DC Inverter Heat Pump

Indoor Unit Nominal Capacity

05 = 5,000 Btu/h

07 = 7,000 Btu/h

09 = 9,000 Btu/h

12 = 12,000 Btu/h

15 = 15,000 Btu/h

Electrical Ratings

3 = 208–230V/60Hz/1Ph

Model

B3 = Ducted (low static - bottom return)

B4 = Ducted (low static - bottom return)

B8 = Ducted (high static)

BG = Ducted (high static)

BR = Ducted (high static)

CE = Floor Standing (small frame)

CF = Floor Standing (large frame)

L1 = Ducted (low static)

L2 = Ducted (low static)

L3 = Ducted (low static)

18 = 18,000 Btu/h

24 = 24,000 Btu/h

28 = 28,000 Btu/h

30 = 30,000 Btu/h

36 = 36,000 Btu/h

42 = 42,000 Btu/h

48 = 48,000 Btu/h

54 = 54,000 Btu/h

76 = 76,000 Btu/h

96 = 96,000 Btu/h

NJ = Vertical/Horizontal Air Handling Unit

NK = Vertical/Horizontal Air Handling Unit

S8 = Wall Mounted/Mirror (large frame)

SE = Wall Mounted/Mirror (small frame)

SB = Standard Wall Mounted

SC = Standard Wall Mounted

TT = 1-Way Ceiling Cassette

TU = 1-Way Ceiling Cassette

TL = 2-Way Ceiling Cassette

TM = 4-Way Ceiling Cassette

4

TN = 4-Way Ceiling Cassette

TP = 4-Way Ceiling Cassette

TQ = 4-Way Ceiling Cassette

TR = 4-Way Ceiling Cassette

VE = Convertible Surface Mounted

VJ = Ceiling Suspended

Feature

A = Basic

C = Plasma Filter

G = Low Static

MULTI V Wall-Mounted Indoor Unit Engineering Manual

L = Neo Plasma

R = Mirror and Neo Plasma

U = Uncased

Generation

2 = Second

4 = Fourth

A = Second, Revision A

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

4 | INTRODUCTION

©

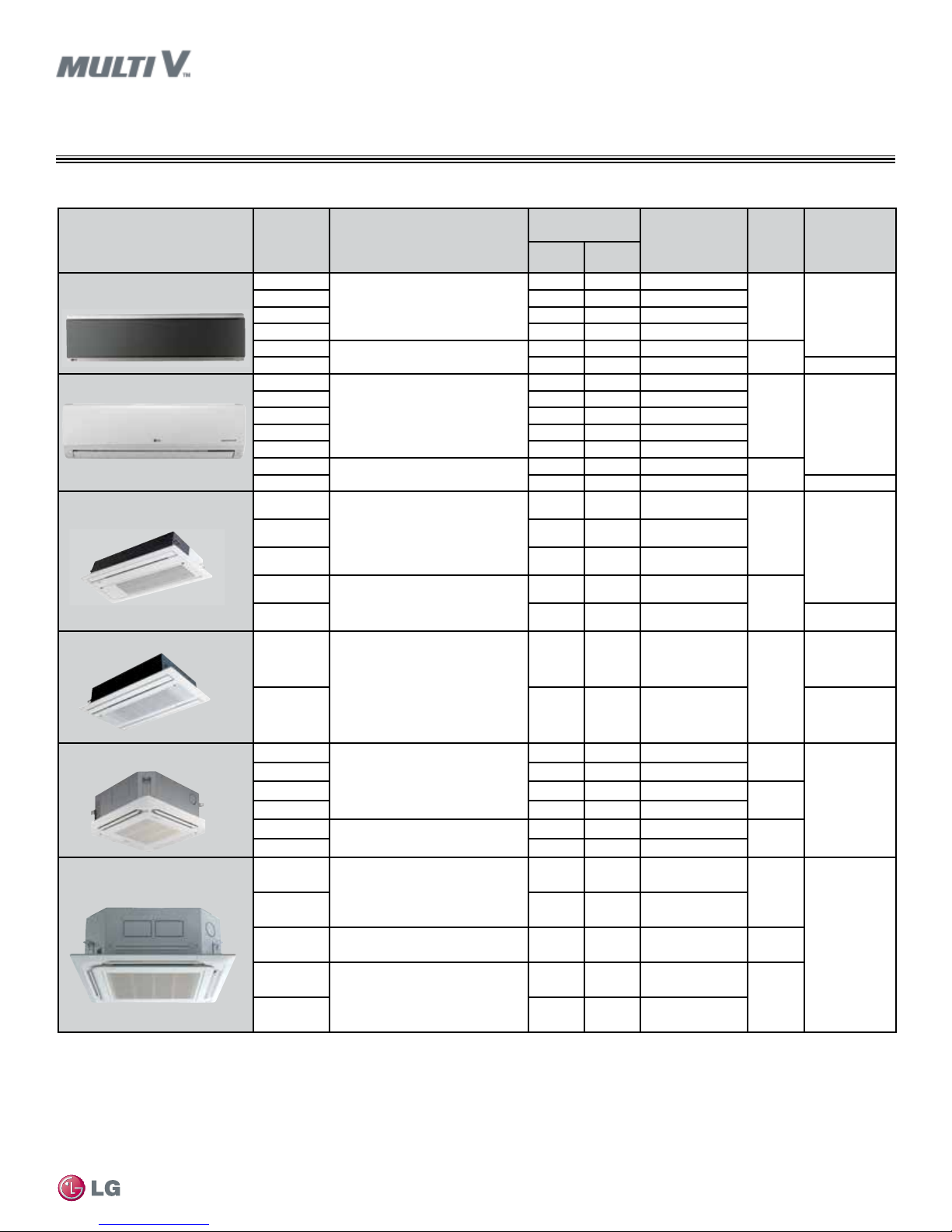

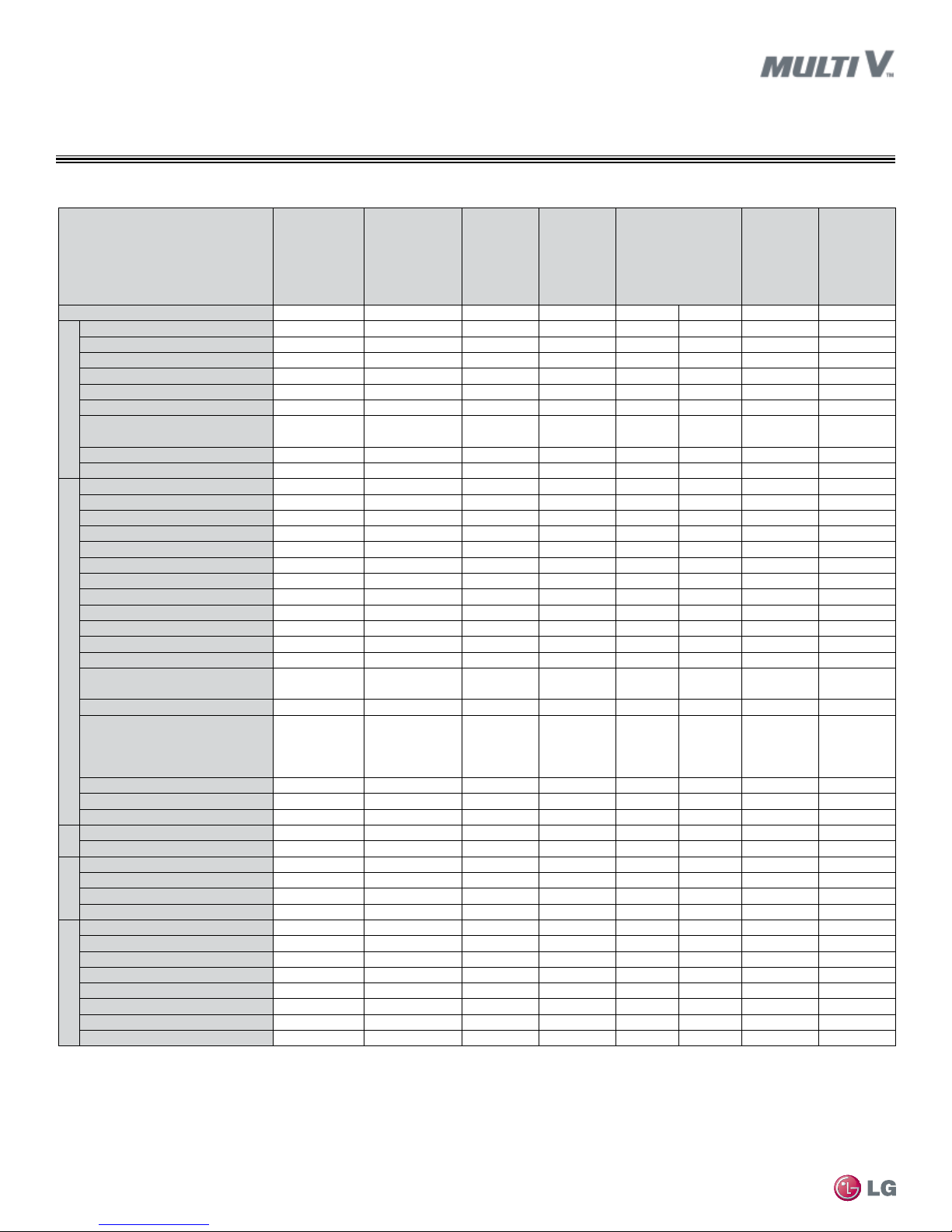

Table 1: Wall-Mounted / Ceiling Cassette Indoor Units.

Unit/Type

1

Wall Mounted–ART COOL

Mirror

TM

ARNU*****

073 SER2

093 SER2 9,600 10,900 282/247/177

2

123 SER2 12,300 13,600 353/283/212

153 SER2 15,400 17,100 371/283/212

183 S8R2

243 S8R2 24,200 27,300 632/508/424 3/8, 5/8

Wall Mounted–Standard

053 SBL4

073 SBL4 7,500 8,500 1,190/1,120/1,050

093 SBL4 9,600 10,900 1,260/1,190/1,050

123 SBL4 12,300 13,600 1,420/1,260/1,120

153 SBL4 15,400 17,100 1,550/1,350/1,190

183 SCL4

243 SCL4 24,200 27,300 1,280/1,140/1,000 3/8, 5/8

Ceiling Cassette–One Way

073 TUC4

093 TUC4 9,600 10,900 325/304/290

Body: 33-7/8 x 17-3/4 x 6-11/16

Panel: 43-5/16 x 19-3/4 x 1-3/8

123 TUC4 12,300 13,600 353/325/290

Dimensions

(W x D x H)

(inches)

36-1/16 x 6-1/2 x 11-1/8

43-9/16 x 7-7/8 x 11-13/16

35-1/4 x 8-15/16 x 11-7/16

40-5/16 x 9-7/8 x 12-13/16

INDOOR UNIT OVERVIEW

Wall-Mounted / Ceiling Cassette

Nominal Capacity

Btu/h

3

Cooling

Heating

Air Flow Rate

(CFM)

3

(H/M/L4)

7,500 8,500 247/212/141

19,100 21,500 508/459/388

5,500 6,100 1,120/1,080/1,050

19,100 21,500 1,120/1,050/980

7,500 8,500 290/258/226

Weight

(lbs.)

25

34

22

31

Body: 33

Panel: 10

Pipe

Connections

(inches, O.D.)

(Liquid, Vapor)

1/4, 1/2

1/4, 1/2

1/4, 1/2

Introduction

183 TTC4

243 TTC4 24,200 24,200 515/470/406 3/8, 5/8

Body: 46-1/2 x 17-3/4 x 6-7/8

Panel: 55-15/16 x 19-3/4 x 1-3/8

Ceiling Cassette–Two Way

183 TLC4

Body: 32-11/16 x 21-5/8 x 8-7/8

Panel: 41-5/16 x 25-3/16 x 1-5/8

243 TLC4 24,200 27,300 601/530/459 3/8, 5/8

Ceiling Cassette–Four Way

(2' x 2')

053 TRC4

073 TRC4 7,500 8,500 265/247/212

093 TRC4 9,600 10,900 283/265/251

Body: 22-7/16 x 22-7/16 x 8-7/16

Panel: 27-9/16 x 27-9/16 x 7/8

123 TRC4 12,300 13,600 307/283/247

153 TQC4

183 TQC4 19,100 21,500 396/388/353

Ceiling Cassette–Four Way

(3' x 3')

243 TPC4

283 TPC4 28,000 31,500 671/565/494

363 TNC4

423 TMC4

483 TMC4 48,100 51,200 1,130/953/883

1

All indoor units require 208–230V/60Hz/1Ph and an AWG18-2 communication cable.

2

Model number shows nominal capacity and frame size designator.

3

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Body: 22-7/16 x 22-7/16 x 10-3/32

Panel: 27-9/16 x 27-9/16 x 7/8

Body: 33-1/16 x 33-1/16 x 8

Panel: 37-3/8 x 37-3/8 x 1-7/16

Body: 33-1/16 x 33-1/16 x 9-5/8

Panel: 37-3/8 x 37-3/8 x 1-7/16

Body: 33-1/16 x 33-1/16 x 11-5/16

Panel: 37-3/8 x 37-3/8 x 1-7/16

19,100 21,500 470/427/385

Body: 42

Panel: 13

19,100 21,500 459/424/353

1/4, 1/2

Body: 49

Panel: 11

5,500 6,100 265/247/212

Body: 29

Panel: 7

15,400 17,100 388/353/328

Body: 32

Panel: 7

Body: 35

1/4, 1/2

Panel: 7

24,200 27,300 600/530/459

Body: 48

Panel: 13

36,200 40,600 883/777/706

42,000 43,800 1,059/918/812

Body: 54

Panel: 13

Body: 59

3/8, 5/8

Panel: 13

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60°

F wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

4

H/M/L = High/Medium/Low

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

INTRODUCTION | 5

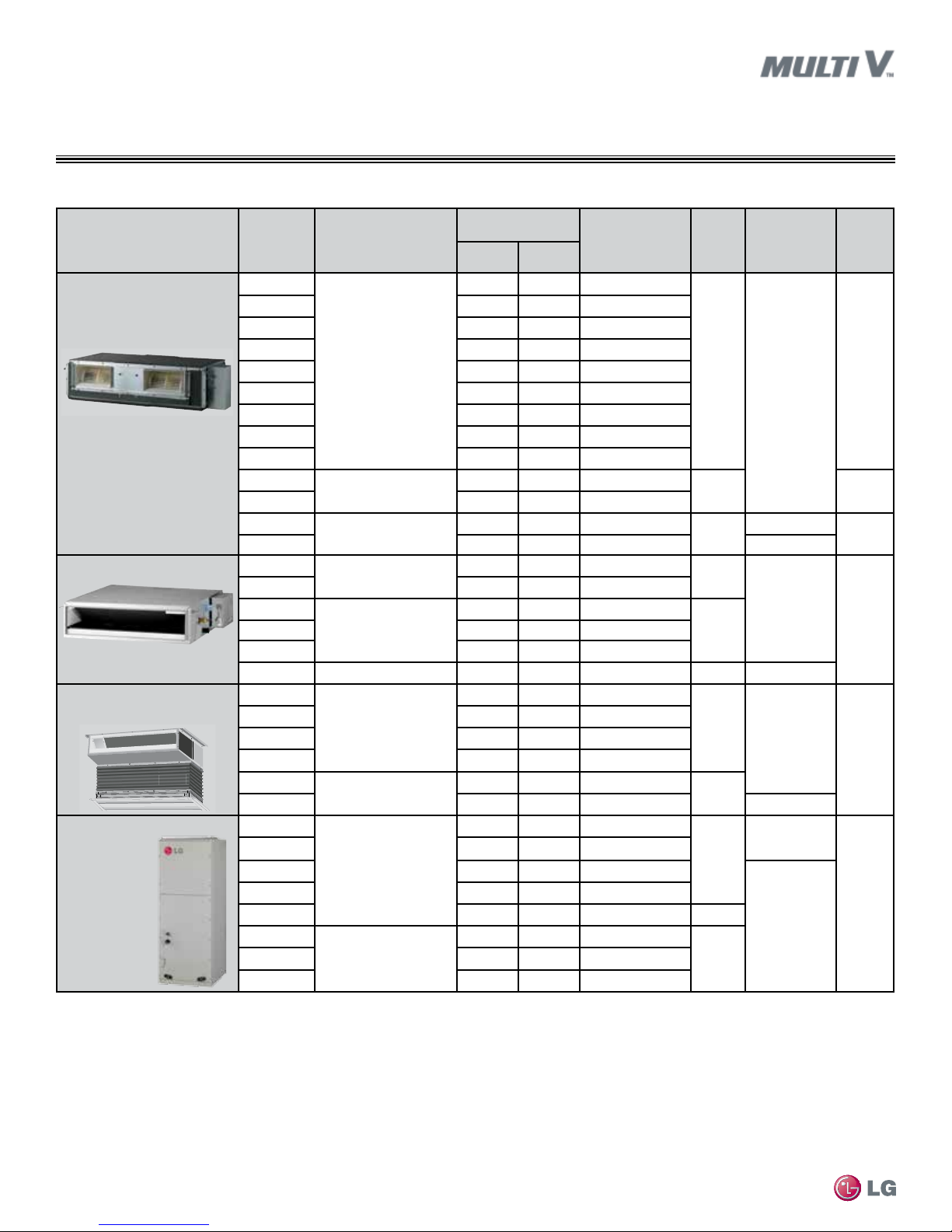

INDOOR UNIT OVERVIEW

Ducted

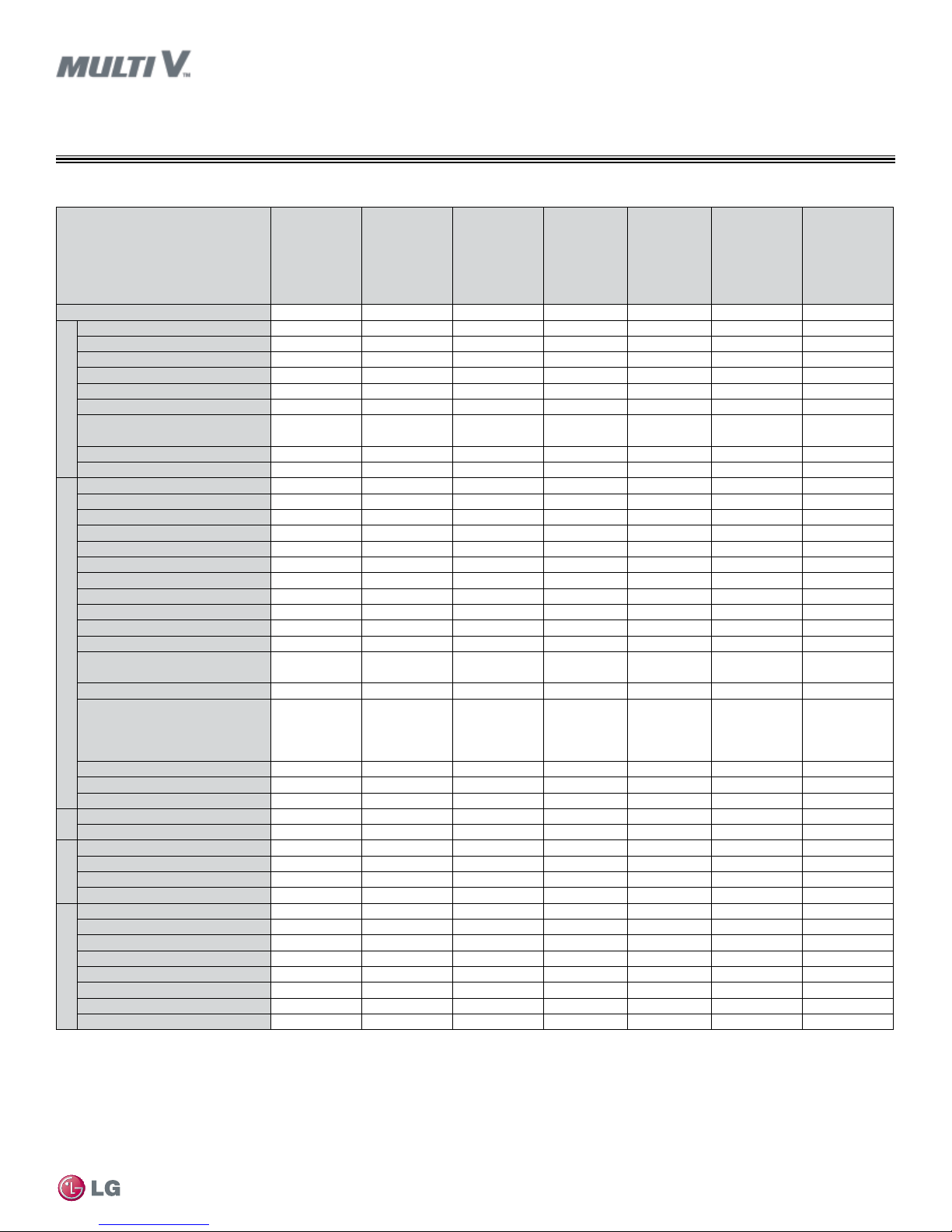

Table 2: Ducted Indoor Units.

Dimensions

(W x D x H)

(inches)

46-1/2 x 17-3/4 x 11-3/4

48-7/16 x 23-3/8 x 15

61-1/2 x 27-1/8 x 18-1/8

27-9/16 x 27-9/16 x 7-1/2

35-7/16 x 27-9/16 x 7-1/2

32-5/8 x 22-5/8 x 7-1/2

43-5/16 x 22-5/8 x 7-1/2

18 x 21-1/4 x 48-11/16

25 x 21-1/4 x 55-3/16

Unit/Type

Ducted High Static

1

ARNU*****

073 BGA4

2

093 BGA4 9,600 10,900 452 / 406 / 332

123 BGA4 12,300 13,600 477 / 427 / 332

153 BGA4 15,400 17,100 487 / 417 / 293

183 BGA4 19,100 21,500 537/487/417

243 BGA4 24,200 27,300 671/537/487

283 BGA4 28,000 31,500 1,130/1,003/961

363 BGA4 36,200 40,600 1,003/894/770

423 BGA4 42,000 43,800 893/770/622

483 BRA4

543 BRA4 54,000 61,400 1,819/1,678/1,395

763 B8A4

963 B8A4 95,900 107,500 2,542/2,260/2,260 3/8, 7/8

Ducted Low Static

073 L1G4

093 L1G4 9,600 10,900 320/250/200

123 L2G4

183 L2G4 19,100 21,500 530/450/360

243 L3G4 43-5/16 x 27-9/16 x 7-1/2 24,000 27,300 710/570/430 60 3/8. 5/8

Ducted Low Static Built In

073 B3G4

093 B3G4 9,600 10,900 318/247/212

123 B3G4 12,300 13,600 353/283/229

153 B3G4 15,400 17,100 388/353/283

183 B4G4

243 B4G4 24,200 27,300 600/530/353 3/8, 5/8

Vertical/Horizontal Air

Handling Unit

MULTI V Wall-Mounted Indoor Unit Engineering Manual

123 NJA4

183 NJA4 18,000 20,000 580/530/480

243 NJA4 24,000 27,000 710/640/480

303 NJA4 30,000 34,000 880/800/630

363 NJA4 36,000 40,000 990/880/800 121

423 NKA4

543 NKA4 54,000 60,000 1,475/1,400/1,260

1

All indoor units require 208–230V/60Hz/1Ph and an AWG18-2 communication cable.

2

Model number shows nominal capacity and frame size designator.

3

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Nominal Capacity

Btu/h

3

Cooling

Heating

Air Flow Rate

3

(CFM)

(H/M/L4)

Weight

(lbs.)

Pipe

Connections

(inches, O.D.)

(Liquid, Vapor)

7,500 8,500 441 / 406 / 332

84

3/8, 5/8

48,100 51,200 1,568/1,395/1,183

76,400 86,000 2,050/1,766/1,766

7,500 8,500 270/230/200

12,300 13,600 360/310/250

112 0.78

192

3/8, 3/4

39

1/4, 1/2

51153 L2G4 15,400 17,100 450/360/310

7,500 8,500 283/229/194

19,100 21,500 494/424/353

12,000 13,500 530/480/380

46

57

1/4, 1/2

1/4, 1/2

117

42,000 46,000 1,250/1,100/1,000

3/8, 5/8

165483 NKA4 48,000 54,000 1,400/1,260/1,000

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60°

F wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

4

H/M/L = High/Medium/Low

Max.

ESP

(inches)

0.62

0.98

0.19

0.15

1.0

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

6 | INTRODUCTION

©

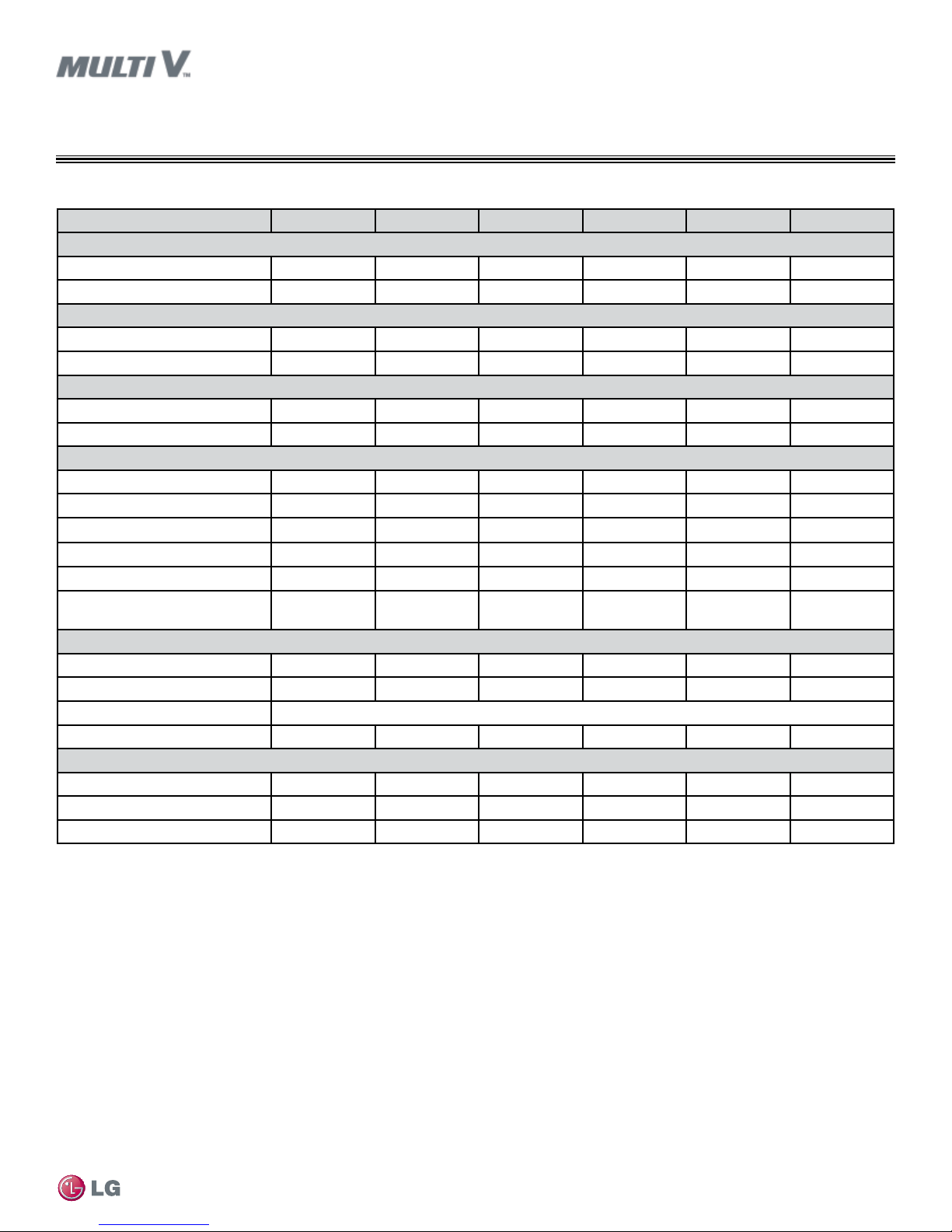

Table 3: Surface Mounted / Floor Standing Indoor Units.

Unit/Type

1

ARNU****

Ceiling Suspended

183VJA2

INDOOR UNIT OVERVIEW

Surface Mounted / Floor Standing

Nominal Capacity

Cooling

Btu/h

3

Heating

2

Dimensions

(W x D x H)

(inches)

19,100 21,500 565/495/424

3

Air Flow

Rate

(CFM)

(H/M/L4)

Weight

(lbs.)

Pipe

Connections

(inches, O.D.)

(Liquid, Vapor)

1/4, 1/2

Convertible Surface Mounted

Floor Standing –Cased

Floor Standing – Uncased

37-7/16 x 8-11/16 x 25-5/8

55

243VJA2 24,200 27,300 636/565/495 3/8, 5/8

093VEA2

35-7/16 x 7-7/8 x 19-5/16

9,600 10,900 268/243/219

31 1/4, 1/2

123VEA2 12,300 13,600 325/268/244

073 CEA4

7,500 8,500 300/265/229

093 CEA4 9,600 10,900 335/300/265

42 x 8 x 25

123 CEA4 12,300 13,600 371/335/300

60

1/4, 1/2

153 CEA4 15,400 17,100 406/353/335

183 CFA4

52-15/16 x 8 x 25

19,100 21,500 565/494/424

75

243 CFA4 24,200 27,300 635/565/494 3/8, 5/8

073 CEU4

7,500 8,500 300/265/229

Introduction

1

All indoor units require 208–230V/60Hz/1Ph and an AWG18-2 communication cable.

2

Model number shows nominal capacity and frame size designator.

3

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

093 CEU4 9,600 10,900 335/300/265

38-1/2 x 7-15/16 x 25-3/16

123 CEU4 12,300 13,600 371/335/300

46

1/4, 1/2

153 CEU4 15,400 17,100 406/353/335

183 CFU4

49-7/16 x 7-1/2 x 25-3/16

19,100 21,500 565/494/424

58

243 CFU4 24,200 27,300 635/565/494 3/8, 5/8

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60°

F wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

4

H/M/L = High/Medium/Low

INTRODUCTION | 7

CONTROLLERS OVERVIEW

Zone Controllers and Communication Cables

Table 4: Zone Controllers.

Zone Controller Name Model No. Case Color

Max Wire

Length (ft)

Description

Simple Controller with

mode selection

Simple Controller

without mode selection

LG Premium

Controller

LG Programmable

Thermostat

PQRCVCL0Q Black

PQRCVCL0QW White

PQRCHCA0Q Black

PQRCHCA0QW White

PREMTA000 Ivory 164

PREMTB10U White 164

Allows control of indoor unit on/off, operation mode, fan speed,

164

Allows control of indoor unit on/off, fan speed, and temperature

164

and temperature setpoint for up to 16 indoor units.

setpoint for up to 16 indoor units.

Allows control of indoor unit on/off, operation mode, occupied/

unoccupied temperature setpoints, fan speed, and air flow

direction for up to 16 indoor units. Programmable schedule with 5

events per day with control of occupied/unoccupied, on/off,

mode, setpoints and fan speed. Advanced functions include

two setpoint autochangeover, minimum difference between

setpoints, setback, timed override, target energy consumption

display, check energy display and master/slave.

Allows control of indoor unit on/off, operation mode, occupied

and unoccupied temperature setpoints, fan speed, and airflow

direction for up to 16 indoor units. Programmable schedule with

5 events per day with control of occupied unoccupied, on/off,

mode, setpoints and fan speed. Advanced functions include two

setpoint autochangeover, minimum difference between setpoints,

setback and timed override.

Wireless Handheld PQWRHQ0FDB Ivory ----

Wall-Mounted Remote

Temperature Sensor

PQRSTA0 Ivory 50

MULTI V Wall-Mounted Indoor Unit Engineering Manual

Before specifying or placing an order, refer to the V-Net Network Solution Engineering Product Data Book and review the detailed technical data provided to fully understand the capabilities and limitations of these

devices.

For information on controller compatibility refer to the Controls and Options Tables on pages 12 and 13.

Table 5: Zone Controller Communication Cables.

Communication Cable Name Model No. Wire Length (ft.) Description

Wired Remote Group

Control Cable Assembly

Wired Remote/Group Control

Extension Cable

Before specifying or placing an order, refer to the V-Net Network Solution Engineering Product Data Book and review the detailed technical data provided to fully understand the capabilities and limitations of these

devices.

For information on controller compatibility refer to the Controls and Options Tables on pages 12 and 13.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

8 | INTRODUCTION

©

PZCWRCG3 33

PZCWRC1 33

Allows control of indoor unit on/off, operation mode, fan speed,

and temperature setpoint.

Allows remote temperature measurement for cassette and

ducted units.

Required when grouping multiple indoor units with a single

zone controller.

Increases the distance between a remote controller and an

indoor unit or between indoor units in a control group.

Table 6: Specialty Application Devices.

Specialty Application

Device

Name Model No.

Simple Dry Contact PQDSB1

Dry Contact for

Economizer, occupied/

unoccupied

Dry Contact Unit for

24V Thermostat

Digital Output

(DO) Kit

I/O Module

Auxiliary Heater

Relay Kit

PQDSBC1

PDRYCB300

PQNFP00T0

PEXPMB000.

ENCXLUS

PRARH0

PRARS0

CONTROLLERS OVERVIEW

Specialty Application Devices

Binary

Connect

to

Indoor

Unit

Comm

Bus

AC

Smart IV

and

ACP IV

Indoor

Unit

Application

On/Off, Run Status,

Error Status

On/Off, Mode,

Controller Lock, Power

Save, Run Status,

Error Status

On/Off, Thermo On/

Off, Mode, Fan Speed,

Run Status, Error

Status

On/Off 0/1

Third party equipment

control. Allows system

expansion through

Digital and Analog

inputs and outputs.

Third party

supplemental heat

control

Signals

Input/

Output

1/2

2/2

---

---

0/1

Description

Enables the indoor unit to be

controlled and monitored by third

party controls using binary inputs

and outputs.

Enables the indoor unit to be

controlled and monitored by a third

party thermostat or controller.

One 25A DPST normally open relay.

Used with central controller to control

third party device manually or by

schedule.

3 Digital Inputs: Dry Contact input only

3 Digital Outputs: Max. 2A@30VAC/DC

4 Analog Outputs: 0 to 10 VDC,

configurable; 0 to 20 mA, configurable

4 Universal Inputs individually

configurable as analog or digital:

Analog: Voltage. Current. Thermistor

(NTC, PT, Ni)

Digital for Dry Contact input only

Adds coordinated control of an

external heater with normal heat

pump operations.

Introduction

Auxiliary Two-Stage

Heater Relay Kit

Power Distribution

Indicator (PDI)

Premium

Mode Selector Switch PRDSBM

Before specifying or placing an order, refer to the V-Net Network Solution Engineering Product Data Book and review the detailed technical data provided to fully understand the capabilities and limitations of these

devices.

For information on controller compatibility refer to the Controls and Options Tables on pages 12 and 13.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

PRARH1

PQNUD1S41

Indoor

Unit

Comm

Bus

Outdoor

Unit

Third party

supplemental heat

control

Energy

consumption

monitoring

Multi V Heat

Pump Only

0/2

8 Watt

Node

Meters

---

Adds coordinated control of an

external heater with normal heat

pump operations.

Monitors total outdoor unit power

consumption for up to eight systems,

and distributes per indoor unit based

on weighted calculation.

Locks outdoor unit into Heat,

Cool, or Fan Mode.

INTRODUCTION | 9

CONTROLLERS OVERVIEW

Central Controllers

Table 7: Central Controllers (connect to the outdoor unit terminals Internet A, Internet B).

Central

Controller

Name Model No.

AC Smart IV

PACS4B000.

ENCXLUS

Devices

per

Controller

128 16 128 1

Systems

per Comm

Bus

Devices

per Comm

Bus

No. of

Comm

Bus

Ports

Binary

Signals

Input/

Output

2 DI /

2 DO

Power,

Conn

24 VAC

Description

Monitors / operates indoor units

through a touch screen. Manages

up to 128 devices. Advanced

functions include programmable

schedules, temperature setpoint

range lock, remote controller lock,

run time limit, manual control and

scheduling of digital output kit,

peak/demand control, visual floor

plan navigation, web access,

operation and error history log, one

digital input and two digital outputs

for device interlocking and error

e-mail notification.

AC Ez PQCSZ250S0 32 16 256 1 ---

Advanced

Control

Platform IV

(ACP IV)

Before specifying or placing an order, refer to the V-Net Network Solution Engineering Product Data Book and review the detailed technical data provided to fully understand the capabilities and limitations of these

devices.

For information on controller compatibility refer to the Controls and Options Tables on pages 12 and 13.

PACP4B000.

ENCXLUS

256 16 64 4 10/4 24 VAC

12 VDC,

ODU

Provides for scheduling in addition

to basic indoor unit control and

monitoring.

Provides for scheduling, remote

controller lock, setpoint range limit,

web access, peak/demand control,

PDI integration, and AC Manager

Plus integration advanced

functionality in addition to basic unit

control and monitoring.

MULTI V Wall-Mounted Indoor Unit Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

10 | INTRODUCTION

©

CONTROLLERS OVERVIEW

Integration Solutions

Table 8: Summary Data—Integration Solutions (connect to outdoor unit terminals Internet A, Internet B).

Systems

per

Comm

Bus

Devices

per Comm

Bus

Integration

Solution

Name Model No.

Devices

per

Controller

ACP IV

®

BACnet

PQNFB17C1 256 16 256 4 24 VAC 10/4

Gateway*

LonWorks

Gateway*

Before specifying or placing an order, refer to the V-Net Network Solution Engineering Product Data Book and review the detailed technical data provided to fully understand the capabilities and limitations of these

devices.

For information on controller compatibility refer to the Controls and Options Tables on pages 12 and 13.

TM

* BACnet

is a trademark of ASHRAE; LonWorksTM is a trademark of Echlelon Corporation.

®

PLNWKB100 64 16 64 1 24 VAC 2/2

No. of

Comm

Bus

Ports

Power

Binary

Signals

Input/

Output

Description

Allow integration of LG equipment

for control and monitoring by open

®

protocol BACnet

and LonWorks®

building automation and controls

systems.*

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

INTRODUCTION | 11

CONTROLLERS OVERVIEW

Options and Features

Table 9: Options and Features.

Feature

Nominal Chassis Size (MBh)

Air supply outlets

Airflow direction (left/right)

Auto airflow direction (up/down)

Fan speed (Heating mode)

Fan speed (Cooling mode)

Fan speed (fan mode)

Airow

Chaos swing (random louver

swing)

Chaos wind (random fan speed)

Jet-cool (power cooling)

E.S.P. control

High ceiling

Auto-restart after power restore

Hot start

Diagnostics

Auto changeover

Auto operation

1

6

Auto clean (coil dry)

Child lock

Dual thermistor control

Dual set-point control

Filter life display

Operation

Power consumption display

(with PDI)

Forced operation

Wall

Mounted—

Standard

Finish

5–24 7–24 7–24 18–24 5–18 24–48 7–96 7–24

1 1 1 2 4 4 1 1

manual auto

√ √ √ √ √ √

3 3 4 4 4 4 3 3

4 4 5 5 5 5 3 3

3 3 4 4 4 4 3 3

√ √

√ √ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √

Wall Mounted—

ART COOL™

Mirror

1-Way

Cassette

√ √ √ √ √ √

√ √ √ √

Group control – Requires the

use of one Group control cable

kit (PZCWRCG3) for every

√ √ √ √ √ √ √ √

additional indoor unit

Timer (on/off)

Weekly schedule

Test operation mode

3

Plasma

Filter

Washable anti-fungal

2

7-day programmable controller

MULTI V Wall-Mounted Indoor Unit Engineering Manual

Simple controller w/mode

Simple controller w/o mode

Controllers

Wireless controller

Condensate lift

Ventilation air

Casing

Standard grille

Auto elevation grille

Others

Suction grille

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √ √ √

o o o o o o o o

o o o o o o o o

o o o o o o o o

o o o o o o o

√ √ √ √ √ √

√ √

√ √ √ √ √ √

√ √ √ √

Suction canvas

Aux. heat kit

1

For Heat Recovery systems only.

2

Primary washable filters.

3

Secondary plasma filters.

4

Requires 7-day programmable zone controller.

5

Requires ventilation kit PTVK430 or PTVK410+PTVK420 (For TP, TN, TM frames)(Temperature, humidity, and volume limitations apply).

6

Heat Pump systems only.

2-Way

Cassette

4-Way Cassette

5

√

o

√ = Standard feature

o = Unit option

5

Ducted High

Static

4

√ √

Ducted Low

Static

4

o

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

12 | INTRODUCTION

©

Table 10: Options and Features, continued.

CONTROLLERS OVERVIEW

Options and Features

Feature

Nominal Chassis Size (MBh)

Air supply outlets

Airflow direction (left/right)

Ducted Low

Static—

Bottom Return

7–24 12-36 42-53 18–24 9–12 7–24 7–24

1 1 1 1 1 1 1

Vert.-Horiz.

AHU (NJ)

Vert.-Horiz.

AHU (NK)

Ceiling

Suspended

manual manual

Auto airflow direction (up/down)

Fan speed (Heating mode)

Fan speed (Cooling mode)

Fan speed (fan mode)

Airow

Chaos swing (random louver

3 3 3 3 3 3 3

3 3 3 4 4 3 3

3 3 3 3 3 3 3

swing)

Chaos wind (random fan speed)

Jet-cool (power cooling)

E.S.P. control

Auto-restart after power restore

Hot start

Diagnostics

Auto changeover

Auto operation

1

6

√ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

Auto clean (coil dry)

Child lock

Dual thermistor control

Dual set-point control

Filter life display

Power consumption display

Operation

(with PDI)

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

Forced operation

Group control – Requires the

use of one Group control cable

kit (PZCWRCG3) for every

√ √ √ √ √ √ √

additional indoor unit

Timer (on/off)

Weekly schedule

Test operation mode

3

Plasma

Filter

Washable anti-fungal

2

7-day programmable controller

Simple controller w/mode

Simple controller w/o mode

Controllers

Wireless controller

Condensate lift

Ventilation air

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √

√ √ √ √ √

o o o o o

o o o o o o o

o o o o o o o

4

o

o o o o o

√

√

Casing

Standard grille

Auto elevation grille

Others

Suction grille

Suction canvas

Aux. heat kit

1

For Heat Recovery systems only.

2

Primary washable filters.

3

Secondary plasma filters.

4

Requires 7-day programmable zone controller.

5

Requires ventilation kit PTVK430 or PTVK410+PTVK420 (For TP, TN, TM frames)(Temperature, humidity, and volume limitations apply).

6

Heat Pump systems only.

o

o

√ √

Convertible

Surface

Mount

Floor Mount—

Cased

√ √

√ √

√ √

√ √

√ √ √

√ = Standard feature

o = Unit option

Floor Mount—

Uncased

Introduction

4

4

o

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

INTRODUCTION | 13

LATS MULTI V PIPING

DESIGN SOFTWARE

The proper design and installation of the refrigerant piping system

is a critical element of a Multi V system. Multi V Heat Pump systems

require two pipes between components – a liquid line and a vapor

line. Multi V Heat Recovery systems require three pipes between the

outdoor unit and the heat recovery unit – a liquid line, a low-pressure vapor line, and a high-pressure vapor line. A properly designed

refrigerant piping system ensures that refrigerant is delivered to the

indoor unit coils for optimal system performance and capacity.

LG Air Conditioner Technical Solution (LATS) software is a total

design solution for LG Multi V air conditioning systems. This

Windows®-based application assists the design engineer with

specifying and sizing outdoor and indoor units (by calculating

component capacity based on design conditions), laying out the

refrigeration distribution pipe system, checking piping limitations,

calculating refrigerant charge, and generating equipment schedules

and piping diagrams in (.dxf) format for use on CAD building design

drawings.*

* Windows® is a registered mark of Microsoft® Corporation.

To ensure that the refrigerant piping design meets LG’s quality standards, a LATS refrigerant piping design must be provided with

every Multi V order. Following the installation, if any changes or variations to the design are necessary, a new LATS file must be

created and provided to LG prior to system commissioning to ensure the proper pipe size has not changed.

Design Choices

LATS Multi V software is flexible, offering the HVAC system engineer an easy to use Tree mode.

Tree Mode

Using the Tree mode, the engineer can quickly create a one-line schematic drawing of a Multi V system. Integration of the engineered pipe

system into the building drawings is done at a later date by the draftsperson using standard drafting software tools.

• Import building loads from an external file (.xls format).

• System components selected using an easy drag and drop process.

• Automatically analyzes and checks the design complies with most

piping design limitations.

• Sizes refrigerant piping.

• Generates a system engineering report (.xls format).

MULTI V Wall-Mounted Indoor Unit Engineering Manual

• Generates an equipment schedule (.xls or .dxf format).

• Generates a system piping diagram (.dxf format).

Figure 1: Screenshot of LATS Pipe System Design Tool in Tree Mode.

LATS Report

LATS Multi V software generates a report file (.xls format) containing

project design parameters, cooling and heating design day system

component performance, and capacity data. The report calculates

the system combination ratio, calculates the system refrigerant

charge, and provides detailed bill of material information including a

list of Multi V outdoor units, air handlers, control devices, accessories, refrigerant pipe sizes segregated by building, by system, by pipe

size, and by pipe segments.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

14 | INTRODUCTION

©

TM

ART COOL

MIRROR

WALL-MOUNTED

Mechanical Specifications on page 16

General Data on page 17

Electrical Data on page 18

External Dimensions on page 19

Electrical Wiring Diagram on page 21

Refrigerant Flow Diagrams on page 23

Acoustic Data on page 24

Air Velocity / Temperature Distribution on page 26

Capacity Tables on page 29

ART COOLTM MIRROR

Mechanical Specications

Casing

Units are designed to mount on a vertical surface and come complete with an installation mounting guide and a separate hanging

bracket. The unit case is manufactured with coated metal. Cold

surfaces are covered with a coated polystyrene insulating material.

Finish

The unit case has a light gray/silver matte finish. The front surface of

the unit has an architectural flat panel smoked mirror finish.

Fan Assembly and Control

The unit has a single, direct-drive, crossflow tangential Sirocco fan

made of high strength ABS BSN-7530 polymeric resin. The fan motor

is a Brushless Digitally Controlled (BLDC) design with permanently

lubricated and sealed ball bearings. The fan motor includes thermal,

overcurrent and low RPM protection. The fan / motor assembly is

mounted on vibration attenuating rubber grommets. The fan impeller

is statically and dynamically balanced. The fan speed is controlled

using a microprocessor-based direct digital control algorithm that

provides a high fan speed in cooling thermal ON and low fan speed

in cooling thermal OFF, high fan speed in heating thermal ON and

fan off in heating thermal OFF. The fan speeds can be field adjusted

between low, medium, and high speeds. The fan speed algorithm

provides a field-selectable fixed-speed or auto-speed setting that

changes the fan speed to simulate natural airflow.

Air Filter

Return air is filtered with a removable, washable filter with antifungal treatment. The unit is also equipped with a plasma filter. Filter

access is from the front of the unit without the use of tools.

Airflow Guide Vanes

The indoor unit is provided with a motorized sweeping guide vane

that automatically changes the direction of airflow from side-to-side

and up-and-down.

Microprocessor Control

The unit is provided with an integrated microprocessor controller

capable of performing functions necessary to operate the system

without the use of a wall-mounted controller. A temperature thermistor is factory mounted in the return air stream. All unit operation parameters, excluding the operating schedule, are stored in

non-volatile memory resident on the unit microprocessor. Operating

MULTI V Wall-Mounted Indoor Unit Engineering Manual

schedules are stored in select models of the optional, wall-mounted,

local or central controllers. The field-supplied communication cable

between the indoor unit(s) and outdoor unit is to be a minimum of 18

AWG, two conductor, stranded, and shielded cable (RS-485), terminated via screw terminals on the control boards. The microprocessor

control provides the following functions: self-diagnostics, auto restart

following power restoration, test run, and will operate the indoor unit

using one of five operation modes:

1. Auto Changeover (Heat Recovery only)

2. Heating

3. Cooling

4. Dry

5. Fan Only

For Heat Recovery systems the Auto Changeover setting automatically switches control of the indoor unit between Cooling and Heating

modes based on

space temperature

conditions.

For Heat Pump

systems, heated or

cooled air delivery is

dependent upon outdoor unit operating mode. In Heating mode, the

microprocessor control will activate indoor unit operation when the

indoor room temperature falls below setpoint temperature. At which

point, a signal is sent to the outdoor unit to begin the heating cycle.

The indoor unit fan operation is delayed until coil pipe temperature

reaches 76°F. Significant airflow is generated when pipe temperature

reaches 80°F. A field-selectable option maintains fan operation for

30 minutes following cooling cycle operations. The unit is equipped

with an infrared receiver designed to communicate with an LG

wireless remote controller. In lieu of wireless remote or factory return

air thermistor, screw terminals on the microprocessor circuit board

accommodate various models of wall-mounted local controllers.

The unit microprocessor is capable of accepting space temperature

readings concurrently or individually from either:

1. Wall-mounted wired controller(s)

2. Factory-mounted return air thermistor

A single indoor unit has the capability of being controlled by up to

two local wired controllers. The microprocessor controls space temperature using the value provided by the temperature sensor sensing

a space temperature that is farthest away from the temperature setpoint. The microprocessor control provides a cooling mode test cycle

that operates the unit for 18 minutes without regard to the space

temperature. If the system is provided with an optional wall-mounted

local or central controller, displayed diagnostic codes are specific,

alpha-numeric, and provide the service technician with a reason for

the code displayed.

Handling Condensate

The unit is designed for gravity draining of condensate. LG provides

a factory insulated flexible drain hose. If condensate lift / pumps are

needed for the application, they are to be field provided.

Condensate Drain Pan

The condensate drain pan is constructed of EPS (expandable polystyrene resin).

Coil

The indoor unit coil is constructed with grooved design copper tubes

with slit coil fins, two (two) rows, eighteen (18) fins per inch.

Controls Features

• Auto changeover

(Heat Recovery only)

• Auto operation

• Auto clean (coil dry)

• Child lock

• Dual thermistor control

• Group control

1

Requires wireless controller.

1

• Hot start

• Self diagnostics

• Timer (on/off)

• Weekly schedule

• Auto direction/swing (up/down)

• Auto direction (left/right)

• Fan speed control

• Jet cool (fast cooling)

16 | ART COOL

TM

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

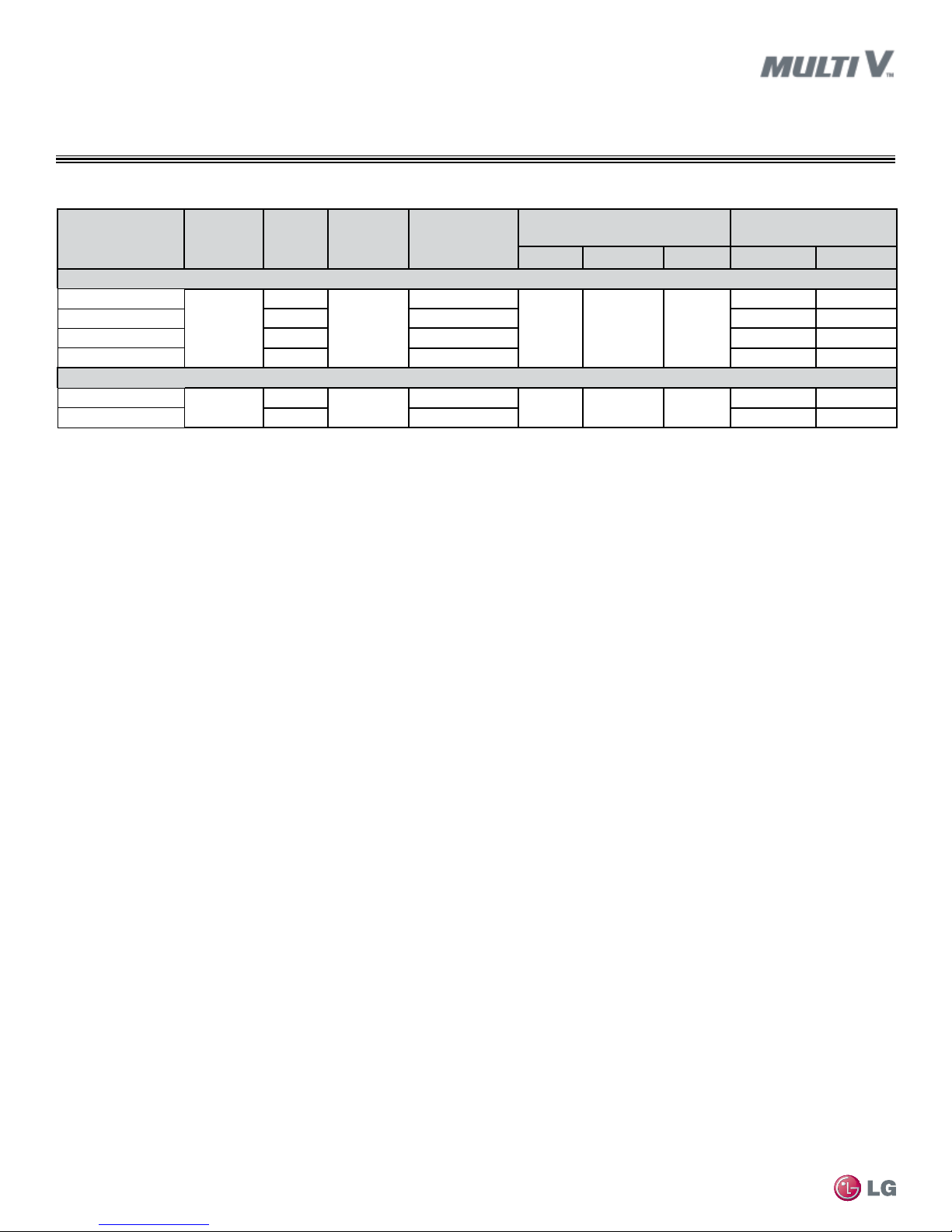

Table 11: Art Cool Mirror Wall-Mounted (SE, S8 Frames) Indoor Unit General Data.

Model No. ARNU073SER2 ARNU093SER2 ARNU123SER2 ARNU153SER2 ARNU183S8R2 ARNU243S8R2

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

7,500 9,600 12,300 15,400 19,100 24,200

40 40 40 40 35 35

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

8,500 10,900 13,600 17,100 21,500 27,300

40 40 40 40 35 35

Entering Mixed Air

Cooling Max (°F WB)

Heating Min (°F DB)

76 76 76 76 76 76

59 59 59 59 59 59

Unit Data

2

Refrigerant Type

Refrigerant Control

Sound Pressure3 dB(A) (H/M/L)

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4

(No. x AWG)

R410A R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV EEV

37 / 33 / 23 39 / 35 / 25 41 / 36 / 27 42 / 36 / 27 37 / 34 / 31 43 / 37 / 32

25 25 25 25 34 34

29 29 29 29 38 38

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Fan

Type

Quantity

Motor/Drive

Airflow Rate H/M/L (CFM)

Cross Flow Cross Flow Cross Flow Cross Flow Cross Flow Cross Flow

1 1 1 1 1 1

Brushless Digitally Controlled / Direct

247 / 212 / 141 282 / 247 / 177 353 / 283 / 212 371 / 283 / 212 508 / 459 / 388 632 / 508 / 424

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national codes.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft level

difference between outdoor and indoor units. All capacities are net with a combination ratio between

95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and 67ºF wet

bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and outdoor

ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

5/8 5/8 5/8 5/8 5/8 5/8

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or destroy

R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F) under section 608

of CAA.

3

Sound Pressure levels are tested in an anechoic chamber under ISO Standard 3745.

4

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and must comply

with applicable and national code. Ensure the communications cable is properly grounded at the master

outdoor unit only. Do not ground the ODU-IDU communications cable at any other point.

ART COOLTM MIRROR

General Data

Art Cool

TM

Mirror

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

ART COOLTM | 17

ART COOLTM MIRROR

Electrical Data

Table 12: Art Cool Mirror Wall-Mounted Indoor Unit Electrical Data.

Model Number

Voltage

Range

MCA MOP Rated Amps (A)

Power Supply Power Input (W)

Hz Volts Phase Cooling Heating

SE Frames

ARNU073SER2

ARNU093SER2 0.29 0.3 40 40

ARNU123SER2 0.29 0.3 40 40

187-253

0.29

15

0.3

40 40

60 208-230V 1

ARNU153SER2 0.29 0.3 40 40

S8 Frames

ARNU183S8R2

ARNU243S8R2 0.29 0.3 35 35

MCA : Minimum Circuit Ampacity.

MOP : Maximum Overcurrent Protection.

187-253

0.29

Units are suitable for use on an electrical system where voltage supplied to unit terminals is within the listed range limits.

Select wire size based on the larger MCA value.

Instead of a fuse, use the circuit breaker.

15

0.3

60 208-230V 1

35 35

MULTI V Wall-Mounted Indoor Unit Engineering Manual

18 | ART COOL

TM

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

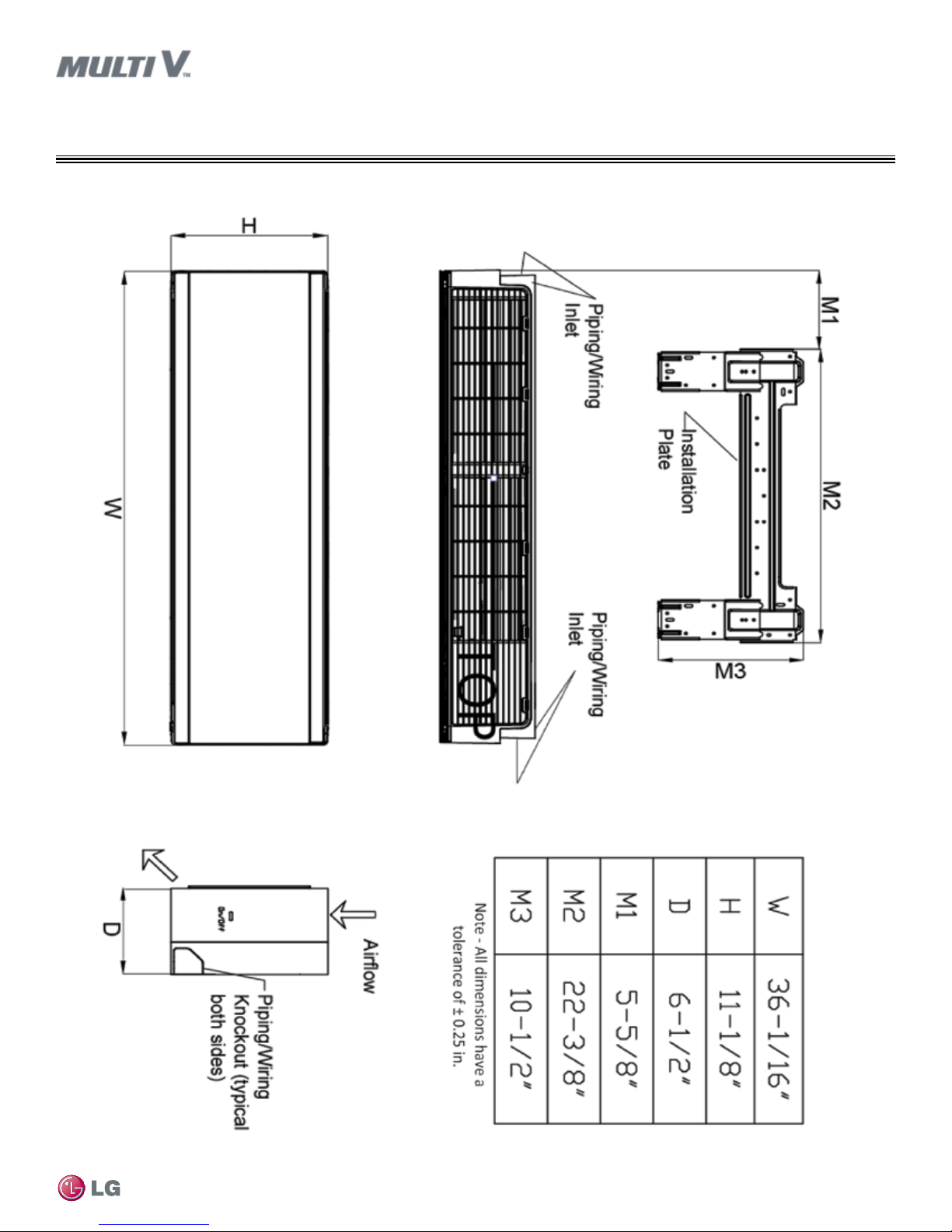

Figure 2: ARNU073SER2, ARNU093SER2, ARNU123SER2, ARNU153SER2 Dimensions.

ART COOLTM MIRROR

External Dimensions

SE Frame

Art Cool

TM

Mirror

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a r egistered tra demark of LG Corp.

©

ART COOLTM | 19

Loading...

Loading...