A INTRODUCTION

This manual consists of the following 11 sections:

No.

A

B

C

D

E

Section Description

INDEX

INTRODUCTION

HOW TO USE

THIS MANUAL

TROUBLE–

SHOOTING

ABBREVIATIONS

GLOSSARY OF

TERMS AND

SYMBOLS

Index of the contents of this manual.

Brief explanation of each section.

Instructions on how to use this manual.

Describes the basic inspection procedures for electrical circuits.

Defines the abbreviations used in this manual.

Defines the symbols and functions of major parts.

F

G

H

J

RELAY LOCATIONS

ELECTRICAL

WIRING ROUTING

POWER SOURCE

(Current Flow Chart)

INDEX

SYSTEM CIRCUITS

I

GROUND POINTS

Shows position of the Electronic Control Unit, Relays, Relay Block, etc.

This section is closely related to the system circuit.

Describes position of Parts Connectors, Splice points, Ground points, etc.

This section is closely related to the system circuit.

Describes power distribution from the power supply to various electrical

loads.

Index of the system circuits.

Electrical circuits of each system are shown from the power supply through

ground points. Wiring connections and their positions are shown and

classified by code according to the connection method. (Refer to the

section, “How to sue this manual”). The “System Outline” and “Service

Hints” useful for troubleshooting are also contained in this section.

Shows ground positions of all the parts decribed in this manual.

2

K

OVERALL

ELECTRICAL

WIRING DIAGRAM

Provides circuit diagrams showing the circuit connections.

HOW TO USE THIS MANUAL B

This manual provides information on the electrical circuits installed on vehicles

by dividing them into a circuit for each system.

The actual wiring of each system circuit is shown from the point where the power

source is received from the battery as far as each ground point. (All circuit

diagrams are shown with the switches in the OFF position.)

When troubleshooting any problem, first understand the operation of the circuit

where the problem was detected (see System Circuit section), the power source

supplying power to that circuit (see Power Source section), and the ground

points (see Ground Points section). See the System Outline to understand the

circuit operation.

When the circuit operation is understood, begin troubleshooting of the problem

circuit to isolate the cause. Use Relay Location and Electrical Wiring Routing

sections to find each part, junction block and wiring harness connectors, wiring

harness and wiring harness connectors, splice points, and ground points of each

system circuit. Internal wiring for each junction block is also provided for better

understanding of connection within a junction block.

Wiring related to each system is indicated in each system circuit by arrows

(from

Wiring Diagram at the end of this manual.

,to ). When overall connections are required, see the Overall Electrical

3

B HOW TO USE THIS MANUAL

* The system shown here is an EXAMPLE ONLY. It is different to the actual

circuit shown in the SYSTEM CIRCUITS SECTION.

4

B

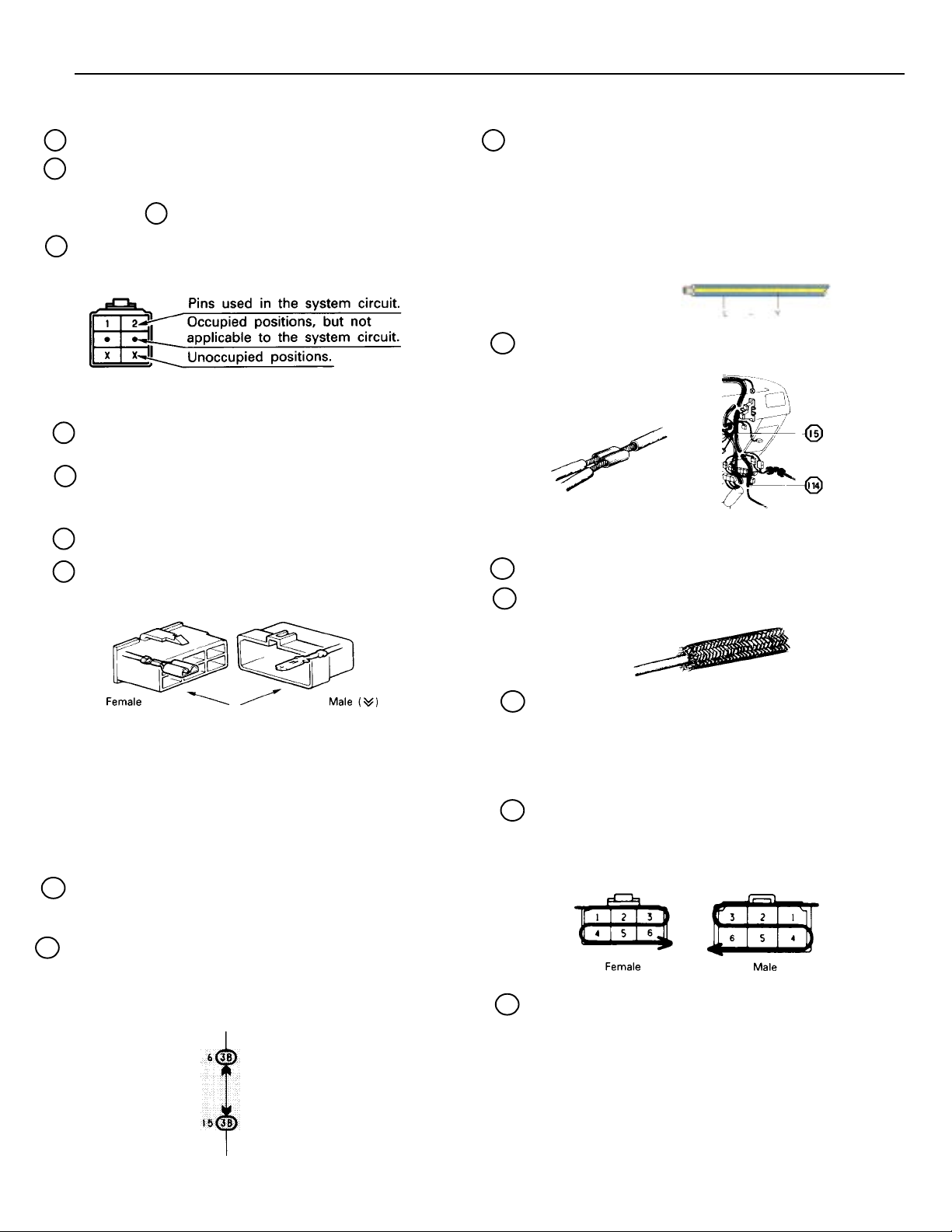

A : System Title

B : Indicates a Relay Block. No shading is used and only the

Relay Block No. is shown to distinguish it from the J/B.

Example: 1 Indicates Relay Block No. 1.

C : Indicates the connector to be connected to a

part (the numeral indicates the pin No.)

Explanation of pin use.

The pins shown are only for the highest grade, or only

include those in the specification.

D : Connector Color Connectors not indicated are milky

white in color:

E : ( ) is used to indicate different wiring and connector, etc.

when the vehicle model, engine type, or specification is

different.

F : Indicates related system.

G : Indicates the wiring harness and wiring harness

connector. The wiring harness with male terminal is

shown with arrows ( ).

v

v

J : Indicates the wiring color.

Wire colors are indicated by an alphabetical code.

B = Black

BR = Brown

G = Green

GR = Gray

L = Black

LG = Light Green

O = Orange

P = Pink

R = Red

V = Violet

W = White

Y = Yellow

The first letter indicates the basic wire color and the second

letter indicates the color of the stripe.

Example: L – Y

(blue) (yellow)

K : Indicates a wiring Splice Point (Codes are “E” for

the Engine Room, “I” for the Instrument Panel,

and “B” for the Body).

Example:

The Location of Splice Point I 5 is indicated by the shaded

section.

L : Page No.

M : Indicates a shielded cable.

The first letter of the code for each wiring harness and wiring

harness connector(s) indicates thecomponent’s location, e.g,

“E” for the Engine Compartment, “I” for the Instrument Panel

and Surrounding area, and “B” for the Body and Surrounding

area.

When more than one code has the first and second letters in

common, followed by numbers (e.g, IH1, IH2), this indicates

the same type of wiring harness and wiring harness connector.

H : Represents a part (all parts are shown in sky

blue). The code is the same as the code used in

parts position.

I : Junction Block (The number in the circle is the

J/B No. and the connector code is shown beside

it). Junction Blocks are shaded to clearly

separate them from other parts (different junction

blocks are shaded differently for further

clarification).

Example:

3B indicates

that it is inside

Junction Block

No. 3.

N : Indicates a ground point.

The first letter of the code for each ground point(s) indicates

the component’s location, e.g. “E” for the Engine

Compartment, “I” for the Instrument Panel and Surrounding

area, and “B” for the Body and Surrounding area.

O : Indicates the pin number of the connector.

The numbering system is different for female and male

connectors.

lower right

lower left

P : When 2 parts both use one connector in common, the parts

connector name used in the wire routing section is shown in

square brackets [ ].

5

B HOW TO USE THIS MANUAL

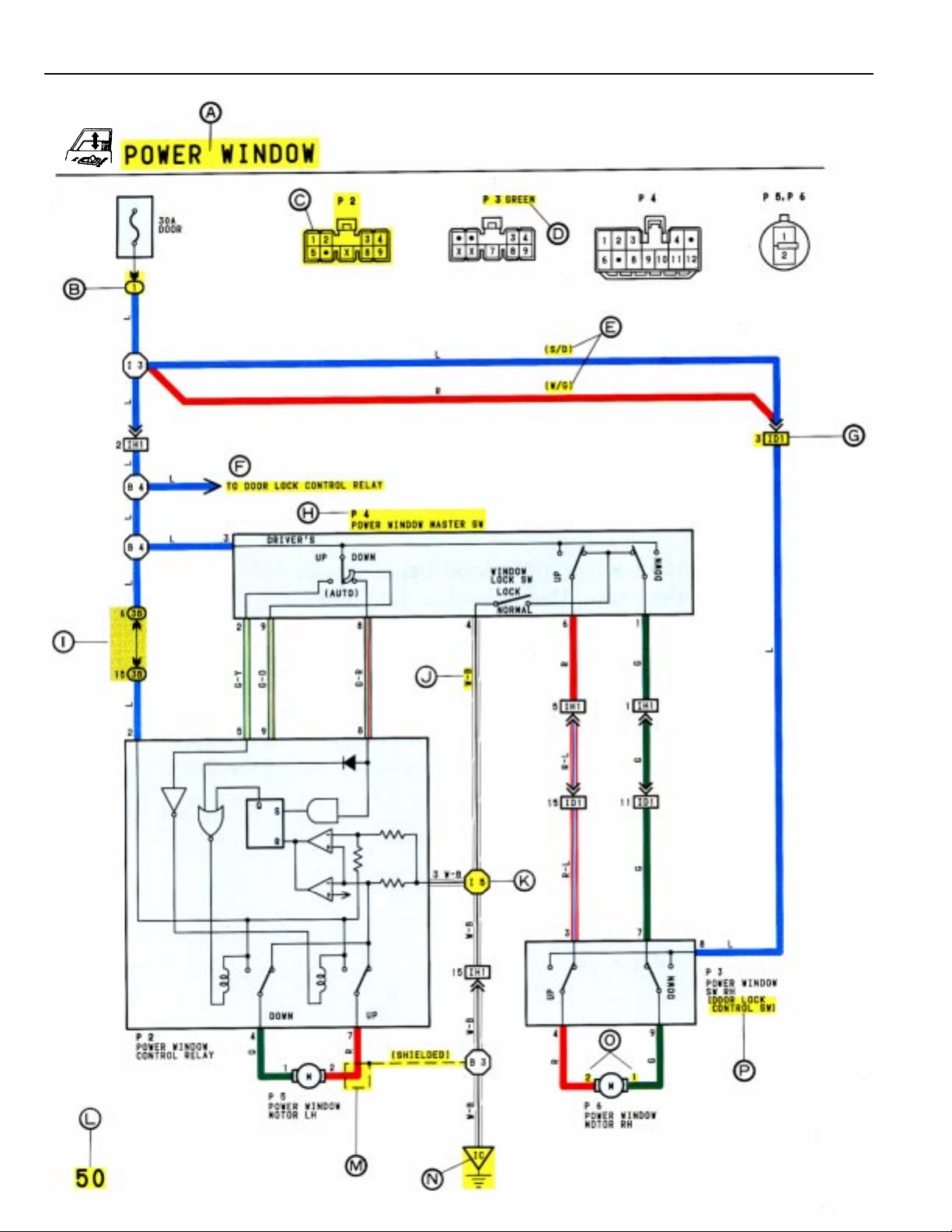

Q

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 3 OF THE POWER WINDOW MASTER SW, TERMINAL 2 OF THE POWER WINDOW CONTROL

RELAY AND TERMINAL 8 OF THE POWER WINDOW SW THROUGH THE DOOR FUSE.

1. DRIVER’S WINDOW “MANUAL UP” OPERATION BY MASTER SW

HOLDING MANUAL SW (DRIVER’S) ON “UP” POSITION LOCATED IN POWER WINDOW MASTER SW, THE CURRENT FLOWS TO TERMINAL 5 OF THE POWER WINDOW CONTROL RELAY THROUGH TERMINAL 3 OF THE MASTER SW TERMINAL 2 TO OPERATE A POWER WINDOW CONTROL RELAY. THUS THE CURRENT INSIDE THE RELAY

FLOWS FROM TERMINAL 2 OF THE RELAY TERMINAL 1 TERMINAL 2 OF THE POWER WINDOW MOTOR TERMINAL 1 TERMINAL 4 OF THE RELAY TERMINAL 3 TO GROUND. THE MOTOR TURNS TO ASCENT THE WINDOW. RELEASING THIS SW, THE ROTATION OF MOTOR IS STOPPED AND THE WINDOWS CAN STOP AT

WILL POINT.

(FOR THE “MANUAL DOWN” OPERATION, CURRENT FLOWS IN THE REVERSE DIRECTION BECAUSE THE TERMINALS WHERE IT FLOW ARE CHANGED).

2. DRIVER’S WINDOW “AUTO DOWN” OPERATION BY MASTER SW

ONCE THE “AUTO DOWN” BUTTON OF THE MASTER SW IS PUSHED, THE CURRENT FLOW TERMINAL 9 OF THE POWER WINDOW CONTROL RELAY THROUGH TERMINAL 3

OF THE MASTER SW TERMINALS 8 AND 9 TO OPERATE THE RELAY. THUS THE CURRENT INSIDE THE POWER WINDOW CONTROL RELAY FLOWS FROM TERMINAL 2 OF

THE RELAY TERMINAL 4 TERMINAL 1 OF THE POWER WINDOW MOTOR TERMINAL 2 TERMINAL 1 OF THE RELAY TERMINAL 3 TO GROUND. THE

MOTOR CONTINUES THE ROTATION ENABLING TO DESCENT THE WINDOW.

THE WINDOW DESCENDS TO THE END POSITION. THE CURRENT WILL BE CUT OFF TO RELEASE THE AUTO DOWN FUNCTION BASED ON THE INCREASING CURRENT

BETWEEN TERMINAL 2 OF THE RELAY AND TERMINAL 1 IN RELAY.

3. DRIVER’S WINDOW AUTO DOWN RELEASE OPERATION BY MASTER SW

HOLDING THE MANUAL SW (DRIVER’S) ON “UP” POSITION IN OPERATING AUTO DOWN. THE CURRENT FROM TERMINAL 3 OF THE MASTER SW PASSING TERMINAL 2

FLOWS TERMINAL 5 OF THE RELAY AND RELEASES THE AUTO DOWN FUNCTION IN THE POWER WINDOW CONTROL RELAY. RELEASING THE HAND FROM SW, WINDOW

STOPS AND CONTINUING ON TOUCHING SW. THE FUNCTION SWITCHES TO MANUAL UP OPERATION.

4. PASSENGER’S WINDOW UP OPERATION (MASTER SW) AND WINDOW LOCK SW OPERATION

HOLDING PASSENGER’S WINDOW SW (MASTER SW) ON “UP”, THE CURRENT FLOWS FROM TERMINAL 3 OF THE MASTER SW PASSING TERMINAL 6 TO TERMINAL 3 OF THE

POWER WINDOW SW (PASSENGER’S) TERMINAL 4 TERMINAL 2 OF THE MOTOR TERMINAL 1 TERMINAL 9 OF THE POWER WINDOW SW TERMINAL 7

TERMINAL 1 OF THE MASTER SW TERMINAL 4 TO GROUND. THE MOTOR RUNS TO ASCENT THE WINDOW. RELEASING THIS SW, THE ROTATION OF MOTOR IS

STOPPED AND WINDOW CAN STOP AT WILL PLACE. SWITCHING THE WINDOW LOCK SW IN “LOCK” POSITION, THE CIRCUIT IS OPENED AND STOPPED THE MOTOR ROTATION.

(FOR THE DOWN OPERATION, CURRENT FLOWS IN THE REVERSE DIRECTION BECAUSE THE TERMINALS WHERE IT FLOWS ARE CHANGED).

R

P 2 POWER WINDOW CONTROL RELAY

3–GROUND: ALWAYS CONTINUITY

2–GROUND: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION

5–GROUND: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT UP POSITION

8–GROUND: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT AUTO DOWN POSITION

9–GROUND: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION AND THE MASTER SW AT DOWN OR AUTO DOWN POSITION

P 4 POWER WINDOW MASTER SW

4–GROUND: ALWAYS CONTINUITY

3–GROUND: APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION

WINDOW LOCK SW

OPEN WITH THE WINDOW LOCK SW AT LOCK POSITION

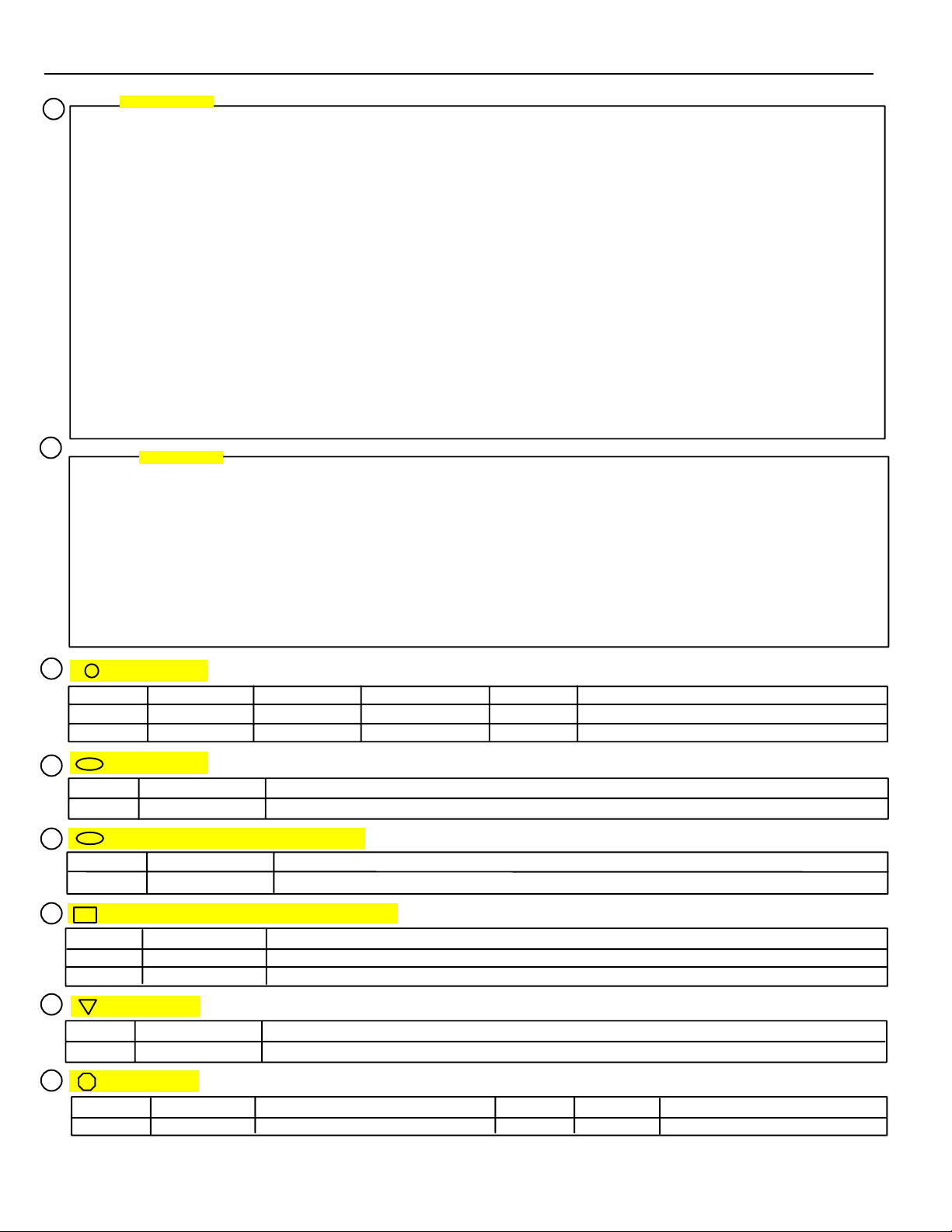

S

SYSTEM OUTLINE

SERVICE HINTS

: PARTS LOCATION

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

P2 21 P4 21 P6 21

P3 21 P5 21

T

: RELAY BLOCKS

CODE SEE PAGE RELAY BLOCK (RELAY BLOCK LOCATION)

1 16 R/B NO. 1 (INSTRUMENT PANEL LEFT)

U

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

38 14 J/B NO. 3 AND COWL WIRE (INSTRUMENT PANEL LEFT SIDE)

V

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE SEE PAGE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

ID1 26 FRONT DOOR RH WIRE AND COWL WIRE (RIGHT KICK PANEL)

IH1 26 FRONT DOOR LH WIRE AND COWL WIRE (LEFT KICK PANEL)

W

: GROUND POINTS

CODE SEE PAGE GROUND POINT LOCATION

IC 24 COWL LEFT

X

: SPLICE POINTS

CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS

I 5 24 COWL WIRE

6

B

Q : Explains the system outline.

R : Indicates values or explain the function for reference during troubleshooting.

S : Indicates the reference page showing the position on the vehicle of the parts in the system circuit.

Example: Part “P 4” (Power Window Master SW) is on page 21 of the manual.

* The letter in the code is from the first letter of the part, and the number indicates its order in

parts starting with the letter.

Example: P 4

Part is 4th in order

Power Window Master SW

T : Indicates the reference page showing the position on the vehicle of Relay Block Connectors in the system

circuit.

Example: Connector “1” is described on page 16 on this manual and is installed on the left side of the

instrument panel.

U : Indicates the reference page showing the position on the vehicle of J/B and Wire Harness in the system

circuit.

Example: Connector “3B”connects the Cowl Wire and J/B No. 3. It is described on page 14 of this manual,

and is installed on the instrument panel left side.

V : Indicates the reference page describing the wiring harness and wiring harness connector (the female wiring

harness is shown first, followed by the male wiring harness).

Example: Connector “ID1”connects the front door RH wire (female) and cowl wire (male). It is described

on page 26 of this manual, and is installed on the right side kick panel.

W : Indicates the reference page showing the position of the ground points on the vehicle.

Example: Ground point “IC” is described on page 24 of this manual and is installed on the cowl left side.

X : Indicates the reference page showing the position of the splice points on the vehicle.

Example: Splice point “I 5” is on the Cowl Wire Harness and is described on page 24 of this manual.

HINTS:

Junction connector (code: J1 to J19) in this manual

include a short terminal which is connected to a

number of wire harnesses. Always perform inspection with the short terminal installed. (When installing the wire harnesses, the harnesses can be connected to any position within the short terminal

grouping. Accordingly, in other vehicles, the same

position in the short terminal may be connected to

a wire harness from a different part.)

Wire harness sharing the same short terminal

grouping have the same color.

7

B HOW TO USE THIS MANUAL

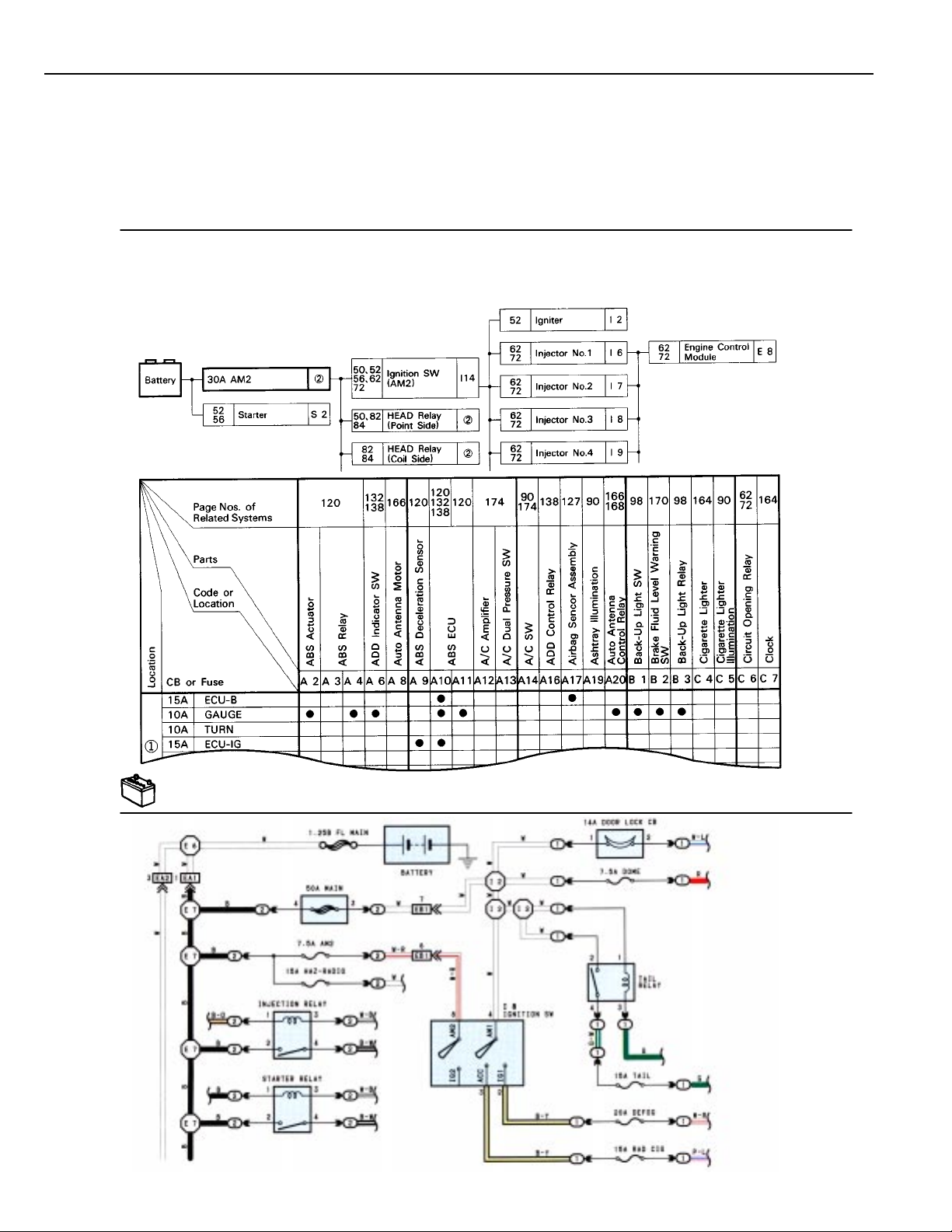

The “Current Flow Chart” section, describes which parts each power source (fuses, fusible links, and circuit

breakers) transmits current to. In the Power Source circuit diagram, the conditions when battery power is

supplied to each system are explained. Since all System Circuit diagrams start from the power source, the power

source system must be fully understood.

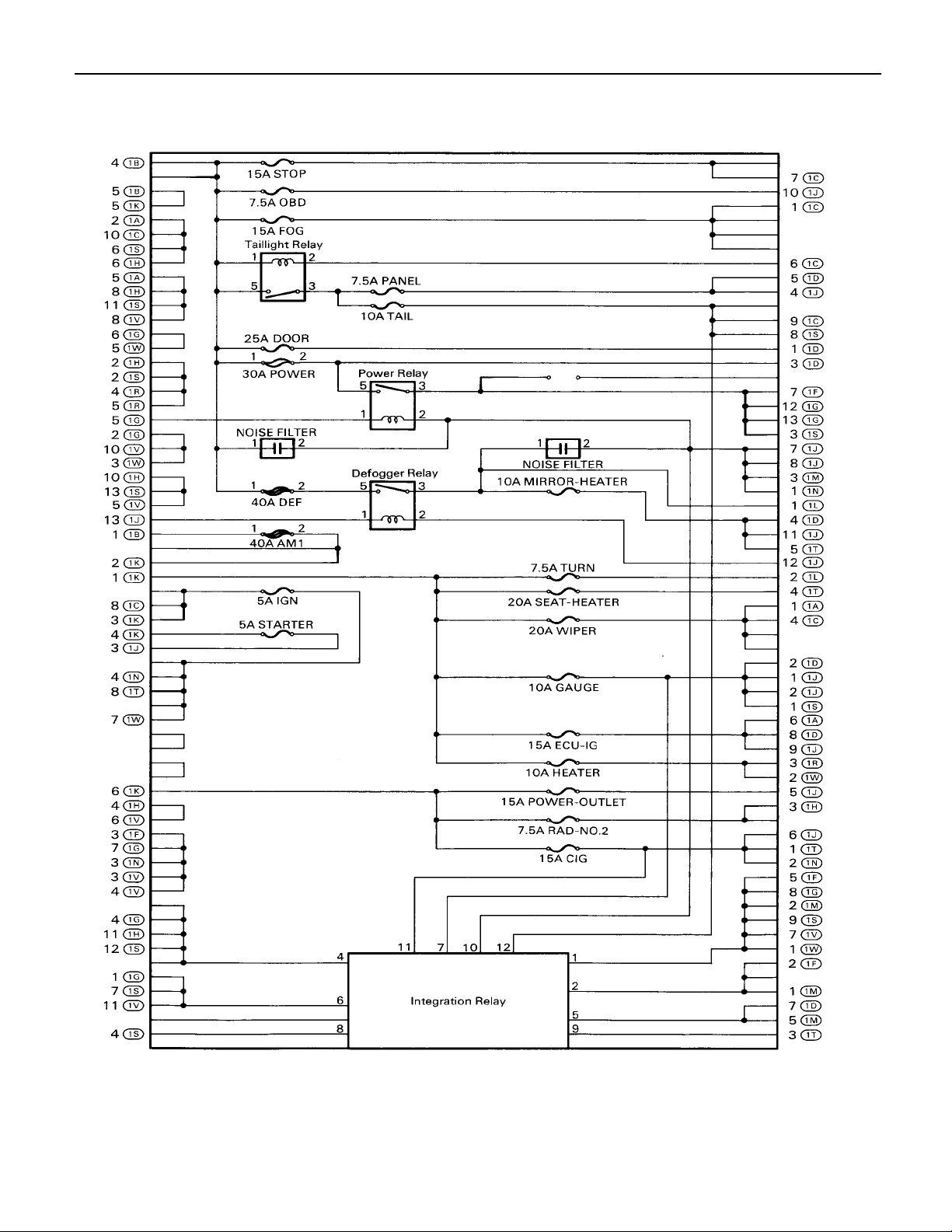

H POWER SOURCE (CURRENT FLOW CHART)

The chart below shows the route by which current flows from the battery to each electrical source (Fusible Link, Circuit Breaker, Fuse,

etc.) and other parts.

The next page and following pages shown the parts to which each electrical source outputs current.

8

POWER SOURCE

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

B

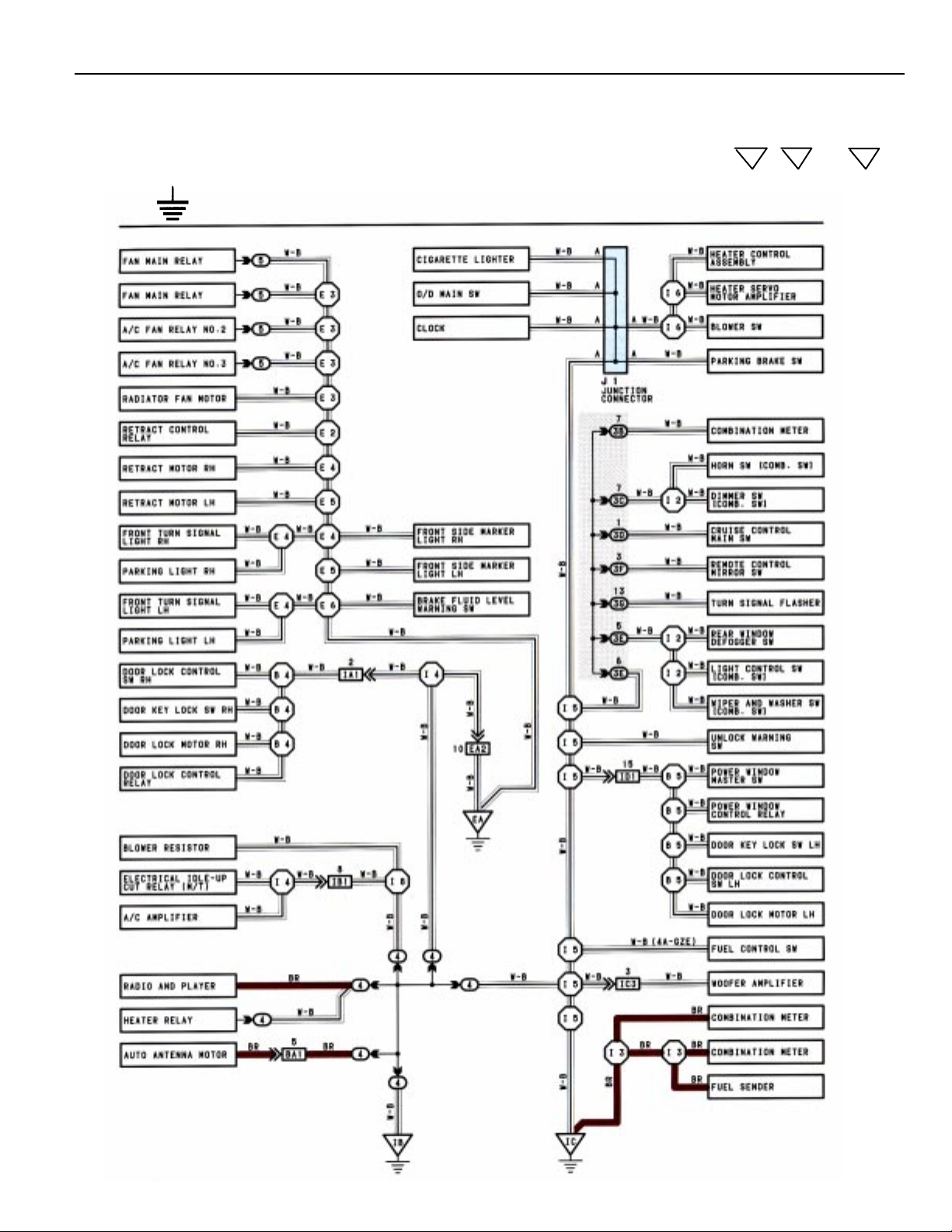

The ground points circuit diagram shows the connections from all major parts to the respective ground points.

When troubleshooting a faulty ground point, checking the system circuits which use a common ground may

help you identify the problem ground quickly. The relationship between ground points ( , and

EA

IB

IC

shown below) can also be checked this way.

J GROUND POINT

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

9

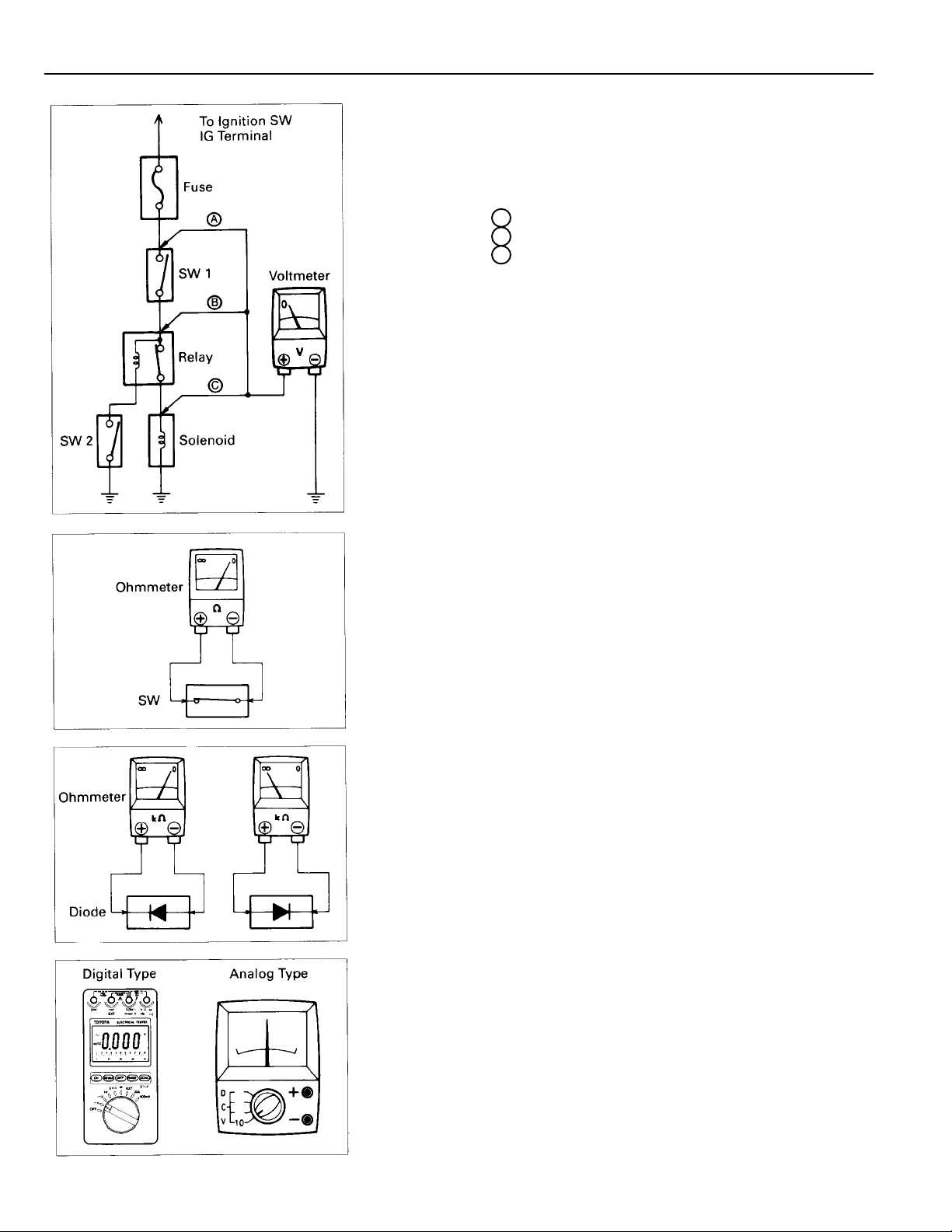

C TROUBLESHOOTING

VOLTAGE CHECK

(a) Establish conditions in which voltage is

check point.

Example:

A – Ignition SW on

B – Ignition SW and SW 1 on

C – Ignition SW, SW 1 and Relay on (SW2 off)

(b) Using a voltmeter, connect the negative lead to a

ground point or negative battery terminal, and a

positive lead to the connector or component terminal.

This check can be done with a test light instead of a

voltmeter.

CONTINUITY AND RESISTANCE CHECK

(a) Disconnect the battery terminal or wire so there is no

voltage between the check points.

(b) Contact the two leads of an ohmmeter to each of the

check point.

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative lead to the diode positive side

and the positive lead to the negative side, there should be

continuity.

When contacting the two leads in reverse, there should be

no continuity.

(c) Use the volt/ohmmeter with high impedance (10kΩ/V

minimum) for troubleshooting of the electrical circuit.

10

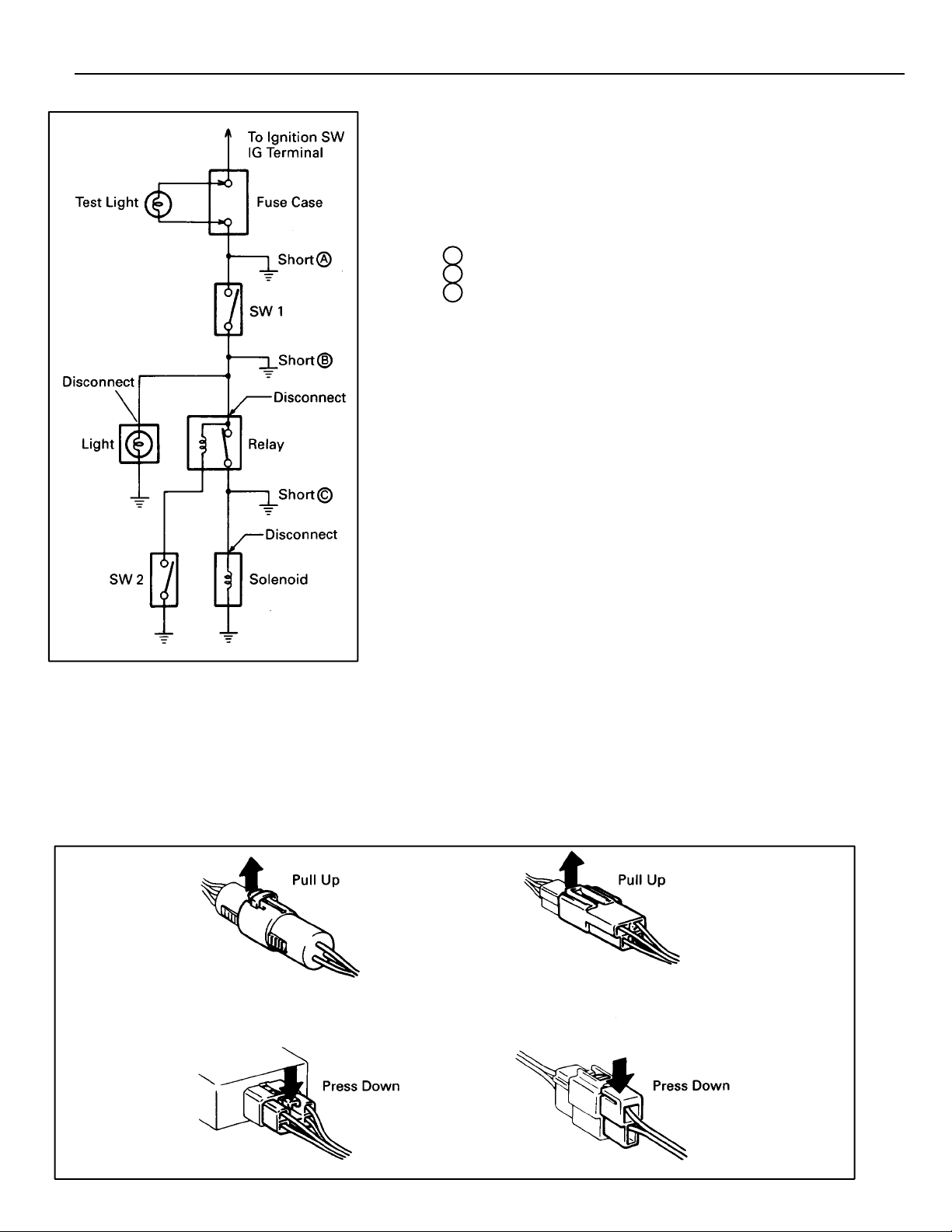

FINDING A SHORT CIRCUIT

(a) Remove the blown fuse and disconnect all loads of the

fuse.

(b) Connect a test light in place of the fuse.

(c) Establish conditions in which the test light comes on.

Example:

A – Ignition SW on

B – Ignition SW and SW 1 on

C – Ignition SW, SW 1 and Relay on (Connect the

Relay) and SW 2 off (or Disconnect SW 2)

(d) Disconnect and reconnect the connectors while watching

the test light.

The short lies between the connector where the test

light stays lit and the connector where the light goes

out.

(e) Find the exact location of the short by lightly shaking

the problem wire along the body.

CAUTION:

C

(a) Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) When replacing the internal mechanism (ECU part) of

the digital meter, be careful that no part of your body

or clothing comes in contact with the terminals of

leads from the IC, etc. of the replacement part (spare

part).

DISCONNECTION OF MALE AND FEMALE

CONNECTORS

To pull apart the connectors, pull on the connector itself, not the

wire harness.

HINT: Check to see what kind of connector you are disconnecting

before pulling apart.

11

C TROUBLESHOOTING

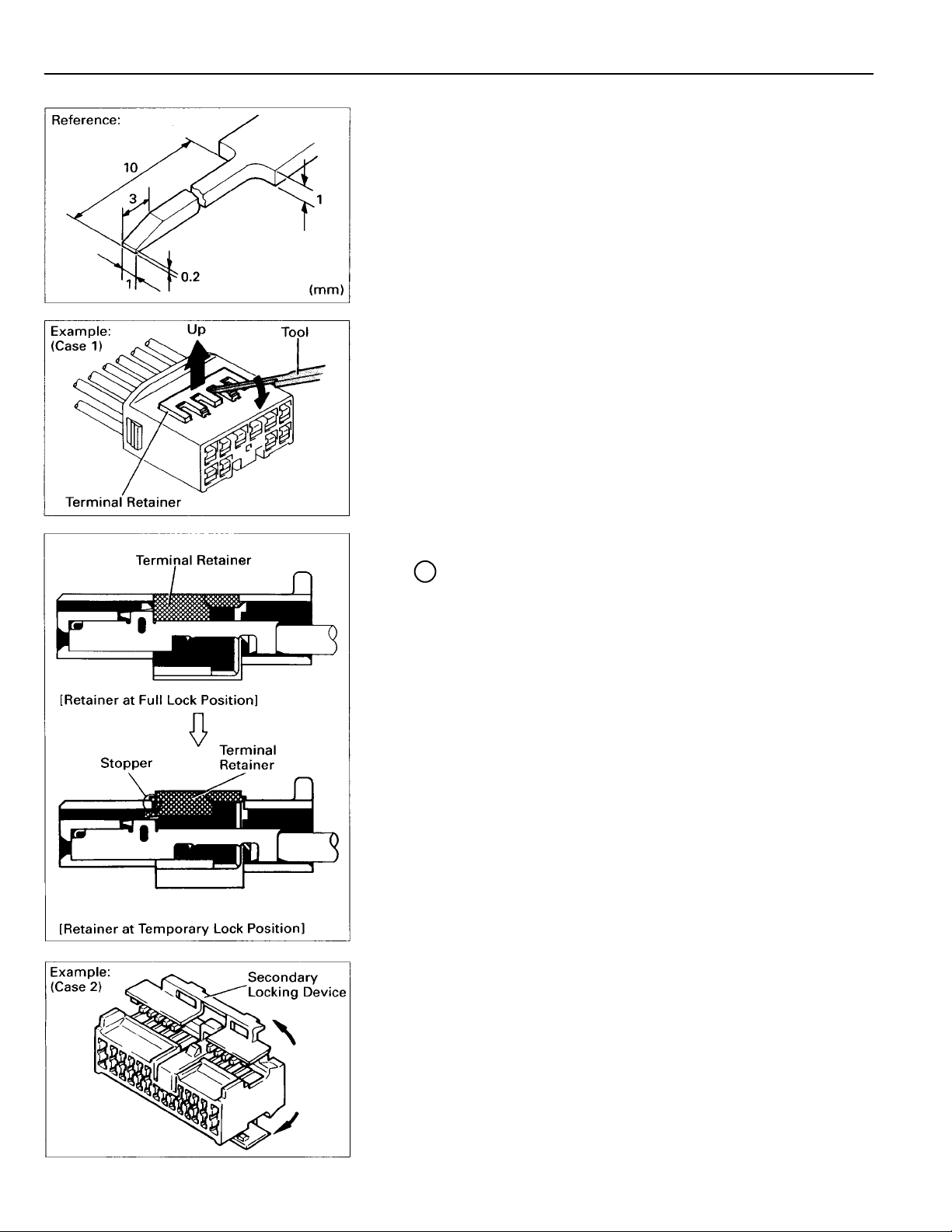

HOW TO REPLACE TERMINAL

(with terminal retainer or secondary locking

device)

1. PREPARE THE SPECIAL TOOL

HINT: To remove the terminal from the connector, please

construct and use the special tool or like object shown

on the left.

2. DISCONNECT CONNECTOR

3. DISENGAGE THE SECONDARY LOCKING DEVICE OR

TERMINAL RETAINER

(a) Locking device must be disengaged before the terminal

locking clip can be released and the terminal removed

from the connector.

(b) Use a special tool or the terminal pick to unlock the

secondary locking device or terminal retainer.

NOTICE:

Do not remove the terminal retainer from connector body.

A For Non–Waterproof Type Connector

HINT: The needle insertion position varies according to

the connector’s shape (number of terminals

etc.), so check the position before inserting it.

“Case 1”

Raise the terminal retainer up to the temporary

lock position.

12

“Case 2”

Open the secondary locking device.

For Waterproof Type Connector

B

HINT: Terminal retainer color is different

according to connector body.

Example:

Terminal Retainer

Black or White :Gray

Black or White :Dark Gray

Gray or White :Black

:Connector Body:

C

“Case 1”

Type where terminal retainer is

pulled up to the temporary lock

position (Pull Type).

Insert the special tool into the

terminal retainer access hole (Mark)

and pull the terminal retainer up to

the temporary lock position.

HINT: The needle insertion position varies

according to the connector’s shape

(number of terminals etc.), so check

the position before inserting it.

“Case 2”

Type which cannot be pulled as far as

Power Lock insert the tool straight

into the access hole of terminal

retainer as shown.

13

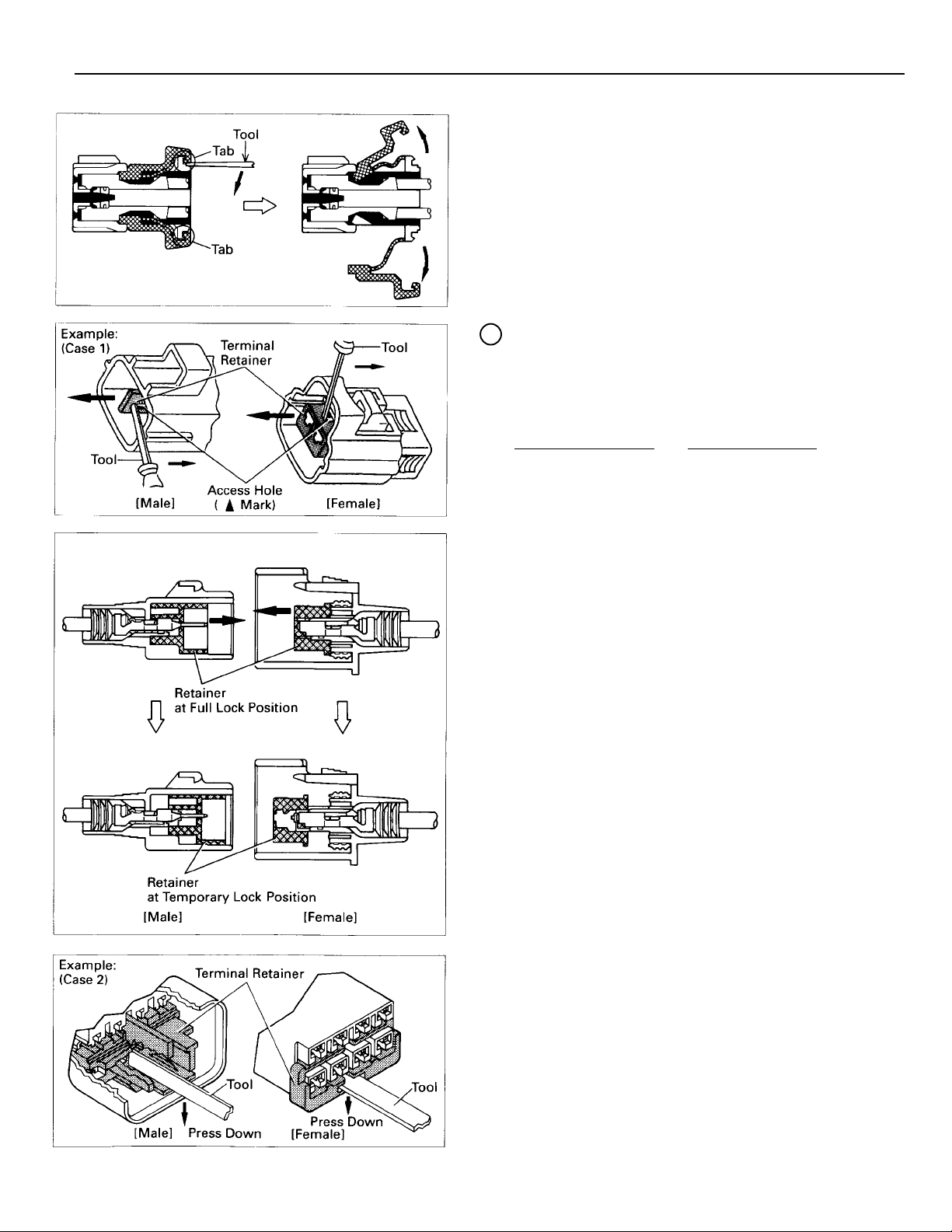

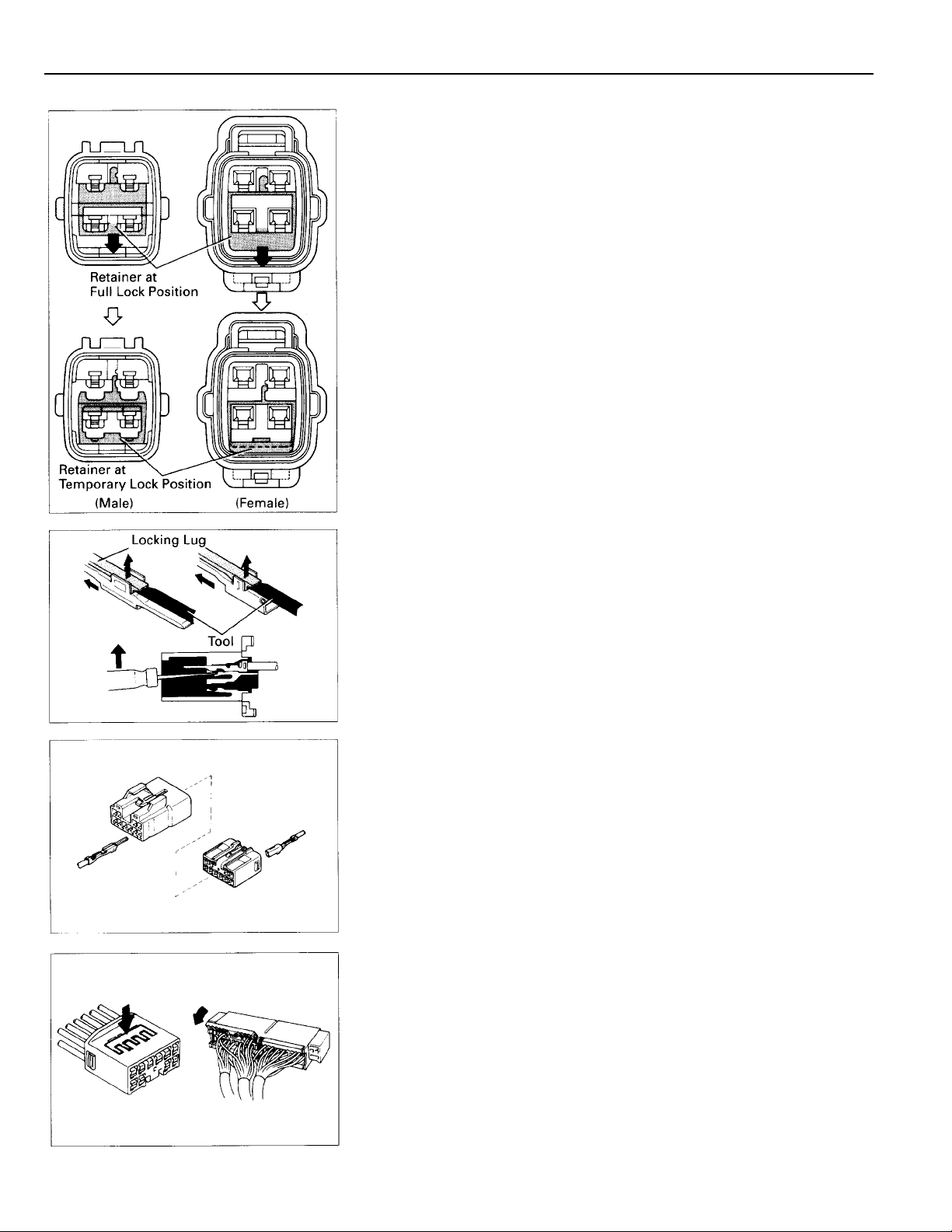

C TROUBLESHOOTING

Push the terminal retainer down to the temporary lock

position.

(c) Release the locking lug from terminal and pull the

terminal out from rear.

4. INSTALL TERMINAL TO CONNECTOR

(a) Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with terminal retainer in the

temporary lock position.

(b) Push the secondary locking device or terminal retainer

into the full lock position.

14

5. CONNECT CONNECTOR

ABBREVIATIONS

T

he following abbreviations are used in this manual.

ABS = Anti–Lock Brake System

A/C = Air Conditioning

ACIS = Acoustic Control Induction System

A/T = Automatic Transaxle

CD = Compact Disc

COMB. = Combination

ECU = Electronic Control Unit

EGR = Exhaust Gas Recirculation

ESA = Electronic Spark Advance

EVAP = Evaporative Emission

FL = Fusible Link

J/B = Junction Block

ABBREVIATIONS D

LH = Left–Hand

O/D = Overdrive

R/B = Relay Block

RH = Right–Hand

SFI = Sequential Multiport Fuel Injection

SRS = Supplemental Restraint System

SW = Switch

TEMP. = Temperature

TRAC = Traction Control

VSV = Vacuum Switching Valve

w/ = With

w/o = Without

* The titles given inside the components are the names of the terminals (terminal codes) and are

not treated as being abbreviations.

15

E GLOSSARY OF TERMS AND SYMBOLS

BATTERY

Stores chemical energy and

converts it int o e l e c trical energy.

Provides DC current for the

auto’s various electrical circuits.

CAPACITOR (Condenser)

A small holding unit for temporary

storage of electrical voltage.

CIGARETTE LIGHTER

An electric resistance heating

element.

CIRCUIT BREAKER

Basically a reusable fuse, a circuit

breaker will heat and open if too

much current flows through it.

Some units automatically reset when

cool, others must be manually reset.

DIODE

A semiconductor which allows

current flow in only one direction.

HEADLIGHTS

1. SINGLE

FILAMENT

2. DOUBLE

FILAMENT

GROUND

The point at which wiring attaches

to the Body, thereby providing a

return path for an electrical circuit;

without a ground, current cannot

flow.

Current flow causes a headlight

filament to heat up and emit light.

A headlight may have either a

single (1) filament or a double (2)

filament.

HORN

An electric device which sounds a

loud audible signal.

IGNITION COIL

Convert low–voltage DC current

into high–voltage ingition current

for firing the spark plugs.

(for Medium Current Fuse)

(for High Current Fuse or

Fusible Link.)

16

DIODE, ZENER

A diode which allows current

flow in one direction but blocks

reverse flo w o n l y u p to a specific

voltage. Above that potential, it

passes the excess voltage.

This acts as a simple voltage

regulator.

PHOTODIODE

The photodiode is a

semiconductor which controls the

current flow according to the

amount of light.

DISTRIBUTOR, IIA

Channels high–voltage current

from the ignition coil to the

individual spark plugs.

FUSE

A thin metal strip which burns

through when too much current

flows through it, thereby stop–

ping current flow and protecting a

circuit from damage.

FUSIBLE LINK

A heavy–gauge wire placed in

high amperage circuits which

burns through on overloads,

thereby protecting the circuit.

The numbers indicate the cross–

section surface area of the wires.

FUEL

M

LIGHT

Current flow through a filament

causes the filament to heat up

and emit light.

LED (LIGHT EMITTING DIODE)

Upon current flow, these diodes

emit light without producing the

heat of a comparable light.

METER, ANALOG

Current flow activates a magnetic

coil which causes a needle to

move, thereby providing a relative

display against a background

calibration.

METER, DIGITAL

Current flow activates one or

many LED’s, LCD’s, or fluoresent

displays, which provide a relative

or digital display.

MOTOR

A power unit which converts

electrical energy into mechanical

energy, especially rotary motion.

E

RELAY

1. NORMALLY

CLOSED

Basically, an electrically

operated switch which

may be normally closed

(1) or open (2). Current

flow through a small

2. NORMALLY

OPEN

coil creates a magnetic

field which either opens

or closes an attached

switch.

RELAY, DOUBLE THROW

A relay which passes current

through one set of contacts or the

other.

RESISTOR

An electrical component with a

fixed resistance, placed in a circuit

to reduce voltage to a specific

value.

RESISTOR, TAPPED

A resistor which supplies two or

more different non adjustable

resistance values.

RESISTOR, VARIABLE or

RHEOSTAT

A controllable resistor with a

variable rate of resistance.

Also called a potentiometer or

rheostat.

SPEAKER

An electromechanical device

which creates sound waves from

current flow.

SWITCH, MANUAL

1. NORMALLY

OPEN

Open and

closes circuits,

thereby

stopping (1) or

allowing (2)

2. NORMALLY

CLOSED

current flow.

SWITCH, DOUBLE THROW

A switch which continuously

passes cureent through one set of

contacts or the other.

SWITCH,

IGNITION

A key operated switch with several

positions which allows various

circuits, particularly the primary

ignition circuit, to become

operational.

SENSOR (Thermistor)

A resistor which varies its

resistance with temperature.

SENSOR, SPEED

Uses magnetic impulses to open

and close a switch to create a

signal for activation of other

components.

SHORT PIN

Used to provide an unbroken

connection within a juction block.

SOLENOID

An electromagnetic coil which

forms a magnetic field when

current flows, to move a plunger,

etc.

SWITCH, WIPER PARK

TRANSISTOR

WIRES

(1) NOT

CONNECTED

(2) SPLICED

Automatically returns wipers to

the stop position when the wiper

switch is turned off.

A solid state device typically used

as an electronic relay; stops or

passes current depending on the

voltage applied at “base.”

Wires are always

drawn as straight lines

on wiring diagrams.

Crossed wires (1)

without a black dot at

the junction are not

joined;

crossed wires (2) and

a black dot or

octagonal ( ) mark at

the juction as spliced

(joined) connections.

17

+

F RELAY LOCATIONS

[Engine Compartment]

[Instrument Panel]

18

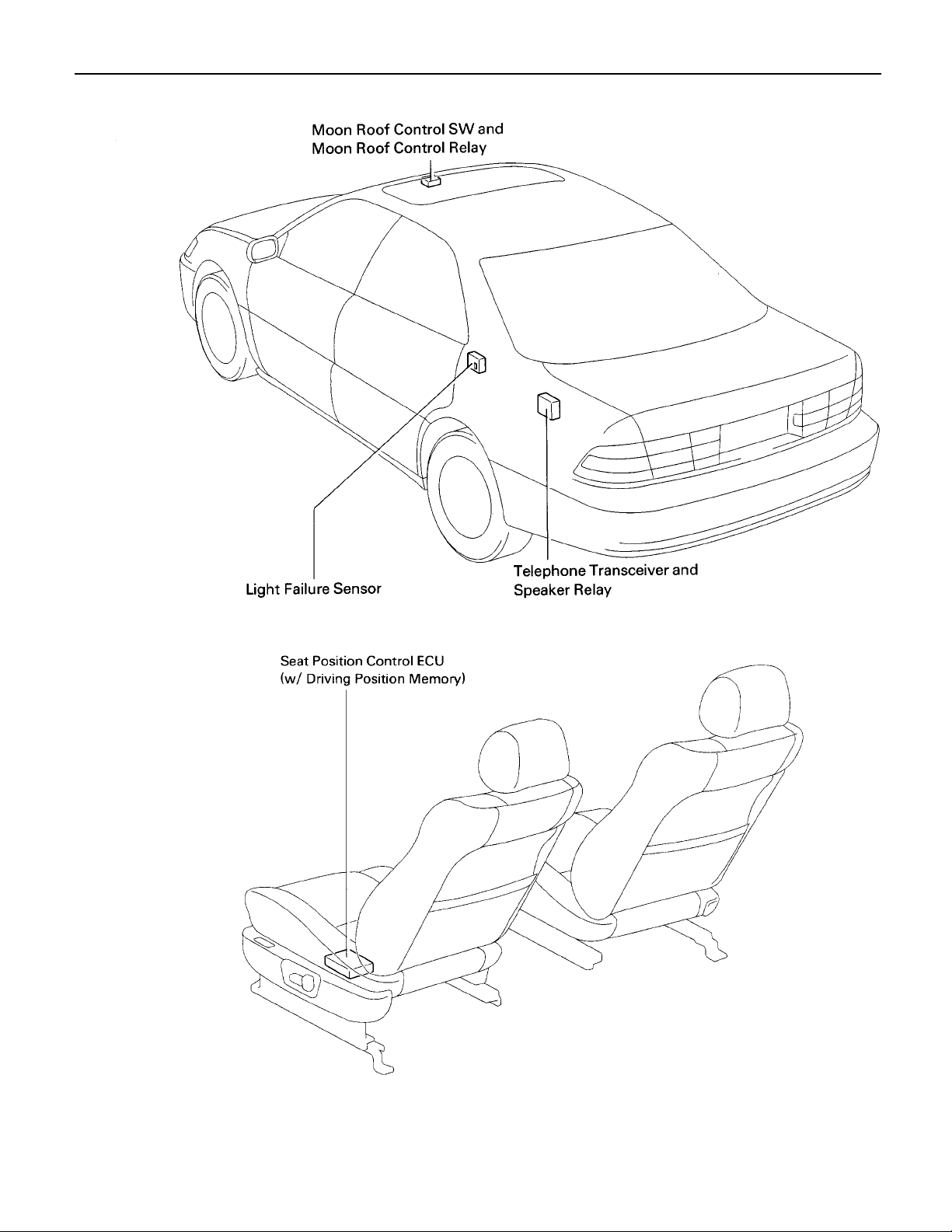

(Body)

F

[Seat]

19

F RELAY LOCATIONS

,

,,,

,,

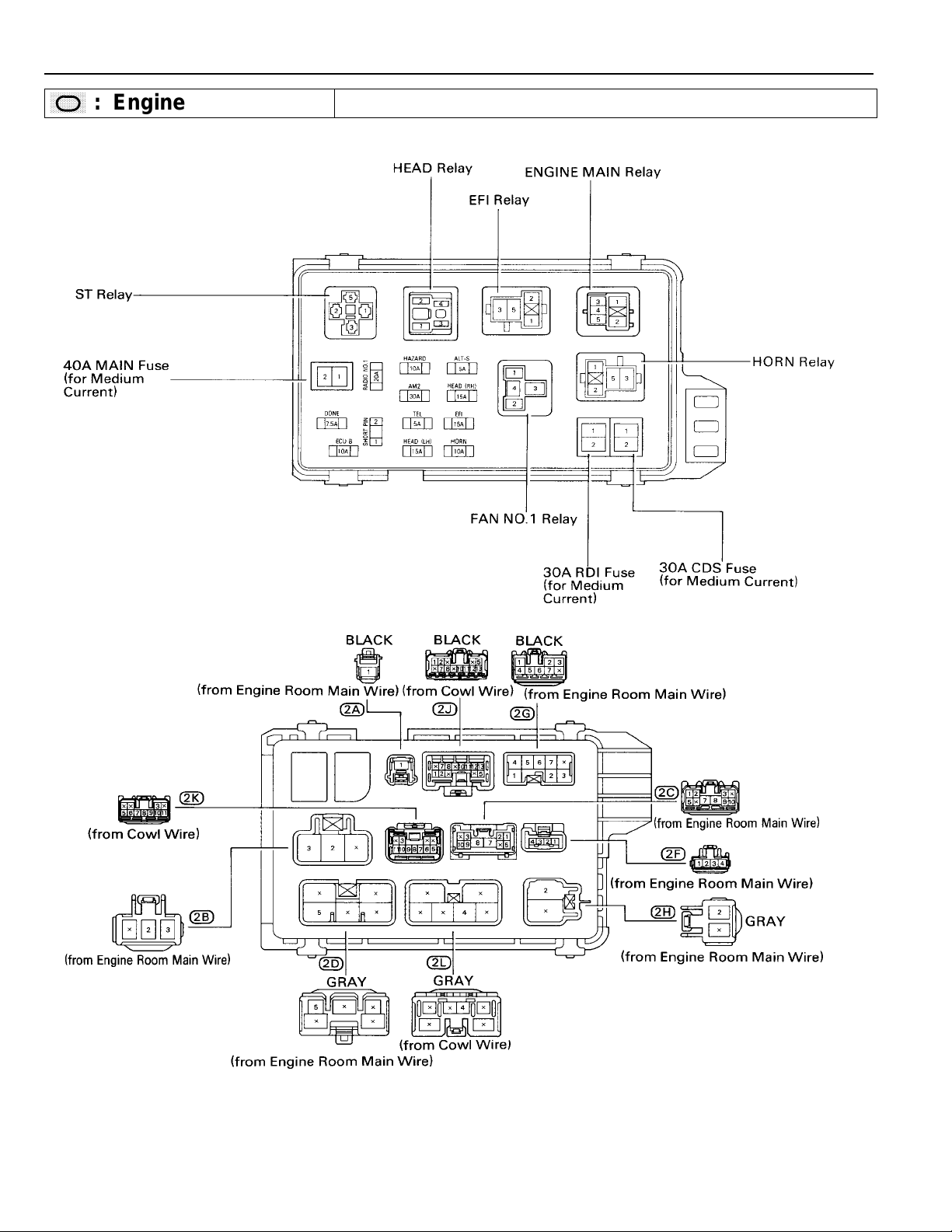

: Engine Room J/B Engine Compartment Left (See Page 18)

20

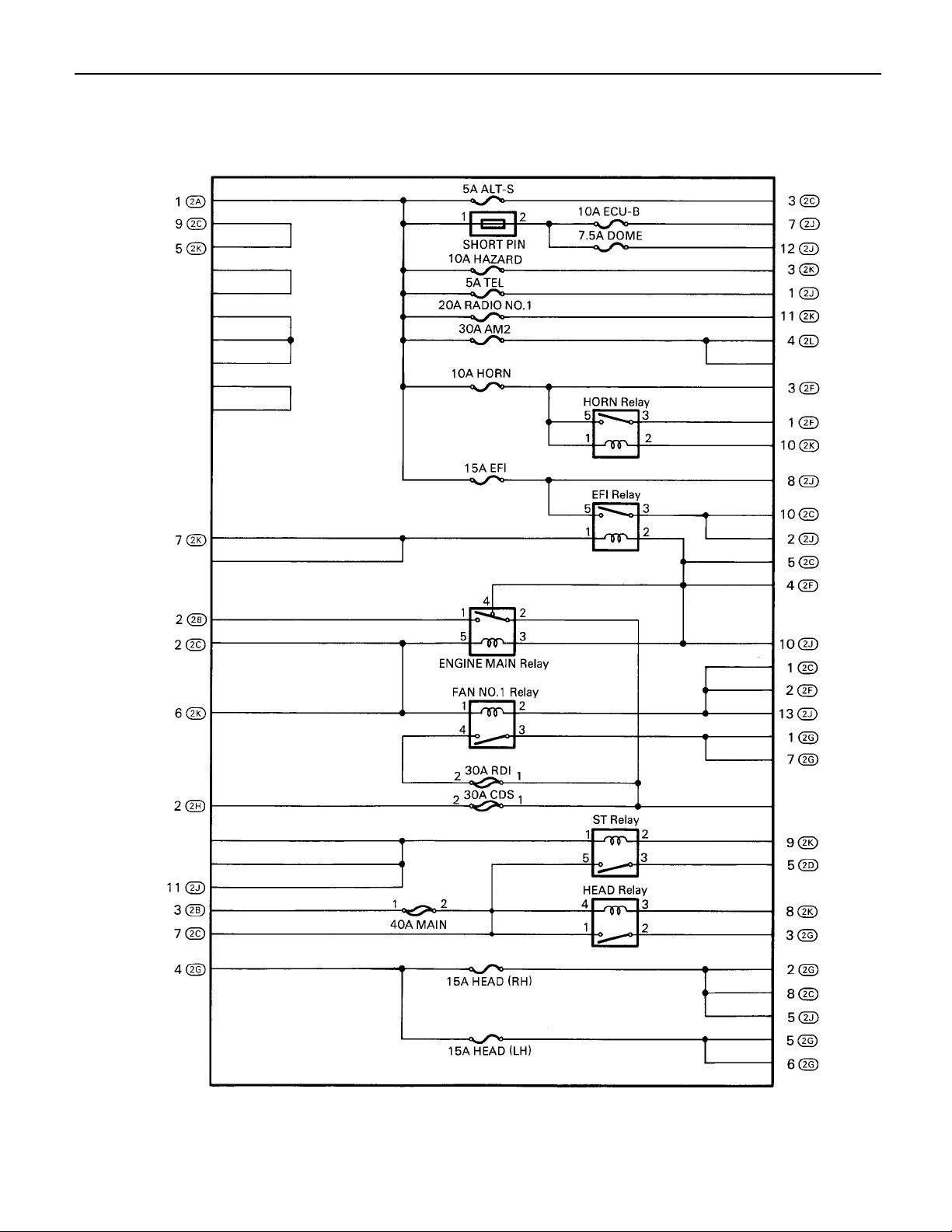

(Engine Room J/B Inner Circuit)

F

21

F RELAY LOCATIONS

R/B

Fusible Link Block

1

: Engine Room

Engine Compartment Left (See Page 18)

(Inside Engine Room J/B)

Engine Compartment Left (See Page 18)

(Inside Engine Room J/B)

22

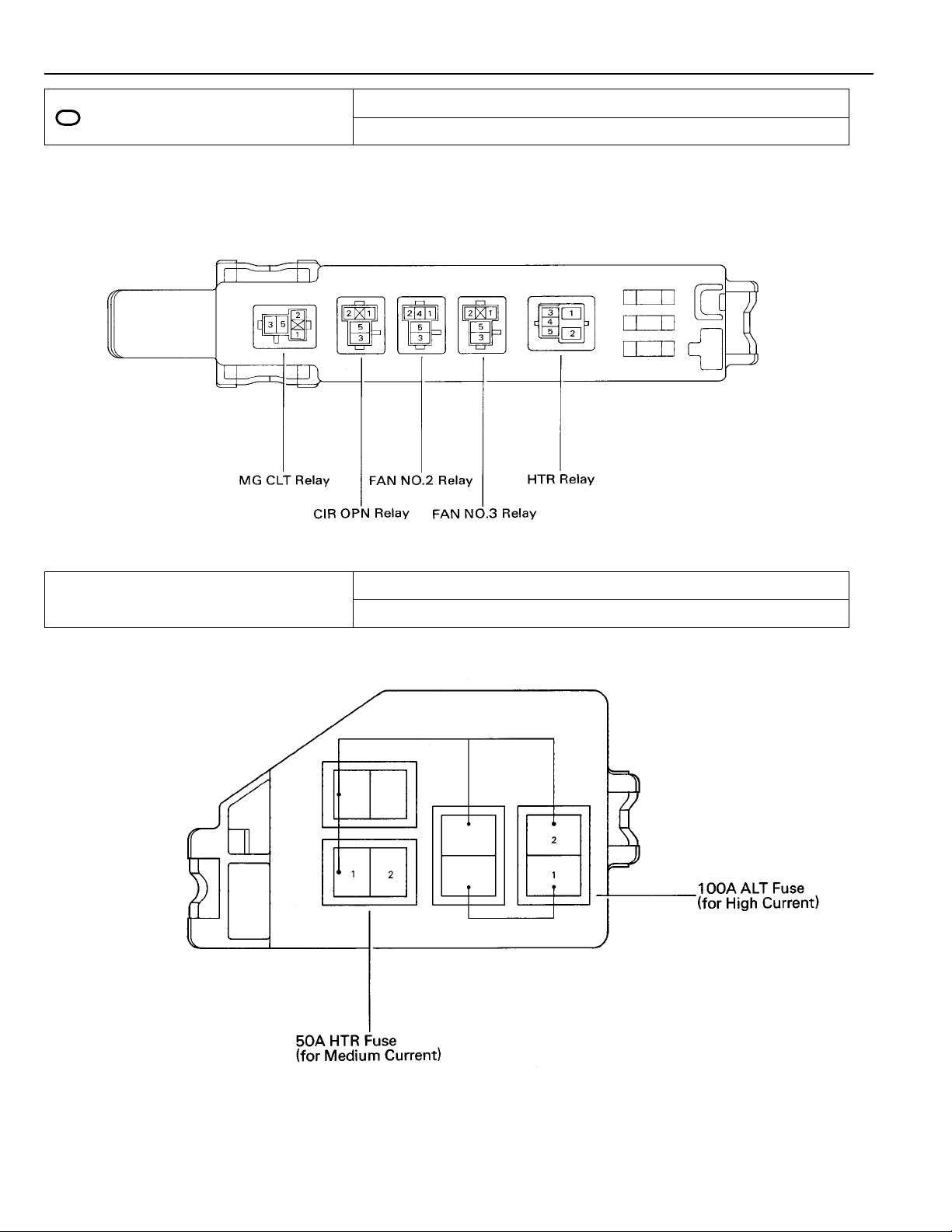

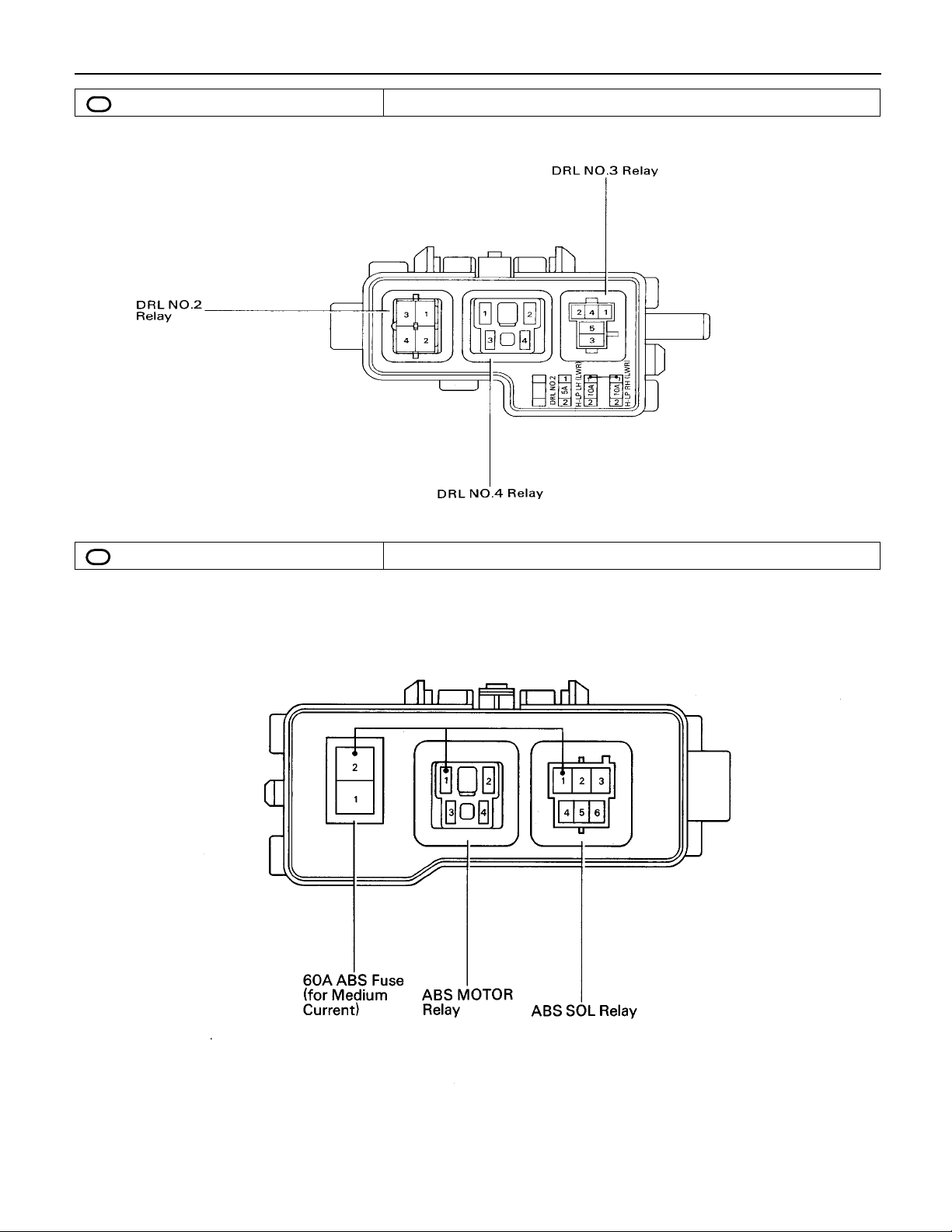

2

: Engine Room No. 2 R/B Engine Compartment Left (See Page 18)

(Canada)

F

3

: Engine Room No.3 R/B Radiator Upper Support RH (See Page 18)

23

F RELAY LOCATIONS

,

,,,

,,

: Instrument Panel J/B Lower Finish Panel (See Page 18)

24

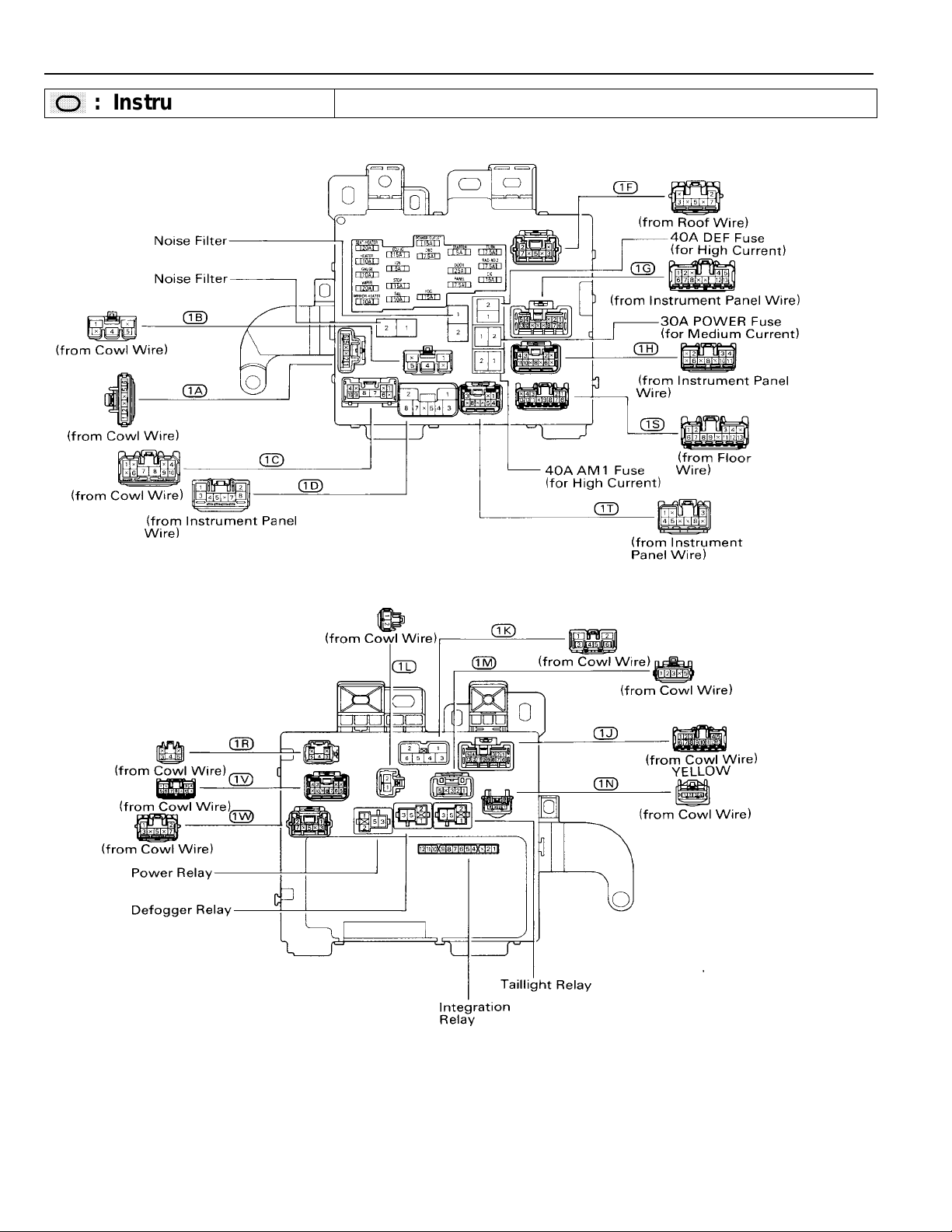

(Instrument Panel J/B Inner Circuit)

F

25

2 6

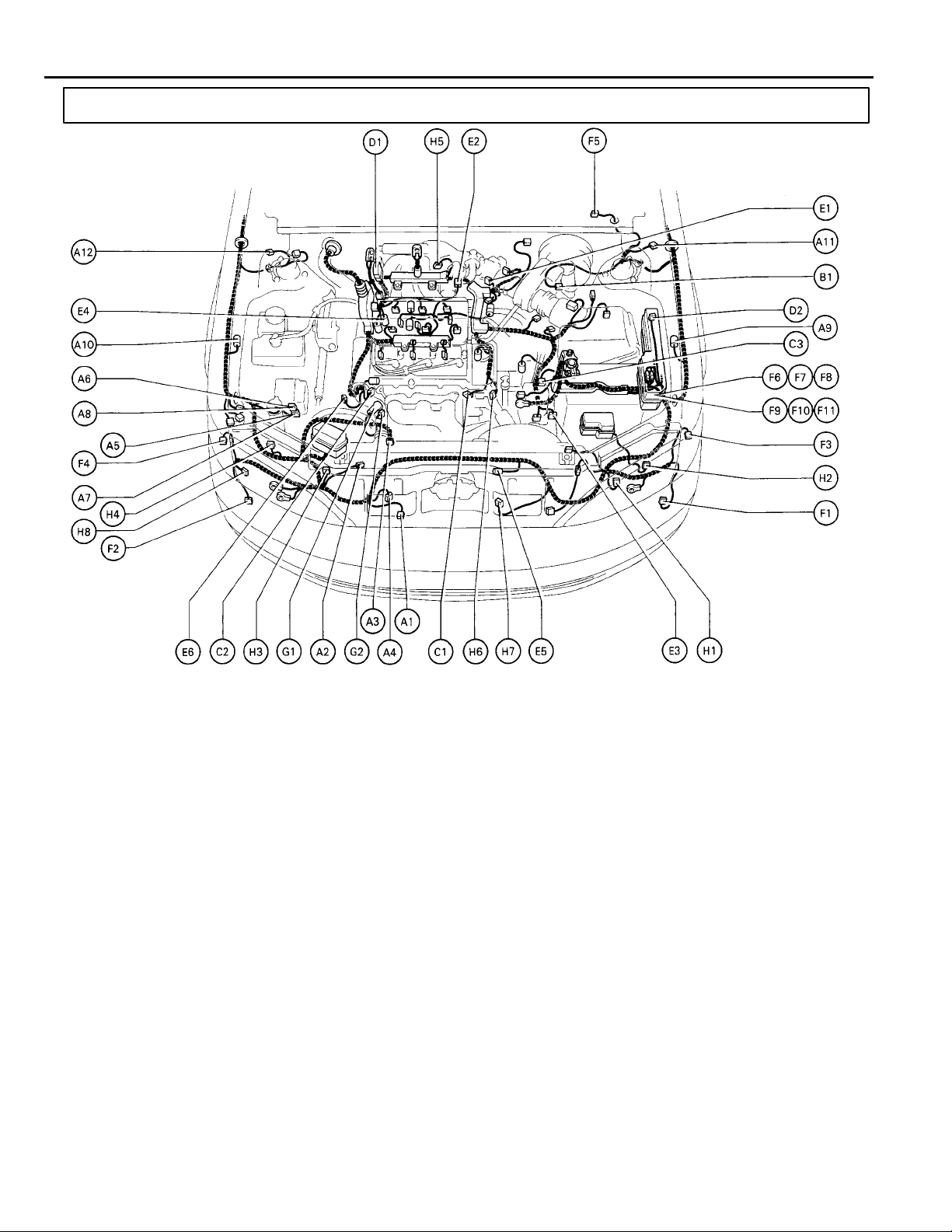

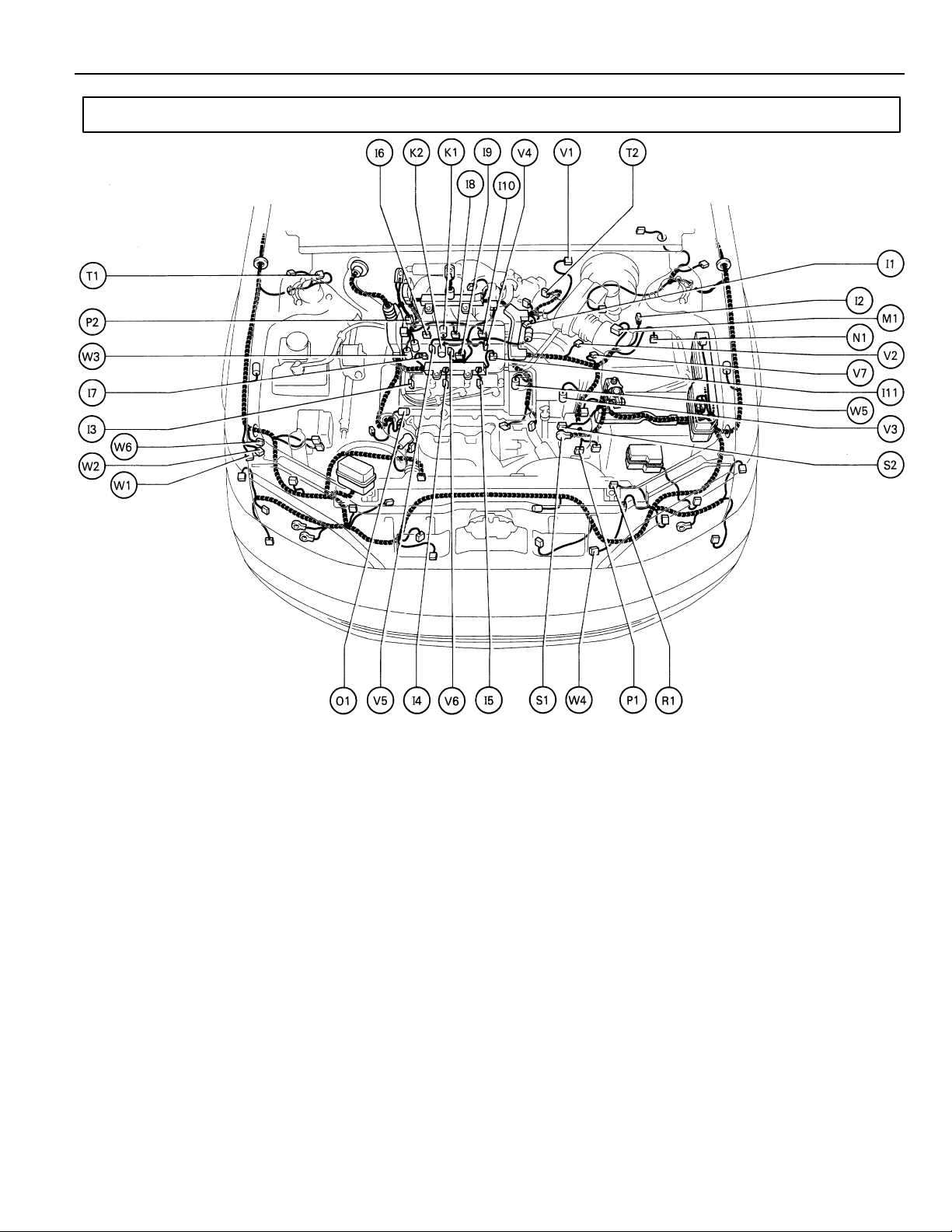

G ELECTRICAL WIRING ROUTING

Position of Parts in Engine Compartment

A 1 Ambient Temp. Sensor

A 2 A/C Condenser Fan Motor

A 3 A/C Magnetic Clutch and Lock Sensor

A 4 A/C Triple Pressure SW (A/C Dual and

Single Pressure SW)

A 5 ABS Actuator

A 6 ABS Actuator

A 7 ABS and Traction Actuator

A 8 ABS and Traction Actuator

A 9 ABS Speed Sensor Front LH

A 10 ABS Speed Sensor Front RH

A 11 Absorber Control Acuator Front LH

A 12 Absorber Control Acuator Front RH

B 1 Brake Fluid Level Warning SW

C 1 Camshaft Position Sensor

C 2 Crankshaft Position Sensor

C 3 Cruise Control Actuator

D 1 Data Link Connector 1

D 2 Diode (A/C)

E 1 EGR Gas Temp. Sensor

E 2 EGR Valve Position Sensor

E 3 Electronically Controlled Transmission

Solenoid

E 4 Engine Coolant Temp. Sensor

E 5 Engine Hood Courtesy SW

E 6 Engine Oil Level Warning SW

26

F 1 Front Fog Light LH

F 2 Front Fog Light RH

F 3 Front Turn Signal and Front Parking Light LH

F 4 Front Turn Signal and Front Parking Light RH

F 5 Front Wiper Motor

F 6 Fusible Link Block

F 7 Fusible Link Block

F 8 Fusible Link Block

F 9 Fusible Link Block

F 10 Fusible Link Block

F 11 Fusible Link Block

G 1 Generator

G 2 Generator

H 1 Headlight LH (HI)

H 2 Headlight LH (LO)

H 3 Headlight RH (HI)

H 4 Headlight RH (LO)

H 5 Heated Oxygen Sensor (Bank 1 Sensor 1)

H 6 Heated Oxygen Sensor (Bank 2 Sensor 1)

H 7 Horn LH

H 8 Horn RH

Position of Parts in Engine Compartment

G

I 1 Idle Air Control Valve

I 2 Igniter

I 3 Ignition Coil No. 1

I 4 Ignition Coil No. 2

I 5 Ignition Coil No. 3

I 6 Injector No. 1

I 7 Injector No. 2

I 8 Injector No. 3

I 9 Injector No. 4

I 10 Injector No. 5

I 11 Injector No. 6

K 1 Knock Sensor 1

K 2 Knock Sensor 2

M 1 Mass Air Flow Meter

N 1 Noise Filter (Ignition)

O 1 Oil Pressure SW

P 1 Park/Neutral Position SW,A/T Indicator

Light SW and Back–Up Light SW

P 2 Power Steering Oil Pressure SW

R 1 Radiator Fan Motor

S 1 Starter

S 2 Starter

T 1 Theft Deterrent Horn

T 2 Throttle Position Sensor

V 1 Vapor Pressure Sensor

V 2 Vehicle Speed Sensor (Combination Meter)

V 3 Vehicle Speed Sensor

(Electronically Controlled Transmission)

V 4 VSV (EGR)

V 5 VSV (EVAP)

V 6 VSV (Intake Air Control)

V 7 VSV (Vapor Pressure Sensor)

W 1 Water Level Warning SW

W 2 Washer Motor

W 3 Water Temp. Sender

W 4 Water Temp. SW No.1

W 5 Water Temp. SW No.2

W 6 Wireless Door Lock Buzzer

27

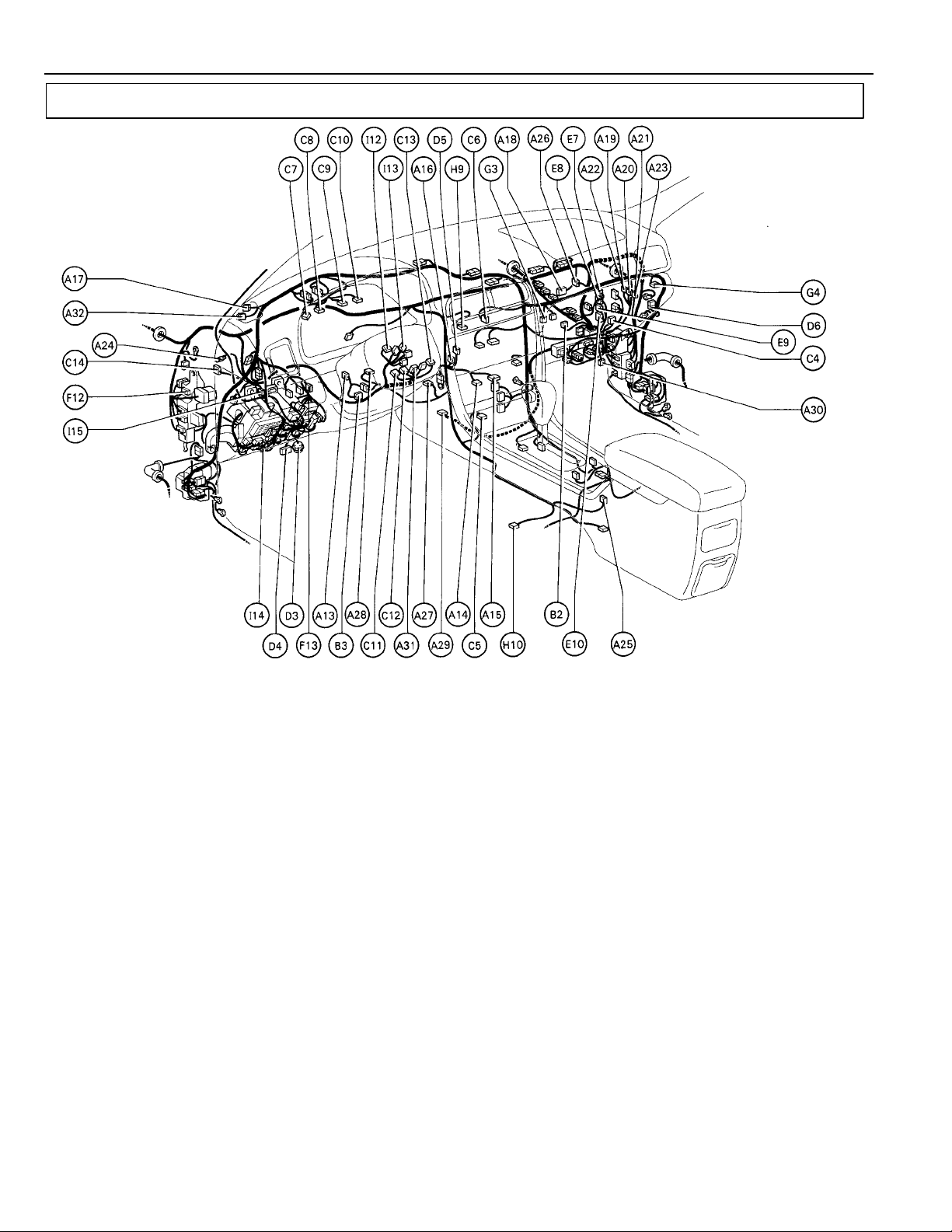

G ELECTRICAL WIRING ROUTING

Position of Parts in Instrument Panel

A 13 A/C Blower Motor Linear Controller

A 14 A/C Control Assembly

A 15 A/C Control Assembly

A 16 A/C Room Temp. Sensor

A 17 A/C Solar Sensor

A 18 A/C Thermistor

A 19 ABS and Traction ECU

A 20 ABS and Traction ECU

A 21 ABS and Traction ECU

A 22 ABS ECU

A 23 ABS ECU

A 24 Absorber Control ECU

A 25 Absorber Control SW

A 26 Air Inlet Control Servo Motor

A 27 Air Mix Control Servo Motor

A 28 Air Vent Mode Control Servo Motor

A 29 Airbag Sensor Assembly

A 30 Airbag Squib (Front Passenger Airbag Assembly)

A 31 Airbag Squib (Steering Wheel Pad)

A 32 Automatic Light Control Sensor

B 2 Blower Motor

B 3 Blower Resistor

C 4 CD Automatic Changer

C 5 Cigarette Lighter

C 6 Clock

C 7 Combination Meter

C 8 Combination Meter

C 9 Combination Meter

26

C 10 Combination Meter

C 11 Combination SW

C 12 Combination SW

C 13 Combination SW

C 14 Cruise Control ECU

D 3 Data Link Connector 2

D 4 Data Link Connector 3

D 5 Daytime Running Light Relay (Main)

D 6 Diode (Courtesy)

E 7 Engine Control Module

E 8 Engine Control Module

E 9 Engine Control Module

E 10 Engine Control Module

F 12 Front Fog Light Relay

F 13 Fuel Lid and Luggage Compartment

Door Opener SW

G 3 Generator Box Light

G 4 Generator Box Light SW

H 9 Hazard SW

H 10 Heated Oxygen Sensor (Bank 1 Sensor 2)

I 12 Ignition Key Cylinder Light

I 13 Ignition SW

I 14 Integration Relay

I 15 Integration Relay

Position of Parts in Instrument Panel

G

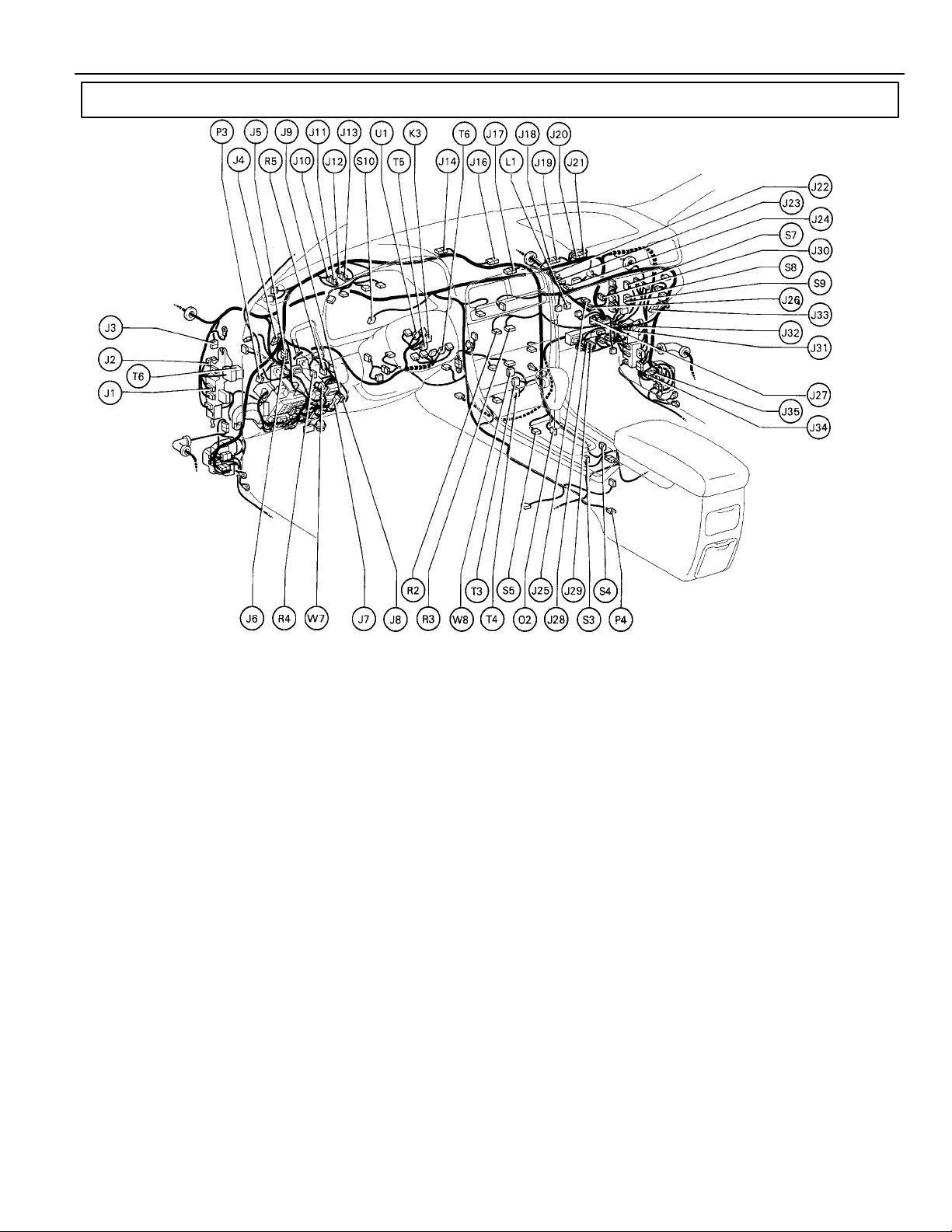

J 1 Junction Connector

J 2 Junction Connector

J 3 Junction Connector

J 4 Junction Connector

J 5 Junction Connector

J 6 Junction Connector

J 7 Junction Connector

J 8 Junction Connector

J 9 Junction Connector

J 10 Junction Connector

J 11 Junction Connector

J 12 Junction Connector

J 13 Junction Connector

J 14 Junction Connector

J 15 Junction Connector

J 16 Junction Connector

J 17 Junction Connector

J 18 Junction Connector

J 19 Junction Connector

J 20 Junction Connector

J 21 Junction Connector

J 22 Junction Connector

J 23 Junction Connector

J 24 Junction Connector

J 25 Junction Connector

J 26 Junction Connector

J 27 Junction Connector

J 28 Junction Connector

J 29 Junction Connector

J 30 Junction Connector

J 31 Junction Connector

J 32 Junction Connector

J 33 Junction Connector

J 34 Junction Connector

J 35 Junction Connector

K 3 Key Interlock Solenoid

L 1 Luggage Compartment Door Opener Main SW

O 2 O/D Main SW and A/T Shift Lever Illumination

P 3 Parking Brake SW

P 4 Power Outlet

R 2 Radio and Player

R 3 Radio and Player

R 4 Remote Control Morror SW

R 5 Rheostat

S 3 Seat Heater SW (Driver’s Seat)

S 4 Seat Heater SW (Front Passenger’s Seat)

S 5 Shift Lock Control ECU

S 6 Steering Sensor

S 7 Stereo Component Amplifier

S 8 Stereo Component Amplifier

S 9 Stereo Component Amplifier

S 10 Stop Light SW

T 3 Theft Deterrent ECU

T 4 Theft Deterrent ECU

T 5 TRAC OFF SW

T 6 Turn Signal Flasher Relay

U 1 Unlock Warning SW (Ignition Key)

W 7 Wireless Door Lock Buzzer Volume SW

W 8 Wireless Door Lock ECU

27

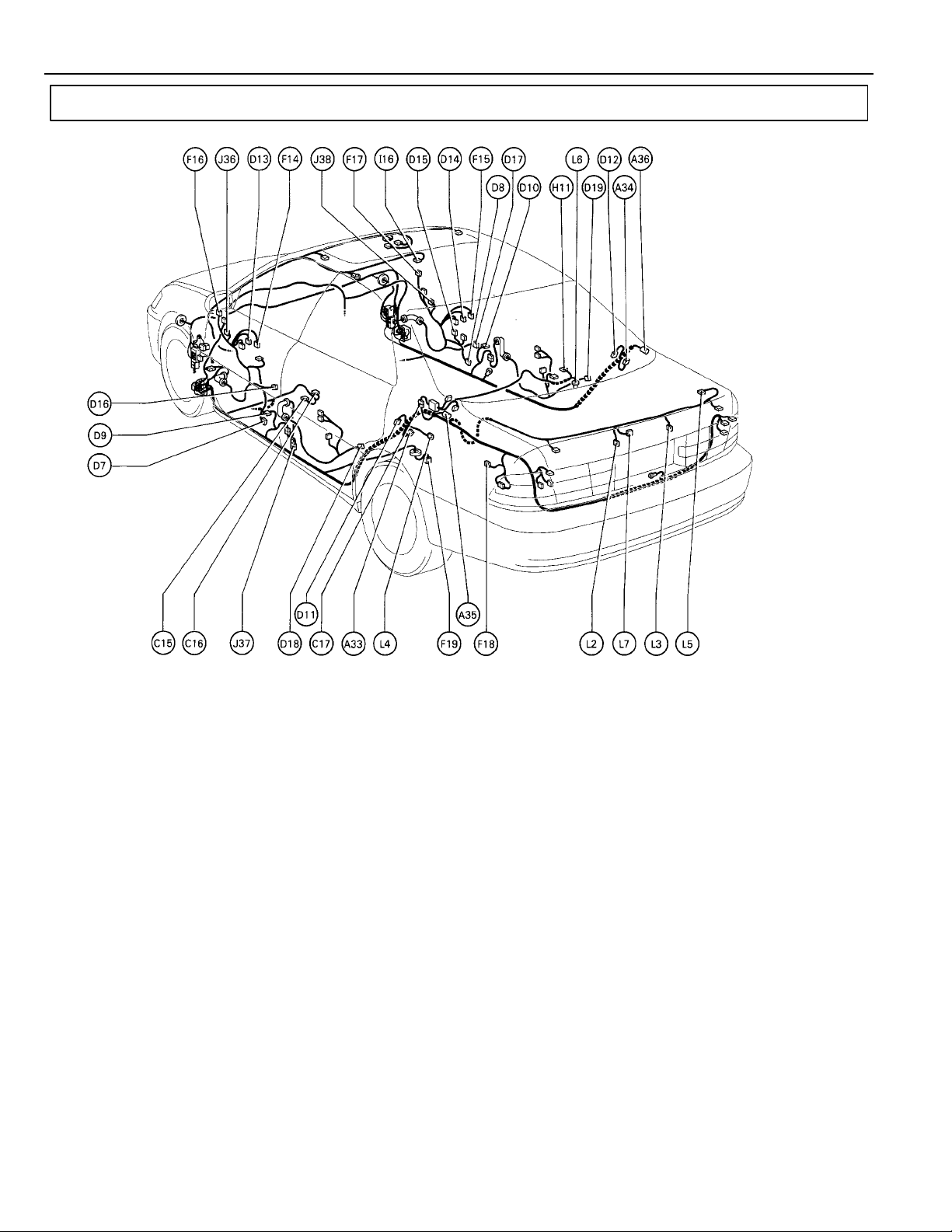

G ELECTRICAL WIRING ROUTING

Position of Parts in Body

A 33 ABS Speed Sensor Rear LH

A 34 ABS Speed Sensor Rear RH

A 35 Absorber Control Actuator Rear LH

A 36 Absorber Control Actuator Rear RH

C 15 Cellular Phone (Hand Set)

C 16 Cellular Phone (Hand Set)

C 17 Choke Coil

D 7 Door Courtesy Light Front LH

D 8 Door Courtesy Light Front RH

D 9 Door Courtesy SW Front LH

D 10 Door Courtesy SW Front RH

D 11 Door Courtesy SW Rear LH

D 12 Door Courtesy SW Rear RH

D 13 Door Key Lock and Unlock SW Front LH

D 14 Door Key Lock and Unlock SW Front RH

D 15 Door Lock Control SW Front RH

D 16 Door Lock Motor and Door Unlock

Detection SW Front LH

D 17 Door Lock Motor and Door Unlock

Detection SW Front RH

D 18 Door Lock Motor and Door Unlock

Detection SW Rear LH

D 19 Door Lock Motor and Door Unlock

Detection SW Rear RH

F 14 Front Door Speaker LH

F 15 Front Door Speaker RH

F 16 Front Tweeter Speaker LH

F 17 Front Tweeter Speaker RH

F 18 Fuel Lid Opener Motor

F 19 Fuel Pump and Fuel Sender

H 11 High Mounted Stop Light

I 16 Interior Light

J 36 Junction Connector

J 37 Junction Connector

J 38 Junction Connector

L 2 License Plate Light LH

L 3 License Plate Light RH

L 4 Light Failure Sensor

L 5 Luggage Compartment Key Unlock SW

L 6 Luggage Compartment Light

L 7 Luggage Compartment Light SW

and Luggage Compartment Door Opener Motor

26

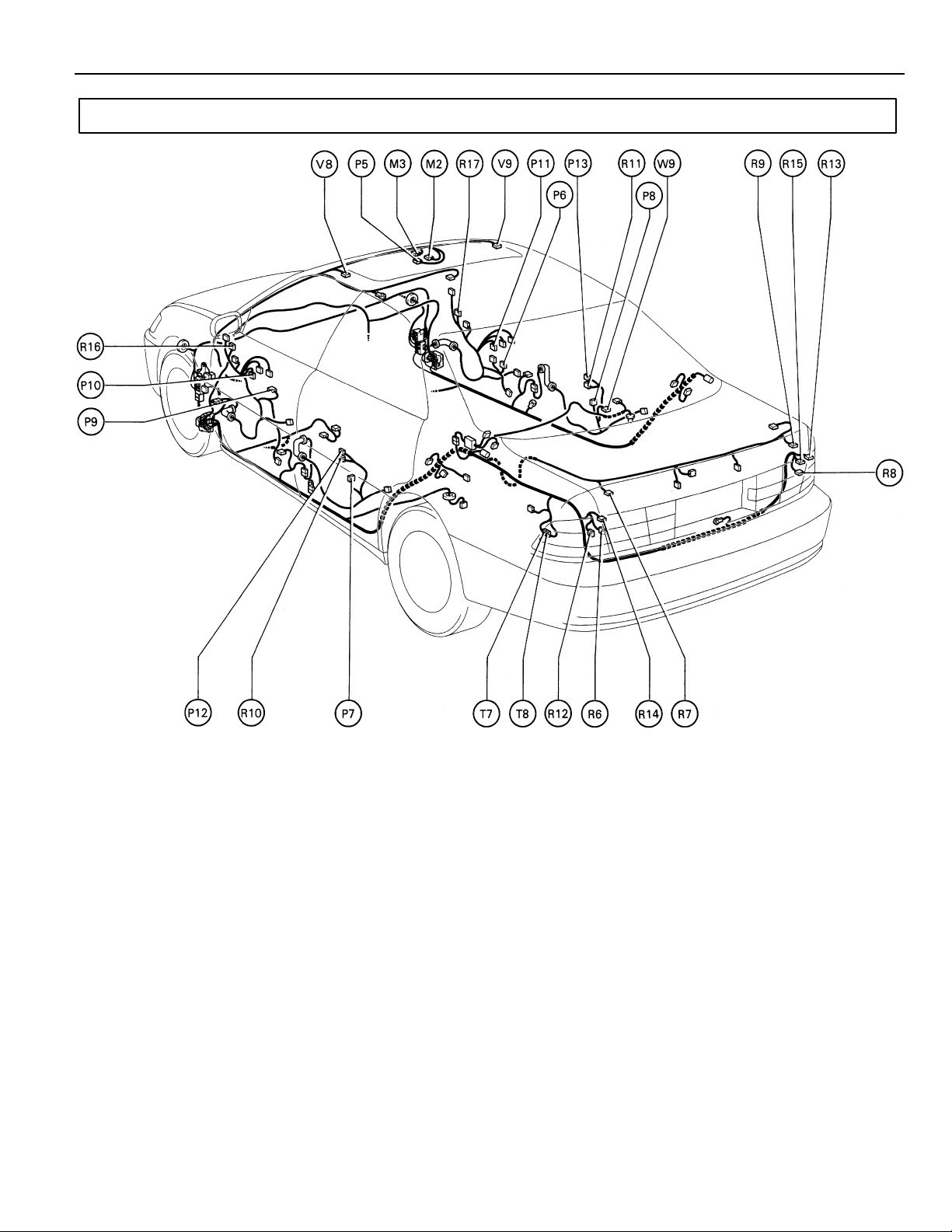

Position of Parts in Body

G

M 2 Moon Roof Control SW and Moon Roof Control Relay

M 3 Moon Roof Moon and Limit SW

P 5 Personal Light

P 5 Personal Light

P 6 Power Window Control SW Front RH

P 7 Power Window Control SW Rear LH

P 8 Power Window Control SW Rear RH

P 9 Power Window Master SW and

Door Lock Control SW Front LH

P 10 Power Window Motor Front LH

P 11 Power Window Motor Front RH

P 12 Power Window Motor Rear LH

P 13 Power Window Motor Rear RH

R 6 Rear Combination Light LH

R 7 Rear Combination Light LH

R 8 Rear Combination Light RH

R 9 Rear Combination Light RH

R 10 Rear Door Speaker LH

R 11 Rear Door Speaker RH

R 12 Rear Side Marker Light LH

R 13 Rear Side Marker Light RH

R 14 Rear Turn Signal Light LH

R 15 Rear Turn Signal Light RH

R 16 Remote Control Mirror and Mirror Heater LH

R 17 Remote Control Mirror and Mirror Heater RH

T 7 Telephone Transceiver and Speaker Relay

T 8 Telephone Transceiver and Speaker Relay

V 8 Vanity Light LH

V 9 Vanity Light RH

W 9 Woofer Speaker

27

G ELECTRICAL WIRING ROUTING

Position of Parts in Seat

B 4 Buckle SW

P 14 Power Seat Control SW

(Driver’s Seat Lumber Support Control)

P 15 Power Seat Control SW

(Driver’s Seat )

P 16 Power Seat Control SW

(Front Passenger’s Seat))

P 17 Power Seat Motor

(Driver’s Seat Front Vertical Control)

P 18 Power Seat Motor

(Driver’s Seat Lumber Support Control)

P 19 Power Seat Motor

(Driver’s Seat Rear Vertical Control)

P 20 Power Seat Motor

(Driver’s Seat Reclining Control)

P 21 Power Seat Motor

(Driver’s Seat Slide Control)

P 22 Power Seat Motor

(Front Passenger’s Seat Front Vertical Control)

P 23 Power Seat Motor

(Front Passenger’s Seat Rear Vertical Control)

P 24 Power Seat Motor

(Front Passenger’s Seat Reclining Control)

P 25 Power Seat Motor

(Front Passenger ’s Seat Slide Control)

P 26 Power Seat Position Sensor

(Driver’s Seat Front Vertical Control)

P 27 Power Seat Position Sensor

(Driver’s Seat Rear Vertical Control)

P 28 Power Seat Position Sensor

(Driver’s Seat Reclining Control)

P 29 Power Seat Position Sensor

(Driver’s Seat Slide Control)

S 11 Seat Heater (Driver ’s Seat)

S 12 Seat Heater (Front Passenger’s Seat)

S 13 Seat Memory SW

S 14 Seat Position Control ECU

S 15 Seat Position Control ECU

26

G ELECTRICAL WIRING ROUTING

: Location of Connector Joining Wire Harness and Wire Harness

: Location of Ground Points

:Location of Splice Points

28

G

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EA1

EB1

EB2

EC1

ENGINE ROOM MAIN WIRE AND ENGINE ROOM MAIN NO. 3 WIRE (BEHIND HEADLIGHT LH)

COWL WIRE AND ENGINE ROOM MAIN WIRE (UNDER THE ENGINE ROOM J/B)

ENGINE WIRE AND SENSOR WIRE (LEFT BANK OF THE CYLINDER HEAD)

29

G ELECTRICAL WIRING ROUTING

: Location of Connector Joining Wire Harness and Wire Harness

: Location of Ground Points

30

Connector Joining Wire Harness and Wire Harness

()

G

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

ID1

ID2

IE1

IE2

IF1

IF2

IF3

IG1

IG2

IH1

FLOOR WIRE AND COWL WIRE (LEFT KICK PANEL)

FRONT DOOR LH WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

FLOOR WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

INSTRUMENT PANEL WIRE AND COWL WIRE (RIGHT SIDE OF INSTRUMENT PANEL J/B)

COWL WIRE AND A/C SUB WIRE (BEHIND RADIO AND PLAYER)

31

G ELECTRICAL WIRING ROUTING

: Location of Connector Joining Wire Harness and Wire Harness

:Location of Splice Points

32

Connector Joining Wire Harness and Wire Harness

()

()

G

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

II1

IJ1

IK1

IK2

IK3

IL1

IM1

IM2

IM3

IN1

IO1

IO2

IP1

FLOOR NO.3 WIRE AND INSTRUMENT PANEL WIRE (UNDER THE CONSOLE BOX)

INSTRUMENT PANEL WIRE AND COWL WIRE (UNDER THE GLOVE BOX)

EWNGINE WIRE AND COWL WIRE (UNDER THE GLOVE BOX)

ENGINE WIRE AND INSTRUMENT PANEL WIRE (UNDER THE GLOVE BOX)

ENGINE ROOM MAIN WIRE AND COWL WIRE (RIGHT KICK PANEL)

FLOOR NO. 2 WIRE AND COWL WIRE (RIGHT KICK PANEL)

FRONT DOOR RH WIRE AND INSTRUMENT PANEL WIRE (RIGHT KICK PANEL)

FRONT NO. 2 WIRE AND INSTRUMENT PANEL WIRE (RIGHT KICK PANEL)

33

G ELECTRICAL WIRING ROUTING

: Location of Connector Joining Wire Harness and Wire Harness

: Location of Ground Points

:Location of Splice Points

34

Connector Joining Wire Harness and Wire Harness

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

BQ1

BR1

REAR DOOR LH WIRE AND FLOOR WIRE (LEFT CENTER PILLAR)

REAR DOOR RH WIRE AND FLOOR NO. 2 WIRE (RIGHT CENTER PILLAR)

G

35

G ELECTRICAL WIRING ROUTING

: Location of Connector Joining Wire Harness and Wire Harness

:Location of Splice Point

36

Connector Joining Wire Harness and Wire Harness

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

BS1

BS2

BT1

FLOOR WIRE AND SEAT NO.1 WIRE (UNDER THE DRIVER’S SEAT)

FLOOR NO.2 WIRE AND SEAT NO. 2 WIRE (UNDER THE FRONT PASSENGER’S SEAT)

’

G

37

POWER SOURCE

B–G

60A ABS

12

3

ABS SOL RELAY

GR GR–R

R–L

6

3

5

3

1

2

1

4

3

3

3

3

2

3

W–L

W–B

W–R

B–R

E 2

B–R

B–R

D1F1F2E1

100A

ALT

A1C1B1

B–G B–G

FL MAIN 3. 0W

BATTERY

50A

HTR

GR–L

4

L–B L–R

L–W

2

2B

L–B

F, F11

C, F 8

BF 6 , F 7A

EF 9 , F1 0D

FUSIBLE LINK BLOCK

B–R

B

B

1

2A

3

2B

1

1

3

1

HTR RELAY

1

3

ENGINE MAIN RELAY

5A TEL

15A EFI

10A HAZARD

20A RADIO NO. 1

10A HORN

30A AM2

SHORT PIN

12

5A ALT–S

40A MAIN

12

15A HEAD (RH

2

5

4

2

5

)

4

3

ABS MOTOR RELAY

W–B

1

1

L–B

1

30A CDS

12

30A RDI

12

10A ECU–B

7. 5A DOME

HEAD RELAY

1

4

3

5

2C

4

2F

4

2L

7

2C

2

3

3

2G

4

2G

GR–R

3

B–R

W–B

W–B

W–R

W–B

W–B

W–B

R–G

(*1)

R–B

(*1)

)

R–B

USA

(

R

(*1)

56

15A HEAD (LH

)

EC

* 1 : CANADA

B–R

W–R

R–G

(*1)

R–B

(*1)

R

(*1)

2

AM1

7

AM2

I13

IGNITION SW

R–G

B–R

I 1

B–R

W

L–R

3

ACC

B–Y

4

IG1

B–R

6

IG2

R

8

ST2

W–R

DRL NO. 2 RELAY

13

2

R–L

TAILLIGHT RELAY

5

1

POWER RELAY

5

1

DEFO G GER RELAY

5

1

2

R–B

2

3

2

3

2

3

2

5A DRL NO. 2

12

10A H–LP RH (LWR

12

10A H–LP LH (LWR

12

10A TAIL

7. 5A PANEL

1

NOISE FILTER

10A MIRROR–HEATER

2

R–L

2

)

2

)

2

W–R

W–R

R–G

R

7

W–B

1J

12

Y–G

1J

J15

JUNCTION

CONNECTOR

W–B

A

II

4

1B

1

1B

2

1K

6

1K

1

1K

3

1K

4

1K

5

1K

5

1B

2

4

15A FOG

25A DOOR

15A STOP

7. 5A ODB

30A POWER

12

NOISE FILTER

1

12

12

R

2

2

2

2

40A DEF

40A AM1

15A CIG

7. 5A RAD–NO. 2

15A POWER–OUTLET

20A SEAT–HEATER

15A ECU–IG

10A HEATER

10A GAUGE

20A WIPER

7. 5A T URN

5A IGN

5A STARTER

57

POWER SOURCE

24

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

20

ENGINE ROOM MAIN WIRE AND ENGINE ROOM J/B (ENGINE COMPARTMENT LEFT)

SERVICE HINTS

T AILIGHT RELAY

5–3:CLOSED WITH THE LIGHT CONTROL SW AT TAIL OR HEAD POSITION

HEAD RELAY(USA)

1–2:CLOSED WITH THE LIGHT CONTROL SW AT HEAD POSITION OR THE DIMMER SW A T FLASH POSITION

HEAD RELAY(CANADA)

1–2:CLOSED WITH THE LIGHT CONTROL SW AT HEAD POSITION OR THE DIMMER SW A T FLASH POSITION

CLOSED WITH THE ENGINE RUNNING AND THE PARKING BRAKE PEDAL RELEASED (PARKING BRAKE SW OFF)

I13 IGNITION SW

2–3:CLOSED WITH THE IGNITION KEY AT ACC OR ON POSITION

2–4:CLOSED WITH THE IGNITION KEY AT ON OR ST. POSITION

7–6:CLOSED WITH THE IGNITION KEY AT ON OR ST POSITION

7–8:CLOSED WITH THE IGNITION KEY AT ST POSITION

: PARTS LOCA TION

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

F 6 A

F 7 B

F 8 C

26

26

26

: RELAY BLOCKS

CODE SEE PAGE RELA Y BLOCKS (RELAY BLOCK LOCATION)

1

22

2

23

3

23

ENGINE ROOM R/B (ENGINE COMPAR TMENT LEFT)

ENGINE ROOM NO.2 R/B (ENGINE COMPAR TMENT LEFT)

ENGINE ROOM NO.3 R/B (RADIATION UPPER SUPPORT RH)

F 9 D

F10 E

F11 F

26

26

26

I13

J15

28

29

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1J

1K

2A

2B

2C

2F

2G

2L

24

20

20

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

ENGINE ROOM MAIN WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

COWL WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

: GROUND POINTS

CODE SEE PAGE GROUND POINTS LOCATION

EC

II

34

36

LEFT RADIATION SIDE SUPPORT

INSTRUMENT PANEL BRACE LH

: SPLICE POINTS

CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS

E 2

34

AF 6 BF 7 CF 8 DF 9 EF10

COWL WIRE

11111

I 1

38 COWL WIRE

FF11 I13 J15

AA

12

58

X234

X678

AAAA

(

HINT : SEE PAGE 7

)

MEMO

59

STARTING AND IGNITION

ACC

AM1

76

AM2

W–R

1K5

1B5

I13

IGNITION SW

IG1

IG2

ST2

8

B–R

R

B–R

R

5A

STARTE

1K4

R

1J3

R

W–

2L4

2A1

B

C1

A1

B–G

30A

AM2

F 6 , F 8

FUSIBLE LINK

BLOCK

FL MAIN

3. 0W

BATTERY

B–W

IK211

6

IK210

GR GR

BC

ABAB

B–WB–W

B

BB–W

B

5

P 1P

PARK/NEUTRAL

POSITION SW

JUNCTION

CONNECTOR

BJ 8 , J 9A

8

IK2

GRGR

2

40A

MAIN

1

2B3

B

C

A

B–R

1

A

STARTER

ST

RELAY

51

32

2D52K92J11

–B

W

IG21

B–R

W–B

1

B

M

BS 1 , S 2A

GR

W–B

T 3

THEFT DETE RR ENT

ECU

9

SRLY

J26

JUNCTION

CONNECTOR

N

60

B–R

1K3

1C8

B–R

IK312

RL

B–

A

J22

JUNCTION CONNECTOR

A

A

B–R

1

B–W

2

IGNITION COIL NO. 3

I 5

21109

IGC3 IGC2 IGC1 +B

IGFIGT3IGT2IGT1 GND

–R

W

14 12 15 1 6 24

NSW

IGF

STA

13

A

B–R

1

2

IGNITION COIL NO. 2

I 4

Y

I 2

IGNITER

G–B

L

IGT3

E10

ENGINE CONTROL

MODULE

A

B–R

1

2

IGNITION COIL NO. 1

I 3

G

R–Y

B

IGT2

GR

IGT1

A

N 1

NOISE FILTER

B–R

1

)

2

IGNITION

(

B–R

37654

BR

GR

BR

EE

61

STARTING AND INGNITION

()

()

SERVICE HINTS

I13 IGNITION SW

7–8 :CLOSED WITH THE IGNITION SW AT ST POSITION

7–6 :CLOSED WITH THE IGNITION SW AT ON OR ST POSITION

S 1 A , S 2 B STARTER

POINTS CLOSED WITH THE PARK/NEUTRAL POSITION SW IN P OR N POSITION AND THE IGNITION SW AT ST POSITION

P1 P ARK/NEUTRAL POSITION SW

5–6 :CLOSED WITH THE A/T SHIFT LEVER IN P OR N POSITION

: PARTS LOCA TION

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

E10

F 6 A

F 8 C

I 2

I 3

I 4

28

26

26

27

27

27

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1C

2D

1J

1K

2A

2B

2J

2K

2L

24

20

20

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

ENGINE ROOM MAIN WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

COWL WIRE AND ENIGNE ROOM J/B (ENGINE COMPAR TMENT LEFT)

I 5

I13

J 8 A

J 9 B

J22

J26

27

28

29

29

29

29

N 1

P 1

S 1 A

S 2 B

T 3

27

27

27

27

29

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE SEE PAGE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IG2 36

IK2

IK3

38 ENGINE WIRE AND COWL WIRE (UNDER THE GLOVE BOX)

INSTRUMENT PANEL WIRE AND COWL WIRE (RIGHT SIDE OF INSTRUMENT PANEL J/B)

: GROUND POINTS

CODE SEE PAGE GROUND POINTS LOCATION

EE 34

REAR SIDE OF SURGE TANK

62

E10 BLACKI 2

AF 6 CF 8

XX

12 14 15 16

13

XXX 24XX

X

XXX

BLACKI 3 BLACKI 4 BLACKI 5

12 12 12

B

GRAY

J 9

CCC

(

HINT : SEE PAGE 7

X

56

AAA AA

AAAAAAAA

(

HINT : SEE PAGE 7

)

GRAYP 1

ORANG E

J22 J26

)

AS 1 B BLACKS 2

11

12345 109X76

I13

X

X67 8

N 1

BBB

(

HINT : SEE PAGE 7

B

)

12

ORANG ET 3

1

1

X9

GRAY

AJ 8

GRAY

BBB

(

HINT : SEE PAGE 7

)

63

CHARGING

B–G

ACC

2

WB–Y

AM1

IG1

4

* 1 : USA

* 2 : CANADA

CF 6 , F 8AD, F 9 F, F11

WB–R

1K21K5

2

1

1B1

B–G

E 2

B–R

D1F1F2

100A

ALT

A1C1

7

I13

W–R

IGNITION SW

40A AM1

B–R

1B5

W–R

2L42C3

30A AM 2

2A1

B

IG2

ST2

W

6AM2

B–R

1K3

5A IGN

1T8

R

B–

B2

BC 7 , C 8A

A10

CHARGE WARNING LIGHT

[COMB. METER]

Y

5A ALT–S

IG24

)

Y

*2

(

ABAB

)

Y

*1

(

BB

)

Y

*2

(

)

MAIN

(

TO DAYTIME RUNNING

LIGHT RELAY

)

Y

*2

(

B–Y

1K1

10A GAUGE

1J2

R–L

IM24

BJ18 , J19A

R–L

JUNCTION

CONNECTOR

64

BATTERY

B

BG 1 , G 2A

GENERATOR

EB26

Y

W

B3B1B2A1

SLIG B

IC REGULATOR

R–L

B–G

FUSIBLE LINK BLOCK

B–G

FL MAIN

3. 0W

SERVICE HINTS

24

()

G 2 B GENERATOR

B 3–GROUND : 13.9–15.1 VOLTS WITH THE ENGINE RUNNING AT 2000 RPM AND 25C (77F)

13.5–14.3 VOLTS WITH THE ENGINE RUNNING AT 2000 RPM AND 115C (239F)

B 2–GROUND : 0–4 VOL TS WITH THE IGNITION SW AT ON POSITION AND ENGINE NOT RUNNING

: PARTS LOCA TION

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

C 7 A

C 8 B

F 6 A

F 8 C

28

28

26

26

F 9 D

F11 F

G 1 A

G 2 B

26

26

26

26

I13

J18 A

J19 B

28

29

29

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1J

1K

1T

2A

2C

2L

24

24

20

20

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

INSTRUMENT PANEL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

ENGINE ROOM MAIN WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

COWL WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE SEE PAGE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EB2

IG2

34

36

COWL WIRE AND ENGINE ROOM MAIN WIRE (UNDER THE ENGINE ROOM J/B)

INSTRUMENT PANEL WIRE AND COWL WIRE (RIGHT SIDE OF INSTRUMENT PANEL J/B)

IN2 38 ENGINE ROOM MAIN WIRE AND COWL WIRE (RIGHT KICK PANEL)

: SPLICE POINTS

CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS

E 2

34

COWL WIRE

ABLUEC 7 BC 8 AF 6

XXX10XX 2XX

DF 9

1

1

12

1

1

B BLACKG 2AG 1FF11CF 8

123

I13

X2 4

X67

ABLACKJ1 8 B BLAC KJ19

BB

(

HINT : SEE PAGE 7

)

BB

(

HINT : SEE PAGE 7

65

)

ENGINE CONTROL

SYSTEM OUTLINE

THIS SYSTEM UTILIZES AN ENGINE CONTROL MODULE AND MAINTAINS OVERALL CONTROL OF THE ENGINE,

TRANSMISSION AND SO ON. AN OUTLINE OF THE ENGINE CONTROL IS EXPLAINED HERE.

1. INPUT SIGNALS

( 1) ENGINE COOLANT TEMP. SIGNAL CIRCUIT

THE ENGINE COOLANT TEMP. SENSOR DETECTS THE ENGINE COOLANT TEMP. AND HAS A BUILT–IN

THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING TO THE WATER TEMP. IS INPUT INTO

TERMINAL THW OF THE ENGINE CONTROL MODULE AS A CONTROL SIGNAL.

( 2) INTAKE AIR TEMP. SIGNAL CIRCUIT

THE INTAKE AIR TEMP. SENSOR IS INSTALLED IN THE MASS AIR FLOW METER AND DETECTS THE INTAKE AIR

TEMP., WHICH IS INPUT AS A CONTROL SIGNAL INTO TERMINAL THA OF THE ENGINE CONTROL MODULE.

( 3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN DENSITY IN THE EXHAUST GASES IS DETECTED AND INPUT AS A CONTROL SIGNAL INTO

TERMINALS OXL1, OXR1 AND OXS OF THE ENGINE CONTROL MODULE TO MAINTAIN STABLE DETECTION

PERFORMANCE BY THE HEATED OXYGEN SENSOR, A HEATER IS USED FOR WARMING THE SENSOR. THE

HEATER IS ALSO CONTROLLED BY THE ENGINE CONTROL MODULE (HTL, HTR AND HTS).

( 4) RPM SIGNAL SYSTEM

CAMSHAFT POSITION AND CRANKSHAFT POSITION ARE DETECTED BY THE CAMSHAFT POSITION SENSOR AND

CRANKSH AFT POSITION SENSOR. THE CAMSHAFT POSITION IS INPUT AS A CONTROL SIGNAL TO TERMINAL

G22+ OF THE ENGINE CONTROL MODULE, AND THE ENGINE RPM IS INPUT INTO TERMINAL NE+.

( 5) THROTTLE SIGNAL CIRCUIT

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE AS A CONTROL SIGNAL,

WHICH IS INPUT INTO TERMINAL VTA1 OF THE ENGINE CONTROL MODULE.

( 6) VEHICLE SPEED SIGNAL SYSTEM

THE VEHICLE SPEED SENSOR, INSTALLED INSIDE THE TRANSMISSION, DETECTS THE VEHICLE SPEED AND

INPUTS A CONTROL SIGNAL INTO TERMINAL SPD OF THE ENGINE CONTROL MODULE.

( 7) PARK/NEUTRAL POSITION SW SIGNAL SYSTEM

THE PARK/NEUTRAL POSITION SW DETECTS WHETHER THE SHIFT POSITION IS IN NEUTRAL, PARKING OR

NOT, AND INPUTS A CONTROL SIGNAL INTO TERMINAL STA OF THE ENGINE CONTROL MODULE

( 8) A/C SW SIGNAL SYSTEM

THE A/C CONTROL ASSEMBLY INPUTS THE A/C OPERATIONS INTO TERMINAL A/C OF THE ENGINE CONTROL

MODULE AS A CONTROL SIGNAL.

( 9) BATTERY SIGNAL CIRCUIT

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ENGINE CONTROL MODULE. WHEN THE

IGNITION SW IS TURNED ON, VOLTAGE FOR THE ENGINE CONTROL MODULE OPERATION IS APPLIED TO

TERMINAL +B OF THE ENGINE CONTROL MODULE VIA THE EFI RELAY.

(10) INTAKE AIR VOLUME SIGNAL CIRCUIT

INTAKE AIR VOLUME IS DETECTED BY THE MASS AIR FLOW METER AND A SIGNAL IS INPUT INTO TERMINAL

VG OF THE ENGINE CONTROL MODULE AS A CONTROL SIGNAL.

(11) NSW SIGNAL CIRCUIT

TO CONFIRM WHETHER THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING

CRANKING IS DETECTED AND THE SIGNAL IS INPUT INTO TERMINAL NSW OF THE ENGINE CONTROL MODULE

AS A CONTROL SIGNAL.

(12) ENGINE KNOCK SIGNAL CIRCUIT

ENGINE KNOCKING IS DETECTED BY THE KNOCK SENSOR 1 AND 2, THEN THE SIGNALS ARE INPUT INTO

TERMINALS KNKR AND KNKL OF THE ENGINE CONTROL MODULE AS A CONTROL SIGNAL.

66

2. CONTROL SYSTEM

SFI (SEQUENTIAL MULTIPORT FUEL INJECTION) SYSTEM

THE SFI SYSTEM MONITORS THE ENGINE CONDITION THROUGH THE SIGNALS, WHICH ARE INPUT FROM EACH

SENSOR (INPUT SIGNALS (1) TO (12)). THE BEST FUEL INJECTION VOLUME IS DECIDED BASED ON THIS DATA

AND

THE PROGRAM MEMORIZED BY THE ENGINE CONTROL MODULE, AND THE CONTROL SIGNAL IS OUTPUT TO

TERMINALS #10, #20, #30, #40, #50, AND #60 OF THE ENGINE CONTROL MODULE TO OPERATE THE INJECTOR

(INJECT THE FUEL). THE SFI SYSTEM PRODUCES CONTROL OF FUEL INJECTION OPERATION BY THE ENGINE

CONTROL MODULE IN RESPONSE TO THE DRIVING CONDITIONS.

ESA (ELECTRONIC SPARK ADVANCE) SYSTEM

THE ESA SYSTEM MONITORS THE ENGINE CONDITION THROUGH THE SIGNALS, WHICH ARE INPUT TO THE

ENGINE CONTROL MODULE FROM EACH SENSOR (INPUT SIGNALS FROM 1, 3, 4, 12). THE BEST IGNITION TIMING

IS DECIDED ACCORDING TO THIS DATA AND THE MEMORIZED DATA IN THE ENGINE CONTROL MODULE AND

THE CONTROL SIGNAL IS OUTPUT TO TERMINALS IGT1, IGT2 AND IGT3. THIS SIGNAL CONTROLS THE IGNITER

TO PROVIDE THE BEST IGNITION TIMING FOR THE DRIVING CONDITIONS.

HEATED OXYGEN SENSOR HEATER CONTROL SYSTEM

THE HEATED OXYGEN SENSOR HEATER CONTROL SYSTEM TURNS THE HEATER ON WHEN THE INTAKE AIR

VOLUME IS LOW (TEMP. OF EXHAUST EMISSIONS IS LOW), AND WARMS UP THE HEATED OXYGEN SENSOR TO

IMPROVE DETECTION PERFORMANCE OF THE SENSOR. THE ENGINE CONTROL MODULE EVALUATES THE

SIGNALS FROM EACH SENSOR (INPUT SIGNALS FROM 1, 4, 9, 10), CURRENT IS OUTPUT TO TERMINALS HTL,

HTR AND HTS, CONTROLLING THE HEATER.

IDLE AIR CONTROL SYSTEM

THE IDLE AIR CONTROL SYSTEM (ROTARY SOLENOID TYPE) INCREASES THE RPM AND PROVIDES IDLE STABILITY

FOR FAST IDLE–UP WHEN THE ENGINE IS COLD, AND WHEN THE IDLE SPEED HAS DROPPED DUE TO ELECTRICAL

LOAD AND SO ON, THE ENGINE CONTROL MODULE EVALUATES THE SIGNALS FROM EACH SENSOR (INPUT

SIGNALS FROM 1, 4, 5, 8, 9), CURRENT IS OUTPUT TO TERMINALS RSO AND RSC TO CONTROL IDLE AIR CONTROL

VALVE.

EGR CONTROL SYSTEM

THE EGR CONTROL SYSTEM DETECTS THE SIGNAL FROM EACH SENSOR (INPUT SIGNALS FROM 1, 4, 9, 10),

AND OUTPUTS CURRENT TO TERMINAL EGR TO CONTROL THE VSV (EGR).

THE EGR VALVE POSITION SENSOR IS MOUNTED ON THE EGR VALVE. THIS SENSOR CONVERTS THE EGR VALVE

OPENING HEIGHT INTO A VOLTAGE AND SENDS IT TO THE ENGINE CONTROL MODULE AS THE EGR VALVE

POSITION SIGNAL.

ACIS (ACOUSTIC CONTROL INDUCTION SYSTEM)

ACIS INCLUDES A VALVE IN THE BULKHEAD SEPARATING THE SURGE TANK INTO TWO PARTS. THIS VALVE IS

OPENED AND CLOSED IN ACCORDANCE WITH THE DRIVING CONDITIONS TO CONTROL THE INTAKE MANIFOLD

LENGTH IN TWO STAGES FOR INCREASED ENGINE OUTPUT IN ALL RANGES FROM LOW TO HIGH SPEEDS.

THE ENGINE CONTROL MODULE JUDGES THE ENGINE SPEED BY THE SIGNALS ((4), (5)) FROM EACH SENSOR

AND OUTPUTS SIGNALS TO THE TERMINAL ACIS TO CONTROL THE VSV (INTAKE AIR CONTROL).

3. DIAGNOSIS SYSTEM

WITH THE DIAGNOSIS SYSTEM, WHEN THERE IS A MALFUNCTION IN THE ENGINE CONTROL MODULE SIGNAL

SYSTEM, THE MALFUNCTIONING SYSTEM IS RECORDED IN THE MEMORY.

4. FAIL–SAFE SYSTEM

WHEN A MALFUNCTION OCCURS IN ANY SYSTEMS, IF THERE IS A POSSIBILITY OF ENGINE TROUBLE BEING

CAUSED BY CONTINUED CONTROL BASED ON THE SIGNALS FROM THAT SYSTEM, THE FAIL–SAFE SYSTEM

EITHER CONTROLS THE SYSTEM BY USING DATA (STANDARD VALUES) RECORDED IN THE ENGINE CONTROL

MODULE MEMORY OR ELSE STOPS THE ENGINE.

67

ENGINE CONTROL

R

B–R

76

W–R

1K5

1B5

2L4

2A1

BW

C1

A1

AM2 IG2

ST2

I13

IGNITION SW CIR OPN

30A

AM2

J22

JUNCTION CONNE CTOR

AAAAAAAAAA

B–R

B–R

A

FUS IBL E LINK

BLOCKCF 6 , F 8

B–R

8

R

B–R

B–R

B–R

2

1

INJECTOR NO. 1

I 6

B–R

2

1

INJECTOR NO. 2

I 7

B–R

1W71K3

1C8

B–R

IK312

B–R

A

B–R

2

1

INJECTOR NO. 3

I 8

B–R

11

15

RELAY

5A

IGN

B–R

2

1

INJECTOR NO. 4

I 9

B–R

2

1

INJECTOR NO. 5

I10

B–R

2

1

INJECTOR NO. 6

I11

23

11

G–R

EB25

G–R G–R

F19

FUEL

PUMP

L–BL–BL–BW–B

EB24

ID17IK23

4

M

5

B–R

68

B–G –R

FL MAIN

3. 0W

BA

TTERY

L

R

Y

W

R–L

G

G–R

G

R–L

W

Y

R

L

B–R

B–R

B–R

B–R

J37

JUNCTION

CONNECTOR

A

BN

FROM POWER SOURCE SYSTEM (SEE PAGE 56

B–R

B–YR

)

B–Y

B–Y

B–R

2K7

15

23

2F42C10 2J22J8

2C5

B–R

W–B

W–B

BJ28 , J29A

15A

EFI

B–YB–Y

B–Y

B–Y

IK39

O. 1

FRO M F AN N

RELAY

IK21

G–W G–W

B9

CF

EFI

RELAY

B–YB–Y

B–Y

ABAB

B–Y

BBBB

UNCTION CONNECT

JOR

A23 A14 D13

+B BATT STA

1K4

5A

STARTER

1J3

B–W

B

B

ONNECTOR

UNCTION

26

B

JCJ

B–W

P 1

IK211

B–W

J 8 , J 9A

JUNCTION

CONNECTOR

8

IK2

GR

ENGINE CONTROL M ODULE

B–W

5

P

N

PARK/NEUTRAL

POSITION SW

B

GR

BE 7 , E 8AC, E 9 D, E10

6

IK210

GR GR

BC

AB

B–W

D14

NSW

G–R

G

R–L

W

Y

R

L

B–R

B–R

B–R

B–R

FC #60#50#40#30#20#10

C18 D5D6D7D8D9D10

G

R–L

W–B

EC

Y

W

R

NEO

EFI+

EFI–

TRC+

A19

A26

A25

L

BR–W

B

W

FROM TRACTION

CONTROL ECU

TRC–

A28

A27

L

G

B–R

B–R

B–R

B–R

B–Y

69

ENGINE CONTROL

B–Y

B–Y

B–Y

FROM POWER SOURCE SYSTEM (SEE PAGE 56

J23

A

A

)

JUNCTION CONNECTOR

AAAA

B–Y

10A

TAIL

10A

MIRROR–

HEATER

1C9

G–OG–O

AA

BJ18 , J1 9A

BC

JUNCTION CONNECTO R

1J11

B–Y

15A

STOP

1C7

2

STOP LIGHT SW

S10

1

WW

G–

1R4

1R5

A

A

G–W

JUNCTION CONNECTOR

J27

G–W

A24

)

NTAKE AIR CONTRO

IL

(

VSV

V 6

B–Y

1

)

EVAP

(

VSV

V 5

2

LG

B2B12B8B6A2A3

EVP1EGRTPCACISSTPELS2ELS

V 4

)

EGR

(

VSV

B–Y

1

2

Y–G

B–Y

1

2

R–Y

B–Y

)

1

2

APOR PRESSURE S

VENSOR

(

VSV

V 7

W–R

70

E 7 , E 8

AC

ENGINE CONTROL MODULE

222

IGNITION COIL NO. 1

I 3

B–R

B–R

B–R

B–R

B–Y

B

IGNITION COIL NO. 2

I 4

, E 9D, E10

IGNITION COIL NO. 3

I 5

111

G

Y

L

21107 6 54

+B GND

I 2

IGNITER

B–R

GR

BR–Y

E2GTHAVGIGFIGT3IGT2IGT1

B7C8C21D12D15D16D24

W–R

LG–B

IGFIGT3IGT2IGT1IGC1IGC2IGC3

BR

EE

P

513

M 1

MASS AIR FLOW METER

B–Y

L–Y

2439

R–B

BR

J23

JUNCTION CONNECTOR

AAA

B–Y

A

B–Y

(

SHIELDED

BR

BR

BR

)

B–Y

B–Y

2

LE AIR CONTROL VALVE

1

ID

I

RSO RSC HTS OXS HTR OXR1 HTL OXL1 TC

31

R–W

D23 D22 A17 A18 B11 C13 B10 C19 B5

Y–B

)

ATED OXYGEN SEN

HE SOR

(

H10

+B E1

HT OX

NK 1 SENSOR 2

BA

P–B

)

SHIELDED

(

IK12

BR BR

42

31

H 5

B

ENGINE CONTROL MODULE

B–Y

)

+B E1

HT OX

D OXYGEN SEN

1 SENSOR 1

BANK

HEATE SOR

(

L–B

BR

42

)

W

SHIELDED

(

BE 7 , E 8AC, E 9 D, E10

)

SHIELDED

(

BR

42

3131

B

B–Y

)

R1

H 6

HEATED OXYGEN SENSOR

+B E1

HT OX

BANK 2 SENSO

(

Y–R

BR

I 5 I 5

BR

B–Y

TE1

8

BR

BR

BR

BR

312

E1+B

DATA LINK

CONNECTOR 1

D 1

L–W

E2 VTA1 VC THG THW PTNK EGLS PS

C22 C7C1B14 C20 B13 B15 D31

L–R

23

PTNK

VCC E2

RESSURE SEN

31 21

POR P SO

VA R

Y

I 5

BR

I 6

E 2

Y

W–G

E POSITION S

VALV ENS

EGR OR

BR

Y

L

BRBR

I 5 I 5

231

E2 VTA VC

T 2

THROTTLE POSITION SENSOR

BR

E 4

G–B

2

1

BR

ENGINE COOLANT TEMP. SENSOR

V 1

BR

Y

G–Y

E 1

2

1

EGR GAS TEMP. SENSOR

BR

Y

I 5

BR

Y

P 2

B–L

1

POWER STEERING

OIL PRESSURE SW

71

ENGINE CONTROL

BR

BR

BR

)

SHIELDED

BR

BR

BR

C 2 C 1

CRANKSHAFT

POSITION SENSOR

)

B–R

SHIELDED

(

BR

BR

(

SHIELDED

A

J24

JUNCTION

CONNECT OR

V–W

BR

)(

BR

W

G–R

BR

BR

BR

BR

BR

BR

BR

BR

I 6

CAMSHAFT POSITION

SENSOR

LL

(

SHIELDED

I 6

1221

B–W

)

BR

BR

W

BR

BR

I 5

A

A

A

A

A

A

A

A

A

C5C6C17 B16 D1A8B3A12

W

W

BE 7 , E 8AC, E 9 D, E10

THWO

I 6

)

SHIELDED

(

TW2

A9

BR

V

B14

B–Y

LG–B

B10 B13 A16

B–O

AFAF

BD

B–O

IGNAC1ACT

B–O

BJ28 , J29A

BR

BD

JUNCTIO N CONNECTOR

B–O

ENGINE CONTROL MODULE

KNKL KNKR ACT A/C TACH E01 E02 E03

)

)(

)(

SHIELDED

(

EC14EC12EC11EC13

)

SHIELDED

(

W

SHIELDED

SHIELDED

(

(

)

)

W

SHIELDED

SHIELDED

11

BR

SPDWSILADJ2E1G22+NE–NE+

D33 D28D34A13A16A5C15C14

BR

BR BR BR

B–O

72

K 2

TO ABSORBER

KNOCK SENSOR 2

K 1

KNOCK SENSOR 1

A/C CONTROL ASSEMBLY

BA1 4 , A1 5A

CONTROL ECU

ED

FROM POWER SOURCE SYSTEM (SEE PAGE 56

)

BR

(

SHIELDED

BR

W

G–R

V–W

MALFUNCTION

10A

GAUGE

1D2

R–LR–L

D

J 4

JUNCTION

CONNECTOR

D

CC 7 , C 9A

D, C10

D3C10

)

SPEEDOMETER

L

IL17IL12

L

PP

23

SESI

INDICATOR LAMP

G–R

G–R

7. 5A

OBD

)

1J10 1J1

6

IK3

BR

)

SHIELDED

(

BJ 8 , J 9A

DATA LIN K

CONNECTOR 3

D 4

C

J17

JUNCTI ON

CONNECTOR

JUNCTION

CONNECTOR

I11

BB

B

AC

BR BR

JUNCTION CONNECTOR

165

BATSG

CGSIL

74

CV–W

V–W

BA

BJ 8 , J 9A

AA

W–BW–B W–B

1J8

AD

BF

R–LR–L

IK22

A

A

JUNCTION

CONNECTOR

V–W

J25

JUNCTION

CONNECTOR

R–L

BJ28 , J2 9A

3

IJ1

COMBINATION METER

TACHOMETER

A13 D5D13D4C9

B–O

IJ16IJ110

B–O

B–O

1J7

BR

A

J15

JUNCTION

CONNECTOR

IIEE

R–L

IK13

IG+

COMBINATION METER

V 2

VEHICLE SPEED SENSOR

G–R

(

1

R–L

BR

IJ

73

ENGINE CONTROL

SERVICE HINTS

CIR OPN RELAY

1 5 – 1 3 : CLOSED WITH THE STARTER RUNNING

EFI RELAY

5–3 : CLOSED WITH THE IGNITION SW AT ON OR ST POSITION

E 4 ENGINE COOLANT TEMP. SENSOR

1–2 : 10.0 –20.0 KΩ (–20C, –4F)

4.0 –07.0 KΩ (000C, 32F)

2.0 –03.0 KΩ (020C, 68F)

0.9 –01.3 KΩ (–40C, 104F)

0.4 –00.7 KΩ (–60C, 140F)

0.2 –00.4 KΩ (–80C, 176F)

E7 A , E 8 B , E 9 C , E10 D ENGINE CONTROL MODULE

VOLTAGE AT ENGINE CONTROL MODULE WIRING CONNECTOR

BATT–E1 : ALWAYS 9.0–14.0 VOLTS

+B–E1 : 9.0–14.0 VOLTS (IGNITION SW TO ON POSITION)

VC–E2 : ALWAYS 4.5–5.5 VOLTS (IGNITION SW A T ON POSITION)

VTA1–E2: 0.3–0.8 VOLTS (IGNITION SW ON AND THROTTLE VALVE FULLY CLOSED)

VG–E2G : 1.1–1.5 VOLTS (ENGINE IDLING AND A/C SW OFF)

THA–E2 : 0.5–3.4 VOLTS (ENGINE IDLING AND INTAKE AIR TEMP. 20C, 68F)

THW–E2 : 0.2–1.0 VOL TS (ENGINE IDLING AND COOLANT TEMP. 80C, 176F)

IGF–E1 : 4.5–5.5 VOLTS (IGNITION SW AT ON POSITION)

G22+–NE : PULSE GENERA TION (ENGINE IDLING)

NE+–NE : PULSE GENERATION (ENGINE IDLING)

SIL–E1 : PULSE GENERATION (DURING TRANSMISSION)

TACH–E1 : PULSE GENERATION (ENGINE IDLING)

STA–E1 : 6.0 VOLTS OR MORE (ENGINE CRANKING)

THG–E2 : 4.5–5.5 VOLTS (IGNITION SW AT ON POSITION)

EGR–EO1: 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

FC–E1 : 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

SPD–E1 : PULSE GENERATION (IGNITION SW ON AND ROTATE DRIVING WHEEL SLOWLY)

W–E1 : BELOW 3.0 VOLTS (IGNITION SW AT ON POSITION)

A/C–E1 : BELOW 2.0 VOLTS (ENGINE IDLING AND A/C SW ON)

ACT–E1 : 9.0–14.0 VOLTS (ENGINE IDLING AND A/C SW ON)

ACIS –EO1: 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

NSW–E1 : 9.0–14.0 VOLTS (IGNITION SW ON AND OTHER SHIFT POSITION IN P OR N POSITION)

EVP–E01 : 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

TC–E1 : 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

STP–E1 : 7.5–14.0 VOL TS (IGNITION SW ON AND BRAKE PEDAL DEPRESSED)

CF–E1 : 9.0–14.0 VOL TS (COOLING FAN IS OPERATING ON HIGH SPEED)

TPC–E1 : 9.0–14.0 VOLTS (IGNITION SW ON AND DISCONNECT THE VACUUM HOSE FROM THE VAPOR PRESSURE SENSOR)

PTNK–E1 : 3.0–3.6 VOLTS (IGNITION SW AT ON POSITION)

RSC,RSO–E1 : 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

KNKL,KNKR–E1 : PULSE GENERATION (ENGINE IDLING)

HTS, HTL, HTR–E03 : 9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

OXS, OXL1, OXR1–E1 : PULSE GENERATION (MAINTAIN ENGINE SPEED AT 2500 RPM FOR TWO MINUTES AFTER WARMING UP)

IGT1, IGT2, IGT3–E1:PULSE GENERATION (ENGINE IDLING)

#10, #20, #30, #40, #50, #60–EO1:9.0–14.0 VOLTS (IGNITION SW AT ON POSITION)

I 6, I 7, I 8, I 9 , I10, I 11 INJECTOR

2–1 : APPROX. 13.8 Ω

T 2 THROTTLE POSITION SENSOR

2–1 : 3.75 KΩ

3.2–4.9 VOLTS (IGNITION SW ON AND THROTTLE VALVE FULLY OPEN)

PULSE GENERATION (ENGINE IDLING)

0–3.0 VOLTS (ENGINE IDLING)

9.0–14.0 VOLTS (A/C SW OFF)

BELOW 2.0 VOLTS (A/C SW OFF)

0–3.0 VOLTS (IGNITION SW ON AND SHIFT POSITION IN P OR N POSITION)

0–1.5 VOLTS (IGNITION SW ON AND BRAKE PEDAL DEPRESSED)

: 0–2.0 VOLTS (COOLING FAN IS OPERATING ON LOW SPEED OR OFF)

1.3–2.1 VOLTS (IGNITION SW ON AND APPLY VACUUM 2.0 KPA)

0–3.0 VOLTS (ENGINE IDLING)

:PULSE GENERATION (ENGINE IDLING)

74

: PARTS LOCATION

20

()

20

()

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

A14 A

A15 B

C 1

C 2

C 7 A

C 9 C

C10 D

D 1

D 4

E 1

E 2

E 4

E 7 A

E 8 B

E 9 C

E10 D

F 6 A

F 8 C

F19

H 5

H 6

28

28

26

26

28

28

28

26

28

26

26

26

28

28

28

28

26

26

30

26

26

H10

I 1

I 2

I 3

I 4

I 5

I 6

I 7

I 8

I 9

I10

I11

I13

J 4

J 8 A

J 9 B

J15

J17

J18 A

J19 B

J22

28

27

27

27

27

27

27

27

27

27

27

27

28

29

29

29

29

29

29

29

29

J23

J24

J25

J26

J27

J28 A

J29 B

J37

K 1

K 2

M 1

P 1

P 2

S10

T 2

V 1

V 2

V 4

V 5

V 6

V 7

29

29

29

29

29

29

29

30

27

27

27

27

27

29

27

27

27

27

27

27

27

: RELAY BLOCKS

CODE SEE PAGE RELA Y BLOCKS (RELAY BLOCK LOCATION)

1

22

ENGINE ROOM R/B (ENGINE COMPAR TMENT LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B

1C

1D

1J

1K

1R

1W

2A

2C

2F

2J

2K

2L

24

24

24

20

20

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

INSTRUMENT PANEL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

COWL WIRE AND INSTRUMENT PANEL J/B (LOWER FINISH PANEL)

ENGINE ROOM MAIN WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

COWL WIRE AND ENGINE ROOM J/B (ENGINE COMPAR TMENT LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE SEE PAGE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EB2

EC1

34

34

COWL WIRE AND ENGINE ROOM MAIN WIRE (UNDER THE ENGINE ROOM J/B)

ENGINE WIRE AND SENSOR WIRE (LEFT BANK OF THE CYLINDER HEAD)

75

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

()

CODE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)SEE PAGE

ID1

IJ1 38 INSTRUMENT PANEL WIRE AND COWL WIRE (UNDER THE GLOVE BOX)

IK1

IK2

IK3

IL1 38 ENGINE WIRE AND INSTRUMENT P ANEL WIRE (UNDER THE GLOVE BOX)

36

38 ENGINE WIRE AND COWL WIRE (UNDER THE GLOVE BOX)

FLOOR WIRE AND COWL WIRE (LEFT KICK PANEL)

76

ENGINE CONTROL

: GROUND POINTS

CODE SEE P AGE GROUND POINTS LOCATION

EC

ED

EE

34

34

34

II

36

IJ

36

BN 40 UNDER THE LEFT CENTER PILLAR

: SPLICE POINTS

CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS CODE SEE PAGE WIRE HARNESS WITH SPLICE POINTS

I 5

I 6

38 ENGINE WIRE

LEFT RADIATOR SIDE SUPPORT

SURGE TANK RH

REAR SIDE OF SURGE TANK

INSTRUMENT PANEL BRACE LH

INSTRUMENT PANEL BRACE RH

I11

38 INSTRUMENT PANEL WIRE

AA14 BA15

16 X X

XX3

X8X X

12

XX

X

X

C 1 C 2

BLACK BLACK

X

10 X X 13 14 X

ABLUEC 7 D BROWNC10CGRAYC 9

13XXXXX 109X 13543

BLACKD 1 D 4 DARK GRAYE 1

X

X