Lexmark™ X264dn, X363dn, X364dn, X364dw

• Tabl e of conte n t s

• Start diagnostics

Revision: January 10, 2014

7013-235

7013-432

7013-436

7013-43W

• Safet y and notices

• Trademarks

• Index

Lexmark and Lexmark with diamond design are

trademarks of Lexmark International, Inc., registered

in the United States and/or other countries .

Edition: January 10, 2014

The following paragraph does not apply to any country where such provisions are inc onsistent with local law:

LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions; there fore, this statement ma y not apply to you.

This publication could include tec hnical inaccuraci es or typographical er rors. Changes are period ically made to the

information herein; these changes wil l be incorporated in later editions. Improvements or changes in the products or the

programs described may be made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22X/002-1, 740 West New Circle Road,

Lexington, Kentuck y 40550 , U.S.A or e-mail at ServiceI nfoAndTr ai ning@Lex mark.com. Lexmar k may use or dist ribu te any

of the information you supply in any way it believes appropriate wi thout incurring any obligation to you.

References i n this publication to products, programs, or services do not i mp ly that the manufacturer intends to make these

available in all countries in which it operates. Any reference to a product, program, or service is not intended to state or

imply that only t hat produ ct, pr ogra m, or serv ice may be used. Any funct ional ly equi valent pro duct, progr am, or servi ce that

does not infringe any existing intellectual property right may be used instea d. Eval uation and verifi cation of operation in

conjunction with other products, programs, or services, except those expressly designated by the manufacturer, are the

user’s respons ibility.

Lexmark, Lexmark wit h diamond design, and MarkVision are trademarks of Lexmark Internati onal, Inc., registered in the

United States and/or other countries.

Optra Forms is a trademar k of Lexmark International, Inc.

PCL® is a registered trademark of the Hewlett-Packard Company.

All other trademarks are the property of their respective owners.

© 2009 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are commercial computer software

and documentation developed exclusively at private ex pense.

7013-XXX

P/N 12G9817

7013-XXX

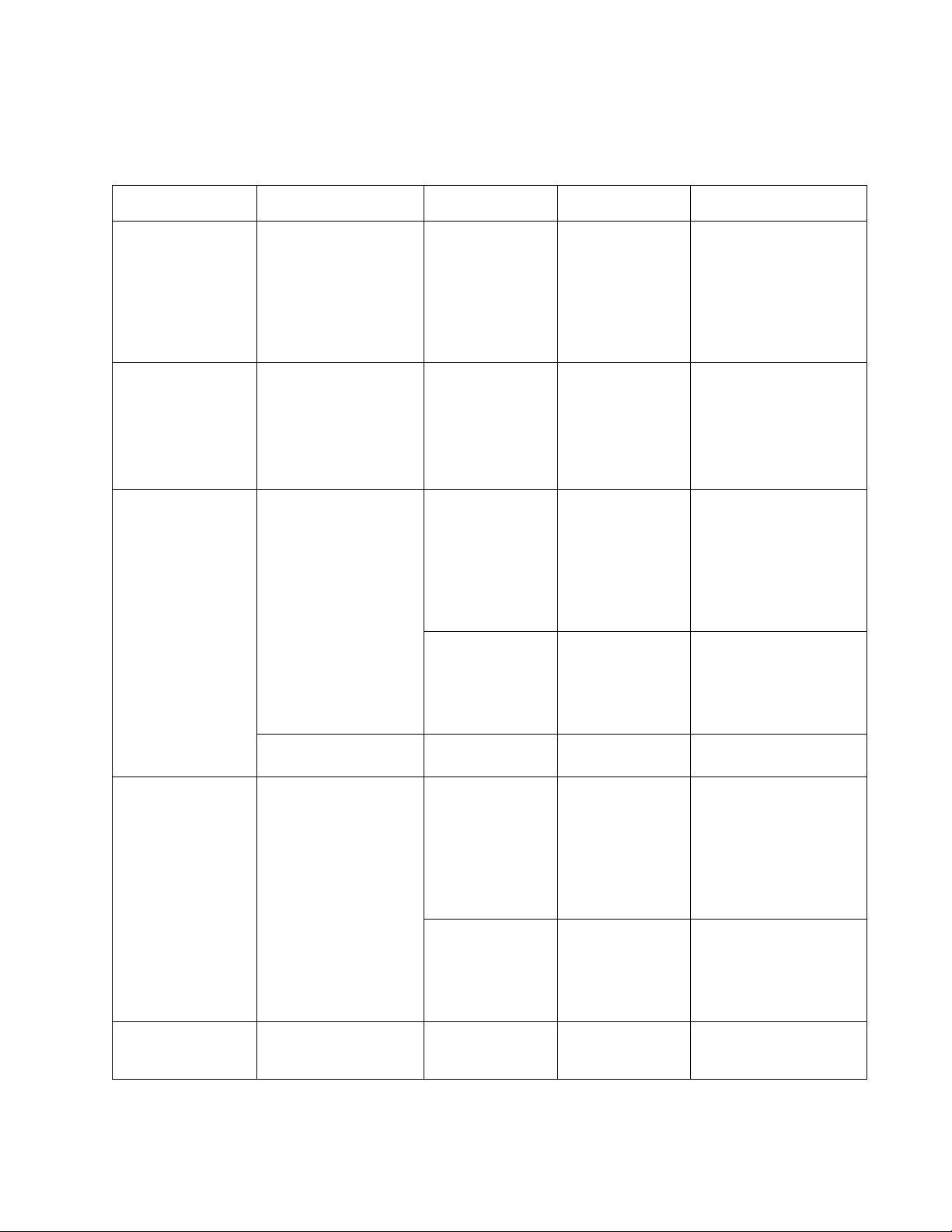

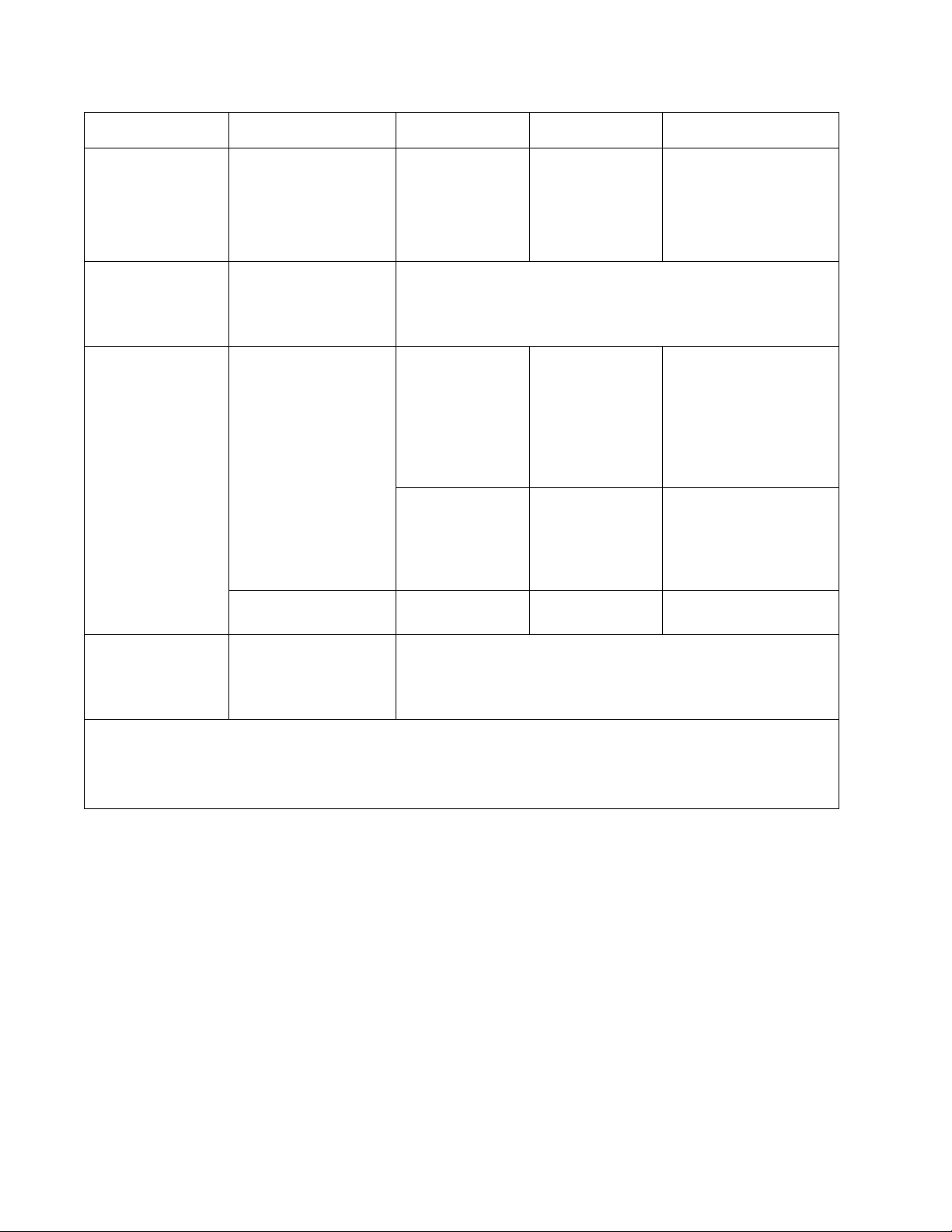

Table of contents

Notices and safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Laser notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Change history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v -x v iii

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview of the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Print q u a lity settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Compatibility and connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Media trays and supply capaci ty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Types of print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Digital imaging specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

ADF Scan speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

ADF Document handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Resolution and color depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Flatbed document specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Flatbed speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Scanner operating environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Storage envir onm ents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Scan and copy specific specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Duplex scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Scan file output formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Supported compressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Supported scan destinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Multiple copies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Reduce/Enlarge (copy only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Fax specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Phone network connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Fax resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Miscellaneous FAX specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Diagnostics information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview of the operator panel and menu s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Understanding the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operator panel buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Diagram of the printer menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Messages and error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

User attendance messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Cartridge error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Paper jam error codes (200-series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Service error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

POST symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

iii

7013-XXX

Printer symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Scan/fax /copy symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Controller board service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Cooling fan service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 27

Cover interlock switch service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Dead machine service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Fuser service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

LVPS/HVPS service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Main motor servi ce check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Media feed clutch service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Operator panel service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Paper feed service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Paper jam error indication during POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Media picks but st ops halfway through the pri nter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Media never picks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Media occasionally mispicks or pi cks multiple sheets at once . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Media skews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Media “trees,” wrinkles, stacks poorly, or curls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

USB port service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Networking service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Print quality service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Blank page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Black page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Heavy background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Partial blank image/white spots (no repeat ing pattern) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Variation in image density horizontally across page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Poor fusing of image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

Light print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

White or black lines or bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -39

Toner on back of page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3 9

Solving print quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Printhead service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

Transfer roll service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

Tray 2 service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

840.xx service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Black or blank page copy service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

CCD service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Flatbed motor service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 46

Flatbed home position service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

ADF cover open service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

ADF streak service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 48

ADF paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

ADF feed errors service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

ADF Duplex service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

Modem / fax card service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

Fax transmission service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

Fax reception service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

Escalating a fax issue to second-level support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

Diagnostic aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Menu key combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Diagnostics Menu (Diag Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Diagnostics menu stru cture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Available tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Margins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Print Quick Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Print tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

iv Service Manual

7013-XXX

Input sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Print Quality Pages (Prt Quality Pgs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Miscellaneous Test s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Motor Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Input sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Print Quality Pages (Prt Quality Pgs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Hardware Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 7

Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

DRAM Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

CACHE Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Duplex Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 9

Quick Test (duplex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Left Margin (duplex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Top Margin (duplex ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Sensor Test (duplex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Input Tray tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Feed Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Output Bin Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Feed Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Base Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Page Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Model Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Configuration ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Enable Edge to Edge Copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Reset Fuser Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

EP Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 14

EP Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Fuser Temperature (Fuser Temp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Print Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Charge Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Gap Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Automatic Darkness Adjustment (Auto Dark Adj) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Menu Settings Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Display Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Print Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Clear Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Scanner Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

ASIC Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

EXIT Diags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Printhead assembly el ectronic adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Printhead assembly mechanical adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Available tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

USB Scan to Local . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Prt Quality Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Menu Settings Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

v

7013-XXX

Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

PPDS Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Energy Conserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Min Copy Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

NumPad Job Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Format Fax Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

ADF Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

FB Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

Scanner Manual Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 30

Disable Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Font Sharpening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Reduced Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

USB Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Exit Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

SE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Print SE Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Code Revision Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

MAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

NPAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

TCP/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Avoiding jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Understanding paper jam codes and locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

200-202 paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3 5

231 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

233 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

234 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

235 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

242 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

251 paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

290-294 paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4 0

291.xx ADF paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4 1

Updating the printer fir mwar e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Using a USB flash drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Using a network computer to update the MFP fi rmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Using FTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Using the MFP’s Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Using the host computer to update the MFP firmware over USB . . . . . . . . . . . . . . . . . . . . . . . .3-43

Scanner th eory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

Duplex ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

Repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensiti ve parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

ACM pick tire roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

ADF removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

ADF cable removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

ADF input tray removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

ADF scanner assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

ADF separator pad remova l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

ADF separator roll assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Controller board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Cover open sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Door mount removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

vi Service Manual

7013-XXX

Duplex removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 16

Duplex ADF rear cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Duplex/main motor gear drive interface removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Fax card removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Flatbed removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Front door access cover bl ank removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Front scanner cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Fuser removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Left side print er cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Left side scanner cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Lower access door assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

LVPS/HVPS removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Main motor gear dri ve rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Manual feed clutch removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Manual feed solenoid re moval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 46

Media ACM ASM feeder removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Media feed clutch removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Media manual input sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Multipurpose fee d er (MPF) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

MPF tray removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Multipurpose fee der (MPF) feed clutch removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Nameplate blank cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 64

Operator panel removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Operator panel cable removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Paper input and duplex sensor assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Printhead removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Rear door and cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 69

Rear exit guide assembly with sensor and reversing sol enoid removal . . . . . . . . . . . . . . . . . . 4- 71

Right side printer cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

Right side scanner cover rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Toner level sensor rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

Top printer cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Transfer roll removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Upper front guide assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 80

Wear strip (tray 1 and 250-sheet tray 2) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 81

Wear strip (550-sheet tray 2) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

Wireless antenna removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Wireless card removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

Locations and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Controller board connector pin values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Preventive mainte nan ce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety inspection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Lubrication spec if ications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Assembly 3: Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Assembly 4: Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Assembly 5: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

vii

7013-XXX

Assembly 6: Power cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Part number index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-5

viii Service Manual

Notices and safety information

The following laser notice labels may be affixed to this printer.

Laser no tice

The printer is certified in the U.S. to conform to the requi rements of DHHS 21 CFR Subchapter J for Class I (1)

laser products, and elsewhere is certified as a Class I laser product conforming to the requirements of IEC

60825-1.

Class I laser products are not considered to be hazardous. The printer contains internall y a Clas s IIIb (3b) laser

that is nomin all y a 5 milliwatt gallium arseni de laser operating i n the wavelength region of 770-795 nanom eters.

The laser system and pri nter are designed so there i s never any human access to las er radiation above a Class

I level during normal operation, user maintenance, or prescribed service condition.

Laser

Der Drucker erfüllt gemäß amt li cher Bestätigung der USA die Anfor derungen der Bestimmung DHHS

(Department of Health and Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1). I n anderen

Ländern gilt der Drucker als Laserprodukt der Klasse I, der die Anforderungen der IEC (International

Electrotechnical Commission) 60825-1 gemäß amtlicher Bestätigung erfül lt .

7013-XXX

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des Druckers befind e t si ch ein Laser der Klasse

IIIb (3b), bei dem es si ch um einen Galliumarsenlaser mit 5 Milliwatt handel t, der Wellen der Länge 770-795

Nanometer ausstr ahlt. Das Lasersystem und der Drucker sind so konzipiert, daß im Normalbetr ieb, bei der

Wartung durch den Benutzer oder bei ordnungsgemäßer Wartung durch den Kundendienst Laserbes tr ahlung,

die Klasse I übersteigen würde, Menschen keinesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est ce rtifiée conforme aux provisions DHHS 21 CFR alinéa J conc ernant

les produits laser de Classe I (1). Pour les aut res pays : cette imprimant e répond aux normes IEC 60825-1

relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits non dangereux. Cette imprimante est

équipée d’un l aser de Classe IIIb (3b) (arséniur e de gallium d’une puissance nominal e de 5 milliwatts ) émettant

sur des longueurs d’onde comprises entre 770 et 795 nanomètres. L’imprimante et son système laser sont

conçus pour impossible, dans des conditions normales d’utilisation, d’entretien par l’utilisateur ou de révision,

l’exposition à des rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampant e è certificata negli Stati Unit i per essere conforme ai requisit i del DHHS 21 CFR Sottocapitolo

J per i prodotti laser di classe 1 ed è certificat a negli altri Paesi come prodotto laser di classe 1 conforme ai

requisiti del la norma CEI 60825-1.

I prodotti laser di classe non sono consider at i pericol osi. La st ampant e contie ne al suo interno un laser d i classe

IIIb (3b) all’arseniuro di gall io della potenza di 5mW che opera sul la lunghezza d’ond a com presa tra 770 e 795

nanometri. Il sistema laser e la stampante sono stati proget tati in modo tale che le persone a contatto con la

stampante, durante il normale funzionamento, le operazioni di servizio o quelle di assistenza tecnica, non

ricevano radi azioni laser superi ori al livello della classe 1.

Notices and safety information ix

7013-XXX

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los requisitos para los productos láser de Clase I (1)

establecidos en el su bcapítulo J de la norma CFR 21 del DHHS (Departamento de Sanid ad y Servicios) y, en

los demás países, reúne todas las condiciones expuestas en la norma IEC 60825-1 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La impresora contiene en su int eri or un láser de

Clase IIIb (3b) de arseniuro de gali o de funcionami ento nominal a 5 m ilivatios en una longitud de onda de 770 a

795 nanómetros. El sistema láser y la impresora están diseñados de forma que ninguna persona pueda verse

afectada por ni ngún ti po de radiación láser superior al nivel de la Clase I dur ante su uso normal, el

mantenimiento realizado por el usuario o cualquier otra situación de servici o técnico.

Declaração sobre Laser

A impressora e stá cer tific ada n os E.U.A . em conf ormidade com os r equisi tos da regu lamentaç ão DHHS 21 CFR

Subcapítulo J para a Clas se I (1) de produt os laser . Em outr os locai s, est á cer tific ada co mo um produ to laser da

Classe I, em conformidade com os requisitos da norma IEC 60825-1.

Os produtos lase r da Class e I não são cons id erados per igosos . Inte rnamen te, a impress ora contém um produ to

laser da Classe IIIb (3b), designado laser de arseneto de potássio, de 5 mill iwatts ,operando numa faixa de

comprimento de onda entre 770 e 795 nanómetros. O sistema e a impressora laser foram concebido s de forma

a nunca existir qualquer possiblidade de acesso humano a radiaç ão laser superior a um nível de Classe I

durante a operação nor m al, a manutenção feita pel o utilizador ou condições de assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een laserprodukt van klasse I. Voor de Verenigde

Staten zijn deze eis en vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in IEC 60825-1.

Laserprodukten van klasse I worden niet als ongevaarlijk aangemerkt. De printer is voorzien van een laser van

klasse IIIb (3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met een golflengte van 770-795

nanometer. Het laser gedee lte en de print er zijn zo ontworp en dat bij normaal gebr uik, bi j onder houd of repar atie

conform de voorschriften, nooi t bl ootstelling mogelijk is aan laserstr aling boven een niveau zoals

voorgeschr even is voor klasse 1.

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i overenstemmelse med kravene i IEC 60825-1.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren indeholder internt en Klasse IIIB (3b)-laser, der

nominelt er en 5 milli watt galliumarsenid laser, som arbejder på bølgelængdeområdet 770-795 nanometer.

Lasersystemet og printeren er udformet således, at mennesker aldrig udsættes for en laserstråling over Klasse

I-niveau ved nor m al dr ift, brugervedl igeholdelse ell er obligatoriske servi cebetingels er.

x Service Manual

Laserilmoitus

Tämä tulostin on sertif ioitu Yhdysvalloissa DHHS 21 CFR Subchapter J -standardin mukaiseksi luokan I (1) lasertuot teeksi ja muualla IEC 60825- 1 -st andardin mukaiseksi luokan I lasertuotteeksi.

Luokan I laser tuot teit a ei pi detä hai tall isi na. Tul ostimen sisäl l ä on luok an III b (3b) laser, joka o n ni mellist eholt aan

5 mW:n galliumarsenidilaser ja toimii 770 - 795 nanometrin aallonpituuksilla. Laserjärjestelmä ja tulost in ovat

rakenteelt aan sellaisia, et tä käyttäjä ei joudu altt iiksi luokkaa 1 suur em m all e säteilylle nor m aalin käytön,

ylläpidon tai huollon aikana.

Huomautu s las er laitteesta

Tämä kirjoi tin on Yh dysval loiss a luokan I (1) las erlai ttei den DHHS 21 CFR Subc hapt er J -määr ity ksen mukai nen

ja muualla luokan I laserlaitteiden IEC 60825-1 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle. Kirjoittimessa on sisäinen luokan IIIb (3b) 5

milliwatin gal liumarsenid il aser, joka toimii aalt oalueella 770 - 795 nanom etriä. Laserjärjestelmä ja kirjoitin on

suunniteltu siten, että käytt äjä ei altistu luokan I määrityksiä voimakkaammalle säteilylle kirj oittimen normaalin

toiminnan, käyttäjän tekemien huoltotoimien tai muiden huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso

säteeseen.

7013-XXX

VARNING! Osynlig laserst rålning när denna del är öppn ad och spärren är urkopplad. Betrakta ej strålen.

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21 CFR, underparagraf J för laserprodukter av

Klass I (1). I andra länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt kraven i IEC 60825-1.

Laserprodukter i Klass I anses ej hälsovådliga. Skriva ren har en inbyggd laser av Klas s II Ib (3b) som består av

en laserenhet av gal lium-arsenid på 5 mil li watt som arbetar i våglängdsområdet 770-795 nanom eter.

Lasersystem et och skrivaren är utfo rmade så att det aldrig finns risk för att någon pe rson utsätts för

laserstrå lning över Klass I-nivå vid normal användning, underhåll som utför s av användaren eller annan

föreskriv en serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR, underkapittel J, for k lasse I (1) laserprodukter, og er

i andre land godkjent som et Klasse I-laser produkt i samsvar med krav ene i I EC 60825-1.

Klasse I-laserprodukte r er ikke å betrakte so m farlige. Skriveren inneholder inter nt en klasse IIIb (3b)-laser, s om

består av en gallium-arsenlaserenhet som avgir stråli ng i bølgelengdeomr ådet 770-795 nanometer .

Lasersystem et og skrive ren er utformet slik at personer aldri utsett es for la serstrål i ng ut over klasse I-n ivå under

vanlig bruk, vedlikehold som utføres av brukeren, ell er fo reskrevne serviceoperasjoner.

Notices and safety information xi

7013-XXX

Avís sobre el Làser

Segons ha estat cert ificat als Estats Units, aquesta impressor a compleix els requi sits de DHHS 21 CFR, apartat

J, pels productes làser de classe I (1), i segons ha estat cer tificat en alt res llocs, és un producte làser de classe

I que compleix els requisits d’IEC 60825-1.

Els productes l àser de classe I no es consideren perillosos. Aquesta impressora con té un làser de classe IIIb

(3b) d’arseniür de gal.li, nominalment de 5 mil.liwats, i funciona a la regió de longi tud d’ ona de 770-795

nanòmetres. El sistema làser i la impressora han sigut concebuts de manera que mai hi hagi exposició a la

radiació làser per sobre d’un nivell de classe I durant una operaci ó normal, durant les tasques de manteniment

d’usuari ni durant els serveis que satisfacin les condicions prescrites.

xii Service Manual

7013-XXX

Notices and safety inf ormation xiii

7013-XXX

xiv Service Manual

Safety information

CAUTION

This product cont ains a lithi um battery. THERE IS A RISK OF EXPL OSION IF THE BATTERY

IS REPLACED BY AN INCORRECT TYPE. Discard used batteries according to the battery

manufacturer’s instructions and local regulations.

• The safety of this product is based on testing and approvals of the original design and speci fi c

components. The man ufacturer is not res ponsible for safety in the event of use of unauthorized

replacement parts.

• The maintenance inf ormation for this product has been prepared for use by a professional ser vice person

and is not intended to be used by others.

• There may be an increased risk of electric shock and personal injury during disassembly and servicing of

this product. Professional service personnel should understand this and take necessary precautions.

• CAUTION: When you see this symbol, there i s a danger from hazardous volta ge i n the area of the

product where you a re work ing. Unp lug th e product be fore y ou begin, or us e cau tion i f th e product

must receive power in order to perform the task.

7013-XXX

Consignes de sécurité

• La sécurité de ce pro duit repose sur des tests et des

agréations por tant sur sa conception d' origine et sur des composants particuliers. Le fabricant n'assume

aucune respon sabilité concernant la sécurité en cas d'ut ilisation de piè ces de rechange non agréées.

• Les consignes d'entretien et de réparation de ce produit s'adressent unique me nt à un personnel de

maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques électriques, le personnel

d'entretien qualifié devra prendre toutes les précautions nécessaires.

• ATTENTION : Ce symbole indique la prés ence d'une tension dangereuse dans la partie du

produit sur laquelle vous travaillez. Débranchez le produit avant de commencer ou fai tes preuve

de vigilance si l' exécution de la tâche exi ge que le produit reste sous tension.

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del progetto originale e dei componenti

specifici. Il produttore non è resp onsabile per la sicur ezza in caso di sostituzione non autorizzata delle

parti.

• Le informazion i riguardanti la manutenzione di questo prodotto sono indirizzate soltanto al pers onale di

assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più elevato. Il personale di assistenza

autorizzat o deve, quindi, adott are le precauzioni necessarie.

• ATTENZIONE: Questo simbolo indica la presenza di tensione pericolosa nell'area del prodotto.

Scollegare il pr odotto prima di iniziare o usare cautela se il prodotto deve essere alimentato per

eseguire l'intervento.

Safety information xv

7013-XXX

Sicherheitshinweise

• Die Sicherheit di eses Produkts basiert auf Tests und Zulassungen des ursprünglichen Mode ll s und

bestimmter Baut eil e. Bei Verwendung nicht genehmigter Ersatzteile wird vom Hersteller keine

Verantwortung oder Haftung für die Sicherheit übernommen.

• Die Wartungsinformationen für dieses Produkt sind ausschl ießlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein zus ätzliches Risiko eines

elektrischen Schlags und körperlicher Verletzung. Das zuständige Fachpersonal sollte entsprechende

Vorsichtsmaßnahmen treffen.

• ACHTUNG: Dieses Symbol weist auf eine gefährliche elektrische Spannung hin, die i n diesem

Bereich des Produkts auf tret en kann. Zieh en Sie vor den Arbeit en am Gerät den Netzsteck er des

Geräts, bzw. arbeiten Sie mit große r Vor sicht, wenn das Produkt für die Ausführung der Arbeiten

an den Strom angeschlossen sein muß.

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y aprobaciones del diseño original y componentes

específico s. El fabri cante no es responsabl e de la seguridad en caso de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimiento de este producto está dirigida exclusivamente al personal

cualificado de mantenimiento.

• Existe mayor riesgo de de scarga e léc trica y de dañ os pe rsonal es du rante e l desmont aj e y la r eparaci ón de

la máquina. El personal cualificado debe ser consciente de este peligro y tomar las precauciones

necesarias.

• PRECAUCIÓN: este símbolo indica que el voltaje de la parte del equi po con la que está

trabajando es peligroso. Antes de empez ar, desenchufe el equipo o te nga cuidado si, para

trabajar con él, debe conectarlo.

Inform a çõ es de Segurança

• A segurança deste produto baseia-se em testes e aprovações do modelo ori ginal e de componentes

específico s. O fabr icante não é responsá vel pela segunrança, no caso de uso de peças de substit uição

não autorizadas.

• As informações de segurança relativas a este produto destinam-se a profissionais destes serviços e não

devem ser utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a desmontagem e manutenção deste produto.

Os profissionais destes serviços devem estar avisados deste facto e tomar os cuidados necessários.

• CUIDADO: Quando vir este símbolo, existe a possível presença de um a potencial tensão

perigosa na zona do produto em que está a trabalhar . Ant es de com eçar, desligue o produt o da

tomada eléctr ica ou seja cu ida doso caso o pr oduto t enha de estar liga do à c orrent e eléc tric a para

realizar a taref a necessária.

xvi Service Manual

Informació de Seguretat

• La seguretat d'aquest producte es basa en l' avaluació i aprovació del disseny original i els components

específics .

El fabricant no es fa responsable de les qüestions de

seguretat si s'u ti litzen peces de recanvi no autoritzades.

• La informació pel ma nteniment d’aquest producte està orient ada exclusivament a professionals i no està

destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar durant el procés de desmuntatge i de servei

d’aquest producte. El personal professional ha d’estar-ne assabentat i prendre

les mesures con venients.

• PRECAUCIÓ: aquest símbol indica que el voltatge de la part de l'equip amb la qual esteu

treballan t és perill ós. Abans de començ ar, desendol leu l'equi p o extremeu les precauc ions si, per

treballar am b l'equip, l'heu de connect ar.

7013-XXX

Safety information xvii

7013-XXX

Preface

This manual contains maintenance procedures for service personnel. It is divided into the following chapters:

1. Gener a l in fo r m a ti o n contains a general description of the printer and the maintenance approach used to

repair it. Speci al tools and test equip me nt, as well as general environmental and safety instructions, are

discussed.

2. Diagnostic information contains an error indicator table, sym ptom tables, and service checks used to

isolate failing field replaceable units (FRUs).

3. Diagnostic aids con tai ns tests and checks used to locate or repeat symp toms of printer probl ems .

4. Rep ai r info rmation provides instructions for maki ng printer adjustments and removing and installing

FRUs.

5. Connector locations uses illustrations to identify the connec tor locations and test points on the printer .

6. Preventive maintenance contains the lubrication specif ications and recomme ndations to prevent

problems.

7. Parts catalog contains illustra ti ons and part numbers for individual FRUs.

Appendix A contains service tips and inf ormation.

Appendix B contains representative print samples .

Change history

Revision date Updates

2014/01/10 Added a note for the Scanner sensor tests in the Diagnostic Aids chapter.

2013/07/16 Updated the Media ACM ASM feeder removal —T he me dia feed clutch should only be

2013/07/01 Replaced 40X5612 with 40X900 0 (Assembly 3: Electronics).

2013/06/03 Registration under Diagnostics menu:

2012/05/06 • Removed logo from namplate cover illustration (page 7-2).

2012/9/19 Changed ADF separator pad PN from 40X5472 to 40X8419.

2012/08/07/ Added PN 40X5961for the Operator panel X264/X364 (DBCS) under “Scanner” on

2012/06/04 Corrected the description for PN 40X5617 to “Operator panel X264/X364” from “Operator

2012/05/02 Replaced all ref erences o f 4 0X5471 to 4 0X7545 for t he ADF separ ator r oll in “ Scanne r” on

2011/10/28 Added this warning: “Warni ng: Do not strip the insulation off the red and black wires. The

2011/9/14 Revised the media feed clutch assembly removal procedure in “Media feed clutch

loosened.

• Removed the Skew menu item.

• Added Right margin menu item and values.

• Added l ogo to nameplate cover ill ustration (page 7-4).

page 7-5.

panel X234/X364” under

page 7-5 and in “Maintenance kits” on page 6-1

connectors will not work if the insulation is removed,” in step 8 of

removal” on page 4-51.

removal” on page 4-51.

“Scanner” on page 7-5.

“Media feed clutch

xviii Service Manual

Conventions

CAUTION

A caution identifies something that might cause a servicer harm.

CAUTION

This type of caution i ndicates there is a danger from hazardous voltage in t he area of the

product where you are working. Unplug the product befor e you begin, or use caution i f th e

product must recei ve power in order to perform the task.

CAUTION

This type of caution i ndicates a hot surface.

CAUTION

This type of caution i ndicates a tipping hazar d.

Note: A note provides additional information.

Warning: A warning identi fi es something that might damage the product hardware or software.

There are several types of caution statements:

7013-XXX

Conventions xix

7013-XXX

xx Service Manual

1. General in formation

The Lexmark™ X364dw, X364dn , X363dn, and X264dn are monochro me laser printers designed for single

users or small workgroups.

7013-XXX

Maintenance approach

The diagnostic information in this manual leads to the correct field replaceable unit (FRU) or part. Use the error

code charts, sympt om index, and service checks to determine the symptom and repair the failure. See

“Diagnostics i nformation” on page 2- 1 for more inf ormation. See “Repair information” on page 4-1 to help

identify parts. After completing the repair, perform tests as needed to verify the repair.

General information 1-1

7013-XXX

Shortcuts

3

DEF

6

MNO

9

WXYZ

#

2

ABC

5

JKL

8

TUV

0

1

@

!.

4

PQRS

7

*

Fax

Redial/Pause

Resolution

Options

Hook

Select

Start

Stop/Cancel

Menu

Back

Copy

Copies

Scale

Options

Content

Darkness

Duplex/2-Sided

Text

Text/Photo

Photo

CopyCopy

Scan/EmailScan/Email

Fax

Overview of the operator panel

The operator panel is divided into three sections:

• Selections and settings area

• Display area

• Keypad area

Selections and sett ings contains ten butt ons (Copy, Scan/Email, Fax, Content, Darkness, Duplex/2-sided,

Copies, Scale, O ption s, and Addre ss boo k) and thr ee lig hts (Text , Text /Photo, and Photo) that l ight up t o displ ay

the chosen content option.

The display area contains seven buttons (Menu, Back, Left arrow, Select, Right arrow, Start, and Stop/Cancel),

an indicator light, and a 2-line liquid crystal display (LCD) that shows text.

The keypad area cont ai ns fi ve butto ns (Redi al/Paus e, Res olution, Opt ions, Ho ok, and Shor tcut s), a key pad, and

a USB port.

For more information on the operator panel, see “Overview of the operator panel and menus” on page 2-2.

1-2 Service Manual

Specifications

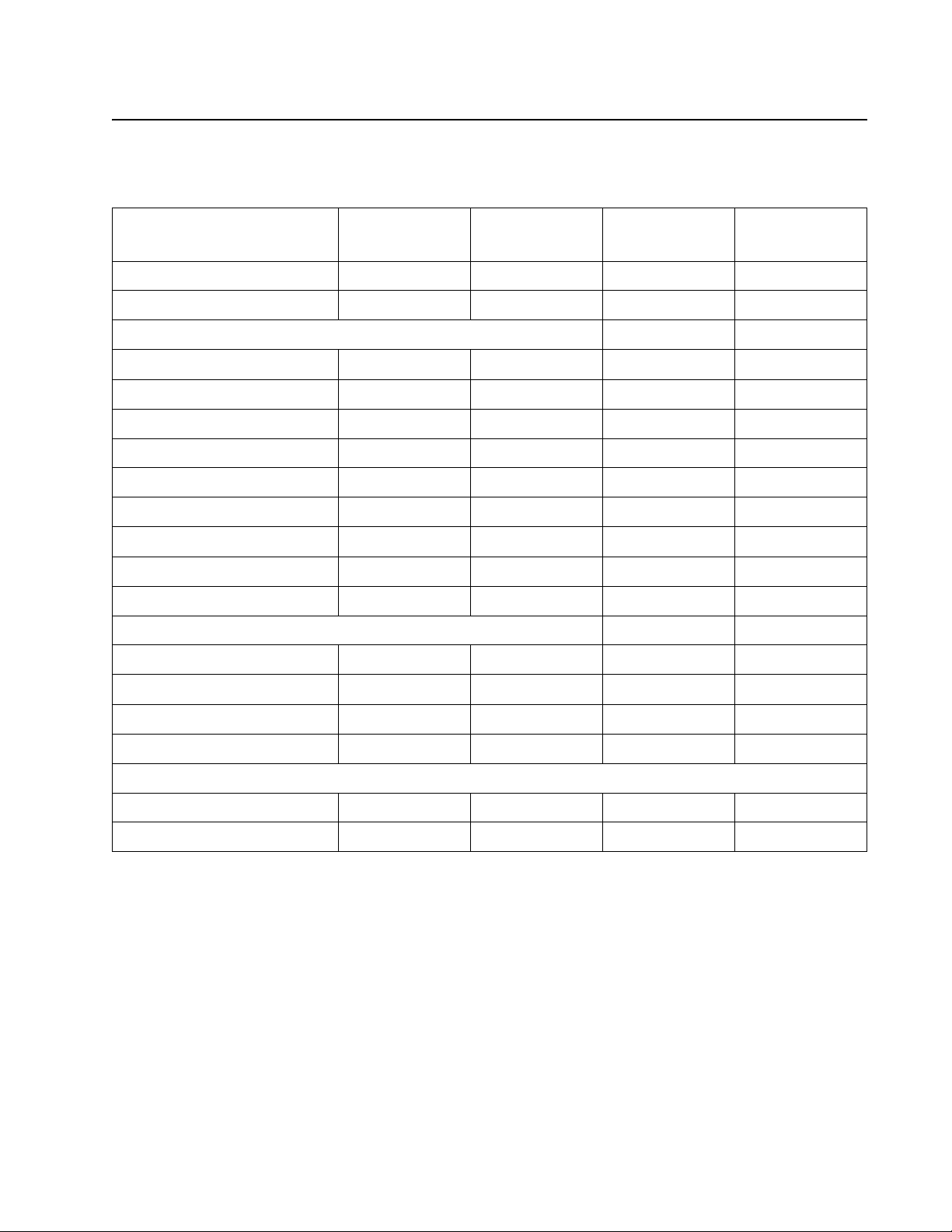

Memory

7013-XXX

Item

Standard memory 64MB 128MB 128MB 128MB

Maximum memory 64MB 128MB 128MB 128MB

Optional memory

8MB x x x x

16MB x x x x

32MB x x x x

64MB x x x x

128MB x x x x

256MB x x x x

512MB x x x x

Standard flash memory x x x x

Maximum flash memory 64MB 64MB 64MB 64MB

Optional flash memory cards

32MB card x x x x

7013-235

Lexmark X264dn

7013-432

Lexmark X363dn

7013-436

Lexmark X364dn

7013-43W

Lexmark X364dw

64MB card ✔ ✔ ✔ ✔

128MV card x x x x

256MB card x x x x

Available daughter card slots

Font card ✔ ✔ ✔ ✔

DLE x x x x

General information 1-3

7013-XXX

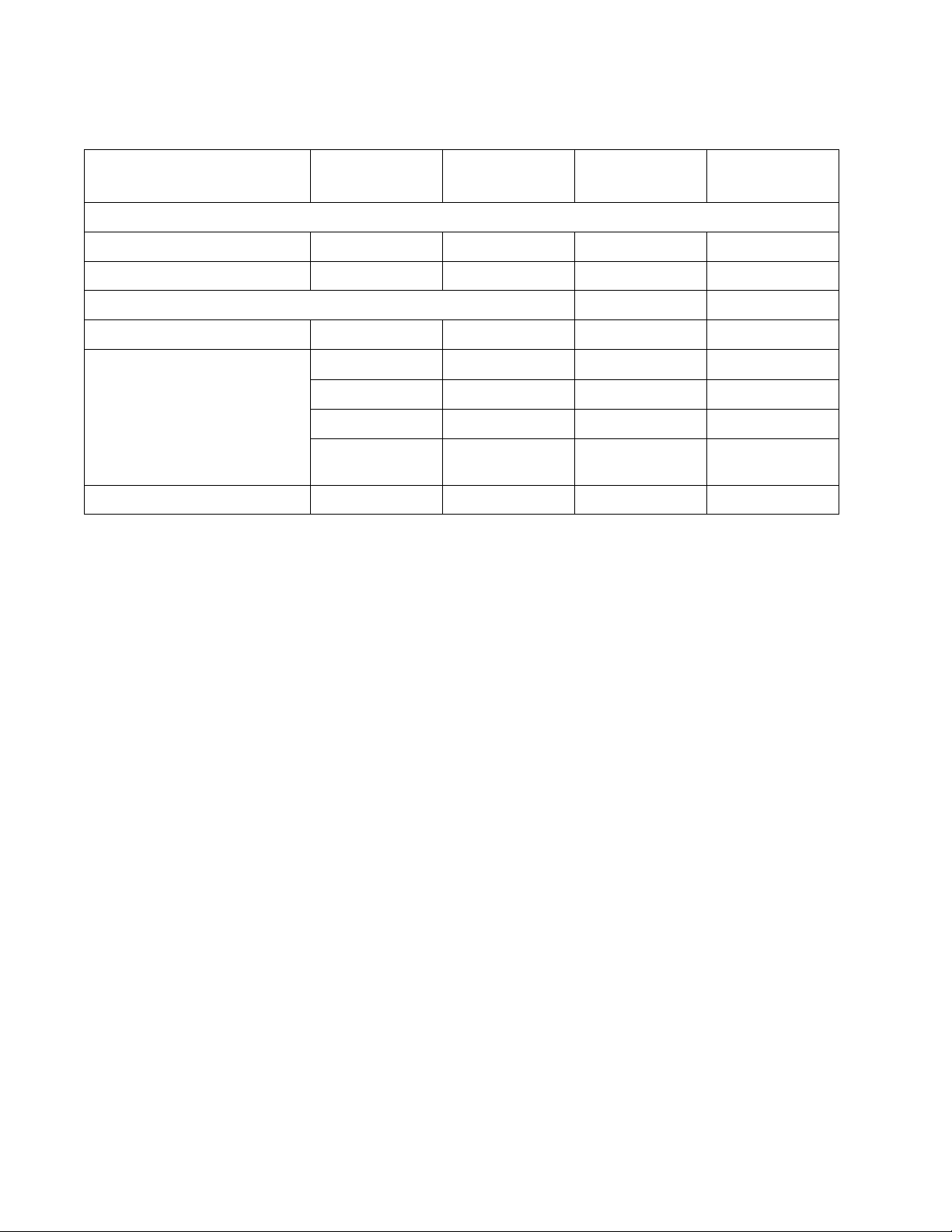

Print quality setti ngs

Item

Image enhancement technology (IET)

2 Bits /p el ✔ ✔ ✔ ✔

4 Bits /p el ✔ ✔ ✔ ✔

Print resolution

300 dpi ✔ ✔ ✔ ✔

600 dpi

• 1200 image qualit y (600

dpi with 2 bits/pel)

• 2400 image qualit y (600

dpi with 4 bits/pel)

• 4800 color quality (600 dpi

with 4 bits/pel)

1200 dpi ✔ ✔ ✔ ✔

7013-235

Lexmark X264dn

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

x x x x

7013-432

Lexmark X363dn

7013-436

Lexmark X364dn

7013-43W

Lexmark X364dw

1-4 Service Manual

Compatibility and connectivity

7013-XXX

Item

Datastreams

XPS x x x x

PCL 6 emulation ✔ ✔ ✔ ✔

PostScript level 3 emulation ✔ ✔ ✔ ✔

NPAP ✔ ✔ ✔ ✔

PJL ✔ ✔ ✔ ✔

PPDS ✔ ✔ ✔ ✔

PDF (version 1.6) x ✔ ✔ ✔

PictBridge x x x x

HTML (including DBCS) x x x x

Direcetimage x ✔ ✔ ✔

Host based printing/graphics device interface

• Version 1 x x x x

• Version 2 x x x x

7013-235

Lexmark X264dn

7013-432

Lexmark X363dn

7013-436

Lexmark X364dn

7013-43W

Lexmark X364dw

• Version 3 (mono) ✔ ✔ ✔ ✔

Compatibility Windows/

Standard connecti ons

Serial interface x x x x

Ethernet 10/100 Base T ✔ ✔ ✔ ✔

USB-B (hi-speed) device port ✔ ✔ ✔ ✔

Fax functionality x x ✔ ✔

USB-A front host port

(low/full speed)

USB-A rear host port x x x x

802.11n wireless networking card x x x ✔

Optional connections x x x x

Macintosh/Linux

x ✔ ✔ ✔

Windows/

Macintosh/Linux

Windows/

Macintosh/Linux

Windows/

Macintosh/Linux

General information 1-5

7013-XXX

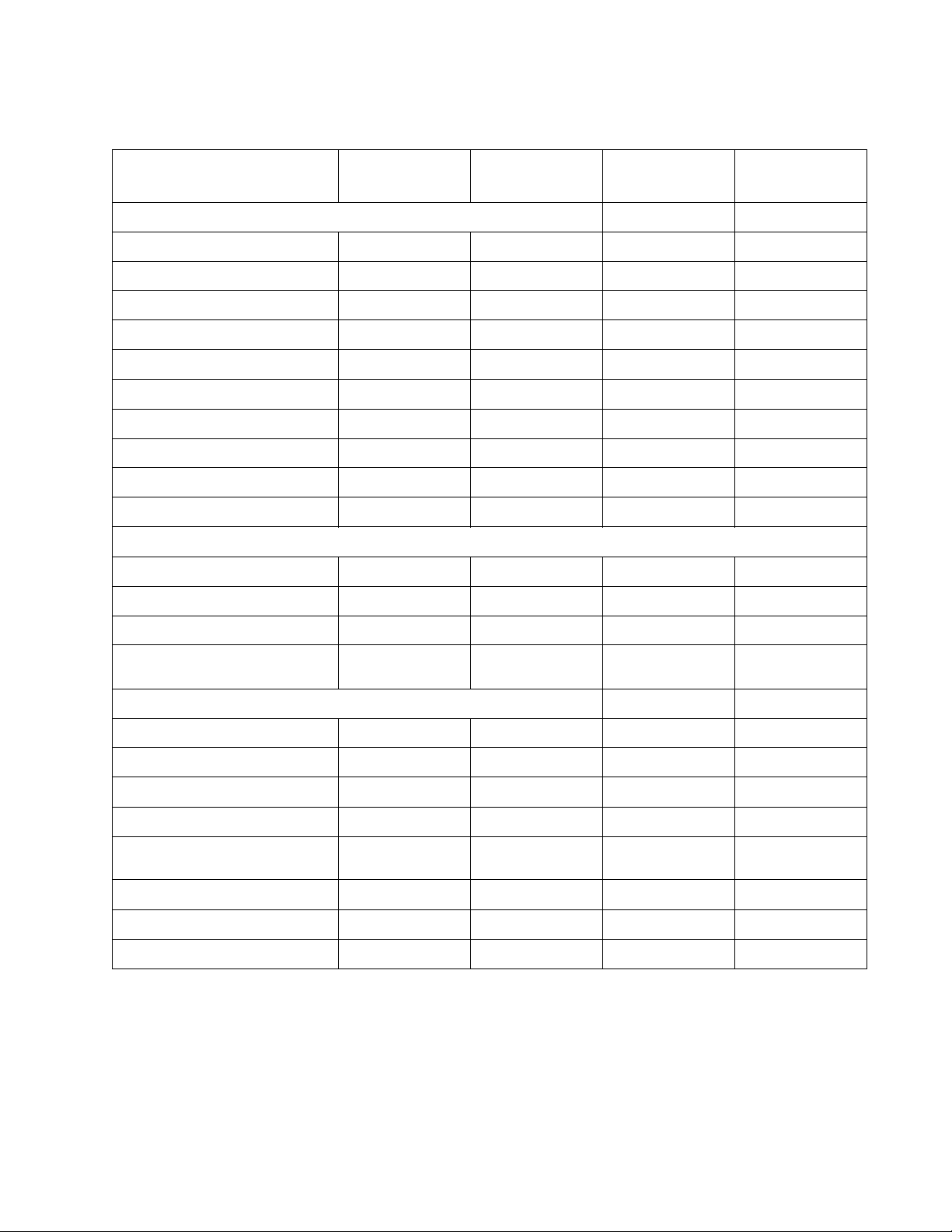

Media trays and supply capacity

Item

Standard input sources

Integrated 250-sheet tray ✔ ✔ ✔ ✔

50-sheet MP feeder x ✔ ✔ ✔

1-sheet manual feed slot ✔ x x x

Optional input sources

250-sheet drawer ✔ ✔ ✔ ✔

550-sheet drawer ✔ ✔ ✔ ✔

Manual/integrated print duplex Integrated Integrated Integrated Integrated

ADF scanner type Simplex Recirculating

Envelope conditioning x x x x

Instant on fuser ✔ ✔ ✔ ✔

Standard output sources

150-sheet sensing bin ✔ ✔ ✔ ✔

Toner and photoconductor

7013-235

Lexmark X264dn

7013-432

Lexmark X363dn

duplex

7013-436

Lexmark X364dn

Recirculating

duplex

7013-43W

Lexmark X364dw

Recirculating

duplex

Toner cartridge 1,500 standard

pages SWE¹

X360 Series standar d yield x 3,500 standard pages SWE¹

High toner cartri dge x 9,000 standard pages¹

Photoconductor kit Up to 30,000 pages²

¹ Declared value in accordance with ISO/IEC 1975 2

² Up to 30,000 pages, based on an average of 3 pages per job and approximately 5% coverage per page. Yields may

vary based on customer usage.

3,000 standard pages SWE¹

1-6 Service Manual

Types of print media

Note: Ensure trays are properly loaded. Never mix media types wit hin a tray.

Source Sizes Types Weight Input capacity* (sheets)

7013-XXX

Input tray 1

(250-sheet tray)

2nd Drawer option

(250-sheet dr awer,

550-sheet drawer)

Manual feeder slo t A4, A5, A6,JIS¹-B5,

A4, A5, A6,JIS¹-B5,

letter, legal, executive,

oficio (Me x ic o )² , fo lio ² ,

statement, uni versal

A4, A5, JIS¹-B5, letter ,

legal, executive, oficio

(Mexico)², folio²,

statement

letter, legal, executive,

oficio (Me x ic o )² , fo lio ² ,

statement, uni versal

Plain paper,

transparency,

recycled, labels,

bond, letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

rough/cotton,

custom type [x]

Plain paper,

recycled, labels,

bond, letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

rough/cotton,

custom ty p e [x]]

Plain paper,

transparency,

recycled, labels,

bond, letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

rough/cotton,

custom type [x]

Card stock*** • 120-163 g/m²

60-9 0 g/m²

(16-24 lb)

60-9 0 g/m²

(16-24 lb)

60-1 63 g/m²

(16-43 lb)

(16-43 lb)

Index Bristol

• 75-163 g/m²

(46-100 lb)

Tag

• 150 paper

• 50 la bels**

• 10 transparencies

• 1 paper

• 1 la bels**

• 1 paper

• 1 la bel* *

• 1 transparency

1

7 ¾, 9, 10, DL, C5, B5,

other

Manual paper A4, A5, A6,JIS¹-B5,

letter, legal, executive,

oficio (Me x ic o )² , fo lio ² ,

statement, uni versal

Manual envelope 7 ¾, 9, 10, DL, C5, B5,

other

Envelopes, rou gh

envelopes

Plain paper,

transparency,

recycled, labels,

bond, letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

rough/cotton,

custom type [x]

Card stock*** • 120-163 g/m²

Envelopes, rou gh

envelopes, cus tom

type [x]

75 g/m² (20 lb) 1

60-1 63 g/m²

(16-43 lb)

(16-43 lb)

Index Bristol

• 75-163 g/m²

(46-100 lb)

Tag

75 g/m² (20 lb) 1

• 1 paper

• 1 la bel* *

• 1 transparency

1

General information 1-7

7013-XXX

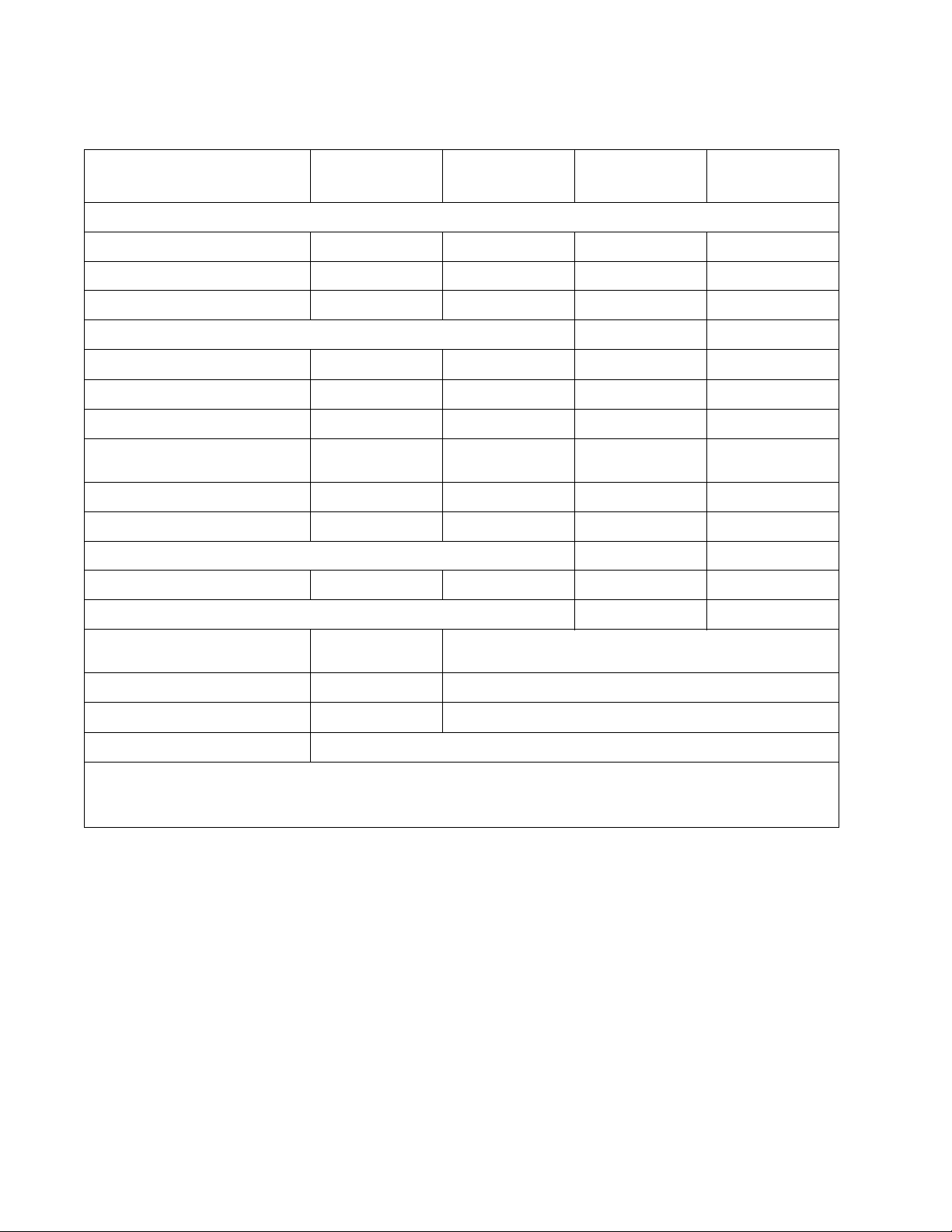

Source Sizes Types Weight Input capacity* (sheets)

Duplex A4, letter, legal, oficio

Automatic document

feeder (ADF)

Multipurpose feeder A4, A5, A6,JIS¹-B5,

(Mexico), fo li o

A4, A5, JIS¹-B5, letter ,

legal, executive, oficio

(Mexico), fo li o,

statement, uni versal,

custom scan typ e [x]

letter, legal, executive,

oficio (Mexico), folio,

statement, uni versal

7 ¾, 9, 10, DL, C5, B5,

other

Plain paper,

recycled, bond,

letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

custom type [x]

Accepts any media type supported by the print engine

Plain paper,

transparency,

recycled, labels,

bond, letterhead,

preprinte d, colored

paper, light paper,

heavy paper,

rough/cotton,

custom type [x]

Card stock*** • 120-163 g/m²

Envelopes

Rough envelopes

60-9 0 g/m²

(16-24 lb)

60-1 63 g/m²

(16-43 lb)

(16-43 lb)

Index Bristol

• 75-163 g/m²

(46-100 lb)

Tag

75 g/m² (20 lb) 7

• 250 paper

• 550 paper

• 50 paper

• 15 la bels**

• 10 transparencies

20

Flatbed Business card, 3 X 5,

4 X 6, A4, A5, JIS¹-B5,

letter, executive,

statement, uni versal,

custom scan typ e [x]

* Capacity for 20 lb print media, unless otherwise noted.

** Use for occasional printing only.

*** Grain short is recommended. Use rear exit for best results.

¹Japanese Indust ry Standard

Accepts any media type supported by the print engine

1-8 Service Manual

Digital imaging specifications

General specifications

ADF Scan sp eed

Simplex ADF - Up to 22 ppm

ADF Document handling

ADF input capacity - 50 sheet s

ADF output capacity - 50 sheets

ADF document width - 4.9” (125mm) to 8.5” (216mm)

ADF document length - 5” (127mm ) to 14.0” (356mm)

Resolution and color depth

• Resolution - 600 dpi opt ical

• Color depth - 24 bit RGB output, 8 bit/channel

7013-XXX

Flatbed document specifications

• Document size- Up to A4 and lett er

4.5” x 5.5” to 8.5”x11” (SEF)

Flatbed speed

3 seconds to scan, 3 seconds to return

Scanner operating environments

• Temperature - 10C to 35C

• Humidity - 15% RH to 85% RH

Storage en vironments

• Temperature - -20C to 43C

• Humidity - 5% RH to 95% RH

Tilt

This device should operate within the stated parameters when it is level wit hin 10mm from front to back and

10mm side to side.

General information 1-9

7013-XXX

Scan and copy specific specifications

Duplex scan

Duplex and copy is available only on X360 Series machines.

Scan file output formats

• TIFF

• JPEG

• PDF

Supported compressions

• PDF - (1 bit,- JBIG2 CCIT G4, Flate), (8/24 bit - Flate JPEG)

• TIFF - (1 bit - CCITT G4), (8/24 bit - Packbit s, LZW)

• JPG - (8/ 24 bi t-JPG)

Supported scan destinations

• Temporary profi le from a user’s PC

• Scan to PC via network TWAIN

• Scan to PC using Web applet

• Scan to E-Mail

• Scan to USB (X364 models only)

• Lexmark Scan Center

Multiple copies

999 copies maximum

Reduce/Enlarge (copy only)

-25% to 400%

1-10 Service Manual

Fax specificat ions

Phone network connectivity

Phone networks types supported PSTN or analog PABX (RJ-11 )

ITU COMPATIBILITY

Standard Resolution

Fine

Superfine

Ultra fine

Coding

Mode m sp ee d V.34 2400-33,600 BPS

Compression MH, MR , M MR , J P E G

Error correction ITU T.30

Line interface selection

Modular Plug

Out Band Signal Level

Input Level Range

Ring Detection

Group 3/ECM

8 x 3.85 pels/mm (200X100dpi) (204x98)

8 x 7.7 pels/mm (200X200dpi) (204x 196)

11.8 x 11.8 pels/mm(300x300 dpi) (204x391)

15.7 x 15.7 pels/mm (400x400 dpi) (408x391)

ITU T.4 and T.6(MH, MR, MMR, JPEG)

V.17 7200-14,400 BPS

V.27 2400-4800 BPS

V.29 7200-9600 B PS

Dual RJ-11C

Guaranteed North American and Europe PTT standard

-16dBm ~ -59dBm

Complies with all regulatory requirements

7013-XXX