Lenze E82xVxxxKxxxxx User Manual

EDS82EV903

.Hõa

Ä.Hõaä

Global Drive

System Manual

8200 vector 0.25 ... 90 kW

E82xVxxxKxxxxx

Frequency inverter

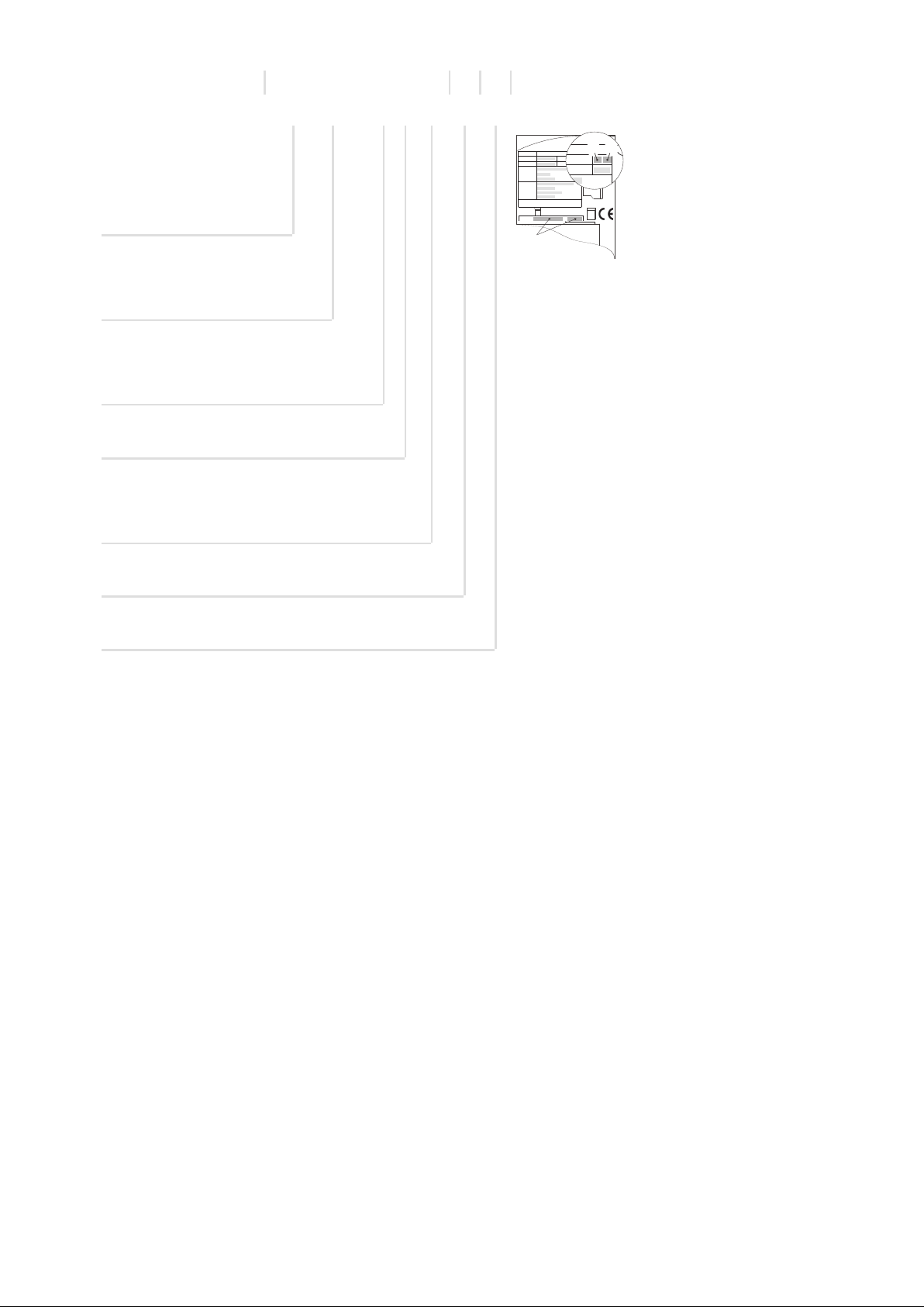

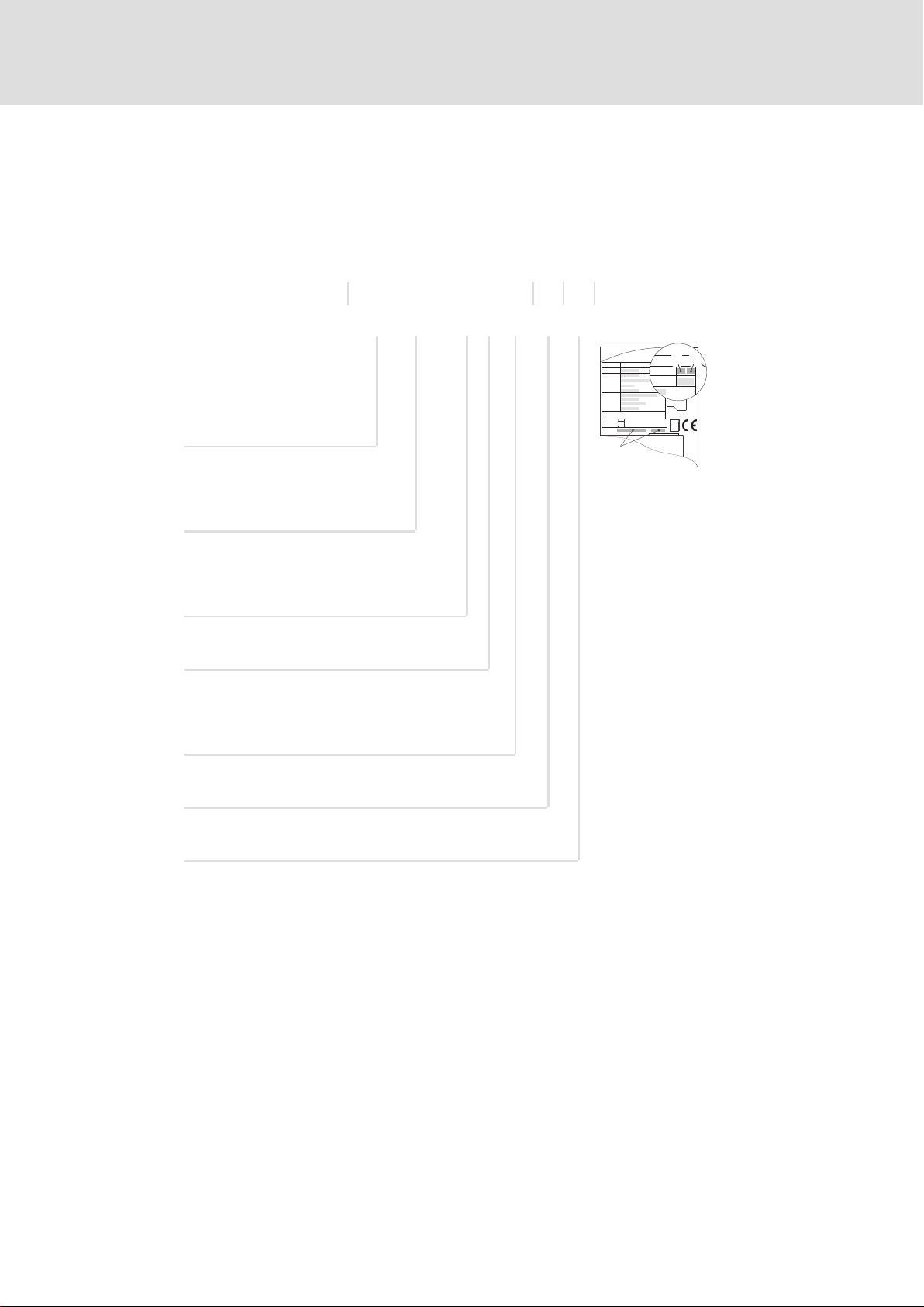

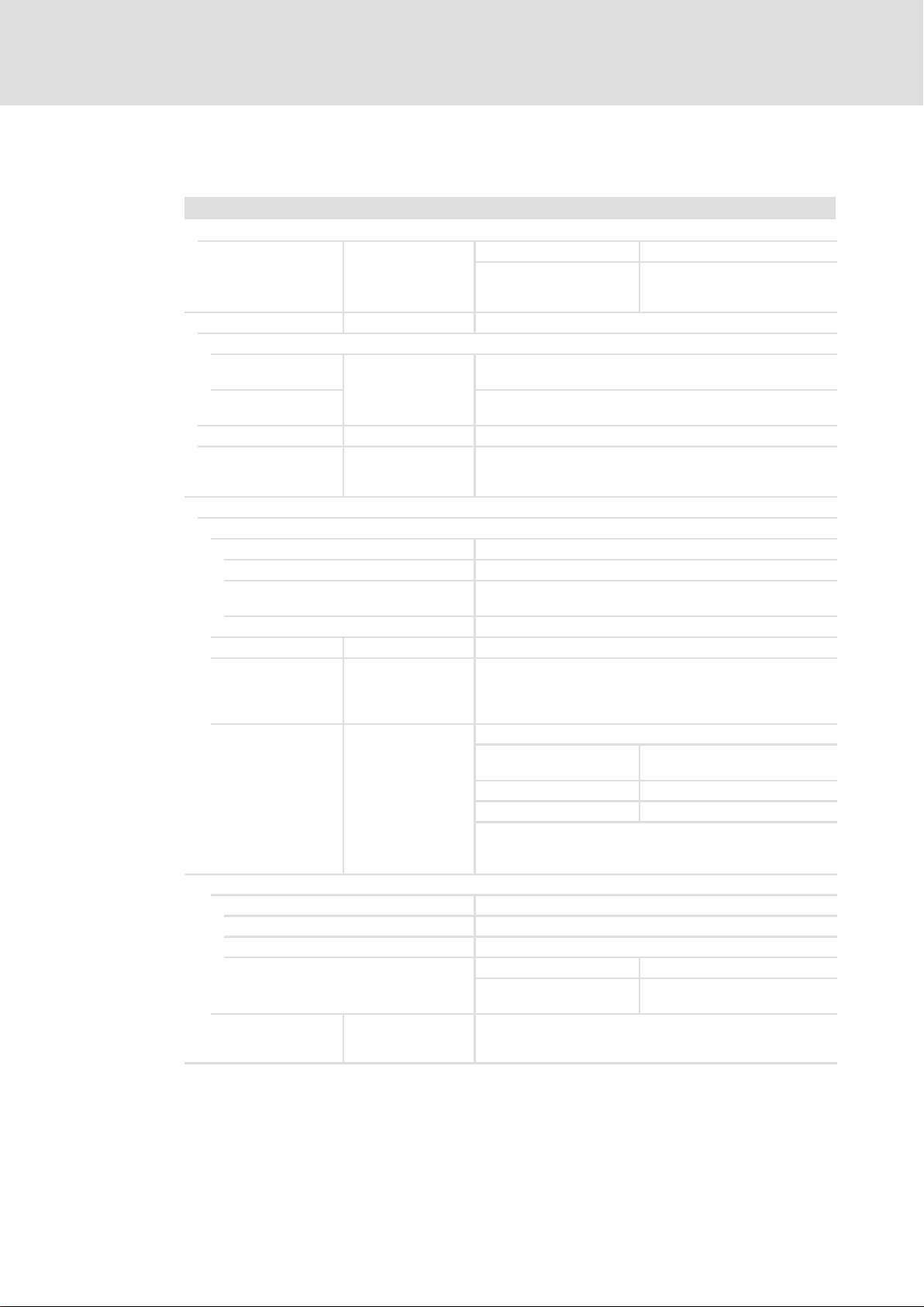

8200 vector type code in a power range from 0.25 ... 11 kW

E82xV xxx K x C xxx 3x 3x

Type

E = panel−mounted unit

D = built−in unit in push−

through design

C = built−in unit in cold−plate

design

Inverter

Id.-No:

Prod.-No:

Input:

Output:

Fordetailed information refer to the manual

EDK82EV222

Type:

Hans-Lenze-Str.1

D-31855Aerzen

8200 vector

Version:

Ser.-No:

Made in Germany

1D74

IndustrialControl

Equipment

_

K

Power

(e.g. 152 = 15 ´ 10

(e.g. 113 = 11 ´ 10

2

W = 1.5 kW)

3

W = 11 kW)

Voltage class

2 = 230 V

4 = 400 V/500 V

Version

Design, variant

2xx = without EMC filter

x4x = with "Safe torque off" function

Hardware version

Software version

0.25 kW ... 11 kW

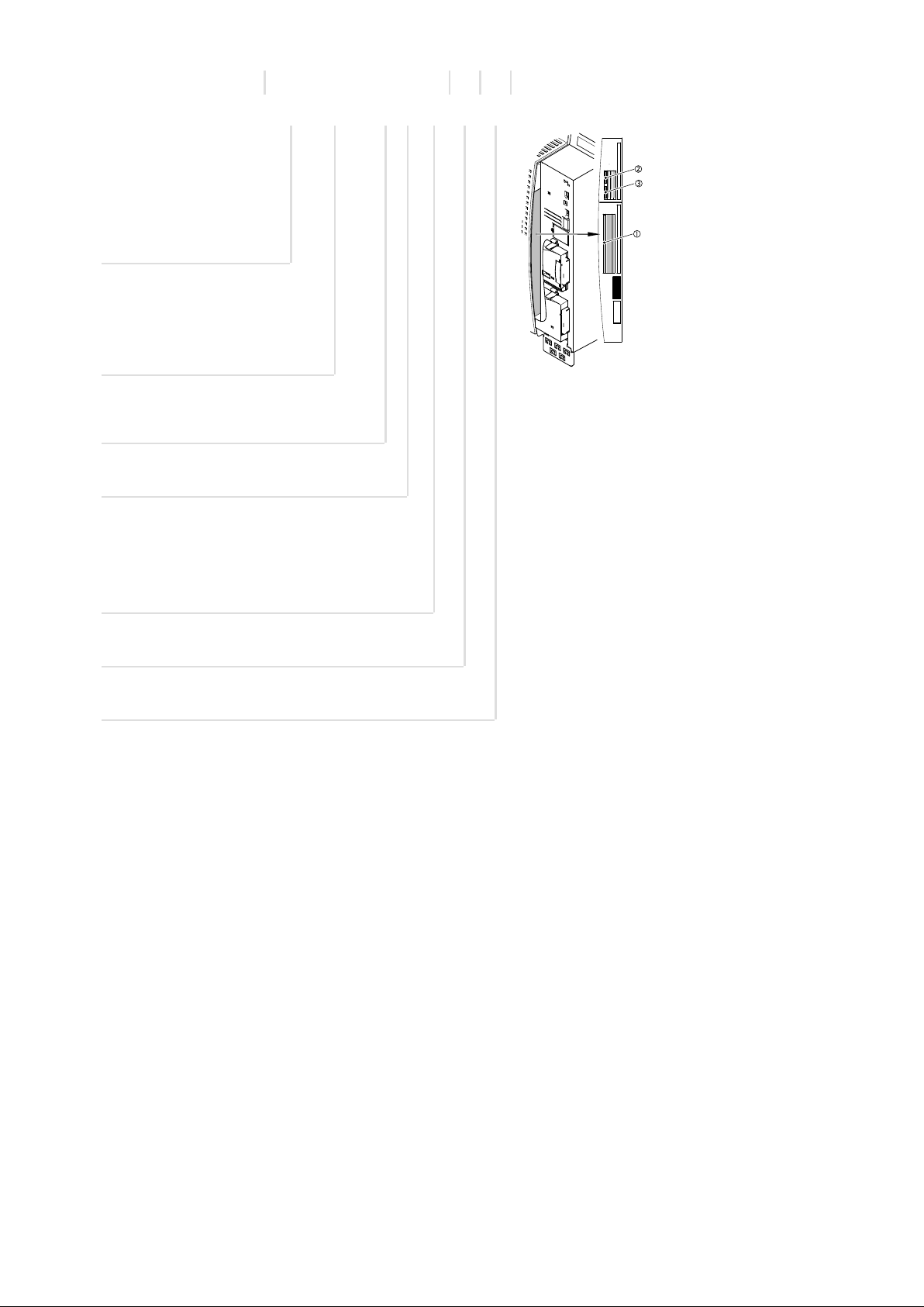

8200 vector type code in a power range from 15 ... 90 kW

E82xV xxx K x B xxx 3x 3x

Type

E = panel−mounted device

D = panel−mounted device in

push−through design

C = panel−mounted device in

cold plate design

Power

(e.g. 153 = 15 ´ 103 W = 15 kW)

(e.g. 903 = 90 ´ 10

Voltage class

4 = 400 V/500 V

Version

3

W = 90 kW)

15 ... 90 kW

Prod.-No.Prod.-No.

Prod.-IDProd.-ID

Ser.-No.Ser.-No.

VersionVersion

InputInput

TypeType

OutputOutput

nash_elmo Industries GmbH

Industriestrasse 26

D-97616 Bad Neustadt

Design, variant

1xx = for IT systems

2xx = without integrated filters

3xx = with footprint mains filters

x4x = with "Safe torque off" function

Hardware version

Software version

0Fig. 0Tab. 0

Contentsi

1 About this documentation 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Target group 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Document history 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Validity information 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Conventions used 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Notes used 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Product description 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Device features 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Application as directed 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety instructions 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 General safety information 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Residual hazards 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Safety instructions for the installation according to UL or UR 25 . . . . . . . . . . . . . . . .

4 Technical data 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Open and closed loop control 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Communication interfaces 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Operation with rated power (normal operation) 32 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Rated data for a mains voltage of 230 V 32 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Rated data for 400 V mains voltage 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Rated data for 500 V mains voltage 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Operation with increased rated power 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Rated data for a mains voltage of 230 V 52 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Rated data for 400 V mains voltage 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Rated data for 500 V mains voltage 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Standard devices in a power range from 0.25 ... 2.2 kW 62 . . . . . . . . . . . . . . . . . . . . .

5.2.1 Mounting with fixing rails (standard) 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Thermally separated mounting (push−through technique) 63 . . . . . . . . . . .

5.2.3 Mounting in "cold plate" technique 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 DIN rail mounting 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Lateral mounting 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

EDS82EV903 EN 3.0

Contents i

5.3 Standard devices in a power range from 3 ... 11 kW 72 . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Mounting with fixing rails (standard) 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Thermally separated mounting (push−through technique) 73 . . . . . . . . . . .

5.3.3 Mounting in "cold plate" technique 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Lateral mounting 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Standard devices in the power range 15 ... 30 kW 79 . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Mounting with fixing brackets (standard) 79 . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Thermally separated mounting (push−through technique) 82 . . . . . . . . . . .

5.4.3 Mounting in "cold plate" technique 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Standard devices with a power of 45 kW 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Mounting with fixing brackets (standard) 85 . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Thermally separated mounting (push−through technique) 88 . . . . . . . . . . .

5.6 Standard devices with a power of 55 kW 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Mounting with fixing brackets (standard) 89 . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Thermally separated mounting (push−through technique) 91 . . . . . . . . . . .

5.6.3 Modification of the fan module for push−through technique 92 . . . . . . . . .

5.7 Standard devices in the power range 75 ... 90 kW 94 . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Mounting with fixing brackets (standard) 94 . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Thermally separated mounting (push−through technique) 97 . . . . . . . . . . .

6 Electrical installation 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Notes on project planning 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Supply forms / electrical supply conditions 99 . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Operation on public supply systems (compliance with EN 61000−3−2) 100 .

6.2.3 Operation at earth−leakage circuit breaker (e.l.c.b.) 101 . . . . . . . . . . . . . . . . .

6.2.4 Interaction with compensation equipment 101 . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 Discharge current for mobile systems 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.6 Optimisation of the controller and mains load 103 . . . . . . . . . . . . . . . . . . . . .

6.2.7 Reduction of noise emissions 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.8 Mains choke/mains filter assignment 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.9 Motor cable 112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Basics for wiring according to EMC 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Cable specifications 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Shielding 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Installation in the control cabinet 117 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 Wiring outside of the control cabinet 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.5 Wiring terminal strips 120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS82EV903 EN 3.0

5

Contentsi

6.4 Standard devices in a power range from 0.25 ... 2.2 kW 121 . . . . . . . . . . . . . . . . . . . . .

6.4.1 EMC−compliant wiring 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Mains connection 123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Fuses and cable cross−sections according to EN 60204−1 124 . . . . . . . . . . . .

6.4.4 Fuses and cable cross−sections according to UL 127 . . . . . . . . . . . . . . . . . . . .

6.4.5 Connection motor/external brake resistor 129 . . . . . . . . . . . . . . . . . . . . . . . .

6.4.6 Connection of relay output 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Standard devices in a power range from 3 ... 11 kW 131 . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 EMC−compliant wiring 131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Mains connection 133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 Fuses and cable cross−sections according to EN 60204−1 135 . . . . . . . . . . . .

6.5.4 Fuses and cable cross−sections according to UL 137 . . . . . . . . . . . . . . . . . . . .

6.5.5 Connection motor/external brake resistor 139 . . . . . . . . . . . . . . . . . . . . . . . .

6.5.6 Connection of relay output 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Standard devices in the power range 15 ... 30 kW 141 . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 EMC−compliant wiring 142 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Mains connection 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Fuses and cable cross−sections according to EN 60204−1 144 . . . . . . . . . . . .

6.6.4 Fuses and cable cross−sections according to UL 145 . . . . . . . . . . . . . . . . . . . .

6.6.5 Motor connection 146 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.6 Connection relay outputs K1 and K2 147 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Standard devices in the power range of 55 kW 149 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 EMC−compliant wiring 150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Mains connection 151 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.3 Fuses and cable cross−sections according to EN 60204−1 152 . . . . . . . . . . . .

6.7.4 Fuses and cable cross−sections according to UL 153 . . . . . . . . . . . . . . . . . . . .

6.7.5 Motor connection 154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.6 Connection relay outputs K1 and K2 155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Standard devices in the power range 75 ... 90 kW 157 . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.1 EMC−compliant wiring 158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.2 Mains connection 159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.3 Fuses and cable cross−sections according to EN 60204−1 160 . . . . . . . . . . . .

6.8.4 Fuses and cable cross−sections according to UL 161 . . . . . . . . . . . . . . . . . . . .

6.8.5 Motor connection 162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.6 Connection relay outputs K1 and K2 163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

EDS82EV903 EN 3.0

Contents i

7 Extensions for automation 165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Standard devices in a power range from 0.25 ... 2.2 kW 165 . . . . . . . . . . . . . . . . . . . . .

7.1.1 I/O function modules 165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Bus function modules 166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Communication modules 166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Combine function and communication modules 167 . . . . . . . . . . . . . . . . . . .

7.1.5 Mounting and dismounting function modules 167 . . . . . . . . . . . . . . . . . . . . .

7.1.6 Mounting and dismounting communication modules 170 . . . . . . . . . . . . . .

7.1.7 Wire and configure standard I/O PT 171 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.8 Wire and configure application I/O PT 171 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Standard devices in a power range from 3 ... 11 kW 172 . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 I/O function modules 172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Bus function modules 173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Communication modules 173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Combine function and communication modules 174 . . . . . . . . . . . . . . . . . . .

7.2.5 Mounting and dismounting function modules 174 . . . . . . . . . . . . . . . . . . . . .

7.2.6 Mounting and dismounting communication modules 177 . . . . . . . . . . . . . .

7.2.7 Wire and configure standard I/O PT 178 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.8 Wire and configure application I/O PT 178 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.9 Safety function − connection of relay KSR 178 . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Standard devices in a power range from 15 ... 90 kW 179 . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 I/O function modules 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Bus function modules 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Communication modules 181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Combine function and communication modules 182 . . . . . . . . . . . . . . . . . . .

7.3.5 Mounting and dismounting function modules 184 . . . . . . . . . . . . . . . . . . . . .

7.3.6 Mounting and dismounting communication modules 187 . . . . . . . . . . . . . .

7.3.7 Wire and configure standard I/O PT 188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.8 Wire and configure application I/O PT 188 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.9 Wiring of controller inhibit (CINH) when two function

modules are operated 189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.10 Safety function − connection of relay KSR 189 . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 I/O function module E82ZAFSCO10 (Standard I/O PT) 190 . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Description 190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Technical data 191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Installation 192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 I/O function module E82ZAFACO10 (application I/O PT) 196 . . . . . . . . . . . . . . . . . . . .

7.5.1 Description 196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Technical data 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Installation 198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS82EV903 EN 3.0

7

Contentsi

8 Commissioning 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Before switching on 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Selection of the correct operating mode 203 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Parameter setting with E82ZBC keypad 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 V/f characteristic control 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Vector control 206 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Parameter setting with the XT EMZ9371BC keypad 209 . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 V/f characteristic control 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Vector control 211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Important codes for quick commissioning 214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Parameter setting 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Important notes 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Parameter setting with E82ZBC keypad 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 General data and operating conditions 224 . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Installation and commissioning 225 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Display elements and function keys 226 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.4 Changing and saving parameters 228 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.5 Transferring parameters to other standard devices 229 . . . . . . . . . . . . . . . . .

9.2.6 Activating password protection 231 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.7 Remote parameter setting for system bus participants 233 . . . . . . . . . . . . .

9.2.8 Menu structure 234 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Parameter setting with the XT EMZ9371BC keypad 235 . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 General data and operating conditions 235 . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Installation and commissioning 236 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.3 Display elements and function keys 237 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.4 Changing and saving parameters 239 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.5 Transferring parameters to other standard devices 240 . . . . . . . . . . . . . . . . .

9.3.6 Activating password protection 242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.7 Remote parameter setting for system bus participants 244 . . . . . . . . . . . . .

9.3.8 Menu structure 245 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Function library 254 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Important notes 254 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Operating mode 255 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 V/f characteristic control 257 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Vector control 261 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Sensorless torque control with speed limitation 264 . . . . . . . . . . . . . . . . . . .

8

EDS82EV903 EN 3.0

Contents i

10.3 Optimising the operating behaviour 268 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 Slip compensation 268 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.2 Inverter switching frequency 270 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.3 Oscillation damping 272 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.4 Skip frequencies 273 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Behaviour in the event of mains switching, mains failure or controller inhibit 275 . .

10.4.1 Start conditions/flying−restart circuit 275 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 Controller inhibit 277 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.3 Controlled deceleration after mains failure/mains disconnection 278 . . . .

10.5 Limit value setting 281 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.1 Speed range 281 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.2 Current limits 284 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 Acceleration, deceleration, braking, stopping 286 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.1 Setting of acceleration times, deceleration times and S−shaped ramps 286

10.6.2 Quick stop 289 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.3 Changing the direction of rotation 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.4 DC braking (DCB) 292 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.5 AC motor braking 294 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 Configuration of analog and digital setpoints and actual values 296 . . . . . . . . . . . . .

10.7.1 Setpoint source selection 296 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.2 Analog setpoints via terminal 298 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.3 Digital setpoints via frequency input 303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.4 Setpoints via function "motor potentiometer" 307 . . . . . . . . . . . . . . . . . . . . .

10.7.5 Setpoints via fixed setpoints (JOG) 309 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.6 Setpoints via keypad 311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.7 Setpoints via a bus system 312 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.8 Setpoint changeover (hand/remote changeover) 313 . . . . . . . . . . . . . . . . . .

10.8 Automatic detection of motor data 315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9 Process controller 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9.1 Set control loop properties 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9.2 Select the setpoint source for the process controller 322 . . . . . . . . . . . . . . . .

10.9.3 Select the actual value source for the process controller 324 . . . . . . . . . . . . .

10.9.4 Influence the process controller during operation 325 . . . . . . . . . . . . . . . . . .

10.10 Current−limit controller 327 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.11 Free interconnection of analog signals 328 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.11.1 Free configuration of analog input signals 328 . . . . . . . . . . . . . . . . . . . . . . . .

10.11.2 Free configuration of analog outputs 332 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.11.3 Free configuration of analog process data output words 338 . . . . . . . . . . . .

10.12 Free interconnection of digital signals 343 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.12.1 Free configuration of digital input signals 343 . . . . . . . . . . . . . . . . . . . . . . . .

10.12.2 Free configuration of digital outputs 348 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.12.3 Free configuration of digital process data output words 354 . . . . . . . . . . . .

EDS82EV903 EN 3.0

9

Contentsi

10.13 Thermal motor monitoring 357 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.13.1 I2t monitoring 357 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.13.2 Temperature monitoring of the motor with PTC and

earth−fault detection 359 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.14 External fault evaluation 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.14.1 External fault detection 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.14.2 Reset of external faults 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.15 Display of operating data, diagnostics 362 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.15.1 Display of operating data 362 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.15.2 Diagnostics 366 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.16 Parameter set management 368 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.16.1 Saving and copying parameter sets 368 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.16.2 Parameter set changeover 372 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.17 Individual summary of drive parameters in the user menu 373 . . . . . . . . . . . . . . . . . .

10.18 Networking 375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.18.1 Interconnection with function module system bus (CAN) E82ZAFCCxxx 375

10.19 Code table 378 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.20 Table of attributes 434 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.20.1 Standard devices in a power range from 0.25 ... 11 kW

with standard I/O 435 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.20.2 Standard devices in a power range from 0.25 ... 11 kW

10.20.3 Standard devices in a power range from 15 ... 90 kW

10.20.4 Standard devices in a power range from 15 ... 90 kW

11 Troubleshooting and fault elimination 453 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Troubleshooting 453 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.1 Status display via LEDs at the controller 453 . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.2 Fault analysis with the history buffer 453 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Drive behaviour in the event of faults 454 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Fault elimination 455 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Drive errors 455 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Fault messages 456 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with application I/O 439 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with standard I/O 444 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with application I/O 448 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Resetting fault messages 459 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

EDS82EV903 EN 3.0

Contents i

12 DC−bus operation 460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 General information 460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Functional description 460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Conditions for trouble−free DC−bus operation 460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.1 Possible combinations of Lenze controllers in a network of

several drives 461 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.2 Mains connection 461 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.3 DC−bus connection 463 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Mains chokes for DC−bus operation 465 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 Fuses and cable cross−sections 467 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5.1 Mains supply 467 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5.2 DC supply 470 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5.3 Protection in DC−bus operation 474 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6 Basic dimensioning 476 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6.1 Conditions 476 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6.2 Supply powers 230 V controllers 477 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6.3 Supply powers 400 V controllers 477 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 Central supply (one supply point) 478 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7.1 Central supply via external DC source 478 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7.2 Central supply 400 V with regenerative power supply unit 934X 479 . . . . . .

12.8 Distributed supply (several supply points) 480 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9 Braking operation in a drive system 481 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9.1 Possibilities 481 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9.2 Selection 482 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Braking operation 483 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Braking operation without additional measures 483 . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Braking operation with external brake resistor 484 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.1 8200 vector 0.25 ... 11 kW 484 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.2 8200 vector 15 ... 90 kW 487 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.3 Selection of the brake resistors 490 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.4 Rating for Lenze brake resistors 491 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.5 Installation and wiring of the components for braking operation 491 . . . . .

14 Safety engineering 492 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Important notes 492 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Operating mode 493 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Safety relay KSR 495 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS82EV903 EN 3.0

11

Contentsi

14.4 Functional test 498 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.1 Important notes 498 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.2 Manual safety function check 499 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.3 Monitoring the safety function with a PLC 500 . . . . . . . . . . . . . . . . . . . . . . . .

15 Application examples 502 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Pressure control 502 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1.1 Example 1: Simple pressure control with fixed setpoint selection 503 . . . . .

15.1.2 Example 2: Simple pressure control with changeable setpoint selection 505

15.2 Operation with mid−frequency motors 507 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Speed control 508 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 Group drive (operation with several motors) 513 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 Setpoint summation (basic and additional load operation) 514 . . . . . . . . . . . . . . . . . .

15.6 Power control (torque limitation) 515 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Signal flow diagrams 516 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Important notes 516 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Signal processing − overview 517 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.1 Controller with standard I/O 517 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.2 Controller with Standard I/O and communication module 518 . . . . . . . . . . .

16.2.3 Controller with application I/O 519 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.4 Controller with Application I/O and communication module 520 . . . . . . . . .

16.2.5 Controller with communication module 521 . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.6 Controller with fieldbus function module 522 . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.7 Controller with fieldbus function module and communication module 523

16.2.8 Controller with system bus function module 524 . . . . . . . . . . . . . . . . . . . . . .

16.2.9 Controller with system bus function module and

communication module 525 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Signal processing in the function blocks 526 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.1 Speed setpoint conditioning (NSET1) 526 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.2 Speed setpoint conditioning (NSET1) with Application I/O 527 . . . . . . . . . . .

16.3.3 Process controller and setpoint processing (PCTRL1) 528 . . . . . . . . . . . . . . . .

16.3.4 Process controller and setpoint processing (PCTRL1)

with Application I/O 529 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.5 Motor control (MCTRL1) 530 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.6 Motor control (MCTRL1) with Application I/O 531 . . . . . . . . . . . . . . . . . . . . .

16.3.7 Device control (DCTRL1) 532 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.8 Controller state (STAT1, STAT2) 533 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.9 Process data of system bus function module (CAN1, CAN2) 535 . . . . . . . . . .

16.3.10 Process data of fieldbus function module (FIF−IN, FIF−OUT) 537 . . . . . . . . . .

17 Index 539 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

EDS82EV903 EN 3.0

1 About this documentation

The system manual supplements the mounting instructions included in the scope of

supply:

ƒ The features and functions are described in detail.

ƒ It describes in detail additional possible applications.

ƒ Examples describe how to set the parameters for typical applications.

ƒ In case of doubt, the operating instructions enclosed with the frequency inverter

always apply.

Each chapter is a complete unit and informs entirely about a subject:

ƒ Therefore, you always need to read the main chapter which contains the

information you require right now.

ƒ The Table of Contents and Index help you to find all information about a certain

topic.

About this documentation

Target group

1

ƒ Further information is provided in the following documents which can be requested

from your Lenze sales partner or downloaded from the Internet as pdf file:

– Order information and information about optional accessories is provided in the

respective product catalogue.

– Descriptions and data about other Lenze products (drive PLC, Lenze geared motors,

Lenze motors, ...) can be found in the respective catalogues, operating instructions

and manuals.

Tip!

Information and auxiliary devices around the Lenze products can be found in

the download area at

http://www.Lenze.com

1.1 Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

1.2 Document history

Material number Version Description

− 1.0 11/2002 − First edition

.Hõa 3.0 01/2012 TD29 Complete revision

EDS82EV903 EN 3.0

13

1

About this documentation

Validity information

1.3 Validity information

This documentation applies to 8200 vector frequency inverters from the

below−mentioned device versions.

8200 vector 0.25 ... 11 kW

Type

E = panel−mounted unit

D = built−in unit in

push−through design

C = built−in unit in cold−plate

design

E82xV xxx K x C xxx 3x 3x

Hans-Lenze-Str.1

D-31855Aerzen

Inverter

8200 vector

Id.-No:

Version:

Ser.-No:

Prod.-No:

Input:

Output:

Fordetailed information refer to the manual

EDK82EV222

Made in Germany

Type:

1D74

IndustrialControl

Equipment

_

K

Power

(e.g. 152 = 15 ´ 10

(e.g. 113 = 11 ´ 10

2

W = 1.5 kW)

3

W = 11 kW)

Voltage class

2 = 230 V

4 = 400 V/500 V

Version

Design, variant

2xx = without EMC filter

x4x = with "Safe torque off" function

Hardware version

Software version

0.25 kW ... 11 kW

14

EDS82EV903 EN 3.0

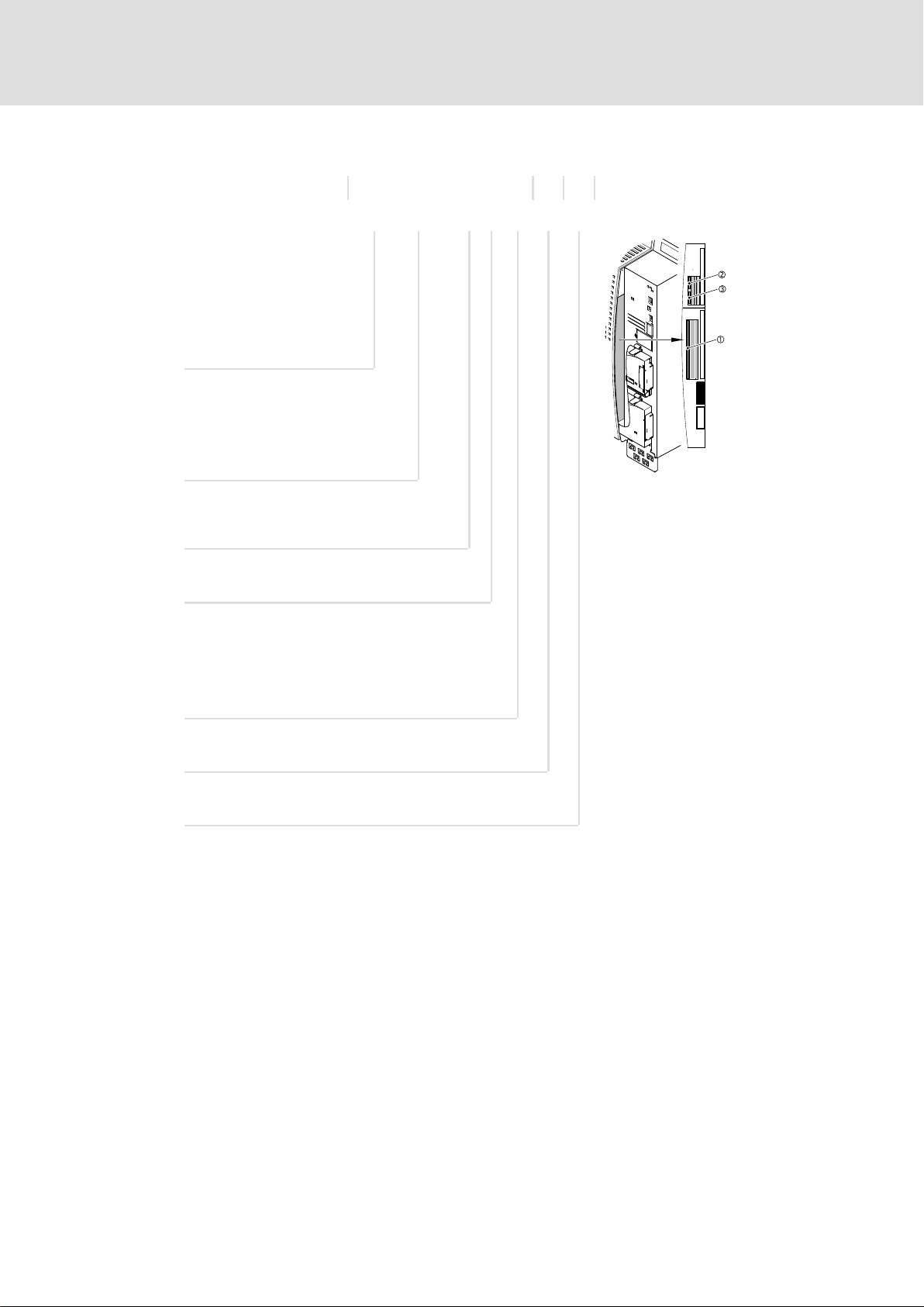

8200 vector 15 ... 90 kW

Type

E = panel−mounted device

D = panel−mounted device in

push−through design

C = panel−mounted device in

cold plate design

Power

(e.g. 153 = 15 ´ 103 W = 15 kW)

(e.g. 903 = 90 ´ 10

3

W = 90 kW)

About this documentation

E82xV xxx K x B xxx 3x 3x

Validity information

Prod.-No.Prod.-No.

Prod.-IDProd.-ID

Ser.-No.Ser.-No.

VersionVersion

InputInput

TypeType

OutputOutput

nash_elmo Industries GmbH

Industriestrasse 26

D-97616 Bad Neustadt

15 ... 90 kW

1

Voltage class

4 = 400 V/500 V

Version

Design, variant

1xx = for IT systems

2xx = without integrated filters

3xx = with footprint mains filters

x4x = with "Safe torque off" function

Hardware version

Software version

EDS82EV903 EN 3.0

15

1

About this documentation

Conventions used

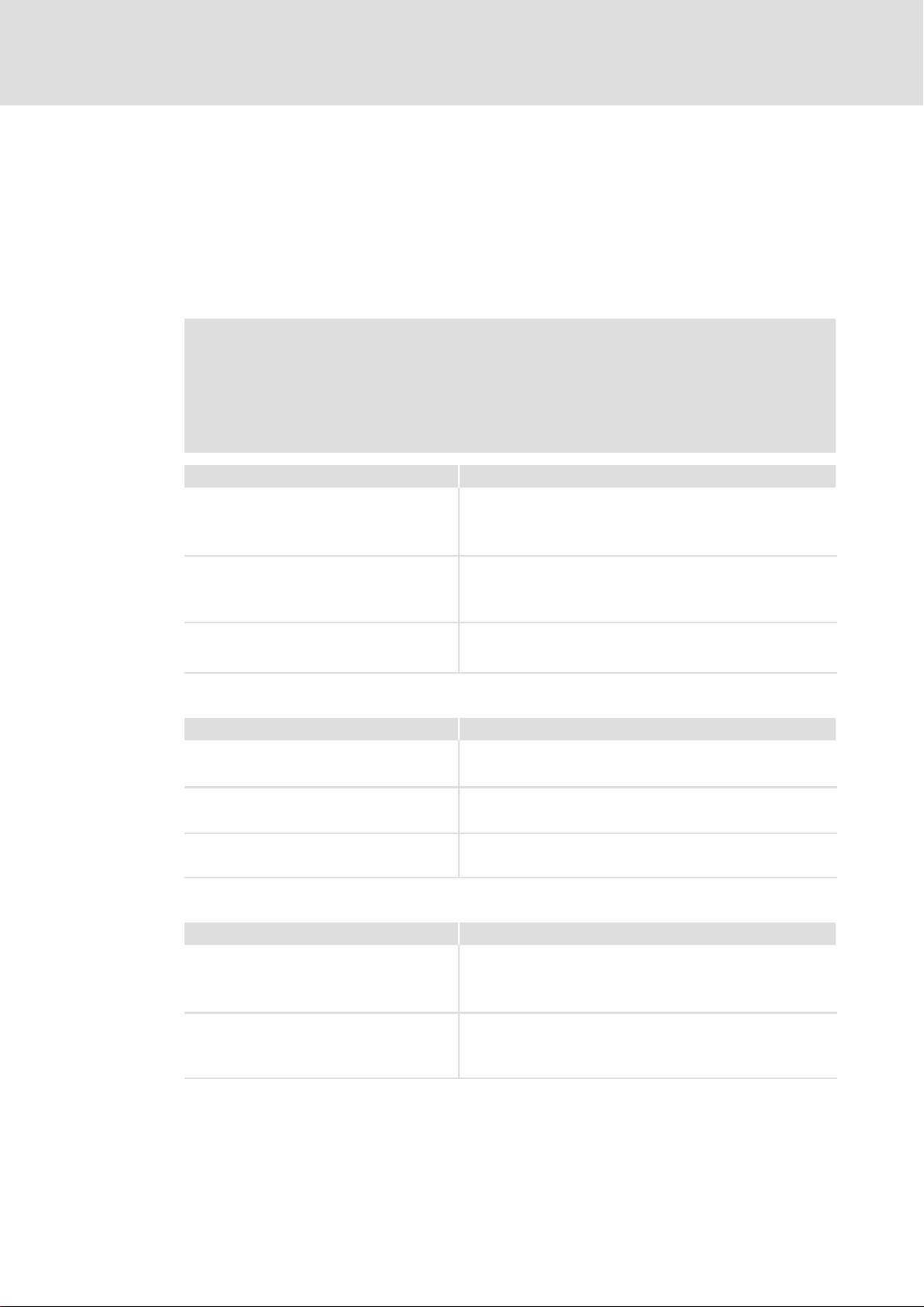

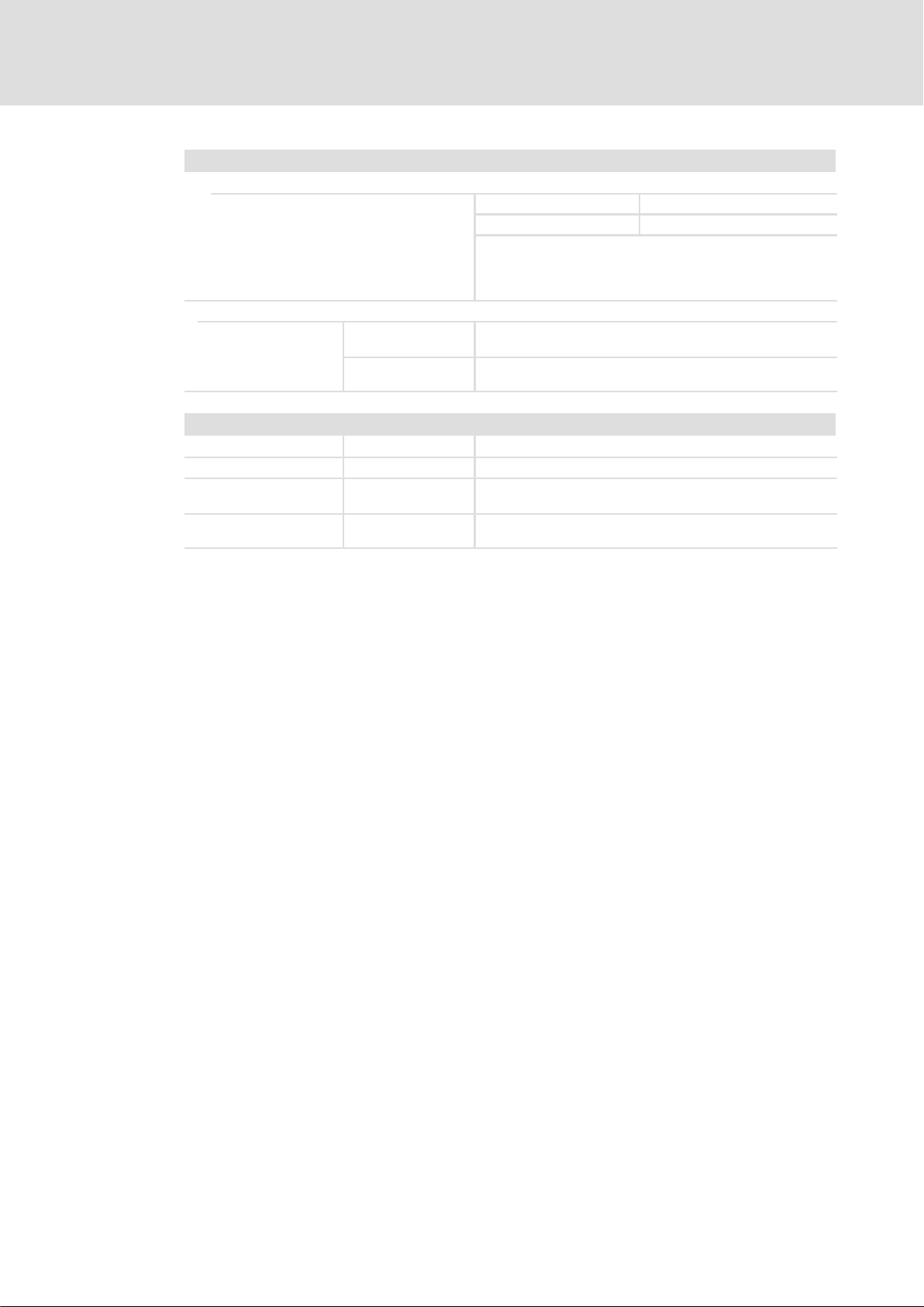

1.4 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Decimal Standard notation For example: 1234

Hexadecimal 0x[0 ... 9, A ... F] For example: 0x60F4

Binary

l Nibble

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

In quotation marks

Point

For instance: 1234.56

For example: ´100´

For example: ´0110.0100´

Are only given in English.

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

16

EDS82EV903 EN 3.0

About this documentation

Notes used

1

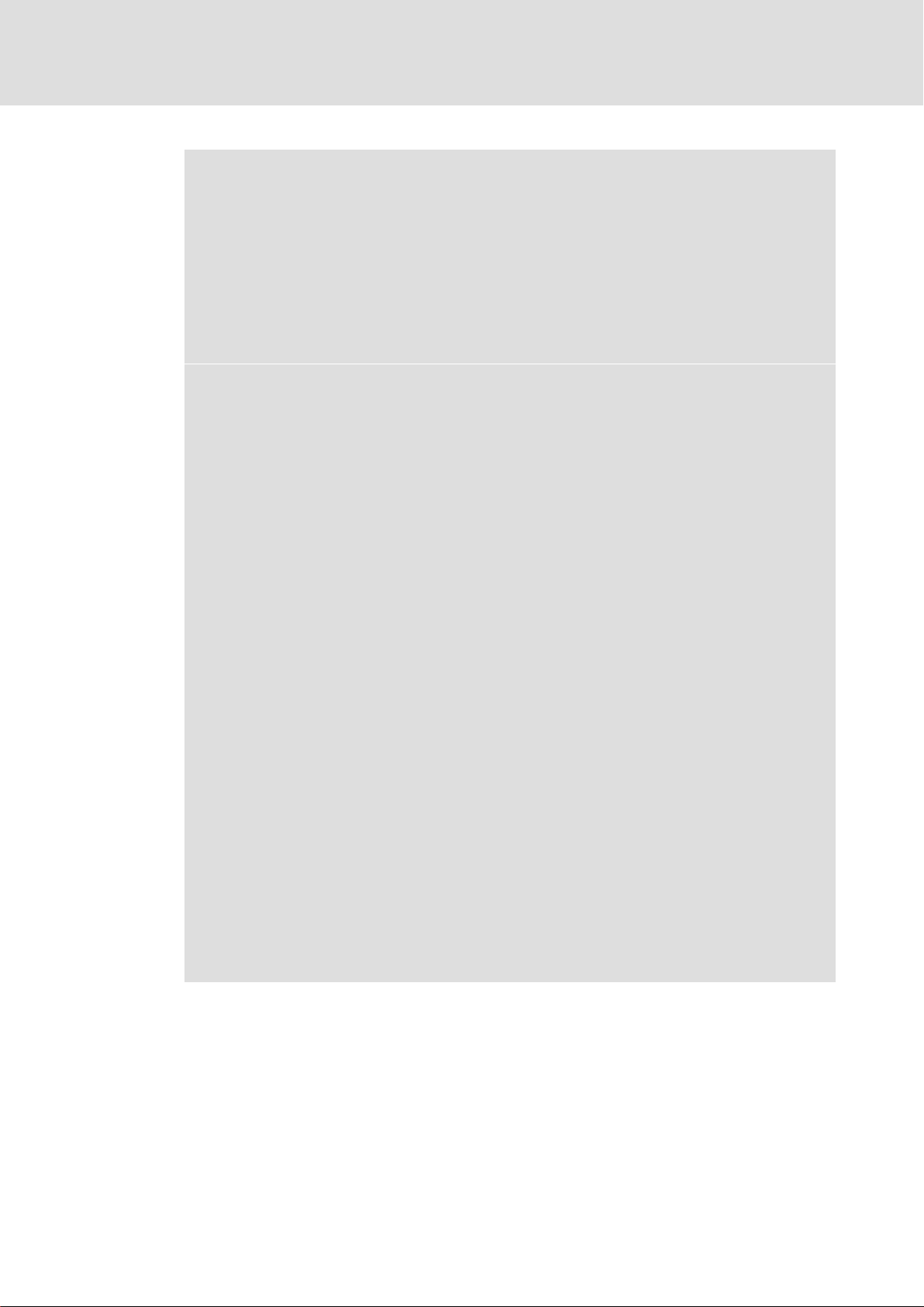

1.5 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes for UL and UR

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety or application note for the operation of a UL−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Safety or application note for the operation of a UR−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

EDS82EV903 EN 3.0

17

2

Product description

Device features

2 Product description

2.1 Device features

Control types / motor control

ƒ V/f control (linear or quadratic)

ƒ Sensorless vector control

Basic functions

ƒ Freely assignable user menu

ƒ 4 freely programmable parameter sets (online switchable)

ƒ Error history buffer

ƒ DC−injection braking

ƒ Flying restart circuit to coasting motor

ƒ S−ramps for smooth acceleration

ƒ Max. output frequency 650 Hz

ƒ Fixed frequencies

ƒ Blocking frequencies

ƒ PID controllers

ƒ Freely configurable inputs and outputs

ƒ Level inversion

Monitorings and protective measures

ƒ Short circuit

ƒ Earth fault

ƒ Overvoltage

ƒ Motor stalling

ƒ Motor phase failure detection

ƒ Motor phase failure detection

2

ƒ I

x t motor monitoring

ƒ Motor overtemperature (input for PTC or thermal contact)

18

EDS82EV903 EN 3.0

2.2 Application as directed

8200 vector frequency inverters and accessories

ƒ are components

– for the control of variable speed drives with asynchronous standard motors,

reluctance motors, PM synchronous motors with asynchronous damper cage.

– for mounting into a machine.

– for the assembly with other components to a machine.

ƒ may only be actuated under the operating conditions specified in this

documentation.

ƒ comply with the protection requirements of the "Low voltage" EC Directive.

ƒ are not machines in terms of the "Machines" EC Directive.

ƒ are not household appliances, but are solely designed as components for

re−utilisation for commercial use or professional use in terms of EN 61000−3−2.

Product description

Application as directed

2

The drive system (frequency inverter and drive) corresponds to the "Electromagnetic

compatibility" EC Directive if it is installed in accordance with the specifications of the

CE−typical drive system.

Any other use shall be deemed as inappropriate!

EDS82EV903 EN 3.0

19

3

Safety instructions

General safety information

3 Safety instructions

3.1 General safety information

Scope

The following general safety instructions apply to all Lenze drive and automation

components.

The product−specific safety and application notes given in this documentation must be

observed!

Note for UL−approved systems: UL warnings are notes which only apply to UL systems. The

documentation contains specific notes with regard to UL.

For your own safety

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

20

EDS82EV903 EN 3.0

Safety instructions

General safety information

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

– Protect against dust and shocks.

– Comply with climatic conditions according to the technical data.

Mechanical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating conditions" in the

chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

ƒ The product contains electrostatic sensitive devices which can easily be damaged by

short circuit or static discharge (ESD). Thus, electronic components and contacts

must not be touched unless ESD measures are taken beforehand.

3

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ Applicable national regulations for the prevention of accidents (e.g. VBG 4) must be

observed when working on live products.

ƒ The documentation contains information about EMC−compliant installation

(shielding, earthing, arrangement of filters and laying cables). The system or

machine manufacturer is responsible for compliance with the limit values required

by EMC legislation.

Warning: The controllers are products which can be used in category C2 drive systems

as per EN 61800−3. These products may cause radio interference in residential areas. If

this happens, the operator may need to take appropriate action.

ƒ For compliance with the limit values for radio interference emission at the site of

installation, the components − if specified in the technical data − have to be mounted

in housings (e. g. control cabinets). The housings have to enable an EMC−compliant

installation. In particular observe that for example control cabinet doors preferably

have a circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

EDS82EV903 EN 3.0

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

ƒ Before commissioning remove transport locking devices and keep them for later

transports.

Operation

ƒ Keep all protective covers and doors closed during operation.

21

3

Safety instructions

General safety information

Safety functions

ƒ Without a higher−level safety system, the described product must neither be used

for the protection of machines nor persons.

ƒ Certain controller versions support safety functions (e.g. "Safe torque off", formerly

"Safe standstill").

The notes on the safety functions provided in the documentation of the versions must

be observed.

Maintenance and servicing

ƒ The components are maintenance−free if the required operating conditions are

observed.

ƒ If the cooling air is polluted, the cooling surfaces may be contaminated or the air

vents may be blocked. Under these operating conditions, the cooling surfaces and air

vents must be cleaned at regular intervals. Never use sharp objects for this purpose!

ƒ Only replace defective fuses in the deenergised state to the type specified.

ƒ After the system has been disconnected from the supply voltage, live components

and power connections must not be touched immediately because capacitors may

be charged. Please observe the corresponding notes on the device.

Disposal

ƒ Recycle metals and plastic materials. Ensure professional disposal of assembled

PCBs.

22

EDS82EV903 EN 3.0

3.2 Residual hazards

Protection of persons

ƒ According to their enclosure, Lenze controllers (frequency inverters, servo inverters,

DC speed controllers) and their components can carry a voltage, or parts of the

controllers can move or rotate during operation. Surfaces can be hot.

– If the required cover is removed, the controllers are used inappropriately or

installed or operated incorrectly, severe damage to persons or material assets can

occur.

– For more detailed information please see the documentation.

ƒ There is a high amount of energy within the controller. Therefore always wear

personal protective equipment (body protection, headgear, eye protection, ear

protection, hand guard) when working on the controller when it is live.

ƒ Before working on the controller, check if no voltage is applied to the power

terminals.

– the power terminals U, V, W, +UG, −UG, BR1 and BR2 still carry dangerous voltage

for at least 3 minutes after power−off.

– the power terminals L1, L2, L3; U, V, W, +UG, −UG, BR1 and BR2 carry dangerous

voltage when the motor is stopped.

– the relay outputs K11, K12, K14 can carry dangerous voltage when the drive

controller is disconnected from the mains.

ƒ Before power−off during DC−bus operation, all controllers must be inhibited and

disconnected from the mains.

Safety instructions

Residual hazards

3

ƒ The discharge current to PE potential is > 3.5 mA. In accordance with EN 61800−5−1

– a fixed installation is required.

– the design of the PE conductor has to be double or, in the case of a single design,

must have a cable cross−section of at least 10 mm

ƒ The controller can only be safely disconnected from the mains via a contactor on the

input side.

ƒ Controllers can cause a DC current in the PE conductor. If a residual current device

(RCD) or a fault current monitoring unit (RCM) is used for protection in the case of

direct or indirect contact, only one RCD/RCM of the following type can be used on

the current supply side:

– Type B for the connection to a three−phase system

– Type A or type B for the connection to a single phase system

Alternatively another protective measure can be used, like for instance isolation from

the environment by means of double or reinforced insulation, or isolation from the

supply system by using a transformer.

2

.

EDS82EV903 EN 3.0

23

3

Safety instructions

Residual hazards

ƒ If you use the Selection of direction of rotation" function via the digital signal

DCTRL1−CW/CCW (C0007 = 0 ... 13, C0410/3 ¹ 255):

– In the event of an open circuit or failure of the control voltage, the drive can

change its direction of rotation.

ƒ If you use the function "flying restart circuit" (C0142 = 2, 3) for machines with a low

moment of inertia and low friction:

– After controller enable at standstill, the motor can start for a short time or change

its direction of rotation for a short time.

Device protection

ƒ Frequent switching of the supply voltage (e.g. inching mode via mains contactor)

can overload and destroy the input current limitation of the controller:

– Wait for at least 3 minutes between two starting operations.

ƒ Only switch contactors in the motor cable when the controller is inhibited.

Otherwise ...

– monitoring functions of the controller can be activated.

– the controller can be destroyed under unfavourable operating conditions.

Motor protection

ƒ For some controller settings, the connected motor may overheat (e.g. when

operating the DC injection brake or a self−ventilated motor at low speed for longer

periods).

– Using an overcurrent relay or a temperature monitoring device provides a large

degree of protection against overload.

– We recommend to use PTC thermistors or thermal contacts for motor temperature

monitoring. (Lenze three−phase AC motors are equipped with thermal contacts

(NC contacts) as standard)

– PTC thermistors or thermal contacts can be connected to the controller.

ƒ Drives can attain dangerous overspeeds (e.g. setting of high output frequencies with

motors and machines not qualified for this purpose).

24

EDS82EV903 EN 3.0

Safety instructions

Safety instructions for the installation according to UL or U

3

R

3.3 Safety instructions for the installation according to UL or U

Warnings!

ƒ Motor Overload Protection

– For information on the protection level of the internal overload protection

for a motor load, see the corresponding manuals or software helps.

– If the integral solid state motor overload protection is not used, external or

remote overload protection must be provided.

ƒ Branch Circuit Protection

– The integral solid state protection does not provide branch circuit

protection.

– Branch circuit protection has to be provided externally in accordance with

corresponding instructions, the National Electrical Code and any

additional codes.

ƒ Please observe the specifications for fuses and screw−tightening torques in

these instructions.

ƒ E82xV251K2C ... E82xV222K2C (0.25 kW ... 2.2 kW, 240 V devices):

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 240 V maximum, when protected by fuses or circuit

breakers.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 240 V maximum, when protected by CC, J, T or R

class fuses.

– Shall be installed in a Pollution Degree 2 macro−environment.

– Maximum surrounding air temperature: 0 ... +55 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

R

ƒ E82xV551K4C ... E82xV222K4C (0.55 kW ... 2.2 kW, 400/500 V devices):

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 500 V maximum, when protected by fuses or circuit

breakers.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 500 V maximum, when protected by CC, J, T or R

class fuses.

– Shall be installed in a Pollution Degree 2 macro−environment.

– Maximum surrounding air temperature: 0 ... +55 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

EDS82EV903 EN 3.0

25

3

Safety instructions

Safety instructions for the installation according to UL or U

ƒ E82xV302K2C ... E82xV752K2C (3.0 kW ... 7.5 kW, 240 V devices):

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 240 V maximum, when protected by fuses.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 240 V maximum. When protected by CC, J, T or R

class fuses.

– Shall be installed in a Pollution Degree 2 macro−environment.

– Maximum surrounding air temperature: 0 ... +55 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

ƒ E82xV302K4C ... E82xV113K4C (3.0 kW ... 11 kW, 400/500 V devices):

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 500 V maximum, when protected by fuses or circuit

breakers (E82xV302K4C only).

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 500 V maximum. When protected by CC, J, T or R

class fuses

– Shall be installed in a Pollution Degree 2 macro−environment.

– Maximum surrounding air temperature: 0 ... +55 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

R

ƒ E82xV153K4B ... E82xV303K4B:

– Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 500 V maximum. When protected by fuses.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 500 V maximum. When protected by J, T or R class

fuses

– Maximum surrounding air temperature: 0 ... +50 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

ƒ E82xV453K4B ... E82xV903K4B:

– Suitable for use on a circuit capable of delivering not more than 10000 rms

symmetrical amperes, 500 V maximum. When protected by fuses.

– Suitable for use on a circuit capable of delivering not more than 50000 rms

symmetrical amperes, 500 V maximum. When protected by J, T or R class

fuses

– Maximum surrounding air temperature: 0 ... +50 °C

– > +40 °C: reduce the rated output current by 2.5 %/°C

– Use 60/75 °C or 75 °C copper wire only.

26

EDS82EV903 EN 3.0

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

General data

Conformity and approval

Conformity

CE

Approval

UL cULus Power Conversion Equipment (File No. E132659)

Protection of persons and equipment

Type of protection EN 60529

Earth leakage current IEC/EN 61800−5−1 > 3.5 mA Observe stipulations and safety

Insulation of control

circuits

Insulation resistance IEC/EN 61800−5−1

Protective measures Against short circuit, earth fault (protected against short to

2006/95/EC Low−Voltage Directive

2004/108/EG EMC Directive

NEMA 250 Protection against accidental contact in accordance with type

IEC/EN 61800−5−1 Safe mains isolation through double (reinforced) insulation

Technical data

IP20

IP41 in case of thermally separated installation

(push−through technique) between the control cabinet

(inside) and the environment.

1

instructions!

< 2000 m site altitude: overvoltage category III

> 2000 m site altitude: overvoltage category II

earth on power−up, limited protection against short to earth

during operation), overvoltage, motor stalling, motor

overtemperature (input for PTC thermistor or thermal

contact, I

2

t monitoring)

4

EMC

Noise emission

Noise immunity IEC/EN 61800−3 Category C2

1)

Motor cable lengths depend on the inverter type and the switching frequency

IEC/EN 61800−3 Cable−guided, category C1 or C2 when using shielded motor

0.25 ... 11 kW

15 ... 90 kW

1)

cables

, dependent on the device variant with integrated

interference suppression or additional RFI/mains filter

E82xVxxxKxC0xx no additional measures

E82xVxxxKxC2xx with external filter techniques

E82EVxxxK4B3xx no additional measures

E82xVxxxK4B2xx with external filter techniques

EDS82EV903 EN 3.0

27

4

Technical data

General data and operating conditions

Operating conditions

Ambient conditions

Climatic conditions

Storage

Transport IEC/EN 60721−3−2 2K3 (−25 ... +70 °C)

Operation

2.2 ... 11 kW

15 ... 90 kW 3K3 (0 ... +50 °C)

Pollution IEC/EN 61800−5−1 Degree of pollution 2

Site altitude < 4000 m amsl

Electrical

AC mains connection

Max. mains voltage range

E82xV251K2... and E82xV371K2... 1/N/PE 180 V − 0 % ... 264 V + 0 %

E82xV551K2... to E82xV752K2... 1/N/PE 180 V − 0 % ... 264 V + 0 % or

E82xV551K4... to E82xV903K4... 3/PE 320 V − 0 % ... 550 V + 0 %

Mains frequency 45 Hz − 0 % ... 65 Hz + 0 %

Mains system With earthed neutral (TT, TN): unrestricted operation

Operation on public

supply systems

DC mains connection

Max. mains voltage range 450 V − 0 % ... 740 V + 0 %

E82xV251K2... and E82xV371K2... not possible

E82xV551K2... to E82xV752K2... 140 V − 0 % ... 370 V + 0 %

E82xV551K4... to E82xV903K4...

Operating conditions The DC voltage must be symmetrical to PE.

IEC/EN 60721−3−1

IEC/EN 60721−3−3

EN 61000−3−2

1K3 (−25 ... +60 °C) < 6 months

1K3 (−25 ... +40 °C) > 6 months

> 2 years: form the DC bus

capacitors

3K3 (−10 ... +55 °C)

> +40 °C: reduce the rated output current by 2.5 %/°C.

> +40 °C: reduce the rated output current by 2.5 %/°C.

> 1000 m amsl: reduce the rated output current by

5 %/ 1000 m.

3/PE 100 V − 0 % ... 264 V + 0 %

permitted

Other mains systems: observe restrictions described in the

system manual, chapter about project planning

Limitation of harmonic currents

Total power drawn from

the mains

< 1 kW With mains choke.

> 1 kW Without additional measures.

1)

The additional measures described only ensure that the controllers comply

with the requirements of EN 61000−3−2. Compliance of the machine/system

with the requirements is in the responsibility of the machine/system

manufacturer!

450 V − 0 % ... 775 V + 0 % Operation at rated power

450 V − 0 % ... 625 V + 0 % Operation at an increased rated

The controller will be destroyed if the +U

conductor is earthed.

Compliance with the

requirements

power

1)

conductor or −U

G

G

28

EDS82EV903 EN 3.0

Technical data

General data and operating conditions

Ambient conditions

Motor connection

Length of the motor cable

Mechanical

Vibration resistance

(9.81 m/s

Mounting conditions

Mounting place

Mounting position Vertical

Dimensions,

free spaces

Weights Chapter "Technical data", "Operation at rated power" or

2

= 1 g)

Germanischer Lloyd

5 ... 13.2 Hz

IEC/EN 60068−2−6

10 ... 57 Hz

< 50 m shielded

< 100 m unshielded

For rated mains voltage and switching frequency £ 8 kHz

without additional output filters.

For compliance with EMC regulations, the permissible cable

length may be different.

Amplitude ±1 mm 13.2 ... 100 Hz:

acceleration resistant up to 0.7 g

Amplitude 0.075 mm 57 ... 150 Hz:

acceleration resistant up to 1 g

In the control cabinet

Chapter "Mechanical installation"

"Operation at increased rated power"

4

EDS82EV903 EN 3.0

29

4

Technical data

Open and closed loop control

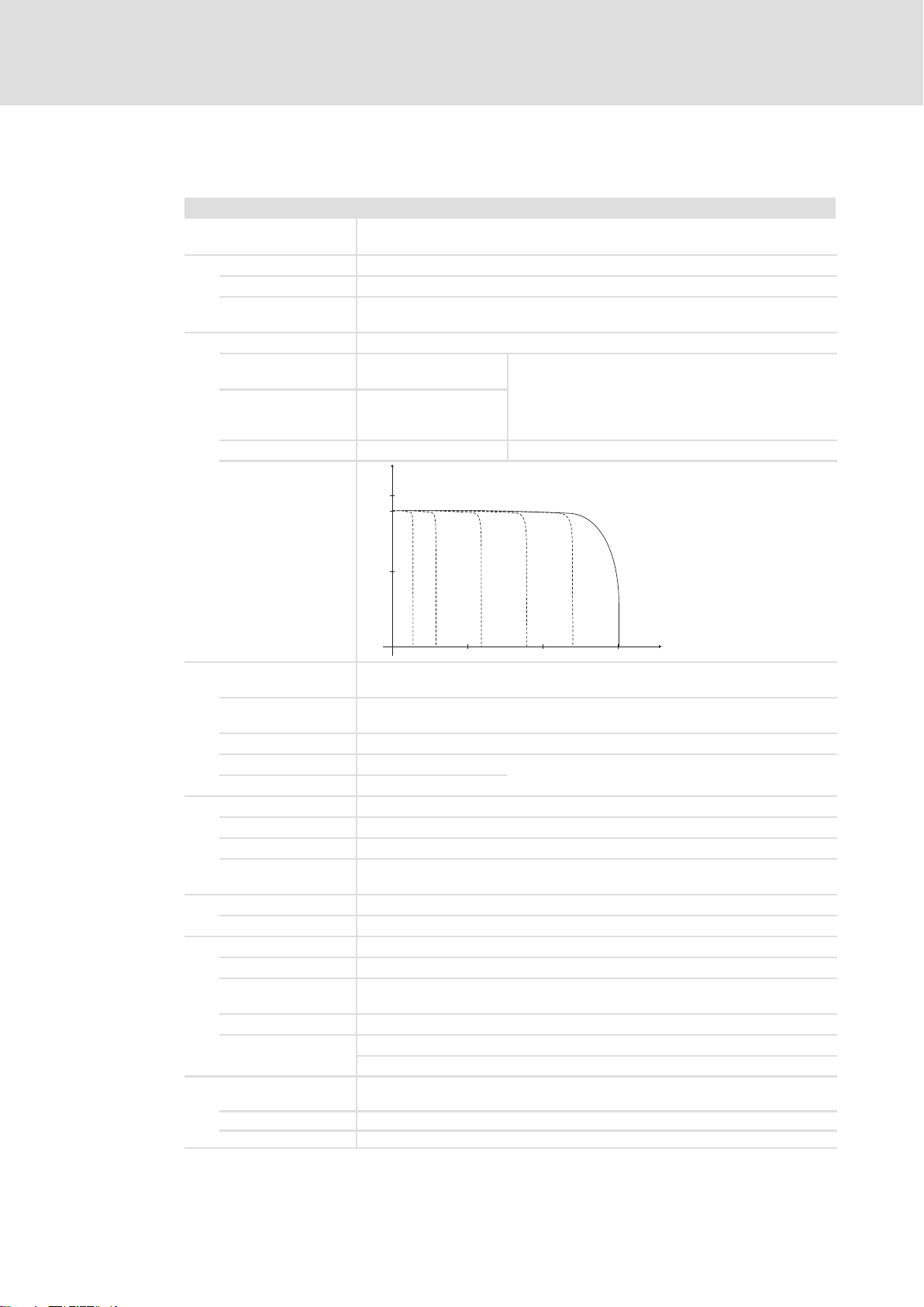

4.2 Open and closed loop control

Open and closed loop control

Open and closed loop

control modes

Switching frequency

0.25 ... 11 kW 2 kHz, 4 kHz, 8 kHz, 16 kHz noise optimised

15 ... 90 kW 1 kHz, 2 kHz, 4 kHz, 8 kHz, 16 kHz,

Torque behaviour

Maximum torque

0.25 ... 11 kW

Maximum torque

15 ... 90 kW

Setting range 1 : 10 in speed setting range 3 ... 50 Hz, accuracy < 8 %

Torque/speed

characteristic

V/f characteristic control (linear, quadratic), vector control, torque selection

optionally noise optimised or power loss optimised

1.8 x M

1.8 x M

2.1 x M

controller enable

M/M

N

2.0

1.8

for 60 s

rated

for 60 s

rated

for 3 s after

rated

if rated motor power = rated controller power

1.0

500 1000 1500

Vector control (sensorless

speed control)

Minimum output

frequency

1.0 Hz (0 ... M

rated

)

Setting range 1 : 50 based on 50 Hz and M

Accuracy ± 0.5 %

Smooth running ± 0.1 Hz

in speed setting range 3 ... 50 Hz

Output frequency

Range − 650 Hz ... + 650 Hz

Absolute resolution 0.02 Hz

Standardised

Parameter data: 0.01 %, process data: 0.006 % (= 214)

resolution

Digital setpoint selection

Accuracy ± 0.0001 %

Analog setpoint selection

Linearity ± 0.5 % based on instantaneous value

Temperature

+ 0.3 % (0 ... +60 °C) based on instantaneous value

sensitivity

Offset ± 0 %

A/D converter

10−bit resolution

Error: 1 digit º 0.1 % based on final value

Operation in generator

mode

0.25 ... 11 kW Integrated brake chopper

15 ... 90 kW With 9352 brake chopper

n [min ]

rated

-1

30

EDS82EV903 EN 3.0

Loading...

Loading...