Page 1

Instructions for Use

Leica ST5020

V1.9 English - 12/2012

Order No. 14 0475 80101 RevD

Always keep this manual together with the instrument.

Read this Instructions for Use carefully

before working with the instrument.

Leica ST 5020

Multistainer

Page 2

Page 3

NOTE

The information, numerical data, notes and value judgments contained in this manual represent the current state of scientific knowledge

and state-of-the-art technology as we understand it following thorough investigation in this

field.

We are under no obligation to update the present manual according to the latest technical

developments, nor to provide our customers

with additional copies, updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations etc. contained in this manual we

exclude liability as far as permissible according

to the national legal system applicable in each

individual case. In particular, no liability

whatsoever is accepted for any financial loss or

consequential damage caused by or related to

compliance with statements or other information in this manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the present manual are not to be considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it

possible to continuously improve the technology and manufacturing techniques used in our

products.

This document is protected under copyright

laws. Any copyrights of this document are retained by Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods – including any electronic systems and media – requires express prior permission in writing by Leica

Biosystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the name plate at

the back of the instrument.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 (0)6224 143-0

Fax: +49 (0)6224 143-2 68

Internet: http://www.LeicaBiosystems.com

Leica ST5020

3

Page 4

Table of Contents

1. Important information ................................................................................................................ 6

1.1 Symbols used in this manual ............................................................................................................ 6

1.2 Designated use ................................................................................................................................... 6

1.3 Qualification of personnel ................................................................................................................. 6

1.4 Instrument type ................................................................................................................................... 6

2. Safety ............................................................................................................................................ 7

2.1 Safety instructions ............................................................................................................................. 7

2.2 Warnings ............................................................................................................................................. 7

3. Instrument components and specifications ....................................................................... 10

3.1 Overview - Instrument components .............................................................................................. 10

3.2 Instrument specifications ............................................................................................................... 12

3.3 Standard delivery - packing list ..................................................................................................... 13

3.4 Technical Data .................................................................................................................................. 14

3.5 Container system .............................................................................................................................. 16

4. Setting up the instrument ....................................................................................................... 17

4.1 Installation site requirements ......................................................................................................... 17

4.2 Installing the instrument .................................................................................................................. 17

4.3 Tap water supply connection ......................................................................................................... 18

4.4 Installing the oven (optional) .......................................................................................................... 21

4.5 Connecting the air evacuation hose (optional) ........................................................................... 24

4.6 Inserting the activated carbon filter .............................................................................................. 25

4.7 Leveling the instrument ................................................................................................................... 25

4.8 Electrical connection ....................................................................................................................... 27

4.9 Alarm functions................................................................................................................................. 28

4.10 Transport ........................................................................................................................................... 28

5. Operation ................................................................................................................................... 29

5.1 Switching the instrument on ........................................................................................................... 29

5.2 Setup checklist ................................................................................................................................. 30

5.3 Touch screen functions .................................................................................................................. 31

5.3.1 User interface - overview ............................................................................................................... 31

5.3.2 Data entry .......................................................................................................................................... 34

5.3.3 Access levels .................................................................................................................................... 36

5.3.4 The main menu.................................................................................................................................. 37

5.4 System SETUP................................................................................................................................... 38

5.4.1 User interface ................................................................................................................................... 39

5.4.2 Alarm .................................................................................................................................................. 40

5.4.3 Password allocation ........................................................................................................................ 42

4

Instructions for Use, V1.9, RevD - 12/2012

Page 5

Table of Contents

5.4.4 Set date/time ..................................................................................................................................... 43

5.4.5 Movement .......................................................................................................................................... 44

5.4.6 View and print ................................................................................................................................... 45

5.4.7 Reagent list ........................................................................................................................................ 46

5.4.8 Station options .................................................................................................................................. 49

5.4.9 Calibration dialog.............................................................................................................................. 50

5.4.10 Data backup ...................................................................................................................................... 51

5.5 Instrument status.............................................................................................................................. 53

5.5.1 Station buttons .................................................................................................................................. 54

5.5.2 Station types ..................................................................................................................................... 54

5.5.3 Select station type............................................................................................................................ 56

5.5.4 Change station type ......................................................................................................................... 58

5.6 Staining programs ............................................................................................................................ 59

5.6.1 Creating programs............................................................................................................................ 60

5.6.2 Defining the program steps ............................................................................................................ 61

5.6.3 Assigning a clip color ...................................................................................................................... 66

5.7 Programs in process ........................................................................................................................ 68

5.8 Staining .............................................................................................................................................. 69

5.8.1 Loading the racks ............................................................................................................................. 69

5.8.2 Starting programs............................................................................................................................. 70

5.8.3 Interrupting a staining program ..................................................................................................... 72

5.8.4 Finishing programs ........................................................................................................................... 73

6. Cleaning and maintenance .................................................................................................... 75

6.1 Cleaning the instrument .................................................................................................................. 75

6.2 General maintenance ...................................................................................................................... 76

6.3 Preventative maintenance schedule ............................................................................................77

7. Troubleshooting ....................................................................................................................... 78

7.1 General ............................................................................................................................................... 78

7.2 Correcting errors .............................................................................................................................. 78

7.3 Power failure ..................................................................................................................................... 78

7.4 Replacing the secondary fuses ..................................................................................................... 80

8. Warranty and service .............................................................................................................. 82

9. Appendix .................................................................................................................................... 83

9.1 Container Map .................................................................................................................................. 83

9.2 Optional accessories ....................................................................................................................... 85

10. Information for the People´s Republik of China .................................................................87

Leica ST5020

5

Page 6

1. Important information

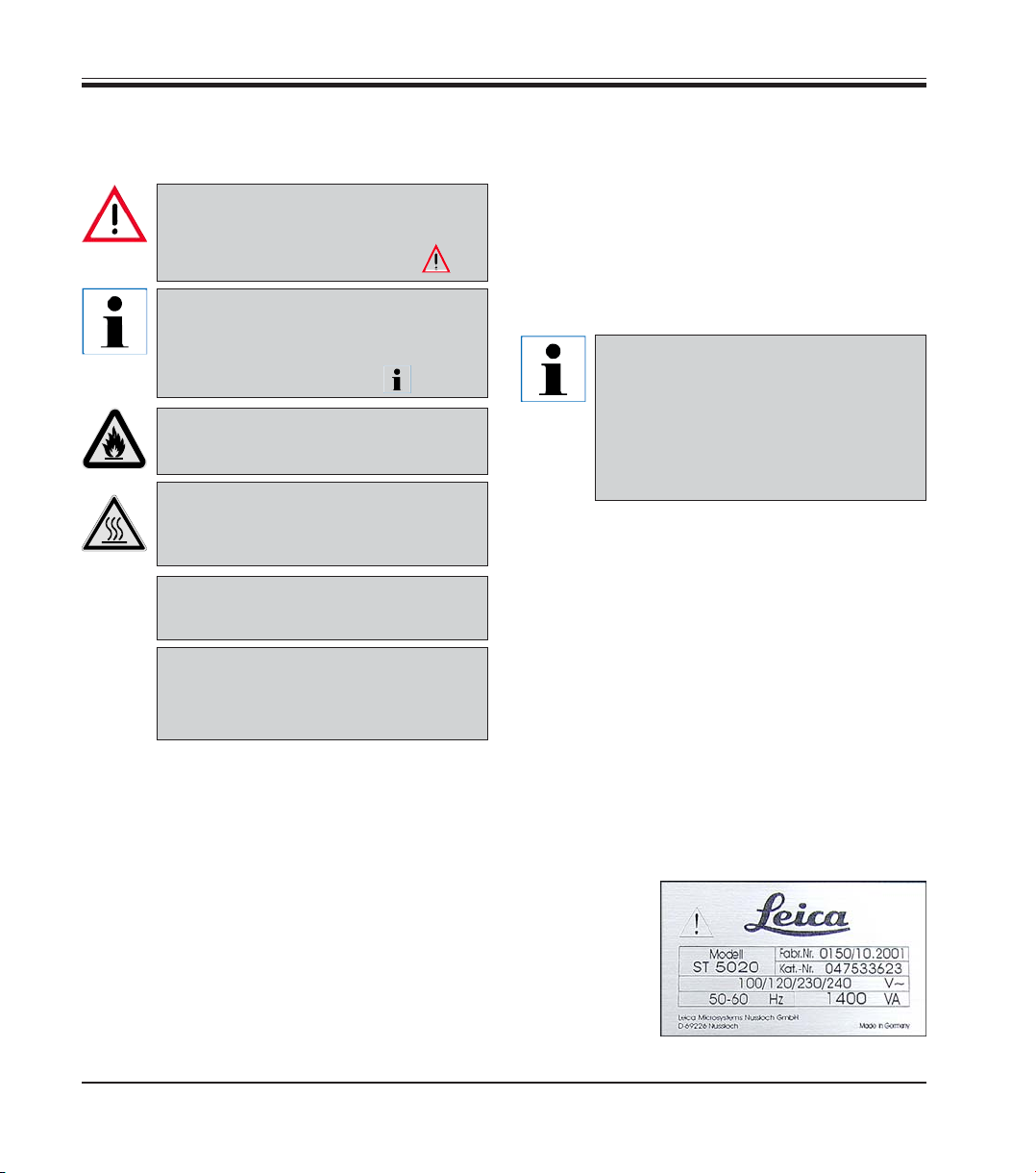

1.1 Symbols used in this manual and their meaning

(5)

ENTER

Warnings

appear in a grey box and are

marked by a warning triangle .

Notes,

i.e. important user information appear in a grey box and are marked

by an information symbol .

Flammable solvents and reagents

are marked with this symbol.

Instrument surfaces which become

hot during operation are marked

with this symbol.

Figures in brackets refer to item

nos. in drawings.

Function keys to be pressed on the

instrument touch screen are written

in bold-print capital letters.

• The instrument may be operated only according to the instructions contained in this

manual.

Any other use of the instrument

is considered improper!

To prevent damages to the

instrument and specimens, only

those accessories and spare parts

which have been authorized by

Leica may be installed or used

with the instrument.

1.3 Qualification of personnel

• The Leica ST5020 may be operated only by

trained laboratory personnel.

• The instrument may be operated only according to the instructions contained in this

manual.

1.2 Designated use

The Stainer Leica ST5020 is an automated stainer for the preparation of histological and cytological routine stainings.

It is designed for use in pathology laboratories,

and only for performing the following tasks:

• Staining of thin sections of tissue specimens

or of cytological samples, attached to microscope slides

6

1.4 Instrument type

All information provided in this manual applies

only to the instrument type indicated on the title

page.

A name plate

indicating the

instrument serial number is

attached to the

back of the instrument.

Instructions for Use, V1.9, RevD - 12/2012

Page 7

Make sure to comply with the safety instructions and warnings in this chapter.

Make sure to read these instructions, even if you are already familiar with the operation

and use of other Leica products.

2.1 Safety instructions

2. Safety

This Instructions for Use includes important information related to the operating safety and

maintenance of the instrument and it is an important part of the product.

If additional requirements on accident prevention and environmental

protection exist in the country of operation, this Instructions for Use must

be supplemented by appropriate instructions to ensure compliance with

such requirements.

Material safety data sheets can be obtained from the supplier of the chemicals.

They are also available on the Internet:

http://www.msdsonline.com

The protective devices on both instrument and accessories may neither be removed nor

modified. Only authorized and qualified service personnel may repair the instrument and

access the instrument’s internal components.

This instrument has been built and tested in accordance with the following safety regulations

on electrical measuring, control, regulating and

laboratory devices.

In order to maintain this condition and to ensure

safe operation, the operator must observe the

instructions and warnings contained in this Instructions for Use.

For current information about

applicable standards, please refer

to the CE declaration of conformity

on our Internet site:

www.LeicaBiosystems.com

2.2 Warnings

The safety devices installed in this instrument by the manufacturer only constitute the basis for

accident prevention. Primarily responsible for accident-free operation is above all the institution which owns the instrument and, in addition, the designated personnel who operates, services or repairs the instrument.

To ensure trouble-free operation of the instrument, make sure to comply with the following instructions and warnings.

Leica ST5020

7

Page 8

2. Safety

Warnings - Markings on the instrument itself

Markings on the instrument showing the warning triangle indicate that the correct

Instructions for Use (as defined in this manual) must be followed when operating or replacing the item marked.

Failure to adhere to these instructions may result in an accident, personal injury, damage

to the instrument or accessory equipment.

Some instrument surfaces, which become hot during operation are marked with

this warning label. Touching these surfaces may cause burns.

Warnings - Transport and Installation

The instrument may only be transported in an upright position.

Four people are needed to lift / carry the instrument.

Install the instrument on an even laboratory bench which must be absolutely level.

Do not expose the instrument to direct sunlight (windows).

The instrument MUST be connected to an earthed mains power outlet socket. The instrument must not be connected to an extension cord without protective earth conductor.

The instrument will automatically adjust to the required voltage and frequency at the

place of installation.

If new ovens are installed, they must be adjusted to the voltage and frequency required at

the installation site.

The instrument must be set up in a well ventilated area, free from any ignition sources.

The chemicals to be used in the Leica ST5020 are both flammable and noxious. Do not operate the instrument in rooms with explosion hazard.

If there is a significant difference in temperature between the warehousing and the installation site of the instrument and if at the same time there is a high air humidity level,

condensation water may form. In this case, a waiting period of at least two hours must be

observed before the instrument is switched on. Failure to adhere to this waiting period

may result in damage to the instrument.

Warnings -handling reagents

Be careful when handling solvents!

Always wear rubber gloves and safety goggles when handling the chemicals used in this

instrument.

Reagents used for tissue infiltration can be both toxic and/or flammable.

Dispose of waste solvents with care according to local regulations and the waste management policy of the company or institution.

8

Instructions for Use, V1.9, RevD - 12/2012

Page 9

Warnings - Operating the instrument

The Leica ST5020 may only be operated by trained laboratory personnel, according to its

designated use and per the present Instructions for Use.

In case of emergency switch off mains and unplug the power chord.

While working with reagents (filling / emptying the reagent stations, working on the instrument while the lid/s is/are open) appropriate protective gear (lab coat, gloves, safety

goggles) must be worn.

Make sure to operate the instrument either with the activated carbon filter or with the exhaust air hose. Even when the instrument is operated according to its designated use,

hazardous solvent fumes develop, which are damaging to the operator’s health and do

also pose a risk of fire!

Risk of fire, when working with an open flame (Bunsen burner) immediately next to the

instrument (solvent fumes)! - Therefore, keep a safety distance of 2 meters!

If a staining program is to be interrupted for an extended period of time, do not leave any

slide racks in the tap water stations, in order to prevent them from drying out.

Warnings - Cleaning and maintenance

Prior to each maintenance and/or cleaning, switch the instrument off and disconnect

mains power. Do not clean the instrument with solvents containing acetone or xylene. No

liquid may be spilled into the internal components of the instrument - neither during operation nor during cleaning.

When working with cleaning detergents, comply with all safety instructions by the manufacturer of the product and the laboratory management policy.

Wash the tap water and reagent stations in the dishwasher at a temperature of max.

+65°C (149 °F). Use a standard detergent for laboratory dishwashers.

At any rate avoid washing the stations at higher temperatures, as the stations may become deformed!

Spilled solvents (reagents) have to be wiped away immediately! - In case of long-term exposure, the lid surfaces are only conditionally resistant to solvents!

To clean the lids, control panel and housing, use mild household detergents; - see safety

instruction above for non-appropriate ingredients!

Caution with sequences which involve an oven at the initial step.

In this case the loading unit, out of which the specimen holder is removed via the

transport arm, must NOT be filled with an inflammable reagent (e.g. xylene).

As the oven temperature is up to 80°C (176 °F), the reagent may ignite and cause damage

to the device and to the samples.

For the same reason, steps conducted INSIDE an oven must never be carried out from a

reagent station with inflammable reagents.

2. Safety

Leica ST5020

9

Page 10

3. Instrument components and specifications

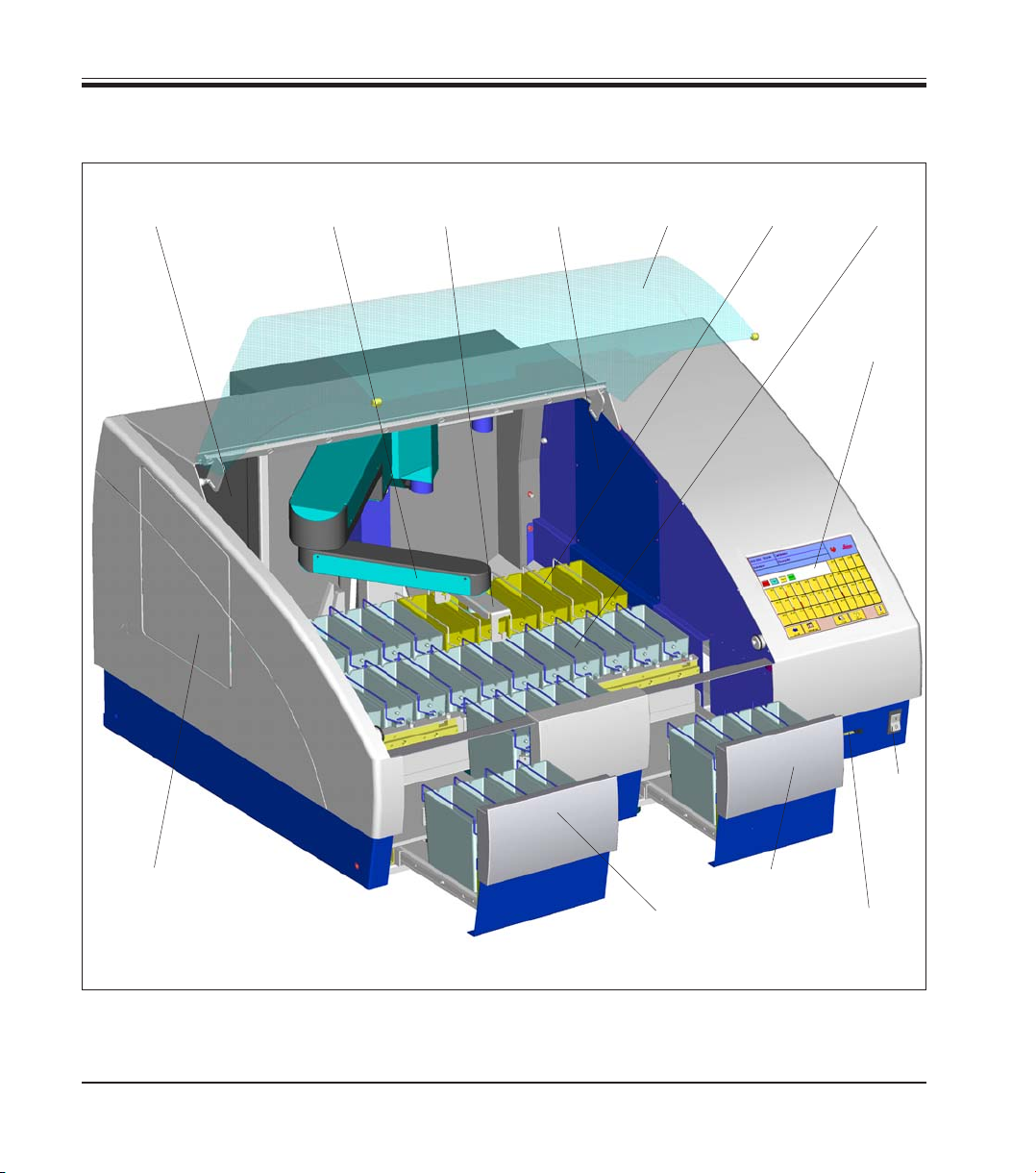

3.1 Overview - Instrument components

Activated

carbon filter

Single (Double)

Transfer arm Lid

carrier

Oven

modules

Wash

stations

Reagent

container

Color touch

screen

Transfer to

Coverslipper

Leica CV5030

10

(optional)

Mains

switch

Load

drawer

Exit

drawer

Slot for

PCMCIA

card

Fig. 1

Instructions for Use, V1.9, RevD - 12/2012

Page 11

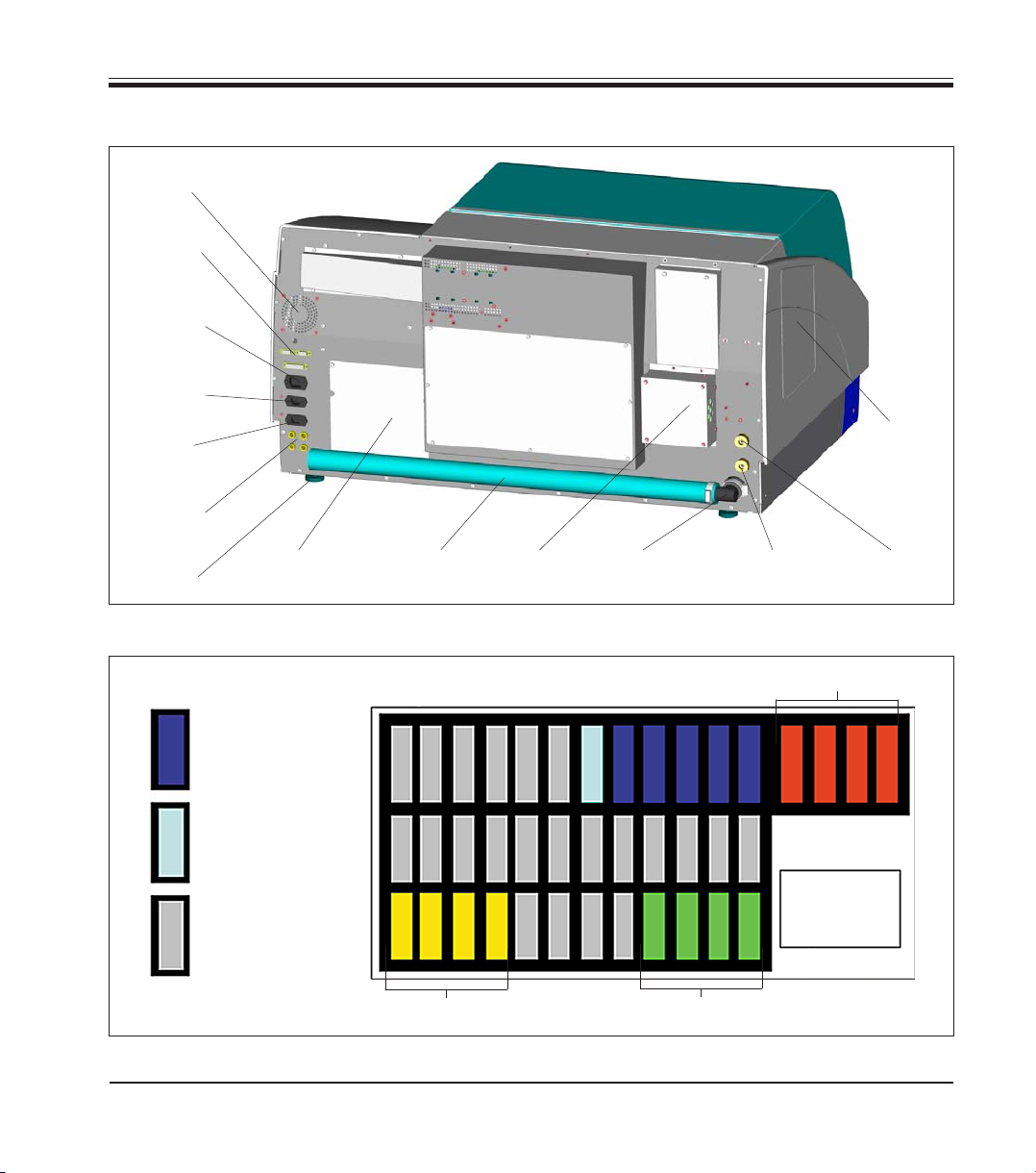

Rear of instrument

Fan

electronic

Data

connections

Power supply

inlet

(electronic)

Power supply

outlet

3. Instrument components and specifications

Mains

Power supply

inlet

Secondary

fuses

adjustable

foot

Container map

Wash

stations

Wash

station

DI-water

Reagent

container

Cover for

Oven-Modules

Transfer to

Coverslipper

(optional)

Drain

hose

12 3 456 7 89101112 37383940

25

Exhaust

air duct

181716151413 2322212019 24

29282726 33323130 363534

Drain

outlet

DI-Water inlet

Station 7

Oven-Modules

Color touch

Water inlet

Stations 8-12

screen

Fig. 2

Leica ST5020

Exit drawer

Load drawer

Fig. 3

11

Page 12

3. Instrument components and specifications

3.2 Instrument specifications

• High specimen throughput (at maximum 12 racks simultaneously)

• Simultaneously processing of multiple different programs

• Color TFT-Touch screen

• Graphical and intelligent user Interface

• Context-sensitive On-line Help

• Graphical process representation on color screen.

• Reagent Management System.

• Multilingual.

• Maximum of 40 stations.

• Load drawer with max. 4 stations.

• Exit drawer with max. 4 stations.

• Maximum of 6 wash stations, 2 different water sources possible.

(individually valve-controlled)

TM

• CodeRack

• Overflow Protector (sensor) in stainless steel sink.

• Integrated fume control system with external hose/filter.

Programmable Slide Rack for automatic rack start.

Optional Accessories

• Oven modules max. +65°C and up to 4 stations.

• Heated reagent stations (35 - 70°C max.), max. 2,

• Special Stain Kit.

(modified container with reduced reagent volume and racks).

• System upgrade for Coverslipper integration.

(automated staining and coverslipping without operator interaction).

• Air evacuation hose.

• Slide rack (plastic).

• Adapter for racks from other manufacturers.

To prevent damages to the instrument and specimens, only those accessories and

spare parts which have been authorized by Leica may be installed or used with the

instrument.

12

Instructions for Use, V1.9, RevD - 12/2012

Page 13

3. Instrument components and specifications

3.3 Standard delivery - packing list

The Leica ST5020 standard delivery consists of the following items:

1 Leica ST5020 basic instrument

31 Reagent vessels, assy. (with handles and lids) 14 0475 33659

5 Wash vessels, assy. 14 0475 33660

2 Activated carbon filter 14 0474 32273

1 Set of power cords:

1 Power cord "D" 14 0411 13558

1 Power cord "UK" ST-BU F-5A 14 0411 27822

1 Power cord "USA-C-J" 14 0411 13559

1 Accessory-Kit consisting off: 14 0475 39617

1 Jumper cable - mains 14 0411 34604

3 Reagent vessels, assy. (with handles and lids) 14 0475 33659

1 Set of clips, red, pack of 5 14 0475 33637

1 Set of clips, yellow, pack of 5 14 0475 33633

1 Set of clips, white, pack of 5 14 0475 33632

1 Set of clips, light blue, pack of 5 14 0475 33634

1 Set of slide racks 30, plastic, pack of 5 14 0475 33750

1 Waste water hose, 4 m length 14 0475 35748

1 Hose clamp for waste water hose 14 0422 31972

1 Tap water inlet hose, 2,50 m length, assy. with 3/4” connection for water tap 14 0475 32325

1 ‘V’ strainer 3/4”-40/22 A6 (strainer for inlet hose) 14 0456 36101

1 Threaded nippel 14 0474 33063

2 Gaskets for tap water inlet hose 14 0300 00132

1 Box level 14 0475 37629

1 Special O-ring grease for valves and O-rings (OHA), 25 ml 14 0336 36657

1 PCMCIA Flash Card, with adapter 14 0475 42526

1 Tool set:

1 Screw driver 5.5 x 200 14 0170 10702

1 Allen key, size 3.0, with handle 14 0194 04764

1 Allen key, size 4.0, with handle 14 0194 04782

1 Allen key, size 6.0 14 0194 03959

1 Ring-head wrench, size 13 14 0330 37628

1 Single-head wrench, size 17 14 0330 19641

1 Set of replacement fuses:

4 x T 2.0 A 14 6943 02001

2 x T 2.5 A 14 6943 02501

2 x T 4.0 A 14 6943 04001

1 Instructions for Use Leica ST5020 Multistainer 14 0475 80101

Leica ST5020

13

Page 14

3. Instrument components and specifications

3.4 Technical Data

General

Approvals: The instrument-specific marks are located next to

the identification label

Nominal voltage: 100 V - 120 V +/- 10%

230 V - 240 V +/- 10%

Nominal frequency: 50 to 60 Hz

Maximum power draw: 1400 VA

IEC 1010 classifications: Protective class 1

Pollution degree 2

Overvoltage installation category II:

• 800 V impulse (120 V systems)

• 1500 V impulse (240 V systems)

Remote alarm relay: 24 V AC/DC, maximum 2 A

Connection:

potential-free contact

(can be operated both as normally open and as

normally closed circuit)

Primary fuses: Fa. Schurter: type FST, mains power inlet 2 x T 8 A

Secondary fuses: Melting fuse, Ø 6.3x32 mm

Type: Schurter FST

F1: T 2.0 A

F2: T 2.0 A

F3: T 2.5 A

F4: T 4.0 A

Operating temperature range: 15 °C to 40 °C

Relative humidity: 10% to 80%, non-condensing

14

Instructions for Use, V1.9, RevD - 12/2012

Page 15

3. Instrument components and specifications

Dimensions and weight

Basic instrument (W x D x H), in mm: 1060 x 750 x 540

Dry weight, unpacked: ca. 90 kg

Weight, packed: ca. 110 kg

Capacity data

Specimen slide throughput: depending on the program-structure

Loading capacity: max.12 slide racks (with 12 different Programs)

Slide rack capacity: 30 specimen slides

Total number of stations: 40 (36 + 4 Oven)

Total number of reagent stations: max. 34

Reagent container volume: 450 ml

Number of wash stations: max. 5 and 1 DI-water (optional)

Oven (optional): 2 or 4

Oven chamber temperature: 40 °C to 70 °C or 104 °F to 158 °F

Incubation time setting: 0 sec. up to 23 hours, 59 min., 59 sec.

Load/unload stations: max. each 4, min. each 1

Permanent memory capacity: max. 50 Programs, up to 40 program steps each

Integration: connection to Leica CV5030 Coverslipper (optional)

Leica ST5020

15

Page 16

3. Instrument components and specifications

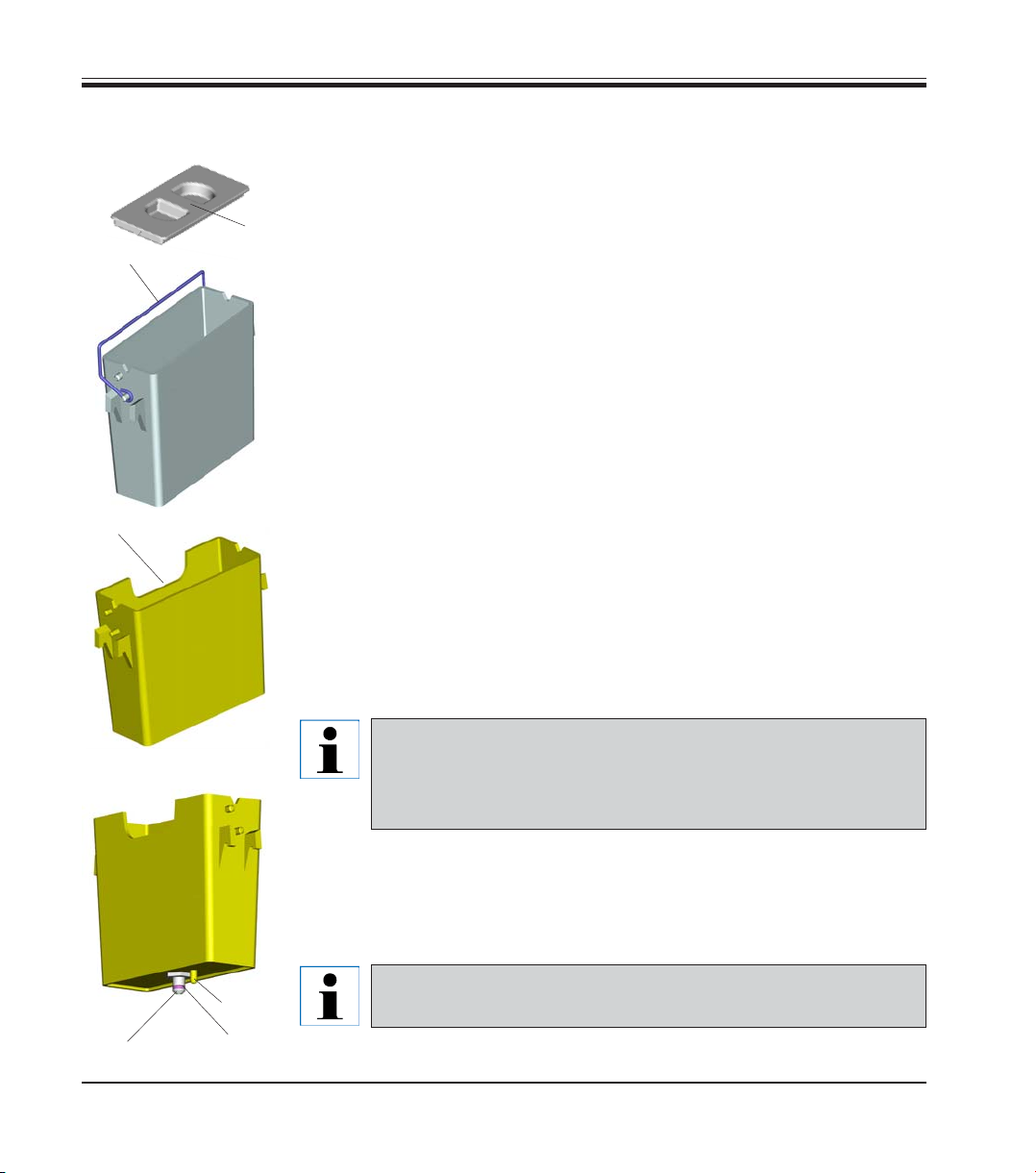

3.5 Container system

Reagent container

The Reagent containers can be individually removed for filling.

For use, fill the reagent containers to the line marked on the inside

6

(approx. 450 ml capacity) and place into position in the instrument consis-

1

3

tent with the programs you wish to run.

Ensure that the reagent containers are correctly seated and that the

handles (1) are over to the side and will not obstruct slide rack movement.

Lids (6) are provided to reduce evaporation while the reagent containers

are not in use.

The Load and Exit drawer containers (E25 and L36) can be filled with a reagent if desired.

However, the instrument will not control the immersion time in these stations.

Wash stations

The wash system consists of five (optional six) wash stations each capable of holding one slide rack. Water enters the wash station through a

connection piece (2) in the base and exits from the overflow lip (3) at the

top left hand edge.

16

Wash stations have a locating pin (4) and can only be inserted

one way. Take care when fitting or removing wash stations as

excessive force may damage the O-ring (5) used as a seal.

Lubricate the O-ring seal before fitting a wash station.

To use the wash system, slowly turn the laboratory tap on fully. The flow

control valve in the Leica ST5020 will limit the total water flow in the wash

stations to 1.6 liters/minute/station.

If the water flow drops below this level for any reason the

4

2

5

Fig. 4

wash period specified in the program may have to be extended.

Instructions for Use, V1.9, RevD - 12/2012

Page 17

4.1 Installation site requirements

4. Setting up the instrument

• Stable, exactly horizontal laboratory bench

with even surface of a minimum width of 1.60

m and minimum depth of 0.80 m.

• Tap water supply located a maximum of 2.50

m and waste water drain pipe a maximum of

2.00 m away from the corresponding in-/outlets at the rear panel of the instrument.

• If the instrument is to be operated with air

evacuation hose, a fume cupboard at a distance of maximum 3.50 m from the instrument is required.

Alternative: operation with activated carbon

filter.

• Sufficient space (ca. 0.90 m) above the laboratory bench for opening / closing the instrument lid without any problem.

4.2 Installing the instrument

• Virtually vibration-free floor.

• Stable ambient temperature between +10 °C

and +40 °C.

• Relative air humidity of maximum 80%, noncondensing.

• Do not place near instruments which might

be sources of vibration.

The chemicals to be used in the

Leica ST5020 are both flammable

and noxious. The instrument must

be set up in a well ventilated area,

free from any ignition sources.

Do not operate the instrument in

rooms with explosion hazard.

• To lift, grip the instrument by the carrying

handles (1, Fig. 5).

Leica ST5020

Four people are required to lift and/

or carry the instrument, as the instrument weighs a total of approx.

95 kg.

• Place the instrument onto the bench.

• Unscrew the carrying handles (remove

1

2

screws (2) with Allen key, size 6.0) and store

away.

• Pull off plastic cover.

Fig. 5

• Check whether all accessories have been

delivered as per your order.

17

Page 18

4. Setting up the instrument

4.3 Tap water supply connection

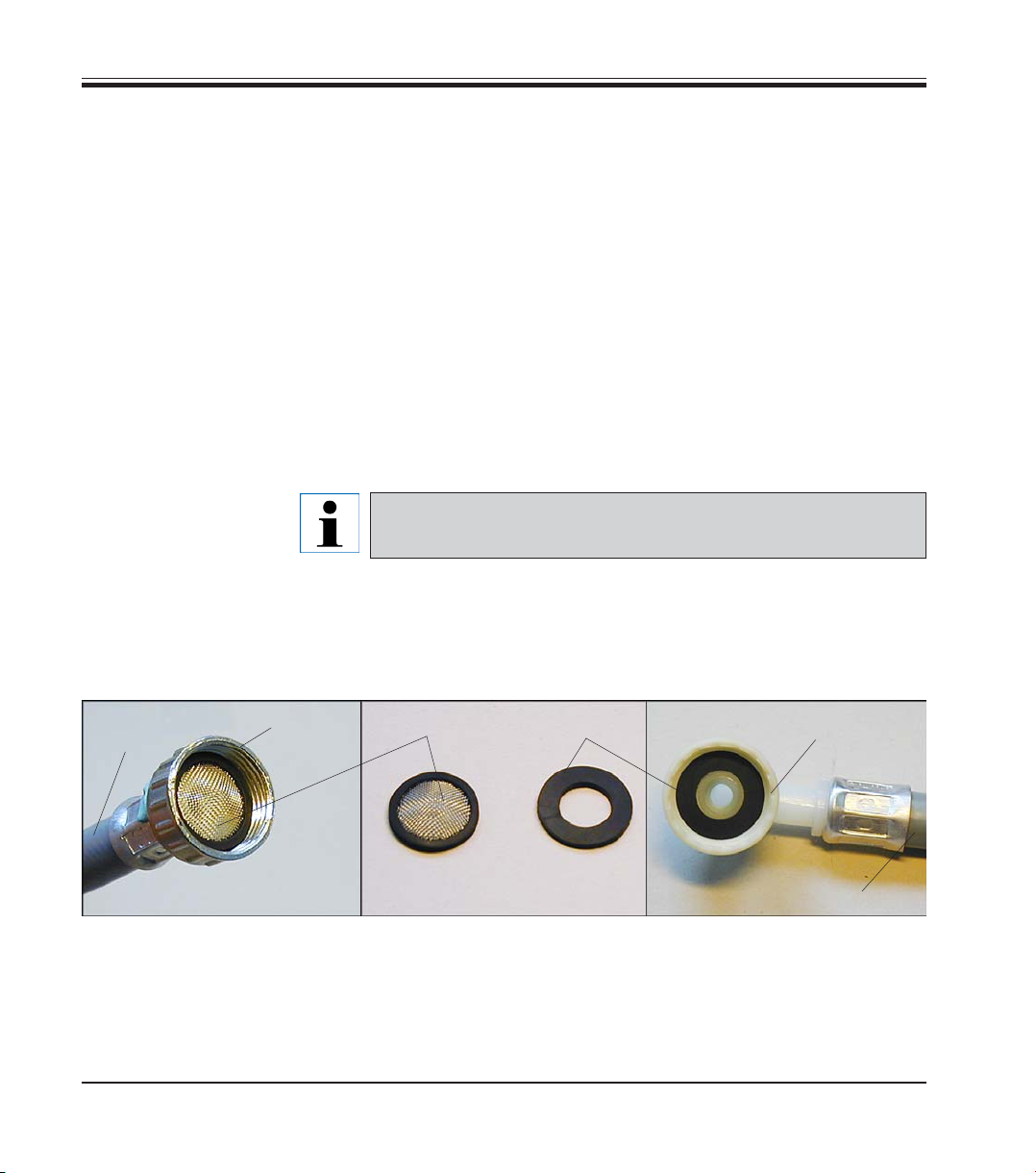

Water filter

In addition to the filter sieve supplied (item 3 in

installing a sediment filter between the water extraction outlet and

ST5020, to guarantee that the instrument is only operated with clean water.

This sediment filter should have the following properties:

Filter fineness: 25 μm

Rate of flow: approx. 10 l/min (with 5 wash stations)

Pressure constancy: 10 bar

Connection to the filter output: 1/2“ external thread

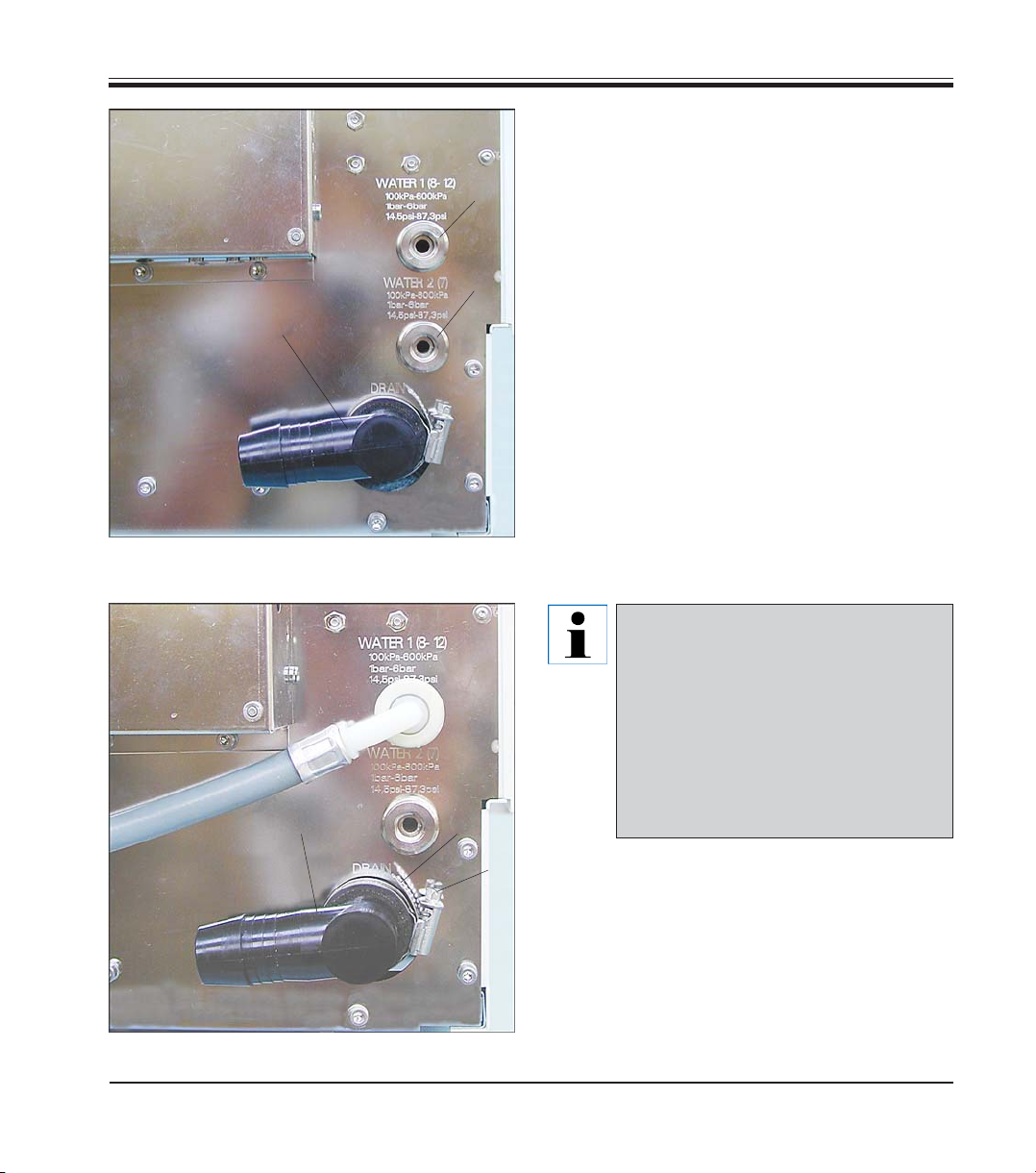

Connecting the tap water inlet hose

• Unpack the tap water inlet hose - mind the two gaskets (4).

7

5

Fig. 6) Leica recommends

This filter insert must be checked and cleaned regularly.

If the filter insert is very dirty it must be replaced.

3

4

6

Fig. 6

18

7

• Insert one gasket (4) into threaded fitting (6). Store away the remaining

gasket(s).

• Insert strainer (3) into union nut (5) (see

Fig. 6) which is screwed onto

the water tap. Do not insert any further gaskets, as the strainer acts

also as a seal.

Instructions for Use, V1.9, RevD - 12/2012

Page 19

Instrument rear panel

- tap water inlets

10

9

4. Setting up the instrument

• Screw tap water inlet hose (7 in Fig. 8) for

tap water stations 8 - 12 onto water tap and

insert the other end into inlet (8 in Fig. 7) .

8

• If station no. 7 (Fig. 3) will also be used as a

tap water station, connect a second tap

water inlet hose (optional accessory) to inlet

(9).

Fig. 7

Instrument rear panel

water in-/outlets

7

Leica ST5020

10

12

Inlet (9) only provides water (or any

other medium supplied via a separate connection) to station no. 7. To

use station 7 as a water station, a

wash vessel must be inserted and

station 7 must be defined as a ‘tap

water’ or ‘fully-de-ionized water’

station (DI water station) in ‘stations

options’. (see also Chapter 5.5.3)

11

Fig. 8

19

Page 20

4. Setting up the instrument

7

13

15

14

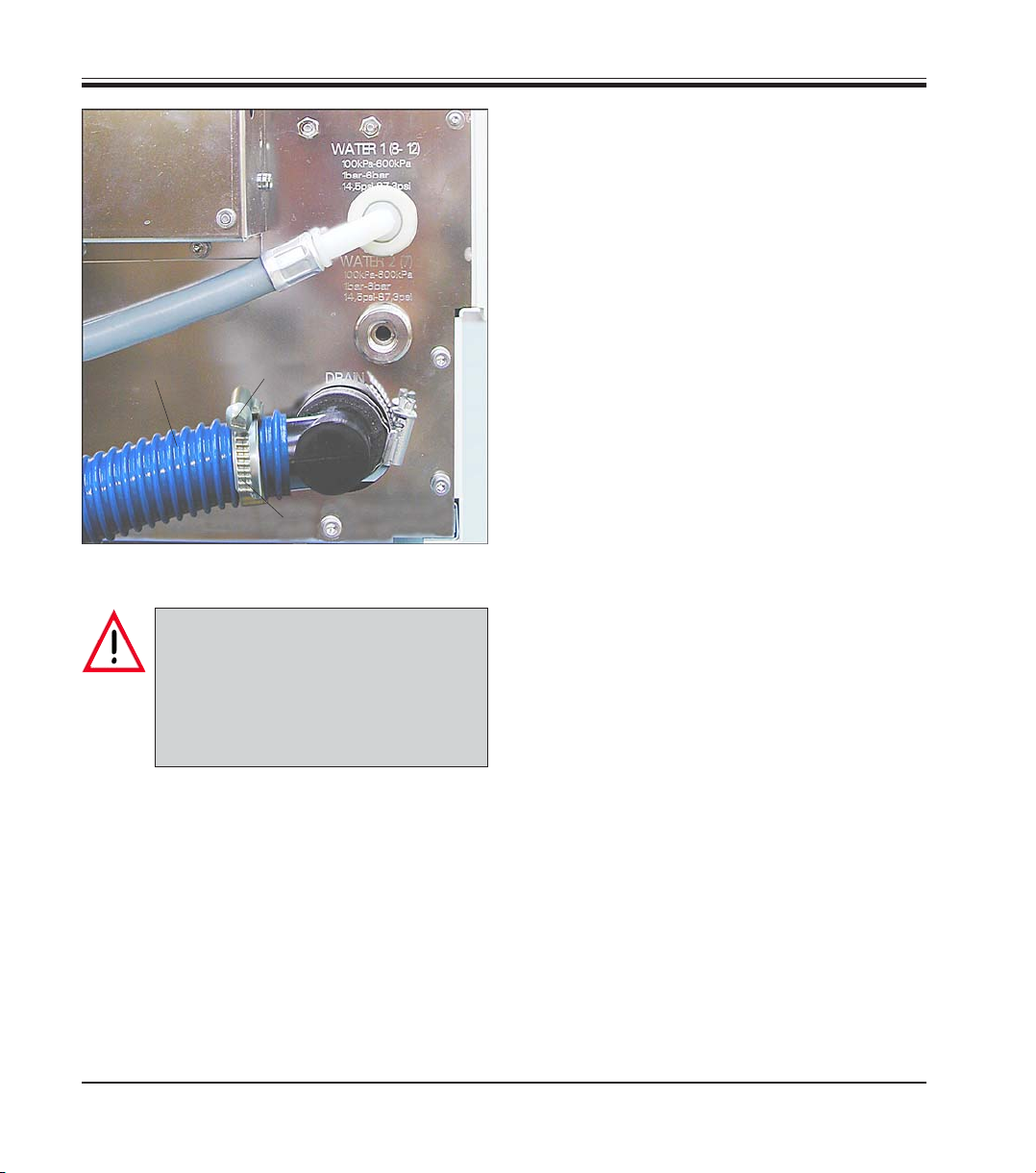

Connecting the waste water hose

• Outlet connection piece (10) can be turned

to point into different directions, depending

on whether the drain water pipe is located to

the left or to the right of the instrument.

• To adjust the connection piece, loosen

screw (11) of hose clamp (12) sufficiently so

that the connection piece (10) can be turned.

Adjust the connection piece as desired (always with the opening pointing slightly

downwards) and retighten screw (11).

• Turn screw (15) to the left (use screwdriver)

until hose clamp (14) opens wide enough to

be slid over waste water hose (13).

20

Fig. 9

Important!

When installing the drain hose always make sure there is a sufficient

descending gradient from the outlet

(connection piece (10)) on the instrument to the drain pipe!

• Fit waste water hose (13) onto outlet connection piece (10) and position hose clamp

(14) as shown in

Fig. 9.

• Turn screw (15) to the right until hose (13) is

secured tightly on connection piece (10) by

hose clamp (12).

• Insert waste water hose (13) into drain pipe

and secure in position.

Instructions for Use, V1.9, RevD - 12/2012

Page 21

4. Setting up the instrument

4.4 Installing the oven (optional)

15

16

Voltage setting

100 - 120 V

23

Voltage setting

230 - 240 V

Rear panel - oven

24

19

21

25

Fig. 11

• Take the oven kit out of the box and verify

whether it is complete.

The following parts must be included:

20

15 - Oven module

16 - Paraffin collecting tray

18

22

17 - Cover

18 - Screws

19 - Washers

20 - Screwdriver

21 - Allen key, size 2.5

22 - Allen key, size 4.0

17

Insert paraffin collecting tray

into corresponding opening in

oven module (possible only in

one direction, as shown here).

Fig. 10

• Check the voltage selector setting and ad-

just if necessary.

Important!

The voltage selector switch must be

set to the same mains voltage as the

instrument.

To adjust the voltage selector setting, insert

screw driver (20) into gap (23) and turn carefully until the white point above the correct

voltage indication is located underneath the

white triangle.

115 means: Instrument voltage 100 -120 V.

230 means: Instrument voltage 230 - 240 V.

Leica ST5020

21

Page 22

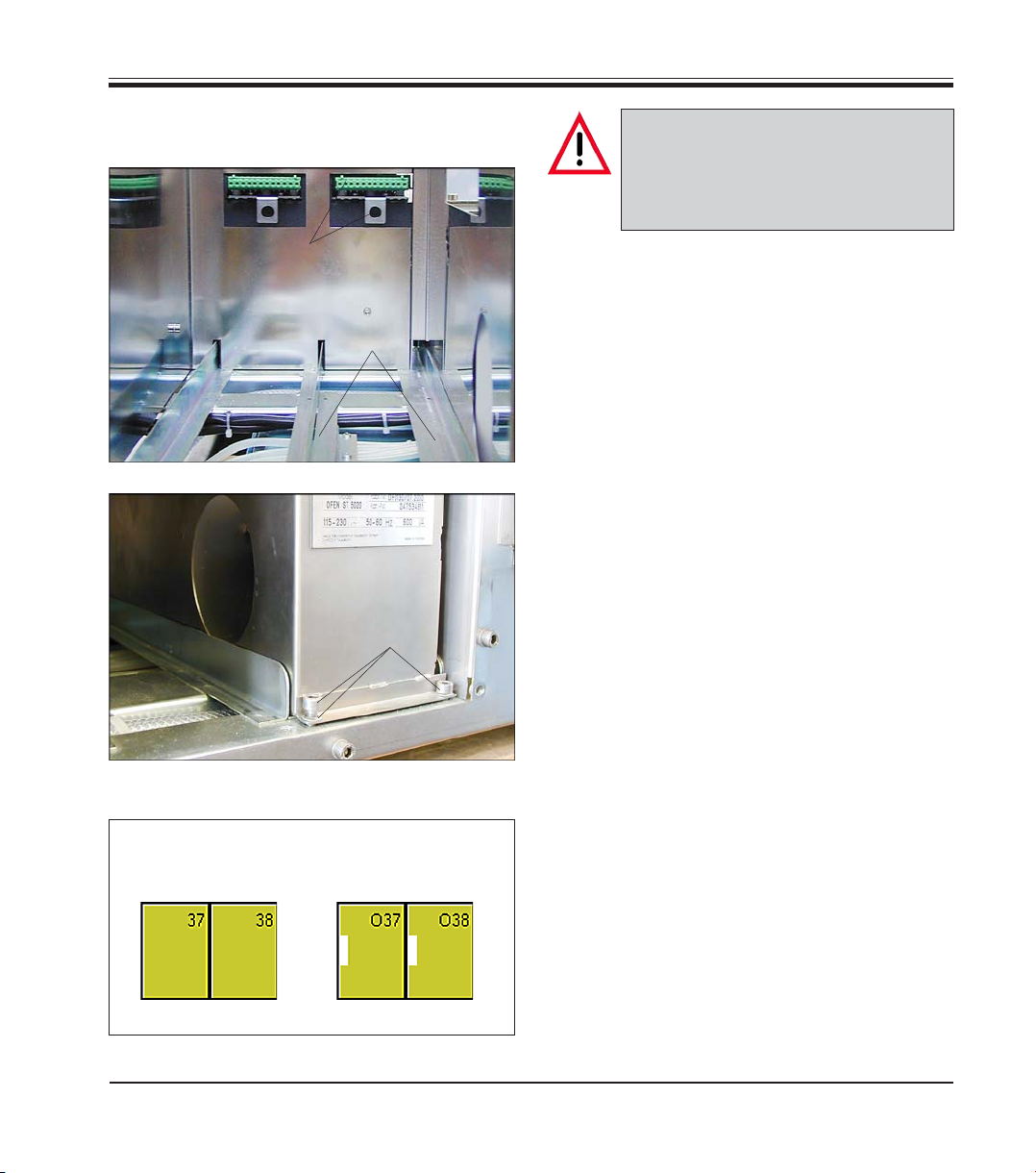

4. Setting up the instrument

27

Important!

Prior to taking any further installation steps, switch the instrument off

and unplug from mains.

29

28

26

29

30

• Cover panel (26) must be removed from the

right inner wall of the instrument, so that the

transfer arm can access the oven stations.

27

• To do so, remove six screws (27) (Allen key,

size 2.5) and remove cover panel (26).

• Store screws and cover panel in safe place

for further use.

Fig. 12

• Remove cover panel (28) located to the right

of the electrical connections at the rear wall

of the instrument.

• To remove panel (28), only remove screws

(29).

Do not loosen the two screws (30)!

22

29

29

Fig. 13

• Once the oven is installed, attach cover

panel (part of oven kit delivery) (17

in Fig. 10)

with four screws (29) in such a way that the

voltage selected is visible from the outside.

Instructions for Use, V1.9, RevD - 12/2012

Page 23

4. Setting up the instrument

Installing the oven

(continued)

31

15

32

18, 19

Fig. 14

Important!

If only one oven is installed, it must

be located on the right side (seen

from the rear of the instrument).

• Place oven on rails (32) and insert.

• Keep pushing until the connection pieces of

the oven (positioning pin (24), connector

strip (25), see

Fig. 11) lock into the corre-

sponding connections (31) in the instrument.

• Next, use the two screws (18) and washers

(19) to secure the oven (15) in the bores provided in the instrument for that purpose.

• If a second oven has been ordered, install it

the same way as the first.

Indication prior to

installing the ovens

Leica ST5020

INSTRUMENT STATUS

Indication with

ovens installed

Fig. 15

Fig. 16

• Fasten cover (item 17, Fig. 10) so that the

voltage range selected for the oven (15) is

the same as the engraved voltage range.

• Plug the instrument back into mains and

switch on. The oven modules are detected

automatically and are displayed accordingly

in ‘instrument status’.

• Go to ‘stations options’ and set the desired

oven temperature.

(See

chapter 5.5.3, page 56 for further de-

tails).

23

Page 24

4. Setting up the instrument

4.5 Connecting the air evacuation hose (optional)

64

65

63

62

61

66

68

63

60

Fig. 17

If the instrument is operated without activated

carbon filter, the air evacuation hose must be

installed instead.

The air evacuation hose is attached to fan housing (68) located at the rear left of the instrument. Unpack the components supplied and

check for completeness. The package must

contain the following items:

60 - Screw driver

61 - Allen key, size 2.5

62 - Hose clamp

63 - Allen screw with washer

64 - Hose connection piece with seal

65 - Air evacuation hose

65

64

67

62

66

• Fasten connection piece (64) with two

screws (63) into tap holes (66) in fan housing

(68).

• Turn clamping screw (67) to the left (use

screw driver (60) until hose clamp (62) is

loosened far enough so that it can be slipped

over the air evacuation hose.

24

Fig. 18

• Place air evacuation hose (65) together with

hose clamp (62) onto connection piece (64)

(see Fig. 18, right).

• Tighten screw (67) of hose clamp (62) (turn

to the right) to secure the hose.

Instructions for Use, V1.9, RevD - 12/2012

Page 25

4.6 Inserting the activated carbon filter

51

33

4. Setting up the instrument

Important for trouble-free

operation:

34

The sealing profiles (33) must

fit against the rear wall of the

filter housing (34).

Filter - inserted

Fig. 18

Make sure to insert the filter

with the correct side pointing

upwards: the three arrows on

the label (51) located at the

right of the filter must point to

front.

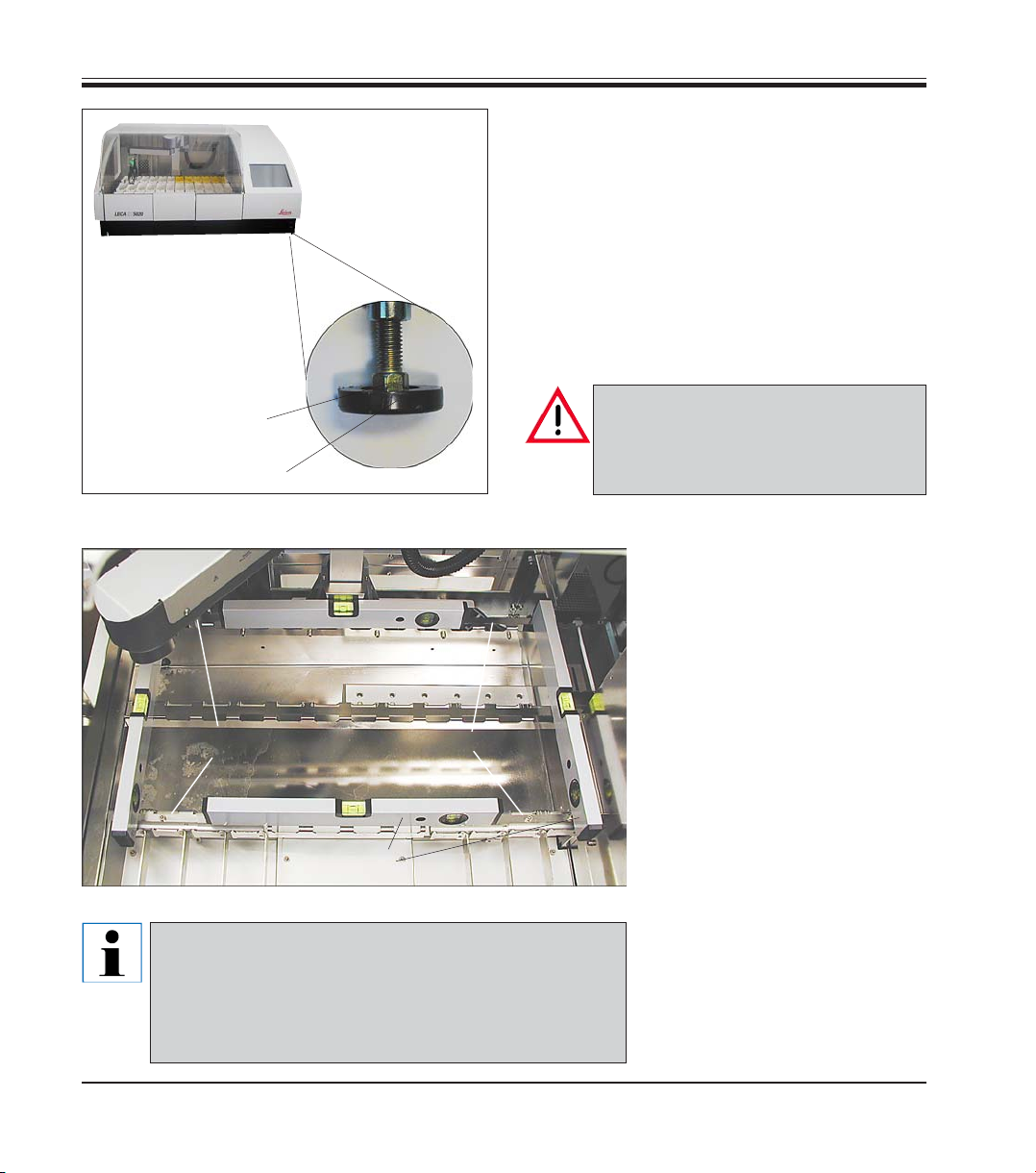

4.7 Leveling the instrument

• Once all accessories are installed (don’t forget the rear panel!), move

the instrument to its final position.

• Prior to leveling the instrument, check whether the bench surface of

the laboratory bench where the instrument will be installed is flat and

exactly horizontal.

• Otherwise, use the box level (standard delivery) to determine the highest point of the bench. Next, the instrument foot located at the highest

point of the bench must be screwed in almost completely (

- Then level the instrument adjusting each foot as needed.

Fig. 19

35

Once the activated carbon filter is inserted, push lever (35)

downwards to properly secure the filter in the filter

housing.

see Fig. 21).

Leica ST5020

25

Page 26

4. Setting up the instrument

instrument feet

Bring the instrument to

an exact horizontal position by screwing the adjustable feet in / out as

needed.

Adjustable

To do so, proceed as follows:

• Remove all vessels located in stations 1 - 24

so that the vessel holder frames can be used

to support the box level for measuring purposes.

• All four instrument feet (37) are height-adjustable.

To adjust, place single head wrench, size 13

(standard delivery) onto hexagon bolt (36)

and adjust each foot as needed.

36

37

Fig. 21

B

C

39

39

D

38

Abb. 22 shows all four points (A to D) where the box

level must be positioned for leveling the instrument.

For leveling, the box level must be placed onto vessel holder frame (39). - Do not place the box level

elsewhere.

Make sure, all four instrument feet

are firmly set on the bench surface

once the instrument adjustment has

been completed.

• For leveling, position box

level (38) alternately in positions (A and B) - see Fig. 22

on the vessel holder frame.

• Screw the instrument feet inward / outward as needed,

A

gradually bringing the instrument into a horizontal position. Start with the instrument

foot located opposite the

highest point of the laboratory bench.

Fig. 22

• Finally, place the box level in

positions (C und D) to doublecheck whether the instrument is in fact in a horizontal

position.

26

Instructions for Use, V1.9, RevD - 12/2012

Page 27

4.8 Electrical connection

The instrument MUST be connected to an earthed mains power outlet socket.

The instrument is supplied with a set of country-specific power cords.

Make sure to use the appropriate mains cable for the local voltage supply (wall outlet).

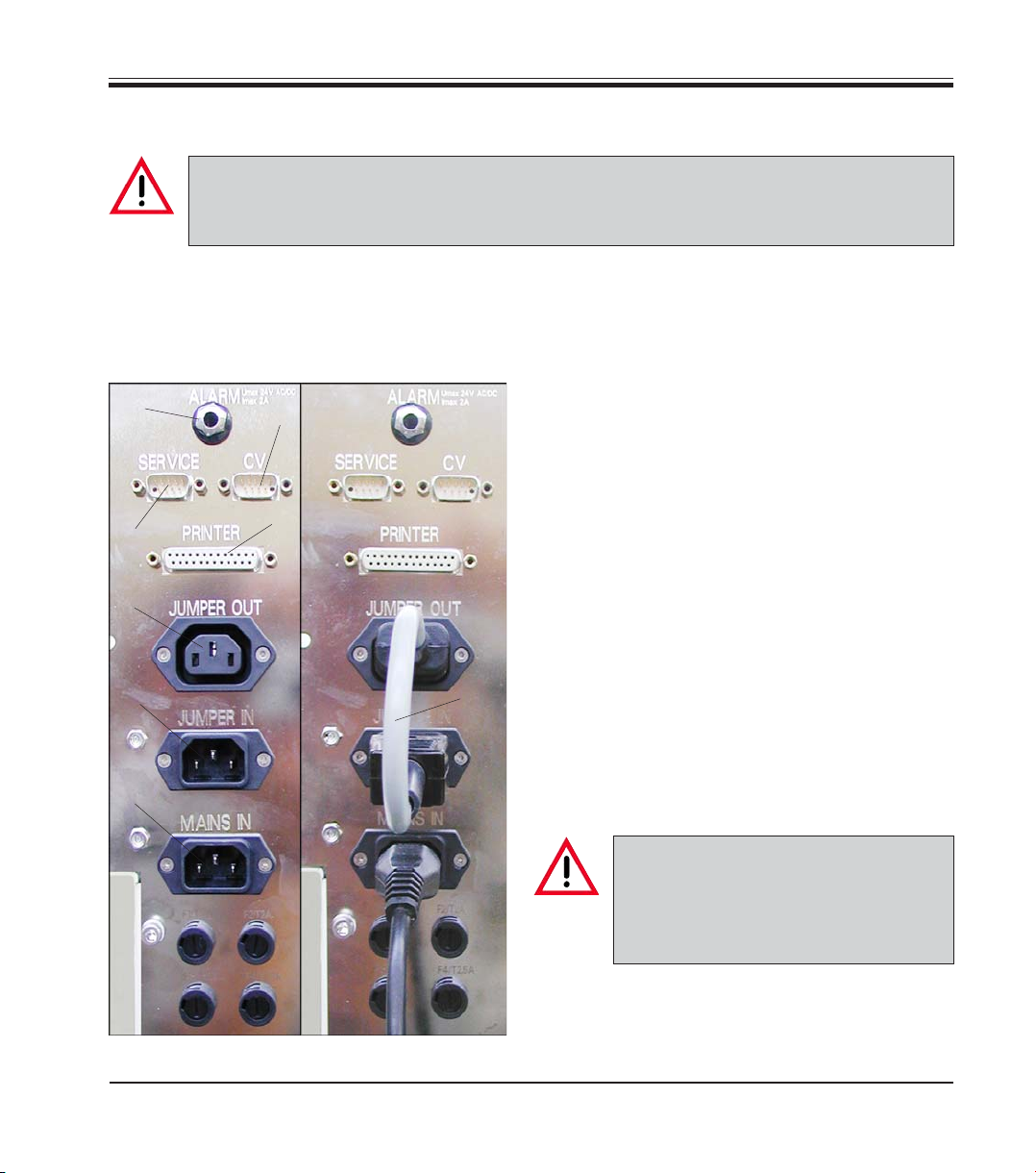

Sockets for mains power

supply and data transfer.

Secondary fuses.

50

48

44

45

42

Jumper cable / power cord

connected correctly

for mains power supply

49

47

43

4. Setting up the instrument

All electrical connections are located at the rear

of the instrument to the left (Fig. 23).

Power supply

• Connect mains cable to mains power supply

socket (42).

• Jumper cable (43) connects the mains power

supply output (44) to the electronics module

input (45).

Data connections

• Printer port (47)

A suitable printer (and cable) can be recom-

mended by your Leica distributor. If conformance to electromagnetic interference standards is essential, a specially shielded printer

cable will be required.

• Serial port (48)

Access for technical service.

• Connection for Leica CV 5030 Cover slipper

(49).

Leica ST5020

46

Fig. 23

All interfaces may be used only with

devices that have been tested in accordance with EN 60950 and which

satisfy the requirements for SELV circuits.

Other connections

• Socket for remote alarm system (50)

• Secondary fuses (46)

27

Page 28

4. Setting up the instrument

4.9 Alarm functions

Instrument alarm

The instrument alarm is generated from within

the Leica ST5020.

The instrument alarm is used for all alarm situations.

Remote alarm

This alarm is external to the Leica ST 5020.

Any alarm generated in the instrument, no matter of which alarm type, is passed on to the remote alarm system, even when the type 1 instrument alarm is switched off.

The remote alarm sound/volume is the same for

all alarm types - individual sound and volume

settings selected in the ALARM menu (see

chapter 5.4.2) are disregarded.

4.10 Transport

The following measures must be taken if the instrument is to be transported:

• Remove all the racks.

• Empty all reagent containers.

• Secure the transport arm of the instrument.

• Disconnect the instrument from the supply

voltage.

• Detach the water inlet hose and the water

drain hose.

• If necessary, detach the air evacuation

hose.

• Reattach the carrying handles (see

4.2).

• If the instrument is transported over longer

distances, pack the instrument in its original

shipping box and follow the measures for

securing it for transport.

Chapter

Connecting a remote alarm device

The remote alarm system which can be optionally connected works with a potential-free relay. If an alarm is generated, the alarm circuit

closes.

The remote alarm device connected to the instrument must be rated at less than 2 amp. A

maximum voltage of 24 V AC/DC may be present.

The remote alarm device is connected to the

printer via a 6.3 mm-diameter jack connector

(optional accessory).

For details on how to connect a remote alarm

device to the Leica IP, please contact your local

Leica sales office or the manufacturer Leica

Microsystems Nussloch GmbH directly.

Securing the transport arm:

• Change to the Supervisor mode.

• Call up the keyboard (e.g. as required for entering the password, see

• Enter the command “#transport“.

The arm moves down into station 6 where it remains and can no longer be moved.

After switching the instrument off, it is ready for

transport.

Chapter 5.4.3)

28

Instructions for Use, V1.9, RevD - 12/2012

Page 29

5.1 Switching the instrument on

Caution!

The instrument MUST be connected to an earthed mains power outlet socket.

It is recommended that the Leica ST5020 be plugged into a wall socket that has Ground

Fault Circuit Interruption (GFCI) protection - as an additional electrical safeguard.

• Before you connect the instrument to the wall socket, make sure the

mains switch at the bottom right of the instrument is in position OFF (‘0’).

• Connect the mains cable to the wall socket and switch on the mains

supply at the wall socket (if applicable).

• Switch the mains switch ON (‘I’).

5. Operation

• When switched on, the instrument will take a

few seconds to initialize. During initialization

the screen is blue, initialization progress is

indicated by a line of white dots.

• After approx. 30 seconds, the graphic surface will become visible. The working area is

still black. A row of “X“ displays the software loading in the information line.

• Next, the LANGUAGE CHOICE menu (

Fig. 24)

will be shown on the screen for approx.

three secs.

Fig.8

• If you select a different language (press the

corresponding button), the MAIN MENU

(Fig. 32, chapter 5.3.4) will be shown next, in

the new language selected.

• If no changes are made, the INSTRUMENT

STATUS menu (

Fig. 25) will open up.

INSTRUMENT STATUS is the standard

screen - all functional descriptions in the

present

chapter 5 start from INSTRUMENT

STATUS.

Leica ST5020

Fig. 24

Fig. 25

29

Page 30

5. Operation

5.2 Setup checklist

Once the instrument is ready to be switched on, all menus listed below must be accessed

and the necessary parameters be properly selected. The Supervisor mode must be active

to have access to all menus. For detailed advice on how to select individual parameters,

refer to the on-line help feature.

Screen →

→

→

→→

→→

→

←

→

Press button

↓

↓

Parameter settings

Select a language - either when switching the instrument on or in the LANGUAGE CHOICE menu.

In USER INTERFACE, set parameters as required.

Verify whether DATE and TIME are correctly set.

Open the REAGENT LIST menu, check the settings

and complete, if necessary.

In INSTRUMENT STATUS, select a STATION TYPE

for each station.

Allocate the correct reagent to each STATION.

Reagents can be allocated either when creating the

programs or in the STATION DETAILS menu.

Be sure to fill the reagent containers with the correct reagents (as allocated)!

Create the PROGRAMS needed.

Existing programs can be copied and modified.

30

→→

→→

→→

In MOVE, select the number of dips and the speed of

the transfer arm.

Allocate a CLIP COLOR to each clip.

Select time, quantity and paper format of the daily

printouts.

Instructions for Use, V1.9, RevD - 12/2012

Page 31

5.3 Touch screen functions

5.3.1 User interface - overview

The Leica ST5020 Multistainer is programmed and

operated via a colored TFT- touch screen.

Basic screen layout

Only those control elements that can actually be accessed by the user are displayed on the screen.

The number of accessible control elements depends

on the access level selected.

Current

date

Current

time

Instrument

name

Menu

currently

selected

Information

line

Access level

selected

5. Operation

The screen is

horizontally

divided into

three functional areas:

↓↓

↓

↓↓

Status bar

Up one

menu level

Leica ST5020

Area for buttons

displayed depen-

ding on current

menu

Up one level

to main

menu

Switching from

user to supervisor

access level and

back

Operation

Button bar

Fig. 26

On-line help

on current

menu

31

Page 32

5. Operation

Button symbols

Enabled

Disabled

The six buttons described below have the same function in all menus.

On the left side of the button bar (

Fig. 26) there will either be the button

BACK → To go back to the previous menu.

or the two buttons

CONFIRM → To exit the current menu (new entries will be

stored upon exiting).

CANCEL → To exit the current menu without storing any

of the modifications made.

PRINT → Displayed in menus containing tables and lists.

If pressed, the list selected will be printed

immediately. Immediate printing does not affect the

daily printout of all protocols (

MENU → To go back to the main menu (

see chapter 5.4.6).

see chapter 5.3.4)

HELP → The on-line HELP feature can be accessed from

any screen. HELP provides context-sensitive

explanations, i.e. help topics displayed will vary

depending on the menu HELP is accessed from.

Some button symbols may look differently depending on whether they

have been enabled or disabled.

Disabled button symbols appear in a lighter color than enabled ones.

They are only shown to complement the menu being displayed, in order to avoid mix-ups and to remind the user that the corresponding

function has been disabled. They can, however, not be accessed.

32

→

There are several functions where the user can choose from a number

of given parameters.

If there are only two parameters available, the parameter currently enabled is shown on the button. Pressing the button switches to the alternative parameter.

If there is a choice of more than two parameters, the range of available

parameters is shown on the button in square brackets.

Each time the button is pressed, the next parameter is accessed, starting again with the first after the last one in the row has been selected.

Instructions for Use, V1.9, RevD - 12/2012

Page 33

Tables/lists

5. Operation

The program contains numerous tables.

The first row of a table contains the headers of

the individual columns.

The rows below contain the actual content.

Selected rows appear in blue color (1).

1

Fig. 27

2

3

Fig. 28

When a tabled is accessed, the blue bar is always located in the first content row.

If a table is empty, no blue bar is displayed.

Headings of column where parameters can be

entered by the user (in supervisor mode) (

Fig.28)

are displayed as buttons (3).

In supervisor mode, some tables also contain a

number of additional buttons (2), depending on

the parameters selectable.

Leica ST5020

The navigation buttons are located at the right border of the screen.

Each table contains two navigation buttons for row-by-row scrolling.

Each time one of the buttons is pressed, the highlighting bar is moved one

row up or down. You can also highlight rows by touching them directly.

For long lists, a set of page-up / page-down buttons will be displayed in

addition.

Pressing on of these buttons moves the highlighting bar one entire page

up or down; the last (first) row of the current page will be the first (last)

row of the new page. If there is no entire page left to the beginning (end)

of the table, the new page will be displayed starting with the first row

(ending with the last row) of the table with the highlighting bar jumping to

the first content row on the page.

Each table contains a PRINT button. If the button is pressed, the current

status will be printed out immediately.

33

Page 34

5. Operation

5.3.2 Data entry

Parameters and data can be set / entered several different ways:

Alphanumeric keyboard

4 5

The maximum number of characters to be entered may not be exceeded.

The following numbers are predefined:

Reagent names: maximum 20 characters

Program names: maximum 20 characters

Program abbreviation: maximum 3 characters

Passwords: minimum 4 characters, maximum 20 characters.

The following buttons have special functions:

If pressed, button remains locked, all letters will be displayed in capitals.

After the first button has been pressed, SHIFT is released and the keyboard will return to small letters.

Fig. 29

The alphanumeric keyboard (Fig.

29) resembles a computer key-

board. An entry field (5) and instructions on what kind of data to

enter (4) are located above the

keyboard. The amount of characters that can be entered varies,

depending on the type of data to

be entered. If there is a predetermined number of characters to

be entered, that number will be

displayed in the entry field. The

cursor is located on the left.

34

If pressed, button remains locked - all letters will be written in capitals.

Press SHIFT LOCK once more to return to small letters.

Press this button to display special characters, above all vowels carrying

accents. These can also be displayed in capitals by pressing SHIFT/SHIFT

LOCK. After a special character has been selected, the keyboard automatically reverts to standard indication.

Instructions for Use, V1.9, RevD - 12/2012

Page 35

Navigation buttons

Numerical keyboard

5. Operation

The navigation buttons have the same function in both keyboard types

(numerical, alphanumeric):

• Cursor jumps to the left / right border of the entry field.

• Cursor is moved one character to the left / right.

• Character on the left of the cursor is deleted.

• Entry field located above the numeric keypad (left

6

Fig. 30

aligned). Instructions on which parameter to be entered (6) are displayed above the entry field. Entry

position is marked by cursor, default parameters will

be stored. Pressing a numerical key deletes default

parameters.

• If a figure entered exceeds or falls short of a limit

setting, that limit setting will be displayed when

CONFIRM in the menu bar is pressed and the entry

field will not be exited.

• Depending on the type of entry to be made, only a

limited number of numeric characters can be entered.

• Press CONFIRM or CANCEL to exit the numerical

keypad.

Leica ST5020

Press CONFIRM to store entries and go back to the previous menu.

Press CANCEL to go back to the previous menu without storing any new

entries.

35

Page 36

5. Operation

5.3.3 Access levels

Administrator symbol

→

User symbol

Fig. 31

The Leica ST5020 may be configured to allow

two level of user access.

User access level

• Users may run programs and view results.

On this level, the USER symbol is displayed

in the upper right corner of the touch screen.

Supervisor access level

• Administrators may perform all user functions, and additionally create programs and

perform the instrument setup functions.

• To access supervisor level, press SUPERVI-

SOR: the keyboard will be displayed. If a

password has been allocated, the keyboard

will appear on the screen.

chapter 5.4.3 for details on password

(See

allocation).

Enter the ‘Admin’ password and confirm.

The SUPERVISOR symbol will then be displayed instead of the USER symbol and the

SUPERVISOR button will be replaced by the

USER button.

36

In SUPERVISOR mode, NO programs

can be run. Switch to USER mode to

start a program.

You can only go back to SUPERVISOR mode (e.g. to select / change

settings) once all running programs

have been finished.

The Leica ST5020 may be configured

so that all functions are accessible

to all staff - effectively the instrument is in Supervisor access level

the whole time. See chapter 5.4

“System setup“.

Instructions for Use, V1.9, RevD - 12/2012

Page 37

5.3.4 The main menu

After switching the instrument on, the main menu will be displayed only if the language is

changed. INSTRUMENT STATUS is actually the standard screen.

In all functional descriptions below, INSTRUMENT STATUS is assumed to be the standard

screen, all buttons shown start from INSTRUMENT STATUS.

↓

5. Operation

Opens up the main menu from where all program functions can be accessed.

The main menu can be accessed directly from almost all functions.

To be able to access

all necessary settings, the instrument

must be operated in

SUPERVISOR mode.

Fig. 32

From the main menu, four subordinate menus can be accessed:

• INSTRUMENT STATUS see chapter 5.5

• STAINING SCHEDULE see chapter 5.7

Leica ST5020

• PROGRAMS see chapter 5.6

• OPTIONS see chapter 5.4

37

Page 38

5. Operation

5.4 System SETUP

In OPTIONS you find all submenus which

• determine what the user interface looks like:

- USER INTERFACE

- CLIP COLOUR

- DATE/TIME

• manage the reagents:

- REAGENT LIST

• control the print functions (optional)

- VIEW/PRINT

All of the settings for the menus STATION OPTIONS, USER INTERFACE, REAGENT LIST and

VIEW/PRINT can be accessed in user mode. All other menus require administrator mode.

Determine speed

and number of

dips

→

• determine the station type and allocate

reagents:

- STATION OPTIONS

• define the dips / transfer speed:

- MOVE

• allow user data to be loaded and backed up

- BACKUP

Set user-defined

system parameters

Set and control

stations

Allocate and

control reagents

Detect color of

unknown clip and

allocate

38

Calibrate screen

Define screen

displays and

printouts

Backup and read in

all user data

Set / control date

and time

Fig. 33

Instructions for Use, V1.9, RevD - 12/2012

Page 39

5. Operation

5.4.1 User interface

→

In this screen you can select:

• BRIGHTNESS OF SCREEN

• TEMPERATURE MEASURING UNIT

• BUTTON CLICK

Two measuring units can be chosen from:

• The parameter selected is displayed on the

button, next to the “=“ sign.

→

←→

Fig. 34

↓

• Press the button to switch to the alternative

measuring unit.

Leica ST5020

Language selection

To select between the two languages that are

available, one of these two languages always

being ‘English’.

The second language (default = German) next to

English is exchangeable.

A PCM-CIA expansion card containing the desired language is needed.

Switch the instrument off and insert the PCMCIA card into the slot next to the mains switch.

Switch the instrument back on, the new language will be automatically loaded.

Fig. 35

39

Page 40

5. Operation

5.4.2 Alarm

→

There are three different types of alarms, each one allocated to certain events. Alarm type

1 can be simply switched off, alarm types 2 and 3 cannot.

Fig. 36

Different sound signals, in several intensity levels, can be allocated to

each alarm type.

→

Alarm type 1:

Alarm 1 is generated when user intervention is

required.

Alarm type 2:

An error has occurred or user intervention is urgently required.

Alarm type 3:

A serious error has occurred.

Follow the instructions provided by the error

message.

If the same error occurs repeatedly, call Leica

Technical Service.

→

40

ALARM TYPE X

• Allocates one of four different sounds to the alarm type. Each time the

button is pressed, a different sound is allocated.

SOUND INTENSITY = Z

• Selects the intensity of the sound. For alarm type 1 settings from 0 to 4

are possible. Intensity level = 0: alarm sound switched off.

For alarm types 2 and 3 only intensity levels 3 and 4 can be set.

The level currently selected is indicated on the button.

TEST

• The alarm type set (sound, intensity) will sound for approx. 10 secs.

→→

→ SOUND Y

→→

Instructions for Use, V1.9, RevD - 12/2012

Page 41

5. Operation

The table below shows the specific events each individual alarm type is allocated to.

Time/Location Event Alarm ceases / switched offAlarm type

Instrument

being

switched on:

Drawers:

Staining:

Alarm 1

Alarm 3

Alarm 3

Alarm 3

Alarm 3

Alarm 1

Alarm 1

Alarm 1

Alarm 3

Alarm 3

All unload containers occupied when instrument is

switched on.

Switching on after power failure while staining

procedure was in progress.

Load/unload drawer open - time limit exceeded.

Load/unload drawer opened while gripper located

in drawer area.

Unload drawer is full or rack was placed into the

unload drawer.

Rack bearing a clip of a color not allocated to any

program placed into load station.

Rack bearing a white clip placed into load station.

Rack bearing an unknown clip placed into load

station.

Pause button has been pressed.

Unload drawer occupied, gripper attempting to

unload completed rack.

- When all racks have been removed.

- When dialog box is acknowledged.

- After drawer has been closed.

- After drawer has been closed.

- After rack has been removed, dialog box has been acknowledged.

- After rack has been removed or

program allocated.

- After rack has been removed or

program allocated.

- After rack has been removed or

color allocated to unknown clip.

- When leaving pause mode.

- After dialog box has been akknowledged (‘successfully removed’).

Ovens:

Malfunctions

requiring

service:

Coverslipper:

Leica ST5020

Alarm 3

Alarm 2

Alarm 3

Alarm 3

A program the last step of which is not allocated to

the unload drawer has been completed. - Rack

must be removed.

One of the ovens does not reach set temperature.

If the error occurs again, there will be a second

alarm after 60 seconds.

Hardware failure, e.g. motion error of transfer arm.

If the error occurs again after the instrument has

been switched back on, the alarm will immediately

sound again.

If the coverslipper requires an intervention by the

user to function or continue functioning.

- After dialog box has been akknowledged (‘successfully removed’).

- After dialog box has been akknowledged

- After dialog box has been akknowledged and instrument switched off.

- After dialog box has been acknowledged

41

Page 42

5. Operation

5.4.3 Password allocation

Any changes in this menu require supervisor access level.

You may switch to supervisor mode only while no racks are being processed.

Switching password verification on/off

When switching between user and supervisor mode, switch the password

verification on or off:

• Press PASSWORD VERIFICATION.

• The alphanumeric keyboard opens up - enter the password.

• If the password is correct, the password verification button will be

switched from ‘yes’ to ‘no’ and vice versa.

Changing the supervisor password

• To change the password, the currently valid password must be entered first.

• Press ENTER, (keyboard opens up) and enter the current password.

• If an erroneous entry is made, an error message will be displayed

which must be acknowledged.

→

→

→

42

Fig. 37

Attention!

• A distinction is made between capital and

small letters.

If the entry made is correct, the new password will have to entered twice. Each time,

press ENTER.

After the new password

has been entered twice, a

confirmation message will

be displayed.

•

Fig. 37 shows all three command prompts

displayed when changing the password.

Instructions for Use, V1.9, RevD - 12/2012

Page 43

5. Operation

5.4.4 Set date/time

Many of the instrument functions are time-controlled. - therefore it is very important to set

date and time correctly.

Date

Fig. 38

→

→

The DATE / TIME window displays the current

calendar month.

• To set the DAY press the corresponding button.

• Set MONTH and YEAR using the

arrow buttons.

• After having set the date, press

CONFIRM to exit.

Time

Leica ST5020

• To set the time, press TIME - the

TIME window opens up.

• Use the arrow buttons to set

HOURS and MINUTES.

• As soon as you press CONFIRM

to store your entries, the clocks

starts running.

Fig. 39

43

Page 44

5. Operation

5.4.5 Movement

Any changes in this menu require administrator mode. For this reason, changes can only

be performed if no staining programs are active.

The parameters set in MOVEMENT are valid for all programs.

→

→

For

• NUMBER OF DIPS

• DIP AMPLITUDE

• LIFTING SPEED

only the settings indicated on

the buttons can be selected.

The currently selected setting

shows on the button next to the

“=“ symbol. Press the button to

go to the next higher setting.

• NUMBER OF DIPS:

Indicates how often the gripper dips the rack

into a reagent container before the rack is

immersed in that container. ‘Yes’ must be

selected in the DIPS column of the corresponding program.

No dips are performed if the setting

“Number of Dips = ’0’“ is used, even

if ‘Yes’ is entered in the DIP column

in the program.

44

Fig. 40

• DIP AMPLITUDE:

Defines the stroke length of the arm when

dipping the rack (‘2’ = longer stroke than ‘1’).

• LIFT SPEED:

Indicates at what speed racks are removed

from reagent containers. The smaller the

numbers selected, the slower the speed. At

slower speeds, less reagent is carried over.

Instructions for Use, V1.9, RevD - 12/2012

Page 45

5. Operation

5.4.6 View and print

→

→

To view all stored protocols. The

button bar of each protocol contains a PRINT button for individual

printouts of each protocol.

• Printing is possible only when a printer is

connected.

• Pressing the PRINT button starts printing the

selected list immediately. If printing is not

possible, the button is disabled.

• Press PRINT ALL to immediately print all six

protocols. Each protocol will start on a new

↓

Fig. 41

↓

page.

Press PRINT OPTIONS to determine which pro-

tocols will be printed at what time.

• “Daily printout“ can be switched OFF and

ON for each protocol (press the corresponding ‘yes / no’ button).

Leica ST5020

→

Fig. 42

If OFF is selected for all printable

protocols, no daily printout will be

made. This does not affect the immediate printout function.

• Press PAPER FORMAT to select between

formats A4 and B4.

• Press DAILY PRINTOUT TIME to access the

daily printout time submenu. Select the daily

printout time as described above.

45

Page 46

5. Operation

5.4.7 Reagent list

The reagent list is an integral part of the user interface and can therefore be accessed

from several different menus. Adjust it to the current reagents as soon as possible, as this

makes programming considerably easier.

Fig. 43

→

• There is a default list of standard reagents

containing all reagents needed for the most

common staining methods.

• All reagents are listed in alphabetical order.

A blue background indicates that a reagent

has been selected.

• Before you allocate any reagents to any programs, make sure to update the reagent list

according to the reagents actually used, i.e.

add reagent names that are not part of the

list and delete reagents that are not used.

• The Reagent - Management - System (RMS)

can be switched on / off in this menu.

→

Adding a reagent to the list

↓

↓

46

←→

• Press NEW - the keyboard opens up.

• Enter the name of the new reagent and confirm.

Up to 20 characters per reagent can be entered.

• The new reagent will be added to the table where it alphabetically belongs and highlighted with the blue bar.

The alphabetical sorting function distinguishes between

small and capital letters as per the ASCII code. Capital

letters precede lower case letters.

Instructions for Use, V1.9, RevD - 12/2012

Page 47

5. Operation

Setting RMS data

↓↓

Deleting a reagent

↓

If the Reagent Management System

(RMS) is switched on, the table headers are displayed as buttons.

The following limit parameters can be defined

for the RMS:

• Maximum number of days the reagent may

be used.

• Maximum number of racks that can be

processed until the next reagent change.

In ‘instrument status’ a red bar in the

station button indicates how long a

reagent has already been used depending on the values entered here.

The longer the red bar, the closer the

time when the reagent will have to

be changed. (See chapter 5.5.1)

Press the header buttons to access the corresponding numerical keypads for entering RMS

data.

Fig. 44

Numbers between 1 and 99 can be entered in

both columns.

• Highlight the reagent you want to delete from the list.

• Press DELETE and confirm the screen prompt. The reagent is removed

from the list and the blue highlighting bar moves one row down.

Leica ST5020

Reagents can only be deleted if they are NOT allocated to any

program or station. Otherwise there will be a message that deleting is not possible.

47

Page 48

5. Operation

The RMS log

The Leica ST5020 is equipped with a Reagent Management System (RMS) graphically

representing processing history of reagents in ‘Instrument Status’ (

These reagent data are stored in the RMS log table.

→

→

→

see chapter 5.5.1).

The RMS log table lists all reagent stations, the reagents allocated to each station as well

as their processing history.

Last change

Date when the reagent was last

changed.

Racks

Number of racks that have been

processed in a particular station since the reagent was last

changed.

→

Information contained in a table row:

Station

Shows the numbers of those stations defined as

reagent stations.

Reagent

Reagent currently in a station or to be added to

that station. The Leica ST5020 does not recognize reagents automatically - reagents are allocated by entry into the reagent list.

48

Fig. 45

Racks max.

Maximum number of racks that should be processed in a particular station without the reagent being changed.

Days

Number of days since the reagent was last

changed.

Days max.

Maximum number of days the reagent should

remain in the station without being changed.

Instructions for Use, V1.9, RevD - 12/2012

Page 49

5. Operation

5.4.8 Station options

This screen provides an overview of all stations. Detailed information on individual stations can be retrieved. Rack movements, however, are not shown.

8

→