Page 1

Instructions for Use

Leica ST4020

V1.1, English – 10/2012

Order No. 14 0509 80101 RevB

Always keep this manual with the instrument.

Read carefully before working with the instrument.

Leica ST4020

Small Linear Stainer

Page 2

Page 3

NOTE

The information, numerical data, notes and value judgments contained in this documentation

represent the current state of scientific knowledge and state-of-the-art technology as we understand it following thorough investigation in

this field.

We are under no obligation to update the

present manual periodically and on an ongoing

basis according to the latest technical developments, nor to provide our customers with additional copies, updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations etc. contained in this manual we

exclude liability as far as permissible according

to the national legal system applicable in each

individual case. In particular, no liability whatsoever is accepted for any financial loss or consequential damage caused by or related to

compliance with statements or other information in this manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the present manual are not to be considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it

possible continuously to improve the technology and manufacturing techniques used in our

products.

This documentation is protected under copyright laws. All copyrights of this document are

retained by Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods—including any electronic systems and media—requires express prior permission in writing by

Leica Biosystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the nameplate at

the back of the instrument.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 (0) 6224 143-0

Fax: +49 (0) 6224 143-268

Internet: http://www.LeicaBiosystems.de

Leica ST4020

3

Page 4

Table of Contents

1. Important Information ................................................................................................................ 6

2. Safety ............................................................................................................................................ 7

2.1 Safety notes ........................................................................................................................................ 7

2.2 Warnings ............................................................................................................................................. 7

3. Instrument Components and Specifications....................................................................... 10

3.1 Overview – Instrument Parts .......................................................................................................... 10

3.2 Instrument specifications ............................................................................................................... 11

3.3 Functional Description of Components - System overview....................................................... 12

3.3 Functional Areas of the Slide Carrier ............................................................................................ 14

3.4 Standard delivery ............................................................................................................................. 15

3.5 Technical Data .................................................................................................................................. 16

4. Setting Up the Instrument ....................................................................................................... 17

4.1 Location Conditions ......................................................................................................................... 17

4.2 Unpacking the Instrument............................................................................................................... 17

4.3 Setup .................................................................................................................................................. 19

4.4 Water Connection ............................................................................................................................ 20

4.5 Installing the Rinsing Water Containers ....................................................................................... 20

4.6 Remedy if hose is too short............................................................................................................. 24

5. Operation ................................................................................................................................... 25

5.1 Switching on the Instrument .......................................................................................................... 25

5.2 Control Panel Functions .................................................................................................................. 25

5.3 Setting the Operating Parameters ................................................................................................. 27

5.4 Setting the Rinsing Water Flow Rate ............................................................................................ 30

5.5 Processing Slides ............................................................................................................................. 31

5.5.1 Starting a staining run ..................................................................................................................... 32

5.5.2 Adding more slide carriers during a staining run........................................................................ 33

5.5.3 Temporarily pausing a staining run ............................................................................................... 34

5.5.4 Ending a staining run prematurely ................................................................................................. 35

5.5.5 Removing Processed Slides ........................................................................................................... 36

4

Instructions for Use V1.1, RevB – 10/2012

Page 5

Table of Contents

6. Cleaning and Maintenance .................................................................................................... 38

6.1 Cleaning the Instrument .................................................................................................................. 38

6.2 Maintenance Instructions............................................................................................................... 39

7. Troubleshooting ....................................................................................................................... 40

7.1 General ............................................................................................................................................... 40

7.2 Alarms ................................................................................................................................................ 40

7.3 Fault Detection and Correction List ............................................................................................... 41

7.4 Power Failure .................................................................................................................................... 43

8. Optional accessories .............................................................................................................. 44

8.1 Ordering information ........................................................................................................................ 44

9. Warranty and service .............................................................................................................. 51

Leica ST4020

5

Page 6

1. Important Information

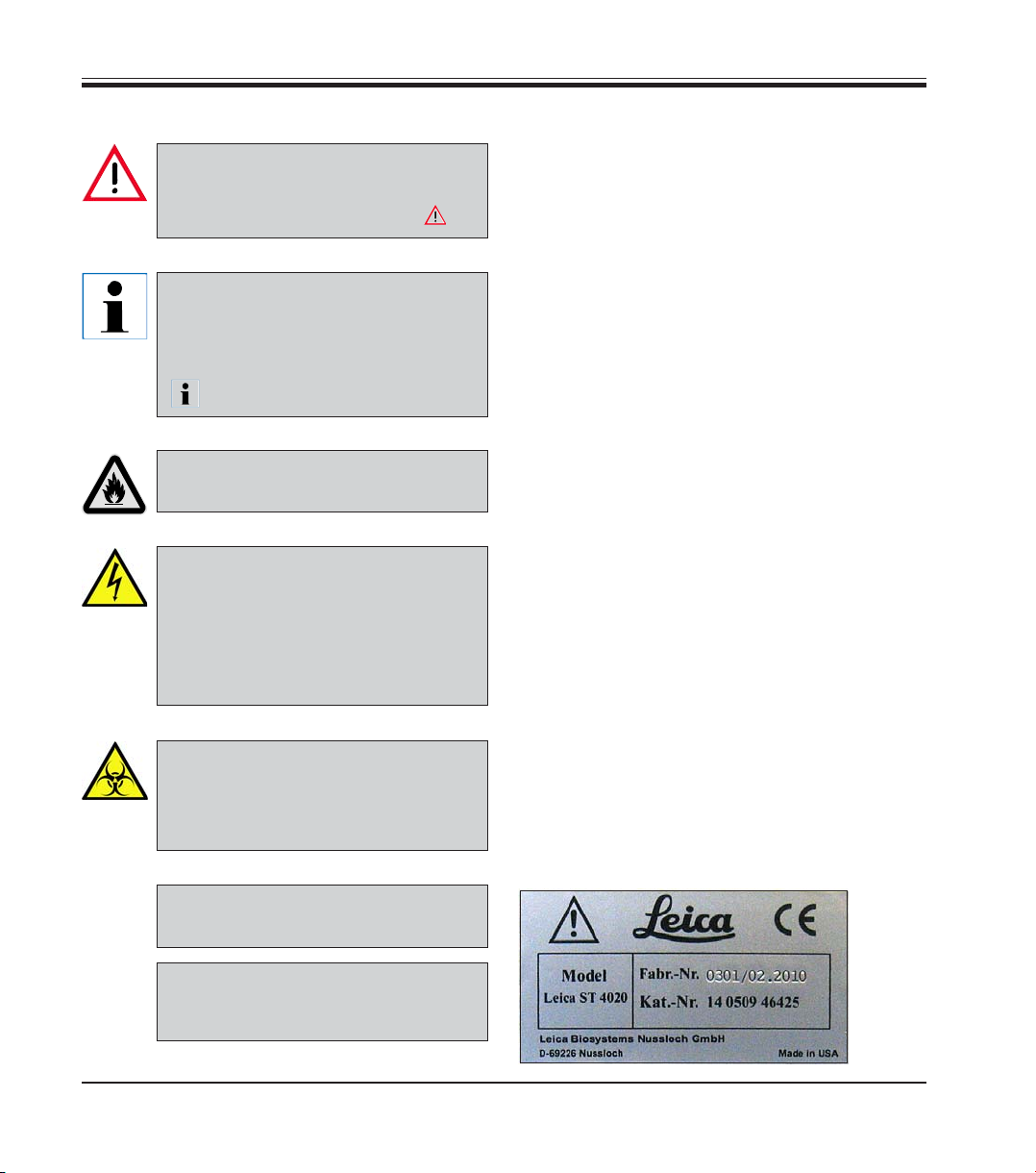

Symbols in the text and their meanings

Warnings

appear in a gray box and are

marked by a warning triangle

Notes,

i.e. important user information,

appear in a gray box and are

marked by an information symbol

.

Inflammable solvents and reagents

are identified using this symbol.

This warning symbol on the device

notifies users of the danger of

electric shock. To avoid the risk of

injury from electric shock, a panel

bearing this marking, or this housing, must not be opened.

Samples processed on this instrument may be biohazard. Appropriate

safety procedures must be followed

to prevent a biohazard.

Intended use

The Leica Small Linear Stainer ST4020 is used

for the automated preparation of routine histo-

.

logical and cytological stains. It is intended for

use in pathology laboratories to assist with the

following tasks:

• Staining thin tissue sections or cytological

specimens on slides. Frozen sections can

also be stained.

• The instrument may be operated only

according to the instructions contained in

this manual.

Any other use of the instrument is considered

improper!

Qualification of personnel

• The Leica ST4020 may be operated by

trained laboratory personnel only.

• All laboratory personnel designated to operate the Leica instrument must read this

Instructions for Use carefully and must be

familiar with all technical features of the

instrument before attempting to operate it.

Type

All information contained in this Instructions for

Use applies solely to the instrument type listed

on the cover page. A nameplate indicating the

instrument serial number is attached to the rear

side of the instrument.

6

(5)

RUN

Numbers in brackets refer to item

numbers in figures.

Function keys to be pressed on the

instrument are written in bold-print

capital letters.

Fig. 1

Instructions for Use V1.1, RevB – 10/2012

Page 7

The safety and caution notes in this chapter must be observed at all times.

Be sure to read these instructions, even if you are already familiar with the operation and

use of other Leica products.

2.1 Safety notes

This Instructions for Use contains important instructions and information regarding the operational safety and maintenance of the instrument.

The Instructions for Use is an important part of

the product, and must be read carefully prior to

startup and use and must always be kept near

the instrument.

2. Safety

This instrument has been built and tested in accordance with the safety regulations for electrical measuring, control, regulating, and laboratory devices.

To maintain this condition and ensure safe operation, the user must observe all notes and

warnings contained in this Instructions for Use.

The Instructions for Use must be expanded by corresponding instructions if this becomes necessary due

to existing national regulations on

accident prevention and environmental protection in the country

where the instrument is operated.

The protective devices located on the instrument and the accessories must not be removed or modified. The instrument must only be opened and repaired by service technicians authorized by Leica.

2.2 Warnings

The safety devices installed in this instrument by the manufacturer only constitute the basis for accident prevention. Operating the instrument safely is, above all, the responsibility

of the owner, as well as the designated personnel who operate, service or repair the instrument.

To ensure trouble-free operation of the instrument, make sure to comply with the following

instructions and warnings.

For current information about applicable standards, please refer to the

CE declaration for the instrument and

to our Internet site:

http://www.LeicaBiosystems.com

Leica ST4020

7

Page 8

2. Safety

Hazards – safety regulations on the instrument itself

Warning labels on the instrument marked with a warning triangle indicate that the correct operating instructions (as defined in this Instructions for Use) must be followed when

operating or replacing the item marked. Failure to adhere to these instructions may result

in an accident, personal injury, damage to the instrument or accessory equipment.

Hazards – transport and installation

Once unpacked, the instrument may be transported only in an upright position.

Place the instrument on a laboratory bench and align it horizontally.

The instrument must not be placed in direct sunlight (e.g., next to a window). Avoid

impacts, bright direct light, and excessive temperature fluctuations.

Only connect the instrument to a grounded power socket. The protective effect may not

be eliminated by an extension cable without a protective grounding conductor.

The instrument will automatically detect the voltage/frequency of the power source.

The installation location must be well ventilated, and must contain no sources of ignition

of any kind. The chemicals used in the Leica ST4020 are easily inflammable and hazardous to health.

Do not operate the instrument in rooms with explosion hazard.

Condensation water may form in the instrument, if there is an extreme difference in temperature between the warehouse and the installation site and if air humidity is high at the

same time. In this case, a two-hour waiting period must be maintained before switching

on the instrument.

Warnings – Handling reagents

Take care when handling solvents!

Always wear rubber gloves and safety goggles when handling the chemicals used in this

instrument.

The reagents used can be both toxic and/or flammable.

When disposing of spent reagents, observe the applicable local regulations and the

waste disposal regulations of the company/institution in which the instrument is being

operated.

Do not smoke near the stainer or the reagents.

The stainer should be operated under an extractor hood.

8

Instructions for Use V1.1, RevB – 10/2012

Page 9

Hazards – working with the instrument

The instrument may be operated by trained laboratory personnel only. It must only be

operated for the purpose of its designated use and according to the instructions contained in this manual.

In the event of an emergency, switch off the power switch and unplug the instrument

from the power supply.

The instrument must be positioned so that the connection socket and the power switch

are easily accessible at all times.

The power supply cord must be routed so that it is not likely to be walked on or pinched

by items placed on or against it.

Suitable protective clothing (lab coat, gloves, protective goggles) must be worn when

working with reagents.

There is a danger of fire if a open flame (e.g. Bunsen burner) is used directly beside the

instrument (solvent fumes). Therefore, keep all ignition sources at least 2 meters away

from the instrument!

While the stainer is not in use, keep the reagent containers covered with the Reagent

Cover provided with the stainer.

2. Safety

Hazards – cleaning and maintenance

Before any maintenance, switch off the instrument and unplug it from power supply.

When using cleaners, please comply with the safety instructions of the manufacturer and

the laboratory safety regulations.

Do not use any of the following for cleaning the outside surfaces of the instrument: alcohol, detergents containing alcohol (glass cleaners), abrasive cleaning powders, solvents

containing acetone, chlorine or xylene!

Clean the Hood and the housing with commercial mild household cleaning agents. The

finished surfaces are not resistant to solvents!

Prevent liquids from entering the interior of the instrument while the instrument is being

cleaned or during operation.

Do not use any attachments or accessories not recommended by the product manufacturer as such attachments and accessories may cause hazards, damage the instrument

and void the warranty.

Leica ST4020

9

Page 10

3. Instrument Components and Specifications

3.1 Overview – Instrument Parts

10

Adjustable

Foot

Reagent

Container

Slide

Carrier

Rinse Station

Lift Bar Hood

(opional)

Exit

Tank

Display

and

Keypad

Platform

Fig. 2

Instructions for Use V1.1, RevB – 10/2012

Page 11

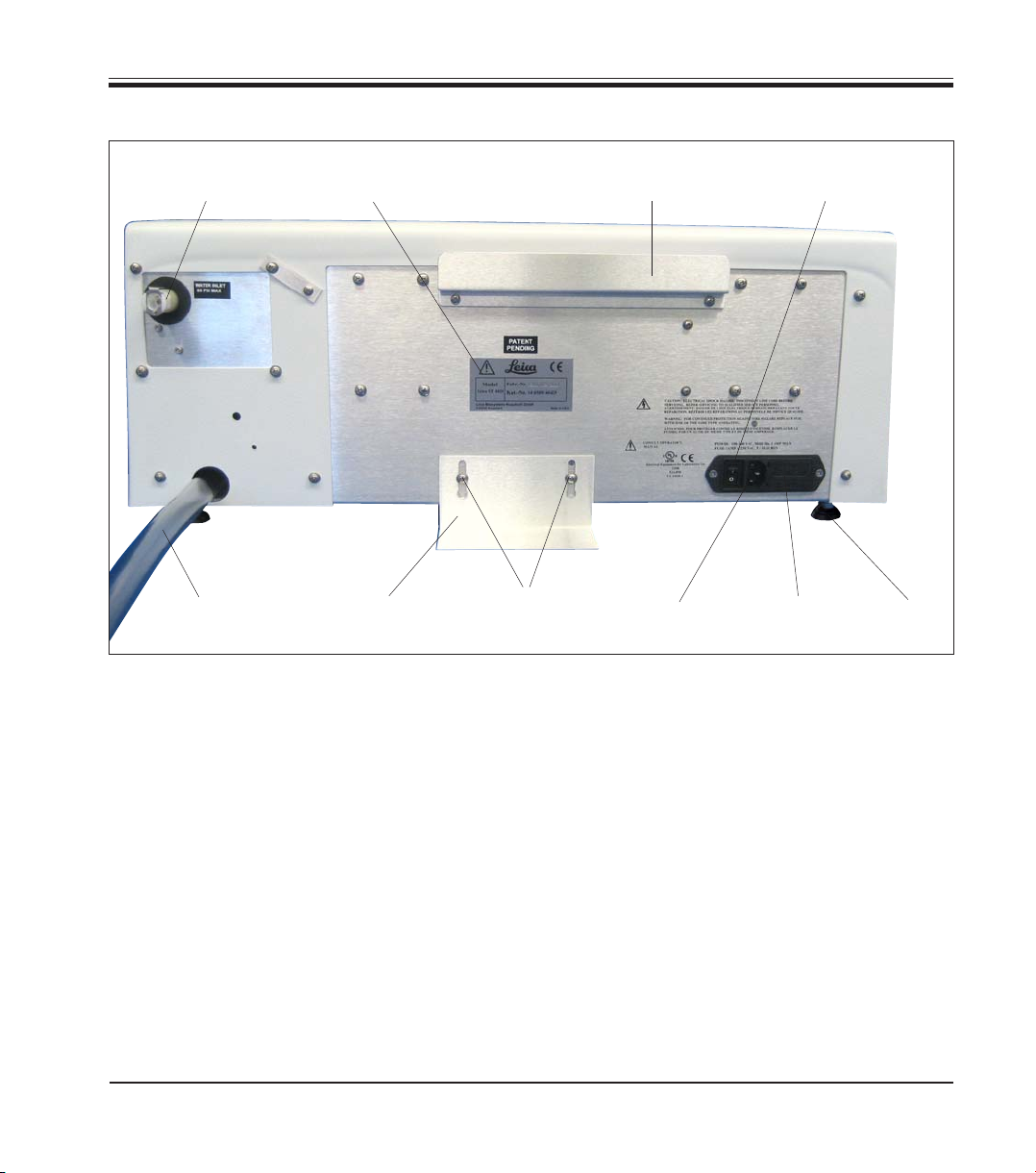

Instrument rear view

3. Instrument Components and Specifications

Rinsing Water

Connection

Waste Water Hose

Identification Label

Support Bracket

for Stabilizing

2 Screws

Support Bracket

3.2 Instrument specifications

The Leica ST4020 is an automatic linear stainer designed for stand-alone use, and can be

used for staining frozen tissue sections in histology labs as well as anatomical pathology

laboratories.

It is ideal for use in staining samples from either

Mohs technique laboratories or sections from

frozen section laboratories or general surgical

pathology. In addition it is intended to be used

in hematology, cytology, as well as performing

routine H & E stains.

Storage for the

Reagent Container Cover

for

Connector for

Power Cord

Power Switch

Power Supply

Adjustable

The user loads the slides in a carrier that can

hold up to 4 slides at a time. The stainer provides 14 reagent stations that can be used as

reagent stations or running rinse water stations

and has an Exit Tank that can hold up to four

processed slide carriers.

The slides will remain in each reagent station for

a fixed programmable time that is applicable to

all stations during staining. Station time, number

of dips and start position are programmable.

Foot

Fig. 3

Leica ST4020

11

Page 12

3. Instrument Components and Specifications

3.3 Functional Description of Components - System overview

Figure 2 on page 10 shows an overview of the stainer.

The Leica ST4020 Linear Stainer has the following functional areas:

13

4

2

4 6

14

Fig. 4

1

3

Fig. 5

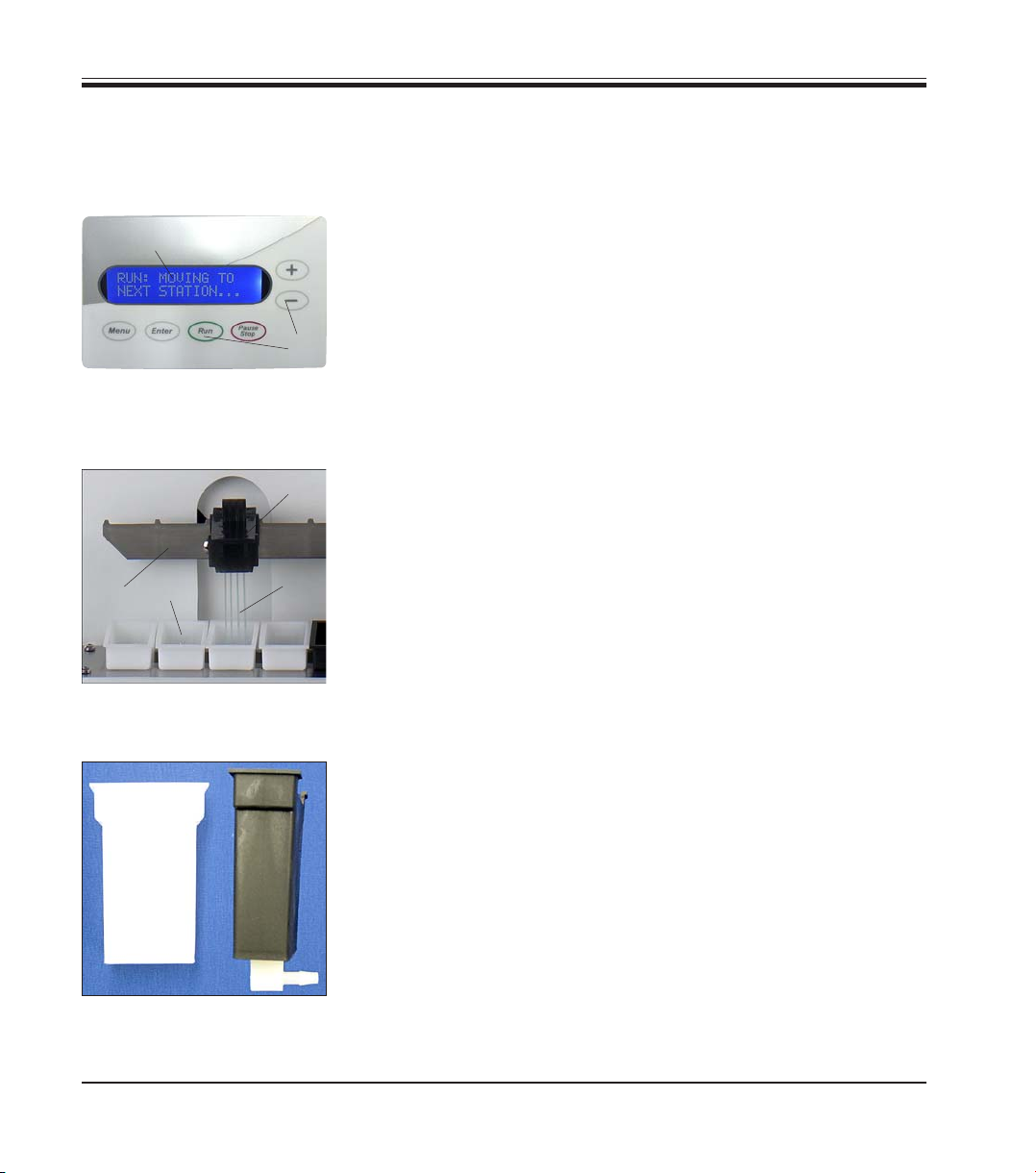

Keypad (14) with Display (13)

A membrane keypad with 6 keys allows the user to set up the

processing parameters and also allows the user to start and stop

the processing runs.

An LCD display consisting of two rows, each row 16 characters

long, in which the progress of slide processing and the stainer's

processing parameters are displayed. The user is directed to take

various actions as necessary.

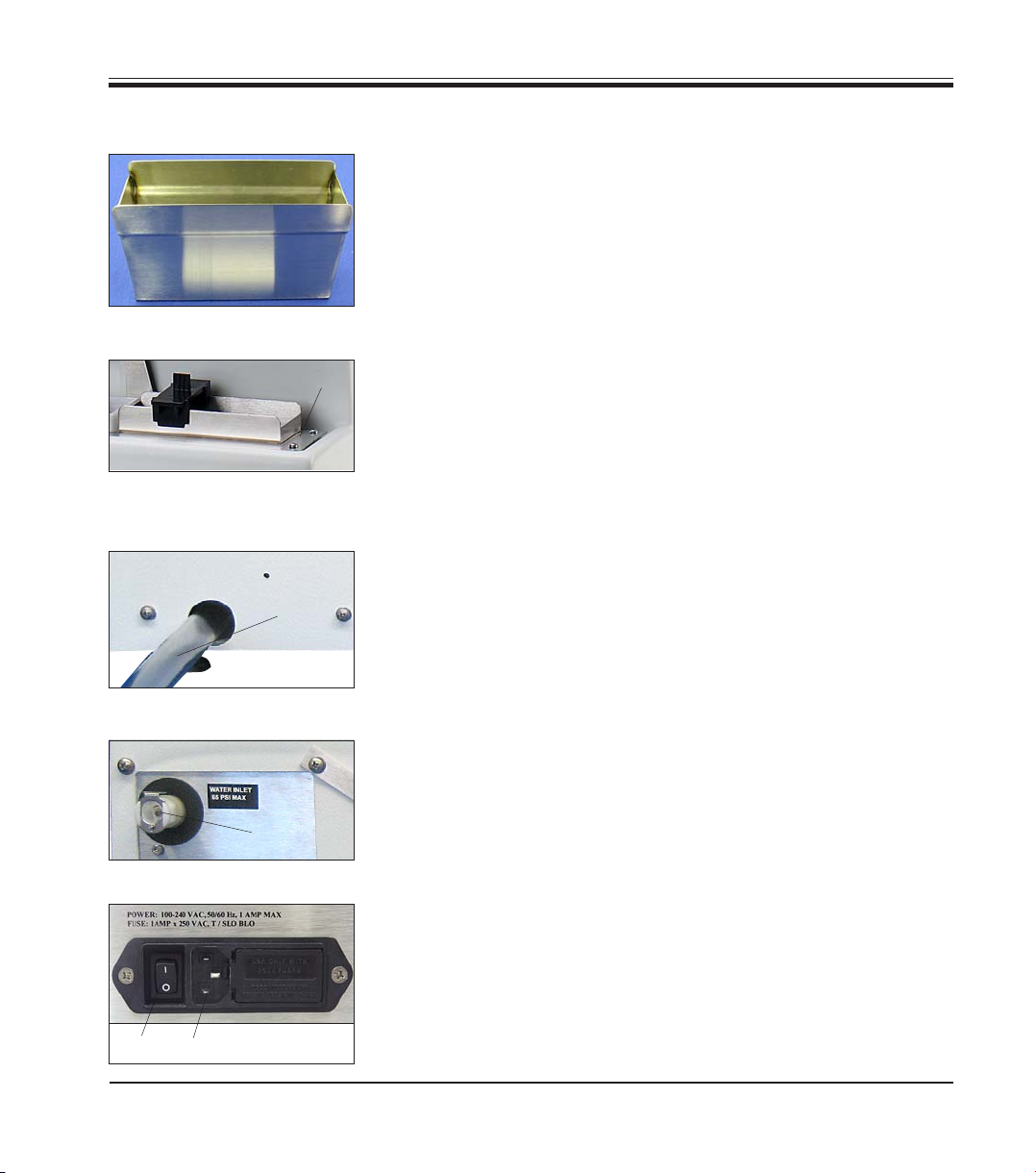

Slide carrier (1) and lift Bar (2)

The user inserts the slides for staining (3) in the slots of the slide

carrier (1). This is then placed onto the lift bar (2) , by which it is

transferred to the first reagent container.

The lift bar moves the slide carriers from one station to the next

station and eventually deposits them in the exit tank.

Reagent container (4) and Rinsing Water Container (6)

Each reagent container (4) can hold up to 50 ml of the reagent for

staining and processing.

A total of 14 reagent and rinse containers (6) can be arranged to

customize the stainer to carry out a specific staining protocol.

Each of the 14 processing positions must have either a reagent

container or a rinse container present.

12

Fig. 6

The rinse containers allow the slides to be subjected to running

rinse water while the slides are being processed.

Instructions for Use V1.1, RevB – 10/2012

Page 13

3. Instrument Components and Specifications

Functional Description of Components (continued)

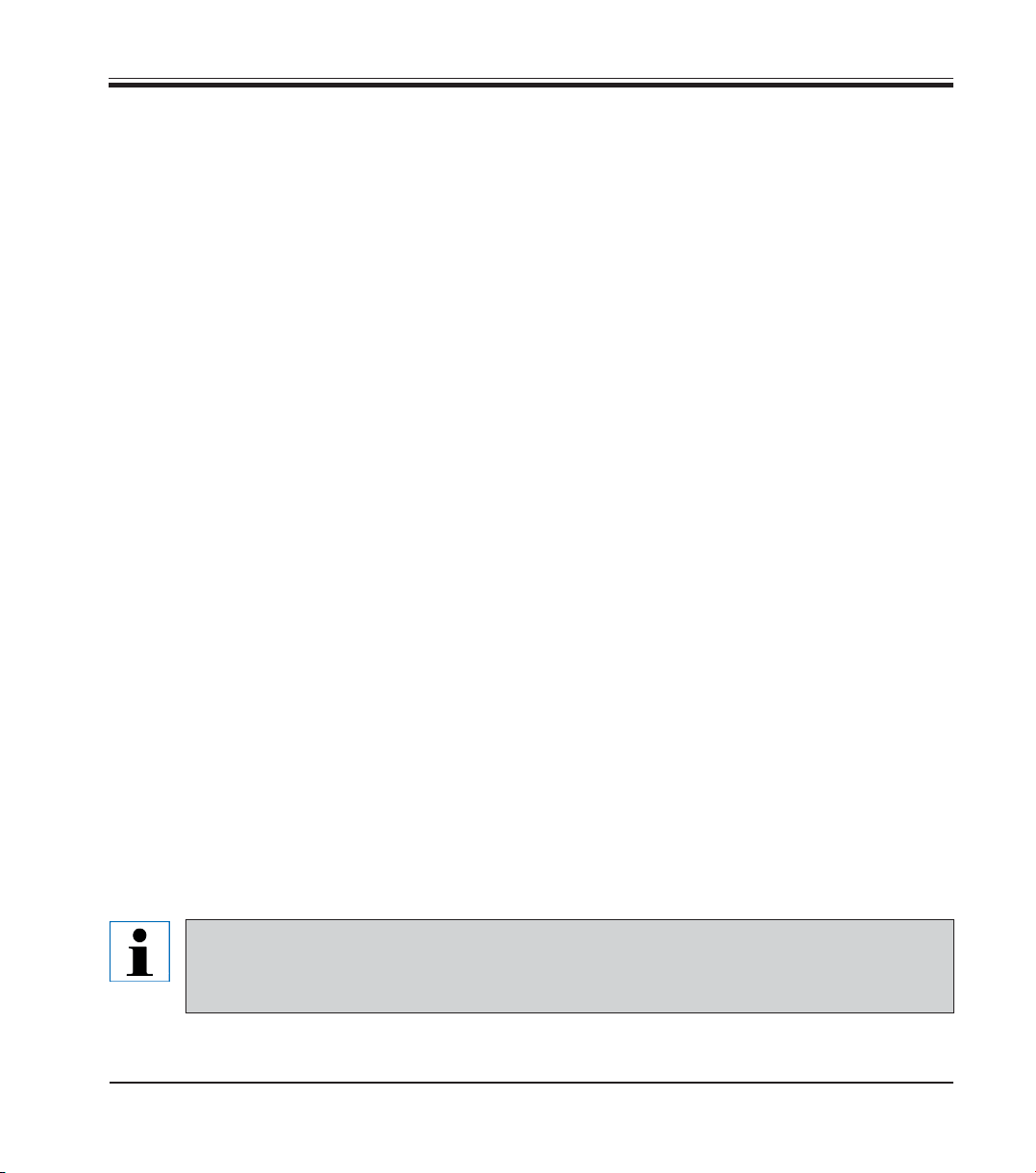

Exit Tank (7)

The exit tank holds the processed slides. It can hold up to 4 slide

carriers.

7

Fig. 7

Fig. 8

9

As soon as the exit tank is full, the stainer pauses processing until

the slide carriers are removed.

Platform (8)

8

The platform holds the reagent containers, rinse containers and

the exit tank in fixed locations to ensure the proper operation of

the stainer. All 14 containers and the exit tank must be placed on

the platform to ensure proper operation of the stainer.

Waste Water Drain Hose (9)

The waste water drain hose must always be inclined downwards

so that the rinsing water drains into a collecting receptacle or

drainage basin, and cannot collect in the stainer.

11

12

Leica ST4020

10

Fig. 9

Rinsing Water Supply (10)

A connection port for the rinsing water supply is located on the

rear of the stainer. The necessary connecting hose is included in

the equipment supplied.

Fig. 10

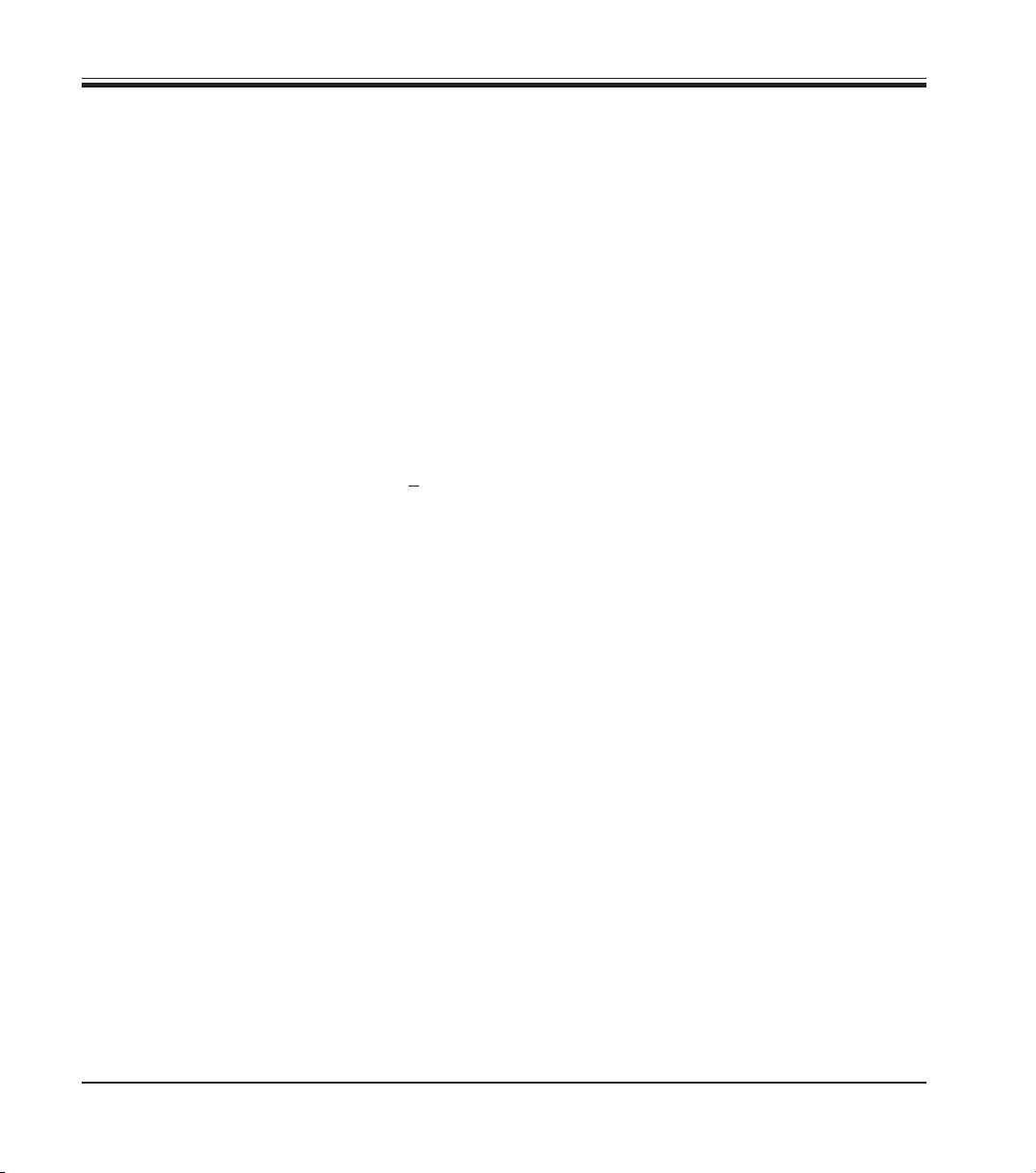

Main Switch and (11) Connection to Power Supply (12)

The stainer is connected to the power supply (12) by the power

supply cord, and activated with the main switch (11).

The instrument can be operated with alternating current at 100 to

230 Volt with a power frequency of 50/60 Hz.

Fig. 11

13

Page 14

3. Instrument Components and Specifications

3.3 Functional Areas of the Slide Carrier

Side

Support

Locating Slots

for Slides

Fig. 12 and Fig. 13 show how the slide carriers are to be positioned

over the reagent containers.

While placing a slide carrier with slides for staining in the lift bar,

ensure that the side supports of the slide carrier are aligned so

that the slide carrier is positioned above the container.

Side Support

Handle

Slides

Fig. 12

14

Lift Bar

Retainer

Reagent

Container

Fig. 13

Instructions for Use V1.1, RevB – 10/2012

Page 15

3. Instrument Components and Specifications

3.4 Standard Delivery

The Leica ST4020 standard delivery consists of the following items:

1 Leica ST4020 basic instrument 14 0509 46425

14 Reagent containers (white) 14 0509 46437

3 Water rinse containers (black) 14 0509 46441

3 Slide carrier 14 0509 46438

1 Set of Power cords:

1 Power cord "D" 14 0509 46480

1 Power cord "UK" ST-BU F-5A 14 0509 46481

1 Power cord "US" 14 0509 46479

1 Water inlet hose 14 0509 46532

1 Water drain hose (already installed) 14 0509 46445

1 Rinse Manifold with restrictor (already installed) 14 0509 46533

1 Exit collection tank 14 0509 46450

1 Set with tubings, fittings, tie wraps: 14 0509 46459

1 Water hose 16“ long, Ø1/8“

3 in line fittings

2 plugs

10 tie wraps

1 Support Bracket 14 0509 46570

1 Metal reagent container cover 14 0509 46442

1 Set replacement fuses:

2 Fuses 250 V, T 1.0 A 14 0509 46463

1 Instruction manual for Leica ST4020 “Small Linear Stainer“ 14 0509 80001

Leica ST4020

Please check all delivered parts against the packing list and against your order to verify

whether the delivery is complete! Should you find any discrepancies, please contact your

Leica sales office without delay.

15

Page 16

3. Instrument Components and Specifications

3.5 Technical Data

General

Admissions: UL, cUL, CE

Nominal voltage: 100 V – 240 V +/- 10% AC

Nominal frequency: 50 to 60 Hz

Power draw: 25 VA

IEC 1010 classification: Protective class 1

Pollution degree 2

Overvoltage installation category II:

Secondary fuses: Melting fuses 1.0 A T Ø 5.0 x 20 mm

Operating temperature range: 15°C to 30°C

Relative humidity: 20% to 80%, non-condensing

Altitude:

Dimensions and weights

Dimensions, (W x D x H): 620 mm x 250 mm x 200 mm

Height with Hood open: 430 mm

Dry weight, unpacked: approx. 16 kg

Instrument with accessories: approx. 19 kg

Weight incl. packing material: approx. 21 kg

< 6500 ft (Ambient pressure. 29 - 31 inch Hg)

Performance

Slide processing rate: Depends on program structure and loading

Loading capacity: max. 4 slide carriers

Stations: max. 14

Reagent stations: max. 14

Washing stations: max. 3 (then only 11 reagent stations are possible)

Reagent container volume: 50 ml

Agitation: 0 to 3 dips per station for dwell times > 30 sec.

Throughput rate of washing stations: 250 ml/min +/-100 ml, depending on number of stations

Dwell time adjustment: 2 to 300 sec. at each station

Capacity of the slide carrier: max. 4 slides

Capacity of the exit tank: max. 4 slide carriers

16

Instructions for Use V1.1, RevB – 10/2012

Page 17

4.1 Location Conditions

4. Setting up the instrument

• The instrument requires an installation area of approx. 250 x 700 mm.

A clearance of at least 25 cm must be left between the instrument and

the closest wall or other instruments.

• If the stainer is to be operated with rinsing stations, fresh water and

waste water connections must be no more than 1.2 m from the ports

on the back of the instrument.

• It must be ensured that there is sufficient clear space (approx. 30 cm)

above the instrument to allow unobstructed opening of the optional

Hood.

• Room temperature consistently between +10°C and +30°C.

• Relative air humidity maximum 80%, non-condensing.

• Practically vibration-free floor. Avoid vibrations, direct sunlight and

heavy variations in temperature.

The chemicals used in the Leica ST4020 are easily inflammable

and hazardous to health.

The installation site for the Leica ST4020 must be well ventilated, and there must be no ignition sources of any kind in the

area.

The instrument must not be operated in areas at risk of

explosion.

4.2 Unpacking the Instrument

• Open the packaging.

• Remove all foam material.

• Take out all accessories and the Instructions for Use.

• Check the contents of the delivered pack against the order form to

ensure that all components and accessories are included.

Leica ST4020

First check the shipment for external damages upon arrival.

If it is evident that the shipment was damaged during transport,

please make a claim to the carrier immediately.

17

Page 18

4. Setting up the instrument

Unpacking the Instrument (continued)

These unpacking instructions only apply if the box is placed with the symbols

facing upwards for unpacking.

35

36

Fig. 14

1. Cut through the packing tape (35) on the top edge

of the box.

2. Remove the yellow envelope with "Documents of

Conformity" (36) and store in a safe place.

38

Fig. 16

4. Use the molded foam pads (38) to pull the

instrument out of the inside packaging

and place it on a firm laboratory bench.

5. Pull the molded foam pads (38) away from the

sides of the instrument.

Remove the protective film (40) from the instrument.

38

37

3. Remove the Accessories (37) , packaging material (39) and Instructions

for Use.

40

39

Fig. 15

38

Fig. 17

18

Fig. 18

6. The instrument must now be prepared for correct

use in accordance with the instructions in the

accompanying Instructions for Use.

The packaging must be retained for the

duration of the warranty period.

To return the instrument, follow the

instructions above in reverse order.

Instructions for Use V1.1, RevB – 10/2012

Page 19

4. Setting up the instrument

4.3 Setup

25

28

27

26

Fig. 19

29

Fig. 20

Horizontal Alignment

For safe and accurate work, it is important that

all instrument feet are in uniform contact with

the installation surface.

The stainer is horizontally aligned at the factory.

If a completely level or horizontal surface is not

available at the installation site, the instrument

must be realigned.

For this purpose, the instrument feet (25) are

height-adjustable.

• For alignment, loosen the locknuts (26) using

7

a size

/16" open-end wrench.

• Adjust the instrument feet (25) until the

instrument is in a stable position at the

installation location according to requirements.

• Retighten the locknuts.

Mounting the Support Bracket

To ensure that the instrument cannot tip over

when its keys are pressed, the support bracket

(27) must be mounted on the rear.

• To do this, first unscrew the two Philips head

screws (28) with a screwdriver. Place them

together with the two associated washers

(29)

• Place the support bracket against the rear of

the instrument (

Fig. 20), reinsert but do not

fully tighten the two screws.

• Press the support bracket down onto the

support surface until a face of the plate lies

flush with the bench surface, then tighten

the plate in this position.

Leica ST4020

19

Page 20

4. Setting up the instrument

4.4 Water Connection

37

10

• Run the drain hose (9) into a suitable collecting tank or waste basin. Make sure that the

hose is not kinked and that the water is able

36

35

to drain freely downwards.

• Then connect the rinsing water supply (35)

to the stainer.

• To do this, push the connector (36) into the

orifice (10) on the instrument until it clicks

into place. To detach the hose, press on the

plate (37) and pull the connector back.

• Connect the other end of the hose to a suitable water tap. Do not open the water supply

yet!

9

Fig. 21

Adjustment of the rinsing water flow rate is

described in

Chapter. 5.4.

4.5 Installing the Rinsing Water Containers

Up to three rinsing stations may be provided on the stainer. The rinsing water containers can

be located at any of the 14 reagent stations.

The equipment supplied includes three hoses with Y-connectors. The cable ties on these

Y-connectors must not be removed. Also, do not detach the Y-connectors from the associated

hoses.

Watertight, functional rinsing stations in accordance with the desired staining protocol can be

set up with the aid of additional cable ties, hoses, plugs and connectors that are also included

in the scope of delivery.

20

While the rinsing stations are being set up, it must be ensured that the rinsing water

containers are positioned horizontally on the platform, and all hoses are lying horizontally on the bottom of the drainage tank, outside of the travel path of the lift bar.

The rinsing water hoses must not be subjected to any kind of pulling or stretching

stresses.

Instructions for Use V1.1, RevB – 10/2012

Page 21

Installing the Rinsing Water Containers (continued)

4. Setting up the instrument

Fig. 22 shows how the hoses

are routed in the instrument.

If you want to work entirely

without water, no further steps

are necessary – simply do not

connect a water supply line to

the instrument.

Hose 1

Hose 2

Hose 3

Area of the

drainage tank

Fig. 22

Place the rinsing water containers (6) in the desired position on the platform. The rinse

container bar fitting pointed (5)

to the exit tank (refer to

fig. 23).

Start with the station closest to

the drainage tank.

6

5

Fig. 23

The hose (15) should run level

along the bottom of the instrument.

Mark the end of the hose that

will connect to the rinsing

water container.

This is "Marking 1".

Leica ST4020

15

Marking 1

Fig. 24

21

Page 22

4. Setting up the instrument

Installing the Rinsing Water Containers (continued)

Lateral surface of the connector

End of the connector

• Now take the rinsing water

container and the hose out

of the stainer.

• Align Marking 1 on the end

of the connector and make

a second marking ("Marking 2") to indicate the lateral

surface of the connector

(Fig. 25).

Marking 2

Marking 2

Marking 1

21

• Cut the hose off at Marking 2.

Fig. 25

• Then push the hose (21)

fully onto the connector by

twisting until the end of the

hose is flush against the

lateral surface of the connector (Fig. 26).

• If the hose is not pushed

completely onto the connector, it may become

detached as soon as the

water supply is turned on.

22

Do not stretch tubing to fit on the fitting.

Fig. 26

Instructions for Use V1.1, RevB – 10/2012

Page 23

Installing the Rinsing Water Containers (continued)

• Place the rinsing water container back in the desired position on the

platform. Check that the rinsing water container is positioned horizontally on the platform.

If the hose is too long, the rinsing water container will tilt to the right; if

it is too short, it will tilt to the left.

If the rinsing water container is not positioned horizontally on

the platform, it cannot be guaranteed that the stainer will function properly.

• Repeat the steps described above for the other rinsing stations.

If only one or two rinsing stations are required,

the hoses that are not used must be sealed with

a plug (17), see Fig. 27.

17

18

• To do this, twist and push the plug fully into

4. Setting up the instrument

the end of the hose, and then secure it with

a cable tie (18).

Leica ST4020

Fig. 27

If two rinsing stations are to be located immediately beside one another, the connector (19) for

the left station must be aligned as shown in

Fig. 28.

19

Fig. 28

23

Page 24

4. Setting up the instrument

4.6 Remedy if Hose is too short

If the hose (21) at one of the stations should be too short, or if a hose has

been cut too short by mistake, the following remedy may help:

20

18

21

Fig. 29

• Cut the hose roughly in the middle between the Y-connector and the

rinsing station.

• Use the extension connector (20) included with the package to attach

an additional hose section (21) of the required length.

• To do this, measure the length of the hose again, and if necessary cut

it to exactly the required length.

• Push both ends of the hose as far as they will go onto the extension

connector, and then secure each hose with a cable tie (18).

• Finally, check again that the rinsing water container is positioned

horizontally on the platform.

24

Instructions for Use V1.1, RevB – 10/2012

Page 25

5.1 Switching on the Instrument

The instrument MUST be connected to a grounded power socket.

Only the power cord provided may be used, which is intended for the local power

supply (socket). The protective effect must not be eliminated by an extension cable

without a protective grounding conductor.

The AC socket used for the power supply must be close to the instrument and easily

accessible.

11

12

5.2 Control Panel Functions

Fig. 30

5. Operation

• Before plugging the instrument into the

mains, make sure that the main switch (11)

on the rear of the instrument is in the

OFF ("0") position.

• Plug the power cable into mains power supply socket (12) and connect it to the power

socket on the wall. If applicable, switch on

the switch for the power socket.

• Then switch on the main switch (11) on the

instrument, (ON = "I").

The control panel consists of a membrane keypad with six pressure keys, and a screen consisting of a two-line display, each line being 16 characters long.

This is used for controlling the functions of the instrument and for programming the software.

The current state of the stainer and ongoing operations are displayed while a staining task is

being processed.

• The instrument will take a few seconds to

initialize. During this time, the installed version of the software will be displayed on the

monitor.

• Then, the lift bar performs a circular motion

to ensure that the bar is in the correct position at the start of staining.

The message FINDING HOME... is displayed

on the screen.

Fig. 31

Leica ST4020

25

Page 26

5. Operation

Control Panel Functions (continued)

There are six push-buttons on the control panel, and these are used to adjust the operating parameters and control the instrument.

The keys have been assigned the following functions:

The operating parameters can be displayed and checked with the MENU

key.

Each time the MENU key is pressed, another one of the six operational

parameters will be displayed.

Whenever a new setting is made, it will take effect immediately. Furthermore, since all settings are saved in memory, it will automatically be used

the next time the system is powered up.

The operating parameter that is currently being displayed can be raised or

lowered by pressing the PLUS ("+", increases the displayed value) and

MINUS ("-", reduces the displayed value) keys respectively.

Pressing the PAUSE/STOP key allows the operator to exit the setup menu

without changing the parameter currently being displayed.

While running:

Pressing PAUSE/STOP once interrupts the current staining operation so

that another slide carrier can be placed in the lift bar.

Pressing PAUSE/STOP twice (in quick succession) terminates the current

program, and the system returns to idle mode.

26

If the ENTER key is pressed, the selected parameter is stored in the

system.

The system returns to its idle mode whenever a new setting is entered, or

whenever the user exits the setup menu by pressing the PAUSE/STOP

key,

Pressing the RUN key starts a staining operation on the basis of the values

shown in the display. At the same time, the flushing valve is activated, the

display changes, and the timer appears, counting down to show the remaining processing time.

Instructions for Use V1.1, RevB – 10/2012

Page 27

5. Operation

5.3 Setting the Operating Parameters

The process of adjusting the operational parameters is simple and direct.

When the system is "ON" and in the idle mode (that is, neither RUNNING nor in a SETUP mode),

the operator may display and check the setup parameters by pressing the MENU key.

If the ENTER key is pressed, the selected parameter is stored in the system.

Pressing the PAUSE/STOP key allows the operator to exit the setup menu without changing

the parameter currently being displayed.

Whenever a new setting is made, it will take effect immediately.

Furthermore, since all settings are saved in memory, it will automatically be used the next time

the system is powered up.

The system returns to its idle mode whenever a new setting is entered, or whenever the user

exits the setup menu by pressing the PAUSE/STOP key.

Processing time

Leica ST4020

The amount of time that the slides are immersed at each station

can be varied from 2 to 300 seconds.

• When the PLUS or MINUS key is pressed ("+" or "-"), the staining time is altered:

one second at a time in a range from 2 to 30 seconds,

five seconds at a time in a range from 30 to 60 seconds,

ten seconds at a time in a range from 60 to 300 seconds.

• After ENTER is pressed, the new processing time is activated,

and this time is stored for future use.

27

Page 28

5. Operation

Display Contrast

Transfer Mechanism Calibration

The contrast on the liquid crystal display can be adjusted

according to the preferences of individual users.

• The adjustment range is between 1 and 15, 1 being the brightest setting.

• Pressing the PLUS or MINUS key changes the number of

contrast for the display.

• After ENTER is pressed, the setted contrast is stored.

The position at which the transfer movement is paused and

processing started may be adjusted by pressing the PLUS (+) or

MINUS (-) keys, followed by the ENTER key.

• Pressing the PLUS or MINUS key changes the number of

steps carried out by the stepping motor by 8. The minimum

permitted value is 704, the maximum permitted value is 1000.

The typical setting is 944 to 960.

• After ENTER is pressed, the number of steps is stored. Also,

the transfer mechanism advances to the next station, stopping when the selected number of steps has been taken.

Number of Dips

28

The number of dips that are carried out for uniform staining can

be set in a range from 0 to 3.

• Pressing the PLUS or MINUS key changes the number of dips

carried out by the instrument.

• After ENTER is pressed, the number of dips is stored.

If a value of 1, 2 or 3 has been selected, the system dips the slide

carriers the corresponding number of times as soon as they

reach a station.

All subsequent dip motions are carried out at intervals of 20 seconds each if the processing time is 30 seconds or more. If the

processing time is less than 30 seconds, then no dips will occur,

regardless of the setting selected.

Instructions for Use V1.1, RevB – 10/2012

Page 29

Start position

Run Forever

5. Operation

The start position has to be set if staining protocols that do not

make use of all 14 staining positions are being run.

In order to make the processed slides available to the user at the

exit tank in the least amount of time possible, a programmable

start position feature has been added.

• Pressing the PLUS or MINUS key changes the number of

start position carried out by the system.

• After ENTER is pressed, the start position is stored.

The user can specify which station is being used for the start

position.

• For example, a protocol that requires only ten stations could

use stations 5 through 14 rather than beginning at the first

station.

• This puts the slides into the exit tank as soon as they leave

the last process station. By specifying the start position as

position 5, the user allows the system to issue its "reminder

beep" at the correct time.

• This beep informs the operator that slides have reached the

exit tank.

Leica ST4020

There are two settings, and these can be set using the PLUS or

MINUS keys.

• With a setting of "00", the stainer runs for as long as slide

carriers are loaded into it and are undergoing the staining

process.

• A beep sounds every time a slide carrier is ready. When

3 racks have reached the exit tank, a signal sounds 5 times.

• With the "01" setting, the stainer runs continuously whether it

is loaded or not. A beep sounds every time a slide carrier is

ready.

• After ENTER is pressed, the run mode is stored.

29

Page 30

5. Operation

5.4 Setting the Rinsing Water Flow Rate

To set the flow rate for the rinsing water, proceed as follows:

• First set a staining time of 60 seconds. To do this, press

MENU once, and then press the PLUS or MINUS key repeatedly until a processing time of 60 seconds is displayed.

• Then press the ENTER key to confirm this processing time.

• Now press RUN. The countdown of station time will be displayed while the rinse water valve inside the unit activates.

30

2x

• Now slowly turn on the tap to which the supply hose is connected, and adjust the flow rate so that water flows into the

rinsing water container at a sufficient rate and the rinsing

water can drain without obstruction.

DO NOT adjust the flow rate too high. This can cause

spills on the platform to the next stain station or can

overflow the drain area of the stainer.

• Once the flow rate is adjusted properly, press the

PAUSE/STOP key twice, and then press the ENTER key to

reinitialize the mechanism when prompted by the instrument.

Instructions for Use V1.1, RevB – 10/2012

Page 31

5. Operation

5.5 Processing Slides

The Leica ST4020 Stainer is a relatively simple and trouble-free system. The user must inform

the system via the keypad whenever slides are to be added to or removed from the stainer.

Directions as to how this is done appear in the following sections. Slides must be loaded and

unloaded in the prescribed fashion.

Important!

Failure to follow the directions given here may result in improper or incomplete

processing of slides.

correctly

arranged

slide carrier

• The slide carrier must be prepared carefully,

because if it is positioned incorrectly, the

slides may not be properly transported by

the lift bar.

There are two occasions that slides may be

loaded onto the start position:

• before the start of processing, and

• after the start of processing.

In both cases, the slides will be immersed in the

start position's reagent.

The user should be prepared to start or resume

the staining run as soon as the slide carrier is in

position, so that extra staining time may be kept

to a minimum.

Reagent

Container

Leica ST4020

Fig. 32

31

Page 32

5. Operation

5.5.1 Starting a staining run

It is, of course, the user's responsibility to verify that each of the setup parameters (station

time, number of steps, number of dips, etc.) is set to an acceptable value before slides are

placed in the starting position and RUN is pressed.

Slides should not be loaded while the user is verifying setup parameters, because changing

the number of steps ("transfer mechanism calibration") will cause the transfer mechanism to

advance to the next position!

All parameters should be verified BEFORE loading the first set of slides.

A staining run cannot be started unless the stainer is in standby-mode.

In this mode, the system displays the process time and instructions to press the RUN key to

start:

When the RUN key is pressed, the flushing valve is actuated, the

display changes and the remaining processing time appears,

counting downwards:

When a staining run is started by pressing the RUN key, the

system receives the information that there are slides in the start

position that are to be stained.

32

Note that the first station's process time begins as

soon as the RUN key is pressed. This means that the

slide carriers must be loaded in the start position

immediately before the RUN key is pressed.

• The stainer will continue running until these slide carriers are

transferred from station 14 to the exit tank.

• The current operation appears successively in the display.

• When the last slide carrier has been transferred to the exit

tank, the system stops the process and returns to IDLE mode,

unless more slides are inserted in the correct manner.

Instructions for Use V1.1, RevB – 10/2012

Page 33

5. Operation

5.5.2 Adding more slide carriers during a staining run

The PAUSE/STOP function can be used to allow additional slide carriers to be placed in the

instrument after processing has begun.

The following procedure should always be followed:

If a staining run is already underway and more slide carriers are

to be inserted, press the PAUSE/STOP key once.

Important!

Only press PAUSE/STOP ONCE!

If this key is pressed twice, the entire staining run

will be aborted.

Please wait, and do not add any

further slides!

This message is displayed until

the slide carriers have been removed from a position by the lift

bar and transferred to the next

station.

When:

LOAD SLIDES...

PRESS RUN

appears in the display, the new slide carriers must be inserted at

the start position immediately, and the RUN key pressed.

As soon as the RUN key is pressed, the system resumes processing, and continues counting down the process time.

It should also be noted that the entire operation is interrupted

until the RUN key is pressed again.

Therefore, the operator should be prepared to load the new

slides as quickly as possible and should then press the RUN key

quickly to avoid having all slides already in the system spend

extra time immersed.

Leica ST4020

33

Page 34

5. Operation

5.5.3 Temporarily pausing a staining run

If the PAUSE/STOP and RUN keys are pressed in this order, the

instrument receives the information that more slide carriers

have been inserted at the start position.

The stainer continues operating until these slide carriers are

transferred from station 14 to the exit tank.

If no other slides have been added in the meantime, it emits an

audible signal to alert the operator that the staining run has

been completed. A corresponding message appears in the

display.

This procedure applies for inserting slide carriers after processing has begun, and must be followed under all circumstances.

Attempting to add slide carriers without pressing the

PAUSE and RUN keys will result in the carriers not

being transported to all of the stations, since the

stainer will not know that additional slide carriers

have been added!

Occasionally, it may be necessary to stop the system when it is processing slides. This too can

be accomplished with PAUSE/STOP key.

Staining can be interrupted,

• to allow access to the instrument if anomalies requiring such arise during staining.

• so that reagents can be checked, and changed if necessary.

Important!

The lift bar will complete the current cycle, and will

move the slide carriers to the next station. Do not

attempt to open the instrument until "LOAD SLIDES...

PRESS RUN" appears in the display.

34

Instructions for Use V1.1, RevB – 10/2012

Page 35

5. Operation

5.5.4 Ending a staining run prematurely

The role of the PAUSE/STOP key in loading additional slides was described in the previous

chapter.

However, this key has a second function, that of terminating a staining run that has already

been started.

It has been noted already that the PAUSE/STOP key should be

2x

pressed only ONCE when additional slides are to be loaded.

Because if the PAUSE/STOP key is pressed TWICE, processing

is stopped. If this happens, the message opposite appears in the

display.

• This means that the staining run has been aborted, and the

instrument must be reset by pressing ENTER.

Important!

All slide carriers must be removed from the instrument, because all the information in the software has

been reset.

Leica ST4020

• As soon as the user presses the ENTER key in this situation,

the transfer mechanism returns to the home position. This is

then the same situation as when the instrument is first

switched on.

• The corresponding message appears in the display.

• As soon as the transfer mechanism reaches the start position, the stainer returns to idle mode; then, the same status

message is displayed as the one shown when the instrument

is initialized after it is switched on.

35

Page 36

5. Operation

5.5.5 Removing Processed Slides

Removing processed slides means more than the mere physical act of removing slides.

It also involves informing the instrument that slide carriers have been removed, so that the

stainer may keep an up-to-date count of how many slide carriers are still in the system.

• Every time the system transfers a slide carrier from station 14 to the exit tank, an audible

signal (beep) is emitted to inform the user that slides are available for removal.

• The system also increments its count of the number of slide carriers that are in the exit

tank.

• The operator should remove processed slides as quickly as possible.

• The exit tank can hold up to four slide carriers. This enables the operator to remove the

slides at a more convenient time.

• As soon as there are 3 slide carriers in the exit tank, the stainer emits a distinctive audible

signal to alert the operator.

• In this case, the slides should be removed immediately, before the counter in the system is

set to 4;

Important!

As soon as there are four slide carriers in the exit tank, the stainer stops processing, because the exit tank cannot hold any more slides.

• It is often convenient to insert new slides for staining at the same time as the processed

slides are being removed.

In this case it may be assumed that the operator normally removes all the stained slides

from the exit tank every time new slides are loaded.

36

Instructions for Use V1.1, RevB – 10/2012

Page 37

5. Operation

Removing Processed Slides (continued)

Of course, there will be times when slides are being removed but no additional slides are being

loaded.

These two different situations are handled in the following ways:

1 To remove processed slides only:

• Take ALL of the slide carriers out of the instrument's exit

tank.

• Press the RUN key once to start processing the loaded slide

carriers.

2. To remove the carriers with stained slides and load fresh

slide carriers:

Leica ST4020

• Press the PAUSE/STOP key once.

• Wait until the system prompts you to load the slides and

press the RUN key.

• Place the new slide carriers in the system.

• Press the RUN key once.

• Remove ALL the slides from the exit tank.

37

Page 38

6. Cleaning and Maintenance

6.1 Cleaning the Instrument

Prior to cleaning the instrument, always switch off power supply and unplug the

power cord!

When using cleaners, comply with the safety instructions from the manufacturer

and the labor-safety regulations at your laboratory.

Dispose of spent reagents in accordance with the laboratory guidelines in force in

your country!

Wipe off spilled solvents (reagents) without delay! The Hood surfaces only have

moderate resistance in the event of prolonged contact with solvents!

The painted surfaces and the control panel of the instrument are not resistant to

xylene or acetone!

Do not use any of the following for cleaning the outside surfaces of the instrument:

alcohol, detergents containing alcohol (window cleaner!), abrasive cleaning

powders, solvents containing acetone or xylene!

No liquid must be allowed to come into contact with the electrical connections or

get inside the instrument!

Instrument interior

Remove the reagent and rinsing water containers. To clean the stainless steel inner walls, use

a normal detergent and then rinse thoroughly with water.

Lift bar

Wipe the surfaces of the lift bar with a damp cloth.

Instrument exterior

The outer surfaces can be cleaned with a mild detergent and wiped off afterwards with a

damp cloth.

Do not use any solvents for cleaning the outer surfaces and the Hood!

Slide carrier

Clean with domestic or laboratory cleaning agents as necessary.

Drain

The drain hose must periodically be checked for contamination, particularly by algae, and bacteriasl cleaned as necessary.

In order to prevent by algae and bacterial contamination, the drainage system can be flushed

with a 5% solution of sodium hypochlorite. However, metal parts must not remain in contact

with this solution for prolonged periods (e.g., overnight). Flush thoroughly with water afterwards.

38

Instructions for Use V1.1, RevB – 10/2012

Page 39

6. Cleaning and Maintenance

Cleaning the Instrument (continued)

Reagent container and rinsing water container

The reagent and rinsing water containers must be cleaned regularly in order to achieve consistently good staining results.

They can also be cleaned in the dishwasher at a max. temperature of +65°C. Any standard

cleaning agent for laboratory dishwashers may be used.

Caution!

The stations must not be exposed to elevated temperatures (e.g., in industrial dishwashers, which operate at a temperature of +85°C), because the heat can deform

the stations!

6.2 Maintenance Instructions

Only authorized and qualified Leica service personnel may repair the instrument

and access the instrument’s internal components.

For your safety, never attempt to repair the instrument yourself.

Unauthorized repairs will render any claims under the warranty null and void.

See also the section on "Warranty" in Chap. 8 on this matter.

The instrument is basically maintenance-free.

To ensure trouble-free operation of the instrument over a long period of time, the following is

recommended:

• Have the instrument checked at least 1 x year by a qualified service technician authorized

by Leica.

• At the end of the warranty period, enter into a service contract. For more information,

please contact your local Leica technical service center.

Leica ST4020

39

Page 40

7. Troubleshooting

In the following table there is a list of the most common problems which can arise

while working with the instrument, along with possible causes and troubleshooting

procedures.

If faults occur that cannot be corrected with the recommended procedures, or if

they occur again, Leica Service Support must be informed immediately.

7.1 General

The Leica ST4020 is equipped with a simple fault detection system, and can identify certain

movement errors automatically.

• If an operation error is detected, the transfer mechanism will first stop moving.

• It will then back up a short distance, stop again, and then move forward in a second

attempt to reach the desired position.

• If this error recovery attempt is successful, processing continues normally.

7.2 Alarms

• However, if the second attempt to reach the position for

advancing the slide carriers is also unsuccessful, the system

emits a continuous audible alarm.

• The message shown here also appears in the display.

40

• As soon as the PAUSE/STOP key is pressed, the system

• In this event, any staining run currently in progress is termi-

returns to the start position, reinitializes, and switches to idle

mode.

nated and must be restarted.

Instructions for Use V1.1, RevB – 10/2012

Page 41

7.3 Fault Detection and Correction List

Possible causeIssue Corrective action

7. Troubleshooting

• The instrument cannot be

started up

• Display appears blue, but

no text is visible.

• Unit powers up, but the

transfer mechanism does

not initialize.

• The power supply cord is

not plugged into wall outlet

properly.

• The power supply cord is

not plugged into the stainer

properly.

• The power supply in the

instrument is faulty.

• The contrast may have to

be adjusted again.

• The control board in the

instrument is faulty.

• The main mechanism is

jammed.

• The motor seems to turn,

but the Lift bar does not

move because a belt is

worn or broken, or a set

screw on the motor has

come loose.

• Check the cable connections at both ends, replace

the power supply cord if

necessary.

• Inform Technical Service.

• Adjust the contrast as

described in

• Inform Technical Service.

• Check for visible external

obstruction and remove as

necessary.

Chapter 5.3.

• The motor does not turn.

Leica ST4020

• Motor or control board faulty.

• Inform Technical Service.

41

Page 42

7. Troubleshooting

Possible causeIssue Corrective action

• Keypad does not respond to

key presses

• Water does not flow. • Water hose is not

• Water overflows at the rinse stations.

• The keypad or the control

board is faulty.

connected.

• Tap is not open.

• The valve in the instrument

is faulty (does not open) or

the control board is faulty.

• Tap is open too far.

• The drain hose is clogged.

• Inform Technical Service.

• Connect the water hose to

the stainer and the tap.

• Turn on the tap.

• Inform Technical Service.

• Adjust the flow rate for the

rinsing water at the tap as

described in Chap. 5.4.

• The drain hose must not be

kinked.

• Check the drain hose for

objects that might block it.

42

• The drain hose is routed

incorrectly, gradient

insufficient.

• Place the drain hose so that

water does not have to rise

above the level of the drain

fitting.

Instructions for Use V1.1, RevB – 10/2012

Page 43

7. Troubleshooting

7.4 Power Failure

• Check whether there is a general power failure (no power).

• Check whether the power cord is inserted correctly into the power socket and whether the

power socket is switched on, if applicable.

• Check whether the power cable is plugged into the socket on the instrument properly.

• Check whether the power switch is switched on correctly.

• Some instrument malfunctions / failures are caused by defective fuses.

Check whether one or both secondary fuse(s) is/are faulty.

Before replacing a fuse, always switch the instrument off and unplug from power

supply. Defective fuses may be replaced only with the replacement fuses supplied

together with the instrument.

To replace a fuse, proceed as follows:

• With a screwdriver (30), carefully push out

the Hood (34) of the fuse insert (31) at rear of

instument and and open it upwards.

(Fig. 33).

30

33

Leica ST4020

34

31

32

Fig. 33

• Remove the fuse insert (31) – it contains two

fuses (32) on its rear.

• Check that the thin wire (33) in the glass

capillary of a fuse is intact. If not, the fuse

must be replaced.

Before plugging the power cable

back in and switching on the instrument, you must have identified and

corrected the cause of the faulty

fuse.

• Insert the fuse insert with the two fuses and

start up the instrument again.

43

Page 44

8. Optional accessories

8.1 Ordering information

Reagent Containers (6 in a pack) ............................................................................................... 14 0509 46437

Reagent Containers (48 in a pack) ............................................................................................ 14 0509 46439

Slide Carriers (4 in a pack) .......................................................................................................... 14 0509 46438

Slide Carriers (48 in a pack) ........................................................................................................ 14 0509 46440

Rinse Station (1container, 1 rinse nozzle, 1 fitting, 1 tubing).................................................. 14 0509 46441

Rinse Tubing (24" long; Ø 1/8”) .................................................................................................... 14 0509 46457

Tubing and Fitting Kit (48” rinse vessel tubing - Ø 1/8", 2 Y fittings, 3 in-line fittings,

2 plugs, 10 tie wraps).................................................................................................................... 14 0509 46459

Water Inlet Hose Assembly (with fitting, in-line filter, and 4 hose clamps,

2 brass fittings, 5' long, Ø 1/4" reinforced tubing) .................................................................... 14 0509 46443

Water Inlet Hose Assembly (with fitting, 2 hose clamps, 5' long, Ø 1/4" reinforced tubing,

no in-line filter) .............................................................................................................................. 14 0509 46532

Adapter kit for Water Inlet Hose Connection to Faucets (including one with

male thread) .................................................................................................................................. 14 0509 46444

3

/4” NPT

Drain Hose (5' long, Ø 5/8”), 1/8" tie wrap ................................................................................. 14 0509 46445

Exit Tank ......................................................................................................................................... 14 0509 46450

Support Bracket ............................................................................................................................ 14 0509 46570

Stabilizer Bar ................................................................................................................................. 14 0509 46451

Reagent Container Cover (metal) ............................................................................................... 14 0509 46442

Optional Plexiglas Hood............................................................................................................... 14 0509 46478

North American Power Cord ...................................................................................................... 14 0509 46479

European Power Cord .................................................................................................................. 14 0509 46480

British Power Cord ....................................................................................................................... 14 0509 46481

44

Instructions for Use V1.1, RevB – 10/2012

Page 45

Fig. 34

8. Optional accessories

Reagent Containers

6 in a pack

Order-No. 14 0509 46437

48 in a pack

Order-No. 14 0509 46439

Slide Carriers

4 in a pack

Order-No. 14 0509 46438

48 in a pack

Order-No. 14 0509 46440

Leica ST4020

Fig. 35

Rinse Station

1 container, 1 rinse nozzle, 1 fitting, 1 tubing

Order-No. 14 0509 46441

Fig. 36

45

Page 46

8. Optional accessories

Rinse Tubing

24" long; Ø 1/8”

Order-No. 14 0509 46457

Fig. 37

Tubing and Fitting Kit

48” rinse vessel tubing - Ø 1/8”, 2 Y fittings, 3 inline fittings, 2 plugs, 10 tie wraps

Fig. 38

46

Order-No. 14 0509 46459

Water Inlet Hose Assembly

with fitting, in-line filter, and 4 hose clamps, 2

brass fittings, 5' long, Ø 1/4" reinforced tubing

Order-No. 14 0509 46443

Fig. 39

Instructions for Use V1.1, RevB – 10/2012

Page 47

Fig. 40

8. Optional accessories

Water Inlet Hose Assembly

with fitting, 2 hose clamps, 5' long, Ø 1/4" reinforced tubing, no in-line filter

Order-No. 14 0509 46532

Adapter kit for Water Inlet Hose Connection to

Faucets

including one with 3/4” NPT male thread

Order-No. 14 0509 46444

Leica ST4020

Fig. 41

Drain Hose

5' long, Ø 5/8”), 1/8" tie wrap

Order-No. 14 0509 46445

Fig. 42

47

Page 48

8. Optional accessories

Exit Tank

Order-No. 14 0509 46450

Fig. 43

Support Bracket

Order-No. 14 0509 46570

48

Fig. 44

Stabilizer Bar

Order-No. 14 0509 46451

Fig. 45

Reagent Container Cover,

metal

Order-No. 14 0509 46442

Fig. 46

Instructions for Use V1.1, RevB – 10/2012

Page 49

Fig. 47

Fig. 48

8. Optional accessories

Optional Plexiglas Hood

Order-No. 14 0509 46478

North American Power Cord

Order-No. 14 0509 46479

European Power Cord

Order-No. 14 0509 46480

Fig. 49

Leica ST4020

British Power Cord

Order-No. 14 0509 46481

Fig. 50

49

Page 50

8. Optional accessories

Packaging,

with foam, outer carton, bubble wrap, and accessory box) with packaging instructions

Order-No. 14 0509 46455

Fig. 51

Outer Carton Only

Order-No. 14 0509 46456

50

Fig. 52

Instructions for Use V1.1, RevB – 10/2012

Page 51

Warranty

Service information

9. Warranty and service

Leica Biosystems Nussloch GmbH guarantees that the contractual product delivered has been subjected to a comprehensive quality control procedure based on the Leica in-house testing standards, and that the product is faultless and complies with all technical specifications and/or

agreed characteristics warranted.

The scope of the warranty is based on the content of the concluded

agreement. The warranty terms of your Leica sales organization or the

organization from which you have purchased the contractual product

shall apply exclusively.

If you are in need of technical customer service or spare parts, please

contact your Leica representative or the Leica dealer where you

purchased the unit.

Please provide the following information:

• Model name and serial number of the instrument.

• Location of the instrument and name of the person to contact.

• Reason for the service call.

• Delivery date

Decommissioning and disposal

The unit or parts of the unit must be disposed of according to existing

local applicable regulations.

Leica ST4020

51

Loading...

Loading...