Page 1

Leica SM2000 R

Sliding Microtome

Instruction Manual

Leica SM2000R – V2.1 English – 03/2004

Always keep this manual near the instrument!

Read carefully prior to operating the instrument!

Page 2

Page 3

1. Important information

Serial No. ...................................................................

Year of manufacture ................................................

Manufactured in: .. Federal Republic of Germany

The model, serial number and year of manufacture are

specified on the nameplate on the left of the instrument.

The information, numerical data, notes and value judgments contained in this manual represent the current

state of scientific knowledge and state-of-the-art technology as we understand it following thorough investigation in this field. We are under no obligation to update the present manual periodically and on an ongoing basis according to the latest technical developments, nor to provide our customers with additional

copies, updates etc. of this manual.

For erroneous statements, drawings, technical illustrations etc. contained in this manual we exclude liability as far as permissible according to the national

legal system applicable in each individual case. In particular, no liability whatsoever is accepted for any financial loss or consequential damage caused by or

related to compliance with statements or other information in this manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the

present manual are not to be considered as warranted

characteristics of our products. These are determined

only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical specifications as well as manufacturing processes without

prior notice. Only in this way is it possible to continuously improve the technology and manufacturing techniques used in our products.

This document is protected under copyright laws. Any

copyrights of this document are retained by Leica

Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of any

parts thereof) by means of print, photocopy, microfiche,

web cam or other methods – including any electronic

systems and media – requires express prior permission in writing by Leica Biosystems Nussloch GmbH.

For the instrument serial number and year of manufacture, please refer to the name plate at the back of

the instrument.

© Leica Biosystems Nussloch GmbH

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17-19

D-69226 Nussloch

Germany

Telephone: 0 62 24/143-0

Telefax: 0 62 24/143-200

eMail: histo_info@leica-microsystems.com

Homepage: http://www.histo-solutions.com

Leica SM2000 R – Sliding Microtome

3

Page 4

2. Table of contents

1. Important information ........................................................................................................................ 3

2. Table of contents ................................................................................................................................ 4

3. Safety instructions for handling the instrument........................................................................... 5

3.1 Safety devices ....................................................................................................................................... 5

4. Technical data..................................................................................................................................... 7

5. General description............................................................................................................................ 8

5.1 Leica SM2000R - Overview ................................................................................................................................ 8

5.2 General description...........................................................................................................................................10

5.3 Standard delivery ................................................................................................................................ 10

6. Unpacking and Setup....................................................................................................................... 11

6.1 Unpacking ........................................................................................................................................................... 11

6.2 Site requirements ..............................................................................................................................................11

6.3 Setup ...................................................................................................................................................................12

6.4 Mounting the accessories................................................................................................................. 13

7. Operating the instrument ................................................................................................................ 14

7.1 Mounting and orienting the specimen ...........................................................................................................14

7.2 Clearance angle adjustment on the knife holder .........................................................................................14

7.3 Inserting the knife or disposable blade holder ............................................................................................. 14

7.4 Trimming ............................................................................................................................................................. 15

7.5 Sectioning ............................................................................................................................................ 15

8. Trouble shooting ............................................................................................................................... 16

9. Cleaning and maintenance ............................................................................................................. 17

9.1 Cleaning .............................................................................................................................................................. 17

9.2 Maintenance........................................................................................................................................ 17

10. Accessories ....................................................................................................................................... 18

10.1 Disposable blade holder ...................................................................................................................................18

10.2 Section waste tray ............................................................................................................................................18

10.3 Distance plate for knife holder ......................................................................................................... 18

11. Ordering information ....................................................................................................................... 19

12. Warranty and service ...................................................................................................................... 20

4

Instruction manual V2.1 – 03/2004

Page 5

3. Safety instructions for handling the instrument

3.1 Safety devices

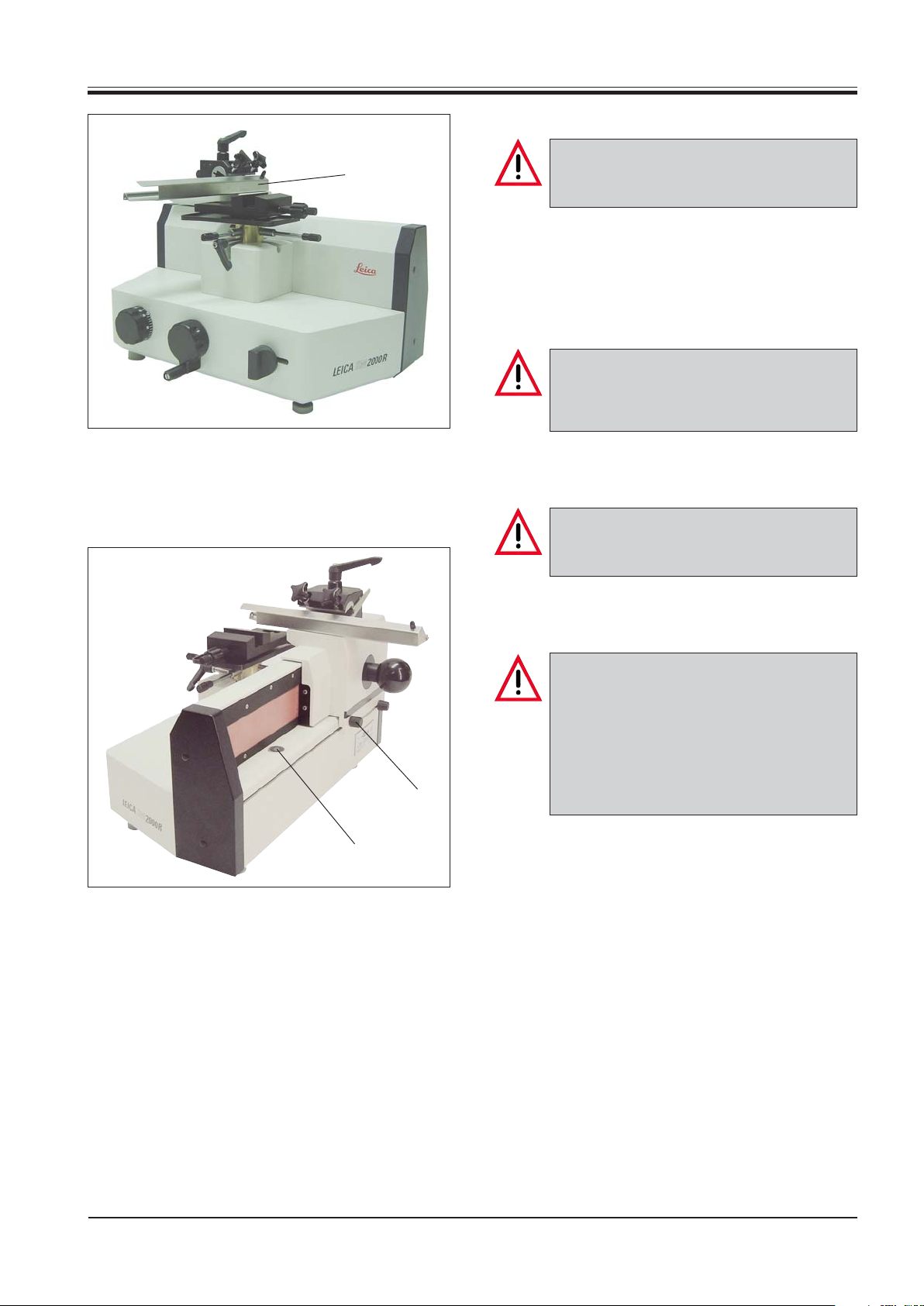

Fig. 5.1

14

The safety devices on the instrument and accessory equipment must not be removed or

modified!

The instrument incorporates the following safety devices: Knife guard (14) on the knife holder, knife sledge

locking knob (23) and magnetic knife sledge immobilizer (24).

Knife guard on the knife holder

Prior to manipulating the knife or specimen,

or changing the knife or specimen, and during breaks, always cover the cutting edge

with the knife guard (14)!

Knife sledge locking knob

Prior to changing the specimen or knife and

before transporting the instrument, lock the

knife sledge with the locking screw (23).

Fig. 5.2

24

23

Magnetic knife sledge immobilizer

Caution! The knife sledge movement is extremely smooth. It may occur that the sledge

moves during section removal.

To prevent the sledge from moving accidentally, pull it to the front limit of the slideway,

where it is held in position by the magnetic

knife sledge immobilizer (24), before removing the section.

Leica SM2000 R – Sliding Microtome

5

Page 6

3. Safety instructions for handling the instrument

Transport and setup

• The instrument must be transported in an

upright position!

• Before transporting the instrument, the

knife sledge must be locked with the locking screw (23, Fig. 4.2)!

• Do not carry the instrument by holding it at

movable parts!

• The safety devices on the instrument and

accessory equipment must not be removed

or modified!

Operating the instrument

• Take care when handling microtome

knives and disposable blades!

The cutting edge is extremely sharp and

may cause severe injury!

• Never leave knives and knife holders with

a mounted knife or blade lying around! Always put the knives back into the knife

case when not in use!

Cleaning

• Before cleaning, remove the knife or disposable blade!

• Do not use solvents that contain acetone

or xylene!

• Ensure that no liquids enter the interior of

the instrument when cleaning!

• When using detergents, please comply

with the safety precautions of the manufacturer!

Maintenance

• Only qualified and authorized service personnel may access the internal components of the instrument for service and repair!

• Do not place a knife on a table with the

cutting edge facing upwards!

• Never try to catch a falling knife!

• Caution! The knife sledge movement is extremely smooth. It may occur that the

sledge moves during section removal.

To prevent the sledge from moving accidentally, pull it to the front limit of the

slideway, where it is held in position by

the magnetic knife sledge immobilizer (24),

before removing the section.

• Always clamp the specimen first clamping before the knife!

• Prior to manipulating the knife or specimen, or changing the specimen or knife,

and during breaks, always cover the cutting edge with knife guard and lock the

knife sledge with the locking knob!

• Always wear protective glasses when

sectioning brittle specimens!

Risk of splintering!

6

Instruction manual V2.1 – 03/2004

Page 7

Type SM 2000 R

Sliding microtome

Operating

temperature range: +10°C to +40°C

Section thickness

setting: 1-60 μm

0-2 μm in 0.5 μm increments

2-10 μm in 1 μm increments

10-20 μm in 2 μm increments

20-60 μm in 5 μm increments

Automatic

specimen advance: 0-30 μm

Overall feed: 40 mm

Dimensions and weight

Width: 300 mm

Depth: 440 mm

Height: 330 mm

4. Technical data

Weight

(incl. knife holder): 25.5 kg

Leica SM2000 R – Sliding Microtome

7

Page 8

5. General description

5.1 Leica SM2000R - Overview

Parts list

1 Section thickness adjusting knob

2 Coarse feed wheel

3 Manual feed

4 Mount for specimen clamp

5 Specimen cylinder

6 Universal cassette clamp

6a 2 attachment screws (universal cassette clamp) - see Fig. 13.1

7 Standard specimen clamp

7a 4 attachment screws (standard specimen clamp) - see Fig. 13.1

8 Locking lever for specimen orientation

9 Adjusting screw for specimen orientation - x-axis

10 Adjusting screw for specimen orientation - y-axis

11 Knife sledge

12 Grip for knife sledge movement

13 Knife holder

14 Knife guard

15 Disposable blade holder (optional accessory)

16 Knife clamping screw

17 Clamping lever for knife holder

18 4 holes in the knife sledge for mounting the knife holder (covered by the knife holder

in Fig. 7.1 and 7.2, see Fig 12.1)

19 Clamping screw for clearance angle adjustment

20 Adjusting lever for clearance angle

21 Clearance angle scale

22 Adjusting knob for automatic feed

23 Locking screw for knife sledge

24 Magnetic knife sledge immobilizer

25 Height adjustment screws

26 Section waste tray (optional accessory)

27 Distance plate for knife holder (optional accessory, Fig. 18.2)

8

Instruction manual V2.1 – 03/2004

Page 9

5. General description

17

15

16

14

6

4

9

8

5

1

2

3

Fig. 9.1

10

25

13

26

20

19

7

Fig. 9.2

21

11

12

22

23

24

Leica SM2000 R – Sliding Microtome

9

Page 10

5. General description

5.2 General description

5.3 Standard delivery

The Leica SM2000R is a manually operated sliding microtome.

The micrometer feed system is located in an enclosed housing. The microtome has

maintenance-free cross roller bearings. Lubricating is therefore not required.

The knife holder can be mounted in any of the four mounting positions on the knife

sledge. The knife holder is designed to accommodate both conventional microtome

knives or a disposable blade holder and has an integrated knife guard. The knife or

disposable blade holder does not need to be removed for clearance angle adjustment.

The microtome can be fitted with a standard specimen clamp for paraffin blocks or a

universal cassette clamp.

The Leica SM2000R was designed to conform with the directives of the European

Union and manufactured using most up-to-date quality control procedures certified

under DIN EN ISO 9001.

The Leica SM 2000 R is available in three configurations:

Leica SM 2000 R without specimen clamp

Leica SM 2000 R with universal cassette clamp

Leica SM 2000 R with fixed-jaw standard specimen clamp

The basic instrument includes the following:

1 Tool set:

-1 Allen key, size 3 14 0194 04764

-1 Single-ended open-jaw wrench, size 10 14 0330 04158

1 Dust cover 14 0212 18961

1 Section waste tray 14 0453 25167

1 Instruction manual Leica SM2000R- G/E/F/S 14 0453 80001

You will find these accessories as well as any further accessories that you may have

ordered, in the cardboard box of the instrument.

Compare the delivered components with the parts list and your order. Should you find

any discrepancies, please contact your Leica sales office without delay.

10

Page 11

6.1 Unpacking

6.2 Site requirements

6. Unpacking and Setup

First check the shipment for external damages upon arrival. If it is evident

that the shipment was damaged during transport, please make a claim to the

carrier immediately.

• Open the cardboard box.

• Remove all foam material.

• Take out all accessories and the instruction manual.

Do not carry the instrument holding it at movable parts!

• To lift the instrument from the box, hold it at the lower part of the housing and

place it on a stable, vibration-free laboratory table.

The installation site must meet the following requirements:

- Stable, plane surface

- Room temperature always between +10°C and +40°C

- Relative air humidity should not exceed 80 %.

11

Page 12

6. Unpacking and setup

6.3 Setup

11

Loosening the knife sledge locking screw

18

Screw (23) secures the knife sledge during

transport.

In daily operation it is also used lock the knife

sledge in place.

• Loosen the screw (23) at the rear of the instrument

to move the knife sledge (11).

25

Fig. 12.1

2

23

12

11

25

Testing the instrument functions

• To test the knife sledge movement hold the sledge

(11) at the grip (12) and move it repeatedly back and

forth over the entire length of the slideway.

• Test the object cylinder movement by turning the

coarse feed wheel (2).

Counterclockwise turning moves the object cylinder

(5) up.

Clockwise turning moves the object cylinder down.

When reaching the upper or lower limit, the wheel cannot be turned further.

Horizontal alignment

The microtome is horizontally aligned at the factory. If

a completely level or horizontal surface is not available at the installation site the instrument can be adjusted to the conditions.

• To horizontally align the instrument, adjust the

height adjustment screws (25) using a size 10 fork

wrench.

Fig. 12.2

12

Instruction manual V2.1 – 03/2004

Page 13

6.4 Mounting the accessories

7a

6a

6. Unpacking and setup

If there is no specimen clamp, mount the

specimen clamp now.

Mounting the specimen clamp

7

Fig. 13.1

6b

Two specimen clamps are available: the universal cassette clamp (6) and the standard specimen clamp (7)

with a fixed and movable jaw.

6

• Fix the universal cassette clamp (6) to the mount (4,

Fig. 7.1) with the two screws (6a) using an Allen key

size 3. The clamping lever (6b) should be directed

to the operator.

• Fix the standard specimen clamp (7) to the mount

(4, Fig. 7.1) with the four screws (7a) using an Allen

key size 3.

Mounting the knife holder

4 mounting positions are available for the

knife holder to meet different sectioning requirements. The knife holder can be mounted

in any of the 4 holes of the knife sledge.

The plastic grip of the clamping lever can be

repositioned as preferred by the user.

Pull the grip out of the lever, hold it in this position, and turn it to the desired position. It will

lock automatically when released.

13

Fig. 13.2

18

17

• Screw the clamping lever (17) for the knife holder

(13) down in one of the four holes (18, Fig. 10.1) of

the knife sledge (11).

• Push the base plate of the knife holder (13) against

the clamping lever (17) and fully screw the lever

down until the knife holder is securely fixed.

Oblique positioning of the knife holder

• Loosen the clamping lever (17) and position the knife

holder (13) as required.

• Retighten the clamping lever (17) to fix the knife

holder in position.

Leica SM2000 R – Sliding Microtome

13

Page 14

7. Operating the instrument

16

15

9

6

8

10

14

7.1 Mounting and orienting the specimen

Prior to manipulating the knife or specimen,

or changing the specimen or knife, and during breaks, always cover the cutting edge

with knife guard and lock the knife sledge

with the locking knob!

• Clamp an embedding cassette in the universal cassette clamp (6) or a paraffin block in the standard

specimen clamp (7).

• To orient the specimen surface towards the knife,

loosen the locking lever (8).

• Orient the sample by means of the adjusting screws

(9) and (10).

• Retighten the locking lever (8) after orienting.

Fig. 14.1

Fig. 14.2

21

16

20

19

7.2 Clearance angle adjustment on the knife

holder

• Loosen the clamping screw (19) and the knife

clamping screw (16).

• Select the desired angle with the adjusting lever (20)

on the clearance angle scale (21).

• Retighten the clamping screws (19) and (16) to fix

the angle setting.

7.3 Inserting the knife or disposable blade

holder

Take care when handling microtome knives

and disposable blades!

The cutting edge is extremely sharp and may

cause severe injury!

• Unscrew the knife clamping screw (16) on the knife

holder.

• Carefully insert the knife or disposable blade holder

(15, Fig. 14.1) with the blade into the knife holder

from the left and hold in place.

• To clamp turn the knife clamping screw (16) clockwise.

The screw does not need to be fully tightened. Good

sectioning results may be obtained when the screw

is tightened with a medium effort.

14

Instruction manual V2.1 – 03/2004

Page 15

7. Operating the instrument

7.4 Trimming

For trimming, the specimen feed can be disengaged

either by turning the coarse feed wheel (2) or by operating the manual feed lever (3).

1

2

Fig. 15.1

14

11

• Hold the knife sledge (11) at the grip (12) and place

the sledge behind the specimen.

• Pull the knife guard (14) of the knife holder to the

right.

• To feed the specimen towards the knife, turn the

coarse feed wheel (2) counterclockwise;

or

select the required section thickness with the section thickness adjusting knob (1) and pull the manual

feed lever to the front (3). Each lever activation

3

causes a specimen feed by the selected value. The

coarse feed wheel will turn at the same time.

• Move the knife sledge forth and back until the speci-

men surface is trimmed as required.

7.5 Sectioning

• Select the required section thickness with the sec-

tion thickness adjusting knob (1, Fig. 15.1).

When using the automatic advance feature,

make sure to move the knife sledge against

the limit stop position to disengage an automatic feed after each section.

Fig. 15.2

24

22

The position of the adjusting knob (22) determines the

point where the automatic feed takes place. The feed

should take place immediately before the specimen,

or behind the sample from the operator‘s view.

• To use the automatic feed feature, loosen the ad-

justing knob (22), place it in the required position,

and retighten the knob.

• To produce the section, pull the knife sledge over

the specimen at a constant speed.

Caution! The knife sledge movement is extremely smooth. It may occur that the sledge

moves during section removal.

To prevent the sledge from moving accidentally, pull it to the front limit of the slideway,

where it is held in position by the magnetic

knife sledge immobilizer (24), before removing the section.

• Carefully remove the section with a small brush.

Leica SM2000 R – Sliding Microtome

15

Page 16

8. Trouble shooting

Possible causeProblem Correction

Thick/thin sections

The section thickness varies from one

section to another. In extreme cases,

sections are skipped meaning that a

section is not obtained.

Compressed sections

The sections are extremely compressed, wrinkled or jammed together.

- Insufficient knife/blade inclination;

consequently the clearance angle is

too small.

- Insufficient clamping of specimen

and/or knife.

- Blunt knife/blade.

- Blunt knife/blade.

- Specimen too warm.

- Clearance angle too big.

Systematically try several clearance

angle adjustments, until the optimum

angle is found.

- Check if all levers are locked and

screws are tightened on the specimen and knife holder systems. Retighten the levers and screws if necessary.

- Use a different part of the knife or

blade edge or use a new knife/blade.

- Use a different part of the knife or

blade edge or use a new knife/blade.

- Precool the specimen on a cold

plate.

- Cool the specimen in iced water immediately before sectioning.

- Systematically decrease the clearance angle until the optimum adjustment is obtained.

Sections exhibit scratches and chatter

marks.

No specimen feed takes place. No section obtained.

- Clearance angle too big.

- Inappropriate knife profile.

- Insufficient clamping of specimen

and/or knife.

- Upper feed limit reached.

- Systematically decrease the clearance angle until the optimum adjustment is obtained.

- Use knife with different profile.

- Check if all levers are locked and

screws are tightened on the specimen and knife holder systems. Retighten the levers and screws if necessary.

- Turn the coarse feed wheel clockwise to lower the specimen.

16

Instruction manual V2.1 – 03/2004

Page 17

9.1 Cleaning

9.2 Maintenance

9. Cleaning and maintenance

The painted surfaces are not resistant against acetone or xylene.

Only use mild commercial detergents or soap solution for cleaning!

Ensure that no liquids enter the interior of the instrument when cleaning!

Before cleaning, remove the knife or disposable blade!

• Clean the painted surfaces with commercial detergents or soap solution.

Standard lacquer cleaners are recommended for the lacquer finish.

• Anodized parts such as specimen clamps may be cleaned with solvent.

Only qualified and authorized service personnel may access the internal components of the instrument for service and repair!

The microtome is virtually maintenance-free. To ensure a smooth operation of the

instrument over several years we recommend the following:

• Have the instrument inspected once a year by a qualified service engineer authorized by Leica.

• Enter into a service contract at the end of the warranty period.

For further information, please contact your local Leica service center.

• Clean the instrument every day.

• Lubricate the object cylinder (5, Fig. 7.1), and knife holder (13) with the oil No. 405

from time to time.

Leica SM2000 R – Sliding Microtome

17

Page 18

10. Accessories

10.1 Disposable blade holder

Fig. 18.1

15a

16

15

26

Instead of a conventional microtome knife, a disposable blade holder (15) can be inserted in the knife

holder.

• To clamp the disposable blade, loosen the three

screws (15a), carefully insert the blade, and retighten the screws evenly.

• To insert the disposable blade holder into the knife

holder, unscrew the knife clamping screw (16) sufficiently, and insert the disposable blade holder

between the jaws of knife holder from the left, and

retighten the clamping screw (16).

• Select the appropriate clearance angle (see 7.2).

10.2 Section waste tray

The section waste tray (26) protects the microtome

housing against paraffin debris. With the section waste

tray section debris is collected can be disposed of rapidly and easily.

• Place the section waste tray (26) on the horizontal

surface of the microtome from the left.

Fig. 18.2

13

27

27a

27a

10.3 Distance plate for knife holder

When sectioning very high blocks, the mounting position of the knife holder can be increased by using a

distance plate (27). The distance plate is delivered with

an overlength clamping lever (27a).

• Carefully remove the knife or disposable blade

holder from the knife holder.

• Remove the knife holder from the knife sledge.

• Screw the clamping lever (27a) in any of the four

holes (18, Fig. 10.1) of the knife sledge.

• Place the distance plate (27) and knife holder (13)

on the knife sledge, push the slot against the clamping lever (27a), and screw the clamping lever (27a)

down until knife holder and distance plate are firmly

secured.

27

Fig. 18.3

18

Instruction manual V2.1 – 03/2004

Page 19

11. Ordering information

SM2000R sliding microtome - Basic instrument ............................................................................................. 14 0453 25122

SM2000R sliding microtome - Basic instrument with universal cassette clamp .......................................14 0453 25120

SM2000R sliding microtome - Basic instrument with standard specimen clamp .....................................14 0453 25121

Accessories

Universal cassette clamp ....................................................................................................................................14 0413 24198

Standard specimen clamp ..................................................................................................................................14 0413 18850

Disposable blade holder EC 240 H for high profile blades including

dispenser of 50 disposable blades, 2 clamping plates, fixing screws and tools ........................................ 14 0368 26456

Disposable blade holder EC 240 L for low profile blades including

dispenser of 50 disposable blades, 2 clamping plates, fixing screws and tools ........................................ 14 0368 26457

Distance plate for knife holder including overlength clamping lever .......................................................... 14 0413 18967

Section waste tray................................................................................................................................................14 0453 25167

Dust cover ..............................................................................................................................................................14 0212 18961

Consumables

Dispenser of 50 disposable blades - high profile.............................................................................................14 0358 12881

Dispenser of 50 disposable blades - low profile ..............................................................................................14 0358 13583

Leica SM2000 R – Sliding Microtome

19

Page 20

12. Warranty and service

Warranty

Leica Biosystems Nussloch GmbH guarantees that the contractual product delivered

has been subjected to a comprehensive quality control procedure based on the Leica

in-house testing standards, and that the product is faultless and complies with all

technical specifications and/or agreed characteristics warranted.

The scope of the warranty is based on the content of the concluded agreement. The

warranty terms of your Leica sales organization or the organization from which you

have purchased the contractual product shall apply exclusively.

Technical service information

If you require technical service or replacement parts, please contact your Leica sales

representative or dealer who sold the product.

Please provide the following information:

• Model name and serial number of the instrument.

• Location of the instrument and name of the person to contact.

• Reason for the service call.

• Date of delivery.

Decommissioning and disposal

The instrument or parts of the instrument must be disposed of in compliance with the

local laws.

20

Instruction manual V2.1 – 03/2004

Page 21

13. EC Declaration of Conformity

EC Declaration of Conformity

We herewith declare, in exclusive responsibility, that the instrument

Leica SM2000 R – Sliding Microtome

was developed, designed and manufactured to conform with the

• Directive 2006/42/EC of the European Parliament and of the Council on machinery

The following harmonized standards were applied:

• DIN EN ISO 12100-1: 2003

Safety of machinery.

Basic concepts, general principles for design.

Part 1: Basic terminology, methodology

• DIN EN ISO 12100-2: 2003

Safety of machinery.

Basic concepts, general principles for design.

Part 2: Technical principles and specifications.

In addition, the following in-house standards were applied:

• DIN EN ISO 9001: 2000.

Quality management systems - Requirements

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17-19

D-69226 Nussloch

May 14, 2008

Leica SM2000 R – Sliding Microtome

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anne De Greef-Safft

President Biosystems Devision

21

Page 22

22

Instruction manual V2.1 – 03/2004

Loading...

Loading...