Page 1

High-Speed Processing of Large

TM

Specimens on the Peloris

Dual

Retort Tissue Processor

Geoffrey Rolls

Leica Microsystems, Biosystems Division, Melbourne, Australia

Page 2

High-Speed Processing of Large Specimens on the

Peloris

TM

Dual Retort Tissue Processor

Geoffrey Rolls

Leica Microsystems, Biosystems Division, Melbourne, Australia

This paper presents the results of comparative evaluations carried out during field trials in two large

public hospitals, that set out to examine whether the design features of the Peloris dual retort tissue

processor led to reduced processing times for large specimens without compromising quality. In the

context of a busy histopathology laboratory, we demonstrate that the introduction of Peloris processing

would allow the processing of large, dense specimens in 6 hours leading to the completion of more runs

in a working day and the reduction of turnaround times.

Ten sequential six hour and nine hour processing runs were undertaken on a Peloris processor at either

45 °C or 55 °C and the resultant blocks and sections were evaluated for quality using a comprehensive

scoring system. Peloris results were compared to those achieved on a matched panel of specimens

processed using a processor that represents the industry standard (the Tissue-Tek

show that for large, dense specimens Peloris can produce results of an equivalent standard to an

“overnight” schedule (13 hours) run on a VIP using much shorter schedules. Results also indicate that

there is some advantage in processing at higher temperature (55 °C) for both the six and nine hour

schedules.

®

VIP™). The results

Introduction

A fundamental requirement in the histopathology laboratory is to

safely and effectively process specimens. Sectioning of paraffin

blocks should be straightforward with the resultant sections

being of a high standard demonstrating excellent morphological

detail. This applies to the complete range of specimen types and

sizes, ranging from tiny, delicate fragments to sizeable wedges

of dense tissue. In busy laboratories these requirements must be

balanced against increasing demands to reduce turnaround times,

to process greater numbers of specimens and to complete more

runs in the working day.

The traditional view embraces a conservative approach to

processing of all specimen types. A survey of standard histology

texts published in the last twenty years reveals an average

processing time of 15.7 hours for “routine overnight processing”

using xylene as a clearing agent. A survey of local and international

laboratories shows that the average duration of a “routine

overnight” schedule on an enclosed processor using xylene and

excluding any additional fixation steps is 10.3 hours (see Table 1 for

details). Of course these laboratories do use shorter schedules for

special purposes, where particular types of specimens are to be

processed (eg. endoscopic biopsies), or where specimens falling

within strict size limits are included.

These field trials were conducted by Vision BioSystems (VBS).

Vision Biosystems has since formed part of the Biosystems Division

of Leica Microsystems. What is needed then, is a processor which

can effectively process a full load of cassettes, say 200 – 300 per

retort, containing the complete range of tissues normally included

in a “routine overnight run”, but doing so in a much shorter time,

preferably within the six hour threshold that would allow them

to be completed within one working day. The Peloris dual retort

tissue processor has been designed with these requirements in

mind. Compared to processors representing the current industry

standard it has a much faster and more even heating response in

the retorts, fast fill and drain actions, a basket design allowing better

fluid exchange with reduced reagent carryover, and more effective

agitation. These features are designed to reduce processing times.

The purpose of this paper is to present the results of comparative

evaluations carried out during field trials that set out to show that

the design features of Peloris lead to reduced processing times

without compromising quality.

/ 1

Page 3

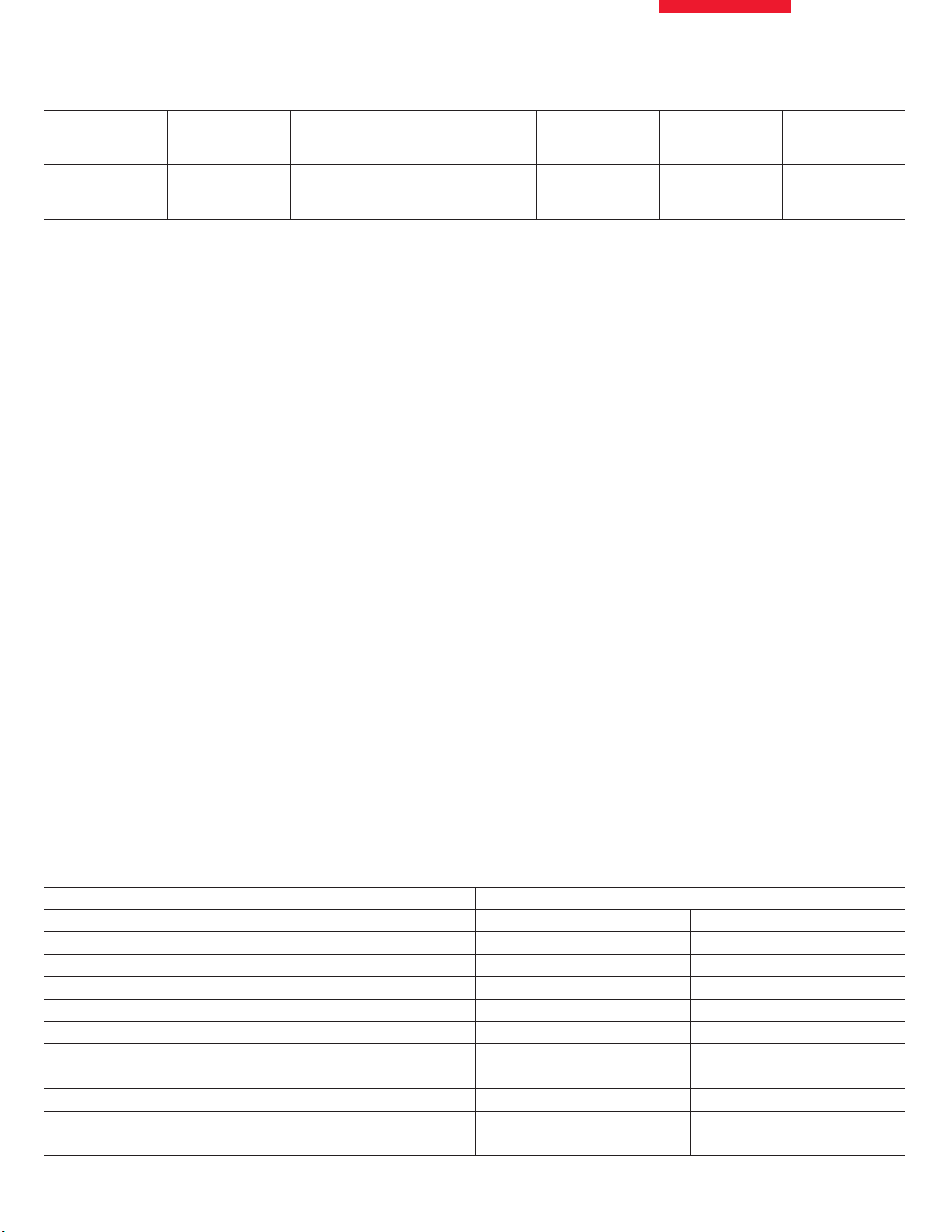

Number of Labs Types of Processor

(number)

25 Leica TP1050 (20)

VIP (4)

Shandon (1)

Table 1. Routine overnight processing schedules

Schedule Description Average Number

of Steps

Routine overnight 13 12 620 694

Average Number

of Steps Excluding

Fixation

Average Total Time

Excluding Fixation

(minutes)

Average Total Time

(minutes)

Independent field trials were carried out in two large public

teaching hospitals in Melbourne, Australia, during 2003 and 2004.

They were conducted in the Anatomical Pathology laboratories

of the Royal Melbourne Hospital (RMH) (1200 beds) and at Austin

Health (AH) (840 beds). The evaluations relating to processing speed

were conducted in a similar fashion during both field trials. They

involved senior histology scientists from both external laboratories

together with scientists from Vision BioSystems, in the assessment

of processed blocks and stained sections from a number of

processing runs. Using duplicate sets of matched specimens of

a variety of dimensions and types, multiple processing runs were

carried out using Peloris and an “industry standard” processor

in each laboratory (in both cases a Tissue-Tek VIP). Results from

Peloris rapid schedules run at 45 °C and 55 °C were compared with

VIP standard “routine overnight schedules” currently used in each

laboratory which served as a normal control.

Processing at elevated temperatures is widely accepted as a

means of accelerating processing by increasing diffusion rates

in specimens (1, 2) although some authors believe that this can

cause additional shrinkage and staining problems (2, 3). We have

certainly not found this to be the case during extensive testing of

Peloris. These trials provided an opportunity to compare results of

rapid processing at 45 °C and 55 °C and to confirm that there were

no adverse effects from using the higher temperatures.

The assessments were carried out independently with staff at

the external sites using slightly different scoring methods, with

the assessors being unaware of the schedules used to process

the specimens. The scoring system used by VBS staff has been

extensively used throughout the development and testing of Peloris

to evaluate the quality of tissue processing and as a mechanism for

optimizing standard processing protocols. A score is calculated by

assessing 23 parameters and is expressed as a percentage. The

complete details are provided elsewhere(4).

Method

Testing throughout the RMH and AH trials was conducted such

that all processing results were compared directly to those of their

existing tissue processors (RMH - Tissue-Tek VIP 4, AH Tissue-Tek

VIP 5). As far as possible specimens for assessment were kept

identical in terms of size, fixation and source on both instruments

for each processing run. All specimens were thoroughly fixed. Not

every specimen in each run was evaluated. Any specimens that

were not for evaluation but loaded into retorts on Peloris to provide

a representative case load comparable to the VIP, consisted of pig

tissue supplied by VBS. Typical specimens used in assessment of

processing and their approximate dimensions are shown in Table 2.

At each laboratory for each of 10 sequential working days, three

processing runs were carried out. Two rapid schedules were run

on Peloris using the two retorts. Retort A was used for the 6 hour

schedule and Retort B for the 9 hour. Runs were carried out daily

at either 45 °C or 55 °C. For each 6 and 9 hour run on Peloris a

routine overnight run was completed on a VIP containing a normal

diagnostic specimen load together with a set of the duplicate test

specimens (200 – 250 cassettes). These served as our normal

control group. Fresh reagents were provided for run 1 and not

changed for the 10 runs on both Peloris and the respective VIP.

For each Peloris run, in addition to the test specimens, cassettes

containing various pig tissues were included to take the specimen

number to 228, which provided an equivalent specimen load to that

in the respective VIP processor (75% capacity of each retort). The

processing schedules used are shown in Tables 3 and 4. Figure

1 illustrates the difference in step times between the various

schedules used. Note that the total pump and drip times in the

Peloris schedules are considerably shorter than those of the VIP.

Royal Melbourne Hospital (RMH) Austin Hospital (AH)

Tissue Dimensions (mm) Tissue Dimensions (mm)

Intestine 15 x 10 x 5 Intestine 30 x 8 x 5

Liver (pig) 25 x 15 x 5 Intestine 20 x 15 x 5

Spleen 15 x 10 x 5 Liver (pig) 20 x 20 x 5

Lung 25 x 15 x 5 Liver 30 x 25 x 5

Kidney (pig) 15 x 10 x 5 Lung 20 x 20 x 5

Heart (pig) 20 x 15 x 5 Lung 20 x 15 x 5

Thyroid 20 x 10 x 5 Kidney (pig) 20 x 15 x 5

Skin 30 x 25 x 5 Kidney 15 x 15 x 5

Breast 30 x 25 x 5 Heart (pig) 20 x 20 x 5

Prostate Chips Heart 20 x 15 x 5

Table 2. Typical specimens used in assessment of processing

/ 2

Page 4

Schedule P1 P2

9 Hour Xylene 6 Hour Xylene

Step No. Reagent Time (minutes) Time (minutes) Drip Time

(seconds)

1 Formalin 0 45 10 45 or 55 Off Med

2 70% ethanol 5 10 10 45 or 55 Off Med

3 90% ethanol 10 10 10 45 or 55 Off Med

4 100% ethanol 15 15 10 45 or 55 Off Med

5 100% ethanol 40 20 10 45 or 55 Off Med

6 100% ethanol 50 20 10 45 or 55 Off Med

7 100% ethanol 50 35 10 45 or 55 Off Med

8 xylene 35 10 10 45 or 55 Off Med

9 xylene 40 25 10 45 or 55 Off Med

10 xylene 50 35 10 45 or 55 Off Med

11 Paraffin wax 35 25 10 60 Vac Med

12 Paraffin wax 50 35 10 60 Vac Med

13 Paraffin wax 65 45 10 60 Vac Med

Total step time 505 330

Total processing

time

Table 3. Peloris processing schedules

531

(8.9 hours)

356

(5.9 hours)

Temp º C P/V Stir

Schedule V1 (RMH) Schedule V2 (AH)

13 Hour Xylene 13 Hour Xylene

Step No. Reagent Time (minutes) Temp ºC P/V Reagent Time (minutes) Temp ºC P/V

1 Formalin 30 40 Yes Formalin 120 45 Yes

2 Formalin 30 40 Yes 70% Ethanol 30 40 Yes

3 70% Ethanol 30 40 Yes 90% Ethanol 30 40 Yes

4 95% Ethanol 45 40 Yes 100% Ethanol 60 40 Yes

5 100% Ethanol 45 40 Yes 100% Ethanol 60 40 Yes

6 100% Ethanol 75 40 Yes 50/50 Eth/Xyl 60 40 Yes

7 50/50 Eth/Xyl 90 40 Yes 100% Ethanol 60 40 Yes

8 100% Ethanol 75 40 Yes Xylene 30 40 Yes

9 Xylene 60 40 Yes Xylene 60 40 Yes

10 Xylene 90 40 Yes Xylene 60 40 Yes

11 Wax 60 58 Yes Wax 30 58 Yes

12 Wax 60 58 Yes Wax 30 58 Yes

13 Wax 60 58 Yes Wax 60 58 Yes

14 Wax 0 58 Yes Wax 60 58 Yes

Total step time 750 750

Total processing

time

Table 4. Tissue-Tek VIP processing schedules

810

(13.5 hours)

810

(13.5 hours)

/ 3

Page 5

Schedule and Processor

Peloris 6 hr at 55 ºC

Peloris 6 hr at 45 ºC

Peloris 9 hr at 55 ºC

Peloris 9 hr at 45 ºC

VIP 13 hr control RMH

VIP 13 hr control AH

Step Times in Minutes

Fixation Dehydration Clearing Infiltration Pumping and drip time

0 200 400 600 800 1,000

Figure 1. Routine overnight processing schedules

After each processing run the specimens were embedded,

sections cut and stained with H&E using the standard methods of

each laboratory. During microtomy all blocks were assessed for

Specimens scoring between 65% and 75% are considered to be of

a good standard for diagnosis. Any specimen scoring above 80% is

considered to be of exceptional quality.

ease of sectioning and other parameters (4). All test sections were

screened on-site by hospital scientists to check that they were of

an overall satisfactory standard. Sections were deemed to be satisfactory if they scored 1 or 2 on a simple three point scale (0, 1, or 2).

A representative sample of blocks and slides from the test group

of at least 4 per run, were scored by VBS staff according to the

full VBS protocol (4). In using this protocol any specimen which

scores <50% in any single parameter is considered a “fail”.

Schedule Number of Runs Number Satisfactory/Number of

Test Slides Screened (RMH & AH)

RMH Evaluation

Peloris 6hr at 45 °C 5 60/60 26/26 73%

Peloris 9hr at 45 °C 5 60/60 26/26 72%

Peloris 6hr at 55 °C 5 60/60 28/28 75%

Peloris 9hr at 55 °C 5 60/60 28/28 75%

VIP 13 hr control 10 88/90 49/51 73%

AH Evaluation

Peloris 6hr at 45 °C 5 52/54 21/22 68%

Peloris 9hr at 45 °C 5 54/54 22/22 69%

Peloris 6hr at 55 °C 5 54/54 22/22 78%

Peloris 9hr at 55 °C 5 54/54 22/22 79%

VIP 13 hr control 10 78/78 24/24 75%

Combined results RMH and AH

Peloris 6hr at 45 °C 10 112/114 47/48 70%

Peloris 9hr at 45 °C 10 114/114 48/48 71%

Peloris 6hr at 55 °C 10 114/114 50/50 77%

Peloris 9hr at 55 °C 10 114/114 50/50 77%

VIP 13 hr control 20 196/198 103/105 74%

Table 5. Combined results from 20 processing runs

Results

Table 5 shows the combined results from 20 processing runs (10

runs at RMH and 10 runs at AH). Figure 2 is included to demonstrate

the consistent quality of processed blocks over 10 days for five

consecutive runs, at either 45 °C or 55 °C, in comparison with the

VIP control. Figures 3 and 4 are micrographs showing typical fields

in the processed tissues.

Number Passed/Number Test

Slides Scored (VBS)

Average Score

/ 4

Page 6

VBS Score

100%

80%

60%

40%

20%

Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7 Day 8 Day 9 Day 10

Processing Runs by Working Day

Peloris 6 hour 45 ºC mean score Retort A Peloris 6 hour 55 ºC mean score Retort A VIP 13 hour mean score

Peloris 9 hour 45 ºC mean score Retort A Peloris 9 hour 55 ºC mean score Retort A

Figure 2. Graph showing the consistency of results of sequential runs for 10 days.

A

Figure 3. A comparison of typical H&E stained sections of pig liver produced using different processing schedules on three matched specimens from the same case. A Peloris 6 hour

at 55 °C, B Peloris 9 hour at 55 °C and C VIP overnight control schedule. Note the well-preserved lobules showing minimal shrinkage with no cracking or separation from the portal

connective tissue in each case. There is no discernable difference in morphological detail or staining quality between the 6 and 9 hour 55 °C runs and the 13 hour control.

A

B

B

C

C

Figure 4. A comparison of typical H&E stained sections of small intestine produced using different processing schedules on three matched specimens from the same case. A

Peloris 6 hour at 55 °C, B Peloris 9 hour at 55 °C and C VIP overnight control schedule. Note the well-preserved intestinal glands and well-defined nuclei in each. There is no

discernable difference in morphological detail or staining quality between the 6 hour and 9 hour runs at 55 °C and the 13 hour control.

/ 5

Page 7

Discussion

The results show that Peloris can process large specimens to

an equivalent standard to an “overnight” 13 hour schedule run

on an industry-standard processor such as the VIP using shorter

schedules – of either 6 or 9 hours. As can be seen in Table 2 the

specimens used were relatively large, having characteristics that

would mean in most laboratories they would be processed on

on “overnight” run. The results also indicate that there is some

advantage in processing at higher temperature (55 °C) for both

the 6 hour and 9 hour schedules. It is likely that for even larger

and denser specimens than those used here, this improvement in

processing quality would be more pronounced.

We consider the overall quality of the sections produced in these

field trials to be satisfactory. When looking at the magnitude of the

VBS scores, it must be remembered that, as well as reflecting the

quality of processing achieved, they are limited by the initial quality

of specimen fixation. As is always the case in histopathology

laboratories some of the specimens showed sub-optimal fixation

particularly noticeable in some larger pieces of tissue that were

intentionally chosen for these trials. However, because we used

matched sets of specimens for assessment we believe our results

are unbiased.

Unlike other processors, in Peloris the chosen processing

temperature in the retort is achieved very rapidly. This is

particularly important if accelerated processing is to be achieved

using short step times. It may explain why, in some processors,

higher temperatures appear not to shorten processing times to the

extent that is possible with Peloris.

Figure 2 indicates that rapid processing on Peloris produces very

consistent results overall, at least the equivalent of the VIP. These

results were achieved without changing reagents on Peloris. It

should also be noted that processing on Peloris was done using

the two retorts. Both the 6 and 9 hour schedules were run at the

same time, the end-points being timed so that the embedding could

be done sequentially. Figure 2 shows the consistency in the results

achieved in each retort. This clearly demonstrates the versatility of

the two-retort design that allowed the processing of at least twice

as many specimens as the VIP in a shorter time.

Conclusion

The results of comparative evaluations carried out during field trials

clearly show that the design features of Peloris lead to reduced

processing times without compromising quality. Tissues processed

at both 45 °C and 55 °C produced consistent, high-quality results

with evidence that the higher temperature is an advantage for

both the 6 hour and 9 hour schedules. The trials were completed

efficiently, causing little disruption in the participating laboratories,

due in large part to the versatility of Peloris in possessing two

retorts that could be used simultaneously.

In the context of a busy histopathology laboratory, our results

indicate that the introduction of Peloris processing would allow

large specimens to be processed in six hours, leading to the

completion of more runs in a working day and the reduction of

turn-around times.

Acknowledgements

The Biosystems Division of Leica Microsystems would like to thank

Mr Terry Cass and the staff of the Anatomical Pathology Department,

Division of Laboratory Medicine, Austin Health, Victoria, Australia

and Mr Richard Lau and the staff of the Anatomical Pathology

Department, Melbourne Health Pathology, Victoria, Australia for

their valuable assistance in conducting the trials described in this

paper and in the preparation of this manuscript. Thanks are also

due to Mr David Roche (Biosystems Division) for coordinating the

project and collecting and collating the data.

References

1. Winsor L. Tissue processing. In: Woods A, Ellis R, editors. Laboratory

histopathology. New York: Churchill Livingstone; 1994. p. 4.2-23.

2. Anderson G, Gordon KC. Tissue processing, microtomy and paraffin sections.

In: Bancroft JD, Stevens A, editors. Theory and practice of histological

techniques. 4th ed. New York: Churchill Livingstone; 1996.

3. Carson FL. Histotechnology. 2nd ed. Chicago: ASCP Press; 1997.

4. Vision BioSystems. Assessing the quality of tissue processing and the

performance of Peloris™ using the VBS scoring system. Melbourne: Vision

BioSystems Ltd May 2005.

08/2007 95.7753 Rev A

Leica Biosystems Melbourne Pty Ltd, 495 Blackburn Road, Mount Waverley VIC 3149, Australia

Telephone +61 3 9211 7400 Fax +61 3 9211 7401 ABN 72 008 582 401

/ 6

Loading...

Loading...