Page 1

™

Leica PELORIS

Leica PELORIS II

Rapid Tissue Processor

User Manual

™

Living up to Life

Page 2

Legal Notices

Intended Use Statement

The Peloris™ dual retort rapid tissue processor prepares tissue samples for sectioning by transforming fixed samples into wax

embedded samples. This is achieved by exposing the tissue samples to a sequence of reagents in the processing retorts.

Trademarks

Leica and the Leica logo are registered trademarks of Leica Microsystems IR GmbH and used under license.

PELORIS, PELORIS II, Waxsol, Parablocks, ActivFlo and RemoteCare are trademarks of Leica Biosystems Melbourne Pty Ltd

ACN 008 582 401. Other trademarks are the property of their owners.

Copyright

Leica Biosystems Melbourne Pty Ltd owns the copyright on this document and any associated software.

Leica Biosystems Melbourne is part of the Leica Microsystems group of companies. Under law, our written permission is

required before either the documentation or the software is copied, reproduced, translated, or converted to electronic or

other machine-readable form, in whole or in part.

Doc. 26.7501.500 Rev K

© Leica Biosystems Melbourne Pty Ltd 2011

Manufacturer

Leica Biosystems Melbourne Pty Ltd

495 Blackburn Rd

Mt. Waverley VIC 3149

Australia

Important Information for All Users

Persons operating the Peloris tissue processor MUST:

Follow the instructions for use exactly as described in this user manual. Any deviation from the

instructions may result in sub-optimal tissue processing, potential loss of the patient sample and the

consequent inability to make a diagnosis.

Receive sufficient training to ensure that the instrument is used in accordance with this user manual.

Be aware of any potential hazards or hazardous procedures before operating the instrument as described

in this user manual.

Warranty claims can be made only if the system has been used for the specified application and operated according to the

instructions in this document. Damage resulting from inappropriate handling and/or misuse of the product will invalidate the

warranty. Leica Microsystems cannot assume liability for any such damage.

Due to a policy of continuous improvement, Leica Microsystems reserves the right to change specifications without notice.

Only trained staff are to remove any covers or parts from the processor, and only if instructed within this manual. Repairs

must only be carried out by qualified service personnel authorized by Leica Microsystems.

The term “Leica Microsystems” when used in text in this document refers to Leica Biosystems Melbourne Pty Ltd.

The term “Peloris” when used in text in this document refers to Peloris and Peloris II.

Revision Record

Rev. Issued Detail

K02 July 2011 Updates to Important Information for All Users and Safety Notices

Section 5.1.5 Tissue Marking added.

Chapter 9 "Troubleshooting" added.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 2

Page 3

Contacting Leica Microsystems

For service or support contact your local representative or see www.leica-microsystems.com.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 3

Page 4

Software Licence Terms

1 Defined terms & interpretation

1.1 Defined terms

In this agreement:

“Leica Microsystems” includes Vision BioSystems Pty Ltd ACN 008 582 401, prior to changing its company name, and Leica

Biosystems Melbourne Pty Ltd ACN 008 582 401 after changing its name.

“Confidential Information” means all information:

(a) treated by Leica Microsystems as confidential or of its nature confidential; and

(b) disclosed by Leica Microsystems to the Licensee or of which the other party becomes aware,

except information:

(c) the other party creates independently of Leica Microsystems; or

(d) that is public knowledge (otherwise than as a result of a breach of confidentiality by the Licensee or any of its

permitted disclosees).

“Designated Computer” means the computer or microprocessor controlled unit supplied by Leica Microsystems to the

Licensee under the Supply Agreement or otherwise recommended for use by Leica Microsystems.

“Documentation” means the manuals, user documentation, proprietary notices, product catalog, website notices and bulletins

generally supplied by Leica Microsystems with or relating to the Software.

“Effective Date” means the date the Goods, as defined in the Supply Agreement, are delivered by Leica Microsystems.

“Intellectual Property” means all existing and future intellectual property rights including:

(e) patents, copyright (including all copyright and software), software and associated documentation including the

specific design and structure of individual programs, registered designs, trade marks, proprietary documentation and

notices, and any right to have information or know-how kept confidential; and

(f) any application or right to apply for registration of any of the rights referred to in paragraph (e) above.

“Licensee” means the Purchaser or lessee of the Goods containing the Software, or, where the Licensee is a distributor of the

Goods containing the Software, the end user of the Goods containing the Software.

“Licensor IP” means all Intellectual Property relating to:

(a) the Software and Documentation;

(b) any modifications, upgrades, new versions or new releases of the materials referred to in paragraph (a) above; and

(c) other works created by Leica Microsystems in the course of, or as a result of, performing this Agreement.

“Release” means each release of a new Version of the Software.”

“Software” means any program, firmware or electronic files that provides instructions or data to a computer or

microprocessor and, shall for the purposes of this agreement, include original versions, modified versions, upgrades, updates,

bug fixes, and backup copies.

“Supply Agreement” means the agreement between the Licensee and Leica Microsystems, or where the Licensee is not a

direct customer of Leica Microsystems, between Leica Microsystems’ distributor and Leica Microsystems, for the sale, lease or

use of the Goods.

“Third Party Material” means any Material owned by a third party that is not a Related Body Corporate (as that term is

defined in the Corporations Act 2001 (Cth)) of Leica Microsystems.

1.2 Other definitions

In this agreement, “Goods”, “Purchaser”, and “Leica Microsystems” have the same meaning as in the Supply Agreement.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 4

Page 5

Software Licence Terms

2 Grant of licence

2.1 Licensee gives consent

The Licensee agrees to be bound by all the terms of this Licence by downloading or installing the Software, or by agreeing to

purchase, lease or otherwise use the Software or the Goods containing the Software.

2.2 Leica Microsystems grants licence

Subject to this agreement, Leica Microsystems grants the Licensee a non-transferable, non-exclusive licence to use the

Software and Documentation for its internal business purposes in accordance with the terms of this agreement.

3Restrictions on use

The Licensee must:

(a) only use the Software on the Designated Computer and in conformity with:

(i) laboratory practices that are consistent with industry practice;

(ii) all applicable laws, regulations, guidelines and decisions of judicial or regulatory bodies;

(iii) any patent or other proprietary rights of third parties; and

(iv) as envisaged by the Documentation, and this agreement;

(b) not install, or procure the installation of, any software on the Designated Computer without Leica Microsystems' prior

written consent;

(c) not copy all or part of the Software or Documentation, or allow all or part of the Software or Documentation to be

copied (other than one copy of the Software for backup purposes), without obtaining Leica Microsystems' prior

written permission;

(d) not publish, distribute or commercialise all or part of the Software or Documentation, or any adaptation, modification

or derivative of the Software or Documentation;

(e) not sell, rent, lease, sub-license, assign or transfer all or part of the Software or Documentation or any of its rights

under this agreement;

(f) not use the Software or the Documentation for the benefit of any third party, or disclose the Software or the

Documentation to any third party, except with Leica Microsystems' prior written consent;

(g) not adapt, reverse engineer, make error corrections, or otherwise modify the Software or Documentation or create

derivative works based on the Software or Documentation (other than to the extent permitted by applicable copyright

laws) or permit third parties to do the same;

(h) not decompile, decrypt, reverse engineer, disassemble or otherwise reduce the Software to human readable form to

gain access to trade secrets or confidential information in the Software or permit third parties to do the same; and

(i) comply with any reasonable directions of Leica Microsystems from time to time in relation to the installation or use of

the Software and the Documentation.

4 Intellectual property

4.1 Licensor IP

All Licensor IP, including but not limited to any images, audio, video and text in the Software, is owned by or licensed to Leica

Microsystems, and no Licensor IP is transferred to the Licensee under this agreement.

4.2 Proprietary markings

The Licensee must not alter or remove any notices of proprietary rights, any rights management information or any serial

numbers appearing on, attached to or incorporated in Licensor IP or any copies thereof, and must not use or attempt to

register any trademark, trade name, business name or company name which is confusingly similar to any trademark or trade

name of Leica Microsystems.

4.3 Violations of intellectual property

The Licensee must:

(a) notify Leica Microsystems immediately if it knows of or suspects any unauthorised use, or violation, of any Licensor

IP; and

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 5

Page 6

Software Licence Terms

(b) provide promptly, at its cost, all assistance reasonably requested by Leica Microsystems to protect the relevant rights

in Licensor IP and prosecute any claims arising from such uses or violations.

4.4 Compliance

The Licensee must comply, at all times, with any terms and conditions relating to the Third Party Material notified to the

Licensee by Leica Microsystems and/or the third party supplier of that Third Party Material.

5 Upgrades and support

5.1 New releases and new versions

Leica Microsystems may, at its sole discretion, provide the Licensee with new Releases or new Versions of the Software.

5.2 Installation

If requested by the Licensee to do so, Leica Microsystems, its designated distributor or agent may, at its sole discretion,

install a new Release or new Version of the Software on the Designated Computer.

5.3 Downloading of data

Leica Microsystems, or its designated agent may, at its sole discretion, download data that has been generated by the use of

the Software by the Licensee as a means of debugging Software faults and otherwise analyzing the performance of the

Software or Goods containing the Software supplied by Leica Microsystems under the Supply Agreement.

6 Back up and security of data

It is the Licensee's responsibility to:

(a) perform regular backups of data and to store these; and

(b) provide contingency plans for the event of a failure of any sort (eg: fire, flood, and theft);

and Leica Microsystems has no liability (including for negligence) for any loss whether direct or indirect, that could have been

prevented by the Licensee performing the above responsibilities, or which occurs as a consequence of inadequate back up,

computer viruses or the ongoing functions of computer hardware (including backup hardware), whether supplied by Leica

Microsystems or any other supplier.

7 Confidentiality and privacy

7.1 Use and disclosure

The Licensee must, in relation to the Confidential Information:

(a) keep it confidential;

(b) use it only as permitted under this agreement and only disclose it:

(i) to employees, contractors and agents that have a need to know and who have undertaken to comply with this

clause 7; or

(ii) to the extent (if any) the Licensee is required by law to do so; and

(c) promptly comply with any request by Leica Microsystems to return or destroy the Confidential Information unless

required by law to be retained.

7.2 Recipient's obligations

The Licensee must:

(a) safeguard the Confidential Information from unauthorised access or use; and

(b) notify Leica Microsystems of, and take all steps to prevent or stop, unauthorised copying, use or disclosure.

7.3 Privacy

In performing its obligations under this agreement, the Licensee must comply, and use all reasonable efforts to ensure that

its contractors comply, with all applicable legislation relating to privacy of personal information.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 6

Page 7

Software Licence Terms

8 Exclusions and limitations

8.1 Acknowledgments

The Licensee acknowledges that:

(a) it has selected the Goods from a range of products and has satisfied itself that the Goods meet the Licensee's

requirements;

(b) no oral or written information, representation or advice given by or on behalf of Leica Microsystems, other than as

contained in this agreement, creates a warranty or in any way increases the scope of this agreement; and

(c) unless expressly agreed otherwise in writing, the Licensee has not relied on any information, representation or advice

given by or on behalf of Leica Microsystems in selecting the Goods; and

(d) Leica Microsystems makes no representation that the Goods conform to country, state or local laws, ordinances,

regulations, codes or standards (except as may otherwise be agreed to in writing by Leica Microsystems) and the

Licensee is responsible for complying with all local laws relating to use of the Goods at its own cost.

8.2 Exclusion of implied terms

Leica Microsystems excludes from this agreement all conditions, warranties and liabilities implied or imposed by law or

custom except any liability or implied condition or warranty the exclusion or limitation of which would contravene any statute

or cause any part of this

8.3 Non-excludable conditions

To the extent permitted by law, Leica Microsystems’ liability for any breach of any Non-Excludable Condition is limited to:

(a) in the case of services, the resupply of the services or the cost of having the services supplied again (at Leica

Microsystems' option); and

clause 8 to be void (‘non-excludable conditions’).

(b) in the case of goods, the lowest of the cost of replacing the goods, acquiring equivalent goods or having the goods

repaired.

8.4 Exclusion of liability

To the extent permitted by law, Leica Microsystems excludes all liability (including liability for negligence) for:

(a) any indirect or consequential expenses, losses, damages or costs (including, without limitation, loss of profits, loss of

revenue, loss of or damage to data, failure to achieve anticipated savings or benefits, and any third party claims)

incurred by or awarded against the Licensee under or in any way connected with this agreement or the use of the

Software or Documentation;

(b) without limiting the foregoing, any expenses, losses, damages or costs incurred by or awarded against the Licensee

arising directly or indirectly in respect of clinical (including without limitation diagnostic, prescription and other

treatment) errors made while using, or otherwise associated with the use of, the Software or Documentation; and

(c) the operation or performance of, and any expenses, losses, damages or costs suffered or incurred by the Licensee as

a result of its use of, any Third Party Material.

8.5 Limitation of liability

To the extent permitted by law, Leica Microsystems limits its total aggregate liability (including liability for negligence) for any

damage arising under or in any way connected with this agreement or the use of the Software to

Licensee for the Software or the Goods containing the Software under the Supply Agreement.

the price paid by the

9 Indemnity

The Licensee indemnifies Leica Microsystems against all expenses, losses, damages and costs (on a solicitor and own client

basis) incurred by or awarded against Leica Microsystems arising directly or indirectly from or in relation to:

(a) any use of the Software not in compliance with this agreement;

(b) any breach of any Third Party Licence Terms by the Licensee;

(c) the Licensee's infringement of Leica Microsystems' Intellectual Property rights;

(d) clinical (including without limitation diagnostic, prescription and other treatment) errors made while using, or

otherwise associated with the use, of the Software or Documentation;

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 7

Page 8

Software Licence Terms

(e) any failure by the Licensee to comply with laboratory practices that are consistent with industry practice, laws,

guidelines or decisions in the handling or use of the Software

(f) the Licensee's negligent acts or omissions; and/ortany other use or misuse of the Software by the Licensee.

10 Term and termination

10.1 Term

This agreement commences on the Effective Date and continues until terminated in accordance with this agreement.

10.2 Termination

(a) The Licensee may terminate this agreement at any time by destroying all copies of the Software and Documentation.

(b) The Licensee’s rights under this agreement will terminate immediately without notice from Leica Microsystems if the

Licensee fails to comply with any provision of this agreement or if the Licensee does not strictly observe the terms of

payment under the Supply Agreement, and on termination, the Licensee must destroy all copies of Software and

Documentation in its possession or control.

10.3 Accrued rights and remedies

Termination of this agreement under this clause 10 does not affect any accrued rights or remedies of either party.

10.4 Survival

Clauses 4 (Intellectual property), 7 (Confidentiality and privacy), 8 (Exclusions and limitations), 9 (Indemnity), 10.3

(Accrued rights and remedies), 10.4 (Survival), 11 (Force majeure) and 12 (General) continue after termination of this

agreement.

11 Force majeure

Neither party will be liable for any delay or failure to perform its obligations pursuant to this agreement (other than on

obligation to pay money) if that delay is due to Force Majeure. If a delay or failure of a party to perform its obligations is

caused by or anticipated due to Force Majeure, the performance of that party’s obligations will be suspended. Either party

may terminate this agreement if a Force Majeure persists for a continuous period of 90 days.

12 General

12.1 Severance

Part or all of any provision of this agreement that is illegal or unenforceable may be severed from this agreement and the

remaining provisions will continue in force.

12.2 Entire agreement

This agreement (including any additional terms notified to the Licensee by Leica Microsystems) constitutes the entire

agreement between the parties and supersedes any prior representations, warranties, understandings or agreements that

relate to the same subject matter.

12.3 Variation

This agreement may only be amended by agreement in writing between the parties.

12.4 Governing law

This agreement is governed by the laws of the State of Victoria, Australia, and the parties submit to the non-exclusive

jurisdiction of the courts in that State.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 8

Page 9

Safety Notices

The Peloris™ tissue processor is designed to provide safe, trouble-free operation when used in accordance with this

document. Follow all safety precautions to avoid personal injury, damage to patient samples, and damage to the instrument.

Clean and maintain the instrument as described in

The Safety Notice Types section below describes the types of safety notices in the manual.

The General Warnings and Cautions section has general warnings for the Peloris instrument – other notices appear in

relevant sections in the manual.

Safety Notice Types

Safety notices in this manual are either warnings or cautions.

Warnings

Warnings are notifications of hazards that could lead to personal injury to Peloris users or people in the vicinity of the

instrument.

Warnings are also used when there is the possibility of damaging patient tissue samples.

Warnings in this manual use symbols with a red border, as illustrated below:

TOXIC HAZARD

There is danger of ingestion, inhalation or skin contact with toxic material.

Chapter 7, Cleaning and Maintenance.

HEAT HAZARD

There is danger of burns.

CHEMICAL HAZARD

There is a danger of exposure to corrosive chemicals.

ELECTRICAL HAZARD

There is danger of electric shock.

GENERAL HAZARD

There is danger of personal injury or damage to patient tissue samples.

Cautions

Cautions are notifications of hazards that could lead to damage to the Peloris instrument or other equipment.

Cautions in this manual use symbols with a yellow border, as illustrated below:

CAUTION

There is danger of damage to the Peloris instrument or other equipment.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 9

Page 10

Safety Notices

General Warnings and Cautions

Persons operating the Peloris must be fully aware of the following warnings, in order to mitigate possible tissue damage or

loss.

Reagent Configuration

WARNING

Always ensure that the reagents configured in the software are the actual reagents loaded on the instrument.

A station containing different reagent could damage tissue samples.

Replacing Reagents

WARNING

Always change reagents when prompted.

Always update station details correctly – never update the details without replacing the reagent.

Failure to follow these directives can lead to tissue damage or loss.

WARNING

Do not alter the concentration of a used reagent unless you are able to verify the actual concentration. If the

concentration is incorrect a reduction in tissue processing quality or damage to the tissue sample may result.

Protocol Validation

WARNING

Do not set new protocols as validated until they have passed the validation procedures for your laboratory.

Only then should you edit the protocol to set it as valid, making it available to operators for clinical use (

4.1.4 Protocol Validation). Use of nonvalidated protocols may result in tissue damage or loss.

Basket and Cassette Loading

WARNING

Always ensure the cassettes are correctly inserted into the baskets and that the baskets are correctly placed in

the retorts. Incorrectly placed cassettes or baskets may lead to samples being damaged as some tissue may not

be fully covered by reagent during processing (see 2.2.4 Cassette Baskets).

WARNING

Never place three baskets into a retort when the instrument is configured with a two-basket fill level. If this

occurs, reagent will not cover the top basket and tissue samples will be damaged.

Cleaning Protocol

WARNING

Remove all tissue from the retort before running a cleaning protocol as the dry step will damage the tissue.

see

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 10

Page 11

WARNING

Do not use cleaning protocols for reprocessing as the dry step will damage the tissue.

WARNING

Do not load unprocessed tissue samples into a retort prior to running a cleaning protocol. Formalin in the

residue purged to the wax bath at the start of the cleaning run may damage tissue on subsequent runs.

If you inadvertently load unprocessed samples into a retort prior to running a cleaning protocol, remove the

samples and attempt to load a processing protocol before loading the cleaning protocol. The purge before the

cleaning run will be skipped.

Instrument Setup

WARNING

Do not use the instrument without installing the drip tray.

WARNING

The instrument must be installed and configured by an approved service representative.

Safety Notices

WARNING

Always use suitably rated lifting equipment (such as a trolley or forklift) when moving a Peloris tissue

processor more than a few metres.

Only use the instrument’s castors to reposition an instrument for service access.

Electrical Hazards

WARNING

The Peloris tissue processor must be connected to an earthed mains power outlet socket.

WARNING

Dangerous voltages are present inside the Peloris tissue processor. Only service technicians approved by the

Biosystems Division of Leica Microsystems should remove any of the instrument’s covers or access the internal

components.

WARNING

The instrument’s operating voltage is factory set and it must not be changed.

Severe damage will occur if an instrument is connected to an incorrect power supply voltage.

WARNING

Do not pull out the mains cable whilst the instrument is operating unless there is an emergency situation and

both the front panel power button and the mains wall switch are inaccessible.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 11

Page 12

Reagents

Safety Notices

WARNING

Locate the instrument so that either the mains wall outlet or the instrument’s appliance inlet socket is

accessible. You must be able to disconnect the mains power cable without moving the instrument.

WARNING

Do not move the instrument unless the power cable is disconnected.

WARNING

Chloroform vapors may cause severe injury, incapacitation, or death.

When using chloroform with the Peloris tissue processor, Leica Microsystems recommends that an external

fume extraction system be installed. Chloroform vapors may accumulate during normal operation or in the

unlikely event of a spill. The extraction system must keep these vapors below dangerous levels.

Never open a retort that contains chloroform or chloroform residue.

WARNING

Do not heat reagents above their boiling points. Boiling reagents will release large quantities of fumes that

may overload the internal carbon filter or (if fitted) the external filtering system. Boiling reagents are also likely

to lead to excessive pressures within the instrument, increased reagent contamination and reagent spills.

Reagent boiling points are lower when in a retort operating with a vacuum or with pressure/vacuum cycling.

WARNING

Handle and dispose of reagents and condensate in accordance with all relevant procedures and government

regulations that apply at the laboratory site.

WARNING

Do not use fixatives containing picric acid as picric acid is explosive when dry.

WARNING

Molten wax is hot and may cause burns. Use caution when handling wax and removing baskets.

CAUTION

Do not use acetone or other ketones. These damage the instrument’s valves.

CAUTION

Do not use reagents containing corrosive chemicals such as mercuric salts, picric acid, nitric acid and

hydrochloric acid.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 12

Page 13

Regulatory Approvals

IEC 61010-1

2nd Edition

UL 61010A-1 Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1

CAN/CSA C22.2

No.1010-1

IEC 61010-2-010 Safety requirements for electrical equipment for measurement, control and laboratory use – Part 2

IEC 61010-2-081 Safety requirements for electrical equipment for measurement, control and laboratory use – Part 2

IEC 61326 Electrical equipment for measurement, control and laboratory use – EMC requirements

FCC Part 15 Class A/B Unintentional Radiators

ISO 13485: 2003 Medical Devices – Quality management systems – Requirements for regulatory compliance

Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1

General requirements

General requirements

Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1

General requirements

Particular requirements for the heating of materials

Particular requirements for automatic and semi-automatic laboratory equipment for analysis and

other purposes

FCC Compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interference received, including interference that may cause undesired operation.

FCC Class B compliance statement

This equipment has been tested and found to comply with the limits for a Class B digital device pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

Consult the dealer or an experienced radio or television technician for help.

CE Marking and European Union Notice

The CE mark on the equipment indicates compliance with the EEC Directives for Electromagnetic

Compatibility (89/336/EEC), Waste Electrical and Electronic Equipment (02/96/EC), Restriction on the Use

of Certain Hazardous Substances in Electrical and Electronic Equipment (02/95/EC), and In Vitro Diagnostic

Medical Devices (98/79/EC). Marking of equipment in this manner denotes that the equipment meets the

technical standards detailed above.

Declaration of Conformity

A “Declaration of Conformity” in accordance with the preceding directives and standards has been made, and is on file at

Leica Biosystems Newcastle Ltd, Balliol Business Park West, Benton Lane, Newcastle upon Tyne, NE12 8EW, United Kingdom.

Note: To maintain compliance with the above CE and FCC Rules and Regulations, use only the cables supplied with the

equipment.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 13

Page 14

Contents

Legal Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contacting Leica Microsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Software Licence Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Regulatory Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.1 Summary of Chapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1.2 Using the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Access Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.1 Switching On and Shutting Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 Retorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Opening and Closing Retort Lids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fill Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Magnetic Stirrer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cassette Baskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3 Wax Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.4 Reagent Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reagent Bottles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Condensate Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Carbon Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5 Touch-screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.6 External Vapor Removal Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.7 Alarm Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3 Running Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.1 Quick Start – Running a Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2 Cleaning Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3 Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Status Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Protocol Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.4 Protocol Run Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Scheduling Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Editing the Protocol for a Single Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 14

Page 15

3.5 Pausing and Abandoning Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.6 Retort Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Delayed End Times and Initial Fills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Unavoidable Reagent Clashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Unavailable Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4 Protocol Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.1 Protocol Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Protocol Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Reagent Selection Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Pre-defined Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Protocol Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Carryover Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Saving Protocol Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.2 Creating, Editing and Viewing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

The Protocol Selection Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Editing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Creating New Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Viewing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5 Reagent Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

5.1 Reagents Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Reagent Groups, Types and Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Concentration Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Recommended Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Tissue Marking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Reagent Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

5.2 Managing Reagent Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Pre-defined Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Editing Active Reagent Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Managing the Reagent Types Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.3 Managing Reagent Stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Reagent Stations Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Setting Reagent Station Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.4 Replacing Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Remote Fill/Drain Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Remote Fill/Drain Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Replacing Reagent – Remote Fill and Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Replacing Reagent – Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing Wax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Filling and Draining Retorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6 Settings & Ancillary Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

6.1 Reagents Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Manual Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Reagent Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 15

Page 16

6.2 Control Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Instrument Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Service Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

File Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7 Cleaning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

7.1 Cleaning and Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.2 Daily Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.3 Weekly Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.4 60–90 Days . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.5 Retort Acid Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

8 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

8.1 Reagent Threshold Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.2 Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Specimen Type and Protocol Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

List of Pre-defined Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Xylene Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Xylene-free Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Cleaning Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8.3 Station Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.4 Protocol Step Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.5 Reagent Compatibility Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

9.1 Preliminary Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.2 Flowcharts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Under-processed Tissue – Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Over-processed Tissue – Instrument Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Under- or Over-processed Tissue – Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Poor Processing – Incorrect Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Poor Processing – Correct Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Cutting Artifact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Staining Artifact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Block Artifact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

9.3 Reprocessing Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10 Consumables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

11 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 16

Page 17

1

Introduction

The Leica Peloris™ rapid tissue processor is a dual retort tissue processor that offers fast, high quality tissue

processing for histology laboratories. With reagent capacity sufficient to run the two retorts independently, it

allows a high degree of scheduling flexibility. Intelligent software lets you configure the instrument to suit your

laboratory’s workflows while providing checks and restrictions that help you avoid mistakes that could damage

tissue. The reagent management system closely tracks reagent condition. Depending on your setup, it uses this

information to select the optimal reagent for each protocol step. It alerts you when to replace reagent so that

quality is never compromised, at the same time ensuring you get full use of all reagents. The clear, intuitive,

touch-screen interface makes loading and monitoring runs easy, and protocol configuration, reagent setup and

other system settings are equally straightforward. And behind all this you have the support of Leica

Microsystems, with years of experience developing top quality, industry-leading histology equipment.

Congratulations on your purchase of the Leica Peloris rapid tissue processor. We trust it will provide you with

years of fast, efficient, high quality tissue processing.

This chapter has the following sections:

1.1 Summary of Chapters

1.2 Using the Software

1.3 Help

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 17

Page 18

1.1 Summary of Chapters

Chapter 1, Introduction: general introduction, chapter summary, general instructions for

using the software, and help resources.

Chapter 2, Hardware: descriptions of the main components of the Peloris instrument.

Chapter 3, Running Protocols: main steps for running protocols, further configuration

options and scheduling, monitoring processing on the Status screen.

Chapter 4, Protocol Setup: descriptions of protocol types and the reagent selection

methods used; protocol validation and the carryover setting. Creating and editing protocols.

Chapter 5, Reagent Setup: reagent groups, types and stations, and reagent management

on the Peloris. Setting up reagent types and stations in the software. Replacing reagents.

Chapter 6, Settings & Ancillary Operations: basic instrument settings, independent

operation of instrument components, event monitoring, alarms, and transfer of system files.

Chapter 7, Cleaning and Maintenance: daily and as-required maintenance, accessories

available from Leica Microsystems.

Chapter 8, Reference: descriptions of the pre-defined protocols and recommended bottle

configurations. Recommended reagent thresholds and reagent compatibility tables.

Introduction

Chapter 10, Consumables and Accessories: a list of Peloris consumables and accessories

with part numbers for easy ordering.

Chapter 11, Specifications: system specifications.

1.2 Using the Software

Control all instrument functions from the touch-screen. This section describes basic touch-screen

operation and how to navigate the software, with a summary of all the software screens. It also

describes user access levels.

See sections:

1.2.1 Basic Operation

1.2.2 Navigation

1.2.3 Access Levels

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 18

Page 19

1.2.1 Basic Operation

Buttons

Tap buttons to open menus, screens and dialogs, and to start and stop actions in the instrument.

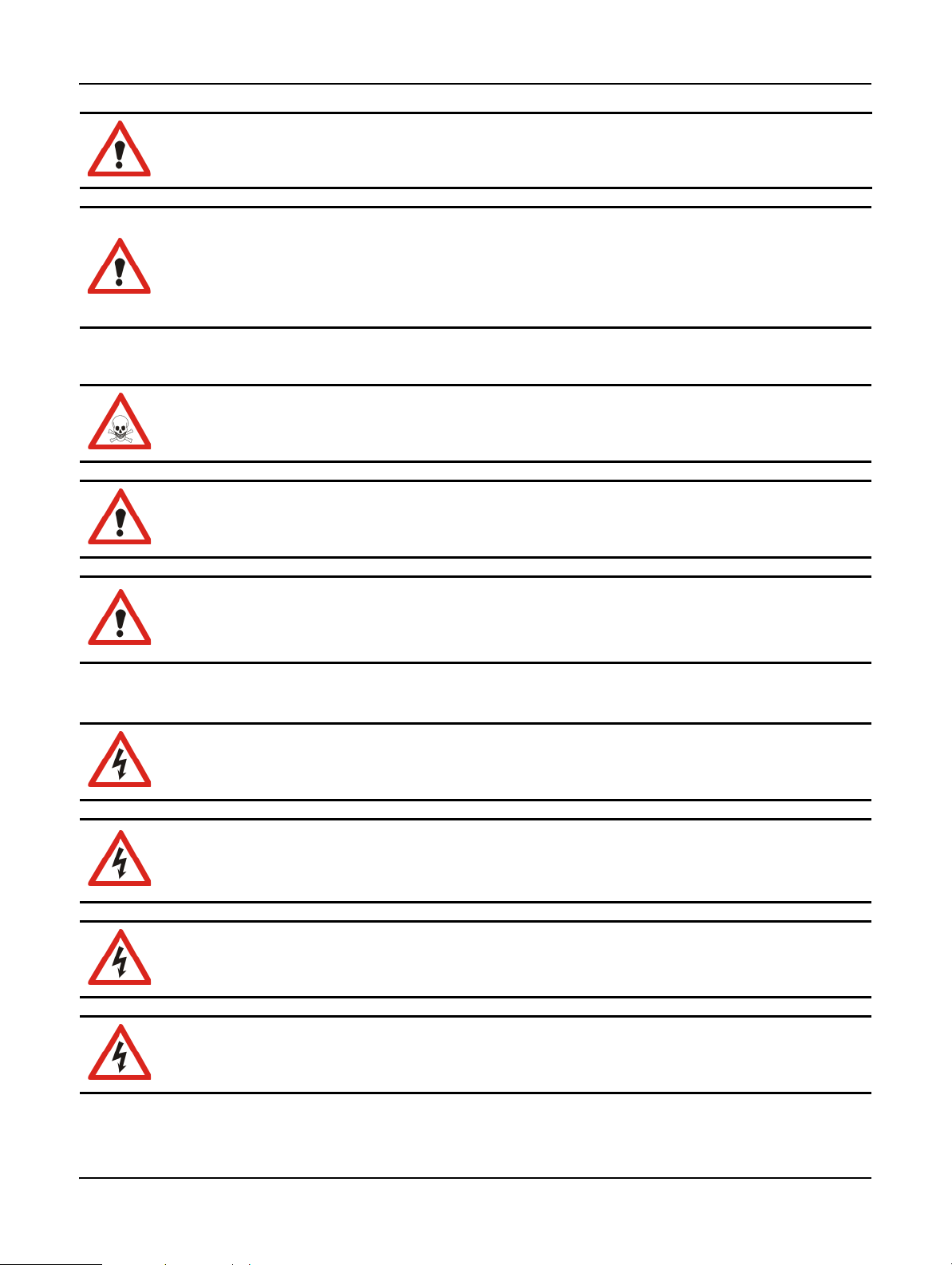

Enabled buttons are blue and appear raised. Selected buttons are orange and appear sunken.

Disabled buttons are dimmed.

Figure 1. Button states—selected, available and unavailable

Icons

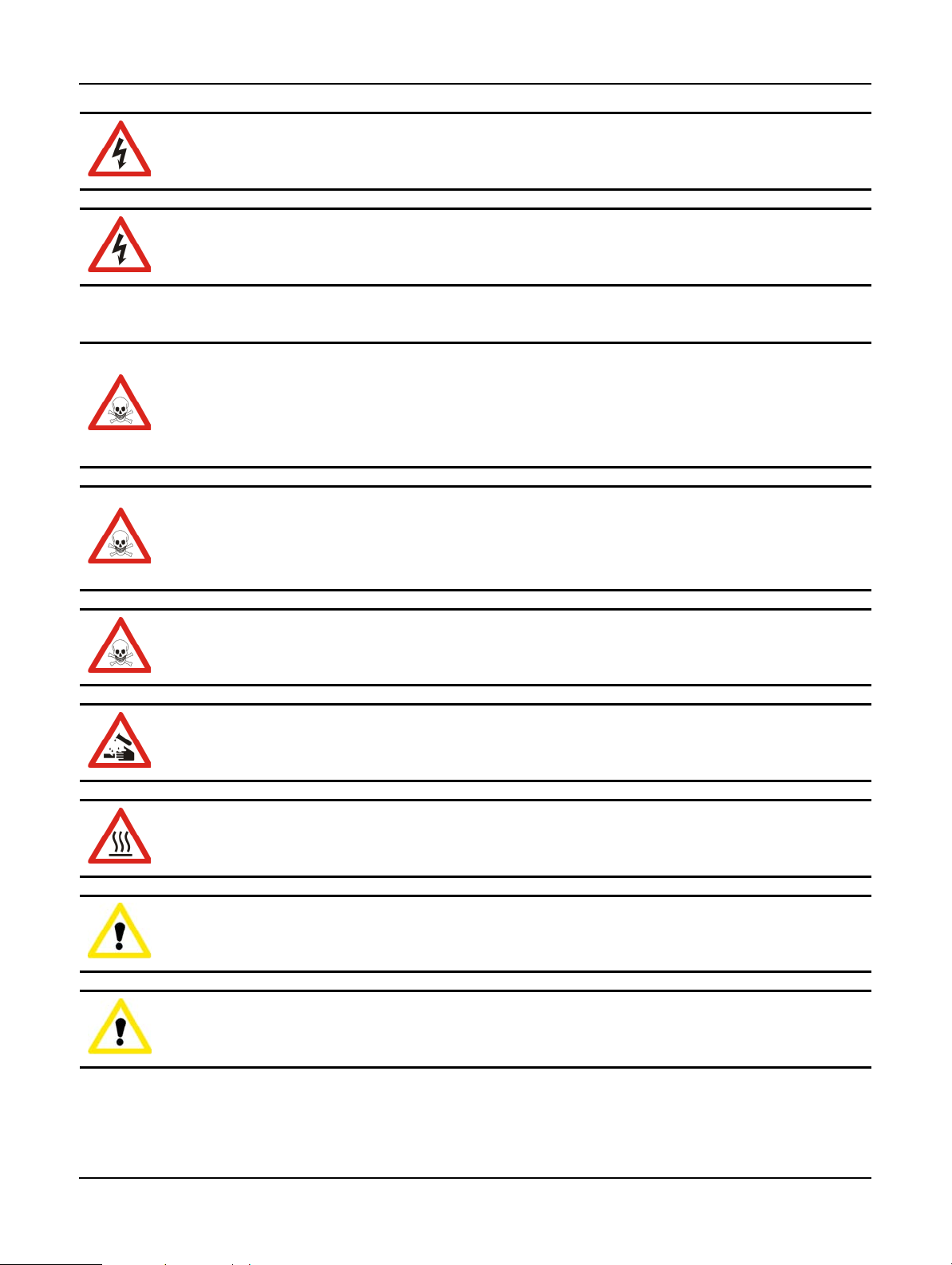

Icons are used to represent various Peloris tissue processor elements including reagent stations and

retorts. Selectable icons appear raised. A selected icon appears raised with a red outline.

Nonselectable elements appear flat and are used for indication only. Select an icon by tapping it, as

you would a button.

Introduction

Figure 2. Reagent station—selectable, selected, not selectable

Tables

Tables display configuration information such as reagent station and protocol setup. You can edit

some table cells but others are locked. The background color of locked cells is dimmed. Select

editable table cells by tapping within the cell boundaries.

Figure 3. Table cells—editable (1) and locked (2)

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 19

Page 20

Introduction

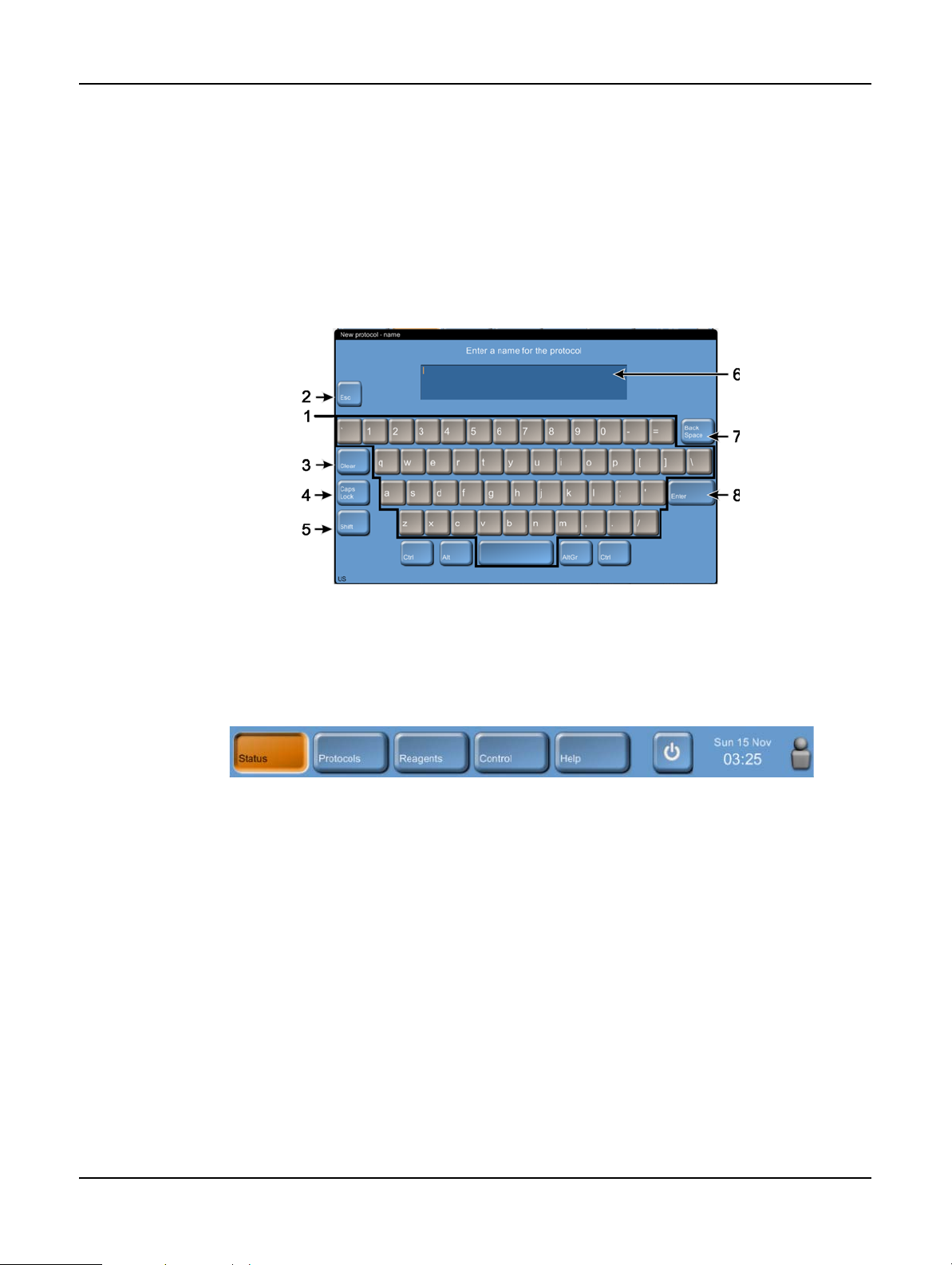

Keypads

Keypads appear as needed to allow you to enter text and numbers. There are two types of keypad:

alphanumeric (text and numbers) and numeric (numbers only). The keypads are analogous to a

computer keyboard with on-screen buttons acting as keys (1). Enter text and numbers by tapping

the appropriate buttons in order and use the Caps Lock button (4) or Shift button (5) to select

upper or lower case characters. As you type, the characters you select are displayed in the text

window (6). The alphanumeric keypad has a Back Space button (7) to delete the last character

while all keypads include a Clear button (3) to remove all characters. When you have finished, tap

the Esc button (2) to exit without saving or the Enter button (8) to confirm your entry.

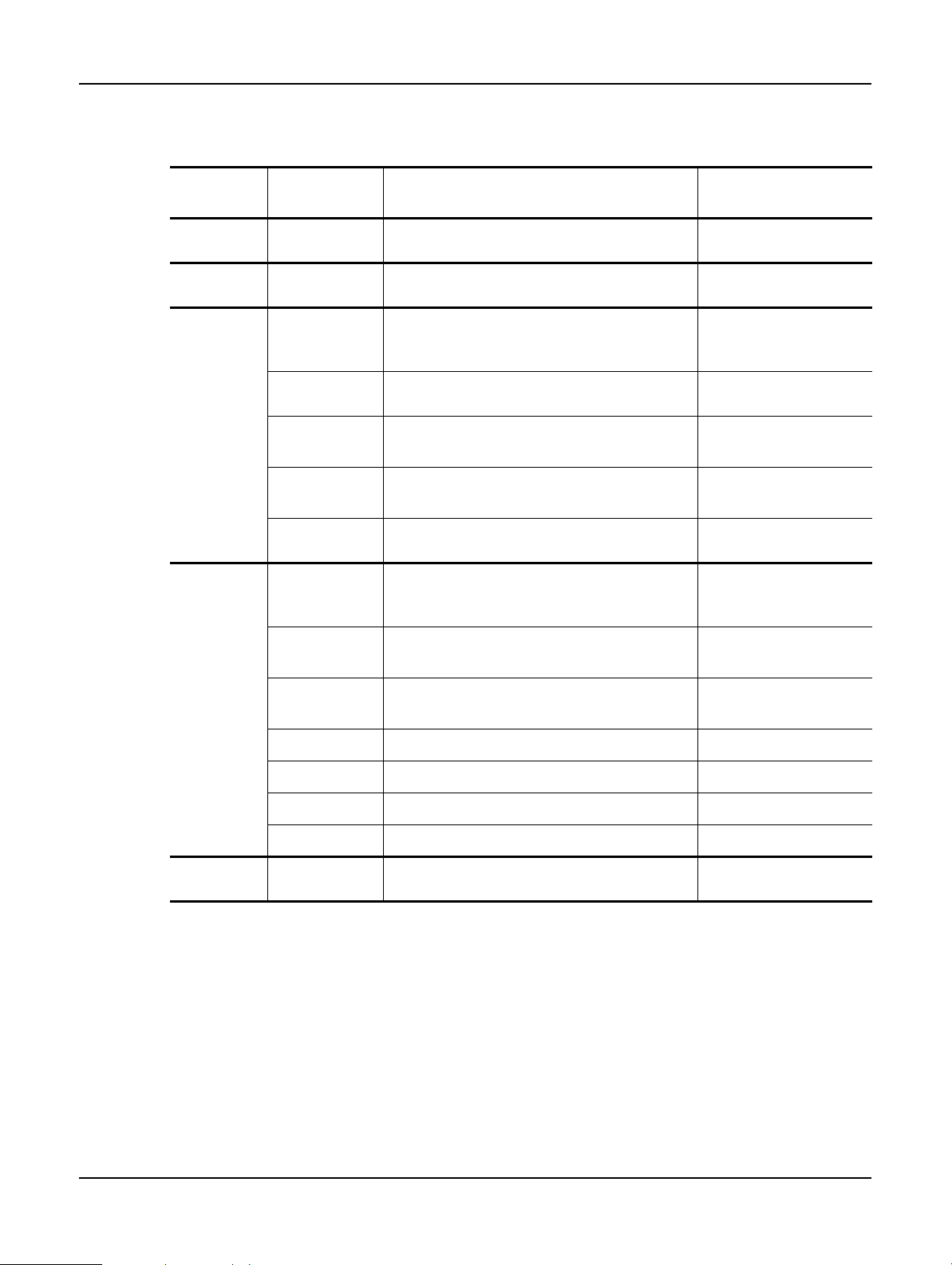

1.2.2 Navigation

Navigate the software from the Function bar at the top of the screen.

The Function bar is always visible, so you can always find the screen you want. Tap a button in the

bar to change screens immediately or open a menu with buttons for a number of related screens.

Some screens have alternative “views” to divide the information presented. For example, the

Reagent stations screen has two views, one each for bottle and wax chamber information. Use

buttons on the screens themselves to move between the alternative views.

Figure 4. Alphanumeric keypad

Figure 5. The Function bar

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 20

Page 21

Introduction

The table below lists all the screens in the Peloris software with brief descriptions of the screen

functions, and links to relevant sections of the manual.

Function

bar button

Menu button Screen purpose Refer to:

Status —

Protocols —

Stations

Types

Reagents

Remote fill/

drain

Manual

operations

Management

Instrument

settings

Device

settings

Load and run protocols, and view system

3.3 Status Screen

status.

Select, create, edit and manage protocols. 4.2 Creating, Editing

and Viewing Protocols

Set up reagent stations. You can also view

the current reagent concentrations and wax

5.3 Managing Reagent

Stations

bath temperatures.

Manage your list of active reagent types. 5.2 Managing Reagent

Typ e s

Fill or drain reagent bottles and drain wax

5.4 Replacing Reagents

stations.

Manually control individual instrument components.

6.1.1 Manual Operations

Set basic reagent management options. 6.1.2 Reagent Manage-

ment

Set options for time display, the carbon filter, fill levels and manual operation drip

6.2.1 Instrument Settings

time.

Change sound, touch-screen and alarm set-

6.2.2 Device Settings

tings.

Service

Control

settings

Event log

Alarms

Access level

File transfer

Help —

View the instrument serial number and soft-

6.2.3 Service Settings

ware versions.

View all system events. 6.2.4 Event Log

Clear or silence active alarms. 6.2.5 Alarms

Set the access level. 6.2.6 Access Level

Transfer files to and from the instrument. 6.2.7 File Transfer

Open an HTML version of the user manual

1.3 Help

in the Peloris software.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 21

Page 22

1.2.3 Access Levels

Peloris has two user access levels available to laboratory staff: operator and supervisor. Operators

can carry out all routine tasks such as running protocols and replacing reagents. But operators

cannot edit protocols or set bottle configurations – you must have supervisor rights for these

actions. Supervisors also have greater rights to configure the system.

Some configuration settings displayed in the software require service level access to change. These

are provided so you can view the settings, but you must contact your customer support

representative if you want to change them.

You automatically begin at operator level when you start the software. Supervisors need a

password to change to their access level on the access level screen (Control menu, Access level).

If a supervisor does not interact with the software for more than 10 minutes the access level

automatically reverts to operator.

An icon on the Function bar indicates your current access level.

Introduction

1.3 Help

This user manual is provided in PDF format on a CD. It is also included (in HTML format) in the

Peloris software. Tap the Help button in the Function bar to open. Use buttons on the Help screen

and links in the text to navigate the online Help.

Figure 6. Access level icons with operator (1) and supervisor (2)

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 22

Page 23

2

Two r e tor t s

Reagent cabinet

Wax bath:

with four wax chambers

Touch-screen

Power button

Hardware

The Peloris™ tissue processor is a free-standing processor with two retorts, sixteen reagent bottles and four wax

chambers. A touch-screen mounted on the top of the instrument connects to an on-board computer for control

of all instrument operations.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 23

Figure 1. Peloris tissue processor – main features

Page 24

This chapter describes the main features of Peloris instrument.

See sections:

2.1 Switching On and Shutting Down

2.2 Retorts

2.3 Wax Bath

2.4 Reagent Cabinet

2.5 Touch-screen

2.6 External Vapor Removal Systems

2.7 Alarm Connections

2.1 Switching On and Shutting Down

Under normal conditions keep the Peloris on at all times, even when idle for extended periods. Shut

down for servicing or if moving the instrument.

Hardware

Start

1. Plug the power cable into the mains socket and switch on the power.

2. Press the power button to start the instrument.

Normal Shutdown

For a normal shutdown the instrument must be idle with no protocols or other operations in

progress:

1. Tap the shutdown button on the Function bar to shut down the software in an orderly

manner.

2. Wait for the touch-screen to go blank then press the power button to remove all power from

the instrument.

3. Switch the power off at the mains socket and pull out the power cable.

Emergency Shutdown

For emergency shutdown, press the power button immediately.

If conditions permit, switch the power off at the mains socket and pull out the power cable.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 24

Page 25

2.2 Retorts

The Peloris tissue processor has two independent processing retorts with each retort holding up to

300 tissue samples in three Peloris cassette baskets. Each retort operates independently with

separate temperature, pressure/vacuum and stirrer speed control. The Peloris tissue processor

schedules resources to ensure both retorts operate efficiently with one set of reagents.

2.2.1 Opening and Closing Retort Lids

2.2.2 Fill Levels

2.2.3 Magnetic Stirrer

2.2.4 Cassette Baskets

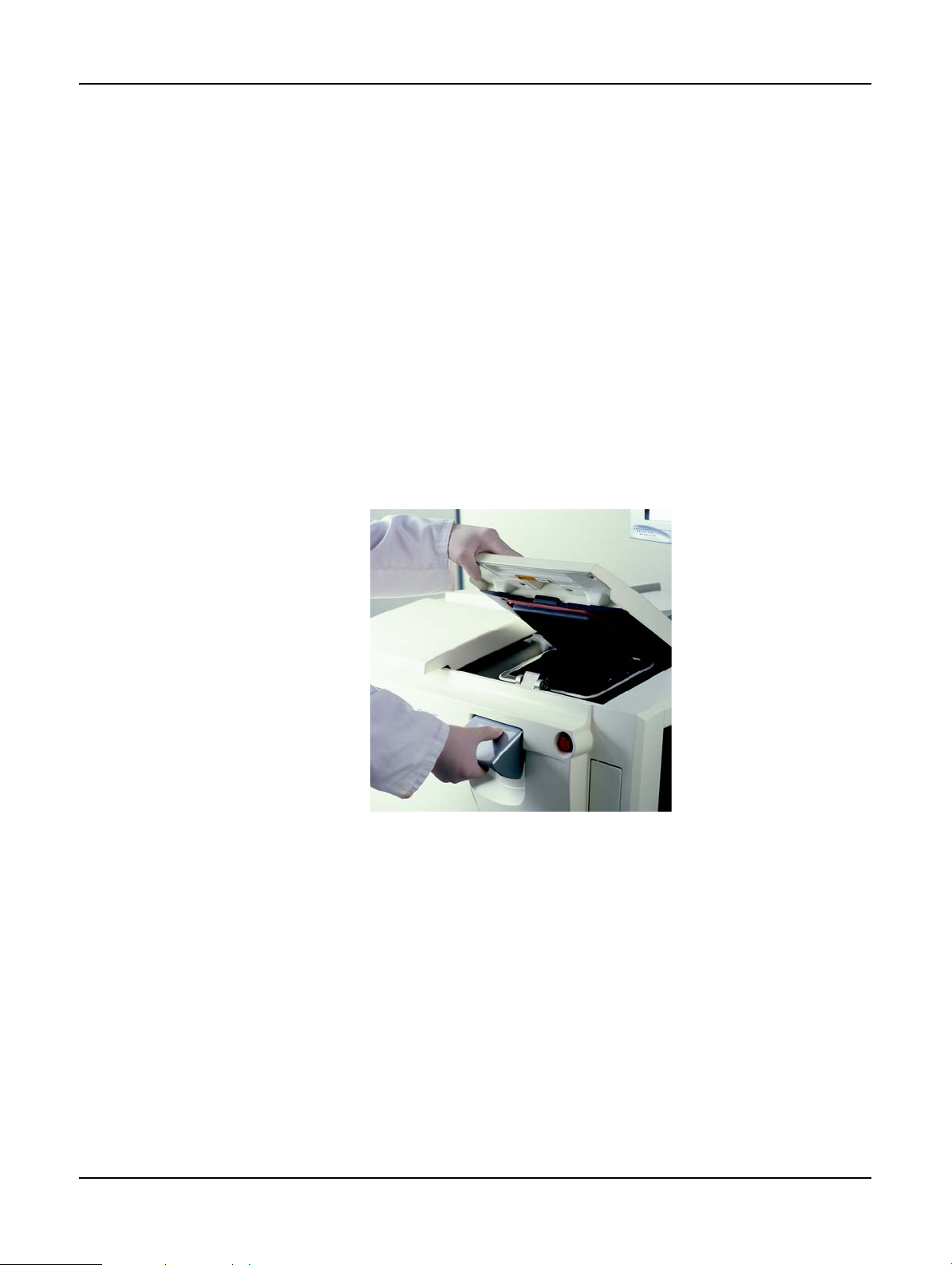

2.2.1 Opening and Closing Retort Lids

Use the handles on the front of the instrument to latch and unlatch the retort lids.

Hardware

Figure 2. Opening a retort lid

Always be aware of the contents, temperature and pressure of a retort before opening it. In some

cases you may need to set the retort pressure and temperature manually before you can safely

open it (see

You may see a warning if the retort temperature is greater than either the retort empty access

temperature (view on the Reagent management screen) or the safe access temperature

associated with the reagent in the retort (set on the Reagent types screen).

The retort lids can be removed for cleaning (see Clean Lids and Seals in 7.2 Daily Tasks).

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 25

Venting a Retort below).

Page 26

Hardware

Some instruments have retort latch locks to disallow opening retorts when a protocol is running or

the retort temperature is high. See your service representative if you have latch locks on your

instrument.

WARNING

Retorts may contain very hot fluid that could cause severe burns. Wear suitable protective

clothing and eyewear when opening a retort.

WARNING

Retorts may contain hazardous reagents and vapors. Wear suitable protective clothing and

eyewear and ensure adequate ventilation when opening a retort.

WARNING

Take care not to knock retort lids when they are open. They could crush fingers or hands.

Venting a Retort

You must ensure there is no pressure or vacuum inside a retort before you open the lid. The retorts

automatically vent at the start and end of a protocol, and also during a pause in a protocol.

However, you may need to manually vent a retort if an automatic vent fails or if you wish to access

a pressurized or evacuated retort at other times.

Use the Manual operations screen to manually vent the retorts. Set the Pressure button to

Ambient for the retort that you want to open. You may need to wait up to one and a half minutes

for the pressure to equalize. If your instrument has retort latch locks, use the Lock/Unlock retort

button; it may take several cycles to successfully vent a retort.

If you leave a hot retort closed for an extended time, the air in the retort will cool and create a

vacuum. You must then vent the retort before attempting to open the lid.

2.2.2 Fill Levels

Retorts can be filled with enough reagent for two or three cassette baskets. Supervisors set the

required fill level on the Instrument settings screen (see

Settings).

The two basket fill volume is 3.8 liters (1 gallon US) and the three basket fill volume is 5 liters (1.32

gallon US).

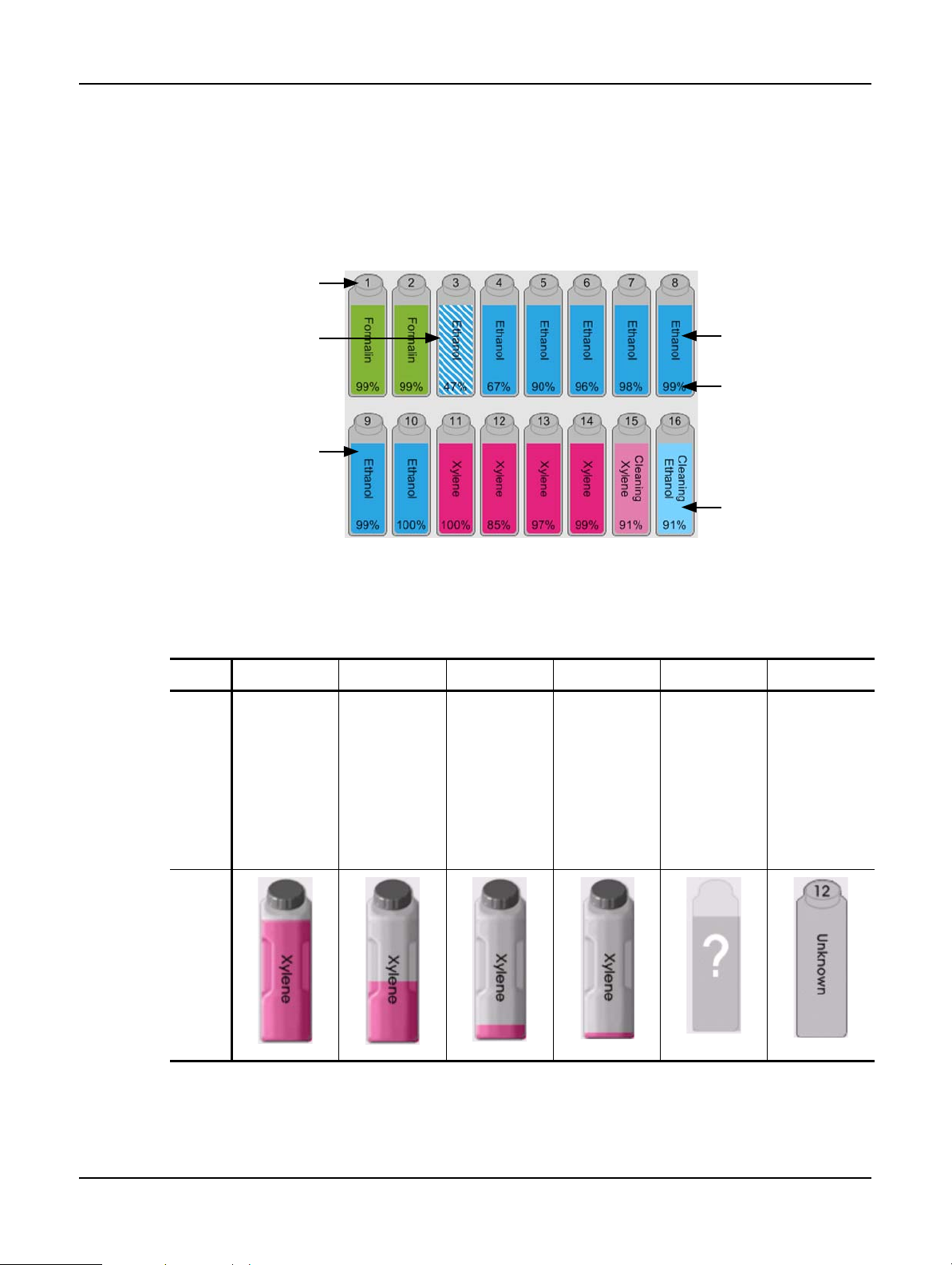

Use markings on the reagent bottles (Figure 3) and wax chambers (Figure 4) to ensure you have

enough reagent to fill the retorts to the required level. Always keep the reagent or wax volumes

Reagent Fill Levels in 6.2.1 Instrument

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 26

Page 27

Hardware

well above the markings, but below the maximum (MAX) level. Reagent levels below the minimum

will cause protocols to either fail or use a sub-optimal reagent sequence.

Figure 3. Bottle fill levels Figure 4. Wax chamber fill levels

Liquid Level Sensors

Figure 5. Liquid level sensors for—

maximum (1), three-basket (3) and two-basket (2) retort fill levels

Each retort has three liquid level sensors to monitor fluid levels. The two lower sensors monitor the

two and three basket levels. The top, maximum, sensor responds to a fluid level of 5.3 liters. It

serves a safety function ensuring no more reagent is pumped into the retort if triggered.

The sensors may occasionally be affected by a buildup of condensation or deposited material. If

this occurs the software will direct you to wipe the appropriate sensor. Always ensure the sensors

are kept clean as part of regular retort cleaning (see

Clean Retorts in 7.2 Daily Tasks).

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 27

Page 28

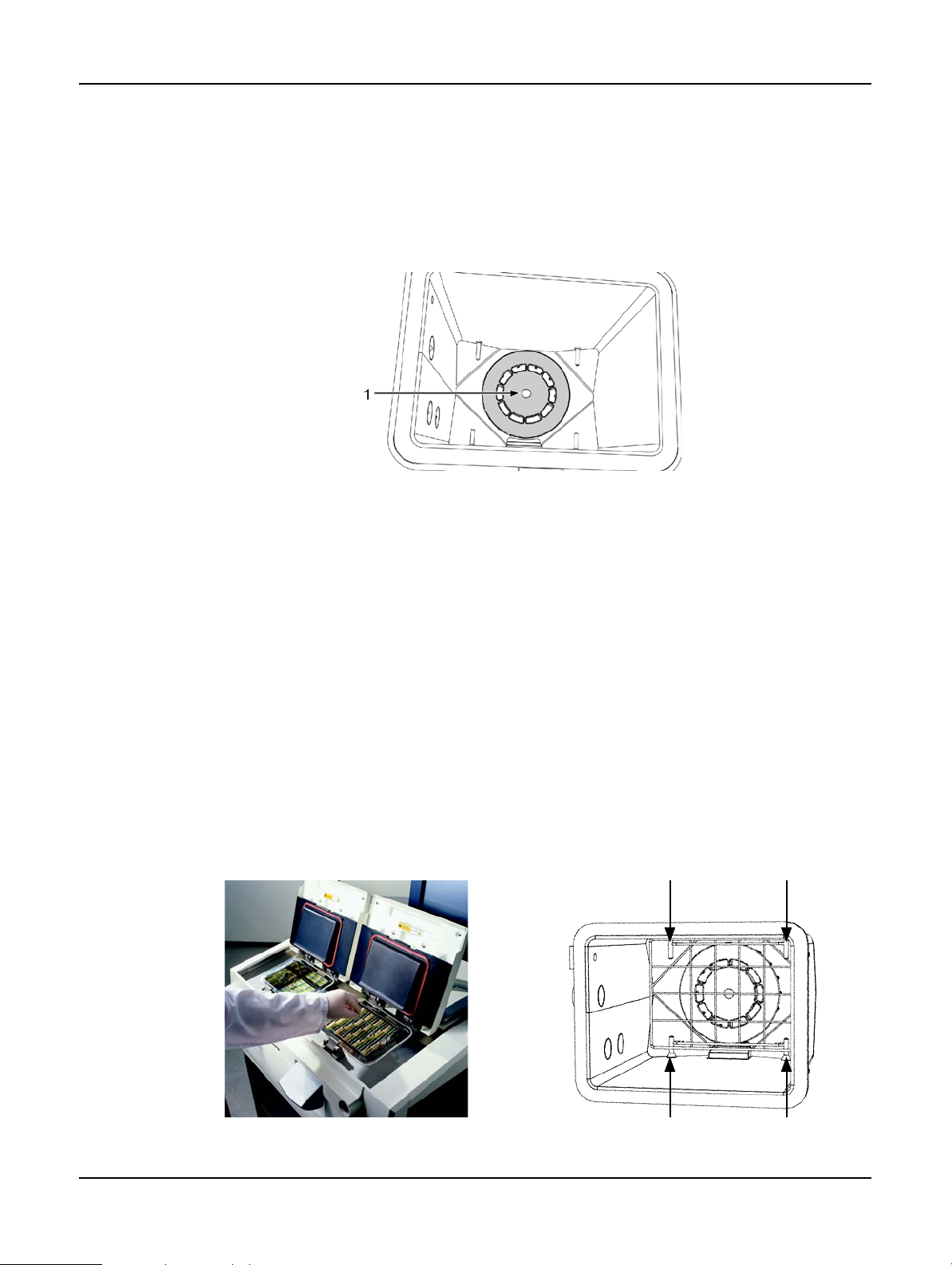

2.2.3 Magnetic Stirrer

Each retort has as magnetic stirrer that stirs the reagent or wax to ensure temperature consistency

and good tissue penetration. The stirrer is driven by a magnetically-coupled external motor. The

stirrer speed can be controlled for each protocol step and is easily removed for cleaning (see

Retorts in 7.2 Daily Tasks).

Hardware

Clean

Figure 6. Magnetic stirrer (1)

2.2.4 Cassette Baskets

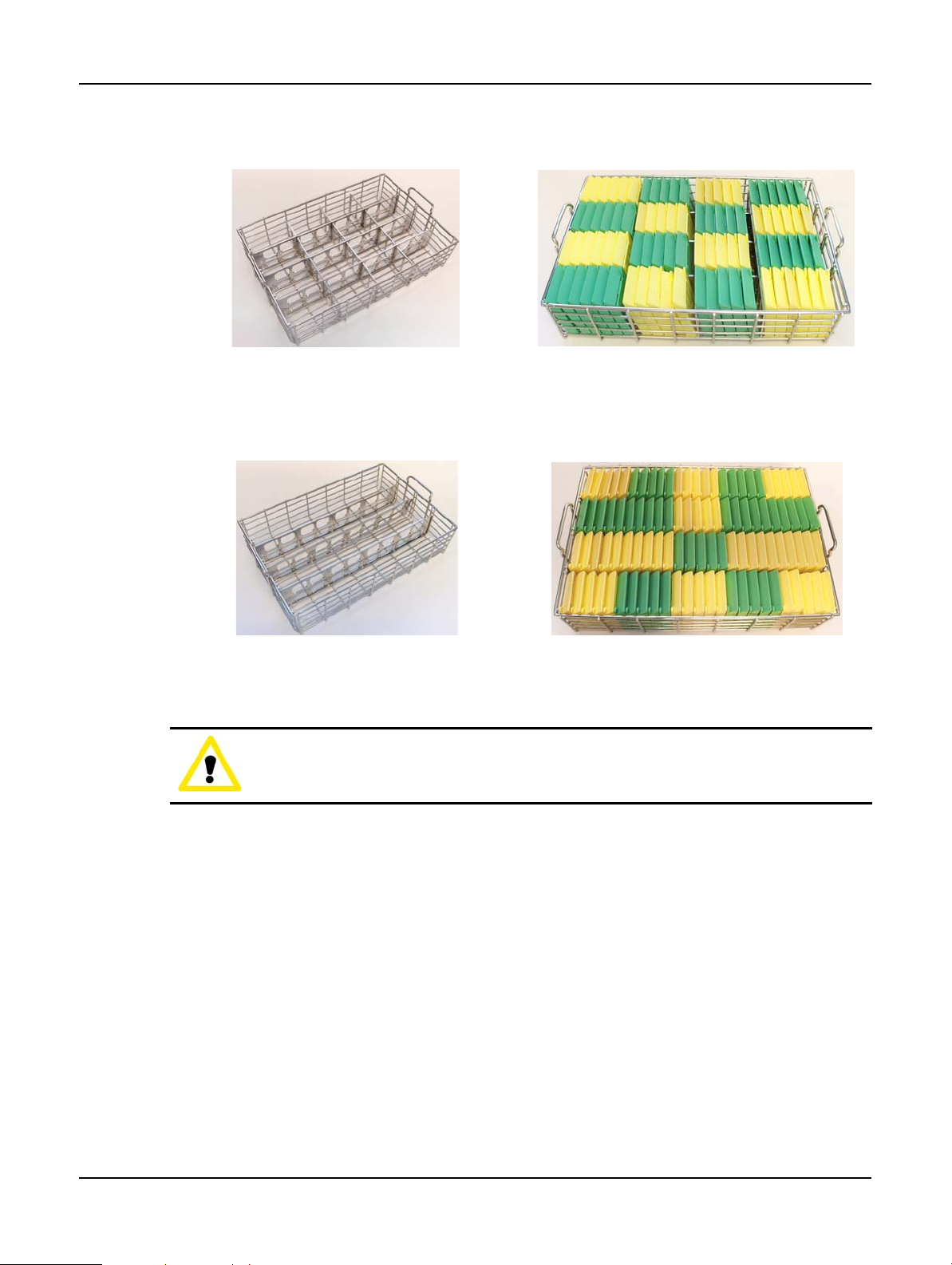

There are two Peloris basket types: the configurable high-capacity basket that accommodates the

maximum number and type of cassettes; and the spaced basket that ensures optimal reagent flow.

The high-capacity cassette baskets accept most common cassette types and include configurable

dividers that allow for different cassette sizes and packing densities.

The spaced baskets include dividers that ensure optimum reagent flow with minimal carryover. This

basket type accepts 72 standard cassettes. Spaced baskets must be used for all xylene-free

protocols.

Cassette baskets stack into the retorts with the lids upwards and handles dropped flat. Make sure

the first basket sits flat on the rack on the pins at the bottom of the retort (

additional baskets so they sit flat on the lower ones – crooked baskets can leave cassettes exposed,

damaging the tissue in them.

Figure 8). Stack

Figure 7. Placing a basket into a retort Figure 8. Retort pins

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 28

Page 29

WARNING

Always ensure the cassettes are correctly inserted into the baskets and that the baskets are

correctly placed in the retorts. Incorrectly placed cassettes or baskets may lead to samples being

damaged as some tissue may not be fully covered by reagent during processing.

WARNING

Never place three baskets into a retort when the instrument is configured with a two-basket fill

level. If this occurs, reagent will not cover the top basket and tissue samples will be damaged.

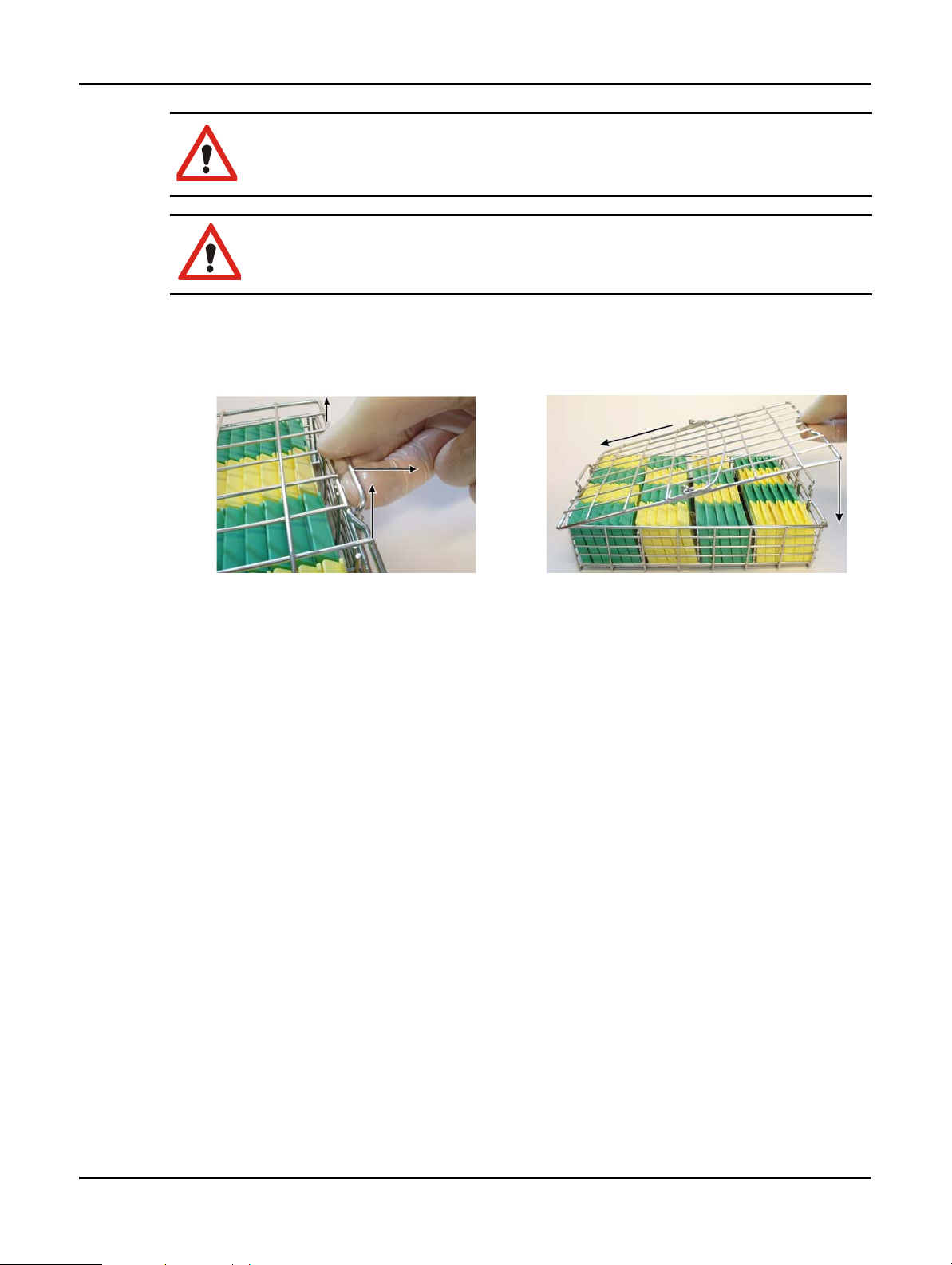

Opening and Closing Cassette Baskets

The lid is held by two catches and is completely removable to aid cassette access.

Hardware

Figure 9. Releasing the lid Figure 10. Replacing the lid

To remove the lid, release one catch then swing the lid up and off the basket (see Figure 9).

To replace the lid, insert one end into a catch then swing the other end down so it firmly

engages the second catch (see

Make sure the lid is firmly held by both catches or the body and cassettes may fall when the

Figure 10).

basket is lifted.

High-capacity Baskets

High-capacity baskets include dividers to configure the baskets to hold different numbers of

cassettes. Use all the dividers to configure the baskets for orderly packing (up to 88 cassettes) or

the long dividers only for tight packing (up to 100 cassettes).

For orderly packing, insert both the long and short dividers into the basket. This arrangement

makes it easier to insert and remove the cassettes (see

Figure 11 and Figure 12). Six standard

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 29

Page 30

Hardware

cassettes can be placed in the end sections of each row and five in the middle sections, giving 88

cassettes per basket.

Figure 11. Basket arranged for orderly packing Figure 12. Basket packed with 88 cassettes

For tight packing, insert only the long dividers. This allows you to pack the maximum number of

cassettes — 25 per row (see

Figure 13 and Figure 14).

Figure 13. Basket arranged for tight packing Figure 14. Basket packed with 100 cassettes

For large or unusually shaped cassettes use the baskets with all dividers removed.

CAUTION

Do not use high-capacity baskets for xylene-free protocols as this may lead to wax build up that

will eventually require service intervention.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 30

Page 31

Hardware

Spaced Baskets

The spaced baskets include a fixed divider that ensures that the cassettes are correctly spaced for

optimal processing. Each spaced basket can fit up to 72 standard cassettes inserted into the

spacing springs as shown in

You must use spaced baskets when running xylene-free protocols.

Figure 15.

Figure 15. Detail of cassettes packed into a spaced basket

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 31

Page 32

2.3 Wax Bath

The wax bath at the top rear of the instrument has four wax chambers accessed by two lids. Each

chamber acts independently, holding enough wax to fill a retort. Although wax does not move

between the chambers, they are connected for air flow and so always have the same pressure.

Use the lid handles to open the lids. Always use the handles to close the lids, ensuring the lids are

properly latched. Be sure not to knock the lids when they are open as they may slam shut.

Always ensure the wax bath pressure is at ambient pressure before opening the lids. If the pressure

is not ambient, vent the bath first. You can do this when you pause a running protocol or from the

Manual operations screen.

Hardware

Figure 16. Opening a wax bath lid

View the current temperature of each wax station in the wax chambers view of the Reagent

stations screen.

Depending on the reagents you use you can set the instrument to clean the wax in the bath (see

Wax Bath Settings in 6.1.2 Reagent Management).

Drain used wax with commands on the Remote fill/drain screen. Directly fill with molten or solid

wax (see

5.4.5 Replacing Wax).

WARNING

Take care when opening the wax bath after a xylene-free protocol as the protocol will leave very

hot wax in the bath.

WARNING

Never open a wax bath lid when there is wax in a retort or wax is being transferred; hot wax

may splash out of the bath.

WARNING

Take care not to knock wax bath lids when they are open. They could crush fingers or hands.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 32

Page 33

2.4 Reagent Cabinet

16 reagent bottles

Carbon filter

Condensate bottle

Hardware

Figure 17. Reagent cabinet

The reagent cabinet houses the reagent bottles, carbon filter, and condensate bottle. The cabinet

has two glass doors that retract into the cabinet when open.

WARNING

To reduce the risk of fluid spills, always keep the reagent cabinet doors closed during instrument

operation unless actually changing a reagent or emptying the condensate bottle.

2.4.1 Reagent Bottles

2.4.2 Condensate Bottle

2.4.3 Carbon Filter

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 33

Page 34

2.4.1 Reagent Bottles

The reagent cabinet holds sixteen reagent bottles. This is three more than standard tissue

processors and it ensures there are sufficient reagents to simultaneously schedule protocols in both

retorts while also having ample cleaning reagents on board and ready to use. The bottle at each

station holds sufficient reagent to fill a single retort.

To remove a bottle, lift open the cabinet door and pull the bottle out. Push back in position to

return – you will feel the bottle pushing into its connection point on the back of the cabinet.

Replace reagent in the bottles either manually, with the bottles removed from the instrument, or in

position on the instrument using the Remote fill/drain screen (see

Screen).

Some chemicals may cause the bottles to expand over time; this is normal and does not impact the

performance of the instrument.

WARNING

Never run the instrument with missing bottles or with loose or missing bottle lids as fluid spills

and vapor leaks will occur.

Hardware

5.4.1 Remote Fill/Drain

2.4.2 Condensate Bottle

A separate bottle collects condensate fluid. It sits beside the reagent bottles in the lower section of

reagent cabinet. Empty weekly. Do not allow the bottle to overflow as condensate fluid will spill

from the instrument or contaminate other reagents.

WARNING

Never run the instrument with the condensate bottle missing or its lid either loose or missing as

fluid spills and vapor leaks will occur.

2.4.3 Carbon Filter

The carbon filter absorbs reagent fumes to prevent them from entering the laboratory atmosphere.

To ensure the filter is operating effectively, it must be replaced periodically. Use the Carbon filter

threshold button to set the replacement interval (see

The carbon filter can be bypassed and the instrument connected to an external vapor removal

system (see 2.6 External Vapor Removal Systems).

WARNING

Never run the instrument without the carbon filter or an external filter system; this will release

potentially dangerous fumes into the laboratory.

6.2.1 Instrument Settings).

The filter must be installed with the direction arrow on the front pointing up and the locking

mechanism closed (see

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 34

Change Carbon Filter in 7.4 60–90 Days).

Page 35

2.5 Touch-screen

A touch-screen mounted on the right of the Peloris connects to a computer in the instrument that

controls all instrument operations.

Use the Peloris software on the touch-screen to configure the instrument, run protocols, and

perform ancillary operations such as replacing reagents. Tap buttons and icons with your finger or a

blunt object – do not use sharp objects. Ensure no strong solvents come into contact with the

touch-screen.

Optional stick-on/ peel-off touch-screen protectors, provided by Leica Microsystems, can be used to

protect to the touch-screen.

In its normal operating position the touch-screen sits over the wax bath lid, but can be rotated to

give clearance to open the lid. The screen can be remounted so its normal position is to the right of

the mounting stem rather than over the instrument. See your service representative if you want to

change the touch-screen position.

CAUTION

If the touch-screen goes blank or is unreadable, turn off the instrument immediately.

Hardware

2.6 External Vapor Removal Systems

Figure 18. Vapor select valve (1) and vapor outlet (2)

The outlet for instrument vapors can be switched between the internal carbon filter and an external

vapor extraction system. At the rear of each instrument there is a valve that directs vapors to either

the carbon filter or to an outlet that can be connected into the external system.

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 35

Page 36

Hardware

For instructions on changing to an external vapor system, see Connecting to an External

System below.

For instructions on returning to the internal carbon filter system, see Returning to the Internal

Filter System.

Some instruments do not have the vapor select valve fitted. However your service representative

can easily connect these instruments to an external vapor system.

Connecting to an External System

WARNING

When the vapor select valve is in the external position, you must ensure an external vapor

system is correctly installed or potentially dangerous fumes will be released into the laboratory

environment.

Use the following procedure to connect the instrument to an external vapor system.

1. Connect the instrument’s vapor outlet into the external system (see item 2 in Figure 18).

2. Turn the vapor select valve a quarter turn anticlockwise to direct vapors to the vapor outlet

(see

Figure 19).

Note: to access the valve you may need to remove a blanking plug.

Figure 19. Vapor select valve in the external system position

3. Set the carbon filter threshold to one of the following options.

(i) The inspection interval for the external system (see 6.2.1 Instrument Settings).

(ii) The maximum value (1000) to limit the number of unwanted warnings (see 6.2.1

Instrument Settings).

(iii) Overridden (contact your service representative to arrange this setting).

Leica PELORIS™ User Manual Rev K © Leica Biosystems Melbourne Pty Ltd 2011 36

Page 37

Hardware

Returning to the Internal Filter System

WARNING

When the vapor select valve is in the internal position, you must ensure the carbon filter is

correctly installed or potentially dangerous fumes will be released into the laboratory

environment.

Use the following procedure to reconfigure an externally connected instrument to internal carbon

filter use.

1. Ensure a new carbon filter is correctly installed (see 2.4.3 Carbon Filter).

2. Turn the vapor select valve a quarter turn clockwise to direct the vapors to the internal carbon

filter (see