La Marzocco Strada MP User Manual

manual

strada mp

Progressive control of water flow and pressure via a mechanical internal valve, thus allowing controlled pre-infusion.

La Marzocco‘s classic paddle interface, manually operated by the Barista.

With dedicated coffee boilers and pressure gauges for each brew group, the Barista benefits by having real time coffee boiler pressure throughout the extraction.

strada mp

Operating Manual V2.0 - 10/2016

MAN.8.1.01

Chapters

1. |

General Warnings and Safety Specifications |

page 3 |

2. |

Definition of Available Models |

page 7 |

3. |

Installation |

page 10 |

4. |

Machine Operation and Coffee Preparation |

page 18 |

5. |

Dispensing Steam and Hot Water |

page 21 |

6. |

Maintenance and Periodic Cleaning Operations |

page 22 |

7. |

De-commissioning and Demolition |

page 25 |

8. |

Mandatory Maintenance and Check-up Operations |

page 26 |

9. |

Software Programming Guide |

page 27 |

La Marzocco S.r.l.

Via La Torre 14/H

Località La Torre

50038 Scarperia e San Piero

(Firenze) - ITALIA

www.lamarzocco.com

info@lamarzocco.com

T: +39 055 849 191 F: +39 055 849 1990

certifications available:

EN

1. General Warnings and Safety Specifications

WARNING

This machine is for professional use only and should be installed in locations where its use and maintenance is restriced to trained personnel. Children are forbidden to operate or play with

the machine.

WARNING

The Coffee machine must be placed in a horizontal position on a counter higher than 80 cm from the ground.

WARNING

This machine is not suitable for outdoor use. Jets of water should not be used to clean the machine, nor should it be placed where water jets are used.

WARNING

As already mentioned in the preceding notes, the manufacturer shall not be held responsible for damage to objects, animals and/or people whenever the machine has not been installed according to the instructions contained in this manual, and is not used to do what it was designed for (i.e. preparing coffee and hot drinks).

1) Important safeguards

• The weighted sound • pressure level of the machine is lower than 70dBA.

• Use, |

|

cleaning |

and |

|

|

|

|

|

|

|

|

|

maintenance of this coffee |

2) |

This |

operating manual |

|

||||||||

machine |

are |

|

realized |

is an integral and essential |

|

|

|

|

|

|||

by |

people |

(including |

part |

of |

the product and |

|

|

|

|

|

||

children |

more |

|

than 8 |

|

|

3EN |

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EN

must be supplied to users. Users are asked to read the enclosed warnings and cautions carefully, as they provide valuable information concerning safety during installation, operation and maintenance. This manual must be kept in a safe place and be available for consultation to new and experienced users alike.

3)Ensure product’s integrity by inspecting the packaging, making sure it presents no signs of damage which might have affected the enclosed machine.

4)Check the machine’s integrity after having carefully removed the packaging.

Note: In case of doubt, do not go on any further and contact your dealer or retailer immediately. They will send out specialized personnel

4

authorized to perform service on |

8) |

Incorrect |

installation |

may |

||||||

the espresso machine. |

cause |

for |

injury/damages to |

|||||||

5) Packaging (boxes, plastic |

people, animals or objects, for |

|||||||||

which the manufacturer shall |

||||||||||

bags, foam parts and whatever |

not be held responsible. |

|

||||||||

else) must not be left around |

9) Safe electrical operation of |

|||||||||

within easy reach of children, |

||||||||||

due to the potential danger it |

this device will be achieved |

|||||||||

represents, nor be discarded |

only when the connection to |

|||||||||

in the environment. |

the power outlet has been |

|||||||||

6) Check to see that data on |

completed |

|

correctly |

|

and |

|||||

in observance of all local, |

||||||||||

the rating |

plate |

corresponds |

national, |

and |

international |

|||||

to those of the main electrical |

electrical |

codes |

and |

safety |

||||||

supply which the machine will |

regulations, |

and |

particularly |

|||||||

be hooked up to. |

|

by |

grounding |

the |

|

unit. |

||||

|

|

|

|

|||||||

7) The equipment must be |

Make |

sure |

grounding |

has |

||||||

installed to comply with the |

been done properly as it |

|||||||||

applicable |

federal, state or |

represents |

|

a |

fundamental |

|||||

local electrical and plumbing |

safety |

requirement. |

Ensure |

|||||||

codes.The |

|

installation |

qualified |

personnel |

check |

|||||

also must comply to the |

such connection. |

|

|

|

||||||

manufacturer’s |

instructions, |

10) |

Furthermore, you |

|

must |

|||||

and must be performed by |

ensure that the capacity of |

|||||||||

qualified |

and |

authorized |

the available electrical system |

|||||||

personnel. |

|

|

|

|

|

|

|

|

|

|

is suitable for the maximum power consumption indicated on the espresso machine.

11)We do not recommend using adapters, multiple plugs and/or extension cords. If you cannot avoid using them, make sure that they are exclusively of the kind which conforms to local, national, and international electrical codes and safety regulations, being careful not to exceed the power and current ratings indicated on such adapters and extension cords.

12)This device must be used exclusively for the functions it has been designed and built for. Any other application is inappropriate and dangerous.

The manufacturer shall not be held responsibleforanydamagescaused by improper and/or irrational use.

This machine should not be installed in kitchens.

13) Using any electrical device requires that certain fundamental rules be observed. In particular:

•do not touch the device with wet or humid hands and feet;

•do not use the device while having no shoes on your feet;

•do not use extension cords in bath or shower rooms;

•do not unplug the device from the power outlet by pulling on the power supply cable;

•do not expose the device to atmospheric agents (rain, sun, etc.);

•do not allow children or untrained people to use this device;

•do not clean the control

panel with a wet cloth since it is not watertight.

14) Before carry5ing out any maintenance and/or cleaning operations, turn the main switch, which is located on the front left of the machine, to the “0” or “OFF” position, and disconnect the machine from the electrical network by unplugging the cord or by switching off the relative circuit breaker. For any cleaning operation, follow exclusively the instructions contained in this manual.

15) In case the machine is operating in a faulty manner or breaks down, disconnect it from the electrical network (as described in the preceding point) and close the water supply valve. Do not attempt

to repair it. Contact a qualified

5EN

and authorized professional to performanyrepair. Anyrepairs must be performed exclusively by the manufacturer or by an authorized centre using only original parts. Non compliance with the above could compromise the safe operation of the machine.

16)You should plan to make use of an omnipolar connector during installation, as required by local, national,andinternationalelectrical codes and regulations.

17)In order to avoid dangerous overheating problems, it is recommended that the power supply cable be fully unfurled.

18)Do not obstruct air intake and exhaust grilles and, in particular, do not cover the cup warmer tray with cloths or other items.

19)The machine’s power supply cable must not be replaced by users. In case the power supply cable becomes damaged, shut off the machine and disconnect the machine from the electctrical network by switching off the relative circuit breaker and

close off the water supply; to replace the power supply cord, contact qualified professionals exclusively.

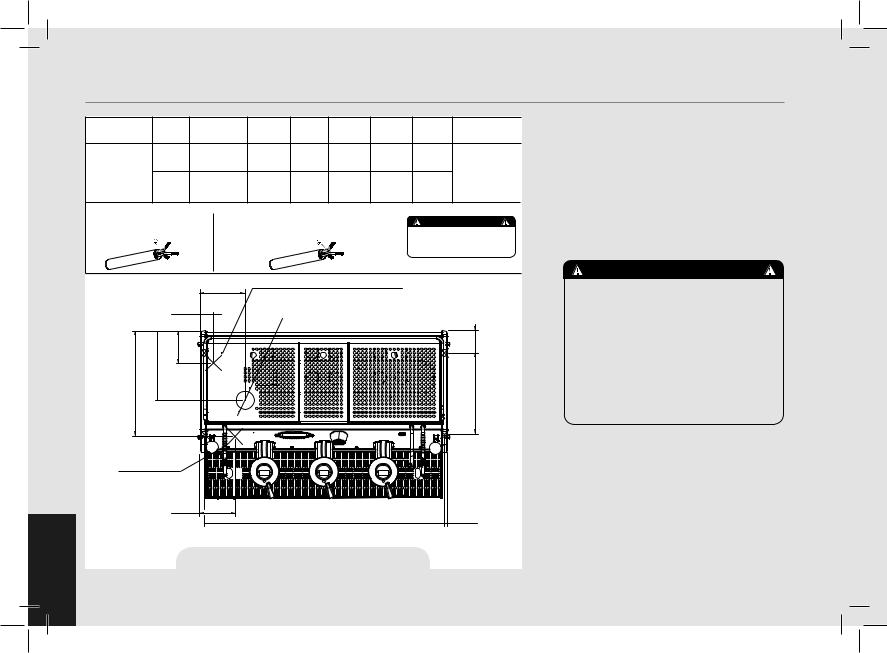

20) Common Dimensions, Weights,

and Features

A B

C

STRADA MP |

2 groups |

3 groups |

|

|

|

A [mm] |

800 |

1000 |

|

|

|

B [mm] |

675 |

675 |

|

|

|

C [mm] |

475 |

475 |

|

|

|

WEIGHT [kg] |

70 |

91 |

EN

6

|

|

|

|

|

|

|

|

|

|

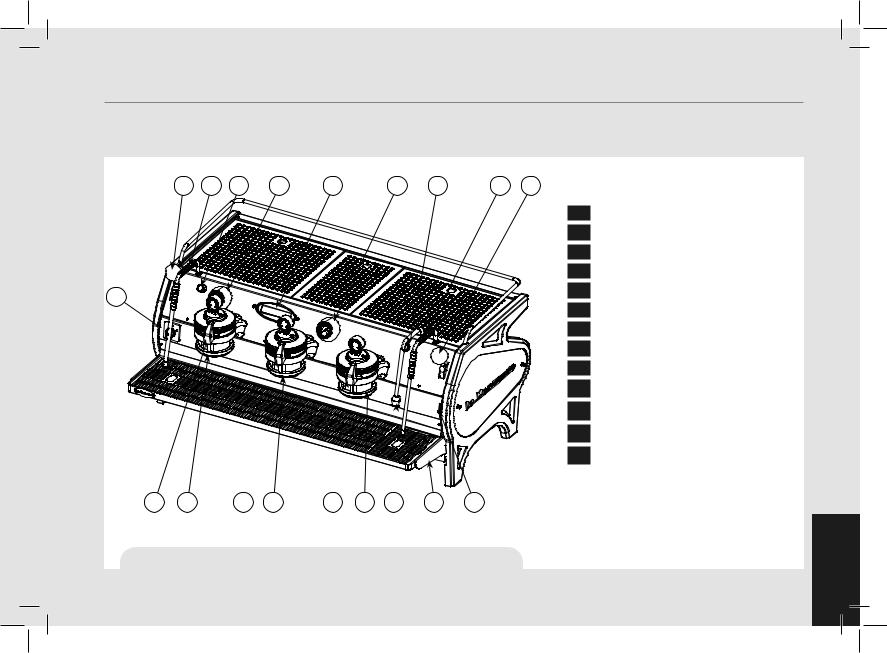

2. Definition of Available Models |

|

|

This operating manual refers exclusively to the following models, of our own manufacture: |

||||||||

|

|

|

|

|

STRADA, Model MP 3 groups |

|

|

|||

9 |

8 |

5 |

2 |

7 |

3 |

6 |

8 |

9 |

Legend |

|

|

|

|

|

|

|

|

|

|

1 |

Main Switch |

|

|

|

|

|

|

|

|

|

2 |

Pressure Gauge (steam boiler) |

|

|

|

|

|

|

|

|

|

3 |

Pressure Gauge (coffee boiler) |

|

|

|

|

|

|

|

|

|

4 |

Brew Groups |

1 |

|

|

|

|

|

|

|

|

5 |

Encoder |

|

|

|

|

|

|

|

|

6 |

Tea Water Button |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

7 |

Digital Display |

|

|

|

|

|

|

|

|

|

8 |

Steam Wand |

|

|

|

|

|

|

|

|

|

9 |

Steam Wand Lever |

|

|

|

|

|

|

|

|

|

10 |

Hot Water Wand |

|

|

|

|

|

|

|

|

|

11 |

Removable Drain Tray |

|

|

|

|

|

|

|

|

|

12 |

Manual Brew Paddle Lever |

|

|

|

|

|

|

|

|

|

13 |

Hot Water Mix Valve |

12 4 |

|

12 |

4 |

12 |

4 10 |

11 |

13 |

|

For additional information on electronics, |

|

|

|

keypads, and software programming, |

||||||||

please see the section entitled Software Programming your Espresso Machine.

Fig. 1 - Model MP with 2 or 3 groups EN

7

EN

1) General Description

The machine is built in 2 and 3 coffee group versions and is essentially composed of the following parts:

•Steam Boiler (produces steam and hot water);

•Coffee (“saturated”) boiler;

•Brewing groups;

•Exterior Cover;

•Water pump.

2) Description of the various parts

• Steam Boiler

The Steam Boiler consists of a cylindrical tank, of varying length according to the number of coffee groups, which is made of AISI 300 series stainless steel. Each unit is subjected to a hydraulic test, at a pressure of 6 bar, and has an operating pressure of 1.3-1.5 bar. The following is a list of effective volumes and power ratings according to the number of groups installed:

2 groups |

8,2 liters |

3000 Watts |

3 groups |

11,8 liters |

4000 Watts |

Covers are welded at either end of the cylindrical tank and on one of them there is a housing for the water heating element, which allows the steam boiler to reach operating pressure within approximately 25 minutes. Operating pressure is

8

maintained by temperature probe. The steam boiler has various fittings used for safety devices, for supplying hot water and steam, and for the heating element.

Composed of AISI 300 series stainless steel tube. Heating is accomplished through an immersion-type plated heating element.

•Operating pressure of 1.3-1.5 bar, controlled automatically through a pressure switch or a temperature probe, adjusted to open the heating element supply circuit at 1.5 bar and close it at 1.3 bar.

•The pressure is displayed by means of a pressure gauge with a scale of 0 to 2 bar.

•Safety device, based on an expansion type mechanical valve, with counteracting spring adjusted to 1.8 bar.

•Testing: hydraulic test at 4.5 bar performed on ready-to-use small boilers, at our factory.

•Coffee Boiler

The Coffee Boiler consists of a cylindrical tank made of AISI 300 series stainless steel. One each group (hot water generator for brewing coffee).

Each unit is subject to a hydraulic test, at a pressure of 18 bar, and has an operating pressure of 9 bar. The following

is a list of effective volume and power ratings according to the number of groups installed:

2 groups |

2 x 1,3 liters |

2 x 800 Watts |

3 groups |

3 x 1,3 liters |

3 x 800 Watts |

Covers are installed at either end of the cylindrical tank and on one of them there is housing for the water heating elements. The temperature of the coffee boiler is maintained by an electronic temperature controller (PID capable) with an accuracy of 0.2°C. The brewing groups are installed on the boiler.

Composed of an AISI 300 series stainless steel tube. Heating is accomplished through an immersion-type plated heating element.

•Operatingtemperature95°C(adjustable), controlled automatically by an electronic temperature controller with an accuracy of 0.2 °C. Operating pressure of 9 bar, developed mechanically by a special

positive-displacement pump which is activated automatically every time coffee is brewed.

•Pressure is displayed through a pressure gauge with a scale from 0 to 15 bar.

•Safety device, based on an expansion type mechanical valve, with counteracting spring adjusted to 13.5 bar.

•Testing: Hydraulic test at 18 bar performed on ready-to-use small boilers, at our factory.

•Brewing groups

They consist of a precision casting made of stainless steel. The brewing group accepts the portafilter used to hold the ground coffee; the espresso flows through the brewing group, through the portafilter basket, through the portafilter spout, and into the cup(s) after the brewing button has been pressed.

• Exterior cover

The exterior consists of painted and stainless sheet steel panels. To provide good aesthetics, to optimize ergonometrics for the operator and to reduce the chance of damage to a minimum.

• Water pump

The rotary vane pump, is installed on the water supply tubing and is set up to operate anytime the coffee groups are activated, and through an autofill system whenever the water boiler needs to be replenished.

9EN

3. Installation

|

|

|

RATED |

RATED |

COFFEE |

STEAM |

TOTAL |

POWER CORD |

|

MODEL/SERIES GROUP |

V/Hz |

POWER |

INPUT |

BOILER |

BOILER |

SIZE (mm²) |

|||

|

|||||||||

|

|

|

(W) |

(A) |

WATTAGE |

WATTAGE |

WATTAGE |

|

|

|

2GR |

AC220-240V/60Hz |

|

20-22 |

|

|

4600 SEE ELECTRICAL |

||

|

AC208-240/60Hz |

4600 |

23 |

1600 |

3000 |

||||

STRADA MP |

AC380/50Hz |

|

12 |

|

|

|

CONNECTIONS |

||

AC220-240V/60Hz |

|

25-29 |

|

|

|

||||

|

|

|

2400 |

4000 |

|

|

|||

|

3GR |

AC208-240/60Hz |

6400 |

30,5 |

6400 |

FOR DETAILS |

|||

|

|

AC380/50Hz |

|

16 |

|

|

|

||

|

|

|

|

|

|

|

|||

|

|

POWER CORD: |

|

|

|

|

|

||

3 X WIRES 1 X BLUE (NEUTRAL) |

5 X WIRES 1 X BROWN (PHASE) 1 X BLUE (NEUTRAL) |

|

WARNING |

||||||

220V |

1 X BROWN (PHASE) |

380V |

1 X GRAY (PHASE) 1 X YELLOW & GREEN (GROUND) |

||||||

|

|

|

|

||||||

|

1 X YELLOW & GREEN (GROUND) |

1 X BLACK (PHASE) |

|

|

THE DETAILS ON THE LEFT DESCRIBE |

||||

|

|

|

|

|

|

|

HOW TO CONNECT EACH WIRE TO THE PLUG. |

||

|

|

|

|

|

|

|

RESPECT ALSO THE LOCAL SAFETY |

||

|

|

|

|

|

|

|

REGULATIONS. |

||

|

|

|

210 mm |

HERE THE POSITION OF THE POWER CORD AND |

|

|

||

|

|

|

WATER INLET HOSES |

|

|

|

||

|

|

|

4 in. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

55 mm |

|

FROM 80 TO 100 mm |

HERE THE POSITION WHERE WE |

|

|

|

|

|

2,1 in. |

|

SUGGEST TO MAKE THE HOLE |

|

|

||

|

|

|

|

FROM 3 in. TO 4 in. |

ON THE TABLE |

|

|

|

|

mm in. |

130 mm 5,1 in. |

|

|

|

|

94 mm |

3,7 in. |

425 mm 16,7 in. |

280 11 |

|

|

|

|

|

328 mm |

13 in. |

HERE THE POSITION |

|

|

|

|

|

|

||

OF THE DRAIN TUBE |

|

|

|

|

|

|

||

|

|

140 mm |

|

|

|

|

|

|

|

|

5,5 in. |

|

775 mm (2 groups) |

975 mm (3 groups) |

12,5 mm |

||

|

|

|

|

|||||

|

|

|

|

30,5 in. (2 groups) |

38 in. (3 groups) |

0,5 in. |

|

|

POSITION OF THE HIGH LEGS MACHINE

EN |

10 |

|

Fig. 2 - Installation guide |

WARNING

The machine is intended to be permanently connected to fixed wiring, and it is mandatory that a residual current device (RCD) with a rated residual operating current not exceeding 30mA is

installed.

WARNING

The Coffee Boiler and Steam Boiler contain water at elevated temperature. Water temperature over 125°F / 52°C can cause severe burns instantly or death

from scalding (Coffee Boiler 207°F/97°C - Steam Boiler 256°F / 124°C)

WARNING

At each installation, the machine should be equipped with a new set of tubes for plumbing and related gaskets.

WARNING

Water pressure supply must be between 2 and 6 bar if sufficient pressure is not available we suggest that an additional water supply system is used.

WARNING |

WARNING |

|

||||

Hazardous voltage disconnect |

Replace fuses with the same |

|

||||

from power supply before |

size, type and rating F1 = 2A, |

|

||||

servicing. |

250V |

|

||||

WARNING |

WARNING |

|

||||

Before making any electrical |

- U.S.A. and CANDA only - Do not |

|

||||

connections make sure that the |

connect to a circuit operating |

|

||||

two strain relief connectors are |

at more than 150V to ground on |

|

||||

firmly secured to the body of |

each leg. |

|

||||

the machine in order to prevent |

|

|

|

|

|

|

inadvertent stress on the power |

WARNING |

|

||||

cables. |

|

|||||

The manufacturer declines |

|

|||||

|

|

|||||

|

any responsibility for any |

|

||||

WARNING |

event leading to liability suits |

|

||||

The motor pump must be |

whenever grounding has not |

|

||||

situated close to the machine |

been completed according to |

|

||||

in an accessible place for |

current local, national, and |

|

||||

maintenance but not for |

international regulations and |

|

||||

accidental interference and |

electrical codes, or other |

|

|

|

|

|

where there is an optimal air |

electrical parts have been |

|

|

|

|

|

circulation. |

connected improperly. |

|

|

|

|

|

|

11EN |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

This machine should not be installed in kitchens.

WARNING

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or with lack of experience and knowledge, unless they have

been given supervision or instruction concerning the use of the appliance by a person responsible for their safety.

WARNING

This machine is not suitable for outdoor use. Jets of water should not be used to clean the machine, nor should it be placed where water jets are used.

WARNING

In order to prevent cracks or leakage: do not store or install the Coffee machine in places where in boiler or hydraulicsystem to freeze.

Note:

•The drinking water mains valve and the circuit breakers for the electrical system need to be located in the most convenient position for the operator to access them easily and quickly.

•The machine should be placed on a flat counter and must be placed in settings with the following temperatures:

Minimum room temperature: 5°C/41°F Maximum room temperature: 32°C/89°F

•If the machine has been temporarily housed in settings with a room temperature of less 0°C/32°F, the machine must be placed in a warmer environment in order to gradually defrost the hydraulic system prior to use.

•Water pressure supply must be between 2 and 6 bar.

•This machine complies with the standard 61000-3-11, the impedance at the supply interface must be Zmax=

0.11 Ω.

EN

12

1) Installation guide

For best results, STRADA needs a minimum flow of water in input of 100 l/h and a pressure of 2.5 bar.

Installations that do not meet these requirements will cause a shorter life of the pump and may cause a high noise level during coffee brewing.

If the pressure and flow are not adequate, air bubbles may develop within the gears. This is called cavitation. Cavitation can impair the performance of the espresso machine.

If the incoming water of the espresso machine falls outside the recommended parameters, it is necessary to carry out one of the following installations:

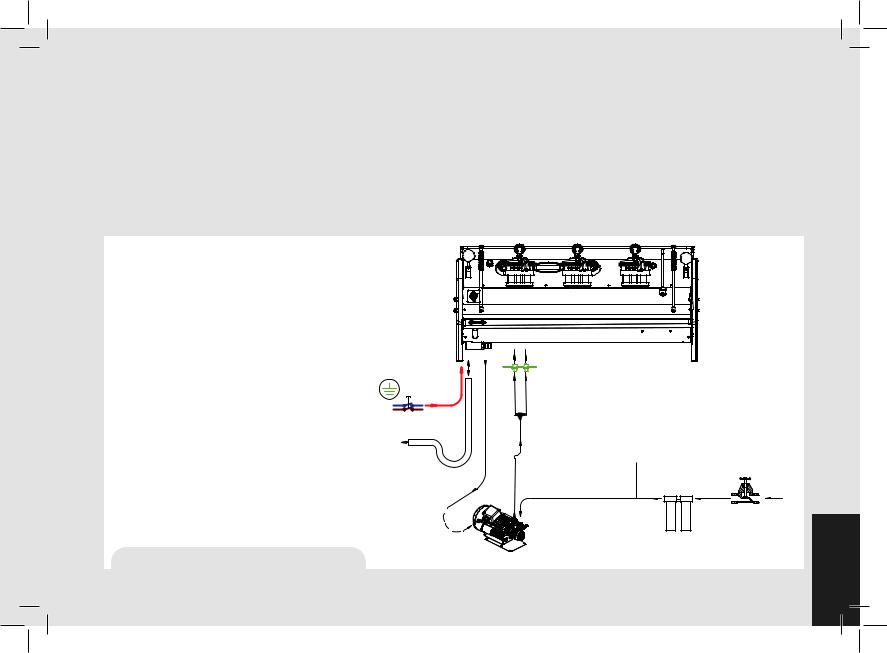

Pressure lower than 9 bar

Flow rate lower than 100 l/h

Installation with the rotary pump immediately after the water treatment system, upstream of the tee.

POWER SUPPLY |

|

|

CORD |

STEAM |

COFFEE |

|

BOILER |

BOILER |

MAIN SWITCH

AND ELECTRICAL SUPPLY CONNECTION

WASTE/DRAIN

ROTARY PUMP

Fig. 3 - Installation guide - type 1

TEE FITTINGS

WATER CHECK POINT:

FLOW RATE < 100 l/h

PRESSURE ≤ 9 BAR

BRAIDED HOSE

MAIN WATER

SUPPLY VALVE

WATER TREATMENT

RECOMMENDED VALUES

www.lamarzocco.com/water_calculator 13EN

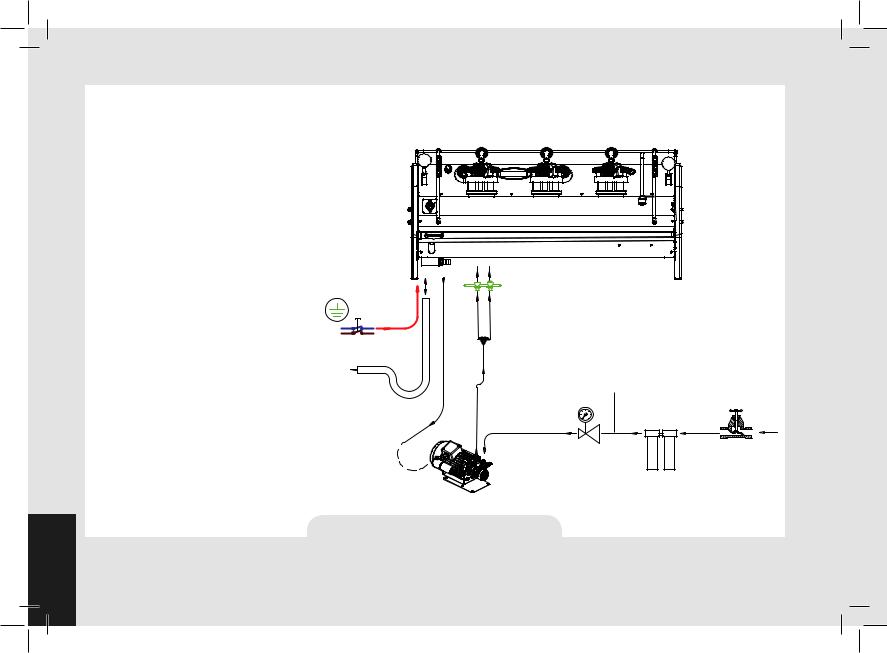

Pressure higher than 9 bar Flow rate lower than 100 l/h

Installation of the pressure reducer immediately after the water treatment system, upstream of the rotary pump.

Installation of the rotary pump (set to 9 bar) immediately after the pressure reducer, upstream of the tee.

POWER SUPPLY |

STEAM |

COFFEE |

CORD |

||

|

BOILER |

BOILER |

MAIN SWITCH

AND ELECTRICAL SUPPLY CONNECTION

WASTE/DRAIN

ROTARY PUMP

TEE FITTINGS

WATER CHECK POINT:

FLOW RATE < 100 l/h

PRESSURE > 9 BAR

BRAIDED HOSE |

|

PRESSURE REDUCER |

MAIN WATER |

PRESSURE ≤ 9 BAR |

SUPPLY VALVE |

WATER TREATMENT

RECOMMENDED VALUES

www.lamarzocco.com/water_calculator

Fig. 4 - Installation guide - type 2

EN

14

2) Accessories

Check the package to make sure that the following accessories are included:

•a number of 1-dose and 2-dose portafilters orresponding to the number of groups;

•replacement 1-dose and 2-dose filters (one of each);

•1 tamper;

•1 blind filter;

•cleaning detergent, for the groups;

•3 stainless steel braided hoses for water connections;

•1,5 mt of reinforced plastic tubing for drainage;

•1 hose clamp;

•1 TEE Fitting.

In order to proceed with installation, it is necessary that the following are available:

•Pipes carrying drinking water with a 3/8”G (BSP) end connection; (3/8” Compression for USA and Canada)

•Electrical Supply according to the specification of the espresso machine purchased:

•Single/Three phase 220VAC - 50/60 Hz electrical connection with ground, protected socket and approved interlock switch

•Single phase 200VAC - 50/60 Hz electrical connection with ground, protected socket and approved interlock switch

•Three-phase, 380VAC - 50 Hz electrical connection with neutral + ground, near the bench on which the machine is installed and terminating in a suitable protected fivepole socket equipped with an approved interlock switch

•Waste water drain system.

3) Water test kit

In order to enable you to check if your water supply is within the suggested ranges, La Marzocco machines will be equipped with two units of a quick water test kit (see image below) including 6 test-strips and instruction cards.

The parameters that you can measure are Total Hardness, Total Iron, Free Chlorine,

Total Chlorine, pH & Total Alkalinity, Chlorides.

Ideally, you should perform a test on the water BEFORE the water treatment system and again AFTER the water system in order to verify if this is actually matching our suggested ranges.

Once the test has been performed, learn which treatment system is most appropriate for your particular water supply by filling out the online water calculator on our website: LA MARZOCCO WATER CALCULATOR (http:// www.lamarzocco.com/water_calculator/).

4) Water supply connection

In order to connect the machine up to the water mains proceed according to the indications given in the chapter about Installation and in compliance with any local/national safety standards of the location in which the machine is being installed.

To guarantee a correct and safe functioning of the machine and to maintain an adequate performance level and a high quality of the beverages being brewed it is important that the incoming water be of a hardness greater than 7°f (70ppm, 4°d) and less than 10°f (100ppm, 6°d), pH should be between 6.5 and 8.5 and the quantity of chlorides be less than 50mg/l . Respecting these values allows

the machine to operate at maximum

15EN

efficiency. If these parameters are not present, a specific filtration device should be installed, while always adhering to the local national standards in place regarding potable water.

Then connect the inlet of the water filter/ softener (if present) to the drinking water supply using one of the supplied stainless steel braided hoses. Before connecting the filter to the water pump, flush the water supply line and the filtration system in order to eliminate any residual particles which could otherwise get stuck in taps or valves thus preventing them from working properly. Connect the water supply connection of the espresso machine to the water pump outlet using one of the supplied stainless steel braided hoses. Then connect the water pump inlet to the water filter/softener outlet (if present).

Note: The water pump is a differential pressure volumetric pump and has been designed to be used exclusively with cold water. Make sure that water is always present while the pump is operating, otherwise air can be introduced into the brew boiler causing an undesireable condition and the pump can be damaged.

5) Electrical connections a) Power supply cord

•This is the main power supply cable that provides power to the entire espresso machine. There are different types of cable based upon the electrical requirements of the espresso machine purchased:

•200/220VAC 1 Phase 3-core cable with 4/6/10mm2 cross section or AWG 12/10/8 for 2,3 4 group versions, secured to espresso machine via a strain relief connector

•220VAC 3 Phase 4-core cable with 4 mm2 cross section for 2 , 3 and 4 group versions, secured to espresso machine via a strain relief connector

•380 VAC 3 Phase 5-core cable with 2.5mm2 cross section for 2, 3 and 4 group versions, secured to espresso machine via a strain relief connector.

b) Water pump motor power cord

This is the power supply for the water pump motor. The internal electronics will switch the pump motor on when needed.

• 3-core cable with 1.5 mm2 cross section or 3-core AWG 16 (for UL version) secured to espresso machine via a strain relief connector.

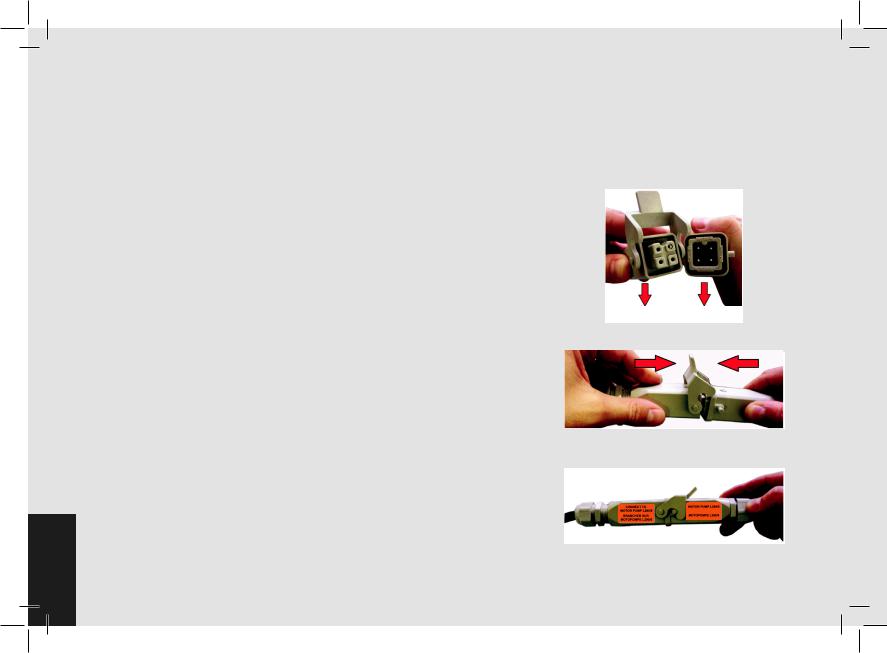

c) Quick connection between the water pump and the espresso coffee machine

The electrical connection must be made through the use of the connectors, as shown in the following figures:

- View of the connectors;

Machine connector Pump connector

-Cable connection;

-Cable tightening;

EN

16

6) Waste water drain connection

The espresso machine drain is to be connected by means of the included reinforced plastic tubing. Connect one end of the reinforced plastic tubing to the drain hose connection on the left side of the espresso machine, secure with included hose clamp. Connect the other end to a suitable waste water collection system.

In case such a system is not available, drained liquids may be collected in a suitable bucket and any necessary drain pipe extensions shall be made using steel-lined PVC tubing and suitable hose clamps.

Water specifications table

|

|

Min. |

Max. |

|

|

|

|

T.D.S. |

ppm |

90 |

150 |

|

|

|

|

Total Hardness |

ppm |

70 |

100 |

|

|

|

|

Total Iron (Fe+2/Fe+3) |

ppm |

0 |

0,02 |

Free Chlorine (Cl2) |

ppm |

0 |

0,05 |

Total Chlorine (Cl2) |

ppm |

0 |

0,1 |

pH |

value |

6,5 |

8,5 |

|

|

|

|

Alkalinity |

ppm |

40 |

80 |

|

|

|

|

Chloride (Cl–) |

ppm |

not more |

50 |

N.B.: Test water quality (the warranty is void if water parameters are not within the range specified in the section “installation”)

17EN

EN

4. Machine Operation and Coffee Preparation

CAUTION

CAUTION  Never remove the filter holder when water is being delivered. This operation can be extremely dangerous since the high pressure built-up inside the blind filter would spray out hot and slightly caustic water, which may cause severe burns. The Coffee Boiler contains water at elevated temperature. Water temperature over 125°F / 52°C can cause severe burns instantly or death from scalding.

Never remove the filter holder when water is being delivered. This operation can be extremely dangerous since the high pressure built-up inside the blind filter would spray out hot and slightly caustic water, which may cause severe burns. The Coffee Boiler contains water at elevated temperature. Water temperature over 125°F / 52°C can cause severe burns instantly or death from scalding.

WARNING

The machine must not be dipped in, nor splashed with, water in order to clean it. For cleaning operations, please follow the instructions listed below very

carefully.

18

WARNING

This machine is designed only for preparing coffee and hot drinks.

IMPORTANT

To improve the flavor of the espresso, the temperatureofthewaterinthecoffeeboiler and therefore of the groups may eventually be raised or lowered via the digital display (please consult the Software Programming Manual for detailed instructions).

1) Starting the Espresso Machine

Filling the Boilers with Water:

Once the installation procedures have been completed, it is necessary to fill the boiler tanks with water. Complete the following procedure to properly fill the boiler tanks:

• Coffee Boiler

The water flows inside the coffee boilers directly, as soon as the water system and water filter/softener valves are opened.

Since the inflow of water will compress the air in the boiler, it will be necessary to remove or “bleed” the air from the coffee boilers. All air must be removed in order to completely “saturate” the coffee boiler/ group assemblies.

To remove the air from the boiler, or “bleed

the groups”, it will be necessary to remove the plastic cap and the handle from the top of the group.

Loosen the bleed screws one at a time to allow air to escape until water flows from below the screw head. Tighten the screw to stop the water from flowing. Over tightening can cause damage to the sealing washer and the group cover. Repeat this procedure on all groups.

• Steam Boiler

Turn the main switch to position “1” or ON, then push the encoder knob for three seconds and the automatic steam boiler level function will be switched on, activating the auto-fill solenoid valve and the motor pump. This will fill the steam boiler to a predetermined level and will shut off when full.

Loading...

Loading...