La Marzocco GS3 User Manual

manual

gs3

Imagine if the sky’s the limit, what would the ultimate light duty/home machine be? That was the question La Marzocco set out to answer.

Years of research and development yielded the creation of a yet another standard setting espresso machine: the GS/3. With La Marzocco performance and technology, the GS/3 is designed for light commercial applications, including restaurants, offices, catering, or the ultimate home coffee bar. All the features and performance of a larger La Marzocco in a compact footprint.

gs3

Operating Manual V1.3 - 09/2016

MAN.2.1.01

Chapters

1.General Information

2.Accessories

3.Machina Description

4.Installation

5.Operation

6.Key Features

7.Preventative Maintenance and Cleaning

8.Maintenance and Periodic Cleaning Operations

9.Installation Guide

10.Software Programming Guide

certifications available:

page 3 page 5 page 6 page 7 page 12 page 14 page 16 page 18 page 19 page 29

La Marzocco S.r.l.

Via La Torre 14/H

Località La Torre

50038 Scarperia e San Piero

(Firenze) - ITALIA

www.lamarzocco.com

info@lamarzocco.com

T: +39 055 849 191 F: +39 055 849 1990

EN

1. General Information

|

|

WARNING |

|

|

Safety Instructions |

5) |

Furthermore, |

you |

must ensure that |

|

|||||

|

|

|

|

1) Check to see that data on the rating |

the |

capacity of |

the |

available electrical |

|

||||||

|

THIS MACHINE IS FOR PROFESSIONAL USE ONLY |

|

|||||||||||||

|

plate corresponds to those of the main |

system is suitable for the maximum power |

|

||||||||||||

AND SHOULD BE INSTALLED IN LOCATIONS WHERE |

|

||||||||||||||

|

ITS USE AND MAINTENANCE IS RESTRICED TO |

electrical supply to which the machine will |

consumption indicated on the espresso |

|

|||||||||||

TRAINED PERSONNEL. CHILDREN ARE FORBIDDEN TO |

be attached. |

machine. |

|

|

|

|

|

|

|

||||||

|

OPERATE OR PLAY WITH THE MACHINE. |

This equipment must be installed to |

|

|

|

|

|

|

|

|

|

||||

About this Manual |

|

|

|

comply with applicable federal, state or |

6) We do not recommend using adapters, |

|

|||||||||

1) This operating guide is an integral and |

local plumbing codes. |

multiple plugs |

and/or extension cords. |

|

|||||||||||

essential part of the product and must be |

|

If you cannot avoid using them, make |

|

||||||||||||

supplied to users. Users |

are asked to read |

2) The installation must be performed |

sure that they are exclusively of the kind |

|

|||||||||||

the enclosed warnings and cautions |

according to local electrical and plumbing |

which conforms to local, national, and |

|

||||||||||||

carefully, as they provide valuable |

codes and regulations. The installation |

international electrical codes and safety |

|

||||||||||||

information |

concerning |

safety |

during |

also must comply to the manufacturer’s |

regulations, being careful not to exceed |

|

|||||||||

installation, operation, and maintenance. |

instructions, and must be performed by |

the power and current ratings indicated on |

|

||||||||||||

This manual must be kept in a safe place |

qualified and authorized personnel. |

such adapters and extension cords. |

|

||||||||||||

and be available for consultation to new |

|

|

WARNING |

|

|||||||||||

and experienced users alike. |

|

|

3) Incorrect installation may cause injury/ |

|

|

||||||||||

|

|

THE MANUFACTURER DECLINES ANY RESPONSIBILITY |

|

||||||||||||

|

|

|

|

|

|

damages to people, animals or objects, for |

|

||||||||

Remove Machine from Packaging |

|

|

|

FOR ANY EVENT LEADING TO LIABILITY SUITS |

|

||||||||||

|

|

which the manufacturer shall not be held |

WHENEVER GROUNDING HAS NOT BEEN COMPLETED |

|

|||||||||||

1) Ensure product’s integrity by inspecting |

responsible. |

|

ACCORDING TO CURRENT LOCAL, NATIONAL, AND |

|

|||||||||||

the |

packaging, making |

sure |

it |

presents |

|

|

INTERNATIONAL REGULATIONS AND ELECTRICAL |

|

|||||||

no |

signs of |

damage which |

might have |

4) Safe electrical operation of this device |

|

CODES, OR OTHER ELECTRICAL PARTS HAVE BEEN |

|

||||||||

|

CONNECTED IMPROPERLY. |

|

|||||||||||||

affected the enclosed machine. |

|

will be achieved only when the connection |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

to the power outlet has been completed |

7) This device must be used exclusively for |

|

|||||||

2) Check the machine’s integrity after |

correctly and in observance of all local, |

the functions it has been designed and built |

|

||||||||||||

having carefully removed the packaging. |

national, and international electrical codes |

for. Any other application is inappropriate |

|

||||||||||||

Packaging (boxes, plastic bags, foam parts |

and safety regulations, and particularly by |

and dangerous. |

|

|

|

|

|

|

|

||||||

and whatever else) must not be left within |

grounding the unit. Make sure grounding |

The manufacturer shall not be held |

|

||||||||||||

easy reach of children, due to the potential |

has been done properly as it represents a |

responsible for any damages caused by |

|

|

|

|

|

||||||||

danger it represents, nor be discarded in |

fundamental safety requirement. Ensure |

improper and/or irrational use. This machine |

|

|

|

|

|

||||||||

the environment. |

|

|

|

qualified personnel check such connection. |

should not be installed in kitchens. |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3EN |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8)Using any electrical device requires that certain fundamental rules be observed. In particular:

- do not touch the device with wet or moist hands and feet

- do not use the device while not wearing shoes

- do not use extension cords in bath or shower rooms

- do not unplug the device from the power outlet by pulling on the power supply cable

- do not expose the device to atmospheric agents

- do not allow children or untrained people to use this device

9)Before performing any maintenance and/ or cleaning operations (other than backflushing the group), turn the main switch to the “0” or OFF position, and disconnect the machine from the electrical network by unplugging the cord or by switching off the relative circuit breaker. For any cleaning operation, follow exclusively the instructions contained in this manual.

WARNING

HAZARDOUS VOLTAGE DISCONNECT FROM POWER

SUPPLY BEFORE SERVICING.

10) If the machine is operating in a faulty manner or stops working, disconnect it from the electrical network (as described in the preceding point). Do not attempt to repair it. Contact a qualified and authorized professional to perform any repair. Any repair must be performed exclusively by the manufacturer or by an authorized centre using only original parts. Non compliance with the above could compromise the safe operation of the machine.

WARNING

THE MACHINE MUST BE INSTALLED SO THAT

QUALIFIED TECHNICAL PERSONNEL CAN EASILY

ACCESS IT FOR MAINTENANCE.

11)In order to avoid dangerous overheating problems, it is recommended that the power supply cable be unfurled completely.

12)Do not obstruct air intake and exhaust grilles and, in particular, do not cover the cup warmer tray with cloths or other items.

Minimum room temperature: 5°C Maximum room temperature: 32°C

13) The machine’s power supply cable must not be replaced by users. In case the power supply cable becomes damaged, shut off the machine and disconnect the machine from the electrical network by unpluging the power cord or switching off the relative circuit breaker and close off the water supply; to replace the power supply cord, contact qualified professionals exclusively.

WARNING

THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

WARNING

IN ORDER TO PREVENT CRACKS OR LEAKAGE: DO NOT STORE OR INSTALL THE COFFEE MACHINE IN PLACES WHERE TEMPERATURE MAY CAUSE BOILER OR HYDRAULIC SYSTEM WATER FREEZING.

EN

4

2. Accessories

Check the package to make sure that the following accessories are included in the packaging:

QTY. |

PART NO. |

DESCRIPTION |

|

|

|

1 |

L111/2NAC |

PORTAFILTER |

|

|

ASSEMBLY, DOUBLE |

|

|

SPOUT, S/STEEL |

|

|

|

1 |

L111/1AC |

PORTAFILTER |

|

|

ASSEMBLY, SINGLE |

|

|

SPOUT, S/STEEL |

|

|

|

1 |

L115/C |

PORTAFILTER BASKET, |

|

|

BLIND |

|

|

|

1 |

F.3.029 |

Precision filter |

|

|

basket 7gr (single) |

|

|

|

1 |

F.3.028 |

Precision filter |

|

|

basket 14gr |

|

|

(double) |

|

|

|

1 |

F.3.027 |

Precision filter |

|

|

basket 17gr |

|

|

|

1 |

F.3.026 |

Precision filter |

|

|

basket 21gr |

|

|

|

1 |

F.3.030/ |

Tamper (according |

|

f.3.031 |

to market) |

|

|

|

1 |

UT003 |

HEX KEY, 5mm |

|

|

|

2 |

L120/2A |

WASHER, FLAT, |

|

|

SEALING TYPE, M6 |

|

|

(12X6.25X0.75) |

|

|

|

1 |

V067 |

ESPRESSO MACHINE |

|

|

CLEANER |

|

|

|

1 |

913 (CE) |

WATER SUPPLY AND |

|

914 (ETL) |

DRAIN CONNECTION |

|

|

KIT |

|

|

|

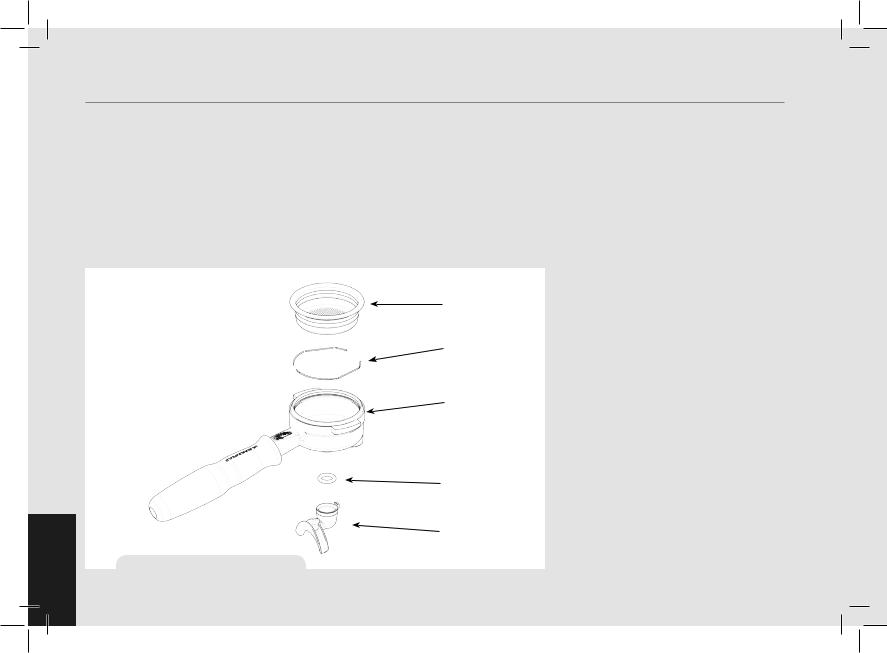

L115/C F.3.029 F.3.028.01

L111/1AC

L111/2NAC

F.3.031.01(U.S.A.) F.3.030.01

Figure 1 - Accessories

F.3.027.01 |

F.3.026.01 |

UT003 |

V067

L120/2A

913 (CE) / 914 (ETL-USA)

L325 (CE)

L326 (ETL-USA)

H.1.010.01

F.8.002

F.8.003 |

L312 |

|

5EN |

|

L308 |

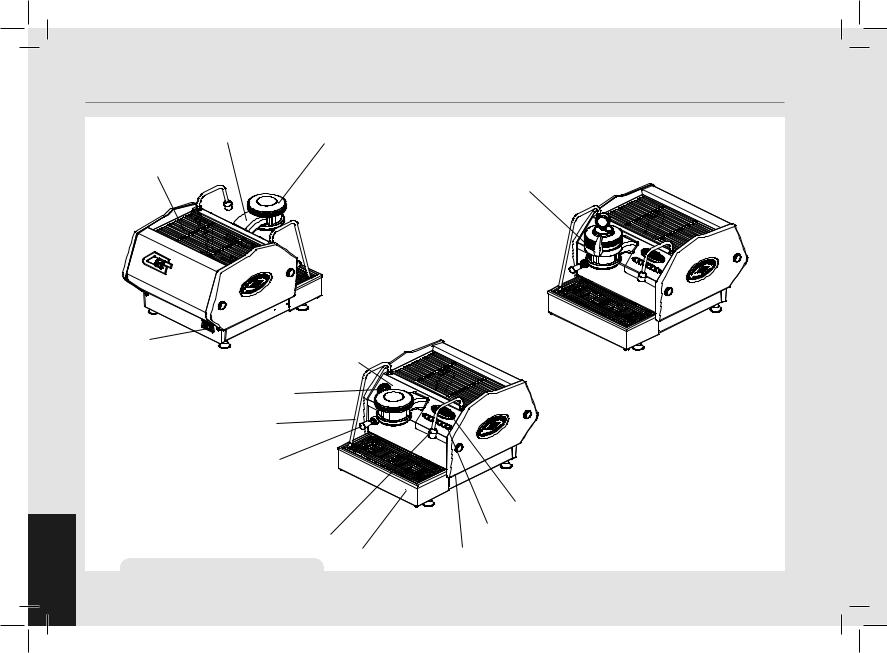

3. Machine Description

|

group head |

group cover |

|

(AV model) |

|

cup tray |

|

|

|

|

paddle group and handle (MP model)

EN

main power switch |

pressure gauge |

|

(steam boiler) |

||

|

||

|

pressure gauge |

|

|

(coffee boiler) |

|

|

steam wand |

|

|

steam activation |

|

|

lever |

hot water dispensing spout

drain box

6 |

Figure 2 - Machine Description |

|

display

keypad

temperature adjustment knob for hot water

4. Installation

|

|

|

WARNING |

|

|

|

the |

quantity |

of |

chlorides |

be less than |

our suggested ranges. |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

50mg/l . |

Respecting these values allows |

Once |

the |

test |

has been |

performed, |

|

||||||||||||||||||||

|

The machine is intended to be permanently |

|

|

||||||||||||||||||||||||||||||

|

|

the |

machine |

to |

operate |

at |

maximum |

learn which treatment system is most |

|

||||||||||||||||||||||||

|

connected to mains power supply. |

|

|

||||||||||||||||||||||||||||||

It is mandatory that a residual current device |

efficiency. |

If |

these parameters are not |

appropriate for your particular water supply |

|

||||||||||||||||||||||||||||

(RCD) with a rated residual operating current not |

present, a specific filtration device should |

by filling out |

the |

online |

water calculator |

|

|||||||||||||||||||||||||||

|

|

exceeding 30 mA is installed. |

|

be installed, while always adhering to the |

on our website: LA MARZOCCO WATER |

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

Espresso Machine Installation, GS/3 |

|

|

local national standards in place regarding |

CALCULATOR |

(http://www.lamarzocco. |

|

|||||||||||||||||||||||||||

|

|

potable water. |

|

|

|

|

|

com/water_calculator/). |

|

|

|

|

|

|

|

|

|

||||||||||||||||

1) Fill Water reservoir with potable water. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

In order to enable |

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|||||||||||||||||

Remove |

the |

drain |

tray |

and |

slide |

the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

you |

|

to |

check |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

water reservoir until |

the |

water |

reservoir |

|

|

|

|

|

THE COFfEE MACHINE MUST BE PLACED IN A |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

if |

your |

water |

|

|

|

|

|

|

|

||||||||||||||||||||

fill |

cover is accessible. Remove the cover |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

HORIZONTAL POSITION ON A COUNTER HIGHER THAN 80 |

|

||||||||||||||||||||||||||||

|

|

|

|

supply |

is |

within |

|

||||||||||||||||||||||||||

and fill water reservoir with potable water. |

|

|

|

|

|

|

CM FROM THE GROUND |

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

the |

|

suggested |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

Replace the fill cover and slide the water |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

ranges, |

La |

2) Connect Espresso Machine to Power Supply. |

|

||||||||||||||||||||||||||

reservoir |

to |

the operating |

position |

and |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

M a r z o c c o |

Connect the espresso machine to a power |

|

|||||||||||||||||||||||||||

replace the drain tray. (See GS/3 Software |

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

machines will be |

supply that is rated in accordance with the |

|

|||||||||||||||||||||||||||

and |

Installation |

Guide |

for additional |

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

equipped |

with |

serial plate on the espresso machine. |

|

|

|

|

|

|

|

||||||||||||||||||||

instructions). |

In |

order |

to |

connect the |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

two |

units |

of a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

machine up to the water mains proceed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

quick |

water test |

3) Filling the Boilers with Water. |

|

|

|

|

|

|

|

|

|||||||||||||||||||

according to the indications given in the |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

kit |

(see |

image |

Once |

the espresso |

machine |

has been |

|

||||||||||||||||||||||

Installation Guide and in compliance with |

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

below) |

including |

unpackaged, |

placed |

on |

a hard surface, |

|

|||||||||||||||||||||||

any local/national safety standards of the |

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

6 test-strips and |

and with the |

water |

reservoir |

full, it |

will |

|

|||||||||||||||||||||||

location |

in which |

the |

machine |

is being |

|

|

|

|

|

||||||||||||||||||||||||

instruction cards. |

|

|

|

|

be necessary to fill the boilers with water. |

|

|||||||||||||||||||||||||||

installed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

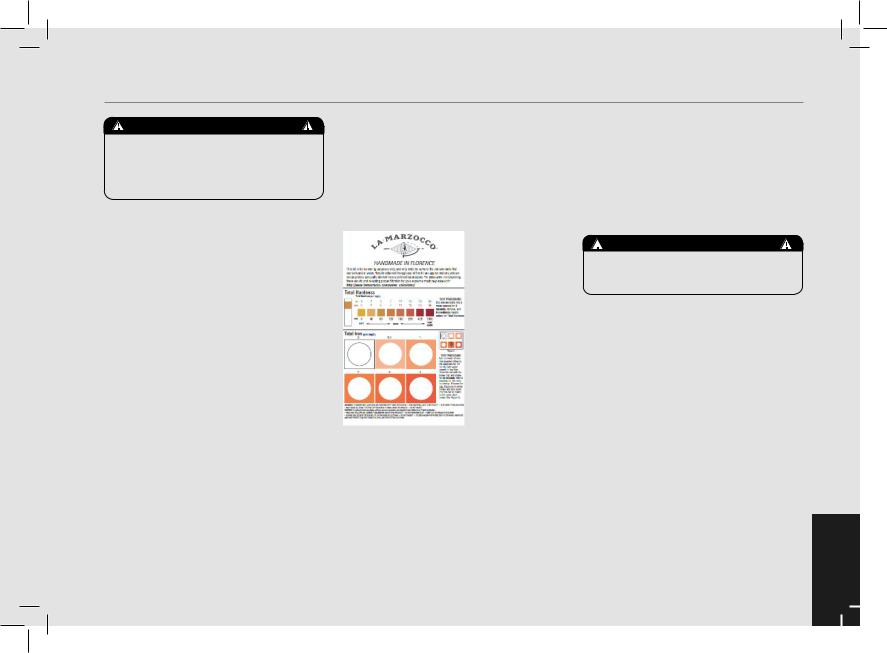

The parameters that you can measure are |

Complete the following steps to properly |

|

|||||||||||||||||||||||

To guarantee a correct and safe functioning |

|

||||||||||||||||||||||||||||||||

Total Hardness, Total Iron, Free Chlorine, |

fill the boiler tanks: |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

of |

the |

machine |

and |

to |

maintain |

an |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

Total Chlorine, pH & Total |

Alkalinity, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

adequate performance |

level |

and a high |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

Chlorides. |

|

|

|

|

|

|

Steam |

Boiler: |

Turn |

the |

main |

switch |

to |

|

|||||||||||||||||||

quality of the beverages being brewed it |

|

|

|

|

|

|

|

||||||||||||||||||||||||||

Ideally, you should perform a test on the |

position “1” or ON, the automatic steam |

|

|||||||||||||||||||||||||||||||

is important that the incoming water be |

|

||||||||||||||||||||||||||||||||

water BEFORE the water treatment system |

boiler |

level |

system |

will |

be switched |

on, |

|

|

|

|

|

|

|||||||||||||||||||||

of a hardness greater than 7°f (70ppm, |

|

|

|

|

|

|

|||||||||||||||||||||||||||

and |

again |

AFTER the water system in |

activating the auto-fill solenoid valve and |

|

|

|

|

|

|

||||||||||||||||||||||||

4°d) and less than 10°f (100ppm, 6°d), |

|

|

|

|

|

|

|||||||||||||||||||||||||||

order to verify if this is actually matching |

the water pump. This will fill the steam |

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

pH should be between 6.5 and 8.5 and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7EN |

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

boiler to a predetermined level and will shut off when full.

NOTE: It may be necessary to re-fill the water reservoir during this process. Check to see if the “Water Tank Empty” error message is present on the display before continuing.

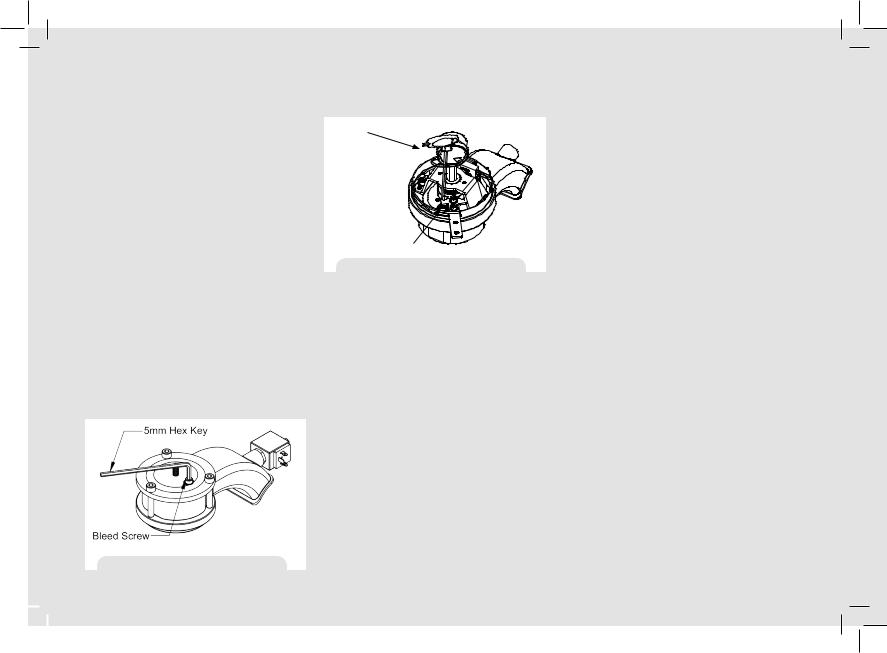

Coffee Boiler: The water flows inside the coffee boiler directly when the water pump is activated. When the GS/3 is turned on the electronics will activate the water pump to fill both boilers. Since the inflow of water will compress the air in the boiler it will be necessary to remove or “bleed” the air from the coffee boiler. All air must be removed in order to completely “saturate” the coffee boiler/group assembly. To remove the air from the boiler (“bleed the groups”) remove the group cover from the top of the group head. Then loosen the bleed screw (see picture) to allow air to escape until water

|

|

|

|

|

|

|

|

|

|

|

|

EN |

8 |

Figure 3a - “Bleed the Group AV” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

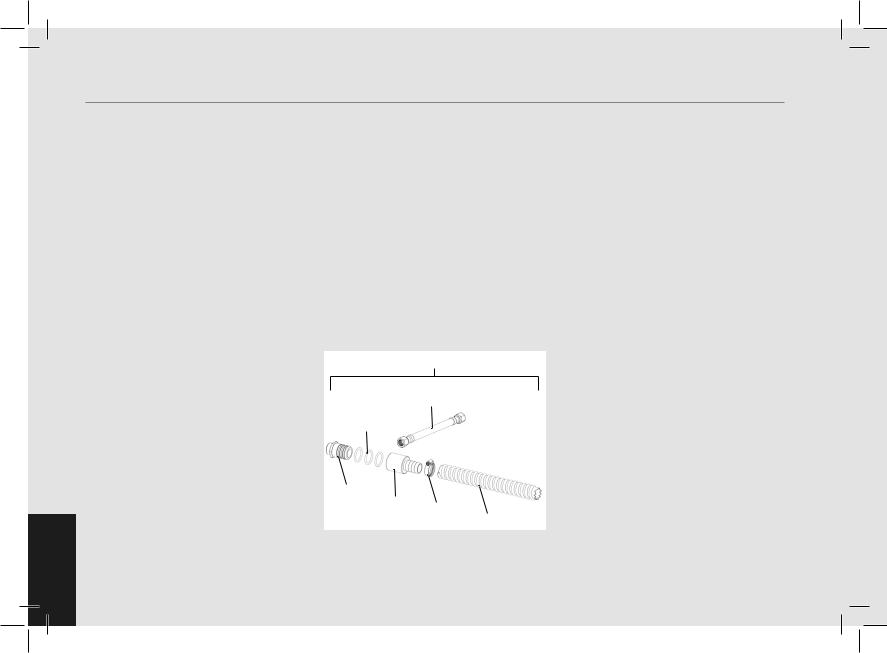

5 mm Hex Key

Bleed Screw

Figure 3b - “Bleed the Group MP”

flows from below the screw head. It may be necessary to activate the brew process by pressing button #5 (the

continuous button) to force the air out of the group. Tighten the screw to stop the water from flowing. Over-tightening can cause damage to the sealing washer and the group cap. If this sealing washer is damaged replace washer with one included in accessory kit. Once all air is removed from the coffee boiler, reinstall the group cover. For more detailed instruction please refer the GS/3 Installation Guide.

NOTE: It may be necessary to re-fill the water reservoir during this process. Check to see if the “Water Tank Empty” error message is present on the display before continuing.

4) Verify filling of Boilers.

The installation is now complete and the espresso machine should be heating to the operating temperatures.

Brewing after first installation

Once the first installation procedures are finished, before proceeding with brewing coffee, hot water and steam, please follow these steps:

• Engage the portafilter by inserting it into the group head and rotate the handle from left to right. Once the portafilter is inserted properly, you can press one of the brewing buttons on the keypad to start the flow of water through the portafilter (AV models) or rotate the handle from left to right (MP models). Brew water through the group for

at least two minutes. |

|

|

|

||

• |

Being careful to |

avoid |

burns, |

turn |

|

on |

steam |

wand |

for |

at |

least |

one minute.

• Turn on the hot water valve for the time necessary to allow at least 1 liter of water to be brewed.

5) Waiting for the Espresso Machine to Heat to Operating Temperature. During this time, the pointer of the coffee boiler pressure gauge may reach as high as 12 bar. This may happen anytime that the heating element is in the “on” condition. If the pressure

exceeds 12 bar then it will

be necessary to adjust the expansion valve in such a manner that the pressure never exceed 12 bar.

In normal operating conditions, the coffee boiler pressure gauge can read anywhere from 0-12 bar. When brewing,

the pressure should be set to approximately 9 bar. When the espresso machine is ready to operate all lights on the keypads will light up.

NOTE: As the steam boiler reaches operating temperature you may hear air and steam escaping from the boiler. This is a normal sound. As the water boils, air in the boiler is replaced by steam and exits through the vacuum breaker. As the boiler get closer to operating temperature the vacuum breaker closes and the steam is no longer able to escape. This process allows the air in the steam boiler to escape and to be replaced by water vapor.

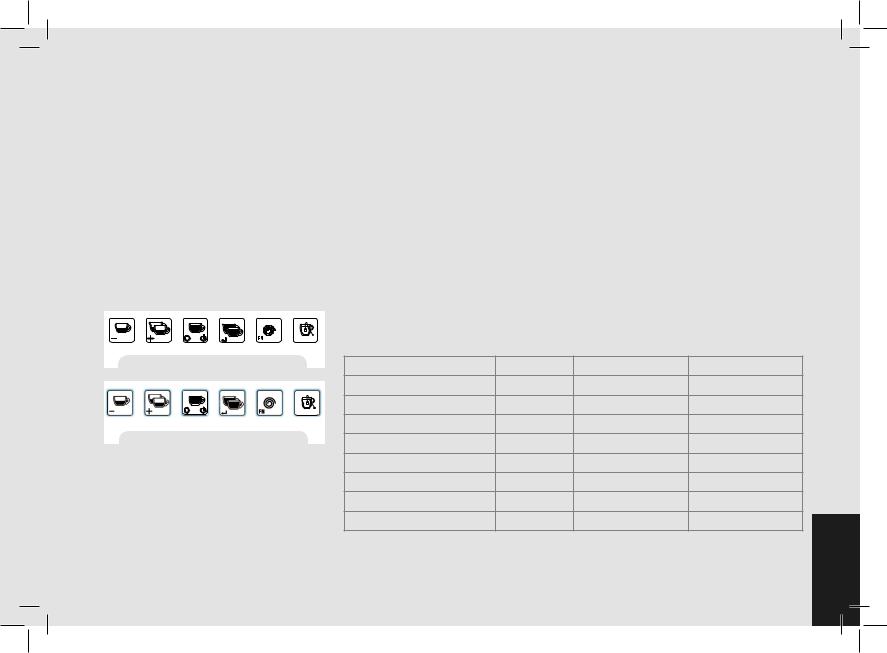

Water specifications table

Figure 4 - Key Pad buttons |

|

|

Min. |

Max. |

|

T.D.S. |

ppm |

90 |

150 |

|

Total Hardness |

ppm |

70 |

100 |

|

Total Iron (Fe+2/Fe+3) |

ppm |

0 |

0,02 |

Figure 5 - Key Pad buttons with lights on |

Free Chlorine (Cl2) |

ppm |

0 |

0,05 |

|

||||

|

Total Chlorine (Cl2) |

ppm |

0 |

0,1 |

|

pH |

value |

6,5 |

8,5 |

|

Alkalinity |

ppm |

40 |

80 |

|

Chloride (Cl–) |

ppm |

not more |

50 |

N.B.: Test water quality (the warranty is void if water parameters are not within the range specified in the section “installation”) EN

9

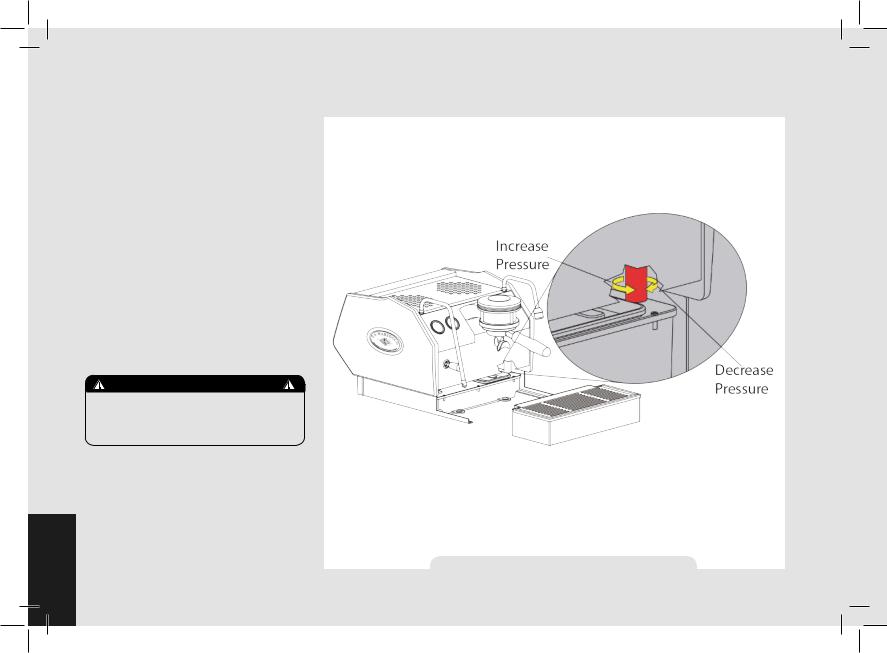

6) Adjusting the Expansion Valve.

The expansion valve is a component that limits the maximum pressure in the coffee boiler. Heating the coffee boiler causes the water within to expand. Since the coffee boiler is completely saturated, the expanding water causes an increase in pressure within the boiler. Without a safety device the increase in pressure could cause a rupture in the boiler. The pressure in the coffee boiler should never exceed 12 bar. The valve is hot, so, using adequate protection, rotate the expansion valve clockwise to increase pressure. To decrease pressure rotate the expansion valve counter clockwise (See the following diagram).

WARNING

The expansion valve can discharge water as hot as 200°F / 93°C. Adequate protection for handling this component is needed before atTempting to adjust.

EN

10

Figure 6 - Expansion Valve Adjustment

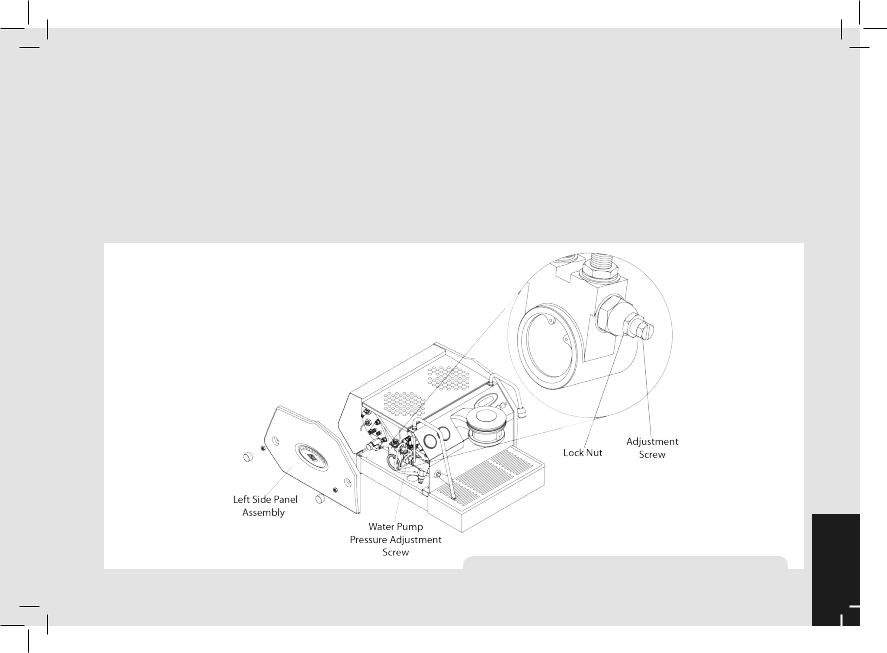

7) Adjusting Water Pump Pressure.

The water pump is factory set at 9 bar pressure. If it becomes necessary to change the pressure please use the following procedure:

1.Remove the left side cover assembly.

2.Locate the water pump adjustment screw and loosen the lock nut.

3.Adjust the water pump pressure to the desired measurement.

4.Rotate Clockwise to increase pressure and counter clockwise to reduce pressure.

NOTE: The water pump pressure should be adjusted when the machine is operating and coffee is present in the portafilter.

Figure 7 - Water Pump Pressure Adjustment |

11 |

EN |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. Operation

1. Installing the Portafilters.

Install the portafilter by inserting it into the group head and rotate the handle from left to right. Once the portafilter is inserted properly, you can press one of the brewing buttons on the keypad (AV model) or move the paddle handle from right to left (MP Model) to start the flow of water through the portafilter. Please refer to the Software Programming Manual for a

description of the functions of the keypad.

It is important that the portafilter is at operating temperature prior to filling with coffee. Allow hot water to pass through the empty portafilter for a few seconds before the brewing process to pre-heat the portafilter.

EN

12

Figure 8 – Portafilter

FILTER

BASKET

SPRING

PORTAFILTER

O-RING

GASKET

DOUBLE

SNAP-ON

SPOUT

Note: It is important to leave the portafilter installed in the espresso machine when not in use. The portafilter must remain heated for the brewing process to function correctly.

2. Brewing Coffee. It is now possible to remove the portafilter to make a coffee beverage. Place some ground coffee in the portafilter basket using the single or double basket. Press down on the ground coffee with the supplied tamper and install the portafilter on the GS/3. On AV model press a brew button to begin the brewing process, or move the paddle handle from right to left to begin brewing on MP model (see Fig.2).

Note: Some users believe it is important to allow water to pass through the the group head prior to installing the portafilter to flush any remaining coffee oils and particles from the group head. Some also flush just after brewing for the same reason. Please experiment to make the best possible procedure for your coffee. There are many techniques for brewing espresso. You can find instructions for many techniques on websites, blogs and forums. Some are even monitored by professional baristas around the world.

3. Dispensing Steam.

In order to allow for any condensed water in the wand to be released ALWAYS allow some steam to be discharged by turning on the valve before inserting the steam wand into the pitcher of liquid to be heated.

Dip the steam wand into the liquid to be heated. Depress the steam valve lever to activate the steaming process.

The steam valve has a variable flow control.

The steam valve will lock in the fully on position only.

The steam will transfer heat to the liquid raising its temperature. Be careful not to allow liquid to overflow in order to avoid severe burns.

In order to prepare milk for making cappuccino with the right amount of foam, go through the following steps:

• After purging the steam wand place the container half-full of milk underneath, carefully open the steam valve and raise the container so as to bring the wand end to a point just below the surface of the milk; at this point, move the container up and down just enough to dip the nozzle end in and out of the milk until you get the right amount of foam, bring the temperature of the milk almost up to 149/158°F or 65/70°C. You can then pour this milk into a cup containing warm espresso and you will end up with a fresh

cup of cappuccino.

NOTE: It is important to have a sufficient volume of liquid in the steaming pitcher. Therefore if you intend to steam small amounts of milk it is necessary to use a small pitcher. If you intend to steam larger quantities of milk then it is necessary to use a larger steaming pitcher.

Using too little milk in a steaming pitcher can allow the milk to be “blown out” of the pitcher. A good rule to follow is to fill the steaming pitcher only half full of liquid.

Note: In order to prevent the heated liquid from being sucked back into the steam boiler it is recommended that you purge the steam system after heating any liquid. Purge the system by opening the steam valve for a few seconds to allow steam to escape to the atmosphere from the end of the steam wand. Failure to do so can cause the heated liquid to transfer from the steaming pitcher to the steam boiler (via vacuum created from cooling parts). This condition is undesireable and can cause contamination in the steam boiler.

4. Dispensing Hot Water.

You may dispense hot water by using the hot water nozzle. To dispense hot water press the hot water button.

Figure 9 - Hot Water Button

This button commands the hot water delivery. The volume of water delivered may be adjusted via the display (see the Software Programming Manual for further instructions). The temperature of the water dispensed may be adjusted by adjusting the mixing valve under the right side cover of the espresso machine (see machine description diagram, Figure 2, and the instructions on the next page).

WARNING

THE COFFEE BOILER AND STEAM BOILER CONTAIN WATER AT ELEVATED TEMPERATU-RE. WATER TEMPERATURE OVER 125°F/52°C CAN CAUSE SEVERE BURNS INSTANTLY OR DEATH FROM SCALDING (COFFEE BOILER 200°F/93.3°C-STEAM BOILER 260°F /127°C)

WARNING

THIS MACHINE IS NOT SUITABLE FOR OUTDOOR USE. JETS OF WATER SHOULD NOT BE USED TO CLEAN THE MACHINE, NOR SHOULD IT BE PLACED WHERE WATER

JETS ARE USED. EN

13

6. Key Features

1.Controlling the Brew Process Using Volumetric Programming.

This espresso machine allows the volumetric programming of each of the first 4 buttons on each group (numbered left to right). Please consult the Software Programming Manual for further instructions.

2.Hot Water Dispensing.

Hot water may be dispensed from the Hot Water Wand on the right side of the machine. This is accomplished by pressing the hot water button (Fig.9). The amount of water dispensed can be programmed via the digital display. Please consult Software Programming Manual for programming instructions. The temperature of the hot water may be adjusted slightly via the Hot Water Adjusting Knob. This adjusting knob is hidden under the right side panel assembly. The knob protrudes slightly form the bottom of the side panel. To find this knob, look at the bottom edge of the right side panel.

The knob may be turned by sliding a finger under the side panel from front to rear (to decrease temperature) or from rear to front (to increase temperature).

3. Quick Keys.

The GS/3 has 4 Quick Keys to allow the user to gain quick and easy access to important parameters that may be changed frequently. Please see the Software Programming Manual.

4. Water and Drain Connection Kit.

The GS/3 comes with a main water supply and waste drain connection kit. This kit allows the GS/3 to be connected to the main water supply and the main waste drain system. Instructions for installing this kit are contained in the GS/3 Installation Manual. The conversion kit contains the following items:

913 (CE) / 914 (ETL-USA)

L325 (CE)

L326 (ETL/USA)

H.1.010.01

F.8.002

F.8.003 L312

L308

5.General Notes for Coffee Preparation. The portafilters must remain heated since they are at the lowest position of the group itself, and they are partially isolated from the same due to the rubber gasket between them. This can be accomplished by leaving the portafilters installed in the machine when not in use. The portafilters may also be actively heated by activating one of the brew buttons to flush hot water through the portafilter then turning off the water flow.

6.Coffee Grind.

The size of the coffee granules is extremely important in preparing a good cup of coffee, along with the type of coffee blend used. The ideal grind can be determined by making various coffees using the amount of ground coffee that you would normally use for each cup (we recommend at least 6g). The best grind is that which allows coffee to flow out from the portafilter spouts neither too slowly, drop by drop, nor too quickly. A general rule is that a double dose should dispense approximately 60mL

/ 2 fluid oz. of espresso in approximately

25 seconds. This time may be adjusted by varing the coarseness of the grind.

EN

14

7. IMPORTANT To improve the flavor profile of the espresso, the temperature of the water in the coffee boiler, and therefore of the groups, may eventually be raised or lowered via the digital display (please consult Software Programming Manual for detailed instructions).

N.B.

If the machine has not been used for more than 8 hours or, in any case, after long periods of being idle, in order to use the machine to its full potential it is necessary to perform some cleaning cycles before brewing beverages as follows:

•Group: with the portafilter engaged in the group brew water through it for at least two minutes

•Being careful to avoid burns, turn on each steam wand for at least one minute.

•Turn on the hot water valve for the time necessary to allow 1 liter of water to be brewed.

•If using machine with water reservoir, change the water in the reservoir daily.

If the machine is not going to be used for long periods of time, it is advisable to follow these safety indications:

•Disconnect the machine from the water mains or interrupt the water connection via a mains tap.

•Disconnect the machine from the electrical mains.

WARNING

If the above-mentioned instructions are not adhered to the manufacturer cannot be held responsible for damage to persons or things.

15EN

EN

7. Preventative Maintenance and Cleaning

Cleaning (Daily)

1. Cleaning the Diffuser Screen.

During the discharge operation (subsequent to coffee brewing), small amounts of coffee grounds may slowly build-up on and obstruct, even partially, the diffuser screen. Turn off the machine and remove the diffuser screen by unscrewing the diffuser screw. Soak in detergent powder liquid following the instructions of detergent manufacturer. Rinse thoroughly with clean water. Install and run hot water through the group head several times with the screen installed.

2. Cleaning the Brewing System.

Insert the blind filter into portafilter and put the correct amount of espresso cleaning product (following the product’s instructions) into the filter, engage the

16

portafilter into the group you want to clean.

•Press the brewing button for said group, as if you were making a regular cup of coffee. Stop the water after about 15-20 seconds.

•Start and stop the group several times until you notice clear water being released instead of soapy water when you remove the portafilter.

Do not remove the portafilter when group is actually brewing water.

CAUTION

DO NOT REMOVE THE FILTER HOLDER WHILE RELATIVE GROUP IS BREWING HOT LIQUIDS. THE COFFEE BOILER CONTAINS WATER AT ELEVATED TEMPERATURE. WATER TEMPERATURE OVER 125°F / 52°C CAN CAUSE SEVERE BURNS INSTANTLY OR DEATH FROM SCALDING.

• Rinse the group using a normal filter in the portafilter, by running hot water through it several times.

3. Cleaning Filter Baskets and Portafilters.

With daily cleaning of the stainless steel filters and portafilters it is sufficient to clean them with water and a cloth or appropriate brush. Otherwise, using an espresso cleaning product, following the product’s instructions put the correct dose in about 1/2 a litre of water inside a

heat-resistant container and heat.

•If using stainless steel portafilters with snap-on spouts remove the spout.Immerge filters and metallic parts of portafilters

(not handles) in the hot solution and leave them submerged for about 30 minutes.

•Rinse thoroughly with clean water and run hot water through the group several times with the filter and portafilter engaged.

4. Cleaning the Drain Box.

Remove the drain box assembly and wash each of the components with hot soapy water. Rinse thoroughly and reinstall the drain box assembly. Hand wash each part with water containing mild soap.

CAUTION

THE MACHINE MUST NOT BE DIPPED IN, NOR SPLASHED WITH, WATER IN ORDER TO CLEAN IT. FOR CLEANING OPERATIONS, PLEASE FOLLOW THE INSTRUCTIONS VERY CAREFULLY.

5. Cleaning the Body.

Wipe the stainless steel surfaces with a soft, non abrasive cloth in the direction of the glazing marks, if any. Do not use any alcohol or solvents whatsoever on painted, imprinted, or plastic parts in order not to damage them. Clean the side panels using

a soft cloth. Do not spray the keypad or display with any liquid. Clean only with a damp soft cloth.

6. Cleaning the Hot Water and Steam Nozzles.

Steam nozzles must be cleaned immediately after use with a damp cloth and by producing a short burst of steam so as to prevent the formation of deposits inside the nozzles themselves, which may alter the flavor of other drinks to be heated. Hot water nozzles must be cleaned periodically with a damp cloth. If milk residue is present on the steam wand, soak the tip in a container of hot water, then it will be possible to wipe the tip clean. Repeat process if residue remains. NOTE: This cleaning schedule is based upon a moderate to average use (20300) cups per day. If machine use is less than moderate then this schedule may be adjusted accordingly.

Cleaning (Periodic)

1. Draining Boilers. Both the coffee boiler and the steam boiler may be drained and refilled to reduce the chance of mineral deposits build up on the inside walls of the inside surfaces. Additionally this draining process can be used to remove water that has a bad odor or taste.

Drain the Steam Boiler: Turn OFF the machine. Remove the left side panel assembly. Locate the ball valve on the bottom left side of the machine. Hold the ball valve with one tool and remove the brass cap on the end of the valve. Move the espresso machine close to a waste drain and tip machine at an angle to point the valve into the waste drain.

Drain the Coffee Boiler: Turn OFF the machine. Using adequate protection or an appropriate tool, loosen the expansion valve until water begins to flow freely. Then remove the group cap cover and loosen the bleed screw. When finished draining empty the drain box assembly.

Steam boiler draining: to activate this function you need to access the programming menu (see p. 50).

2. Clean the Water Reservoir.

The water reservoir needs to be cleaned periodically to ensure that no algae forms ontheinside surfaces. To clean first remove the water reservoir form the machine. Disconnect the clear plastic water intake hose. Unscrew all screws from the cover to separate the parts. Wash all parts with warm soapy water. Hand wash each part with water containing mild soap.

WARNING

The expansion valve can discharge water as hot as 200°F / 93°C. Adequate protection for handling this component is needed before atTempting to adjust.

Cleaning frequency

Daily

•Portafilter

•Filter

•Diffuser screen

•Diffuser screw

•Steam wand (just after use)

•Drain grille

Weekly

•Water Reservoir

•Drain Box

Monthly

• Cleaning the hot water nozzle

17EN

8. Mandatory Maintenance and Check-up Operations

These operations are in addition to the Maintenance and Periodic Cleaning Operations as specified in Chapter 7.

The following maintenance and check-up operations sould be carried out by a qualified technician.

The time required for the periodic maintenance is determinated by the quantity of daily work and/or coffee consumption.

N.B. These periodic maintenance operations are not covered by warranty.

|

|

|

EVERY THREE/FOUR MONTHS |

||

▪▪ Replace group gaskets |

▪▪ Check brew temperature |

on Installation, otherwise |

|||

▪▪ Replace diffuser screens |

▪▪ Check that brew pressure is |

warranty is voided) |

|||

▪▪ Clean auto-fill probe |

at 9bar |

|

|

▪▪ Check filter basket condition |

|

▪▪ Check vacuum breaker for |

▪▪ Check all switches for proper |

If AV Model: |

|||

proper operation |

operation |

|

|

||

|

|

▪▪ Check shot volumes |

|||

▪▪ Inspect water inlet valve |

▪▪ Check/note water hardness |

||||

▪▪ Test flowmeter’s ohm value |

|||||

▪▪ Inspect drain system for leaks |

▪▪ (Water quality must be within |

||||

or clogs |

the range |

of |

parameters |

(ohm value is acceptable if |

|

greater than 1.8 K ohm, and |

|||||

▪▪ Check flow rate for each group |

specified |

in |

the chapter |

||

less than 2.2 K ohm |

|||||

|

|

|

|

||

EVERY SIX/EIGHT MONTHS (in addition to the above)

▪▪ Rebuild steam assemblies

EN

|

EVERY YEAR (in addition to the above) |

|

|

▪▪ Replace portafilter baskets |

▪▪ Inspect electrical wiring |

tightness at 2,4Nm of |

If MP Model: |

▪▪ Inspect group valve plungers |

condition |

each cable on the terminal |

▪▪ Disassembly and lubrication |

▪▪ Inspect vacuum breaker |

▪▪ Inspect boilers safety switches |

block. |

of the components of the MP |

▪▪ Inspect steam boiler |

▪▪ Replace over-pressure valve |

|

valve |

pressurestat |

(safety valve) |

|

|

▪▪ Inspect expansion valve |

▪▪ Accurate control of the |

|

|

|

|

|

|

EVERY 3 YEARS (in addition to the above)

▪▪ Check the condition of the inside of boilers and if necessary rinse out with a proper cleaning product allowed for food and beverage appliances.

18

gs3

Installation Guide

Chapters

1. |

Unpackage GS/3 Espresso Machine |

pag 20 |

8. Remove air from group head |

pag 23 |

|

2. |

Fill with water |

pag 20 |

(bleeding the group) |

|

|

|

|

|

|||

(Initial Fill) |

|

9. Monitor coffee boiler pressure |

pag 24 |

||

3. |

Drain box alignment |

pag 21 |

10. |

Adjust the expansion valve |

pag 25 |

4. |

Connect to power supply |

pag 21 |

11. |

Monitor steam boiler pressure |

pag 26 |

5. |

Turn on main power |

pag 22 |

12 . Brew espresso |

pag 27 |

|

6. |

Turn on espresso machine |

pag 22 |

13. |

Verify working boiler pressures |

pag 27 |

7. |

Remove group cover |

pag 23 |

14. |

Connect to main water supply |

pag 28 |

19EN

Loading...

Loading...