Page 1

KMR 1250 B

1.091-104

1.091-124

www.karcher.com 5.956–707 A2003105 (06/02)

Page 2

Deutsch

Betriebsanleitung für Anwender 3

Ersatzteilliste 228

English

Français

Español

Hrvatski

български

Slovensko

Slovensky

User Instructions 28

Spare Parts List 228

Notice d’instructions pour l`utilisateur 53

Liste des pièces de rechange 228

Instrucciones de servicio 78

Lista de repuestos 228

Uputstvo za upotrebu za korisnik 103

Popis rezervnih dijelo 228

Ръководство за работа 128

Списък на резервни части 228

Navodila za uporabo namenjena uporabniku 153

Seznam nadomestnih delov 228

Návod na obsluhu pre pouívate¾a 178

Zoznam náhradných dielcov 228

ЕллзнйкЬ

ПдзгЯет лейфпхсгЯбт гйб фпхт чсЮуфет 203

ЛЯуфб бнфбллбкфйкюн 228

Page 3

English User Instructions KMR 1250 B

Contents

For your safety ..........................................................................................................................................29

On behalf of the environment....................................................................................................................30

Intended usage..........................................................................................................................................31

Sweeper functions ....................................................................................................................................31

Prior to initial start-up ................................................................................................................................32

Operating controls ....................................................................................................................................33

Preparing the sweeper for use..................................................................................................................34

Adjusting the driver’s seat ....................................................................................................................................34

Filling the fuel tank...............................................................................................................................................34

Opening the fuel tap .............................................................................................................................................34

Starting the sweeper .................................................................................................................................35

Initial driving trials.................................................................................................................................................35

Moving off and sweeping.......................................................................................................................................35

Braking ................................................................................................................................................................36

Stopping the sweeper and s witching off ................................................................................................................36

Cleaning the filter .................................................................................................................................................36

Emptying the waste hopper..................................................................................................................................37

Typical applications...................................................................................................................................38

Sweeping on dry ground.......................................................................................................................................38

Sweeping on damp or wet ground.........................................................................................................................38

Shutting the sweeper down for longer periods..........................................................................................39

Transporting the sweeper .........................................................................................................................40

Cleaning and care.....................................................................................................................................40

Maintenance ..............................................................................................................................................41

Daily maintenance ...............................................................................................................................................41

Maintenance intervals...........................................................................................................................................41

Maintenance tasks ....................................................................................................................................42

Opening/closing the unit cover .............................................................................................................................42

Disconnecting the battery ....................................................................................................................................42

Checking tyre pressures ......................................................................................................................................43

Checking the oil level ...........................................................................................................................................43

Filling up with oil ..................................................................................................................................................43

Changing the engine oil ........................................................................................................................................43

Cleaning or replacing the air cleaner.....................................................................................................................44

Cleaning the fuel filter holder ................................................................................................................................44

Checking the hydraulic system ............................................................................................................................44

Checking the level of electrolyte in the battery......................................................................................................45

Charging the battery.............................................................................................................................................45

Replacing the sealing skirts .................................................................................................................................46

Replacing the side brush......................................................................................................................................46

Replace light unit .................................................................................................................................................46

Adjusting the sweeping pattern ............................................................................................................................47

Replacing the main brush roller ............................................................................................................................48

Replacing fuses ...................................................................................................................................................49

Replacing the dust filters......................................................................................................................................49

Troubleshooting.........................................................................................................................................50

Technical specifications............................................................................................................................51

28

Page 4

KMR 1250 B User Instructions English

For your safety

Before you use this machine for the first time, please read

the following:

– these operating instructions

– the enclosed leaflet Safety Information No. 5.956-250.

Make sure that all information contained therein is complied

with.

!

Explosion hazard while refuelling!

n Do not fill up with fuel

– in an enclosed space

– while the engine is running.

n Do not smoke while refuelling the vehicle.

n Fuel expands as it becomes warmer.

Do not fill the tank right up to the top. Leave a gap of at

least 1 cm under the bottom edge of the filler neck.

n Wipe up any fuel they may have been spilt and ensure

that the cap is replaced firmly on the tank.

!

Fire hazard while sweeper is operating!

n Keep highly inflammable materials away from the engine

and the exhaust while the sweeper is operating.

!

Danger of toppling over on steep slopes!

The sweeper could topple over while it is being driven

across or turning round on a sleep slope.

n The maximum gradient up or down which the sweeper

can be driven is 18%.

n Do not drive at right angles to a slope with a gradient

steeper than 10%.

!

Danger of toppling over if bends are negotiated at

high speed!

n The sweeper could topple over if it is driven round a bend

at high speed. Drive slowly round bends.

!

Caution when carrying out maintenance or repairs!

In order to prevent the engine from being started unintentionally, proceed as follows:

n Remove the ignition key.

n Disconnect the battery at the negative terminal.

!

Caution while handling the battery!

Observe the safety information provided by the battery

manufacturer.

Always use batteries and chargers recommended by

KÄRCHER, otherwise your warranty could be rendered

invalid.

29

Page 5

English User Instructions KMR 1250 B

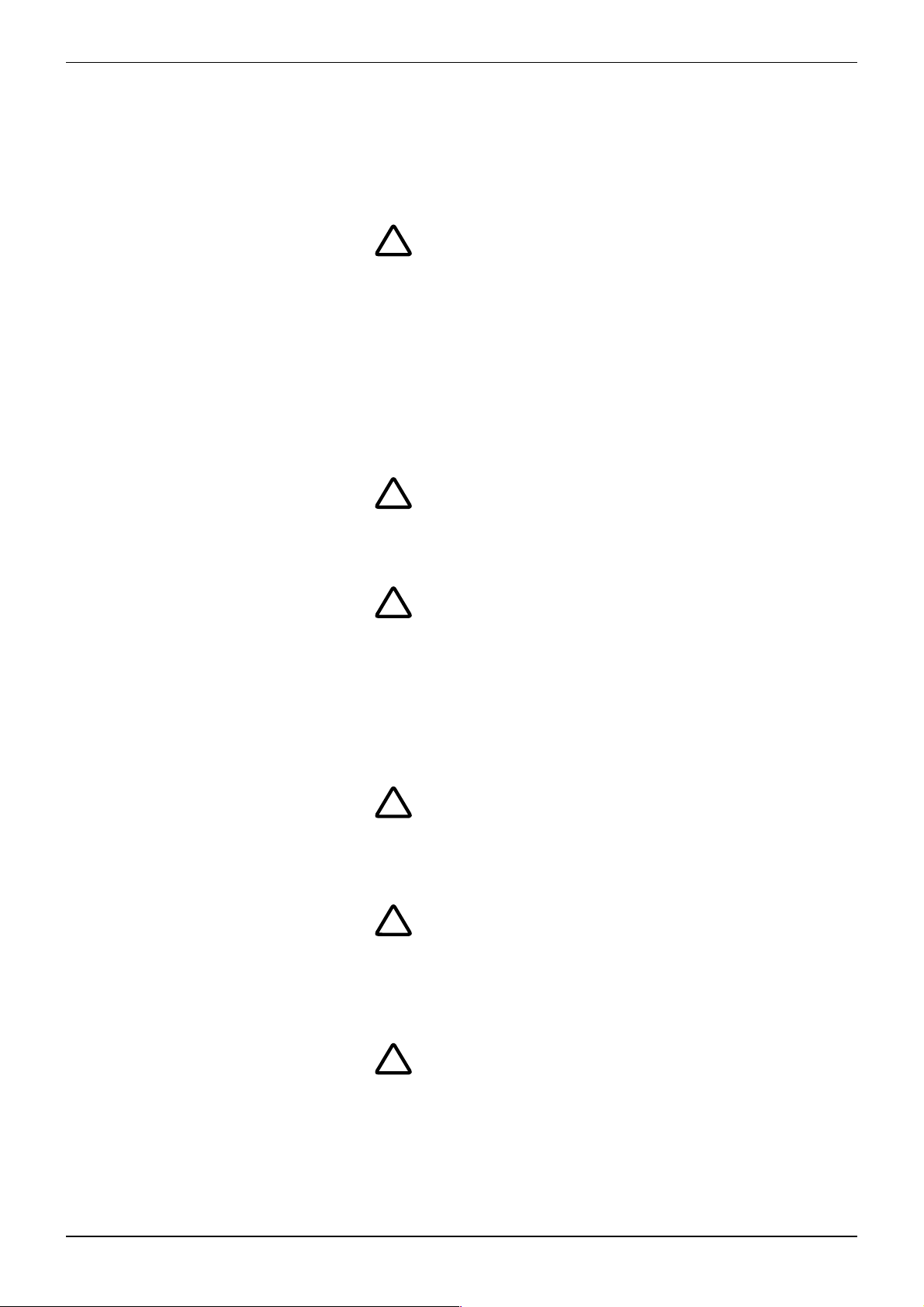

!

Caution while transporting the sweeper!

Make sure that the sweeper is secured properly if you are

going to transport it to a different location.

Do not use a forklift truck for loading purposes as it could

damage the sweeper.

n Apply the parking brake.

n Secure the sweeper as shown in the illustration, using

– web belts

or

– ropes

or

– chains.

On behalf of the

environment

!

Caution, environmental hazard due to exhausted

batteries!

Exhausted batteries should not be treated as domestic

refuse. Make sure that are disposed of in an environmentally

appropriate manner.

!

Caution, environmental hazard due to engine oil or

hydraulic fluid!

After you have changed the engine oil or hydraulic fluid, take

the waste product to a recognised collection point or to a

waste disposal company.

30

Page 6

KMR 1250 B User Instructions English

Intended usage

Sweeper functions

This sweeper

– is intended to be used for sweeping outdoor surfaces,

– corresponds to application category BIA KAT ”U” for

dusts which present no health hazard

– should not be used in enclosed spaces,

– can only be used on public paths and highways if it has

been fitted with the StVZO Accessory Kit.

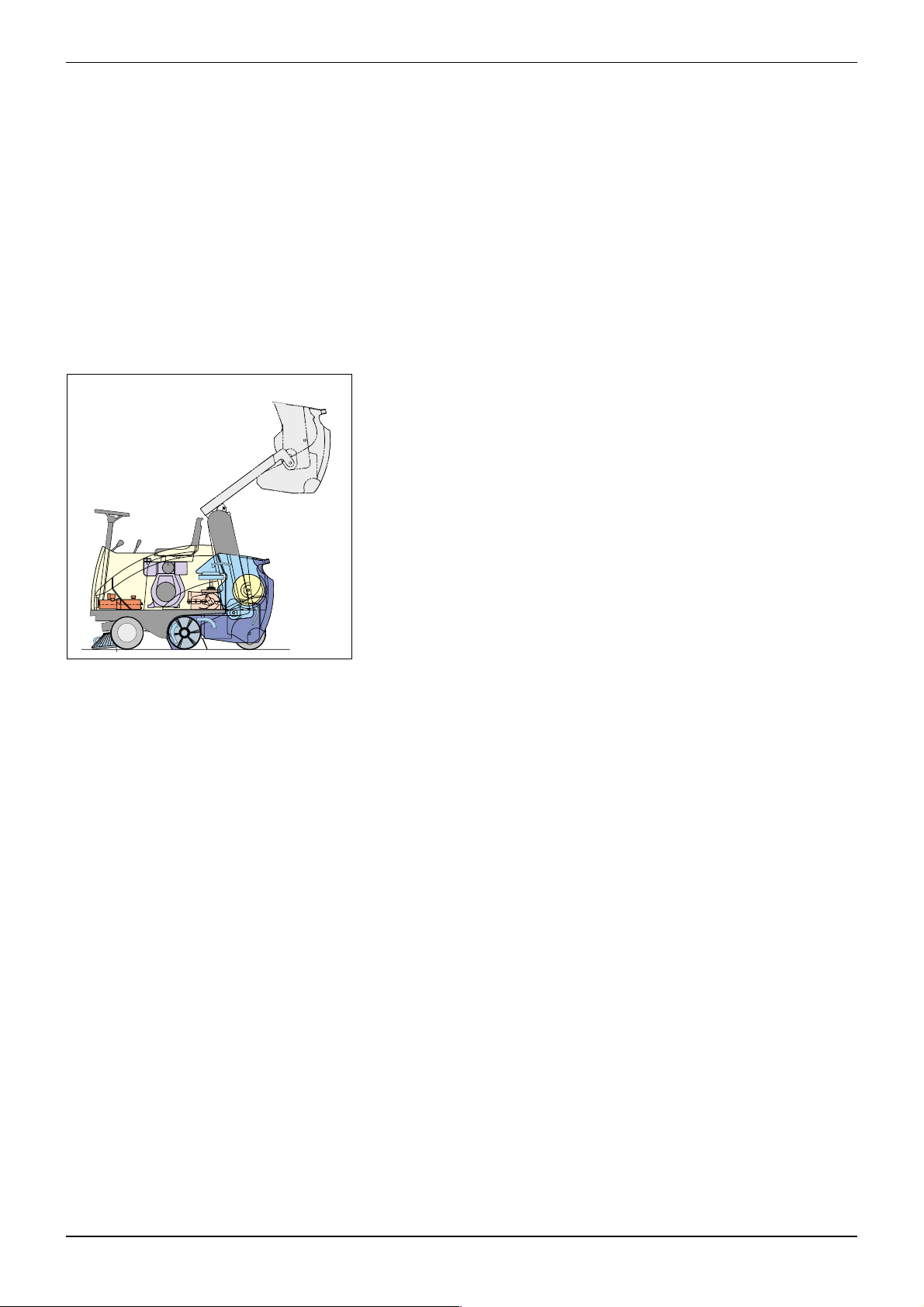

Main components

Drive unit

– single-cylinder petrol engine (6.6 kW according to SAE J

6070a)

– continuously-adjustable hydraulic drive to rear wheels

– main brush and side brush driven via belts

– hydraulically controlled emptying of waste hopper

– high-performance generator

Sweeping mechanism

– main brush employing throw-over principle for particularly

effective filling of waste hopper

– floating main brush roller with adjustable height above

ground

– quick-change mechanism for main brush

– side brush can be raised and swivels automatically

– bulk waste flap for picking up larger items (e.g. cigarette

packs or drink cans)

Filter system

– integrated dust extraction for main roller by means of

radial turbine

– 2 circular filters with 2 x 3 m

2

effective surface area

– electric filter cleaner with automatic shaking mechanism

31

Page 7

English User Instructions KMR 1250 B

Prior to initial start-up

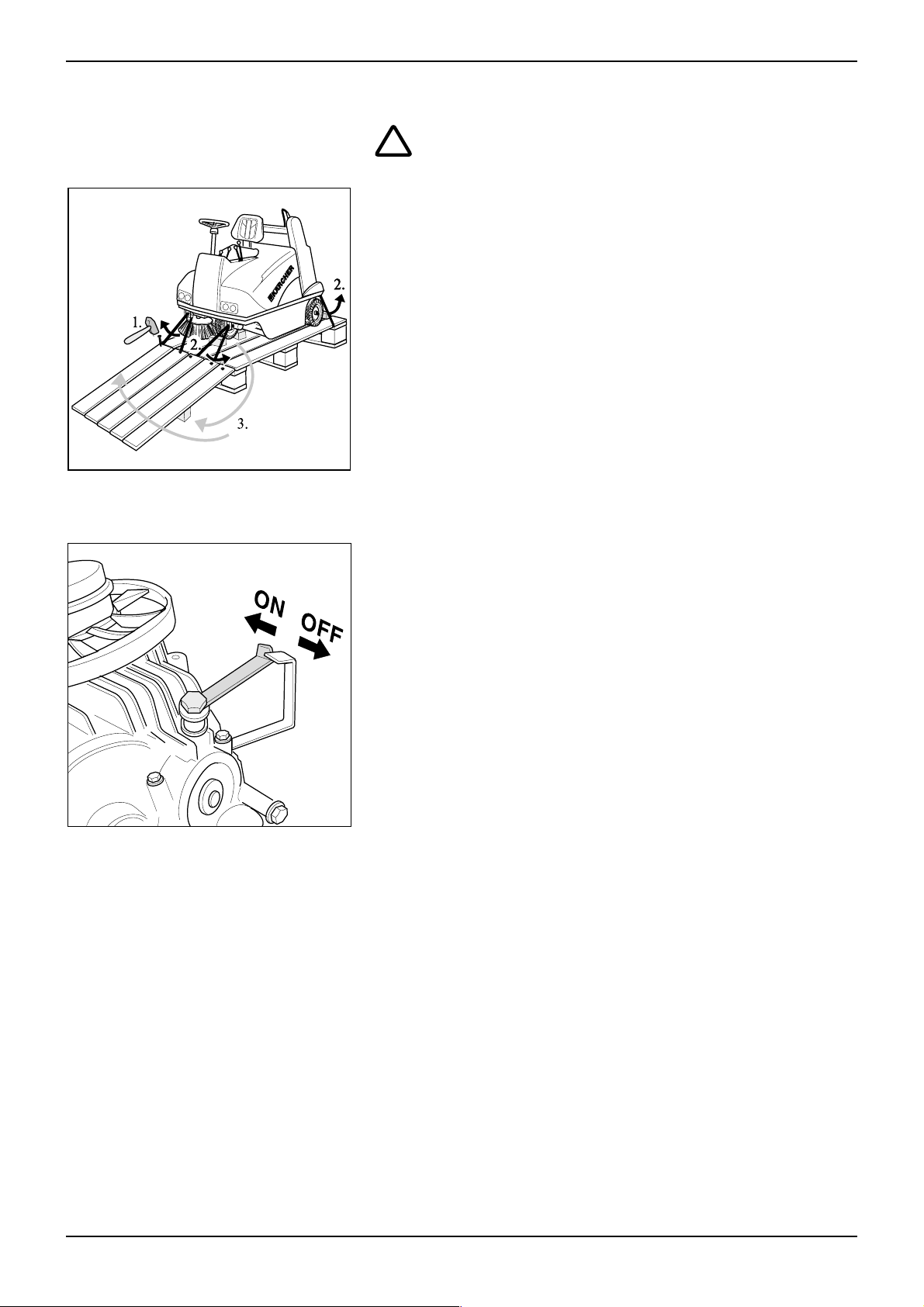

Unloading procedure

Do not use a forklift truck for unloading as it could

!

cause damage to the sweeper.

The sweeper has been lashed onto a pallet to ensure that

it can be transported safely. The procedure for unpacking

the sweeper is as follows:

1. Remove the wooden boards from the pallet and nail

them onto the end of the pallet (in front of the sweeper).

2. Detach the wires holding the sweeper in place at the

ends of the pallet.

3. Knock away the blocks used for locking the wheels and

use them for the support of the wooden planks on the left

and right.

4. Drive the sweeper off the pallet and down the ramp

made from the boards.

5. The side brush has been tied to the chassis for trans-

port. Undo the cord holding it in place.

Pushing the sweeper by hand

If you wish to move the sweeper without using its own drive:

n Open the engine cover.

n Fold the cover towards the rear; it will be held in place by

the pneumatic spring.

ç Turn the lever for allowing freewheeling to position ”OFF”.

n Release the handbrake.

n Push the sweeper to the required destination.

Note:

Do not move the sweeper over long distances without using

its own drive or at higher speeds than 10 km/h (e.g. whilst

being towed).

After moving the machine

n Put the parking brake on.

n Set free-wheeling lever to position ”ON”.

32

Page 8

KMR 1250 B User Instructions English

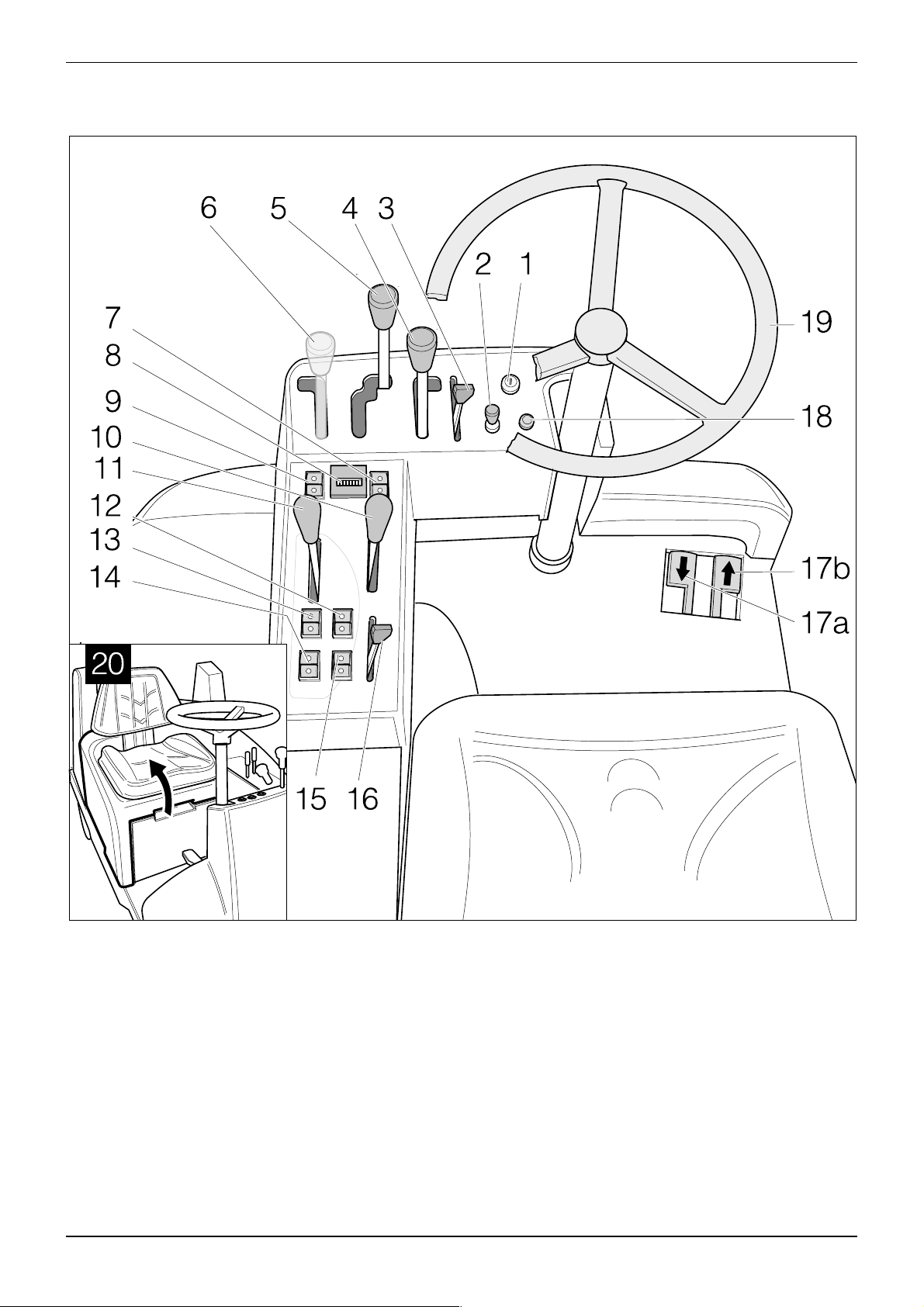

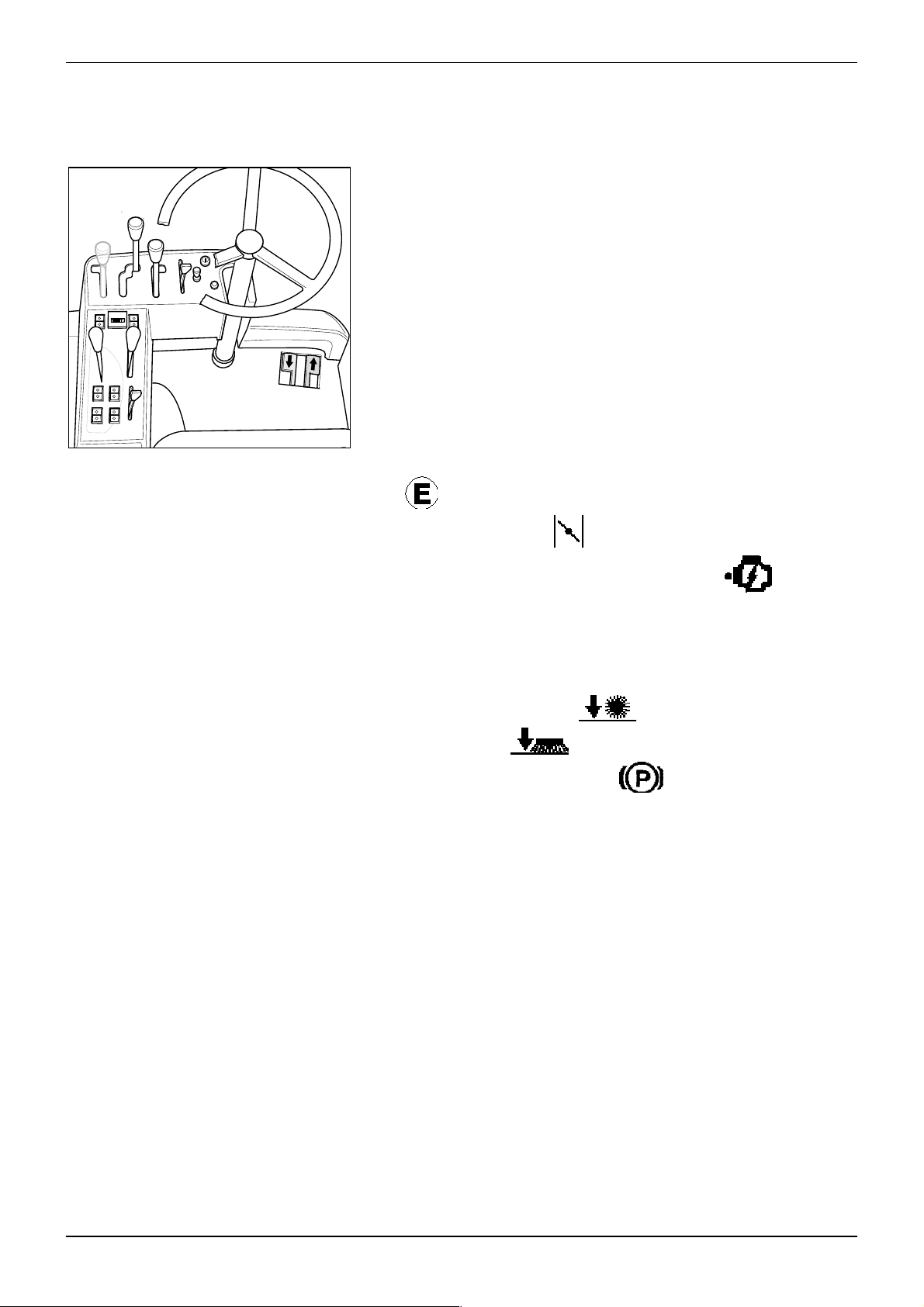

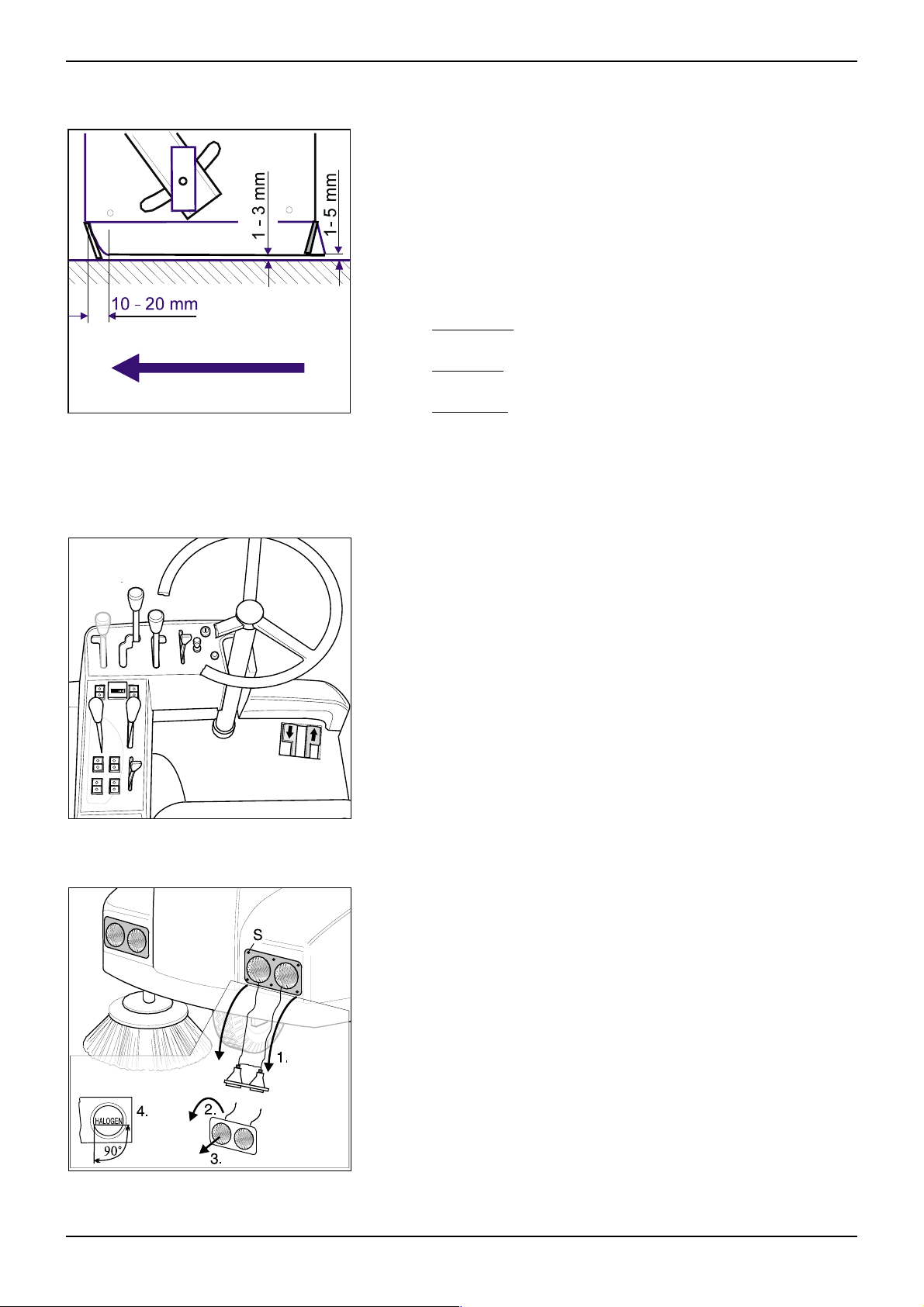

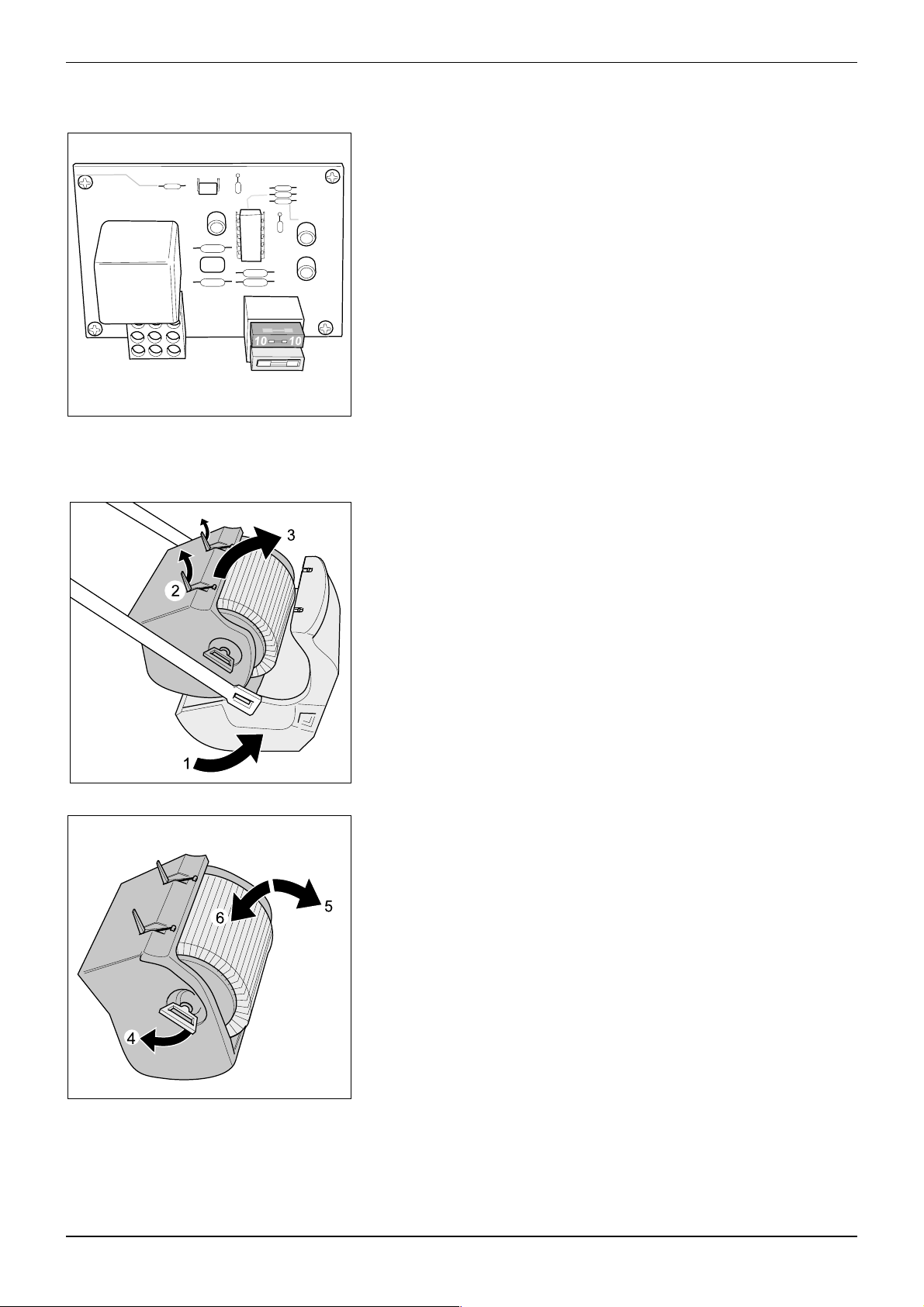

Operating controls

1. Ignition lock

2. Choke

3. Throttle lever

4. Raise / lower RH side brush

5. Raise / lower main brush

6. Raise / lower LH side brush (optional)

7. Switch for two-handed operation

8. Operating hour counter

9. Lights

10. Bulk waste flap

* Function only operative in conjunction with 7 (two-handed operation).

11. Parking brake / Driving brake

12. Tip waste hopper *

13. Raise waste hopper *

14. Lower waste hopper *

15. Filter cleaning

16. Sweeping mode, wet / dry

17a. Drive pedal backwards

17b. Drive pedal forwards

18. Horn

19. Steering wheel

20. Open/close unit cover

33

Page 9

English User Instructions KMR 1250 B

Preparing the sweeper for

use

All directions given (left/right, front/rear) are as seen from

the driver’s seat.

n Check the oil level in the engine (see Chapter: “Mainte-

nance”).

n Check the amount of fuel in the tank and fill up, if required

(see below).

n Check the level of hydraulic fluid and top up, if required

(see Chapter: “Maintenance”).

n Check the air pressure in the tyres (see Chapter:

“Maintenance”).

n Inspect the brush roller and remove any string, rope, etc.,

that may be caught up in the brushes.

n Check the dust filter. If it is very dirty, operate the shaker

to clean it off.

n Empty the waste container.

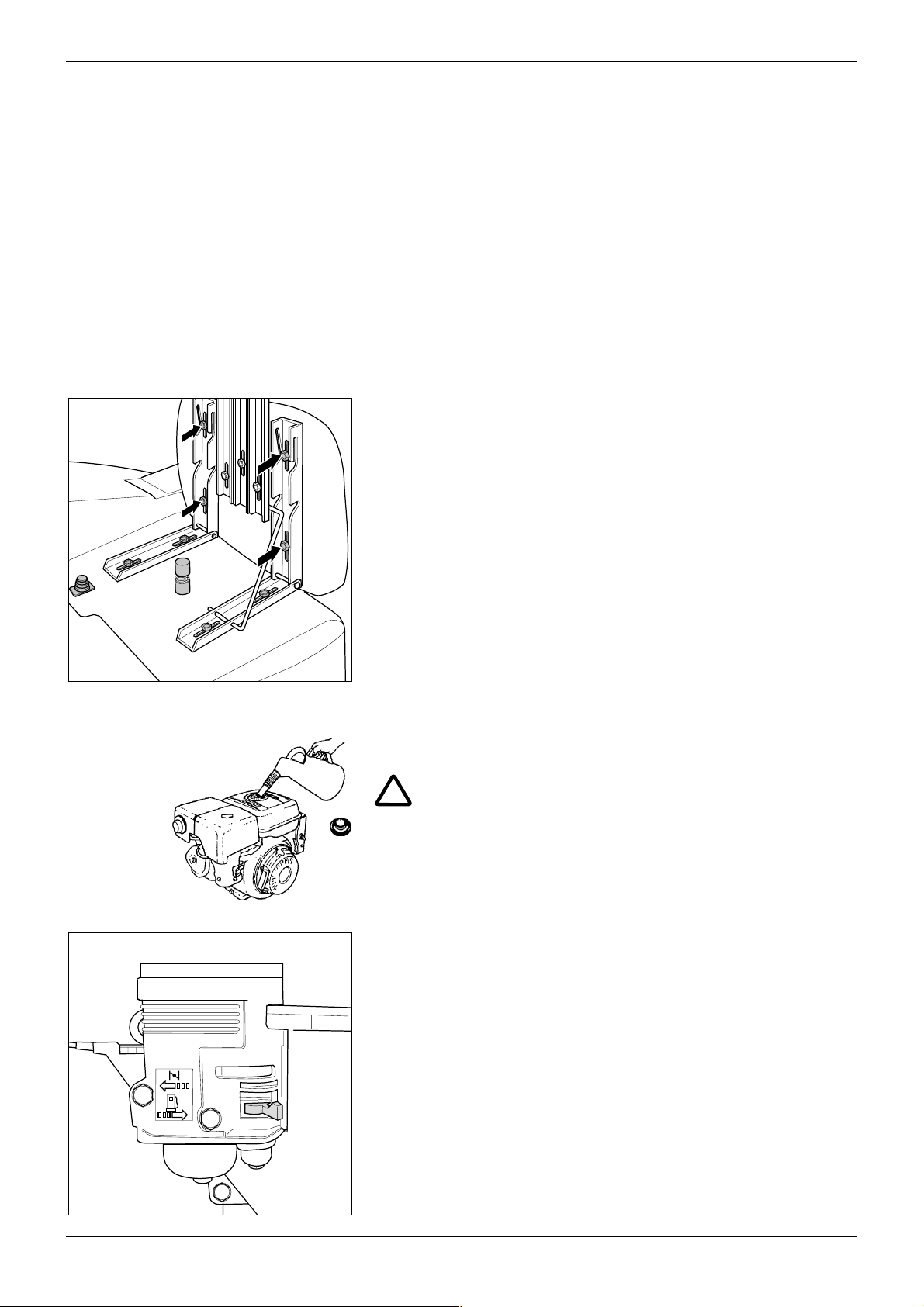

Adjusting the driver’s seat

The driver’s seat can be adjusted to suit persons of various

heights.

n Unhook the rods in the seat tilting device.

ç Undo the 4 screws.

n Move the seat to the desired position.

n Tighten the screws and hook the rods back into the tilting

device.

Filling the fuel tank

!

Explosion hazard while refuelling!

n Do not fill up with fuel

– in an enclosed space

– while the engine is running.

n Do not smoke while refuelling the vehicle.

n Fuel expands as it becomes warmer.

Do not fill the tank right up to the top. Leave a gap of at

least 1 cm under the bottom edge of the filler neck.

n Wipe up any fuel they may have been spilt and ensure

that the cap is replaced firmly on the tank.

n Use petrol, regular (lead-free).

Opening the fuel tap

n Open the unit cover.

ç Open the fuel tap.

OPEN = lever pushed to side opposite to direction of

travel

n Close the unit cover.

34

Page 10

KMR 1250 B User Instructions English

Starting the sweeper

Initial driving trials

Carry out initial driving trials in an area where there is plenty

of free space until you are familiar with individual operating

controls and their functions.

All indications of direction (right/left, front/rear) are given in

relation to the direction of travel as seen from the driver’s

seat.

n Sit down on the driver’s seat.

The engine cannot be started until the driver has sat

down (seat contact switch). As soon as driver gets up

from the seat, the engine switches off (safety cut-out).

n Make sure that

– the LH side brush (if fitted) is in the raised position,

– the RH side brush is in the raised position,

– the main brush is in the raised position.

n Set the throttle lever to the middle position

[

] (operating speed).

n Pull out the choke [

] .

n Turn the ignition key to the start position [

n When the engine has started running, set the control for

the choke back to its home position.

Moving off and sweeping

n Lower the main brush [

brush as well [ ].

n Release the parking brake [

– push the lever towards the front.

n Slowly depress drive pedal

– depress right pedal, machine travels forwards

– depress left pedal, machine travels backwards.

Whichever drive pedal is being used at the time, the driving

speed can be uniformly and smoothly regulated backwards

or forwards. Avoid jerky operation of the pedals, as the

hydraulic system could suffer damage in this way.

] and, if required, the side

]

].

35

Page 11

English User Instructions KMR 1250 B

Braking

n Release the drive pedal and the sweeper will brake auto-

matically.

Important note: Safety!

It is possible that the automatic braking function will not be

sufficient to bring the sweeper to a halt. In this case, either

make use of the parking brake as well or gently press the

drive pedal in the opposite direction to travel.

Stopping the sweeper and switching off

n Release the drive pedal. The sweeper brakes automati-

cally and comes to a halt.

Cleaning the filter

n Apply the parking brake [

n Set the throttle lever to minimum engine speed (to the

rear).

n Make sure the main roller [

are raised so that the bristles are not damaged.

n Switching off

– Turn the ignition key counter-clockwise to the 0 positi-

on and then remove it.

After the engine has been switched off, the filter is

automatically cleaned for approx. 10 seconds.

Automatic cleaning

n Stop the sweeper and switch off the engine.

After the engine has been switched off, the filter is auto-

matically cleaned for approx. 10 seconds.

].

] and side brush [ ]

36

Manual cleaning

While the sweeper is operating, the filter should be cleaned

approx. every 15–30 minutes (depending on amount of

dust).

n Stop the sweeper.

n Set the sweeping mode lever to wet [

n Briefly operate the filter cleaning button

the filter will be cleaned for a duration of approx. 10 secs.

n Set the sweeping mode lever back to dry [

n Continue with cleaning task as before.

].

, whereupon

].

Page 12

KMR 1250 B User Instructions English

Emptying the waste hopper

!

Important information

Injury hazard!

No person or animal should be allowed to stand in the area traversed by the hopper while it is

being emptied.

Danger of being crushed!

Do not reach into the shafts and linkage of the emptying mechanism.

Do not stand under the hopper.

Risk of sweeper toppling over!

If the sweeper is standing on a slope with a gradient of more than 5%, it could topple over while

the hopper is being emptied. The hopper should therefore only be emptied when the gradient at

the location where the sweeper is standing is less than 5% for the direction in which it is facing.

n Stop the sweeper.

n Raise the main brush [

Note: Following steps can only be performed with the

sweeper set to two-handed operation.

n Raise the waste hopper, [

When the hopper has reached the required height:

n Tip the hopper outwards, [

].

+ ].

+ ].

Note:

The hopper must have reached a certain minimum height

before it can be tipped out. The best position for emptying

the hopper is when it has been fully extended.

As soon as you release the button for activating the tipping

system, the hopper automatically returns to its original

position.

n Lower the hopper, + .

37

Page 13

English User Instructions KMR 1250 B

Typical applications

!

Caution while sweeping!

Do not sweep up packing bands, wires or similar items,

otherwise the sweeping mechanism will be damaged.

Do not sweep any burning/glowing objects.

Sweeping on dry ground

For a small amount of normal dirt

n

on an even surface:

lower main brush

– set the lever to the middle position [

brush wear).

n

on an uneven surface:

lower main brush

– set the lever to the lower position [

brush wear).

n switch on dust extraction

– set the switching mode lever to dry [

n for cleaning right up to the edges – lower the side brush

[

At regular intervals:

n clean the filter,

n empty the waste hopper.

Notes: If you are sweeping up fine dust, use the side brush

as little as possible as it will increase the amount of dust

stirred up by the sweeper. If the side brush encounters an

obstacle, it automatically swivels back inside the outer

contours of the sweeper. You should nevertheless try to

avoid collisions.

While the sweeper is operating, the filter should be cleaned

approx. every 15–30 minutes (depending on amount of

dust).

].

] (minimum

] (increased

].

38

Sweeping on damp or wet ground

Follow the same procedure as for sweeping on dry ground.

In order to protect the filter from moisture

n switch off the dust extraction

– set the sweeping mode lever to wet [

At regular intervals:

n empty the waste hopper.

].

Page 14

KMR 1250 B User Instructions English

Picking up larger items (sticks, tins, etc.)

Caution!

When the bulk waste flap is open, stones or grit could be

thrown at the front by the main brush. Make sure therefore

that when you open the flap no persons, animals or property

are endangered.

n Open the bulk waste flap [ ] by pulling back the

corresponding lever.

n Drive over the items to be picked up, at low speed and

with the bulk waste flap open.

Note:

In order to avoid stirring up dust unnecessarily, close the

bulk waste flap again as soon as possible.

Shutting the sweeper down

for longer periods

Overcoming obstacles

Obstacles up to 5 cm in height

– can be driven over without any problems. Before you do

so, open the bulk waste flap and raise the main brush.

Obstacles more than 5 cm in height

– can be only be driven over with the aid of a suitable ramp.

If you do not intend to use the sweeper for a longer period of

time (e.g. during the winter), please observe the following.

n It is most important that the main brush and side

brush(es) are kept raised in order to avoid damage to the

bristles.

n Clean the interior and exterior of the sweeper.

n Close the fuel tap.

n Change the engine oil (see Chapter: “Maintenance”).

n Store the sweeper in a protected environment and ensure

that it cannot roll away.

n Remove the ignition key.

n Disconnect the battery.

n Charge the battery with a suitable charger approx. every

two months (see Chapter: “Maintenance”).

39

Page 15

English User Instructions KMR 1250 B

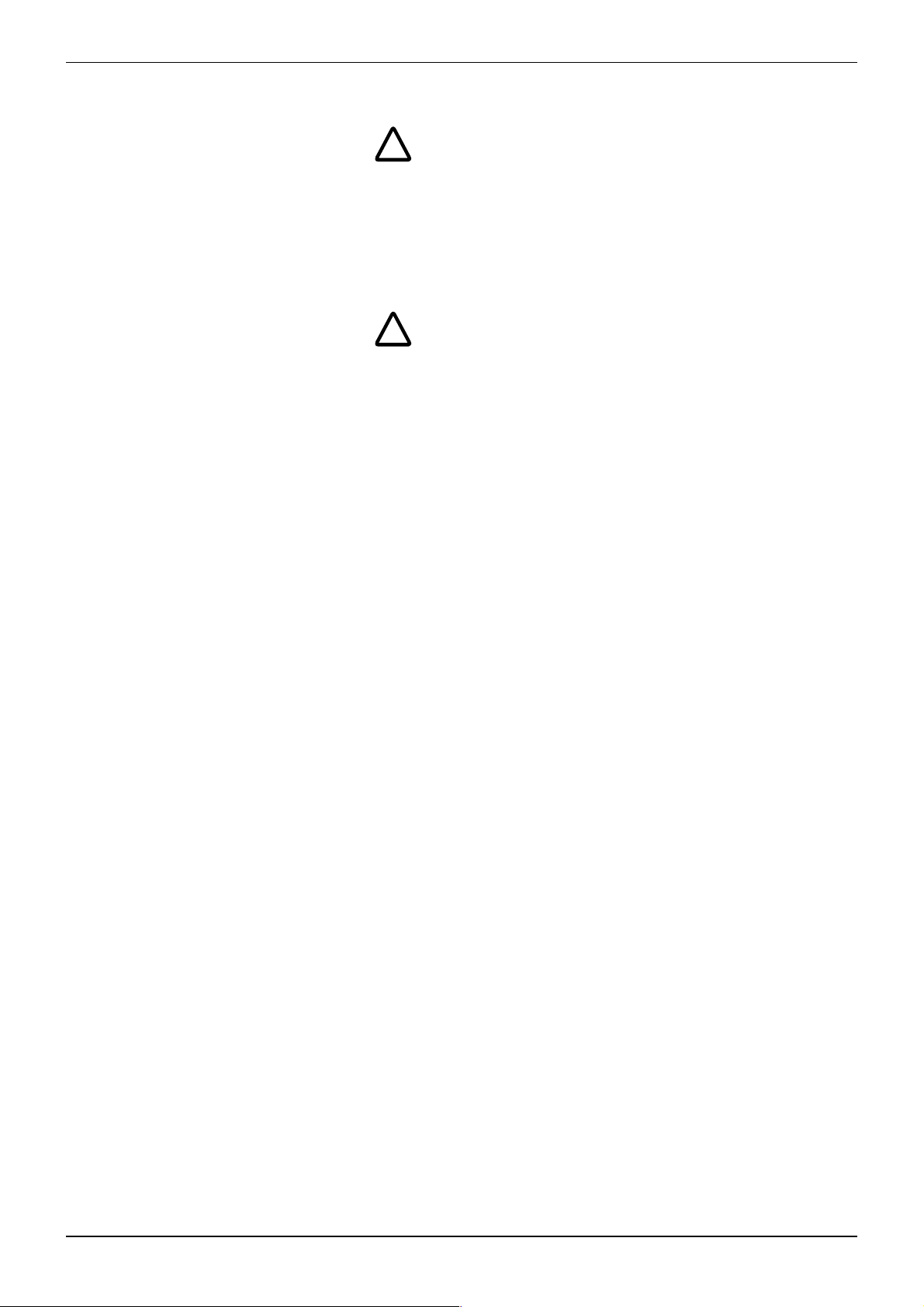

T ransporting the sweeper

Cleaning and care

If the sweeper is going to be transported on the back of a

vehicle, it must be properly secured so that it cannot move

unintentionally.

n Apply the parking brake.

n Secure the sweeper in the manner shown in the illustrati-

on only, using

– web belts

or

– ropes

or

– chains.

Before you carry out any cleaning or general maintenance

tasks,

n park the sweeper and switch off the engine.

Cleaning the inside of the sweeper:

You can clean out the inner parts of the sweeper by blowing

them through with compressed air.

Cleaning the outside of the sweeper:

The outside of the sweeper can be wiped off with a damp

cloth. Do not use any aggressive cleaning agents which

might cause damage to the plastic components.

40

Page 16

KMR 1250 B User Instructions English

Maintenance

First engine oil change

!

Caution!

When an engine is new, it is subject to increased abrasion.

In order that the engine does not suffer any damage, we

recommend that you change the engine oil and the oil filter

after the first 8 operating hours.

Initial inspection after 8 operating hours

!

Caution!

In order to ensure that your sweeper functions safely and

reliably, it should undergo an initial inspection after approx. 8

operating hours. The inspection should be carried out by an

authorised service agent.

n Check all Bowden cables and make adjustments where

necessary.

n Change the engine oil.

n Check that there are no leaks in the hydraulic system and

all components function correctly.

n Check that the parking brake functions correctly.

n Check the air pressure in the tyres (correct level: 6 bar).

Daily maintenance

n Check the engine oil level.

n Check the tyre pressure (correct level: 6 bar).

n Inspect the brush roller and remove any string, rope, etc.,

that may be caught up in the brushes.

n Check the dust filter. If it is very dirty, operate the shaker

to clean it off.

n Empty the waste container.

Maintenance intervals

Keep to the service intervals set out in the maintenance

booklet so that your sweeper functions reliably and you

retain the full benefit of the warranty.

The maintenance booklet (Order-no. 5.950-533) can be

found in the tool compartment on the sweeper (under the

bonnet).

The necessary maintenance tasks should be carried out by

an authorised service agent.

41

Page 17

English User Instructions KMR 1250 B

!

Safety information applicable to maintenance

tasks

Before you begin any maintenance tasks, please read the

enclosed leaflet Safety Information No. 5.956-250.

Caution! Make sure engine cannot be started unintentionally.

In order to prevent the engine from being started unintentionally, proceed as follows after you have parked the

sweeper.

n Pull out the ignition key.

n Disconnect the battery at the negative terminal.

The necessary maintenance tasks or daily inspections can

be carried out with the bonnet raised.

Injury hazard!

Do not open the bonnet until the motor has been switched

off.

Burns hazard!

Take care not to touch the exhaust when you open the

bonnet.

Injury hazard!

ç If you need to work under the waste container while it is

in the raised position, you must first of all secure the

container to prevent it from dropping down unintentional-

ly:

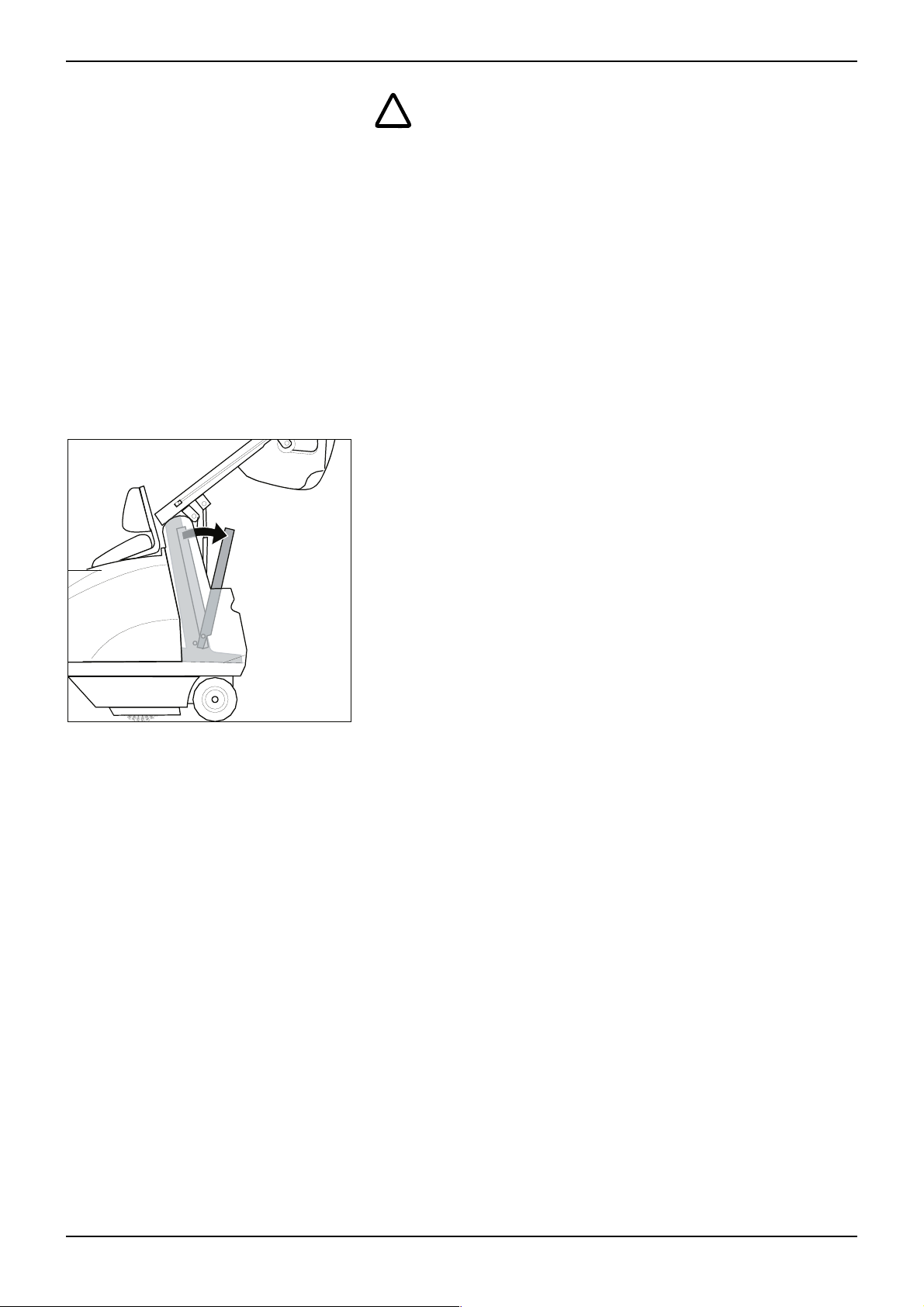

Maintenance tasks Opening/closing the unit cover

n Tip the seat forwards.

n Take hold of the unit cover by the recessed grip and open

it by pulling upwards.

Disconnecting the battery

n Open the unit cover.

n First of all disconnect the cable from the negative termi-

nal (–), then disconnect the positive terminal (+).

42

Note:

When reconnecting the battery, proceed in reverse order –

connect the positive terminal (+) first of all, then the negative terminal (–).

Page 18

KMR 1250 B User Instructions English

Checking tyre pressures

Checking the oil level

n Park the sweeper on a level surface.

n Check air pressure and adjust pressure as required.

Air pressure for front and rear wheels = 6 bar

n Park the sweeper on a level surface.

ç Pull out the dipstick.

n Wipe the dipstick clean and re-insert it in the filler hole.

n Pull out the dipstick again and check the result.

The oil level should be between the MIN and MAX marks.

If the oil level is below MIN – top up with oil.

If the oil level is above MAX – drain off the surplus.

n Insert the dipstick back into the filler hole.

Filling up with oil

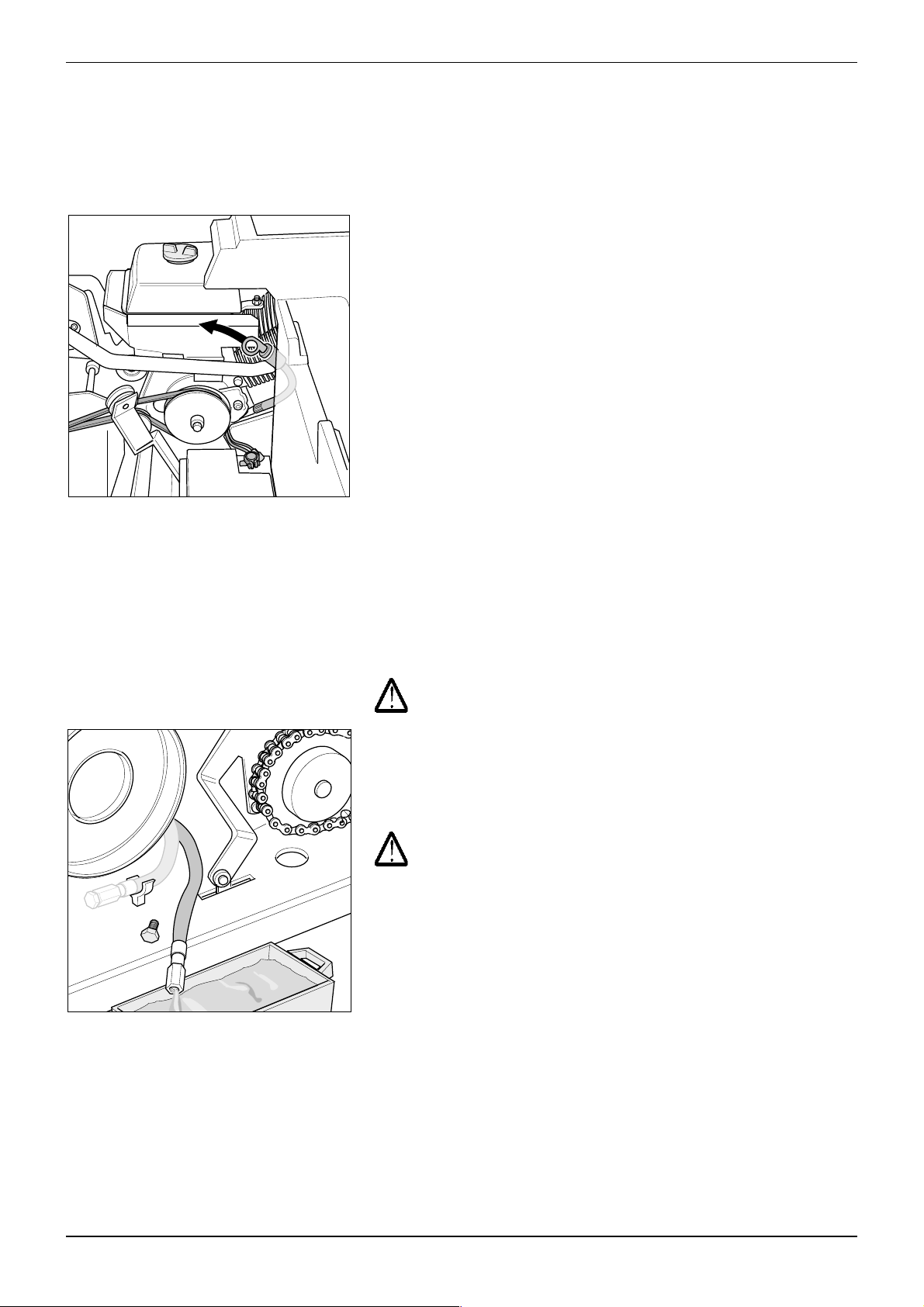

Changing the engine oil

n Pour engine oil type SAE 15W40 into the hole for the

dipstick.

Caution! Danger to the environment from engine

oil

After carrying out an oil change, ensure that the waste oil is

passed to an appropriate collection point or official disposal

company.

Caution,

n Run the engine until it reaches its normal operating tem-

perature.

n Make sure the sweeper is standing on a level surface.

n Open the unit cover.

n Place a drip pan under the engine.

ç Hold the end of the drain tube over the drip pan and let

the old oil run out.

n Close off the end of the drain tube again.

n Pour engine oil into the filler hole.

Capacity = 1.1 litres

n Check the oil level with the dipstick – see “Checking the

oil level”.

n Wipe up any oil spillage and dispose of the waste oil

appropriately.

43

Page 19

English User Instructions KMR 1250 B

Cleaning or replacing the air

cleaner

1

2

Do not run the engine without an air cleaner otherwise this will lead to increased wear on the engine

The air cleaner must be washed out more frequently if the

engine is run in particularly dusty environment.

Do not wash the air cleaner in petrol or a cleaning

solvent with a low flash point.

n

Paper insert 1: Replace the insert if it is very dirty. Other-

wise, blow compressed air through the insert from the

inside to out or knock it against a hard surface. Do not

brush it off, otherwise the dirt will be compacted between

the fibres.

Foam insert 2: Wash out the insert in a solution of was-

n

hing-up liquid and warm water. Rinse it out and allow it to

dry out thoroughly. Immerse the clean insert in engine oil

and squeeze out the excess fluid. If too much oil is left in

the insert, smoke will be given off by the engine when it is

next started.

Cleaning the fuel filter

holder

1

2

Checking the hydraulic

system

Petrol is highly flammable and under certain conditions it is also explosive. Do not smoke within

the working area and keep away from open flames

or sparks.

When the filter holder is refitted, check that it

seals properly and make sure the whole area is dry

before starting the engine.

n Set the fuel tap to OFF 1.

n Detach the filter holder and O-ring 2 and wash it out in a

non-flammable or flame-resistant solvent. Allow the

holder to dry out thoroughly and then screw it on tight.

n Set the fuel tap to OPEN. Check that there is no leakage.

n Carry out a visual inspection. If there is any loss of fluid

from the hydraulic unit, cylinder or hoses, call KÄRCHER

Customer Service.

44

Page 20

KMR 1250 B User Instructions English

Safety information

which must be observed when handling batteries.

Comply with the user instructions and ensure that these are displayed at the

charging station. Before the operator carries out any work on batteries, he/she

must have received proper instruction from a suitably qualified person.

Wear safety goggles and protective clothing when working on batteries. Observe accident prevention regulations, as well as DIN VDE 0510, VDE 0105

Part 1.

Smoking is forbidden!

Make sure that there are no naked flames, other source of heat or sparks in

the proximity of the battery, otherwise there is a danger of explosion or fire.

If electrolyte comes into contact with skin or eyes, rinse the affected area with

plenty of clean water. The metal parts of battery cells are permanently live.

Therefore do not place any tools or other objects on top of the battery.

Explosion and fire hazard! Avoid short-circuits.

Warning! The metal parts of battery cells are permanently live. Therefore do

not place any tools or other objects on top of the battery.

Electrolyte is highly corrosive. Under normal operating conditions it is not

possible for anything to come into contact with the electrolyte. If the battery

housing is destroyed, the bound electrolyte that leaks out is just as corrosive

as liquid electrolyte.

Return to manufacturer!

Exhausted batteries bearing this symbol are a re-usable resource which

should be recycled accordingly. Exhausted batteries that are not intended to

be recycled must be disposed of as hazardous waste in compliance with all

relevant regulations.

Checking the level of

electrolyte in the battery

Charging the battery

Note: concerns only batteries which are not totally

maintenance-free.

Check the level of electrolyte in batteries filled with acid.

Make sure the battery is fully charged before you carry out

the check. If required:

n Top up each cell with distilled water until the lead plates

are covered by approx. 1 cm of liquid.

Note:

We recommend using the automatic battery charger (part

no. 6.654-116) for starter batteries. Use only battery

chargers with test certification mark.

Only undertake the charging procedure in dry, weatherprotected areas.

n Bring machine to a halt, pull out ignition key

n Tip seat forwards and open unit cover

n Connect positive post (+) to battery charger (red pole

clamp)

n Connect negative post (–) to battery charger (black pole

clamp)

n Connect battery charger to mains power supply and

switch on if applicable. Charging period as specified by

the battery charger manufacturer.

45

Page 21

English User Instructions KMR 1250 B

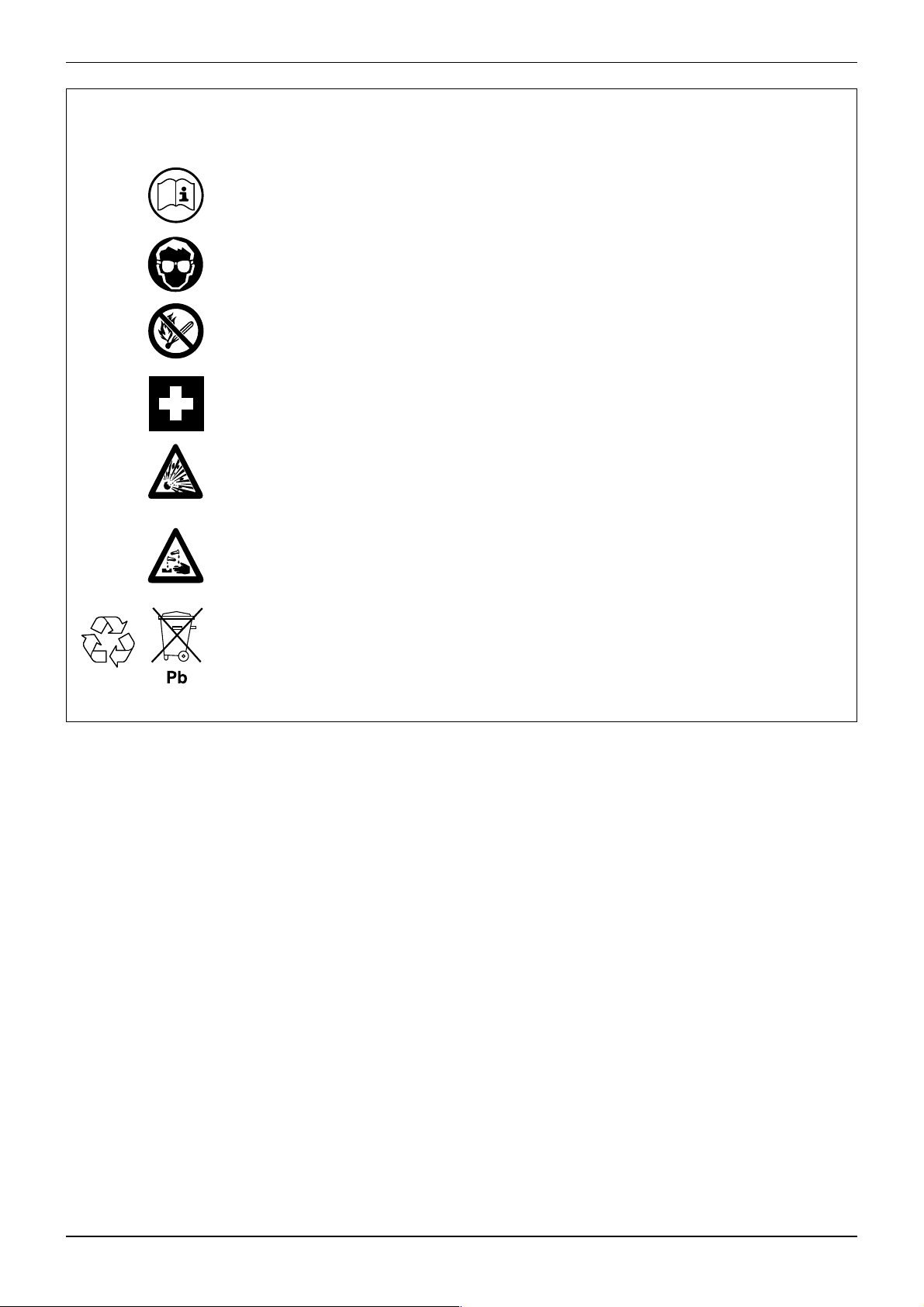

Replacing the sealing skirts

Direction of travel

Replacing the side brush

The sealing skirts fulfil an important function. They retain the

partial vacuum in the area round the brushes which is essential so that the sweeper can function properly. They

ensure that sweeping can take place without clouds of dust

being formed at the same time. If the sealing skirts are

damaged or worn out, they must be replaced immediately.

n Park the sweeper and switch off the engine.

n Remove the retaining screws and detach the sealing

skirts.

n Fit new skirts, and align them as follows:

The

side skirts should be adjusted so that they clear the

ground by 1–3 mm.

The rear skirt should be adjusted so that they clear the

ground by 1–5 mm.

n The front skirt cannot be adjusted. Replace the skirt as

soon as you see signs of excessive wear.

n Tighten the retaining screws.

n Park the sweeper and switch off the engine.

n Raise the side brush.

n Remove the three hex-socket bolts (5 mm Allen key).

n Detach the side brush.

n Push the new side brush onto the drive pin.

n Refit and tighten the three hex-socket bolts.

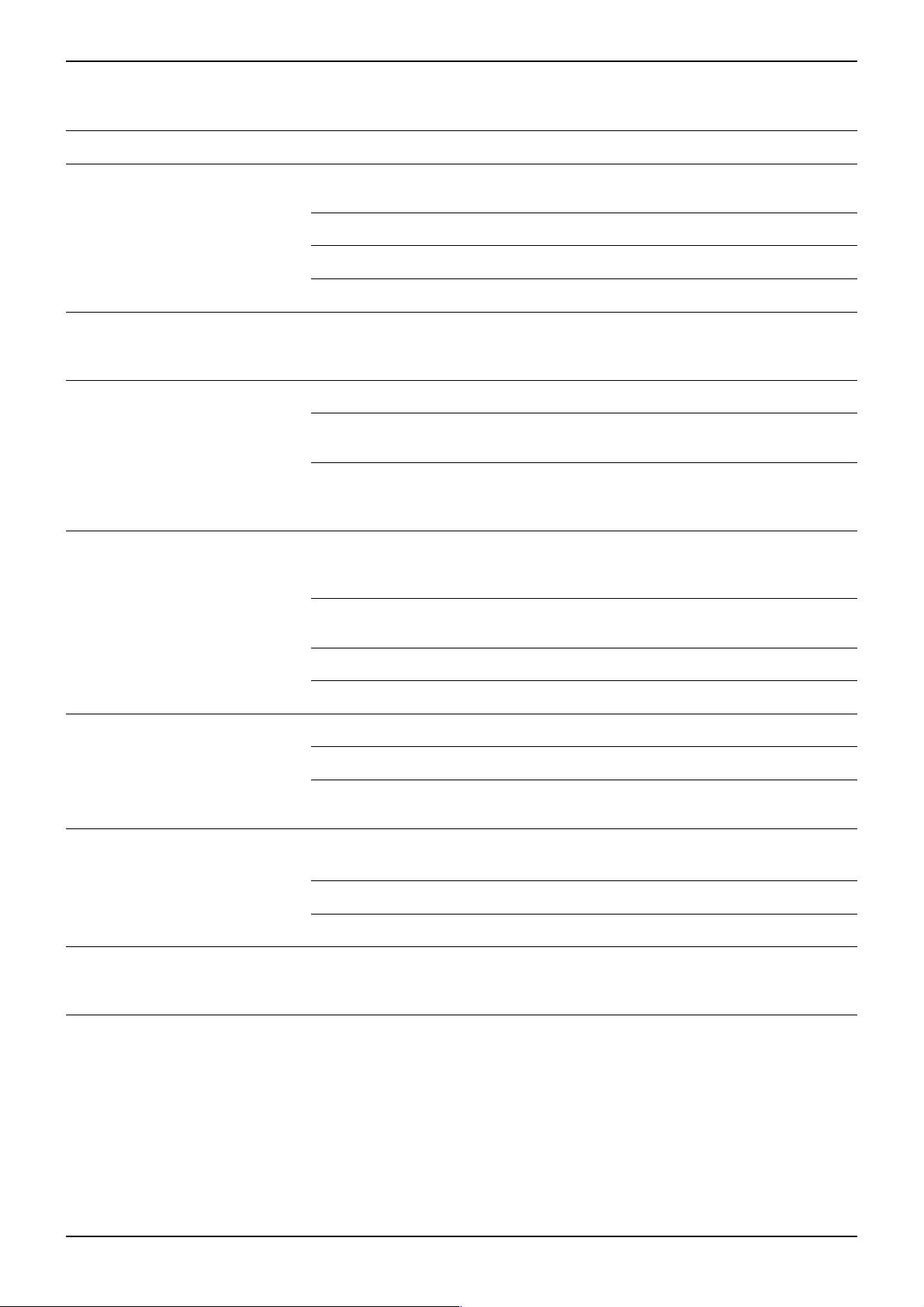

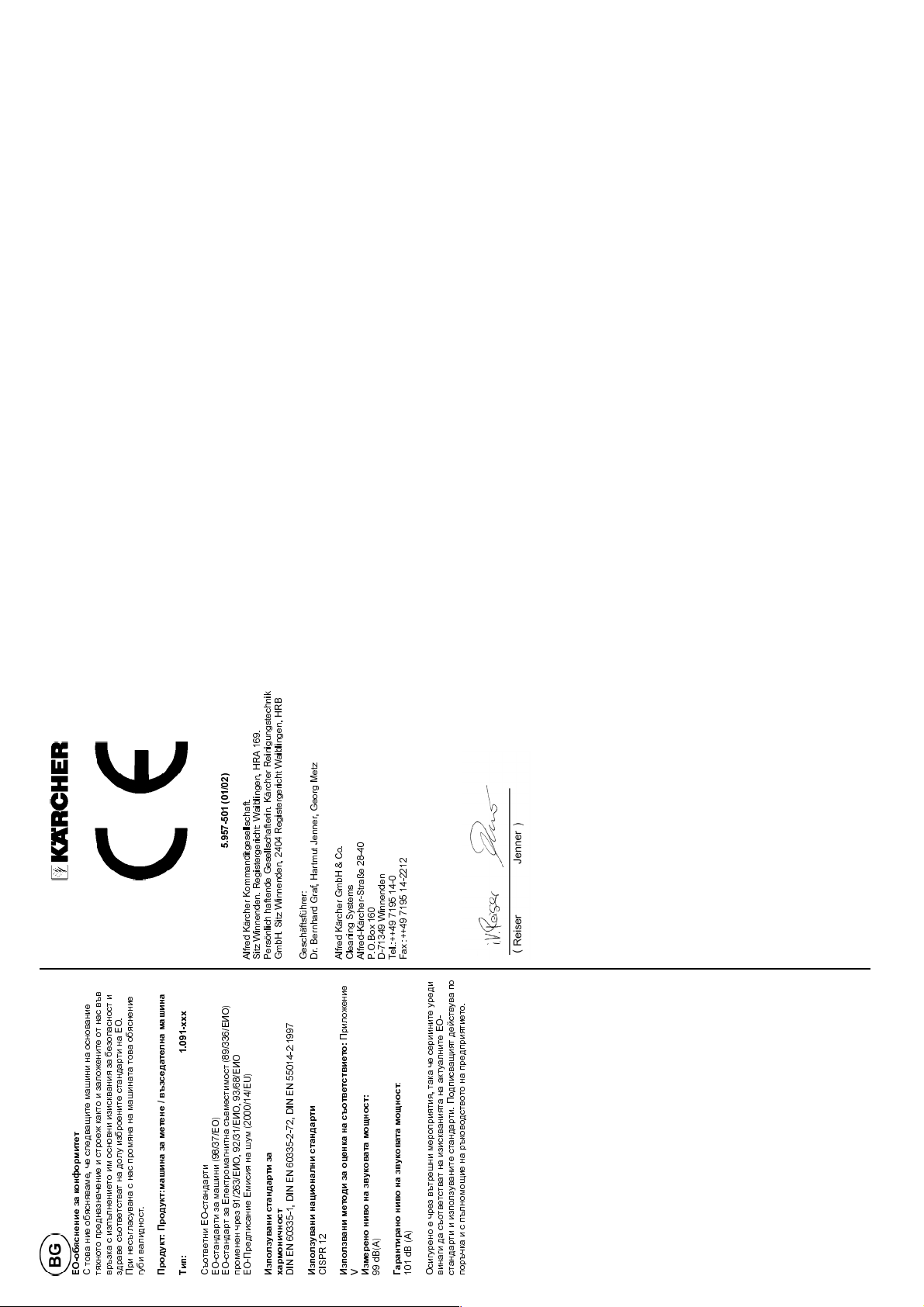

Replace light unit

46

n Stop the machine and turn it off.

n Take out the ignition key.

n Undo 6 screws S on the panel.

n Remove the panel 1.

n Unscrew the Phillips screw between the supports of the

lamp holder on the defective headlight.

n Turn the lens of the defective headlight anti-clockwise

about 1/4 of a turn 2 and take out reflector housing 3.

n Replace light unit.

n Insert reflector housing with new light unit in panel again

from below and secure with about 1/4 of a turn clockwise. Make certain it engages properly, the label

HALOGEN on the headlight glass must be able to be read

horizontally 4.

n Screw in again the screw between the supports, then

secure the panel with the 6 screws.

Page 22

KMR 1250 B User Instructions English

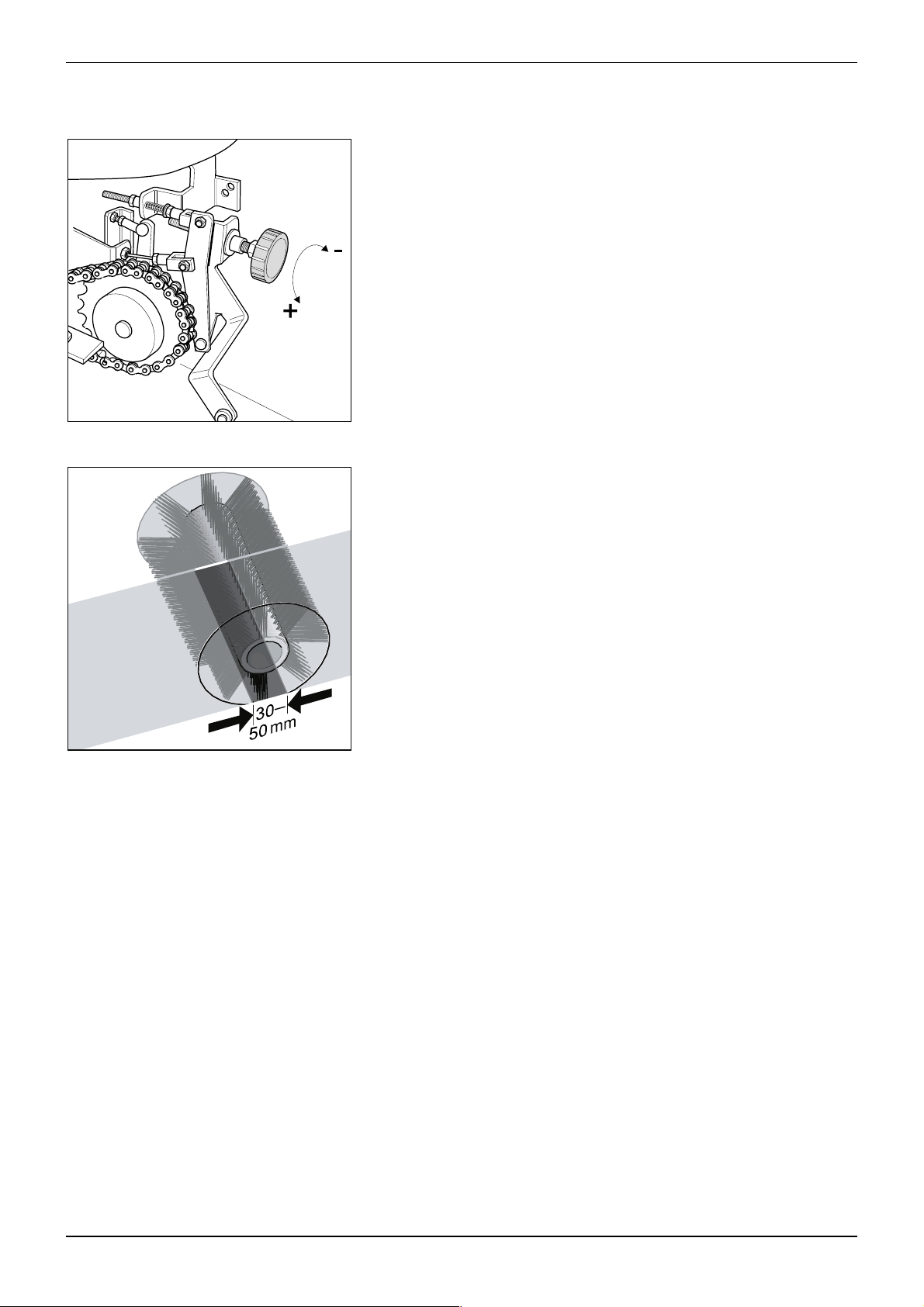

Adjusting the sweeping

pattern

(only valid for main brush roller with

”fixed setting”)

n Open the unit cover and secure it in place.

ç The sweeping pattern can be altered by turning the cen-

tral adjusting knob.

– To increase size of sweeping pattern: turn adjusting

knob counter-clockwise (towards +).

– To reduce size of sweeping pattern: turn adjusting

knob clockwise (towards –).

After any adjustments have been made, check the sweeping

pattern.

n Drive the sweeper onto a dusty surface and apply the

parking brake.

n Lower the main brush (lever set to middle position) and

allow it to brush the floor for several seconds.

n Raise the main brush and drive backwards a short di-

stance with the bulk waste flap open (first release the

parking brake).

n The width of the sweeping pattern should be 30–50 mm.

Note:

The shape of the sweeping pattern should not be trapezoidal. If it is, call customer service.

47

Page 23

English User Instructions KMR 1250 B

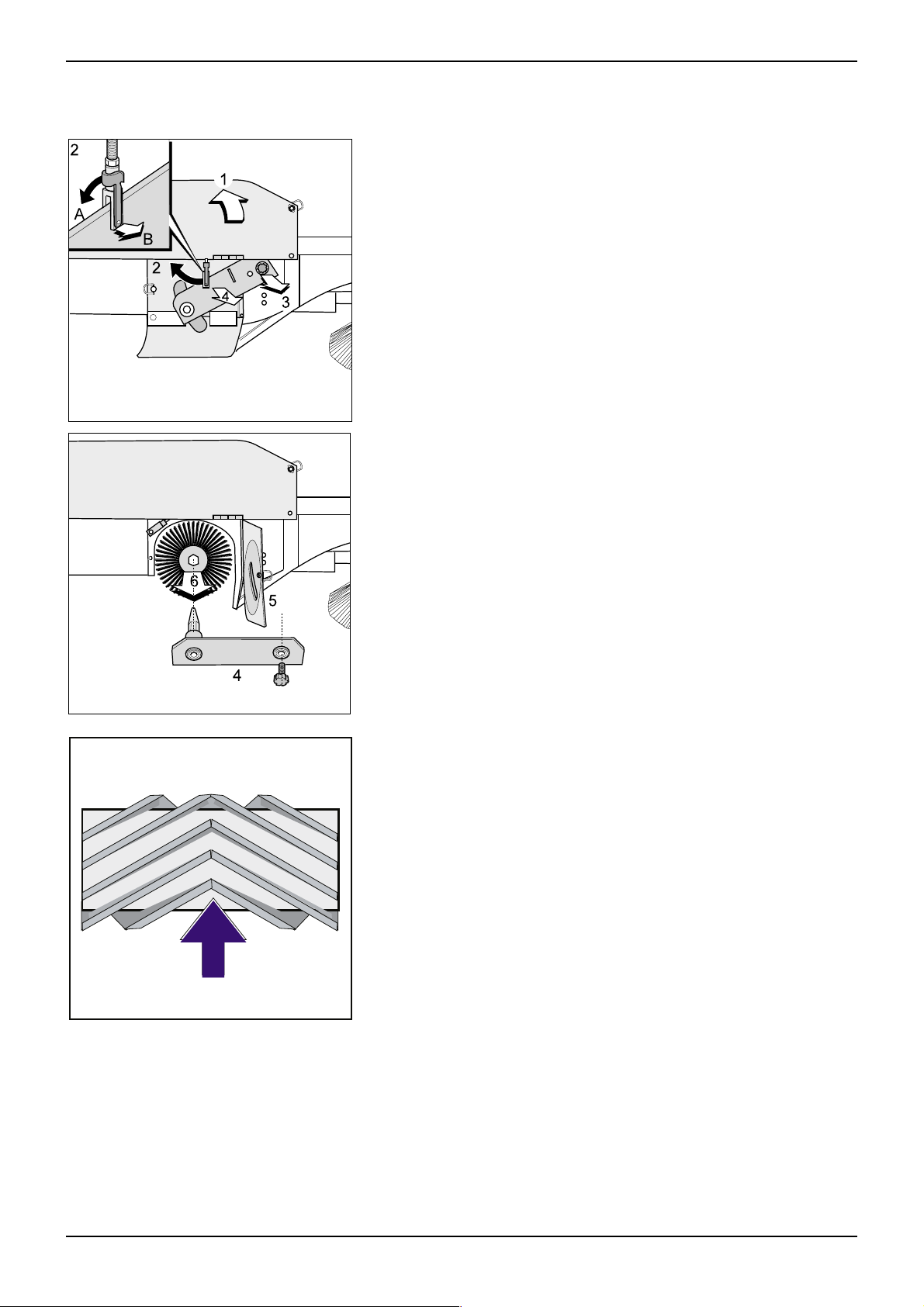

Replacing the main brush

roller

n Park the sweeper and switch off the engine

n Lower the brush roller.

n Open the RH side flap

n Undo the retaining bolt on the lower forked head

swivel the push rod towards the rear.

n Unscrew the knurled knob

n Remove the oscillating linkage

1 (seen in direction of travel).

2 and

3.

4.

Brush roller seen from above

n Open the flap over the end of the brush roller

fastener).

n Pull out the brush roller

n Screw in the knob for adjusting the sweeping pattern as

far as it will go (clockwise, towards –).

n Fit the new brush roller in reverse order to the removal

procedure.

Note:

Make sure the bristles point in the right direction – see

illustration.

n Set up the sweeping pattern by turning the adjusting knob

– see “Adjusting the sweeping pattern”.

6.

5 (turn-lock

48

Direction of travel

Page 24

KMR 1250 B User Instructions English

Replacing fuses

n Park the sweeper and switch off the engine.

n Open the unit cover.

n Replace a defective fuse with one of the same current

value.

Note:

Repeated defects of the same fuse indicate a technical fault

in the electrical system. Please call Kärcher Customer

Service.

Replacing the dust filters

The dust filters should be inspected for damage every 50

operating hours.

A significant build-up of dust at the air outlet from the fan is

a sign of a filter that is not fitted properly or is defective.

n Raise the hopper half way

n Release the catches on the filter box

n Swivel the filter box forwards and lift it off

n Open out the handle, pull it outwards and turn it through

90º (make sure it engages)

n Remove the filter cartridge

n Insert a new filter cartridge (pins should fit into the

holes)

n Set the handle back to its original position and lock it.

Make sure the filter is correctly seated.

n Mount the filter box and engage the catches.

6.

1.

2.

3.

4.

5.

49

Page 25

English User Instructions KMR 1250 B

Troubleshooting

Fault Possible cause Remedy

Engine does not start

Machine does not move

Main brush roller and side

brush

Dust generation when

sweeping

Battery discharged Re-charge or replace batteries

No fuel in tank Fill up with fuel

Fuel tap closed Open fuel tap

Low oil level Fill up with oil

Hand lever (by-pass valve) on

torque converter is at OFF

V-belt torn Inform Customer Service

V-belt to loose Check V-belt tension and

Main brush roller or side brush

blocked with tape or similar

Seals on the machine worn, filter

not installed correctly or

defective

Lever for sweeping mode

wet/dry set to wet

Set hand lever to ON - see

chapter on pushing the

sweeper by hand

adjust

Remove tape

Replace seals, mount filter

correctly/replace

Set lever to “dry”

Machine sweeps badly

High-emptying does not

function

Machine moves forwards

or backwards when drive

pedal is released

Blower fan is not rotating Check V-belt

Filter is blocked Clean or replace filter

Brushes worn out Replace

Waste hopper is full Empty waste hopper

Sweeping pattern wrongly

adjusted

Fuse defective Change fuse or inform

Switch defective Inform Customer Service

Hydraulic unit is defective Inform Customer Service

Neutral position not correct Inform Customer Service

Adjust sweeping pattern

Customer Service

50

Page 26

KMR 1250 B User Instructions English

Technical specifications

* Travel speed for driving in traffic

should be reduced from 8 to

6 km/h and a 6 km/h sign

displayed, or ABS (mounting kit)

StVZO (vehicle construction and

use regulations) (Order no.

2.638-754) displayed.

Dimensions and weights

Length 1.650 mm

Width 1.000 mm

Height 1.270 mm

Unladen weight (ready for operation) 450 kg

Max. permissible overall weight 600 kg

Driving and sweeping performance

Max. travelling speed 8 * km/h

Max. climbing ability/gradient 18 %

Effective sweeping width without side brush 750 mm

Effective sweeping width with 1 side brush 1.000 mm

Effective sweeping width with 2 side brushes1.300 mm

Area rating (theoretical)

without side brush 6.000 m²/h

with 1 side brush 8.000 m²/h

with 2 side brushes 10.400 m²/h

Waste container

Theoretical capacity 100 L

Max. usable capacity 80 L

Lifting height 1.430 mm

Filter surface area 6 m²

Sweeping unit

Brush roller with V-shaped rows of bristles

Diameter of brush roller 285 mm

Diameter of side brush 450 mm

Vehicle tyres

Pneumatic, diameter 300 mm

Type 4.00-4

Air pressure, front 6 bar

Air pressure, rear 6 bar

Lighting

Light unit DIN 49848

HS3 6V/2.4 W

Engine

Model Honda GX 270

Type 4-stroke

Cylinders 1

Capacity 270 cm³

Output (9 HP at 3600 r.p.m.) 6.6 kW

Fuel petrol, regular (lead free)

Engine oil

SAE15W40 1.1 L

Battery 12 Volt

44 Ah

51

Page 27

English User Instructions KMR 1250 B

Starter electric

Drive system

Maintenance-free, fully enclosed hydrostatically driven axle

with differential

Hydraulic fluid

Class DIN HVLP 51524/2

46 c St /40 °C

Capacity * 1.4 L

* We recommend Wintershall Wiolan HX 46 Hydraulic Fluid.

Protection type typedrip-proof IPX3

Ambient conditions

- temperature -5 to + 40 °C

- air humidity, not wet with dew 0 – 90 %

Operating cycle

Under favourable conditions, the sweeper has an operating

cycle of 3 hours with a full fuel tank at the start. The actual

time is dependent upon several factors:

– surface structure of the ground and how level it is

– how well the sweeper has been maintained

– type of brush roller and its degree of wear.

Noise emission

Sound level (EN 60704-1) 79 dB(A)

Guaranteed noise level

(2000/14/EC) 101 dB(A)

Machine vibration

Rated vibration value

(ISO 5349) < 2,5 m/s²

52

Page 28

KMR 1250 B

1.091-104.0

1.091-124.0

7.654-002.0

6.348-316.0

24V 30A Wa

>>MICROMP<< LADETECHNIK

6.654-116.0

6.618-090.0

6.491-500.0

6.491-514.0

6.414-532.0

6.491-566.0

6.348-337.0

6.435-295.0

6.435-331.0

KMR

0

5

2

1

6.435-289.0

7.651-002.0

6.651-382.0

KARCHER

6.491-596.0

6.682-378.0

6.435-288.0

6.435-331.0

6.435-295.0

6.303-058.0

6.303-125.0

5.031-452.0

7.644-017.0

7.644-007.0

6.644-277.0

7.644-018.0

6.905-986.0

7.312-003.0

7.313-003.0

7.306-501.0

06/99 - S 1/2

Page 29

KMR 1250 B

1.091-104.0

1.091-124.0

KMR

0

5

2

1

KARCHER

5.190-083.0

5.365-215.0

5.190-084.0

4.038-524.0

5.190-055.0

5.394-439.0

5.190-082.0

5.190-089.0

5.365-216.0

5.031-378.0

5.190-084.0

6.905-982.0

5.190-082.0

5.190-083.0

5.365-215.0

06/99 - S 2/2

Page 30

DECLARACIÓN DE CONFORMIDAD DE LA UNIÓN EUROPEA

Por la presente declaramos los abajo firmantes que la máquina

designada a continuación cumple, tanto por su concepción y clase de

DÉCLARATION DE CONFORMITÉ EUROPÉENNE

Par la présente, nous déclarons que la machine ci-après répond, de par

sa conception et sa construction ainsi que de par le modèle que nous

construcción como por la ejecución que hemos puesto en circulación,

avons mis sur le marché, aux exigences de sécurité et d’hygiène en

las normas fundamentales de seguridad y protección de la salud

formuladas en las directivas comunitarias correspondientes.

La presente declaración pierde su validez en caso de alteraciones en la

máquina efectuadas sin nuestro consentimiento explícito.

Producto: Barredora de suelos

Modelo: 1.091-xxx

Directivas comunitarias aplicables:

Directiva comunitaria sobre máquinas (98/37/EG)

Directiva sobre compatibilidad electromagnética (89/336/EWG)

vigueur de la directive européenne.

En cas de modification de la machine effectuée sans notre accord, cette

déclaration sera caduque.

Produit: Balayeuse / machine autoporteuse

Type: 1.091-xxx

Directives européennes en vigueur:

Directive européenne sur les machines (98/37/EG)

Directive européenne sur la compatibilité électromagnétique

(89/336/EWG) modifiée par 91/263/EWG, 92/31/EWG, 93/68/EWG

Directive CE relative aux émissions sonores (2000/14/UE)

modificada mediante 91/263/EWG, 92/31/EWG, 93/68/EWG

Normativa UE sobre emisiones de ruidos (2000/14/EU)

Normes harmonisées appliquées:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Normas armonizadas aplicadas:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Normes nationales appliquées:

CISPR 12

Normas nacionales aplicadas:

CISPR 12

Proceso de valoración de conformidad utilizado

Procédure d’analyse de conformité utilisée

Annexe V

Anexo V

Nivel de potencia acústica medido:

99 dB(A)

Niveau de puissance sonore mesuré:

99 dB(A)

Niveau de puissance sonore garanti:

Nivel de potencia acústica garantizado:

101 dB(A)

101 dB(A)

La conformité permanente des appareils de série avec les exigences

consignées dans les directives actuelles de la CE et avec les normes

Mediante una serie de medidas internas, queda asegurado que los

aparatos y equipos de serie cumplan siempre las exigencias formuladas

appliquées est garantie par des mesures internes.

Les soussignés agissent par ordre et avec les pleins pouvoirs de la

en las directivas comunitarias actuales y en las normas

correspondientes a aplicar.

Los firmantes actúan autorizados y con poder otorgado por la dirección

Direction commerciale.

de la empresa

EU DECLARATION OF CONFORMITY

We hereby declare that the equipment described below conforms to the

relevant fundamental safety and health requirements of the appropriate

EU Directives, both in its basic design and construction as well as in the

version marketed by us.

This declaration will cease to be valid if any modifications are made to

the machine without our express approval.

Product: Sweeper / Ride-on unit

Model: 1.091-xxx

Relevant EU Directives:

EU Machinery Directive (98/37/EG)

EG - KONFORMITÄTSERKLÄRUNG

Hiermit erklären wir, daß die nachfolgend bezeichnete Maschine

aufgrund ihrer Konzipierung und Bauart sowie in der von uns in Verkehr

gebrachten Ausführung den einschlägigen grundlegenden Sicherheits-

und Gesundheitsanforderungen den unten aufgeführten EG-Richtlinien

entspricht. Bei einer nicht mit uns abgestimmten Änderung der

Maschine verliert diese Erklärung ihre Gültigkeit.

Produkt:Kehrsaugmaschine / Aufsitzgerät

Typ: 1.091-xxx

Einschlägige EG-Richtlinien

EG-Maschinenrichtlinie (98/37/EG)

EU Directive on Electromagnetic Compatibility (89/336/EWG)

amended by 91/263/EWG, 92/31/EWG, 93/68/EWG

EU guideline on noise emissions (2000/14/EU)

Harmonised standards applied:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Relevant EU Directives:

CISPR 12

EG-Richtlinie Elektromagnetische Verträglichkeit (89/336/EWG)

geändert durch 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-Richtlinie über Geräuschemissionen (2000/14/EU)

Angewandte harmonisierte Normen:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Angewandte nationale Normen:

CISPR 12

Angewandtes Konformitäts- Bewertungsverfahren

Applied conformity valuation method

Appendix V

Measured noise level:

99 dB(A)

Anhang V

Gemessener Schallleistungspegel:

99 dB(A)

Guaranteed noise level:

Garantierter Schallleistungspegel:

101 dB(A)

101 dB(A)

Appropriate internal measures have been taken to ensure that series-

production units conform at all times to the requirements of current EU

Prüfgrundsätze des Hauptverbandes der gewerblichen

Berufsgenossenschaft Kehrsaugmaschinen

Es ist durch interne Maßnahmen sichergestellt, daß die Seriengeräte

Directives and relevant standards.

immer den Anforderungen der aktuellen EG-Richtlinien und den

The signatories are empowered to represent and act on behalf of the

angewandten Normen entsprechen.

company management.

Die Unterzeichnenden handeln im Auftrag und mit Vollmacht der

Geschäftsführung.

Page 31

Izjava o sukladnosti s EU

Ovime izjavljujemo da niže opisani stroj na temelju svoje koncepcije i

izvedbe kao i naša izvedba koju smo dali u prodaju odgovara

relevantnim osnovnim sigurnosnim i zdravstvenim zahtjevima niže

navedenih odredaba Europske unije. U slučaju izmjene na stroju koja

nije dogovorena s nama, ova izjava gubi svoju valjanost.

Proizvod: Stroj za smeæe / stroj s vozaèkim sjedalom

Tip: 1.091-xxx

Relevantne odredbe Europske unije

Odredbe o strojevima Europske unije (98/37/EU)

EU-odredbe o elektromagnetskoj kompatibilnosti (89/336/EWG)

zamijenjene sa 91/263/EWG, 92/31/EWG, 93/68/EWG

Odredbe EU emisija buke (2000/14/EU)

Primijenjene usklađene norme

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Primijenjene nacionalne norme

CISPR 12

Primijenjeni postupak procjene konformnosti:

Dodatak V

Izmjerena razina buke:

99 dB(A)

Zajamčena razina buke:

101 dB (A)

Internim mjerama osigurano je da serijski uređaji uvijek odgovaraju

zahtjevima aktualnih odredaba Europske unije i primijenjenim normama.

Niže potpisani djeluju na osnovu naloga i punomoći uprave.

Prehlásenie o zhode ES

Týmto prehlasujeme, že tento uvedený prístroj na základe svojej

koncepcie a typu konštrukcie i v typu, ktorý sme uviedli do prevádzky,

zodpovedá základným príslušným bezpečnostným a zdravotným

požiadavkám dolu uvedených smerníc Európskych spoločenstiev.

V prípade zmeny, ktorú neschválime, stráca toto prehlásenie platnosť.

Produkt: Zametací stroj / stroj so sedadlom

Typ: 1.091-xxx

Príslušné smernice ES

Strojárenské smernice ES (98/37/EG)

Smernice ES Elektromagnetická kompatibilita (89/336/EWG)zmenené

na základe 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-Smernica vyžarovanie hluku (2000/14/EU)

Izjava o konformnosti ES

S tem izjavljamo, da stroj, označen v nadaljevanju na podlagi koncepta

in načina izdelave ter izvedbe, ki jo s tem dajemo v promet, zadošča

ustreznim varnostnim in zdravstvenim zahtevam smernic ES, ki so

navedene spodaj. V primeru izvajanja samovoljnih sprememb na stroju

brez našega dovoljenja je ta izjava neveljavna.

Izdelek: Pometalni stroj z sedežem šoferja

Tip: 1.091-xxx

Ustrezne smernice ES

Strojne smernice ES (98/37/ES)

ES (89/336/EGS) spremenjena s 91/263/EGS, 92/31/EGS, 93/68/EGS

Smernica EU glede emisij hrupa (2000/14/EU)

1.091-xxx

Použité harmonizačné normy

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Uporabljeni usklajeni standardi

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Použité národné normy

Uporabljeni nacionalni standardi

CISPR 12

CISPR 12

Použitá metóda ocenenia zhody:

Príloha V

Uporabljen postopek o ocenitvi skladnosti

Dodatek V

Nameraná hladina akustického výkonu:

Izmerjen nivo proizvedenega hrupa:

99 dB(A)

99 dB(A)

Garantovaná hladina akustického výkonu:

Zagotovljen nivo proizvedenega

hrupa:

101 dB (A)

Na základe vnútorných opatrení je zaistené, že sériové prístroje

zodpovedajú vždy požiadavkám aktuálnych smerníc ES a použitým

101 dB (A)

Z internimi ukrepi zagotavljamo, da serijske naprave vedno ustrezajo

aktualnim zahtevam smernic ES in uporabljenim standardom.

normám. Dolu podpísaní jednajú z poverenia a na základe plnej moci

Podpisniki ravnajo po naročilu in s pooblastilom poslovodstva.

vedenia podniku.

Дюлщуз рйуфьфзфбò åê

ЕмеЯт, дзлюнпхме ìå ôçí рбспэуб, üôé ôï мзчЬнзмб ðïõ

чбсбкфзсЯжефбé рбсбкЬфщ, ëüãù ôïõ óчедйбумпэ êáé ôïõ

фсьрпх кбфбукехЮт, üðùò êáé ëüãù ôçò рбсбллбгЮт ðïõ

äéáôЯиефбй áðü ìáò óôçí бгпсЬ, бнфбрпксЯнефбé óôéò ó÷åôéêÝò

âбуйкЭт брбйфЮуейт буцблеЯбт êáé хгеЯбт ôùí Пдзгйюн ÅÊ. Óå

ресЯрфщуз бллбгюн óôï мзчЬнзмб чщсЯт рспзгпэменç

ухнненьзуз ìáæß ìáò, рбэей íá йучэей ç рбспэуб дЮлщуз.

Рспъьí: МзчбнéêÞ óêïýðá/ МзчбнЮ кбибсйумпэ ìå èÝóç ãéá ôïí

ïäçãü

Ôýðïò:

Ó÷åôéêýò ПдзгЯет ÅÊ:

ПдзгЯб ÅÊ учефйкЬ ìå ôéò мзчбнЭт (98/37/EG)

ПдзгЯб ÅÊ ðåñß злекфспмбгнзфйкЮт óõìâбфьфзфпт (89/336/EWG)

ðïõ фспрпрпйЮизке ìå ôçí ПдзгЯб 91/263/EWG, 92/31/EWG,

93/68/EWG

ПдзгЯб ÅÊ ðåñß ЕкрпмрÝò ипсэвùí (2000/14/EÅ)

ЕнбсмпнйумЭнб ðñüôõðá ðïõ Эчпхн åöáсмпуиåß:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

ЕинйкЬ рсьфхрб ðïõ Эчпхн ецбсмпуиеЯ:

CISPR 12

ЕцбсмпуиеЯуб мЭипдпт áîéпльгзузт óõììüñöùóçò

РбсЬсфзмб V

Мефсзиåßóá уфЬимз бкпхуфйкЮт рЯеузт:

99 dB(A)

ДйбуцблйумЭнз уфЬимз бкпхуфйкЮт рЯеузт:

101 dB(A)

Ìå лзциЭнфб еущфесйкЬ мЭфсб Ý÷åé еобуцблйуиеЯ, üôé ïé

ухукехЭт уейсЬт кбфбукехЮт бнфбрпксЯнпнфбé рЬнфб óôéò

брбйфЮуейт ôùí ерйкбЯсщн пдзгйюн ÅÊ êáé óôá ецбсмпуиЭнфб

рсьфхрб. Ïé хрпгсЬцпнфет енесгпэн ìå енфплЮ êáé кбфьрйí

еопхуйпдьфзузт ôçò ГенйкЮт Дйеэихнузт.

Page 32

5.957-501 (01/02)

Alfred Kärcher Kommanditgesellschaft.

Sitz Winnenden. Registergericht: Waiblingen, HRA 169.

Persönlich haftende Gesellschafterin. Kärcher Reinigungstechnik

GmbH. Sitz Winnenden, 2404 Registergericht Waiblingen, HRB

Geschäftsführer:

Dr. Bernhard Graf, Hartmut Jenner, Georg Metz

Alfred Kärcher GmbH & Co.

Cleaning Systems

Alfred-Kärcher-Straße 28-40

P.O.Box 160

D-71349 Winnenden

Tel.:++49 7195 14-0

Fax :++49 7195 14-2212

Приложение

ЕО-обяснение за конформитет

С това ние обясняваме, че следващите машини на основание

тяхното предназначение и строеж както и заложените от нас във

връзка с изпълнението им основни изисквания за безопасност и

здраве съответстват на долу изброените стандарти на ЕО.

При несъгласувана с нас промяна на машината това обяснение

губи валидност.

Продукт: Продукт:машина за метене / възседателна машина

Тип: 1.091-xxx

Съответни ЕО-стандарти

ЕО-стандарти за машини (98/37/ЕО)

ЕО-стандарт за Електромагнитна съвместимост (89/336/ЕИО)

променен чрез 91/263/ЕИО, 92/31/ЕИО, 93/68/ЕИО

ЕО-Предписание Емисия на шум (2000/14/EU)

Използувани стандарти за

хармоничност

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 55014-2:1997

Използувани национални стандарти

CISPR 12

Използвани методи за оценка на съответствието:

V

Измерено ниво на звуковата мощност:

99 dB(A)

Гарантирано ниво на звуковата мощност: 101 dB (A)

Осигурено е чрез вътрешни мероприятия, така че сериините уреди

винаги да съответстват на изискванията на актуалните ЕО-

стандарти и използуваните стандарти. Подписващият действува по

поръчка и с пълномощие на ръководството на предприятието.

Loading...

Loading...