Page 1

HD 3.5/30-4S Ea

English 3

Français 14

Español 26

Register and win!

www.kaercher.com

59658310 04/13

Page 2

2

Page 3

IMPORTANT SAFETY IN-

STRUCTIONS

몇 WARNING

When using this product basic precautions should always be followed, including the following:

1 Read all the instructions before us-

ing the product.

2 High pressure jets can be danger-

ous if misused. The jet must not be

directed at persons, animals, electrical devices, or the unit itself.

3 To reduce the risk of injury, close

supervision is necessary when a

product is used near children.

4 Know how to stop the product and

bleed pressures quickly. Be thoroughly familiar with the controls.

5 Stay alert – watch what you are do-

ing.

6 Wear safety goggles.

7 Do not use acids, alkaline, solvents,

or any flammable material in this

product. These products can cause

physical injuries to the operator and

irreversible damage to the ma-

chine.

8 Do not operate the product when fa-

tigued or under the influence of al-

cohol or drugs.

9 Do not overreach or stand on unsta-

ble support. Keep good footing and

balance at all times.

10 To reduce the risk of electrocution,

keep all connections dry and off the

ground. Do not touch plug with wet

hands.

11 The Trigger Gun Safety Lock pre-

vents the trigger from accidentally

being engaged. This safety feature

DOES NOT lock trigger in the ON

position.

12 Keep operating area clear of all per-

sons.

13 Follow the maintenance instruc-

tions specified in the manual.

14 This product is provided with a

Ground Fault Circuit Interrupter

built into the power cord plug. If replacement of the plug or cord is

needed, use only identical replacement parts.

15

Risk of Injection or Injury – Do Not Direct Discharge Stream At Persons.

16 Do not use extension cord with this

product.

몇 Warning

To reduce the risk of electrocution,

keep all connections dry and off the

ground. Do not touch plug with wet

hands.

GROUNDING INSTRUCTIONS

This product must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This product

is equipped with a cord having an

equipment-grounding conductor and a

grounding plug. The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and ordinances.

DANGER

Improper connection of the equipmentgrounding conductor can result in a

risk of electrocution. Check with a qualified electrician or service personnel if

you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product - if it

will not fit the outlet, have a proper outlet installed by a qualified electrician.

Do not use any type of adapter with this

product.

– 1

3EN

Page 4

GROUND FAULT CIRCUIT IN-

TERRUPTER PROTECTION

This Product is supplied with a Ground

Fault Circuit Interrupter (GFCI) built

into the power cord plug. This device

provides additional protection from the

risk of electric shock. If power is interrupted in the line, the GFCI will automatically re-close the circuit to the load

after power is restored. Depending on

the GFCI model, it may be necessary

to manually operate the reset button to

restore power to the GFCI load circuit.

If the replacement of the plug or cord is

needed use identical replacement

parts.

WATER SUPPLY

(Cold Water Only)

몇 CAUTION

When connecting the water inlet to the

water supply mains, local regulations

of your water company must be observed. In some areas the unit must

not be connected directly to the public

drinking water supply. This is to ensure

that there is no feedback of chemicals

into the water supply. Direct connection via a receiver tank or backflow preventer, for example, is permitted.

Dirt in the feed water will damage the

unit. To avoid this risk, we recommend

fitting a water filter.

– Never use the pressure washer to

draw in water contaminated with

solvents, e.g. paint thinners, gaso-

line, oil, etc.

– Always prevent debris from being

drawn into the unit by using a clean

water source. Use additional water

filter.

Please read and comply with

these original instructions

prior to the initial operation of your appliance and store them for later use or

subsequent owners.

Contents

Device elements . . . . . . . . . EN . . 2

Safety instructions . . . . . . . . EN . . 3

Proper use. . . . . . . . . . . . . . EN . . 3

Safety Devices . . . . . . . . . . EN . . 3

Environmental protection. . . EN . . 4

Before Startup . . . . . . . . . . . EN . . 4

Start up . . . . . . . . . . . . . . . . EN . . 4

Operation. . . . . . . . . . . . . . . EN . . 6

Transport . . . . . . . . . . . . . . . EN . . 8

Storage . . . . . . . . . . . . . . . . EN . . 8

Maintenance and care. . . . . EN . . 8

Troubleshooting. . . . . . . . . . EN . . 9

Accessories and Spare Parts EN . 10

Warranty . . . . . . . . . . . . . . . EN . 10

Technical specifications. . . . EN . 11

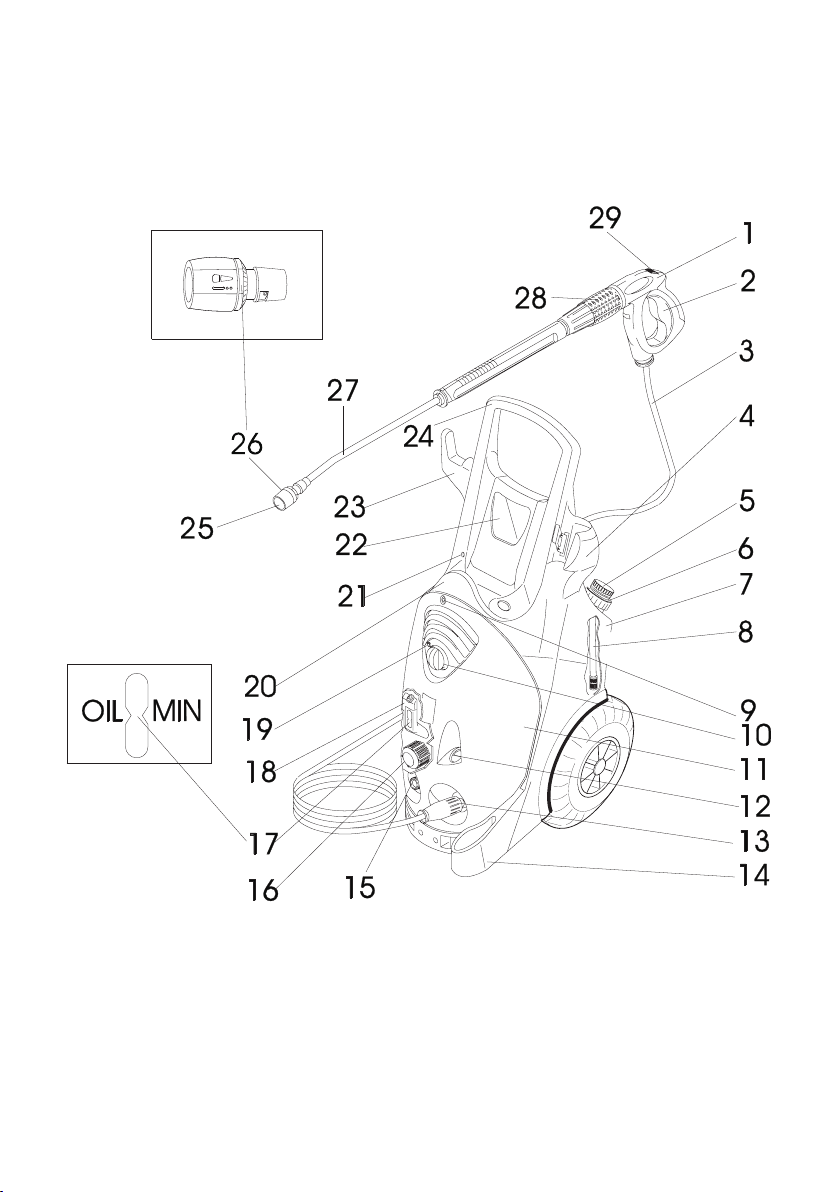

Device elements

Please unfold the front picture side

1 Hand blowing gun

2 Lever for hand spray gun

3 High pressure hose

4 Storage for hand spray gun

5 Dosage valve for detergent

6 Detergent tank lid

7 Detergent Tank

8 Detergent suction hose with deter-

gent filter and lid

9 Fastening screw for device hood

10 Power switch

11 Cover

12 Manometer

13 High pressure connection

14 Nozzle holder

15 Water connection

16 Fine filter

17 Oil level indicator

4 EN

– 2

Page 5

18 Oil tank

19 Indicator lamp

20 Storage compartment for hoses

21 Deaerating the detergent tank

22 Accessory compartment

23 Cable clamp

24 Handle

25 Nozzle

26 Marking of the nozzle

27 Spray lance

28 Pressure and volume regulation

29 Safety lever

Colour coding

– The operating elements for the

cleaning process are yellow.

– The controls for the maintenance

and service are light gray.

Safety instructions

– Before first start-up it is definitely

necessary to read the operating instructions and safety indications Nr.

5.951-949.0!

– Please follow the national rules and

regulations for fuel spray jets of the

respective country.

– Please follow the national rules and

regulations for accident prevention

of the respective country. Fuel

spray jets must be tested regularly

and the results of these tests must

be documented in writing.

Symbols in the operating in-

structions

Caution

Possible hazardous situation that

could lead to mild injury to persons or

damage to property.

Symbols on the machine

High-pressure jets can be

dangerous if improperly

used. The jet may not be directed at persons, animals, live electrical equipment or at the appliance itself.

According to the applicable

regulations, the appliance

must never be used on the

drinking water net without a system

separator. Use a suitable system separator manufactured by Kärcher; or, as

an alternative, a system separator as

per EN 12729 Type BA.

Water flowing through a system separator is considered non-drinkable.

Proper use

Use this high pressure cleaner exclusively for

– Cleaning using low pressure jet and

detergent (for e.g. for cleaning machines, cars, buildings, tools),

– For cleaning using high pressure jet

without detergent (for e.g. for cleaning facades, terraces, garden appliances).

For stubborn dirt, we recommend the

use of the dirt blaster as a special accessory.

Safety Devices

Danger

Immediate danger that can cause severe injury or even death.

몇 Warning

Possible hazardous situation that

could lead to severe injury or even

death.

Safety devices serve for the protection

of the user and must not be put out of

operation or bypassed with respect to

their function.

– 3

5EN

Page 6

Overflow valve with pressure

switch

While reducing the water supply/quantity

regulation at the pump head, the overflow valve opens and part of the water

flows back to the pump suck side.

If the lever on the trigger gun is released the pressure switch turns off the

pump, the high pressure jet is stopped.

If the lever is pulled the pump is turned

on again.

The overflow valve and pressure

switch are set and sealed at the factory. Setting only by customer service.

Environmental protection

The packaging material can

be recycled. Please do not

throw the packaging material into household waste;

please send it for recycling.

Old appliances contain

valuable materials that can

be recycled; these should

be sent for recycling. Batteries, oil, and similar substances must not enter the

environment. Please dispose of your old appliances

using appropriate collection

systems.

Before Startup

Unpacking

– Check the contents of the pack be-

fore unpacking.

– In case of transport damage inform

vendor immediately

Check oil level

Read the oil level display when the

device is not running. The oil level

must be above the two pointers.

Activate deaeration of oil container

Unscrew the fastening screws of the

device hood; remove the device hood.

Cut off tip of oil container cover

Fasten the device hood.

Attaching the Accessories

Mount the nozzle on the spray pipe

(markings on the adjustment ring at

the top).

Install spray pipe on the hand-spray

gun with pressure and volume regulation.

Lock in the cable hook in the side-

hole on the handle.

Fasten the high pressure hose to

the high pressure connection.

Start up

Electrical connection

Please do not release engine oil, fuel

oil, diesel and petrol into the environment Protect the ground and dispose

of used oil in an environmentallyclean manner.

Notes about the ingredients

(REACH)

You will find current information about

the ingredients at:

www.kaercher.com/REACH

6 EN

몇 Danger

Danger of injury by electric shock.

The appliance may only be connected to

an electrical supply which has been installed in accordance with IEC 60364.

The voltage indicated on the type plate

must correspond to the voltage of the

electrical source.

The minimum fuse rating required at

the socket outlet is (see technical

specifications).

– 4

Page 7

The appliance should always be connected to the electrical mains using a

plug. It is forbidden to permanently connect the appliance to the power supply.

The plug is only for mains separation.

Check the power cord with mains plug

for damage before every use. If the

power cord is damaged, please arrange immediately for the exchange by

an authorized customer service or a

skilled electrician.

The plug and coupling of the extension

cable used must be watertight.

Use the extension cord that has an adequate cross-section (see "Technical

Data") and unwind it fully from the cable drum.

Unsuitable extension cables can be

hazardous. Only use extension cables

outdoors which have been approved

for this purpose and labelled with a sufficient cable cross section:

For connection values, see type plate/

technical data.

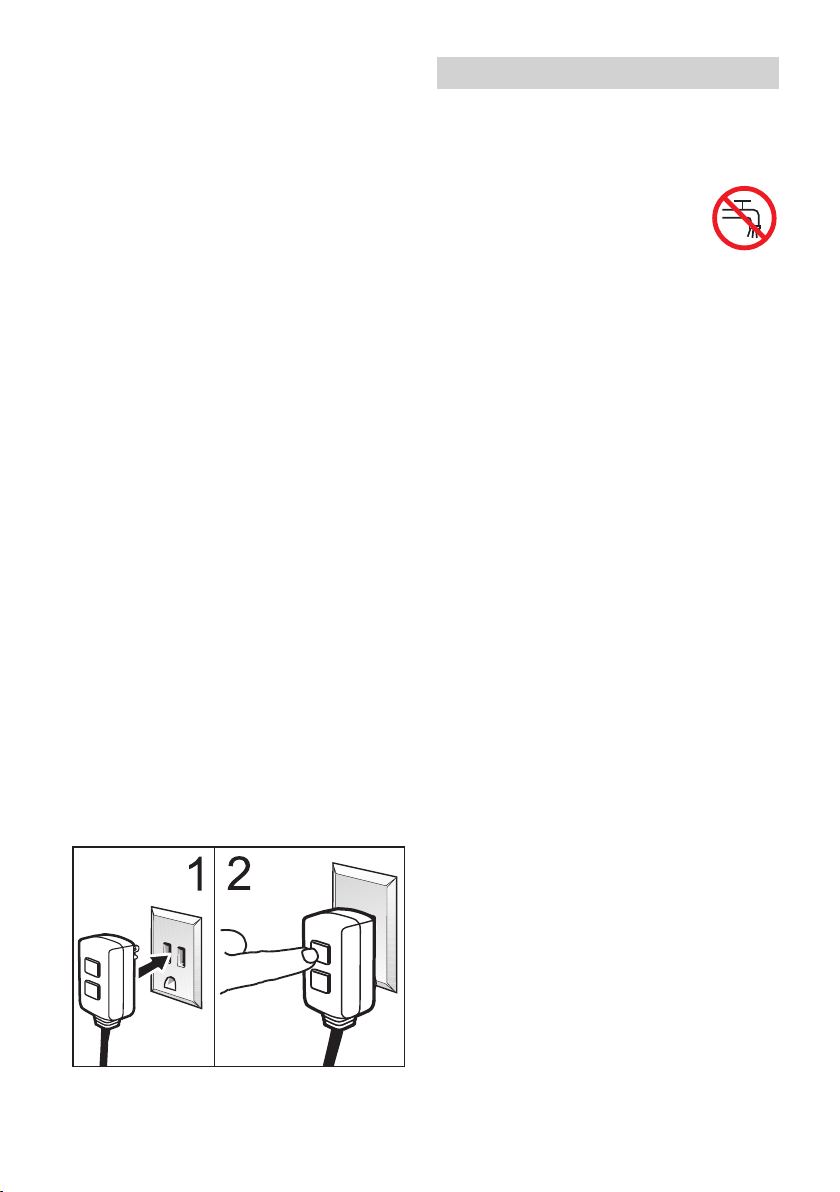

GFCI INSTRUCTIONS

– STEP 1: Plug the Ground Fault Cir-

cuit Interrupter (GFCI) into a working outlet.

– STEP 2: Press ’’TEST’’, then press

’’RESET’’ to assure proper connection to power.

Note: The actual appearance of the

GFCI may be different from this illustration.

Water connection

Connection to the water supply

몇 Warning

Observe regulations of water supplier.

According to the applicable

regulations, the appliance

must never be used on the

drinking water supply without a system

separator. Use a suitable system separator manufactured by KÄRCHER; or,

as an alternative, a system separator

as per EN 12729 Type BA. Water flowing through a system separator is considered non-drinkable.

Caution

Always connect the system separator

to the water supply, never directly to

the appliance!

For connection values refer to technical specifications

Connect the supply hose (minimum

length 7.5 m, minimum diameter 3/

4“) to the water connection point of

the machine and at the water supply point (for e.g. a tap).

Note

The supply hose is not included.

Open the water supply.

Drawing in water from open reservoirs

Screw the suction hose with filter

(order no. 4.440-238.0) to the water

connection.

Deaerate the appliance:

Unscrew the nozzle.

Switch on the appliance and let it run

until the water exiting is bubble-free.

At the end let the appliance run for

approx. 10 seconds - then switch

off. Repeat the procedure for a couple of times.

Switch off the appliance and fit the

nozzle again.

– 5

7EN

Page 8

Operation

Danger

Risk of explosion!

Do not spray flammable liquids.

If the appliance is used in hazardous

areas (e.g. filling stations) all of the

safety provisions and operating instructions detailed in this manual must

be observed.

Caution

Clean engines only at places with corresponding oil separators (environmental safety).

High pressure operation

Note

The appliance is equipped with a pressure switch. The motor starts up only

when the lever of the pistol is pulled.

Set the appliance switch to "I".

The indicator lamp glows green.

Unlock the hand-spray gun and pull

the lever of the gun.

Set working pressure and water

quantity by turning (rungless) at the

pressure and quantity regulation (+/

-).

For transporting small quantities, the

engine heat ensures that water is heated up to approx. 15 °C.

Select spray type

Close the hand spray gun.

Turn the casing of the nozzle till the

desired symbol matches the marking.

Select round or flat spray using

touch-less switching:

Turn the spray-pipe that is inclined

about 45° downward to the left or

the right.

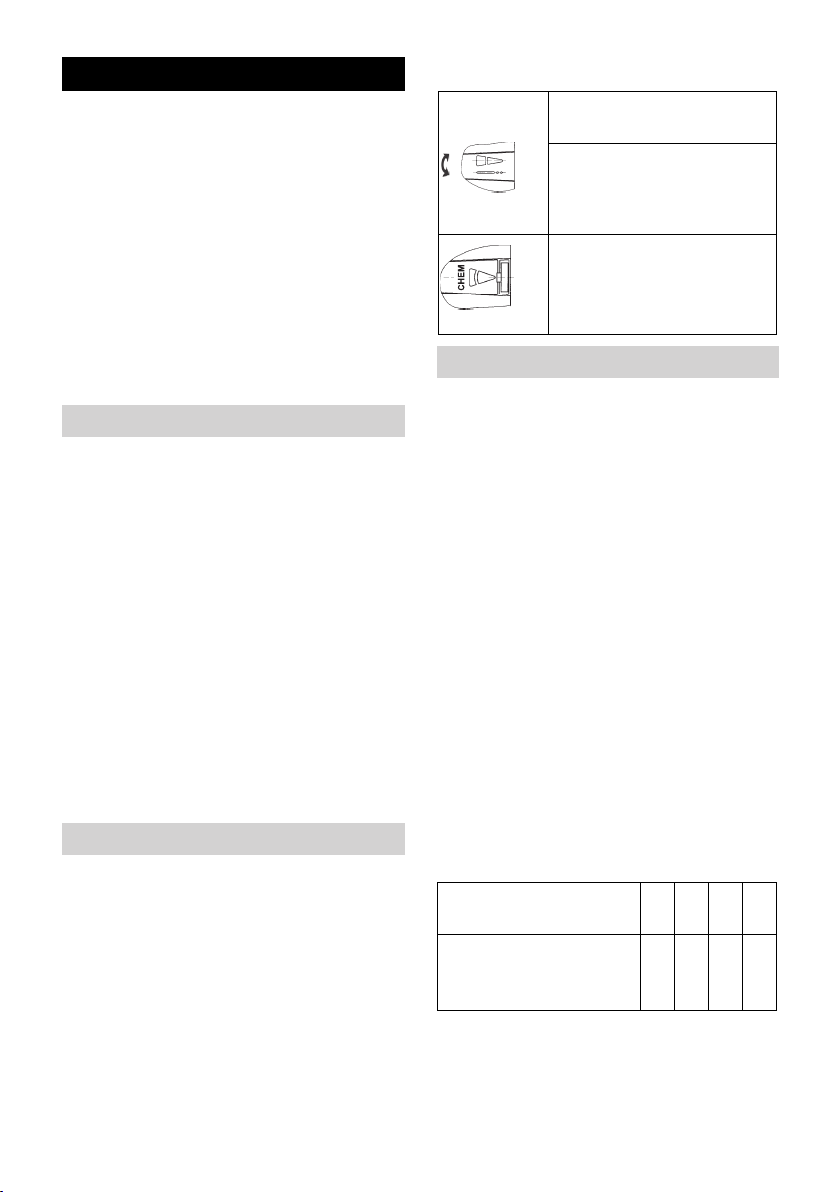

Meaning of the symbols

High pressure flat spray

(25°) for large dirt areas

High pressure circular

spray (0°) for specially

stubborn dirt

Flat low pressure spray

(CHEM) for operating using detergents or cleaning at low pressure.

Operation with detergent

몇 Warning

Unsuitable detergents can cause damage to the appliance and to the object

to be cleaned. Use only those detergents that have been approved by

Kärcher. Observe the dosage and other instructions provided with these detergents. For considerate treatment of

the environment use detergent economically.

Follow the safety instructions for using

detergents.

Kärcher detergents ensure smooth

functioning. Please consult us or ask

for our catalogue or our detergent information sheets.

Fill detergent tank.

Set nozzle to "CHEM".

Set dosing value for detergent to

the desired concentration.

Position of the dosing

valve

Detergent concentration [%]

(for max. flow quantity)

Recommended cleaning method

Spray the detergent sparingly on

the dry surface and allow it to react,

but not to dry.

1357

0,5 2,5 5,0 7,0

8 EN

– 6

Page 9

Spray off loosened dirt with the

high-pressure ray.

Set dosing value for detergent to "0"

after operation with cleaners. Start

the appliance and rinse for one minute with clear water with an open

hand spray gun.

Interrupting operation

Release the lever of the hand-spray

gun; the device will switch off.

Release again the lever of the

hand-spray gun; the device will

switch on again.

Operational readiness period

On opening the hand-spray gun, the

device starts within the readiness period. The indicator lamp glows green.

The readiness period is over if the

hand-spray gun remains closed for 30

minutes. The indicator lamp blinks

green.

Reset readiness period

Set the appliance switch to "0".

Wait for a while.

Set the appliance switch to "I".

Customer Service can switch the device to continuous operations.

Turn off the appliance

Set the appliance switch to "0".

Disconnect the mains plug from the

socket.

Shut off water supply.

Activate hand spray gun until de-

vice is pressure-less.

Press the safety lever of the hand-

spray gun to secure the lever of the

pistol against being released accidentally.

Danger

Danger of scalding by means of hot water. The water remaining in the switched

off device can get heated up. When you

remove the hose from the water inlet, the

heated water can spray out and cause

scalding. Remove the hose only when

the device has cooled down.

Storing the Appliance

Insert the hand-spray gun in the

holder.

Wind up the high-pressure hose

and hang it over the hose storage.

Wind the connection cable around

the cable holder.

Fasten the plug with the mounted

clip.

Frost protection

몇 Warning

Frost will destroy the not completely

water drained device.

Store the appliance in a frost free area.

If you cannot store it in a frost-free

place:

Drain water.

Emptying the detergent tank (see

"Care and Maintenance/ as required").

Pump in conventional frost protec-

tion agents through the appliance.

Note

Use normal glycol-based anti-freezing

agents for automobiles.

Observe handling instructions of the

anti-freeze agent manufacturer.

Operate device for max. 1 minute

until the pump and conduits are

empty.

– 7

9EN

Page 10

Transport

Caution

Risk of injury and damage! Observe

the weight of the appliance when you

transport it.

Pull the device behind you at the

handle for transporting it over longer distances.

Hold the device at the handles for

carrying, not at the push handle.

Empty the detergent tank before

transporting in horizontal position.

When transporting in vehicles, se-

cure the appliance according to the

guidelines from slipping and tipping

over.

Storage

Caution

Risk of injury and damage! Note the

weight of the appliance in case of storage.

This appliance must only be stored in

interior rooms.

Maintenance and care

Danger

Risk of injury by inadvertent startup of

appliance and electrical shock.

First pull out the plug from the mains

before carrying out any tasks on the

machine.

Note

Please dispose off used oil only in the

collection points provided for them.

Please hand over old oil, if any, only at

such places. Polluting the environment

with used oil is a punishable offence.

Safety inspection/ maintenance

contract

You can sign with your dealer a contract for regular safety inspection or

even sign a maintenance contract.

Please take advice on this matter.

Before each use

Check connection cable for damag-

es (risk of electrical shock); get the

damaged connection cable replaced immediately by an authorised customer service person/

electrician.

Check the high pressure hose for

damages (risk of bursting).

Please arrange for the immediate

exchange of a damaged high-pressure hose.

Check appliance (pump) for leaks.

3 drops per minute are permitted

and can come out from the lower

side of the appliance. Call Customer Service if there is heavy leakage.

Weekly

Check oil level Please contact Cus-

tomer Service immediately if the oil

is milky (water in oil).

Clean the fine filter.

Unpressurize the appliance.

Unscrew the fastening screws of

the device hood; remove the device

hood.

Unscrew lid with filter.

Clean the filter with clean water or

compressed air.

Reinstall in reverse sequence.

Clean filter at the detergent suck

hose.

10 EN

– 8

Page 11

monthly or after 500 operating

hours

Oil change.

Oil change

Note

See "Technical Details" for details of oil

quantity and type.

Unscrew the fastening screws of

the device hood; remove the device

hood.

Loosen the oil drain screw at the

rear on the motor casing.

Drain the oil in a collection basin.

Screw in the oil drain screw.

Fill in new oil slowly; air bubbles

should go out.

Attach the lid of the oil container.

Fasten the device hood.

If required

Empty and clean the detergent tank.

Pull out the locking cap for the de-

tergent tank along with the suction

hose.

Lay the device on the reverse.

Empty and clean the detergent tank.

Troubleshooting

Danger

Risk of injury by inadvertent startup of

appliance and electrical shock.

First pull out the plug from the mains

before carrying out any tasks on the

machine.

Get the electrical components checked

and repaired only by authorised customer service persons.

Contact an authorised customer service person in case of problems not

mentioned in this chapter or if you are

in doubt or when you have been explicitly asked to do so.

Indicator lamp

The indicator lamps display the operating states (green) and interruptions

(red).

Reset:

Set the appliance switch to "0".

Wait for a while.

Set the appliance switch to "I".

Operating status display

– Continuous green:

The appliance is now ready for operation.

– blinks green once:

Operational readiness has expired

after 30 minutes.

The appliance has switched off after 30 minutes of continuous operation (safety if the high pressure

hose bursts).

Fault indication

– blinks red once:

High-pressure side is leaky.

Check high pressure hose, hose

connections and hand spray gun for

leaks.

– blinks red twice:

Engine is too hot.

Set the appliance switch to "0".

Allow device to cool down.

Set the appliance switch to "I".

– blinks red thrice:

Fault in the voltage supply.

Check main connections and mains

fuse.

– blinks red four times:

Excessive power consumption.

Call Customer Service.

– 9

11EN

Page 12

Appliance is not running

Operational readiness period has

expired. Indicator lamp is blinking

green. Switch on/off the device

switch again.

Check connection cable for damag-

es.

Call Customer Service in case of

electrical defects.

Pressure does not build up in the

appliance

Set nozzle to "High pressure".

Clean/ replace nozzle.

Clean the fine filter; replace it, if

necessary.

Deaerate the appliance (see "Start-

up")

Check water supply level (refer to

technical data).

Check all inlet pipes to the pump.

Contact Customer Service if need-

ed.

Pump leaky

3 drops per minute are permitted and

can come out from the lower side of the

appliance. Call Customer Service if

there is heavy leakage.

With stronger leak, have device

checked by customer service.

Pump is vibrating

Check suction pipes for water and

detergent and ensure that they are

leak-proof.

Deaerate the appliance (see "Start-

up")

Clean the fine filter.

Contact Customer Service if need-

ed.

Detergent is not getting sucked

in

Set nozzle to "CHEM".

Check/ clean detergent suction

hose with filter.

Clean/ replace backflow valve in

the connection of the detergent

suction hose.

Open or check/clean detergent

dosing valve.

Clean the deaerating hole of the de-

tergent tank in the casing.

Contact Customer Service if need-

ed.

Accessories and Spare Parts

– Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive

use of original accessories and

original spare parts ensures that

the appliance can be operated

safely and trouble free.

– At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

– For additional information about

spare parts, please go to the Service section at www.kaercher.com.

Warranty

The warranty terms published by the

relevant sales company are applicable

in each country. We will repair potential

failures of your appliance within the

warranty period free of charge, provided that such failure is caused by faulty

material or defects in manufacturing. In

the event of a warranty claim please

contact your dealer or the nearest authorized Customer Service centre.

Please submit the proof of purchase.

12 EN

– 10

Page 13

Technical specifications

Main Supply

Voltage V 220...240

Current type Hz 1~ 60

Power Input hp/kw 9/6.7

Protection (slow, char. C) A 30

Type of protection IPX5

Water connection

Max. feed temperature °F (°C) 140 (60)

Min. feed volume GPM / l/min 5.3/20

Suck height from open container (20 °C) ft/m 1.6/0.5

Max. feed pressure PSI (MPa) 145 (1)

Performance data

Working pressure PSI (MPa) 435...3000

(3...20.6)

Max. operating over-pressure PSI (MPa) 3300 (22.7)

Nozzle size 045

Flow rate GPM / l/min 1.8...3.5/

6.8...13.2

Detergent suck in GPM / l/min 0...0.3 / 0...1.1

Max. recoil force of hand spray gun

Values determined as per EN 60355-2-79

Hand-arm vibration value

Hand spray gun

Spray lance m/s

Uncertainty K m/s

Sound pressure level L

Uncertainty K

pA

Sound power level L

pA

+ Uncertainty K

WA

WA

Fuel

Amount of oil l 1.2

Oil grade -- SAE 15W40

Dimensions and weights

Length mm 560

Width mm 500

Height mm 1090

Volume detergent tank l 6

Typical operating weight

N62

2

m/s

2

2

<2.5

<2.5

0.3

dB(A) 72

dB(A) 2

dB(A) 87

kg 62

– 11

13EN

Page 14

CONSIGNES DE SÉCURITÉ

IMPORTANTES

몇 AVERTISSEMENT

En utilisant ce produit, toujours observer une certaine prudence élémentaire, incluant notamment :

1 Lire toutes les instructions de ser-

vice avant d'utiliser l'appareil.

2 En cas d'utilisation incorrecte, les

jets haute pression peuvent être

dangereux. Ne jamais diriger les

jets de vapeur en direction d'individus, d'animaux, de dispositifs électriques ou de l'appareil lui-même.

3 Afin de minimiser les risques de

blessure, ne jamais laisser l'appareil sans surveillance lorsque celuici est utilisé à proximité d'enfants.

4 Il est impératif de savoir arrêter et

mettre l'appareil hors pression rapidement. Une connaissance approfondie des commandes est

nécessaire.

5 Rester attentif – se concentrer sur

la tâche en cours.

6 Le port de lunettes de protection est

obligatoire.

7 N'utiliser en aucun cas d'acides, de

solutions alcalines, de solvants ou

de produits inflammables dans cet

appareil. Ces produits peuvent être

à l'origine de blessures graves ou

d'endommagement irréversible de

l'appareil.

8 L'utilisateur ne doit jamais faire

usage de l'appareil lorsqu'il est fatigué ou sous l'emprise d'alcool ou

de drogues.

9 Ne jamais passer ou monter sur

des supports instables. Toujours

rester stable et équilibré.

10 Afin de réduire le risque d'électro-

cution, garder toutes les

connexions au sec et ne pas les

laisser à terre. Ne pas toucher la

fiche avec les mains mouillées.

11 Le dispositif de sécurité de la poi-

gnée-pistolet permet d'éviter tout

actionnement accidentel de la gâchette. Ce dispositif de sécurité NE

verrouille PAS la gâchette en position marche (ON).

12 Veiller à ce qu'aucun individu ne se

trouve dans la zone de travail.

13 Respecter les consignes d'entre-

tien figurant dans le manuel.

14 Ce produit est fourni avec un dis-

joncteur différentiel monté dans la

fiche du cordon d'alimentation. Si le

remplacement de la fiche ou du cordon d'alimentation s'avère nécessaire, n'utiliser que des pièces de

rechange identiques.

15 Risque de projection ou de bles-

sure – Ne pas diriger le jet de vapeur en direction d'individus.

16 Ne pas utiliser que des rallonges.

몇 Avertissement

Afin de réduire le risque d'électrocution, garder toutes les connexions au

sec et ne pas les laisser à terre. Ne pas

toucher la fiche avec les mains mouillées.

INSTRUCTIONS DE MISE À

LA TERRE

Ce produit doit-être mis à la terre. En

cas de mauvais fonctionnement ou de

panne, la mise à la terre établit un chemin de moindre résistance pour le courant électrique afin de réduire le risque

de décharge électrique. Ce produit est

équipé d'un cordon doté d'un conducteur de mise à la terre de l'équipement

14 FR

– 1

Page 15

et d'une prise de mise à la terre. La

prise doit être branchée dans une prise

appropriée qui est correctement installée et mise à la terre en conformité

avec les codes et ordonnances locaux.

DANGER

Un conducteur de mise à la terre

d'équipement incorrectement branché

peut entraîner un risque d'électrocution. Vérifier avec un électricien ou un

technicien d'entretien qualifié en cas

de doute sur la mise à terre correcte de

la prise. Ne pas modifier la fiche fournie avec le produit - si elle ne peut pas

être branchée, faire installer une prise

appropriée par un électricien qualifié.

Ne pas utiliser n'importe quel type

d'adaptateur avec ce produit.

PROTECTION PAR DISJONC-

TEUR DIFFÉRENTIEL

Ce produit est fourni avec un interrupteur différentiel (GFCI) intégré dans la

fiche du câble d'alimentation. Cet appareil fournit une protection supplémentaire contre les risques

d'électrocution. Si le courant est interrompu dans la ligne, le GFCI refermera

automatiquement le circuit vers la

charge quand le courant sera restauré.

En fonction du modèle de GFCI, il peut

être nécessaire d'actionner manuellement le bouton de réinitialisation pour

restaurer le courant vers le circuit de

charge du GFCI. Si le remplacement

de la fiche ou du câble est nécessaire,

utiliser des pièces de remplacement

identiques.

les régulations locales de votre compagnie d'eau doivent être observées.

Dans certaines zones, l'appareil ne

doit pas être connecté directement à

l'alimentation en eau potable publique.

Il s'agit de s'assurer qu'il n'y a pas de

retour de produits chimiques dans l'alimentation en eau. Une connexion directe par l'intermédiaire d'un réservoir

de réception ou d'un disconnecteur hydraulique par exemple est autorisée.

D'éventuelles impuretés dans l'eau

d'alimentation endommagent l'appareil. Pour prévenir ce risque, nous recommandons d'installer un filtre à eau.

– Ne jamais aspirer d'eau contami-

née par des solvants, par exemple

des diluants pour peinture, de l'essence, de l'huile, etc..

– Toujours utiliser une source d'eau

propre afin d'éviter toute infiltration

de débris dans l'appareil. Utiliser un

filtre à eau supplémentaire.

ALIMENTATION EN EAU

(eau froide uniquement)

몇 ATTENTION

Lors de la connexion de l'entrée d'eau

à la canalisation d'alimentation en eau,

– 2

15FR

Page 16

Lire ces notice originale

avant la première utilisation

de votre appareil, se comporter selon

ce qu'elles requièrent et les conserver

pour une utilisation ultérieure ou pour

le propriétaire futur.

Table des matières

Éléments de l'appareil . . . . FR . . .3

Consignes de sécurité . . . . FR . . .3

Utilisation conforme . . . . . . FR . . .4

Dispositifs de sécurité . . . . FR . . .4

Protection de l’environnement FR . . .4

Avant la mise en service . . FR . . .5

Mise en service . . . . . . . . . FR . . .5

Utilisation . . . . . . . . . . . . . . FR . . .6

Transport . . . . . . . . . . . . . . FR . . .8

Entreposage. . . . . . . . . . . . FR . . .9

Entretien et maintenance . . FR . . .9

Assistance en cas de panne FR . .10

Accessoires et pièces de re-

change . . . . . . . . . . . . . . . . FR . . 11

Garantie . . . . . . . . . . . . . . . FR . . 11

Caractéristiques techniques FR . .12

Éléments de l'appareil

Veuillez ouvrir la page d'image devant

1 Poignée-pistolet

2 Manette de la poignée-pistolet

3 Flexible haute pression

4 Support pour la poignée pistolet

5 Vanne de dosage du détergent

6 Couvercle réservoir de détergent

7 Réservoir de détergent

8 Tuyau d’aspiration de détergent

avec filtre à détergent et bouchon

9 Vis de fixation du capot

10 Interrupteur principal

11 Capot

12 Manomètre

13 Raccord haute pression

14 Porte buse

15 Arrivée d'eau

16 Filtre fin

17 Indicateur de niveau d'huile

18 Réservoir d'huile

19 Lampe témoin

20 Dépose du flexible

21 Ventilation du réservoir de dé-

tergent

22 Espace de rangement pour les ac-

cessoires

23 Attache-câble

24 Poignée

25 Buse

26 Marquage de la buse

27 Lance

28 Régulation de pression et de débit

29 Manette de sécurité

Repérage de couleur

– Les éléments de commande pour le

processus de nettoyage sont

jaunes.

– Les éléments de commande pour la

maintenance et l'entretien sont en

gris clair.

Consignes de sécurité

– Avant la première mise en service,

vous devez impérativement avoir lu

les consignes de sécurité N° 5.951-

949.0 !

– Respecter les dispositions légales

nationales respectives pour les jets

de liquide.

– Respecter les dispositions légales

nationales respectives pour la pré-

vention des accidents. Les jets de

liquides doivent être contrôlés régu-

lièrement et le résultat du contrôle

consigné par écrit.

16 FR

– 3

Page 17

Symboles utilisés dans le mode

d'emploi

Danger

Pour un danger immédiat qui peut

avoir pour conséquence la mort ou des

blessures corporelles graves.

몇 Avertissement

Pour une situation potentiellement

dangereuse qui peut avoir pour conséquence des blessures corporelles

graves ou la mort.

Attention

Pour une situation potentiellement

dangereuse qui peut avoir pour conséquence des blessures légères ou des

dommages matériels.

Des symboles sur l'appareil

Une utilisation incorrecte des

jets haute pression peut pré-

senter des dangers. Le jet ne

doit pas être dirigé sur des personnes,

animaux, installations électriques actives ni sur l'appareil lui-même.

Selon les directives en vigueur, l'appareil ne doit jamais

être exploité sans séparateur

système sur le réseau d'eau potable.

Utiliser un séparateur système approprié de la Sté. Kärcher ou en alternative un séparateur système selon EN

12729 type BA.

L'eau qui s'est écoulée à travers un séparateur system est classifiée comme

non potable.

Utilisation conforme

Utiliser exclusivement ce nettoyeur

haute pression

– pour nettoyer au jet basse pression

et avec du détergent (par exemple

pour le nettoyage de machines, véhicules, bâtiments, outils),

– pour nettoyer au jet haute pression

sans détergent (par ex. nettoyage

de façades, de terrasses, d'appareils de jardinage).

Pour des salissures tenaces nos recommandons le fraiseur de saleté

comme accessoire en option.

Dispositifs de sécurité

Les dispositifs de sécurité ont pour but

de protéger l'utilisateur. Par conséquent, ils ne doivent en aucun cas être

désactivés ou transformés.

Clapet de décharge avec pres-

sostat

En cas de réduction de la quantité

d'eau avec le réglage de pression/

quantité, la clapet de décharge s'ouvre

et une partie de l'eau est évacuée vers

le côté aspiration de la pompe.

Si vous relâchez la gâchette, la pompe

est éteinte par un manu contacteur, le

jet haute pression est interrompu. Si

vous appuyez à nouveau sur le levier,

la pompe est remise en marche.

Le clapet de dérivation et l'interrupteur

de pression sont réglé et plombé par

l'usine. Seul le service après-vente est

autorisé à effectuer le réglage.

Protection de l’environne-

ment

Les matériaux constitutifs

de l’emballage sont recyclables. Ne pas jeter les

emballages dans les ordures ménagères, mais les

remettre à un système de

recyclage.

– 4

17FR

Page 18

Les appareils usés

contiennent des matériaux

précieux recyclables lesquels doivent être apportés

à un système de recyclage.

Il est interdit de jeter les batteries, l'huile et les substances similaires dans

l'environnement. Pour cette

raison, utiliser des systèmes de collecte adéquats

afin d'éliminer les appareils

hors d'usage.

Ne jetez pas l'huile moteur, le fuel, le

diesel ou l'essence dans la nature. Protéger le sol et évacuer l'huile usée de

façon favorable à l'environnement.

Instructions relatives aux ingrédients (REACH)

Les informations actuelles relatives

aux ingrédients se trouvent sous :

www.kaercher.com/REACH

Avant la mise en service

Déballage

– Vérifier le contenu du paquet lors

de l'ouverture de l'emballage.

– Contactez immédiatement le reven-

deur en cas d'avarie de transport.

Contrôle du niveau d'huile

Affichage du niveau d'huile avec

l'appareil à l'arrêt. Le niveau d'huile

doit reposer au-dessus des deux indicateurs.

Activer la purge du carter d'huile

Dévisser la vis de fixation du capot

et retirer celui-ci.

Couper la pointe du couvercle du

réservoir d'huile.

Fixer le capot.

Montage des accessoires

Monter la buse sur la lance (marquage

sur la bague de butée en haut).

Monter le tube de pulvérisation sur

la poignée-pistolet avec la régulation de quantité et de pression.

Enclencher le crochet de câble dans

l'alésage latéral sur la poignée.

Visser fermement le flexible haute

pression sur le raccord haute pression.

Mise en service

Branchement électrique

몇 Danger

Risque d'électrocution.

L’appareil doit uniquement être raccordé à un branchement électrique mis en

service par un électricien conformément à la norme IEC 60364.

La tension indiquée sur la plaque signalétique de l'appareil doit correspondre à celle de la prise.

Protection minimale par fusible de la prise

de courant (cf. Données techniques).

L'appareil doit impérativement être

raccordé au secteur avec une fiche

électrique. Une connexion au secteur

ne pouvant pas être coupée est interdite. La fiche électrique sert à la séparation du secteur.

Vérifier avant chaque utilisation que le

câble et la fiche secteur ne sont pas

endommagés. Un câble d’alimentation

endommagé doit immédiatement être

remplacé par le service après-vente ou

un électricien agréé.

Les fiches mâles et les raccords des

câbles de rallonge utilisés doivent être

étanches à l’eau.

Utiliser un câble de prolongation avec

une section suffisante (voir "Caractéristiques techniques") et le dérouler

complètement de l'enrouleur.

Des rallonges non adaptées peuvent

présenter des risques. N'utiliser en

18 FR

– 5

Page 19

plein air que des rallonges homologuées avec une section suffisante:

Données de raccordement, voir plaque signalétique / caractéristiques techniques

DISJONCTEUR DIFFERENTIEL

–

ETAPE 1 : Brancher le disjoncteur

différentiel dans une prise alimentée.

– ETAPE 2 : Appuyer d’abord sur

« TEST », puis sur « RESET » pour

assurer le branchement correct au

secteur.

Remarque : L’apparence effective du

disjoncteur différentiel peut différer de

l’illustration.

Arrivée d'eau

Raccordement à la conduite d'eau

몇 Avertissement

Respecter les prescriptions de votre

société distributrice en eau.

Selon les directives en vigueur,

l'appareil ne doit jamais être

exploité sans séparateur système sur le réseau d'eau potable. Utiliser un séparateur système approprié

de la Sté. Kärcher ® ou en alternative

un séparateur système selon EN

12729 type BA. L'eau qui s'est écoulée

à travers un séparateur system est

classifiée comme non potable.

Attention

Toujours raccorder le séparateur du système au niveau de l'alimentation en eau

et jamais directement sur l'appareil!

Pour les valeurs de raccordement, se

reporter à la section Caractéristiques

techniques.

Raccorder la conduite d'alimentation

(longueur minimale 7,5 m, diamètre

minimum 3/4") au raccord pour l'arrivée d'eau de l'appareil et à l'alimentation en eau (ex. un robinet).

Remarque

La conduite d'alimentation n'est pas

comprise dans la livraison.

Ouvrir l'alimentation d'eau.

Aspiration d'eau depuis des réservoirs ouverts

Visser le flexible d’aspiration avec

le filtre (n° de commande 4.440-

238.0) sur la prise d’eau.

Purge d'air de l'appareil :

Dévisser l'injecteur.

Laisser l'appareil en route jusqu'à

l'eau sorte sans faire de bulles.

Faire tourner l'appareil éventuelle-

ment pendant 10 secondes - le

mettre hors service. Répéter le processus à plusieurs reprises.

Arrêter l'appareil et dévisser de

nouveau l'injecteur.

Utilisation

Danger

Risque d'explosion !

Ne pas pulvériser de liquides inflammables.

Si l’appareil est utilisé dans des zones de

danger (par exemple des stations essence), il faut tenir compte des

consignes de sécurité correspondantes.

Attention

Nettoyer les moteurs uniquement à

des endroits équipés des séparateurs

d'huile nécessaires (protection de l'environnement).

– 6

19FR

Page 20

Fonctionnement à haute pres-

sion

Remarque

L'appareil est équipé d'un mano

contacteur. Le moteur ne démarre que

lorsque le levier du pistolet est tiré.

Régler l'interrupteur principal sur "I".

La lampe témoin est allumée en vert.

Décrochez le pistolet de giclage à

main et tirer le levier du pistolet.

Ajuster la pression de travail et la

quantité d'eau en tournant (sans

échelon) à la régulation de pression

et de quantité (+/-).

Avec les débits réduits, la chaleur

émise par le moteur assure un réchauffement de l'eau d'env. 15° C.

Choisir le type de jet

Fermer la poignée-pistolet.

Tourner le logement de la buse jus-

qu'à ce que le symbole désiré corresponde avec le marquage :

Sélectionner jet bâton ou jet plat,

commutant sans toucher:

Tourner le tube en acier orienté à

env. 45° vers le bas vers la droite

ou vers la gauche.

Signification des symboles

Jet plat à haute pression

(25°) pour des salissures sur des grandes

surfaces

Jet bâton à haute pression (0°) pour des salissures très tenaces

Jet plat à basse pression (CHEM) pour le

service avec détergent

ou nettoyer avec une

pression basse

Fonctionnement avec détergent

몇 Avertissement

Des détergents peu appropriés peuvent

endommagés l'appareil et l'objet pour

nettoyer. Utiliser uniquement des détergents qui sont validés par Kärcher. Respecter les consignes et

recommandations de dosage jointes aux

détergents. Protéger l'environnement en

utilisant le détergent avec parcimonie.

Respecter les consignes de sécurité figurant sur les détergents.

Des détergents de Kärcher garantissent un travail sans défauts. Veuillez-vous conseiller ou demander notre

catalogue ou notre bulletins d'information sur des produits de nettoyage.

Remplir le réservoir de détergent.

Placer l'injecteur sur la position

"CHEM".

Régler le clapet de dosage du détergent sur la concentration souhaitée.

Réglage de la sou-

1357

pape de dosage

Concentration de dé-

0,5 2,5 5,0 7,0

tergent [%]

(avec le débit max.)

Méthode de nettoyage conseillée

Pulvériser le détergent sur la sur-

face sèche et laisser agir sans toutefois le laisser sécher

complètement.

Ôter les salissures décollées à

l'aide du jet haute pression.

Après le fonctionnement avec le

produit de nettoyage , positionner la

vanne de dosage sur "0". Démarrer

l'appareil et rincer le pistolet ouvert

à l'eau claire pendant une minute.

Interrompre le fonctionnement

Relâcher le levier de la poignée-pistolet, l'appareil se met hors service.

20 FR

– 7

Page 21

Tirer de nouveau sur le levier de la

poignée-pistolet, l'appareil se remet

en service.

Durée de disponibilité

L'appareil démarre avec l'ouverture de

la poignée pistolet pendant la période

de disponibilité. Le témoin de contrôle

s'allume en vert.

Si la poignée pistolet reste fermée pendant 30 minutes, la période de disponibilité s'arrête. La lampe témoin clignote

en vert.

Réinitialiser la durée de disponi-

bilité

Mettre l'interrupteur principal sur "0".

Attendre quelques secondes.

Régler l'interrupteur principal sur "I".

L'appareil peut être basculé en fonctionnement continu par le service

après-vente.

Mise hors service de l'appareil

Mettre l'interrupteur principal sur "0".

Retirer la fiche secteur de la prise

de courant.

Couper l'alimentation en eau.

Actionner la poignée-pistolet jusqu'à

ce que l'appareil soit hors pression.

Actionner le cran de sûreté de la poignée-pistolet pour sécuriser le pistolet

contre un déclenchement intempestif.

Danger

Risque de brûlure provoquée par l'eau

chaude . lorsque l'appareil est hors

service, l'eau résiduelle contenue peut

se réchauffer. Lors de l'enlèvement du

tuyau de l'arrivée d'eau, l'eau réchauffée peut être projetée et provoquer des

ébouillantements. Retirer tout d'abord

le tuyau lorsque l'appareil a refroidi.

Ranger l’appareil

Enficher la poignée-pistolet dans le

support.

Enrouler le flexible haute pression

et l'accrocher sur la dépose du

flexible.

Enrouler le câble d'alimentation au-

tour de l'attache-câbles.

Fixer la fiche électrique avec le clip

monté.

Protection antigel

몇 Avertissement

Le gel peut endommager l'appareil si

l'eau n'a pas été intégralement vidée.

Conserver l'appareil dans un lieu à

l'abri du gel.

Si un entreposage à l'abri du gel

n'est pas possible :

Purger l'eau.

Vidanger le réservoir de détergent

(voir "Maintenance et entretien/si

nécessaire").

Pomper produit antigel d'usage par

l'appareil.

Remarque

utiliser un produit antigel courant pour

automobile à base de glycol.

Respecter les consignes d'utilisation

du fabricant du produit antigel.

Faire tourner l'appareil au max. 1

minute jusqu'à ce que la pompe et

les conduites soient entièrement

vides.

Transport

Attention

Risque de blessure et

d'endommagement ! Respecter le

poids de l'appareil lors du transport.

Pour transporter l’appareil sur de

plus longues distances, le tirer derrière soi au moyen du manche de

poussée.

Soulever l'appareil avec la poignée

et le porter.

– 8

21FR

Page 22

Vidanger le réservoir de détergent

avant un transport en position allongée.

Sécuriser l'appareil contre les glis-

sements ou les basculements selon

les directives en vigueur lors du

transport dans des véhicules.

Entreposage

Attention

Risque de blessure et

d'endommagement ! Prendre en compte

le poids de l'appareil à l'entreposage.

Cet appareil doit uniquement être entreposé en intérieur.

Entretien et maintenance

Danger

Risque de blessure et de choc électrique par un démarrage inopiné de

l'appareil.

Avant d'effectuer tout type de travaux

sur l'appareil, le mettre hors service et

débrancher la fiche électrique.

Remarque

L'huile usagée doit impérativement

être éliminée auprès d'un point de collecte compétent. Y apporter l'huile usagée. L'huile usagée est polluante.

Toute élimination incorrecte est passible d'une amende.

Inspection de sécurité/Contrat

d'entretien

Vous pouvez accorder avec votre commerçant une inspection de sécurité régulière ou passer un contrat

d'entretien. Conseillez-vous.

Avant chaque mise en service

Contrôler que le câble d'alimentation

n'est pas endommagé (risque de choc

électrique), faire remplacer immédiatement tout câble d'alimentation endom-

magé par un service après-vente

autorisé/un électricien spécialisé.

Vérifier le tuyau à haute pression

s'il est endommagé (danger d'éclatement).

Un flexible haute pression endommagé doit immédiatement être remplacé.

Vérifier l'étanchéité de l'appareil

(pompe).

3 gouttes d'eau par minute sont ad-

missibles et peuvent s'écoulent au

côté inférieure de l'appareil. En cas

de non étanchéité plus forte, adressez-vous au Centre de Service

Après-vente.

Hebdomadairement

Vérifier le niveau d'huile Si l'huile

est laiteux (eau dans l'huile), adressez-vous immédiatement au Centre

de Service Après-vente.

Nettoyer le filtre fin.

Mettre l'appareil hors pression.

Dévisser la vis de fixation du capot

et retirer celui-ci.

Dévisser le couvercle et le filtre.

Nettoyer le filtre à l'eau propre ou à

l'air comprimé.

Remonter en suivant les étapes

dans l'ordre inverse.

Nettoyer le filtre situé sur le tuyau

d'aspiration de détergent.

Annuellement ou après 500

heures de service

Remplacer l'huile.

Vidange d'huile

Remarque

Quantités et sortes d'huiles, voir les

"Caractéristiques techniques".

Dévisser la vis de fixation du capot

et retirer celui-ci.

Dévisser la vis de vidange à l'ar-

rière sur le logement du moteur.

22 FR

– 9

Page 23

Vider l'huile dans la cuvette de ré-

cupération.

Visser le bouchon de vidange d'huile.

Remplir lentement la nouvelle huile

; les bulles d'air doivent s'échapper.

Apporter le couvercle du réservoir

d'huile.

Fixer le capot.

Si nécessaire

Vider et nettoyer le réservoir de dé-

tergent.

Tirer le couvercle de fermeture pour

le réservoir de détergent avec le

tuyau d'aspiration.

Disposer l'appareil sur le côté arrière.

Vider et nettoyer le réservoir de dé-

tergent.

Assistance en cas de panne

Danger

Risque de blessure et de choc électrique par un démarrage inopiné de

l'appareil.

Avant d'effectuer tout type de travaux

sur l'appareil, le mettre hors service et

débrancher la fiche électrique.

Seul le service après-vente autorisé

est habilité à contrôler et réparer les

composants électriques.

S'il se produit des défauts qui ne sont

pas répertoriés dans ce chapitre, en

cas de doute ou si cela est explicitement indiqué, s'adresser à un service

après-vente autorisé.

Lampe témoin

La lampe témoin affiche les états de

service (vert) et les défauts (rouge).

Retourner:

Mettre l'interrupteur principal sur "0".

Attendre quelques secondes.

Régler l'interrupteur principal sur "I".

Indicateur de l'état de service

– Lumière permanente verte:

L'appareil est en service.

– 1 clignotement vert :

La disponibilité opérationnelle expire après 30 minutes.

L'appareil s'arrêt après 30 minutes

de fonctionnement permanent (sécurité en cas de tuyau à haute pression éclaté).

Affichage des défauts

– 1 clignotement rouge :

Le côté à haute pression fuit.

Vérifier le tuyau à haute pression,

les raccords pour tuyau et la poignée-pistolet à l'étanchéité.

– 2 clignotement rouge :

Moteur trop chaud.

Mettre l'interrupteur principal sur "0".

Laisser refroidir l'appareil.

Régler l'interrupteur principal sur "I".

– 3 clignotement rouge :

Défaut dans l'alimentation électrique.

Vérifier l'alimentation électrique et

les fusibles.

– 4 clignotement rouge :

Le courant absorbé est trop grand.

Adresser au Centre de Service

Après-vente.

L'appareil ne fonctionne pas

La durée de disponibilité est expire.

La lampe témoin clignote en vert.

Arrêter et redémarrer le sectionneur général.

Contrôler que le câble de raccorde-

ment n'est pas endommagé.

En cas de défaut électrique, consul-

ter le service après-vente.

L'appareil ne monte pas en pression

Placer l'injecteur sur la position

"Haute pression".

Nettoyer/échanger l'injecteur.

– 10

23FR

Page 24

Nettoyer le filtre fin, le remplacer si

nécessaire.

Purger l'air de l'appareil (voir "Mise

en service").

Contrôler le débit de l'alimentation

en eau (voir la section Caractéristiques techniques).

Vérifier toutes les conduites d'ali-

mentation vers la pompe.

Si nécessaire, visiter le service

après-vente.

La pompe fuit

3 gouttes d'eau par minute sont admissibles et peuvent s'écoulent au côté inférieure de l'appareil. En cas de non

étanchéité plus forte, adressez-vous

au Centre de Service Après-vente.

En cas de fuite plus importante,

faire vérifier l'appareil par le service

après-vente.

La pompe frappe

Vérifier les conduites d'aspiration

de l'eau et de détergent par rapport

à une perte d'étanchéité.

Purger l'air de l'appareil (voir "Mise

en service").

Nettoyer le filtre fin.

Si nécessaire, visiter le service

après-vente.

Le détergent n'est pas aspirée

Placer l'injecteur sur la position

"CHEM".

Vérifier/nettoyer le flexible d'aspira-

tion du détergent avec filtre.

Nettoyer/échanger la clapet de re-

tenue à la butée du flexible d'aspiration du détergent.

Ouvrir ou vérifier/nettoyer le doseur

du détergent.

Nettoyer l'alésage de ventilation du

réservoir de détergent dans le logement.

Si nécessaire, visiter le service

après-vente.

Accessoires et pièces de re-

change

– Utiliser uniquement des acces-

soires et des pièces de rechange

autorisés par le fabricant. Des accessoires et des pièces de rechange d’origine garantissent un

fonctionnement sûr et parfait de

l’appareil.

– Une sélection des pièces de re-

change utilisées le plus se trouve à

la fin du mode d'emploi.

– Plus information sur les pièces de

rechange vous les trouverez sous

www.kaercher.com sous le menu

Service.

Garantie

Dans chaque pays, les conditions de

garantie en vigueur sont celles publiées par notre société de distribution

responsable. Les éventuelles pannes

sur l’appareil sont réparées gratuitement dans le délai de validité de la garantie, dans la mesure où celles-ci

relèvent d'un défaut matériel ou d'un

vice de fabrication. En cas de recours

en garantie, adressez-vous à votre revendeur ou au service après-vente

agréé le plus proche munis de votre

preuve d'achat.

24 FR

– 11

Page 25

Caractéristiques techniques

Raccordement au secteur

Tension V 220...240

Type de courant Hz 1~ 60

Puissance absorbée hp/kw 9/6.7

Protection (à action retardée, carat. C) A 30

Type de protection IPX5

Arrivée d'eau

Température d'alimentation (max.) °F (°C) 140 (60)

Débit d'alimentation (min.) GPM / l/min 5.3/20

Hauteur d'aspiration à partir du réservoir ouvert

(20 °C)

Pression d'alimentation (max.) PSI (MPa) 145 (1)

Performances

Pression de service PSI (MPa) 435...3000

Pression de service max. PSI (MPa) 3300 (22.7)

Taille d'injecteur 045

Débit GPM / l/min 1.8...3.5/6.8...13.2

Aspiration de détergent GPM / l/min 0...0.3 / 0...1.1

Force de réaction max. de la poignée-pistolet N 62

Valeurs déterminées selon EN 60355-2-79

Valeur de vibrations bras-main

Poignée-pistolet m/s

Lance m/s

Incertitude K m/s

Niveau de pression sonore L

Incertitude K

pA

Niveau de pression sonore L

pA

+ incertitude K

WA

Carburants

Quantité d'huile l 1.2

Types d'huile -- SAE 15W40

Dimensions et poids

Longueur mm 560

Largeur mm 500

Hauteur mm 1090

Volume réservoir de détergent l 6

Poids de fonctionnement typique kg 62

ft/m 1.6/0.5

2

2

2

dB(A) 72

dB(A) 2

dB(A) 87

WA

(3...20.6)

<2.5

<2.5

0.3

– 12

25FR

Page 26

INSTRUCCIONES IMPOR-

TANTES DE SEGURIDAD

몇 ADVERTENCIA

Al utilizar este producto, tome siempre

las precauciones básicas, incluidas las

siguientes:

1 Lea todas las instrucciones antes

de usar el producto.

2 Los aparatos a alta presión pueden

resultar peligrosos si se usan de

forma incorrecta. No se debe dirigir

el aparato a personas, animales,

dispositivos eléctricos o la equipo

mismo.

3 Para reducir el riesgo de lesiones,

es preciso vigilar atentamente si se

usa el producto cerca de niños.

4 Es necesario saber cómo parar rá-

pidamente el producto y parar hemorragias. Estar familiarizado con

los mandos.

5 Estar atento, prestar atención a lo

que se está haciendo.

6 Utilizar gafas de seguridad.

7 No usar ácidos, alcalinos, disolven-

tes, o cualquier material inflamable

con este producto. Estos productos

pueden causar heridas físicas al

operario y daños irreparables a la

máquina.

8 No ponga en funcionamiento el pro-

ducto si está cansado o está bajo la

influencia de alcohol o drogas.

9 No sobrecargar o colocar sobre un

soporte inestable. Mantener el

equilibrio en todo momento.

10 Para reducir el riesgo de electrocu-

ción, mantenga todas las conexio-

nes secas y alejadas del suelo. No

toque el enchufe con las manos

mojadas.

11 El seguro del gatillo de la pistola

evita que el gatillo salte de forma involuntaria. El dispositivo de seguridad NO bloquea el gatillo en la

posición ON (encendido).

12 Mantenga la zona de trabajo libre

de personas.

13 Seguir las instrucciones de mante-

nimiento especificadas en el manual.

14 Este producto se suministra con un

interruptor de circuito de avería por

puesta a tierra, que está montado

en el enchufe del cable de potencia.

Si es necesario reemplazar el enchufe o el cable, utilice sólo piezas

de repuesto idénticas.

15 Riesgo de inyección o lesiones; no

dirija el chorro directamente a personas.

16 No se debe usar el cable de exten-

sión para esta máquina.

몇 Advertencia

Para reducir el riesgo de electrocución,

mantenga todas las conexiones secas

y alejadas del suelo. No toque el enchufe con las manos mojadas.

INSTRUCCIONES DE PUES-

TA A TIERRA

Este producto se tiene que poner a tierra. Si funcionase mal o si se rompiese, la puesta a tierra proporcionaría

una circuito menos resistente a la

energía eléctrica para reducir el riesgo

de electrochoque. Este producto está

equipado con un cable que tiene un

conductor a tierra y un enchufe a tierra

para el equipo. El enchufe se tiene que

enchufar a un tomacorriente adecuado, que esté correctamente instalado y

puesto a tierra conforme a todas las

normas y reglamentos locales.

26 ES

– 1

Page 27

PELIGRO

Si la conexión del conductor a tierra

del equipo es incorrecta puede existir

riesgo de electrochoque. En caso de

duda, compruebe con ayuda de un

electricista cualificado o del personal

del servicio técnico que el tomacorriente está correctamente puesto a tierra.

No modifique el enchufe proporcionado con el producto; si no encaja en el

tomacorriente, pida a un electricista

cualificado que le instale un tomacorriente adecuado. No utilice ningún

tipo de adaptador con este producto.

PROTECCIÓN MEDIANTE IN-

TERRUPTOR DE CIRCUITO

DE AVERÍA POR PUESTA A

TIERRA

Este producto esta dotado de un interruptor de protección GFCI incorporado en el enchufe de alimentación

eléctrica. Este dispositivo proporciona

protección adicional ante el riesgo de

descargas eléctricas. Si se interrumpiese el flujo de electricidad, el interruptor GFCI volverá a conectar

automáticamente el circuito a la unidad

de consumo después que se restablezca el suministro. Dependiendo del

modelo de GFCI puede ser necesario

accionar manualmente el botón Reset

para restablecer el suministro del circuito de consumo del GFCI. Si fuese

necesario sustituir el enchufe o el cable de alimentación se deberán utilizar

repuestos idénticos.

por la compañía del agua. En algunas

zonas, está prohibido conectar la unidad directamente a la red pública de

suministro de agua potable. Esto es

así para garantizar que no penetren

sustancias químicas en la red de suministro del agua. Sí se permite efectuar

la conexión directamente por ejemplo

a través de un depósito receptor o un

dispositivo antirretorno.

Si el agua de alimentación está sucia,

la unidad sufrirá daños. Para evitar

este riesgo, le recomendamos que

monte un filtro de agua.

– No usar la limpiadora de alta pre-

sión para agua contaminada con disolventes, por ejemplo para diluir

pintura, gasolina, aceite etc.

– Evitar que entren escombros en la

unidad, para ello use una fuente de

agua limpia. Use un filtro adicional

de agua.

SUMINISTRO DE AGUA

(Únicamente agua fría)

몇 ATENCIÓN

Al conectar la toma de agua a la red de

suministro del agua, es obligatorio respetar la normativa local establecida

– 2

27ES

Page 28

Antes del primer uso de su

aparato, lea este manual original, actúe de acuerdo a sus indicaciones y guárdelo para un uso

posterior o para otro propietario posterior.

Índice de contenidos

Elementos del aparato . . . . ES . . .3

Indicaciones de seguridad . ES . . .3

Uso previsto . . . . . . . . . . . . ES . . .4

Dispositivos de seguridad . ES . . .4

Protección del medio ambiente ES . . .4

Antes de la puesta en marcha ES . . .5

Puesta en marcha . . . . . . . ES . . .5

Manejo . . . . . . . . . . . . . . . . ES . . .7

Transporte . . . . . . . . . . . . . ES . . .9

Almacenamiento . . . . . . . . ES . . .9

Cuidados y mantenimiento. ES . . .9

Ayuda en caso de avería . . ES . .10

Accesorios y piezas de repues-

to . . . . . . . . . . . . . . . . . . . . ES . .12

Garantía . . . . . . . . . . . . . . . ES . .12

Datos técnicos . . . . . . . . . . ES . .13

Elementos del aparato

Desplegar las páginas delanteras

1 Pistola pulverizadora manual

2 Palanca de la pistola pulverizadora

manual

3 Manguera de alta presión

4 Soporte para la pistola pulverizado-

ra manual

5 Válvula dosificadora de detergente

6 Tapa depósito de degergente

7 Depósito de detergente

8 Manguera de detergente con filtro

de detergente y tapa

9 Tornillo de fijación del capó del apa-

rato

10 Interruptor del aparato

11 Capó del aparato

12 Manómetro

13 Conexión de alta presión

14 Soporte de boquilla

15 Conexión de agua

16 filtro de depuración fina

17 Indicador del nivel de aceite

18 Recipiente de aceite

19 Piloto de control

20 Soporte para manguera

21 Ventilación depósito de detergente

22 Compartimento para los accesorios

23 Portacables

24 asidero

25 boquilla

26 Marca de la boquilla

27 Lanza dosificadora

28 Regulación de presión y caudal

29 Palanca de seguro

Identificación por colores

– Los elementos de control para el

proceso de limpieza son amarillos.

– Los elementos de control para el

mantenimiento y el servicio son de

color gris claro.

Indicaciones de seguridad

– ¡Antes de la primera puesta en mar-

cha lea sin falta las instrucciones de

uso y las instrucciones de seguridad n.° 5.951-949.0!

– Respetar las normativas vigentes

nacionales correspondientes para

eyectores de líquidos.

– Respetar las normativas vigentes

nacionales correspondientes de

prevención de accidentes. Los

eyectores de líquidos deben ser

examinados regularmente y tiene

que guardarse una copia escrita de

la revisión.

28 ES

– 3

Page 29

Símbolos del manual de instruc-

ciones

Peligro

Para un peligro inminente que acarrea

lesiones de gravedad o la muerte.

몇 Advertencia

Para una situación que puede ser peligrosa, que puede acarrear lesiones de

gravedad o la muerte.

Precaución

Para una situación que puede ser peligrosa, que puede acarrear lesiones leves o daños materiales.

Símbolos en el aparato

Los chorros a alta presión

pueden ser peligrosos si se

usan indebidamente. No dirija el chorro hacia personas, animales o

equipamiento eléctrico activo, ni apunte con él al propio aparato.

De acuerdo con las normativas vigentes, está prohibido

utilizar el aparato sin un separador de sistema en la red de agua potable. Se debe utilizar un separador de

sistema apropiado de la empresa Kärcher o, alternativamente, un separador

de sistema que cumpla la norma EN

12729 tipo BA.

El agua que haya pasado por un separador del sistema será catalogada

como no potable.

Uso previsto

Utilizar exclusivamente esta limpiadora a presión

– la limpieza con chorros a baja pre-

sión y detergente (p. ej., limpieza

de máquinas, vehículos, edificios,

herramientas),

– para limpiar con el chorro a alta pre-

sión sin detergente (p. ej. limpieza

de fachadas, terrazas, herramientas de jardinería).

Recomendamos que use la fresadora

de suciedad para la suciedad más resistente.

Dispositivos de seguridad

La función de los dispositivos de seguridad es proteger al usuario y está prohibido ponerlos fuera de servicio y

modificar o ignorar su funcionamiento.

Válvula de derivación con pre-

sostato

Al reducir la cantidad de agua con la

regulación de presión y caudal se abre

la válvula de rebose y una parte del

agua refluye al lado de succión de la

bomba.

Cuando se suelta la palanca de la pistola pulverizadora manual, un presostato desconecta la bomba y el chorro

de alta presión se para. Cuando se acciona la palanca, se conecta la bomba

nuevamente.

La válvula de derivación y el presostato viene configurados y precintados de

fábrica. El ajuste lo debe realizar solamente el servicio postventa.

Protección del medio ambiente

Los materiales empleados

para el embalaje son reciclables y recuperables. No

tire el embalaje a la basura

doméstica y entréguelo en

los puntos oficiales de recogida para su reciclaje o recuperación.

– 4

29ES

Page 30

Los aparatos viejos contienen materiales valiosos reciclables que deberían ser

entregados para su aprovechamiento posterior. Evite

el contacto de baterías,

aceites y materias semejantes con el medio ambiente.

Por este motivo, entregue

los aparatos usados en los

puntos de recogida previstos para su reciclaje.

Por favor, no deje que el aceite para

motores, el aceite caliente y la gasolina dañen el medio ambiente. Evite

que sustancias nocivas penetren en

el suelo y elimine el aceite usado de

forma que no dañe el medio ambiente.

Indicaciones sobre ingredientes

(REACH)

Encontrará información actual sobre

los ingredientes en:

www.kaercher.com/REACH

Antes de la puesta en marcha

Desembalar

– Comprobar el contenido del paque-

te al desembalar.

– En caso de daños de transporte in-

forme inmediatamente al fabricante.

Controle el nivel de aceite

Leer el indicador de nivel de aceite

con el aparato parado. El nivel de

aceite tiene que estar por encima

de ambas agujas.

Activar la ventilación del reci-

piente de aceite

Extraer el tornillo de fijación del

capó del aparato, retirar el capó.

Cortar la punta de la tapa del depó-

sito de aceite.

Fijar el capó del aparato.

Montaje de los accesorios

Monte la boquilla en la lanza dosifi-

cadora (la marca del aro de apoyo

tiene que estar arriba).

Monte la lanza dosificadora con re-

gulación de presión y caudal en la

pistola pulverizadora manual.

Encajar el gancho de cable en el

orificio lateral del asa.

Atornilllar la manguera de alta pre-

sión a la conexión de alta presión.

Puesta en marcha

Conexión eléctrica

몇 Peligro

Peligro de lesiones por descarga eléctrica.

El aparato sólo debe estar conectado a

una conexión eléctrica que haya sido

realizada por un electricista de conformidad con la norma CEI 60364.

La tensión de la fuente de corriente tiene que coincidir con la indicada en la

placa de características.

Protección mínima por fusible de la

toma de corriente (vea los datos técnicos).

Es imprescindible que el aparato esté

conectado con un enchufe a la red

eléctrica. Está prohibido establecer

una conexión no separable con la red

eléctrica. El enchufe sirve para poder

desconectarse de la red.

Antes de cada puesta en servicio,

compruebe si el cable de conexión y el

enchufe de red presentan daños. Si el

30 ES

– 5

Page 31

cable de conexión estuviera deteriorado, debe encargar sin demora a un

electricista especializado del servicio

de atención al cliente autorizado que lo

sustituya.

El enchufe y el acoplamiento del cable

de prolongación utilizado tienen que

ser impermeables.

Utilizar un alargador con suficiente corte trasversal (véase "Datos técnicos")

y enrollar desde la parte delantera del

tambor del cable.

El uso de cables de prolongación inadecuados puede resultar peligroso.

Para el exterior, utilice sólo cables de

prolongación autorizados expresamente para ello, adecuadamente marcados y con una sección de cable

suficiente:

Valores de conexión: véase la placa de

características/datos técnicos.

Instrucciones del Interruptor de Circuito de Avería por Puesta a Tierra

– PASO 1: Enchufe el interruptor de

circuito de avería por puesta a tierra

a un tomacorriente de servicio.

– PASO 2: Presione ’’TEST’’ (PRUE-

BA) y, después, presione ’’RESET"

(REINICIO) para asegurarse de

que la conexión a la toma de energía eléctrica es correcta.

Nota: El aspecto actual del interruptor

de circuito de avería por puesta a tierra

puede ser distinto al de la ilustración.

Conexión de agua

Conexión a la toma de agua

몇 Advertencia

Tenga en cuenta las normas de la empresa suministradora de agua.

De acuerdo con las normativas

vigentes, está prohibido utilizar

el aparato sin un separador de

sistema en la red de agua potable. Se

debe utilizar un separador de sistema

apropiado de la empresa KÄRCHER o,

alternativamente, un separador de sistema que cumpla la norma EN 12729

tipo BA. El agua que haya pasado por

un separador del sistema será catalogada como no potable.

Precaución

Conectar el separador del sistema

siempre a la toma de agua, nunca directamente al aparato!

Valores de conexión, ver datos técnicos.

Conectar la tubería de abasteci-

miento (largo mín. 7,5m, diámetro

mín. 3/4“) a la conexión de agua del

aparato y a la alimentación de agua

(como el grifo).

Nota

La tubería de abastecimiento de agua no

está incluida en el volumen de suministro.

Abrir el suministro de agua.

Aspiración del agua de depósitos

abiertos

Atornille la manguera de aspiración

con filtro (nº referencia 4.440-

238.0) a la conexión del agua.

Purgar el aire del aparato:

Desenroscar la boquilla.

Dejar funcionar el aparato hasta

que salga el agua sin burbujas.

Si es necesario, dejar funcionar el

aparato 10 segundos y apagar. Repetir el proceso varias veces.

Desconecte el aparato y vuelva a

atornillar la boquilla.

– 6

31ES

Page 32

Manejo

Peligro

Peligro de explosiones

No pulverizar ningun líquido inflamable.

Para usar el aparato en zonas con peligro de explosión (p. ej., gasolineras)

son de obligado cumplimiento las normas de seguridad correspondientes.

Precaución

Limpiar los motores sólo en las zonas

con el separador de aceite correspondiente (protección del medio ambiente).

Funcionamiento con alta pre-

sión

Nota

El aparato está equipado con un presostato. El motor sólo se pone en marcha cuando se ha accionado el gatillo

de la pistola.

Colocar el interruptor principal en la

posición "I".

El piloto de control se ilumina en

verde.

Desbloquear la pistola pulverizado-

ra manual y tirar de la palanca de la

pistola.

Ajuste la presión de servicio y la

cantidad de agua girando (ajuste

continuo) el control de presión y

cantidad (+/-).

Cuando se transporte una cantidad mínima, el calor del motor se encarga de

calentar el agua a aprox. 15 ºC.

Selección del tipo de chorro

Cerrar la pistola de pulverización

manual.

Girar la carcasa de la boquilla hasta

que coincida en símbolo deseado

con la marca:

Elija entre chorro circular o chorro

plano cambiando sin contacto.

Girar hacia la izquierda o derecha

la lanza dosificadora orientada 45º