Page 1

B 150 R

English 3

Français 22

Español 41

www.kaercher.com/register-and-win

59662740 06/14

Page 2

2

Page 3

NOTICE:

This device complies with Part 15 of

the FCC Rules and Industry Canada

licence-exempt RSS standard(s)

Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

NOTICE:

Changes or modifications made to

this equipment not expressly approved by Kärcher may void the FCC

authorization to operate this equipment

NOTE: This equipment has been

tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency

energy and, if not installed and used

in accordance with the instructions,

may cause harmful interference to radio communications. However, there

is no guarantee that interference will

not occur in a particular installation. If

this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the

user is encouraged to try to correct

the interference by one or more of the

following measures

• Reorient or relocate the receiving

antenna.

• Increase the separation between

the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

IMPORTANT SAFETY IN-

STRUCTIONS

Read all the instructions before using

the product.

몇 WARNING

To reduce the risk of fire, electric

shock, or injury:

1 Do not leave the unit when plugged

in. Unplug from outlet when not in

use and before servicing.

2 To reduce the risk of electric shock

use indoors only.

3 Do not allow to be used as a toy.

Close attention is necessary when

used near children.

4 Use only as discribed in this manu-

al. Use only manufacturer’s recommended attachments.

5 Do not use with damaged cord or

plug. If the unit is not working as it

should, has been dropped, damaged, left outdoors, or dropped into

water, return it to a service center.

6 Do not pull or carry by cord, use

cord as a handle, close a door on

cord, or pull cord around sharp edges or corners. Do not run the unit

over cord. Keep cord away from

heated surfaces.

7 Do not unplug by pulling on cord. To

unplug, grasp the plug, not the

cord.

8 Do not handle plug or unit with wet

hands.

9 Do not put any object into openings.

Do not use with any opening

blocked; keep free of dust, lint, hair,

and anything that may reduce air

flow.

10 Keep hair, loose clothing, fingers,

and all parts of body away from

openings and moving parts.

11 Turn off all controls before unplug-

ging.

12 Use extra care when cleaning on

stairs.

13 Do not use to pick up flammable or

combustible liquids, such as gasoline, or use in areas where they may

be present.

14 Connect to a properly grounded

outlet only. See Grounding Instructions.

SAVE THESE INSTRUCTIONS!

GROUNDING INSTRUCTIONS

This product must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This product

is equipped with a cord having an

equipment-grounding conductor and a

grounding plug. The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and ordinances.

DANGER

Improper connection of the equipmentgrounding conductor can result in a

risk of electrocution. Check with a qualified electrician or service personnel if

you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product - if it

will not fit the outlet, have a proper outlet installed by a qualified electrician.

Do not use any type of adapter with

this product.

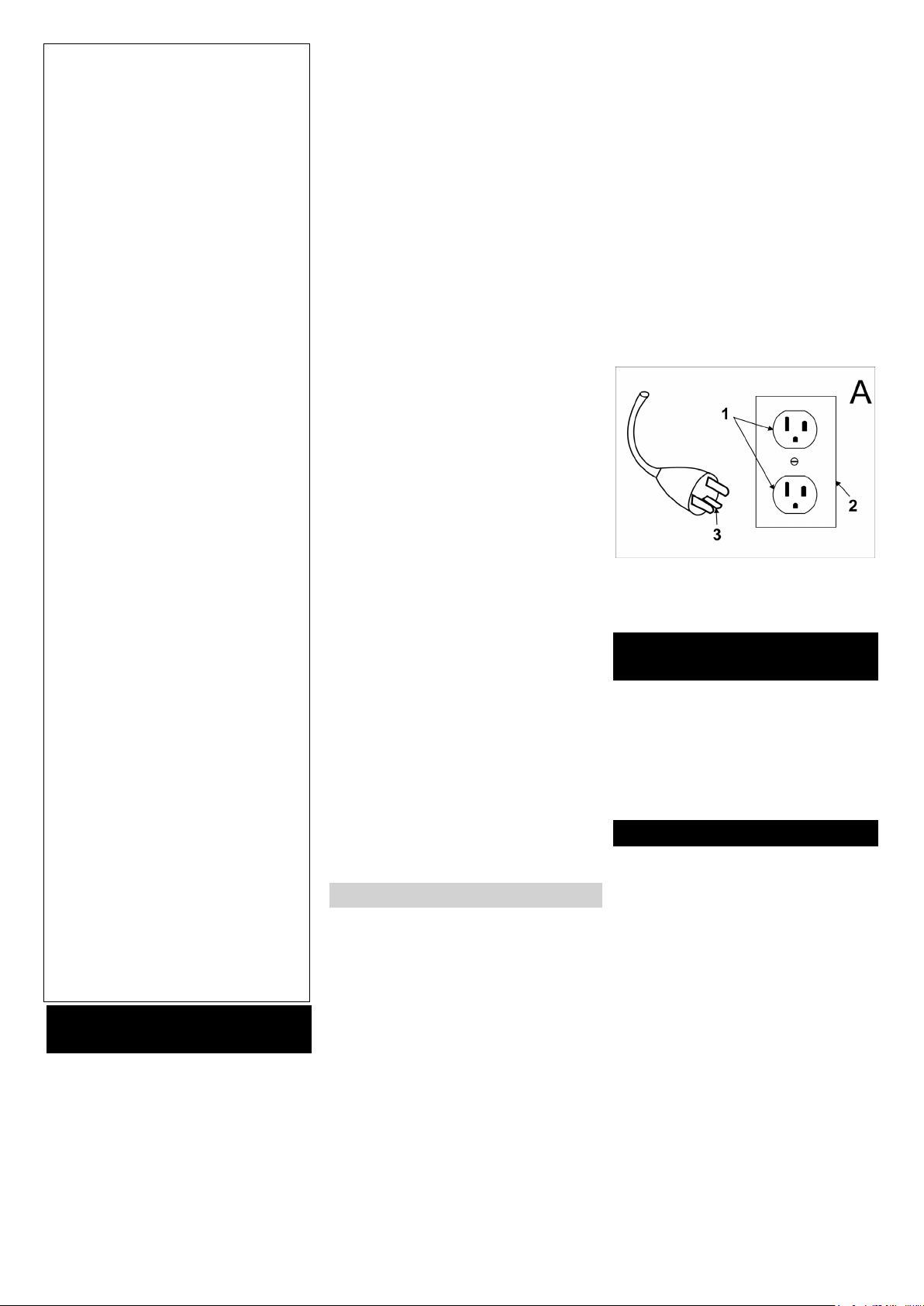

This appliance is for use on a nominal

120-volt circuit and has a grounding attachment plug that looks like the plug

illustrated in sketchpicture A. Make

sure that the appliance is connected to

an outlet having the same configuration as the plug. No adaptor should be

used with this appliance.

CONNECT TO A PROPERLY

GROUNDED OUTLET ONLY

1 Grounded outlet

2 Grounded outlet box

3 Grounded pin

OPERATOR QUALIFICA-

TIONS

Only trained and authorized persons

shall be permitted to operate a powered floor scrubber. Operators of powered floor scrubbers shall be qualified

as to visual, auditory, phisical, and

mental ability to operate the eqipment

safely.

OPERATOR TRAINING

Personnel who have not been trained

to operate powered floor scrubbers

may operate a floor scrubber for the

purposes of training only, and under

the direct supervision of the trainer.

This training should be conducted in an

area away from other trucks, obstacles, and pedestrians.

The operator training program should

include the user’s policies for the site

where the trainee will operate the floor

scrubber, the operating conditions for

that location, and the specific floor

scrubber the trainee will operate. The

training program shall be presented to

all new operators regardless of previous experience.

The training shall inform the trainee

that:

A The primary responsibility of the op-

erator is to use the powered floor

- 1

3EN

Page 4

scrubber safely following the instructions given in the training program.

B Unsafe or improper operation of a

powered floor scrubber can result

in: death or serious injury to the operator or others; damage to the

powered floor scrubber or other

property.

The training program shall emphasize

safe and proper operation to avoid injury to the operator and others and prevent property damage, and shall cover

the following areas.

A Fundamentals of the powered floor

scrubber(s) the trainee will operate:

1 characteristics of the powered floor

scrubber(s), including variations

between powered floor scrubbers in

the workplace;

2 similarities to and differences from

automobiles;

3 significance of nameplate data,

warnings, and instructions affixed

to the powered floor scrubber;

4 operating instructions and warnings

in the operating manual for the

powered floor scrubber, and instructions for inspection and maintenance to be performed by the

operator;

5 type of motive power and its char-

acteristics;

6 method of steering;

7 braking method and characteristics;

8 visibility forward and reverse;

9 stability characteristics with and

without load, with and without at-

tachments;

10 controls-location, function, method

of operation, identification of sym-

bols;

11 battery charging;

12 guards and protective devices for

the specific type of powered floor

scrubber;

13 other caracteristics of the specific

powered floor scrubber.

B Operating enviroment and its effect

on powered floor scrubber operation,

including:

1 floor or ground conditons including

temporary conditions;

2 ramps and inclines;

3 battery charging facilities;

4 narrow aisles, doorways, overhead

wires and piping, and other areas of

limited clearance;

5 areas where the powered floor

scrubber may be operated near

other powered industrial trucks,

other vehicles, or pedestrians;

6 use and capacity of elevators;

7 operation near edge of dock or

edge of improved surface;

8 other special operating conditions

and hazards which may be encountered.

C Operation of the powered floor

scrubber, including:

1 proper preshift inspection and ap-

proved method for removing from

service a powered floor scrubber

which is in need or repair;

2 travelling, turning corners;

3 parking and shutdown procedures;

4 other special operating conditions

for the specific application.

D Operating safety rules and practic-

es, including:

1 provisions of this Standard in Sec-

tion „operating safety rules and

practices“;

2 other rules, regulations, or practic-

es specified by the employer at the

location where the powered floor

scrubber will be used.

E Operational training practice, in-

cluding:

1 if feasible, practice in the operation

of powered floor scrubbers shall be

conducted in an area separate from

other workplace activities and per-

sonnel;

2 training practice shall be conducted

under the supervision of the trainer;

3 training practice shall include the

actual operation or simulated per-

formance of all operating tasks

such maneuvereing, travelling,

stopping, starting, and other activi-

ties under the conditions which will

be encountered in the use of the

powered floor scrubber.

TESTING, RETRAINING AND

ENFORCEMENT

A During training, performance and

oral and/or written tests shall be

given by the employer to measure

the skill and knowledge of the oper-

ator in meeting the requirements of

the Standard. Employers may dele-

gate such testing to others but shall

remain responsible for testing. Ap-

propiriate records shall be kept.

B Operators shall be retrained when

new equipment is introduced, exist-

ing equipment is modified, operat-

ing conditions change, or an

operator’s performance is unsatis-

factory.

C The user shall be responsible for

enforcing the safe use of the pow-

ered floor scrubber according to the

provisions of this Standard.

NOTE: Information on operator training is available from such sources as

powered floor scrubber manufacturers,

government agencies dealing with employee safety, trade organizations of

users of powered industrial trucks,

public and private organizations, and

safety consultants.

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility

of the operator.

The operator shall develop safe working habits and also be aware of hazardous conditions in order to protect

himself, other personnel, the powered

floor scrubber, and other material.

The operator shall be familiar with the

operation and function of all controls

and instruments before undertaking to

operate the unit.

Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular

unit being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require additional safety precautions or special operating instructions.

General

Before starting to operate the powered

floor scrubber:

A be in operating position;

B place directional controls in neutral;

C apply brake;

D turn switch to ON position.

Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designated

operators position.

Keep hands and feet inside the operator’s designated area or compartment

of the unit.

Understand unit limitations and operate the unit in a safe manner so as not

to cause injury to personnel. Safeguard pedestrians at all times.

A Do not drive a powered floor scrub-

ber up to anyone standing in front of

an object.

B Ensure that personnel stand clear

of the rear swing area before conducting turning maneuvers.

C Exercise particular care at cross

aisles, doorways, and other locations where pedestrians may step

4 EN

- 2

Page 5

into the path of travel of the powered floor scrubber.

Do not permit passengers to ride on

powered floor scrubbers unless a safe

place to ride has been provided by the

manufacturer.

A powered floor scrubber is attended

when the operator is less than 25 ft.

(7.6 m) from the unit, which remains in

his view.

A powered floor scrubber is unattended when the operator is more than 25

ft. (7.6 m) from the unit, which remains

in his view, or whenever the operator

leaves the unit and it is not in his view.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B place the directional controls in

neutral;

C apply the parking brake;

D stop the engine or turn off the con-

trols;

E if the unit must be on an incline,

block the wheels.

Maintain a safe distance from the edge

of ramps, platforms, and other similar

working surfaces.

When powered floor scrubbers are

driven on and off highway trucks or

trailers, the brakes on the highway

trucks or trailers shall be applied and

wheel chocks or other positive mechanical means shall be used to prevent unintentional movement of

highway trucks and trailers.

Whenever powered floor scrubbers

are driven on and off semitrailers that

are not coupled to a tractor, supports

may be needed to prevent upending or

corner dipping.

Care shall be taken not to contact overhead installations such as lights, wiring, pipes, sprinkler systems, etc.

Report all accidents involving personnel, building structures, and equipment

to the supervisor or as directed.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Travelling

Observe all traffic regulations including

authorized plant speed limits. Under

normal traffic conditions, keep to the

right. Maintain a safe distance, based

on speed of travel, from the unit ahead;

and keep the unit under control at all

times.

Yield the right of way to pedestrians

and emergency vehicles such as ambulances and fire trucks.

Do not pass another truck travelling in

the same direction at intersections,

blind spots, or at other dangerous locations.

Slow down and sound the audible

warning device(s) at cross aisles and

other locations where vision is obstructed.

Cross railroad tracks at an angle wherever possible. Do not park closer than

6 ft (1800 mm) to the nearest rail of a

railroad track.

Ascend or descend grades slowly, and

with caution. Avoid turning, if possible,

and use extreme caution on grades,

ramps, or inclines; normally travel

straight up and down.

Keep a clear view of the path of travel

and observe for other traffic, personnel, and safe clearances.

Under all travel conditions, operate the

unit at a speed that will permit it to be

brought to a stop in a safe manner.

Make starts, stops, turns, or direction

reversals in a smooth manner so as

not to shift load and/or overturn the

powered floor scrubber.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors.

Before driving over a dockboard or

bridge plate, be sure that it is properly

secured. Drive carefully and slowly

across the dockboard or bridge plate,

and never exceed its rated capacity.

Do not drive powered floor scrubbers

onto any elevator unless specifically

authorized to do so. Approach elevators slowly, and then enter squarely after the elevator car is properly leveled.

Once on the elevator, neutralize the

controls, shut off power, and set

brakes. It is advisable that all other personnel leave the elevator before the

powered floor scrubber is allowed to

enter or leave.

When negotiating turns, reduce speed

to a safe level consistent with the operating environment. Make the turns

smoothly. Except when maneuvering

at a very low speed, turn the steering

control at a moderate, even rate.

The operation of a powered floor

scrubber requires special safety considerations, as follows:

A A powered floor scrubber may tip

over if an operator fails to slow down to

a safe speed before making turns. Indications that a truck is being driven at

an excessive speed during turning maneuvers include:

1 tire skidding;

2 unit side sway;

3 wheel lift; and

4 the need to grip the steering wheel

tightly to keep from sliding out of the

seat.

B The likelihood of lateral tipover is increased under any of the following

conditions, or combinations of them:

1 travelling on an uneven surface;

2 travelling at excessive speed.

C

Tipping forward can occur and its likeliehood is increased under the following

conditions, or combination of them:

1 The operator should stay with the

powered floor scrubber if it falls off

a loading dock or ramp. The operator should hold on firmly and lean

away from the point of ipact.

2 Where the enviroment presents a

severe hazard, or there are other

unusual operating conditions, the

user may need to establish different

and/or additional safety precautions

and special operating instructions

appropriate for the conditions.

Operator care of the unit

At the beginning of each shift and before operating the powered floor scrubber, check its condition, giving special

attention to the following:

A condition of tires

B if pneumatic tires, check inflation

pressures

C warning and safety devices

D lights

E battery

F controls

G lift and tilt systems

H chains and cables

I limit switches

J brakes

K steering mechanism

L additional items or special equip-

ment as specified by the user and/

or manufacturer

If the unit is found to be in need of re-

pair or in any way unsafe, or contributes to an unsafe condition, the matter

shall be reported immediately to the

user’s designated authority, and the

unit shall not be operated until it has

been restored to safe operating condition.

If during operation the unit becomes

unsafe in any way, the matter shall be

reported immediately to the user’s designated authority, and the unit shall not

be operated until it has been restored

to safe operating condition.

Do not make repairs or adjustments

unless specifically authorized to do so.

Do not use open flames when checking electrolyte level in storage batteries.

- 3

5EN

Page 6

MAINTENANCE AND RE-

BUILD PRACTICES

Operation of the unit may be hazardous if maintenance is neglected or repairs, rebuilds, or adjustments are not

performed in accordance with the manufacturer’s design criteria. Therefore,

maintenance facilities (on or off premises), trained personnel, and detailed

procedures shall be provided.

Parts manuals and maintenance manuals may be obtained by the powered

floor scrubber manufacturer.

In unusual cases not covered by the

manuals referred above, consult the

powered floor scrubber manufacturer.

Maintenance and inspection of the unit

shall be performed in conformance

with the following practices:

A a schedules planned maintenance,

lubrication, and inspection system

shall be followed; consult the manufacturer’s recommendations.

B only tranined and authorized per-

sonnel shall be permitted to maintain, repair, adjust, and inspect the

unit, and in accordance with manufacturer’s specifications.

When lifting powered floor scrubbers

for repair or inspection, the units shall

be lifted in a safe, secure, stable manner. Removal of components such as

counterweights or uprights will change

the center of gravity and may create an

unstable condition.

Before starting inspection and repair of

powered floor scrubber:

A raise drive wheels free of floor and

disconnect battery and use chocks

or other positive truck-posirioning

devices;

B block chassis before working on

them;

C disconnect battery before working

in the electrical system;

D the charger connector shall be

plugged only into the battery connector and never into the unit connector.

Operation of the powered floor scrubber to check the performance shall be

conducted in an authorized area where

safe clearance exists.

A Before starting to operate the unit:

1 be in operating position;

2 apply brake;

3 place directional controls in neutral;

4 turn switch to ON position;

5 check functioning of lift and tilt sys-

tems, steering, warning devices,

and brakes.

B Before leaving the unit:

1 stop unit;

2 place directional control in neutral;

3 apply the parking brake;

4 stopp the engine or turn off the pow-

er;

5 turn off the control circuit;

6 if the unit must be left on an incline,

block the wheels.

Avoid fire hazards and have fire pro-

tection equipment present in the work

area. Do not use an open flame to

check the level of any fluid, especially

battery electrolyte. Do not use open

pans of fuel or flammable cleaning fluids for cleaning parts.

Properly ventilate work area, vent exhaust fumes, and keep shop clean and

dry.

Brakes, steering mechanisms, control

mechanisms, warning devices, lights,

governors, guards and safety devices,

articulating axle stops, and frame

members shall be carefully and regularly inspected and maintained in safe

operating condition.

FIRE SAFETY STANDARD

Any unit not in safe operating condition

shall be removed from service.

Repairs shall not be made in Class I,

Class II, and Class III locations.

Repairs to the electrical system of battery powered floor scrubbers shall be

performed only after the battery has

been disconnected.

Operating Temperature. When the

temperature of any part of any powered floor scrubber is found to be in excess of its normal operating

temperature and creates a hazardous

condition, the vehicle shall be removed

from service and shall not be returned

to service until the cause for such overheating has been eliminated.

Fire Prevention.The unit shall be kept

in a clean condition and reasonably

free of lint, excess oil, and grease.

Noncombustible agents are preferred

for cleaning the unit. Flammable liquids

[those having flash points at or above

100°F (37,8°C)] are not allowed. Precautions regarding toxicity, ventilation,

and fire hazard shall be appropriate for

the agent or solvent used.

Nameplate Visibility. The unit type

designations as shown on the nameplate and the type markers shall not be

covered over with paint so that their

identification information is obscured.

Changing and Charging Storage

Batteries.

This section shall apply to batteries

used on electric trucks. The two types

of batteries commonly are lead and

nickel-iron. They contain corrosive

chemical solutions, either acid or alkali,

and, therefore, present a chemical

hazard. While being charged, they give

off hydrogen and oxygen, which, in

certain concentrations, are explosive.

Battery-charging installations shall be

located in areas designated for that

purpose; such areas shall be kept free

of extraneous combustible materials.

Facilities shall be provided for the following:

A Flushing spilled electrolyte;

B Fire protection;

C Protecting charging apparatus from

damage by trucks, and

D Adequate ventilation for dispersal

of fumes from gasing batteries.

Where on-board chargers are used,

charging shall be accomplished at locations designated for that prupose,

taking into account the electrical requirements of the charger and facilities

for fire protection.

Exception: Flushing facilities shall not

be required if charging is accomplished

without removing the battery from the

vehicle.

Where handling acid concentrates

greater than 50 percent acid (above

1.400 specific gravity) an eye-wash

fountain shall be provided.

A conveyor, overhead hoist, or equivalent material handling equipment shall

be provided for handling batteries.

Chain hoists shall be equipped with

load-chain containers. Where a hand

hoist is used, uncovered batteries shall

be covered with a sheet of plywood or

other nonconducting material to prevent the hand chain from shorting in

cell connectors or terminals. A properly

insulated spreader bar shall be used

with any overhead hoist.

Reinstalled or new batteries shall meet

or exceed the battery type marked on

the unit. Reinstalled batteries shall be

positioned properly and secured in the

unit.

A carboy tilter or siphon shall be provided where acid in carboys is used.

Where diluting concentrated sulfuric

acid to make up elektrolyte, the acid

ALWAYS shall be added to the water –

not reverse. Battery maintenance personnel shall wear protective clothing

such as eye protection, long sleeves,

and gloves.

Exception: Removal and replacement

of batteries shall not require the use of

protective clothing.

Electrical installations shall be in accordance with NFPA 70, National electric code, and any local ordinances.

6 EN

- 4

Page 7

Trained and authorized personnel

shall change or charge batteries.

The powered floor scrubber shall be

positioned properly and brakes shall

be applied before attempting to change

or charge batteries.

Where charging batteries, the vent

caps shall be kept in place to avoid

electrolyte spray. Care shall be taken

to ensure that vent caps are functionning. The battery (or compartment)

cover(s) shall be open to dissipate heat

and gas.

Smoking shall be prohibited in the

charging area.

Precautions shall be taken to prevent

open flames, sparks, or electric arcs in

battery-charging areas.

Tools and other metallic objects shall

be kept away from the tops of uncovered batteries.

The unit shall not be used in classified

areas.

- 5

7EN

Page 8

Please read and comply with

these original instructions

prior to the initial operation of your appliance and store them for later use or

subsequent owners.

Contents

Safety instructions . . . . . . . EN . . 6

Function . . . . . . . . . . . . . . . EN . . 6

Proper use . . . . . . . . . . . . . EN . . 6

Environmental protection . . EN . . 6

Control elements. . . . . . . . . EN . . 7

Before Startup. . . . . . . . . . . EN . . 8

Operation . . . . . . . . . . . . . . EN . 10

Grey Intelligent Key . . . . . . EN . 12

Transport. . . . . . . . . . . . . . . EN . 11

Storage . . . . . . . . . . . . . . . . EN . 13

Maintenance and care . . . . EN . 13

Troubleshooting . . . . . . . . . EN . 16

Technical specifications . . . EN . 18

Accessories and Spare Parts EN . 19

Warranty . . . . . . . . . . . . . . . EN . 19

Safety instructions

Before using the appliance for the first

time, read and observe these operating instructions and the accompanying

brochure: Safety information for brush

cleaning units and spray-extraction

units, 5.956-251.

The appliance has been approved for

use on surfaces with max. gradients as

listed under "Technical Specifications".

Safety Devices

Safety devices serve to protect the

user and must not be rendered in operational or their functions bypassed.

Safety button

To take all functions out of operation

immediately: Bring the safety switch

into the "0" position.

– When switching off the safety

switch, the appliances brakes hard.

– The emergency-stop has a direct

effect on all machine functions.

Seat switch

Switches off the drive motor after a

short delay, if the operator leaves the

operator seat during operation or while

moving.

Symbols on the machine

CAUTION

Risk of injury on account

of being crushed.

Keep hands away from

this area while swivelling

down the waste water

tank.

DANGER

Increased risk of accidents due to high speed.

Drive slowly on slopes.

Danger or hazard levels

DANGER

Immediate danger that can cause severe injury or even death.

몇 WARNING

Possible hazardous situation that

could lead to severe injury or even

death.

CAUTION

Pointer to a possibly dangerous situation, which can lead to minor injuries.

ATTENTION

Pointer to a possibly dangerous situation, which can lead to property damage.

Function

The scrubber vacuum is used for wet

cleaning or polishing of level floors.

You can adjust the machine to suit the

cleaning task by modifying the settings

for water quantity, contact pressure of

the brushes, detergent quantity and

driving speed.

Proper use

Use this appliance only as directed in

these operating instructions.

– The appliance may only be used for

the cleaning of hard surfaces that

are not sensitive to moisture and

polishing operations.

– This appliance is intended for inside

use.

– The application temperature ranges

from +5°C to +40°C.

– The appliance is not suited for the

cleaning of frozen grounds (e.g. in

cold stores).

– The appliance is suitable for a max.

water depth of 1 cm. Do not drive

into an area where there is a risk of

this max. water height being exceeded.

– The appliance may only be

equipped with original accessories

and spare parts.

– The appliance is not intended for

the cleaning of public traffic routes.

– The machine should not be used on

surfaces that are sensitive to pressure. Please consider the allowed

load per surface unit of the floor.

Details of load per surface unit can

be found in the technical data.

– The appliance is not suited for the

use in potentially explosive environments.

– The machine should not be used to

suck in inflammable gases, undiluted acids or solvents.

This includes petrol, thinning

agents or hot oil that can form an

explosive mixture when it comes in

contact with sucked air. Do not use

acetone, undiluted acids and solvents as they are aggressive towards the materials from which the

appliance is made.

Environmental protection

The packaging materials

are recyclable. Please do

not throw packaging in the

domestic waste but pass it

on for recycling.

Old units contain valuable

recyclable materials. Batteries, oil and similar substances may not be released into

the environment. Therefore

please dispose of old units

through suitable collection

systems.

Notes about the ingredients

(REACH)

You will find current information about

the ingredients at:

www.kaercher.com/REACH

8 EN

- 6

Page 9

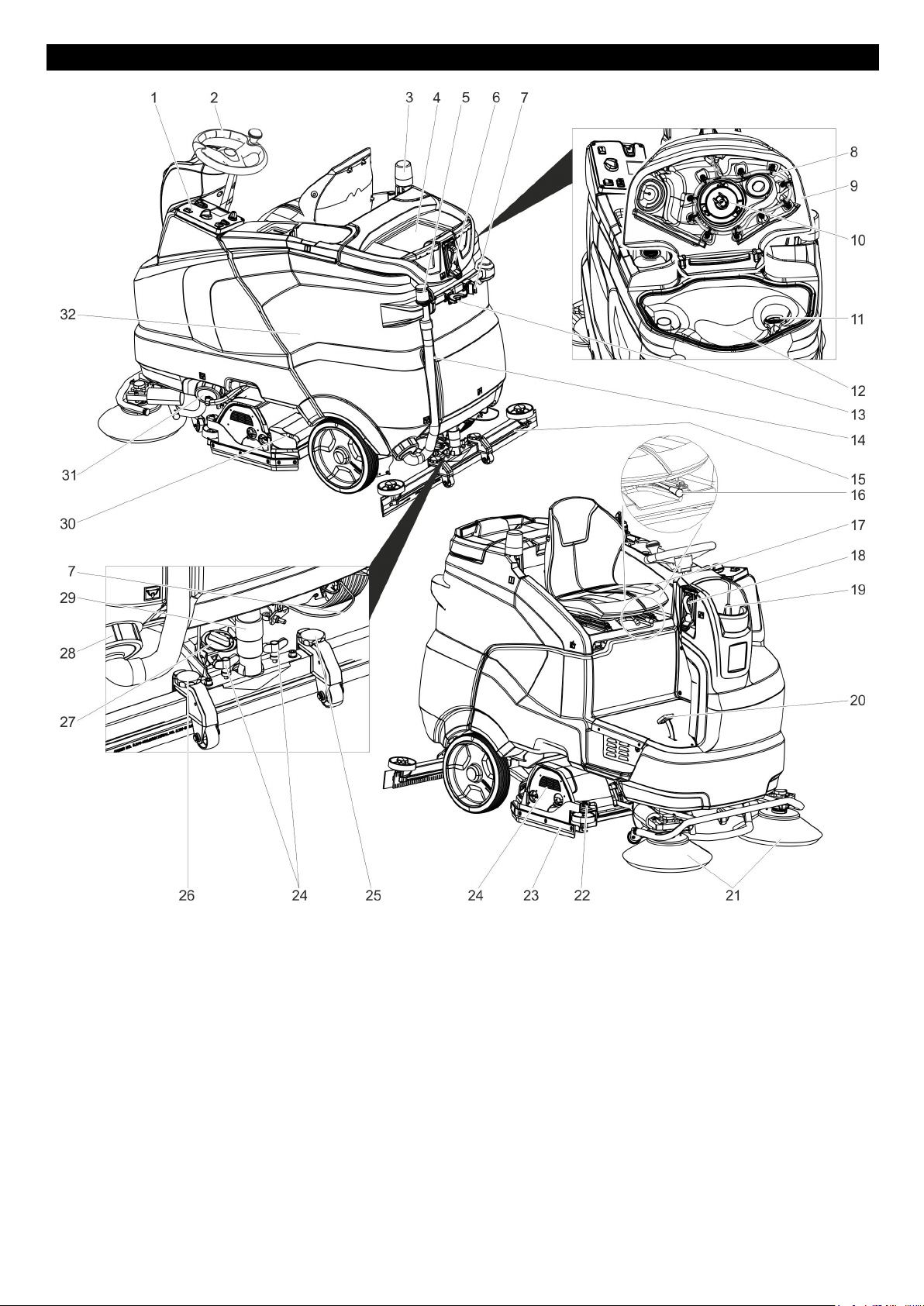

Control elements

1 Operating field

2 Steering wheel

3 Warning lamp **

4 Storage surface for cleaning set

"Home base box“

5 Dosing equipment for dirt water

6 Water connection for wastewater

tank rinsing system **

7 Mop holder **

8 Wastewater tank rinsing system **

9 Cover dirt water reservoir

10 Float

11 Fluff filter

12 Dirt water reservoir

13 Tool holder **

14 Dirt water discharge hose

15 Vacuum bar *

16 Lever for seat adjustment

17 Seat (with seat switch)

18 Filling system **

19 Fresh water tank cover

20 Drive pedal

21 Side brush (only SB version)

22 Adjustment wheel for wiping flap*

23 Wiping flap

24 Cleaning head *

25 Height adjustment of suction bar

26 Wing nuts for fastening the vacuum

bar

27 Rotary handle to incline the vacuum

bar

28 Lock, dirt water reservoir

29 Suction hose

- 7

30 Waste container (only with R clean-

ing head) *

31 Closure fresh water tank with fresh

water filter

32 Battery

* not included in the delivery

** option

9EN

Page 10

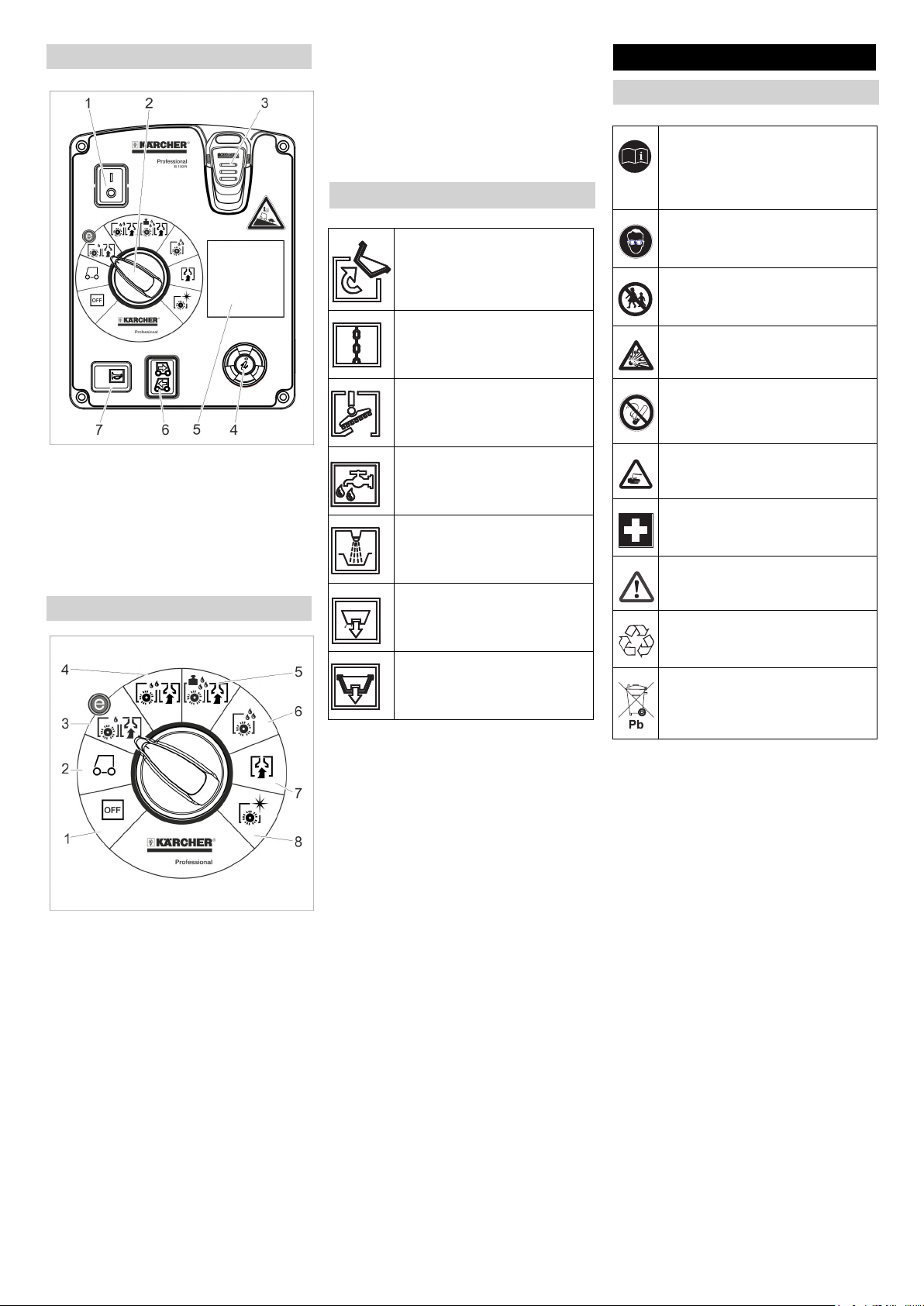

Operator console

Wet clean the floor and allow the

detergent to react.

7 Vacuuming

Suck in the dirt fleet.

8 Polishing

Polishing the floor without the appli-

cation of liquid.

Symbols on the machine

Handle for swivelling up the

waste water tank

Lashing point

Before Startup

Batteries

Observe the directions on the

battery, in the instructions for

use and in the vehicle operating instructions

Wear eye protection

Keep children away from acid

and batteries

Danger of explosion

1 Safety button

2 Programme switch

3 Intelligent Key

4 Info button

5 Display

6 Drive direction switch

7 Horn

Programme switch

1 OFF

Device is switched off

2 Transport run

Driving to the Place of Use.

3 Eco programme

Wet clean the floor (with reduced

brush speed) and vacuum up

wastewater (with reduced suction).

4 Scrubbing suction

Wet clean the floor and vacuum up

dirt water.

5 Heavy programme

Wet clean the floor (with increased

brush contact pressure) and vacuum up dirt water.

6 Scrubbing

** option

Mop holder **

Water connection filling

system **

Water connection for

wastewater tank rinsing

system **

Drain outlet fresh water

tank

Drain outlet waste water

tank

Fire, sparks, naked flames

and smoking must be strictly

avoided

Danger of chemical burns

First aid

Warning note

Disposal

Do not throw the battery into

the regular waste

DANGER

Risk of explosion!

Do not place tools or similar items on

the battery. Risk of short-circuit and explosion.

Risk of injury. Ensure that wounds never come into contact with lead. Always

clean your hands after having worked

with batteries.

10 EN

- 8

Page 11

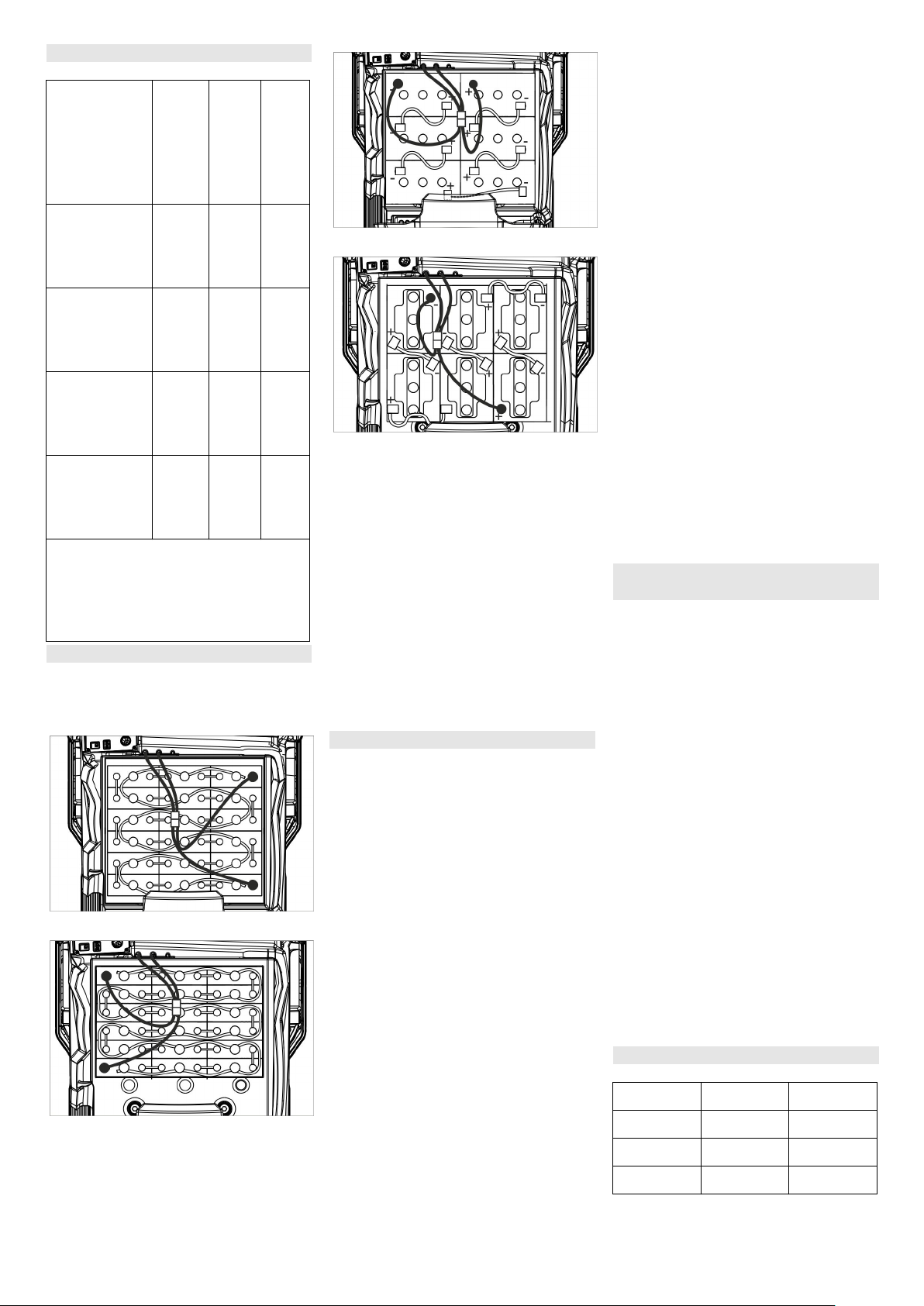

Recommended batteries

NOTICE

Average charging time is approx. 10 12 hours.

} *

3

/h] **

3

The recommended chargers (matching the batteries used) are regulated

electronically and will automatically

switch off the charging process.

Battery set

240Ah,

Order No.

4.035-

987.7

Volume [m

Air flow [m

27 10,8

trough, lowmaintenance

Battery set

180Ah,

4.035-

988.7

20,25 8,1

trough, lowmaintenance

Battery set

240Ah, 6

4.654-

306.7

6,975 2,79

blocks, maintenance-free

Battery set

180Ah, 6

4.654-

307.7

5,175 2,07

blocks, maintenance-free

* Minimum volume of the battery

charging room

** Minimum air flow between the battery charging room and the surroundings

Insert batteries and connect

Bring the safety switch into the "0"

position.

Tilt the wastewater tank backwards.

4.035-987.7

4.035-988.7

4.654-306.7 (arrangement A)

4.654-307.7 (arrangement B)

ATTENTION

Risk of damage. Ensure correct polarity.

Lubricate the battery pole with pole

grease.

Connect pole using the enclosed

connecting cable.

Connect the connection cable to

the free battery poles (+) and (-).

Insert battery plug.

ATTENTION

Risk of damage due to full discharge!

Charge the batteries before commissioning the appliance.

Charge the batteries

NOTICE

The appliance is equipped with a total

discharge protection, i.e. if the still admissible minimum of the capacity is

reached, the appliance can only be

driven. The display shows the message "Battery low - cleaning not possible" and "Battery empty - please

charge".

Drive the appliance directly to the

charging station; avoid any steep

gradients in the process.

NOTICE

While using other batteries (for e.g.

batteries from other manufacturers)

the total discharge protection level

must be reset by the Kärcher aftersales service according to the respective battery.

DANGER

Risk of electric shock. Observe supply

network and fuse protection - see

"Charger". Only use the charger in dry

rooms with sufficient ventilation!

DANGER

Danger of explosion. The room, where

the machine is kept to charge the battery, must feature a minimum volume

and an air exchange with a minimum

flow rate, depending on the type of battery (see "Recommended Batteries").

Danger of explosion. The charging of

wet batteries is only permitted if the

waste water reservoir is tilted up.

Swivel the wastewater tank up-

wards.

Separate the battery plug and con-

nect the charger cable.

Plug in the mains plug of the char-

ger.

Execute the charging process ac-

cording to the seperate instrucion

manual of the battery charger.

Low maintenance batteries (wet batteries)

Add distilled water one hour before

the charging process comes to an

end; follow the correct acid level.

There are corresponding indicators

on the battery. At the end of the

charging process, all cells must

gas.

DANGER

Danger of chemical burns. Filling water

in while the battery is discharged can

lead to acid leaks!

Wear goggles when handling battery

acid and adhere to instructions to prevent injuries and damage to clothing.

Flush any acid drops on the skin or

clothes immediately with plenty of water.

ATTENTION

Use only distilled or desalinated water

(EN 50272-T3) for filling the battery.

Do not add any substances (so-called

performance improving agents), else

warranty claims will not be entertained.

Maximum battery dimensions

Layout A B

Length 244 mm 312 mm

Width 190 mm 182 mm

Height 275 mm 365mm

- 9

11EN

Page 12

Information on the initial charge

With the initial charge, the control will

not yet be able to detect which battery

type has been installed. Keep charging

the batteries until the display shows a

full charge (batteries may still not be

completely charged). The next charging process will have an accurate display and charge power and the

batteries will be fully charged.

Note:

A "V" to the right of the bar of the battery indicator shows that the initial

charge has not been performed yet.

Use the appliance until the deep discharge protection switches off the

brush motor and the turbine after the

initial charge of the battery. This procedure is necessary to adjust the battery

indicator. Only then the correct battery

status is displayed.

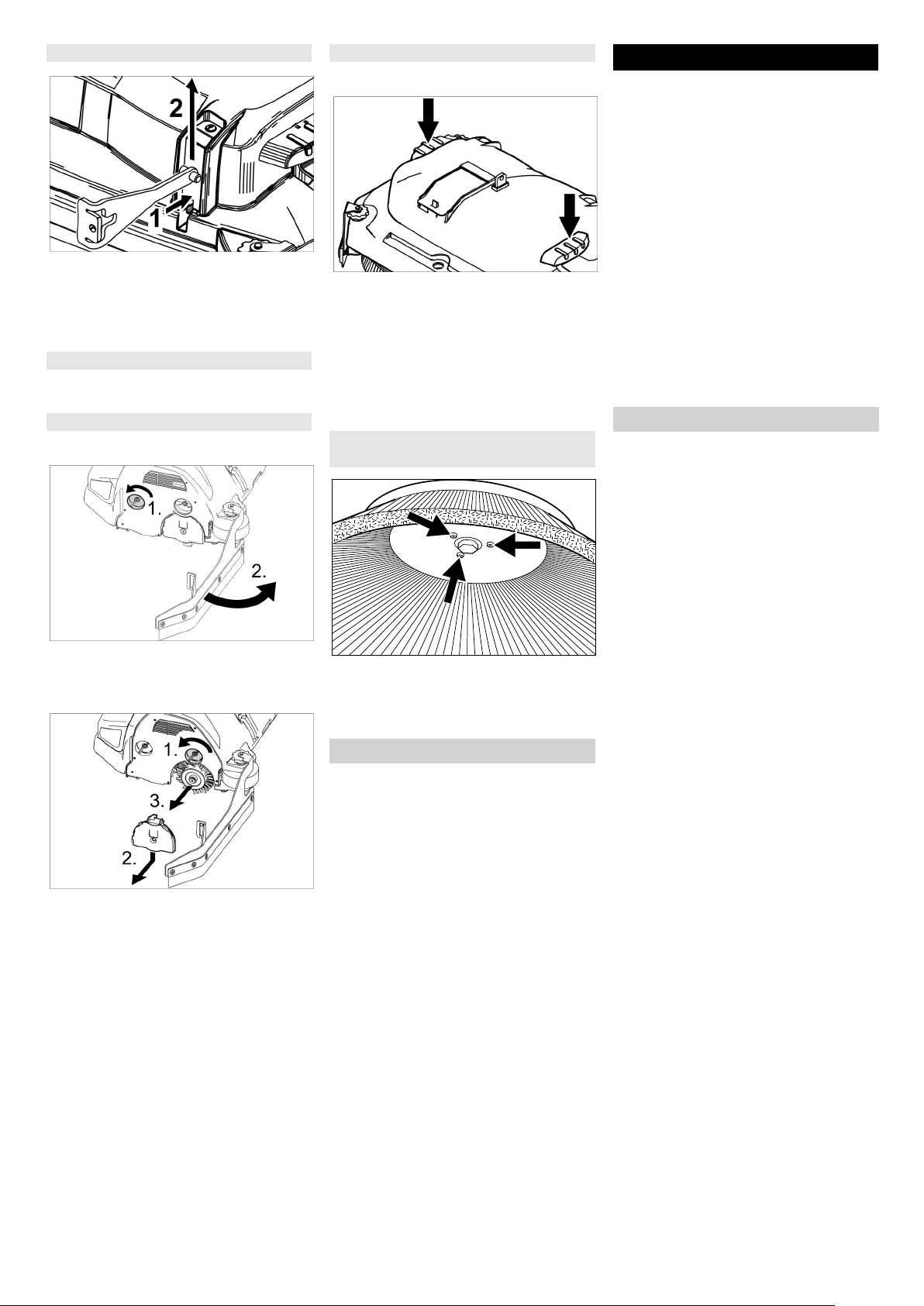

Removing the batteries

Bring the safety switch into the "0"

position.

Tilt the wastewater tank backwards.

Clamp off the minus pole of the bat-

tery.

Clamp off the remaining cables

from the battery.

Remove the batteries.

Dispose of the used batteries ac-

cording to the local provisions.

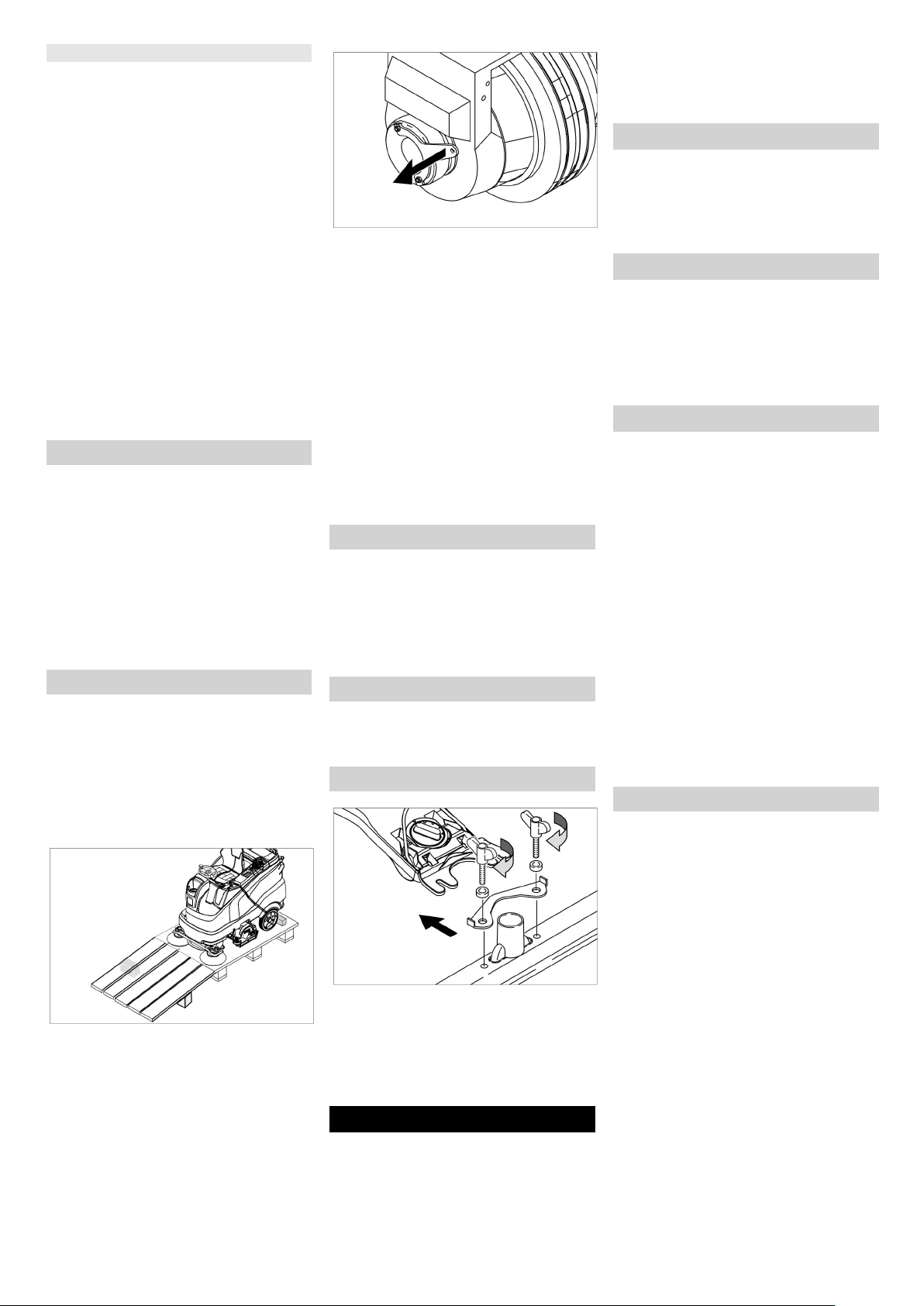

Unloading

NOTICE

To take all functions out of operation

immediately, bring the safety switch

into the "0" position.

Four floor boards of the pallet are

fastened with screws. Unscrew

these boards.

Place the boards on the edge of the

pallet. Place the boards in such a

way that they lie in front of the four

wheels of the machine. Fasten the

boards with screws.

Slide the four support beams in-

cluded in the packaging under the

ramp.

Remove the wooden bars in front of

the wheels.

Pull the brake lever and push the

appliance down the ramp with the

level pulled.

or

Plug in the Intelligent Key.

Bring the safety switch into the "1"

position.

Set programme selector switch to

transport run.

Set the travel direction switch to

"forward".

Actuate the accelerator pedal.

Drive the appliance off the pallet.

Bring the safety switch into the "0"

position.

Install cleaning head

The procedure for changing the cleaning head is described in the chapter

"Maintenance Tasks".

NOTICE

On some models, the cleaning head is

already installed.

Installing the Brushes

The installation of the brushes is described in the chapter "Maintenance

Tasks".

Installing the Vacuum Bar

Insert the vacuum bar into the vac-

uum bar suspension in such a man-

ner that the profiled sheet is

positioned above the suspension.

Tighten the wing nuts.

Insert the suction hose.

Operation

DANGER

Risk of injuries. Never use the unit

without protective roof in areas where

the operators can be hit by dropping

objects.

NOTICE

To take all functions out of operation

immediately, bring the safety switch

into the "0" position.

Adjusting driver's seat

Operate the lever for the seat ad-

justment and move the seat to the

desired position.

Release the seat adjustment lever

and lock the seat in place.

Turning on the Appliance

Take the seating position.

Plug in the Intelligent Key.

Bring the safety switch into the "1"

position.

Turn the programme switch to the

desired function.

Check parking brake

DANGER

Risk of accident. Prior to every operation, the parking brake must be

checked for proper function on a level

ground.

Turn on the appliance.

Set the travel direction switch to

"forward".

Set programme selector switch to

transport run.

Gently depress drive pedal.

The brake must unlock audibly. The

machine must roll easily on a plane

surface. When the pedal is released, the brake locks audibly.

Switch off the machine and call the

aftersales service if the above-mentioned events do not occur.

Driving

DANGER

Danger of accident. If the machine

does not brake, then proceed as follows:

If the appliance does not stop when

the accelerator is released on a

ramp with more than 2% inclination,

the safety switch may only be

brought in the "0" position if the

proper mechanical function of the

parking brake has been checked

prior to every operation of the appliance for safety reasons.

Switch off the machine only after it

comes to a complete halt (on an

even surface) and call up the aftersales service!

Further, follow all warning instruc-

tions for braking.

12 EN

- 10

Page 13

DANGER

Danger of tipping if gradient is too high.

The gradient in the direction of trav-

el should not exceed 10% (Adv

15%).

Drive only lengthwise on uphill and

downhill gradients, do not turn.

Danger of tipping when driving round

bends at high speed.

Danger of slipping on wet floors.

Drive slowly when cornering.

Danger of tipping on unstable ground.

Only use the machine on sound

surfaces.

Danger of tipping with excessive sideways tilt.

Driving

Take the seating position.

Plug in the Intelligent Key.

Bring the safety switch into the "1"

position.

Set programme selector switch to

transport run.

Set the drive direction using the

drive direction button at the operator console.

Determine the driving speed by

pressing the drive pedal.

Stop the machine: Release the

drive pedal.

NOTICE

The drive direction can also be

changed during the drive. Thus, very

blunt edges can be polished by moving

forward and backward a few times.

Overload

In case of overloading, the drive motor

automatically switches off after a certain period. A fault message is displayed on the console. The concerned

unit gets switched off if the controls get

overheated.

Allow machine to cool down at least

for 15 minutes.

Turn the programme switch to

"OFF", wait for a short period of

time and turn it back to the desired

programme.

Filling in detergents

Detergent

ATTENTION

Risk of damage. Only use the recommended detergents. With respect to

different detergents the operator bears

the increased risk regarding the operational safety and danger of accident.

Only use detergents that are free from

solvents, hydrochloric acid and hydrofluoric acid.

Follow the safety instructions for using

detergents.

Note

Do not use highly foaming detergents.

Recommended detergents:

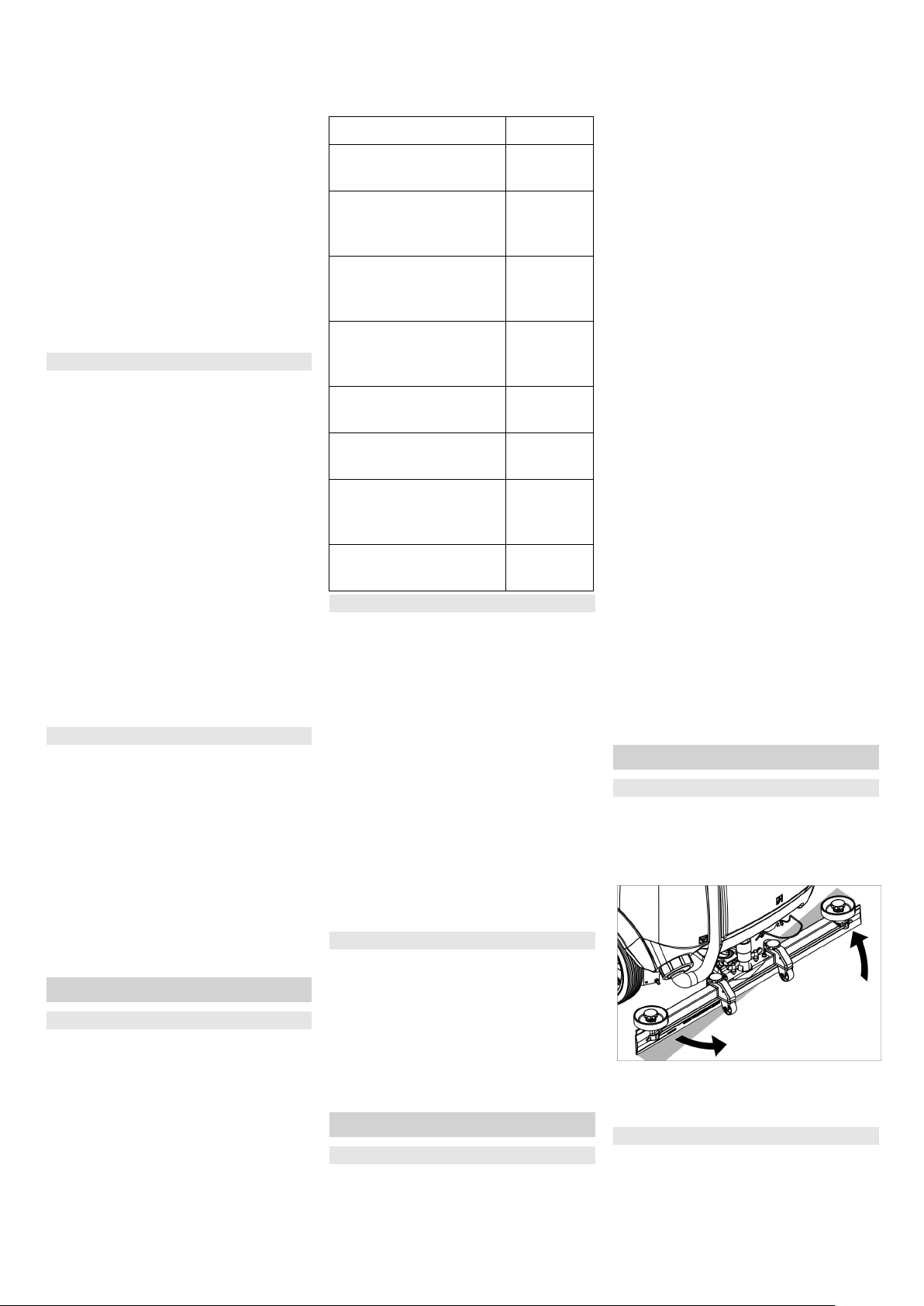

Application Detergent

Routine cleaning of all

water resistant floors

Routine cleaning of

RM 746

RM 780

RM 755 es

glossy surfaces (e.g.

granite)

Routine cleaning and

basic cleaning of indus-

RM 69

ASF

trial floors

Routine cleaning and

RM 753

basic cleaning of fine

stoneware tiles

Routine cleaning of tiles

RM 751

in sanitary areas

Cleaning and disinfec-

RM 732

tion in sanitary areas

Removal of coating

RM 752

from all alkali-resistant

floors (e.g. PVC)

Removal of coating

RM 754

from linoleum floors

Fresh water

Open the cover of the fresh water

reservoir.

Fill fresh water (max. 60 °C) until 15

mm below the upper edge of the

tank.

Pour in detergent.

NOTICE

If detergent is added to the cleaning

detergent tank first, followed by water,

there could be a lot of foam.

Close the cover of the fresh water

reservoir.

NOTICE

Fill up the fresh water tank completely

before starting up the machine to ventilate the water supply system.

Filling system (optional)

Connect the water hose to the con-

nection neck on the filling system.

Open the water supply.

Once the maximum fill level is

reached, the built-in floater valve

will stop the water inflow.

Shut off water supply.

Remove the water hose.

Setting the parameters

With yellow Intelligent Key

Parameters for the different cleaning

programmes are preset in the appliance.

Depending on the authorisation of the

yellow Intelligent Key, individual parameters can be changed.

The modification of the parameters is

only valid until another cleaning programme is selected via the programme

selection switch.

If you wish to permanently change the

parameters, you must use a grey Intelligent Key. This adjustment procedure

is described in the section "Grey Intelligent Key“.

Note:

Almost all displayed text regarding parameter adjustment is self-explanatory. The only exception is the parameter

FACT:

– Fine Clean: Lower brush speed for

removing the grey film on fine stone

floors.

– Whisper Clean: Medium brush

speed for regular cleaning with reduced noise level.

–

Power Clean: High brush speed for

polishing, crystallising and sweeping.

Turn the program selection switch

to the desired cleaning program.

Turn the info button until the de-

sired parameter is displayed.

Press Info button - the set value

blinks.

Set the desired value by turning the

info button.

Confirm the changed setting by

pressing the Info button or wait till

the set value is automatically accepted after 10 seconds.

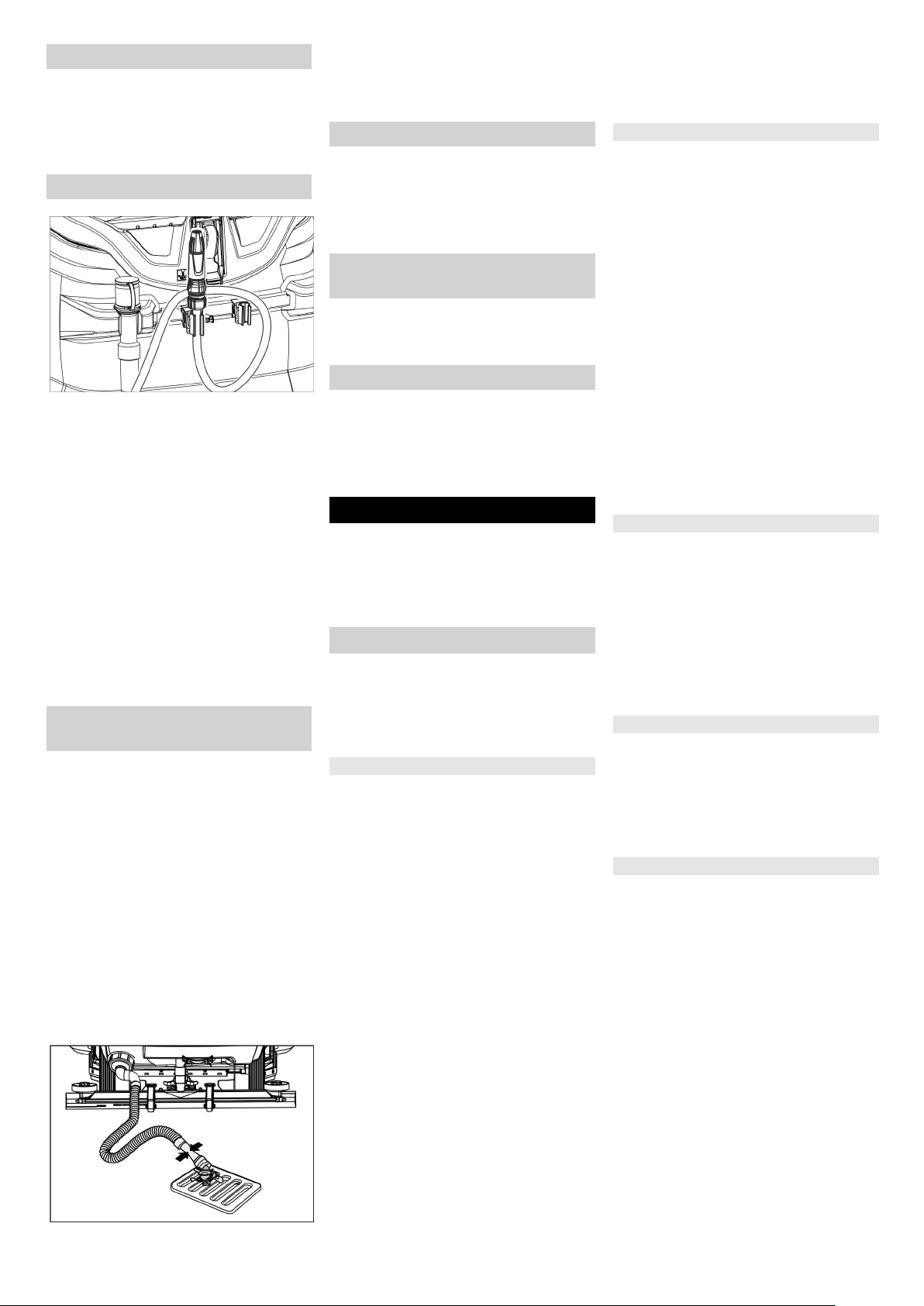

Setting the Vacuum Bar

Oblique position

To improve the vacuuming result on

tiled floors the vacuum bar can be

turned to an oblique position of up to

5°.

Release the wing nuts.

Turn the vacuum bar.

Tighten the wing nuts.

Inclination

If the vacuum result is unsatisfactory

the inclination of the straight vacuum

bar can be modified.

Adjust the rotary handle to incline

the suction bar.

- 11

13EN

Page 14

Adjust wiping flaps

Adjust the wiper flaps by turning the

adjustment wheel so that they

touch the floor.

Turn the adjustment wheel an addi-

tional turn toward the bottom.

Spray nozzle (option)

The hose with the spray nozzle is attached to the back of the appliance. It

serves for washing away dirt and for

manual cleaning of the wastewater

tank.

Turn programme selector switch to

"transport run".

Press Info button.

Turn the info button until "tank rins-

ing" is shown on the display.

Press Info button.

Turn the info button until "ON" is

displayed.

Press Info button.

The water pump delivers fresh water through the spray nozzle.

Emptying the Dirt Water Reser-

voir

NOTICE

Overflow wastewater tank. When the

wastewater tank is full, the suction turbine switches off and "Wastewater

tank full" is shown on the display.

몇 WARNING

Please observe the local provisions regarding the wastewater treatment.

Take the dirt water discharge hose

from the support and lower above a

suited collection device.

NOTICE

The wastewater flow can be controlled

by squeezing the dosing unit.

Let off water by opening the dosage

device at the discharge hose.

The rinse the dirt water reservoir

with clear water.

Emptying the Fresh Water Tank

Open the lock of the fresh water

reservoir.

Drain the fresh water.

Attach the closure of the fresh wa-

ter tank.

Empty waste container (only

with R cleaning head)

Check the waste container. If need-

ed, remove and empty waste container after work.

Shutting down

Remove the Intelligent Key.

Secure the machine with wheel

chocks to prevent it from rolling

away.

Charge battery, if required.

Grey Intelligent Key

Plug in the Intelligent Key.

Select the desired function by turn-

ing the Info button.

The different functions are described in

the following.

Transport run

Turn programme selector switch to

"transport run".

Press Info button.

In the transport run menu the following

settings can be made:

Key management

In this menu item the authorisations for

yellow intelligent keys as well as the

language of the display texts are selected.

Turn the info button until "key man-

agem." is shown on the display.

Press Info button.

Remove the grey Intelligent Key

and insert the yellow Intelligent Key

to be programmed.

Select the desired menu item to be

modified by turning the Info button.

Press Info button.

Adjust the menu item by turning the

Info button.

Confirm the setting by pressing the

menu item.

Select the next menu item to be

modified by turning the Info button.

In order to save the authorisations,

call the "Save?" menu by turning

the info button and then press the

info button.

"Continue key menu":

Yes: Programme further Intelligent

Key.

No: Exit key menu.

Press Info button.

Selecting the brush shape

This function is required when changing the cleaning head.

Turn the info button until "brush

head" is shown on the display.

Press Info button.

Turn the info button until the de-

sired brush shape is highlighted.

Press Info button.

Move the hoist drive for replace-

ment of the cleaning head by turning the info button:

up: Raise

down: Lower

OFF: Stop

Exit menu: Select "OFF" by turning

the info button and press the info

button.

When exiting the menu, the control

performs a restart.

Stopping times

Turn the info button until "stopping

times" is shown on the display.

Press Info button.

Turn the info button until the de-

sired assembly is highlighted.

Press Info button.

Turn the info button until the de-

sired stopping time is reached.

Press Info button.

Setting the battery type

Turn the info button until "Battery

menu" is displayed.

Press Info button.

Turn the info button until the de-

sired battery type is highlighted.

Press Info button.

Standard setting

Changes of the parameters of the individual cleaning programmes that were

made during the operation are reset to

the basic setting after switching off the

appliance.

Turn the info button until "Basic set-

ting" is displayed.

Press Info button.

Turn the info button until the de-

sired cleaning programme is displayed.

Press Info button.

Turn the info button until the de-

sired parameter is displayed.

Press Info button - the set value

blinks.

Set the desired value by turning the

info button.

Press Info button.

14 EN

- 12

Page 15

Setting the language

Turn the info button until "Lan-

guage" is displayed.

Press Info button.

Turn the info button until the de-

sired language is highlighted.

Press Info button.

Factory setting

The factory settings of all parameters

are restored.

Cleaning Programs

Parameters that are adjusted with the

grey Intelligent Key, are kept until another setting is selected.

Turn the program selection switch

to the desired cleaning program.

Press the info button - the first ad-

justable parameter is displayed.

Press Info button - the set value

blinks.

Set the desired value by turning the

info button.

Confirm the changed setting by

pressing the Info button or wait till

the set value is automatically accepted after 10 seconds.

Select the next parameter by turn-

ing the Info button.

After all desired parameters have

been modified, turn the info button

until "Exit menu" is displayed.

Press the info button - you will exit

the menu.

Transport

DANGER

Risk of injury! When loading or unloading the appliance, it may only be operated on gradients of max. 10% (Adv

15%). Drive slowly.

CAUTION

Risk of injury and damage! Observe

the weight of the appliance when you

transport it.

When transporting in vehicles, se-

cure the appliance according to the

guidelines from slipping and tipping

over.

With mounted D cleaning head

Remove brushes from the brush

head.

Maintenance and care

DANGER

Risk of injury! Before working on the

appliance, remove the Intelligent Key

and the mains plug of the charger.

Pull out the battery plug.

Drain and dispose of the dirt water

and the residual fresh water.

몇 CAUTION

Risk of injury due to overrun of the suction turbine.

Suction turbine will continue to run for

a while after switch-off. Carry out maintenance tasks only after the suction

turbine has come to a halt.

Maintenance schedule

After the work

ATTENTION

Risk of damage. Do not sluice the appliance with water and do not use aggressive detergents.

Drain off dirt water.

Clean protective turbine strainer.

Only with R cleaning head Remove

bulk waste container and empty it.

Clean the outside of the appliance

with a damp cloth which has been

soaked in mild detergent.

Clean the vacuum lips and the wip-

ing lips, check for wear and replace

if required.

Check the brushes for wear, re-

place if required.

Charge battery.

Monthly

During long operating pauses: Car-

ry out refill charging for the battery.

Check battery pole for oxidation;

brush it if required and lubricate it

using pole grease. Ensure that the

connection cable sits firmly.

Clean the seals between dirt water

reservoir and cover and check for

tightness, replace if required.

Check the acid density of the cells if

the batteries are not maintenancefree batteries.

Clean the brush tunnel (only R

cleaning head)

Remove the water distribution strip

from the cleaning head and clean

water canal (only R cleaning head).

Yearly

Have the prescribed inspection car-

ried out by the customer service.

Maintenance Works

Maintenance contract

To ensure a reliable operation of the

appliance maintenance contracts can

be concluded with the competent

Kärcher sales office.

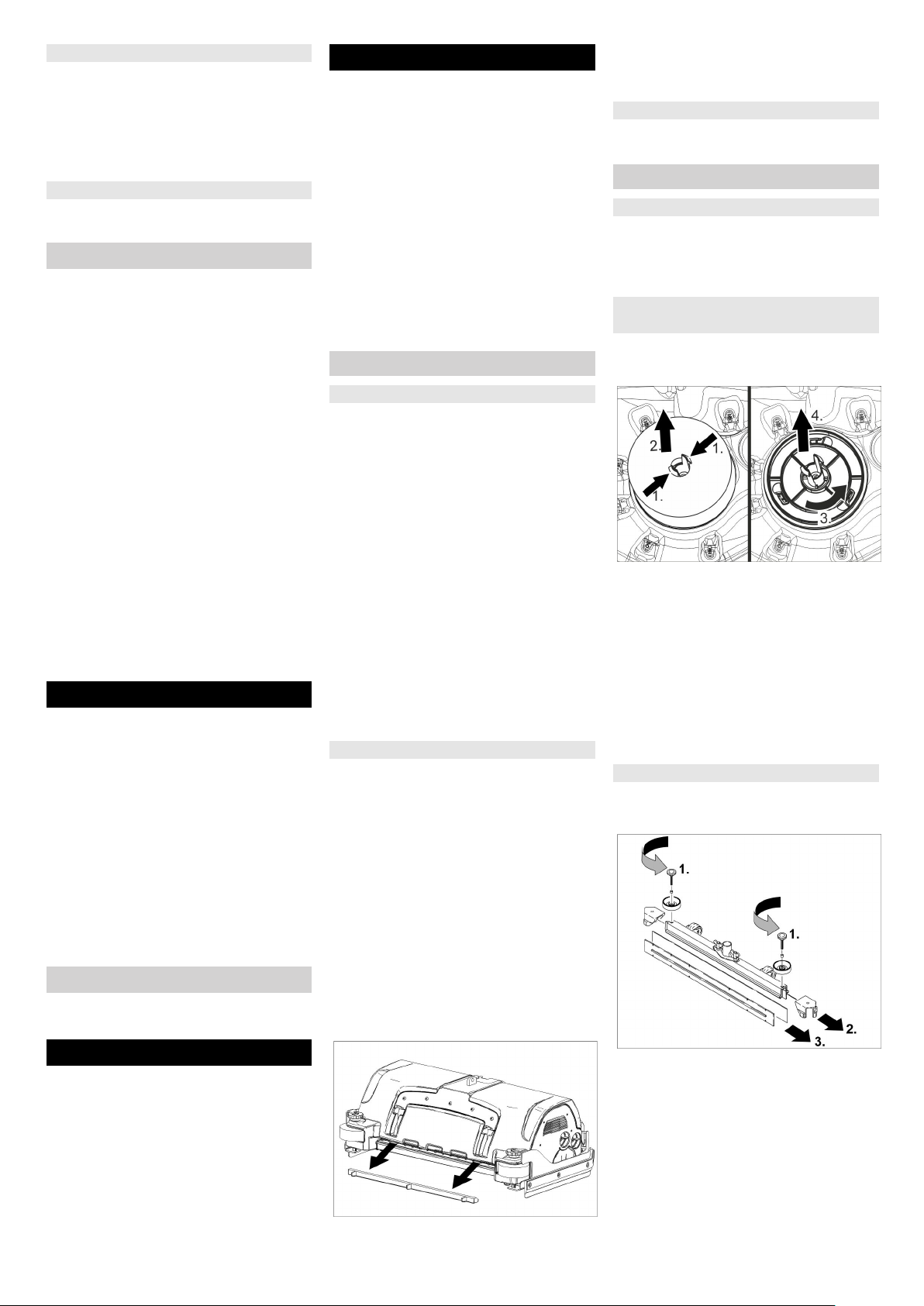

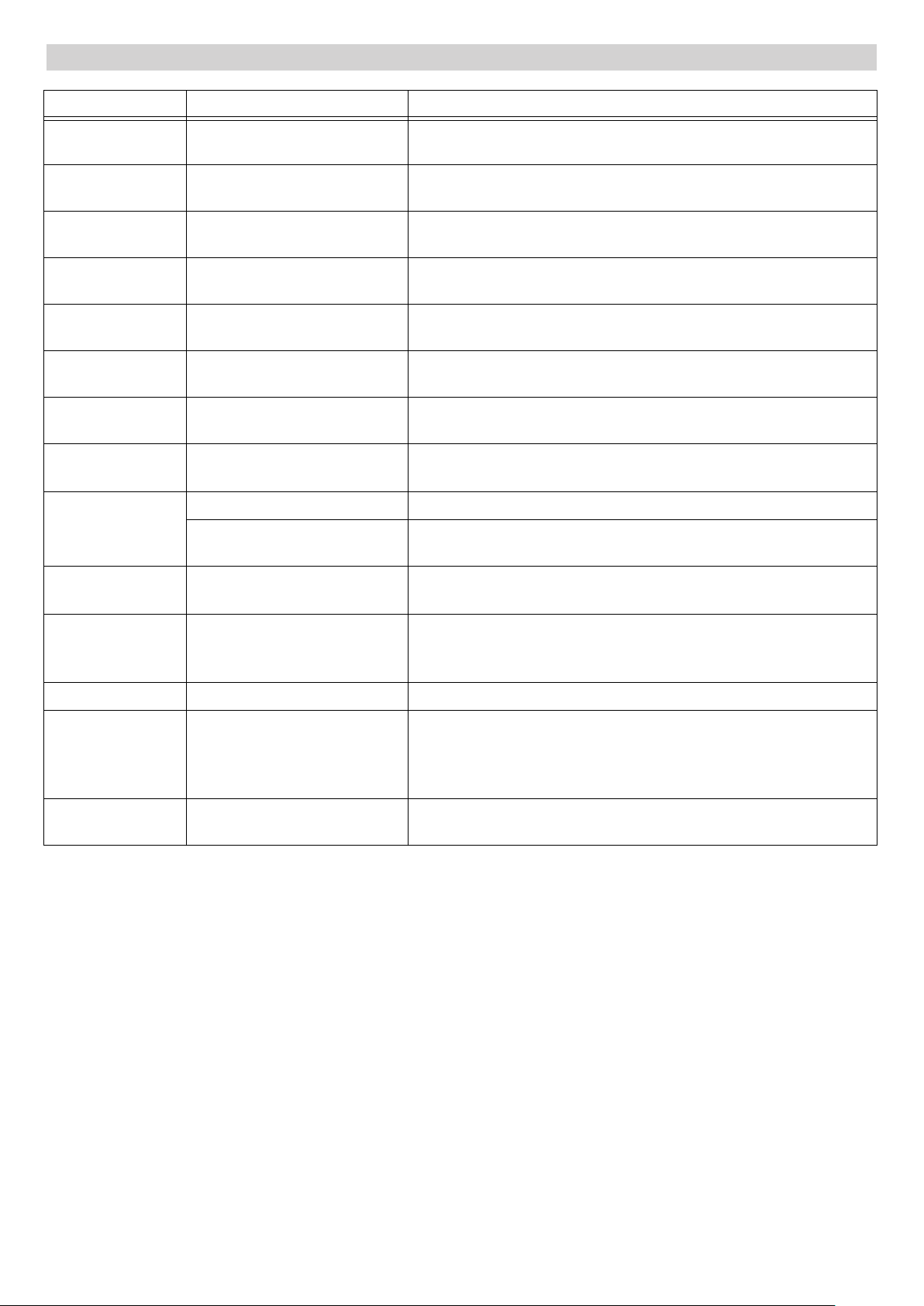

Cleaning the protective turbine

strainer

Open the cover of the wastewater

reservoir.

Squeeze the locking hooks.

Pull off the float.

Turn the protective turbine strainer

in a counter-clockwise direction.

Remove protective turbine strainer.

Rinse dirt off the protective turbine

strainer with water.

Reattach protective turbine strain-

er.

Attach float.

Replacing the vacuum lips

Remove the vacuum bar.

Unscrew the star grips.

Storage

CAUTION

Risk of injury and damage! Note the

weight of the appliance in case of storage.

This appliance must only be stored

in interior rooms.

Select the storage site for the appliance taking into consideration the permissible total weight of the appliance

in order not to impact its stability.

- 13

Remove the plastic parts.

Remove the vacuum lips.

Insert new vacuum lips.

Insert the plastic parts.

Screw in and tighten the star grips.

15EN

Page 16

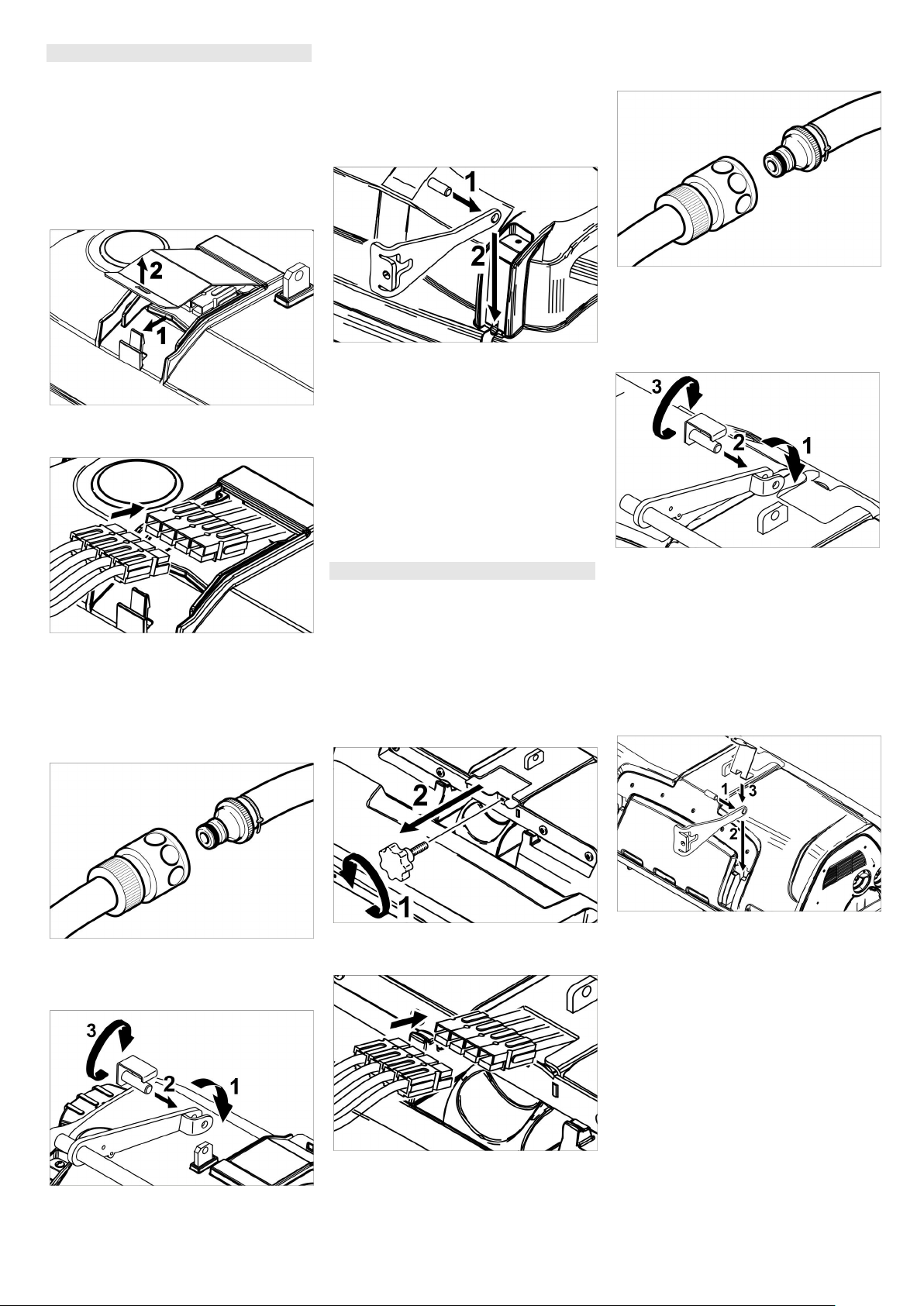

Install D cleaning head

Lift the holder of the cleaning head

(see Chapter "Grey intelligent key/

.../cleaning head replacement".

Slide the cleaning head under the

appliance so that the hose points

toward the rear.

Only slide the cleaning head halfway under the appliance.

Remove the lid of the cleaning

head.

Connect the power cord of the

cleaning head to the appliance

(same colours must meet).

Replace the lid and lock it.

Slide the cleaning head halfway un-

der the appliance.

Align the holder of the cleaning

head so that the drilled holes in the

lever and the cleaning head match.

Insert the stop pin through the

bushings and swivel the locking

plate downward.

Insert the cylinder pin into the bor-

ing of the drawbar.

Slide the drawbar with the pin the

guide channel on the cleaning head

all the way to the bottom.

Insert the locking plate into the

guide channel and lock it in.

Repeat process on the drawbar on

the opposite side.

Insert the grey intelligent key.

Set brush type "Disc".

Install R cleaning head

Lift the holder of the cleaning head

(see Chapter "Grey intelligent key/

.../cleaning head replacement".

Slide the cleaning head under the

appliance so that the hose points

toward the rear.

Only slide the cleaning head halfway under the appliance.

Slide the cleaning head halfway un-

der the appliance.

Connect the hose couplers on the

cleaning head to the hose on the

appliance.

Insert the tab into the middle of the

cleaning head, between the fork of

the lever.

Align the holder of the cleaning

head so that the drilled holes in the

lever and the cleaning head match.

Insert the stop pin through the

bushings and swivel the locking

plate downward.

Unscrew the star handle and re-

Connect the hose couplers on the

move the lid.

cleaning head to the hose on the

appliance.

Connect the power cord of the

cleaning head to the appliance

Insert the tab into the middle of the

cleaning head, between the fork of

(same colours must meet).

Slide the lid in and screw tight.

the lever.

16 EN

Insert the cylinder pin into the bor-

ing of the drawbar.

Slide the drawbar with the pin the

guide channel on the cleaning head

all the way to the bottom and lock.

Repeat process on the drawbar on

the opposite side.

Insert the grey intelligent key.

Set brush type "Brush".

- 14

Page 17

Remove D cleaning head

Press in the locking plate and swiv-

el the drawbar upward.

The subsequent removal will take

place in the opposite order of the installation.

Remove R cleaning head

The removal will take place in the opposite order of the installation.

Replacing the brush rollers

Lift the cleaning head.

Loosen the lock of the wiper flap.

Swivel the wiping flap out of the

way.

Replacing the Disk Brushes

Lift the cleaning head.

Press the pedal for changing the

brushes downward beyond its resistance.

Pull the disc brush out of the side

below the cleaning head.

Hold the new disc brush under the

cleaning head, push upward and

lock.

Replacing the side brush (only with

SB version)

Loosen 3 screws.

Remove the wiper blade.

Push in the new side brush.

Tighten 3 screws.

Frost protection

In case of danger of frost:

Empty the fresh and dirt water res-

ervoirs.

Store the appliance in a frost-pro-

tected room.

Troubleshooting

DANGER

Risk of injury! Before working on the

appliance, remove the Intelligent Key

and the mains plug of the charger.

Pull out the battery plug.

Drain and dispose of the dirt water

and the residual fresh water.

CAUTION

Risk of injury due to overrun of the suction turbine.

Suction turbine will continue to run for

a while after switch-off. Carry out maintenance tasks only after the suction

turbine has come to a halt.

In case of faults that cannot be remedied using the table below please contact the customer service.

Fault indication

If errors appear on the display, then

proceed as follows:

Turn the program selection switch

to "OFF".

Wait till the text on the display has

disappeared.

Turn the programme switch into the

previous position.

Only carry out the troubleshooting

measures in the indicated order if

the error occurs again. The key

switch must be in the "0" position

and the emergency stop button

pressed.

If the fault cannot be repaired, call

customer service and mention the

error message.

NOTICE

Error messages that are not listed in

the following table, point to errors that

cannot be fixed by the operator. If

these are displayed, consult Customer

Service.

Loosen the lock of the wiper flap.

Push the bearing lid down and re-

move.

Pull out the brush roller.

Insert a new brush roller.

Reattach the bearing lid and the

wiper flap in reverse sequence.

Repeat process on the opposite

side.

- 15

17EN

Page 18

Faults with display

Display Cause Remedy

Seat switch open! Seat contact switch has not

Release the drive pedal. Have a seat.

been activated.

Release accelerator!

No direction of

travel!

Battery dis-

The gas pedal is depressed

Release drive pedal and reactivate.

when the main switch is on.

Travel direction switch or cable

Call customer service.

connection defective.

Battery voltage too low. Charge battery.

charged!

Battery voltage inadmissible!

Charger defective! Error on the charger, charging

Battery voltage is above or below the admissible range.

Call customer service.

Check the charger.

is not possible.

Fresh water tank

The fresh water tank is empty. Fill up fresh water reservoir.

empty!

Brush pressure not

reached!

Waste water tank

full!

Timeout brush contact pressure control.

Check brush wear, replace brush if required.

Check the function of the brush heads: lowering, raising.

wastewater reservoir is full. Empty the dirt water reservoir.

Level sensor or cable connec-

Call customer service.

tion defective.

Brake defective! Brake defective. Do not drive the appliance.

Call customer service.

Propulsion motor

hot! Allow to cool

down!

Motor protection was triggered Bring the safety switch into the "0" position.

Allow machine to cool down at least for 15 minutes.

Contact aftersales service in case of recurrence.

Horn defective! Horn defective. Call customer service.

Control is hot! Allow to cool down!

Brush motors overloaded!

Performance electronics of lift

module (A4) too hot

Load of the brush heads asymmetric.

Bring the safety switch into the "0" position.

Allow control to cool down at least 5 minutes.

Significantly reduce the brush pressure with rough ground.

Contact aftersales service in case of recurrence.

Adjust brush level.

18 EN

- 16

Page 19

Faults without display on the console

Fault Remedy

Appliance cannot be start-edSeat switch not operated, sit down on the seat.

The machine operates only if the operator is seated on the seat.

Bring the safety switch into the "1" position.

Set the programme switch to "OFF". Wait for 10 seconds. Set the programme selector

switch to previous function. If possible, drive the appliance on level grounds only. Check

parking brake and foot brake if necessary.

Take the foot off the accelerator pedal prior to switching on the safety switch. If the fault recurs, call the aftersales service.

Check battery; charge it, if needed

Insufficient water quantity Check fresh water level, refill tank if necessary.

Check hoses for blockages; clean if required.

R cleaning head: Remove the water distributor strip and clean it.

Clean the fresh water filter.

Insufficient vacuum performance

Insufficient cleaning result Set/ adjust contact pressure.

Brushes do not turn Reduce contact pressure.

Drain hose for dirty water is

blocked

Clean the seals between dirt water reservoir and cover and check for tightness, replace if

required.

Check protective turbine strainer for soiling, clean if necessary.

Clean the vacuum lips on the vacuum bar, turn or replace if required

Check if the cover on the dirt water discharge hose is closed

Check suction hose for blockages; clean if required.

Check the suction hose for tightness; replace if required.

Check the setting of the vacuum bar.

Attach additional weight (accessory) to the vacuum bar.

Adjust wiper lips.

Check the brushes for wear, replace if required.

Check if foreign matters block the brushes; remove foreign matter if required.

Motor overloaded, allow to cool down. Set the programme switch to "OFF". Wait for 10 seconds. Set the programme selector switch to previous function.

Open dosing equipment at the drain hose. Pull out the suction hose from suction beam and

close it by hand. Set the program selection switch to suction or vacuuming. The blockage

will be sucked out from the drain hose into the dirt water tank.

Detergent metering Dose

(only Dose) does not function properly

Inform Customer Service.

- 17

19EN

Page 20

Technical specifications

B 150 R 75 D 75 R 90 D90

Power

Nominal voltage V 36

Battery capacity Ah

(5h)

Average power consumption W 2700 2400 2800 2500

Nominal power engine (Adv) W 600 (1400)

Suction engine output W 750

Brush engine output W 2 x 600 2 x 750 2 x 600

Vacuuming

Cleaning power, air quantity l/s 26

Cleaning power, negative pressure kPa 18,0

Cleaning brushes

Working width mm 750 900

Brush diameter mm 105 410 105 450

Brush speed 1/min 1200 140 1200 140

Dimensions and weights

Driving speed, max. (Adv) km/h 6 (10)

Slope max. (Adv) % 10 (15)

Theoretical surface capacity (Adv) m2/h 4500 (7500) 5400 (10000)

Fresh/dirt water reservoir volume l 150

Capacity coarse dirt container l 7 - 9 -

Water pressure filling system**, waste water tank rinsing system**,

max.

MPa

(bar)

Length mm 1690

Width (without vacuum bar) mm 810 810 910 980

Height mm 1390

Permissible overall weight (Adv) kg 820 (838)

Transport weight (Adv) kg 586 (604)

Surface load (with driver and full fresh water tank)

Front wheel N/cm

Rear wheel N/cm

2

2

Values determined as per EN 60335-2-72

Vibration total value on arms m/s

Vibration total value on seat area m/s

Uncertainty K m/s

Sound pressure level L

Uncertainty K

pA

Sound power level LWA + Uncertainty K

pA

WA

2

2

2

dB(A) 67

dB(A) 2

dB(A) 85

** option

180/240

1 (10)

94

51

<2,5

<2,5

0,1

20 EN

- 18

Page 21

Accessories and Spare Parts

– Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive

use of original accessories and

original spare parts ensures that

the appliance can be operated

safely and trouble free.

– At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

– For additional information about

spare parts, please go to the Service section at www.kaercher.com.

Warranty

The warranty terms published by the

relevant sales company are applicable

in each country. We will repair potential

failures of your appliance within the

warranty period free of charge, provided that such failure is caused by faulty

material or defects in manufacturing. In

the event of a warranty claim please

contact your dealer or the nearest authorized Customer Service centre.

Please submit the proof of purchase.

- 19

21EN

Page 22

REMARQUE :

Cet appareil est conforme à la

section 15 des réglementations de la

FCC et aux normes RSS exemptes

de licence d'Industrie Canada.

Le fonctionnement est sujet aux deux

conditions suivantes :

(1) cet appareil ne doit pas provoquer d'interférences néfastes, et

(2) cet appareil doit tolérer les interférences reçues, y compris celles qui

risquent de provoquer un fonctionnement indésirable.

REMARQUE :

Tout changement ou toute modification apporté à cet équipement qui ne

serait pas expressément approuvé

par Kärcher pourrait annuler l'autorisation de la FCC d'exploiter cet équipement.

REMARQUE : Cet appareil a été testé et déclaré conforme aux limites relatives aux dispositifs numériques de

classe B, conformément à la

section 15 des réglementations de la

FCC. Ces limites sont destinées à assurer un niveau de protection adéquat contre les interférences dans les

installations résidentielles. Cet équipement produit, utilise et peut

émettre des fréquences radioélectriques et, s’il n’est pas installé ou utilisé conformément aux directives,

peut brouiller les ondes radio. Toutefois, il est impossible de garantir

qu'aucune interférence ne se produira dans une installation particulière.

Si cet équipement brouille la réception des ondes radio et télévision, ce

que vous pouvez déterminer en éteignant et en rallumant l’appareil, nous

vous encourageons à prendre l’une

ou plusieurs des mesures correctives

suivantes :

• Réorienter ou déplacer l’antenne de

réception.

• Augmenter l’écart entre l’équipement et le récepteur.

• Connecter l’équipement à une prise

ou à un circuit électrique différent de

celui auquel est branché le récepteur.

• Consultez votre revendeur ou un

technicien radio/télé expérimenté si

vous avez besoin d'aide.

CONSIGNES DE SÉCURITÉ

IMPORTANTES

Lire toutes les instructions de service

avant d'utiliser l'appareil.

몇 AVERTISSEMENT

Afin de réduire les risques d'incendie,

d'électrocution et de blessures,

prendre les précautions suivantes :

1 Ne pas laisser l'appareil sans sur-

veillance lorsqu'il est branché. Débrancher l'appareil lorsqu'il n'est

pas utilisé et avant de procéder à

l'entretien.

2 Utiliser l'appareil exclusivement en

intérieur pour réduire les risques

d'électrocution.

3 Cet appareil n'est pas un jouet. Ne

jamais le laisser sans surveillance

lorsqu'il est utilisé à proximité d'enfants.

4 Respecter impérativement les

consignes d'utilisation de ce manuel.

Utiliser uniquement les accessoires

recommandés par le fabricant.

5 Ne pas mettre l'appareil en service

en cas d'endommagement du cordon ou de la prise. Si l'appareil ne

fonctionne pas correctement, s'il

est tombé, s’il a été endommagé,

s’il est resté à l’extérieur ou est tombé dans l’eau, le retourner à un

centre de service.

6 Ne pas tirer ou transporter l’appa-

reil par le cordon électrique ou se

servir de ce dernier comme d’une

poignée. Veiller à ne pas coincer le

cordon dans une porte et éviter de

le tirer sur des bords ou des coins

tranchants. Ne pas rouler sur le cordon électrique. Tenir le cordon à

l'écart des surfaces chaudes.

7 Ne pas tirer sur le cordon électrique

pour débrancher l'appareil. Tirer au

niveau de la fiche pour déconnecter

l'appareil du secteur.

8 Ne pas manipuler l’appareil ou la

fiche avec les mains mouillées.

9 Ne rien introduire dans les orifices.

Ne pas utiliser l’appareil si l’un des

orifices est obstrué. Protéger les

orifices de la poussière, des peluches, des cheveux et autres matières susceptibles de réduire le

débit d'air.

10

Veiller à ne pas approcher les cheveux, vêtements larges, doigts ou

toute autre partie du corps des orifices

et composants mobiles de l’appareil.

11 Désactiver toutes les commandes

avant de débrancher l'appareil.

12 Faire particulièrement attention lors

du nettoyage d'escaliers.

13 Ne pas aspirer de liquides inflam-

mables ou combustibles, tels que

de l’essence avec l'appareil. Ne pas

utiliser ce dernier dans des zones

susceptibles de contenir de tels

produits.

14 Brancher uniquement sur une prise

correctement reliée à la terre. Voir

les instructions de mise à terre.

CONSERVER CES INSTRUCTIONS !

Instructions de mise à terre

Ce produit doit-être mis à la terre. En

cas de mauvais fonctionnement ou de