Kyocera FS-C8600DN, FS-C8650DN SERVICEBULLETINS 3NB 0022 C252

Subject

Measures against Misalignment of the Second Sheet of

A4E/LetterE/B5E Size Paper Bundle in the Punch and Stapling

Mode

Model l:

DF-790/DF-790(B)

KMC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures:

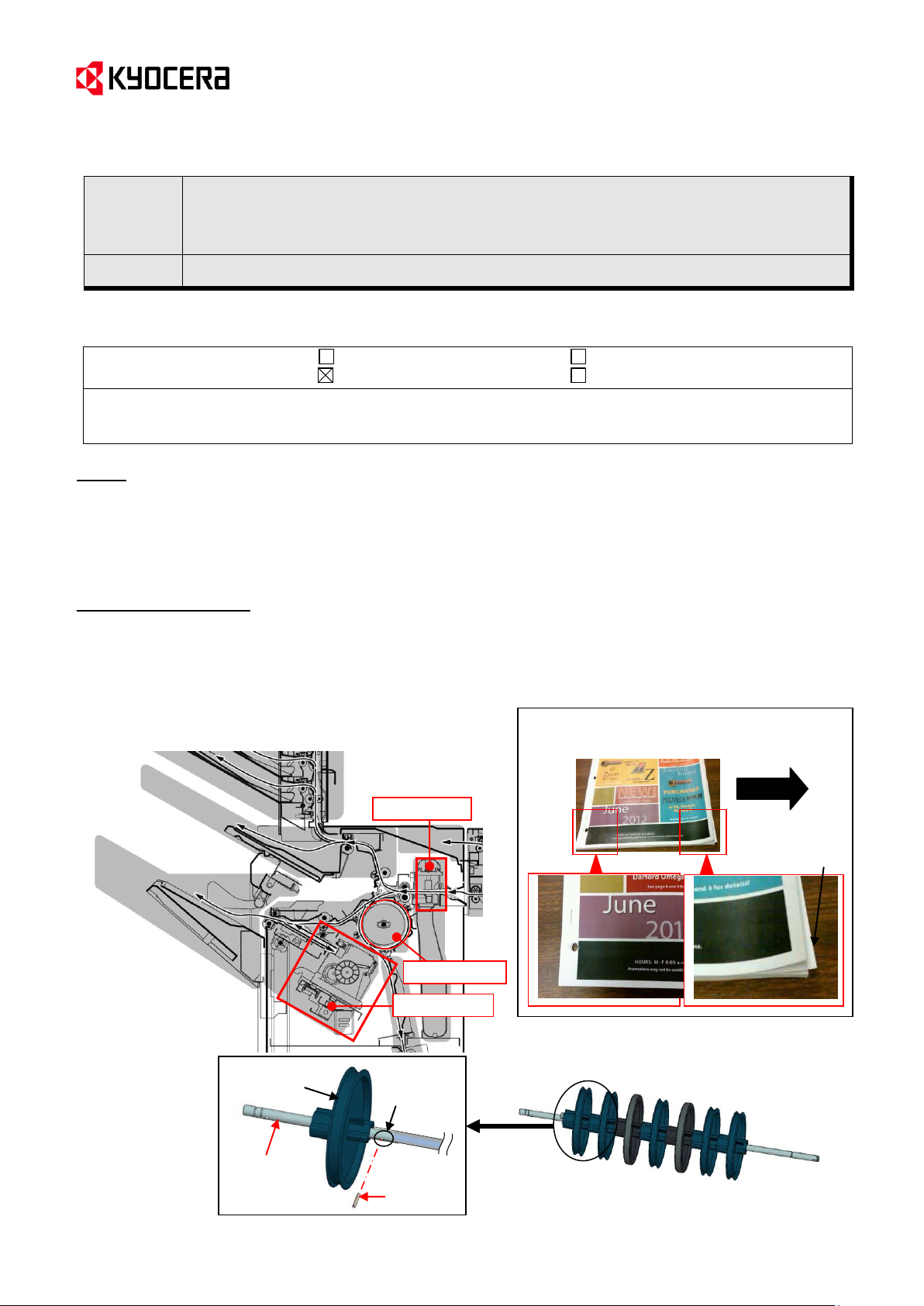

When the phenomenon described below occurs, please replace the shaft (No.1) with the new one and fix the

relief drum (Y in the figure below) on the machine front side with the parallel pin (No.2).

Staple unit

Punch unit

Relief drum

<Sample>

<Relief drum>

(Machine rear side)

Paper

conveying

direction

2nd sheet

New shaft

(No.1)

Relief drum (Y)

Parallel

pin (No.2)

Hole (X)

added

(Machine front side)

(Page.1/3)

Service Bulletin Ref. No. 3NB-0022 (C252)

<Date> October 25, 2012

Installation target models: TASKalfa 5550ci/4550ci/3550ci/3050ci, TASKalfa 5500i/4500i/3500i

FS-C8650DN, FS-C8600DN ((B) type only)

Topic

In a rare case, the backlashes of the relief drum in the paper conveying direction might become severe. If the

machine is operated in the punch and stapling mode with this condition, the second sheet of A4E/LetterE/B5E size

paper bundle might be shifted toward the paper conveying direction. As a result, the paper bundle might be stapled

in this state. Therefore, the following changes were made. (For more details, please refer to the following pages.)

Content of changes

1) The hole (X in the figure below) to insert a parallel pin was added to the rear side of the shaft (No.1) for the

relief drum in order to reduce the backlash of the relief drum.

2) The fixation of the relief drum to the shaft by the parallel pin was changed from one side (1 pc. of No.2 on the

machine front side) to the both sides (2 pcs. of No.2 on the machine front and rear sides).

<Cross section of the finisher>

(Punch unit, relief drum and staple unit)>

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

(Page.2/3)

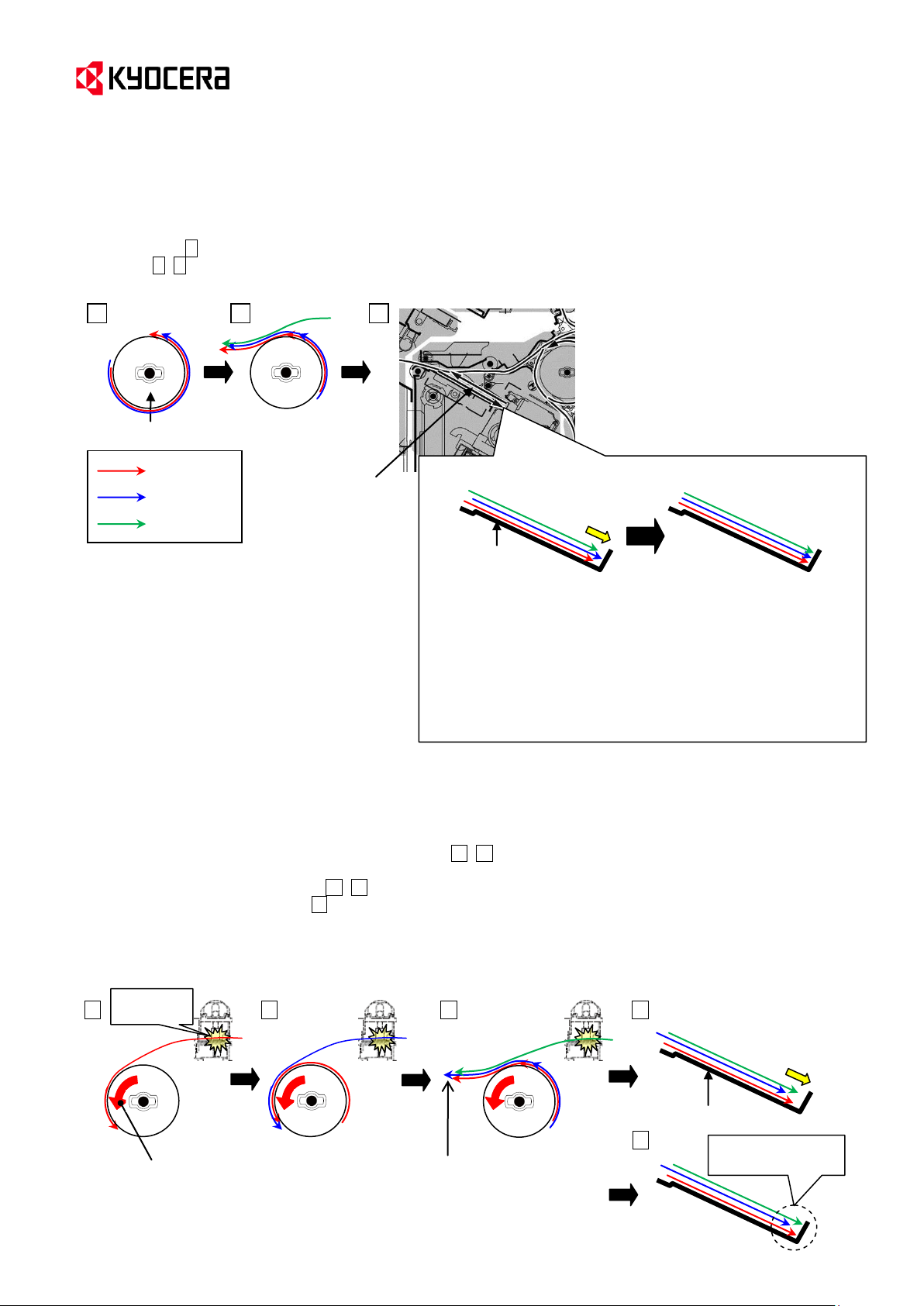

A B

C

Adjustment tray:

After entering the

processing section,

paper is switched back

and conveyed to the

adjustment tray.

[1st to 3rd sheets on the adjustment tray]

2nd sheet (blue arrow in the figure above) is aligned with trailing

edge of 1st and 3rd sheets by bumping against the inner wall of the

adjustment tray when conveyed to the adjustment tray. (Since 2nd

paper is conveyed before conveyed into the adjustment tray, its

trailing edge is slightly more sticking out than the trailing edges of 1st

and 3rd sheets.)

1st, 3rd sheet and the sheet after are conveyed to the inner part of

the adjustment tray by direct conveying drive of the paddle, etc. (The

conveying drive is not directly applied to 2nd sheet.)

Adjustment

tray

Relief drum

: 1st sheet

: 2nd sheet

: 3rd sheet

Backlash toward the

paper conveying direction

Punch

operation

Leading edge of 2nd sheet is shifted

toward the paper conveying direction.

Adjustment tray

Only 2nd sheet is

shifted.

Service Bulletin Ref. No. 3NB-0022 (C252)

<Date> October 25, 2012

[Paper conveying at the relief drum section]

<OK>

When processing A4E/LetterE/B5E size paper bundles for stapling, etc, first and second sheets are rolled around

the relief drum (A in the figure below) and they are conveyed to the adjustment tray in the processing section with

3rd paper (B, C). After aligning all sheets of the paper bundle (the sheet after the third sheet is directly conveyed to

the adjustment tray), the paper bundle is stapled and ejected to the eject tray.

<NG>

In a rare case, the backlash of the relief drum in the paper conveying direction might be abnormally large.

In this condition, if influence of the backlash of the relief drum becomes more than the normal paper ejection due to

the punch operation (*), the timing of the leading edge of the first and second sheets rolling around the relief drum

might be shifted toward the paper conveying direction (A’, B’). As a result, if the first to third sheets are conveyed

to the adjustment tray while the leading edge of the second sheet is shifted toward the paper conveying direction

more than the first and third sheets (C’, D’), the second sheet cannot be aligned on the adjustment tray since it

cannot bump against the stopper (E’). Then, the paper bundle containing the misaligned second sheet is stapled

and ejected into the eject tray although the paper trailing edge and the punched hole positions are shifted.

(Please refer to <Sample> on the page 1.)

(*) In the punch mode, the influence of the backlash becomes severer as the temporary stop operations are

inserted when first and second sheets are rolled around the relief drum.

A’ B’ C’ D’

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

E’

Loading...

Loading...