Kyocera FS-C8020MFP, FS-8025MFP SERVICEBULLETINS 2KZ 0031 C258 1

(Revised Issue 1) (Page.1/3)

Subject

Field Measures against the Image with Color Shading, Foggy

Background and Toner Smudge

FS-C8020MFP_FS-C8025MFP_v06.00.0010_(2012-07-04)

Model l:

FS-C8025MFP, FS-C8020MFP

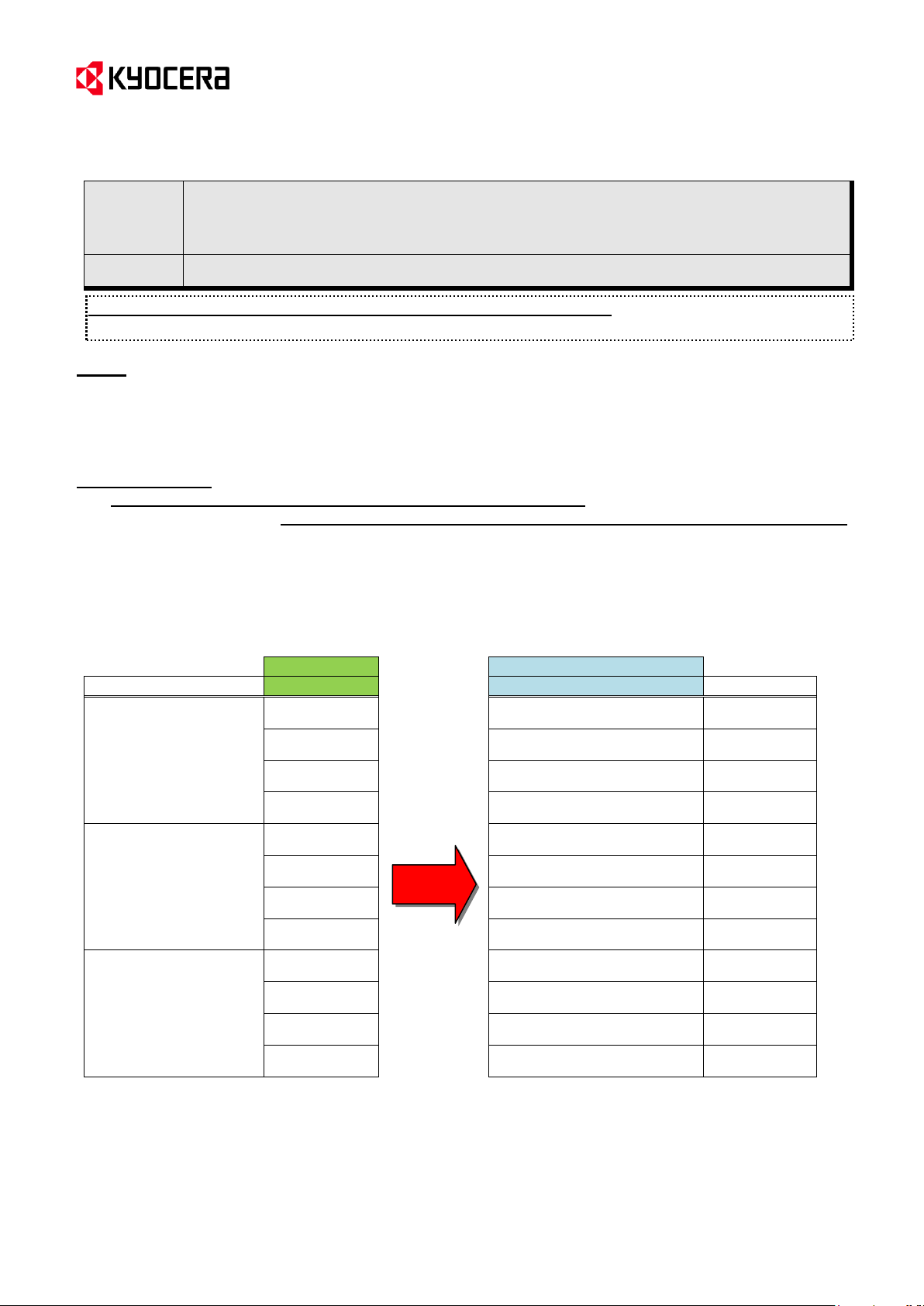

DV-895 DV-896

Destination

Part Number

(-->) Part Number (Note 3)

Color

Except KDCN/KDKR

302K093025

2K093025

302MY93020

2MY93020

Yellow

302K093034

2K093034

302MY93030

2MY93030

Magenta

302K093044

2K093044

302MY93040

2MY93040

Cyan

302K093054

2K093054

302MY93050

2MY93050

Black

KDCN

302K09C025

2K09C025

302MY9C020

2MY9C020

Yellow

302K09C034

2K09C034

302MY9C030

2MY9C030

Magenta

302K09C044

2K09C044

302MY9C040

2MY9C040

Cyan

302K09C054

2K09C054

302MY9C050

2MY9C050

Black

KDKR

302K09K025

2K09K025

302MY9K020

2MY9K020

Yellow

302K09K034

2K09K034

302MY9K030

2MY9K030

Magenta

302K09K044

2K09K044

302MY9K040

2MY9K040

Cyan

302K09K054

2K09K054

302MY9K050

2MY9K050

Black

Service Bulletin Ref. No. 2KZ-0031 (C258)

[Service Information] <Date> October 25, 2012

This time, the description with (-->) was revised from the previous information.

<Number of changes: 2> The last digit of the part number of DV-896 was corrected from 1 to 0. (Note 3) was added.

Topic

Abnormal image with color shading, foggy background image or toner smudge, etc might be printed out depending

on the operating environment (high temperature and high humidify) or the operating conditions.

If this phenomenon occurs in the field, please execute the following measures.

Field Measures

1) Replace the four pieces of DV-895 with DV-896 at the same time. (Note 1)

2) Upgrade the firmware to Upgrade Pack Ver.6.00 or later (ENGINE firmware: 2K0_1000.010.002 or later).

(Note 2)

3) After upgrading the firmware, change the setting of [Belt(A)] in the maintenance mode U107 [Setting the

voltage for the intermediate transfer cleaning]. (For the setting values, please refer to the next page.)

(Note 1) Please refer to the tables below for the number of affected part. This change was applied to the main unit

manufactured since April 2012. (Refer to the next page.)

Please note that a part of the controls will not be executed after the firmware upgrade of [Field measure 2)] unless

four developing units were replaced with DV-896 at the same time (if using DV-895 and DV-896 together).

(The affected controls are indicated as “*1” in the list on the next page.)

The current quality is kept if the old developer unit (DV-895) is used together with the new firmware.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

(Revised Issue 1) (Page.2/3)

Item

Content

Measures

against

Remark

Developer

unit

A rib was added to the side of the developer unit base in order to

prevent the backlash when driving the developer unit.

Color shading

The carrier in the developer was changed in order to stabilize the

charging performance of the toner.

Foggy background/

Toner smudge

The structure to reversly rotate the magnet roller was added in

order to collect the deteriorated toner in the developer unit.

Toner smudge

The shape of the magnet cover was changed in order to prevent

accumulation of the deteriorated toner.

Toner smudge

Viser shape was added to the developing case at upper side of the

magnet roller in order to prevent the deteriorated toner from falling

on the magnet roller.

Toner smudge

Firmware

The drum surface potential was changed in order to decrease

color shading (-50V).

Color shading

*1

The developing bias value was changed in order to decrease color

shading.

Color shading

T/C was changed in order to increase the margins against foggy

background and toner smudge. (Environmental variation)

Toner smudge

The drum aging in the high temperature/high humidify environment

was added.

Foggy background

The control to reversely rotate the magnet roller was added in

order to collect the scattered toner in the developer unit.

Toner smudge

*1

Service Bulletin Ref. No. 2KZ-0031 (C258)

[Service Information] <Date> October 25, 2012

(Note 2)

The details on upgrade of the firmware were informed by the service bulletin SB-2KZ-0030-C209.

(However, the corrective measures described in this bulletin were not mentioned.)

This change was applied to the main units from the July 2012 production. (Please refer to the next page.)

(-->)(Note 3) DV-896 with 0 as the last digit of the part number can be applied for this field measure. (The latest last

digit of the part number is 1 as of October, 2012.)

* Please refer to the following for more details on the corrective field measures.

[Details of the corrective field measures]

The following corrective measures will be applied by executing the field measures described on the page 1.

*1: The measures above will be applied only in the combination of installation of 4 pcs. of DV-896 and the latest

firmware.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...