Kyocera FS-C8020MFP, FS-8025MFP SERVICEBULLETINS 2KZ 0022 C004

Q’

Com

bi

p

ati-

The cam is current

l

y rotated to narrow the center distance

Service Bulletin Ref. No.

Subject

(Page.1/1)

2KZ-0022 (C004)

<Date> January 10, 2012

Measures against the Motion Sound (Clunk) When Applying

the Fusing Pressure

Model

FS-C8020MFP, FS-C8025MFP

Topic

The following change was made in order to eliminate the motion sound (clunk) which is generated when the center

distance between the heat roller and the press roller is automatically narrowed to apply the fusing pressure for print.

Content of Change

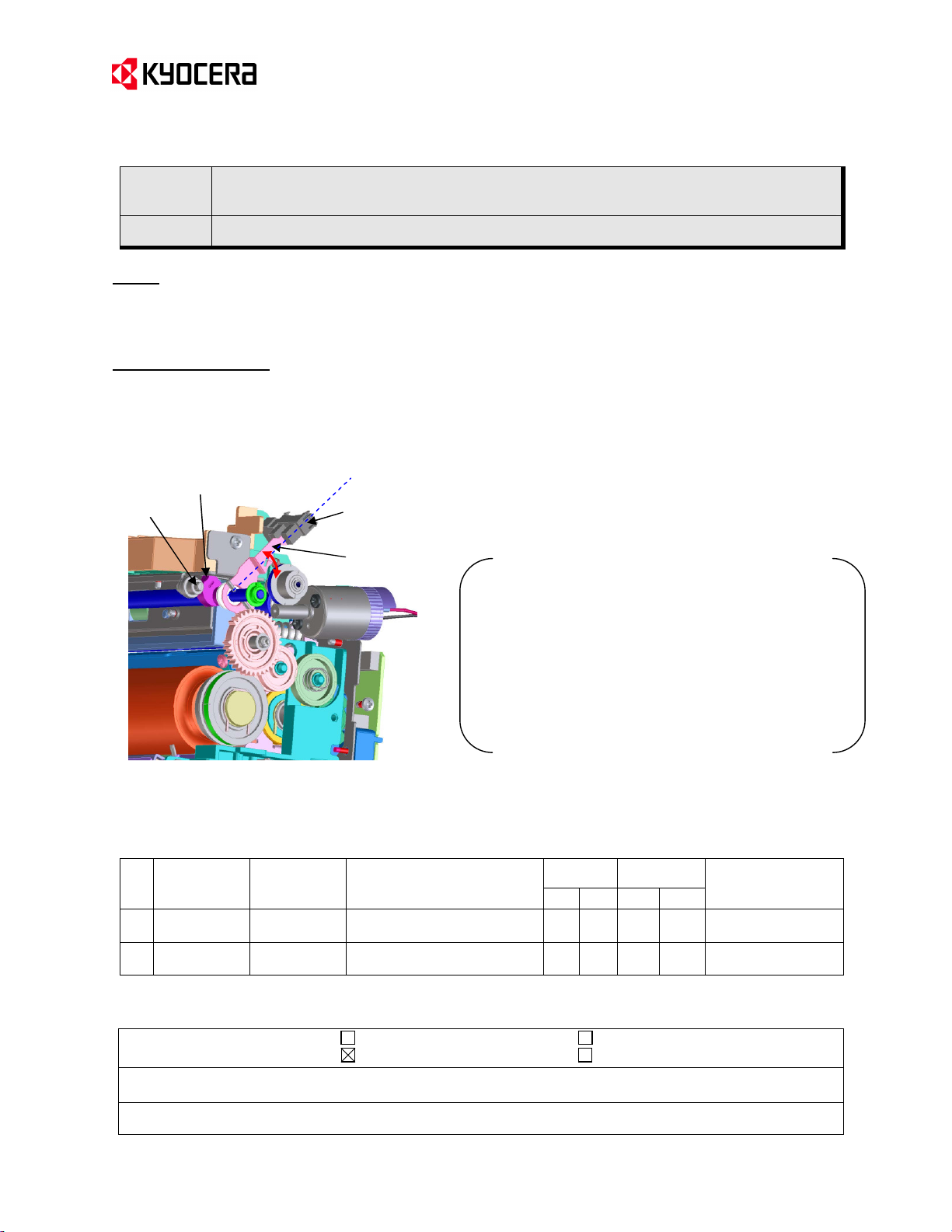

The fuser pressure system was changed from mechanical lock type to PI detection type.

<New type fuser unit>

Slit on cam

Shaft

Machine front side

*The parts other than the ones in the above figures (inside of

the fuser unit) were also changed.

302K093092

1

302K09K092

2

Old Part

No.

2K093092

2K09K092

No.

KMC’s Classification Entire Stock Rework In-Field modification at next visit

Field Measure: Please replace the fuser unit (No.1,2) when the motion sound described above is recognized.

Serial Nos. of the Affected Machines: Planned from the December 2011* production

New Part

No.

302K093093

2K093093

302K09K093

2K09K093

Sensing position

PI sensor added

Actuator added

between the heat roller and the press roller.

There is a slit at the point where the specified fusing

pressure is applied. The motion sound (clunk) is

recognized when the cam is locked there.

In order to eliminate this motion sound (clunk), the fusing

pressure system was changed from mechanical lock type

to PI detection type where the cam rotation is stopped by

sensing the specified fusing pressure position with the PI

sensor.

Description

FK-895 1 1

FK-895(KR) 1 1

In-Field modification by case No modification necessary

*The above is the plan at the present moment. Please note that this information is subject to change.

KYOCERA MITA Europe B.V.

European Service & Development Center (ESDC)

ty

Old New Old New

lity

X O

X O

Remarks

Except KMKR specs.

KMKR specs.

Loading...

Loading...