Page 1

Page 2

Page 3

Contents

1 Paper Handling ........................................................................... 1-1

General Guidelines ..................................................................... 1-2

Selecting the Right Paper .......................................................... 1-4

Paper Type ................................................................................ 1-11

2 Using the Operation Panel ......................................................... 2-1

General Information ................................................................... 2-2

Understanding the Operation Panel ......................................... 2-3

Using the Menu Selection System ............................................ 2-8

Report Print ............................................................................... 2-11

USB Memory (USB flash memory selection) ......................... 2-16

Counter (Viewing the counter value) ...................................... 2-18

Paper Settings .......................................................................... 2-19

Print Settings ............................................................................ 2-27

Network (Network settings) ..................................................... 2-39

Device Common (Selecting/Setting the common device) .... 2-44

Security ..................................................................................... 2-55

Admin (Administrator settings) ............................................... 2-63

Adjust/Maintenance (Adjust/Maintenance selection/setting) 2-65

3 Option .......................................................................................... 3-1

General Information ................................................................... 3-2

Expansion Memory Modules ..................................................... 3-3

Paper Feeder (PF-100) ................................................................ 3-5

CompactFlash (CF) Card ........................................................... 3-6

USB Flash Memory ..................................................................... 3-6

4 Computer Interface ..................................................................... 4-1

General Information ................................................................... 4-2

USB Interface .............................................................................. 4-2

Network Interface ....................................................................... 4-3

Glossary

Index

i

Page 4

ii

Page 5

Introduction

This guide has the following chapters:

1 Paper Handling

This chapter explains how choose, handle and load paper.

2 Using the Operation Panel

This chapter explains how to use the operation panel to configure the

printer.

3Option

This chapter explains the options for this printer.

4 Computer Interface

This chapter explains the possible connections between the printer and

your computer.

Glossary

A Glossary of terms used is provided here.

iii

Page 6

Conventions in This Guide

This manual uses the following conventions.

Convention

Italic

Typeface

Bold Used to denote buttons on the

Bracket Bold Used to denote operation panel

Note Used to provide additional or

Important Used to provide important

Caution Cautions are statements that

Description Example

Used to emphasize a key word,

phrase or reference to additional

information.

software.

keys.

useful information about a

function or feature.

information.

suggest mechanical damage as

a result of an action.

Refer to Configuration Tool on page 3-9.

To start printing, click OK.

Printing resumes when [GO] is

pressed.

Note Do not remove the toner

container from the carton until you

are ready to install it in the printer.

IMPORTANT Take care not to touch

the transfer roller (black) during

cleaning.

CAUTION When pulling the paper, pull

it gently so as not to tear it. Torn pieces

of paper are difficult to remove and may

be easily overlooked, deterring the

paper jam recovery.

Warning Used to alert users to the

possibility of personal injury.

WARNING If you ship the printer,

remove and pack the developer unit

and drum unit in a plastic bag and ship

them separately from the printer.

iv

Page 7

1 Paper Handling

This chapter explains paper specifications for this printer.

General Guidelines 1-2

Selecting the Right Paper 1-4

Paper Type 1-11

Paper Handling 1-1

Page 8

General Guidelines

The machine is designed to print on standard copier paper, but it can

also accept a variety of other types of paper within the limits specified

below.

Note The manufacturer assumes no liability for problems that

occur when paper not satisfying these requirements is used.

Selection of the right paper is important. Using the wrong paper can

result in paper jams, curling, poor print quality, and paper waste, and in

extreme cases can damage the machine. The guidelines given below

will increase the productivity of your office by ensuring efficient, troublefree printing and reducing wear and tear on the machine.

Paper Availability

Most types of paper are compatible with a variety of machines. Paper

intended for xerographic copiers can also be used with the machine.

There are three general grades of paper: economy, standard, and

premium. The most significant difference between grades is the ease

with which they pass through the machine. This is affected by the

smoothness, size, and moisture content of the paper, and the way in

which the paper is cut. The higher the grade of paper you use, the less

risk there will be of paper jams and other problems, and the higher the

level of quality your printed output will reflect.

Differences between paper from different suppliers can also affect the

machine's performance. A high-quality printer cannot produce highquality results when the wrong paper is used. Low-priced paper is not

economical in the long run if it causes printing problems.

Paper in each grade is available in a range of basis weights (defined

later). The traditional standard weights are 60 to 120 g/m

2

(16 to 31.9b).

Paper Specifications

The following table summarizes the basic paper specifications. Details

are given on the following pages:

Item Specifications

Weight Cassette: 60 to 120 g/m² (16 to 31.9 lb/ream)

MP tray: 60 to 220 g/m² (16 to 58.5 lb/ream)

Thickness 0.086 to 0.110mm (3.4 to 4.3 mils)

Dimensional

Accuracy

Squareness of

Corners

Moisture Content 4 to 6%

Direction of Grain Long grain

Pulp Content 80% or more

±0.7 mm (±0.0276 inches)

90±0.2°

1-2 Paper Handling

Page 9

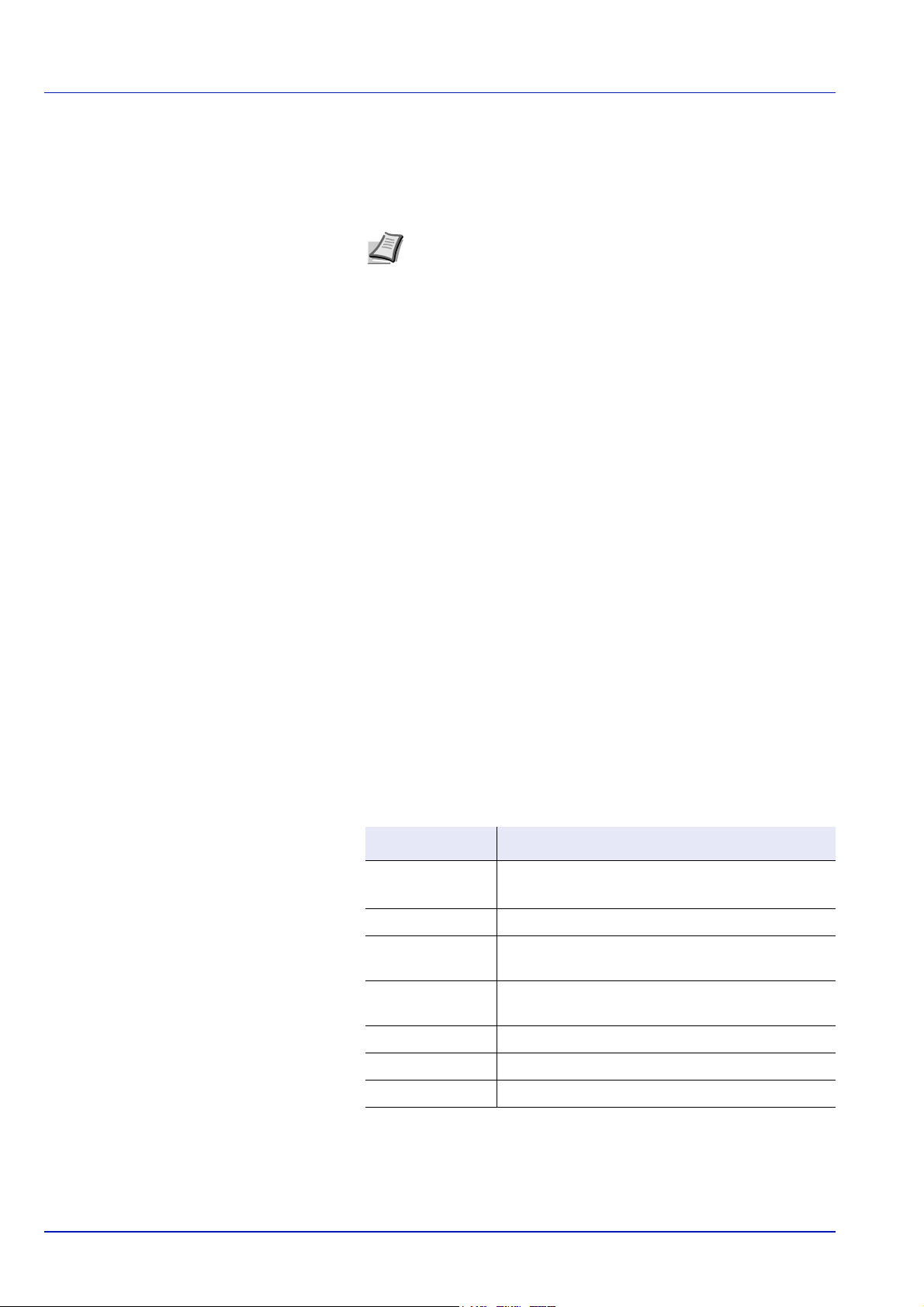

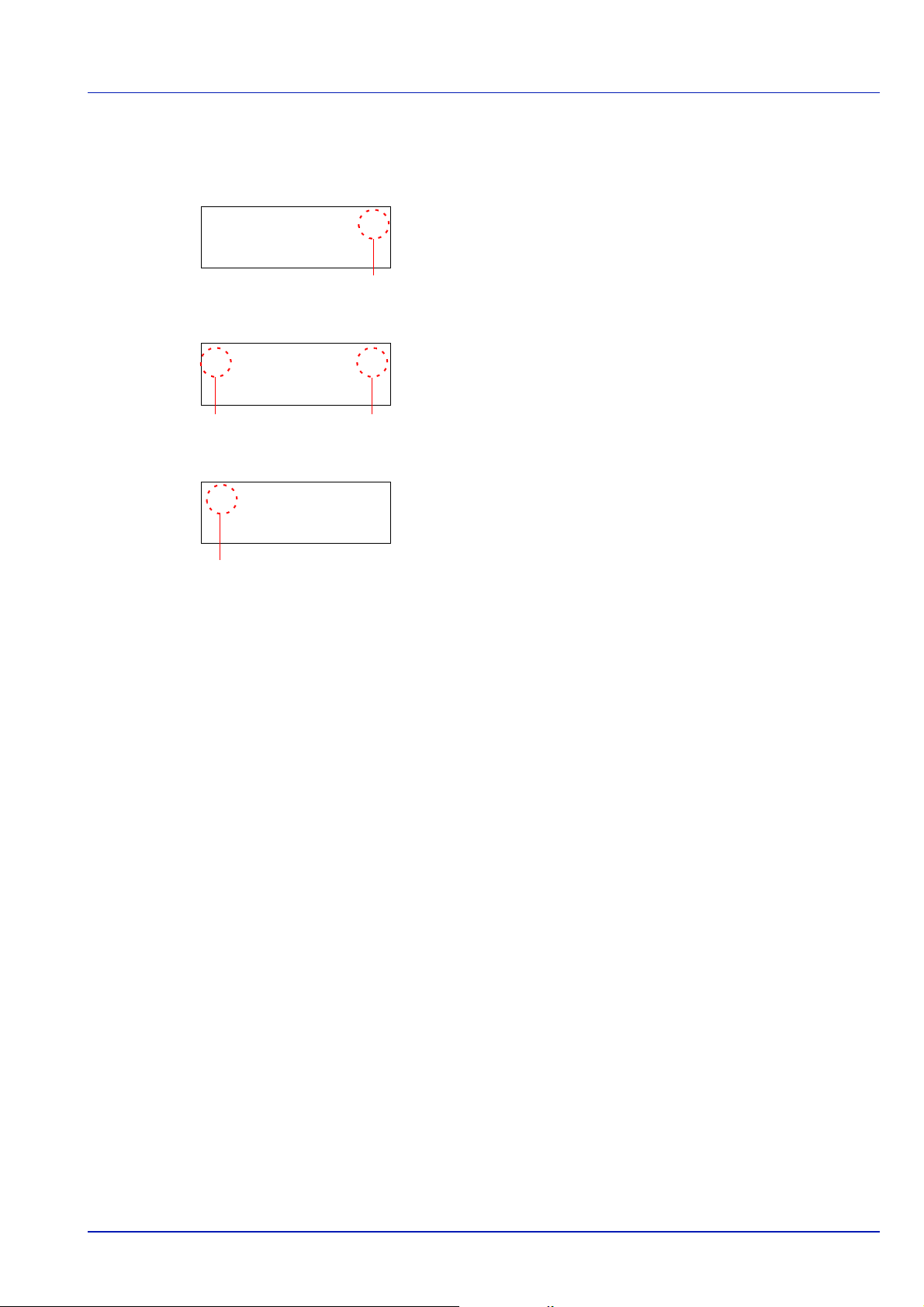

Minimum and Maximum Paper Sizes

105mm

(4-1/8 inches)

216mm (8-1/2 inches)

356mm (14 inches)

Minimum

Paper Size

Maximum

Paper Size

Paper cassette

70mm

(2-3/4 inches)

148mm (5-13/16 inches)

Minimum

Paper Size

Maximum

Paper Size

MP tray

216mm (8-1/2 inches)

148mm (5-13/16 inches)

356mm (14 inches)

The minimum and maximum paper sizes are as follows. For the paper

smaller than JIS B6, postcards, and envelopes, the MP tray must be

used.

Note The minimum paper size of the optional paper feeder (PF-

100) is 148 x 210 mm (5-13/16 x 8-5/16 inches).

Paper Handling 1-3

Page 10

Selecting the Right Paper

This section describes the guidelines for selecting paper.

Condition

Avoid using paper that is bent at the edges, curled, dirty, torn,

embossed, or contaminated with lint, clay, or paper shreds.

Use of paper in these conditions can lead to illegible printing and paper

jams, and can shorten the life of the machine. In particular, avoid using

paper with a surface coating or other surface treatment. Paper should

have as smooth and even a surface as possible.

Composition

Do not use paper that has been surface-treated and contains plastic or

carbon. The heat of fusing can cause such paper to give off harmful

fumes.

Bond paper should contain at least 80% pulp. Not more than 20% of the

total paper content should consist of cotton or other fibers.

Paper Sizes

Cassettes and the MP Tray are available for the paper sizes shown

below. The dimensional tolerances are ±0.7mm for the length and width.

The angle at the corners must be 90° ±0.2°.

MP Tray:

Envelope Monarch, Envelope #10, Envelope #9, Envelope #6, Envelope

C5, Envelope DL, Legal, Letter, Statement, Oficio II, Executive, ISO A4,

ISO A5, ISO A6, Folio, ISO B5, JIS B5, JIS B6, Hagaki, Ofuku-Hagaki,

Youkei 2, Youkei 4, 16 kai, Custom (70 × 148 to 216 × 356mm (2-13/16 ×

5-13/16 to 8-1/2 × 14 inches))

Note If the length of custom paper is larger than 297mm (11-11/16

inches), the printer can be specified ISO A4, Oficio II, Folio, and

Legal as the standard paper size.

Cassette:

Legal, Letter, Statement (only for machine’s paper cassette), Oficio II,

Executive, ISO A4, ISO A5, A6 (only for machine’s paper cassette),

Folio, ISO B5, JIS B5, Envelope C5, 16 kai, Custom (Paper Cassette:

105 × 148 to 216 × 356mm (4-1/8 × 5-13/16 to 8-1/2 × 14 inches), Paper

Feeder: 148 × 210 to 216 × 356mm (5-13/16 × 8-5/16 to 8-1/2 × 14

inches))

Note If the length of custom paper is larger than 297mm (11-11/16

inches), the printer can be specified ISO A4, Oficio II, Folio, and

Legal as the standard paper size.

Smoothness

The paper should have a smooth, uncoated surface. Paper with a rough

or sandy surface can cause blank spaces in the printed output. Paper

that is too smooth can cause multiple feeding and fogging problems.

(Fogging is a gray background effect.)

1-4 Paper Handling

Page 11

Basis Weight

Basis weight is the weight of paper expressed in grams per square meter

(g/m²). Paper that is too heavy or too light may cause feed errors or

paper jams as well as premature wear of the product. Uneven weight of

paper, namely uneven paper thickness may cause multiple-sheet

feeding or print quality problems such as blurring because of poor toner

fusing.

The recommended basis weight is between 60 and 120g/m² (16 to 31.9

lib/ream) for the cassette and between 60 and 220g/m² (16 to 59

lib/ream) for the MP tray.

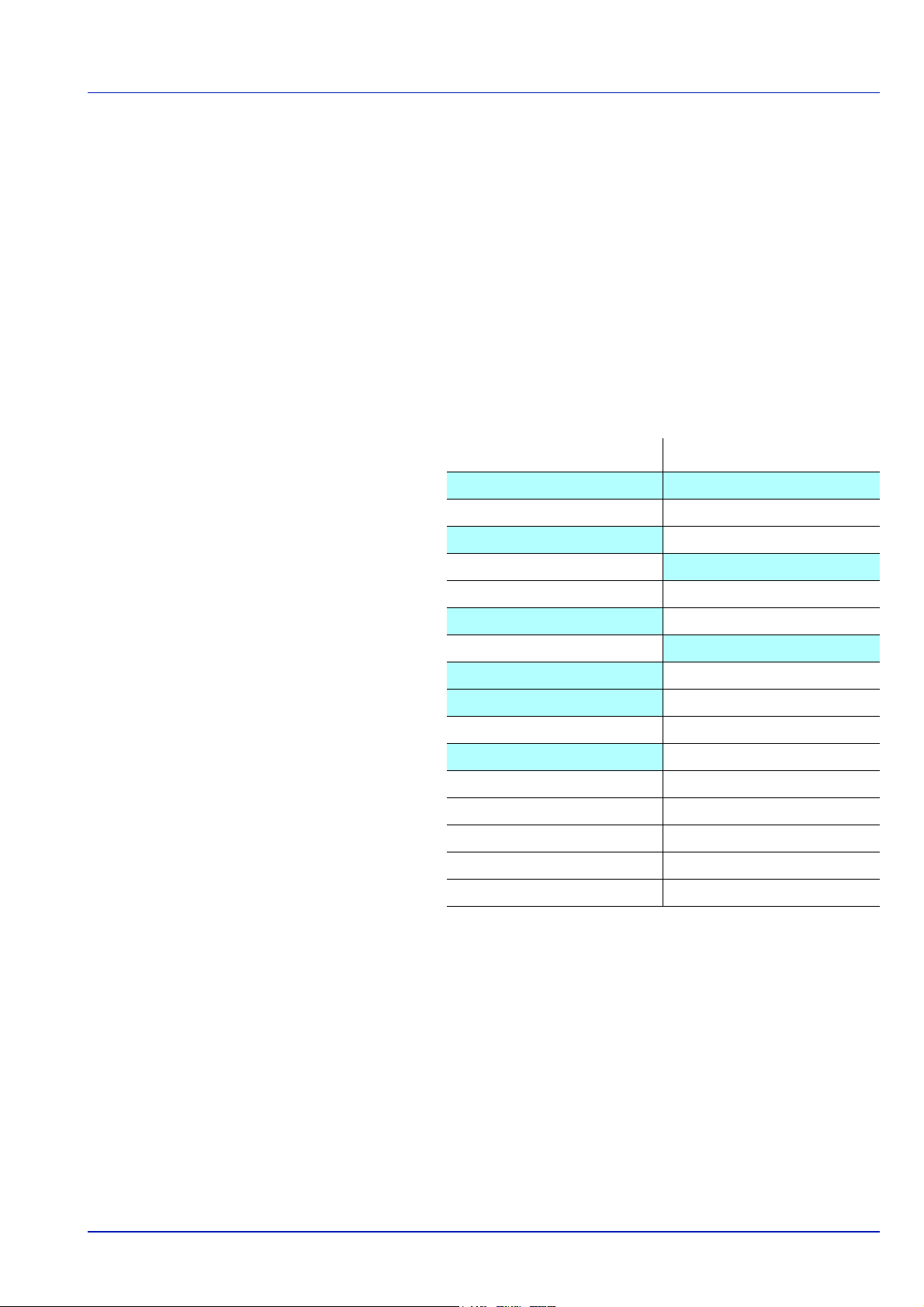

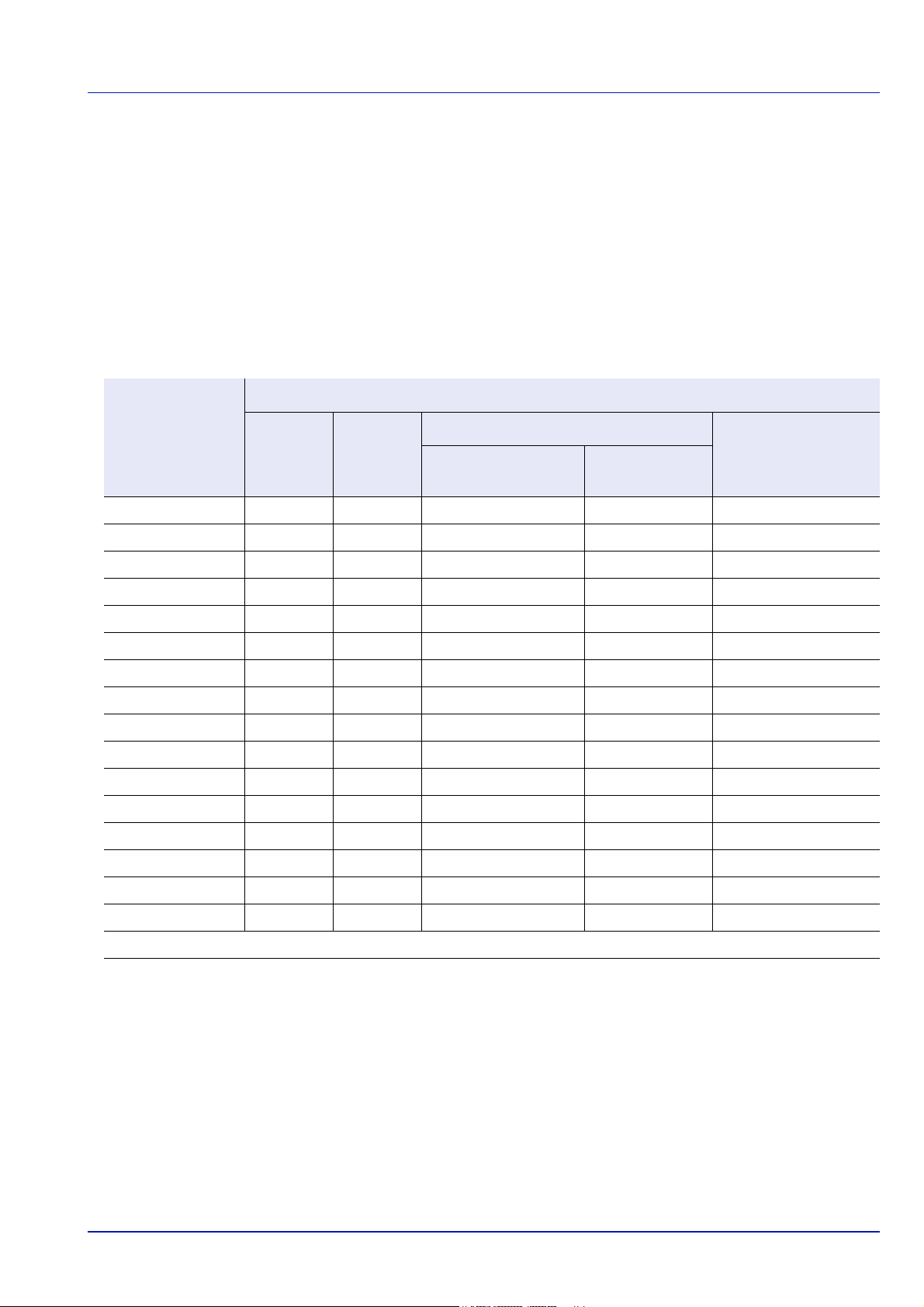

Paper Weight Equivalence Table

The paper weight is listed in pounds (lb) and metric grams per square

meter (g/m²). The shaded part indicates the standard weight.

U. S. Bond Weight (lb) Europe Metric Weight (g/m²)

16 60

17 64

20 75

21

22 81

24 90

27

28 105

32 120

34 128

36 135

39 148

42 157

43 163

47 176

53 199

80

100

Thickness

The paper used with the machine should be neither extremely thick nor

extremely thin. If you are having problems with paper jams, multiple

feeds, and faint printing, the paper you are using may be too thin. If you

are having problems with paper jams and blurred printing the paper may

be too thick. The correct thickness is 0.086 to 0.110mm (3.4 to 4.3 mils).

Moisture Content

Moisture content is defined as the percent ratio of moisture to the dry

mass of the paper. Moisture can affect the paper’s appearance, feed

ability, curl, electrostatic properties, and toner fusing characteristics.

Paper Handling 1-5

Page 12

The moisture content of the paper varies with the relative humidity in the

room. When the relative humidity is high and the paper absorbs

moisture, the paper edges expand, becoming wavy in appearance.

When the relative humidity is low and the paper loses moisture, the

edges shrink and tighten, and print contrast may suffer.

Wavy or tight edges can cause jams and alignment anomalies. The

moisture content of the paper should be 4 to 6%.

To ensure correct moisture content, it is important to store the paper in a

controlled environment. Some tips on moisture control are:

• Store paper in a cool, dry location.

• Keep the paper in its wrapping as long as possible. Re-wrap paper

that is not in use.

• Store paper in its original carton. Place a pallet etc. under the carton

to separate it from the floor.

• After removing paper from storage, let it stand in the same room as

the machine for 48 hours before use.

• Avoid leaving paper where it is exposed to heat, sunlight, or damp.

Paper Grain

When paper is manufactured, it is cut into sheets with the grain running

parallel to the length (long grain) or parallel to the width (short grain).

Short grain paper can cause feeding problems in the machine. All paper

used in the machine should be long grain.

Other Paper Properties

Porosity: Indicates the density of paper fiber.

Stiffness: Limp paper may buckle in the machine, resulting in paper

jams.

Curl: Most paper naturally tends to curl one way if left unpacked. When

paper passes through the fixing unit, it curls upward a little. To produce

flat printouts, load the paper so that the upward pressure from the

machine can correct their curling.

Electrostatic discharge: During the printing process the paper is

electrostatically charged to attract the toner. The paper must be able to

release this charge so that printed sheets do not cling together in the

Output Tray.

Whiteness: The contrast of the printed page depends on the whiteness

of the paper. Whiter paper provides a sharper, brighter appearance.

Quality control: Uneven sheet size, corners that are not square, ragged

edges, welded (uncut) sheets, and crushed edges and corners can

cause the machine to malfunction in various ways. A quality paper

supplier should take considerable care to ensure that these problems do

not occur.

Packaging: Paper should be packed in a sturdy carton to protect it from

damage during transport. Quality paper obtained from a reputable

supplier is usually correctly packaged.

1-6 Paper Handling

Page 13

Special Paper

The following types of special paper can be used:

Paper type to be used Paper type to be selected

Thin paper (60 to 64 g/m²) Vellum

Thick paper (90 to 220 g/m²) Thick

Colored paper Color

Recycled paper Recycled

Overhead projector transparencies Transparency

Cardstock Cardstock

Envelopes Envelope

Label Labels

Use paper that is sold specifically for use with copiers or printers (heatfusing type). When using transparencies, labels, envelopes, cardstock,

or thick paper, feed the paper from the MP Tray.

Since the composition and quality of special paper vary considerably,

special paper is more likely than white bond paper to give trouble during

printing. No liability will be assumed if moisture and so forth given off

during printing on special paper causes harm to the machine or operator.

Note Before purchasing any type of special paper, test a sample

on the machine and check that printing quality is satisfactory.

Transparency

This printer is available for monochrome printing on transparencies.

Transparencies must be fed to the MP Tray. One transparency can be

loaded at a time.

Transparencies must be able to withstand the heat of fusing during the

printing process.

Transparencies must be placed on the MP tray with the long edge

towards the printer.

When unloading transparencies (e.g., for clearing jams), hold them

carefully by the edges to avoid leaving fingerprints on them.

Labels

Labels must be fed to the MP tray. One label can be loaded at a time.

Paper Handling 1-7

Page 14

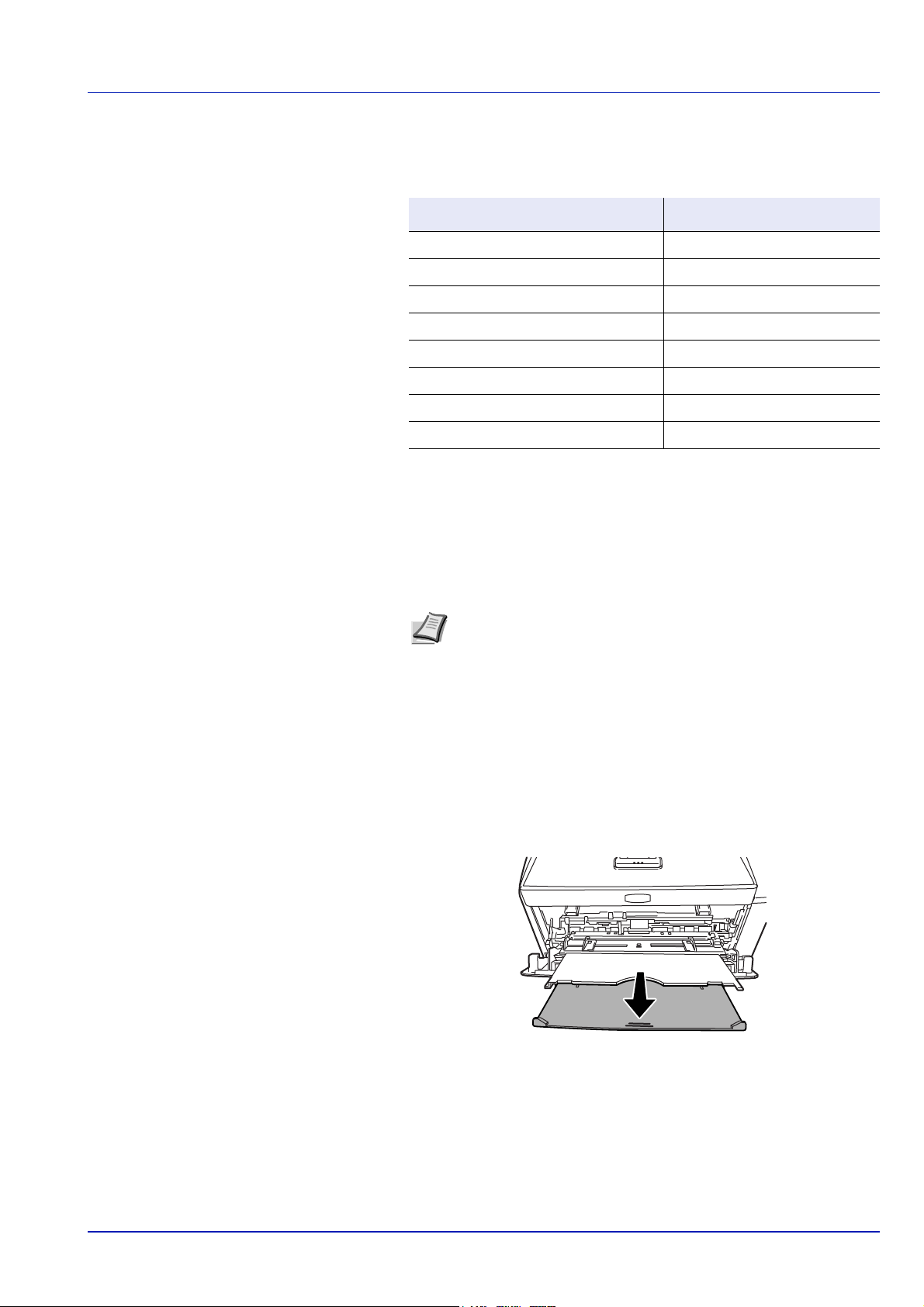

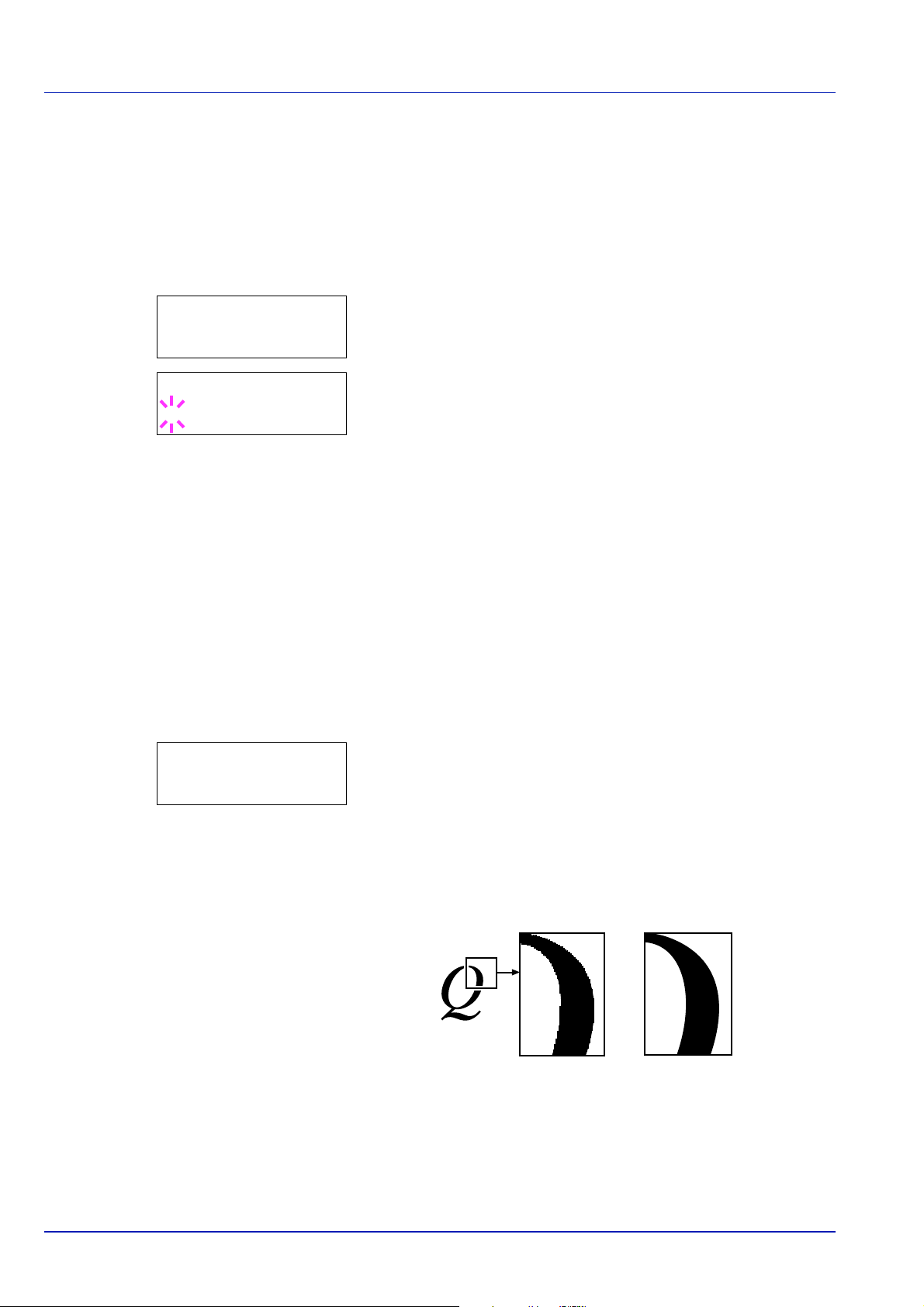

The basic rule for printing on adhesive labels is that the adhesive must

Top sheet (white

bond paper)

Adhesive

Carrier sheet

Top sheet

UnacceptableAcceptable

Carrier sheet

never come into contact with any part of the machine. Adhesive paper

sticking to the drum or rollers will damage the machine.

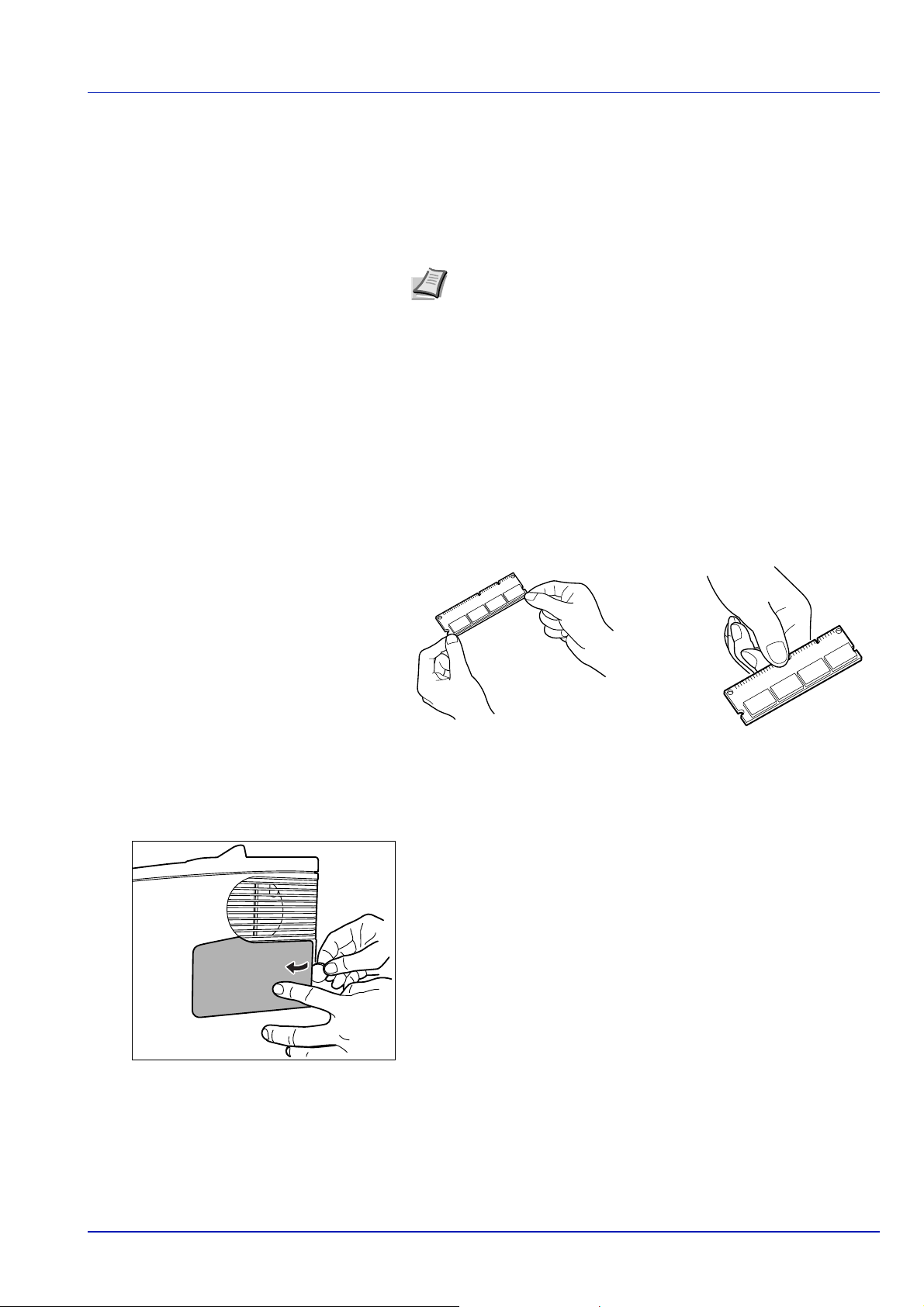

Label paper has a structure

comprising of three layers, as

shown in the diagram. The top

sheet is printed on. The

adhesive layer consists of

pressure-sensitive adhesives.

The carrier sheet (also called

the linear or backing sheet)

holds the labels until used.

Due to the complexity of its

composition, adhesivebacked label paper is particularly likely to give printing problems.

Adhesive label paper must be entirely covered by its top sheet, with no

spaces between the individual labels. Labels with spaces in between are

liable to peel off, causing serious paper jam problems.

Some label paper is manufactured with an extra margin of top sheet

around the edge. Do not remove the extra top sheet from the carrier

sheet until after printing is finished.

The table below lists the specifications for adhesive label paper.

Item Specification

Weight of top sheet 44 to 74 g/m² (12 to 20 lb/ream)

Composite weight 104 to 151 g/m² (28 to 40 lb/ream)

Thickness of top sheet 0.086 to 0.107 mm (3.9 to 4.2 mils)

Composite thickness 0.115 to 0.145 mm (4.5 to 5.7 mils)

Moisture content 4 to 6 % (composite)

Postcards

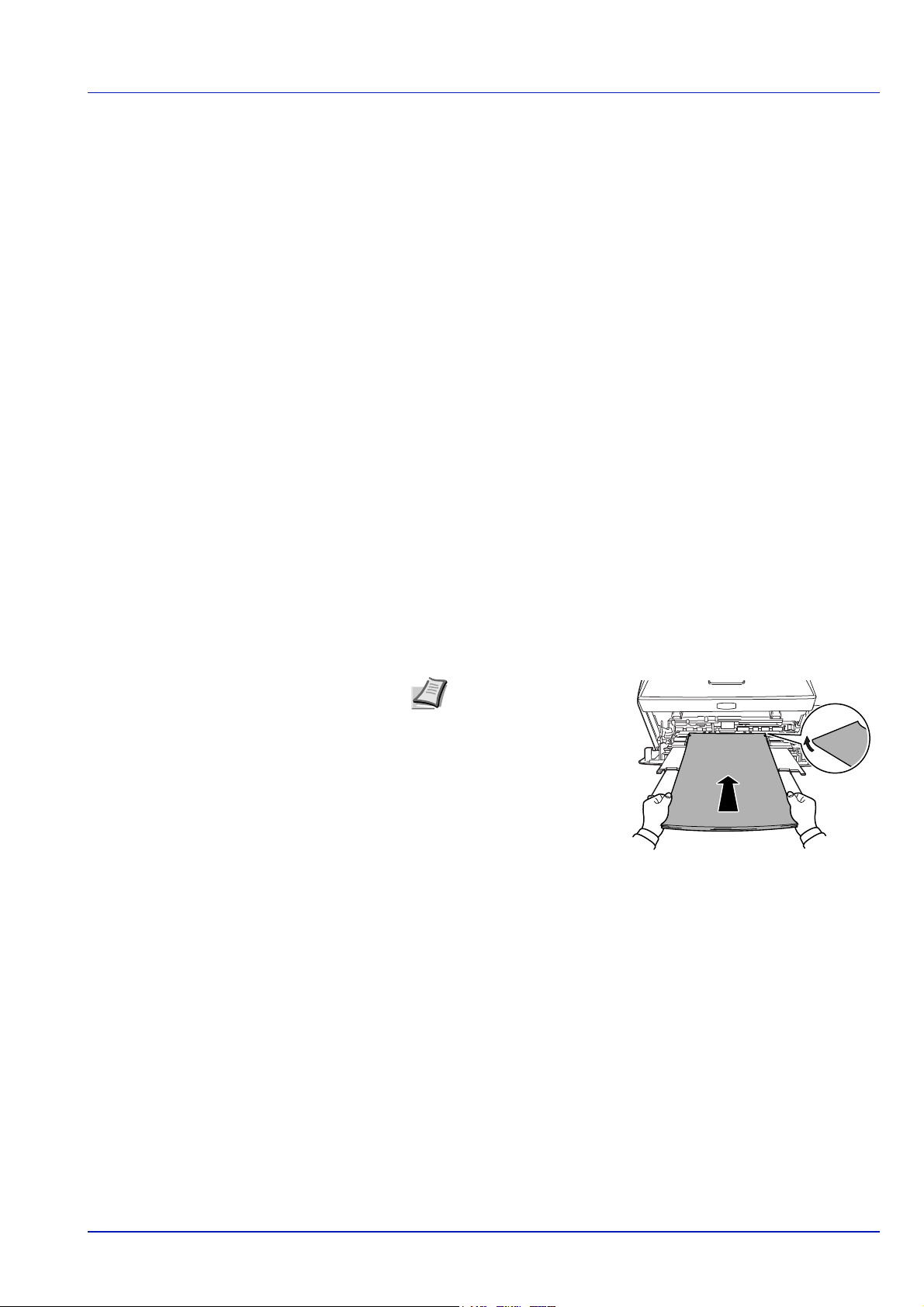

Up to 10 postcards can be

loaded at a time. Fan the

stack of postcards and align

the edges before loading

them in the MP tray. Make

sure the postcards you are

1-8 Paper Handling

going to set are not curled.

Feeding curled postcards

may cause paper jams.

Page 15

Some postcards have rough edges on the back (those are created when

the paper is cut). In this case, put the postcards on a flat place and rub

the edges with, for example, a ruler to smooth them.

Envelopes

Up to 5 envelopes can be loaded at a time. Envelopes should be fed in

the face-up position, right edge first.

Since the composition of an envelope is more complex than that of

ordinary paper, it is not always possible to ensure consistent printing

quality over the entire envelope surface.

Normally, envelopes have a diagonal grain direction. Refer to Paper

Grain on page 1-6. This direction can easily cause wrinkles and creases

when envelopes pass through the printer. Before purchasing envelopes,

make a test print to check whether the printer accepts the envelope.

• Do not use envelopes that have an encapsulated liquid adhesive.

• Avoid a long printing session for envelopes only. Extended envelope

printing can cause premature printer wear.

• If jams occur, try setting less envelopes on the MP tray.

• To avoid jams caused by curled envelopes, stack no more than 10

printed envelopes on the output tray.

Thick Paper

Fan the stack of paper and align the edges before loading them in the

MP tray. Some types of paper have rough edges on the back (those are

created when the paper is cut). In this case, put the paper on a flat place

and rub the edges once or twice with, for example, a ruler to smooth

them. Feeding rough edged paper may cause paper jams.

Note If the paper jams

even after you smooth it

out, load the paper in

the MP tray with the

leading edge raised up

a few millimeters as

shown in the

illustration.

Colored Paper

Colored paper should satisfy the same conditions as white bond paper.

Refer to Paper Specifications on page 1-2. In addition, the pigments

used in the paper must be able to withstand the heat of fusing during the

printing process (up to 200 °C or 392 °F).

Preprinted Paper

Preprinted paper should satisfy the same conditions as white bond

paper. Refer to Paper Specifications on page 1-2.The preprinted ink

must be able to withstand the heat of fusing during the printing process,

and must not be affected by silicone oil.

Do not use paper with any kind of surface treatment, such as the type of

paper commonly used for calendars.

Paper Handling 1-9

Page 16

Recycled Paper

Select recycled paper that meets the same specifications as the white

bond paper except for whiteness. Refer to Paper Specifications on

page 1-2.

Note Before purchasing recycled paper, test a sample on the

machine and check that the printing quality is satisfactory.

1-10 Paper Handling

Page 17

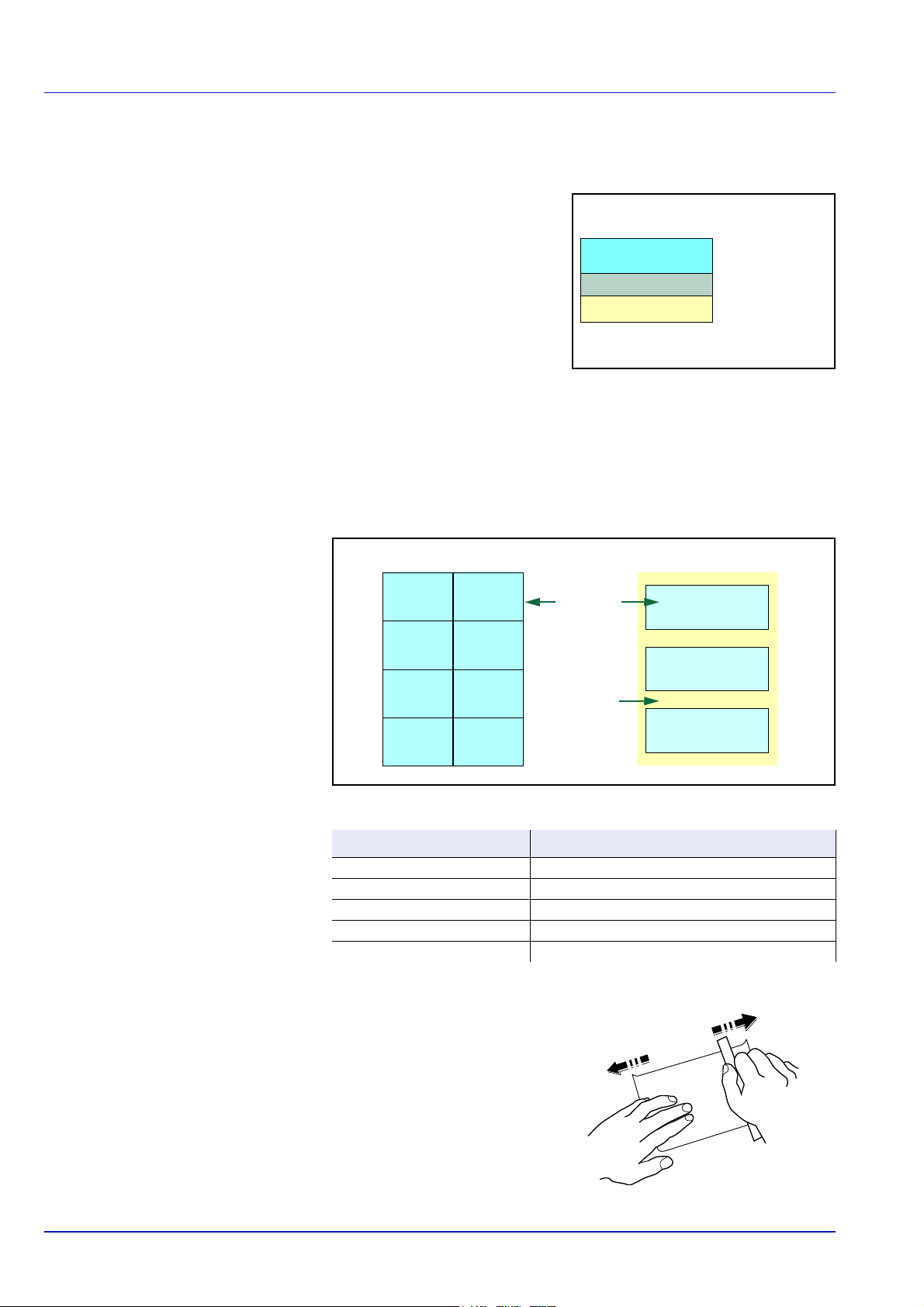

Paper Type

The printer is capable of printing under the optimum setting for the type

of paper being used.

Setting the paper type for the paper source from the printer’s operation

panel will cause the printer to automatically select the paper source and

print in the mode best suited to that type of paper.

A different paper type setting can be made for each paper source

including the MP tray. Not only can preset paper types be selected, but it

is also possible for you to define and select customized paper types.

Refer to Type Adjust (Creating custom paper type) on page 2-25. The

following types of paper can be used.

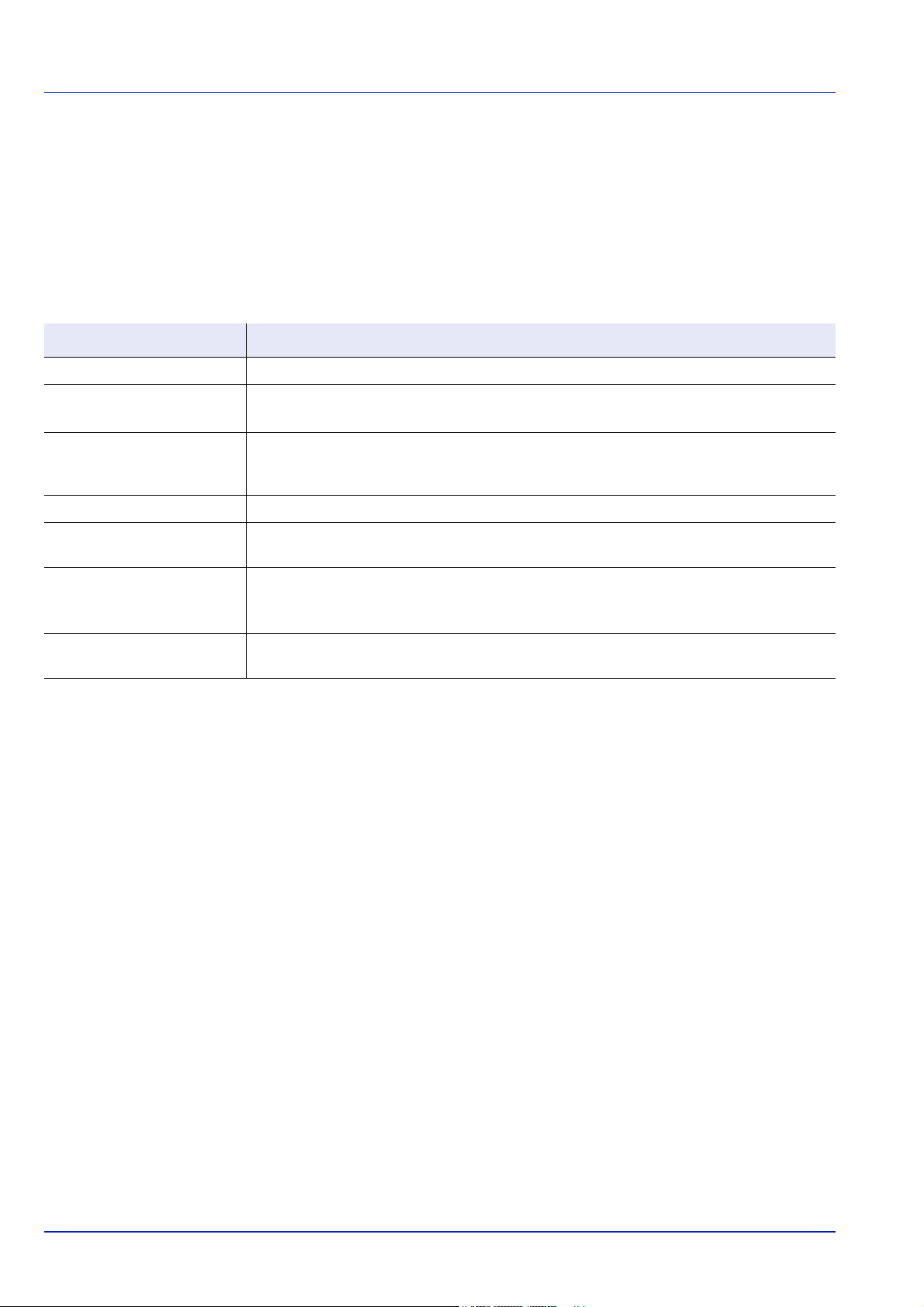

Paper source

Paper Type

MP tray

Paper

Cassette

Plain Yes Yes 70 to 90g/m

Paper Weight

Range

Display in

Duplex path

Operation Panel

2

Normal2 Yes

Transparency Yes No Transparency Extra Heavy No

Preprinted Yes Yes 70 to 90g/m

2

Labels Yes No 90 to 120g/m

Bond Yes Yes 90 to 120g/m

Recycled Yes Yes 70 to 90g/m

2

Vellum Yes No Less than 64g/m

Rough Yes Yes 90 to 120g/m

Letterhead Yes Yes 90 to 120g/m

Color Yes Yes 90 to 120g/m

Prepunched Yes Yes 70 to 90g/m

2

Envelope Yes No 120 to 220g/m

Cardstock Yes No 120 to 220g/m

Thick Yes No 120 to 220g/m

High quality Yes Yes 70 to 90g/m

Custom 1 (to 8)

*

Yes Yes 70 to 90g/m

2

2

2

2

2

2

2

2

2

2

2

Normal2 Yes

Heavy1 No

Normal3 Yes

Normal2 Yes

Light No

Normal3 Yes

Normal3 No

Normal3 Yes

Normal2 Yes

Heavy3 No

Heavy3 No

Heavy3 No

Normal2 Yes

Normal2 Yes

Yes: Can be stored No: Cannot be stored

*. This is a paper type defined and registered by the user. Up to eight types of user settings may be defined. User

can also enable or disable the duplex path when using Custom. For more information, refer to Type Adjust

(Creating custom paper type) on page 2-25.

Paper Handling 1-11

Page 18

1-12 Paper Handling

Page 19

2 Using the Operation

Panel

This chapter contains explanations on the following topics:

General Information 2-2

Understanding the Operation Panel 2-3

Using the Menu Selection System 2-8

Report Print 2-11

USB Memory (USB flash memory selection) 2-16

Counter (Viewing the counter value) 2-18

Paper Settings 2-19

Print Settings 2-27

Network (Network settings) 2-39

Device Common (Selecting/Setting the common device) 2-44

Security 2-55

Admin (Administrator settings) 2-63

Adjust/Maintenance (Adjust/Maintenance selection/setting) 2-65

Using the Operation Panel 2-1

Page 20

General Information

This chapter provides the information you need to configure the Ecosys

printer. In general you need to use the operation panel only to make

default settings. You can make most changes to the printer settings

using the printer driver through the application software.

Note Changes to printer settings made using a software

application override changes made using the operation panel.

You can also access the printer's various settings from a remote

location, by using the control panel, the printer driver or other utilities

such as the Status Monitor Utility. Other printer utilities can be installed

using the CD-ROM supplied with the printer.

The chapter describes the operation panel in detail, including its menus

and the procedures for changing various printer settings.

2-2 Using the Operation Panel

Page 21

Understanding the Operation Panel

The operation panel on the top of the printer has a 2-line by 16-character

liquid crystal display (LCD), eight keys, and three indicators (LED).

Messages that appear on the display and functions of indicators and

keys are explained in this chapter.

Using the Operation Panel 2-3

Page 22

Message Display

The message display on the operation panel shows:

• Status information, the ten messages listed below which are

displayed during normal operation.

• Error codes, when the printer requires the operator’s attention; as

explained in the Operation Guide.

Status Information

Message Meaning

Self test The printer is performing self-diagnostics after power-up.

Please wait The printer is warming up and is not ready.

When the printer is switched on for the first time, this message will take several minutes.

Please wait

(Adding toner)

Ready The printer is ready to print.

Processing The printer is receiving data to print. This is also shown when the printer is reading a CF

Sleeping The printer is in Auto Sleep. The printer wakes from Auto Sleep whenever a print job is

Canceling data Jobs inside the printer are being canceled. To cancel a job, refer to Canceling a Printing

Toner is currently being replenished. This message may be displayed during continuous

printing of a large volume of pages which require a large amount of toner such as with

photographs, etc.

card, USB flash memory or RAM disk.

received. The printer then warms up and goes on-line.

For details on Auto Sleep, refer to Sleep Timer (Sleep timer timeout time) on page 2-52.

Job on page 2-6.

Error Codes

Refer to the Troubleshooting section in the Operation Guide.

2-4 Using the Operation Panel

Page 23

Indicators in Message Display

Ready

Ready, Data, and Attention Indicators

The following indicators light during normal operation and whenever the

printer needs attention. Depending on the status of lighting, each

indicator has the following meaning:

Indicator Description

Flashing. Indicates an error that you can resolve. For

details, refer to the Troubleshooting section in the

Operation Guide.

On. Indicates that the printer is ready and on-line. The

printer prints the data it receives.

Off. Indicates that the printer is off-line. Data can be

received but will not be printed. Also, indicates when

printing is automatically stopped due to an error condition.

For details, refer to the Troubleshooting section in the

Operation Guide.

Flashing. Indicates that a data is being received.

On. Indicates either that data received is being processed

before printing starts, or that data received is being written

to or read from a CompactFlash (CF) card, RAM disk, or

USB flash memory.

Flashing. Indicates that the printer requires maintenance

or is warming up.

On. Indicates the occurrence of a problem or an error. For

details, refer to the Troubleshooting section in the

Operation Guide.

Using the Operation Panel 2-5

Page 24

Keys

The operation panel keys are used to configure the printer operation.

Note that certain keys have a secondary function.

GO Key

Use this key to:

• Recover from certain errors.

• Recover from Auto Sleep mode.

Cancel Key

This key is used to:

• Cancel a printing job.

• Stop the alarm sound.

• Reset numeric values or cancel a setting procedure while using

menu system.

Canceling a Printing Job

1 While the printer displays Processing, press [Cancel].

Print Cancel? appears on the message display followed by the

job name currently in progress.

2 Press U or V to display the desired job and [OK].

Canceling data appears on the message display and printing

stops after the current page is printed.

MENU Key

[MENU] lets you enter the menu system to change the setup and

printing environment of the printer.

Pressing this key during a menu selection will terminate the selection

and return the printer to the normal operation.

2-6 Using the Operation Panel

Page 25

Cursor Keys

The four cursor keys are used in the menu system to access an item or

enter numeric values. Use U and V to change menus, and Y and Z to

move to the sub menu.

The cursor key with the question mark ( ) may be pressed when the

paper jam message has appeared on the message display. A help

message will then appear to facilitate jam clearing in the location.

When Use alternative? is shown in the message display, use the U

and V key to select the paper source.

OK Key

This key is used to:

• Finalize settings of numeric values and other selections.

• Set the paper source when Use alternative? is shown in the

message display.

Using the Operation Panel 2-7

Page 26

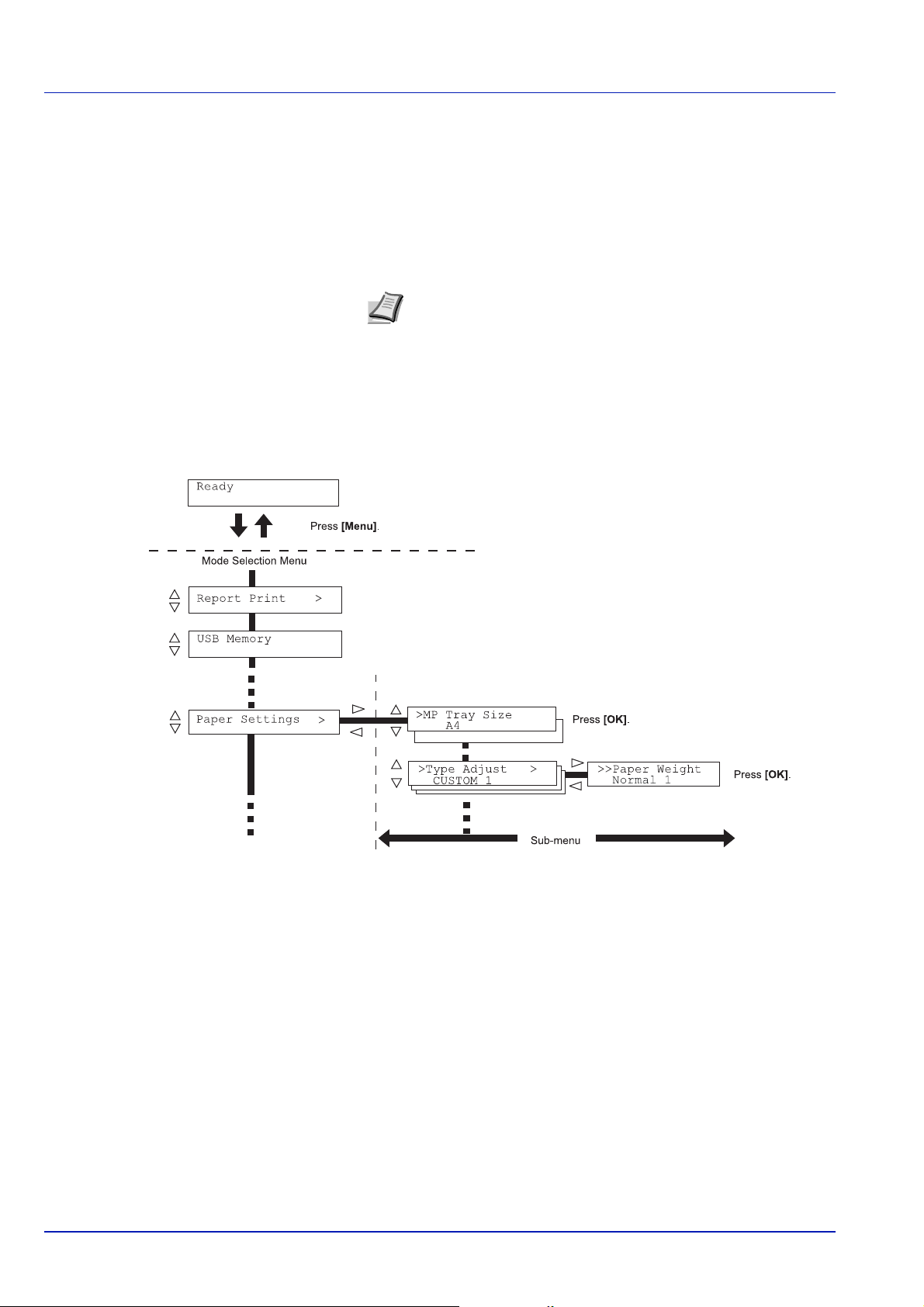

Using the Menu Selection System

Menu Selection System

This section explains how to use the menu selection system. [MENU] on

the operation panel allows you to use the menu to configure the printer

settings to your specific needs. Settings can be made when Ready is

indicated on the printer message display.

Note Settings that are received from application software and the

printer driver will take priority over settings made in the operation

panel.

Entering the Mode Selection Menu

Press [MENU] when Ready, Please wait, Sleeping or

Processing is indicated on the printer message display.

The mode selection menu is displayed.

2-8 Using the Operation Panel

Page 27

Selecting a Menu

Paper Settings >

Indicates that there is a sub-menu

>Type Adjust >

CUSTOM 1

Indicates that there is

another sub-menu

Indicates that this is

the sub-menu

>>Paper Weight

Normal 1

Indicates that this is the second sub-menu

The mode selection menu is hierarchical. Press U or V to display the

desired menu.

If the selected menu has a sub-menu, > is displayed after the menu.

Press Z to move to the sub-menu or Y to go back.

> is displayed before the sub-menu.

Press Z to move to another sub-menu or Y to go back.

>> is displayed before the second sub-menu.

Setting a Menu

Select the desired menu and press [OK] to set or change the

configuration.

Press U or V to display the desired item and [OK] to finalize the value

or selections set.

Cancelling Menu Selection

If you press [MENU] when a menu is selected, the message display

returns to Ready.

Using the Operation Panel 2-9

Page 28

Setting a Mode Selection Menu

Report Print >

This section explains the setting procedures used for each menu item in

the mode selection menu.

1 While the printer displays Ready, Please wait, Sleeping and

Processing, press [MENU]. The mode selection menu is

displayed. (For example : Report Print)

2 Each time you press U or V, the selection changes.

• Report Print

• USB Memory

• Counter

• Paper Settings

• Print Settings

• Network

• Device Common

• Security

• Admin

• Adjust/Maintenance

Note If you use the mode first selected when the printer is turned

on, Report Print is displayed. For the second and subsequent

times, the last menu option you selected the previous time is

displayed.

2-10 Using the Operation Panel

Page 29

Report Print

Report Print >

>Print

Menu Map ?

The printer prints the report. Report Print includes the following items:

• Print Menu Map

• Print Status Page

• Print Fonts List

• Print RAM Disk File List

• Print Mem. Card File List

1 Press [MENU].

2 Press U or V repeatedly until Report Print > appears.

Note that menus shown in the list may vary depending on which optional

units installed in the printer.

Print Menu Map

The printer prints a full list of the menu selection system menu map.

1 Press Z while Report Print > is displayed.

2 >Print Menu Map appears. In other displays, press U or V

repeatedly until the map appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK]. The message Processing appears and the printer

prints a Menu Map.

Using the Operation Panel 2-11

Page 30

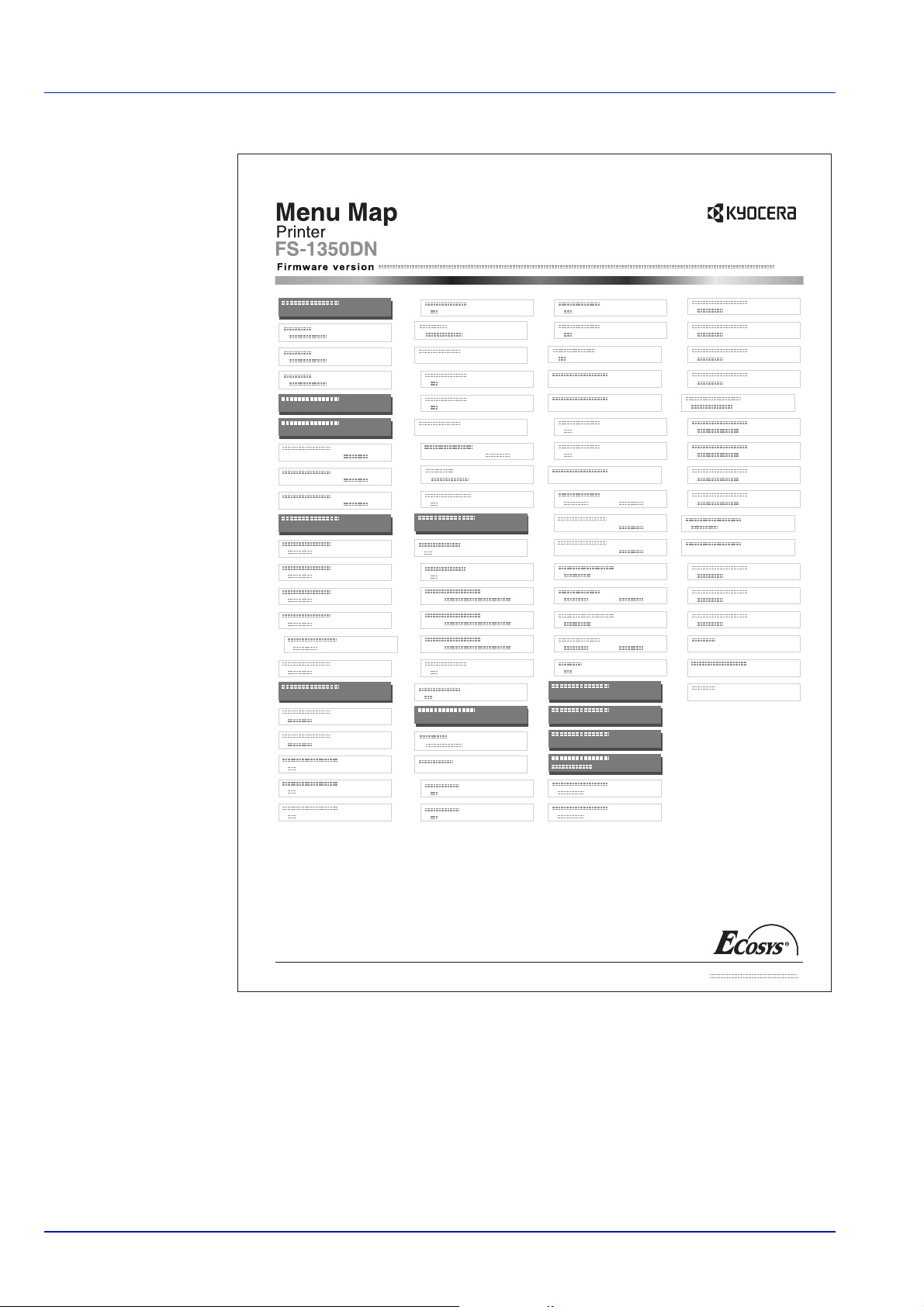

Menu Map Sample

2-12 Using the Operation Panel

Page 31

Print Status Page

>Print

Status Page ?

2

3

4

6

1

7

8

9

5

You can check the printer's current status, including available memory

space and option settings by printing a status page.

1 Press Z while Report Print > is displayed.

2 Press U or V repeatedly until >Print Status Page appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The message Processing appears and the

printer prints a status page.

For a sample status page and its full description, refer to the next section

Understanding the Status Page.

Understanding the Status Page

The numbers in the following diagram refer the items explained below

the diagram. The items and values on the status page may vary

depending on the printer’s firmware version.

Status Page

Printer

Firmware version

Group Settings

Print Settings

Device Common Settings

Option Status

Interface BlockPaper Settings

Memory

Emulation

Network

Counters

Toner Gauge

Using the Operation Panel 2-13

Page 32

1 Firmware Version

This item shows the version and release date of the printer firmware.

2 Printer Settings Information

This item shows various printer settings for hardware-related items:

• MP tray paper size and type

• Paper cassette size and type

• Sleep time

• Formfeed timeout time

3 Installed Options

This item shows the option installed in the printer:

• Memory card (CompactFlash card)

4 Network Status

This item shows the IP address, subnet mask address, and default

gateway address for the network interface card in the printer.

5 Interface Information

This information shows the settings for all interfaces installed in the

printer.

6Memory

This item shows:

• Standard memory in the printer

• Option memory slot status in kilobytes

• Total memory in the printer

• Current status of the RAM disk

7Emulation

This item shows all available emulations of the printer. The PCL 6

emulation is set as default when the printer is shipped from the

factory. The emulations are:

• PCL 6

• KPDL

• Line Printer

• IBM Proprinter

• DIABLO 630

• EPSON LQ-850

8 Page Information

This item shows the page related items:

• Total printed page count

• Total page count of each paper size

9 Consumable Status

This item shows the approximate level of remaining toner. When the

value is 100, the toner container is full. The closer to 0, the smaller

the amount of remaining toner.

2-14 Using the Operation Panel

Page 33

Print Fonts List

>Print

Fonts List ?

>Print RAM Disk

File List ?

>Print Mem. Card

File List ?

To help you decide in selecting a font, you can printout lists of the

internal fonts or the optional fonts.

1 Press Z while Report Print > is displayed.

2 Press U or V repeatedly until >Print Fonts List appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The message Processing appears and the

printer prints a list of fonts with a sample and font ID (number) for

each of them.

Print RAM Disk File List

This allows you to print a list of the files on the RAM disk.

IMPORTANT This is displayed when RAM disk mode is enabled.

1 Press Z while Report Print > is displayed.

2 Press U or V repeatedly until >Print RAM Disk File List

appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The message Processing appears and the

printer prints a list of files stored in a RAM disk.

Print Mem. Card File List

This allows you to print a list of the files on a CompactFlash (memory)

card.

IMPORTANT This message will be displayed when the

CompactFlash (CF) card installed in the printer.

1 Press Z while Report Print > is displayed.

2 Press U or V repeatedly until >Print Mem. Card File List

appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The message Processing appears and the

printer prints a list of files stored in a

CF card.

Using the Operation Panel 2-15

Page 34

USB Memory (USB flash memory selection)

USB Memory >

/

/00:Folder 1

/00:Folder 1

/01:Folder 2

/.../01:Folder 2

02:File 3

/.../01:Folder 2

? 02:File 3

Copies

001

This specifies the settings for removing the USB flash memory and

printing USB flash memory content.

IMPORTANT This message is displayed only when the USB host

block is set to

(Interface (external device) block setting) on page 2-56.

The options available in USB flash memory are as follows:

• Print File (Printing a file)

• Copies (Number of copies)

• Paper Source (Selecting the paper feed source)

• Remove Device (Removing the USB flash memory)

• Print File List (Printing a list of the files on a USB flash memory)

1 Press [MENU].

2 Press U or V repeatedly until USB Memory > appears.

Note that menus shown in the list may vary depending on which

optional units installed in the printer.

Print File (Printing a file)

You can use this to specify printing for files in the USB flash memory.

1 Press Z while USB Memory > is displayed.

2 >Print File appears. In other displays, press U or V repeatedly

until the map appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The folder or file appears.

(For example : Folder 1)

Each time you press U or V, the next folder or file appears in

succession.

To view lower-level folders or files, press Z.

(For example : Folder 2)

Unblock. For more information, refer to Interface Block

To view folders or files on still lower levels, press Z.

(For example : File 3)

IMPORTANT The Print File menu option is only displayed

when there is a PDF or TIFF file in the USB flash memory. Note

also that up to 3 levels of folders or files are displayed. It might

take some time before the folder or file name appears, depending

on the size of the USB flash memory or the number of files.

You can move between the folder levels by pressing U and V or Y

and Z.

5 Press [OK]. A question mark (?) appears.

(For example : File 3)

6 Press [OK] again. Copies appears.

2-16 Using the Operation Panel

Page 35

Copies (Number of copies)

Copies

010

Paper Source

? Cassette 1

Paper Source

? Cassette 2

>Remove Device ?

>Print

File List ?

Sets the number of copies printed of the specified file in USB flash

memory.

1 While Copies in step 5 above is displayed, press U and V or Y

and Z to display the number of copies. (E.g.: 10)

2 Press [OK]. Paper Source and a question mark (?) appears.

Paper Source (Selecting the paper feed source)

Sets the paper used for printing the specified file in USB flash memory.

1 While Paper Source in step 2 above is displayed, press U and V

or Y and Z repeatedly until the paper source appears.

(For example : Cassette 2)

Note that menus shown in the list may vary depending on which

optional units installed in the printer.

2 Press [OK]. The message Processing appears and the printer

prints a file stored in a USB flash memory.

Remove Device (Removing the USB flash memory)

Specifies the setting for USB flash memory removal.

1 Press Z while USB Memory > is displayed.

2 Press U or V repeatedly until >Remove Device appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. Menu display ends and the USB flash memory

device can be removed.

Print File List (Printing a list of the files on a USB flash memory)

This allows you to print a list of the files on a USB flash memory device.

1 Press Z while USB Memory > is displayed.

2 Press U or V repeatedly until >Print File List appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. The message Processing appears and the

printer prints a list of files stored in a USB flash memory.

Using the Operation Panel 2-17

Page 36

Counter (Viewing the counter value)

Counter >

>Printed Pages

0002000

This only displays the total number of pages printed. You cannot change

the displayed number.

1 Press [MENU].

2 Press U or V repeatedly until Counter > appears.

3 Press Z. >Printed Pages appears as he total number of pages

printed. (E.g.: 2000)

4 Press [MENU]. The display returns to Ready.

2-18 Using the Operation Panel

Page 37

Paper Settings

Paper Settings >

This sets the paper size and type for the MP tray and cassettes from

which paper is supplied.

The options available in Paper Settings are as follows:

• MP Tray Size (Setting MP tray paper size)

• MP Tray Type (Setting the MP tray paper type)

• Cassette (1 to 3) Size (Setting the cassette paper size)

• Cassette (1 to 3) Type (Setting the cassette paper type)

• Type Adjust (Creating custom paper type)

• Reset Type Adjust (Resetting the custom paper type)

1 Press [MENU].

2 Press U or V repeatedly until Paper Settings > appears.

Using the Operation Panel 2-19

Page 38

MP Tray Size (Setting MP tray paper size)

>MP Tray Size

? A4

When you use the MP tray, you should set the MP tray size to the paper

size that is used to format the job to print. If the sizes do not match,

printing will not be performed on the correct size paper.

The default setting is Letter size for the U.S. and Canada and A4 for

other countries. For more information about the paper sizes that you can

feed from the MP tray, refer to Paper Specifications on page 1-2.

Note Feeding the paper having a paper size which does not

match the current paper size from the MP tray can cause paper

jam.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >MP Tray Size appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V to display the desired paper size. The message

display toggles through the following paper sizes:

Env. Monarch

Envelope #10

Envelope #9

Envelope #6

Envelope DL

Envelope C5

A6

B6

A5

B5

ISO B5

A4

Executive

Letter

Legal

Custom

Oficio II

Statement

Folio

Youkei 2

Youkei 4

16K

Hagaki

OufukuHagaki

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

MP Tray Type (Setting the MP tray paper type)

You can use this to set the paper type that can be supplied from the MP

tray. The default setting is PLAIN.

For more information about paper types that you can feed from the MP

tray, refer to Paper Specifications on page 1-2.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >MP Tray Type appears.

2-20 Using the Operation Panel

Page 39

3 Press [OK]. A blinking question mark (?) appears.

>MP Tray Type

? PLAIN

4 Press U or V to display the desired paper type. The message

display toggles through the following paper types:

PLAIN

TRANSPARENCY

PREPRINTED

LABELS

BOND

RECYCLED

VELLUM

ROUGH

LETTERHEAD

COLOR

PREPUNCHED

ENVELOPE

CARDSTOCK

THICK

HIGH QUALITY

CUSTOM 1 (to 8)

Note You can define any paper type and store that definition

in the printer. For more information, refer to Type Adjust

(Creating custom paper type) on page 2-25.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Cassette (1 to 3) Size (Setting the cassette paper size)

To set the size for the paper cassette, load the paper into a paper

cassette, adjust the paper size, and select the paper size from the

operation panel.

If the PF-100 optional paper feeder is installed, use the same procedure

to load paper into the paper feeder cassettes.

1 Pull the cassette out of the printer.

2 Adjust the position of the width guides located on the left and right

sides of the cassette. Press the release button on the left guide and

slide the guides to the paper size required, and load the paper into

the cassette.

Using the Operation Panel 2-21

Proceed to the next section to select the paper size from the operation

panel.

Page 40

Setting the Paper Size from the Operation Panel

>Cassette Size >

? Custom

Use the operation panel to set the size of paper loaded in the cassette

on the printer.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >Cassette Size > appears. If

optional paper feeders are added, Cassette1 Size will appear for

the standard paper cassette and Cassette2 Size, and

Cassette3 Size will appear for the optional paper feeders.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V to display the desired paper size. The message

display toggles through the following paper sizes:

Envelope C5

A6

A5

B5

ISO B5

A4

Executive

Letter

Legal

Custom

Oficio II

Statement

Folio

16K

Note A6 and Statement will not appear if Cassette 2 to

3 of optional paper feeder PF-100 is selected.

5 When the desired paper size is displayed, press [OK]. The paper

size is set for the paper cassette.

If you selected Custom in step 4, be sure to set the unit of

measurement and the dimensions of the paper as described in the

following sections.

Select the units of measurement as described in the next section.

2-22 Using the Operation Panel

Page 41

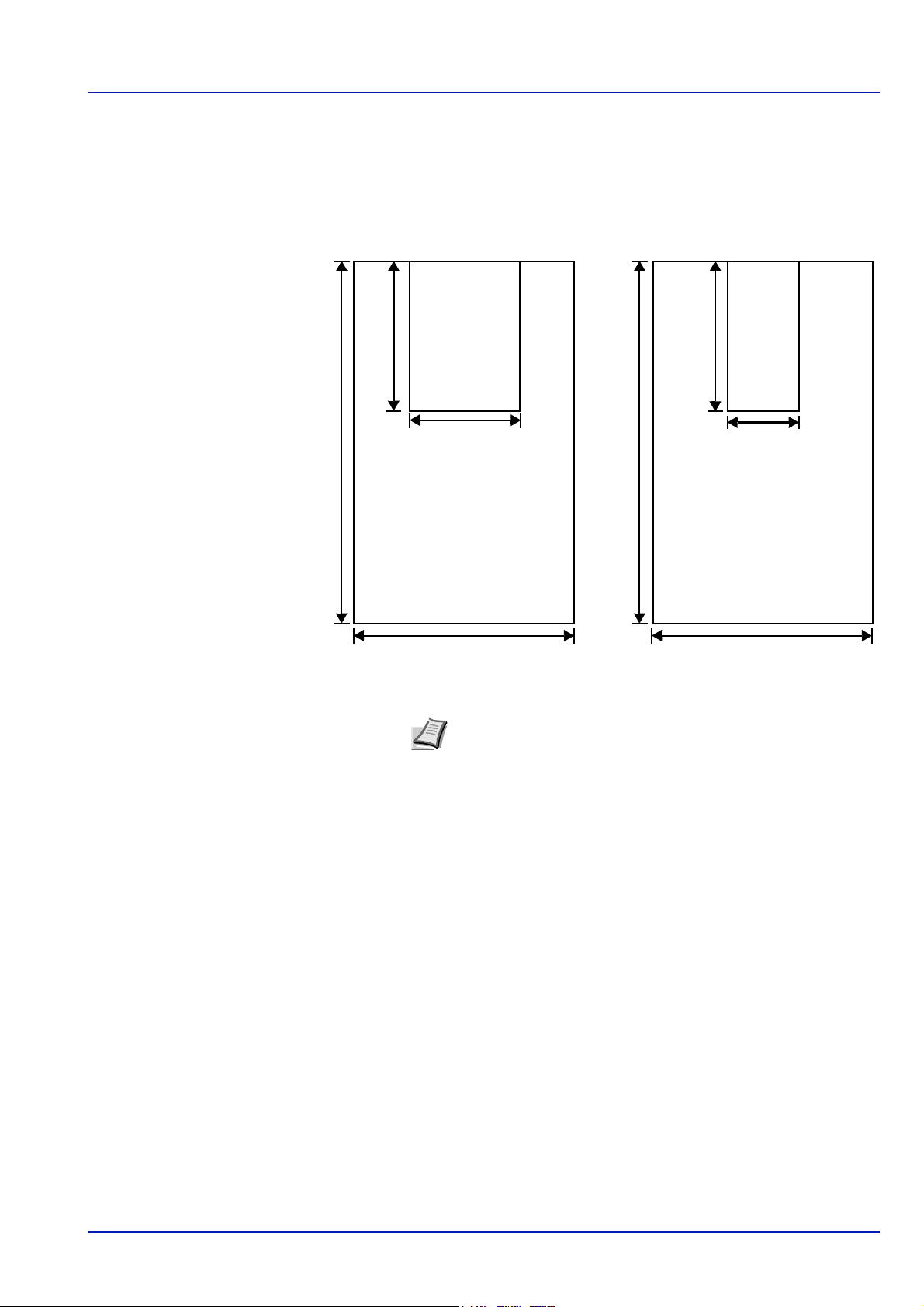

Unit (Selecting the unit of measurement)

>>Unit

? mm

X Dimension

Y Dimension

105 to 216mm

(4-1/8 to 8-1/2 inches)

148 to 356mm

(5-13/16 to 14 inches)

>>X Dimension

216

mm

1 Press Z.

2 Press U or V repeatedly until >>Unit appears. The unit of

measurement can be selected between millimeters and inches. The

current unit of measurement is displayed (the default setting is mm).

3 Press [OK]. A blinking question mark (?) appears.

4 Select mm or inch using U or V.

5 Press [OK].

Set the dimensions of the paper as described in the next section.

Entering the Width and Length

Enter the paper size for X Dimension and Y Dimension as shown in

the figure.

Using the Operation Panel 2-23

1 When the unit of measurement is set, press V.

2 Press [OK]. A blinking cursor (_) appears.

3 Press U or V to increase or decrease the value of the figure where

4 Display the paper width and press [OK].

5 When the width is set, press V. >>Y Dimension appears (the

6 Display the paper length, press [OK].

7 Press [MENU]. The display returns to Ready.

>>X Dimension appears (the paper width setting).

the cursor is blinking and display the desired width.

Acceptable paper widths are as follows:

• Cassette: 105 to 216 mm (4.13 to 8.5 inches)

• Paper Feeder PF-100 (optional): 148 to 216 mm (5.83 to 8.5

inches)

paper length setting). Set the desired length in the same way as the

width.

Acceptable paper lengths are as follows:

• Cassette: 148 to 356 mm (5.83 to 14.02 inches)

• Paper Feeder PF-100 (optional): 210 to 356 mm (8.5 to 14.02

inches)

Page 42

Cassette (1 to 3) Type (Setting the cassette paper

>Cassette Type

? PLAIN

type)

By setting a paper type (plain, recycled, etc.) for the paper cassette, you

can automatically select the paper in the paper cassette according to the

paper type you command on the printer driver. The default setting is

plain paper for all paper cassettes.

If the PF-100 optional paper feeder is installed, use the same procedure

to setting the cassette paper type.

For more information about paper types that you can feed from the paper

cassette, refer to Paper Specifications on page 1-2.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >Cassette Type appears.

If optional paper feeders are added, Cassette 1 Type will appear

for the standard paper cassette and Cassette 2 Type, and

Cassette 3 Type will appear for the optional paper feeders.

3 To change paper type, press [OK]. A blinking question mark (?)

appears.

4 Press U or V to display the desired paper type. The message

display toggles through the following paper types:

PLAIN

PREPRINTED

BOND

RECYCLED

ROUGH

LETTERHEAD

COLOR

PREPUNCHED

HIGH QUALITY

CUSTOM 1 (to 8)

Note You can define any paper type and store that definition

in the printer. For more information, refer to Type Adjust

(Creating custom paper type) on page 2-25.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

2-24 Using the Operation Panel

Page 43

Type Adjust (Creating custom paper type)

>Type Adjust >

? PLAIN

>>Paper Weight

? Normal 2

The following describes the procedure used to set a user-defined paper

type for the printer. Eight custom user settings may be registered. After

having been set, any of these may be called up when setting the paper

type for a paper source.

The paper weight and duplex path can be set (refer to Paper Weight

(Setting the paper weight) on page 2-25, and Duplex Path (Setting the

duplex path) on page 2-26) after selecting the paper type to be

customized as follows. For how to reset the customized settings, refer to

Reset Type Adjust (Resetting the custom paper type) on page 2-26.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >Type Adjust > appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V to display the desired paper type. The display

changes as shown below.

PLAIN

TRANSPARENCY

PREPRINTED

LABELS

BOND

RECYCLED

VELLUM

ROUGH

LETTERHEAD

COLOR

PREPUNCHED

ENVELOPE

CARDSTOCK

THICK

HIGH QUALITY

CUSTOM 1 (to 8)

5 Press [OK].

6 Press Z and proceed to the next step Paper Weight (Setting the

paper weight).

Using the Operation Panel 2-25

Paper Weight (Setting the paper weight)

You can set the paper thickness for your custom paper type to be

customized.

1 Display the custom paper type (refer to Type Adjust (Creating

custom paper type) on page 2-25) and press Z.

2 Press U or V repeatedly until >>Paper Weight appears.

3 Press [OK]. A blinking question mark (?) appears.

Page 44

4 Press U or V to display the desired paper thickness. The display

>>Duplex Path

? Enable

>Reset Type

Adjust ?

changes as shown below. For details of the default setting for each

paper type, refer to Paper Specifications on page 1-2.

Light

Normal 1

Normal 2

Normal 3

Heavy 1

Heavy 2

Heavy 3

Extra Heavy

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Duplex Path (Setting the duplex path)

1 Display the custom paper type (refer to Type Adjust (Creating

custom paper type) on page 2-25) and press Z.

2 Press U or V repeatedly until >>Duplex Path appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Select Enable or Disable using U or V. For details of the default

setting for each paper type, refer to Paper Specifications on page 1-

2.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

The custom paper type setting is completed.

Reset Type Adjust (Resetting the custom paper type)

Reset all the custom paper type that was set in Type Adjust (Creating

custom paper type) on page 2-25.

1 Press Z while Paper Settings > is displayed.

2 Press U or V repeatedly until >Reset Type Adjust appears.

3 Press [OK]. A question mark (?) appears.

4 Press [OK] again. All customized paper types will be reset to the

default. The display returns to Ready.

2-26 Using the Operation Panel

Page 45

Print Settings

Print Settings >

>Paper Source

? Cassette 1

These settings specify printing parameters such as the print quality used

for printing (Normal or Fine), the gloss mode (Low or High), the number

of copies, reduced printing and the page orientation.

The options available in Print Quality are as follows:

• Paper Source (Selecting the paper feed source)

• Paper Feed Mode (Setting the paper feed source)

• Duplex (Duplex Printing)

• Override A4/LT (Overriding difference between A4 and Letter)

• Emulation (Setting the emulation)

• Font Select (Selecting the default font)

• Code Set (Setting the code set)

• Print Quality (Setting print quality)

• Page Set (Setting pagination)

1 Press [MENU].

2 Press U or V repeatedly until Print Settings > appears.

Paper Source (Selecting the paper feed source)

You can select the paper source, from which the printer feeds paper as

the default. If an optional paper feeder(s) is installed, it is also available

for the default paper source.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Paper Source appears.

3 To change the current paper feed source, press [OK]. A blinking

question mark (?) appears.

4 Press U or V to display the desired paper feed source. The

message display toggles through the following paper feed sources,

depending on the installed optional paper feeders (from the top most

paper cassette to the bottom paper cassette):

MP tray

Cassette 1

Cassette 2

Cassette 3

Cassettes 2 and 3 are available for selection when the optional

paper feeders are installed.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Using the Operation Panel 2-27

Page 46

Paper Feed Mode (Setting the paper feed source)

>Paper Feed Mode

? Auto

This mode specifies how the paper should be fed, after the paper feed

source and paper type has been chosen. If Auto is selected, the printer

searches for a paper feed source that matches the paper size and type,

and paper is delivered from that source. An error message is displayed if

Fixed is selected, but a match is not found. The default setting is Auto.

To change the settings, follow the steps described below.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Paper Feed Mode appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V until Auto or Fixed appears.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

When the Paper Runs Out During Printing

When Paper Feed Mode is set to Fixed, if the paper in the cassette

runs out during printing, Load Cassette 1 is displayed and the printer

stands by. In this event, either replenish the paper in the empty cassette

or use the procedure below to print from another paper source.

1 While Load Cassette 1 is displayed, press U or V repeatedly

until Use alternative? appears.

2 Press U or V repeatedly until the desired paper source and size

appears.

Each time you press U or V, another paper cassette or the paper

size that can currently be fed from the MP tray appears.

3 Press [OK]. Printing continues.

2-28 Using the Operation Panel

Page 47

Duplex (Duplex printing)

(1)

(3)

(2)

(4)

Portrait,

long-edge

Landscape,

long-edge

Portrait,

short-edge

Landscape,

short-edge

>Duplex

? Off

Using the duplexer, you can automatically print on both sides of the

paper. The duplexer is mounted underneath the printer.

Duplex printing is available for the following paper types:

PLAIN

PREPRINTED

BOND

RECYCLED

ROUGH

COLOR

PREPUNCHED

HIGH QUALITY

CUSTOM 1 (to 8)

Activating the duplexer is done by selecting either short edge or long

edge binding mode.

Note Duplex printing can be also performed from the MP tray. If

the paper to be fed from the MP tray does not match the paper size

and paper type of the current paper feed source cassette, a paper

jam may occur.

Binding Modes

Binding refers to the manner in which printed pages of paper are joined

together (by gluing, stitching, etc.) in book form. The two possible types

of binding are: long-edge binding, in which pages are joined together

along their long edge; and short-edge binding, in which they are joined

together along their short edge. In selecting a binding type, you must

also consider the orientation of the printed page. You can use long-edge

or short-edge binding with either landscape or portrait printing.

Depending on the binding type and print orientation, the duplexer

provides four types of binding. These are: (1) portrait, long-edge, (2)

portrait, short edge, (3) landscape, long-edge, and (4) landscape, shortedge. The figure below shows these binding methods.

1 Press Z while Print Settings > is displayed.

Using the Operation Panel 2-29

2 Press U or V repeatedly until >Duplex appears.

3 Press [OK]. A blinking question mark (?) appears.

Page 48

4 Press U or V to display the desired binding mode. The message

>Override A4/LT

? Off

>

Emulation

? PCL 6

display toggles through the following:

Off (default)

Short edge bind

Long edge bind

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Override A4/LT (Overriding difference between A4 and Letter)

When the Override A4/LT is turned On using the operation panel, the

printer ignores the difference between A4 and Letter paper sizes.

Printing is performed without an error message even if the actual paper

size in the current cassette differs from the paper size formatting the job.

By default, this feature is On.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Override A4/LT appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Select On or Off using U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Emulation (Setting the emulation)

You can change the emulation mode for the current interface. Use the

procedure below to select the mode.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Emulation > appears on the

message display. One of the emulation modes appears, indicating

the emulation currently in use.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V repeatedly until the desired emulation mode is

displayed.

PCL 6 (default)

KPDL

KPDL (AUTO)

Line Printer

IBM Proprinter

DIABLO 630

EPSON LQ-850

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

2-30 Using the Operation Panel

Page 49

Alternative Emulation for KPDL Emulation

>

Emulation

? PCL 6

>

Emulation

? KPDL (AUTO)

>>Alt. Emulation

PCL 6

>

Emulation

? PCL 6

>Emulation >

? KPDL (AUTO)

>>Error Report

? On

KPDL is Kyocera’s implementation of the PostScript language. The

KPDL (AUTO) emulation enables the printer to automatically change the

emulation mode according to the data received when printing.

In addition to KPDL (AUTO) emulation, you can use the operation panel

to set another emulation mode that is used very often. The default

setting is PCL 6.

1 Press [MENU].

2 Press U or V repeatedly until >Emulation > appears on the

message display.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V repeatedly until KPDL (AUTO) appears.

5 Press [OK].

6 Press Z. When >>Alt. Emulation is displayed, press U or V.

The names of alternative emulations appear - PCL 6, Line

Printer, IBM Proprinter, DIABLO 630 or EPSON LQ-850.

7 Press [OK]. A blinking question mark (?) appears.

8 Press U or V repeatedly until the desired alternative emulation

appears.

9 Press [OK].

10Press [MENU]. The display returns to Ready.

Error Report (Printing KPDL errors)

The printer can print error descriptions when printing error occurs during

KPDL emulation. The default changes according to the destination.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Emulation > appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Select KPDL or KPDL (AUTO) using U or V. Press [OK].

5 Press Z. >>Error Report appears.

6 Press [OK]. A blinking question mark (?) appears.

7 Select On or Off using U or V. Press [OK].

Using the Operation Panel 2-31

8 Press [MENU]. The display returns to Ready.

Page 50

Font Select (Selecting the default font)

>Font Select >

Internal

>> I000

>>?I000

>Font Select >

Internal

>>Courier

Regular

You can select the default font for the current interface. The default font

can be one of the internal fonts or a font that is downloaded to the printer

memory or stored on CompactFlash (CF) card.

In this menu, you can also set the type and pitch for Courier and Letter

Gothic; as well as to print a font list.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Font Select > appears.

3 To select an internal font, make sure that Internal is displayed

and press Z. The display changes. If Internal is not displayed, press

[OK], then press U or V until it appears.

To select an optional font, press [OK] while >Font Select > is

displayed. Press U or V repeatedly until Option appears and then

press [OK]. Press Z next to display the font selection shown above.

You can perform this operation only when optional fonts are installed

in the printer.

The letter before the number indicates the location of the font, as

shown below.

I: Internal font

S: Soft (downloaded) font

M: Fonts in optional CompactFlash card

H: Fonts in RAM disk

4 Press [OK]. A blinking question mark (?) appears.

5 Press U or V repeatedly until the desired font number appears. For

font numbers of the internal fonts, refer to Print Fonts List on page 2-

15.

6 When the desired font is displayed, press [OK].

7 Press [MENU]. The display returns to Ready.

Selecting Regular or Dark Courier/Letter Gothic

Courier or Letter Gothic font thickness can be selected as Regular or

Dark. In the procedure below, it is assumed that Courier is selected. The

procedure is the same for Letter Gothic.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Font Select > appears.

3 Make sure that Internal is displayed and press Z.

4 Press U or V repeatedly until >>Courier appears. If you are

selecting the thickness of the Letter Gothic font, choose >> Letter

Gothic here instead.

2-32 Using the Operation Panel

Page 51

5 Press [OK]. A blinking question mark (?) appears.

>>Courier

?Regular

>Font Select >

Internal

>>Size

012.00 point(s)

>>Size

012.0

0 point(s)

>Font Select >

Internal

>>Pitch

10.00 cpi

>>Pitch

10.00

cpi

6 Select Regular or Dark using U or V.

7 Press [OK].

8 Press [MENU]. The display returns to Ready.

Changing the Default Font Size

You can change the size of the default font. If you selected a proportional

font, the character size can also be changed.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Font Select > appears.

3 Make sure that Internal is displayed and press Z.

4 Press U or V repeatedly until >>Size appears.

5 Press [OK]. A blinking question mark (?) appears.

6 Press U or V to increase or decrease the value at the blinking

cursor. The font size can be set between 4 and 999.75 points, in

0.25-point increments. Use Z or Y to move the cursor right and left.

7 When the desired size is displayed, press [OK].

8 Press [MENU]. The display returns to Ready.

Character Pitch

You can set the character pitch for fixed fonts.

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Font Select > appears.

3 Make sure that Internal is displayed and press Z.

4 Press U or V repeatedly until >>Pitch appears.

5 Press [OK]. A blinking question mark (?) appears.

Using the Operation Panel 2-33

6 Press U or V to increase or decrease the value at the blinking

cursor. The character pitch can be set 0.44 and 99.99 characters per

inch, in 0.01 character-per-inch increments. Use Z or Y to move the

cursor right and left.

Page 52

7 When the desired size is displayed, press [OK].

>Code Set

IBM PC-8

>Code Set

?IBM PC-8

>Print Quality >

with KIR Off

with KIR On (default)

8 Press [MENU]. The display returns to Ready.

Code Set (Setting the code set)

You can change the character code set. Available character code sets

vary depending on the current font. (The default is IBM PC-8.)

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Code Set appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Press U or V until the desired character code set appears.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Print Quality (Setting print quality)

In Print Quality menus, you can set the following settings.

The options available in Print Quality are as follows:

• KIR Mode (Selecting the KIR mode)

• EcoPrint Mode (Selecting the EcoPrint mode)

• Resolution (Selecting the Print Resolution)

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Print Quality > appears.

KIR Mode (Selecting the KIR mode)

This printer incorporates the KIR (Kyocera Image Refinement)

smoothing function. KIR users the software to enhance resolution,

resulting in high quality printing at resolution of 600 dpi and 300 dpi. The

default is On. KIR has no effect on the printing speed.

1 Press Z while >Print Quality > is displayed.

2 Press U or V repeatedly until >>KIR Mode appears.

2-34 Using the Operation Panel

Page 53

3 Press [OK]. A blinking question mark (?) appears.

>>KIR Mode

? On

EcoPrint setting is

Off (default)

EcoPrint setting is

On

>>EcoPrint Mode

? Off

>>Resolution

? Fast 1200 mode

4 Select On or Off using U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

EcoPrint Mode (Selecting the EcoPrint mode)

By enabling EcoPrint mode, you can minimize the amount of toner used

during printing. Because images printed in this mode may be slightly

coarser than those printed in standard resolution, you should use

EcoPrint for test prints or other situations where high-quality prints are

not required.

Use the procedure below to select EcoPrint mode. The default setting is

Off.

1 Press Z while >Print Quality > is displayed.

2 Press U or V repeatedly until >>EcoPrint Mode appears.

3 Press [OK]. A blinking question mark (?) appears.

4 Select On or Off using U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Resolution (Selecting the print resolution)

You can set the default print resolution in four ways: 300dpi, 600dpi, Fast

1200 mode and Fine 1200 mode. The clarity of printed characters and

graphics becomes sharper in this order.

1 Press Z while >Print Quality > is displayed.

2 Press U or V repeatedly until >>Resolution appears.

3 Press [OK]. A blinking question mark (?) appears.

Using the Operation Panel 2-35

4 Select Fine 1200 mode, Fast 1200 mode, 600 dpi or 300

dpi using the U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

Page 54

Page Set (Setting pagination)

>Page Set >

>>Copies

001

Portrait Orientation

A

Landscape Orientation

A

In Page Set menus, you can set the number of copies, page orientation,

and other settings regarding pagination.

The options available in Page Set are as follows:

• Copies (Number of copies)

• Orientation (Print orientation)

• LF Action (Linefeed)

• CR Action (Carriage-Return)

• Wide A4 (Wide A4 pitch)

1 Press Z while Print Settings > is displayed.

2 Press U or V repeatedly until >Page Set > appears.

Copies (Number of copies)

You can set the number of copies of each page to be printed for the

current interface.

1 Press Z while >Page Set > is displayed.

2 Press U or V repeatedly until >>Copies appears.

3 Press [OK]. A blinking cursor (_) appears.

4 Press U or V to increase or decrease, respectively, the value at the

blinking cursor. The number of copies can be set between 1 and

999. Use Y and Z to move the cursor right and left.

5 When the desired size is displayed, press [OK].

6 Press [MENU]. The display returns to Ready.

Orientation (Print orientation)

You can select portrait (upright) or landscape (sideways) page

orientation.

1 Press Z while >Page Set > is displayed.

2 Press U or V repeatedly until >>Orientation appears.

2-36 Using the Operation Panel

Page 55

3 Press [OK]. A blinking question mark (?) appears.

>>Orientation

? Portrait

>>LF Action

?

LF only

>>CR Action

?

CR only

4 Select Portrait or Landscape using U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

LF Action (Linefeed)

This procedure instructs the printer what to do when it receives a

linefeed code (0AH).

• LF only: Linefeed is performed (Default).

• CR and LF: A linefeed and carriage return are performed.

• Ignore LF: The linefeed is ignored.

1 Press Z while >Page Set > is displayed.

2 Press U or V repeatedly until >>LF Action appears.

3 Press [OK]. A blinking cursor (_) appears.

4 Press U or V repeatedly until the desired linefeed action appears.

5 When the desired action is displayed, press [OK].

6 Press [MENU]. The display returns to Ready.

CR Action (Carriage-Return)

This procedure instructs the printer what to do when it receives a

carriage return code (0DH).

• CR only: A carriage-return is performed (Default).

• CR and LF: A linefeed and carriage return are performed.

• Ignore CR: The carriage-return is ignored.

1 Press Z while >Page Set > is displayed.

2 Press U or V repeatedly until >>CR Action appears.

3 Press [OK]. A blinking cursor (_) appears.

4 Press U or V repeatedly until the desired carriage-return appears.

5 When the desired action is displayed, press [OK].

6 Press [MENU]. The display returns to Ready.

Wide A4 (Wide A4 pitch)

Turn this to On to increase the maximum number of characters that can

be printed in a line for an A4 page (78 characters at 10 pitch) and Letter

size page (80 characters at 10 pitch). This setting is only effective in PCL

6 emulation.

1 Press Z while >Page Set > is displayed.

2 Press U or V repeatedly until >>Wide A4 appears.

Using the Operation Panel 2-37

Page 56

3 Press [OK]. A blinking question mark (?) appears.

>>Wide A4

? Off

4 Select On or Off using U or V.

5 Press [OK].

6 Press [MENU]. The display returns to Ready.

2-38 Using the Operation Panel

Page 57

Network (Network settings)

Network >

>TCP/IP

? Off

This printer supports TCP/IP and TCP/IP (IPv6) protocols.

IP is an abbreviation for Internet Protocol. This printer routinely uses the

TCP/IP (IPv4) protocol, but provides a separate setting for the nextgeneration IP, IPv6.

TCP/IP (IPv4) uses 32-bit IP addresses, but the rapid growth in the

number of Internet users has resulted in a shortage of IP addresses.

IPv6 was developed to expand the range of available IP addresses by

using 128-bit IP addresses.

The options available in the Network settings are as follows:

• TCP/IP (IPv4 settings)

• TCP/IP (IPv6) (IPv6 settings)

Note Check with your network administrator when selecting the

network setting.

After all network related settings have been done, turn the

machine OFF and ON again. This is mandatory to make the

settings effective.

1 Press [MENU].

2 Press U or V repeatedly until Network > appears.

TCP/IP (IPv4 settings)

This selects the settings for TCP/IP (IPv4).

The TCP/IP system refers to the Internet system, which has a 5-layer

structure consisting of the interface layer, link layer, network (IP) layer,

transport (TCP/UDP) layer and application layer.

The interface layer is a key layer in the TCP/IP system that provides an

abstracted interface that is not dependent on the link (communication

line: frame relay or Ethernet, etc.) to the IP module (IP layer). This

means that the IP module can use this abstracted interface (which is not

dependent on the link type) to exchange IP packets back and forth with

the link layer.

The options available in the TCP/IP (IPv4) settings are as follows:

• DHCP (DHCP setting)

• IP Address (IP address setting)

• Subnet Mask (Subnet mask setting)

• Gateway (Gateway setting)

• Bonjour (Bonjour setting)

IMPORTANT The DHCP, IP address, subnet mask, gateway and

Bonjour menu options for TCP/IP are displayed when TCP/IP is

enabled.

1 Press Z while Network > is displayed.

2 Press U or V repeatedly until >TCP/IP > appears.

3 Press [OK]. A blinking question mark (?) appears.

Using the Operation Panel 2-39

Page 58

4 Select On or Off using U or V.

>>DHCP

? Off

>>IP Address

000.000.000.000

5 Select On and press [OK]. The display changes to the settings

shown below.

DHCP (DHCP setting)

DHCP (Dynamic Host Configuration Protocol) is the protocol that