Page 1

FS-1120D

FS-1320D

SERVICE

MANUAL

Published in June 2010

842LZ112

2LZSM062

Rev. 2

Page 2

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF

USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your local

solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE

TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les fonctionnaires municipaux de votre région pour les détails concernant des déchets solides et une mise

au rebut appropriée.

Page 3

Revision history

Revision Date Replaced pages Remarks

1 March 4, 2010 1-1-2, 1-2-1 -

2 June 4, 2010 1-1-1, 1-3-1, 1-3-11, 1-3-12 -

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect com-

pliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point of attention is

shown inside the symbol.

General warning. Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action. Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required. Remove the power plug from the wall outlet.

Always ground the copier.

Page 7

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check that

it is adequate for the rated current. .....................................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper

authorities. ..........................................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .........

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. .................

• Do not install the copier near a radiator, heater, other heat source or near flammable material. This

may cause fire. ...................................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ............

• Always handle the machine by the correct locations when moving it. .................................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ..............................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally

ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately.

If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. .....................................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .........................................................................................................................

Page 8

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ................

• Always follow the procedures for maintenance described in the service manual and other related

brochures. ..........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. ........................................................................................................................

• Always use parts having the correct specifications. ............................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure

when replacing them. Using a piece of wire, for example, could lead to fire or other serious acci-

dent. ...................................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ..................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ...............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. .................................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ...............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely

secured so they will not be caught in rotating sections. ......................................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ..........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ...........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ......................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ........................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ................................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ..........

• Remove toner completely from electronic components. .....................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ......................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. .......................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. .......................................

• Handle greases and solvents with care by following the instructions below: ......................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet immedi-

ately. ...................................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. ........................................................................................

Page 10

This page is intentionally left blank.

Page 11

CONTENTS

1-1 Specifications

1-1-1 Specifications ..........................................................................................................................................1-1-1

1-1-2 Parts names ............................................................................................................................................1-1-3

(1) Overall ...............................................................................................................................................1-1-3

(2) Operation panel.................................................................................................................................1-1-4

1-1-3 Machine cross section ............................................................................................................................1-1-5

1-2 Installation

1-2-1 Installation environment ..........................................................................................................................1-2-1

1-2-2 Unpacking ...............................................................................................................................................1-2-2

(1) Removing the tapes ..........................................................................................................................1-2-3

1-2-3 Installing the expanded memory (option)................................................................................................1-2-4

1-2-4 Installing the memory card (option).........................................................................................................1-2-5

1-2-5 Installing the network interface card (option) ..........................................................................................1-2-6

1-3 Maintenance Mode

1-3-1 Maintenance mode .................................................................................................................................1-3-1

(1) Executing a service mode .................................................................................................................1-3-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection .........................................................................................................................1-4-1

(1) Paper misfeed indication ...................................................................................................................1-4-1

(2) Paper misfeed detection condition ....................................................................................................1-4-2

1-4-2 Self-diagnostic function ...........................................................................................................................1-4-3

(1) Self-diagnostic function .....................................................................................................................1-4-3

(2) Self diagnostic codes indication ........................................................................................................1-4-4

(3) Self diagnostic codes ........................................................................................................................1-4-5

1-4-3 Image formation problems ......................................................................................................................1-4-9

(1) Completely blank printout................................................................................................................1-4-10

(2) All-black printout..............................................................................................................................1-4-10

(3) Dropouts..........................................................................................................................................1-4-11

(4) Black dots........................................................................................................................................1-4-11

(5) Black horizontal streaks. .................................................................................................................1-4-11

(6) Black vertical streaks.......................................................................................................................1-4-12

(7) Unsharpness. ..................................................................................................................................1-4-12

(8) Gray background.............................................................................................................................1-4-12

(9) Dirt on the top edge or back of the paper........................................................................................1-4-13

(10) Undulated printing at the right edge (scanning start position).........................................................1-4-13

1-4-4 Electric problems ..................................................................................................................................1-4-14

1-4-5 Mechanical problems ............................................................................................................................1-4-16

2LY/2LZ

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly............................................................................................1-5-1

(1) Precautions .......................................................................................................................................1-5-1

(2) Drum..................................................................................................................................................1-5-1

(3) Toner container .................................................................................................................................1-5-1

(4) How to tell a genuine Kyocera Mita toner container ..........................................................................1-5-2

1-5-2 Outer covers ...........................................................................................................................................1-5-3

(1) Detaching and refitting the top cover.................................................................................................1-5-3

(2) Detaching and refitting the right and left covers................................................................................1-5-4

1-5-3 Paper feed section ..................................................................................................................................1-5-6

(1) Detaching and refitting the paper feed assembly (paper feed roller and pickup roller).....................1-5-6

(2) Detaching and refitting the retard roller assembly.............................................................................1-5-8

(3) Detaching and refitting the MP paper feed roller.............................................................................1-5-10

1-5-4 Developing section................................................................................................................................1-5-11

(1) Detaching and refitting the developing unit .....................................................................................1-5-11

1-5-5 Drum section .........................................................................................................................................1-5-12

(1) Detaching and refitting the drum unit ..............................................................................................1-5-12

(2) Detaching and refitting the main charger unit..................................................................................1-5-13

Page 12

2LY/2LZ

1-5-6 Transfer/separation section ..................................................................................................................1-5-14

(1) Detaching and refitting the transfer roller ........................................................................................1-5-14

1-5-7 Fuser section ........................................................................................................................................1-5-16

(1) Detaching and refitting the fuser unit...............................................................................................1-5-16

(2) Switching the fuser pressure...........................................................................................................1-5-18

1-5-8 PWBs ....................................................................................................................................................1-5-19

(1) Detaching and refitting the control PWB .........................................................................................1-5-19

(2) Detaching and refitting the power source PWB...............................................................................1-5-22

(3) Detaching and refitting the operation panel PWB ...........................................................................1-5-24

(4) Detaching and refitting the high voltage PWB .................................................................................1-5-25

1-5-9 Others ...................................................................................................................................................1-5-29

(1) Detaching and refitting the main motor ...........................................................................................1-5-29

(2) Detaching and refitting the laser scanner unit.................................................................................1-5-30

(3) Detaching and refitting the eraser lamp ..........................................................................................1-5-32

(4) Direction of installing the left and right cooling fan motors ..............................................................1-5-33

1-6 Firmware

1-6-1 Downloading firmware ............................................................................................................................1-6-1

(1) Downloading the firmware from the memory card.............................................................................1-6-2

2-1 Mechanical Construction

2-1-1 Paper feed/conveying section.................................................................................................................2-1-1

(1) Cassette paper feed section..............................................................................................................2-1-1

(2) MP tray paper feed section ...............................................................................................................2-1-2

(3) Paper conveying section ...................................................................................................................2-1-3

2-1-2 Drum section ...........................................................................................................................................2-1-4

(1) Drum section .....................................................................................................................................2-1-4

(2) Main charger unit...............................................................................................................................2-1-5

2-1-3 Expose section........................................................................................................................................2-1-6

(1) Laser scanner unit.............................................................................................................................2-1-6

2-1-4 Developing section..................................................................................................................................2-1-8

2-1-5 Transfer/separation section ....................................................................................................................2-1-9

2-1-6 Cleaning section ...................................................................................................................................2-1-10

2-1-7 Fuser section ........................................................................................................................................2-1-11

2-1-8 Paper exit section .................................................................................................................................2-1-13

2-1-9 Duplex/conveying section .....................................................................................................................2-1-15

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ..............................................................................................................................2-2-1

(1) PWBs ................................................................................................................................................2-2-1

(2) Switches and sensors .......................................................................................................................2-2-2

(3) Other electrical components..............................................................................................................2-2-3

2-3 Operation of the PWBs

2-3-1 Power source PWB .................................................................................................................................2-3-1

2-3-2 Control PWB ...........................................................................................................................................2-3-3

2-4 Appendixes

2-4-1 Appendixes .............................................................................................................................................2-4-1

(1) Wiring diagraml .................................................................................................................................2-4-1

(2) Repetitive defects gauge...................................................................................................................2-4-2

(3) Self diagnostic codes indication (Animation) .....................................................................................2-4-3

(4) Maintenance parts list .......................................................................................................................2-4-5

Page 13

1-1 Specifications

1-1-1 Specifications

Type................................................Desktop

Printing method...............................Electrophotography, laser scan

Paper weight...................................Cassette: 60 to 120 g/m

MP tray: 60 to 220 g/m

Paper type ......................................Cassette:

Plain, Preprinted, Bond, Recycled, Rough, Letterhead, Color (Colour), Prepunched,

High quality, Custom 1 to 8

MP tray:

Plain, Transparency, Preprinted, Labels, Bond, Recycled, Rough, Vellum,

Letterhead, Color (Colour), Prepunched, Envelope, Cardstock, Thick paper,

High quality, Custom 1 to 8

Paper size ........................................Cassette:

A4, JIS B5, A5, Follio, Legal, Letter, Oficio II, Statement, Executive, A6, B6, ISO B5,

Envelope C5, 16K, Custom (105 148 to 216 356 mm/4

MP tray:

A4, JIS B5, A5, Follio, Legal, Letter, Oficio II, Statement, Executive, A6, B6, ISO B5,

Envelope C5, Envelope #10, Envelope #9, Envelope #6Envelope DL, Hagaki, Ofuku Hagaki, 16K, Yokei 2, Yokei 4, Custom (70

356 mm/2

13/16

Printing speed.................................30/32 ppm model (A4/Letter)

Simplex printing Duplex printing

A4: 30 ppm A4: 17 ppm

Letter: 32 ppm Letter: 18 ppm

A5: 17 ppm

35/37 ppm model (A4/Letter)

Simplex printing Duplex printing

A4: 35 ppm A4: 19 ppm

Letter: 37 ppm Letter: 20 ppm

A5: 17 ppm

First print time .................................30/32 ppm model (A4/Letter)

6 s or less (A4, feed from cassette)

35/37 ppm model (A4/Letter)

7 s or less (A4, feed from cassette)

Warm-up time .................................Room temperature 22

120 V AC model

Power on: 20 s or less

Sleep mode:15 s or less

220 - 240 V AC model

Power on: 19 s or less

Sleep mode:14 s or less

Paper capacity ................................ Cassette: 250 sheets (80 g/m

MP tray: 50 sheets (80 g/m

Output tray capacity........................Simplex printing: 250 sheets (80 g/m

Duplex printing: 200 sheets (80 g/m2)

Continuous printing.........................1 to 999 sheets

Photoconductor...............................OPC drum (diameter 30 mm)

Image write system.........................Semiconductor laser (1 beam)

Charging system.............................Scorotron (positive charging)

Developing system .........................Mono component dry developing method

Toner replenishing: Automatic from the toner container

Transfer system .............................. Transfer roller (negative-charged)

Separation system..........................Small diameter separation, discharger brush

Cleaning system .............................Drum: Counter blade

Charge erasing system...................Exposure by eraser lamp (LED)

Fusing system................................. Heat roller system

Resolution.......................................30/32 ppm model (A4/Letter)

Fast 1200 mode, 600 dpi, 300 dpi

35/37 ppm model (A4/Letter)

Fine 1200 mode, Fast 1200 mode, 600 dpi, 300 dpi

2

(Duplex: 60 to 105 g/m2)

2

5

13/16

" to 8

°C/71.6°F, 60% RH

2

2

, Letter/A4 or smaller)

1/2

14")

, Letter/A4 or smaller)

2

)

1/8

5

13/16

" to 8

3/4

, Envelope Monarch,

148 to 216

2LY/2LZ-2

1/2

14")

1-1-1

Page 14

2LY/2LZ-1

Operating environment ................... Temperature: 10 to 32.5

Humidity: 15 to 80%

Altitude: 2,500 m/8,202 ft maximum

Brightness: 1,500 lux maximum

Controller ........................................PowerPC 405F5/360 MHz

Supported OS ................................. Microsoft Windows 2000/XP/Vista/7, Windows Server 2003/2008, Mac OS X 10.x

Interface..........................................Standard: Hi-Speed USB × 1

Option: Network interface card × 1 (10BASE-T/100BASE-TX)

PDL.................................................PRESCRIBE

Memory...........................................Standard: 32 MB

Maximum: 544 MB

Dimension (W × D × H)...................375 × 393 × 250 mm

14 3/4 × 15 1/2 × 9 7/8"

Weight (without toner container).....12 kg/26.5 lb

Power source..................................120 V AC, 60 Hz, 8.0 A/220 to 240 V AC, 50 Hz, 4.2 A

Power consumption ........................ 30/32 ppm model (A4/Letter)

[Standard]

Maximum: 911 W 976 W

During printing: 555.1 W 524.1 W

During standby: 6.6 W (EcoFuser ON) 7.3 W (EcoFuser ON)

Sleep mode: 4.3 W 4.4 W

[Full options]

Maximum: 921 W 986 W

During printing: 559.2 W 527.1 W

During standby: 9.2 W (EcoFuser ON) 9.2 W (EcoFuser ON)

Sleep mode: 6.4 W 6.5 W

°C/50 to 90.5 °F

120 V AC model 220 - 240 V AC model

79.8 W (EcoFuser OFF) 82.0 W (EcoFuser OFF)

120 V AC model 220 - 240 V AC model

81.1 W (EcoFuser OFF) 80.8 W (EcoFuser OFF)

35/37 ppm model (A4/Letter)

[Standard]

120 V AC model 220 - 240 V AC model

Maximum: 917 W 981 W

During printing: 573.9 W 543.6 W

During standby: 6.5 W (EcoFuser ON) 7.2 W (EcoFuser ON)

76.5 W (EcoFuser OFF) 80.1 W (EcoFuser OFF)

Sleep mode: 4.2 W 4.3 W

[Full options]

120 V AC model 220 - 240 V AC model

Maximum: 933 W 995 W

During printing: 592.9 W 561.1 W

During standby: 9.9 W (EcoFuser ON) 10.0 W (EcoFuser ON)

81.1 W (EcoFuser OFF) 82.9 W (EcoFuser OFF)

Sleep mode: 6.6 W 6.6 W

Options ...........................................30/32 ppm model (A4/Letter)

Expanded memory, Paper feeder (250-sheet × 1), Network interface card (IB-23)

35/37 ppm model (A4/Letter)

Expanded memory, Paper feeder (250-sheet × 2), Network interface card (IB-23)

NOTE: These specifications are subject to change without notice.

1-1-2

Page 15

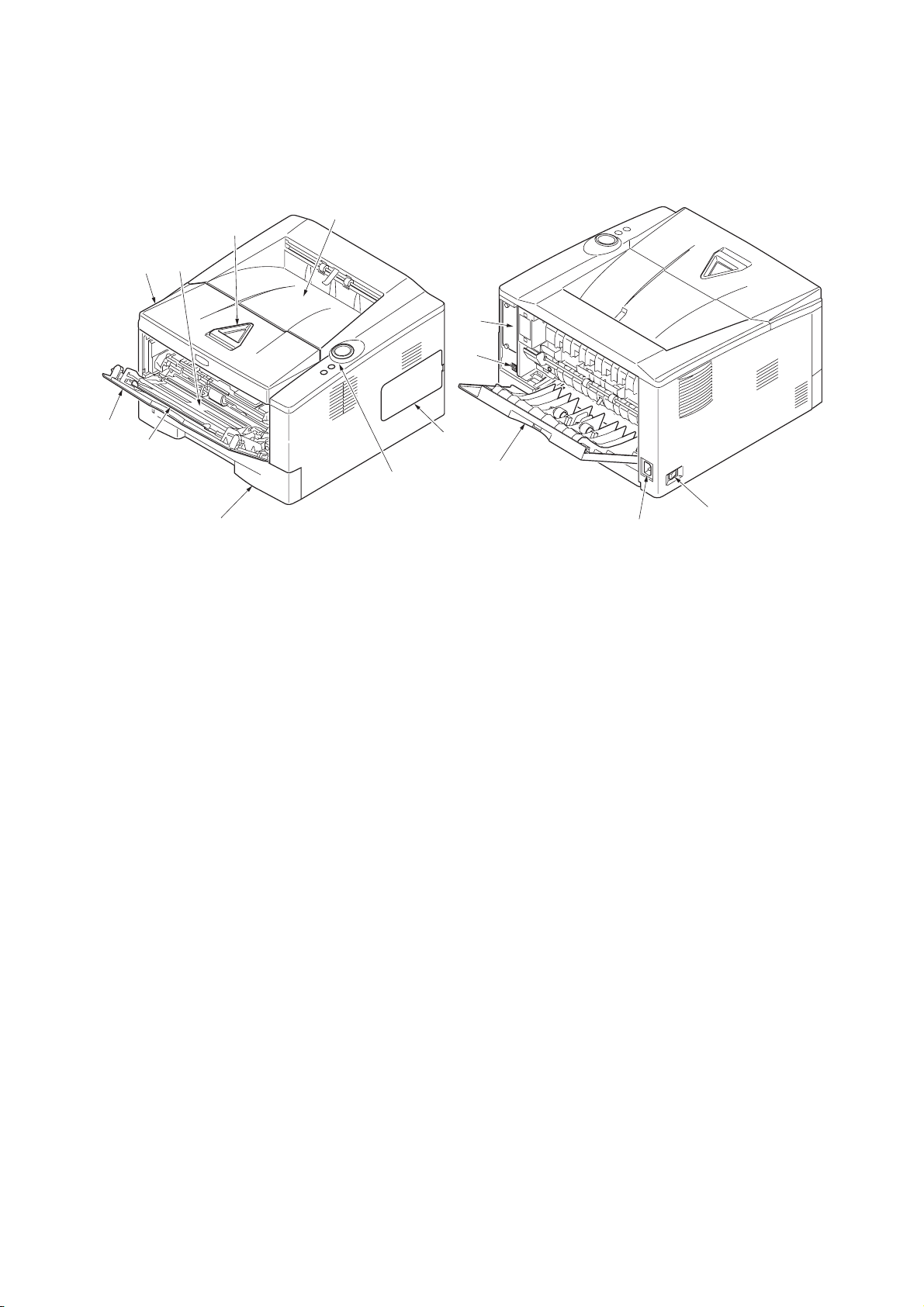

1-1-2 Parts names

(1) Overall

8

1

2LY/2LZ

3

2

10

11

7

9

4

6

1. Top cover

2. Paper stopper

3. Top tray

4. Operation panel

5. Right side cover

6. Cassette

7. Front cover

5

12

14

13

Figure 1-1-1

8. MP tray

9. Sub tray

10. Optional interface slot cover

11. USB interface connector

12. Rear cover

13. Power cord connector

14. Power switch

1-1-3

Page 16

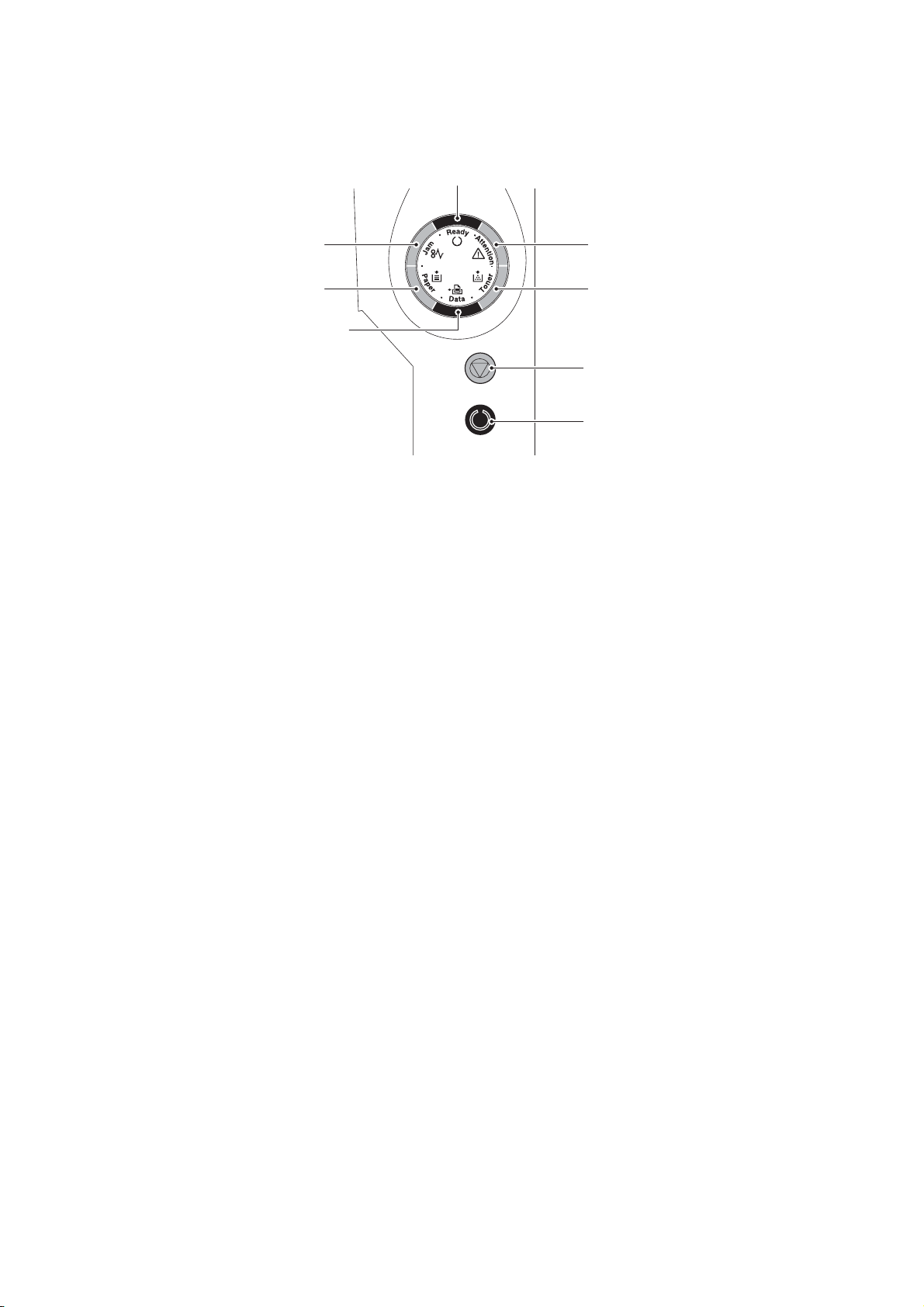

2LY/2LZ

(2) Operation panel

1

6

5

2

3

4

7

8

Figure 1-1-2

1. Ready indicator

2. Attention indicator

3. Toner indicator

4. Data indicator

5. Paper indicator

6. Jam indicator

7. Cancel key

8. GO key

1-1-4

Page 17

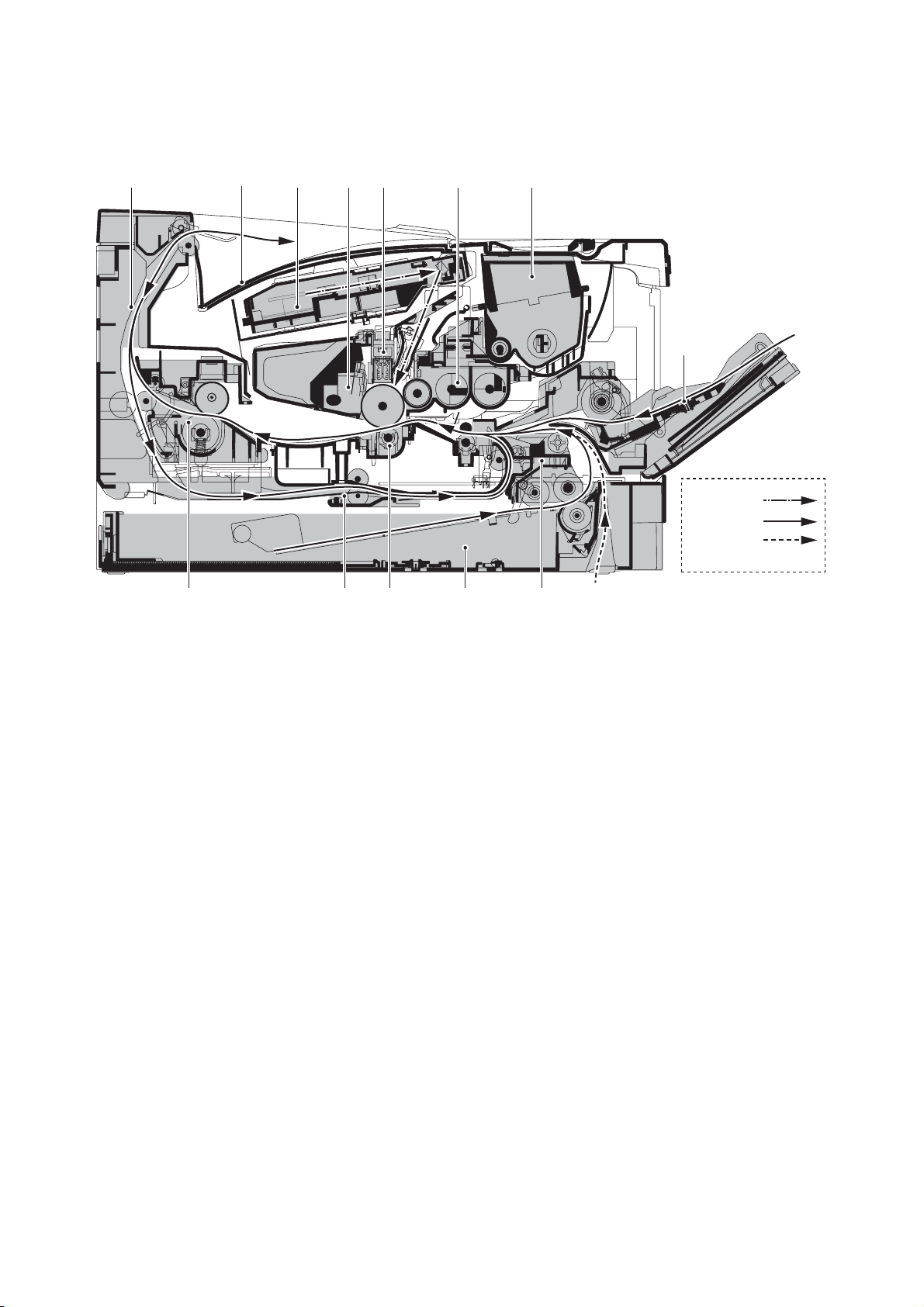

1-1-3 Machine cross section

l

2LY/2LZ

12

10 13

7

456811

2

Light path

Paper path

Paper path

(option)

9

13

1. Cassette

2. MP tray

3. Paper feed/conveying section

4. Toner container

5. Developing unit

6. Main charger unit

7. Drum unit

Figure 1-1-3

8. Laser scanner unit

9. Transfer/separation section

10. Fuser section

11. Exit section

12. Top tray

13. Duplex/conveying section

1-1-5

Page 18

2LY/2LZ

This page is intentionally left blank.

1-1-6

Page 19

1-2 Installation

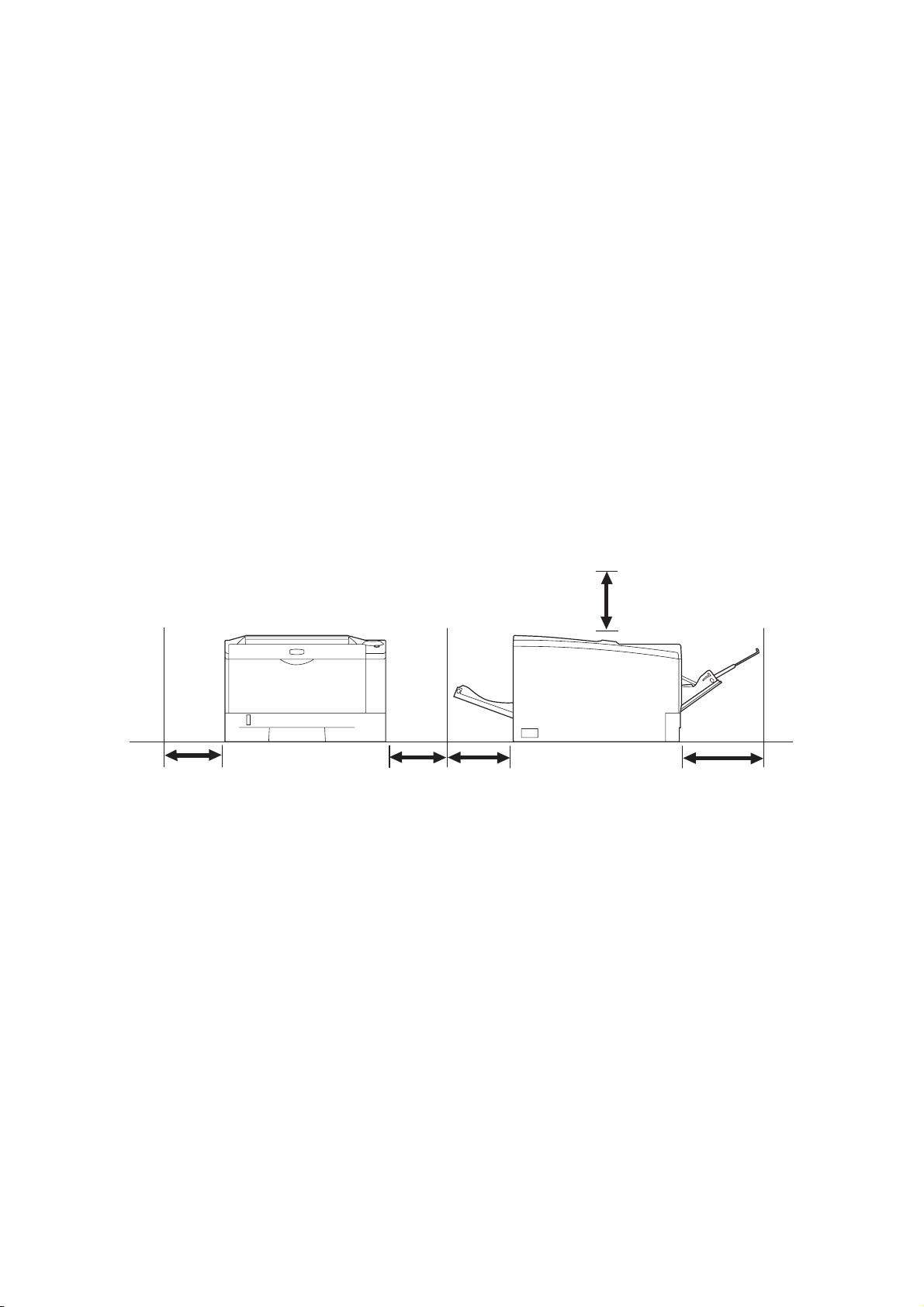

1-2-1 Installation environment

1. Temperature: 10 to 32.5°C/50 to 90.5°F

2. Humidity: 15 to 80%RH

3. Power supply: 120 V AC, 8.0 A

220 - 240 V AC, 4.2 A

4. Power source frequency: 50 Hz ±0.3%/60 Hz ±0.3%

5. Installation location

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or

other strong light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an abrupt

change in the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

6. Allow sufficient access for proper operation and maintenance of the machine.

°).

2LY/2LZ-1

Machine front: 500 mm/19

11/ 16"

Machine rear: 200 mm/7 7/8"

Machine right: 300 mm/11

13/16"

Machine left: 300 mm/11 13/16"

Machine top: 400 mm/15 3/4"

300 mm

11

13/16"

300 mm

11 13/16"

Figure 1-2-1

200 mm

7 7/8"

400 mm

15

3/4"

500 mm

19 11/16"

1-2-1

Page 20

2LY/2LZ

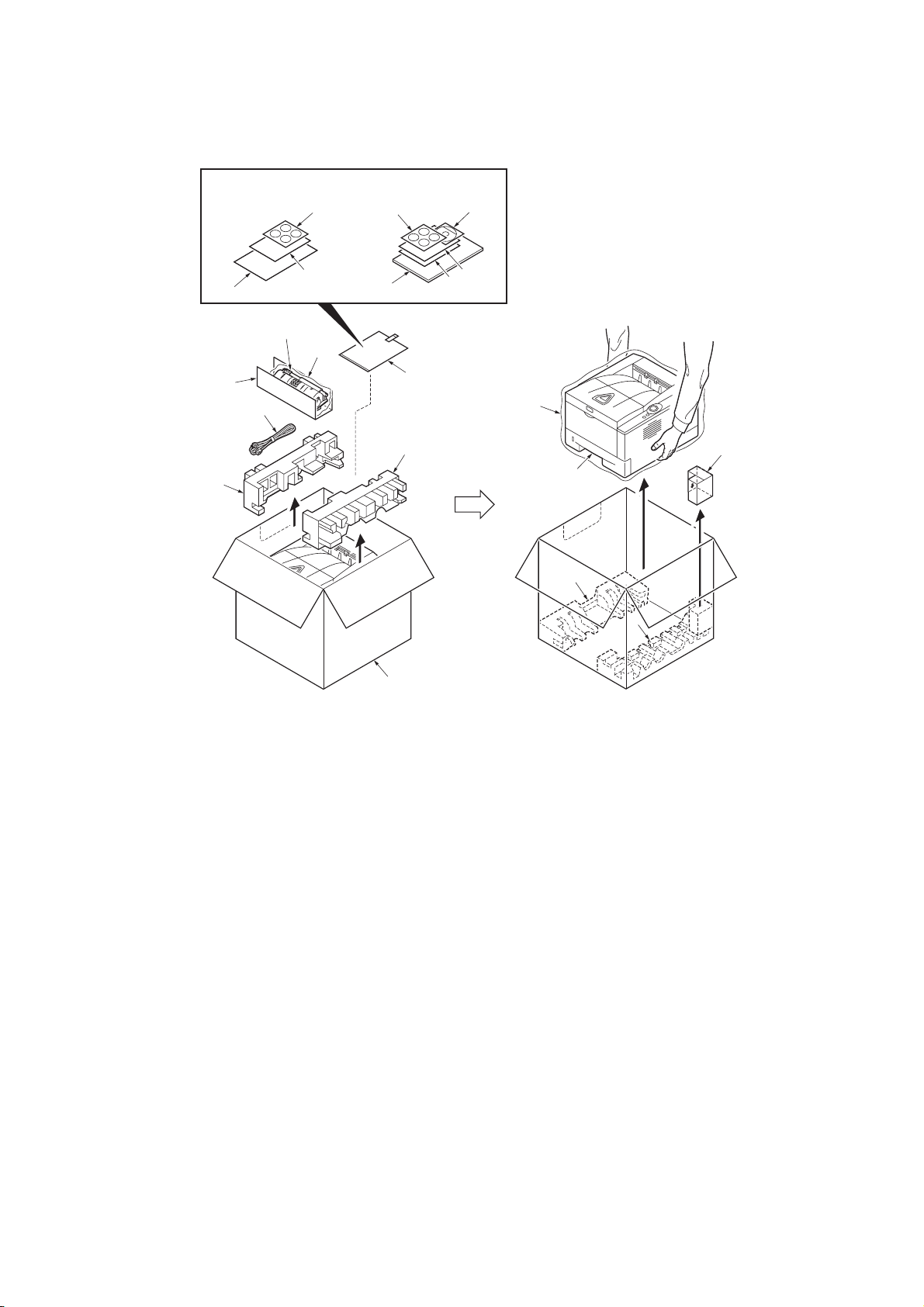

1-2-2 Unpacking

15

15

120 V AC model220 - 240 V AC model

19

16

14

9

10

8

11

6

17

13

7

2

14

18

5

12

1

3

4

1. Printer

2. Outer case

3. Bottom pad L

4. Bottom pad R

5. Machine cover

6. Top pad L

7. Top pad R

8. Spacer

9. Toner container

10. Plastic bag

Figure 1-2-2

11. Pow er c ord

12. Pad

13. Plastic bag

14. Installation guide

15. Panel GFIS sheet

16. EEA information leaflet

17. Operation guide

18. Energy star leaflet

19. CD-ROM

1-2-2

Page 21

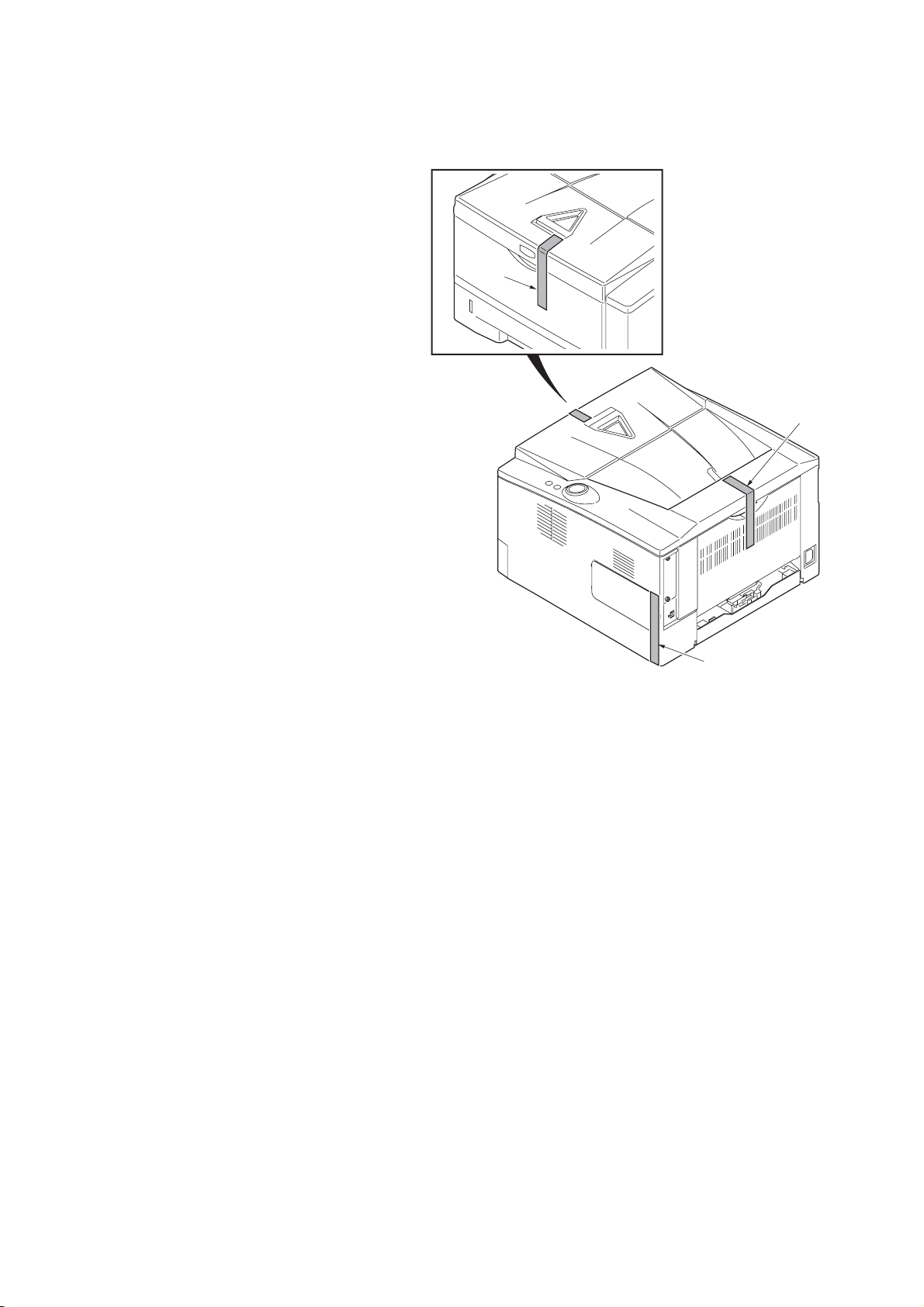

(1) Removing the tapes

Procedure

1. Remove three tapes.

2LY/2LZ

Ta pe

Ta pe

Figure 1-2-3

Ta pe

1-2-3

Page 22

2LY/2LZ

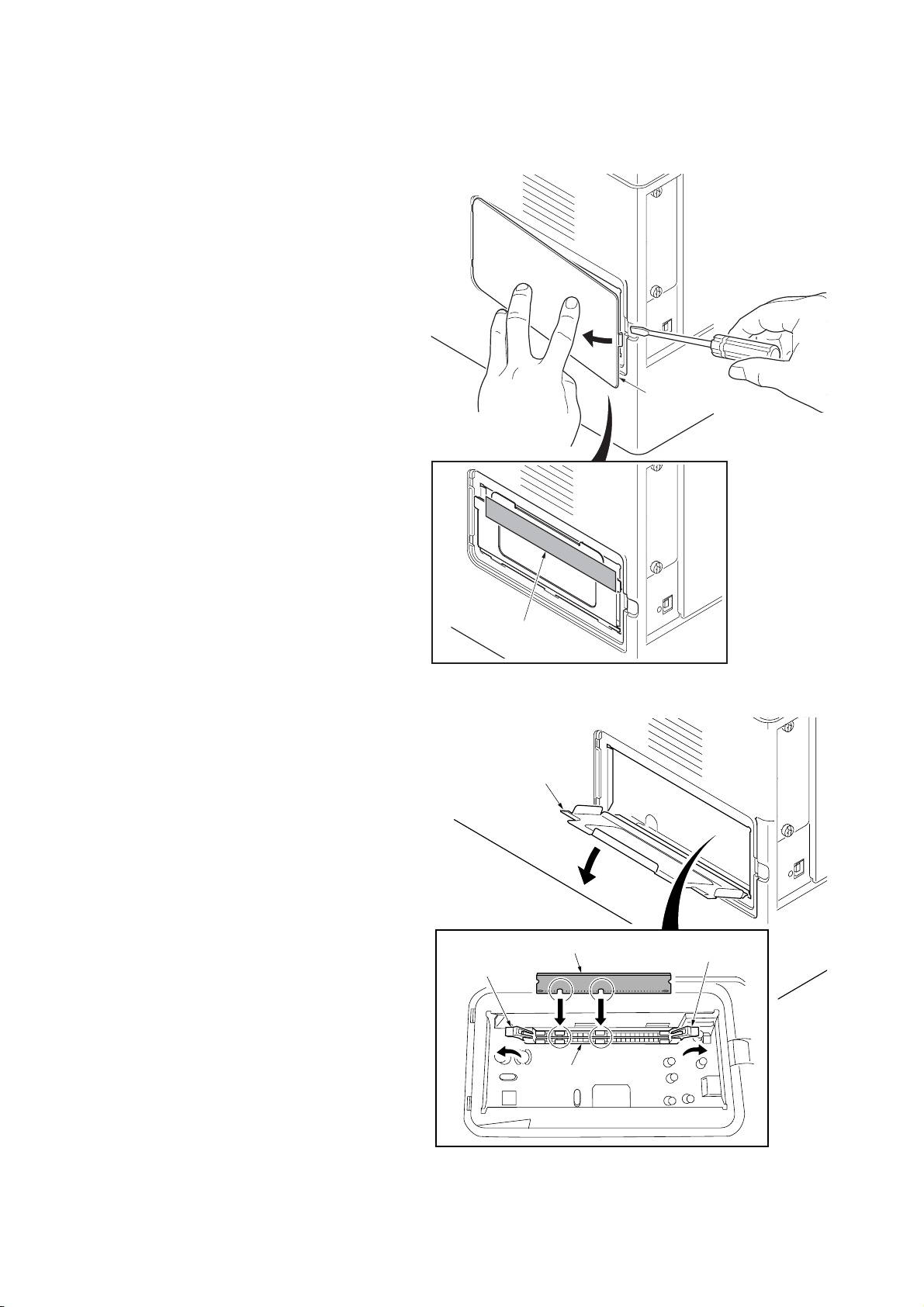

1-2-3 Installing the expanded memory (option)

Procedure

1. Turn off printer power switch.

Caution: Do not insert or remove expanded

memory while printer power is on.

Doing so may cause damage to the printer

and the expanded memory.

2. Remove the right side cover.

3. Remove the tape.

Right side cover

4. Open the memory slot cover.

5. Open clamps on both ends of the memory

socket on the control PWB.

6. Insert the expanded memory into the mem-

ory socket so that the notches on the memory align with the corresponding protrusions

in the slot.

The memory module is secured to the memory socket with the clamps.

7. Close the memory slot cover.

8. Refit the right side cover.

9. Print a status page to check the memory

expansion (See page P.1-3-2).

If memory expansion has been properly performed, information on the installed memory

is printed with the total memory capacity has

been increased. Standard memory capacity

32 MB.

Ta pe

Memory slot cover

Expanded memory

Clamp

Figure 1-2-4

Clamp

Memory socket

1-2-4

Figure 1-2-5

Page 23

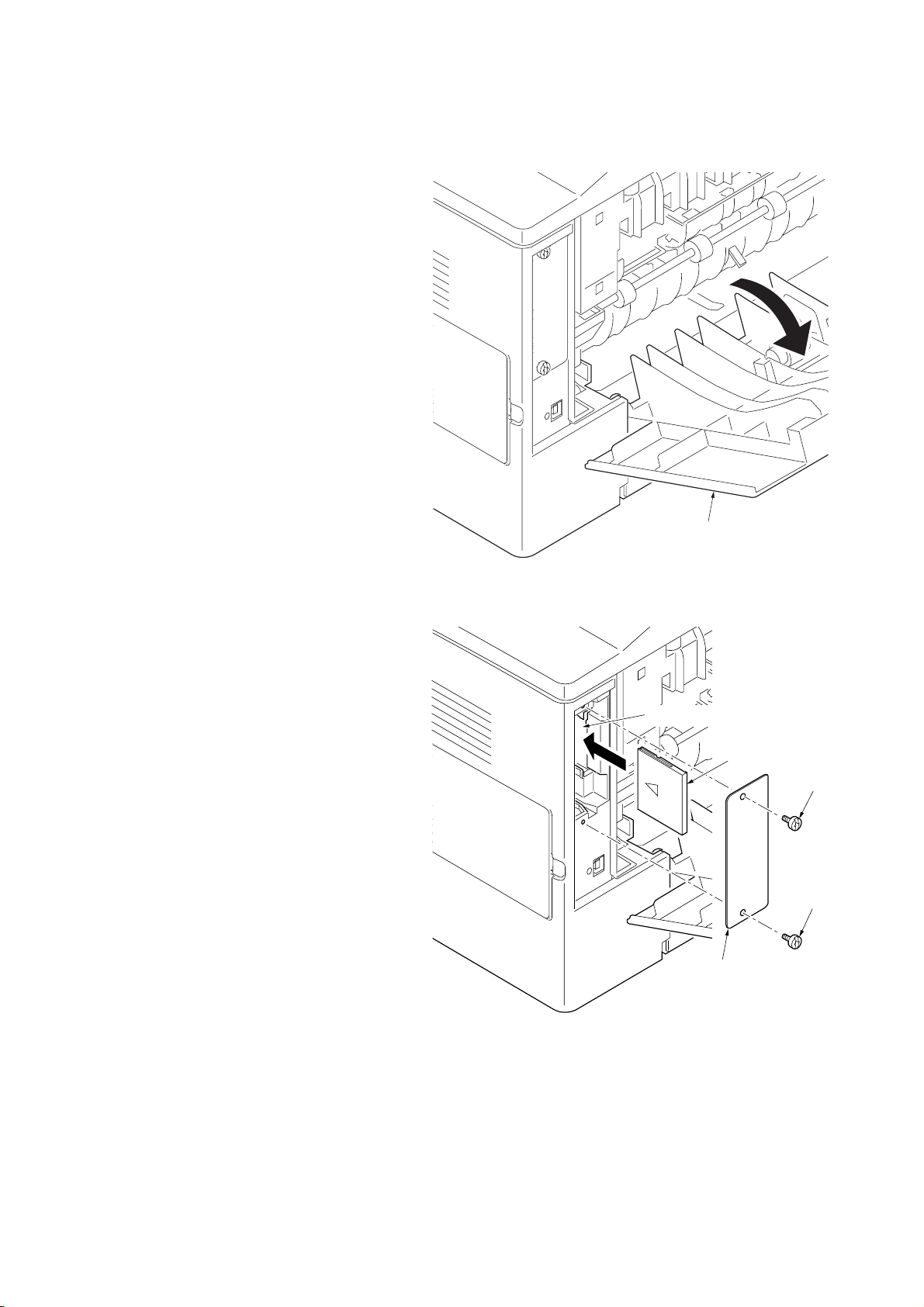

1-2-4 Installing the memory card (option)

Procedure

1. Turn off printer power switch.

Caution: Do not insert or remove memory

card while printer power is on.

Doing so may cause damage to the printer

and the memory card.

2. Open the rear cover.

2LY/2LZ

3. Remove two screws and then remove the

optional interface slot cover.

4. Insert the memory card into the memory

card slot. Push it in all the way.

5. Secure the optional interface slot cover by

using two screws.

6. Format the memory card before use.

To format the memory card:

Send the following PRESCRIBE command

sequence from the PC to the printer.

!R! RWER F, A; EXIT;

Note: To send a PRESCRIBE command

sequence to the printer, use COMMAND

CENTER (the printer's embedded web)

while the printer is connected to the PC via

its network interface.

Rear cover

Figure 1-2-6

Memory card slot

Memory card

Screw

Screw

Optional interface

slot cover

Figure 1-2-7

1-2-5

Page 24

2LY/2LZ

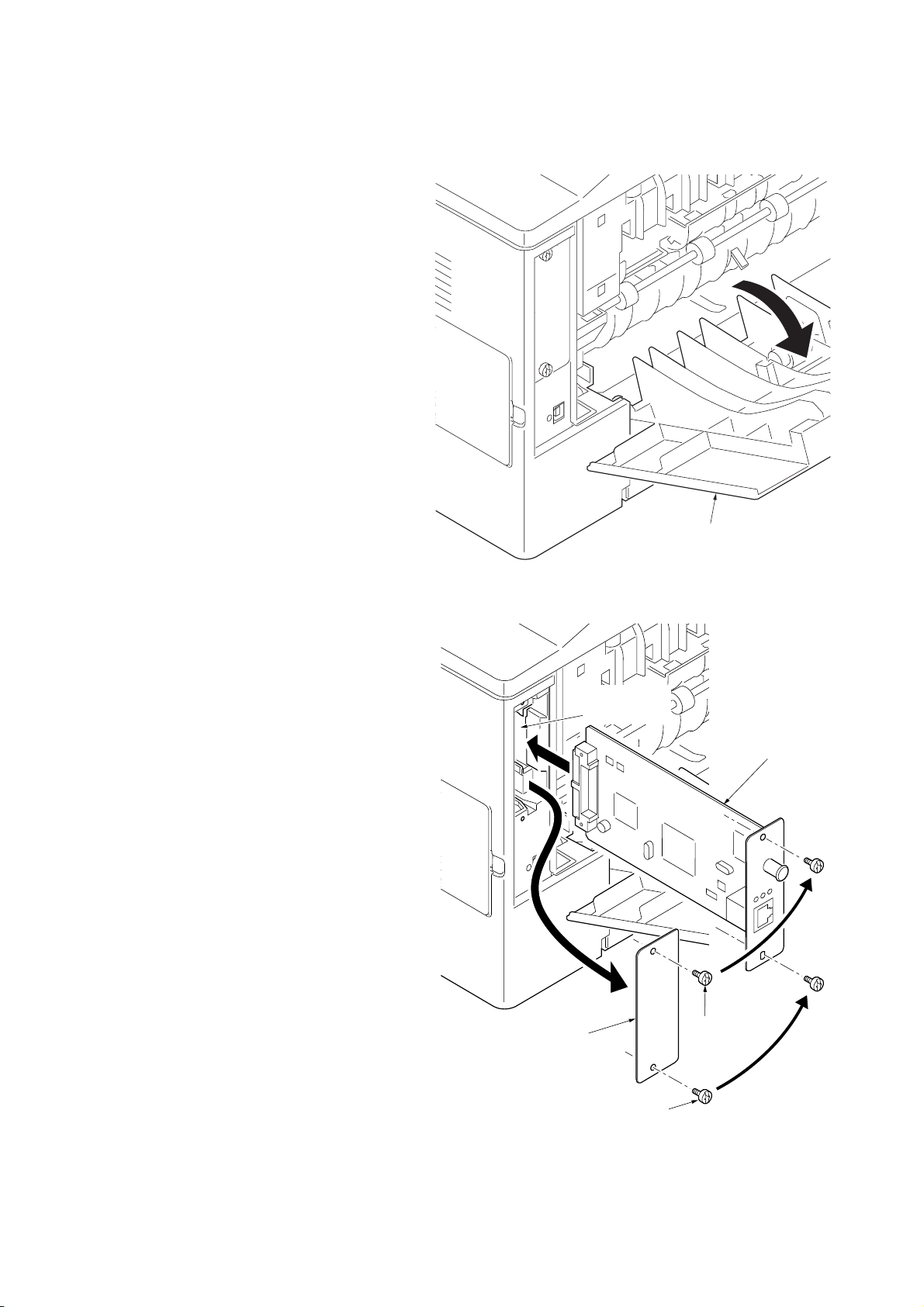

1-2-5 Installing the network interface card (option)

Procedure

1. Turn off printer power switch.

Caution: Do not insert or remove network

interface card while printer power is on.

Doing so may cause damage to the printer

and the network interface card.

2. Open the rear cover.

3. Remove two screws and then remove the

optional interface slot cover.

4. Insert the network interface card into the

network interface slot. Push it in all the way.

5. Secure the network interface card by using

two screws.

Rear cover

Figure 1-2-8

Network

interface slot

Network interface

card

1-2-6

Optional interface

slot cover

Screw

Screw

Figure 1-2-9

Page 25

2LY/2LZ-2

1-3 Maintenance Mode

1-3-1 Maintenance mode

The product incorporates several service modes which are activated by using the keys on the operation panel or by commanding from a PC.

(1) Executing a service mode

Printing a status page for service purpose................................... See page 1-3-2.

Printing an event log (EVENT LOG)............................................ See page 1-3-6.

Toner install mode........................................................................ See page 1-3-11.

[REPLACE MAINTENANCE KIT] message sheet....................... See page 1-3-12.

1-3-1

Page 26

2LY/2LZ

[XXXXXXXX][XXXXXXXX][01/00] Printed Page(s) 9690

/t/U00/F00/N00

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

/0000/0000/

/00/300/81/31/81/31/

A:1234567890123456

/02870284/03028003/83030286/86000086/02000000/02020202/02020202/

/03030303/03030303/03030303/03030303/03000000/03030303/03030303/

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

XXXXXXXX

/00000000/00000000/00000000000000000000000000000000/00000000000000000000000000000000/0000/00/00

SN:SPL9200010

Service items Description

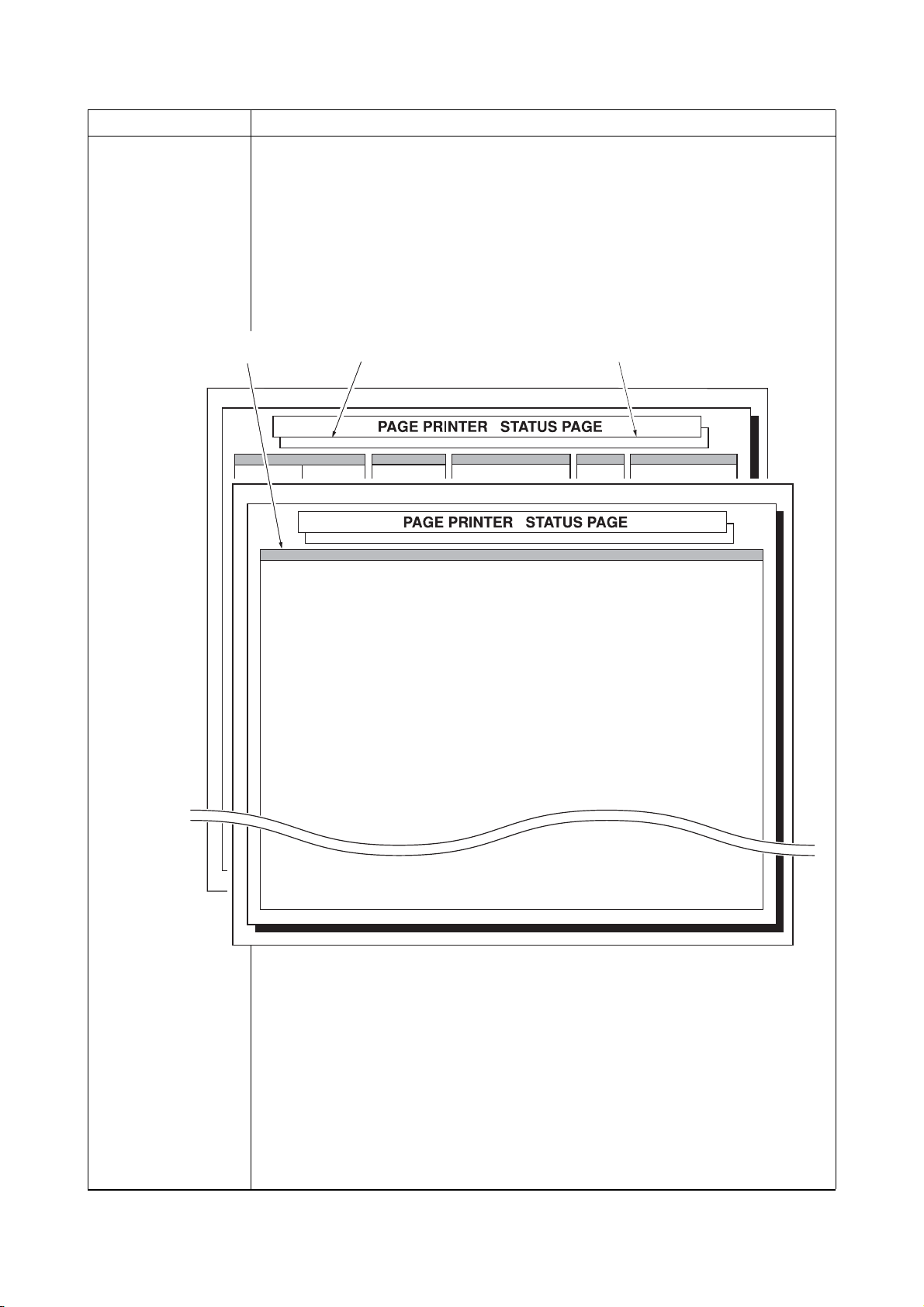

Printing a status page

for service purpose

Service information

(Refer to next page) Control PWB firmware version Firmware release date

Description

Prints a status page for service purpose. The status page includes various printing settings

and service cumulative.

Purpose

To acquire the current printing environmental parameters and cumulative information.

Procedure

1. Press the GO key for 10 seconds or more.

Two pages will be printed. (The second page includes service information.)

Firmware version: 2LZ_3000.001.024

Firmware version: 132.00

Service Information

Released: 20/January/2010

Released: 20/January/2010

Figure 1-3-1 Service status page

1-3-2

Page 27

Service items Description

Detail of service information

Service information

2LY/2LZ

[XXXXXXXX][XXXXXXXX][01/00]

(1)

/t/U00/F00/N00

(7)

(6)

(5)

/0020/0020/1061/0811/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/ 0/

(9)

(13)

/0000/0000/

/00/300/81/31/81/31/

(2) (3)

(8)

(10) (11) (12)

Total page 9690

(14)(15)(16)(17)(18)(19)

A:1234567890123456

(20)

(21)

/02870284/03028003/83030286/86000086/02000000/02020202/02020202/

/03030303/03030303/03030303/03030303/03000000/03030303/03030303/

(22)

SPD1:0203040508090A0B0C0D0F101112131415161718191A1B1C1D1E1F202122235E

(23)

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

(24)

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

(25)

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

/8088808880808000/8088808880808000/8088808880808000/8088808880808000

XXXXXXXX

(26)

/00000000/00000000/00000000000000000000000000000000/00000000000000000000000000000000/0000/00/00

(27)

(4)

(28)

SN:SPL9200010

Figure 1-3-2 Detail of service information

1-3-3

Page 28

2LY/2LZ

Code conversion

ABCDEF GHI J

0123456789

No. Items Description

(1) Engine ROM information [Flash ROM version]

(2) Boot ROM information [Boot ROM version]

(3) Software jumper switch

information

(hexadecimal)

[First byte/Second byte

(displayed in OEM model

only)]

First byte

bit 0 = 1: (Fixed)

bit 1 = 0: Overseas, 1: Domestic (Japan)

bit 2, 3 (Not used)

bit 4 = 0: Kyocera, 1: OEM

bit 5 = 0: For Europe, 1: For US

bit 6 = 0: Non MICR mode, 1: MICR mode

bit 7 (Not used)

Second byte: Displayed in OEM model only

(4) Total p a g e -

(5) Toner install information -

(6) USB information 00: Not connected

01: Full-Speed

02: Hi-Speed

(7) Operation panel lock sta-

tus (displayed only when

locked)

01: Partial lock

02: Full lock

(8) NVRAM error (displayed

only when any error has

occurred)

01: ID error

02: Version error

03: Checksum error

04: NVRAM crush error

(9) Printable area setting /Top offset/Left offset/Page length/Page width

(10) Left offset for each paper

source

/MP tray/Cassette1/Cassette 2/Cassette 3/Duplex

(1/600 inches unit)

(11) Top offset for each paper

source

/MP tray/Cassette 2/Cassette 3/Duplex

(1/600 inches unit)

(12) Offset for rotation /Top offset/Left offset/

(1/600 inches unit)

(13) Optional paper feeder ver-

sion

/Paper feeder 1/Paper feeder 2/

(14) Calibration table setting Setting value (FRPO I4), Hexadecimal

(15) Resolution Current value of bit-per-pixel

(16) Copy quantity -

(17) Installed device/function

information

bit0: HDD

bit1: Optional ROM

bit2: Memory card

bit3: USB memory

bit4: HDD security

(18) Operation panel message

language

PMSG command setting (decimal)

(19) Current temperature

0 to 50 C/32 to 122 F (in 1 C/1.8 F increment, “-” = Temperature sensor

is abnormal.)

Service items Description

1-3-4

Page 29

Service items Description

No. Items Description

(20) Fixed asset number (Maximum 16 characters)

(21) Paper type attributes Paper type setting value from 1 to 28 (fuser, weight, duplex)

(unused paper type are always 0x00.)

(22) Paper type attributes Paper type setting value from 1 to 28 (density)

(unused paper type are always 0x00.)

(23) Memory SPD information (slot 1)2 to 6 bytes, 8 to 36 bytes, 94 to 95 bytes (total 32 bytes)

(24) DRT correction coefficient 4 bytes 11 23 groups

(25) Engine parameter Hexadecimal, 256 bytes

(26) RFID reader/writer version

information

-

(27) RFID information -

(28) Machine serial number -

NOTE:

Code conversion

ABCDEFGH I J

0123456789

2LY/2LZ

1-3-5

Page 30

2LY/2LZ

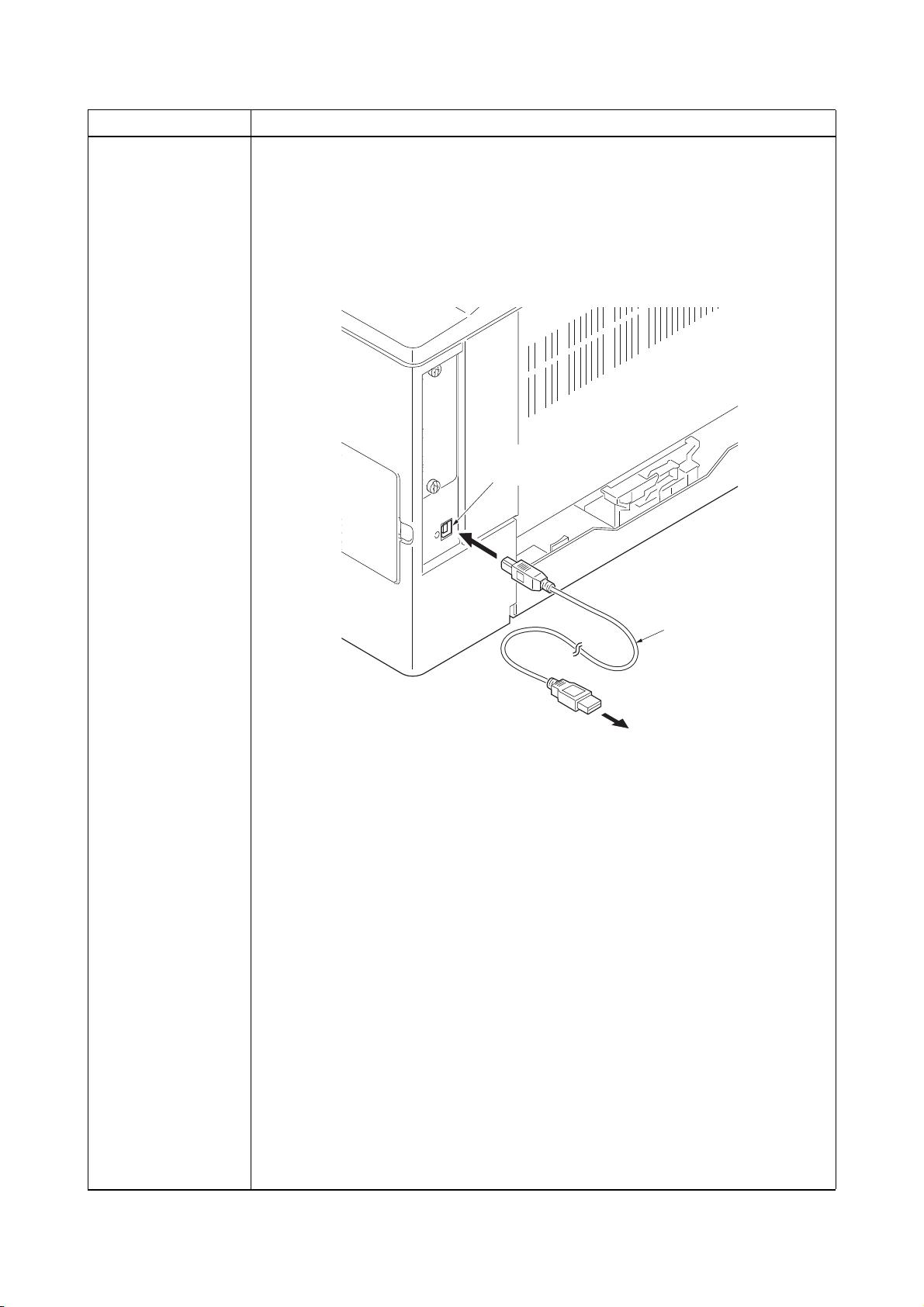

To PC

USB cable

USB interface

connector

Service items Description

Printing an event log

(EVENT LOG)

Description

Prints a history list of occurrences of paper jam, self-diagnostics, toner replacements, etc.

Purpose

To allow machine malfunction analysis based on the frequency of paper misfeeds, self diagnostic errors and replacements.

Procedure

1. Connect the USB cable between printer and PC.

1-3-6

Figure 1-3-3

2. Connect the power cord.

3. Turn printer power on. Make sure the printer is ready.

4. At the DOS prompt, send the following command to the printer:

echo !R! ELOG;EXIT;>prn

Event log will be printed.

Page 31

Service items Description

[EB20MA001/2LZ_1000.001.019] [40.00SFLB] [01]

Printed page(s) 12345

SN:SPL0000000

Firmware version: 2LZ_30000.001.024

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

10.48.01.08.01.01

J10: 0 C:6000: 4 T00: 1

J11: 0 C:6020: 1

J12: 0

J20: 0

J21: 0

J22: 0

J30: 0

J31: 0

J32: 0

J40: 0

J41: 0

J42: 0

Released: 20/January/2010

# Count. Event # Count. Service Code

8 11234 01.6000

7 10000 01.6000

6 9999 01.6000

5 9998 01.6000

4 9997 01.6000

3 9996 01.6000

2 9995 01.6000

1 9994 01.6000

8 11234 01.00

7 10000 01.00

6 9999 01.00

5 9998 01.00

4 9997 01.00

3 9996 01.00

2 9995 01.00

1 9994 01.00

# Count. item

(1)

(6)

(7)

(2)

(9)(8)

(12)

(10)

(11)

5 9800 01.00

4 9700 01.00

3 9600 01.00

2 9500 01.00

1 9400 01.00

# Count. item

(3) (4)

(5)

(i)

8 9993

7 9992

6 9991

5 9990

4 9989

3 9979

2 9969

11

(h)

(g)

Unknown Toner Log

Counter Log

Maintenance Log

Service Call LogPaper Jam Log

EVENT LOG

10.48.01.08.01.01

(a) (b) (c) (d) (e) (f)

2LY/2LZ

Figure 1-3-4Event log (EVENT LOG)

1-3-7

Page 32

2LY/2LZ

No. Items Description

(1) Control PWB mask version [Engine mask version/Engine software version]

(2) BROM version -

(3) Software jumper switch informa-

tion

(hexadecimal)

[First byte/Second byte (displayed in OEM mode only)]

First byte

bit 0 = 1: (Fixed)

bit 1 = 0: Overseas, 1: Domestic (Japan)

bit 2, 3 (Not used)

bit 4 = 0: Kyocera, 1: OEM

bit 5 = 0: For Europe, 1: For US

bit 6 = 0: Non MICR mode, 1: MICR mode

bit 7 (Not used)

Second byte: Displayed in OEM mode only

(4) Control PWB firmware version -

(5) Control PWB firmware release

date

-

(6) Total page counter -

(7) Printer serial number -

(8) Paper Jam Log # Count. Event

Remembers 1 to 8 of

occurrence. If the occurrence of the previous

paper jam is less than 8,

all of the paper jams are

logged. When the occurrence excesseds 8, the

oldest occurrence is

removed.

The total page count

at the time of the

paper jam.

Log code (2 digit,

hexadecimal, 6

categories)

(a) Cause of a

paper jam

(b) Position of

paper jam

(c) Paper source

(d) Paper size

(e) Paper type

(f) Paper exit

Refer to the next

page for the details

of each log code.

Service items Description

Detail of event log (EVENT LOG) information

1-3-8

Page 33

Service items Description

No. Items Description

(8)

cont.

Paper Jam

Log

(a) Cause of paper jam

10: Paper does not arrive at the registration sensor. (MP tray) [42]

10: Paper does not arrive at the registration sensor. (Cassette 1) [31]

10: Paper does not arrive at the registration sensor. (Cassette 2) [31]

10: Paper does not arrive at the registration sensor. (Cassette 3) [31]

10: Paper does not arrive at the registration sensor. (Duplex conveying) [49]

11: Paper does not pass the registration sensor. [48]

12: Paper remains at the registration sensor when power is turned on. [48]

20: Paper does not arrive at the exit sensor. [48]

21: Paper does not pass the exit sensor. [47]

22: Paper remains at the exit sensor when power is turned on. [47]

30: Paper does not arrive at the paper feeder 1’s PF paper feed sensor. (Cassette 2) [32]

30: Paper does not arrive at the paper feeder 1’s PF paper feed sensor. (Cassette 3) [33]

31: Paper does not pass the paper feeder 1’s PF paper feed sensor. (Cassette 2) [32]

32: Paper remains at the paper feeder 1’s PF paper feed sensor when power is turned on.

(Cassette 2) [32]

40: Paper does not arrive at the paper feeder 2’s PF paper feed sensor. (Cassette 3) [33]

41: Paper does not pass the paper feeder 2’s PF paper sensor. (Cassette 3) [33]

42: Paper remains at the paper feeder 2’s PF paper feed sensor when power is turned on.

(Cassette 3) [33]

A1: Paper does not arrive at the exit sensor. [47]

A3: Paper does not pass the exit sensor. [49]

E0: Paper misfeed occurs due to forced stop when an error occurs during printing. (such as

opening of a cover) [00]

F0 to FE: Paper misfeed by another cause. [00]

Note:

Values (hexadecimal) within [ ] indicate paper misfeed locations.

(b) Detail of jam location

Paper feeder 1

Paper feeder 2

Printer

[42]

[32]

[31]

[48]

[47]

[33]

(c)

(b)

(a)

(e)

(f)

(e)

(f)

(d)

(a) Registration sensor

(b) Paper sensor

(c) MP paper sensor

(d) Paper exit sensor

(e) PF paper sensor

(f) PF paper feed sensor

Sensors

[49]

[31] Cassette 1

[32] Cassette 2

[33] Cassette 3

[42] MP tray

[47] Fuser/Exit section

[48] Printer inside

[49] Duplex section

Paper jam location

2LY/2LZ

1-3-9

Page 34

2LY/2LZ

No. Items Description

(8)

cont.

Paper Jam Log

(c) Detail of paper source (Hexadecimal)

00: MP tray

01: Cassette 1 (printer)

02: Cassette 2 (paper feeder 1)

03: Cassette 3 (paper feeder 2)

07: Duplex

(d) Detail of paper size (Hexadecimal)

00: (Undefined)

01: Monarch

02: Business

03: International DL

04: International C5

05: Executive

06: Letter-R

07: Legal

08: A4R

09: B5R

0D: A5R

0E: A6

0F: B6

10: Commercial #9

11: Commercial #6

12: ISO B5

13: Custom

1F: Post card

20: Reply-paid postcard

21: Oficio II

28: 16K-R

32: Statement-R

33: Folio

34: Western type 2

35: Western type 4

(e) Detail of paper type (Hexadecimal)

01: Plain

02: Transparency

03: Preprint

04: Labels

05: Bond

06: Recycle

07: Vellum

08: Rough

09: Letterhead

0A: Color

0B: Prepunched

0C: Envelope

0D: Cardstock

10: Thick

11: High quality

15: Custom 1

16: Custom 2

17: Custom 3

18: Custom 4

19: Custom 5

1A: Custom 6

1B: Custom 7

1C: Custom 8

(f) Detail of paper exit location (Hexadecimal)

01: Top tray

(9) Service Call

(Self diagnostic

error) Log

# Count. Service Code

Remembers 1 to 8 of occurrence of self diagnostics error.

If the occurrence of the previous diagnostics error is less

than 8, all of the diagnostics

errors are logged.

The total page count at

the time of the self diagnostics error.

Self diagnostic error

code (See page 1-4-5)

Example

01.6000

01 means a self-diagnostic error; 6000

means a self diagnostic error code.

(10) Maintenance

Log

NOTE:

It is not logged if

100 or more

counts are not

added to the

count at the last

occurrence of

replacement.

# Count. Item

Remembers 1 to 8 of occurrence of replacement. If the

occurrence of the previous

replacement of toner container is less than 8, all of the

occurrences of replacement

are logged.

The total page count at

the time of the replacement of the toner container.

This is virtually logged as

the occurrence of the

“Toner Empty” condition

since the replacement of

the toner container is not

precisely detectable.

Code of maintenance

replacing item (1 byte, 2

categories)

First byte (Replacing

item)

01: Toner container

Service items Description

1-3-10

Page 35

Service items Description

No. Items Description

(11) Unknown Toner

Log

NOTE:

It is not logged if

100 or more

counts are not

added to the

count at the last

error.

# Count. Item

Remembers 1 to 5 of occurrence of unknown toner

detection.

If the occurrence of the previous unknown toner detection

is less than 5, all of the

unknown toner detection are

logged.

The total page count at

the time of the “Toner

Empty” condition with

using an unknown toner

container.

Unknown toner log code

(1 byte, 2 categories)

First byte

01: Fixed (Toner container)

Second byte

00: Fixed (Black)

(12) Counter Log

Comprised of

three log counters including

paper jams, self

diagnostics errors,

and replacement

of the toner container.

NOTE:

It is not logged if

100 or more

counts are not

added to the

count at the last

error.

(g) Paper jam (h) Self diagnostic error (i) Maintenance item

replacing

Indicates the log counter of

paper jams depending on

location.

Refer to (8) Paper Jam Log.

All instances including those

are not occurred are displayed.

Indicates the log counter

of self diagnostics errors

depending on cause.

(See page 1-4-5)

Example

C6000: 4

Self diagnostics error

6000 has happened four

times.

Indicates the log counter

depending on the maintenance item for maintenance.

T: Toner container

00: Black

Example

T00: 1

The (black) toner container has been replaced

once.

2LY/2LZ-2

Toner install mode Description

Replenishes toner rapidly from the toner container into the developing unit.

Purpose

To execute after replacing the developing unit to replenish toner rapidly into the developing

unit.

Procedure

Toner install mode is performed by simultaneously pressing and holding the GO and Cancel

keys for more than 5 seconds. To abort toner install mode, turn power on while pressing and

holding the GO and Cancel keys.

1-3-11

Page 36

2LY/2LZ-2

Service items Description

[REPLACE MAINTENANCE KIT] message

sheet

Description

[REPLACE MAINTENANCE KIT] message sheet is printed at the 1st power-up after the

page count exceeding 100,000 pages.

Procedure

Replace the maintenance kit.

30/32 ppm model (A4/Letter)

Maintenance kit MK-162 (for 120 V specifications)

Maintenance kit MK-160 (for 230 V specifications)

Maintenance kit MK-164 (for 240 V specifications)

35/37 ppm model (A4/Letter)

Maintenance kit MK-172 (for 120 V specifications)

Maintenance kit MK-170 (for 230 V specifications)

Maintenance kit MK-174 (for 240 V specifications)

Procedure for replacing

Drum unit (See page 1-5-12)

Developing unit (See page 1-5-11)

1-3-12

Figure 1-3-5 [REPLACE MAINTENANCE KIT] message sheet

Page 37

2LY/2LZ

1-4 Troubleshooting

1-4-1 Paper misfeed detection

(1) Paper misfeed indication

If paper jams in the paper conveying system, or no paper sheets are fed at all, the printer automatically goes offline, and

the jam indicator will flash rapidly. Status Monitor or COMMAND CENTER can indicate the location of the paper jam (the

component where the paper jam has occurred). After removing the jammed paper, the printer will resume printing.

Jam indicator

(Amber, Lit)

Figure 1-4-1

1-4-1

Page 38

2LY/2LZ

r

(2) Paper misfeed detection condition

Printer

(3)

(4)

Peper feeder 1

(Option)

Peper feeder 2

(Option)

(1)

(5)

(5)

Figure 1-4-2

(6)

(6)

(2)

(1) Registration sensor

(2) Paper sensor

(3) MP paper sensor

(4) Paper exit sensor

(5) PF paper sensor

(6) PF paper feed senso

1-4-2

Page 39

2LY/2LZ

r

1-4-2 Self-diagnostic function

(1) Self-diagnostic function

The printer is equipped with self-diagnostic function which automatically halts the printer when an error is detected. The

four indicators (Jam, Paper, Attention, Toner) are simultaneously lit, then indicate a specific error by the combination of the

four indicators.

Jam indicator

(Amber, Lit)

Paper indicator

(Amber, Lit)

Attention indicato

(Amber, Lit)

Toner indicator

(Amber, Lit)

Figure 1-4-3

1-4-3

Page 40

2LY/2LZ

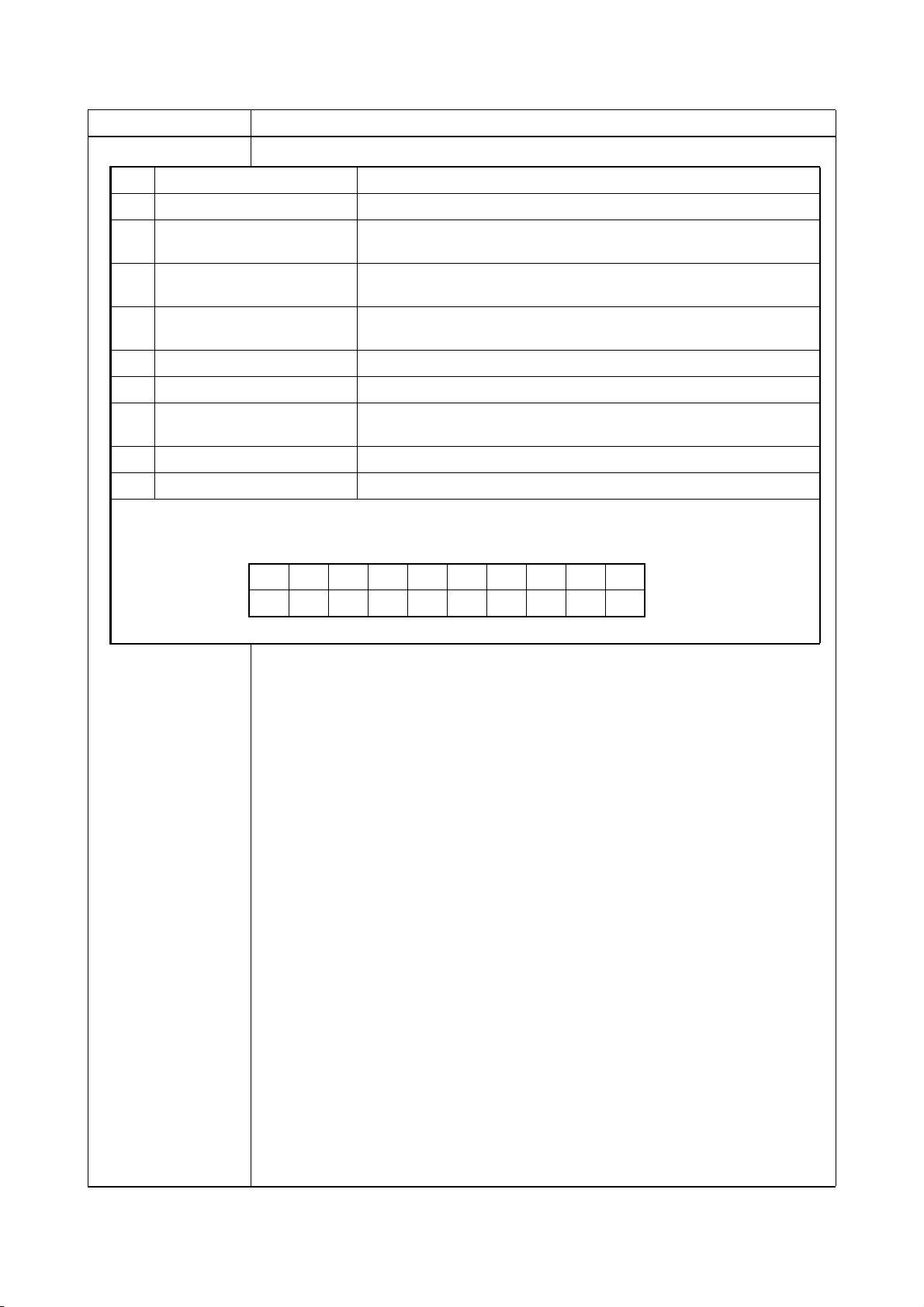

(2) Self diagnostic codes indication

Sequence of display

1.6 s

Indicates the

occurrence of a self

diagnostics error.

Repeat

1.6 s

0.8 s

0.8 s

0.8 s

0.8 s

0.8 s

0.8 s

2

6

Example of self-diagnostic code: 2610

(Refer to the following code conversion table)

1

Indication example

0

Off (Amber)

Lit (Amber)

Lit (Green)

Lit (Amber)

Off (Amber)

Code conversion table

Indicator

Code

Indicator

1Code

67890F

2345

Self diagnostic codes indication (Animation). See page 2-4-3.

Figure 1-4-4

1-4-4

Off (Green)

Page 41

(3) Self diagnostic codes

2LY/2LZ

Code Contents

0150 Control PWB EEPROM error

Detecting control PWB EEPROM

(U300) communication error.

0420 Paper feeder communication error

Communication error between control PWB and optional paper feeder.

2000 Main motor error

The main motor ready input is not

given for 2 s during the main motor is

ON.

Remarks

Causes Check procedures/corrective measures

Improper installation

control PWB EEPROM

(U300).

Defective control

PWB.

Improper installation

paper feeder.

Defective harness

between control PWB

(YC318) and paper

feeder interface connector, or improper

connector insertion.

Defective control

PWB.

Defective harness

between PF main

PWB (YC5) and paper

feeder interface connector, or improper

connector insertion.

Defective PF mainPWB.

Defective harness

between main motor

(CN1) and control

PWB (YC305), or

improper connector

insertion.

Defective drive transmission system of the

main motor.

Defective main motor. Replace the main motor (See page 1-5-29).

Check the installation of the EEPROM

(U300) and remedy if necessary (See page

1-5-19).

Replace the control PWB (See page 1-5-

19).

Follow installation instruction carefully again.

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness.

Replace the control PWB (See page 1-5-

19).

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness (Refer to the

service manual for the paper feeder).

Replace the PF main PWB (Refer to the service manual for the paper feeder).

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective control

PWB.

Replace the control PWB (See page 1-5-

19).

1-4-5

Page 42

2LY/2LZ

Code Contents

2610 PF paper feed motor error (Paper

feeder 1)

The PF paper feed motor of paper

feeder 1 ready input is not given for 2

s during the PF paper feed motor is

ON.

2620 PF paper feed motor error (Paper

feeder 2)

The PF paper feed motor of paper

feeder 2 ready input is not given for 2

s during the PF paper feed motor is

ON.

Remarks

Causes Check procedures/corrective measures

Defective harness

between PF paper

feed motor and PF

main PWB (YC4), or

improper connector

insertion.

Defective drive

transmission system of

the PF paper feed

motor.

Defective PF main

motor.

Defective control

PWB.

Defective harness

between PF paper

feed motor and PF

main PWB (YC4), or

improper connector

insertion.

Defective drive

transmission system of

the PF paper feed

motor.

Defective PF main

motor.

Defective control

PWB.

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness (Refer to the

service manual for the paper feeder).

Check if the gears rotate smoothly. If not,

grease the bushings and gears. Check for

broken gears and replace if any.

Replace the PF main motor (Refer to the

service manual for the paper feeder).

Replace the control PWB (See page 1-5-

19).

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness (Refer to the

service manual for the paper feeder).

Check if the gears rotate smoothly. If not,

grease the bushings and gears. Check for

broken gears and replace if any.

Replace the PF main motor (Refer to the

service manual for the paper feeder).

Replace the control PWB (See page 1-5-

19).

4000 Polygon motor (laser scanner unit)

error

The polygon motor ready input is not

given for 6 s during the polygon

motor is ON.

Defective harness

between polygon

motor and control

PWB (YC319), or

improper connector

insertion.

Defective laser scanner unit.

Defective control

PWB.

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness.

Replace the laser scanner unit (See page 15-30).

Replace the control PWB (See page 1-5-

19).

1-4-6

Page 43

2LY/2LZ

Code Contents

6000 Broken fuser heater lamp wire

The fuser temperature does not rise

after the fuser heater lamp has been

turned on.

6020 Abnormally high fuser thermistor

temperature

Fuser thermistor detects abnormally

temperature.

6030 Broken fuser thermistor wire

Input from fuser thermistor is 0 (A/D

value).

Remarks

Causes Check procedures/corrective measures

Poor contact in the

fuser thermistor connector terminals.

Poor contact in the

fuser heater lamp connector terminals.

Fuser thermistor

installed incorrectly.

Fuser thermal cutout

triggered.

Fuser heater lamp

installed incorrectly.

Broken fuser heater

lamp wire.

Shorted fuser thermistor.

Defective control

PWB.

Poor contact in the

fuser thermistor connector terminals.

Broken fuser thermistor wire.

Fuser thermistor

installed incorrectly.

Reinsert the connector (See page 1-5-16).

Reinsert the connector (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the control PWB (See page 1-5-

19).

Reinsert the connector (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

6400 Zero cross signal error

The zero cross signal does not reach

the control PWB for specified time.

Fuser thermal cutout

triggered.

Fuser heater lamp

installed incorrectly.

Broken fuser heater

lamp wire.

Defective harness

between high voltage

PWB (YC202) and

control PWB (YC311),

or improper connector

insertion.

Defective harness

between power source

PWB (YC103) and

high voltage PWB

(YC201), or improper

connector insertion.

Defective power

source PWB.

Defective control

PWB.

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Replace the fuser unit (See page 1-5-16).

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness (See page 15-25).

Reinsert the connector. Also check for continuity within the connector harness. If none,

remedy or replace the harness (See page 15-25).

Replace the power source PWB (See page

1-5-22).

Replace the control PWB (See page 1-5-

19).

1-4-7

Page 44

2LY/2LZ

Code Contents

7990 Waste toner full

The waste toner sensor has detected

that the waste toner reservoir (drum

unit) is full.

F010 Control PWB checksum error Defective code ROM

F020 Control PWB RAM checksum error Defective main mem-

F030 Control PWB general failure Defective control

Causes Check procedures/corrective measures

Waste toner reservoir

(drum unit) is full.

Defective waste toner

sensor.

Defective control

PWB.

(flash memory).

Defective control

PWB.

ory (RAM) on the control PWB.

Defective expanded

memory (DIMM).

PWB.

Remarks

Turn the main power switch off/on to restart

the printer. If the error is not resolved,

replace the drum unit (See page 1-5-12).

Replace the waste toner sensor.

Replace the control PWB (See page 1-5-

19).

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

the control PWB (See page 1-5-19).

Replace the control PWB (See page 1-5-

19).

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

control PWB (See page 1-5-19).

Replace the expanded memory (DIMM)

(See page 1-2-4).

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

control PWB (See page 1-5-19).

F040 Control PWB engine communica-

tion error

F050 Control PWB engine checksum

error

F226 Control PWB video data control

error

Defective control

PWB.

Some error may have

occurred when downloading the firmware of

the control PWB.

Defective control

PWB.

Defective control

PWB.

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

control PWB (See page 1-5-19).

Download the firmware of the control PWB

again using the memory card (See page 16-2).

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

control PWB (See page 1-5-19).

Turn the power switch off/on to restart the

printer. If the error is not resolved, replace

control PWB (See page 1-5-19).

1-4-8

Page 45

1-4-3 Image formation problems

2LY/2LZ

(1)Completely blank

printout.

See page 1-4-10 See page 1-4-10 See page 1-4-11 See page 1-4-11 See page 1-4-11

(6)Black vertical

streaks.

ABC

123

(2)All-black printout. (3)Dropouts. (4)Black dots. (5)Black horizontal

streaks.

ABC

123

(7)Unsharpness. (8)Gray background. (9)Dirt on the top

ABC

123

ABC

123

edge or back of the

paper.

ABC

123

ABC

123

(10)Undulated printing at the right edge

(scanning start position).

This vertical

line should

be straight.

See page 1-4-12 See page 1-4-12 See page 1-4-12 See page 1-4-13 See page 1-4-13

1-4-9

Page 46

2LY/2LZ

(1) Completely blank printout.

Print example Causes Check procedures/corrective measures

Defective drum unit or developing

unit.

Defective transfer bias output or

developing bias output.

Poor contact of developing bias terminal (spring) and high voltage output

terminal B (J401, J402, J403) on the

high voltage PWB.

Poor contact of transfer bias terminal

(spring) and transfer bias terminal T

(J201, J202, J203) on the high voltage PWB.

Defective laser scanner unit. Replace the laser scanner unit (See page 1-5-30).

Defective control PWB. Replace the control PWB (See page 1-5-19).

(2) All-black printout.

Print example Causes Check procedures/corrective measures

Defective main charger unit. Open the top cover and check that the drum unit and develop-

Poor contact of main charger terminal

(spring) and main charger output terminal M on the high voltage PWB.

Defective main charging output. Replace the high voltage PWB (See page 1-5-25).

Broken main charger wire. Replace the main charger unit (See page 1-5-13).

Open the top cover and check that the drum unit and developing unit are correctly seated. Investigate that the terminals

between the main charger unit and the drum unit are not in

loose contact (See page 1-5-12 and 1-5-11).

Replace the high voltage PWB (See page 1-5-25).

Check the high voltage PWB visually and correct or replace if

necessary (See page 1-5-25).

ing unit are correctly seated (See page 1-5-12).

Investigate that the terminals between the main charger unit

and the drum unit are not in loose contact.

Check the high voltage PWB visually and correct or replace if

necessary (See page 1-5-25).

1-4-10

Defective control PWB. Replace the control PWB (See page 1-5-19).

Page 47

(3) Dropouts.

Print example Causes Check procedures/corrective measures

2LY/2LZ

ABC

123

(4) Black dots.

Defective developing roller (developing unit).

Defective drum unit. If the defects occur at regular intervals of 94 mm/3

Defective fuser unit (heat roller or

press roller).

Defective paper specifications. Paper with rugged surface or dump tends to cause dropouts.

Defective transfer roller installation. The transfer roller must be supported by the bushes at the

Defective transfer bias output. Replace the high voltage PWB or control PWB (See page 1-5-

If the defects occur at regular intervals of 62.8 mm/2

page 2-4-2), the problem may be the damaged developing

roller (in the developing unit). Replace the developing unit

(See page 1-5-11).

page 2-4-2), the problem may be the damaged drum (in the

drum unit). Replace the drum unit (See page 1-5-12).

If the defects occur at regular intervals of 73.162 mm/2

78.5 mm/3 1/16" (See page 2-4-2), the problem may be the

damaged heat roller or press roller (in the fuser unit). Replace

fuser unit (See page 1-5-16).

Replace paper with the one that satisfies the paper specifications.

both ends. Clean the bush to remove oil and debris. Replace

the transfer roller if necessary (See page 1-5-14).

25 or 1-5-19).

1/2" (See

11/ 16" (See

7/8", or

Print example Causes Check procedures/corrective measures

Defective drum unit or developing

ABC

unit.

123

(5) Black horizontal streaks.

Print example Causes Check procedures/corrective measures

Defective drum unit's ground. Check that the drum shaft and the grounding tab (printer) are

ABC

123

Defective drum unit. Replace the drum unit (See page 1-5-12).