Page 1

Duplexer

Duplexeinheit

Module recto-verso

Unità duplex

Duplexor

Instructions

Anleitung

Instructions

Istruzioni

Instrucciones

For the Kyocera Laser Printers

Für Kyocera Laserdrucker

Pour imprimantes laser Kyocera

Per le stampanti laser Kyocera

Para las impresoras láser Kyocera

Page 2

We shall have no liability or responsibility to customers or any other person or

entity with respect to any liability, loss or damage caused or alleged to be caused

directly or indirectly by equipment sold or furnished by us, including but not

limited to, any interruption of service, loss of business or anticipatory profits, or

consequential damages resulting from the use or operation of the equipment or

software.

Caution

English

NO LIABILITY IS ASSUMED FOR ANY DAMAGE CAUSED BY IMPROPER

INSTALLATION.

Notice

The information in this manual is subject to change without notification.

Additional pages may be inserted in future editions. The user is asked to excuse

any technical inaccuracies or typographical errors in the present edition.

No responsibility is assumed if accidents occur while the user is following the

instructions in this manual.

The contents of this manual are protected by copyright. No part of this manual may

be reproduced or copied by any means without the permission of the copyright

holder.

Regarding Tradenames:

PRESCRIBE is a registered trademark of Kyocera Corporation.

Deutsch

FrançaisItalianoEspañol

1

Page 3

According to Council Directive 89/336/EEC and 73/23/EEC

Manufacturer’s name: Kyocera Corporation, Printer Division

Manufacturer’s address: 2-14-9 Tamagawadai, Setagaya Ward, Tokyo 158-8610, Japan

declares that the product

Product name: Dupex Unit

Model number: DU-31 (as tested with Page Printer FS-7000+ and other enhancement

Conforms to the following product specifications.

EN 55 022:1994 Class B

EN 60 950:1992+A1+A2+A3+A4

The manufacturer and its merchandising companies retain the following technical documentation in

anticipation of the inspection that may be conducted by the authorities concerned.

optional units: PF-30, DF-31, UF-1, BC-1 and HD-2)

User’s instruction that conforms to the applicable specifications

Technical drawings

Descriptions of the procedures that guarantee the conformity

Other technical information

KYOCERA ELECTRONICS EUROPE GmbH

Tetsuo Okada, President

Revised Date:

Contact in Europe:

KYOCERA ELECTRONICS EUROPE GmbH

Mollsfeld 12

40670 Meerbusch, Germany

Phone: +49 21 59 918 0

Fax: +49 21 59 918 100

Declaration of Conformity

Manufacturer’s name: Kyocera Corporation, Printer Division

Manufacturer’s address: 2-14-9 Tamagawadai, Setagaya Ward, Tokyo 158-8610, Japan

declares that the product

Product name: Duplex Unit

Model number: DU-31 (as tested with FS-7000+ and enhancement option units: as PF-30,

Description of device: This Page Printer Model FS-7000+ is the 28ppm; A3 size and utilized plain

2

DF-31, UF-1, BC-1 and HD-2)

paper; laser; dry toner etc.. The printer can be equipped with several

enhancement optional units as a paper feeder as PF-30, a document finisher

DF-31, etc..

Page 4

Conforms to the following product specifications.

AS/NZS 3548:1995

(EN 55 022: 1994 Class B)

IEC60 950

(EN 60 950:1992+A1+A2+A3+A4)

The manufacturer and its merchandising companies retain the following technical documentation in

anticipation of the inspection that may be conducted by the authorities concerned.

User’s instruction that conforms to the applicable specifications

Technical drawings

Descriptions of the procedures that guarantee the conformity

Other technical information

David Finn

Managing Director

Date:

Unit 8, 43-45 Herbert Street,

Artarmon NSW 2064, Australia

Phone: +61 2-9-906-8075

Fax: +61 2-9-906-8153

English

Deutsch

FrançaisItalianoEspañol

3

Page 5

Warning

FCC Regulations state that any unauthorized changes or modifications to

this equipment not expressly approved by the manufacturer could void the

user’s authority to operate the equipment.

Note: The equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

The equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of the equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own expense.

Radio interference requirement in European countries

The optional universal feeder DU-31 is intended for use with the printer

models FS-7000, FS-7000+ and FS-9000 which are type tested and categorized as a Class B computing device in accordance with the EN55022 rules.

A device in the Class B category may cause interference to radio or television

reception, particularly in a residential installation.

4

Page 6

Information to users:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guaranteee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

❒ Reorient or relocate the receiving antenna.

❒ Increase the separation between the equipment and receiver.

❒ Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

❒ Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the manufacturer for compliance could void the user’s authority to operate the equipment.

Contents

Introduction .............................................................................................................6

Names of Parts.........................................................................................................6

Installing the Duplexer ............................................................................................7

Duplex Printing .......................................................................................................9

Clearing Paper Jams ..............................................................................................14

Paper Selection ......................................................................................................20

Specification ..........................................................................................................26

English

Deutsch

FrançaisItalianoEspañol

5

Page 7

Introduction

The DU-31 duplexer is an optional duplex printing unit for the Kyocera Page

Printers.

Before using the DU-31 duplexer, please read this manual, then carefully follow all

instructions given for installing and using the duplexer. Adhere to any cautions and

warnings indicated on the unit itself.

Retain this manual in an easily accessible place. You may need it for future

consultation if you later have questions about the operation or what to do in case of

troubles.

Packing List

DU-31 1

Instruction manual (this booklet) 1

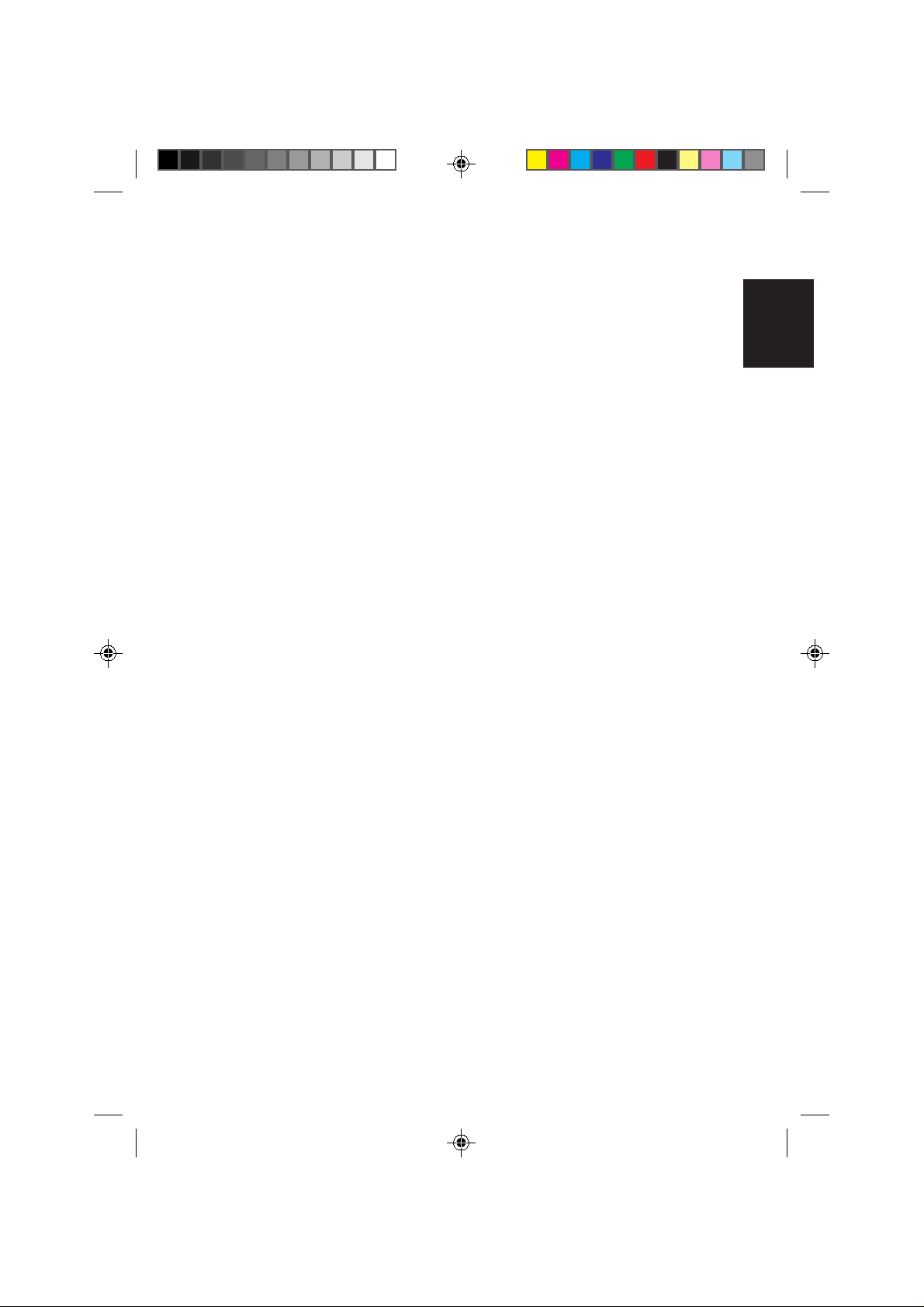

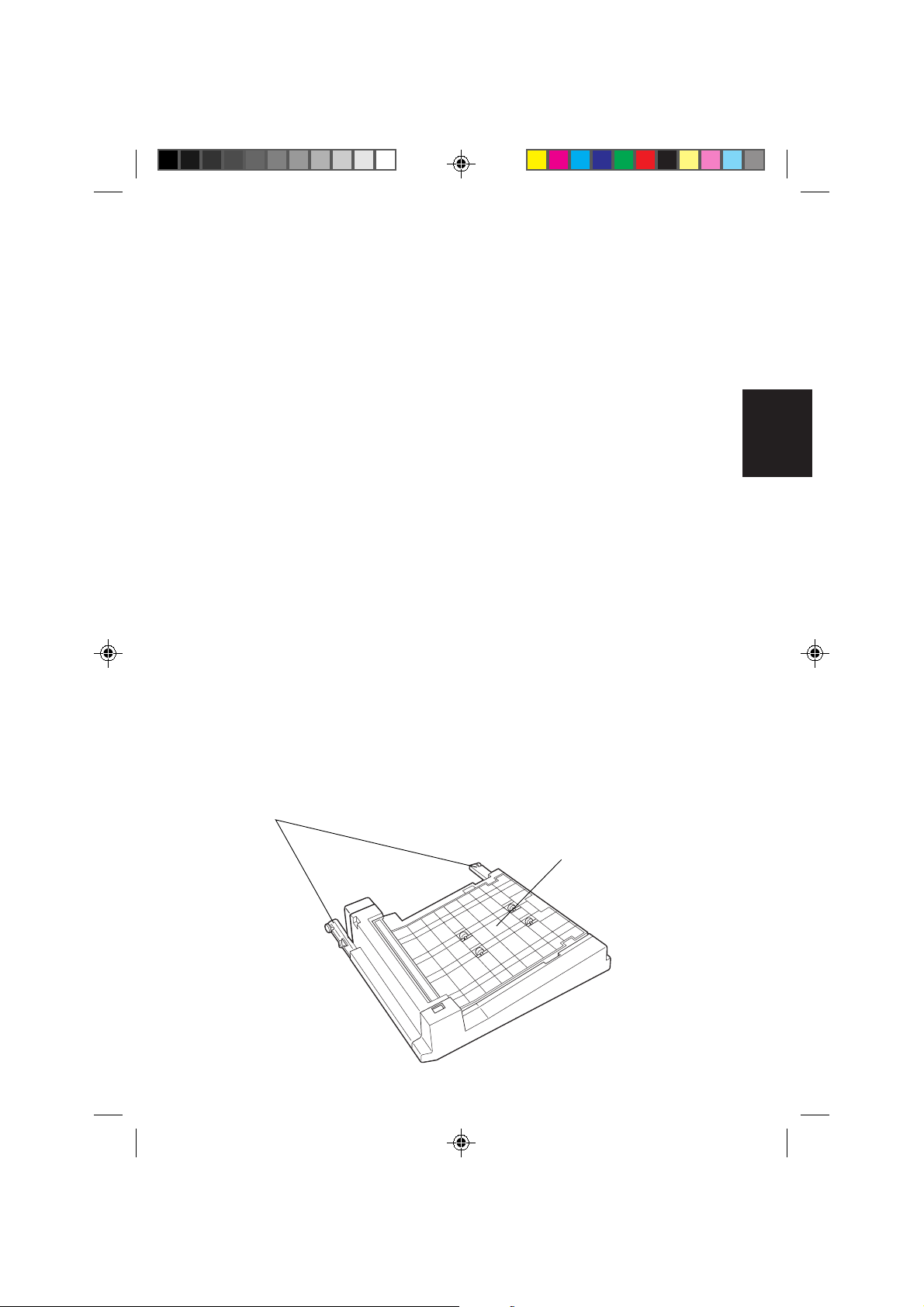

Names of Parts

Before installing the duplexer, please study the following part names. These names

are used in describing procedures for installing and using the duplexer.

Installation rails

6

Transparent plastic cover

(two covers)

Duplexer (DU-31)

Page 8

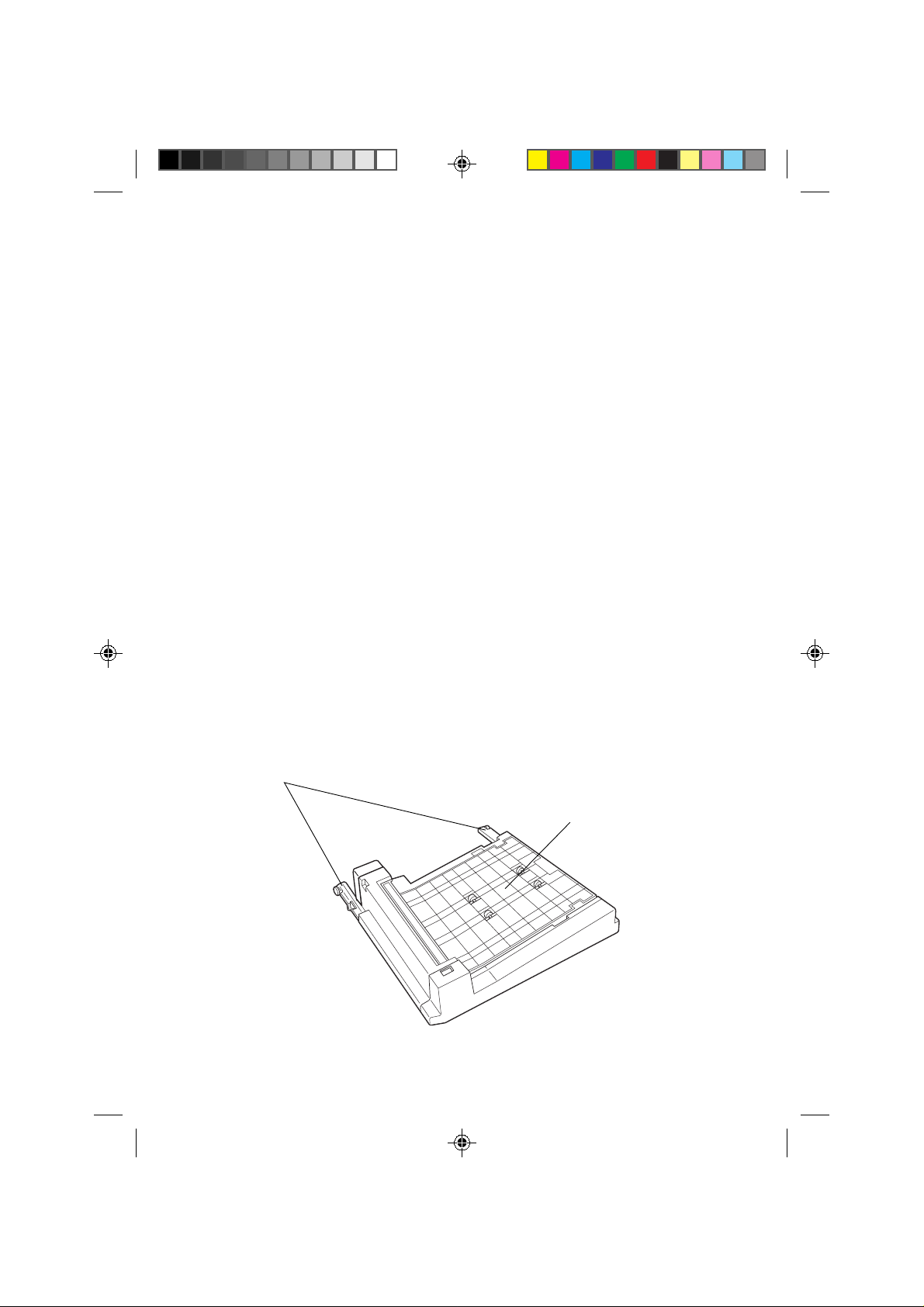

Installing the Duplexer

Open the front cover of the printer, and install the DU-31 in the vacant space below

the transfer unit.

CAUTION Before installing (or removing) the optional duplexer, be sure

to turn off the printer’s power and disconnect the power cord

plug from the AC outlet.

1. Open the printer’s front cover.

Front cover

Installation space for the

DU-31

2. After removing the duplexer from the packing materials, remove the

adhesive tape holding the cover in place.

English

Deutsch

FrançaisItalianoEspañol

Tape

Tape

7

Page 9

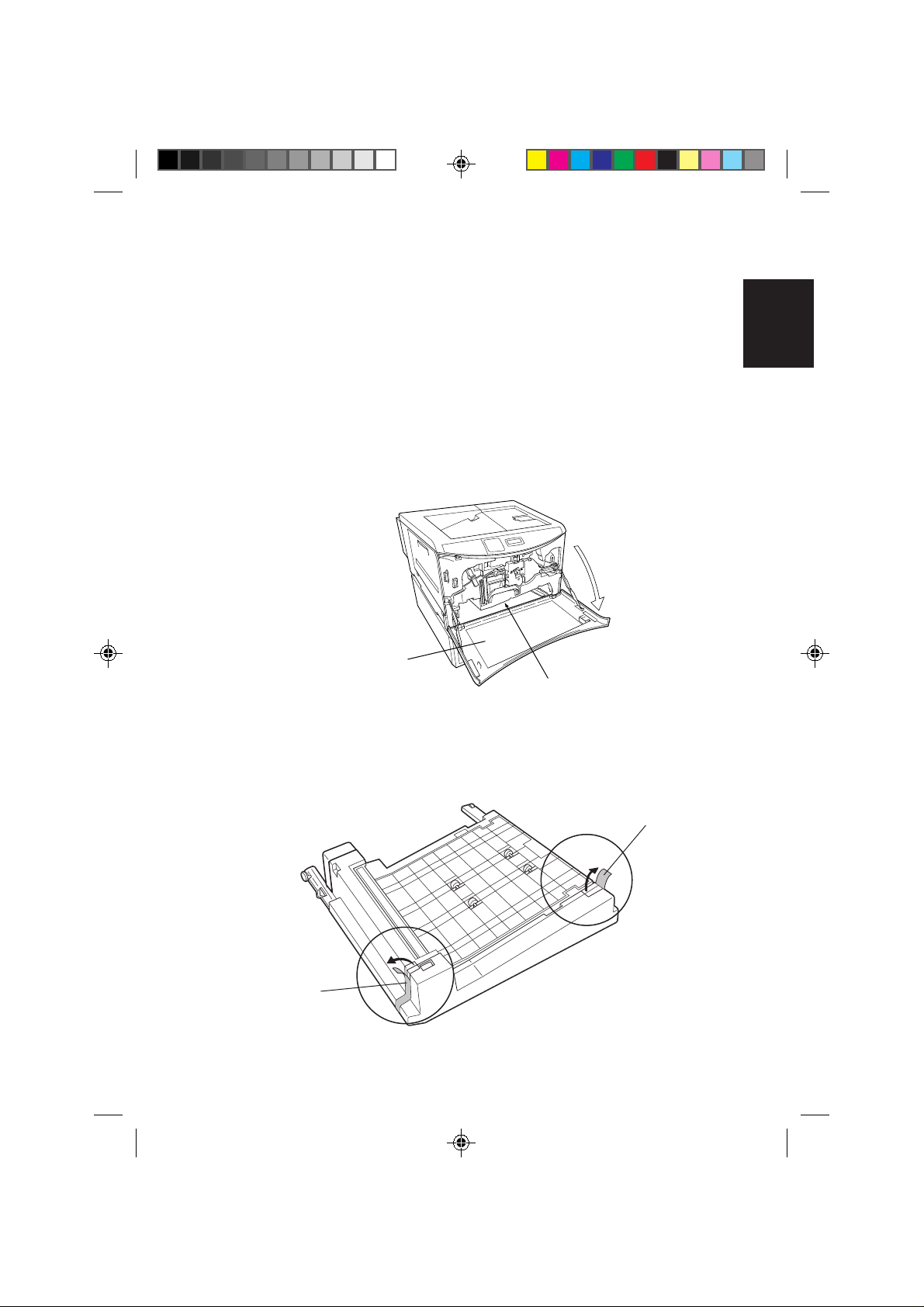

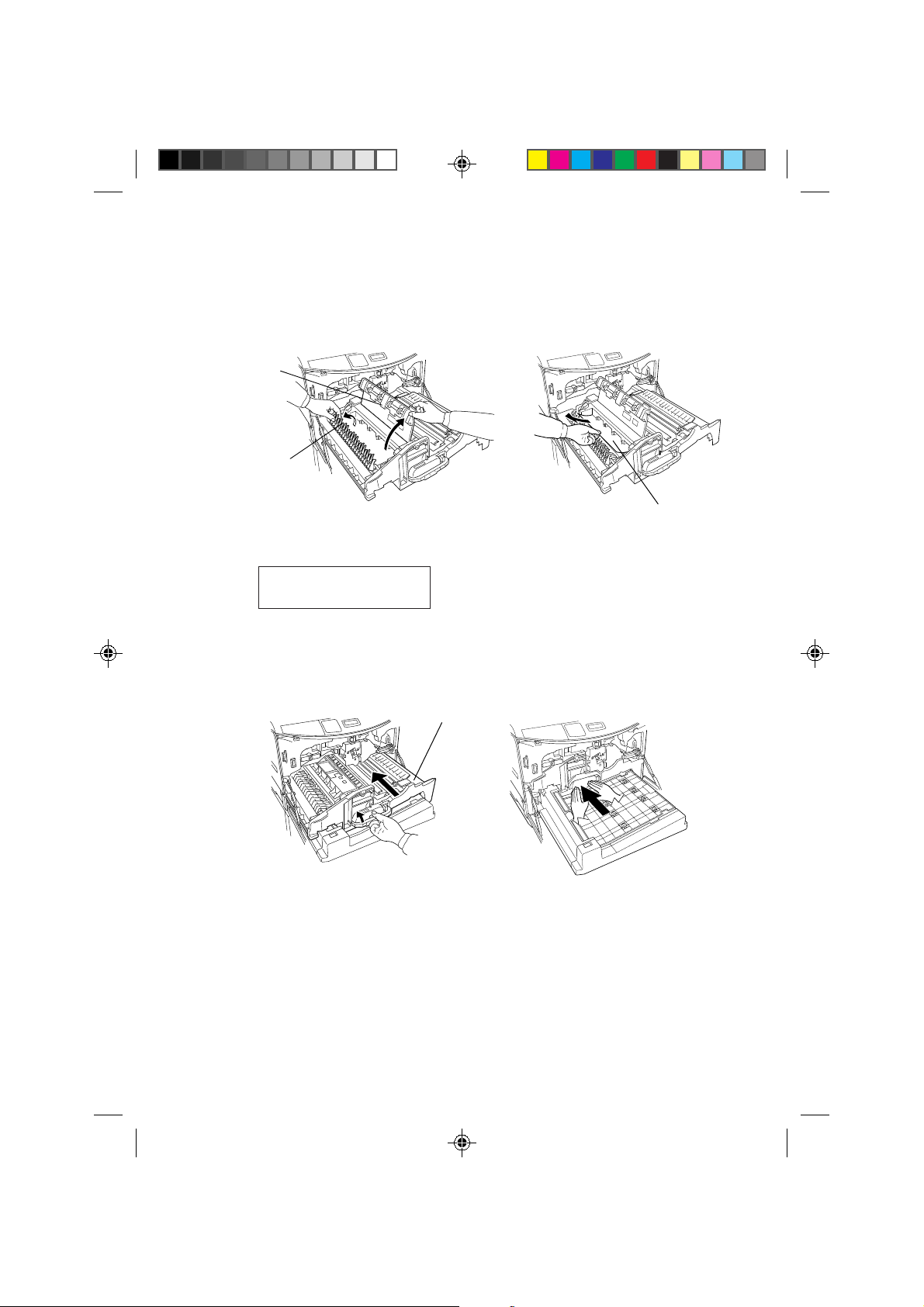

3. Remove the duplexer from the packing materials and install in the printer

as shown in the figure. Install so that the left and right rails are correctly

resting on the rails of the printer.

Rail

4. Push the DU-31 all the way into the printer.

Rail

5. Close the printer’s front cover. This completes installation of the duplexer.

8

Page 10

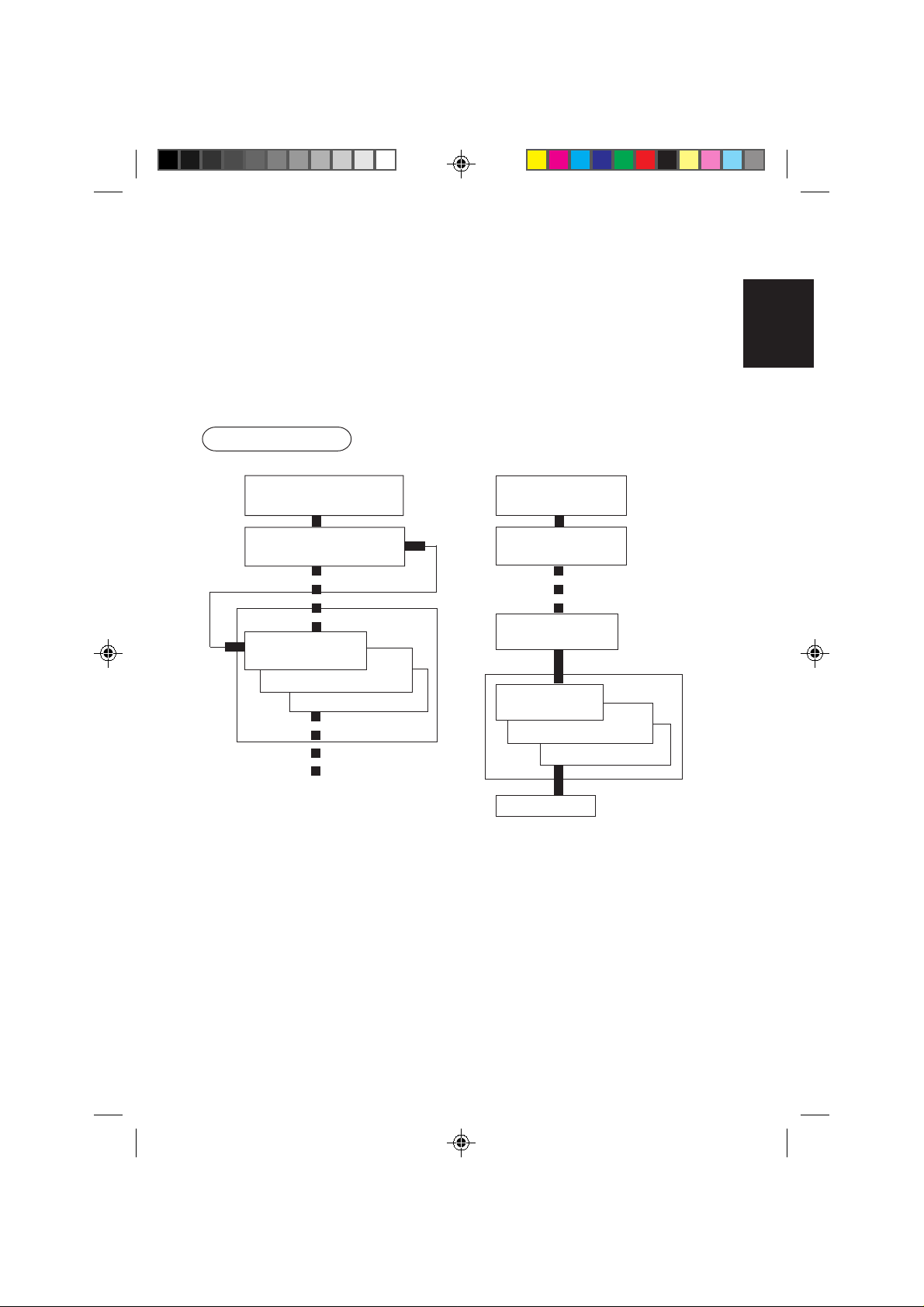

Duplex Printing

After the duplexer is installed, the duplex printing menu is added to the printer’s

mode selection menu as shown below (added menu enclosed in frame), and it is

used to switch the duplex printing mode on/off and to set the orientation for duplex

printing.

Mode selection menu

(FS-7000 only)

Ready

PAR 600 A4 001

Paper handling >

Duplex mode

None

Short edge bind

Long edge bind

Ready

PAR 600 A4 001

Interface >

Parallel

Paper type

Normal

Duplex mode

None

Short edge bind

Long edge bind

English

Deutsch

FrançaisItalianoEspañol

Others >

The duplex printing mode is explained on the following pages.

9

Page 11

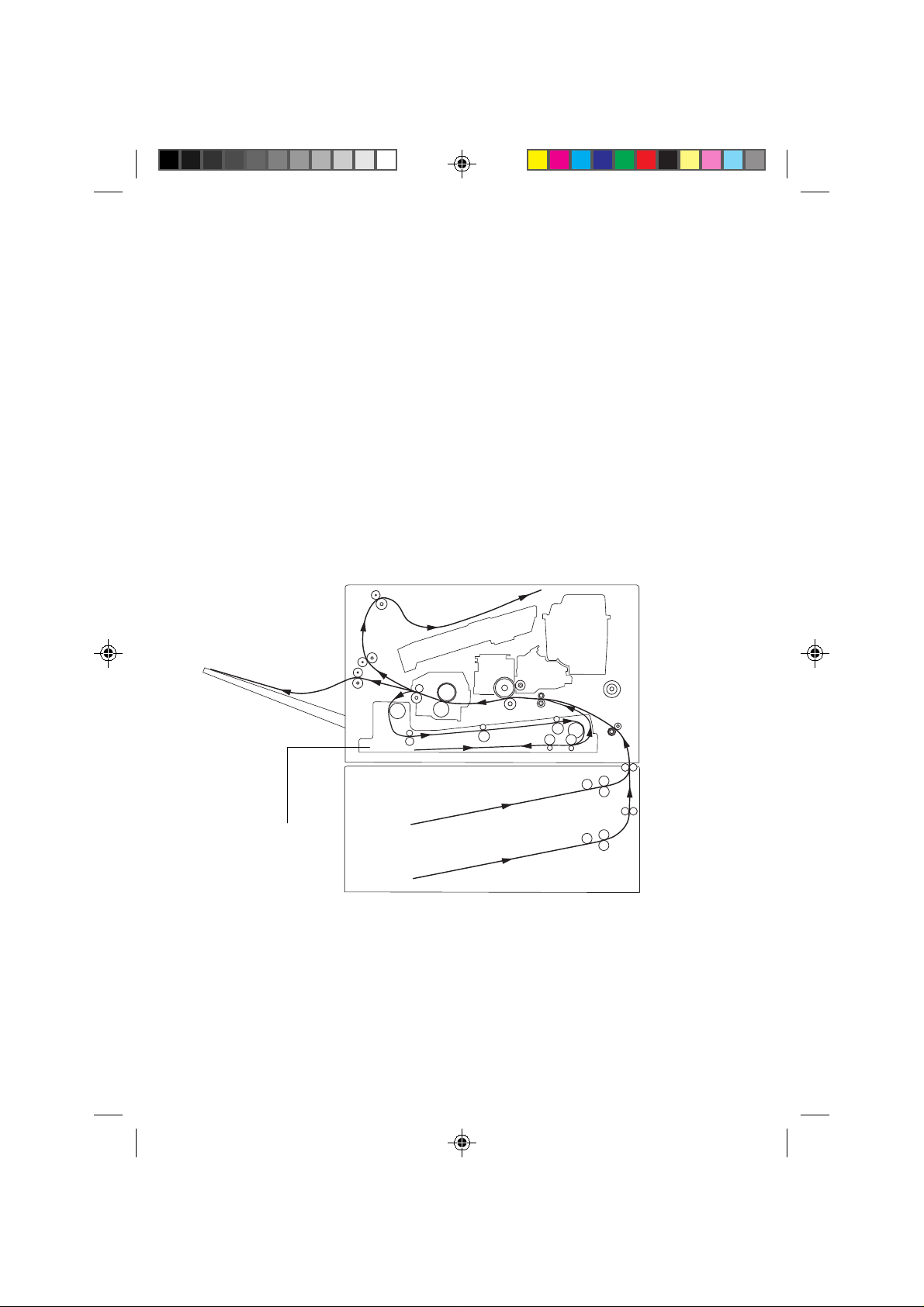

Duplex Printing Mode

The printing operation flow in duplex printing mode is as follows. Initially, the first

sheet is fed and page 2 of the document is printed on one side of the sheet. The first

printed sheet is temporarily transferred to the duplexer. Then the printer feeds the

second sheet on which page 4 is printed on one side. After page 4 has printed, the

first sheet held in the duplexer is again sent to the printer’s transfer unit for printing

of page 1. This completes printing of the first sheet and this is output. Following

this and while the second sheet, on which page 4 has been printed on one side, is

retained on standby in the duplexer, the printer feeds the third sheet and prints page

6 on this sheet. The operation is now repeated as described above to perform the

duplex printing.

Duplex Printing Flow

Printer

Duplexer (DU-31)

10

Paper feeder

(PF-30)

Page 12

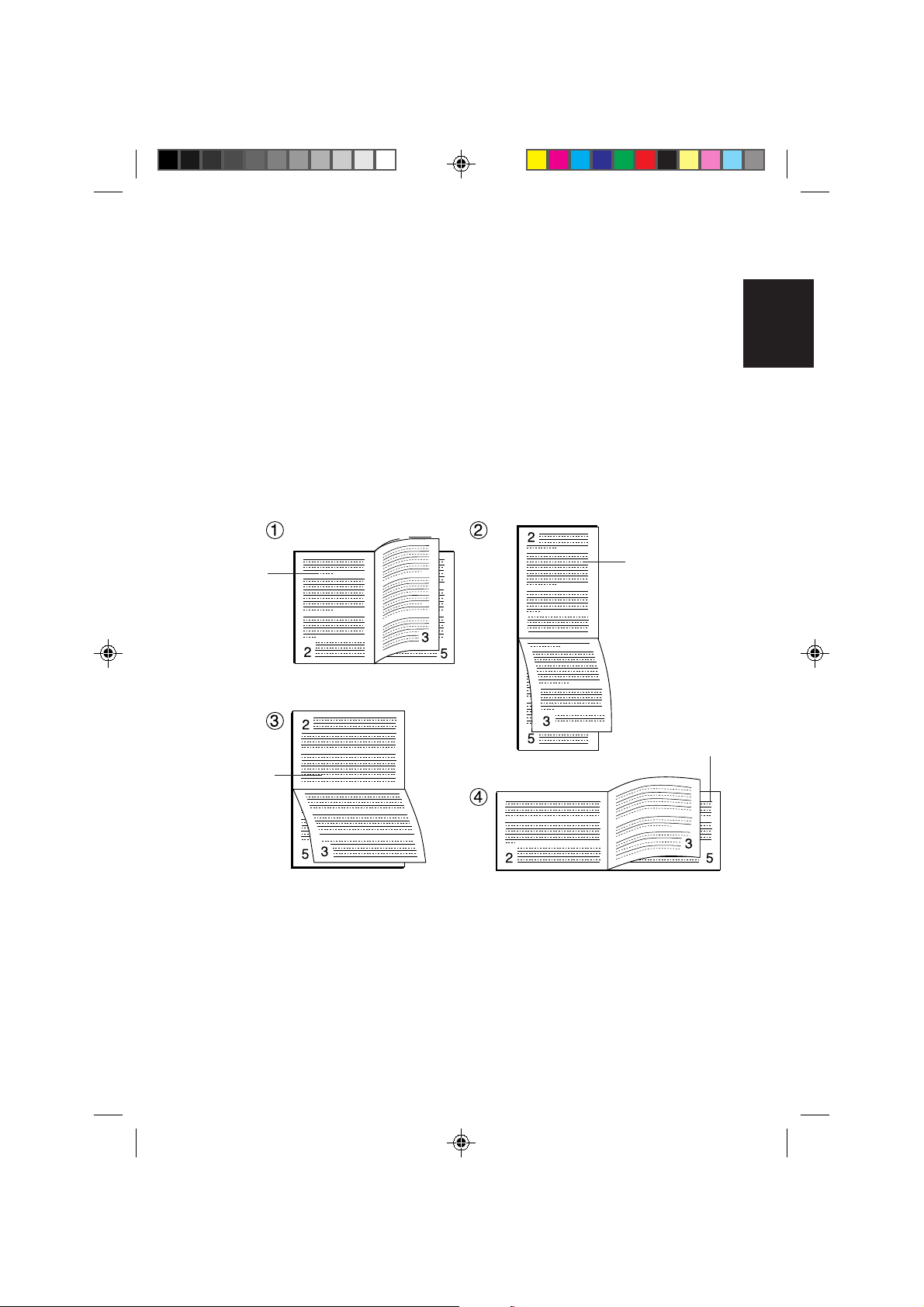

Setting the Binding Mode

To bind printed sheets like a book is called “binding.” There are two forms of

binding; “long edge” which is binding on the long side of the page, and “short

edge” which is binding on the short side of the page. You can select both portrait

and landscape printing for both long edge and short edge binding.

Binding type and printing direction can be set using the following four binding

modes. These are 1 Portrait / Long edge, 2 Portrait / Short edge, 3 Landscape /

Long edge, 4 Landscape / Short edge. (See the figures below.)

Binding mode

English

Deutsch

Portrait /

Long edge

Landscape /

Long edge

Portrait /

Short edge

Landscape /

Short edge

In the portrait/long edge and landscape/short edge modes (1, 4), both sides of the

page are printed in the up to down direction.

In the portrait/short edge mode and landscape/long edge mode (2, 3), the front

side of the page and the rear side of the page are printed in reverse up/down

directions.

FrançaisItalianoEspañol

11

Page 13

Duplex Printing Mode Settings

Settings for the duplex printing mode are made on the printer’s control panel.

Settings on the Printer’s Control Panel

Make the settings for duplex printing and binding on the printer’s control panel

using the following procedure.

1. Confirm that Ready is indicated on the printer’s message display and

that the on-line indicator is lit.

2. Press the printer’s MODE key.

3. Display “paper handling >”, press the key, and press the + or –

key to display “ > Duplex mode”. The second line indicates the

current mode. (In the initial state, None is shown.) In the case of an FS7000, using the + or – key, display Duplex mode on the message

display.

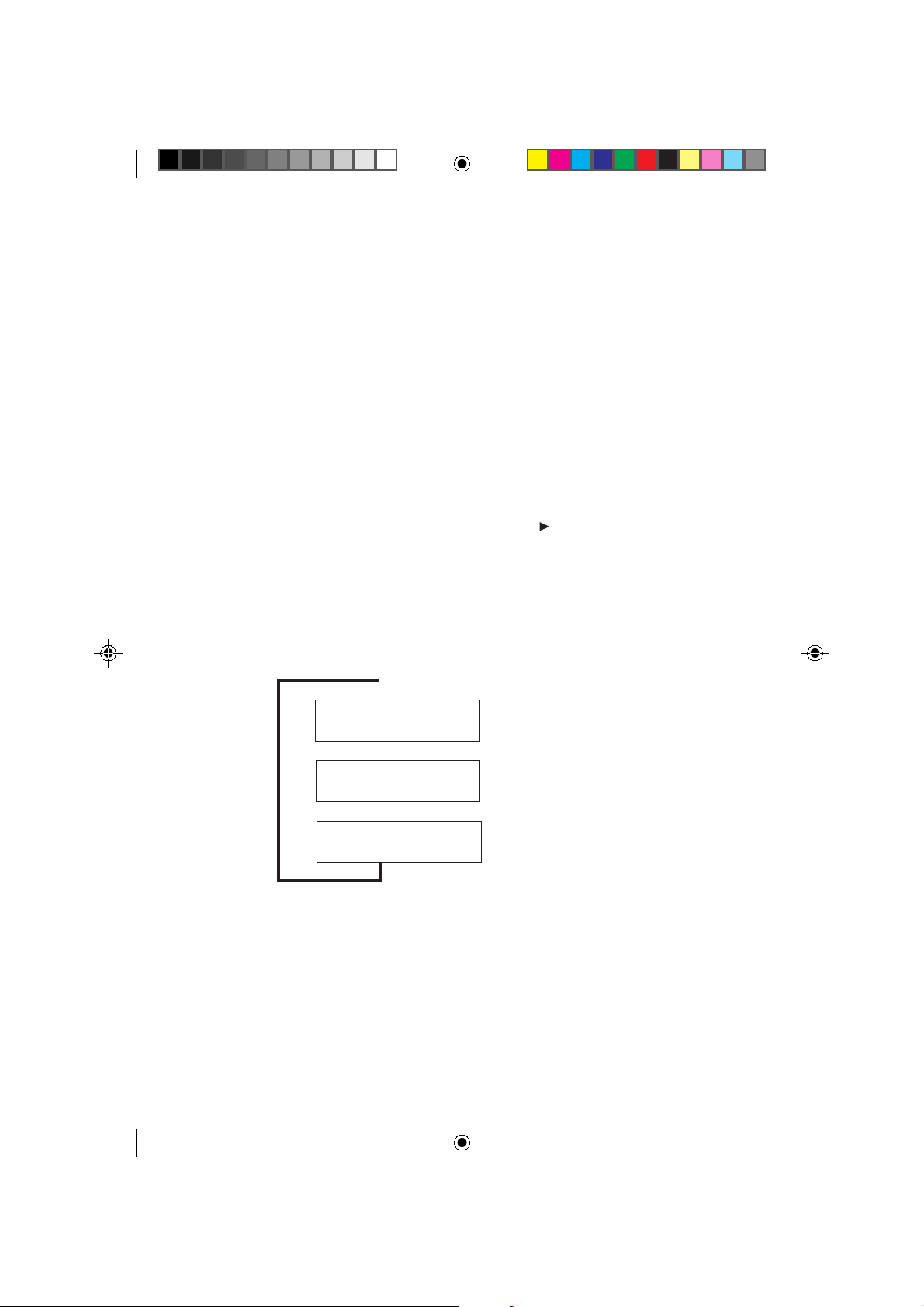

4. When the ENTER key is pressed, the ? mark flashes and the display can

be changed by pressing the + or – key as shown in the following diagram.

➔

Duplex mode

?None

Duplex mode

?Short edge bind

➔➔

Duplex mode

?Long edge bind

To abandon the setting, press the CANCEL key.

5. Select the desired binding mode and press the ENTER key.

6. When the MODE key is pressed, the message display indication returns to

Ready.

The same setting can also be performed by accessing the printer driver from the

printer setting menu of your appplication software.

12

Duplex printing is not performed.

(Initial setting)

Short edge binding

Long edge binding

Page 14

Duplex printing from the Multi-Purpose Tray

In first mode, be sure to set the MP tray to the same paper size, paper type and feed

direction as set for the current cassette. If the paper size, type or feed direction

differs, a paper jam may result. Also note that it is not possible to select the multipurpose tray as the current cassette and perform duplex printing. We therefore

recommended that duplex printing be performed from the paper cassette.

Note In the case of an FS-7000, duplex printing is not possible from the

printer’s MP (multi-purpose) tray, the optional envelope feeder (EF-

1), or optional universal feeder (UF-1). If duplex printing is attempted from these paper sources, the mode is automatically

canceled and the printed paper is output from the face-up tray.

When the duplex printing mode is set to off, paper can also be

output from the face-down tray. However, when feeding paper from

the envelope feeder, output is through the face-up tray.

English

Deutsch

FrançaisItalianoEspañol

13

Page 15

Clearing Paper Jams

Error messages and remedial actions when paper jamming has occurred during

duplex printing are explained in the following section.

WARNING Take care not to leave any small pieces of paper in the printer

when removing paper jams. This could result in fire.

This section describes how to remove paper when it jams in the printer. The printer

will stop whenever paper jams in the printer or paper is not fed from a cassette. The

printer will go offline and the message Paper jam Open front cover

will appear on the message display.

Paper jam

Open front cover

Opening the printer’s front cover will cause the message display to change. It will

now indicate the coded location (A through I and 1 through 6) of the paper jam.

Example

Paper jam

C, H, I, 3

In this example, paper is jammed in the paper feeder (C), paper feed unit (H),

duplexer (I), and in the upper cassette of the optional paper feeder (3). The

corrective action to take in cases like this is explained using actual examples

beginning from page 17.

The meanings of symbols appearing on the message display and the corresponding

locations of paper jams are given in the table on the next page. Be sure to correct

paper jams according to the procedure given on the following pages.

14

Page 16

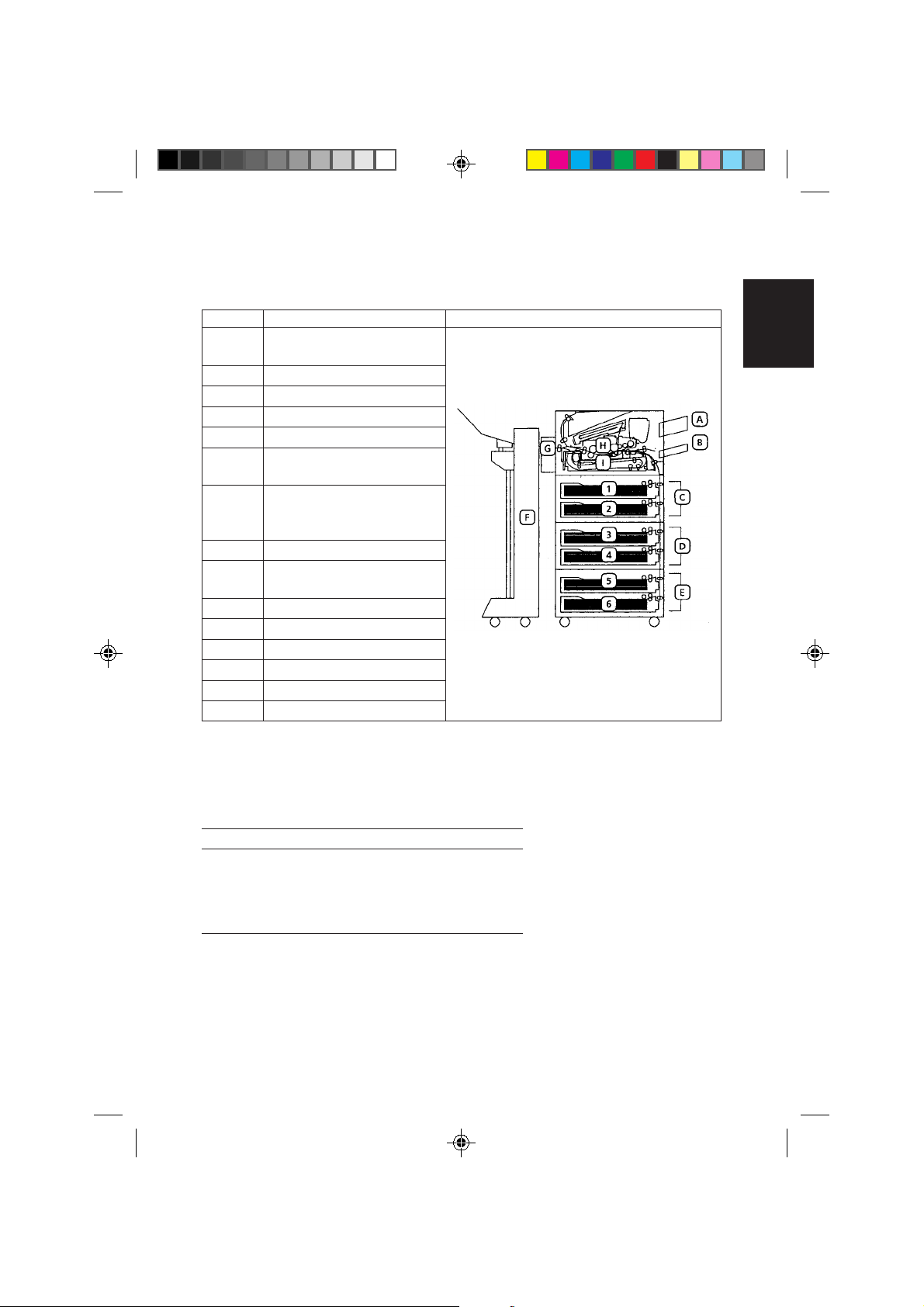

Message Display Indicator and Paper Jam Location

Indicator Meaning of Indicator Corresponding Printer Location

Optional paper feeder

A

(EF-1 or UF-1)

MP (multi-purpose) tray

B

Paper feeder included with printer

C

Optional paper feeder (PF-30)

D

Optional paper feeder (PF-30)

E

Optional unit

F

(DF-30/DF-31, SO-30 or ST-30)

Face-up output tray

/face-down output tray

G

(connection with optional unit)

Paper feed unit

H

Optional duplexer

I

(DU-31 [this unit])

Cassette 1

1

Cassette 2

2

Cassette 3

3

Cassette 4

4

Cassette 5

5

Cassette 6

6

A label titled “Paper Jam Location Indicators” is also

attached to the back of the front cover.

English

Deutsch

FrançaisItalianoEspañol

When a paper jams, the indicator on the printer’s control panel also flashes to

indicate the location of the jam. When a paper jam occurs in a paper feeder, the

LED at the front of this paper feed cassette also flashes. The meanings of the

flashing modes can be seen in following table.

LED status Meaning

Fast flashing Paper is jammed in this cassette.

Slow flashing No paper in this cassette.

Lit Currently selected cassette

Off • Cassette improperly inserted.

• Cassette is not currently selected.

In case of a paper jam, after checking the location of the paper jam using the above

table, take corrective action according to the table on the next page. After removing

all jammed paper, the printer will automatically resume printing.

15

Page 17

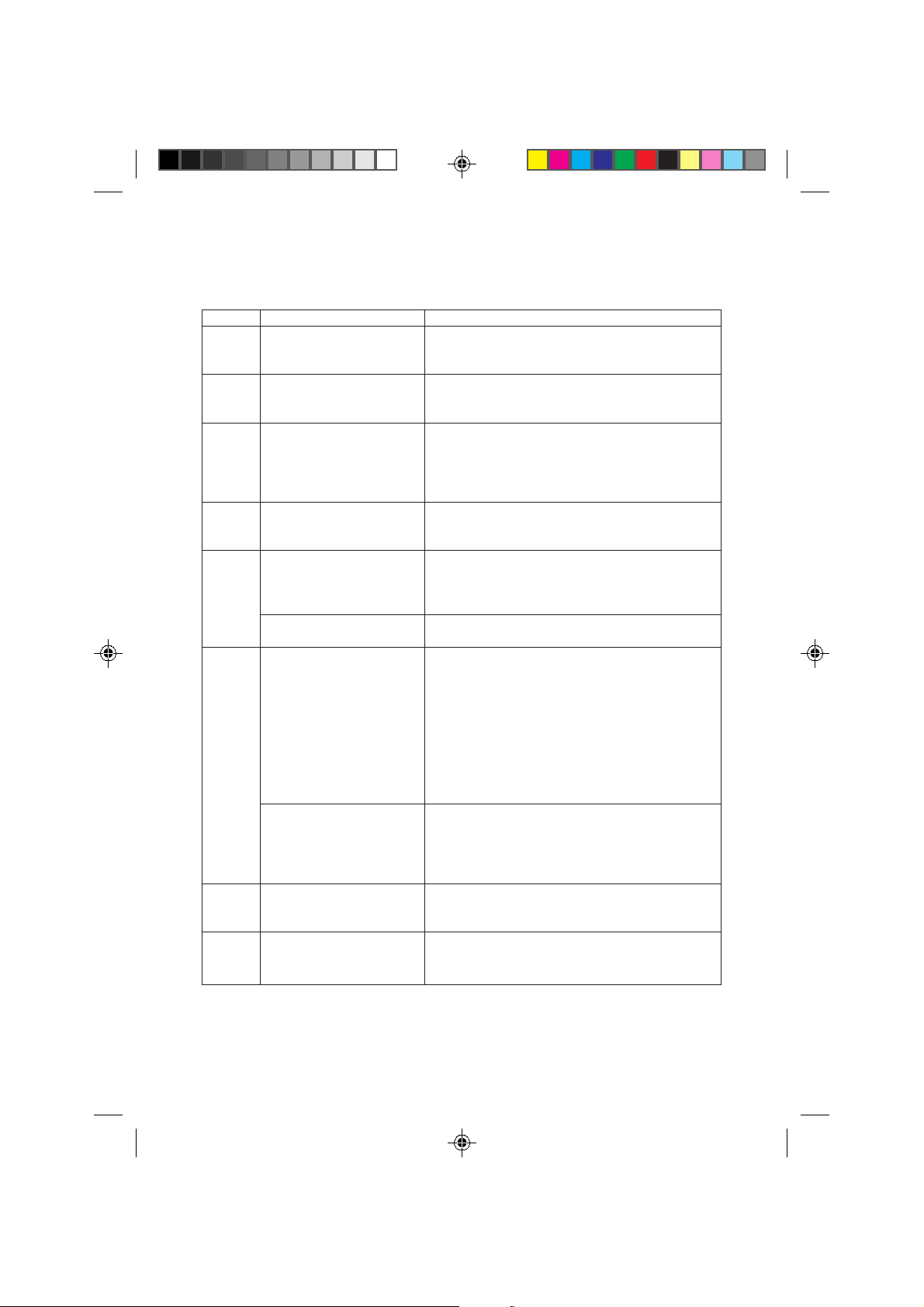

Corrective Action for Paper Jam

Indicator

A

B

C

D

E

F

G

H

I

1 to 6

Meaning of Indicator

Check the optional paper

feeder (EF-1 or UF-1). (Only

when installed)

Check the printer’s MP

(multi-purpose) tray.

Check the paper feeder

(main unit).

(D and E are only displayed

when an optional PF-30 is

installed.)

Check the optional unit

(DF-30/DF-31/SO-30/ST-

30). (Only when installed)

Check the printer’s face-up

output tray.

(connection with optional

unit)

Check the printer’s facedown output tray.

Check the printer’s paper

feed unit.

Check the printer’s fuser

unit.

Check the optional duplexer

(DU-31 [this unit]).

Check the paper feed

cassette indicated.

Corrective Action

A paper jam has occurred in the optional feeder.

Carefully pull out the jammed paper. (For details, read

the EF-1/UF-1 instruction manual.)

A paper jam has occurred in the MP (multi-purpose)

tray. Carefully pull out the jammed paper. Then open

and close the front cover of the printer once.

Open the side cover of the paper feeder indicated and

remove the jammed paper. (Refer to the example on the

next page.)

Remove the paper jammed in the paper stacker. (For

details, read the DF-30/DF-31/SO-30/ST-30 instruction

manual.)

Paper is jammed before being completely output. Open

the side cover of the printer and carefully remove the

jammed sheet. (For details, read the printer’s instruction

manual.)

If printing stops before a sheet is completely output,

carefully remove that sheet.

Open the front cover and carefully pull out the paper

feed unit as far as it will go. If paper is jammed in the

registration rollers, remove it by pulling out in the

direction where this is most easily accomplished. (For

details, read the printer’s instruction manual.)

If paper is jammed in the fuser unit, remove the paper in

the same manner. (For details, read the printer’s

instruction manual.)

After all paper has been completely removed, return the

paper feed unit to its original folded down position.

Open the front cover and carefully pull out the paper

feed unit as far as it will go. Open the fuser unit cover

(hold the [green] knob), and check the interior of the

fuser unit. Paper may remain trapped inside the fuser

unit.

Open the front cover, pull out the duplexer and remove

the jammed paper. (For details, read the following

pages.)

Pull out the paper feed cassette indicated and remove the

jammed paper. After all paper has been completely

removed, open and close the front cover once.

16

Page 18

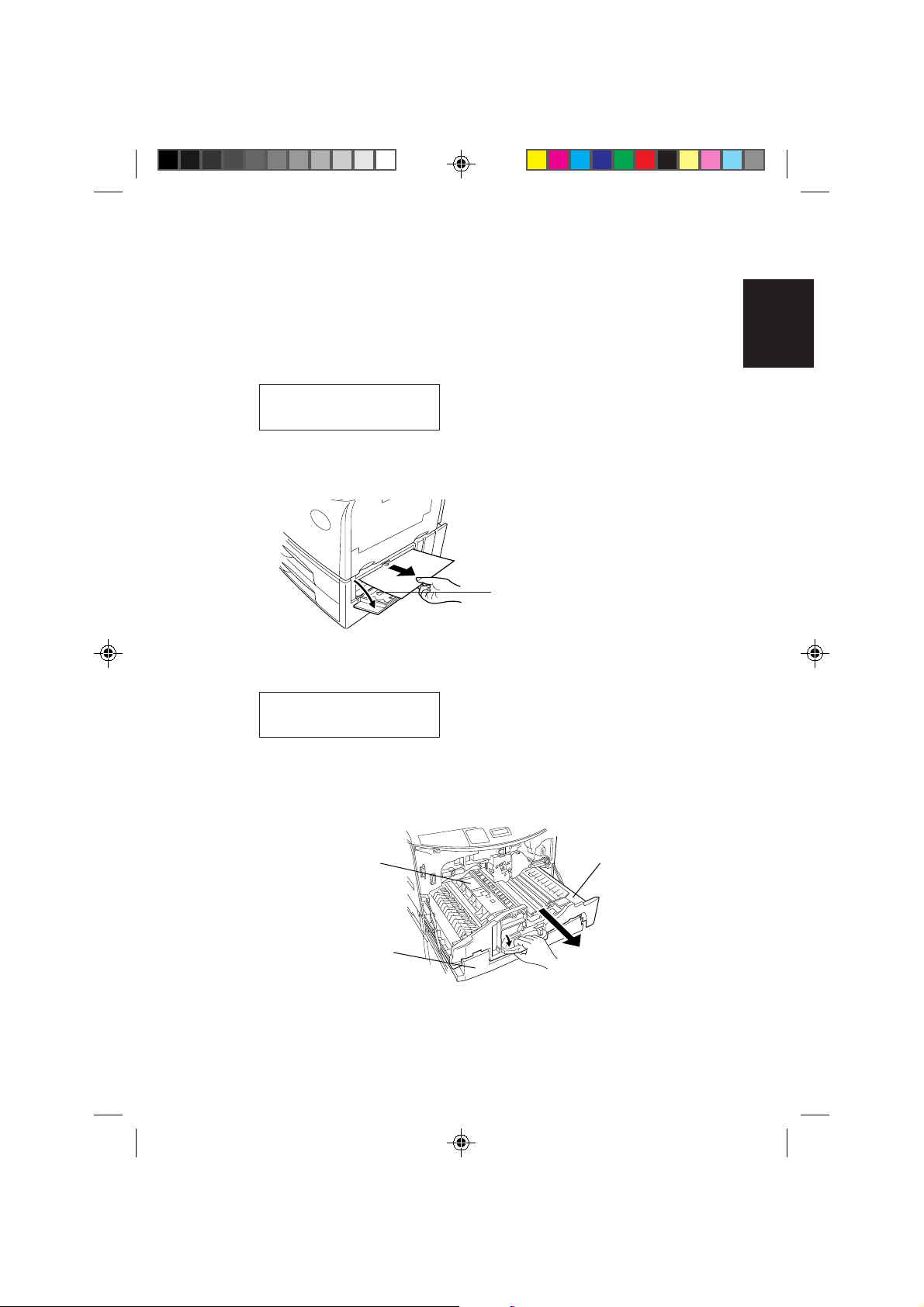

Example

In the example given on page 14, paper is jammed in the paper feeder (C), the

paper feed unit (H), the duplexer (I), and upper cassette of the optional paper

feeder (3).

Paper jam

C, H, I, 3

English

1. When paper jams in multiple locations such as in this example, begin

taking corrective action from the location displayed at the left.

Side cover of the paper feeder

After the paper jam in the paper feeder (C) has been corrected, the display

will change as follows:

Paper jam

H, I, 3

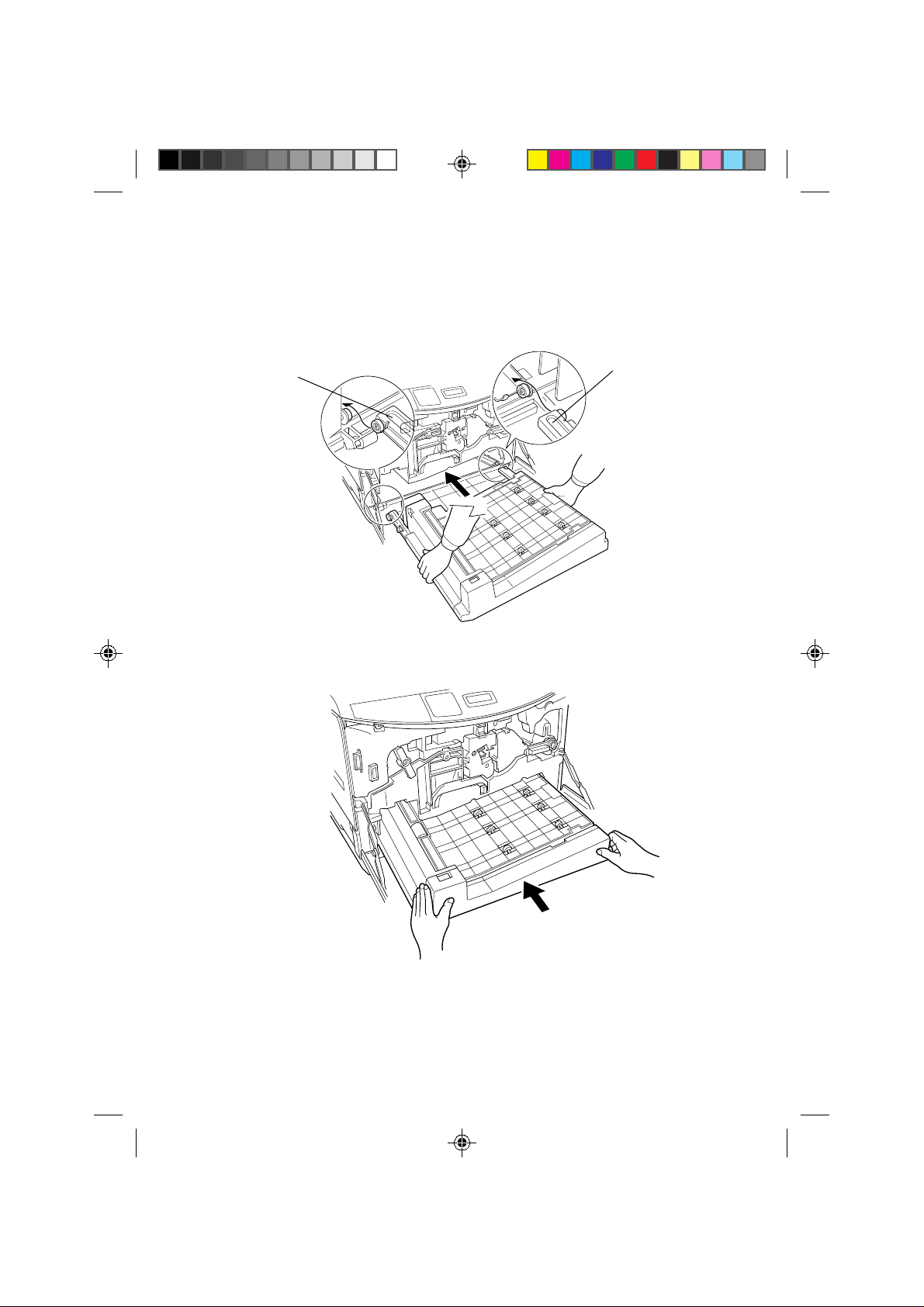

2. Next, open the printer’s front cover and turn the lock lever counter

clockwise (except for the FS-7000). And then carefully pull the transfer

unit out as far as it will go. (At this point, the duplexer is simultaneously

pulled out.)

Fuser unit

Transfer unit

Deutsch

FrançaisItalianoEspañol

Duplexer

CAUTION For a while after the transfer unit is pulled out, the fuser unit

inside will be hot. Do not touch with bare hands as burns

could result.

17

Page 19

3. Check the guide changer on the left side of the fuser unit. Should paper be

jammed underneath, raise the guide changer and the fuser unit cover

(hold the [green] knob). Remove paper as shown in the following figure.

Fuser unit

cover

Guide changer

➞

Jammed paper

After remedying, the message display indication changes to the following:

Paper jam

I, 3

4. After confirming that paper is not jammed in the transfer unit, return the

transfer unit alone into the printer.

Transfer unit

➞

5. Turn the lock lever clockwise to securely lock the transfer unit.

18

Page 20

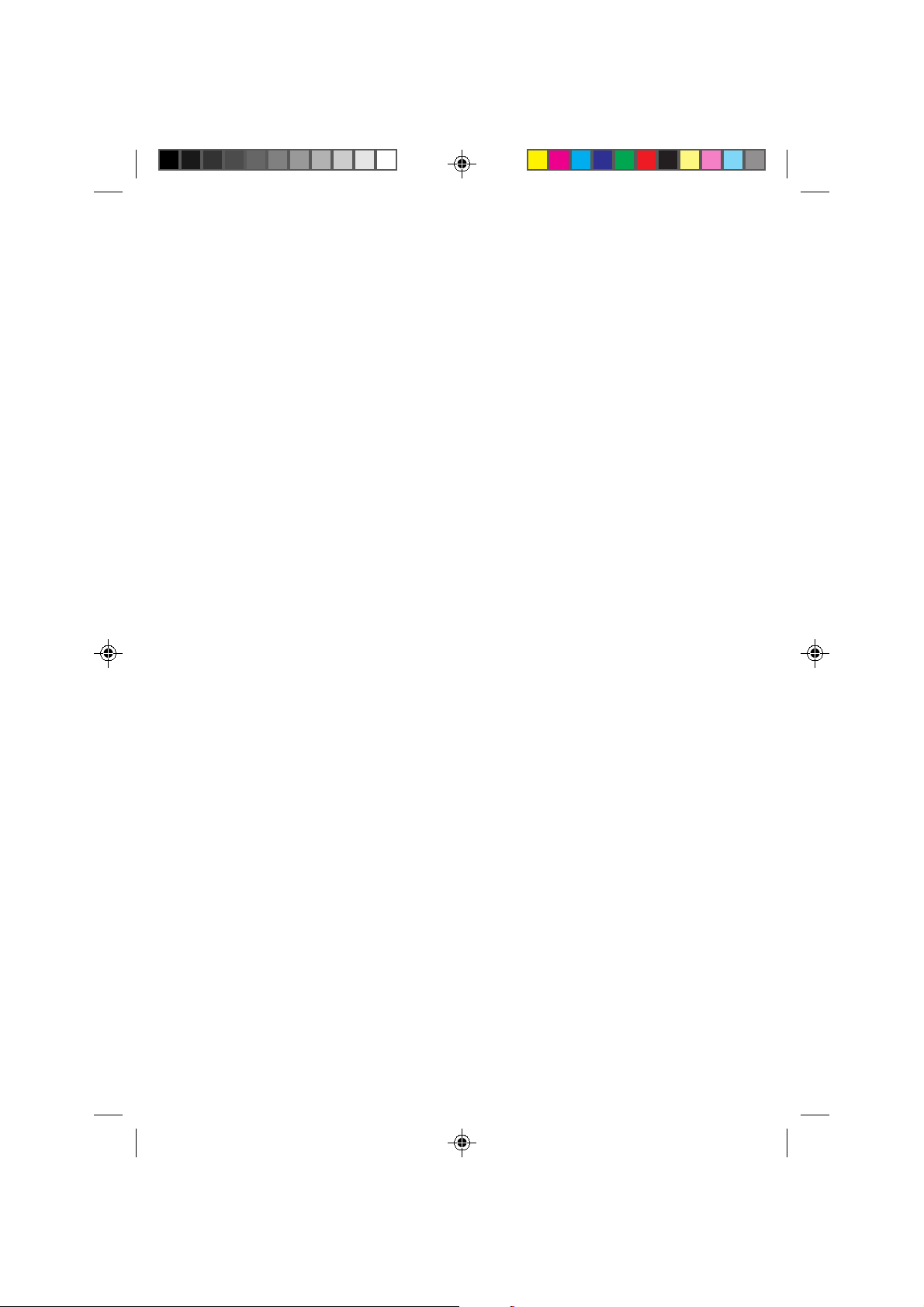

6. Open the two transparent plastic covers at the top of the duplexer.

Remove any jammed paper from the inside as shown in the following

figure.

Open the first cover and

remove paper.

Transparent

plastic cover

Open the second cover

and remove paper.

English

Deutsch

Transparent

plastic cover

7. Following removal of the paper, return the transparent plastic covers to

their original positions and reinsert the duplexer into the printer. The

message display indication changes to Front cover Open.

8. Close the printer’s front cover. This completes the actions for clearing

paper jamming.

Notes • Sometimes the page on which the paper jam occurred will not be

re-printed depending on the location of the paper jam.

• Note that your hands may become dirty from unfused toner when

removing paper jams.

Frequent occurrence of paper jams may indicate you are using a paper specification

which does not suit the printer. If this appears to be the case, please change to a

different type of paper.

If you have tried changing paper types and paper jams still occur frequently, there

may be a problem with the printer. In this case, please contact your Kyocera

dealer.

FrançaisItalianoEspañol

19

Page 21

Paper Selection

Although the page printer is designed for printing on standard dry PPC photocopier

copy paper (standard paper), it can print on various types of paper that conform to

the specifications given in this chapter. For details on paper which can be used,

also refer to the printer’s User’s Manual.

Select paper carefully as using paper inappropriate for the printer may result in

paper jams or wrinkling of output paper. Low-quality paper may reduce printing

quality, not only wasting paper but possibly leading to damage to the printer. It is

possible to achieve efficient printing with few problems and minimize the risk of

printer damage or wear by following the precautions listed below.

Usable Paper

Be sure to use copy paper (standard paper) used in standard dry PPC photocopiers.

Note Some recylced paper does not meet the necessary specifications

(Table 1) for use in this printer due to conditions such as stored

water and pulp content. Before purchasing recycled paper, test a

sample on the printer and check that printing quality is satisfactory.

Be sure to select a brand of recycled paper which offers good

printing quality and does not contain excessive paper dust.

There are differences in grade between each paper manufacturer, and these

differences can affect printer operations. Satisfactory printing results cannot be

obtained through the use of poor-quality paper. Even inexpensive paper may turn

out to be uneconomical from a results standpoint if its quality is inappropriate for

the printer.

20

Page 22

Basic Paper Specifications

The following table summarizes the basic paper specifications.

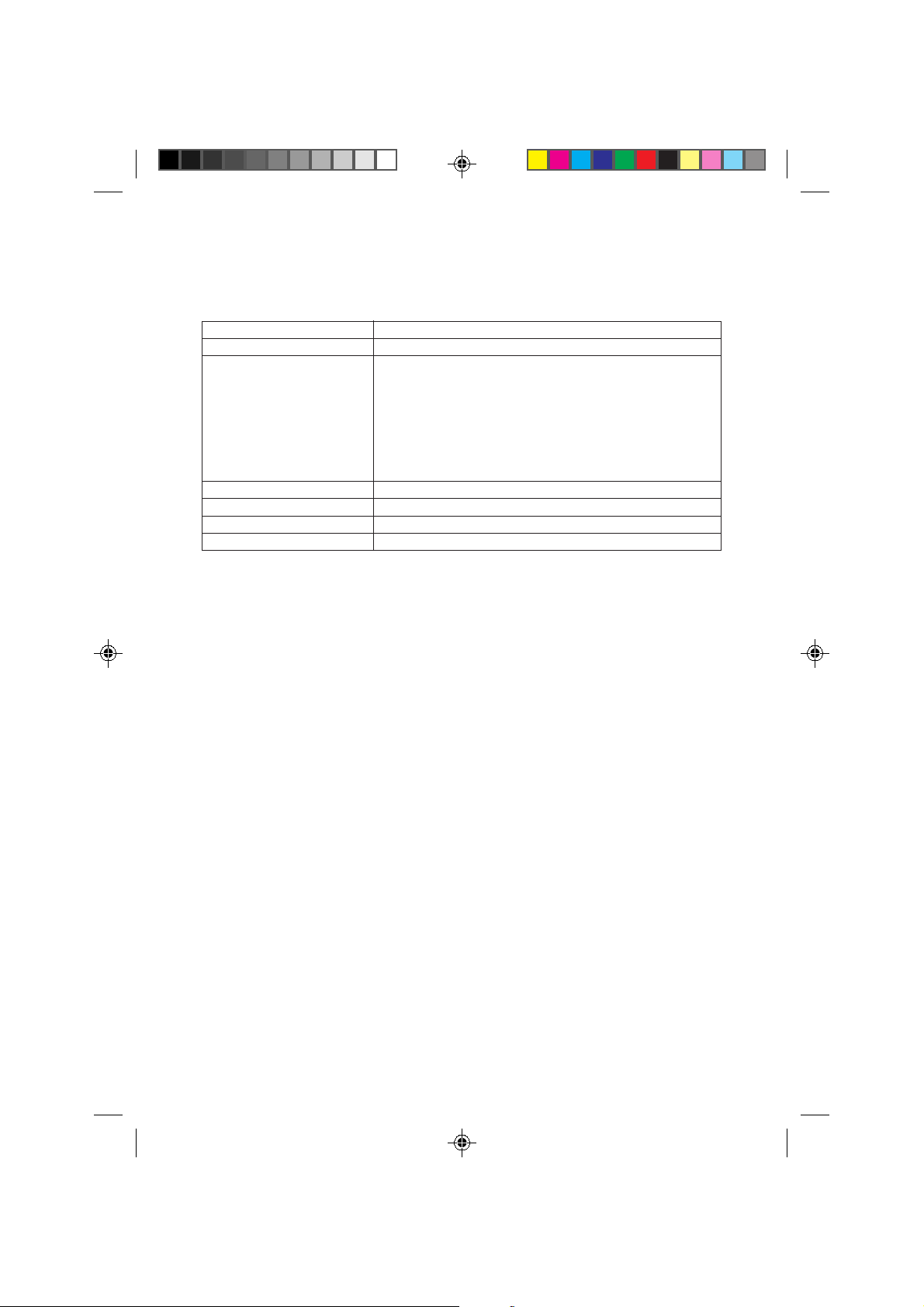

Table 1. Basic Paper Specifications

English

Item Specification

Weight 60 to 90 g/m

Thickness 0.086 to 0.110 mm

Dimensional accuracy ±0.7 mm

Squareness of corners 90° ±0.2°

Moisture content 4% to 6%

Pulp content 80% or more

2

Note When performing duplex printing on paper larger than A4, espe-

cially with thin paper weighing less than 65 g/m2, the edges may

become slightly dirty. Use standard paper weighing more than

70 g/m2.

Kyocera bears absolutely no responsibility for accidents resulting

from the use of inappropriate paper which does not meet the

specifications listed above. Consult with your Kyocera dealer before

purchasing any specially treated paper or special application paper.

Selecting the Right Paper

High quality printing is possible when using paper that conforms to the conditions

in Table 1. Points that must be taken into consideration when selecting paper for

duplex printing are discussed below.

Deutsch

FrançaisItalianoEspañol

Condition of the Paper

Avoid using paper that is folded at the corners, curled, dirty, torn, has rough edges,

fuzzy fibers, a rough surface or is easily torn.

Use of paper in these conditions can lead to illegible printing, misfeeding, and

paper jams, and can shorten the life of the printer. Select paper which has as

smooth and even a surface as possible. Note that the use of paper with a surface

coating or other surface treatement may damage the drum or fuser unit.

21

Page 23

Composition

Do not use paper that has been coated or surface-treated and contains plastic or

carbon. The heat of fusing can cause such paper to give off harmful fumes, and

may damage the drum.

Bond paper should contain at least 80% pulp. Not more than 20% of the total paper

content should consist of cotton or other fibers.

Paper Size

Cassettes and the MP (multi-purpose) tray can handle the paper sizes listed in Table

2. The printer automatically detects the paper size loaded in a cassette.

Table 2. Paper Sizes for Paper Feeding

Paper Size

ISO A3 297 × 420 mm

ISO A4 210 × 297 mm

ISO A5 148 × 210 mm

JIS B4 257 × 364 mm

JIS B5 182 × 257 mm

Ledger 11 × 17 inches

Letter 8.5 × 11 inches

Legal 8.5 × 14 inches

Smoothness

Although it is important to use paper with a smooth and even surface, do not use

paper which has been coated. Paper that is too smooth can cause multiple feeding

and paper jams.

Basis Weight

Basis weight is the weight of a one square meter sheet of paper. Paper that is too

light or too heavy can cause misfeeding, jams, and premature wear of the printer.

Uneven paper weight can cause multiple feeds, print defects, poor toner fusing,

blurring, and other print quality problems. The appropriate paper weight range for

normal paper is 60 to 90 g/m2 (16 to 24 lbs/ream) and 90 to 200 g/m2 (24 to 53 lbs/

ream) for thick paper.

22

Page 24

Thickness

The paper used with the printer should be neither extremely thick nor extremely

thin. If you are having problems with multiple feeds and paper jams, the paper may

be too thin. The paper may also be too thick if you are having problems with paper

jams. The proper thickness is 0.086 to 0.110 mm (3.4 to 4.3 mils).

Moisture Content

English

Moisture content is defined as the percentage ratio of moisture to the dry mass of

the paper. Moisture can affect the paper’s appearance, feedability, curl, electrostatic

properties, and toner fusing characteristics.

The moisture content of paper varies with the relative humidity in the room. When

the relative humidity is high and the paper absorbs moisture, the paper edges

expand, becoming wavy in appearance. When the relative humidity is low and the

paper loses moisture, the edges shrink and tighten, and print contrast may suffer.

Wavy or tight edges can cause misfeeding and alignment anomalies. The moisture

content of the paper should be 4% to 6%.

To ensure the proper moisture content, it is important to store the paper in a

controlled environment. Some tips on moisture control are:

• Store paper in a dry, well-ventilated location.

• Keep the paper flat and in its wrapping as long as possible. Rewrap paper that is

not in use.

• Store paper in its original carton. Place a pallet etc. under the carton to separate

it from the floor. Keep paper away from boarded or concrete floors during rainy

weather.

• Avoid leaving paper where it is exposed to heat, sunlight, or damp.

Deutsch

FrançaisItalianoEspañol

23

Page 25

Other Paper Properties

Stiffness: Paper that is too limp or too stiff may fold or bend inside the printer,

resulting in a paper jam.

Curl: Most paper has a natural tendency to curl in one direction or the other if it is

stored unwrapped. Paper will curl slightly upward when it passes through the fuser

unit. Load the paper with its natural curl downward so that it will come out flat.

Some paper also has a front and back surface. If this is indicated on the paper’s

packaging, be sure to load the paper into the cassette face down.

Note If curl is large, load the paper into the cassette in such a manner

that the paper’s back surface is facing down.

Electrostatic properties: During the printing process, the paper is electrostatically charged to attract the toner. The paper must be able to release this charge so

that printed sheets do not cling together in the output tray.

Quality control: Uneven sheet size, corners that are not square, ragged edges,

welded (uncut) sheets, and crushed edges and corners can cause the printer to

malfunction in various ways. Pay particular attention to these considerations if you

are choosing paper yourself.

Packaging: Select paper that is wrapped by the ream and then placed in a box.

The best wrapping is one whose inner surface is coated to protect against humidity.

Specially treated paper: We recommend that you avoid using paper listed

below which has been specially treated, even if it meets basic specifications. If you

wish to use such paper, test a sample on the printer and check that the printing

quality is satisfactory before purchasing.

• Paper with a glossy finish

• Paper with sections cut out

• Paper which is embossed

• Paper with feed holes in it

• Paper with punch holes in it

24

Page 26

Special paper

The page printer can use the following types of special paper:

• Colored paper

• Preprinted paper (letter head, etc.)

When using the above types of paper, be sure to use products that are specified for

use with photocopiers and/or page printers.

Since the composition and quality of special paper vary considerably, special paper

is more likely than white bond paper to give trouble during printing. Some special

paper will emit harmful gases during printing. When using a new type of special

paper for the first time, make sure to perform a test first.

English

Deutsch

Note Before purchasing any type of special paper, test a sample on the

printer and check that the printing quality is satisfactory.

Following are the specifications for special paper.

Colored paper

Colored paper should meet the same specifications as those listed for white bond

paper in Table 1. In addition, the pigments used in the paper must be able to

withstand the heat of fusing during the printing process.

Preprinted paper (letter head, etc.)

When printing on preprinted paper, the preprinted ink must be able to withstand the

heat of fusing during the printing process, and must not be affected by silicone oil.

Do not use paper with any kind of surface treatment.

Note In the duplex printing mode, page 2 is printed first. When using

letter head paper, etc. for duplex printing, it is recommended to

place the paper with the sides reversed in the cassette.

FrançaisItalianoEspañol

25

Page 27

Specifications

Model name DU-31 Duplexer

Compatible printer Kyocera Page Printers

Loadable paper sizes ISO A3 (297 mm × 420 mm)

ISO A4 (210 mm × 297 mm)

ISO A5 (148 mm × 210 mm)

JIS B4 (257 mm × 364 mm)

JIS B5 (182 mm × 257 mm)

Letter size (8.5 × 11 inches)

Legal (8.5 × 14 inches)

Ledger (11 × 17 inches)

Installation Environment Conforms to the printer’s installation environment

Dimensions (H × W × D) 96 mm (3.8") × 455 mm (17.9") × 451 mm (17.8")

Weight 5 kg (11 lbs.)

Power supply From printer

26

Page 28

Kyocera übernimmt keinerlei Haftung für direkte oder indirekte Verluste oder Schäden,

die einem Kunden oder irgendeiner anderen Person oder Rechtspersondurch von

Kyocera verkaufte oder ausgerüstete Geräte direkt oder indirekt entstehen oder geltend

gemacht werden, und lehnt jedwede Haftung für eine eventuelle Unterbrechung einer

Dienstleistung, für Geschäftsverluste oder für den Verlust erwarteter Profite sowie

für Folgeschäden ab, die aus der Benutzung des Gerätes oder der Software entstehen

können.

Achtung

FÜR SCHÄDEN, DIE AUF UNSACHGEMÄSSE INSTALLIERUNG

ZURÜCKZUFÜHREN SIND, WIRD KEINERLEI HAFTUNG ÜBERNOMMEN.

Hinweis

English

Deutsch

Änderungen des Inhalts dieser Anleitung bleiben jederzeit vorbehalten.

In zukünftigen Ausgaben können zusätzliche Seiten eingefügt werden. Der Benutzer

wird gebeten, eventuelle technische Ungenauigkeiten oder drucktechnische Fehler

in der vorliegenden Ausgabe zu entschuldigen.

Für Unfälle, die sich trotz Befolgung aller in dieser Anleitung gegebenen Anweisungen

ereignen, wird keinerlei Haftung übernommen.

Der Inhalt dieser Anleitung ist urheberrechtlich geschützt. Kein Teil dieser Anleitung

darf in irgendeiner Form ohne schriftliche Genehmigung des Urheberrechtinhabers

reproduziert oder kopiert werden.

Warenzeichen

PRESCRIBE ist ein eingetragenes Warenzeichen von Kyocera Corporation.

FrançaisItalianoEspañol

27

Page 29

Europäische Funkstörschutzauflagen

Die Universal-Papierzuführung DU-31 ist für den Einsatz mit den

Druckermodellen FS-7000, FS-7000+ und FS-9000 bestimmt, die

typengeprüft und gemäß den Bestimmungen von EN55022 als Digitalgerät

der Klasse B eingestuft sind.

Digitalgeräte der Klasse B können Störungen des Rundfunk- oder

Fernsehempfangs verursachen, vor allem bei Betrieb in einer Wohngegend.

Inhaltsverzeichnis

Einleitung ..............................................................................................................29

Bezeichnung der Teile ...........................................................................................29

Installieren der Duplexeinheit ............................................................................... 30

Duplexdruck .......................................................................................................... 32

Beseitigen von Papierstaus ....................................................................................37

Wahl des Papiers.................................................................................................... 43

Technische Daten................................................................................................... 49

28

Page 30

Einleitung

Die Duplexeinheit DU-31 ist ein zur Verwendung mit Kyocera Laserdruckern

konzipiertes Zusatzgerät.

Bitte lesen Sie diese Anleitung vor Verwendung der Duplexeinheit DU-31

sorgfältig durch und folgen Sie anschließend genau den Anweisungen zum

Installieren und Einsatz dieses Zusatzgerätes. Beachten Sie auch alle Vorsichtsund Warnaufkleber, die an der Duplexeinheit selbst angebracht sind.

Bewahren Sie diese Anleitung griffbereit auf. Dann können Sie sofort darauf

Bezug nehmen, falls Sie Fragen zum Betrieb der Duplexeinheit haben oder eine

Störung vorliegt.

Verpackungsinhalt

Duplexeinheit DU-31 1

Anleitung (diese Broschüre) 1

Bezeichnung der Teile

Bitte überprüfen Sie vor dem Installieren der Duplexeinheit die folgende Liste der

Bezeichnungen der verschiedenen Teile der Duplexeinheit, da diese

Bezeichnungen in den Erklärungen zum Installieren und Gebrauch der

Duplexeinheit verwendet werden.

English

Deutsch

FrançaisItalianoEspañol

Montageschienen

Transparente

Kunststoffabdeckung

(zwei Abdeckungen)

Duplexeinheit (DU-31)

29

Page 31

Installieren der Duplexeinheit

Öffnen Sie die vordere Abdeckung des Druckers und setzen Sie die Duplexeinheit

DU-31 in den Freiraum unterhalb der Transfereinheit ein.

VORSICHT Achten Sie vor dem Installieren (bzw. Entfernen) der

optionalen Duplexeinheit unbedingt darauf, den Drucker

auszuschalten und das Netzkabel von der Netzsteckdose zu

trennen.

1. Öffnen Sie die vordere Abdeckung des Druckers.

Vordere

Abdeckung

Einbauplatz für DU-31

2. Nachdem Sie die Duplexeinheit aus der Verpackung genommen haben,

entfernen Sie das Klebeband, das die Abdeckung in ihrer

Ausgangsstellung hält.

30

Klebeband

Klebeband

Page 32

3. Entfernen Sie die Duplexeinheit aus der Verpackung und installieren Sie

sie wie in der Abbildung gezeigt im Drucker. Achten Sie dabei darauf, daß

die linke und die rechte Montageschiene richtig auf den Schienen des

Druckers zu liegen kommen.

English

Schiene

Schiene

4. Schieben Sie die DU-31 bis zum Anschlag in den Drucker.

Deutsch

FrançaisItalianoEspañol

5. Schließen Sie die vordere Abdeckung des Druckers. Damit ist die

Installierung der Duplexeinheit beendet.

31

Page 33

Duplexdruck

Nach der Installierung der Duplexeinheit wird das Duplexdruck-Menü dem

Moduswahl-Menü des Druckers wie unten gezeigt hinzugefügt (das zusätzliche

Menü wird im Diagramm eingerahmt dargestellt) und wird verwendet, um den

Duplexdruck-Modus ein- und auszuschalten und die Orientierung für den

Duplexdruck zu wählen.

Moduswahl-Menü

(nur FS-7000)

Bereit

PAR 600 A4 001

Bereit

PAR 600 A4 001

Papierhandling >

Duplex Aus

kurze Seite

lange Seite

Schnittstelle >

Parallel

Papierstärke

Normal

Duplex Aus

kurze Seite

lange Seite

Andere >

Die Betriebsarten der Duplexeinheit werden auf den folgenden Seiten erläutert.

32

Page 34

Betriebsart Duplexdruck

Die Duplexeinheit ermöglicht ein doppelseitiges Bedrucken von Blättern, wobei

der Druckvorgang wie folgt abläuft. Zunächst wird das erste Blatt eingezogen und

Seite 2 des Dokuments auf der einen Seite des Blattes ausgedruckt. Danach wird

das erste bedruckte Blatt vorübergehend an die Duplexeinheit übergeben, wonach

das zweite Blatt in den Drucker eingezogen und Seite 4 des Dokuments auf der

einen Seite des Blattes ausgedruckt wird. Nach Drucken von Seite 4 wird das erste,

inzwischen in der Duplexeinheit gehaltene Blatt an die Transfereinheit des

Druckers zurückgeführt, um Seite 1 des Dokuments auf der anderen Seite dieses

Blattes auszudrucken. Damit ist der Druck des ersten Blattes beendet, und dieses

Blatt wird ausgegeben. Danach wird das dritte Blatt in den Drucker eingezogen,

während das zweite Blatt, das bisher nur mit Seite 4 des Dokuments bedruckt ist,

weiter in der Duplexeinheit bereitgehalten wird, und der Drucker bedruckt das

dritte Blatt mit Seite 6 des Dokuments. Anschließend wird der oben beschriebene

Vorgang wiederholt, um den doppelseitigen Druck des Dokuments bis zum Ende

fortzusetzen.

Ablauf beim Duplexdruck

English

Deutsch

FrançaisItalianoEspañol

Duplexeinheit

(DU-31)

Drucker

Papierzuführung

(PF-30)

33

Page 35

Binden einstellen

Der Ausdruck “binden” bezieht sich auf die Art, in der die einzelnen Blätter in

Buchform miteinander verbunden (z.B. durch Kleben, Heften usw.) werden. Die

beiden möglichen Arten sind das längsseitige Binden (“long-edge binding”), wobei

die Blätter an den langen Kanten verbunden werden, sowie das kurzseitige Binden

(“short-edge binding”), wobei die Blätter an den kurzen Kanten verbunden werden.

Beim Wählen der Art des Bindens müssen Sie auch die Orientierung der bedruckten

Seite berücksichtigen. Sowohl beim Drucken im Hochformat als auch beim Drucken

im Querformat ist ein längsseitiges oder kurzseitiges Binden möglich.

Abhängig von der Art des Bindens und der Orientierung kann das Binden auf vier

verschiedene Weisen geschehen. Diese vier möglichen Einstellungen sind: 1

Hochformat längsseitig, 2 Hochformat kurzseitig, 3 Querformat längsseitig und 4

Querformat kurzseitig (siehe die nachfolgenden Abbildungen).

Betriebsart Binden

Hochformat

längsseitig

Querformat

längsseitig

Hochformat

kurzseitig

Querformat

kurzseitig

Bei Hochformat und längsseitigem Binden sowie bei Querformat und kurzseitigem

Binden (Einstellung 1 und 4 in der Abbildung) ist der Text auf beiden Seiten des

Blattes gleich ausgerichtet.

Bei Hochformat und kurzseitigem Binden sowie bei Querformat und längsseitigem

Binden (Einstellung 2 und 3 in der Abbildung) wird der Text auf der Rückseite des

Blattes, verglichen mit dem Text auf der Vorderseite, verkehrt gedruckt.

34

Page 36

Einstellungen der Betriebsart Duplexdruck

Die Einstellungen für den Duplexdruck werden im Bedienfeld des Druckers

vorgenommen.

Einstellungen im Bedienfeld des Druckers

Nehmen Sie die Einstellung für die Betriebsart Duplexdruck und das Binden

anhand des folgenden Verfahrens im Bedienfeld des Druckers vor.

1. Vergewissern Sie sich, daß das Display des Druckers Bereit anzeigt

und daß die Online-Anzeige leuchtet.

2. Drücken Sie im Bedienfeld des Druckers die Taste MENÜ.

3. Bringen Sie zunächst “Papierhandling >” zur Anzeige, drücken Sie

die Taste und betätigen Sie dann die Taste + oder –, wonach das

Display “> Duplex” zeigt. Auf der zweiten Zeile wird der aktuelle

Duplexmodus angezeigt. (Im ursprünglichen Zustand wird Aus

angezeigt.) Beim Modell FS-7000 betätigen Sie die Taste + oder –,

wonach das Display Duplex zeigt.

4. Nach Drücken der Taste ENTER zeigt das Display ein blinkendes

Fragezeichen (?) an. Danach betätigen Sie die Taste + oder –, bis das

Display die gewünschte Art des Bindens anzeigt (siehe das nachfolgende

Diagramm).

➔

English

Deutsch

FrançaisItalianoEspañol

Duplex ? Aus

Duplex ? Binden

kurze Seite

➔➔

Duplex ? Binden

lange Seite

Um den Einstellvorgang abzubrechen, drücken Sie die Taste ABBRUCH.

5. Nachdem Sie die gewünschte Art des Bindens gewählt haben, drücken Sie

die Taste ENTER.

6. Drücken Sie die Taste MENÜ, wonach das Display wieder Bereit anzeigt.

Die gleiche Einstellung kann auch vorgenommen werden, indem Sie im DruckerEinstellmenü Ihres Anwendungsprogramms auf den Druckertreiber zugreifen.

Kein Duplexdruck

(Standardeinstellung)

Kurzseitiges Binden

Längssseitiges Binden

35

Page 37

Duplexdruck von der Multifunktionszufuhr

Achten Sie im ersten Modus darauf, die Multifunktionszufuhr auf die gleichen

Einstellungen von Papierformat, Papiersorte und Vorschubrichtung zu bringen, die

für die aktuelle Kassette eingestellt sind. Bei einer unterschiedlichen Einstellung

von Papierformat, Papiersorte oder Vorschubrichtung kann es zu einem Papierstau

kommen. Beachten Sie außerdem, daß es nicht möglich ist, die

Multifunktionszufuhr als aktuelle Kassette zur Ausführung des Duplexdrucks

anzuwählen. Es wird daher empfohlen, den Duplexdruck von der Papierkassette

auszuführen.

Hinweis Beim Modell FS-7000 ist Duplexdruck von der

Multifunktionszufuhr des Druckers, der optionalen

Umschlagzuführung (EF-1) oder der optionalen

Universalzuführung (UF-1) nicht möglich. Falls versucht wird,

einen Duplexdruck von diesen Papierquellen auszuführen, wird die

Betriebsart Duplexdruck automatisch aufgehoben und das

bedruckte Papier über die linke Papierausgabe ausgegeben. Wenn

die Betriebsart Duplexdruck ausgeschaltet ist, kann das Papier auch

über die Standard-Papierausgabe ausgegeben werden. Wenn die

Papierzufuhr jedoch vom Kuverteinzug erfolgt, muß die linke

Papierausgabe verwendet werden.

36

Page 38

Beseitigen von Papierstaus

In diesem Abschnitt werden die Fehlermeldungen und Abhilfemaßnahmen beim

Auftreten eines Papierstaus erläutert.

WARNUNG Achten Sie beim Beseitigen von Papierstaus unbedingt

darauf, daß keine Papierfetzen im Drucker zurückbleiben.

Anderenfalls kann ein Brand verursacht werden.

In diesem Abschnitt wird das Verfahren zum Entfernen von gestautem Papier aus

dem Drucker erläutert. Der Drucker unterbricht den Betrieb, wenn ein Papierstau

aufgetreten ist oder kein Papier aus einer Kassette zugeführt wird. In einem

solchen Fall geht der Drucker offline, und das Display zeigt Papierstau

vorne öffnen an.

Papierstau

vorne öffnen

Nach Öffnen der vorderen Abdeckung wechselt das Display auf die Anzeige eines

Codes (Buchstaben A bis I und Ziffern 1 bis 6), der die Lage des Papierstaus

kennzeichnet.

Beispiel

Papierstau

C, H, I, 3

English

Deutsch

FrançaisItalianoEspañol

In obigem Beispiel befindet sich der Papierstau in der Papierzuführung (C), im

Papiereinzug (H), in der Duplexeinheit (I) und in der oberen Kassette der

optionalen Papierzuführung (3). Die in einem solchen Fall zu ergreifenden

Abhilfemaßnahmen werden anhand von Beispielen ab Seite 40 erläutert.

Die Tabelle auf der nächsten Seite zeigt den Zusammenhang zwischen den

verschiedenen Codes, die im Display erscheinen, und der jeweiligen Lage des

Papierstaus. Achten Sie stets darauf, Papierstaus anhand des auf den folgenden

Seiten beschriebenen Verfahrens zu beseitigen.

37

Page 39

Angezeigter Code und Lage des Papierstaus

Code Bedeutung Entsprechende Lage

Optionale Papierzuführung

A

(EF-1 oder UF-1)

Multifunktionszufuhr

B

Standardmäßige Papierzuführung

C

des Druckers

Optionale Papierzuführung (PF-30)

D

Optionale Papierzuführung (PF-30)

E

Optionale Einheit

F

(DF-30/DF-31, SO-30 oder ST-30)

Linke Papierausgabe/StandardPapierausgabe

G

(Auschluß an optionale Einheit)

Papiereinzug

H

Optionale Duplexeinheit

I

(DU-31, dieses Gerät)

Kassette 1

1

Kassette 2

2

Kassette 3

3

Kassette 4

4

Kassette 5

5

Kassette 6

6

An der Innenseite der vorderen Abdeckung des Druckers

befindet sich ein Aufkleber “Paper Jam Location Indicators” (Papierstau-Lagecodes).

Bei Auftreten eines Papierstaus blinkt außerdem eine Anzeige im Bedienfeld des

Druckers, um die Lage des Papierstaus zu kennzeichnen. Tritt der Papierstau in

einer Papierzuführung auf, so blinkt die LED an der Vorderseite der betreffenden

Papierkassette ebenfalls. Die folgende Tabelle erläutert die Bedeutungen der

verschiedenen Zustände dieser LED.

LED-Zustand Bedeutung

Schnelles Blinken Papierstau in dieser Kassette

Langsames Blinken Kein Papier in dieser Kassette

Stetiges Leuchten Momentan gewählte Kassette

Ausgeschaltet • Kassette falsch eingesetzt

• Kassette momentan nicht gewählt

Ermitteln Sie die Lage des Papierstaus anhand der obigen Tabelle und ergreifen Sie

dann die in der Tabelle auf der nächsten Seite aufgeführten Abhilfemaßnahmen.

Nachdem das gestaute Papier vollständig entfernt worden ist, setzt der Drucker den

Ausdruck automatisch fort.

38

Page 40

Abhilfemaßnahmen bei Papierstau

Code

A

B

C

D

E

F

G

H

I

1 bis 6

Bedeutung

Überprüfen Sie die optionale

Papierzuführung (EF-1 oder

UF-1), falls diese installiert ist.

Überprüfen Sie die

Multifunktionszufuhr des

Druckers.

Überprüfen Sie die (mitgelieferte) Papierzuführung.

(D und E werden nur

angezeigt, wenn eine optionale

PF-30 installiert ist.)

Überprüfen Sie die optionale

Einheit (DF-30/DF-31/SO-30/

ST-30), falls diese installiert ist.

Überprüfen Sie die linke

Papierausgabe des Druckers.

(Auschluß an optionale

Binheit)

Überprüfen Sie die StandardPapierablage des Druckers.

Überprüfen Sie den

Papiereinzug des Druckers.

Überprüfen Sie die

Fixiereinheit des Druckers.

Überprüfen Sie die optionale

Duplexeinheit (DU-31, dieses

Gerät).

Überprüfen Sie die

angegebene Papierkassette.

Fehlerbehebung

In der optionalen Papierzuführung ist ein Papierstau

aufgetreten. Ziehen Sie das gestaute Papier vorsichtig

heraus. Öffnen und schließen Sie dann die vordere

Abdeckung des Druckers einmal. (Einzelheiten finden Sie in

der Anleitung der EF-1/UF-1.)

In der Multifunktionszufuhr ist ein Papierstau aufgetreten.

Ziehen Sie das gestaute Papier vorsichtig heraus. Öffnen

und schließen Sie dann die vordere Abdeckung des

Druckers einmal.

Öffnen Sie die Seitenabdeckung der angegebenen

Papierzuführung und entfernen Sie das gestaute Papier.

(Siehe das Beispiel auf der nächsten Seite.)

Entfernen Sie das gestaute Papier aus dem Stapler.

(Einzelheiten finden Sie in der Anleitung des DF-30/DF31/SO-30/ST-30.)

Das Papier staut sich, bevor das Blatt vollständig

ausgegeben werden kann. Öffnen Sie die Seitenabdeckung

des Druckers und entfernen Sie das gestaute Blatt

vorsichtig. (Einzelheiten finden Sie in der Anleitung des

Druckers.)

Falls der Druckvorgang stoppt, bevor ein Blatt vollständig

ausgegeben wurde, entfernen Sie dieses vorsichtig.

Öffnen Sie die vordere Abdeckung und ziehen Sie den

Papiereinzug vorsichtig bis zum Anschlag heraus. Falls das

Papier zwischen den Registrierwalzen gestaut ist, ziehen Sie

das Blatt in derjenigen Richtung heraus, in der sich dies mit

dem geringsten Widerstand bewerkstelligen läßt.

(Einzelheiten finden Sie in der Anleitung des Druckers.)

Falls das Papier in der Fixiereinheit gestaut ist, entfernen

Sie es auf gleiche Weise. (Einzelheiten finden Sie in der

Anleitung des Druckers.)

Nachdem Sie das gestaute Papier vollständig entfernt haben,

schieben Sie den Papiereinzug wieder in seine

Ausgangsstellung.

Öffnen Sie die vordere Abdeckung und ziehen Sie den

Papiereinzug vorsichtig bis zum Anschlag heraus. Öffnen

Sie die Abdeckung der Fixiereinheit

(wobei Sie den

grünen Knopf anfassen) und überprüfen Sie das Innere der

Fixiereinheit. Gestautes Papier ist möglicherweise in der

Fixiereinheit zurückgeblieben.

Öffnen Sie die vordere Abdeckung, ziehen Sie die

Duplexeinheit heraus und entfernen Sie das gestaute Papier.

(Einzelheiten finden Sie auf den nächsten Seiten.)

Ziehen Sie die angegebene Papierkassette heraus und

entfernen Sie das gestaute Papier. Öffnen und schließen

Sie

dann die vordere Abdeckung des Druckers einmal.

English

Deutsch

FrançaisItalianoEspañol

39

Page 41

Beispiel

In dem auf Seite 37 gezeigten Beispiel befindet sich der Papierstau in der Papierzuführung (C), im Papiereinzug (H), in der Duplexeinheit (I) und in der oberen

Kassette der Papierzuführung (3).

Papierstau

C, H, I, 3

1. Wenn sich Papier wie in diesem Beispiel an mehreren Stellen staut,

beginnen Sie die Abhilfemaßnahmen an der ganz links angezeigten

Stelle.

Seitenabdeckung der

Papierzuführung

Nachdem Sie den Papierstau in der Papierzuführung (C) beseitigt haben,

ändert sich die Anzeige im Display wie folgt:

Papierstau

H, I, 3

2. Als nächstes öffnen Sie die vordere Abdeckung des Druckers und drehen

den Arretierhebel entgegen den Uhrzeigersinn (außer beim Modell FS-

7000). Ziehen Sie dann die Transfereinheit vorsichtig bis zum Anschlag

heraus. (Dadurch wird die Duplexeinheit gleichzeitig herausgezogen.)

Fixiereinheit

Duplexeinheit

Transfereinheit

VORSICHT Nach dem Herausziehen der Transfereinheit ist das Innere

der Fixiereinheit extrem heiß. Vermeiden Sie sorgfältig

jegliche Berührung der Fixiereinheit, da die Gefahr von

Verbrennungen besteht.

40

Page 42

3. Überprüfen Sie die Führungswechsler an der linken Seite der

Fixiereinheit. Falls Papier darunter gestaut, heben Sie die Führung und die

Abdeckung der Fixiereinheit an (wobei Sie den grünen Knopf

anfassen). Entfernen Sie das gestaute Papier wie in der Abbildung unten

gezeigt.

Abdeckung der

Fixiereinheit

Führungswechsler

➞

Gestautes Papier

Nach Beseitigen des Papierstaus an dieser Stelle ändert sich die Anzeige

im Display wie folgt:

Papierstau

I, 3

4. Nachdem Sie sich überzeugt haben, daß kein Papier in der Transfereinheit

gestaut ist, setzen Sie nur die Transfereinheit wieder in den Drucker ein.

English

Deutsch

FrançaisItalianoEspañol

Transfereinheit

➞

5. Drehen Sie den Arretierhebel im Uhrzeigersinn, um die Transfereinheit zu

arretieren.

41

Page 43

6. Öffnen Sie die beiden transparenten Kunststoffabdeckungen an der

Oberseite der Duplexeinheit. Entfernen Sie das gestaute Papier wie in der

Abbildung unten gezeigt.

Die erste Abdeckung öffnen und

das gestaute Papier entfernen.

Transparente

Kunststoffabdeckung

Die zweite Abdeckung öffnen und

das gestaute Papier entfernen.

Transparente

Kunststoffabdeckung

7. Nachdem Sie das gestaute Papier entfernt haben, bringen Sie jede

transparente Kunststoffabdeckung wieder in ihre Ausgangsstellung und

setzen die Duplexeinheit in den Drucker ein. Danach ändert sich die

Anzeige im Display wie folgt: Drucker vorne offen.

8. Schließen Sie die vordere Abdeckung des Druckers. Damit ist die

Beseitigung dieses Papierstaus abgeschlossen.

Hinweise • Ob der Drucker die gestaute Seite abermals druckt, hängt

davon ab, wo der Papierstau aufgetreten ist.

• Bitte beachten Sie, daß Sie sich beim Beseitigen von Papierstaus

die Hände mit lose auf dem Papier liegendem Toner

beschmutzen können.

Ein häufiges Auftreten von Papierstaus kann ein Anzeichen dafür sein, daß eine für

diesen Drucker ungeeignete Papiersorte verwendet wird. Verwenden Sie in einem

solchen Fall ein anderes Papier.

Wenn es trotz Wechseln der Papiersorte häufig zu Papierstaus kommt, liegt

möglicherweise ein Defekt des Druckers vor. Bitte wenden Sie sich in einem

solchen Fall an Ihren Kyocera-Händler.

42

Page 44

Wahl des Papiers

Obwohl der Drucker primär auf das Bedrucken von Trockenkopierer-Normalpapier

(Standardpapier) ausgelegt ist, können auch verschiedene andere Papiersorten

verwendet werden, sofern diese den Papierspezifikationen in diesem Kapitel

entsprechen. Einzelheiten zu den geeigneten Papiersorten finden Sie in der

Bedienungsanleitung des Druckers.

Der Wahl des richtigen Papiers kommt große Bedeutung zu. Der Gebrauch einer

für diesen Drucker ungeeigneten Papiersorte kann zu Papierstaus, Fehleinzügen,

schlechter Druckqualität und im Extremfall zu einer Beschädigung der

Papierzuführung und des Druckers führen. Die nachfolgenden Richtlinien sollen

Ihnen helfen, wirtschaftlich und problemfrei zu drucken und die Abnutzung von

Papierzuführung und Drucker möglichst niedrig zu halten.

Geeignetes Papier

Verwenden Sie ausschließlich Kopierer-Normalpapier (Standardpapier), das für

den Gebrauch mit herkömmlichen Trockenkopierern vorgesehen ist.

Hinweis Bestimmte Arten von Recycling-Papier sind aufgrund ihres Wasser-

und Zellstoffgehalts nicht für den Gebrauch mit diesem Drucker

geeignet (Tabelle 1). Vor dem Ankauf von Recycling-Papier sollten

Sie damit mehrere Probeausdrucke machen, um sicherzustellen, daß

eine einwandfreie Druckqualität erzielt wird. Achten Sie bei der

Wahl von Recycling-Papier nicht nur auf eine gute Druckqualität,

sondern auch darauf, daß möglichst wenig Papierstaub beim

Drucken abfällt.

English

Deutsch

FrançaisItalianoEspañol

Auch Unterschiede in der Papierqualität verschiedener Hersteller haben Einfluß

auf die Leistung der Papierzuführung. Ein Drucker kann keine guten

Druckergebnisse liefern, wenn ungeeignetes Papier benutzt wird. Billiges Papier ist

langfristig gesehen nicht wirtschaftlich, wenn es ständig Druckprobleme

verursacht.

43

Page 45

Grundlegende Papierspezifikationen

Die folgende Tabelle faßt die grundlegenden Papierspezifikationen zusammen.

Tabelle 1. Grundlegende Papierspezifikationen

Eigenschaft Spezifikation

Gewicht 60 bis 90 g/m

Stärke 0,086 bis 0,110 mm

Abmessungstoleranz ±0,7 mm

Rechteckigkeit der Kanten 90° ±0,2°

Feuchtigkeitsgehalt 4 % bis 6 %

Zellstoffgehalt 80 % oder mehr

2

Hinweis Beim Duplexdrucken auf Papier eines größeren Formats als A4,

insbesondere bei Verwendung eines leichten Papiers mit einem

Gewicht von weniger als 65 g/m2, kann es vorkommen, daß die

Randzonen der Blätter geringfügig verschmutzt werden. Ersetzen Sie

das Papier in einem solchen Fall durch Normalpapier mit einem

Gewicht von mehr als 70 g/m2.

Kyocera übernimmt keinerlei Haftung für Probleme, die auf die

Verwendung der Papierzuführung mit Papier zurückzuführen sind,

das nicht den Anforderungen der obigen Tabelle entspricht. Bitte

konsultieren Sie Ihren Kyocera-Händler vor dem Ankauf von Papier

mit Spezialbeschichtung oder Papier für besondere Anwendungen.

Wahl des richtigen Papiers

Eine hochwertige Druckqualität kann nur bei Verwendung von Papier erzielt

werden, das die in Tabelle 1 gestellten Anforderungen erfüllt. Die folgenden

Abschnitte erläutern die wichtigsten Faktoren, die bei der Papierwahl für den

Duplexdruck zu berücksichtigen sind.

Zustand des Papiers

Vermeiden Sie den Gebrauch von Papier, dessen Kanten eingebogen oder rauh

sind oder das gekrümmt, schmutzig, eingerissen oder durch Fusseln, Staub oder

Papierschnitzel verunreinigt ist oder eine rauhe Oberfläche aufweist.

Papier in solchem Zustand kann zu unleserlichen Ausdrucken, Fehleinzügen und

Papierstaus führen und die Lebensdauer der Papierzuführung und des Druckers

verkürzen. Die Oberfläche des Papiers sollte so glatt und eben wie möglich sein.

Vermeiden Sie insbesondere oberflächenbeschichtetes Papier oder solches, dessen

Oberfläche anderweitig behandelt wurde, da derartiges Papier eine Beschädigung

von Trommel und Fixiereinheit verursachen kann.

44

Page 46

Zusammensetzung

Verwenden Sie kein Papier, das beschichtet oder dessen Oberfläche sonstwie

behandelt wurde und Kunststoff oder Karbon enthält. Die beim Fixieren entstehende

Hitze könnte dazu führen, daß solches Papier schädliche Gase abgibt und die

Trommel beschädigt.

Der Zellstoffgehalt von Feinpostpapier sollte mindestens 80 % betragen. Das Papier

darf insgesamt nicht mehr als 20 % Baumwollfasern oder andere Fasern enthalten.

English

Papierformat

Die Papierkassetten und die Multifunktionszufuhr können Papier der in der Tabelle 2

aufgelisteten Formate aufnehmen. Der Drucker erkennt das Format des in eine

Kassette eingelegten Papiers automatisch.

Tabelle 2. Papierformate für Einzug

Papierformat Abmessungen

ISO A3 297 × 420 mm

ISO A4 210 × 297 mm

ISO A5 148 × 210 mm

JIS B4 257 × 364 mm

JIS B5 182 × 257 mm

Ledger 11 × 17 Zoll

Letter 8,5 × 11 Zoll

Legal 8,5 × 14 Zoll

Glätte

Das Papier sollte eine möglichst glatte und ebene Oberfläche besitzen, aber nicht

beschichtet sein. Zu glattes Papier allerdings kann zu Mehrfacheinzügen und

Papierstaus führen.

Papiergewicht

Deutsch

FrançaisItalianoEspañol

Unter Papiergewicht versteht man das Gewicht einer Standardmenge von 1

Quadratmeter. Zu leichtes oder zu schweres Papier kann zu Fehleinzügen,

Papierstaus oder vorzeitiger Abnutzung von Papierzuführung und Drucker führen.

Unebenes Papier kann zu Mehrfacheinzügen, Druckfehlern, schlechter Fixierung des

Toners, Verschmieren und anderen Druckproblemen führen. Das richtige

Papiergewicht beträgt 60 bis 90 g/m

2

für Normalpapier und 90 bis 200 g/m2 für

dickes Papier .

45

Page 47

Dicke

Das mit dem Drucker verwendete Papier sollte weder extrem dick noch extrem dünn

sein. Wenn Sie Probleme mit Mehrfacheinzügen und Papierstaus haben, liegt das

vielleicht an zu dünnem Papier. Papierstaus können jedoch auch auf ein zu dickes

Papier zurückzuführen sein. Die richtige Papierdicke beträgt 0,086 bis 0,110 mm.

Feuchtigkeitsgehalt

Der Feuchtigkeitsgehalt wird als prozentuales Verhältnis zwischen Trockenmasse

und Feuchtigkeit angegeben. Der Feuchtigkeitsgehalt beeinflußt das

Erscheinungsbild des Papiers sowie dessen Einzugsfähigkeit und Krümmung, die

elektrostatischen Eigenschaften und die Tonerfixierung.

Der Feuchtigkeitsgehalt des Papiers richtet sich nach der relativen Luftfeuchtigkeit

im Raum. Wenn die relative Luftfeuchtigkeit hoch ist und das Papier Feuchtigkeit

aufnimmt, dehnen sich die Papierkanten aus und erscheinen wellig. Wenn die

relative Luftfeuchtigkeit niedrig ist und das Papier Feuchtigkeit abgibt, ziehen sich

die Papierkanten zusammen, und das Papier wird straffer, was den Druckkontrast

herabsetzen kann.

Wellige oder straffe Kanten können zu Fehleinzügen und unregelmäßiger

Ausrichtung führen. Der Feuchtigkeitsgehalt des Papiers sollte 4 % bis 6 % betragen.

Damit das Papier den richtigen Feuchtigkeitsgehalt aufweist, ist es wichtig, den

Feuchtigkeitsgehalt des Lagerraums zu regulieren. Einige Tips zur

Feuchtigkeitsregelung sind:

• Bewahren Sie Papier stets an einem trockenen, gut belüfteten Ort auf.

• Bewahren Sie Papier so lange wie möglich flach in seiner Verpackung liegend

auf. Packen Sie nicht benutztes Papier wieder ein.

• Bewahren Sie Papier in dessen Originalkarton auf. Legen Sie eine Palette o.ä.

unter den Karton, um direkten Kontakt mit dem Fußboden zu vermeiden. Bei

Regenwetter sollte Papier nicht auf Brettern oder Betonböden liegen.

• Lassen Sie das Papier nicht an Orten zurück, wo es hohen Temperaturen, direkter

Sonneneinstrahlung oder Nässe ausgesetzt ist.

46

Page 48

Sonstige Papiereigenschaften

Steife: Zu schlaffes oder zu steifes Papier kann in der Papierzuführung oder im

Drucker einknicken oder sich verklemmen. Beides führt zu einem Papierstau.

Krümmung: Bei Aufbewahrung außerhalb seiner Verpackung besitzt Papier meist

eine natürliche Tendenz, sich in eine bestimmte Richtung zu krümmen. Legen Sie

das Papier so ein, daß die natürliche Krümmung nach unten weist, um der beim

Durchlaufen der Fixiereinheit verursachten geringfügigen Aufwärtskrümmung

entgegenzuwirken. Meistens besitzt Papier eine unterschiedlich strukturierte

Vorder- und Rückseite. Wenn dies auf der Papierverpackung z. B. mit einem Pfeil

angegeben ist, achten Sie darauf, das Papier mit der Vorderseite in die Kassette

einzulegen.

Hinweis Wenn die Krümmung stark ausgeprägt ist, legen Sie das Papier mit

der Rückseite nach unten in die Kassette ein.

Elektrostatische Eigenschaften: Beim Bedrucken wird das Papier

elektrostatisch aufgeladen, um Toner anzuziehen. Das Papier muß diese Ladung

freigeben können, damit die Blätter im Ausgabebehälter nicht zusammenhaften.

Qualitätskontrolle: Ungleiche Abmessungen der Blätter, nicht rechteckige oder

ausgefranste Kanten, verschweißte (nicht beschnittene) Blätter und eingebogene

Kanten und Ecken können zu verschiedenen Störungen der Papierzuführung und

des Druckers führen. Ein guter Papierlieferant sollte stets darauf achten, daß es

nicht zu solchen Problemen kommt.

English

Deutsch

FrançaisItalianoEspañol

Verpackung: Das Papier sollte in einem festen Karton verpackt sein, um

Transportschäden vorzubeugen. Bei der besten Art von Verpackung ist die

Innenseite des Verpackungspapiers mit einer Beschichtung zum Schutz gegen

Feuchtigkeit versehen.

Spezialpapier: Vom Gebrauch der nachfolgend aufgeführten Spezialpapierarten

wird abgeraten, selbst wenn diese ansonsten den grundlegenden Anforderungen

entsprechen. Falls Sie unbedingt ein derartiges Papier mit dem Drucker verwenden

möchten, sollten Sie vor dem Kauf damit mehrere Probeausdrucke machen, um

sicherzustellen, daß eine einwandfreie Druckqualität erzielt wird.

• Hochglanzpapier

• Blätter, aus denen Teile herausgeschnitten sind

• Geprägtes Papier

• Papier mit Perforationen für Traktorvorschub

• Gelochtes Papier

47

Page 49

Spezialpapier

Die folgenden Spezialpapierarten können mit dem Seitendrucker benutzt werden:

• Farbpapier

• Vorbedruckte Formulare (Briefkopfpapier usw.)

Benutzen Sie nur solche Arten von Spezialpapier, die ausdrücklich für den

Gebrauch mit Kopierern und/oder Seitendruckern angeboten werden.

Da die Zusammensetzung und Qualität von Spezialpapier sehr unterschiedlich ist,

kommt es beim Bedrucken von Spezialpapier häufiger zu Problemen als mit

weißem Feinpostpapier. Bestimmte Sorten von Spezialpapier können außerdem

schädliche Gase abgeben. Führen Sie daher einen Drucktest aus, bevor Sie erstmals

mit einem neuen Spezialpapier drucken.

Hinweis Vor dem Ankauf von Spezialpapier sollten Sie damit mehrere

Probeausdrucke machen, um sicherzustellen, daß eine

einwandfreie Druckqualität erzielt wird.

In diesem Abschnitt wird die Verwendung von Spezialpapier erläutert.

Farbpapier

Farbpapier muß den gleichen Anforderungen entsprechen, die in Tabelle 1 an

weißes Feinpostpapier gestellt werden. Außerdem müssen die im Papier

enthaltenen Pigmentstoffe der beim Fixieren entstehenden Hitze widerstehen

können.

Vorbedrucktes Papier (Briefkopfpapier usw.)

Die auf dem vorbedruckten Papier aufgebrachte Tinte muß der beim Fixieren

entstehenden Hitze widerstehen können und gegen Silikonöl beständig sein.

Benutzen Sie kein Papier, dessen Oberfläche auf irgendeine Weise behandelt

wurde.

Hinweis Beim doppelseitigen Bedrucken wird Seite 2 des Dokuments zuerst

ausgedruckt. Wird daher Papier mit Briefkopf o.ä. zum

Duplexdruck verwendet, sollten Sie die Blätter umgekehrt (mit der

Rückseite nach unten weisend) in die Kassette einlegen, damit die

richtige Seite unter dem Briefkopf ausgedruckt wird.

48

Page 50

Technische Daten

Modellbezeichnung Duplexeinheit DU-31

Geeigneter Drucker Kyocera Laserdrucker

Verfügbare Papierformate ISO A3 (297 × 420 mm)

ISO A4 (210 × 297 mm)

ISO A5 (148 × 210 mm

JIS B4 (257 × 364 mm)

JIS B5 (182 × 257 mm)

Ledger (11 × 17 Zoll)

Letter (8,5 × 11 Zoll)

Legal (8,5 × 14 Zoll)

Umgebungsbedingungen Wie beim Drucker

Abmessungen 96 (H) × 455 (B) × 451 (T) mm

Gewicht 5 kg

Stromversorgung Über Drucker

English

Deutsch

FrançaisItalianoEspañol

49

Page 51

Diese Seite wurde absichtlich freigelassen.

50

Page 52

Nous ne pourrons être tenus responsables envers un client ou toute autre personne,

physique ou morale, pour des pertes ou dommages quelconques causés, directement

ou indirectement, par un matériel vendu ou fourni par nous, y compris sans limitation, toute interruption de service, manque à gagner ou dommage indirect résultant

de l’utilisation du matériel ou du logiciel.

Attention

NOUS DÉCLINONS TOUTE RESPONSABILITÉ POUR DES DOMMAGES

DUS À UNE INSTALLATION INCORRECTE.

Avertissement

Les informations de ce manuel sont susceptibles d’être modifiées sans avertissement.

Il se peut que des pages supplémentaires soient ajoutées dans les futures éditions.

L’utilisateur est prié de bien vouloir excuser toute inexactitude technique ou erreur

typographique de la présente édition.

Notre responsabilité ne saurait être engagée en cas d’accident alors que l’utilisateur

suit les instructions de ce manuel.

Le contenu de ce manuel est protégé par la loi sur le droit d’auteur. Aucune partie

de ce manuel ne peut être reproduite ou copiée, par quelque moyen que ce soit,

sans l’autorisation du titulaire du droit d’auteur.

English

Deutsch

FrançaisItalianoEspañol

Marque

PRESCRIBE est une marque déposée de Kyocera Corporation.

51

Page 53

Brouillage radioélectrique dans les pays européens

Le chargeur de papier universel DU-31 en option est destiné aux

imprimantes de modèles FS-7000, FS-7000+ et FS-9000 qui ont été

homologuées et classées comme périphériques de la classe B

conformément aux règles EN55022.

Les périphériques de la classe B peuvent brouiller la réception de radio ou

de télévision, tout particulièrement en zone résidentielle.

Sommaire

Introduction ........................................................................................................... 53

Nomenclature des pièces .......................................................................................53

Installation du module recto-verso ........................................................................54

Impression recto-verso .......................................................................................... 56

En cas de bourrage papier......................................................................................61

Choix du papier ..................................................................................................... 67

Caractéristiques ..................................................................................................... 73

52

Page 54

Introduction

Le module recto-verso DU-31 est un dispositif d’impression sur les deux faces

disponible en option pour les imprimantes feuille à feuille Kyocera.

Avant d’utiliser le module recto-verso DU-31, veuillez lire attentivement ce

manuel. Suivez toujours toutes les instructions données lorsque vous installez et

utilisez le module recto-verso. Observez les avertissements et consignes indiqués

sur le module lui-même.

Conservez ce manuel dans un endroit facilement accessible. Vous pourrez avoir

besoin de le consulter ultérieurement en cas de question sur son fonctionnement ou

de problème.

Contenu de l’emballage

DU-31 1

Mode d’emploi (ce manuel) 1

Nomenclature des pièces

Avant d’installer le module recto-verso, veuillez vous familiariser avec le nom des

pièces. Ces noms sont utilisés pour décrire les opérations d’installation et d’utilisation

du module recto-verso.

English

Deutsch

FrançaisItalianoEspañol

Rails d’installation

Couvercle en plastique transparent

(deux couvercles)

Module-recto verso (DU-31)

53

Page 55

Installation du module recto-verso

Ouvrez le capot avant de l’imprimante et installez le DU-31 dans l’espace vide

sous l’ensemble de transfert.

ATTENTION Avant d’installer (ou de retirer) le module recto-verso en

option, mettez l’imprimante hors tension et débranchez la

fiche secteur de la prise de courant.

1. Ouvrez le capot avant de l’imprimante.

Capot avant

Espace pour l’installation

du DU-31

2. Après avoir retiré le module recto-verso des cales de transport, retirez le

ruban adhésif maintenant le capot en place.

54

Ruban

Ruban

Page 56

3. Retirez le module recto-verso des cales de transport et installez-le dans

l’imprimante comme sur la figure. Lors de l’installation, veillez à ce que les

rails droit et gauche reposent correctement sur les rails de l’imprimante.

Rail

Rail

4. Enfoncez complètement le DU-31 dans l’imprimante.

English

Deutsch

FrançaisItalianoEspañol

5. Refermez le capot avant de l’imprimante. Ceci termine l’installation du

module recto-verso.

55

Page 57

Impression recto-verso

Lors de l’installation du module recto-verso, le menu d’impression recto-verso

s’ajoute au menu de sélection de mode de l’imprimante comme sur l’illustration cidessous (la partie ajoutée est entourée d’un cadre). Ce menu permet d’activer/

désactiver le mode Impression recto-verso et de choisir l’orientation de

l’impression recto-verso.

Menu de sélection de mode

(FS-7000 seulement)

Prêt

PAR 600 A4 001

Prêt

PAR 600 A4 001

Gestion papier >

Mode duplex

Inactif

Bord relié court

Bord relié long

Interface >

Parallèle

Type papier

Normal

Mode duplex

Inactif

Bord relié court

Bord relié long

Autres >

Le mode Impression recto-verso est expliqué aux pages suivantes.

56

Page 58

Mode Impression recto-verso

En mode Impression recto-verso, l’ordre des opérations d’impression est le suivant.

La première feuille est d’abord introduite et la page 2 du document est imprimée sur

une face. Après l’impression, la première feuille est transférée provisoirement au

module recto-verso. La seconde feuille est ensuite introduite dans l’imprimante et la

page 4 du document y est imprimée. Après l’impression de la page 4, la première

feuille, qui se trouve en attente dans le module recto-verso, est renvoyée à l’ensemble

de transfert de l’imprimante pour l’impression de la page 1. Ceci termine l’impression

de la première feuille qui sort alors de l’imprimante. Après cela, et alors que la seconde

feuille sur laquelle se trouve imprimée la page 4 est en attente dans le module rectoverso, la troisième feuille est introduite dans l’imprimante et la page 6 y est imprimée.