Kubota ZD1211, ZD1211R, ZD1211L, ZD1211RL Operators Manual

OPERATOR'S MANUAL

MODELS ZD1211

ZD1211R

ZD1211L

ZD1211RL

ENGLISH

1BDABEJAP0010

K3441-7125-2

READ AND SAVE THIS MANUAL

ENGLISH

ABBREVIATION LIST

Abbreviations |

Definitions |

|

|

API |

American Petroleum Institute |

PTO |

Power Take Off |

RH/LH |

Right-hand and left-hand sides are determined by facing in |

|

the direction of forward travel |

ROPS |

Roll-Over Protective Structures |

rpm |

Revolutions Per Minute |

SAE |

Society of Automotive Engineers |

|

|

UNIVERSAL SYMBOLS

As a guide to the operation of your machine, various universal symbols have been utilized on the instruments and controls. The symbols are shown below with an indication of their meaning.

|

Safety Alert Symbol |

Cutting Height |

|

Diesel Fuel |

Mower-Lowered position |

|

Fuel-Level |

Mower-Raised position |

|

||

|

||

|

||

|

Parking Brake |

Fast |

|

Engine-Stop |

Slow |

|

Preheat |

Engine Speed Control |

|

Engine-Run |

Neutral |

|

Starter Control |

Battery |

|

Power Take-Off Clutch Control-Off Position |

Oil Pressure |

|

(Disengaged) |

Coolant Temperature |

|

Power Take-Off Clutch Control-On Position |

|

|

|

|

|

(Engaged) |

|

California Proposition 65

WARNING

WARNING

Engine exhaust, some of its constituents, certain vehicle components and fluids, contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

FOREWORD

You are now the proud owner of a KUBOTA ZERO TURN MOWER. This machine is a product of KUBOTA's quality engineering and manufacturing. It is made of excellent materials and under a rigid quality control system. It will give you long, satisfactory service. To obtain the best use of your machine, please read this manual carefully. It will help you become familiar with the operation of the machine and contains many helpful hints about machine maintenance. It is KUBOTA's policy to utilize, as quickly as possible, every advance in our research. The immediate use of new techniques in the manufacturing of products may cause some small parts of this manual to become outdated. KUBOTA distributors and dealers will have the most up-to-date information. Please do not hesitate to consult them.

3SAFETY FIRST

This symbol, the industry's ''Safety Alert Symbol'', is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully. It is essential that you read the instructions and safety regulations before you attempt to assemble or use this unit.

3DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

3WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

3CAUTION : Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result if instructions are not followed.

NOTE : Gives helpful information.

ENGLISH

CONTENTS |

|

SAFE OPERATION ............................................................................................ |

-1 |

SERVICING OF MACHINE ......................................................................................... |

1 |

SPECIFICATIONS....................................................................................................... |

3 |

IMPLEMENT LIMITATIONS ........................................................................................ |

5 |

INSTRUMENT PANEL AND CONTROLS................................................................... |

6 |

MOWER MOUNTING .................................................................................................. |

8 |

MOUNTING THE MOWER DECK ........................................................................... |

8 |

ADJUSTING THE MOWER ..................................................................................... |

9 |

DISMOUNTING THE MOWER DECK ..................................................................... |

9 |

INSTALLING PARTS TO THE MOWER.................................................................. |

9 |

Installation of Skid............................................................................................................. |

9 |

Installation of Gauge Wheel.............................................................................................. |

9 |

Installation of Bolt (Adjuster)........................................................................................... |

10 |

OPERATING THE ENGINE....................................................................................... |

11 |

GET ON AND GET OFF MACHINE SAFELY........................................................ |

11 |

STARTING THE ENGINE ...................................................................................... |

11 |

Key Switch...................................................................................................................... |

13 |

STOPPING THE ENGINE...................................................................................... |

14 |

Engine Stop Lever (Inside the Hood).............................................................................. |

14 |

CHECK DURING OPERATING ............................................................................. |

14 |

Immediately Stop the Engine if:...................................................................................... |

14 |

Easy Checker (TM)......................................................................................................... |

14 |

LCD MONITOR ...................................................................................................... |

15 |

Fuel Gauge..................................................................................................................... |

15 |

Coolant Temperature Gauge.......................................................................................... |

16 |

Hourmeter....................................................................................................................... |

16 |

Battery Voltage Meter..................................................................................................... |

16 |

Service Code Display ..................................................................................................... |

17 |

Overheat Alarm............................................................................................................... |

17 |

Fuel Gauge, Warning Lamp and Fuel Valve................................................................... |

17 |

COLD WEATHER STARTING ............................................................................... |

18 |

WARMING UP ....................................................................................................... |

18 |

Warm-up and Transmission Oil in the Low Temperature Range.................................... |

18 |

JUMP STARTING .................................................................................................. |

19 |

OPERATING THE MACHINE.................................................................................... |

20 |

OPERATING NEW MACHINE ............................................................................... |

20 |

Changing Lubricating Oil for New Machines................................................................... |

20 |

Engine Break-in .............................................................................................................. |

20 |

Machine Break-in............................................................................................................ |

20 |

OPERATING FOLDABLE ROPS ........................................................................... |

21 |

ENGLISH

To Fold the ROPS .......................................................................................................... |

21 |

To Raise the ROPS to Upright Position.......................................................................... |

22 |

Adjustment of Foldable ROPS........................................................................................ |

22 |

ENGLISH

CONTENTS |

|

STARTING ............................................................................................................. |

23 |

Operator's Seat............................................................................................................... |

23 |

Seat Belt ......................................................................................................................... |

24 |

Hydraulic Lift Control Pedal ............................................................................................ |

24 |

Throttle Lever.................................................................................................................. |

24 |

Parking Brake Pedal....................................................................................................... |

25 |

Motion Control Lever ...................................................................................................... |

25 |

STOPPING............................................................................................................. |

28 |

FIXING FRONT AXLE............................................................................................ |

28 |

OSCILLATING FRONT AXLE................................................................................ |

28 |

PARKING............................................................................................................... |

29 |

TRANSPORTING................................................................................................... |

29 |

OPTION ................................................................................................................. |

30 |

OPERATING THE MOWER ...................................................................................... |

31 |

MAKING THE MOST OF YOUR MOWER............................................................. |

31 |

ADJUSTING CUTTING HEIGHT ........................................................................... |

31 |

OPERATING MOWER........................................................................................... |

34 |

PTO Lever ...................................................................................................................... |

34 |

Starting ........................................................................................................................... |

34 |

TREATMENT OF MOWER DECK INSIDE SKID................................................... |

35 |

Removing Skids.............................................................................................................. |

35 |

PREVENTING GRASS CLIPPINGS AND DUST FROM SCATTERING............... |

35 |

Rubber Plates Installation............................................................................................... |

35 |

TIRES AND WHEELS ............................................................................................... |

37 |

TIRES..................................................................................................................... |

37 |

Inflation Pressure............................................................................................................ |

37 |

WHEELS ................................................................................................................ |

37 |

Remove and Install Front Caster Wheels....................................................................... |

38 |

PERIODIC SERVICE................................................................................................. |

39 |

HOW TO OPEN THE HOOD, FRONT COVER & STEP ....................................... |

39 |

Hood ............................................................................................................................... |

39 |

Front Cover..................................................................................................................... |

39 |

Step ................................................................................................................................ |

39 |

HOW TO RAISE THE OPERATOR'S SEAT.......................................................... |

40 |

HOW TO TILT UP THE MACHINE ........................................................................ |

41 |

HOW TO OPEN THE LEVER GUIDE.................................................................... |

42 |

LIFT-UP POINT...................................................................................................... |

43 |

Front side:....................................................................................................................... |

43 |

Rear side: ....................................................................................................................... |

43 |

DAILY CHECK ....................................................................................................... |

44 |

LUBRICANTS, FUEL AND COOLANT .................................................................. |

45 |

Checking Engine Oil Level.............................................................................................. |

47 |

Checking Amount of Fuel and Refueling ........................................................................ |

47 |

Checking Transmission Fluid Level................................................................................ |

48 |

Checking Coolant Level.................................................................................................. |

48 |

Checking and Cleaning Radiator Screen and Hood Screen........................................... |

49 |

Checking Tire Pressure .................................................................................................. |

50 |

Inflation Pressure............................................................................................................ |

50 |

Lubricating All Grease Fittings........................................................................................ |

50 |

|

CONTENTS |

MAINTENANCE......................................................................................................... |

51 |

SERVICE INTERVALS .......................................................................................... |

51 |

PERIODIC SERVICE CHART LABEL ................................................................... |

53 |

EVERY 50 HOURS ................................................................................................ |

54 |

Checking Engine Start System....................................................................................... |

54 |

Checking OPC System................................................................................................... |

55 |

Checking Gear Box Oil Level.......................................................................................... |

55 |

Greasing ......................................................................................................................... |

56 |

Oiling............................................................................................................................... |

57 |

EVERY 100 HOURS .............................................................................................. |

58 |

Cleaning Air Cleaner Primary Element........................................................................... |

58 |

Checking Fuel Filter........................................................................................................ |

58 |

Adjusting Fan Drive Belt Tension ................................................................................... |

59 |

Adjusting Parking Brake ................................................................................................. |

60 |

Greasing ......................................................................................................................... |

61 |

Checking Battery Condition ............................................................................................ |

61 |

EVERY 150 HOURS .............................................................................................. |

63 |

Changing Gear Box Oil................................................................................................... |

63 |

EVERY 200 HOURS .............................................................................................. |

64 |

Changing Engine Oil....................................................................................................... |

64 |

Replacing Engine Oil Filter ............................................................................................. |

64 |

Replacing Transmission Oil Filter [HST]......................................................................... |

65 |

Adjusting Front Axle Pivot............................................................................................... |

65 |

EVERY 400 HOURS .............................................................................................. |

66 |

Changing Transmission Fluid and Rear Axle Gear Case Oil (RH and LH) .................... |

66 |

Replacing Hydraulic Oil Filter ......................................................................................... |

67 |

Replacing Fuel Filter....................................................................................................... |

67 |

EVERY 1000 HOURS or EVERY 1 YEAR............................................................. |

67 |

Replacing Air Cleaner Primary Element and Secondary Element.................................. |

67 |

EVERY 1500 HOURS ............................................................................................ |

68 |

Checking Fuel Injection Nozzle (Injection Pressure) ...................................................... |

68 |

EVERY 2000 HOURS or EVERY 2 YEARS .......................................................... |

68 |

Flushing Cooling System and Changing Coolant ........................................................... |

68 |

Anti-freeze ...................................................................................................................... |

69 |

EVERY 3000 HOURS ............................................................................................ |

70 |

Checking Injection Pump................................................................................................ |

70 |

EVERY 1 YEAR ..................................................................................................... |

70 |

Checking Fuel Lines ....................................................................................................... |

70 |

Checking Radiator Hose and Clamp .............................................................................. |

70 |

Checking Hydraulic Hose ............................................................................................... |

71 |

Checking Intake Air Line................................................................................................. |

71 |

Checking Engine Breather Hose .................................................................................... |

71 |

Checking Mower Gear Box Oil Seal ............................................................................... |

71 |

EVERY 4 YEARS................................................................................................... |

72 |

Replacing Hydraulic Hose .............................................................................................. |

72 |

Replacing Fuel Lines ...................................................................................................... |

72 |

Replacing Engine Breather Hose ................................................................................... |

72 |

Replacing Radiator Hose................................................................................................ |

72 |

Replacing Mower Gear Box Oil-Seal .............................................................................. |

72 |

Replacing Intake Air Line................................................................................................ |

72 |

ENGLISH

SERVICE AS REQUIRED...................................................................................... |

72 |

ENGLISH

CONTENTS |

|

Replacing Fuses............................................................................................................. |

72 |

Bleeding Fuel System..................................................................................................... |

72 |

Checking and Replacing Blade....................................................................................... |

73 |

Replacing Mower Belt..................................................................................................... |

74 |

ADJUSTMENT........................................................................................................... |

75 |

MOTION CONTROL LEVER ................................................................................. |

75 |

HST NEUTRAL............................................................................................................... |

75 |

MAXIMUM SPEED (FORWARD) ................................................................................... |

75 |

MOTION CONTROL LEVER OPERATING FORCE ...................................................... |

75 |

MOTION CONTROL LEVER ALIGNMENT .................................................................... |

76 |

MOWER DECK LEVEL.......................................................................................... |

77 |

ANTI-SCALP ROLLERS................................................................................................. |

77 |

LEVEL MOWER DECK (Side-to-Side) ........................................................................... |

78 |

LEVEL MOWER DECK (Front-to-Rear) ......................................................................... |

79 |

GENERAL TORQUE SPECIFICATION ................................................................. |

81 |

TIGHTENING TORQUE CHART ........................................................................... |

82 |

STORAGE ................................................................................................................. |

83 |

MACHINE STORAGE ............................................................................................ |

83 |

REMOVING THE MACHINE FROM STORAGE.................................................... |

83 |

TROUBLESHOOTING............................................................................................... |

84 |

ENGINE TROUBLESHOOTING ............................................................................ |

84 |

POWER TRAIN TROUBLESHOOTING................................................................. |

85 |

BATTERY TROUBLESHOOTING ......................................................................... |

86 |

MACHINE TROUBLESHOOTING ......................................................................... |

87 |

MOWER TROUBLESHOOTING............................................................................ |

88 |

INDEX........................................................................................................................ |

90 |

SAFE OPERATION  -1

-1

SAFE OPERATION

Careful operation is your best insurance against an accident. The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other people or property. Read and understand this manual carefully before operating the machine. All operators, no matter how much experience they may have had, must read this and other related manuals before operating the machine or any implement attached to it. It is the owner's obligation to instruct all operators in safe operation.

If the operator(s) or mechanic(s) cannot read English it is the owner's responsibility to explain this material to them. This mowing machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury or death.

1.BEFORE OPERATING

1.The ZERO TURN MOWING MACHINE has different steering characteristics than other machines with a steering wheel and does not have a service brake pedal (but, has a parking brake lock pedal that can be used to stop the machine in an emergency. Normal slowing down and stopping is done with the motion control levers.). Read and understand the operators manual before operating the machine. Practice operating machine at low engine speed without mower engaged in an unobstructed area.

2.Know your equipment and its limitations. Read all instructions in this manual before attempting to start and operate the machine.

3.Pay special attention to the danger, warning and caution labels on the machine itself.

4.The ROPS is an integral and effective safety device. KUBOTA recommends the use of a Roll Over Protective Structures (ROPS) and seat belt in almost all applications. This combination will reduce the risk of serious injury or death, should the machine be upset.

The machine is equipped with a Foldable ROPS, which may be temporarily folded down only when absolutely necessary for areas with height constraints. There is no operator protection provided by the ROPS in the folded position. For operator safety you must set the ROPS in the upright and locked position and put on the seat belt for all other operations.

DO NOT remove the ROPS.

If the ROPS is loosened or removed for any reason, make sure that all parts are reinstalled correctly before operating the machine.

Never modify or repair a ROPS because welding, bending, drilling, grinding, or cutting may weaken the structure.

If any structural member of the ROPS is damaged, replace the entire structure at your local KUBOTA Dealer. Any alterations to a ROPS must be approved by the manufacturer.

Check the area to be mowed and never fold down a folding ROPS in areas where there are slopes, drop offs or water.

Check carefully for overhead clearances (i.e. branches, doorways, electrical wires) before driving under any objects and do not contact them.

Keep the ROPS in safe operating condition by periodically thoroughly inspecting for damage and keeping all mounting fasteners tight.

ENGLISH

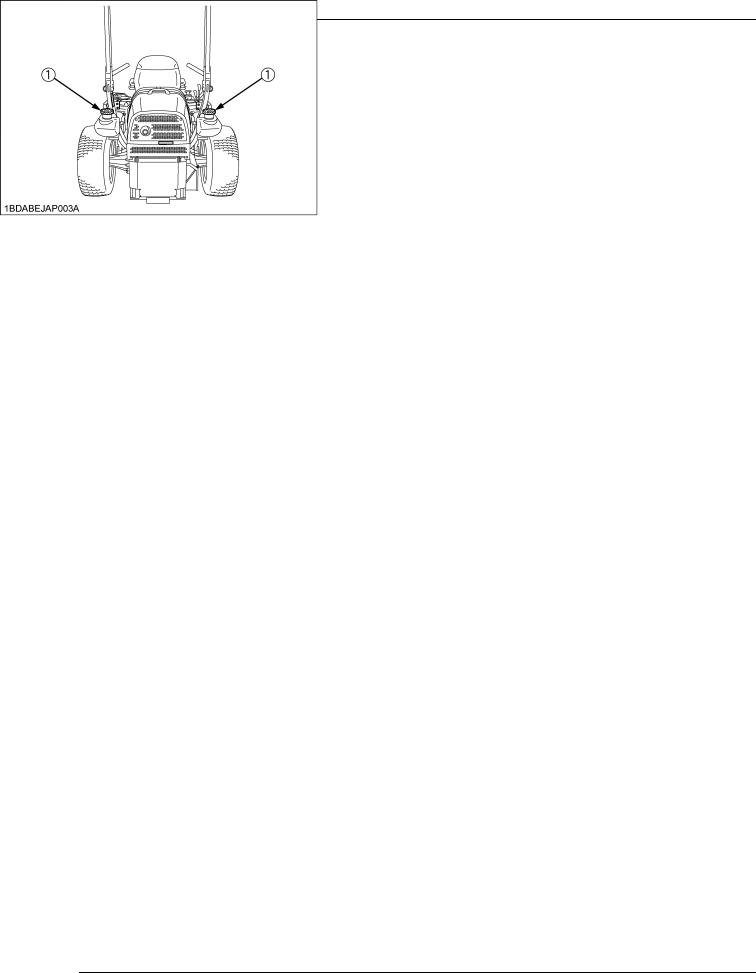

(1)ROPS

(2)Seat belt

ENGLISH

-2 SAFE OPERATION

-2 SAFE OPERATION

5.Always use the seat belt when the ROPS is upright. Do not use the seat belt if the ROPS is down or if there is no ROPS. Check the seat belt regularly and replace if frayed or damaged. Be certain that the seat belt can be released quickly in the event of an emergency.

6.Do not operate the machine or any attachments while under the influence of alcohol, medication, controlled substances or when fatigued.

7.Do not wear loose, torn, or bulky clothing around machine. The clothing may catch on moving parts or controls, leading to the risk of accident. Wear and use any additional safety items such as hard hat, safety boots or shoes, eye and hearing protection, gloves, etc., as appropriate or required.

8.Do not wear radio or music headphones while operating the machine.

Safe operation requires your full attention.

9.Carefully check the vicinity before operating machine or any implement attached to it. Clear the work area of objects (wires, rocks, etc.) that might be picked up and thrown. Check for overhead clearance which may interfere with a grass catcher.

10.Check brakes and other mechanical parts for correct adjustment and wear. Replace worn or damaged parts promptly. Check the tightness of all nuts and bolts regularly. (For further details, see "PERIODIC SERVICE" and "ADJUSTMENT" section.)

11.Keep all shields and guards in place. Replace any that are damaged or missing. Do not operate unless they are functioning properly.

12.Before allowing other people to use your machine, explain how to operate and have them read this manual before operation.

13.Do not allow any bystanders around or near machine during operation.

14.Do not allow passengers, children or non-qualified operators on the machine at any time. The operator must remain in the machine seat throughout operation.

15.In addition to the design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, and prudence of personnel involved in the operation, transport, maintenance of facilities.

16.Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Keep the machine and attachments in good operating condition and keep safety devices in place and in proper working condition. Do not operate unless they are functioning properly.

17.Do not modify the machine. Unauthorized modification may affect the function of the machine, which may result in personal injury.

18.Use only implements recommended by KUBOTA. Use proper ballast to front or rear of machine to reduce the risk of upsets. Follow the "SAFE OPERATION" procedures, specified in the manuals with equipment.

19.Keep your machine clean. Accumulations of dirt, grease, and trash can contribute to fires and lead to personal injury.

20.The exhaust gas from the muffler is very hot. To prevent fire, do not expose dry grass, mowed grass, oil and any other combustible materials to exhaust gas. Use a spark arrester where required. Also keep the engine and muffler clean all the time.

2.OPERATING

C Starting

1.Always sit in the operator's seat when starting engine or operating levers or controls.

2.Before starting the engine make sure that the motion control levers are in neutral lock, the parking brake is applied, and Power Take Off (PTO) is disengaged (OFF).

3.Do not start engine by shorting across starter terminals. The machine may start in gear and move if normal starting circuitry is bypassed.

4.Do not operate or idle engine in a non-ventilated area. Carbon monoxide gas is colorless, odorless, and deadly.

5.Do not start engine while tilting deck.

C Working

1.Do not turn sharply when driving at high speed.

2.To avoid tip over, slow down when turning on uneven terrain or before stopping.

3.Do not operate near ditches, holes, embankments, or other terrain, which may collapse under the machine weight. The risk of machine tip over increases when the ground is loose or wet.

4.Park the machine on a firm and level surface.

5.Watch where you are going at all times. Watch for and avoid obstacles. Be alert at curbs, shrubs, near trees, and other obstructions and hidden hazards. Obstacles can damage machine (fuel hoses, wire harness etc.).

6.Know what is behind you before backing up. Look to the rear before and when backing. Do not mow while in reverse unless absolutely necessary and make sure the area immediately behind you is clear of obstructions or holes and small children. Use extra caution when machine is equipped with Grass Catcher. Your view to the rear is restricted.

7.When working in groups, always let others know what you are doing ahead of time.

8.Do not drive machine on streets or highways. Watch for traffic when you cross roads or operate near roads.

9.Be aware of the mower discharge direction and do not point it at anyone.

Never operate with the discharge deflector raised, removed or altered, unless using a grass catcher.

SAFE OPERATION  -3

-3

10.When using any attachments, never direct discharge material toward bystanders. Do not allow anyone and pets near the attachments while in operation.

Do not mow when bystanders are present in the mowing area.

11.To reduce fire hazards, keep the engine exhaust area free of grass or leaves.

12.Be sure rotating blades and engine are stopped and the key is removed before placing hands or feet near blades and cleaning blockages or unclogging chute.

13.Keep hands and feet away from the cutting units. Shut the engine off and wait for all movement to stop before removing grass catcher or unclogging chute.

14.Always inspect the mower for damage after striking a foreign object. Repair or replace any damaged parts before restarting.

15.Operate during daylight or in bright artificial light.

16.If the machine starts to vibrate abnormally, disengage the drive to the attachments, stop the engine and remove the key. Then check the machine immediately.

17.Do not operate the machine when there is a possibility of lightning. Even if the machine is equipped with a cabin, the operator is not protected from lightning.

18.Never raise the deck with the blades running. Stop blades if not mowing.

C Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are attracted to the machine and mowing activity.

Never assume that children will remain where you last saw them.

1.Keep children out of the mowing area and under the watchful care of another responsible adult.

2.Be alert and turn machine off if children enter the area.

3.Before and when backing, look behind and down for small children.

4.Never carry children. They may fall off and be seriously injured or interfere with safe machine operation.

5.Never allow children to operate the machine, even under adult supervision. Local regulation can restrict the age of the operator.

6.Use extra care when approaching blind corners, shrubs, trees, or other obstructions that might hide children from sight.

7.Do not mow in reverse unless it is absolutely necessary.

C Operators, age 60 years and above

Data indicates that operators, age 60 years and above, are involved in a large percentage of machine-related injuries. These operators must evaluate their ability to operate the machine safely enough to protect themselves and others from serious injury.

C Pulling loads

Use extra care when pulling loads to reduce the risk of serious personal injury or death due to a machine tip-over.

a)Pull only from the hitch. Never attach loads to the axle housing or any other point above hitch.

b)Limit loads to those you can safely control.

c)Do not turn sharply.

d)Use care when backing.

e)Use front ballast or wheel weights when suggested in

this Operator's Manual.

A Stopping distance increases with speed and weight of towed load. Travel slowly and allow extra time and distance to stop.

A Never allow children or others in or on towed equipment.

A Use additional caution when turning or operating under adverse surface conditions.

C Operation on slopes

Slopes are major factor related to loss-of-control and tipover accidents, which can result in severe injury or death. All slopes require extra caution.

If you cannot back up the slope or if you feel uneasy on it, do not mow it.

If the engine stops when operating on a slope apply the parking brake immediately to prevent machine run away.

DO

1.To avoid tip over, operate across the slopes not up and down. Stay off hills and slopes too steep for safe operation.

2.Remove obstacles such as rocks, tree limbs, etc.

ENGLISH

ENGLISH

-4 SAFE OPERATION

-4 SAFE OPERATION

3.Stay alert for holes in the terrain and other hidden hazards. Keep away from drop-offs. Uneven terrain could overturn the machine. Tall grass can hide obstacles.

4.Follow the manufacturer's recommendations for wheel weight or counterweights to improve stability.

5.Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction. If tires lose traction, disengage PTO and proceed slowly straight down the slope.

6.Reduce speed and exercise extreme caution on slopes and in sharp turns to prevent tip-over or loss of control.

7.Use special caution when changing direction on slopes. Slow down, and use extra caution when changing direction on a slope.

DO NOT

1.Do not turn on slopes unless necessary. If necessary, turn uphill slowly and gradually.

2.Do not mow near drop-offs, ditches, or embankments. The mower could suddenly turn over if a wheel is over the edge of cliff or ditch, or if an edge caves in.

3.Do not mow on wet grass. Reduced traction could cause sliding and loss of control.

4.Do not try to stabilize the machine by putting your foot on the ground.

5.Do not use grass catcher on steep slopes.

6.Do not start or stop suddenly on slopes. If tires lose traction, disengage PTO and proceed slowly straight down the slope.

7.Never "freewheel". Do not let the machine travel downhill with motion control levers at neutral lock position or in neutral.

8.Do not operate machine without the mower deck installed.

C Stopping

1.Park the machine on level ground.

2.Make sure that the machine and all attachments have come to a complete stop before you get off.

3.Before you get off, apply parking brake, place the motion control levers in their neutral lock positions, disengage the PTO, lower all attachments to the ground, turn off the engine, and remove the key.

4.Do not park the machine on dry grass or leaves.

3.USING THE PTO

1.Before installing or using PTO-driven equipment, read the manufacturer's manual and review the safety labels attached to the equipment.

2.Wait until all moving components have completely stopped before connecting, disconnecting, adjusting, cleaning, or servicing any PTO-driven equipment.

3.Use the PTO with KUBOTA approved attachments.

The speed of PTO:

ZD1211 / ZD1211R / ZD1211L / ZD1211RL Without mower: 2450 to 2550 rpm at 3000 engine rpm

4.USING THE LIFT LINK

1.Use lift link only with authorized attachments designed for lift link usage.

5.TRANSPORTING

1.Disengage power to attachment(s) when transporting or not in use.

2.Do not tow this machine. Use a suitable truck or trailer when transporting on public roads.

3.Use extra care when loading or unloading the machine into a trailer or truck. Use full width ramps for loading machine into trailer or truck.

4.This machine is not allowed to be used on public roads.

5.Shut off fuel while storing or transporting.

6.Tie the machine down securely using straps, chains, cable, or ropes.

7.Both front and rear straps should be directed down and outward from the machine.

6.SERVICING AND STORAGE

C Servicing

1.Before servicing, park the machine on a firm, level surface and apply the parking brake. Remove the key to prevent accidental start-up.

2.Allow the machine time to cool before touching the engine, muffler, radiator, etc.

3.Always stop the engine before refueling. Avoid spills and overfilling. Wipe up spilled fuel immediately.

(1) Fuel tank cap

4.Use extra care in handling diesel fuels. They are flammable.

SAFE OPERATION  -5

-5

(1)Use only an approved container.

(2)Do not remove fuel cap or refuel with the engine running. Allow engine to cool before refueling. Do not smoke while refueling or when standing near fuel.

(3)Do not refuel the machine indoors and always clean up spilled fuel or oil.

(4)Do not store the machine or fuel container inside where there is an open flame, such as in a water heater.

5.Do not smoke when working around battery or when refueling. Extinguish all cigarettes, cigars, pipes, and other sources of ignition. Keep all sparks and flames away from battery and fuel tank.

Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner.

Always place containers on the ground away from your vehicle before filling.

Remove equipment from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment with a portable container, rather than from a fuel dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

Do not use a nozzle lock open device.

If fuel is spilled on clothing, change clothing immediately.

Replace fuel cap and tighten securely.

Charge batteries in an open well ventilated area, away from spark and flames.

A battery, especially when charging, will give off hydrogen and oxygen gases, which can explode and cause serious personal injury.

Unplug charger before connecting or disconnecting from battery.

6.Before "jump starting" a dead battery, read and follow all the instructions.

7.Disconnect battery or remove spark plug wire before making any repairs. Disconnect the negative terminal first and the positive last. Reconnect positive first and negative last. Wear protective clothing and use insulated tools.

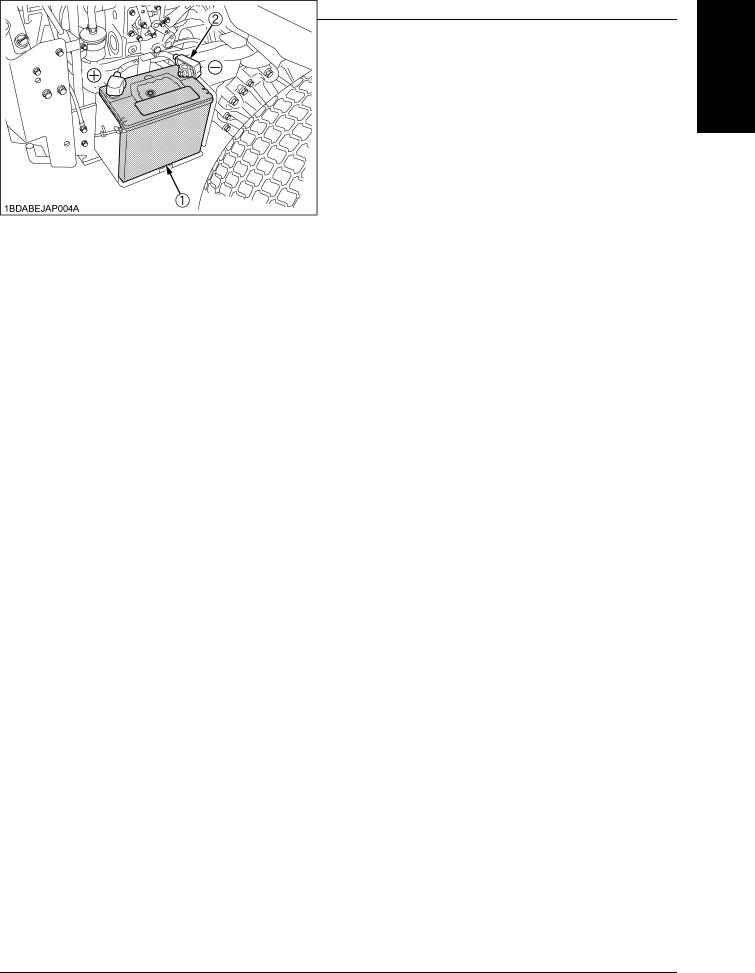

(1) Battery |

(+): Positive terminal |

(2) Ground cable |

(-): Negative terminal |

8.Do not use or charge the refillable type battery if the fluid level is below the LOWER (lower limit level) mark. Otherwise, the battery component parts may prematurely deteriorate, which may shorten the battery's service life or cause an explosion. Check the fluid level regularly and add distilled water as required so that the fluid level is between the UPPER and LOWER levels.

ENGLISH

ENGLISH

-6 SAFE OPERATION

-6 SAFE OPERATION

9.Keep first aid kit and fire extinguisher handy at all times.

10.Do not remove the radiator cap while coolant is hot. When cool, slowly rotate cap to the first stop and allow sufficient time for excess pressure to escape before removing the cap completely. If the machine has a coolant recovery tank, add coolant there instead of the radiator.

11.Do not attempt to mount a tire on a rim unless qualified to do so and all proper safety precautions are followed. Never allow untrained personnel to service machine.

12.Always maintain the correct tire inflation pressure. Do not inflate tires above the recommended pressure shown in the Operator's Manual.

16.Fluid escaping from pinholes may be invisible. Use a piece of cardboard or wood to search for suspected leaks: do not use hands. Use safety goggles or other eye protection.

If you get injured by escaping fluid, see a medical doctor at once. Serious infection or reaction will result if proper medical treatment is not administered immediately. This fluid can produce gangrene or severe allergic reaction.

13.Provide adequate support when changing wheels.

14.Make sure that wheel nuts and bolts have been tightened to the specified torque.

15.Escaping hydraulic fluid under pressure has sufficient force to penetrate the skin causing serious personal injury. Before disconnecting lines, be sure to relieve all pressure. Before applying pressure to the system, make sure all connections are tight and that lines, pipes, and hoses are not damaged.

(1)Cardboard

(2)Hydraulic line

(3)Magnifying glass

17.Keep hands and feet away from moving parts. If possible, do not make adjustments or repairs with the engine running.

18.Keep machine free of grass, leaves, or other debris build-up.

19.Do not change the engine governor setting or overspeed the engine.

20.Do not run a machine inside a closed area.

21.Mower blades are sharp and can cut your hands. Wrap the blade(s) or wear gloves, and use extra caution when servicing them. Never straighten or weld blades.

22.Keep nuts and bolts, especially blade attachment bolts, tight and keep equipment in good condition.

23.Never tamper with safety devices. Check their operation for proper function regularly.

24.Waste products such as used oil, fuel, coolant, brake fluid, and batteries, can harm the environment, people, pets and wildlife. Please dispose of properly.

25.Do not use beverage containers for waste fluids or other products. Someone, particularly children, may drink them by mistake.

26.Securely support machine or any machine elements with stands or suitable blocking before working underneath. For your safety do not rely on hydraulically supported devices, they may leak down, suddenly drop or be accidently lowered.

27.See your local Recycling Center or KUBOTA Dealer to learn how to recycle or get rid of waste products.

A A Material Safety Data Sheet (MSDS) provides specific details on chemical products; physical and health hazards, safety procedures, and emergency response techniques. The seller of the chemical products used with your machine is responsible for providing the MSDS for that product upon request.

C Storage

1.Keep the machine and supply of fuel in locked storage and remove the ignition key to prevent children or others from playing or tampering with them.

2.To avoid sparks from an accidental short circuit, always disconnect the battery's ground cable (-) first and reconnect it last.

(1) |

Battery |

(+): Positive terminal |

(2) |

Ground cable |

(-): Negative terminal |

3.To avoid the danger of exhaust fume poisoning, do not operate the engine in a closed building without adequate ventilation.

4.To reduce fire hazards, clean the machine thoroughly before storage. Dry grass and leaves around the engine and muffler may ignite.

5.Let engine cool before storing and do not store near flame.

6.Shut off fuel while storing or transporting.

SAFE OPERATION  -7

-7

ENGLISH

ENGLISH

-8 SAFE OPERATION

-8 SAFE OPERATION

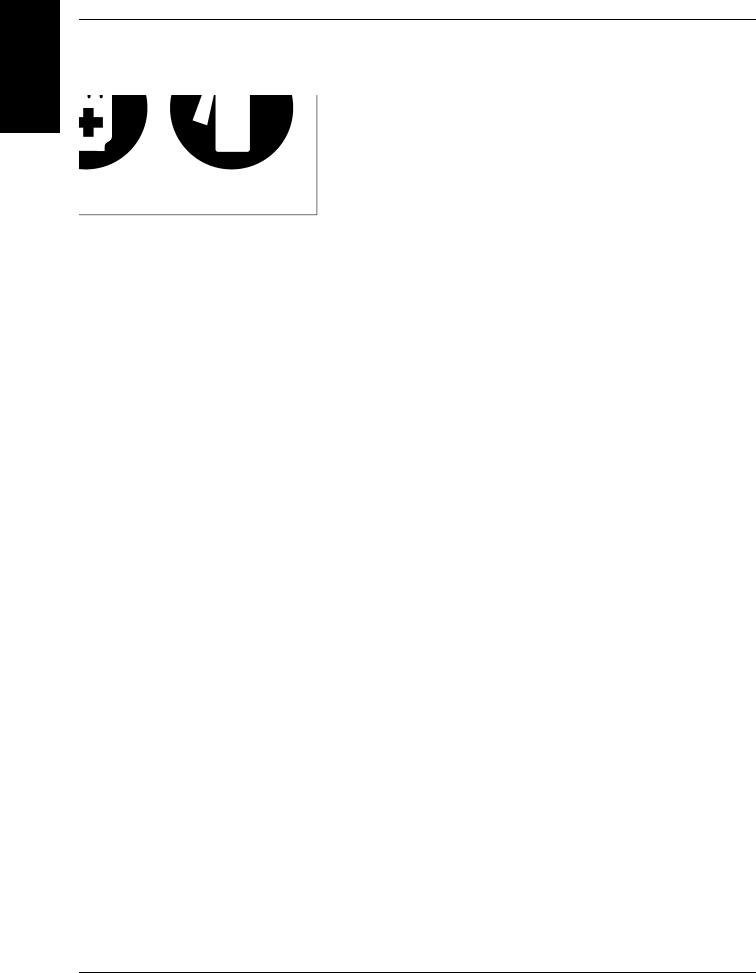

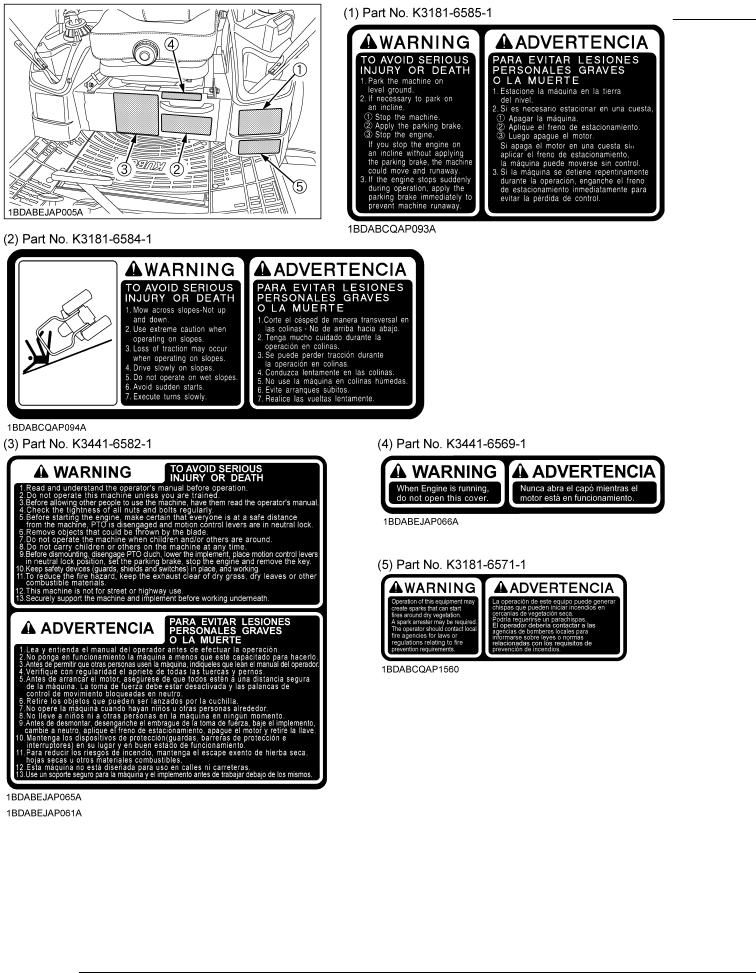

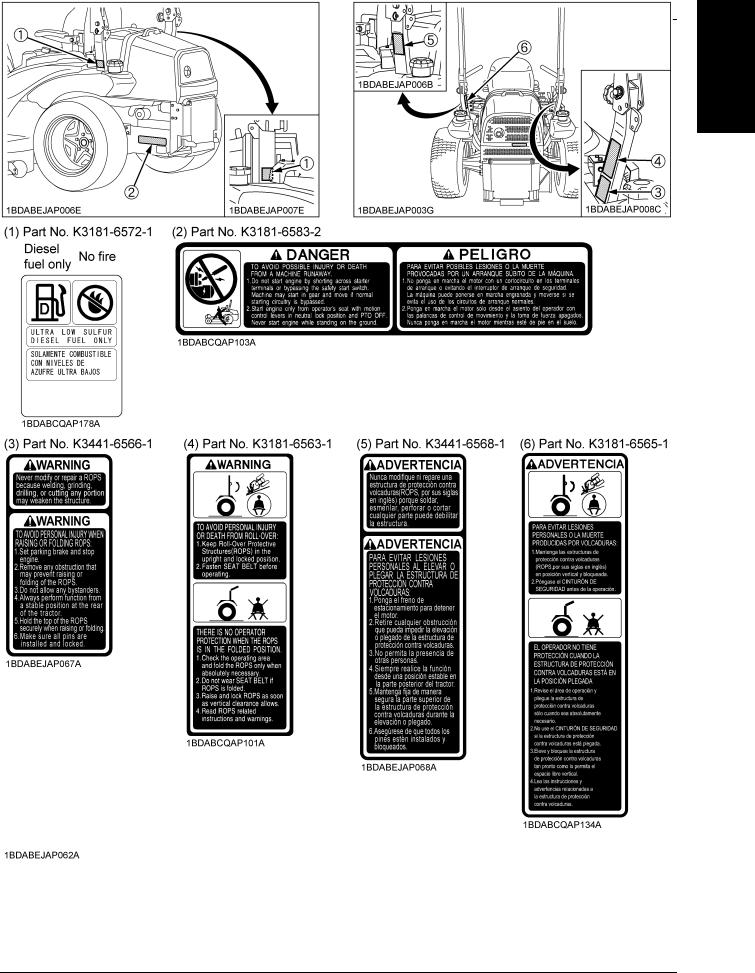

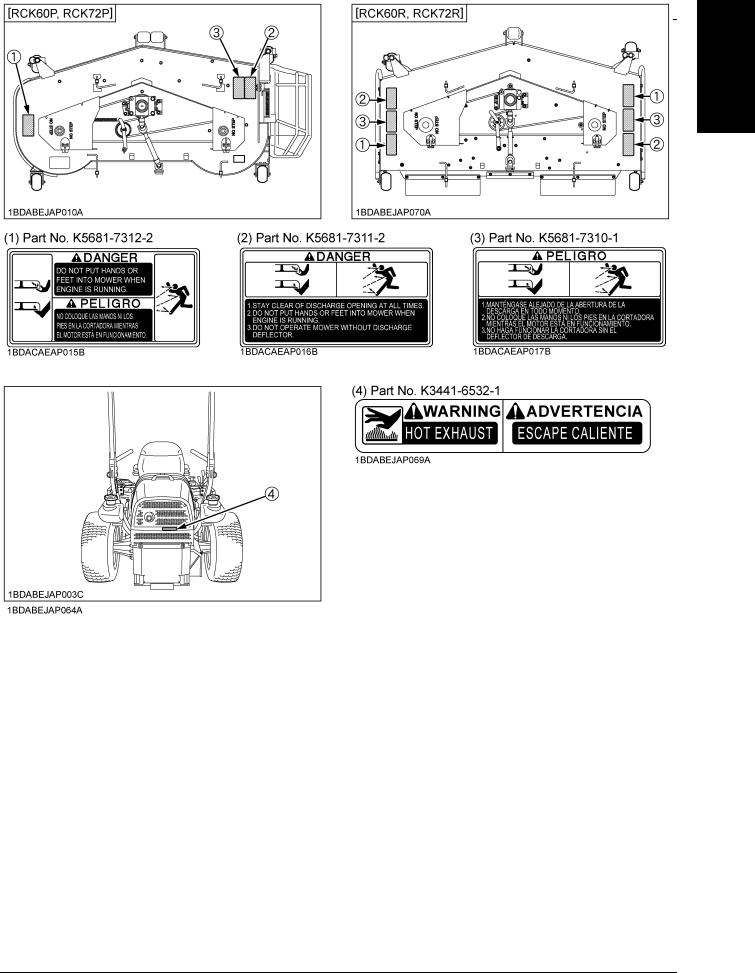

7. DANGER, WARNING AND CAUTION LABELS

SAFE OPERATION  -9

-9

ENGLISH

-10 SAFE OPERATION

-10 SAFE OPERATION

ENGLISH

SAFE OPERATION  -11

-11

ENGLISH

8.CARE OF DANGER, WARNING, AND CAUTION LABELS

1.Keep danger, warning and caution labels clean and free from obstructing material.

2.Clean danger, warning and caution labels with soap and water, and dry with a soft cloth.

3.Replace damaged or missing danger, warning and caution labels with new labels from your local KUBOTA Dealer.

4.If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new label(s) is (are) attached in the same location(s) as the replaced component.

5.Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to outside edge.

SERVICING OF MACHINE 1

SERVICING OF MACHINE

After reading this manual thoroughly, you will find that you can do some of the regular maintenance yourself. Your dealer is interested in helping you get the best performance from your new machine and wants to help you get the most value from it. When in need of parts or major service, be sure to see your KUBOTA Dealer with the machine, engine and mower serial numbers.

Locate the serial numbers now and record them in the space provided.

Type |

Serial No. |

Machine

ROPS

Engine

Mower

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

C Warranty

This machine is warranted under the Kubota Limited Express warranty, a copy of which may be obtained from your selling dealer. No warranty shall, however, apply if the machine has not been handled according to the instruction given in the Operator's Manual even it is within the warranty period.

C Scrapping the machine and its procedure

To put the machine out of service, correctly follow the local rules and regulations of the country or territory where you scrap it. If you have questions, consult your local KUBOTA Dealer.

(1)Machine identification plate

(2)Machine serial No.

(3)ROPS serial No.

(1) Engine serial No.

ENGLISH

(1)Mower identification plate

(2)Mower serial No.

2 SERVICING OF MACHINE

ENGLISH

(1)Mower identification plate

(2)Mower serial No.

SPECIFICATIONS 3

SPECIFICATIONS

|

Model |

|

ZD1211 |

|

ZD1211R |

|

ZD1211L |

|

|

ZD1211RL |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

|

D1105 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Max. engine power |

kW (HP) |

|

18.5 (24.8) (*1) (*2) |

|

|

|

|

|||||

|

(Gross) |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Type |

|

|

|

|

Liquid-cooled |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

Number of cylinders |

|

|

|

|

3 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

Bore and stroke |

mm (in.) |

|

|

78 x 78.4 (3.07 x 3.09) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

|

Total displacement |

cm (cu. in.) |

|

1123 (68.5) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

Engine |

Rated revolution |

rpm |

|

|

|

3000 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

Low idling revolution |

rpm |

|

|

1400 to 1500 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel |

|

|

|

|

Diesel fuel No.1 [below -10 |

(14 |

)] |

|

|

|||

|

|

|

|

|

Diesel fuel No.2 [above -10 |

(14 |

)] |

|

|

||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

Starter |

|

|

|

Electric starter with battery, glow plug, 12V, 1.2kW |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||

|

Lubrication |

|

|

|

|

Forced lubrication by gear pump |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

Cooling |

|

|

|

|

Liquid with pressurized radiator |

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

Battery |

|

|

|

|

SMF51R (12V, RC:80min, CCA:430A) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Fuel tank |

|

L (U.S.gals.) |

|

49 (12.9) |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Engine crankcase |

L (U.S.qts.) |

|

3.9 (4.1) |

|

|

|

|

|||||

|

(with filter) |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||

Capacities |

Engine coolant |

L (U.S.qts.) |

|

3.5 (3.7) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recovery tank |

L (U.S.qts.) |

|

0.25 (0.26) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Transmission case |

|

|

|

|

|

|

|

|

|

|

||

|

including Rear axle |

L (U.S.qts.) |

|

12.1 (12.8) (*3) |

|

|

|

|

|||||

|

gear case |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Overall length |

mm (in.) |

2260 (89.0) |

|

|

|

2380 (93.7) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Overall width |

mm (in.) |

1510 (59.4) |

|

|

|

1540 (60.6) |

||||||

|

w/o mower deck |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With |

|

|

|

|

|

|

|

|

|

|

|

|

|

ROPS |

mm (in.) |

|

2000 (78.7) |

|

|

|

|

|||

|

Overall |

|

upright |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

height |

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

|

With |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

ROPS |

mm (in.) |

|

1640 (64.6) |

|

|

|

|

||||

|

|

|

folded |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Wheelbase |

|

mm (in.) |

1440 (56.7) |

|

|

|

1560 (61.4) |

|||||

|

|

|

|

|

|

|

|

||||||

|

Min. ground |

mm (in.) |

135 (5.31) |

|

|

|

135 (5.31) |

||||||

|

clearance |

|

W/60" |

|

|

|

W/72" |

||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Tread |

|

Front |

mm (in.) |

1064 (41.9) |

|

|

|

1250 (49.2) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rear |

mm (in.) |

|

1210 (47.6) |

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weight |

|

|

|

kg (lbs.) |

760 (1676) with 60" |

|

765 (1687) with 60" |

|

790 (1742) with 72" |

|

805 (1775) with 72" |

||

(W/O FUEL, W/MOWER DECK) |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENGLISH

4 SPECIFICATIONS

ENGLISH |

|

|

|

|

|

|

|

|

|

|

|

Model |

|

ZD1211 |

ZD1211R |

|

ZD1211L |

ZD1211RL |

|||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front |

|

|

15 x 6.0 - 6 |

|

|

|

|

|

|

|

|

|

Smooth semi-pneumatic Non flat tire |

|

|||

|

|

Tires |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rear |

|

|

26 x 12.0 - 16 |

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

4PR Turf Low profile tire |

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Traveling |

Traveling |

|

Forward |

mph (km/h) |

|

0 to 10.6 (0 to 17.0) (*2) |

|

||

|

|

|

|

|

|

|

|

|

||

|

speeds |

|

|

|

|

|

|

|

|

|

|

|

Reverse |

mph (km/h) |

|

0 to 5.3 (0 to 8.5) (*2) |

|

||||

|

system |

|

|

|

||||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering |

|

|

|

2 - Hand levers |

|

|

||

|

|

|

|

|

|

|

||||

|

|

Transmission |

|

|

2 - HST w / Gear |

|

||||

|

|

|

|

|

|

|

||||

|

|

Parking brake |

|

|

Wet multi disk / Foot applied, released |

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

Min. turning radius |

mm (in.) |

|

0 (0) |

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

Revolution |

|

|

|

1 speed (2540 rpm at 3000 engine rpm) |

|

|||

|

|

|

|

|

|

|

||||

|

PTO |

Drive system |

|

|

Shaft drive, KUBOTA 10 tooth involute spline |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Clutch type |

|

|

|

Wet multi disks |

|

|

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

PTO brake |

|

|

|

Wet single disk |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

(Specifications and design subject to change without notice)

NOTE:

*1: Manufacturer's estimate, SAE J1940

*2: At 3000 engine rpm [ZD1211, ZD1211R, ZD1211L, ZD1211RL] *3: Oil amount when the oil level is at the upper level.

|

Model |

|

RCK60P-1200Z |

RCK60RP-1200Z |

RCK72P-1200Z |

RCK72RP-1200Z |

||

|

|

|

|

|

|

|

|

|

|

Suitable machine |

|

ZD1211 |

ZD1211R |

|

ZD1211L |

ZD1211RL |

|

|

|

|

|

|

|

|

||

|

Mounting method |

|

|

Quick joint, Parallel linkage |

|

|||

|

|

|

|

|

||||

|

Adjustment of cutting height |

|

Dial gauge |

|

||||

|

|

|

|

|

|

|

|

|

|

Cutting width |

mm (in.) |

1524 (60.0) |

|

1829 (72.0) |

|||

|

|

|

|

|

|

|

||

|

Cutting height |

mm (in.) |

|

25 to 127 (1.0 to 5.0) |

|

|||

|

|

|

|

|

|

|

|

|

PRO |

Weight (Approx.) |

kg (lbs.) |

140 (306) |

145 (320) |

|

165 (364) |

160 (353) |

|

|

|

|

|

|

|

|

|

|

Commercial |

Blade spindle speed |

r/s (rpm) |

55.9 (3355) *1 |

52.4 (3145) *1 |

|

46.7 (2800) *1 |

||

Deck |

|

|

|

|

|

|

|

|

(Fabricated |

Blade tip velocity |

m/s (fpm) |

92 (18050) *1 |

86 (16900) *1 |

|

92 (18050) *1 |

91 (18000) *1 |

|

deck) |

|

|

|

|

|

|

|

|

Blade length |

mm (in.) |

523 (20.6) |

|

625 (24.6) |

||||

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Number of blades |

|

|

|

3 |

|

||

|

|

|

|

|

|

|

|

|

|

Mower gear box capacity |

L (U.S.qts.) |

0.5 (0.53) |

0.4 (0.42) |

|

0.5 (0.53) |

0.4 (0.42) |

|

|

|

|

|

|

|

|

|

|

|

|

Total length |

mm (in.) |

974 (38.4) |

1000 (39.4) |

|

1162 (45.8) |

1155 (45.5) |

|

|

|

|

|

|

|

|

|

|

Dimensions |

Total width |

mm (in.) |

1875 (73.8) |

1600 (63.0) |

|

2180 (85.8) |

1910 (75.2) |

|

|

|

|

|

|

|

|

|

|

|

Total height |

mm (in.) |

426 (16.8) |

420 (16.5) |

|

421 (16.6) |

413 (16.3) |

|

|

|

|

|

|

|

|

|

*1: Engine Max rpm

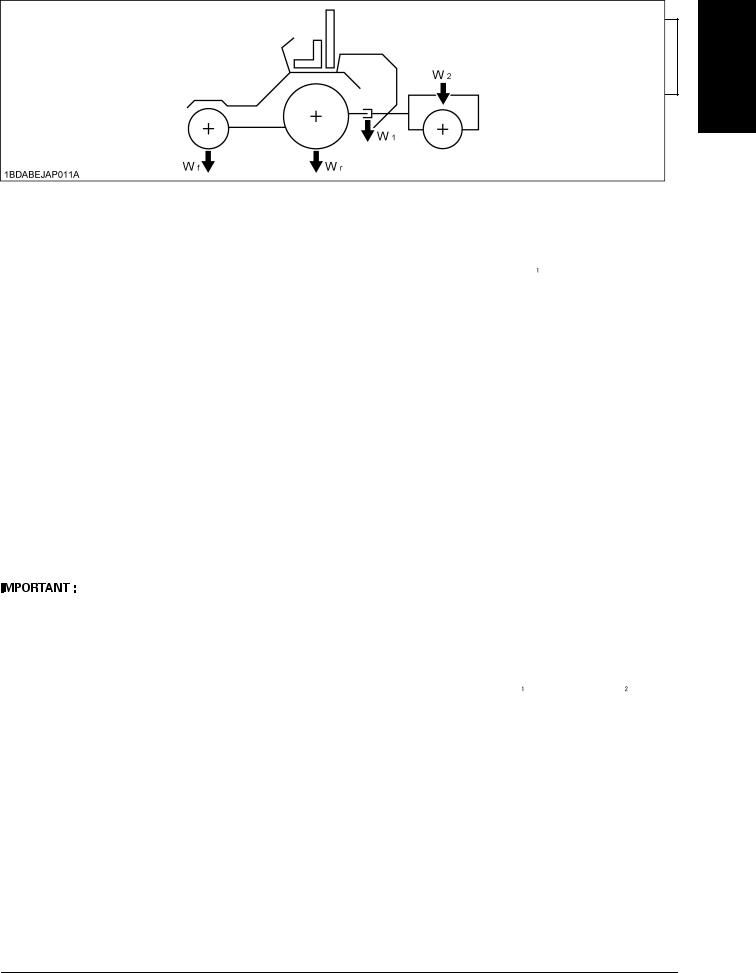

IMPLEMENT LIMITATIONS |

5 |

IMPLEMENT LIMITATIONS

The KUBOTA Machine has been thoroughly tested for proper performance with implements sold or approved by KUBOTA. Use with implements below may result in malfunctions or failures of the machine, damage to other property and injury to the operator or others.

A Implements are not sold or approved by KUBOTA

A Implements exceed the maximum specifications listed below, or A Implements are otherwise unfit for use with the KUBOTA Machine

[Any malfunctions or failures of the machine resulting from use with improper implements are not covered by the warranty.]

UNIT |

Maximum loading weight |

Implement weight W |

Maximum total weight |

||

|

|

||||

Front axle Wf |

Rear axle Wr |

||||

|

|

|

|||

|

|

|

|

|

|

ZD1211, ZD1211R |

200 kg (440 lbs.) |

920 kg (2028 lbs.) |

200 kg (440 lbs.) |

1120 kg (2468 lbs.) |

|

ZD1211L, ZD1211RL |

|||||

|

|

|

|

||

|

|

|

|

|

|

OPTION: When using the hitch kit.

A Do not operate on slope when pulling loads.

A Total towed weight must not exceed combined weight of pulling machine, ballast and operator. A Follow the manufacturer's recommendations for weight limits for towed equipment.

UNIT |

Maximum loading weight |

Maximum total |

Tongue weight |

Towing capacity |

||

|

|

weight |

W |

W |

||

Front axle Wf |

Rear axle Wr |

|||||

|

||||||

|

|

|

|

|

|

|

ZD1211, ZD1211R |

200 kg (440 lbs.) |

630 kg (1388 lbs.) |

830 kg (1829 lbs.) |

30 kg (66 lbs.) |

100 kg (220 lbs.) |

|

ZD1211L, ZD1211RL |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

ENGLISH

ENGLISH

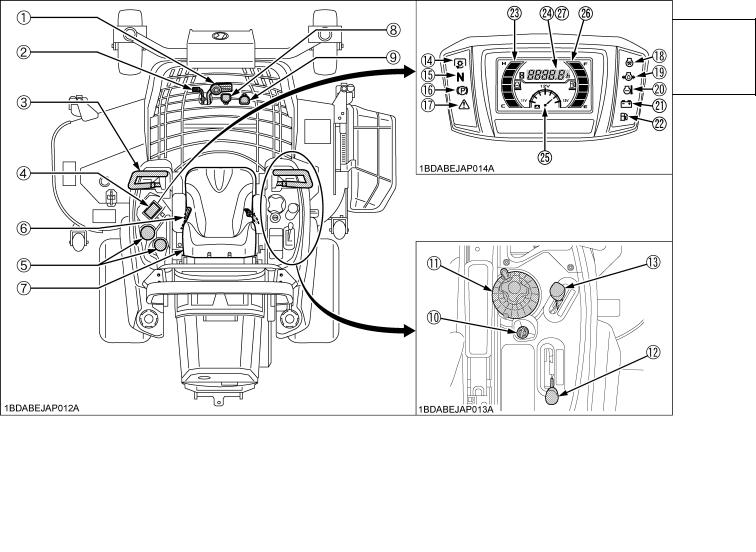

6 INSTRUMENT PANEL AND CONTROLS

INSTRUMENT PANEL AND CONTROLS

|

ILLUSTRATED CONTENTS |

|

ILLUSTRATED CONTENTS |

||

(1) |

Parking brake pedal................................ |

11, 25 |

(15) |

Neutral indicator (Motion control lever)... |

12 |

(2) |

Parking brake lock pedal........................ |

11, 25 |

(16) |

Parking brake warning indicator............. |

11 |

(3) |

Motion control lever................................ |

12, 25 |

Easy Checker (TM): (17) to (22) |

|

|

(4) |

LCD monitor........................................... |

15 |

(17) |

Master system warning indicator............ |

14 |

(5) |

Cup holder.............................................. |

- |

(18) |

Glow plug indicator................................. |

14 |

(6) |

Seat belt................................................. |

24 |

(19) |

Engine oil pressure warning indicator..... |

14 |

(7) |

Operator's seat....................................... |

23 |

(20) |

Engine overheat warning indicator......... |

14 |

(8) |

Hydraulic lift control pedal (DOWN)........ |

24 |

(21) |

Electrical charge warning indicator......... |

14 |

(9) |

Hydraulic lift control pedal (UP)............... |

24 |

(22) |

Fuel level indicator.................................. |

14 |

(10) |

Key switch.............................................. |

13 |

(23) |

Coolant temperature gauge.................... |

16 |

(11) |

Cutting height control dial....................... |

31 |

(24) |

Hourmeter.............................................. |

16 |

(12) |

PTO lever............................................... |

12, 34 |

(25) |

Battery voltage meter............................. |

16 |

(13) |

Throttle lever.......................................... |

24 |

(26) |

Fuel gauge............................................. |

15 |

(14) |

PTO clutch indicator............................... |

11 |

(27) |

Service code display............................... |

17 |

|

|

|

|

|

|

INSTRUMENT PANEL AND CONTROLS 7

ENGLISH

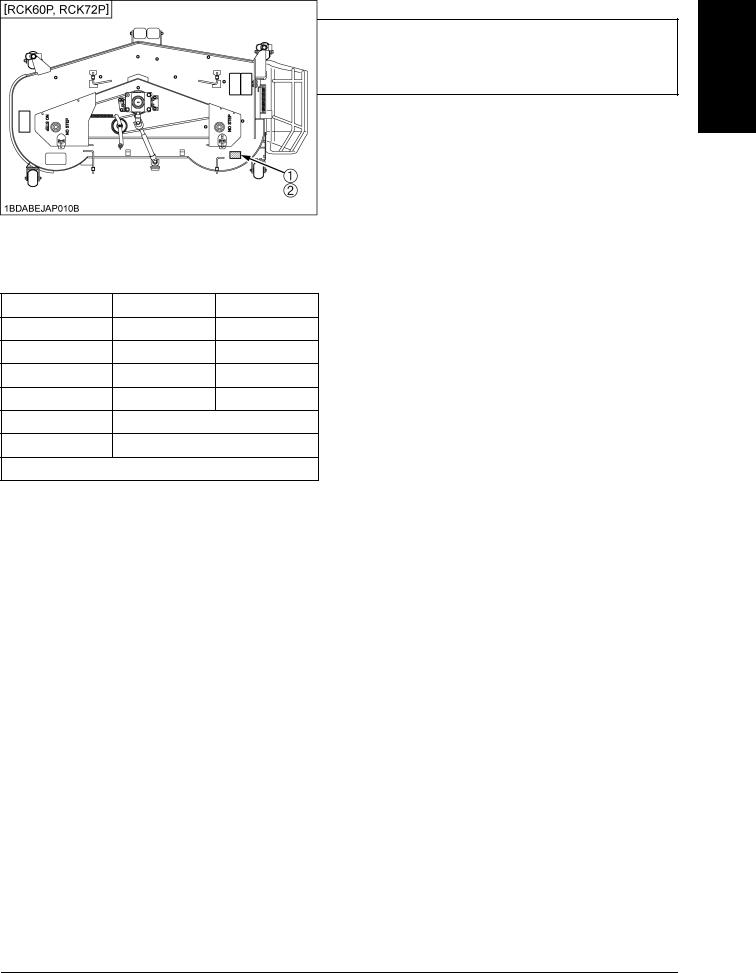

|

ILLUSTRATED CONTENTS |

|

ILLUSTRATED CONTENTS |

||

(1) |

Anti-scalp roller (Front, swivel type).......... |

32 |

(1) |

Anti-scalp roller (Front, swivel type).......... |

32 |

(2) |

Anti-scalp roller (Rear, bolt shift type) |

|

(2) |

Anti-scalp roller (Rear, bolt shift type)........ |

32 |

|

Rear RH roller is only for RCK72P........... |

32 |

|

|

|

ENGLISH

8 MOWER MOUNTING

MOWER MOUNTING

MOUNTING THE MOWER DECK

To avoid serious injury or death:

A Park the machine on a firm and level surface. A Apply the parking brake.

A Chock the rear tires.

A Stop the engine and remove the key.

1.Before mounting the mower deck, raise the lift links to the full up position.

2.Adjust the cutting height control dial to 1 in. position.

3.Tilt up the machine with the maintenance lift system. (See "HOW TO TILT UP THE MACHINE" in "PERIODIC SERVICE" section.)

4.Place the mower deck at the left side of the machine.

6.Place 50 mm (2 in.) wood blocks under each side of the mower deck.

7.Depress the hydraulic lift control pedal (DOWN) and pull down the lift links.

8.Attach the lift links to the mower deck with attaching hardwares.

(1) Lift link

(2) Clevis pin, Plain washer, Snap ring

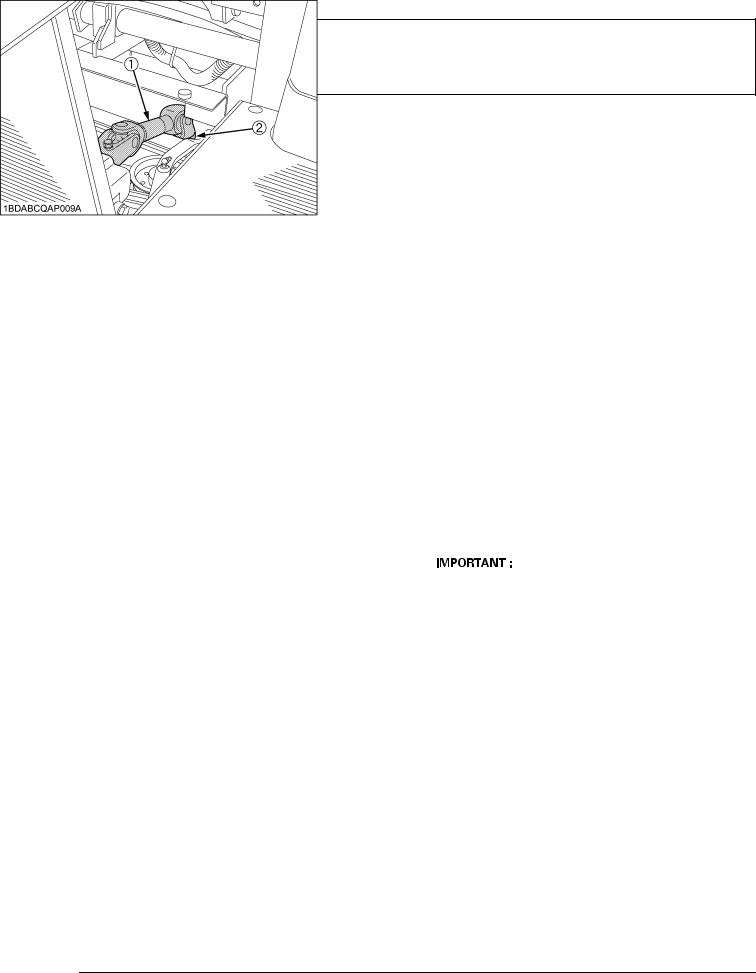

9. Install universal joint.

Pull back the coupler of the universal joint.

Push the universal joint onto the PTO shaft until the coupler locks.

A Tug the universal joint backward and forward to make sure it is locked securely.

5.Slide the mower deck under the machine, and make sure that the mower gear case is placed properly in the center of the machine, lower the axle from the tilt-up position to the normal position.

MOWER MOUNTING 9

(1) |

Universal joint |

(A) "PULL" |

(2) |

Coupler |

|

10.After mounting the mower, check the mower level. If necessary, adjust the mower level and anti-scalp rollers.

ADJUSTING THE MOWER

See "OPERATING THE MOWER" and "ADJUSTMENT" section.

DISMOUNTING THE MOWER DECK

For dismounting the mower deck, reverse the above procedures.

INSTALLING PARTS TO THE MOWER

BInstallation of Skid

[RCK60R, RCK72R]

Install the skid with 5 flange bolts.

A Right side shown, left side similar

(1)Skid (RH)

(2)Flange bolt (M10)

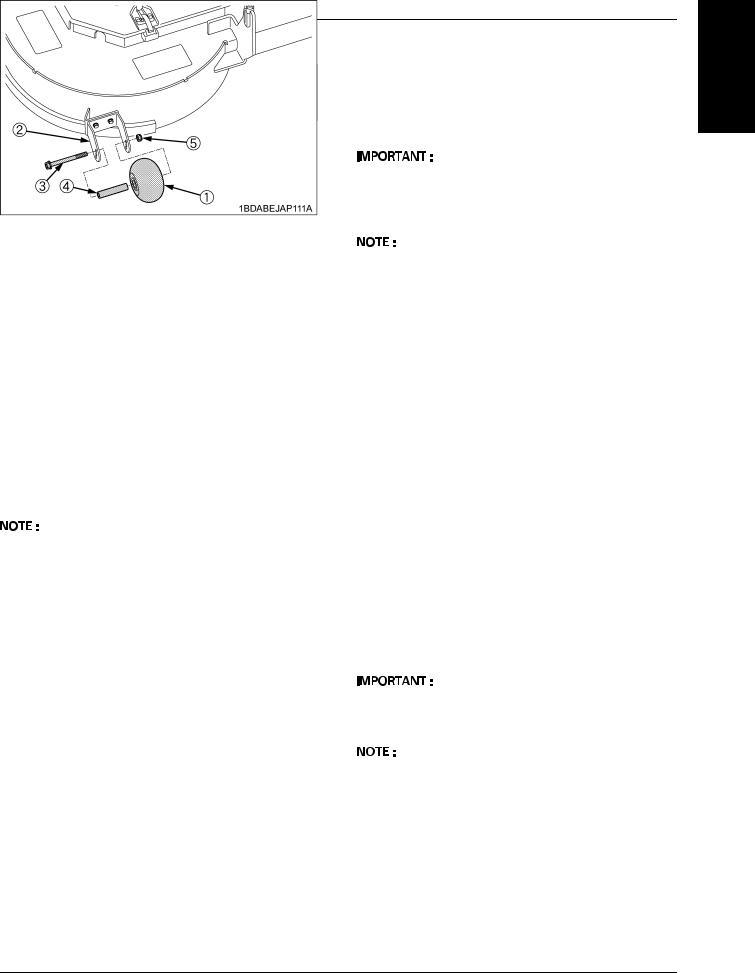

BInstallation of Gauge Wheel

[RCK60P, RCK72P]

Install the gauge wheel to the stay (3L gauge) with gauge wheel boss, sems bolt and locking nut.

A Choose the hole of the stay (3L gauge) by cutting height.

(See "ADJUSTING CUTTING HEIGHT" in "OPERATING THE MOWER" section.)

ALeft side of RCK72P shown, right side of RCK72P and left side of RCK60P similar

A Install the sems bolt from outside.

(1)Gauge wheel

(2)Stay (3L gauge)

(3)Sems bolt

(4)Gauge wheel boss

(5)Locking nut

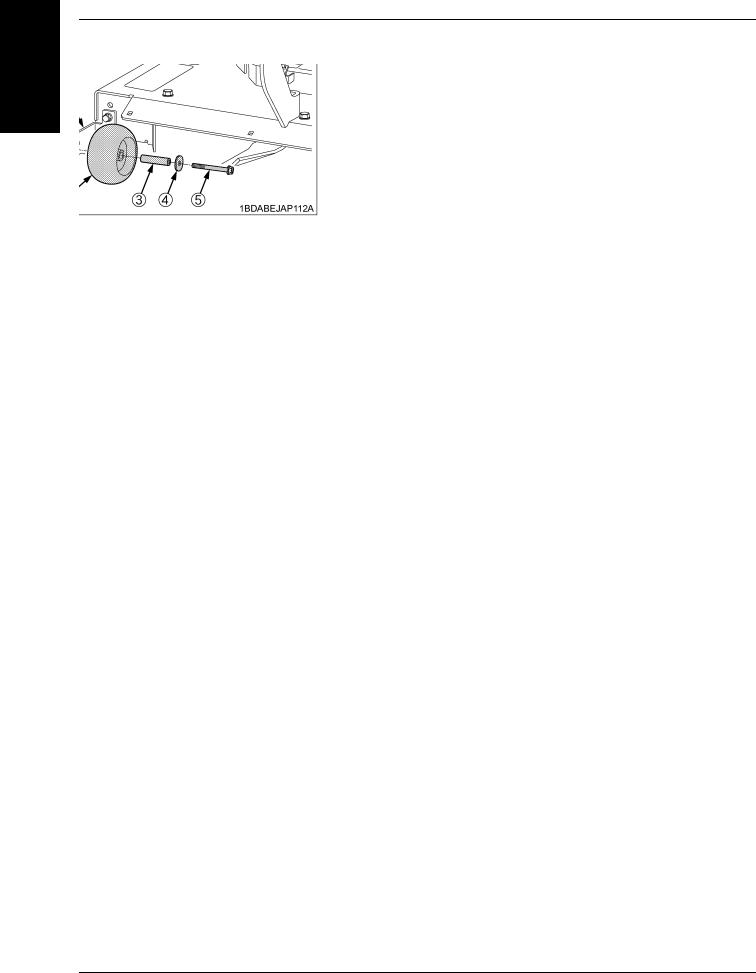

[RCK60R, RCK72R]

Install the gauge wheel with gauge wheel boss, plain washer, sems bolt and locking nut.

AChoose the hole of the skid by cutting height.

(See "ADJUSTING CUTTING HEIGHT" in "OPERATING THE MOWER" section.)

ALeft side of RCK72R shown, right side of RCK72R and both side of RCK60R similar

A Install the sems bolt from inside.

ENGLISH

10 MOWER MOUNTING

ENGLISH

(1)Gauge wheel

(2)Skid (Left)

(3)Gauge wheel boss

(4)Plain washer

(5)Sems bolt

(6)Locking nut

BInstallation of Bolt (Adjuster)

1.Install the bolt (adjuster) with the nut.

2.Adjust length (L).

3.Tighten the nut.

(1) |

Bolt (Adjuster) |

(L) 25 mm (Reference) |

(2) |

Nut |

|

OPERATING THE ENGINE 11

OPERATING THE ENGINE

To avoid serious injury or death:

A Read and understand "SAFE OPERATION" in the front of this manual.

A Read and understand the danger and warning labels located on the machine.

ATo avoid danger of exhaust fume poisoning, do not operate the engine in a closed building

without proper ventilation.

A Never start the engine while standing on the ground. Start the engine only from operator's seat.

STARTING THE ENGINE

1.Sit on the operator's seat. Put on the seat belt.

2.Apply the parking brake.

To apply the parking brake:

Depress the parking brake pedal firmly with your right foot and the parking brake lock pedal simultaneously with your left foot. Then release the parking brake pedal while holding the parking brake lock pedal down. Parking brake warning indicator will come ON.

GET ON AND GET OFF MACHINE SAFELY

DO NOT step on either side of the mower deck when getting on and getting off the machine. When getting on the machine from either side, step over the mower deck.

ENGLISH

(1) Parking brake pedal |

(A) "DEPRESS" |

(2)Parking brake lock pedal

(3)Parking brake warning indicator

To release the parking brake:

Depress the brake pedal and release slowly with your right foot without pressing the parking brake lock pedal.

Loading...

Loading...